TWR-SER2

User’s Manual

Rev. 1.2

Freescale Semiconductor Inc.

Contents

1 Overview ...................................................................................................................................................... 3

2 Reference Documents .............................................................................................................................. 5

3 Hardware Features ................................................................................................................................... 5

3.1 Power Supply ....................................................................................................................................................................... 6

3.2 Dual Ethernet PHYs ........................................................................................................................................................... 6

3.3 Hi-Speed Dual Role USB ................................................................................................................................................... 6

3.4 Low/Full-Speed Host USB............................................................................................................................................... 7

3.5 Serial Communications Interface ................................................................................................................................ 7

3.5.1 RS-232/485 Interface ....................................................................................................................................................................... 7

3.5.2 Serial-to-USB ........................................................................................................................................................................................ 8

3.5.3 Additonal RS232 Interfaces ........................................................................................................................................................... 8

3.6 CAN Bus .................................................................................................................................................................................. 9

3.7 Elevator Connections ..................................................................................................................................................... 10

4 Configuration Settings .......................................................................................................................... 15

4.1 Switch Settings ................................................................................................................................................................. 15

4.2 Jumper Settings ................................................................................................................................................................ 16

5 Mechanical Form Factor ...................................................................................................................... 17

TWR-SER2 User’s Manual Page 2 of 17

1 Overview

The Serial2 Tower Board (TWR-SER2) is a peripheral Tower System Module designed to be used with a

compatible MCU/MPU Tower Card. The TWR-SER2 provides additional interfaces that are common to

feature rich MPU’s.

The TWR-SER2 features the following:

Industrial-grade Dual Ethernet PHY Transceiver w/ dual RJ-45 Ethernet Jacks, with integrated

magnetics and LED’s

Industrial-grade High Speed Dual Role USB PHY (utilizes MPU’s ULPI interface)

Full Speed / Low Speed Host only USB (utilizes USB Host controller interface)

Four Serial Ports

o Serial-to-USB (MC9S08JS16) w/ USB mini-B connector

o RS-232 / RS-485 Transceivers on shared DB9 connector

o 2x RS-232 Transceivers with option for full flow control on 2x5 Headers

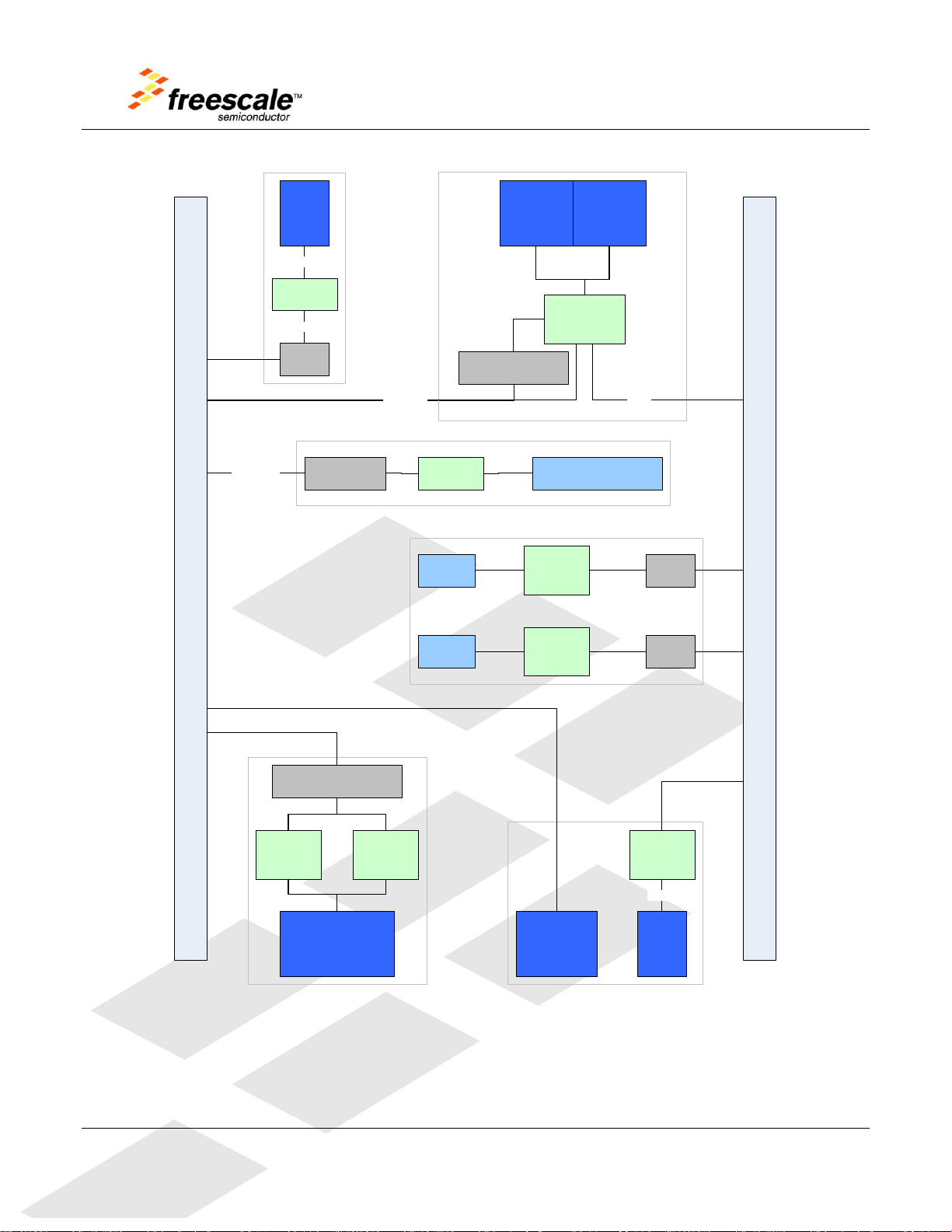

A block diagram for the TWR-SER2 is shown in the figure below.

TWR-SER2 User’s Manual Page 3 of 17

DP/DN

ULPI

CAN RX/TX

RMII1MII / RMII0

RX/TX

DP/DN

UART0

SMSC

USB3300

USB mini-B

(OTG)

USB A

(HOST)

Secondary Elevator Connection

RJ-45 Jack

RJ-45 Jack

National Semi

DP83849I

Strap Option Jumpers

MII/RMII Signal Select

Primary Elevator Connection

NXP

TJA1050

2x5 Header

CAN Bus Pin Out

CAN Isolation

Jumpers

DB9

Freescale

MC9S08JS16

USB mini-B

(Serial COM)

Intersil

ICL3225

(RS-232)

Intersil

ISL3176

(RS-485)

Selection / Isolation Jumpers

RS-232 / RS-485

Intersil

ICL3225

(RS-232)

Intersil

ICL3225

(RS-232)

2x5 Header

2x5 Header

Isolation

Jumpers

Isolation

Jumpers

Isolation

Jumpers

Serial-to-USB

Dual Ethernet

CAN

RS-232 (w/ optional flow control) – 2x5 Header Interface

RS-232 or RS-485

DB9 Interface

USB OTG /

USB Host

CANH/

CANL

RX/

TX

UART2

UART3

RXD/TXD

CTS/RTS

RS-232

RXs/TXs

UART1

RXD/TXD

CTS/RTS

RXD/TXD

RS-232

RX/TX

RS-495

RX/TX

RS-232

RXs/TXs

USB DP/DM

TPTD/TPRD

LEDs

TWR-SER2 User’s Manual Page 4 of 17

Figure 1 - TWR-SER2 Block Diagram

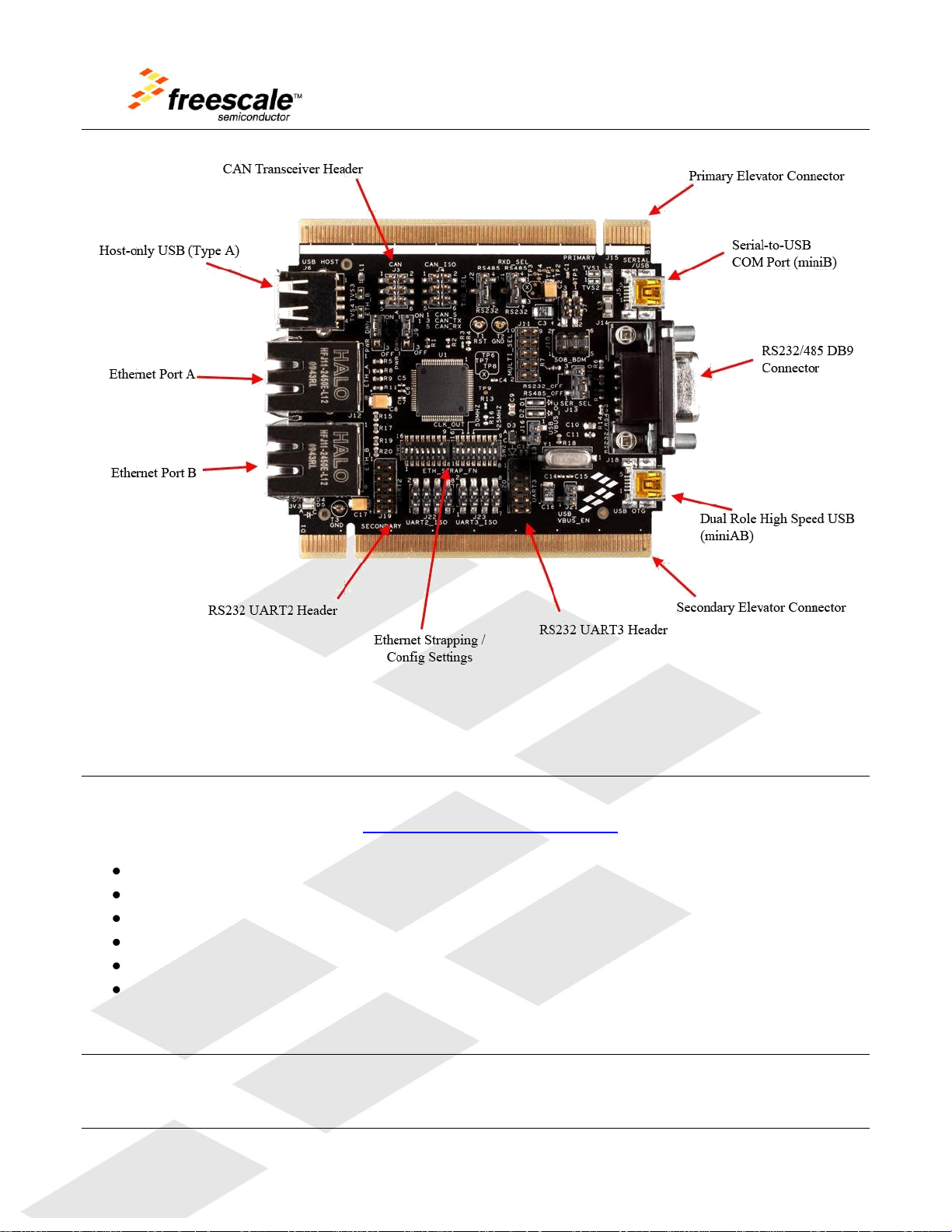

Figure 2 - TWR-SER2 Image

2 Reference Documents

The documents listed below should be referenced for more information on the Freescale Tower

system and the TWR-SER2. Refer to http://www.freescale.com/tower for the latest revision of all

released Tower documentation.

TWR-SER2 Schematics

TWR-SER2 Quick Start Guide

Freescale MC9S08JS16 Microcontroller with integrated USB Transceiver

DP83849I PHYTER DUAL Industrial Temp Ethernet PHY Transceiver

USB3300 Industrial Temp Hi-Speed USB PHY with ULPI Interface

TJA1051T/3 High-Speed CAN Transceiver

3 Hardware Features

This section provides more details about the features and functionality of the TWR-SER2.

TWR-SER2 User’s Manual Page 5 of 17

3.1 Power Supply

It is intended that the TWR-SER2 be powered from a source in an assembled Tower System via the

5.0V and 3.3V supplies on the TWR-ELEV. This includes the functional Tower Elevator USB power

connector, a capable MCU/MPU controller module, or other Tower System module capable of

providing power to the entire Tower System. The TWR-SER2 is can also provide power to the Tower

System when configured and used as a USB device through the Hi-Speed USB connection (Jumper J24).

3.2 Dual Ethernet PHYs

The TWR-SER2 module utilizes an industrial applicable National Semiconductor Dual Ethernet PHY

Transceiver (DP83849I). The DP83849I features two fully independent 10/100 ports for multi-port

applications. The TWR-SER2 is capable of supporting a single MII interface, a single RMII interface, or

dual RMII interfaces.

The Ethernet PHY is configurable via two sets of micro dip switches (SW1 and SW2).

Refer to these settings for typical Ethernet setting. For specific setting details refer to the TWR-SER2

Jumper Options section.

10/100 Dual RMII

o J8 and J9 should be un-shunted

o Configure SW1 (1-8) as 11000000

o Configure SW2 (1-8) as 10100000

10/100 Signal Port RMII

o J9 should be un-shunted

o Configure SW1 (1-8) as 11000000

o Configure SW2 (1-8) as 10100000

10/100 Signal Port MII

o J9 should be un-shunted

o Configure SW1 (1-8) as 00110000

o Configure SW2 (1-8) as 00010000

3.3 Hi-Speed Dual Role USB

The TWR-SER2 features Hi-Speed Dual Role USB. This feature is implemented using the SMSC

USB3300 USB Transceiver with ULPI interface. The ULPI interface is connected to the TWR-SER2 PCI

edge connector connect to a Tower MCU module.

Refer to these settings to configure the High Speed USB ULPI Transceiver.

Host Mode – TWR-SER2 will be connected to a device, such as a USB Memory Stick using the

appropriate mini USB adaptor.

o J24 should be un-shunted

TWR-SER2 User’s Manual Page 6 of 17

Jumper

Pin

Description

J1

2-3

RXD_SEL – Specifies the SCI RX signal is routed to the RS232 Transceiver

J2

2-3

TXD_SEL – Specifies the SCI TX signal is routed to the RS232 Transceiver

J13

1-2

SER_SEL – Disables communication to and from the RS485 Transceiver

Jumper

Pin

Description

J1

1-2

RXD_SEL – Specifies the SCI RX signal is routed to the RS485 Transceiver

J2

1-2

TXD_SEL – Specifies the SCI TX signal is routed to the RS485 Transceiver

J13

2-3

SER_SEL – Disables communication to and from the RS232 Transceiver

MULTI_SEL

(J2)

Pin

Description

1-2

Connects RS485 Receive EN and Driver EN

3-4

Connects RS485 RX+ to TX+; Loopback

5-6

Connects RS485 RX- to TX-; Loopback

7-8

NC

9-10

Connects 5V supply to DB9 pin 6

Device Mode – TWR-SER2 will be connected to a host, such as a host PC.

o J24 should be shunted, if it is desired that the entire Tower system be powered via this

connection.

3.4 Low/Full-Speed Host USB

The TWR-SER2 features a Host Type-A USB receptacle. The USB differential signals are connected

directly to the Tower Elevator USB Signals and will be connected to a compatible Tower System

MCU/MPU module’s USB Host controller. In addition to the differential data pair, the MCU should

provide the VBUS_EN signal and respond to the VBUS_OC signals. J16 and J21 should be shunted to

connect VBUS enable/over-current control to the MCU signals.

3.5 Serial Communications Interface

The TWR-SER2 is capable of providing up to four additional SCI’s. The number of accessible SCI’s on

the TWR-SER2 will depend on the capabilities and Tower Elevator signals connections of the

MCU/MPU Module.

3.5.1 RS-232/485 Interface

UART1 (RXD/TXD) is connected to both an RS-232 transceiver and an RS-485 transceiver, selectable

by a series of selection jumpers (J1, J2, & J13). The RS-232 and RS-485 transceivers are terminated

at a common DB9 connector (J11). This SCI does not feature any type of flow control capabilities.

Additional configurations related to the RS485 interface can be made using the MULTI_SEL jumper

(J2). Refer to the following tables for jumper setting details.

TWR-SER2 User’s Manual Page 7 of 17

Pins

Description

1-2

Remove to Isolate UART0_TX

3-4

Remove to Isolate UART0_RX

J19 & J20

Pin #

Signal Name

1

NC 2 NC

3

RXD

4

RTS

5

TXD

6

CTS 7 NC 8 NC

9

GND

10

NC

3.5.2 Serial-to-USB

UART0 (RXD/TXD) is connected to a Freescale MC9S08JS16. The MC9S08JS16 provides a Serial-toUSB conversion that will transmit/receive external data via its USB transceiver connected to an

USB mini-B connector. When this USB receptacle is connected to a host PC it will enumerate as a

USB CDC. The driver required for the CDC device is located on the included CD and is also available

on the TWR-SER2 webpage found at www.freescale.com/tower.

If needed the UART0 transceiver signals can be isolated from the Tower Elevator using J7.

3.5.3 Additonal RS232 Interfaces

UART2 and UART3 (RXD/TXD/RTS/CTS) are connected to additional RS-232 transceivers. The RS232 transceivers are terminated to 2x5 headers (refer to table for pinout).

These interfaces are capable of utilizing the optional RTS/CTS signals for flow control.

TWR-SER2 User’s Manual Page 8 of 17

10 Pin IDC

0.1” 2x5

DB-9 Male

Function

1 1 DCD

2 6 DSR

3 2 RX 4 7

RTS 5 3

TX 6 8

CTS 7 4

DTR

8 9 RI 9 5

GND

10

NC

NC

Pins

Description

1-2

Remove to Isolate UARTx_TX

3-4

Remove to Isolate UARTx_RX

5-6

Remove to Isolate UARTx_RTS

7-8

Remove to Isolate UARTx_CTS

Pin #

Signal Names

Signal Description

1

Not Used

2 CAN_V+

Power

3

CAN_GND

Ground

4

CAN_L

Dominant Low

5

CAN_H

Dominant High

6

Not Used

The 2x5 header is intended to be used with a DB-9 Male to 10 PIN IDC socket adaptor cable. The cable

should conform to the following pin assignments.

By default the UART2 and UART3 transceiver signals are isolated from the Tower Elevator. The signals

can be connected to the Tower Elevator connector using J22 and J23 respectively.

3.6 CAN Bus

The TWR-SER2 features a Controller Area Network interface using an NXP TJA1051T/3 CAN

transceiver. The signals from the transceiver are connected to a 6-pin (2x3) header using the following

CAN Bus Pin Out.

TWR-SER2 User’s Manual Page 9 of 17

Table 1 – 2x3 Header CAN Bus Pin Out

Pins

Description

1-2

Remove to Isolate CAN_S

3-4

Remove to Isolate CAN_TX

5-6

Remove to Isolate CAN_RX

TWR-SER2 Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B1

5V

5.0V Power

X A1

5V

5.0V Power

X B2

GND

Ground

X A2

GND

Ground

X B3

3.3V

3.3V Power

X A3

3.3V

3.3V Power

X B4

ELE_PS_SENSE

Elevator Power Sense

X A4

3.3V

3.3V Power

X B5

GND

Ground

X A5

GND

Ground

X B6

GND

Ground

X A6

GND

Ground

X B7

SDHC_CLK / SPI1_CLK

A7

I2C0_SCL

B8

SDHC_D3 / SPI1_CS1_b

A8

I2C0_SDA

B9

SDHC_D3 / SPI1_CS0_b

A9

GPIO9 / UART1_CTS

B10

SDHC_CMD / SPI1_MOSI

A10

GPIO8 / SDHC_D2

B11

SDHC_D0 / SPI1_MISO

A11

GPIO7 / SD_WP_DET

B12

ETH_COL

MII_COL

X A12

ETH_CRS

MII_CRS

X

B13

ETH_RXER

MII_RXER / RMII0_RXER

X A13

ETH_MDC

MII_MDC /

RMII0_MDC

X

B14

ETH_TXCLK

MII_TXCLK

X A14

ETH_MDIO

MII_MDIO /

RMII0_MDIO

X

B15

ETH_TXEN

MII_TXEN / RMII0_TXEN

X A15

ETH_RXCLK

MII_RXCLK

X

B16

ETH_TXER

A16

ETH_RXDV

MII_RXDV /

RMII0_CRS_DV

X

B17

ETH_TXD3

MII_TXD3

X A17

ETH_RXD3

MII_RXD3

X

B18

ETH_TXD2

MII_TXD2

X A18

ETH_RXD2

MII_RXD2

X

B19

ETH_TXD1

MII_TXD1 / RMII0_TXD1

X A19

ETH_RXD1

MII_RXD1 /

RMII0_RXD1

X

B20

ETH_TXD0

MII_TXD0 / RMII0_TXD0

X A20

ETH_RXD0

MII_RXD0 /

RMII0_RXD0

X

B21

GPIO1 /UART1_RTS

X

A21

I2S0_MCLK

If needed the CAN transceiver signals can be isolated from the Tower Elevator using J4.

3.7 Elevator Connections

The TWR-SER2 features two expansion card-edge connectors that interface to Elevator boards in a

Tower System: the Primary and Secondary Elevator connectors. Table 2 provides the pinout for the

Primary and Secondary Elevator Connector. An “X” in the “Used” column indicated that there is a

connection from the TWR-MEM to that pin on the Elevator connector. An “X” in the “Jmp” column

indicates that a jumper is available that can configure or isolate the connection from the Elevator

connector.

Table 2 - TWR-SER2 Primary Elevator Connector Pinout

TWR-SER2 User’s Manual Page 10 of 17

TWR-SER2 Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B22

GPIO2 / SDHC_D1

X A22

I2S0_DOUT_SCK

B23

GPIO3

A23

I2S0_DOUT_WS

B24

CLKIN0

RMII_REF_CLK

X X A24

I2S0_DIN0

B25

CLKOUT1

A25

I2S0_DOUT0

B26

GND

Ground

X A26

GND

Ground

X B27

AN7

A27

AN3

B28

AN6

A28

AN2

B29

AN5

A29

AN1

B30

AN4

A30

AN0

B31

GND

Ground

X A31

GND

Ground

X B32

DAC1

A32

DAC0

B33

TMR3

A33

TMR1

B34

TMR2

A34

TMR0

B35

GPIO4

USB_VBUS_EN

X X A35

GPIO6

USB_VBUS_OC

X

X

B36

3.3V

3.3V Power

X A36

3.3V

3.3V Power

X B37

PWM7

A37

PWM3

X

B38

PWM6

A38

PWM2

X

B39

PWM5

X A39

PWM1

X

B40

PWM4

X A40

PWM0

X

B41

CAN0_RX

CAN_RX

X

X

A41

UART0_RX

UART0_RX

X

X

B42

CAN0_TX

CAN_TX

X

X

A42

UART0_TX

UART0_TX

X

X

B43

1WIRE

CAN_S

X

X

A43

UART1_RX

UART1_RX

X

X

B44

SPI0_MISO (IO1)

X

A44

UART1_TX

UART1_TX

X

X

B45

SPI0_MOSI (IO0)

X

A45

VSSA

B46

SPI0_CS0_b

X

A46

VDDA

B47

SPI0_CS1_b

X

A47

CAN1_RX

B48

SPI0_CLK

X

A48

CAN1_TX

B49

GND

Ground

X A49

GND

Ground

X B50

I2C1_SCL

A50

GPIO14

B51

I2C1_SDA

A51

GPIO15

B52

GPIO5 / SPI0_HOLD (IO3)

X A52

GPIO16 / SPI0_WP (IO2)

B53 USB D+ Pulldown Control

X

A53

GPIO17

B54 USB D- Pulldown Control

X

A54

USB0_DM

USB D-

X

B55

IRQ_H

A55

USB0_DP

USB D+

X

B56

IRQ_G

A56

USB0_ID

B57

IRQ_F

A57

USB0_VBUS

USB VBUS HST

X

B58

IRQ_E

A58

I2S0_DIN_SCK

B59

IRQ_D

A59

I2S0_DIN_WS

B60

IRQ_C

A60

I2S0_DIN1

B61

IRQ_B

A61

I2S0_DOUT1

B62

IRQ_A

A62

RSTIN_b

B63

EBI_ALE / EBI_CS1_b

A63

RSTOUT_b

Reset to Ethernet

PHY / SPI

X B64

EBI_CS0_b

A64

CLKOUT0

CLOCKOUT0

X B65

GND

Ground

X A65

GND

Ground

X

TWR-SER2 User’s Manual Page 11 of 17

TWR-SER2 Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B66

EBI_AD15

A66

EBI_AD14

B67

EBI_AD16

A67

EBI_AD13

B68

EBI_AD17

A68

EBI_AD12

B69

EBI_AD18

A69

EBI_AD11

B70

EBI_AD19

A70

EBI_AD10

B71

EBI_R/W_b

A71

EBI_AD9

B72

EBI_OE_b

A72

EBI_AD8

B73

EBI_D7

A73

EBI_AD7

B74

EBI_D6

A74

EBI_AD6

B75

EBI_D5

A75

EBI_AD5

B76

EBI_D4

A76

EBI_AD4

B77

EBI_D3

A77

EBI_AD3

B78

EBI_D2

A78

EBI_AD2

B79

EBI_D1

A79

EBI_AD1

B80

EBI_D0

A80

EBI_AD0

B81

GND

Ground

X A81

GND

Ground

X B82

3.3V

3.3V Power

X A82

3.3V

3.3V Power

X

TWR-SER2 User’s Manual Page 12 of 17

TWR-SER2 Secondary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

D1

5V

5.0V Power

X C1

5V

5.0V Power

X D2

GND

Ground

X C2

GND

Ground

X D3

3.3V

3.3V Power

X C3

3.3V

3.3V Power

X D4

ELE_PS_SENSE

Elevator Power Sense

C4

3.3V

3.3V Power

X D5

GND

Ground

X C5

GND

Ground

X D6

GND

Ground

X C6

GND

Ground

X D7

SPI2_CLK

C7

I2C2_SCL

D8

SPI2_CS1_b

C8

I2C2_SDA

D9

SPI2_CS0_b

C9

GPIO25

D10

SPI2_MOSI

C10

ULPI_STOP

ULPI_STP

X

D11

SPI2_MISO

C11

ULPI_CLK

ULPI_USB_CLK

X

D12

ETH_COL

C12

GPIO26

D13

ETH_RXER

RMII1_RXER

X

C13

ETH_MDC

D14

ETH_TXCLK

C14

ETH_MDIO

D15

ETH_TXEN

RMII1_TXEN

X

C15

ETH_RXCLK

D16

GPIO18

C16

ETH_RXDV

RMII1_CRS_DV

X

D17

GPIO19 / SDHC_D4

C17

GPIO27 / SDHC_D6

D18

GPIO20 / SDHC_D5

C18

GPIO28 / SDHC_D7

D19

ETH_TXD1

RMII1_TXD1

X

C19

ETH_RXD1

RMII1_RXD1

X

D20

ETH_TXD0

RMII1_TXD0

X

C20

ETH_RXD0

RMII1_RXD0

X

D21

ULPI_NEXT / USB_HS_DM

ULPI_NXT

X C21

ULPI_DATA0 / I2S1_MCLK

ULPI_DATA0

X D22

ULPI_DIR / USB_HS_DP

ULPI_DIR

X C22

ULPI_DATA 1 / I2S1_DOUT_SCK

ULPI_DATA1

X D23

UPLI_DATA5 / USB_HS_VBUS

ULPI_DATA5

X C23

ULPI_DATA2 / I2S1_DOUT_WS

ULPI_DATA2

X D24

ULPI_DATA6 / USB_HS_ID

ULPI_DATA6

X C24

ULPI_DATA3 / I2S1_DIN0

ULPI_DATA3

X D25

ULPI_DATA7

ULPI_DATA7

X C25

ULPI_DATA4 / I2S1_DOUT0

ULPI_DATA4

X D26

GND

Ground

X C26

GND

Ground

X D27

LCD_HSYNC / LCD_P24

C27

AN11

D28

LCD_VSYNC / LCD_P25

C28

AN10

D29

AN13

C29

AN9

D30

AN12

C30

AN8

D31

GND

Ground

X C31

GND

Ground

X D32

LCD_CLK / LCD_P26

C32

GPIO29 / UART2_DCD

D33

TMR11

C33

TMR9

D34

TMR10

C34

TMR8

D35

GPIO21

C35

GPIO30 / UART3_DCD

D36

3.3V

3.3V Power

C36

3.3V

3.3V Power

X D37

PWM15

C37

PWM11

D38

PWM14

C38

PWM10

D39

PWM13

C39

PWM9

D40

PWM12

C40

PWM8

D41

CAN2_RX

C41

UART2_RXD / TSI0

UART2_RX

X

X

D42

CAN2_TX

C42

UART2_TXD / TSI1

UART2_TX

X

X

Table 3 - TWR-SER2 Secondary Elevator Connector Pinout

TWR-SER2 User’s Manual Page 13 of 17

TWR-SER2 Secondary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

D43

LCD_CONTRAST

C43

UART2_RTS / TSI2

UART2_RTS

X

X

D44

LCD_OE / LCD_P27

C44

UART2_CTS / TSI3

UART2_CTS

X

X

D45

LCD_D0 / LCD_P0

C45

UART3_RXD / TSI4

UART3_RX

X

X

D46

LCD_D1 / LCD_P1

C46

UART3_TXD / TSI5

UART3_TX

X

X

D47

LCD_D2 / LCD_P2

C47

UART3_RTS / CAN3_RX

UART3_RTS

X

X

D48

LCD_D3 / LCD_P3

C48

UART3_CTS / CAN3_TX

UART3_CTS

X

X

D49

GND

Ground

X C49

GND

Ground

X D50

GPIO23

C50

LCD_D4 / LCD_P4

D51

GPIO24

C51

LCD_D5 / LCD_P5

D52

LCD_D12 / LCD_P12

C52

LCD_D6 / LCD_P6

D53

LCD_D13 / LCD_P13

C53

LCD_D7 / LCD_P7

D54

LCD_D14 / LCD_P14

C54

LCD_D8 / LCD_P8

D55

IRQ_P / SPI2_CS2_b

C55

LCD_D9 / LCD_P9

D56

IRQ_O / SPI2_CS3_b

C56

LCD_D10 / LCD_P10

D57

IRQ_N

C57

LCD_D11 / LCD_P11

D58

IRQ_M

C58

I2S1_DIN_SCK

D59

IRQ_L

C59

I2S1_DIN_WS

D60

IRQ_K

C60

I2S1_DIN1

D61

IRQ_J

C61

I2S1_DOUT1

D62

IRQ_I

C62

LCD_D15 / LCD_P15

D63

LCD_D18 / LCD_P18 / SD_RX_0

C63

LCD_D16 / LCD_P16 / SD_GND

D64

LCD_D19 / LCD_P19 / SD_RXb_0

C64

LCD_D17 / LCD_P17 / SD_GND

D65

GND

Ground

X C65

GND

Ground

X D66

EBI_AD20 / LCD_P42 / SD_GND

C66

EBI_BE_32_24_b / LCD_P28 / SD_TX_0

D67

EBI_AD21 / LCD_P43 / SD_GND

C67

EBI_BE_23_16_b / LCD_P29 /

SD_TXb_0

D68

EBI_AD22 / LCD_P44 / SD_RX_1

C68

EBI_BE_15_8_b / LCD_P30 / SD_GND

D69

EBI_AD23 / LCD_P45 / SD_RXb_1

C69

EBI_BE_7_0_b / LCD_P31 / SD_GND

D70

EBI_AD24 / LCD_P46 / SD_GND

C70

EBI_TSIZE0 / LCD_P32 / SD_TX_1

D71

EBI_AD25 / LCD_P47 / SD_GND

C71

EBI_TSIZE1 / LCD_P33 / SD_TXb_1

D72

EBI_AD26 / LCD_P48 / SD_RX_2

C72

EBI_TS_b / LCD_P34 / SD_GND

D73

EBI_AD27 / LCD_P49 / SD_RXb_2

C73

EBI_TBST_b / LCD_P35 / SD_GND

D74

EBI_AD28 / LCD_P50 / SD_GND

C74

EBI_TA_b / LCD_P36 / SD_TX_2

D75

EBI_AD29 / LCD_P51 / SD_GND

C75

EBI_CS4_b / LCD_P37 / SD_TXb_2

D76

EBI_AD30 / LCD_P52 / SD_RX_3

C76

EBI_CS3_b / LCD_P38 / SD_GND

D77

EBI_AD31 / LCD_P53 / SD_RXb_3

C77

EBI_CS2_b / LCD_P39 / SD_GND

D78

LCD_D20 / LCD_P20 / SD_GND

C78

EBI_CS1_b / LCD_P40 / SD_TX_3

D79

LCD_D21 / LCD_P21 / SD_REFCLK

C79

GPIO31 / LCD_P41 / SD_TXb_3

D80

LCD_D22 / LCD_P22 /

SD_REFCLKb

C80

LCD_D23 / LCD_P23 / SD_GND

D81

GND

Ground

X C81

GND

Ground

X D82

3.3V

3.3V Power

X C82

3.3V

3.3V Power

X

TWR-SER2 User’s Manual Page 14 of 17

Switch Options

Setting

Description

SW1

Ethernet Strapping Functions / Settings

Dip 1

*On*

Enables RMII mode for Ethernet PHY A

Off

Enables MII mode for Ethernet PHY A

Dip 2

*On*

Connects RX_CRS to RMII0_CRS_DV (required for RMII operation)

Off

Disconnects RX_CRS from RMII0_CRS_DV (required for MII operation)

Dip 3

On

Connects RX_CRS to MII_CRS (required for MII operation)

*Off*

Disconnects RX_CRS from MII_CRS (required for RMII operation)

Dip 4

On

Connects RX_DV to MII_RXDV (required for MII operation)

*Off*

Disconnects RX_DV from MII_RXDV (required for RMII operation)

Dip 5

On

Enables Dual PHY Extender Mode

*Off*

Disables Extender Mode

Dip 6

On

PHY A - Auto Negotiation (Use AN0/AN1 to set highest capability)

*Off*

PHY A - Forced Mode (Use AN0/AN1 to set forced mode)

Dip 7

On

AN0_A - Full-Duplex on PHY A

*Off*

AN0_A - Half-Duplex on PHY A

Dip 8

On

AN1_A - 100Base-TX on PHY A

*Off*

AN1_A - 10Base-T on PHY A

SW2

Ethernet Strapping Functions / Settings

Dip 1

*On*

Enables RMII mode for Ethernet PHY B

Off

Enables MII mode for Ethernet PHY B

Dip 2

On

Connects CLOCKOUT0 to Ethernet PHY Clock

*Off*

Isolates CLOCKOUT0 from Ethernet PHY Clock

Dip 3

*On*

Connects onboard 50MHz clock to Ethernet PHY Clock

Off

Isolates onboard 50MHz clock from Ethernet PHY Clock

Dip 4

On

Connects onboard 25MHz clock to Ethernet PHY Clock

*Off*

Isolates onboard 25MHz clock from Ethernet PHY Clock

Dip 5

On

Disables onboard 25MHz / 50MHz clock

*Off*

Enables onboard 25MHz / 50MHz clock

Dip 6

On

PHY B - Auto Negotiation (Use AN0/AN1 to set highest capability)

*Off*

PHY B - Forced Mode (Use AN0/AN1 to set forced mode)

Dip 7

On

AN0_B - Full-Duplex on PHY B

*Off*

AN0_B - Half-Duplex on PHY B

Dip 8

On

AN1_B - 100Base-TX on PHY B

*Off*

AN1_B - 10Base-T on PHY B

4 Configuration Settings

There are several jumpers provided for isolation, configuration, and feature selection. Refer to the

following table for details. The default installed jumper settings are shown in *bold*.

4.1 Switch Settings

TWR-SER2 User’s Manual Page 15 of 17

Figure 3 - TWR-SER2 Switch Settings

Jumper Options

Setting

Description

J1

RS232/485 RX Select (UART 1)

1-2

RS485 Mode (connects RX to RO)

*2-3*

RS232 Mode (connects RX to R1OUT)

J2

RS232/485 TX Select (UART 1)

1-2

RS485 Mode (connects TX to DI)

*2-3*

RS232 Mode (connects TX to T1IN)

J4

CAN Isolation

1-2

Connects CAN_S to S

3-4

Connects CAN_TX to TXD

5-6

Connects CAN_RX to RXD

J7

JS16 RS232 Isolation (UART 0)

*1-2*

Connects RX to S08JS16 RXD

*3-4*

Connects TX to S08JS16 TXD

J8

Power Down Port B

1-2

Disables Ethernet PHY B

J9

Power Down Port A

1-2

Disables Ethernet PHY A

J11

RS485 Config (UART 1)

1-2

Loopback Mode (connects RE to DE)

3-4

Loopback Mode (connects TX0_P to RX0_P)

5-6

Loopback Mode (connects TX0_N to RX0_N)

7-8

NC

9-10

5V Supply to DB9

J13

RS232/485 Disable (UART 1)

*1-2*

Disables RS485

2-3

Disables RS232

J16

VBUS OC Isolation

1-2

Connects USB VBUS OC to Elevator

J21

VBUS EN Isolation

1-2

Connects USB VBUS EN to Elevator

J22

RS232 (UART2) Isolation

1-2

Connects TX to T1IN

3-4

Connects RX to R1OUT

5-6

Connects RTS to T2IN

7-8

Connect CTS to R2OUT

J23

RS232 (UART3) Isolation

1-2

Connects TX to T1IN

3-4

Connects RX to R1OUT

5-6

Connects RTS to T2IN

7-8

Connects CTS to R2OUT

J24

USB Device Mode

1-2

Device Mode (capable of powering Tower

System)

4.2 Jumper Settings

TWR-SER2 User’s Manual Page 16 of 17

Figure 4 - TWR-SER2 Jumper Settings

Freescale™ and the Freescale l ogo are trademarks of

Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners.

© Freescale Semiconductor, Inc. 2009. All rights reserved.

5 Mechanical Form Factor

The TWR-SER2 is designed for the Freescale Tower System as a side mounting peripheral and complies

with the electrical and mechanical specification as described in Freescale Tower Electromechanical

Specification.

TWR-SER2 User’s Manual Page 17 of 17

Loading...

Loading...