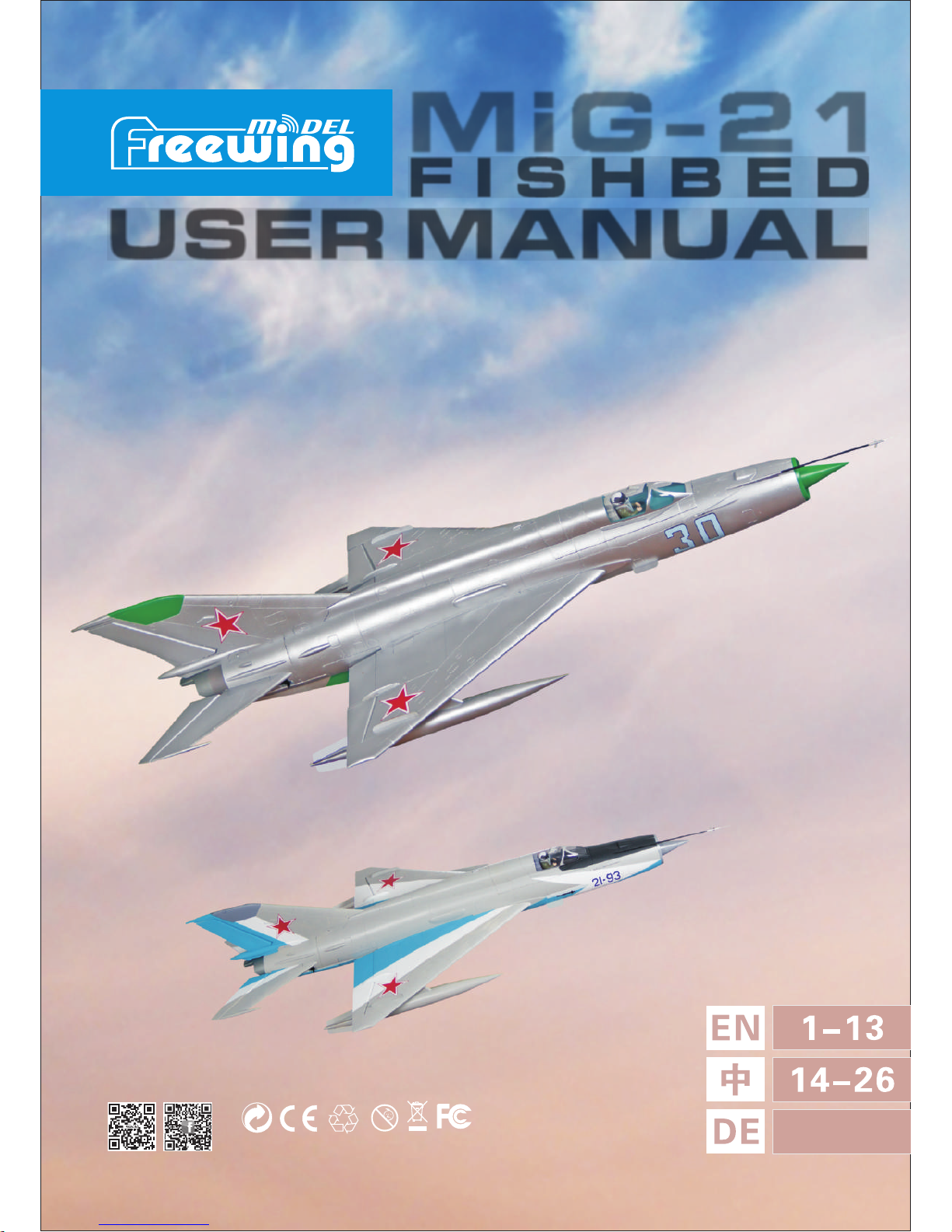

Freewing MIG-21 FISHBED, MiG-21 User Manual

www.sz-freewing.c om

0-14

MAD E IN CHIN A

M

I

I

G - 2 1

1/9 SCALE 80MM EDF JET

F I S H B E D

USER M A N UAL

LENGTH:1730mm

WINGSPAN:800mm

1

MI G- 21MF F IS HB ED

It em No .:F J210

Brief History

First designed in 1 95 3, t he MiG-21 is widely renowned as a classic Cold War er a brute and holds the distinction

of being the most produced supersonic jet fighter in the world. More than 11,000 MiG-21s of different variations

have flown for over 6 0 countries over a period of mo re than 60 years. In f ac t, the unmistakable outline of the Mi G21 can still be seen today in the sk ie s of ov er 15 countries that still oper at e this hi st or ic warplane. Th e MiG-21 ha s

earned its place i n av ia ti on h is to ry a s a versatile workhorse and venerable foe.

Overview

Dominate the ski es with Freewing’s 1/9 scale MiG-21! Its impressive 1730mm length makes t hi s MiG-21 one of

Freewing’s longest mod el a ir cr af t. Its removable wings, horizon ta l st ab ilizer, and vertical stabilizer ma ke t ra nsport

very e as y. Even t he nose c on e and pitot tube are re mo va bl e! Freewing h as recreate d ma ny scale de ta il s of the

MiG-21 “MF” variant, an d the ai rc ra ft is powered b y an 80mm 12-blade ED F and an all-new 3 53 0- 18 00 KV outrunner motor and 1 00 A ESC. Newly de si gn ed metal ge ar digital servos co ntrol the ail er on s, flaps, elevators, and

rudder, and an i nt eg ra te d circuit boa rd simplifies wiring in the la rg e battery bay. M ag ne ti c fuel tanks and the i co ni c

“blisters” throughout the f us el ag e help complete the loo k and feel of the menacin g MiG-21. Although an 80mm

class aircraft, the Freewing MiG-21 features th e retr ac ta bl e landin g gear of a 90mm cl as s ai rc ra ft . Durabl e

aluminum trail in g li nk s tr ut s an d ta ll wheels allow operation on short grass fields.

Flight Features

The Freewing Mi G- 21 is suitable for in termediate and advanced p il ot s with EDF flying e xp er ie nc e. The model’s

strong th ru st an d flaps shortens the takeoff distance to 30 m et er s. Optimized design allows the F re ew in g M iG-21

to fly sta bl y a t b ot h fast and slow speeds. In fact, the ai rc ra ft ca n m aintain a slow “high alpha” attitude of up to 40

degrees withou t st al li ng . The delta wing and swe pt t ai l gi ve t he a ir cr aft crisp responsiveness but gentle handling.

Al so , the battery bay w as d esigned to accommodate an optional Freewing Gyro E 51 , sold separately, to further

supplement the stable fly in g characteristics of th e Freewing MiG-21. Experience the th ri ll of a 4 0 degree pass w it h

ease!

Color Scheme Introdu ction

Freewing presents it s M iG -2 1 in two color schemes. The class ic “S ov ie t Silver” scheme includes d ec al s from

four countries in si de the bo x to al lo w pilots to customize their m od el aircraft. A “High Vis” sc he me is a lso available

that features the bl ue /w hi te /g re y co lor scheme of the MiG-21-93 variant for increased visibility in the sky.

1. This is not a toy! Operators should have some basic experience. Beginners should operate only under the guidance

of a professional instructor.

2. Before beginning assembly, please read through the instructions and carefully follow them throughout the build.

3. Freewing and it's vendors will not be held responsible for any losses due to improper assembly and operation.

4. Model airplane operators must be at least 14 years of age.

5. This airplane is made of EPO foam material, covered with surface spray paint. Don't use chemicals to clean as it may

cause damage.

6. You should avoid flying in areas such as public places, areas with high voltage power lines, nearby highways, airports

or in other areas where laws and regulations clearly prohibit flight.

7. Do not fly in bad weather conditions, including thunderstorms, snow, etc.

8. Lipo batteries should be properly stored in a fire proof container and be kept at a minimum of 2M distance away from

flammable or explosive materials.

9. Damaged or scrap batteries must be properly discharged before disposal or recycling to avoid spontaneous

combustion and fire.

10. At the Flying Field, properly dispose of any waste you have created, don't leave or burn your waste.. Ensure that your

throttle is in the low position and that your radio is turned on before connecting the Lipo battery.

11. Ensure that the throttle is in the lowest position and transmitter is turned on, before connecting a Lipo Battery to the

ESC of the aircraft.

12. Do not try to catch the airplane while in flight. Wait for the airplane to come to a complete stop before handling.

Index

1.Introduction

2.Product Basic Information

2. Package list

3.PNP Assembly Instructions

6. Servo installation instruction

7. Landing Gear assembly/installation

8. Control board use introduction

9. 3-Axis Gyro use introduction

10.Center of Gravity

11.Power system introduction

11.Motor Parameters

12.Control direction test

13.Dual Rates

9.Battery Installation.

10.Servo Introduction.

2

PNP

ARF Plu s

ARF

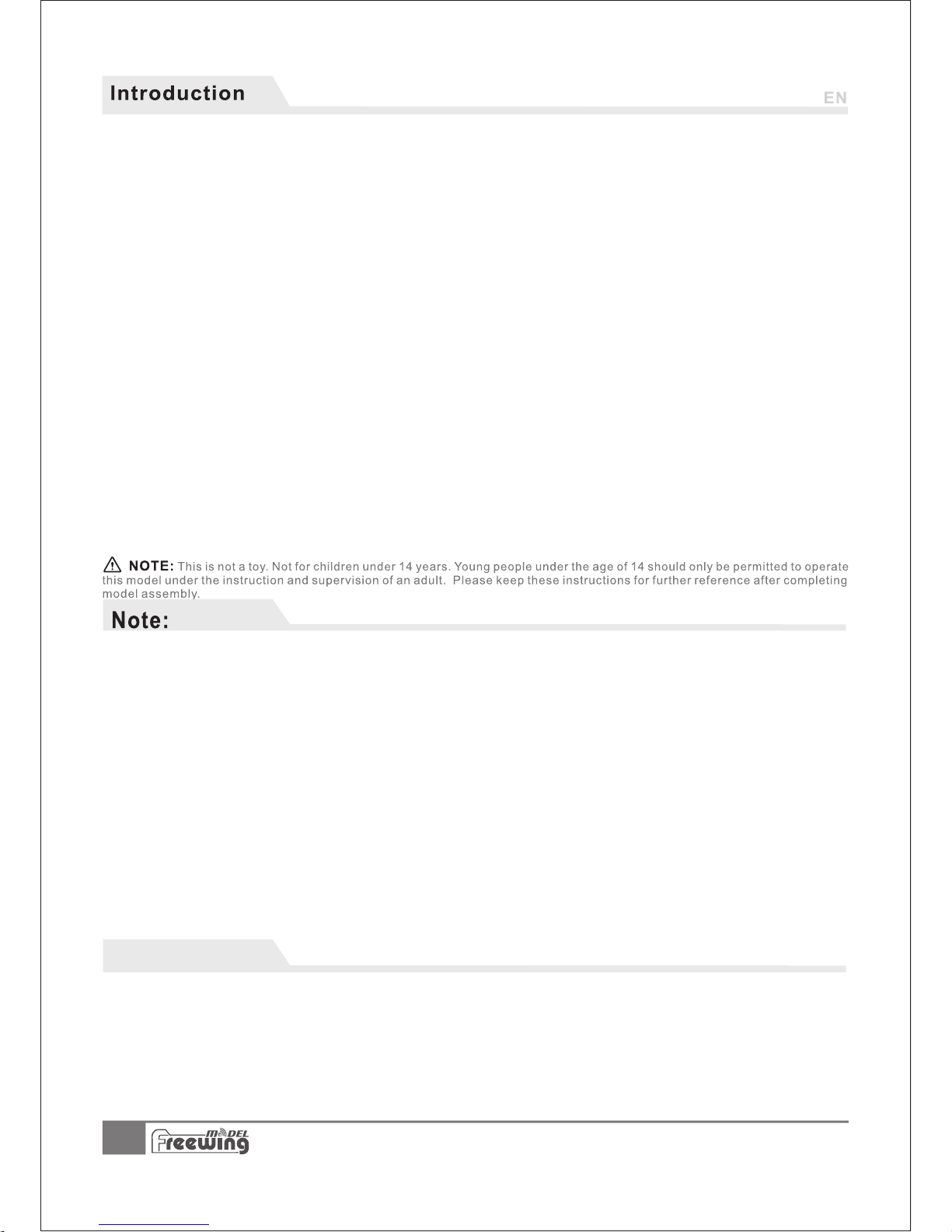

1605 mm(63.2 in.)

755m m(29.73 i n.)

比例 1.000

1730mm

(68.1" )

800mm( 31 .5")

2

Wingl oadin g:123 g/dm

Motor:3 530-1 800 KV outr unner m oto r

Fan:80m m 12- Bl ade f ans

ESC:100 A UBEC 5A

Servo s:9g Digi tal M G

Wei ght:218 0g

Thrus t:300 0g

(8pcs )

(W/O ba ttery )

MI G- 21MF F IS HB ED

It em No .:F J210

1

2

3

4

5

6

7

8

9

10

Standard Version

2

Wingloa di ng:125g /d m

Motor:3 65 8-1820K V in runner mo to r

Fan:80m m 12 -Blade fa ns

ESC:100 A UB EC 5A

Servos: 9g D ig ital MG

Weigh t:2215g

Thrust: 32 00g

(8pcs)

(W/O ba ttery )

Upgrade Version

Package list

No.

Spare part name

PNP

ARF Plu s

ARF

No.

Spare part name

Nose\Re ar fuselag e

Mainwin g

Horizon tal tail

Verti cal ta il

Oil-tan k&py lons

Carbo n fiber

Pilot t ube/A nte nna

Ventra l Fins

Pushr od/Sc rew s

Manua l/Dec als

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

The parameters stated here are derived from test results using our

accessories. If you use other accessories, the test results will differ. We

c

annot provide technical support if you have a problem when using other accessories.

Different types of kits will come with certain specific parts. Refer to the list of parts for your type of kit in the chart below.

3

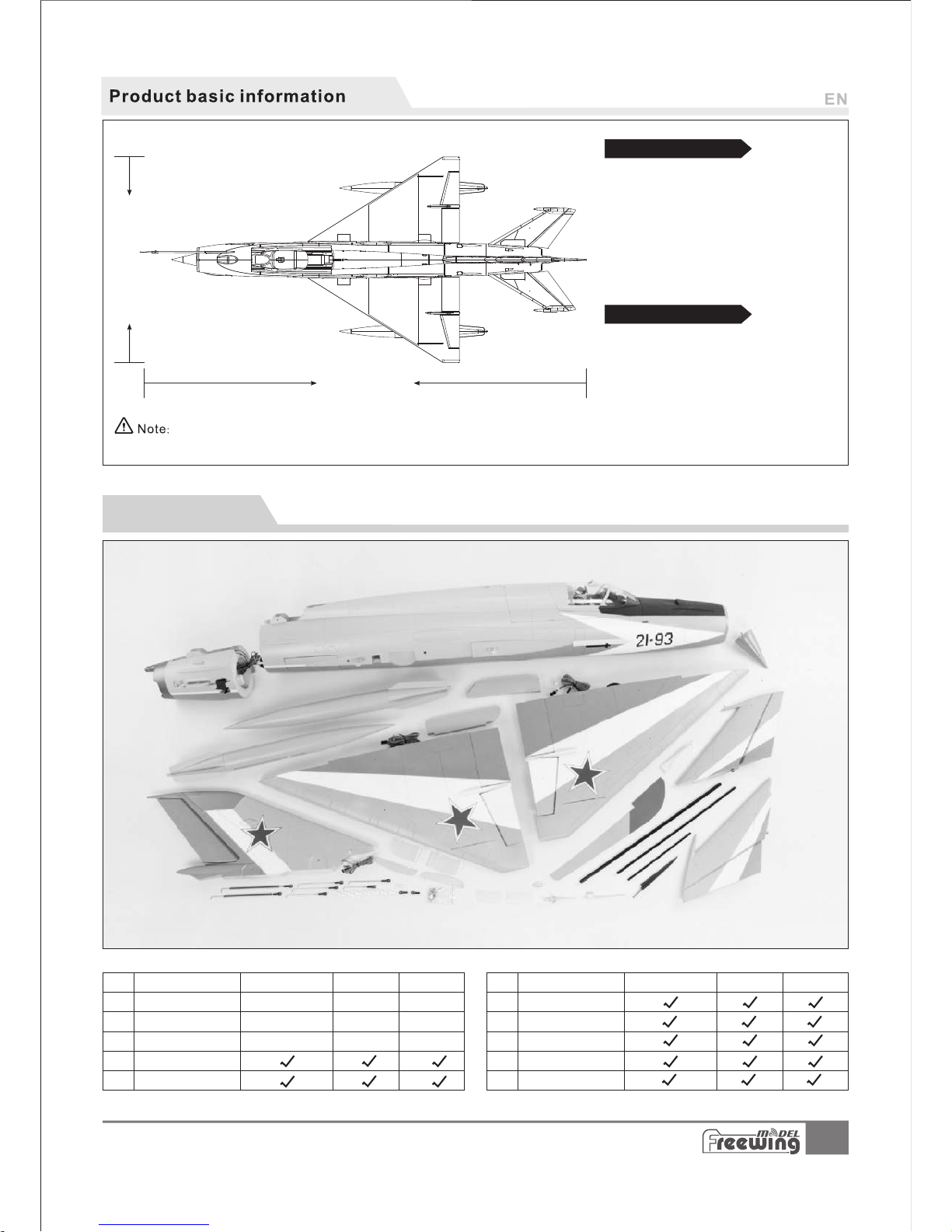

(Ø8 x400m m)

main wing t ro ugh port

Intake

Elevator Servo wires

2.Use the steel wire to pull the elevator servo cables to the battery compartment.

MI G- 21MF F IS HB ED

It em No .:F J210

Carbo n tub e A

(Ø6 x345m m)

Carbo n tub e B

Battery t ra y

1.Use the provided glue to attach front\rear

fuselage parts.

Screws (KA3x10mm 4pcs)

PNP Assembly Instructions

Steel wire use instructions

Pre- Installation Preparation

1.Open the hatch and loosen the screws which hold the battery tray in

place. Remove the battery tray.

2. Re mo ve t he i ntake plate.

Fuselage Assembly

Main Wing Installation

Back of fus e

l

age

1.Insert the carbon tube A and B into fuselage.

2.insert the main wing servo cables into the fuselage wire trough

and into the ports.

Steel wire

B

a

t

t

e

r

y c

o

m

p

a

r

t

m

e

n

t

Our tests show that excessively long servo extension lines increase the risk of poor connections that can lead to servo

brown outs or failure, causing accidents during flight. Instead, this kit contains a steel wire that can be used to pull the

main wing/elevator and rudder servo wires through the airplane to the battery compartment, eliminating the need for

extension wires.

There is EPO glue provided with the kit. Apply the glue to the fuselage parts and allow it to

sit for 2 minutes. Press the two pieces together several times and allow the glue to get 'stringy'.

Push the two parts together a final time and allow the glue to set.

4

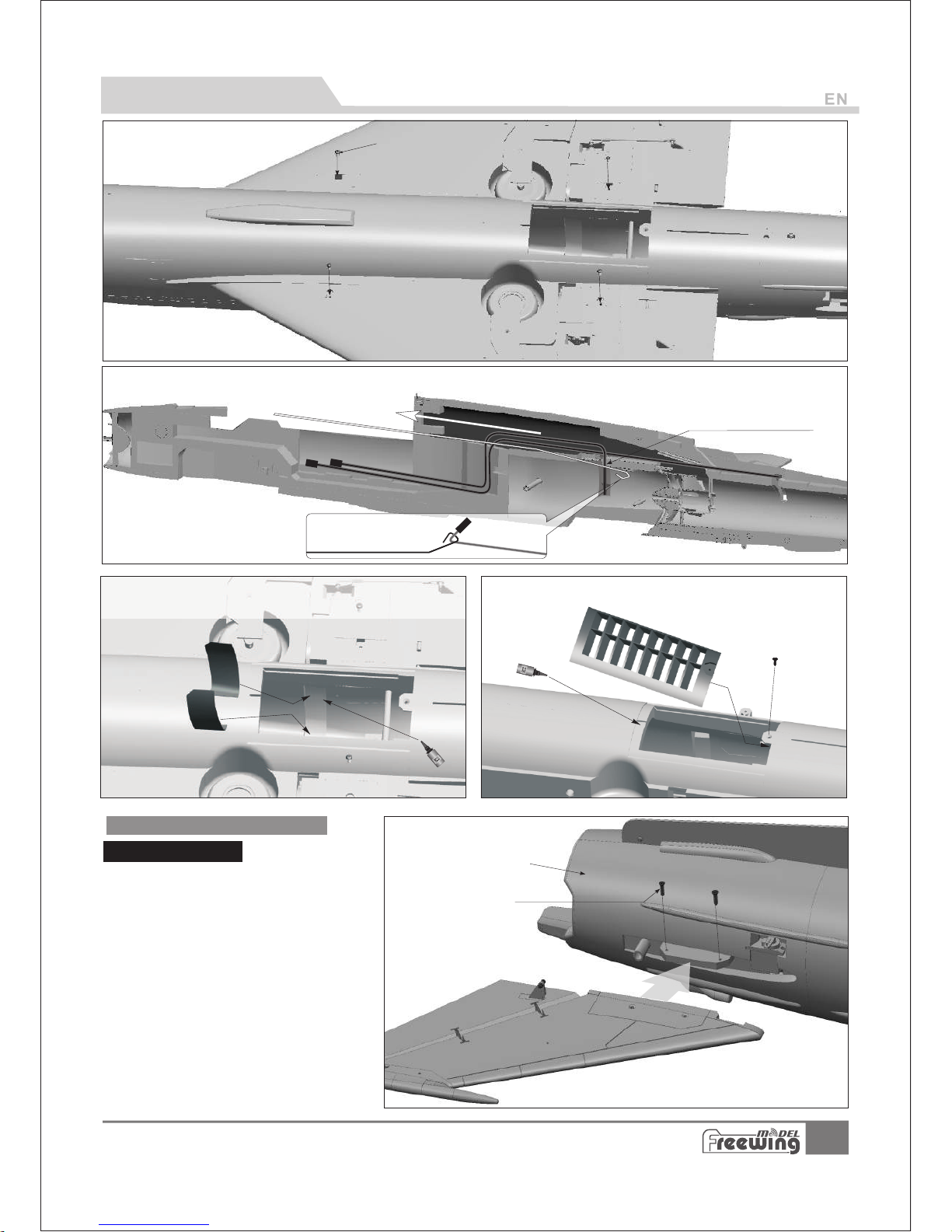

Main wing s er vos wire

Landing g ea r wire

Screws (PM3x6 4pcs)

E

SC

A-Tail fuselage

B-

Screws (KA2.6x8 4pcs)

A

B

MI G- 21MF F IS HB ED

It em No .:F J210

Screw

(FA 3x8 mm)

PNP Assembly Instructions

6.Use glue and screw to secure the intake plate.

3.Use 4 screws to secure the main wing.

4.Use the steel wire to pull the left and right wing connection wires to the battery compartment.

5.Use pla st ic cover to c lose the ma in w ing conne ct ion cable

trough on t he i nner wall .

Battery c o

mpar

tme

nt

1. Place the elevator onto the tail of the fuselage

2. Use 2 screws to

secure the elevator

3. Repeat the above steps to install the other

elevator.

Elevator and Rudder Installation

Elevator Installation

I

5

D

C

A

B

H

F

A B CDE F GHI J K -

J

K

D

B

C

A

G

E

MI G- 21MF F IS HB ED

It em No .:F J210

(Ø

5x180 mm

)

Carbon tube

PNP Assembly Instructions

1.Use the steel wire to pull the rudder servo cable through to the

battery compartment.

2. Use 4 screws to secure the rudder.

A. Vertical tail

B. Tail

fuselage

C. Servo wire

D. Screws (FA3x8 4pcs)

Rudder Installation

Nose cone, pitot tube, wing fence and drop tank pylons Installation

Nose cone

Antenna

Pitot tub e pa rt 1

Carbon tu be

Pitot tub e pa rt 2

Plastic p ar t 1

Plastic p ar t 2

Wing fenc e

Fin

Pylon

Drop tank

(left /ri gh t)

Note:

1.

2.

After finishing the above steps, depending on the model of the control board, insert all servo cables to the control board.

Finally use 4 screws to secure the battery tray . (all servo cables run under the battery tray)

6

A

B

C

B

C

A

B

A

C

Ser

v

os

wire

D

Pus hrod di amete r Ø1. 5m m

90m m

(3- 1/2")

Pus hrod di amete r Ø1. 5m m

80m m

(3- 1/8")

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

Pus hrod di amete r Ø1. 5m m

158 mm

(6- 1/4")

Pus hrod di amete r Ø1. 5m m

58m m

(2- 5/16" )

MI G- 21MF F IS HB ED

It em No .:F J210

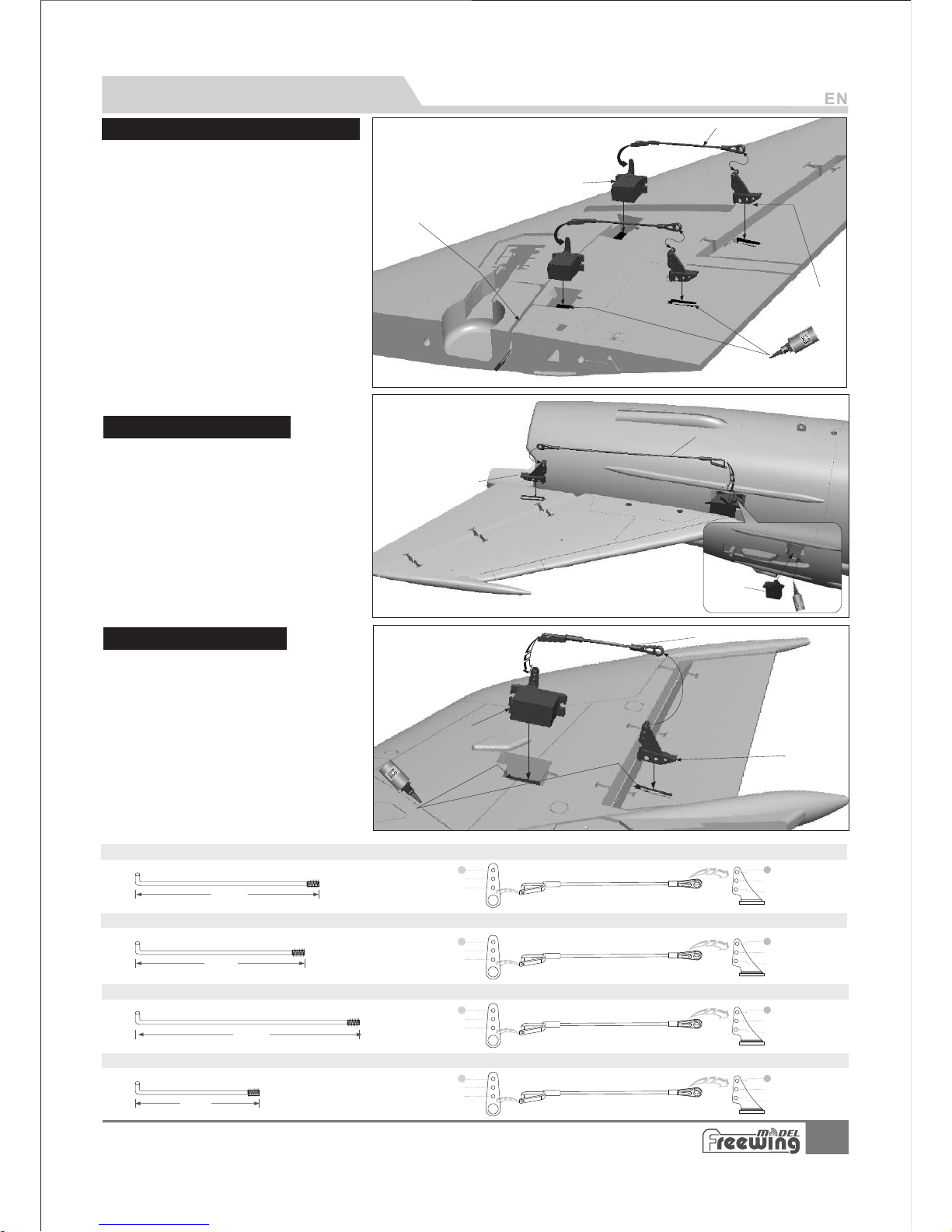

Servo Installation Instructions

1.

Use a servo tester or radio to center the

servo.

2.

Use glue to install the servos and control

horns to the main wing.

3.Feed the servo cables through the trough,

after all the cables are in place, apply the

decal over the trough.

4.

Feed one end of the pushrod into the

aileron servo arm and adjust its length.

Snap the clevis to the aileron control

horn's ball link.

5.

Feed one end of the pushrod into the

flap servo arm and adjust its length.

Snap the clevis to the flap control

horn's ball link.

6.

Repeat the above four steps for the

other aileron and flap servo.

Flap and Aileron Servo Installation

A - 9g servo

B - Main wing pushr od

C - Aileron horn

D - Main wing servo t ro ug h

Elevator Servo Installation

1.

2.

Use a servo tester or radio to center

the servo arm.

Use glue to intall the servos on the

elevator servo mounts.

3.Feed one end of the pushrod into the

servo arm and adjust its length. Snap

the clevis to the elevator control horn's

ball link.

4.Repeat the above steps to install

the servo on the opposite side.

A - 9g servo

B - Elevator horn

C - Elevator push ro d

1. Use a servo tester or radio to center

the servo arm.

2. Use glue to install the servo to the

Horizontal Stabilizer and the control horn

to the rudder.

3. Feed the servo cables into the trough.

4. Feed one end of the pushrod into the

servo arm and adjust its length. Snap

the clevis to the rudder control horn's ball

link.

A - 9g servo

B - Rudder ho rn

C - Rudder pu sh rod

Rudder Servo Installation

Aileron p us hrod size

Flap push ro d size

Aileron p us hrod moun ting hole

Flap push ro d mountin g hole

Rudder pu sh rod size

Rudder pu sh rod mount ing hole

Elevato r pu shrod siz e

Elevato r pu shrod mou nting hol e

A B CDE F GHI J -

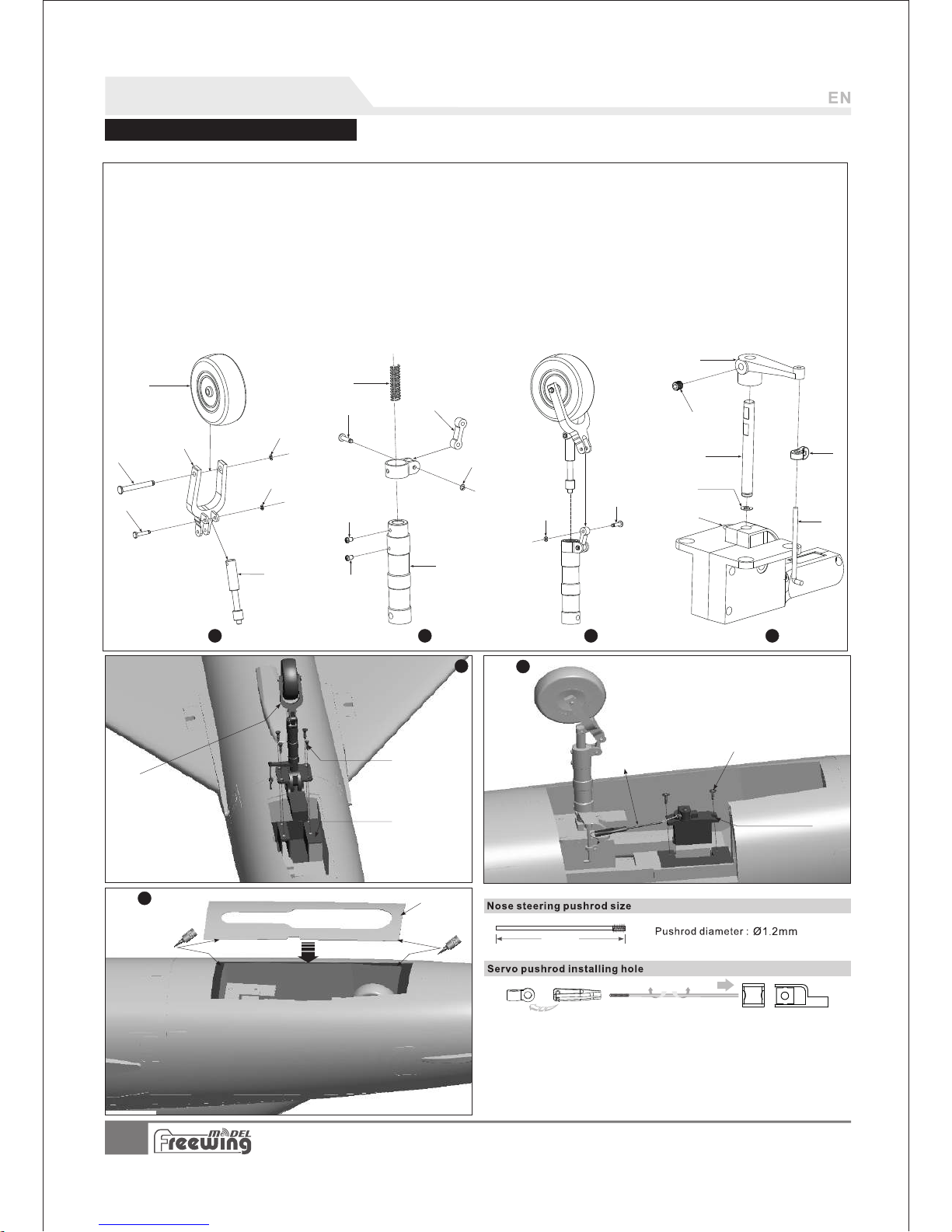

Nose wheel

Nose gear axle

U-shape slant supporting rod

E-clip

Pin

E-Clip

(Ø2.0pcs)

(Ø3.5X9.2mm 2pcs)

(Ø1.5mm 2pcs)

Nose gear shock absorber active rod

Spring

8-shape connecting arm

Screw (PM2x3 1pc)

Screw

Nose gear main supporting rod

Pin

Nose gear steering arm

Screw

Nose gear main rod

Nose gear steering control ring

Nose gear steering rod

E-clip

(PM2x4 1pc)

E-clip (Ø1.5mm)

(Ø3.5x9.2mm)

(M3x3mm)

(Ø2mm)

K L MN OP QR S T -

Nose landing gear set

Screws

Retract controller

(FA3x8 4pcs)

Nose landing gear mount

Nose steering pushrod

9g servo

Screws (PWA2x8mm 2pcs)

Nose landing gear cover

U-

V-

W-

XABACADAE-

( 2- 9/16 ")

65m m

AE

A

B

C

D

E

F

G

E1

F1

H

I

J

K

L

M

N

P

O

Q

R

S

T

U

Step

1 2 3 4

W

X

V

AB

AC

AD

5

6

7

7

MI G- 21MF F IS HB ED

It em No .:F J210

Landing Gear

Nose Landing Gear Assembly

Assemble and disassemble the nose landing gear according to the following photos.

Step Step Step

Step Step

Step

A B C D E F GH I J K L MN OR -

Main gear axle

Screw

Rear gear slant supporting rod

Pin

E clip

Main gear trunion A

Screw

Spring

Screw

Main wheel

(M3x3mm)

(Ø3.5X9.2mm 1pc)

(Ø1.5mm 1pc)

(M4x3mm)

(PM3x4 1pc)

Main gear main supporting rod

B

Main gear main rod

Grub screws (M4x4mm)

Retract controller

Nose gear door

Screws (PM2x5 2pcs)

A

B

C

D

E

F

G

ST U-

Main landing gear set

Screws (FA3x8 4pcs)

Main landing gear mount

S

T

U

1

H

I

J

K

2

M

L

N

3

O

R

4

5

8

MI G- 21MF F IS HB ED

It em No .:F J210

Landing Gear Installation

Rear Landing Gear Assembly

Assemble and disassemble the rear landing gear according to the following photo.

Step

Step

Step

Step

Step

When you use a gyro,

Elevator \ Aileron \ Rudder channels

from the Control Board connect directly

to the gyro outputs, then from the gyro

inputs to the receiver. All the other

channels will connect directly to the

receiver from the Control Board.

Refer to the model of the control board, insert all

the connection cables to the control board.

( Not including throttle, the throttle cable goes directly to

the receiver .)

Contr ol boar d

Landing G ea r

Flap

Landing gear

Rudder

Elevator

Aileron

(power to the receiver)

Landing G ea r

Rudder/Nose steering

Elevator

Aileron

Flap

Rudder/Nose steering

Elevator

Aileron

Flap

M

Control Board Introduction and Use

Loading...

Loading...