Page 1

WC45i-GW-485 Modbus Gateway

User & Reference Manual

Part Number: LUM0086AA

Revision: Mar-2018

Page 2

Safety Information

The products described in this manual can fail in a variety of modes due to misuse, age, or malfunction and is not

designed or intended for used in systems requiring fail-safe performance, including life safety systems. Systems

with the products must be designed to prevent personal injury and property damage during product operation

and in the event of product failure.

Warning! Remove power before connecting or disconnecting the interface or RF cables.

FreeWave Technologies, Inc. warrants the FreeWave® WC45i-GW-485 Modbus Gateway (Product) that you

have purchased against defects in materials and manufacturing for a period of three years from the date of

shipment, depending on model number. In the event of a Product failure due to materials or workmanship,

FreeWave will, at its discretion, repair or replace the Product. For evaluation of Warranty coverage, return the

Product to FreeWave upon receiving a Return Material Authorization (RMA). The replacement product will

remain under warranty for 90 days or the remainder of the original product warranty period, whichever is longer.

IN NO EVENT WILL FREEWAVE TECHNOLOGIES, INC., ITS SUPPLIERS, OR ITS LICENSORS BE LIABLE FOR ANY DAMAGES ARISING

FROM THE USE OF OR INABILITY TO USE THIS PRODUCT. THIS INCLUDES BUSINESS INTERRUPTION, LOSS OF BUSINESS

INFORMATION, INABILITY TO ACCESS OR SEND COMMUNICATION OR DATA, PERSONAL INJURY OR DAMAGE, OR OTHER LOSS

WHICH MAY ARISE FROM THE USE OF THIS PRODUCT. THE WARRANTY IS EXCLUSIVE AND ALL OTHER WARRANTIES EXPRESS

OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE

ARE EXPRESSLY DISCLAIMED.

FreeWave’s Warranty does not apply in the following circumstances:

1. If Product repair, adjustments, or parts replacements are required due to accident, neglect, or undue

physical, electrical, or electromagnetic stress.

2. If Product is used outside of FreeWave specifications as stated in the Product's data sheet.

3. If Product has been modified, repaired, or altered by Customer unless FreeWave specifically authorized

such alterations in each instance in writing.

FreeWave Technologies, Inc.

5395 Pearl Parkway, Suite 100

Boulder, CO 80301

303-381-9200

Toll Free: 1-866-923-6168

Fax: 303-786-9948

Copyright © 2018 by FreeWave Technologies, Inc.

All rights reserved.

www.freewave.com

LUM0086AA Rev Mar-2018 Page 2 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 3

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Table of Contents

Preface 5

1. Overview 7

1.1. Operation 8

1.1.1. Remote WC45i-GW-485s and Non-sleeping Radio Only Endpoints 8

1.1.2. Remote WC45i-GW-485 Endpoint Re-Scan 8

2. Equipment 9

2.1. Included Equipment 9

2.1.1. User-supplied Equipment 9

3. WC45i-GW-485 Connections 10

3.1. Connections 11

3.1.1. Connections - WC45i-BB 11

3.2. Power and Gateway Connections 13

4. WC Toolkit Installation 14

5. WC Toolkit Update 21

6. Configuration 24

7. Gateway Event Log 30

8. Firmware Updates 32

8.1. Gateway Firmware Update 33

8.2. RadioFirmware Update 35

8.3. Rescue Gateway (ARM) Bootload 37

9. Remote Endpoint Configuration 40

10. Remote Shutdown (RSD) and Local Digital Output Control 44

10.1. Example: WC45i-GW-485 Modbus Gateway Topology 45

10.2. Remote Shutdown Configuration 46

11. Slave Register Remapping 48

12. Modbus Gateway Register Map 51

12.1. Boolean Registers 52

12.2. Read / Write Registers 52

12.3. Read-only Registers 53

13. WC Toolkit Software Environment 56

13.1. Device Configuration window 57

13.1.1. Modbus Slaves Reporting table 62

13.2. Edit Configurationwindow 64

13.2.1. Edit Configuration window - General Sensor 65

13.3. Firmware Updates window 71

13.3.1. Update Gateway Firmware menu - Firmware Updates window 71

13.3.2. Update Radio Firmware menu - Firmware Updates window 72

13.4. Gateway Log window 73

LUM0086AA Rev Mar-2018 Page 3 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 4

13.4.1. Gateway Log tab 74

13.4.2. Log Statistics tab 76

13.5. (RegisterView) Slave 1 window 80

13.6. Remote Shutdown Settings window 84

13.6.1. Source Node(Endpoint) area 86

13.6.2. Relay Control Logic Section 88

Relay Details 88

13.6.3. Destination Counter/ RSD Stick Section 90

13.7. Slave Register Remapping window 91

14. WAVECONTACT Network Frequencies 95

14.1. Radio Network Group Selection: 0, 1, 2, or 3 96

14.2. Radio Network Group Selection: 4, 5, 6, or 7 97

14.3. Radio Network Group Selection: 8, 9, 10, 11 98

14.4. Radio Network Group Selection: 12, 13, 14, 15 99

14.5. Radio Network Group Selection: 16, 17, 18, or 19 100

14.6. Radio Network Group Selection: 20, 21, 22, 23 101

14.7. Radio Network Group Selection: 24, 25, 26, 27 102

14.8. Radio Network Group Selection: 28 or 29 103

Appendix A: Technical Specifications 104

Appendix B: Connection Troubleshooting 106

Appendix C: LEDs 107

Appendix D: Available Accessories 108

Appendix E: FreeWave Legal Information 109

LUM0086AA Rev Mar-2018 Page 4 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 5

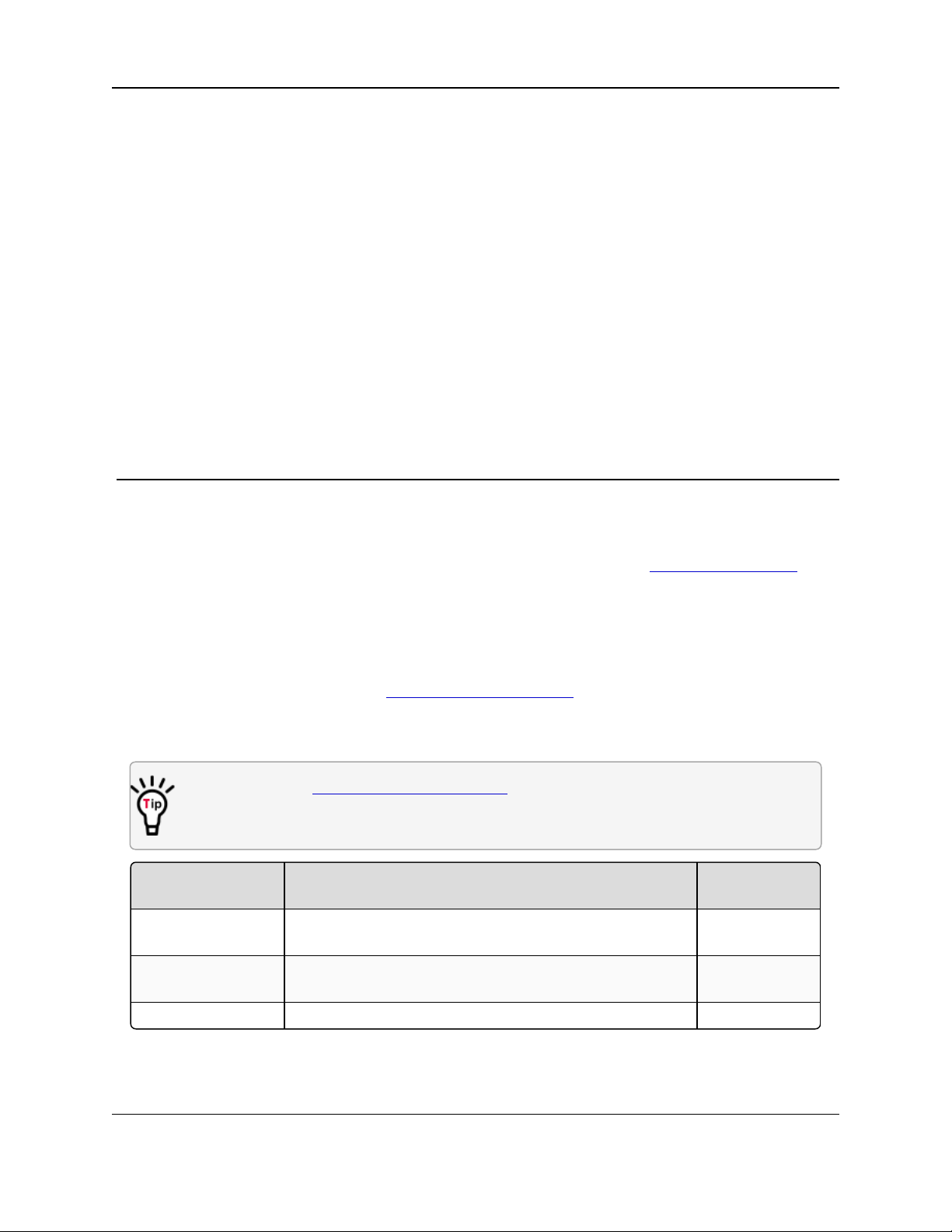

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Document Description

FreeWave

Part Number

User Manual The User Manual provides setup, configuration, andsafety

information for the WC45i-GW-485.

LUM0086AA

Quick Start Guide The Quick Start Guide provides the out-of-the-box setup of

the WC45i-GW-485.

QSG0035AA

ApplicationNote Remote Shutdown System LAN5510AA

Preface

Contact FreeWave Technical Support

For up-to-date troubleshooting information, checkthe Support page at www.freewave.com.

FreeWave provides technical support MondaythroughFriday, 8:00 AM to 5:00 PM Mountain

Time (GMT -7).

l Call toll-free at 1-866-923-6168.

l In Colorado, call 303-381-9200.

l Contact us through e-mail at moreinfo@freewave.com.

Other WAVECONTACT Information

Use the FreeWave http://support.freewave.com/ website to download the latest versionof

these documents.

Registration is required to use this website.

LUM0086AA Rev Mar-2018 Page 5 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 6

Preface

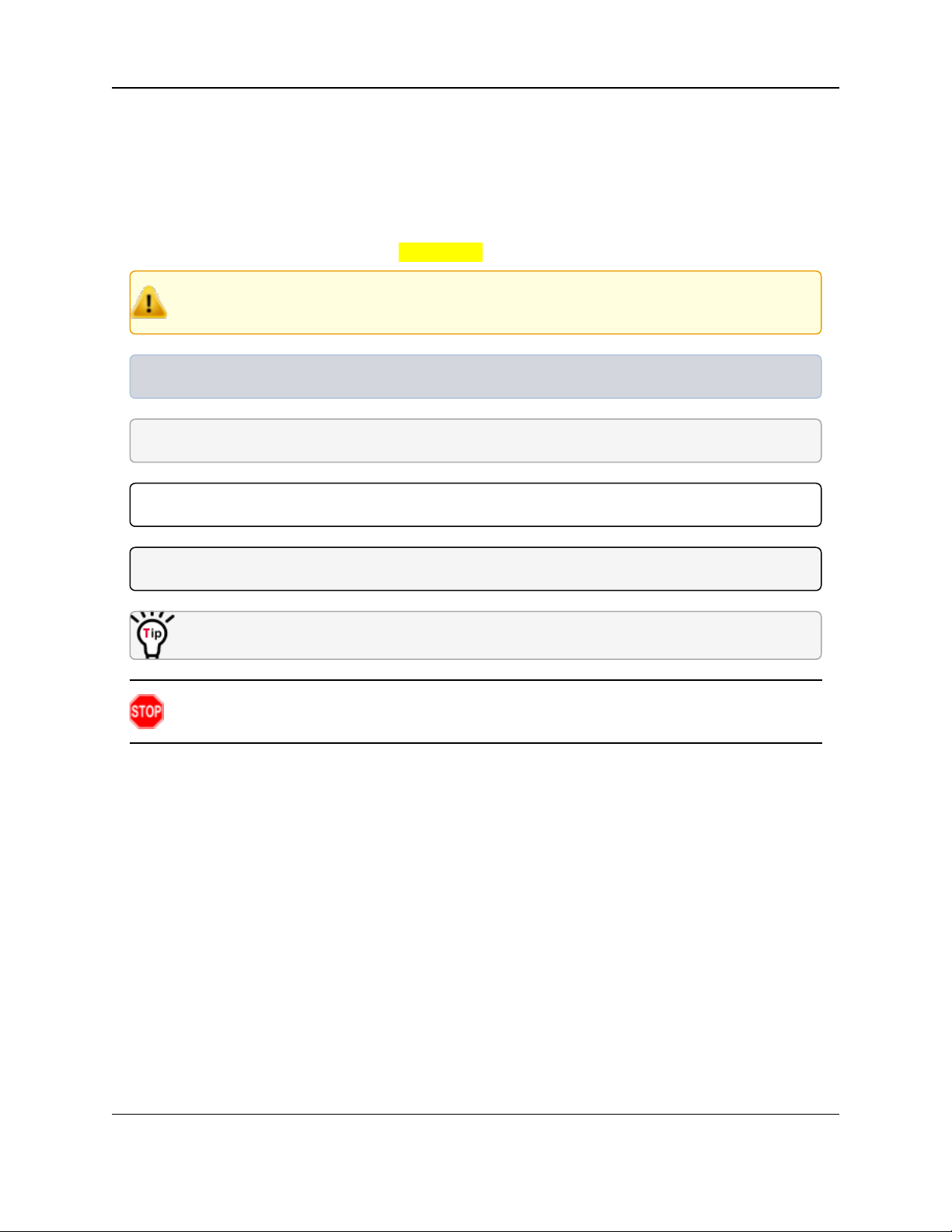

Document Styles

This document uses these styles:

l Parameter setting text appears as: [Page=radioSettings]

l File names appear as: configuration.cfg.

l File paths appear as: C:\Program Files (x86)\FreeWave Technologies.

l User-entered text appears as: xxxxxxxxx.

Caution: Indicates a situationthat MAY cause damage to personnel, the radio, data, or

network.

Example: Provides example information of the related text.

FREEWAVE Recommends: Identifies FreeWave recommendation information.

Important!: Provides crucial information relevant to the text or procedure.

Note: Emphasis of specific information relevant to the text or procedure.

Provides time saving or informative suggestions about using the product.

Warning! Indicates a situation that WILL cause damage to personnel, the radio, data, or

network.

LUM0086AA Rev Mar-2018 Page 6 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 7

WC45i-GW-485 Modbus Gateway: User & Reference Manual

1. Overview

Thank you for purchasing the WC45i-GW-485 Modbus Gateway.

The WAVECONTACT WC45i-GW-485 has these features:

l AES 128-bit Encryption

l Class 1 Division 2 Area certification

l RS485 connection to a Modbusmaster device.

l Wide range DC power input: +6 to +36VDC.

l Collectsand cachesModbus data from all WAVECONTACT remote devices.

l Providesconfiguration and status registers for remote configuration and status monitoring.

l Stores a maximum of 4700 register values from any combination of remote Endpoints.

l Supports transparent Modbus mode.

l Internal Remote Shut Down (RSD) logic control option.

l Slave register re-mapping.

l Remote configuration of WAVECONTACT devicesthrough an Ethernet Gateway

connection.

l Remote sensor configuration (PACTware™ and RadarMaster).

l Integrated500mW FHSS 900MHz ISM band radio and high gain antenna.

Note: The terms node and Endpoint are used interchangeably in this document.

LUM0086AA Rev Mar-2018 Page 7 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 8

1. Overview

1.1. Operation

The WC45i-GW-485 supports all remote WAVECONTACT Endpoints. This allows all remote

sensor data to be available in Modbus format.

l The register data from remote sensor Endpointsis available by requesting the remote

Endpoint’s Modbus Slave ID and register address from that Endpoint’s register map.

l The WC45i-GW-485:

l responds with the most recent copy of the data from the remote Endpoint.

l automatically times out data from a remote Endpoint it stops receiving data for.

1.1.1. Remote WC45i-GW-485s and Non-sleeping Radio Only Endpoints

l Pre-configured remote Endpoints forward their set of registers to the Modbus Gateway on

a pre-defined schedule (1 minuteto 5 minutes is typical).

l The register data is then buffered in the Gateway and can be read by the RTU at any

time.

l If a Modbus request is received by the WC45i-GW-485 for a Modbus ID and address where

buffered data does NOT exist but the Modbus ID is known, the Modbus request is

forwarded to the remote Modbus Endpoint over the WAVECONTACT network.

l The response is returned to the RTU.

l If a request for multiple registersis issued by the RTU AND if the WC45i-GW-485 does

NOT have all registered data buffered, an exception is returned.

l The system will NOT combine buffered and transparent data within a single Modbus

response.

1.1.2. Remote WC45i-GW-485 Endpoint Re-Scan

It is possibleto cause a remote WC45i-GW-485 to re-scan for attachedModbus devices by writing

to one of the Gateway’s configuration registers.

l This is useful to discover a Modbus device that is added to an existing Modbus Endpoint.

l The scan may be initiated by one of these methods:

l If the radio address of the Gateway is known, writing this address to Gateway register

3000 will result in a scan.

l If the ModbusID of one of the already registered devices attached to a WC45i-GW-485 is

known, a scan is started by writing the ID to Gateway register 3002.

LUM0086AA Rev Mar-2018 Page 8 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 9

WC45i-GW-485 Modbus Gateway: User & Reference Manual

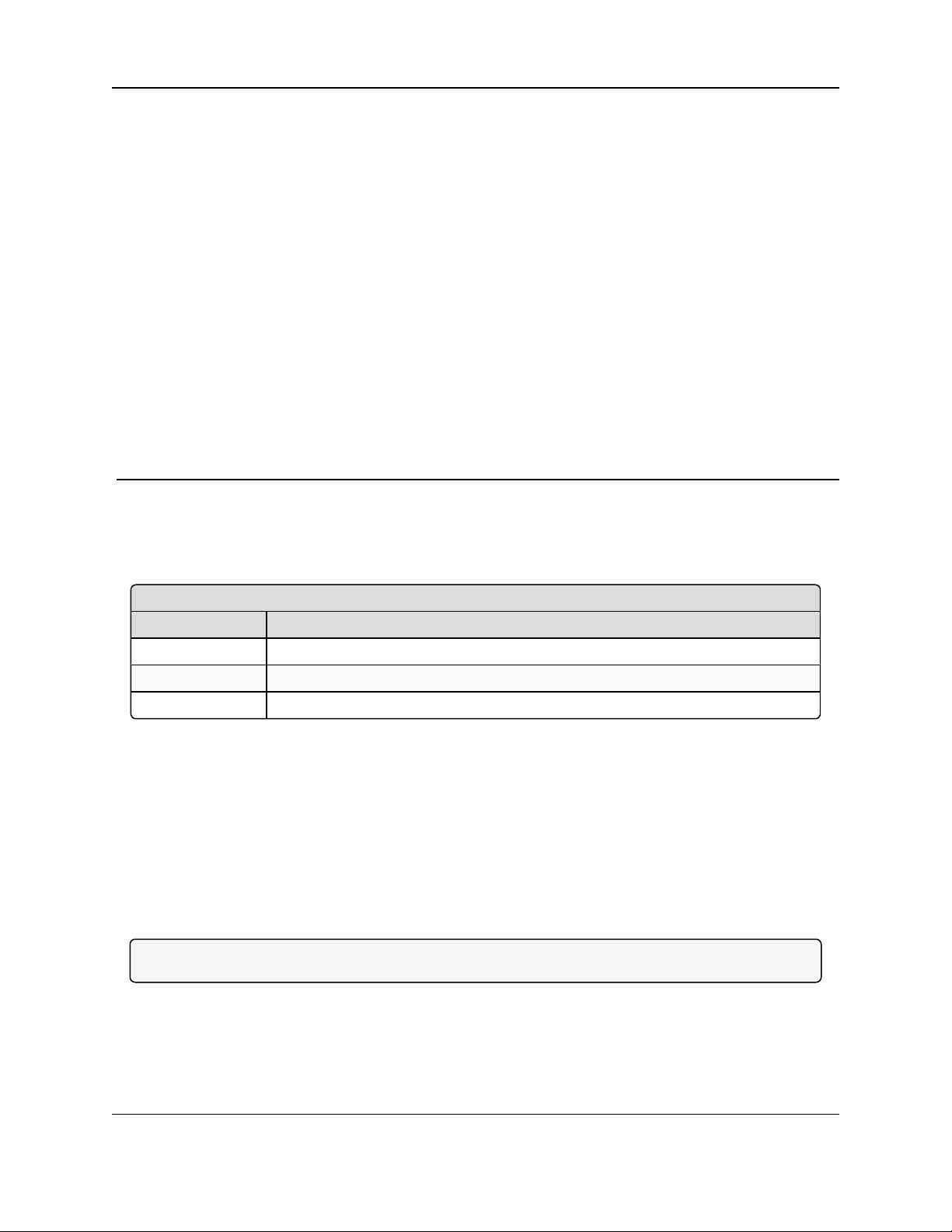

Included Equipment - WC45i-GW-485

Qty Description

1 WC45i-GW - Gateway with Modbus Interface and 25ft cable

1 WC45i-BB - Smart Breakout Board

1 WC45i-GW-485 Quick Start Guide

2. Equipment

2.1. Included Equipment

The WC45i-GW-485 package contains these items:

2.1.1. User-supplied Equipment

l Small, flathead screwdriver

l Mounting equipment for the WC45i-GW-485.

l USB to Serial DB9 programming cable (FreeWave Part #: WC-USB-DB9)

l DC Adapter Power Supply (+6 to +36VDC)

l Barrel connector with Ground and Power flying leads

l Computer for WAVECONTACT device configuration.

Note: See Available Accessories (on page 108) for additional equipment.

LUM0086AA Rev Mar-2018 Page 9 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 10

WC45i-GW-485 Modbus Gateway: User & Reference Manual

3. WC45i-GW-485 Connections

l Connections (on page 11)

l Power and Gateway Connections(on page 13)

LUM0086AA Rev Mar-2018 Page 10 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 11

3. WC45i-GW-485 Connections

3.1. Connections

Important!: The WC45i-GW-485 Modbus Gateway is configured using the WC Toolkit.

Downloadthe WC Toolkit software from http://support.freewave.com/.

Registration is required to use this website.

Note: The RS232 Config / Debug connector on the WC45i-GW MUST be used for WC Toolkit

access.

The Config / Debug port is accessed by a direct connection to the WC45i-GW-485 RS232 Config /

Debug connector port.

The WC45i-GW-485 usesa 6-conductor cable and the WC45i-BB Smart Breakout Board for

power and serial communications.

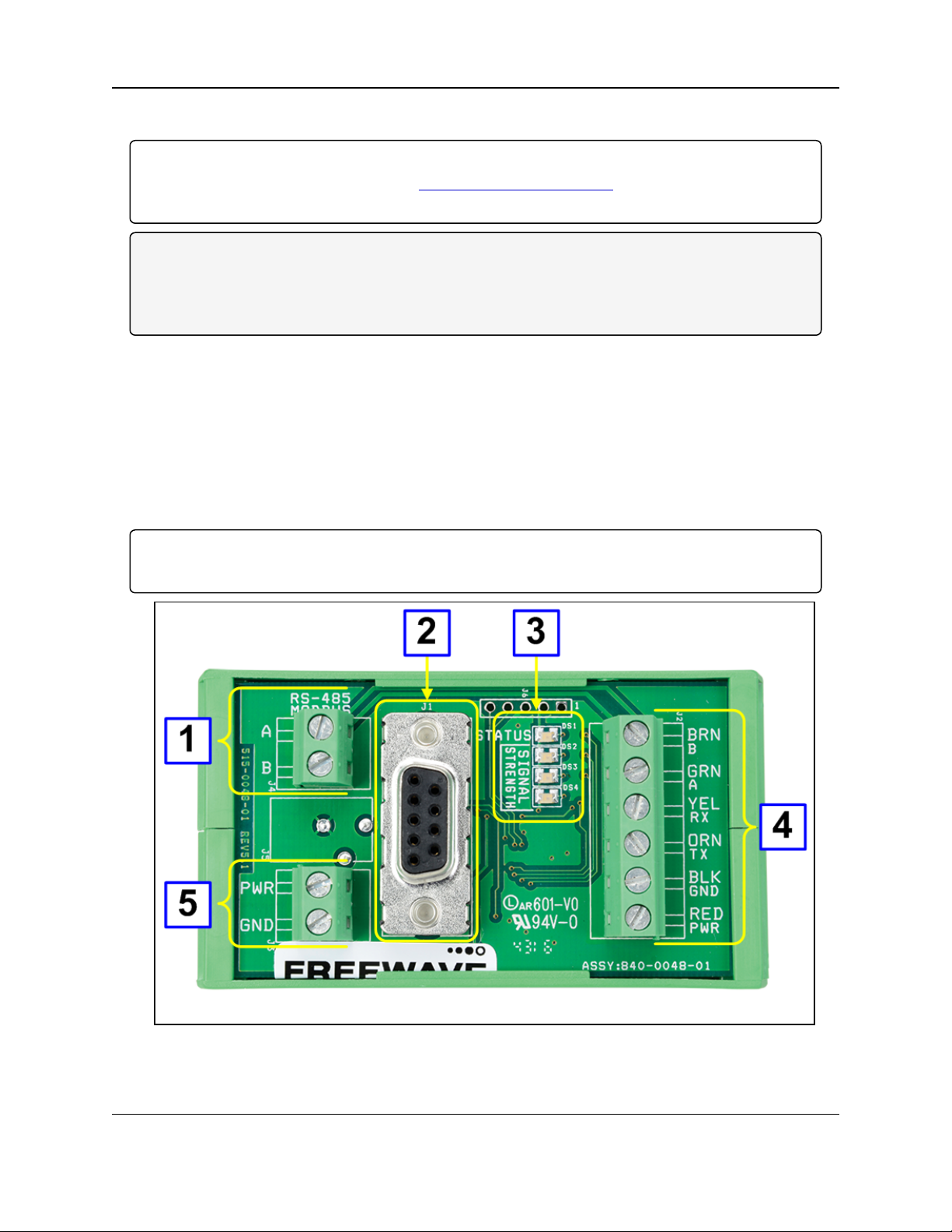

3.1.1. Connections - WC45i-BB

The WC45i-BB Smart Breakout Board (FreeWave Part #: WC45i-BB, Figure 1), is used to:

l Connect to the RS232 lines (#2)

l Configure the WC45i-GW-485 system (#4).

l Power the WC45i-GW-485 (#5).

Important!: The Signal Strength LEDs (#3) do NOT light at the Gateway as multiple Endpoints with

varying signal strength may be connected at one time.

Figure 1: WC45i-BB Smart Breakout Board used with the WC45i-GW-485

LUM0086AA Rev Mar-2018 Page 11 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 12

WC45i-GW-485 Modbus Gateway: User & Reference Manual

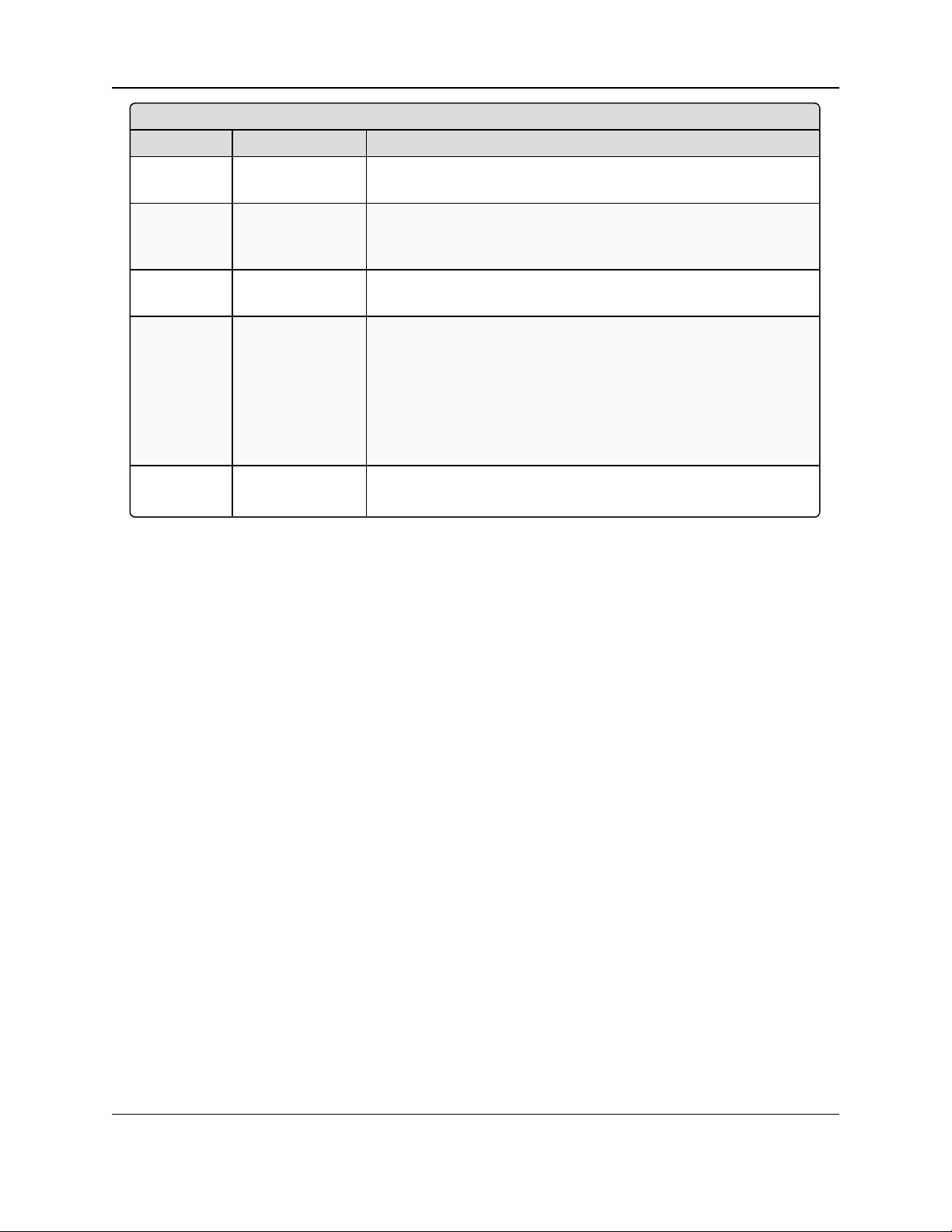

WC45i-BB Smart Breakout Board Connections

Location # Title Description

1 RS485 Modbus

Block

Connect the Modbus master to the RS485 Modbus Block.

2 RS232 RS232

Config / Debug

connector

The RS232 Config / Debug connector is for the USB to Serial

DB9 programming cable (FreeWave Part # WC-USB-DB9).

3 Signal Strength

LEDs

See LEDs (on page 107) for detailed information.

4 l BRN-B

l GRN-A

l YEL-RX

l ORG-TX

l BLK-GND

l RED-PWR

l RS485B - 9600 Baud

l RS485A - 9600 Baud

l RS232Config / Debug connector RX - 9600 Baud

l RS232Config / Debug connector TX - 9600 Baud

l Ground

l Positive Power (+6 to +36VDC)

5 PWR

GND

Power Source from an external power supply of +6 to +36VDC.

External power ground.

LUM0086AA Rev Mar-2018 Page 12 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 13

3. WC45i-GW-485 Connections

3.2. Power and Gateway Connections

Important!: Verify the items listed in Equipment (on page 9) are availablebefore starting this

procedure.

It is assumed that the readerand installer have completed the FreeWave WC45i-GW-485 installation

andsetup training to follow the procedures in this document.

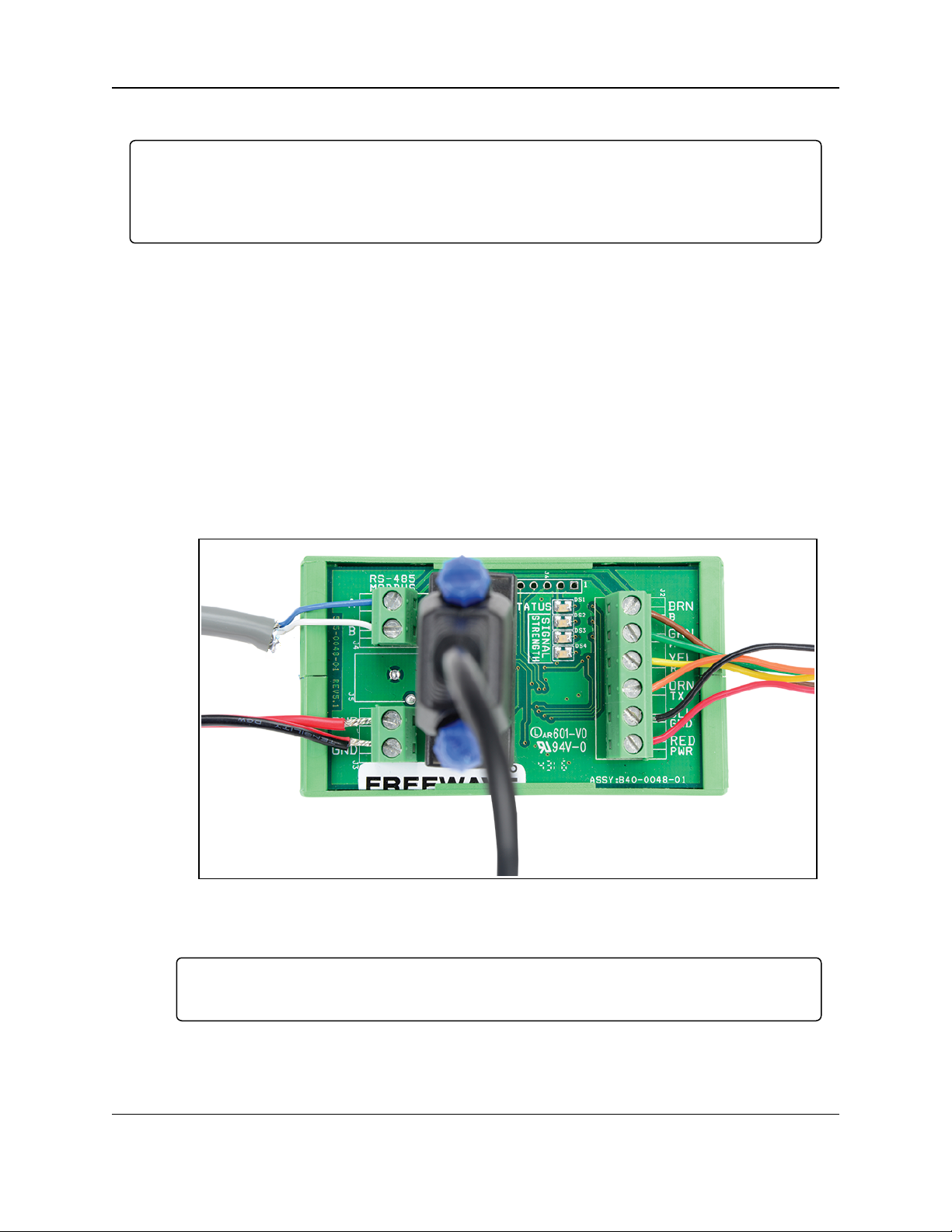

1. All wiring shouldbe neat and orderly.

2. On the WC45i-BB Smart Breakout Board:

a. Connect the configuration wires of the Gateway to their respectivecolor-designated

screw terminal connections.

b. Connect the Serial end of the WC-USB-DB9 cable to the RS232 Config / Debug

connector port and the USB connection to the computer.

c. Use the PWR screw terminal connection to connect the Power Source from an

external power supply of +6 to +36VDC.

d. Use the GND screw terminal connection to connect the External power ground.

e. Connect the Modbus master to the RS485 Modbus Block.

The WC45i-BB connections are similar to Figure 2:

Figure 2: WC45i-BB Connections

3. If this is the first time the WC45i-GW-485 is installed, wait for the drivers to install.

Important!: Depending on the computer and connection, the driverinstallationcan take 3-6

minutes.

4. Continue with:

l WC Toolkit Installation (on page 14)

l Configuration (on page 24)

LUM0086AA Rev Mar-2018 Page 13 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 14

WC45i-GW-485 Modbus Gateway: User & Reference Manual

4. WC Toolkit Installation

Note: The images in this procedure are for Windows® 7 and/or Firefox®.

The dialog boxes and windows may appear differently on each computer.

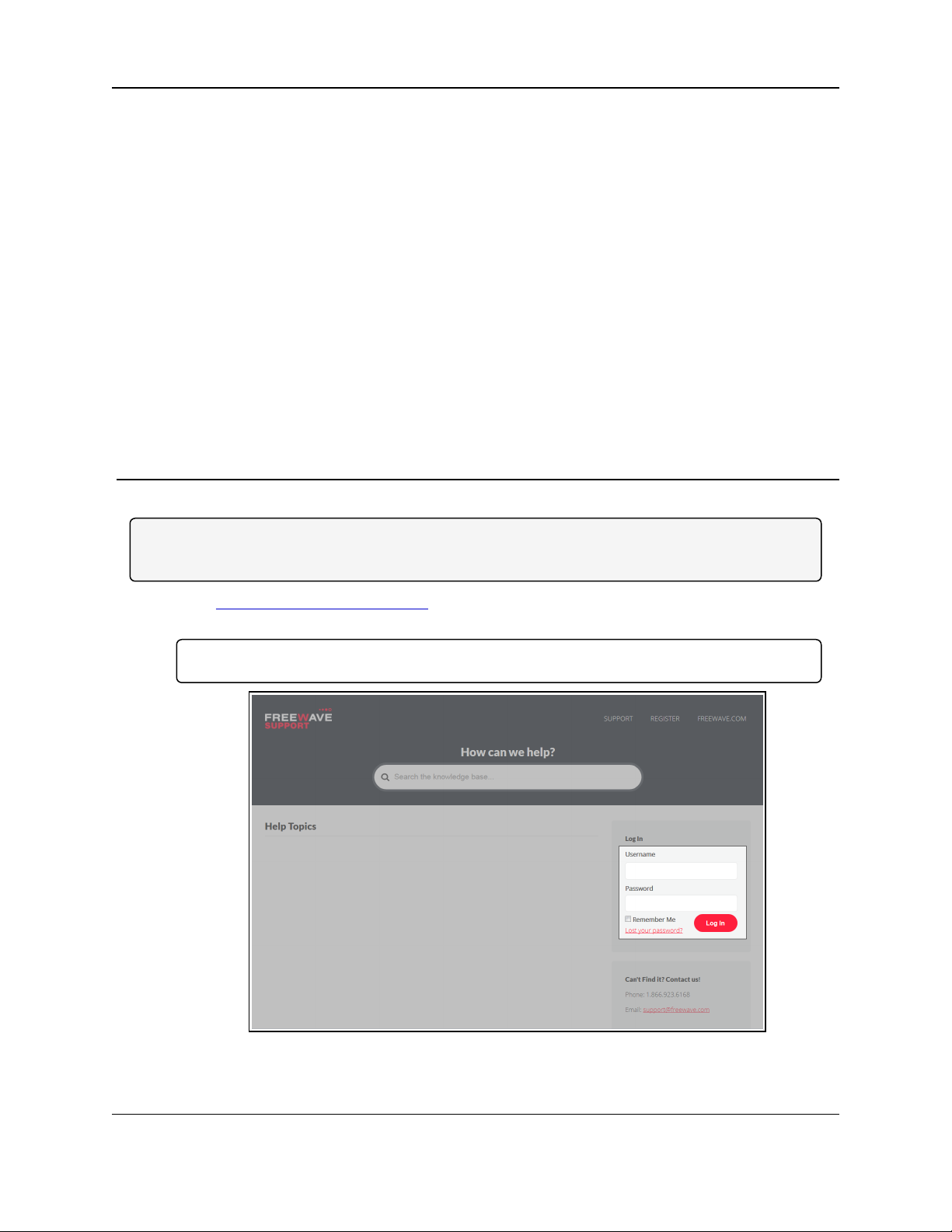

1. Click http://support.freewave.com/.

The FreeWave Support site opens.

Important!: Registration is required to use this website.

Figure 3: FreeWave Login window

2. Enter the User Name and Password.

LUM0086AA Rev Mar-2018 Page 14 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 15

4. WC Toolkit Installation

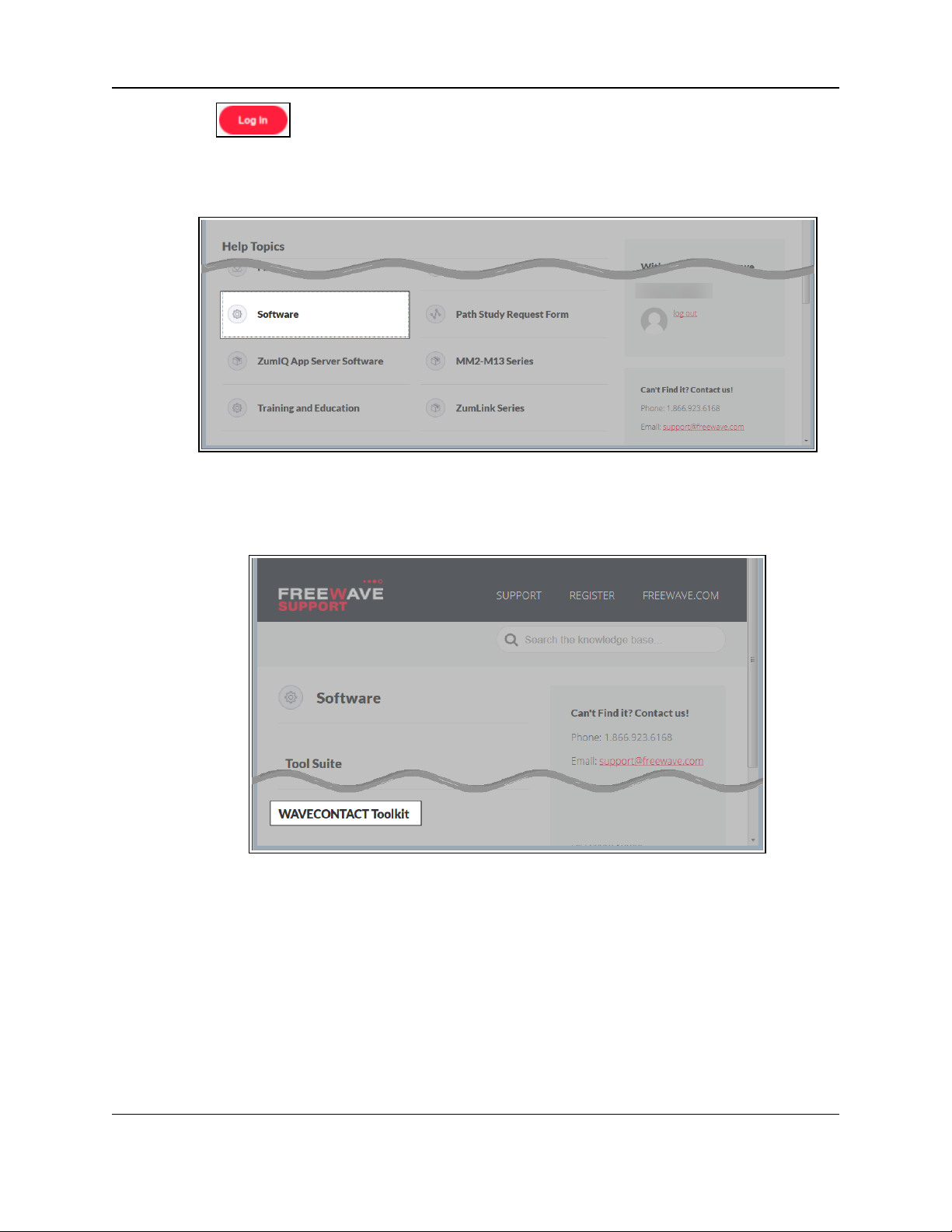

3.

Click .

A successful Login message briefly appears.

The Help Topics window opens.

4. Click the Software link.

Figure 4: Help Topics window

The Software window opens.

5. Click the WAVECONTACT Toolkit link.

Figure 5: Software window

The available software appears in the window.

6. Select and click the attachment.

LUM0086AA Rev Mar-2018 Page 15 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 16

WC45i-GW-485 Modbus Gateway: User & Reference Manual

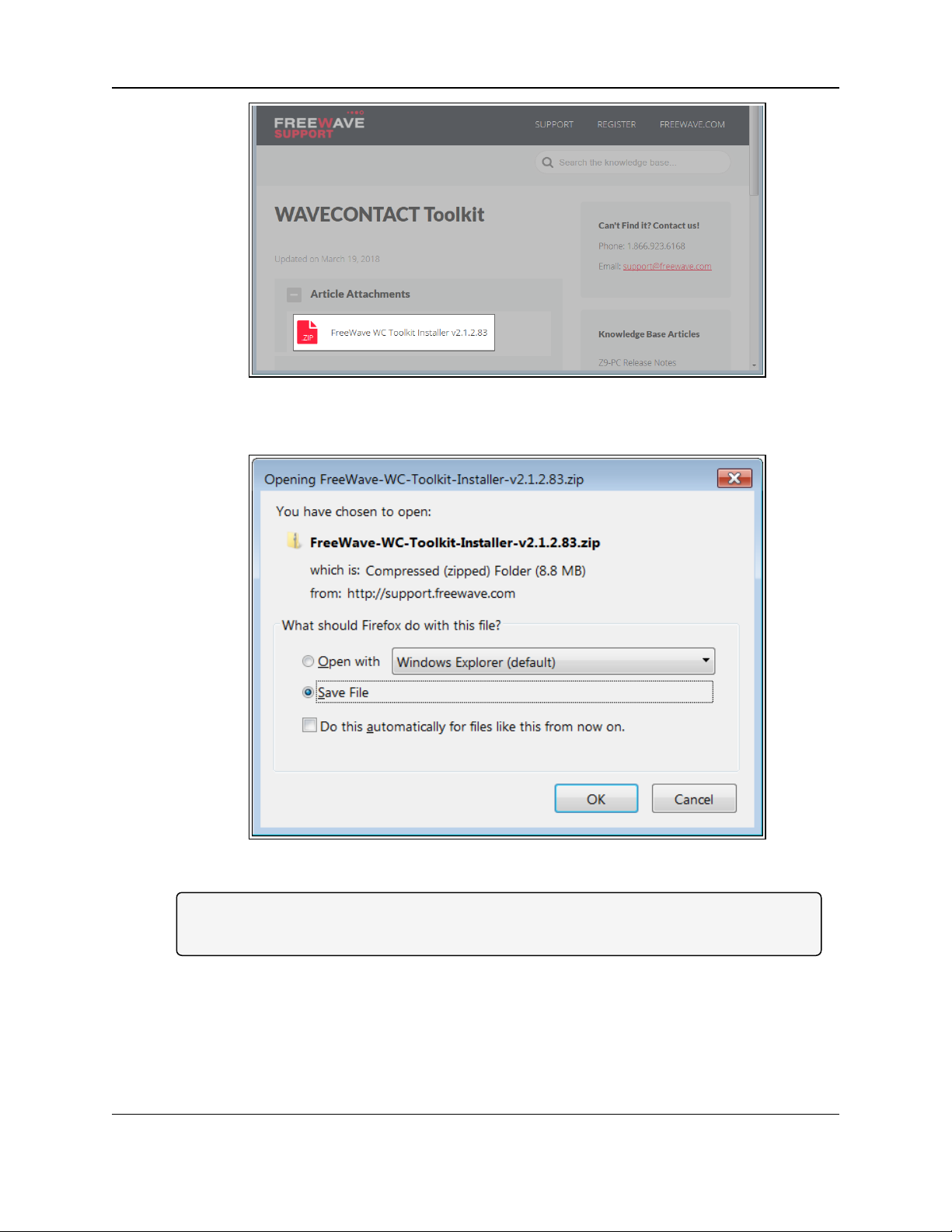

Figure 6: WAVECONTACT Toolkit window

The Opening dialog box opens.

Figure 7: WC Toolkit Opening dialog box

Note: This procedure shows Firefox® dialog boxes.

Otherbrowsers will have different dialogboxes andprocedures.

7. Click OK.

The Enter name of file to save to dialog box opens.

LUM0086AA Rev Mar-2018 Page 16 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 17

4. WC Toolkit Installation

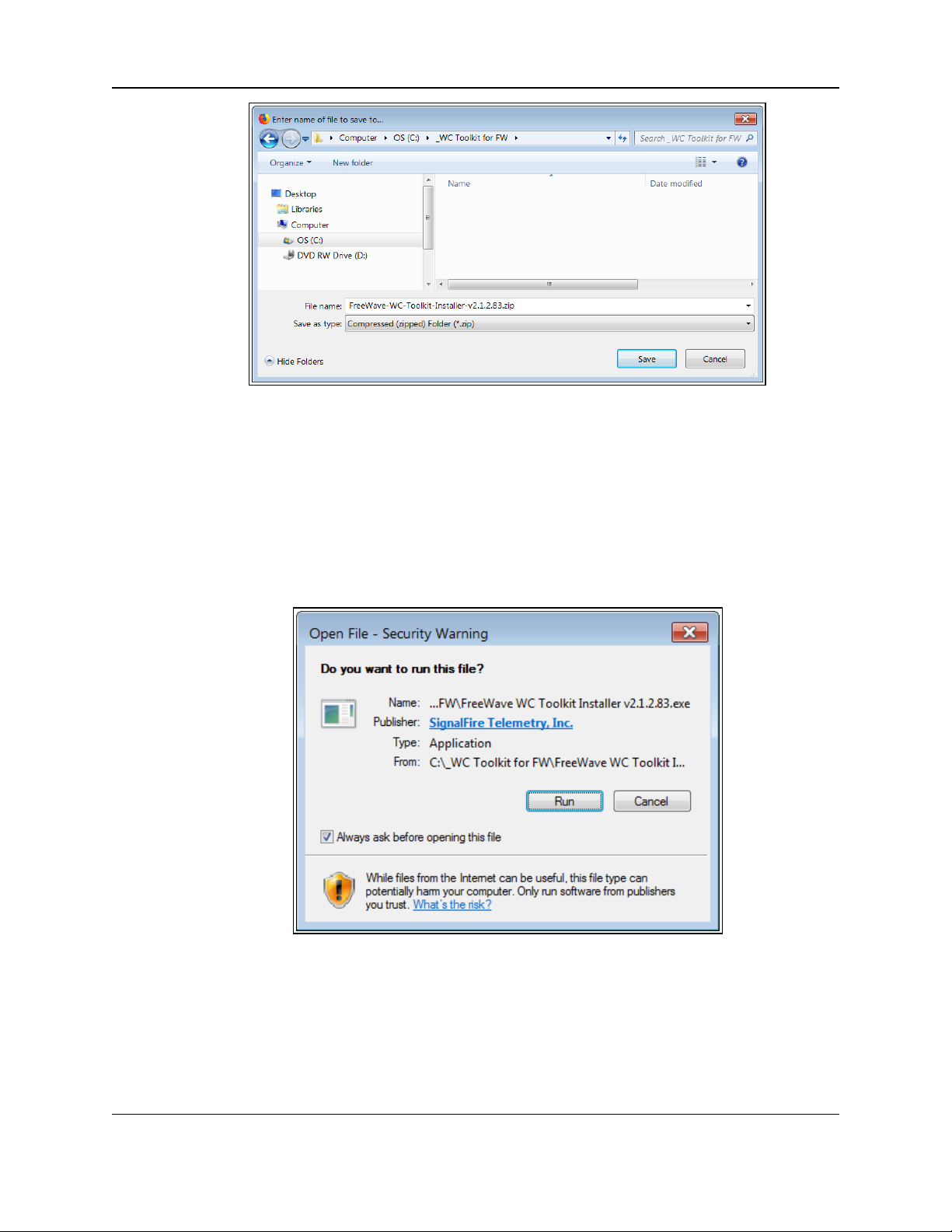

Figure 8: Enter name of file to save to dialog box

8. Search for and select a location to save the .zip file to and click Save.

The Enter name of file to save to dialog box closes.

9. Open a Windows® Explorer window and find the location where the .zip file was saved.

10. Double-click the .zip file.

11. Extract the .exe file from the .zip file into a parent location.

12. Double-click the .exe file to run the WC Toolkit installer.

The Open File - Security Warning dialog box opens.

Figure 9: Open File - Security Warning dialog box

13. Click Run.

The User Account Control dialog box opens.

LUM0086AA Rev Mar-2018 Page 17 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 18

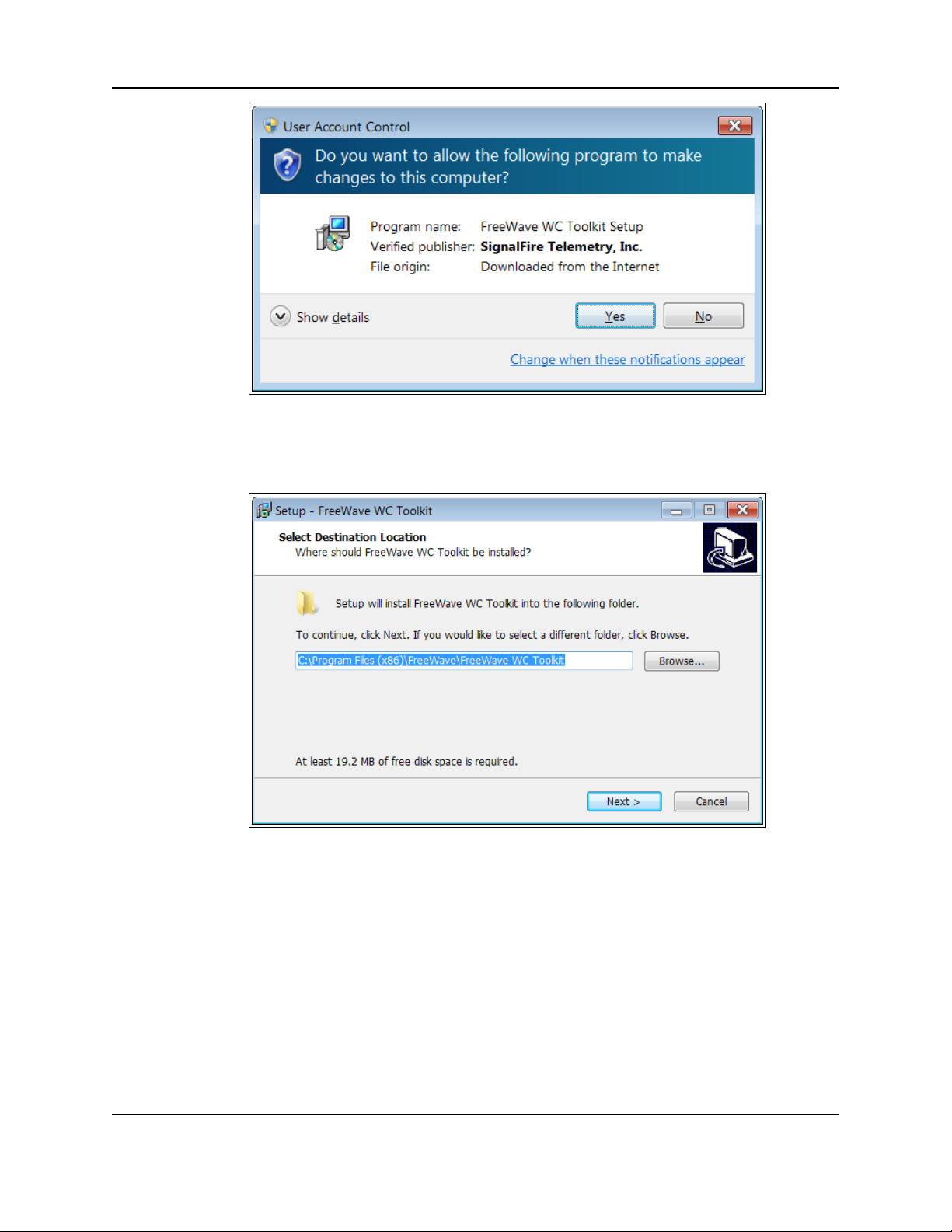

Figure 10: User Account Control dialog box

14. Click Yes.

The WC Toolkit Setup Wizard starts.

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 11: WC Toolkit Setup Wizard - Select Destination Location window

15. Click Next to continue.

The Ready to Install window opens.

LUM0086AA Rev Mar-2018 Page 18 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 19

4. WC Toolkit Installation

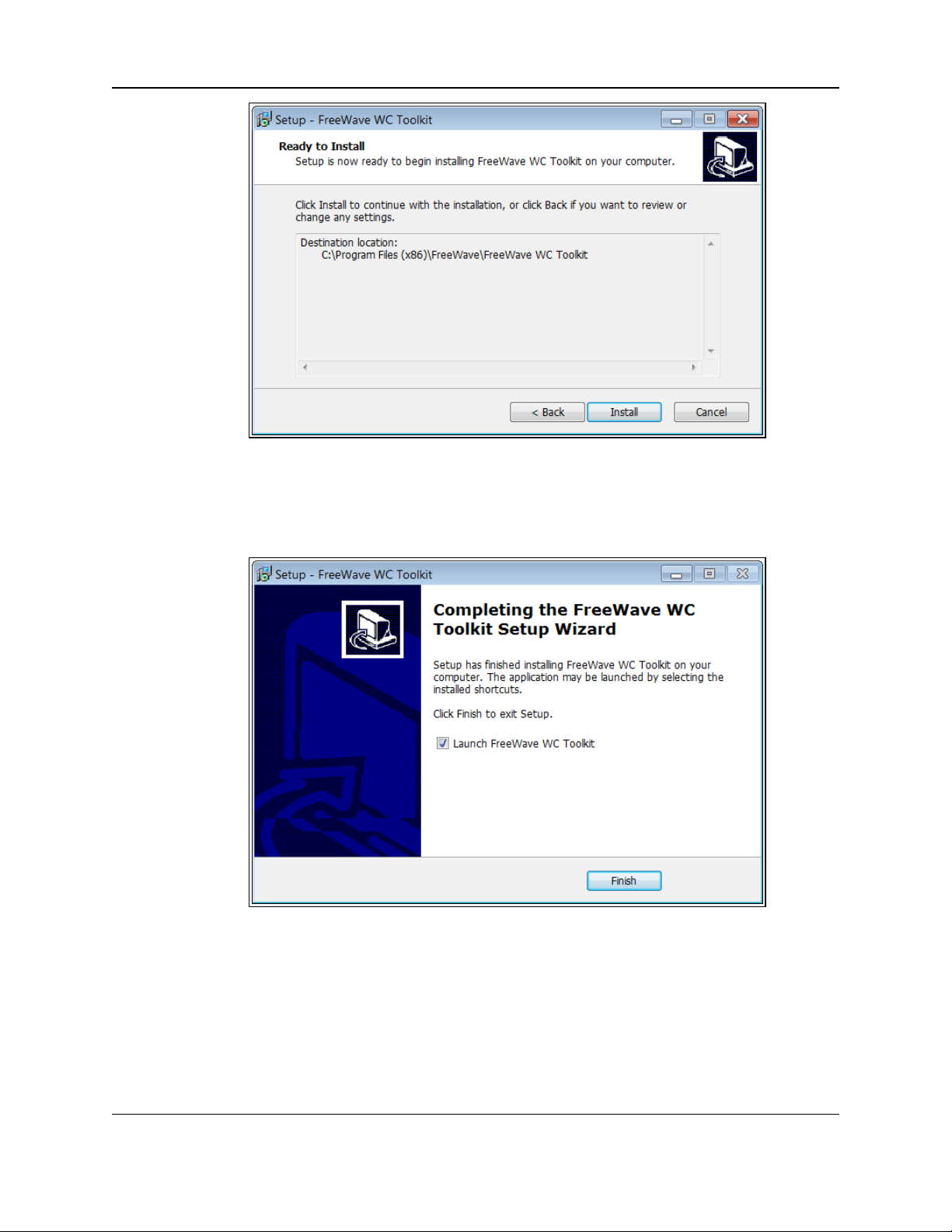

Figure 12: WC Toolkit Setup Wizard - Ready to Install window

16. Click Install.

The installprocess is very quick.

The Installation Complete window opens.

Figure 13: WC Toolkit Setup Wizard - Installation Complete window

17. Click Finish to open WC Toolkit.

An Update message appears in the WC Toolkit window is an update is available.

LUM0086AA Rev Mar-2018 Page 19 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 20

WC45i-GW-485 Modbus Gateway: User & Reference Manual

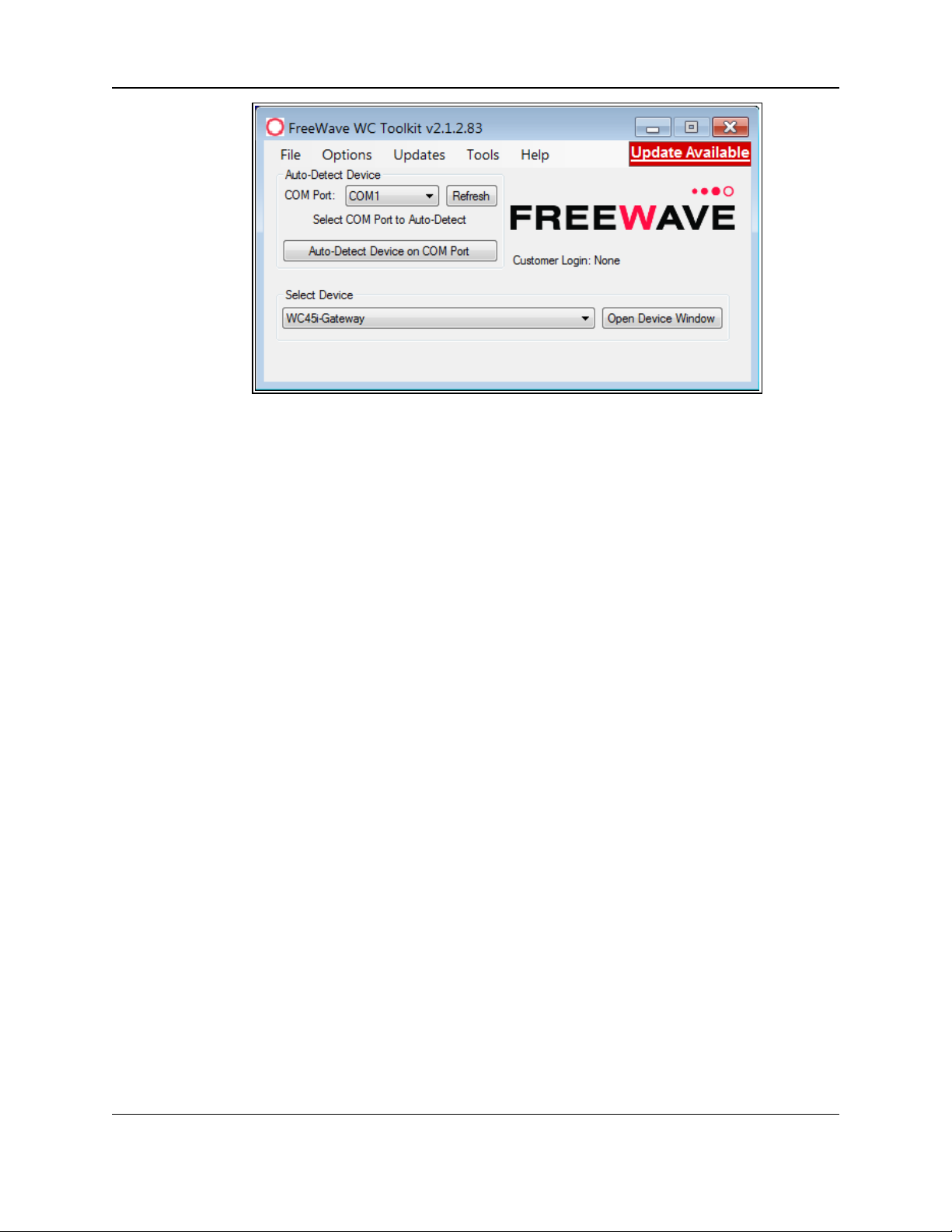

Figure 14: WC Toolkit - Update Available message

18. Continue with the WC Toolkit Update (on page 21) procedure.

LUM0086AA Rev Mar-2018 Page 20 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 21

WC45i-GW-485 Modbus Gateway: User & Reference Manual

5. WC Toolkit Update

If the WAVECONTACT device is connected to the internet, WC Toolkit automaticallysearches for

an update for either the WC Toolkit itself or the connected device's firmware.

An Update Available message appears if an update is available.

Note: An Update Available message also appears in the Device Configuration window (onpage 57)

for any connected WAVECONTACT device when an update is availablefor that device.

The update procedure is the same for the device and WC Toolkit.

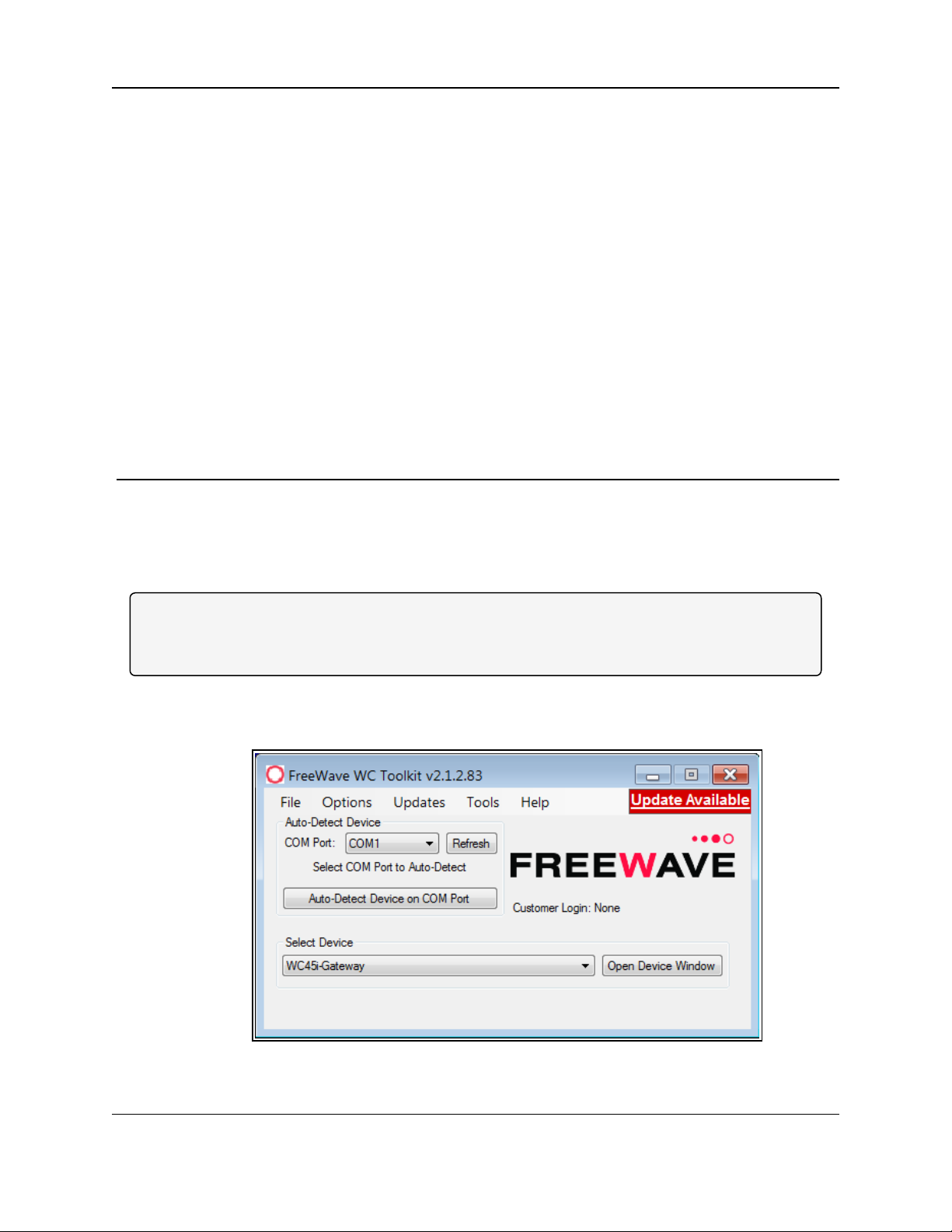

1. Open the WC Toolkit software.

The Update Available message appears in the window. (Figure 15)

Figure 15: WC Toolkit - Update Available message

LUM0086AA Rev Mar-2018 Page 21 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 22

5. WC Toolkit Update

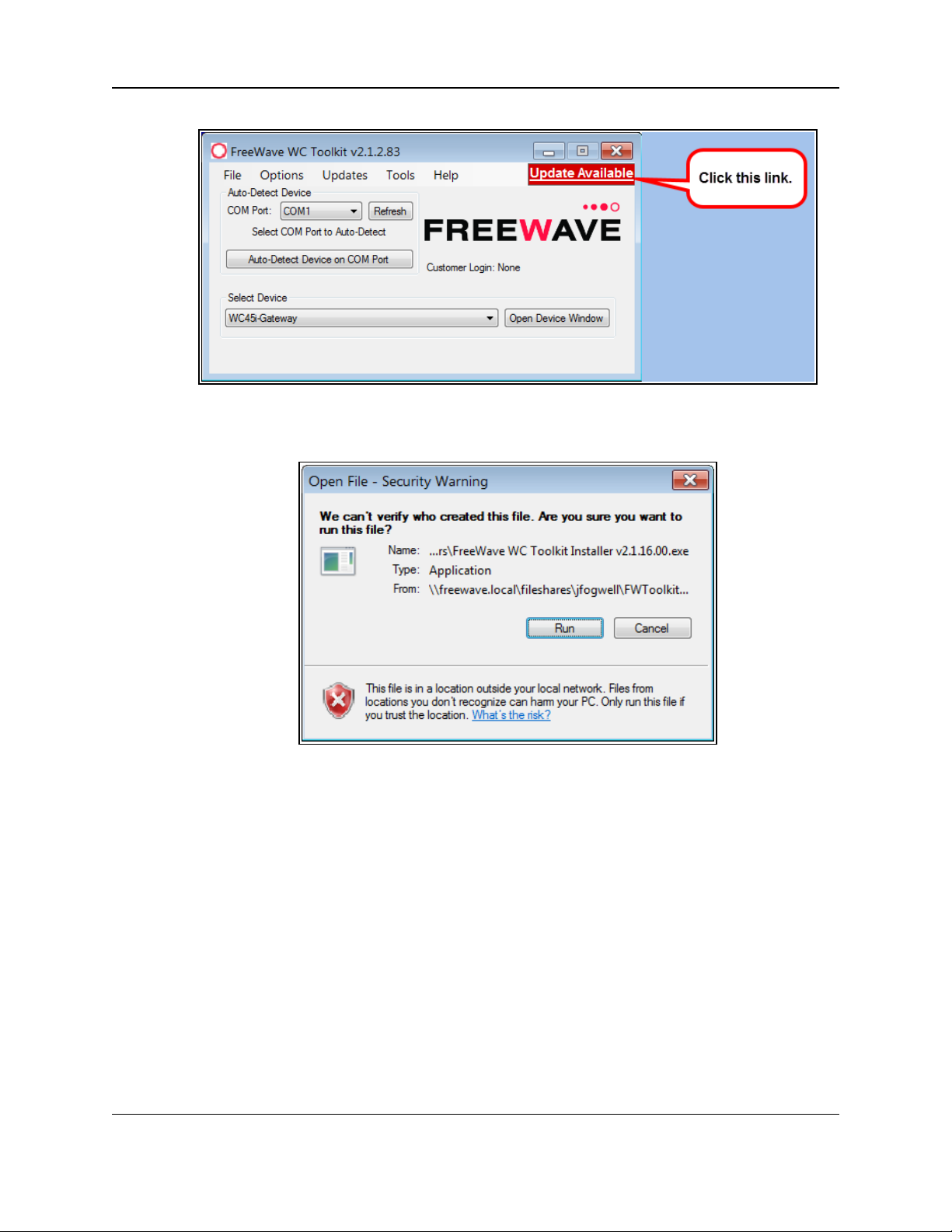

2. Click the Update Available message link.

Figure 16: Click the Update Available message link

The Open File - Security Warning dialog box opens.

Figure 17: Open File - Security Warning dialog box

3. Click Run.

The User Account Control dialog box opens.

LUM0086AA Rev Mar-2018 Page 22 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 23

WC45i-GW-485 Modbus Gateway: User & Reference Manual

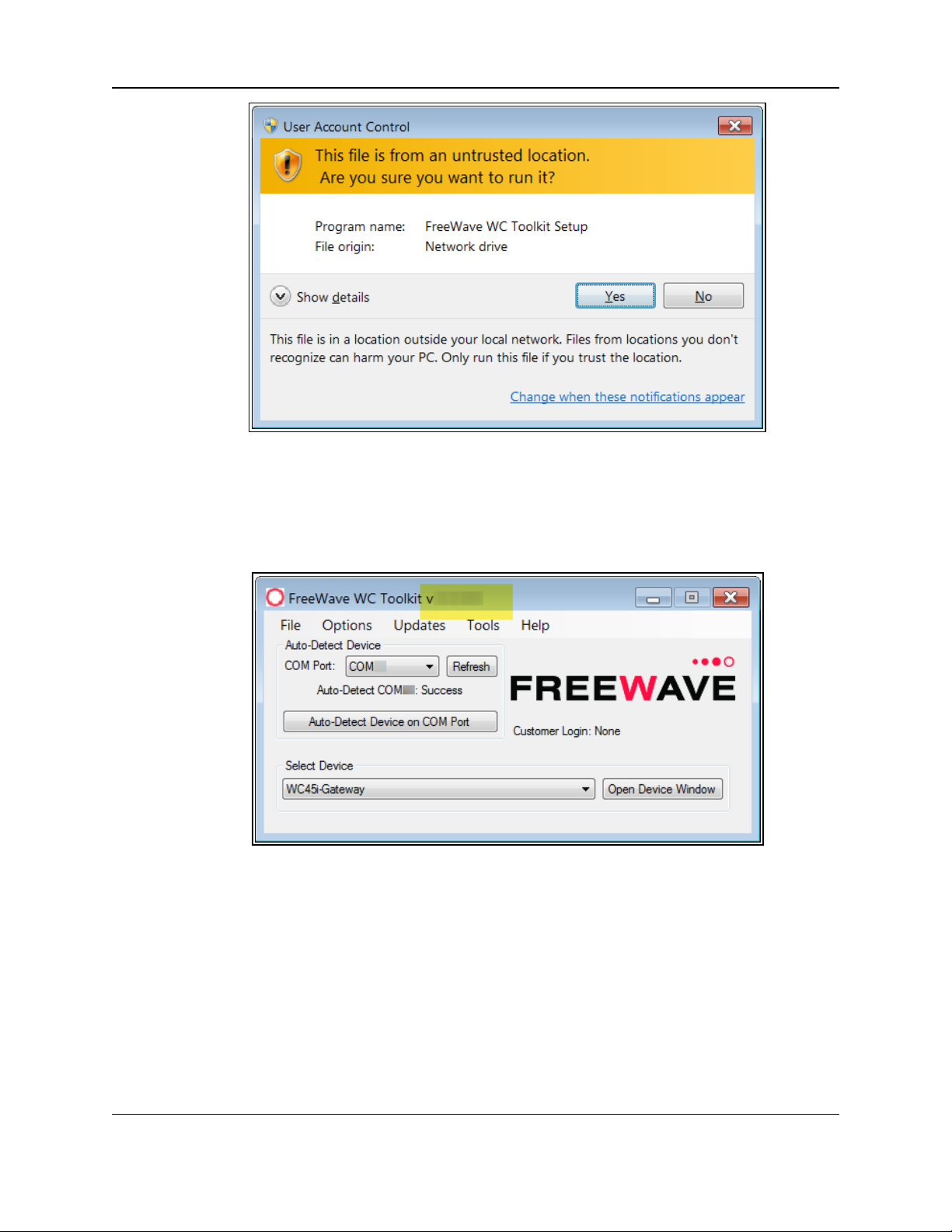

Figure 18: User Account Control dialog box

4. Click Yes.

The WC Toolkit update processis very quick.

When the update is completed, WC Toolkit re-opens the Select Device window showing

the updated software version in the WC Toolkit window. (Figure 19)

Figure 19: Select Device window

5. Continue with Configuration of the WC45i-GW-485.

LUM0086AA Rev Mar-2018 Page 23 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 24

WC45i-GW-485 Modbus Gateway: User & Reference Manual

6. Configuration

Note: The terms node and Endpoint are used interchangeably in this document.

FREEWAVE Recommends: Install and configurethe WC45i Gateway before any Endpoints to

ensure the Endpoints have connectivity after installation.

Important!: The WC45i-GW-485 Modbus Gateway is configured using the WC Toolkit.

Downloadthe WC Toolkit software from http://support.freewave.com/.

Registration is required to use this website.

Important!: The RS232 Config / Debug connector on the WC45i-GW MUST be used for WC

Toolkit access.

The Config / Debug port is accessed by a direct connection to the WC45i-GW-485 RS232 Config /

Debug connector port.

LUM0086AA Rev Mar-2018 Page 24 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 25

6. Configuration

Procedure

Note: The screenshots are examples only.

The dialog boxes and windows appear differently on each computer.

1. Verify the WC Toolkit software is installed on the computer connected to the WC45i-GW-

485.

Note: See WC Toolkit Installation (on page 14) and WC Toolkit Update (on page 21).

2. Open the WC Toolkit software.

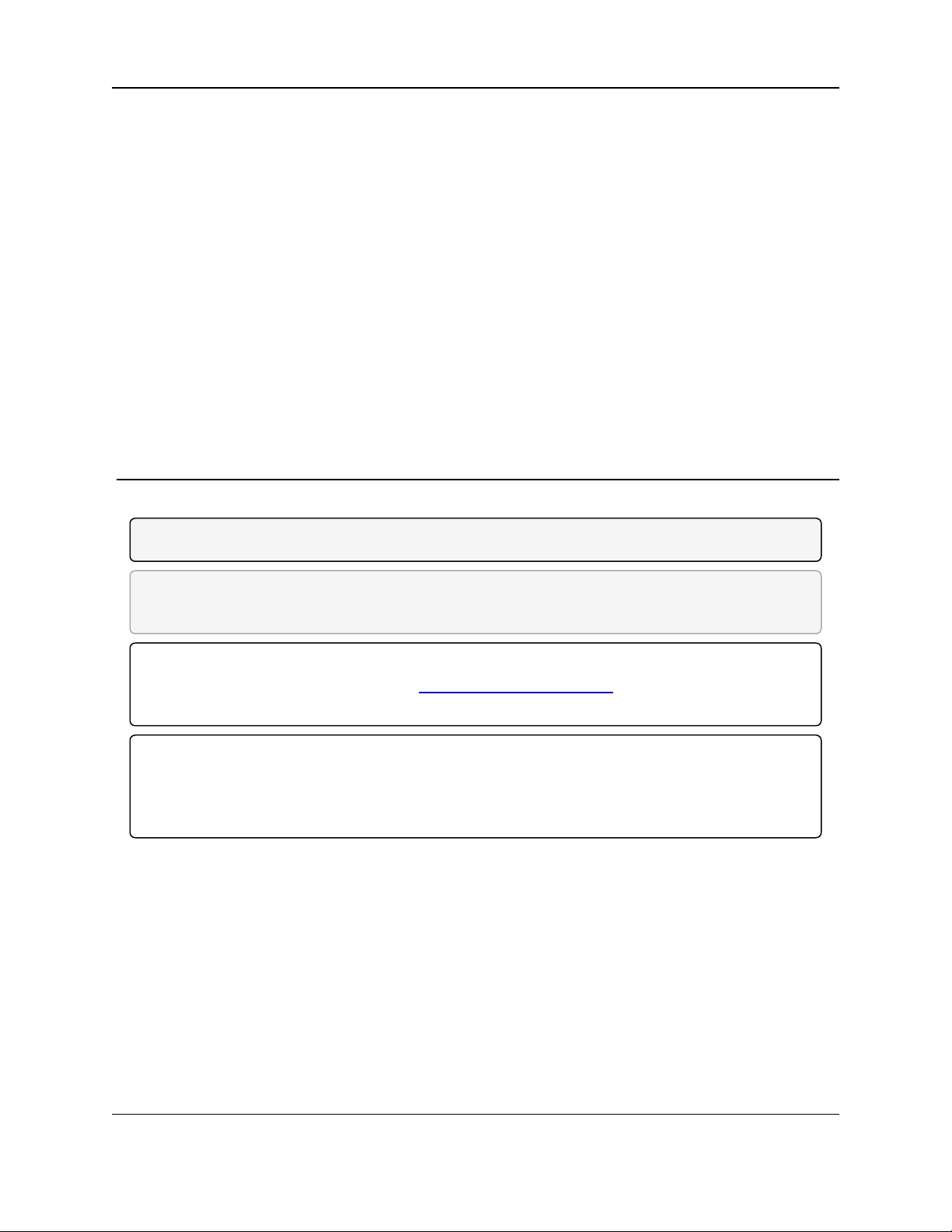

The Select Device window opens. (Figure 20)

Figure 20: Select Device window

3. Click the Refresh button to have WC Toolkit search for and list the available COM ports

reported by Windows and connected devices in the COM Port list box.

4. Click the COM Port list box arrow and select the COM port on the computer associated

with the connected WC45i-GW-485.

5. Click the Auto-Detect Device on COM Port button to have WC Toolkit connect the

device to the COM Port selected in the COM Port list box.

Note: Optional: Click the Select Device list box arrow and select the connected WC45i-

Gateway device.

Click the Open Device Window button to open the Device Configuration window (on page

57).

LUM0086AA Rev Mar-2018 Page 25 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 26

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 21: Select Device list box

The Device Configuration window opens for the selected device.

Note: See Device Configuration window (on page 57) for detailed information.

LUM0086AA Rev Mar-2018 Page 26 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 27

6. Configuration

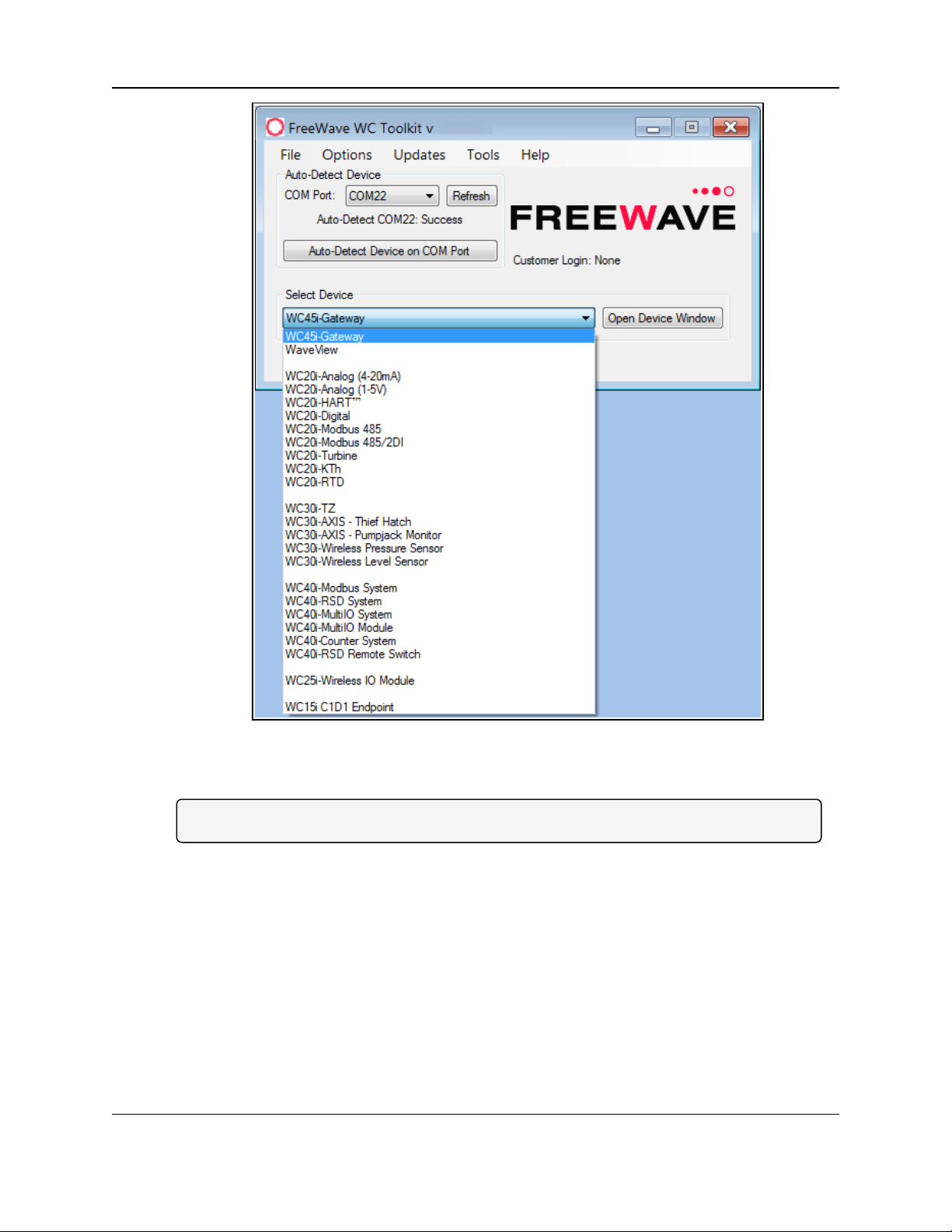

Figure 22: Device Configuration window: WC45i-Gateway

6. In the Settings area (#5), change these settings:

Note: The Network settings are used to create separate networks using multiple Gateways

(that are in close proximity to oneanother).

Important!: The Radio Network andRadio Network Group settings are selected by the

user but MUST MATCH the existing Gateway network for successful communication

between the Gateway and Endpoint.

See WAVECONTACT Network Frequencies (on page 95) for additional information.

a. Click the Radio Network list box arrow and select 0 (zero) to 7 for the assigned

number.

b. Click the Radio Network Group list box arrow and select 0 (zero) to 29 for the network

group assigned number.

c. Click the Set button to save the information.

7. In the Set Encryption Key area (#6), change these settings:

a. In the Key text box, enter the encryption key for the device using 6 to 16 characters.

b. Click the Set button to save the information.

Important!: A Key CANNOT contain spaces or angle brackets.

The Gateway andEndpoints only communicate if they areconfigured with the same Key.

When setting up a new network, use this same encryption Key on all the devices.

LUM0086AA Rev Mar-2018 Page 27 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 28

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Note: When the WC45i-GW-485 drops its network, it attempts to join networks using the

same encryption Key.

Caution: It is possible to hide the encryption Key so it cannot be read.

This is the most secure option, but if the Key is forgotten, there is no way to recover it.

The Key must be reset on every device on the network.

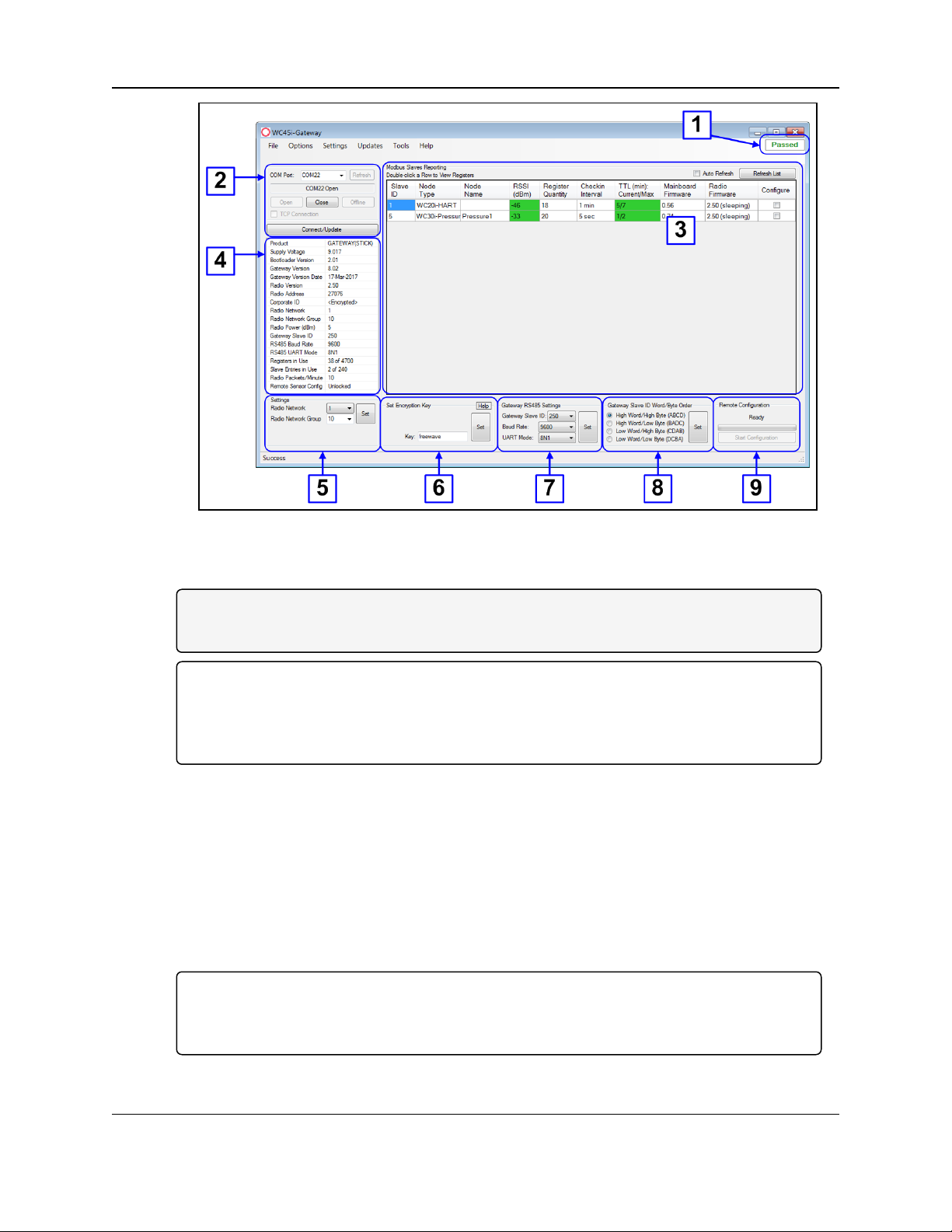

8. Optional: Click the Settings menu and select Set Encryption Key Unrecoverable to

permanently hide the key.

Figure 23: Settings menu > Set Encryption Key Unrecoverable

9. Click Refresh List button to update the Modbus Slaves Reporting table with all

connected remote Endpoints.

Figure 24: Modbus Slaves Reporting table

10. Configure the Endpoints attached to the WC45i-GW-485.

Note: Use the Configuration procedure in the User Manual for these WAVECONTACT

Endpoints:

WC15i Multi-Input C1D1 Endpoint, WC20i Endpoint,

WC30i Wireless Pressure Sensor, WC40i Modbus Endpoint,

WC40i-COUNT CounterEndpoint, or WC40i-MB-RSD Modbus Endpoint.

11. Optional: On the WC20i or WC45i-GW-485Endpoint, press the Check-in button to apply

power to the configured sensor, read the sensor values, and send the collected sensor data

to the Gateway.

12. Verify the Gateway is communicating with the Endpoints.

LUM0086AA Rev Mar-2018 Page 28 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 29

6. Configuration

Note: A successful connection on the WAVECONTACT Endpoint is indicatedwith Green

blinking TX and ACT lights and a Red blinking light for RX.

If the connection is NOT successful, a Green blinking TX light appears for 10 seconds.

13. If applicable, continue with these other WC45i configuration procedures:

l Remote Endpoint Configuration (on page 40)

l Remote Shutdown (RSD) and Local Digital Output Control (on page 44)

l Slave Register Remapping (on page 48)

14. Close the WC Toolkit software.

15. Remove the WC-USB-DB9 USB to Serial DB9 programming cable from the computer and

the WC45i-BB.

16. As applicable, replace the Endpoint cover.

17. Mount the Gateway device.

LUM0086AA Rev Mar-2018 Page 29 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 30

WC45i-GW-485 Modbus Gateway: User & Reference Manual

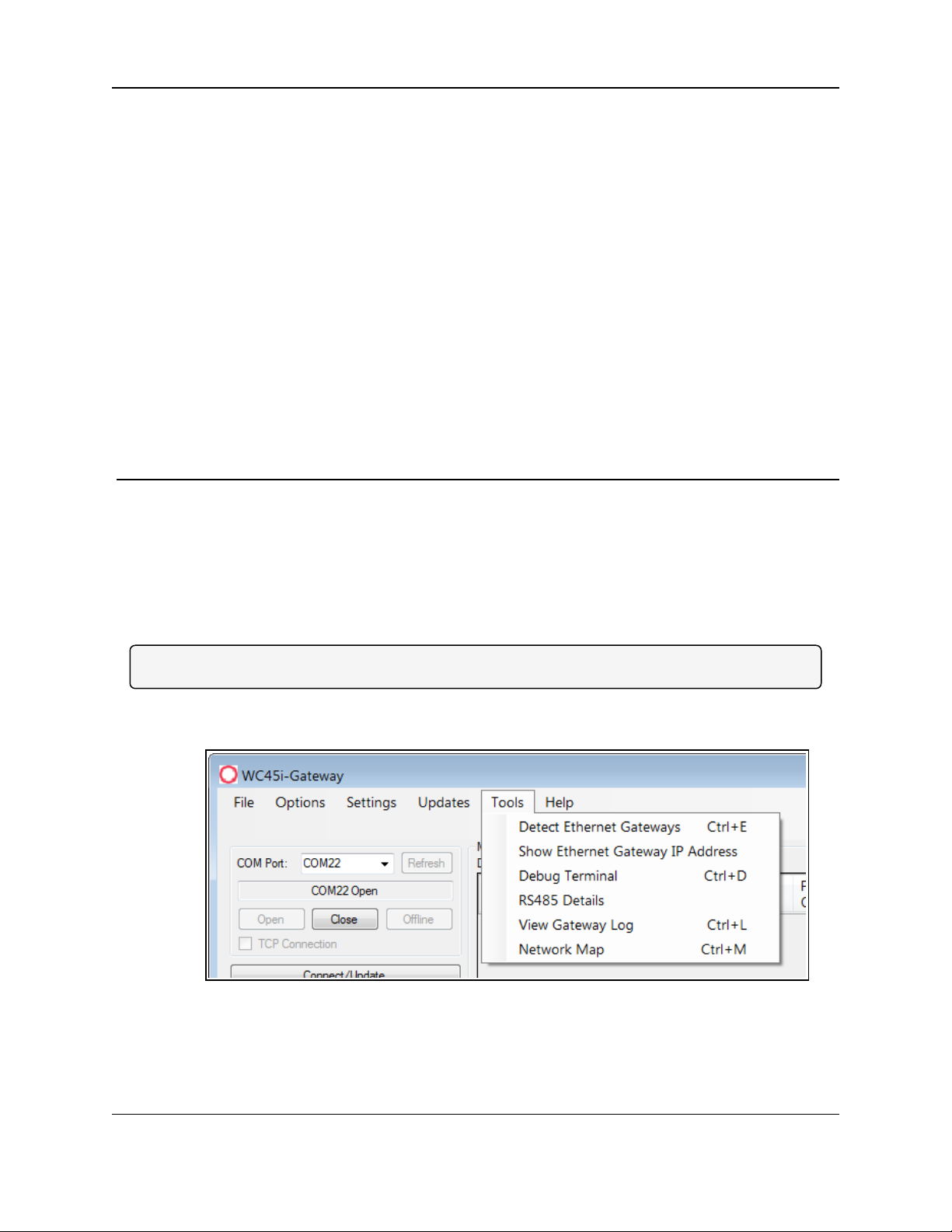

7. Gateway Event Log

The Gateway keeps an internal log of eventsthat are viewed in the Gateway Log window (on

page 73) of WC Toolkit.

The Gateway Log window is used to log eventssuch as reboots, remote Endpoints joining and/or

timing out, localRSD control events, remote configuration sessions, firmware updates, etc.

Procedure

Note: The terms node and Endpoint are used interchangeably in this document.

1. Open the Device Configuration window (on page 57).

2. On the Tools menu, click View Gateway Log.

Figure 25: Tools menu > View Gateway Log

The Gateway Log window opens.

The Gateway Log tab is active.

LUM0086AA Rev Mar-2018 Page 30 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 31

7. Gateway Event Log

Figure 26: Gateway Log window - Gateway Log tab

3. Complete any of these options:

l Click the Refresh or Refresh List button to update the informationin the table.

l Click the Log Entries list box arrow and select how many log entries to view on the

Gateway Log tab.

l Click the Load Log from File button to open the Microsoft® Open dialog box with the

default location where the .csv file of the log information is saved.

l Click the Save Log to File button to open the Microsoft® Save As dialog box with the

default location to save the .csv file of the log information in.

4. Optional: Click the Log Statistics tab to view statistics about the log events.

Figure 27: Gateway Log window - Log Statistics tab

5. Optional: Click the Refresh or Refresh List button to update the information in the table.

6. Optional: Click the Save Report to File button to open the Microsoft® Save As dialog box

with the default location to save the CSV version of the log file in.

7. Close the Gateway Log window.

LUM0086AA Rev Mar-2018 Page 31 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 32

WC45i-GW-485 Modbus Gateway: User & Reference Manual

8. Firmware Updates

Firmware updates for both the Gateway and the built-in radio are completedover:

l the RS232 Config / Debug connector port usingWC Toolkit.

l a remote TCP connection if a WC45i-GW-P Ethernet Gateway is used.

Note: These procedures are for both the WC45i-GW-485 and WC45i-GW-DIN devices.

l Gateway Firmware Update (on page 33)

l Radio Firmware Update (on page 35)

l Rescue Gateway (ARM) Bootload (on page 37)

LUM0086AA Rev Mar-2018 Page 32 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 33

8. Firmware Updates

8.1. Gateway Firmware Update

1. Verify the WC Toolkit software is installed on the computer connected to the WC45i-GW-

485.

Note: See WC Toolkit Installation (on page 14) and WC Toolkit Update (on page 21).

2. Open the WC Toolkit software.

The Select Device window opens. (Figure 28)

Figure 28: Select Device window

3. Click the Refresh button to have WC Toolkit search for and list the available COM ports

reported by Windows and connected devices in the COM Port list box.

4. Click the COM Port list box arrow and select the COM port on the computer associated

with the connected WC45i-GW-485.

5. Click the Auto-Detect Device on COM Port button to have WC Toolkit connect the

device to the COM Port selected in the COM Port list box.

The Device Configuration window opens for the selected device.

6. On the Update menu, click Update Gateway Firmware.

Figure 29: Updates menu > Update Gateway Firmware

The Firmware Updates window opens.

Note: See Firmware Updates window (on page 71) for detailedinformation.

LUM0086AA Rev Mar-2018 Page 33 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 34

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 30: Firmware Updates window

Note: By default, the latest firmware file is selected from the update server.

When the Update Gateway Firmware menu is selected, the WC45i-Gateway searches for

the most recent modbusGW file to update.

7. Click the Start Transfer button to load the file to the device.

8. Wait while the Firmware Updates window progressbar shows the file transfer.

Figure 31: Progress bar of firmware update

A message appears when the firmware update is successful.

Figure 32: Successful firmware update message

9. Click OK to close the message.

LUM0086AA Rev Mar-2018 Page 34 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 35

8. Firmware Updates

8.2. Radio Firmware Update

1. Verify the WC Toolkit software is installed on the computer connected to the WC45i-GW-

485.

Note: See WC Toolkit Installation (on page 14) and WC Toolkit Update (on page 21).

2. Open the WC Toolkit software.

The Select Device window opens. (Figure 28)

Figure 33: Select Device window

3. Click the Refresh button to have WC Toolkit search for and list the available COM ports

reported by Windows and connected devices in the COM Port list box.

4. Click the COM Port list box arrow and select the COM port on the computer associated

with the connected WC45i-GW-485.

5. Click the Auto-Detect Device on COM Port button to have WC Toolkit connect the

device to the COM Port selected in the COM Port list box.

The Device Configuration window opens for the selected device.

6. On the Update menu, click Update Gateway Firmware.

Figure 34: Updates menu > Update Radio Firmware

The Firmware Updates window opens.

Note: See Firmware Updates window (on page 71) for detailedinformation.

LUM0086AA Rev Mar-2018 Page 35 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 36

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 35: Firmware Updates window

Note: By default, the latest firmware file is selected from the update server.

When the Update Radio Firmware menu is selected, the WC45i-Gateway searches for the

most recent appNode file to update.

7. Click the Start Transfer button to load the file to the device.

8. Wait while the Firmware Updates window progressbar shows the file transfer.

Figure 36: Progress bar of firmware update

A message appears when the firmware update is successful.

Figure 37: Successful firmware update message

9. Click OK to close the message.

LUM0086AA Rev Mar-2018 Page 36 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 37

8. Firmware Updates

8.3. Rescue Gateway (ARM) Bootload

Possible causesto run a Rescue Bootload:

l Power failure.

l Communications failure during firmware update process.

l The base LED is solidon and/or the WC Toolkit is unableto communicatewith the

Gateway.

Procedure

1. Remove the DC power from the Gateway.

2. Verify the WC Toolkit software is installed on the computer connected to the WC45i-GW-

485.

Note: Download the WC Toolkit softwarefrom http://support.freewave.com/.

3. Open the WC Toolkit software.

The Select Device window opens. (Figure 28)

Figure 38: Select Device window

4. Click the Refresh button to have WC Toolkit search for and list the available COM ports

reported by Windows and connected devices in the COM Port list box.

5. Click the COM Port list box arrow and select the COM port on the computer associated

with the connected WC45i-GW-485.

6. Click the Auto-Detect Device on COM Port button to have WC Toolkit connect the

device to the COM Port selected in the COM Port list box.

The Device Configuration window opens for the selected device.

7. On the Update menu, click Update Gateway Firmware.

LUM0086AA Rev Mar-2018 Page 37 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 38

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 39: Updates menu > Update Gateway Firmware

The Firmware Updates window opens.

Note: See Firmware Updates window (on page 71) for detailedinformation.

Figure 40: Firmware Updates window

Note: By default, the latest firmware file is selected from the update server.

When the Update Gateway Firmware menu is selected, the WC45i-Gateway searches for

the most recent modbusGW file to update.

8. Click the Start Transfer button to load the file to the device.

Wait while the Firmware Updates window progress bar shows the file transfer.

Figure 41: Progress bar of firmware update

A message appears when the firmware update is successful.

LUM0086AA Rev Mar-2018 Page 38 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 39

8. Firmware Updates

Figure 42: Successful firmware update message

9. Re-connect the DC power to the Gateway.

The firmware update process starts.

Note: If the firmware update does NOT start, remove power for at least 10 seconds and re-try.

LUM0086AA Rev Mar-2018 Page 39 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 40

WC45i-GW-485 Modbus Gateway: User & Reference Manual

9. Remote Endpoint Configuration

The WC45i-GW-485 Modbus Gateway allows configuration changes to be made to any of the

connected WAVECONTACT remote Endpoints wirelessly.

l The WC45i-GW-485 requiresan initialconfiguration using the Config / Debug connector.

l The Config / Debug port is accessed by a direct connection to the WC45i-GW-485

RS232 Config / Debug connector port.

Note: This procedure assumes WC Toolkit has been installed.

Downloadthe WC Toolkit software from http://support.freewave.com/.

Registration is required to use this website.

Procedure

Note: The terms node and Endpoint are used interchangeably in this document.

1. Open the Device Configuration window (on page 57).

2. In the Configure column, select the check-box next to the Endpoint to configure.

LUM0086AA Rev Mar-2018 Page 40 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 41

9. Remote Endpoint Configuration

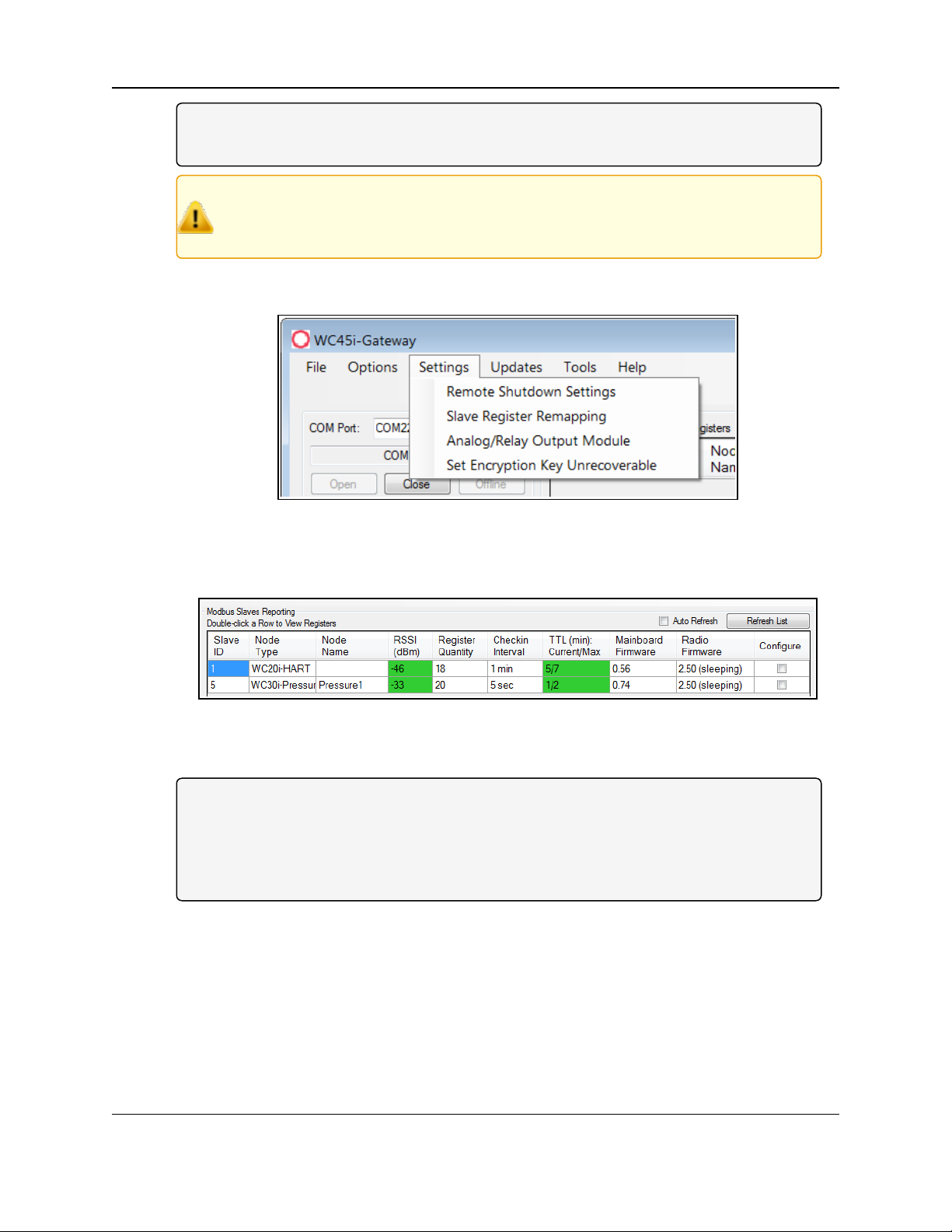

Figure 43: Detail of Endpoint in Modbus Slaves Reporting Table

3. Click the Start Configuration button to activate a Remote Configuration session.

l If the Endpoint has a Non-Sleeping radio, the Remote Configuration session is

ready immediately.

l If it is a Sleeping device, wait for the Endpoint to either check-inor send a beacon so it

can be commanded into Configuration mode.

l A WC20i Endpoint sends a beaconevery 2½ minutes.

l All other Sleeping Endpoints send a beacon every 5½ minutes.

l When the device has entered a Remote Configuration session, a message indicating

the Slave is Ready appears.

LUM0086AA Rev Mar-2018 Page 41 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 42

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Figure 44: Remote Configuration area - Slave is Ready

4. Click the Configure button to open the Edit Configurationwindow (on page 64).

Important!: The Remote Configuration session automatically times out after 10 minutes of

inactivity and the Endpoint will resume normal operation.

Note: The Edit Configuration window is uniquefor the selected Endpoint device.

Figure 45 shows the Edit Configuration window for a WC20i-HART Endpoint.

LUM0086AA Rev Mar-2018 Page 42 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 43

9. Remote Endpoint Configuration

Figure 45: Edit Configuration window - WC20i-HART

5. Make any necessary changes in the active areas of the window and click the corresponding

Set button to save the changes.

6. When finished changing the configuration, closethe Edit Configuration window and

return to the Device Configuration window.

7. Click the End button to stop the Remote Configuration session.

Note: The Remote Configuration session automatically times-out after 10 minutes of

inactivity.

8. Optional: On the WC20i or WC45i-GW-485Endpoint, press the Check-in button to apply

power to the configured sensor, read the sensor values, and send the collected sensor data

to the Gateway.

9. Verify the Gateway is communicating with the Endpoints.

Note: A successful connection on the WAVECONTACT Endpoint is indicatedwith Green

blinking TX and ACT lights and a Red blinking light for RX.

If the connection is NOT successful, a Green blinking TX light appears for 10 seconds.

10. Close the WC Toolkit software.

11. Remove the WC-USB-DB9 USB to Serial DB9 programming cable from the computer and

the WC45i-BB.

12. As applicable, replace the Endpoint cover.

13. Mount the Gateway device.

LUM0086AA Rev Mar-2018 Page 43 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 44

WC45i-GW-485 Modbus Gateway: User & Reference Manual

10. Remote Shutdown (RSD) and Local Digital Output Control

The WC45i-GW-485 Modbus Gateway supportsInternalLogic Control capabilitywhich enables

the Gateway to control output relays on the WC40i-MB-RSD Modbus Endpoint or WC40iCOUNT.

Note: The WC40i-MB-RSD Modbus Endpoint bundle includes the WC40i-MB and the WC40i-RSD

products.

l The WC45i-GW-485 receives data from multiple remote Endpoints.

l The data is used from those remote Endpoints to set the relay output on one or more

remote WC40i-MB-RSD or WC40i-COUNT.

l An example of the topologyis shown in Figure 46.

Note: See Connections (on page 11) for port locations.

Use the Remote Shutdown Configuration (on page 46) procedure to control the output relays.

LUM0086AA Rev Mar-2018 Page 44 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 45

10. Remote Shutdown (RSD) and Local Digital Output Control

10.1. Example: WC45i-GW-485 Modbus Gateway Topology

Figure 46: Example: WC45i-GW-485 Modbus Gateway Topology

LUM0086AA Rev Mar-2018 Page 45 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 46

WC45i-GW-485 Modbus Gateway: User & Reference Manual

10.2. Remote Shutdown Configuration

Note: The terms node and Endpoint are used interchangeably in this document.

1. Open the Device Configuration window (on page 57).

2. On the Settings menu, click Remote Shutdown Settings.

Figure 47: Settings menu > Remote Shutdown Settings

The Remote Shutdown Settings window (on page 84) opens.

Figure 48: Remote Shutdown Settings window

3. As appropriate, completethese sectionsof the window:

a. Source Node (Endpoint) area (on page 86).

b. Relay Control LogicSection (on page 88).

c. Destination Counter / RSD StickSection (on page 90).

4. Click the Write Remote Shutdown Settings to Gateway button to store the settingsin

the WC45i-Gateway.

5. Optional: Click the Failsafe Enabled check box to require ALL rules to have valid data for

the relay to be energized.

LUM0086AA Rev Mar-2018 Page 46 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 47

10. Remote Shutdown (RSD) and Local Digital Output Control

Important!: If one or moreof the Endpoints time-out or does not exist, the relay is de-

energized.

If this option is NOT selected, then an Endpoint that is not installedor fails to check in is

ignored and the relay is energized using logic only from the units that are active.

6. Optional: Click the Latch De-Energized check box so the rules may only de-energize the

relay.

Note: For the relay to be energized again, a Modbus write from a PLC to the Gateway for the

destination WC40i-MB-RSD or WC40i-COUNT relay must occur.

This is useful if manual intervention is required before the relay is energized after an event.

In 10, a Modbus coil write to Slave ID 5 relay channel 1 (which is register 1) is required to

energize the relay.

LUM0086AA Rev Mar-2018 Page 47 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 48

WC45i-GW-485 Modbus Gateway: User & Reference Manual

11. Slave Register Remapping

The Gateway allows any of the remote register data to be remappedto a single block of registers

available at the Gateway’s Slave ID.

Note: The default is 247.

l This is useful for collecting a subset of register data from multipleEndpoints and making it

readable in a single blockof registers.

l A maximum of 750 registerscan be remapped to the Gateway’s Slave ID starting at register

5000.

Procedure

Note: The terms node and Endpoint are used interchangeably in this document.

1. Open the Device Configuration window (on page 57).

2. On the Settings menu, click Slave Register Remapping.

Figure 49: Settings menu > Slave Register Remapping

LUM0086AA Rev Mar-2018 Page 48 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 49

11. Slave Register Remapping

The Slave Register Remapping window (on page 91) opens.

Figure 50: Slave Register Remapping window

3. In the Slave ID column / text box, enter the remote source Endpoint ModbusSlaveID.

Important!: Verify there are no duplicate Slave IDs in a given network.

The Gateway only caches oneset of data for each Slave ID.

A duplicate is overwritten.

4. In the Register Address column text box, enter the register addressto map to each

Gateway register.

Note: The Node Name, Data Type, Register Value, and Description columns are

automatically filled in by the Gateway once the mapping is written to the Gateway.

5. Click the Write Mapping to Gateway button to remap the registers.

Figure 51 shows an exampleof a the Slave Register Remapping window.

l Slave ID 1 is a WC20i-AN Analog Endpoint mapped to have sensor current, RSSI

and battery voltageavailable at Gateway registers 5000 through 5002.

l Slave ID 5 is NOT reporting data to the Gateway so its registers are failing high.

Figure 51: Example of the Slave Register Remapping window

LUM0086AA Rev Mar-2018 Page 49 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 50

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Important!: If the Gateway does NOT have data for a remapped value, it will respond with

0xFFFF, or 0x0000 for the register request.

Use the Fail Mode settings to configure this globally.

Note: 0xFFFF = 65535, 0x0000 = 0.

LUM0086AA Rev Mar-2018 Page 50 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 51

WC45i-GW-485 Modbus Gateway: User & Reference Manual

12. Modbus Gateway Register Map

Important!: By default, the WAVECONTACT Modbus Gateway is assigned Modbus Slave ID

number247.

l Onlythe Gateway status / configuration registers are read at this address.

l All remote Endpoint registers are read from the Slave ID and Register Address of the

remote Endpoint, unless the SlaveRegister Remapping (on page 48) procedure is used.

l Registers include:

l Boolean Registers(on page 52)

l Read / Write Registers (on page 52)

l Read-only Registers(on page 53)

LUM0086AA Rev Mar-2018 Page 51 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 52

12. Modbus Gateway Register Map

Boolean Registers

Register Number

Register Address

(Offset)

Description

00001 0000 Resets the Gateway and radio.

00002 0001 Resets the radio leaving the Gateway on.

00003 0002 Resets all counters to zero.

Note: See Modbus Gateway Register Map

(onpage 51) 2026-2031.

Read / Write Registers

Register Number

Register Address

(Offset)

Description

41001 1000 Resets the Gateway and radio

41002 1001 Resets the radio leaving the Gateway on

41003 1002 Resets all GW status counters to zero.

Note: See Modbus Gateway Register Map

(onpage 51) 2026-2031.

12.1. Boolean Registers

l These are 1-bit coil registers.

l They can only be written to Modbus opcode 0x05 (Write Single Coil).

l Writing 0x0000 to a coil has NO effect.

l To perform these resets, write a 0xFF00 to the respective coil:

12.2. Read / Write Registers

l These are 16-bit read/write registers.

l They can be written to by Modbus opcode 0x06 or 0x10 (Write Single and Multiple

Registers, respectively).

l They can be read with Modbusopcode 0x03 or 0x04 (Read Discrete Input and Holding

Registers, respectively).

l The first three registersare identical to the previous three write coils and behave similarly.

l They will be read as 0x0000 and can be triggered by writing 0xFF00 to them.

l The remaining must be written with 16-bit values in the range specified in the Read / Write

Registers (on page 52) table:

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

LUM0086AA Rev Mar-2018 Page 52 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave Technologies, Inc.

Page 53

12.3. Read-only Registers

Read-only Registers

Register Number

Register Address

(Offset)

Description

42001 2000 Upper 16 bits of SFTS GW Endpoint address (the radio

ID).

42002 2001 Lower 16 bits of SFTS GW Endpoint address (the radio

ID).

42003 2002 Upper 16 bits of RadioFirmware version number.

42004 2003 Lower 16 bits of RadioFirmware version number.

42005 2004 Upper 16 bits of Gateway firmwareversionnumber.

42006 2005 Lower 16 bits of Gateway firmwareversionnumber.

42007 2006 Number of slave Endpoints that data is cached for this

Gateway.

42008 2007 Total number of registers allocated to slave devices.

42009 2008 Total number of freeregisters available for slave

devices.

42010 2009 Bitmask for active slave IDs 15-0 (LSB is 0).

42011 2010 Bitmask for active slave IDs 31-16 (LSB is 16).

42012 2011 Bitmask for active slave IDs 47-32 (LSB is 32).

42013 2012 Bitmask for active slave IDs 63-48 (LSB is 48).

42014 2013 Bitmask for active slave IDs 79-64 (LSB is 64).

42015 2014 Bitmask for active slave IDs 95-80 (LSB is 80).

42016 2015 Bitmask for active slave IDs 111-96 (LSB is 96).

42017 2016 Bitmask for active slave IDs 127-112(LSB is 112).

42018 2017 Bitmask for active slave IDs 143-128(LSB is 128).

42019 2018 Bitmask for active slave IDs 159-144(LSB is 144).

42020 2019 Bitmask for active slave IDs 175-160(LSB is 160).

42021 2020 Bitmask for active slave IDs 191-176(LSB is 176).

42022 2021 Bitmask for active slave IDs 207-192(LSB is 192).

42023 2022 Bitmask for active slave IDs 223-208(LSB is 208).

Note: If the Gateway has a large total number of registers approaching 4700, register 2008 should be

monitored to ensure that freeregisters are available before adding a new Endpoint.

WC45i-GW-485 Modbus Gateway: User & Reference Manual

l These are 16-bit Read-onlyregisters.

l They can be read with Modbusopcode 0x03 or 0x04 (Read Discrete Input and Holding

Registers, respectively).

LUM0086AA Rev Mar-2018 Page 53 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 54

12. Modbus Gateway Register Map

Read-only Registers

Register Number

Register Address

(Offset)

Description

42024 2023 Bitmask for active slave IDs 239-224(LSB is 224).

42025 2024 Bitmask for active slave IDs 255-240(LSB is 240).

42026 2025 Gateway power supply voltage in mV.

42027 2026 Radio packets received count.

42028 2027 Radio packets sent count.

42029 2028 RS-485 messages received count.

42030 2029 RS-485 messages sent count .

42031 2030 Total Modbus errors from master andslaves.

42032 2031 Modbus exceptions from slave Endpoints.

42033 2032 Radio packets received / transmitted per minute.

FREEWAVE Recommends: Less than60

42034 2033 Radio packets per minute alert.

l 0 (zero) if packets/min <= 60.

l 1 if packets/min > 60.

42101 2100 Address test register.

Note: This register always returns 2100.

42102 2101 Address test register.

Note: This register always returns 2101.

42103 2102 Address test register.

Note: This register always returns 2102.

43001 3000 Writes the radio address of an Endpoint to this register

to cause that WC45i-GW-485 to perform a scan for

attached Modbus sensors.

43004 3003 Writes Modbus ID for a Modbus Client Endpoint to this

register to cause that remote Endpoint to perform a scan

for attached Modbus sensors.

44002 4001 Status of Slave ID 1.

Note: This register returns 1 if Slave is present

and0 (zero) if Slave is not present.

LUM0086AA Rev Mar-2018 Page 54 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 55

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Read-only Registers

Register Number

Register Address

(Offset)

Description

44003 4002 Status of Slave ID 2.

Note: This register returns 1 if Slave is present

and0 (zero) if Slave is not present.

44241 4240 Status of Slave ID 240.

Note: This register returns 1 if Slave is present

and0 (zero) if Slave is not present.

LUM0086AA Rev Mar-2018 Page 55 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 56

WC45i-GW-485 Modbus Gateway: User & Reference Manual

13. WC Toolkit Software Environment

The WC Toolkit software environment usesthese windows to configure all WAVECONTACT

devices:

l Device Configuration window (on page 57)

l Edit Configuration window (on page 64)

l Firmware Updates window (on page 71)

l Gateway Log window (on page 73)

l Remote Shutdown Settings window (on page 84)

l Slave Register Remapping window (on page 91)

LUM0086AA Rev Mar-2018 Page 56 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 57

13. WC Toolkit Software Environment

13.1. Device Configuration window

The Device Configuration window is used to configure the settingson the WC45i-GW-485

ModbusGateway.

l If one or more remote Endpoints are configuredwith the correct network settingsthey send

their data to the Gateway.

l The Gateway shows the Endpoint type, Endpoint name, RSSI signal strength,

programmed Endpoint check-in interval, the Time To Live (TTL), and the Endpoints radio

and main firmware versions.

Access and Window Description

1. Verify the WC Toolkit software is installed on the computer connected to the WC45i-GW-

485.

Note: See WC Toolkit Installation (on page 14) and WC Toolkit Update (on page 21).

2. Open the WC Toolkit software.

The Select Device window opens. (Figure 52)

Figure 52: Select Device window

3. Click the Refresh button to have WC Toolkit search for and list the available COM ports

reported by Windows and connected devices in the COM Port list box.

4. Click the COM Port list box arrow and select the COM port on the computer associated

with the connected WC45i-GW-485.

5. Click the Auto-Detect Device on COM Port button to have WC Toolkit connect the

device to the COM Port selected in the COM Port list box.

Note: Optional: Click the Select Device list box arrow and select the connected WC45i-

Gateway device.

The Device Configuration window opens for the selected device.

LUM0086AA Rev Mar-2018 Page 57 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 58

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Device Configuration window: WC45i-GW-485

Control Area Control Title Control Description

Set button Click the Set button to save the information.

1 - Status of Last

Operation text

boxtext box

The Status of Last Operation text box indicates

whether the last command from the WC Toolkit to the

connected device is Active or has Passed.

Note: A Firmware Update Available message

appears in this text box when the WC Toolkit

has detected that a newer version of firmwareis

available for download than what is installedon

the device.

Note: This information is read-only.

2 - Serial Port

Settings area

The Serial Port Settings area shows the connected

COM port and is used to re-connect to the COM port if

the connection is lost.

2 - Serial Port

Settings area

COM Port list box Click the COM Port list box arrow and select the COM

port on the computer associated with the connected

WC45i-GW-485.

Figure 53: Device Configuration window: WC45i-Gateway

LUM0086AA Rev Mar-2018 Page 58 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 59

13. WC Toolkit Software Environment

Device Configuration window: WC45i-GW-485

Control Area Control Title Control Description

2 - Serial Port

Settings area

Refresh button Click the Refresh button to have WC Toolkit search for

andlist the available COM ports reported by Windows

andconnected devices in the COM Port list box.

2 - Serial Port

Settings area

COM text box The COM text box shows the COM port the

WAVECONTACT device is connected to.

Note: This information is read-only.

2 - Serial Port

Settings area

Open button Click the Open button to re-connect the

WAVECONTACT device to the COM port.

2 - Serial Port

Settings area

Close button Click the Close button to disconnect the

WAVECONTACT device from the COM port.

2 - Serial Port

Settings area

Offline button Click the Offline button to disconnect the

WAVECONTACT device from the COM port but

continue to configure the device offline.

2 - Serial Port

Settings area

TCP Connection

check box

Note: The TCP Connection check box is only

available for the WC45i-GW-P Ethernet

Gateway.

2 - Serial Port

Settings area

Connect / Update

button

Click the Connect / Update button to re-connect to the

COM port of the WAVECONTACT device.

3 - Modbus Slaves

Reporting table

The Modbus Slaves Reporting table shows all

connected remote Endpoints.

Note: This information is read-only.

See the Modbus Slaves Reportingtable (on

page 62)for detailed information about the table.

4 - Information area The Information area of the Device Configuration

window shows connection informationabout the

connected WAVECONTACT device.

Note: This information is read-only.

5 - Settings area The Settings area is used to define the radio mode and

radio network.

LUM0086AA Rev Mar-2018 Page 59 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 60

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Device Configuration window: WC45i-GW-485

Control Area Control Title Control Description

5 - Settings area Radio Network list

box

Click the Radio Network list box arrow and select 0

(zero) to 7 for the assigned number.

Note: The default value is 1.

Important!: The Radio Network andRadio

Network Group settings areselected by the

user but MUST MATCH the existing Gateway

network for successful communication between

the Gateway and Endpoint.

See WAVECONTACT Network Frequencies

(onpage 95) for additional information.

5 - Settings area Radio Network

Group list box

Click the Radio Network Group list box arrow and

select 0 (zero) to 29 for the network group assigned

number.

Note: The default value is 10.

Important!: The Radio Network andRadio

Network Group settings areselected by the

user but MUST MATCH the existing Gateway

network for successful communication between

the Gateway and Endpoint.

See WAVECONTACT Network Frequencies

(onpage 95) for additional information.

6 - Set Encryption

Key area

The Set Encryption Key areais used to activate and

define the encryption key for the WAVECONTACT

device.

6 - Set Encryption

Key area

Help button Click to open the Encryption Help message.

6 - Set Encryption

Key area

Key text box In the Key text box, enter the encryption key for the

device using 6 to 16 characters.

Important!: A Key CANNOT contain spaces or

angle brackets.

The Gateway andEndpoints only communicate

if they are configured with the same Key.

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

LUM0086AA Rev Mar-2018 Page 60 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave Technologies, Inc.

Page 61

13. WC Toolkit Software Environment

Device Configuration window: WC45i-GW-485

Control Area Control Title Control Description

7 - Gateway RS485

Settings area

The Gateway RS485 Settings area is used to define

the RS485 settings and communication timing.

Note: The Gateway has registers that are read

for diagnostics. They are not often used except

when remappingModbus data. When

remapping, read all data from this Slave ID.

7 - Gateway RS485

Settings area

Gateway Slave ID

list box

Click the Gateway Slave ID list box arrow and select

the Modbus Slave ID for the Gateway.

7 - Gateway RS485

Settings area

Baud Rate list box Click the Baud Rate list box arrow and select the baud

rate for the RS485 Modbus port.

7 - Gateway RS485

Settings area

UART Mode list

box

Click the UART Mode list box arrow and select the

numberof data bits, parity, and stop bits used with the

RS485 Modbus port.

8 - Gateway Slave

ID Word / Byte

Order area

The Gateway Slave ID Word / Byte Order areais

used to set communication timing by selecting one of

the byte orderoptions for transmission of Modbus data.

.

8 - Gateway Slave

ID Word / Byte

Order area

High Word / High

Byte (ABCD) option

button

Select the High Word / High Byte (ABCD) option

button to transmit the Modbus data in a High Word /

High Byte order.

8 - Gateway Slave

ID Word / Byte

Order area

High Word / Low

Byte (BACD) option

button

Select the High Word / Low Byte (BACD) option

button to transmit the Modbus data in a High Word /

Low Byte order.

8 - Gateway Slave

ID Word / Byte

Order area

Low Word / High

Byte (CDAB) option

button

Select the Low Word / High Byte (CDAB) option

button to transmit the Modbus data in a Low Word /

High Byte order.

8 - Gateway Slave

ID Word / Byte

Order area

Low Word / Low

Byte (DCBA) option

button

Select the Low Word / Low Byte (DCBA) option

button to transmit the Modbus data in a Low Word / Low

Byte order.

9 - Remote

Configuration area

The Remote Configuration area is used to start and

enda Remote Configuration session.

LUM0086AA Rev Mar-2018 Page 61 of 112 Copyright © 2018FreeWave

This document is the property of FreeWave Technologies, Inc. and contains proprietary information owned by

FreeWave. This document cannot be reproduced in whole or in part by any means without written permission from

FreeWave Technologies, Inc.

Page 62

WC45i-GW-485 Modbus Gateway: User & Reference Manual

Device Configuration window: WC45i-GW-485

Control Area Control Title Control Description

9 - Remote

Configuration area

Start

Configuration

button

Click the Start Configuration button to activate a

Remote Configuration session.

l If the Endpoint has a Non-Sleeping radio, the

Remote Configuration session is ready

immediately.

l If it is a Sleeping device, wait for the Endpoint to

either check-in or send a beacon so it can be

commanded into Configuration mode.

l A WC20i Endpoint sends a beacon every 2½

minutes.

l All other Sleeping Endpoints senda beacon

every 5½ minutes.

l When the device has entered a Remote

Configuration session, a message indicating

the Slave is Ready appears.

9 - Remote

Configuration area

Configure button Click the Configure button to openthe Edit

Configuration window (on page 64).

9 - Remote

Configuration area

End button Click the End button to stop the Remote