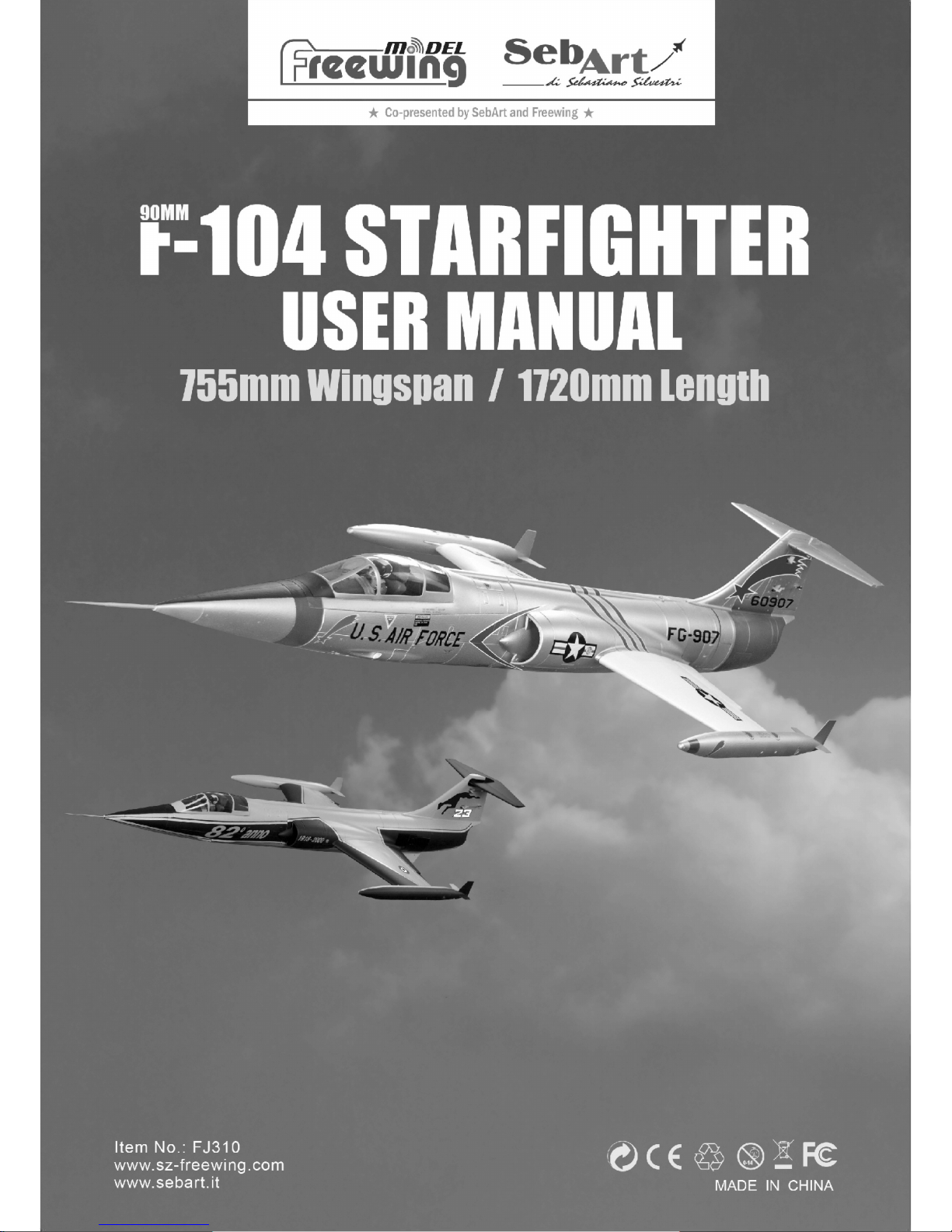

Freewing F-104 Starfighter User Manual

The famous Lockheed F-104 Starfighter has been recreated in this amazing 90 mm EDF jet. Following up on their

popular 70 mm variant, Freewing has answered the customer demands for a 90mm Super Scale version of this iconic jet

fighter.

Co-presented by SebArt and Freewing, the F-104 Starfighter 90 mm EDF jet is constructed with EPO foam,

with a wingspan of 755mm and a length of 1720mm and is available in two different color schemes. The silver color

scheme of the George Air Force Base's 479th Tactical Fighter Wing FG-907, and the yellow/black Italian Air Force 82th

anniversary paint scheme .

Other than some small adjustments in main wing and horizontal stabilizer shape, to increase its flight stability,

we have replicated the original shape of the F-104 as well as using a scale afterburner, warning lights and landing lights to

make the airplane more realistic looking during flight. The aluminum shock absorbing landing gear incorporates an electric

worm controller to effectively reduce the impact on landing . Fiberglass material is incorporated to make the nose and

main landing gear doors lighter to reduce weight as well as reduce its wind resistance during flight. A specially designed

air-brake will allow more airflow during flight, and help reduce landing speed. All this In addition to the many scale details

such as the scale pilot, instrumentation sticker, pitot tube…etc.

The main wing, horizontal stabilizer, vertical stabilizer all can be easily removed for transport. In order to enhance

the overall strength, several carbon tubes are located in the main wing, horizontal and vertical stabilizers as well as 2x16g

metal gear servos, 7x17g metal servos and 3x9g metal servos all using ball link connectors to increase flight stability.

The pre-installed 90mm 12-blade ducted fan with 3748-1550KV brushless motor and Hobbywing 130A (8A UBEC) ESC

gives it a great sound combined with powerful thrust and the use of a control board creates a less cluttered battery

compartment .

The 90mm F104S “Starfighter” comes with a Freewing 3-axis Gyro (E51) pre-installed to further increase its

flight stability. During flight, its excellent speed and climb performance can easily emulate conventional tactical

flight maneuvers. With the F104's special aerodynamic shape, a long glide path with the air speed brakes and

about 30 degrees elevation angle is needed to decelerate for landing.

1

R

Item N o.:FJ310

F-104S Starfighter

Index

EN

Introduction

Product Basic Information

Package list

Assembly

Nose cone Installation

Air-brake Installation

Landing gear Installation

Gear door Installation

3-Axis Gyro Introduction and use

1

2

2

3

6

6

7

10

11

Control board Introduction and use

Servo introduction

Battery

Installation

Center of Gravity

Motor Parameters

Power system Installation

Control direction test

Dual Rates

12

12

13

13

13

14

15

16

1. This is not a toy! Operators should have some basic experience. Beginners should operate only under the guidance

of a professional instructor.

2. Before beginning assembly, please read through the instructions and carefully follow them throughout the build.

3. Freewing and it's vendors will not be held responsible for any losses due to improper assembly and operation.

4. Model airplane operators must be at least 14 years of age.

5. This airplane is made of EPO foam material, covered with surface spray paint. Don't use chemicals to clean as it may

cause damage.

6. You should avoid flying in areas such as public places, areas with high voltage power lines, nearby highways, airports

or in other areas where laws and regulations clearly prohibit flight.

7. Do not fly in bad weather conditions, including thunderstorms, snow, etc...

8. Lipo batteries should be properly stored in a fire proof container and be kept at a minimum of 2M distance away from

flammable or explosive materials.

9. Damaged or scrap batteries must be properly discharged before disposal or recycling to avoid spontaneous

combustion and fire.

10. At the Flying Field, properly dispose of any waste you have created, don't leave or burn your waste.. Ensure that

your throttle is in the low position and that your radio is turned on before connecting the Lipo battery.

11. Ensure that the throttle is in the lowest position and transmitter is turned on, before connecting a Lipo Battery to

the ESC of the aircraft.

12. Do not try to catch the airplane while in flight or during landing. Wait for the airplane to come to a complete stop

before handling.

2

R

PNP

KIT Plus

Airfr ame

PNP

KIT Plus

Airfr ame

Item N o.:FJ310

F-104S Starfighter

1

2

3

4

5

6

7

8

9

10

Fuselage

Main wing

Tail wing set

Rudder

Nose cone

Fuel tank

Hardware

Carbon rods

Glue/Decals

Manual

Different types of kits will come with certain specific parts. Refer to the list of parts for your type of kit in the chart below.

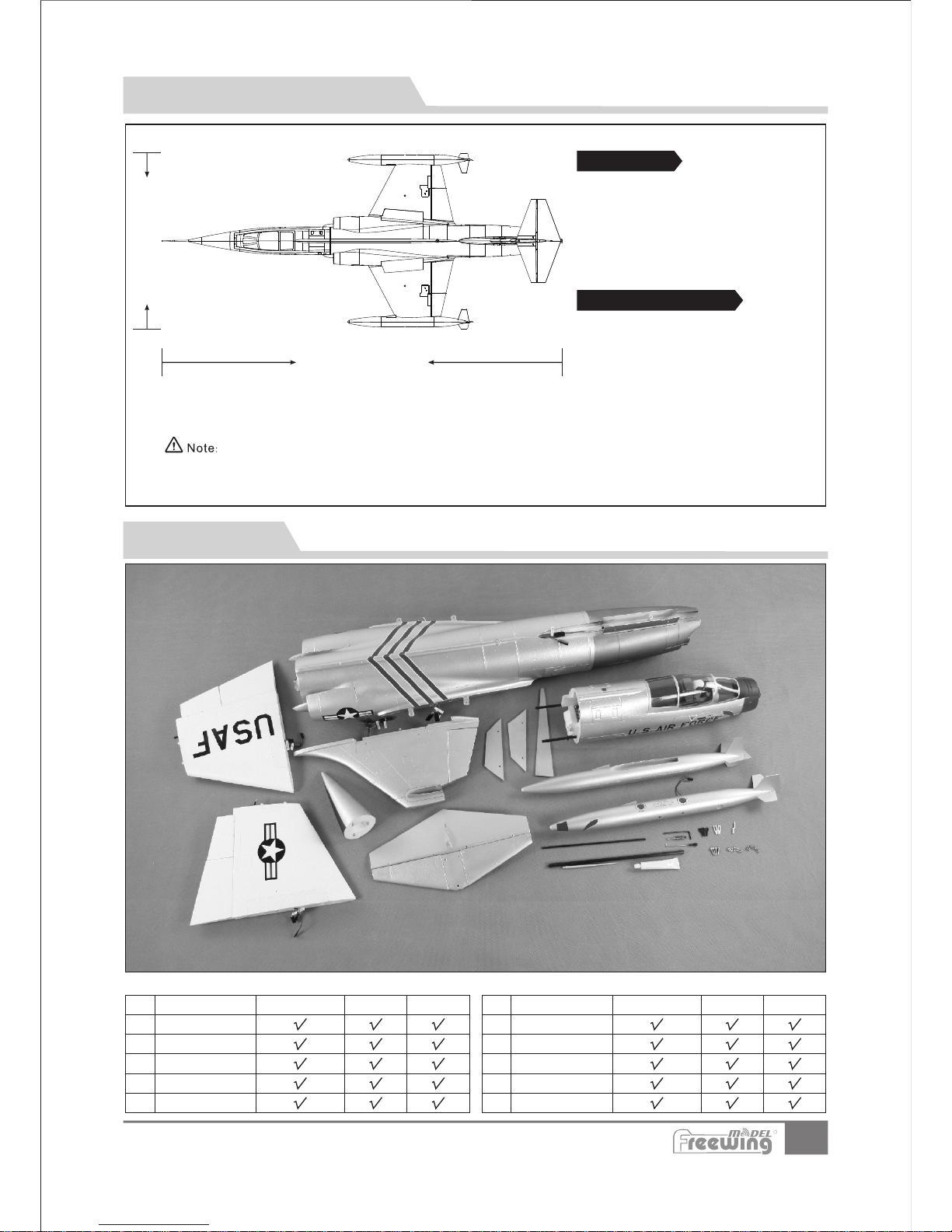

Product Basic Information

EN

Package list

NO.

Part Name Part Name

NO.

1720mm(67.7in.)

755mm(29.73 in.)

Specifications

Required to Complete

·

·

·

·Take-off weight:

2800g (99 oz.) w/o battery

·Thrust:3150g (112 oz)

Ducted Fans:12-Bladed 90mm EDF

·Motor:3748-1550KV

Brushless out-runner motor

·ESC:130A ESC With UBEC 8A

·Servo:9g*3pcs,16g*2pcs,17g*7pcs

7-channel Transmitter and Receiver

(minimum)

·6 Cell 5000mAh-6000mAh Li-po battery Lipo

battery charger

The parameters stated here are derived from test results using our accessories.

If you use other accessories, the test results will differ. We cannot provide technical

support if you have a problem when using other accessories.

3

Item N o.:FJ310

F-104S Starfighter

;

A

B

C

3

Step

1

2

D

E

F

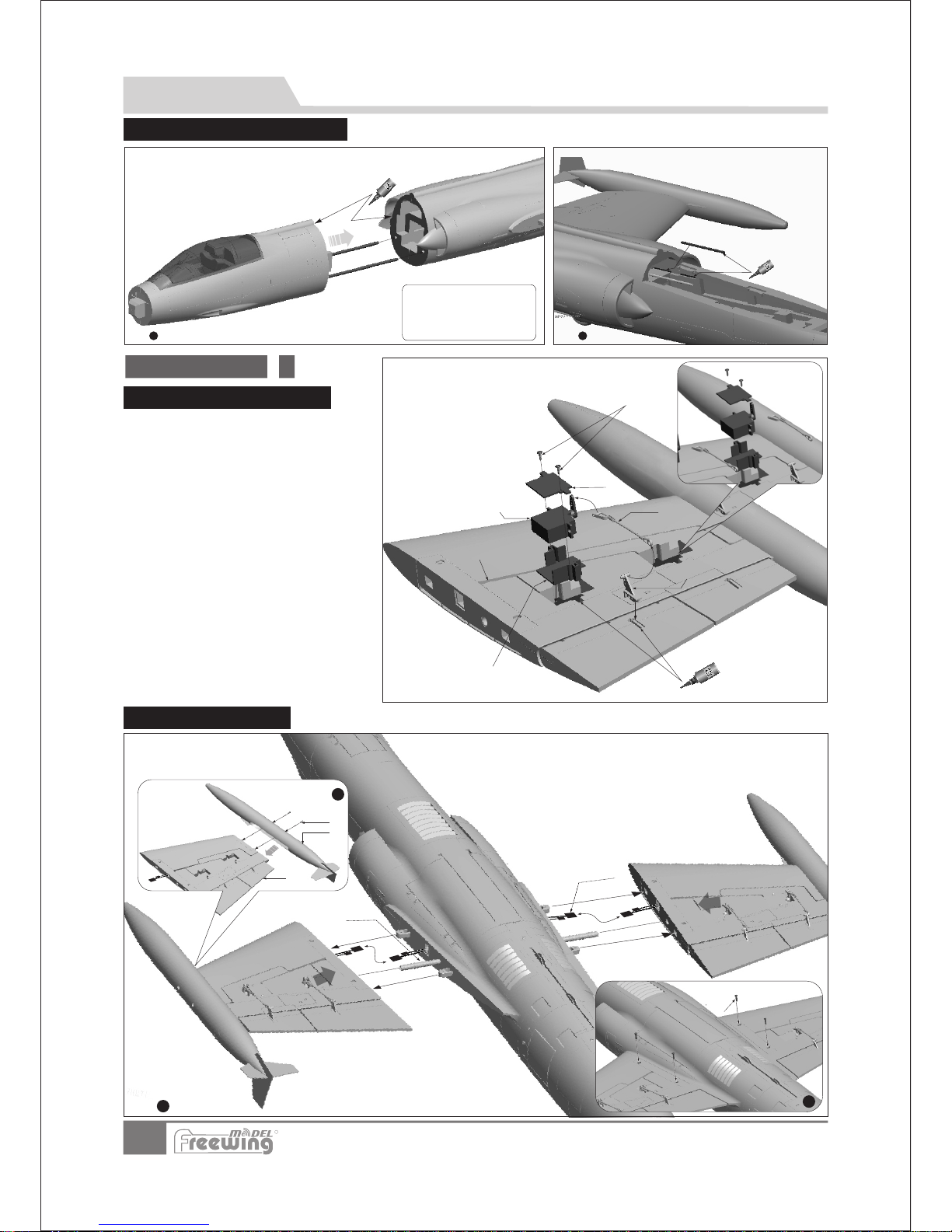

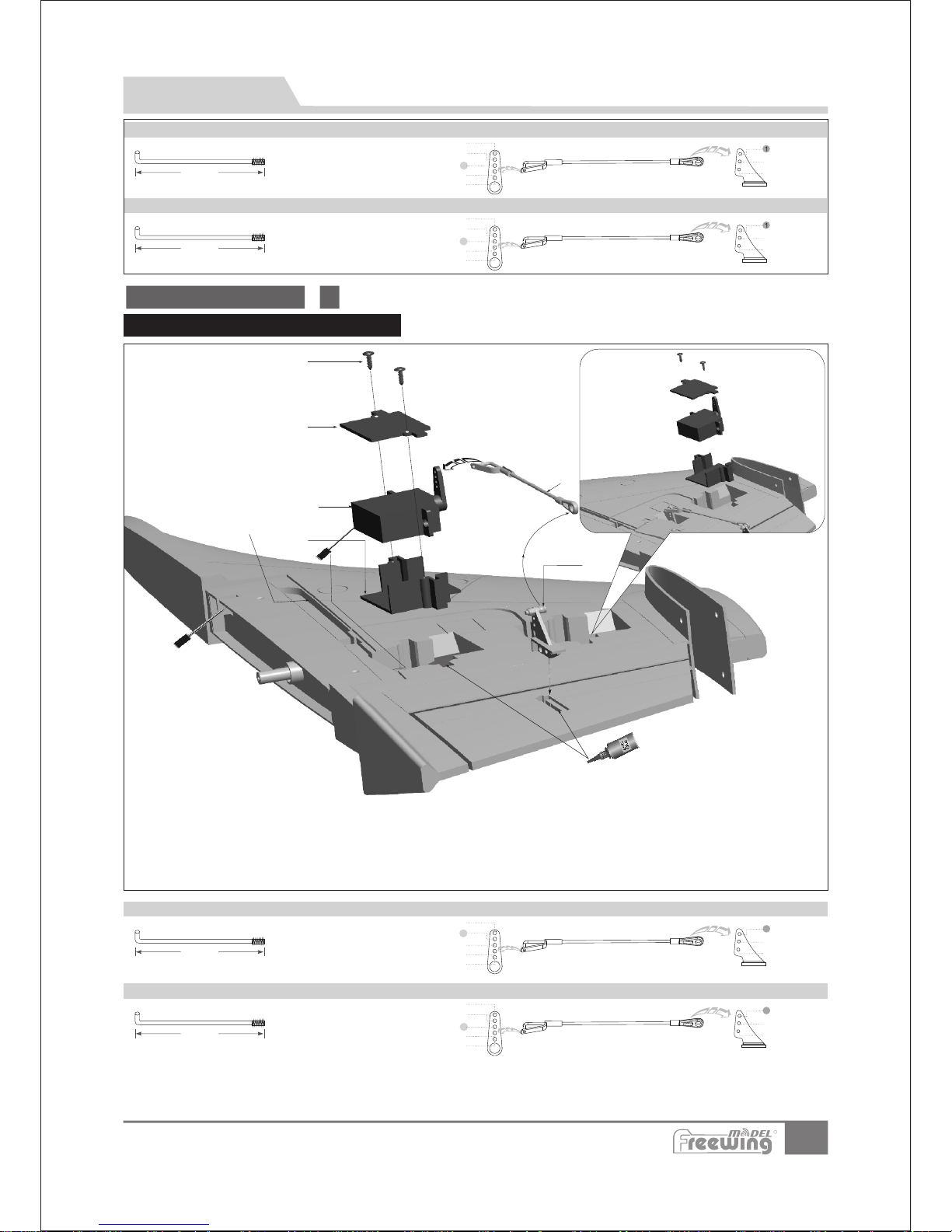

Assembly

Main Wing

Main Wing Servo Installation

1.

2.

3.

Use a servo tester or radio to center

the servo arm.

Use glue to anchor the 17g servo

box (C) and control horn(D)to the

main wing.

Place the 17g servo into the servo

box(C),and press the servo cable into

the servo cable trough (F), position the

17g servo cover(B) and use 2

screws(A), to secure the servo cover.

Connect pushrod (E) to the Servo Arm

and adjust its length so the control

surface is in the neutral position. Then

lock the clevis over the ball link on the

control horn (D)

A-Screw

B-Servo cover

C-Servo box

D-Horn

E-Pushrod

F-Servo cable trough

(PWA2x 8mm 4 pcs )

Servo

Step

Step

Main Wing Installation

EN

A

B

D

E

C

F

Note:There is EPO glue included

with the kit. . The glue should be

spread evenly then let it set for 90

seconds before joining the parts for

best glue strength.

Use glue and the Carbon rods to join the front and rear

fuselage sections. Carbon rods:Ø6x180mm 2pcs

1 2

Step Step

Carbon rods:Ø4x100mm 2pcs

Glue the carbon rods into the trough.

R

Front/Rear Fuselage Assembly

4.

1. Connect the servo cables to the fuselage extension cable.

2. Slide the main wings onto the fuselage.

3. Use 4 screws to secure the main wings.

A- Screws (PA3x8mm 4pcs)

B- Fuel tank

C- Main wing

D- Carbon rod (08x300 mm)

E- Servo/LED light extension cable

F- Screws (PM3x14mm 4 pcs)

Ailer on pushr od size Ailer on pushr od mounti ng hole

Fl ap pus hro d siz e Flap pus hro d mou nti ng hol e

4

Item N o.:FJ310

F-104S Starfighter

Pus hrod di amete r:Ø1 .5m m

1

2

3

4

5

1

2

3

1

2

3

4

5

1

2

3

A

B

C

E

D

F

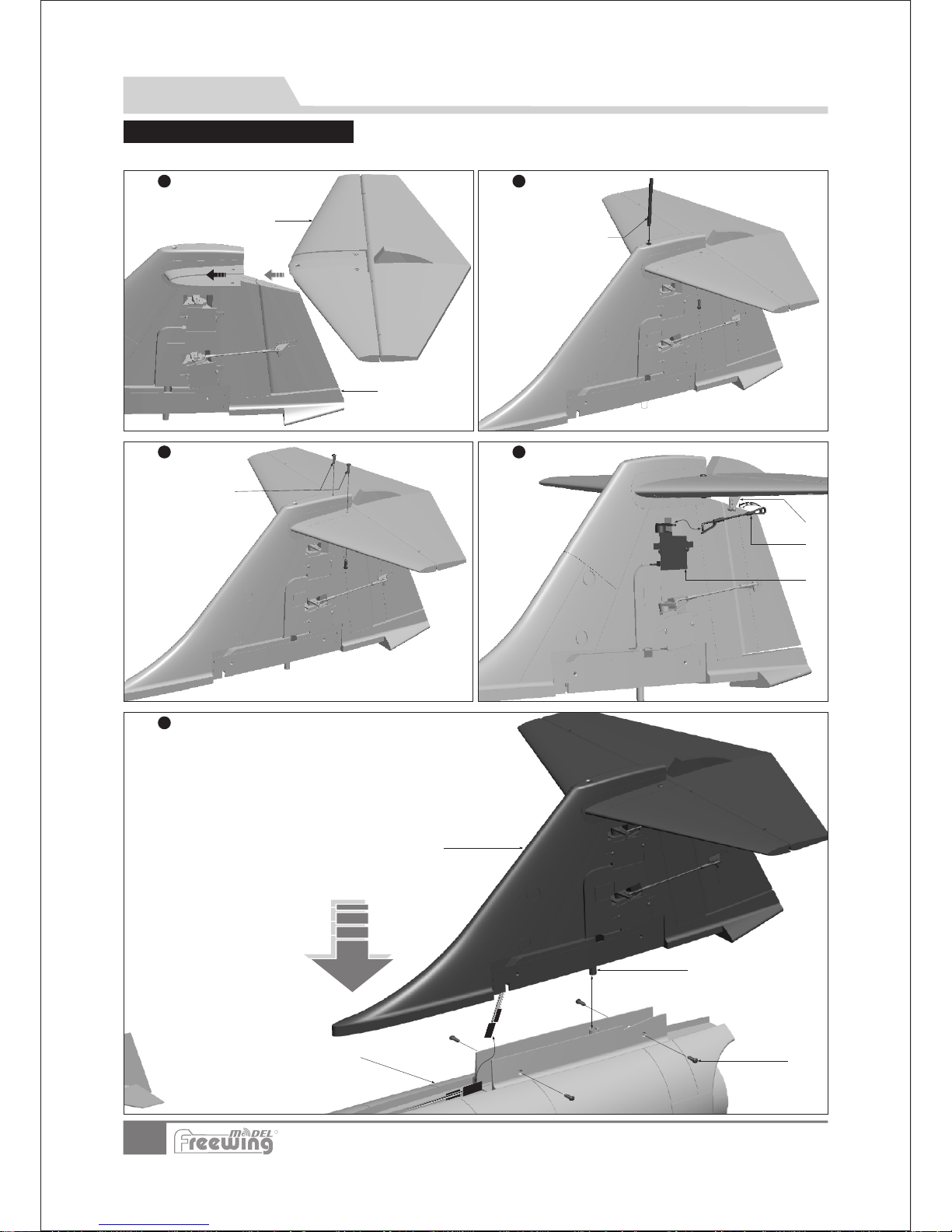

Pushrods

1. Use a servo tester or radio to center the servo arm.

2. ;

3. Place the servo into the 17g servo box(C),and press the servo cable into the cable trough (F).

4. Place the 17g servo cover(B) over the servo and use 2 screws(A)to secure it.

5. Connect pushrod (E)to the servo arm and adjust its length so the control surface is in the neutral

position then snap it over the ball link on the rudder control horn(D).

Use glue to attach the 17g servo box(C) and control arm(D)to the elevator and rudder.

Servo

Elevator and rudder

Elevator and Rudder Servo Installation

El evat or push rod size

Rudde r pushro d size

El evat or push rod moun tin g hole

Rudde r pushro d moun ting ho le

EN

A-Screws

B-Servo cover

C-Servo box

D-Rudder horn

E-Rudder pushrod

F-Servo cable trough

(PWA 2x8 mm 4p cs)

Pus hrod di amete r:Ø1 .5m m

Servo arm

Servo arm

58m m

(2. 28 in)

80m m

(3. 15 in)

1

2

4

5

70m m

(-2/3")2

2

3

1

2

3

4

5

70m m

(2-2/3")

2

3

3

Pus hrod di amete r:Ø1 .5m m

Pus hrod di amete r:Ø1 .5m m

Servo arm

Servo arm

R

5

Item N o.:FJ310

F-104S Starfighter

A

B

Carbon rod(Ø4x200mm)

1

A

B

C

Screws(FWA3x8 4pcs)

A-Horn

B-Elevator pushrod

C-Elevator servo

2

43

EN

Assembly

Step

Step

Step Step

A-Elevator

B-Rudder

Horizontal Stabilizer Installation

Please refer to the following photos to install the Horizontal Stabilizer.

A

B

C

D

A-Carbon rod

B-Screws

CD- Rud der

(FA3x8 4pcs)

Rear fuselage

5

Step

R

6

Item N o.:FJ310

F-104S Starfighter

Magnet

1

A

2

B

C

3

DD

4

E

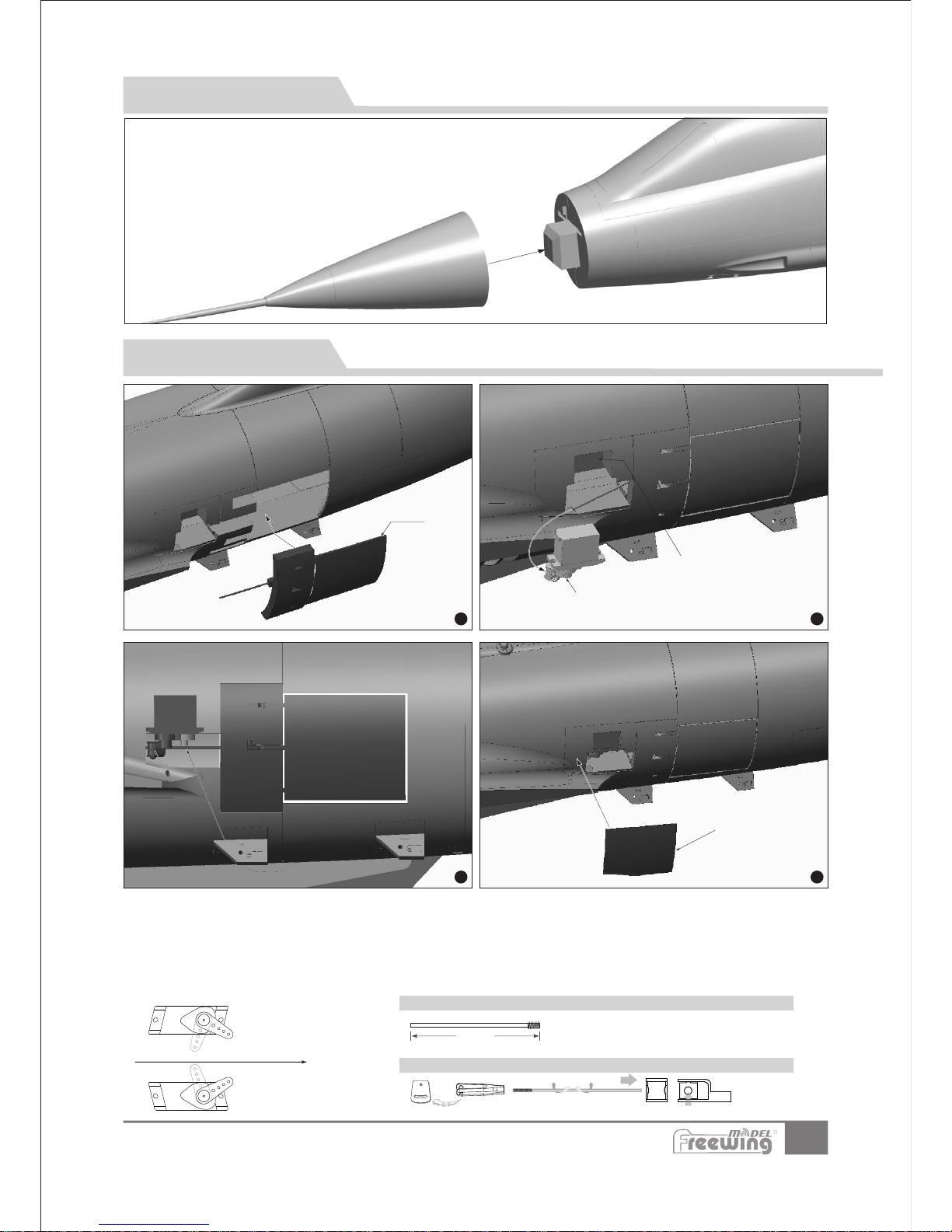

1. Use a servo tester or radio to center the

servo.

2.Use glue to attach the speed brake set (A) to both sides of the fuselage.

3.Use glue to attach servo(B) to the servo mount(C).

When installing, please note:

4.Ensure the servo and fuselage extension cables are properly attached and secure.

5.Insert the pushrod into the bolt of servo arm.

4.Keep the air brakes in the closed position, and tighten the screw of the bolt.

5.Test the system to make sure it is operating properly. Use glue to attach the servo

box cover in order to protect servo.

move forward toward the nose

EN

Air-Brake Installation

Step Step

StepStep

(1. 97in)

50m m

Rotating the pushrod,will increase

or reduce it's length.

Air-br ake pu shr od si ze

Air-br ake pu shr od mo unt ing ho le

Pus hrod di amete r:Ø1 .5m m

AB-16g Servo

C-Servo hard point.

Air-brake set

E-Servo cover

D-Pushrod

EN

Nose Cone Installation

Since a magnet is used to secure the nose cone, all you

need to do is to put it in place.

R

7

Item N o.:FJ310

F-104S Starfighter

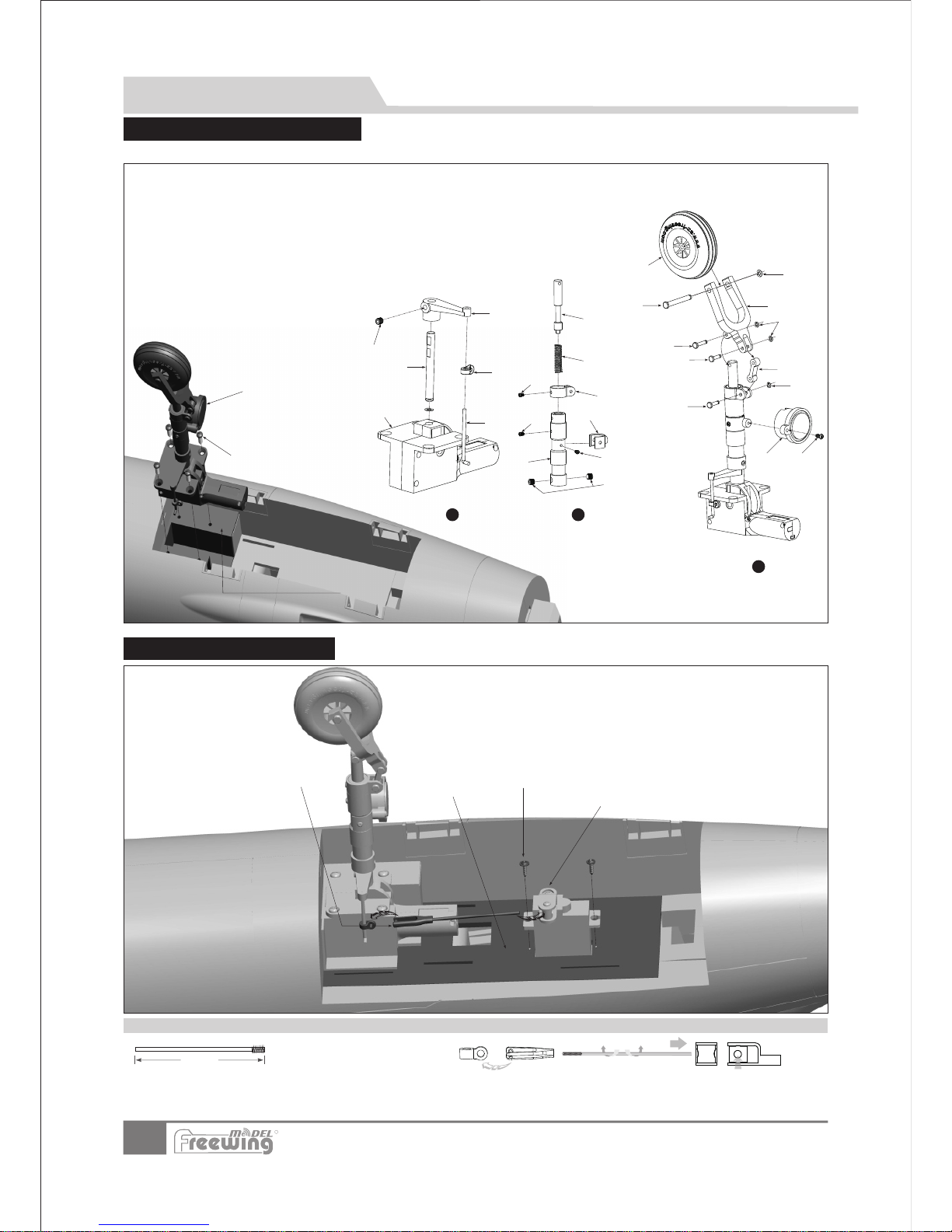

A

B

D

C

( 3.7 8in)

96m m

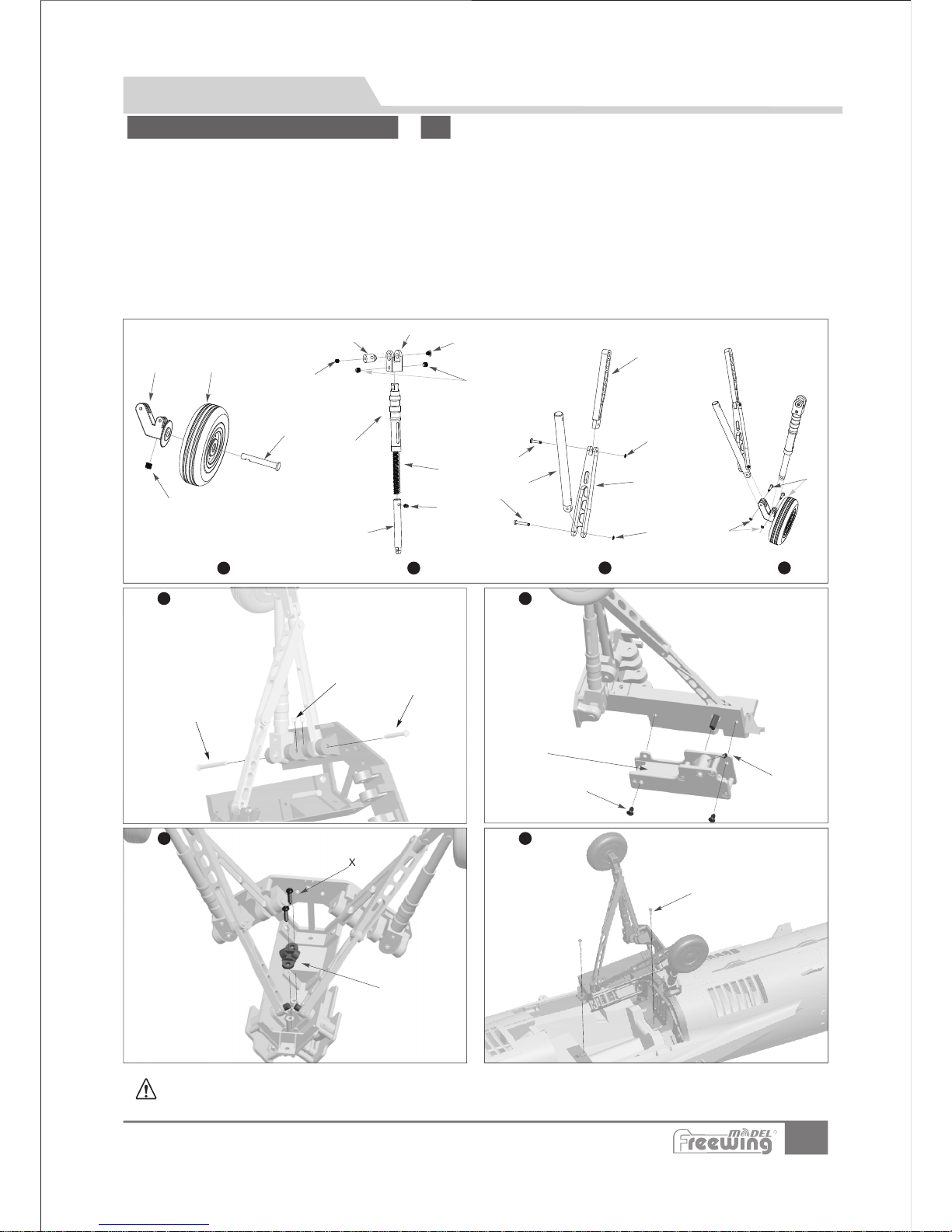

Please assemble and disassemble the nose gear by referring to the following photo.

Acces sor ies n ame and spec ifi cat ion

A- electric retract

B- Nose gear steering pushrod

C- Nose gear steering control ring

D- Nose gear metal shaft

E- L-shape arm

F-Grub screw

G-Grub screws

H-Nose landing gear main strut

I-Screw

(M3×3mm 1pc)

(M4 ×4m m 2pc s)

(PM2×3mm 1pc)

Nose gear assembly installed

Screws(PWA3x12 4pcs)

Nose gear mount

PQ

R

S

T

R1

S1

U

V

X

W

AB

3

Nose Gear Assembly

A

B

C

D

E

1

F

Step

G

H

I

K

J

M

L

N

O

2

Step

Step

M-Screw

N-Spring

O-Damping lever

P-Screw

Q-LED light

R-Pin

J-Screw(PM2x4mm) KLED light attachment arm

L-U-shape damping arm.

(PM2x3mm)

(PA2 ×8m m)

(Ø3.5x9.2mm)

STUV-

W-

X-

AB-

E-clip

8-shape connecting arm

Pin

U-shape slant supporting rod

Wheel shaft

E-clip

Wheel

(Ø1.5mm)

(Ø3.5x11.3 mm)

(Ø5x25.5mm)

(Ø2mm)

(Ø45x16mm)

Nose st eer ing p ushrod siz e

Servo p ush rod i nstallin g hol e

Rotating the pushrod,will increase

or reduce it's length.

Pus hrod di amete r:Ø1 .5m m

Landing gear Installation

EN

Nose gear servo Installation

R

A- Screws (PMA2x8mm 2pcs)

B- Servo

C- Landing gear pushrod

D- Nose gear hard point

Note:When installing, check that the flat position of the part is aligned with the Grub screw hole. The flat position must face

the hole in order for the Grub screw to lock the part in place and ensure it does not come loose.

8

Item N o.:FJ310

F-104S Starfighter

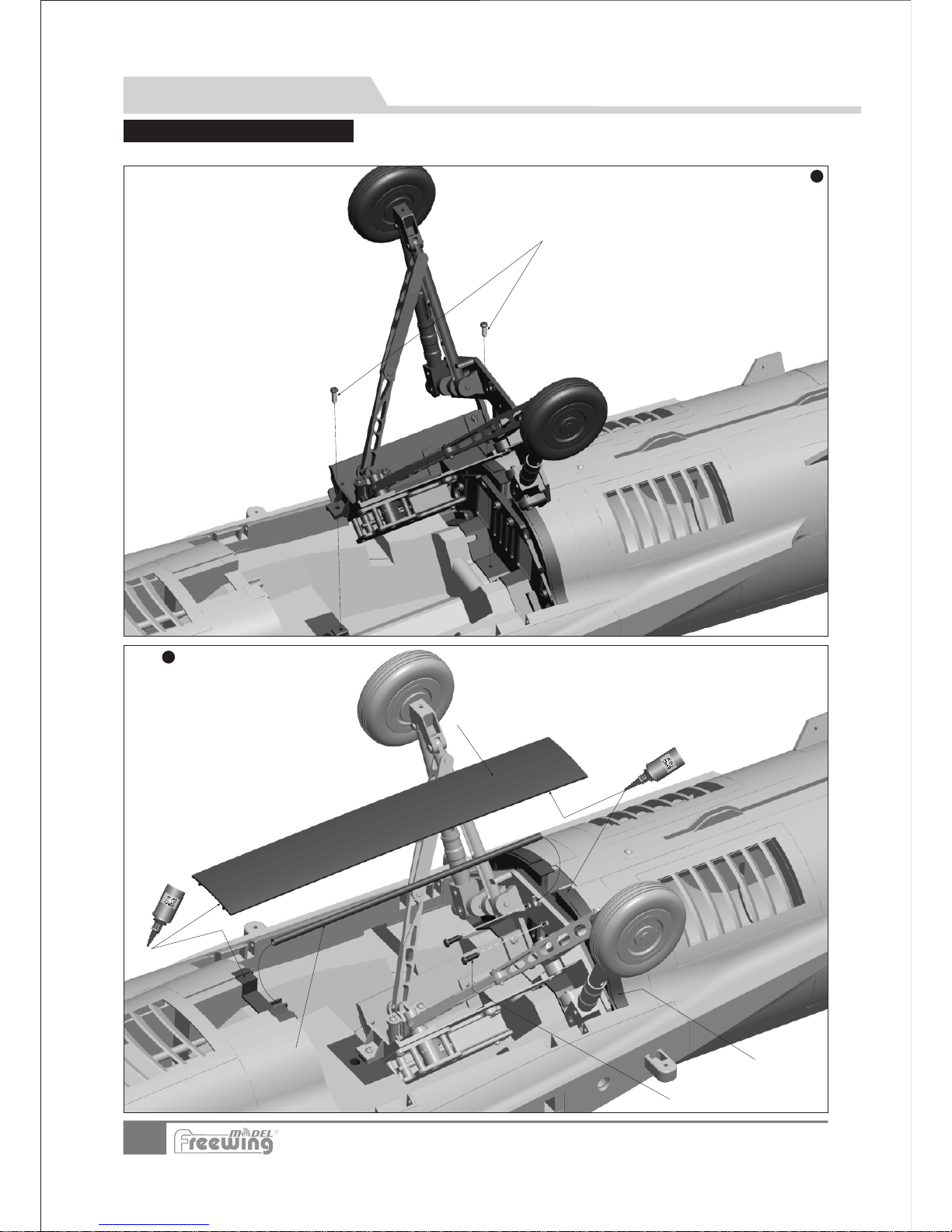

Please assemble and disassemble the rear landing gear by referring to the following photos.

W

X

M

X

X

Y

T

U

V

A

B

C

L

D

E

F

G

H

M

N

O

R

S

I

J

K

L

P

Q

S

S

1

2

3

4

5

6

7 8

Landing gear Assembly

EN

Rear Landing Gear Assembly

Accessories n am e and specifica ti on

Rear ge ar shock ab sorbe r conne cting arm

Rotat ing shaft

Rotat ing sleev e

Wheel

Rear ge ar axle

Rear ge ar main sup porti ng rod

Rear landing gear damping lever Rear

gear folding strut 1

( )

(Ø6.5x 24mm)

Ø60x1 6mm

A B CDE F G-

Springs(2pcs)

HI -

J K L MN OP QR-

Rear ge ar strut 3

Rear ge ar foldin g strut 2

Grub screws

Grub screws

Screws

Grub screws

Pins

Pins

Pins

(M4×3m m 6pcs)

(M3×3m m 4pcs)

(PWA 3×4mm 2 pcs)

(M3×5m m 2pcs)

(2pcs )

(2pcs )

(4pcs )

E-clips

E-clips

Pins

Pins

(Ø1. 5mm 8pc s)

(Ø2. 0mm 4pc s)

(2pcs )

(2pcs )

Electric retract

Screws(PWA3×12mm 2pcs)

Rear gear drive rod cover

S T U V WX Y -

Step

Step

Step

Step

Step

Step

StepStep

R

9

Item N o.:FJ310

F-104S Starfighter

( 4 x18 3.6 mm)

A-

CD-

(Ø4x183.6mm)

Screws(s(PPWWAA33xx8 28 2ppccss))

(Ø4x183.6mm)

B-Carbon rod

Rear gear mount

Plastic Fuselage cover

1

2

Screws(PWA3x12 2pcs)

A

B

C

D

Please assemble and disassemble the rear landing gear by referring to the following photos.

Landing gear Installation

EN

Main Landing Gear Assembly

Step

Step

R

41. 5mm

(1. 63 in)

10

Item N o.:FJ310

F-104S Starfighter

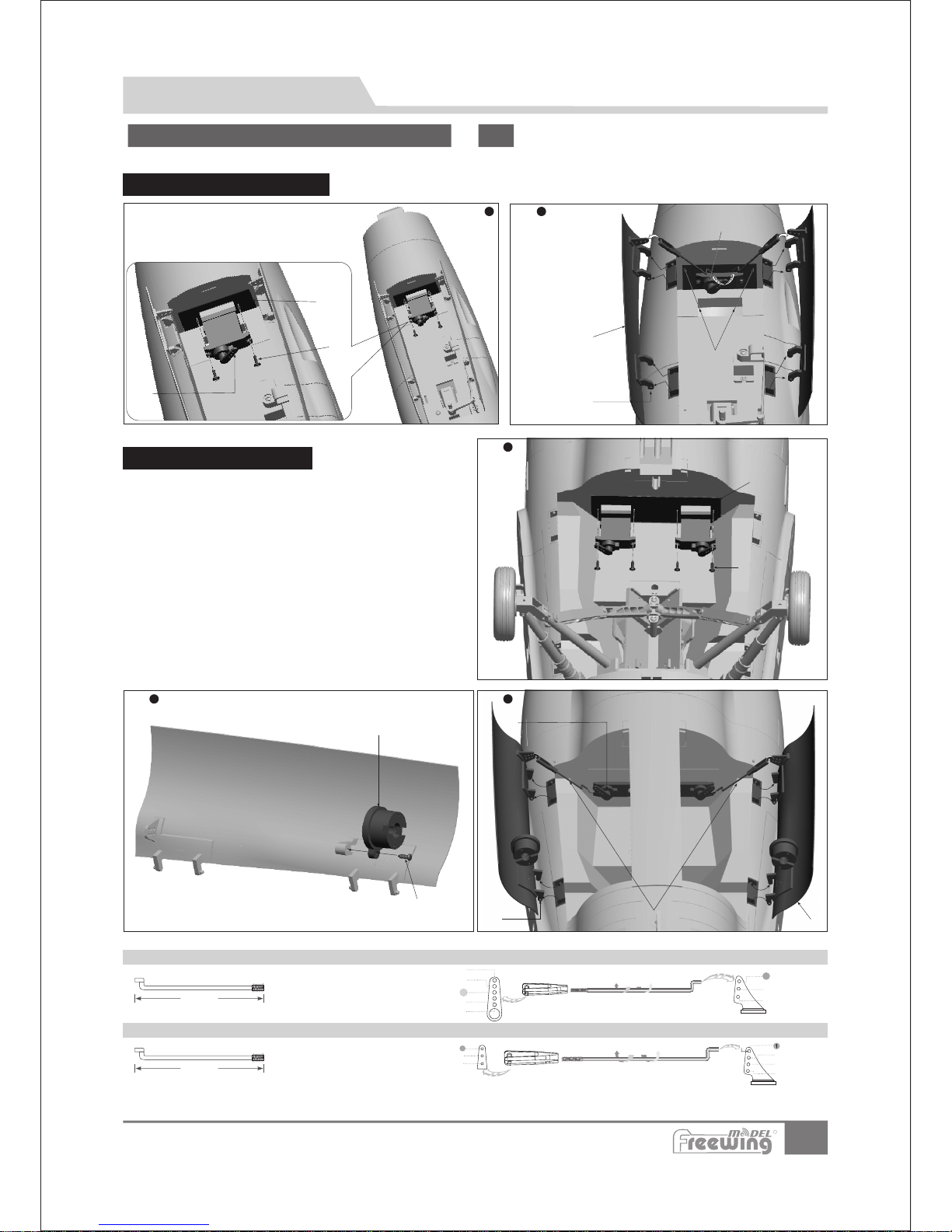

Gear Door Installation

EN

Nose and main gear

door Installation

Assemble, disassemble and replace the nose/rear landing gear doors by referring to the following photos.

Nose Gear Door Installation

A-17g servo

BC-Screws

Servo hard point.

(PWA 2x 8mm 2pcs)

A

B

C

1

2

Step

Step

C

D

B

A

A-Screws

B-Servo hard point.

C-LED light

D-Screw

EFGH-Servo

(PWA 2x 8mm 2pcs)

(PA2x8mm 1pc)

Gear Door rotating shaft

Rear Gear Door (left/right)

Gear Door pushrod

A

B

1

Step

Main Gear Doors

C

D

G

F

H

E

2

Step

3

Step

2

3

4

1

2

3

1

2

3

4

5

2

3

1

33m m

(1. 3 in)

Rot ating p ushro d,can i ncrea se

or re duce co ntrol d istan ce.

R

Pus hrod di amete r:Ø1 .2m m

Pus hrod di amete r:Ø1 .2m m

Nose ca bin d oor p ushrod siz e

Rear ca bin d oor p ushrod siz e(2 pcs )

Servo p ush rod i nstallin g hol e

Servo p ush rod i nstallin g hol e(2 pcs)

A- Gear door rotating shaft

B- Nose Gear Door (left/right)

C- Servo

Loading...

Loading...