www.sz-freewing.c om

0-14

MAD E IN CHIN A

M

I

I

G - 2 1

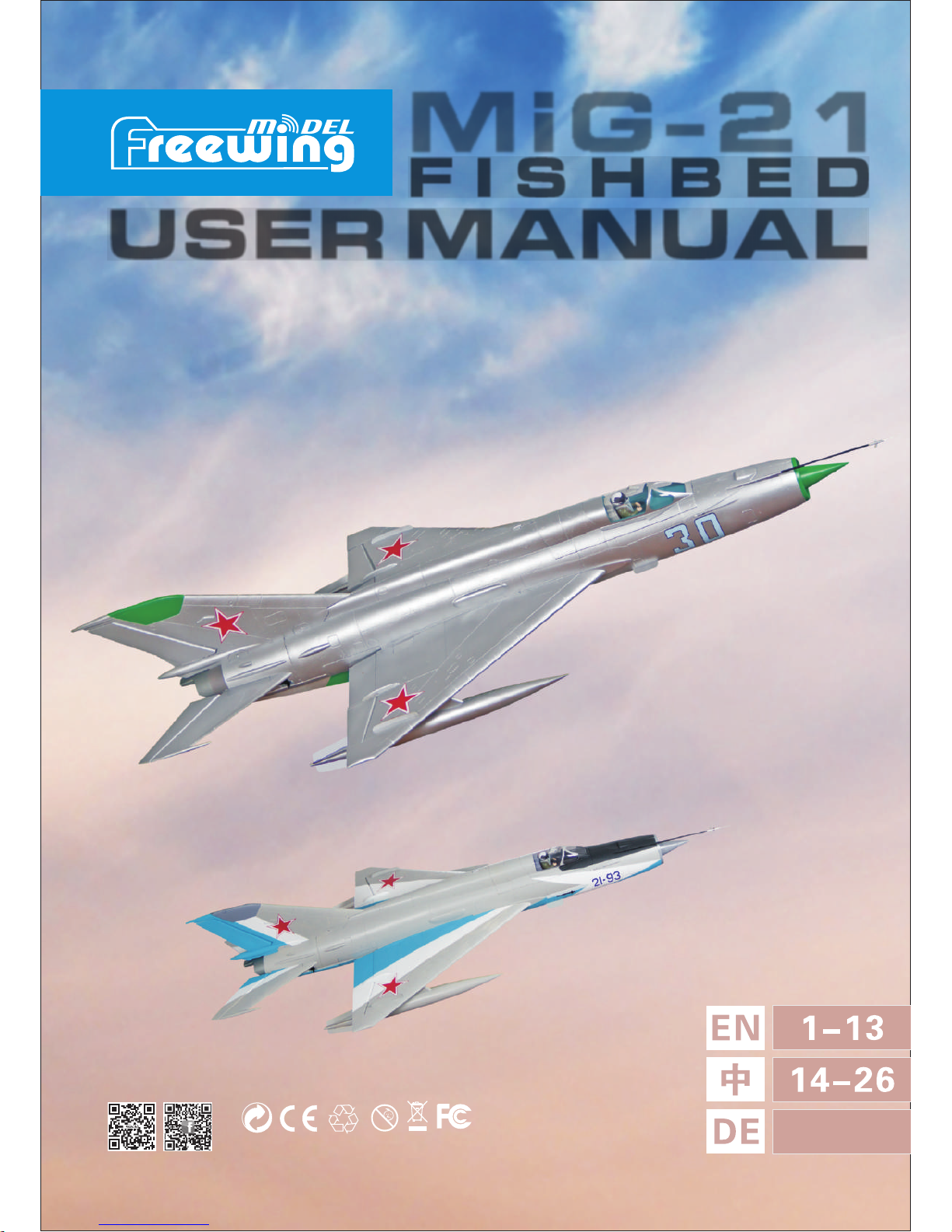

1/9 SCALE 80MM EDF JET

F I S H B E D

USER M A N UAL

LENGTH:1730mm

WINGSPAN:800mm

1

MI G- 21MF F IS HB ED

It em No .:F J210

Brief History

First designed in 1 95 3, t he MiG-21 is widely renowned as a classic Cold War er a brute and holds the distinction

of being the most produced supersonic jet fighter in the world. More than 11,000 MiG-21s of different variations

have flown for over 6 0 countries over a period of mo re than 60 years. In f ac t, the unmistakable outline of the Mi G21 can still be seen today in the sk ie s of ov er 15 countries that still oper at e this hi st or ic warplane. Th e MiG-21 ha s

earned its place i n av ia ti on h is to ry a s a versatile workhorse and venerable foe.

Overview

Dominate the ski es with Freewing’s 1/9 scale MiG-21! Its impressive 1730mm length makes t hi s MiG-21 one of

Freewing’s longest mod el a ir cr af t. Its removable wings, horizon ta l st ab ilizer, and vertical stabilizer ma ke t ra nsport

very e as y. Even t he nose c on e and pitot tube are re mo va bl e! Freewing h as recreate d ma ny scale de ta il s of the

MiG-21 “MF” variant, an d the ai rc ra ft is powered b y an 80mm 12-blade ED F and an all-new 3 53 0- 18 00 KV outrunner motor and 1 00 A ESC. Newly de si gn ed metal ge ar digital servos co ntrol the ail er on s, flaps, elevators, and

rudder, and an i nt eg ra te d circuit boa rd simplifies wiring in the la rg e battery bay. M ag ne ti c fuel tanks and the i co ni c

“blisters” throughout the f us el ag e help complete the loo k and feel of the menacin g MiG-21. Although an 80mm

class aircraft, the Freewing MiG-21 features th e retr ac ta bl e landin g gear of a 90mm cl as s ai rc ra ft . Durabl e

aluminum trail in g li nk s tr ut s an d ta ll wheels allow operation on short grass fields.

Flight Features

The Freewing Mi G- 21 is suitable for in termediate and advanced p il ot s with EDF flying e xp er ie nc e. The model’s

strong th ru st an d flaps shortens the takeoff distance to 30 m et er s. Optimized design allows the F re ew in g M iG-21

to fly sta bl y a t b ot h fast and slow speeds. In fact, the ai rc ra ft ca n m aintain a slow “high alpha” attitude of up to 40

degrees withou t st al li ng . The delta wing and swe pt t ai l gi ve t he a ir cr aft crisp responsiveness but gentle handling.

Al so , the battery bay w as d esigned to accommodate an optional Freewing Gyro E 51 , sold separately, to further

supplement the stable fly in g characteristics of th e Freewing MiG-21. Experience the th ri ll of a 4 0 degree pass w it h

ease!

Color Scheme Introdu ction

Freewing presents it s M iG -2 1 in two color schemes. The class ic “S ov ie t Silver” scheme includes d ec al s from

four countries in si de the bo x to al lo w pilots to customize their m od el aircraft. A “High Vis” sc he me is a lso available

that features the bl ue /w hi te /g re y co lor scheme of the MiG-21-93 variant for increased visibility in the sky.

1. This is not a toy! Operators should have some basic experience. Beginners should operate only under the guidance

of a professional instructor.

2. Before beginning assembly, please read through the instructions and carefully follow them throughout the build.

3. Freewing and it's vendors will not be held responsible for any losses due to improper assembly and operation.

4. Model airplane operators must be at least 14 years of age.

5. This airplane is made of EPO foam material, covered with surface spray paint. Don't use chemicals to clean as it may

cause damage.

6. You should avoid flying in areas such as public places, areas with high voltage power lines, nearby highways, airports

or in other areas where laws and regulations clearly prohibit flight.

7. Do not fly in bad weather conditions, including thunderstorms, snow, etc.

8. Lipo batteries should be properly stored in a fire proof container and be kept at a minimum of 2M distance away from

flammable or explosive materials.

9. Damaged or scrap batteries must be properly discharged before disposal or recycling to avoid spontaneous

combustion and fire.

10. At the Flying Field, properly dispose of any waste you have created, don't leave or burn your waste.. Ensure that your

throttle is in the low position and that your radio is turned on before connecting the Lipo battery.

11. Ensure that the throttle is in the lowest position and transmitter is turned on, before connecting a Lipo Battery to the

ESC of the aircraft.

12. Do not try to catch the airplane while in flight. Wait for the airplane to come to a complete stop before handling.

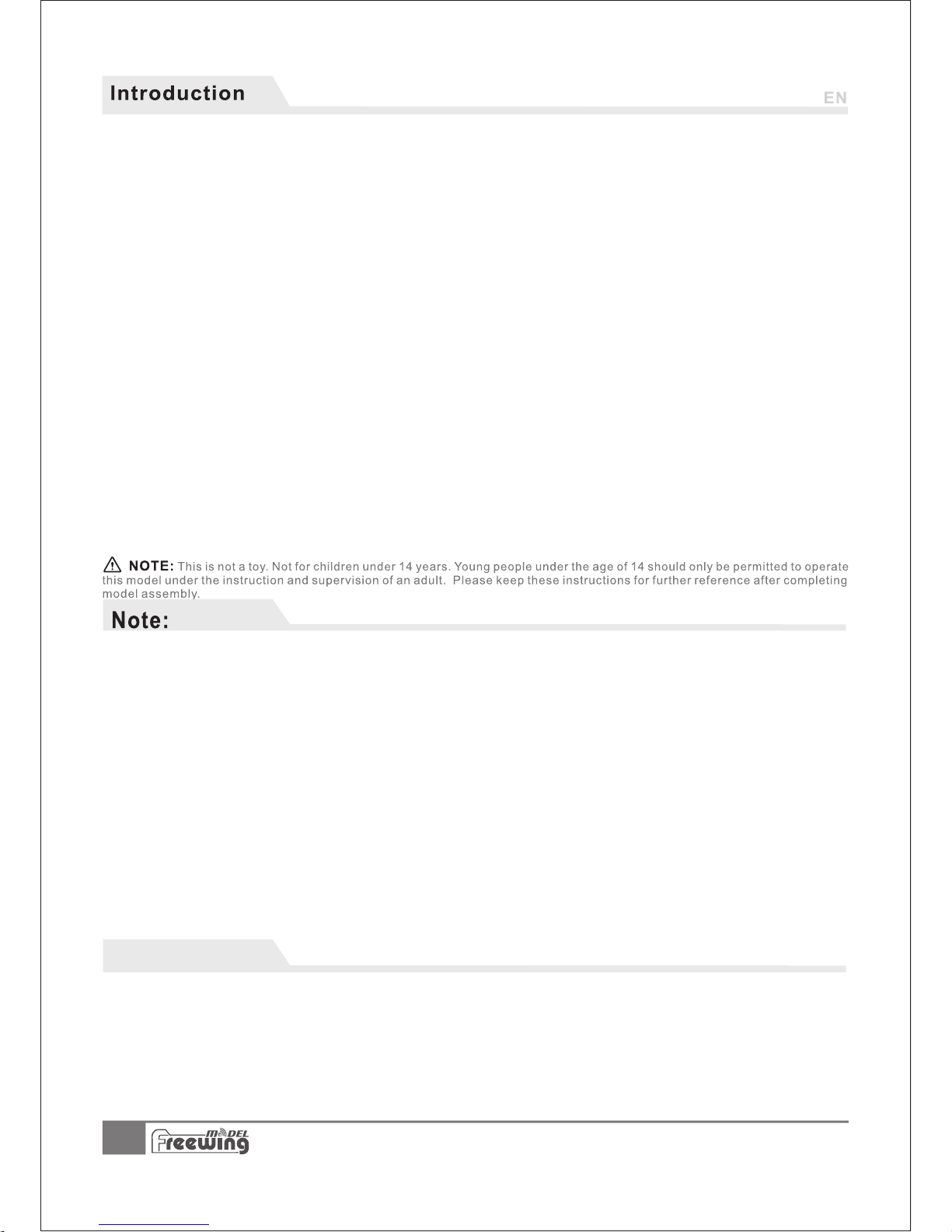

Index

1.Introduction

2.Product Basic Information

2. Package list

3.PNP Assembly Instructions

6. Servo installation instruction

7. Landing Gear assembly/installation

8. Control board use introduction

9. 3-Axis Gyro use introduction

10.Center of Gravity

11.Power system introduction

11.Motor Parameters

12.Control direction test

13.Dual Rates

9.Battery Installation.

10.Servo Introduction.

2

PNP

ARF Plu s

ARF

1605 mm(63.2 in.)

755m m(29.73 i n.)

比例 1.000

1730mm

(68.1" )

800mm( 31 .5")

2

Wingl oadin g:123 g/dm

Motor:3 530-1 800 KV outr unner m oto r

Fan:80m m 12- Bl ade f ans

ESC:100 A UBEC 5A

Servo s:9g Digi tal M G

Wei ght:218 0g

Thrus t:300 0g

(8pcs )

(W/O ba ttery )

MI G- 21MF F IS HB ED

It em No .:F J210

1

2

3

4

5

6

7

8

9

10

Standard Version

2

Wingloa di ng:125g /d m

Motor:3 65 8-1820K V in runner mo to r

Fan:80m m 12 -Blade fa ns

ESC:100 A UB EC 5A

Servos: 9g D ig ital MG

Weigh t:2215g

Thrust: 32 00g

(8pcs)

(W/O ba ttery )

Upgrade Version

Package list

No.

Spare part name

PNP

ARF Plu s

ARF

No.

Spare part name

Nose\Re ar fuselag e

Mainwin g

Horizon tal tail

Verti cal ta il

Oil-tan k&py lons

Carbo n fiber

Pilot t ube/A nte nna

Ventra l Fins

Pushr od/Sc rew s

Manua l/Dec als

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

No el ectro nic

equ ipmen t

Pre -inst alled a ll

ele ctron ic part s

Pre -inst alled

ser vo

The parameters stated here are derived from test results using our

accessories. If you use other accessories, the test results will differ. We

c

annot provide technical support if you have a problem when using other accessories.

Different types of kits will come with certain specific parts. Refer to the list of parts for your type of kit in the chart below.

3

(Ø8 x400m m)

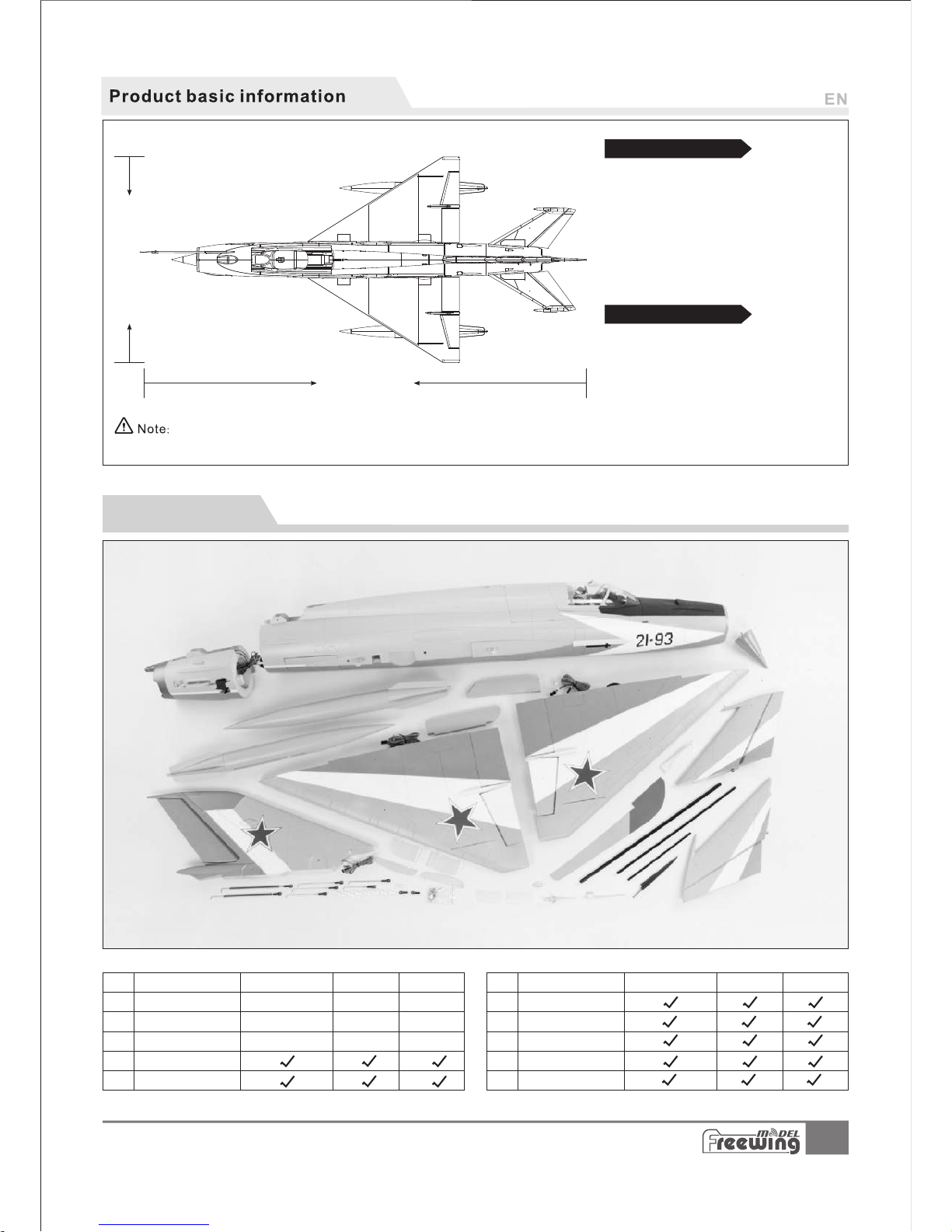

main wing t ro ugh port

Intake

Elevator Servo wires

2.Use the steel wire to pull the elevator servo cables to the battery compartment.

MI G- 21MF F IS HB ED

It em No .:F J210

Carbo n tub e A

(Ø6 x345m m)

Carbo n tub e B

Battery t ra y

1.Use the provided glue to attach front\rear

fuselage parts.

Screws (KA3x10mm 4pcs)

PNP Assembly Instructions

Steel wire use instructions

Pre- Installation Preparation

1.Open the hatch and loosen the screws which hold the battery tray in

place. Remove the battery tray.

2. Re mo ve t he i ntake plate.

Fuselage Assembly

Main Wing Installation

Back of fus e

l

age

1.Insert the carbon tube A and B into fuselage.

2.insert the main wing servo cables into the fuselage wire trough

and into the ports.

Steel wire

B

a

t

t

e

r

y c

o

m

p

a

r

t

m

e

n

t

Our tests show that excessively long servo extension lines increase the risk of poor connections that can lead to servo

brown outs or failure, causing accidents during flight. Instead, this kit contains a steel wire that can be used to pull the

main wing/elevator and rudder servo wires through the airplane to the battery compartment, eliminating the need for

extension wires.

There is EPO glue provided with the kit. Apply the glue to the fuselage parts and allow it to

sit for 2 minutes. Press the two pieces together several times and allow the glue to get 'stringy'.

Push the two parts together a final time and allow the glue to set.

4

Main wing s er vos wire

Landing g ea r wire

Screws (PM3x6 4pcs)

E

SC

A-Tail fuselage

B-

Screws (KA2.6x8 4pcs)

A

B

MI G- 21MF F IS HB ED

It em No .:F J210

Screw

(FA 3x8 mm)

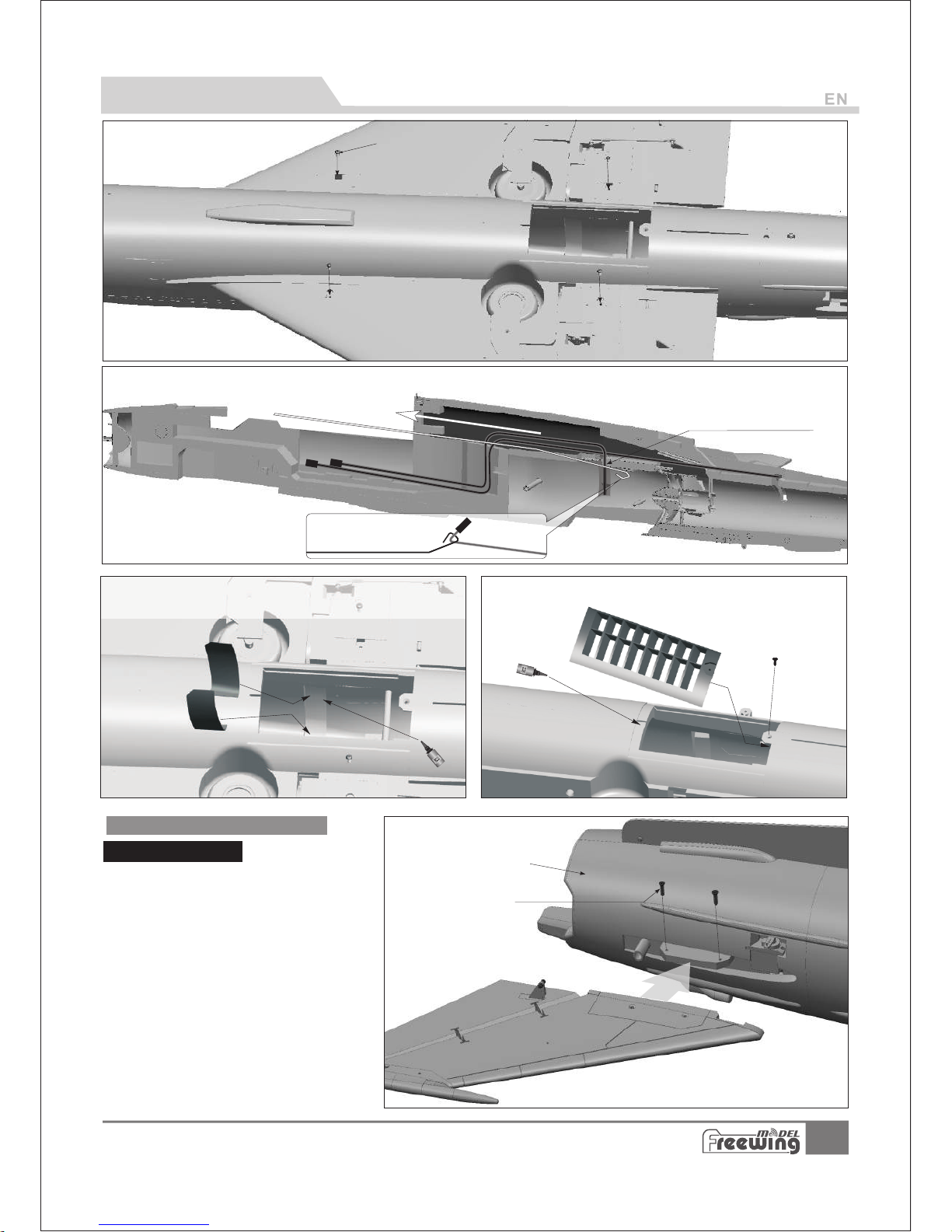

PNP Assembly Instructions

6.Use glue and screw to secure the intake plate.

3.Use 4 screws to secure the main wing.

4.Use the steel wire to pull the left and right wing connection wires to the battery compartment.

5.Use pla st ic cover to c lose the ma in w ing conne ct ion cable

trough on t he i nner wall .

Battery c o

mpar

tme

nt

1. Place the elevator onto the tail of the fuselage

2. Use 2 screws to

secure the elevator

3. Repeat the above steps to install the other

elevator.

Elevator and Rudder Installation

Elevator Installation

I

5

D

C

A

B

H

F

A B CDE F GHI J K -

J

K

D

B

C

A

G

E

MI G- 21MF F IS HB ED

It em No .:F J210

(Ø

5x180 mm

)

Carbon tube

PNP Assembly Instructions

1.Use the steel wire to pull the rudder servo cable through to the

battery compartment.

2. Use 4 screws to secure the rudder.

A. Vertical tail

B. Tail

fuselage

C. Servo wire

D. Screws (FA3x8 4pcs)

Rudder Installation

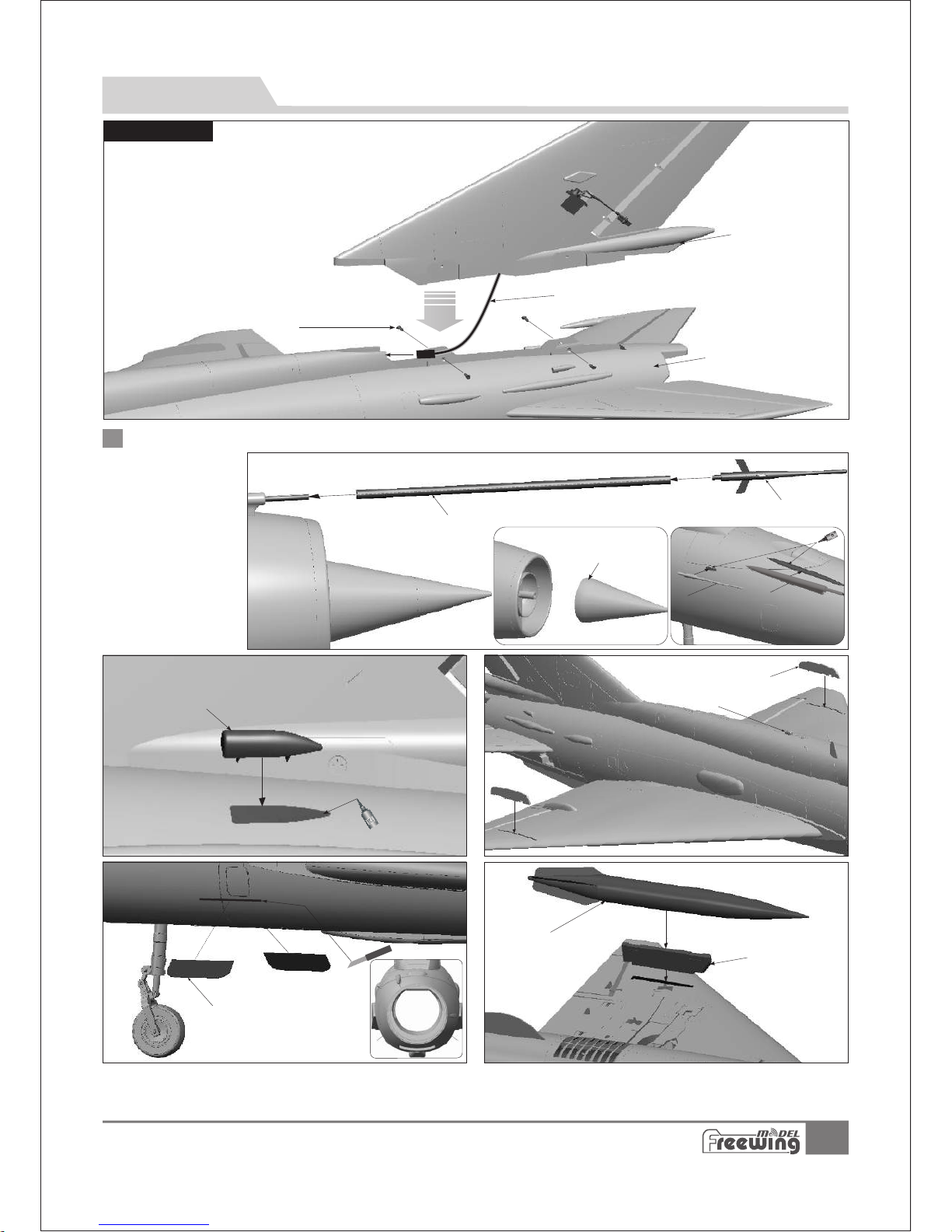

Nose cone, pitot tube, wing fence and drop tank pylons Installation

Nose cone

Antenna

Pitot tub e pa rt 1

Carbon tu be

Pitot tub e pa rt 2

Plastic p ar t 1

Plastic p ar t 2

Wing fenc e

Fin

Pylon

Drop tank

(left /ri gh t)

Note:

1.

2.

After finishing the above steps, depending on the model of the control board, insert all servo cables to the control board.

Finally use 4 screws to secure the battery tray . (all servo cables run under the battery tray)

6

A

B

C

B

C

A

B

A

C

Ser

v

os

wire

D

Pus hrod di amete r Ø1. 5m m

90m m

(3- 1/2")

Pus hrod di amete r Ø1. 5m m

80m m

(3- 1/8")

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

Pus hrod di amete r Ø1. 5m m

158 mm

(6- 1/4")

Pus hrod di amete r Ø1. 5m m

58m m

(2- 5/16" )

MI G- 21MF F IS HB ED

It em No .:F J210

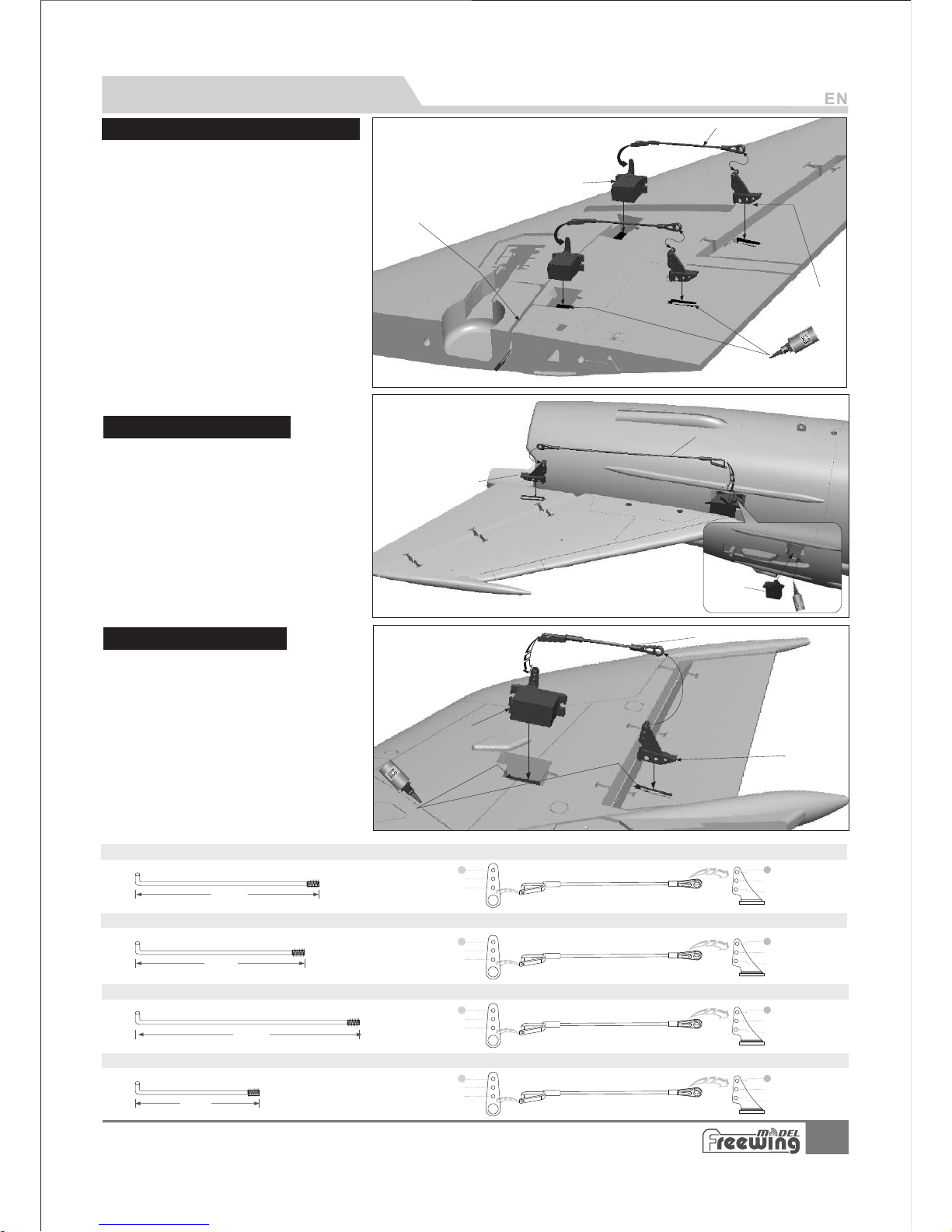

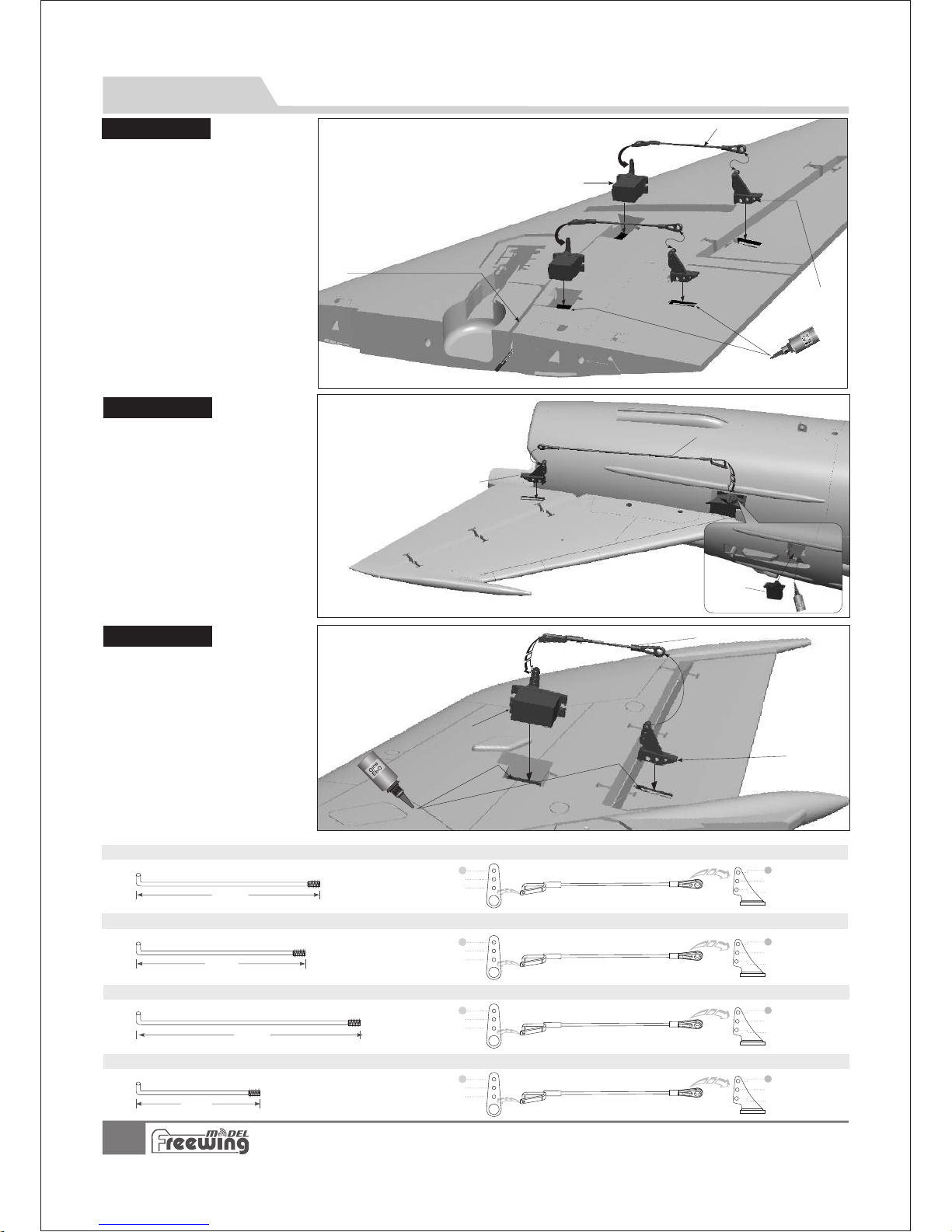

Servo Installation Instructions

1.

Use a servo tester or radio to center the

servo.

2.

Use glue to install the servos and control

horns to the main wing.

3.Feed the servo cables through the trough,

after all the cables are in place, apply the

decal over the trough.

4.

Feed one end of the pushrod into the

aileron servo arm and adjust its length.

Snap the clevis to the aileron control

horn's ball link.

5.

Feed one end of the pushrod into the

flap servo arm and adjust its length.

Snap the clevis to the flap control

horn's ball link.

6.

Repeat the above four steps for the

other aileron and flap servo.

Flap and Aileron Servo Installation

A - 9g servo

B - Main wing pushr od

C - Aileron horn

D - Main wing servo t ro ug h

Elevator Servo Installation

1.

2.

Use a servo tester or radio to center

the servo arm.

Use glue to intall the servos on the

elevator servo mounts.

3.Feed one end of the pushrod into the

servo arm and adjust its length. Snap

the clevis to the elevator control horn's

ball link.

4.Repeat the above steps to install

the servo on the opposite side.

A - 9g servo

B - Elevator horn

C - Elevator push ro d

1. Use a servo tester or radio to center

the servo arm.

2. Use glue to install the servo to the

Horizontal Stabilizer and the control horn

to the rudder.

3. Feed the servo cables into the trough.

4. Feed one end of the pushrod into the

servo arm and adjust its length. Snap

the clevis to the rudder control horn's ball

link.

A - 9g servo

B - Rudder ho rn

C - Rudder pu sh rod

Rudder Servo Installation

Aileron p us hrod size

Flap push ro d size

Aileron p us hrod moun ting hole

Flap push ro d mountin g hole

Rudder pu sh rod size

Rudder pu sh rod mount ing hole

Elevato r pu shrod siz e

Elevato r pu shrod mou nting hol e

A B CDE F GHI J -

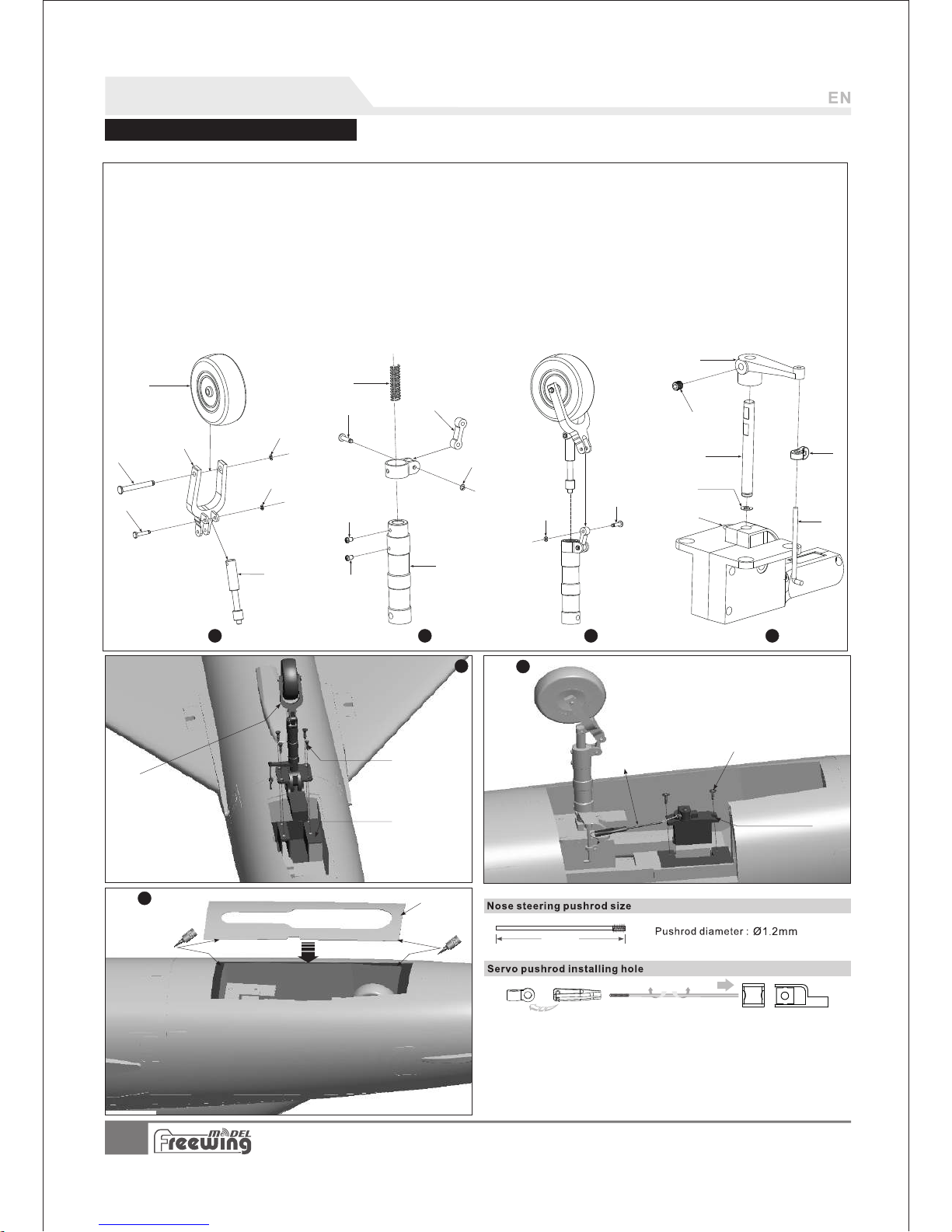

Nose wheel

Nose gear axle

U-shape slant supporting rod

E-clip

Pin

E-Clip

(Ø2.0pcs)

(Ø3.5X9.2mm 2pcs)

(Ø1.5mm 2pcs)

Nose gear shock absorber active rod

Spring

8-shape connecting arm

Screw (PM2x3 1pc)

Screw

Nose gear main supporting rod

Pin

Nose gear steering arm

Screw

Nose gear main rod

Nose gear steering control ring

Nose gear steering rod

E-clip

(PM2x4 1pc)

E-clip (Ø1.5mm)

(Ø3.5x9.2mm)

(M3x3mm)

(Ø2mm)

K L MN OP QR S T -

Nose landing gear set

Screws

Retract controller

(FA3x8 4pcs)

Nose landing gear mount

Nose steering pushrod

9g servo

Screws (PWA2x8mm 2pcs)

Nose landing gear cover

U-

V-

W-

XABACADAE-

( 2- 9/16 ")

65m m

AE

A

B

C

D

E

F

G

E1

F1

H

I

J

K

L

M

N

P

O

Q

R

S

T

U

Step

1 2 3 4

W

X

V

AB

AC

AD

5

6

7

7

MI G- 21MF F IS HB ED

It em No .:F J210

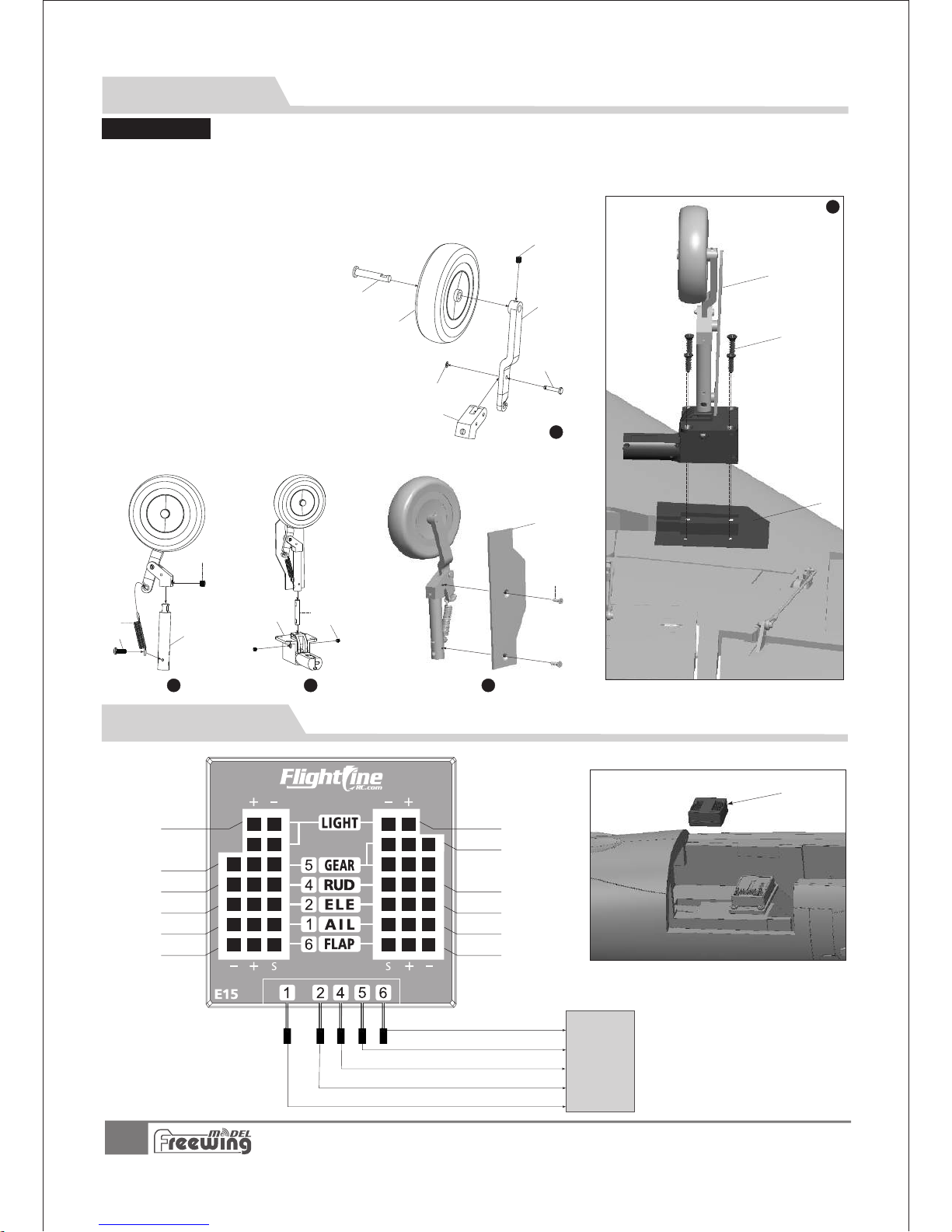

Landing Gear

Nose Landing Gear Assembly

Assemble and disassemble the nose landing gear according to the following photos.

Step Step Step

Step Step

Step

A B C D E F GH I J K L MN OR -

Main gear axle

Screw

Rear gear slant supporting rod

Pin

E clip

Main gear trunion A

Screw

Spring

Screw

Main wheel

(M3x3mm)

(Ø3.5X9.2mm 1pc)

(Ø1.5mm 1pc)

(M4x3mm)

(PM3x4 1pc)

Main gear main supporting rod

B

Main gear main rod

Grub screws (M4x4mm)

Retract controller

Nose gear door

Screws (PM2x5 2pcs)

A

B

C

D

E

F

G

ST U-

Main landing gear set

Screws (FA3x8 4pcs)

Main landing gear mount

S

T

U

1

H

I

J

K

2

M

L

N

3

O

R

4

5

8

MI G- 21MF F IS HB ED

It em No .:F J210

Landing Gear Installation

Rear Landing Gear Assembly

Assemble and disassemble the rear landing gear according to the following photo.

Step

Step

Step

Step

Step

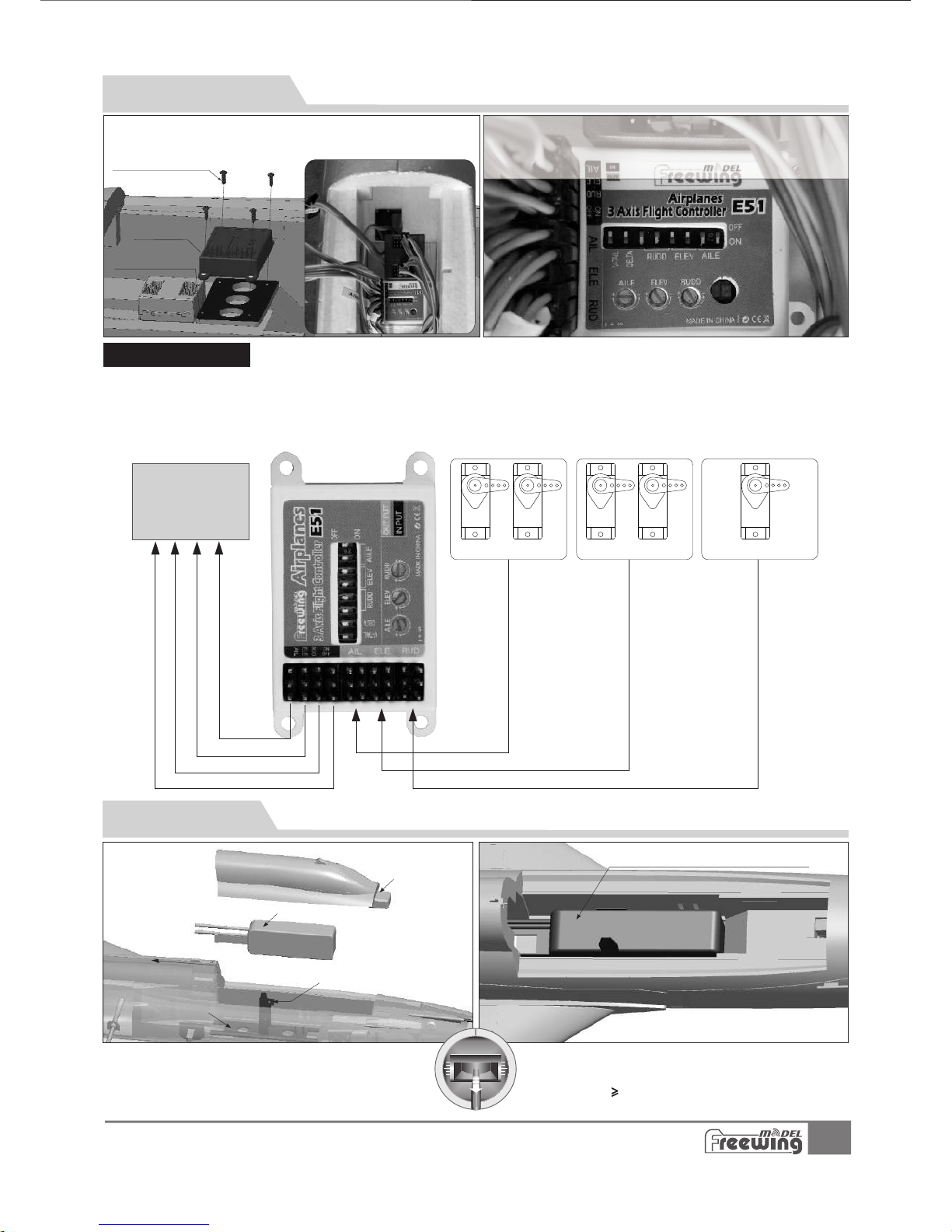

When you use a gyro,

Elevator \ Aileron \ Rudder channels

from the Control Board connect directly

to the gyro outputs, then from the gyro

inputs to the receiver. All the other

channels will connect directly to the

receiver from the Control Board.

Refer to the model of the control board, insert all

the connection cables to the control board.

( Not including throttle, the throttle cable goes directly to

the receiver .)

Contr ol boar d

Landing G ea r

Flap

Landing gear

Rudder

Elevator

Aileron

(power to the receiver)

Landing G ea r

Rudder/Nose steering

Elevator

Aileron

Flap

Rudder/Nose steering

Elevator

Aileron

Flap

M

Control Board Introduction and Use

9

6S 22.2V 4000mAh~6S 22.2 5500mAh

Dischar ge r ate of C 35C>

MI G- 21MF F IS HB ED

It em No .:F J210

Before connecting the battery to the ESC, please

switch on the transmitter power and make sure the

throttle stick is in the lowest position. Engage the kill

switch if you have one assigned.

Battery t ra y

Install the battery to the front of fuselage,

and use the velcro strap to

secure it.

Ve

lcro

Battery

Pus

h b

a

ck the le v

er

to open t he co c

kp

it

Battery Hatch size : L=280 , W=66 , H=70 (mm)

Screws (PA2.3x8mm)

3-Axis Gyro Introduction and Use

Use 4 screws to secure the gyro onto the board at the front of the

battery compartment. Make sure the gyro decal is facing the nose cone

when installing.

The gyro was factory tested and set up at default sensitivity. You can

fine tune it according to your preference and flight conditions. Refer to

the photo to reset factory default settings.

Battery Installation

Hatch

The recommended battery size and

discharge rate is:

10

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

100mm

950mm

950mm

800mm

800mm

1050mm

1050mm

1050mm

比例 1.000

265mm

(10-1/2")

MI G- 21MF F IS HB ED

It em No .:F J210

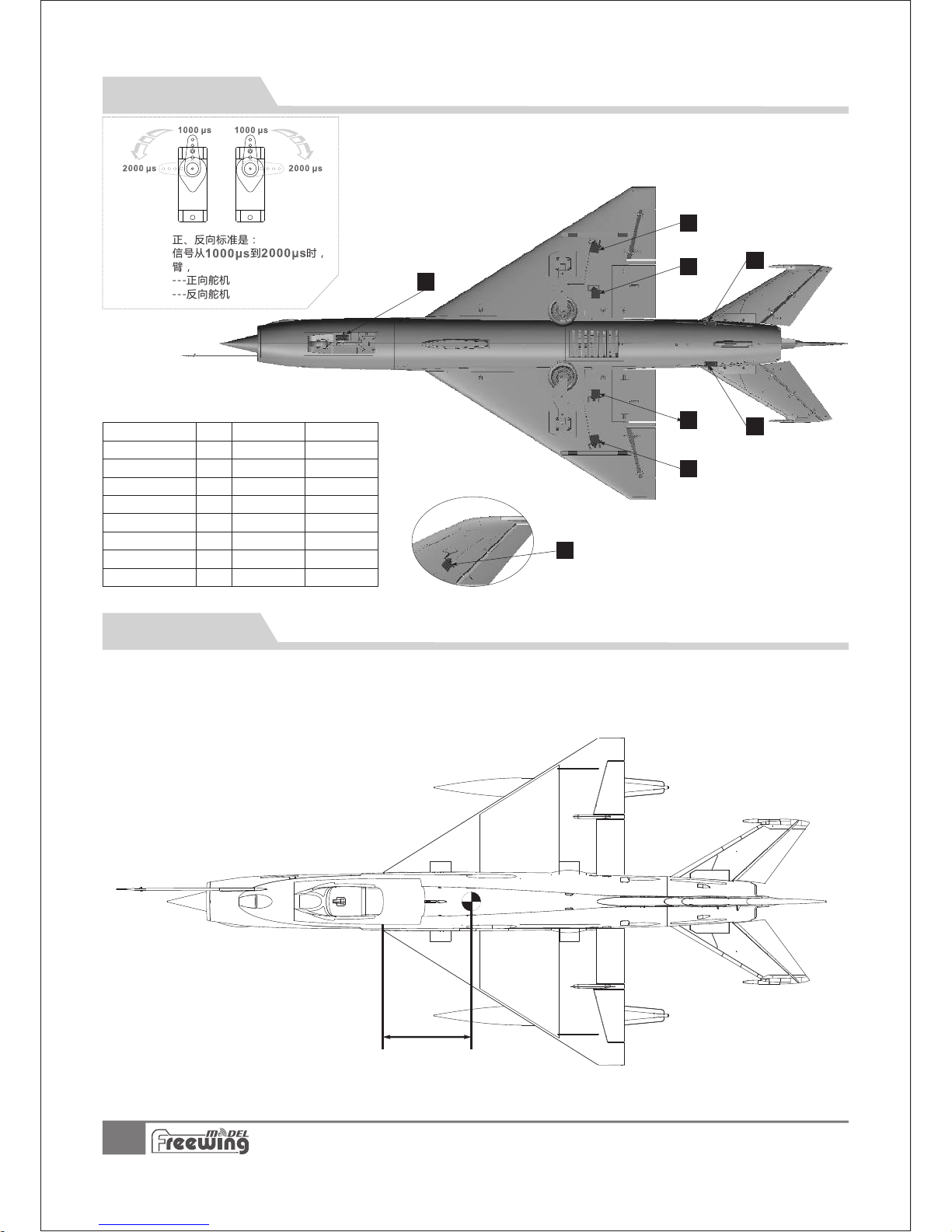

Servo Introduction

Center of Gravity

Correct center of gravity is directly related to the success of the initial flights. Refer to the following CG diagram to adjust

your plane's center of gravity.

- You can move the battery forward or backward to

adjust the center of gravity.

- If you can not adjust the CG by moving the battery,

you can also use some other suitable material weight

to counterweight, to achieve the correct CG .

If you choose to use another brand

of servo

, please

refer

to the following list to ensure it is the correct size .

Installing position

No.

Pos./ Rev.

Servo Cable Length

Positiv e

Positiv e

Positiv e

Positiv e

Reverse

Positiv e

Reverse

Positiv e

Nose gear steering

Aileron(L)

Aileron(R)

Flap(L)

Flap(R)

Elevator(L)

Elevator(R)

Rudder

A servo or reversed servo is defined as

follows:

When the servo input signal changes from

1000ųs to 2000ųs, if the servo arm rotates

clockwise, it's a positive servo. If it rotates

counter clockwise, it's a reversed servo.

11

ABCDEF -

ESC fixed wood pi ec e1

ESC

ESC fixed wood pi ec e2

Screws (

80mm EDF power sy st em

Screws (

PWA 3x 8mm 4pcs)

PM3x25mm 2pcs )

GHI J K -

Screws

Ventral Fins

Ventral Fins mou nt

Screw

Ducted fan cove r

(FA3x8mm 2pcs)

(KA2.6x8mm 1pc)

G

H

I

J

K

2

E

F

Step

1

MO035 302

MO035302

100A

86

3000

1800R PM /V

MI G- 21MF F IS HB ED

It em No .:F J210

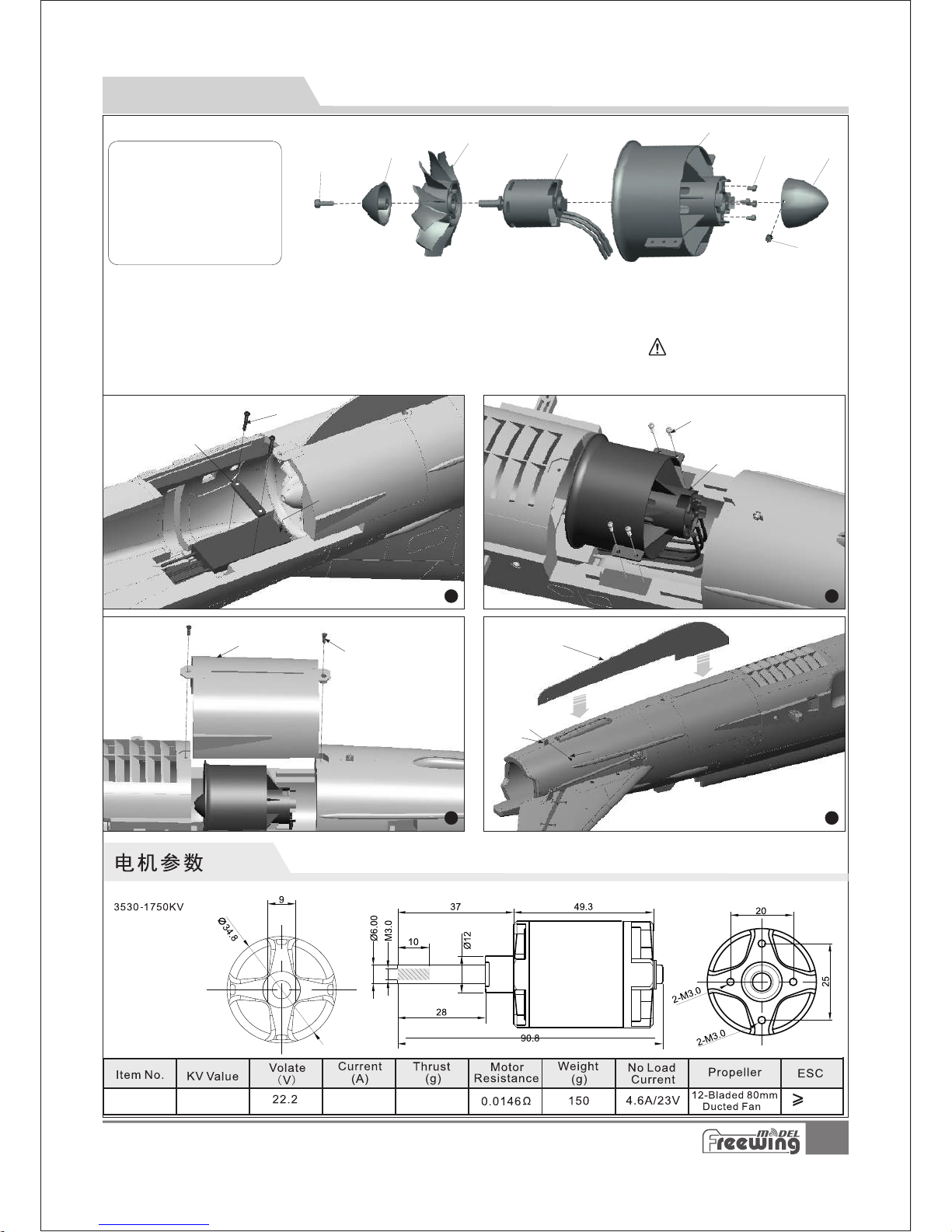

Motor parameters

Unit: mm

Step

3

Step

4

Step

H

A

B

C

D

E

F

G

A

B

C

D

E

F

G

H

-

-

-

-

-

-

-

-

(PM3×10mm 1pc)

( 3×3mm 2pcs)M

Power System Assembly

Motor spinner

Screws

80mm ducted fan metal

frame for outrunner motor

3553-1800KV motor

90mm 12-blade ducted fan

Spinner

Screw

Screws

Note: When you have a battery connected to

the ESC , do not touch either by hand to avoid

accidental injury. When testing EDF, use a safety

test stand.

Refer to the following photo to install power system and ESC.

A

B

C

D

12

MI G- 21MF F IS HB ED

It em No .:F J210

Control direction test

After the build is complete, power up the radio and connect a fully charged battery to the ESC. Use the

radio to ensure correct control direction.

Aileron

Stick Rig ht

Stick Lef t

Elevator

Stick Back

Stick Forward

Rudder

Stick Lef t

Stick Rig ht

Optional Flaps

Flaps dow n

H1

H2

H1

H1

H2

H1

H2

13

MI G- 21MF F IS HB ED

It em No .:F J210

H1/H2 16mm/ 16 mm

H1/H2 30mm/30mm

H1/H2 30mm/30mm

H1/H2 24mm/24mm

H1/H2 20mm/20mm

H1 45mm

H1 30mm

H1/H2 20mm/ 20 mm

Ailerons

Elevator Rudder

Flaps

Low Rate

High Rate

D/R Rate:10 0% D/R Ra te:1 00% D/R Rate:10 0%

D/R Rate:80 % D/R Rate:10 0% D /R R ate:85%

Ailerons

Elevator

Rudder

Flaps

Dual Rates

According to our test results, the following rates proved to be a good starting point. Low rates are

good for initial flights or less experienced pilots. High Rates will be more sensitive to control

inputs After initial flights, adjust the rates to suit your own style.

14

MI G- 21MF F IS HB ED

It em No .:F J210

注意:模型产品是具一 定危险性的 产品, 请禁止14岁以 下的儿童玩 耍,14 岁 以上的儿童 ,请在有飞行经验 的成人指导 下使用 ,无飞行经 验的购买者 ,应当 在具有

一定电动涵 道飞机 飞行经验的 成人指导下使用! 组 装模型前, 请仔细阅读说明书 ,按照说明 书的要 求进行安装. 进 行调试和飞 行时, 请根据说明 书指示的参数进行 调整。

前 言

重 要 提 示

1.模型飞机不是玩具,操作者需要具备一定的经验;没有经验的初学者,必须在有丰富经验的专业人士指引下,逐步学习!

2.在组装之前,必须认真阅读产品说明书,严格按照说明书指示操作。

3.飞翼模型及其销售商,对于违反说明书的要求操作而造成的损失、将不负任何法律责任!

4.模型飞机的使用年龄必须是14岁以上的儿童或者成人。

5.此模型产品使用EPO材料制成,表面喷涂油漆,不可随意使用化学制剂擦拭,否则会损坏模型产品。

6.不可以在公共场合、高压线密集区、高速公路附近、机场附近或者其它法律法规明确禁止飞行的场合飞行。

7.不可以在雷雨、大风、大雪或者其它恶劣气象环境下飞行。

8.模型飞机的电池产品,不可以随意乱扔,乱放。存放时,必须保证周边2M范围内,无易燃、易爆物体。

9.损坏或者报废处理的模型飞机电池,应妥善回收处理,不准随意抛弃,避免自燃而引发火灾。

10.在飞场飞行时,应做到妥善处理飞行后所产生的垃圾,不可随意抛弃、焚毁模型及其配件。

11.在任何情况下,都必须保证油门杆处于起始位、发射机处于打开状态时,才能连接模型飞机内部的动力电池.

12.无论是模型飞机是在正常飞行过程中,或者是在缓慢降落过程中,都不要尝试用手去回收模型。必须等模型降落停

稳以后 ,再进行回收!

目 录

前言

产品基本参数

包装清单

PNP组装

舵机组装介绍

起落架组装介 绍

集线盒使用说 明

陀螺仪使用说 明

14

15

15

16

19

20

21

22

电池安装说明

舵机使用介绍

重心示意图

动力系统的安 装

电机参数

舵面测试

大、小舵参数

22

23

23

24

24

25

26

中文版

历史简介

1953年开始设计的MIG-21,是60年代前苏 联空军主力制空战斗机。此机是第二次世界大战后,生产数量最多的超音

速喷 气式战斗机,总产量超过6000架(不包括中国引进改型 的歼7系列 战斗机),在全世界,约50个国家和地区使用过该

款战斗机。

模型概述

飞翼1/9比例MIG-21MF,机 长1730mm,翼展800mm,这款模型的 外形线条 及轮廓, 完全依据 真实飞机 按比例缩

小制作,细节的 处理,使外形更加逼真。大量 使用塑料零件,使我们可以快 速、便捷安装主翼、平尾及垂 尾。较长的空速

管和机 鼻,可重 复拆解,防 止运输过 程造成损坏 。MIG-21MF模型,采 用12叶80mm金属外 框涵道风 扇,3553-1720外

转无刷马达,100A ESC。 全机采用了8个9g金属数字分别控制垂尾、方向舵、升降 舵、副翼和襟翼,新型集线盒的使用,

不仅使设备舱更 加整洁,而且能够有效减少内 置连接线,降低飞行时接触不 良导致事故的风险。更大型号 的涡杆控制器和

全金属避震起落架,更加牢固、可靠。

新 的 80mm外 转 动 力 系 统 , 在 高 性 价 比 的 基 础 上 , 给 MIG-21MF模 型 带 来 强 悍 的 动 力 , 最 高 时 速 达 到

160kph/100mph。 虽然MIG-21的机体内

部空间非常难以设计,但是经过优化的电池舱空间,在保证重心的前提下,可以使用6S 4000mAh ~ 6S 5200mAh电池,

达到5分钟的最高飞行时长。

飞行特性

飞翼Mig-21MF电动涵道模型,非常适合中 、高级涵道 玩家,是一款非常富有操作乐 趣的产品。强劲的动力,使得 模

型最少起飞距离缩短到30M。经过气动优化 设计的MIG-21MF模型 ,在高速和低速 二种飞行状态下,均能保持非常稳定的

飞行,动作指令 响应迅速,易于控制和保持。 三角翼主翼及后掠水平尾翼设 计,使得它具有非常优秀的爬 升速度。低速大

仰角动作易于实现、不易失 速。降落时 ,开启襟翼 后,减速明 显,姿态不会出现过大的变化,机体呈18~45度仰角,配合

油门,慢速、轻柔降落。

涂装介绍

我们为这款产品准备了二 个涂装:蓝白灰色和银色。其 中,银色涂装的包装盒内,分 别包含了四 个国家的战斗涂装贴

纸,可供选择。

(注 :搭 配飞 翼模型80mm内 转动 力组 最高时 速达 到180kp h/113 mph ,此动 力组 ,可联系经销商 选购 !)

同样地,飞 翼模型 的E51三轴增 稳陀螺仪, 可以完 美的使用于M IG-21MF,我 们为这个电 子配件预留了安装 位置,您可 以参考说明书,自 行安装!MI G-2 1MF模型,

在陀螺仪的 帮助下 ,飞行将变 得更加容易控制, 可以更轻松 的实现 相关飞行动 作!

15

MI G- 21MF F IS HB ED

It em No .:F J210

打开产品包装,核对包装清单。(不同配 置的版 本,包含内 容不同)

产 品 包 装 清 单

序号

配件名称

PNP

KIT Plu s

Airfr am e

序号

配件名称

PNP

KIT Plu s

Airfr am e

中文版

产 品 基 本 参 数

注意: 此处 各项 参数 ,均使 用本 公司配 件测 试得 出,如 果使 用副 厂配件 ,会 有所 差异。

使用 副厂配件时 所产 生的问题, 我们 将无法 给予 技术 支持!

1605 mm(63.2 in.)

755m m(29.73 i n.)

比例 1.000

1730mm

(68.1" )

800mm( 31 .5")

-涡杆电动收放起落架

-新型铝合金减震起落架

-仿真座舱、飞行员

-磁吸附副油箱及挂架

其 它 特 性

2

翼载荷:123g/d m

电机:3530-18 00KV外转无刷电机

涵道风扇:80mm 12叶 涵道

电调:100A无刷电调 U BE C 5A

舵机:9g数字金属舵机

重量:2180g

推力:3000g

(8pcs)

(不含电池)

标 准 版

升 级 版

2

翼载荷:125g/dm

电机:3658-182 0KV内转无刷电机

涵道风扇:80mm 12叶 涵道

电调:100A无刷电调 U BEC 5A

舵机:9g数字金属舵机

重量:2215g

推力:3200g

(8pcs)

(不含电池)

前\后机身

主翼

平尾

垂尾

副油箱\挂架

1

2

3

4

5

预装所有电 子设备

预装舵机

6

7

8

9

10

预装所有电 子设备

预装所有电 子设备

预装舵机

预装舵机

无电子设备

无电子设备

碳纤管

空速管及天线配件

吸塑片及腹鳍

钢丝及螺丝包

贴纸\说明书

无电子设备

16

MI G- 21MF F IS HB ED

It em No .:F J210

1.分别将碳纤管A、B穿入机身。

碳纤管A

(Ø8x400 mm )

碳纤管B

(Ø6x345 mm )

2.将主翼舵机线沿机身线槽端口穿入机体内部。

主翼线槽端口

主 翼 组 装

中文版

PNP 组装说明

牵 引 钢 丝 使 用 说 明

注:包装盒 内有赠送的E PO胶水,请 使

用这支 赠送的胶水 进行粘合作 业。涂

摸胶水 应该均匀。 胶水均匀涂 摸完毕,

不要立 即粘合,请 等待90秒时间 ,再

进行粘 合,效果最 佳!

机 身 组 装

1.使用胶水粘合前、后段机体

通过调查,过多的舵机延 长线 会加大连接处接触不良的风险,严 重时,导致飞行过程,舵机断电而造成 飞行事故。由于MIG-21内部线

槽空间大且平直,故此模 型的 机体内,未使用舵机延长线。如下 图所示,包装盒内包含一根牵引钢丝,P NP配置下,我们可以利用这根

牵引钢丝,顺利的将主翼 、平 尾、垂尾舵机线布置到电池舱内。

进气栅

电池托盘

组 装 前 准 备

1.打开座舱,松开固定电池托盘的二颗螺丝,取出电池托盘。

2.取下机腹进气栅。

电

池

舱

牵

引

钢

丝

平尾舵机线

2.使用牵引钢丝,将平尾舵机线拉入电池舱内。

背

脊

背

脊

(KA3x 10mm 4p cs)

螺丝

17

MI G- 21MF F IS HB ED

It em No .:F J210

中文版

主翼舵机、起落架连接线

螺丝 (PM3 x6 4pcs )

3.用4颗螺丝固定主翼。

E

S

C

电

池

舱

4.使用牵引钢丝,分二次将左、右二侧主翼连接线拉入电池舱内。

5.使用线槽塑料盖封闭进气道内壁上的主翼连接线线槽。 6.使用胶水和螺丝固定进气栅。

平 尾 组 装

平 尾 、 垂 尾

1.将平尾插入到机身尾部。

2.用2颗螺丝拧紧固定平尾。

3.重复以上步骤安装另一侧平尾。

AB-

尾部

螺丝 机身(KA2.6x8 4pcs)

A

B

PNP 组装说明

(FA 3x8 mm)

螺丝

D

C

A

B

18

MI G- 21MF F IS HB ED

It em No .:F J210

H

F

配件名称及规 格参数

A B CDE F GHI J K -

机

天线

空速管零件1

碳纤管

空速管零件2

塑料件1(左、右)

塑料件2

翼刀

腹鳍

挂架

副油箱

鼻

J

K

机鼻、空速管、 及 挂架组装翼刀 副油箱

D

B

C

A

G

E

注意:1.完成以上步骤后,根据集线盒上的内容通道标识,将所有舵机插入到集线盒内。

2. 最后用4颗螺丝固定电池托盘(所有舵机线处于电池托盘下方)。

(Ø5x1 80m m)

碳

纤

管

(

Ø

5

x

1

8

0

m

m

)

PNP 组装说明

中文版

垂 尾 组 装

ABCD-

垂尾

尾部机身

舵机线

螺丝 (FA3x8 4pc s)

1.

2.用4颗螺丝固定垂尾。

使用牵引钢丝,将方向舵机线拉入电池舱内。

I

19

中文版

平 尾 舵 机 安 装

1.通过舵机测试仪或者遥控器,把舵

机摇臂校正到居中位置;

2.如右图所示,使用胶水把舵机和舵

面摇臂粘到平尾;

3.钢丝一端穿入到舵机摇臂后,调

节钢丝长度,在保持舵面居中的

情况下,将夹头扣入舵面摇臂内;

4.重复以上3个步骤,安装另外一侧

平尾舵机。

A

B

C

ABC-

舵机

舵面摇臂

舵机控制钢丝

垂 尾 舵 机 安 装

1.通过舵机测仪或者遥控器,把舵

机摇臂校正到居中位置;

2.用胶水分别把舵机和舵面摇臂粘

到垂尾上;

3.钢丝一端穿入到舵机摇臂后,调

节钢丝长度,在保持舵面居中的

情况下,将夹头扣入舵面摇臂内。

B

C

A

ABC-

舵面摇臂

垂尾舵机控制钢丝

舵机

舵机安装说明

主 翼 舵 机 安 装

1.通过舵机测试仪或者遥控器,把

舵机摇臂校正到居中位置;

2.用胶水分别把舵机和舵面摇臂粘

到主翼;

3.将舵机线卡到舵机线槽内,待所

有主翼舵机安装完成,贴上贴纸;

4.钢丝一端穿入到舵机摇臂后,调

节钢丝长度,在保持舵面居中的

情况下,将夹头扣入舵面摇臂内;

5.重复以上4个步骤,安装另外一侧

主翼舵机。

B

A

C

舵

机

线

D

ABCD-

舵机

主翼舵机控制钢丝

舵面摇臂

舵机线槽

副翼舵机钢 丝安 装孔位副翼控制钢 丝尺 寸

钢丝 直 径 1 . 5m mØ

90m m

(3- 1/2")

襟翼舵机钢 丝安 装孔位襟翼控制钢 丝尺 寸

钢丝 直 径 1 . 5m mØ

80m m

(3- 1/8")

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

1

2

3

2

3

1

平尾舵机钢 丝安 装孔位平尾控制钢 丝尺 寸

钢丝 直 径 1 . 5m mØ

158 mm

(6- 1/4")

垂尾舵机钢 丝安 装孔位垂尾控制钢 丝尺 寸

钢丝 直 径 1 . 5m mØ

58m m

(2- 5/16" )

MI G- 21MF F IS HB ED

It em No .:F J210

20

MI G- 21MF F IS HB ED

It em No .:F J210

中文版

起落 架 组装 介 绍

前 起 落 架 组 装

请参考以下图示,组装、更换、维修前起落架

A B CDE F GHI J -

前机轮

前轮轮轴

U型斜撑杆

E型扣

梢钉

E型扣

减震活动杆

弹簧

8字型减震转轴

螺丝

(Ø2.0pc s)

(Ø3.5X9 .2 mm 2pcs)

(Ø1.5mm 2 pc s)

(PM2x3 1p cs )

螺丝

前起落架主撑杆

E型扣

梢钉

L型摇臂

机米螺丝

前起落架主钢丝

前起落架转向控制环

前起落架转向钢丝

E型扣

(PM2x4 1p cs )

(Ø1.5mm )

(Ø3.5x9 .2 mm)

(M3x3mm )

(Ø2mm)

K L MN OP QR S T -

前起落架收放控制器

前起落架组件

螺丝

前起落架固定座

前起落架舵机控制钢丝

前起落架舵机

螺丝

前舱门盖

(PA3x8 4 pc s)

(PWA2x8mm 2p cs )

U-

V-

W-

X-

ABACADAE-

注意:在整 个起落 架组装过程 中,所有带扁口的 零件,在用 螺丝固 定时,

扁口面必须 面向螺 丝孔,只有 这样,螺丝的固定 才是有效的 ,零件 才能不会

转动和脱落 。

钢丝直径 Ø1.2mm

( 2- 9/16 ")

65m m

起落架转向 控制 钢丝尺寸

转向舵机钢 丝安 装孔位

旋转钢 丝,可以增加或 者减少

控制距 离

AE

A

B

C

D

E

F

G

E1

F1

H

I

J

K

L

M

N

P

O

Q

R

S

T

U

步骤

1

步骤

2

步骤

3

步骤

4

W

X

V

AB

AC

AD

步骤

5

步骤

6

步骤

7

21

MI G- 21MF F IS HB ED

It em No .:F J210

后 起 落 架 组 装

请参考以下图示,组装、更换、维修后起落架

A B C D E F GH I J K L MN OR -

轮轴

机轮

机米螺丝

后起落架斜撑杆

梢钉

E型扣

后起落架主撑杆A

机米螺丝

弹簧

螺丝

后起落架主撑杆B

后起落架钢丝

机米螺丝

电动起落架收放控制器

后起落架随动舱门

螺丝

(M3x3mm )

(Ø3.5X9 .2 mm 1pcs)

(Ø1.5mm 1 pc s)

(M4x3mm )

(PM3x4 1p cs )

(M4x4mm )

(PM2x5 2p cs )

A

B

C

D

E

F

G

ST U-

后起落架组件

螺丝

后起落架固定座

(FA3x8 4pc s)

S

T

U

集 线 盒 使 用 说 明

步骤

1

H

I

J

K

步骤

2

M

L

N

步骤

3

O

R

步骤

4

步骤

5

参考集线盒上的通道标识,将所有

电池舱内的连接线插入集线盒。

(不包含油门,此通道直接接入陀螺仪)

集线盒

单闪灯

起落架

方向

升降

副翼舵机

襟翼舵机

单闪灯

起落架

方向

升降

副翼舵机

襟翼舵机

接收机

中文版

起落 架 组装 介 绍

襟翼

起落架及接收机供电

方向

升降

副翼

当您使用陀螺仪时,升降、副翼、方向

舵三个通道经由陀螺仪连接到接收机上。

此处应该取消这三个通道与接收机的连

接,其它通道连接不变。

22

MI G- 21MF F IS HB ED

It em No .:F J210

中文版

副翼舵机 升降舵机 方向舵机

遥控 器

接收 机

1.请正确安放陀螺仪,

2.将平尾、方向及副翼舵机线分别接入陀螺仪输出端;

3.使用3根连接线,将陀螺仪输入端与接收机对应通道连接;

4.如果您的接收机通道数目允许,您可以再使用一根连接线连接陀螺仪与接收机,用来设置陀螺仪(开启/关闭)开关。

5.陀螺仪详细使用方法,请参考《陀螺仪使用说明书》。

陀 螺 仪 连 接 示 意 图

陀 螺 仪 使 用 说 明

电 池 安 装 说 明

拔

杆

向

后

推,打

开

座

舱

电池舱罩

电池

魔术贴

电池托盘

电池舱尺寸:L=280 W=66 H=70(mm)

电池安装在最前方,用魔 术带 绑紧

我们建议使用的电池容量和放电倍率如下:

6S 22.2V 4000mAh~6S 22.2 5500mAh

放电倍率 35C > 电池型号:40 00 ma /h 6 s

将电池与接收机连前,首先请打开发射机电源,

确认油门杆处于低位。

用四颗螺丝将陀螺仪固定在电池舱最前端的固定板上。安装时,

确定陀螺仪贴纸上的LOGO朝机头方向!

出厂时,陀螺仪已经通过测试,并设置好默认感度值,您可以

根据实际情况,进行小幅度调整。

MIG-21使用E51陀螺仪建议感度值,请参考此图。

固定板

螺丝 (PA2.3x8mm 4 pcs)

陀螺仪

23

中文版

我们的舵机 正、反向标准是:

当舵机输入 信号从 到 时,

如果舵机摇 臂,

顺时针旋转- --正向舵机

逆时针旋转- --反向舵机

1

2

3

4

5

6

7

8

舵 机 使 用 介 绍

如果您需要选购其它品牌的舵机进行安装,

请参考下面的表格选择正确的舵机

舵机使用位 置

序号

正、反向

舵机线长

前轮转向

左副翼

右副翼

左襟翼

右襟翼

左平尾

右平尾

垂尾

1

2

3

4

5

6

7

8

正向

正向

正向

反向

正向

反向

正向

正向

100mm

950mm

950mm

800mm

800mm

1050mm

1050mm

1050mm

重 心 示 意 图

正确的重心,直接关系到飞行的成功与否,请参考下面的重心标示图,来调整飞机的重心。

-您可以将电池向前,或者向后移动,来调整飞机的重心;

-如果通过电池的移动无法调整到正确的重心位置,您还可以适当的使用一些其它材料来配重,使

飞机的重心处于正确的位置!

比例 1.000

265mm

(10-1/2")

MI G- 21MF F IS HB ED

It em No .:F J210

24

MI G- 21MF F IS HB ED

It em No .:F J210

中文版

动 力 系 统 的 安 装

注意:当电 调与电 池连接后, 禁止用手

触摸电调和 涵道, 防止意外伤 害!测试涵道

时,请使用 安全的 测试架进行 测试,禁止用

手抓住涵道 的行为 。

按以下图示安 装动力组及电调:

ABCDEF -

螺丝

电调固定木片1

电调

电调固定木片2

螺丝 (

80mm涵道动力组

(

PWA 3x8mm 4pc s)

PM3x25m m 2p cs)

GHI J K -

涵道底盖

螺丝

腹鳍

腹鳍固定座

螺丝

(FA3x8mm 2 pc s)

(KA2.6x 8m m 1pcs)

G

H

I

J

K

步骤

3

步骤

4

步骤

2

E

F

电机整流罩

螺丝

80金属外转 涵道框

3553- 1800K V外转无刷马达

80mm 12叶 风扇叶

整流罩

螺丝

机米螺丝

(PM3x 6mm)

(PM3x 10mm)

(M3x3 mm)

ABCDEFGH-

标准版

步骤

1

MO035 302

MO035302

单位: 毫米(mm)

100A

86

3000

1800R PM /V

H

A

B

C

D

E

F

G

A

B

C

D

中文版

当您按前面的步骤组装好飞机后,在飞行前,我们需要用一块充饱电的电池,连接到电调。用遥控

器测试每个舵面的工作情况,检查是否正常!

副翼摇杆

向右运动

升降摇杆

向上运动

方向摇杆

向右运动

MI G- 21MF F IS HB ED

It em No .:F J210

25

舵 面 测 试

副 翼

升降舵

方向舵

襟 翼

副翼摇杆

向左运动

升降摇杆

向下运动

方向摇杆

向左运动

襟翼放下

26

MI G- 21MF F IS HB ED

It em No .:F J210

根据我们的测试经验,我们认为,按以下参数来设置副翼和升降舵的大、小舵,将有助于

飞行。在小舵角的情况下,飞机的可操控性能会好一些,适合初次飞行或者不太熟练的玩

家飞行。而大舵角的设置,可以提高动作灵敏度,使用经验丰富的玩家。您可以根据自身

的情况,来选择其中一种舵量进行飞行!

大 、 小 舵 参 数

副翼

升降舵

小舵量

大舵量

H1/H2 16mm/16 mm

舵量比率:80%

H1/H2 20mm/20 mm

舵量比率:100%

H1/H2 30mm/30 mm

舵量比率:100%

H1/H2 30mm/30 mm

舵量比率:100%

副 翼

升 降 舵

H1

H2

H1

H2

中文版

方向舵

襟翼

H1/H2 20mm/20 mm

舵量比率:85%

H1/H2 24mm/24 mm

舵量比率:100%

H1 30mm

H1 45mm

襟 翼

H1

方 向 舵

H1

H2

Add.:

FeiYi Building,face to Labor Bureau, Fumin Middle Road, Dalang Town,

Dongguan City,Guangdong Province, China

HK Freewing Model International Limited

东莞 市 飞 翼电子 科 技 有限公 司

香 港 飞 翼 模 型 国 际 有 限 公 司

地址: 广东省 东 莞 市 大 朗镇富民 中 路4 02 -40 8号飞翼 楼 四 楼

Web: http://www.sz-freewing.com

Email:freewing@sz-freewing.com

Tel: 86-769-82669669 Fax:86-769-82033233

Web: http://www.sz-freewing.com

Email:freewing@sz-freewing.com

Tel: 86-769-82669669 Fax:86-769-82033233

Dongguan Freewing Electronic Technology Ltd

R

Loading...

Loading...