Page 1

TWR-P1025 Tower Module

Hardware User Guide

TWR-P1025HUG

Rev. 0, 3/2012

Page 2

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or

+1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku

Tokyo 153-0064

Japan

0120 191014 or

+81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor China Ltd.

Exchange Building 23F

No. 118 Jianguo Road

Chaoyang District

Beijing 100022

China

+86 010 5879 8000

support.asia@freescale.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of

any product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters which may be

provided in Freescale Semiconductor data sheets and/or specifications can and do

vary in different applications and actual performance may vary over time. All operating

parameters, including “Typicals” must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescale and the Freescale logo are trademarks of Freescale

Semiconductor, Inc., Reg. U.S. Pat. & Tm. Off. QUICC Engine is trademarks

of Freescale Semiconductor, Inc. All other product or service names are the

property of their respective owners.

© Freescale Semiconductor, Inc., 2012

Document Number: TWR-P1025HUG

Rev. 0, 3/2012

Page 3

Contents

Paragraph

Number Title

Page

Number

Chapter 1

TWR-P1025 Overview

1.1 Introduction...................................................................................................................... 1-1

1.2 Contents ........................................................................................................................... 1-2

1.3 Features............................................................................................................................ 1-2

1.4 Getting Started ................................................................................................................. 1-4

1.5 Reference Documents ...................................................................................................... 1-4

Chapter 2

Power Requirements

2.1 Overview.......................................................................................................................... 2-1

Chapter 3

Hardware Description

3.1 P1025 Microprocessor ..................................................................................................... 3-1

3.2 Clocking........................................................................................................................... 3-2

3.3 System Power .................................................................................................................. 3-5

3.4 Debug Interface................................................................................................................ 3-5

3.5 Accelerometer.................................................................................................................. 3-5

3.6 Pushbutton and LEDs ...................................................................................................... 3-5

3.7 Ethernet............................................................................................................................ 3-5

3.8 USB.................................................................................................................................. 3-7

3.9 Micro Secure Digital Card Slot (micro SDHC)............................................................... 3-8

3.10 Local Bus Interface .......................................................................................................... 3-8

3.11 UART ............................................................................................................................... 3-8

3.12 I2C ................................................................................................................................... 3-9

3.13 SPI.................................................................................................................................... 3-9

3.14 DDR3 ............................................................................................................................... 3-9

3.15 GPIO & Interrupts ......................................................................................................... 3-12

4.1 P1025 Jumper Table......................................................................................................... 4-1

Freescale Semiconductor iii

Chapter 4

Switch Table

TWR-P1025 Hardware User Guide, Rev. 0

Page 4

Contents

Paragraph

Number Title

Page

Number

Chapter 5

Input/Output Connectors and Pin Usage Table

5.1 LED Usage....................................................................................................................... 5-1

5.2 I/O Connectors and Pin Usage Table ............................................................................... 5-1

Chapter 6

Tower Elevator Connections

6.1 Overview.......................................................................................................................... 6-1

Appendix A

Revision History

A.1 Version Number 0 ............................................................................................................ 7-1

iv Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 5

Figures

Figure

Number Title

Page

Number

1-1 Freescale Tower System.......................................................................................................... 1-1

1-2 Callouts on front side of the TWR-P1025 .............................................................................. 1-3

1-3 Callouts on back side of the TWR-P1025............................................................................... 1-3

2-1 Power Supply Barrel Connector (J2) Polarity......................................................................... 2-1

3-1 TWR-P1025 Block Diagram................................................................................................... 3-1

3-2 P1025 Clocking Scheme ......................................................................................................... 3-3

3-3 eTSEC connection to AR8035 PHY....................................................................................... 3-6

3-4 NOR Local Bus Connection ................................................................................................... 3-8

Freescale Semiconductor v

TWR-P1025 Hardware User Guide, Rev. 0

Page 6

Tables

Table

Number Title

Tables

Page

Number

2-1 Power Distribution Summary.................................................................................................. 2-1

3-1 P1025 CCB to SYSCLK Ratio Selection ............................................................................... 3-4

3-2 P1025 e500 Core 0 & 1 to CCB Clock Ratio Selection.......................................................... 3-4

3-3 P1025 DDR Clock PLL Ratio................................................................................................. 3-4

3-4 CPU Speed Selection .............................................................................................................. 3-5

3-5 eTSEC1 PHY Connectivity .................................................................................................... 3-6

3-6 eTSEC1 PHY Connectivity .................................................................................................... 3-7

3-7 I2C1 Connectivity ................................................................................................................... 3-9

3-8 I2C2 Connectivity ................................................................................................................... 3-9

3-9 DDR3 Signals ....................................................................................................................... 3-10

3-10 P1025 Interrupt Usage .......................................................................................................... 3-13

3-11 P1025 GPIO Usage ............................................................................................................... 3-13

4-1 P1025 Jumper Table................................................................................................................ 4-1

5-1 LED Usage Table .................................................................................................................... 5-1

5-2 I/O Connectors and Pin Usage Table ...................................................................................... 5-1

6-1 TWR-P1025 Primary Connector Pinout ................................................................................. 6-1

6-2 TWR-P1025 Primary Connector Pinout ................................................................................. 6-4

Freescale Semiconductor vii

TWR-P1025 Hardware User Guide, Rev. 0

Page 7

Chapter 1

TWR-P1025 Overview

1.1 Introduction

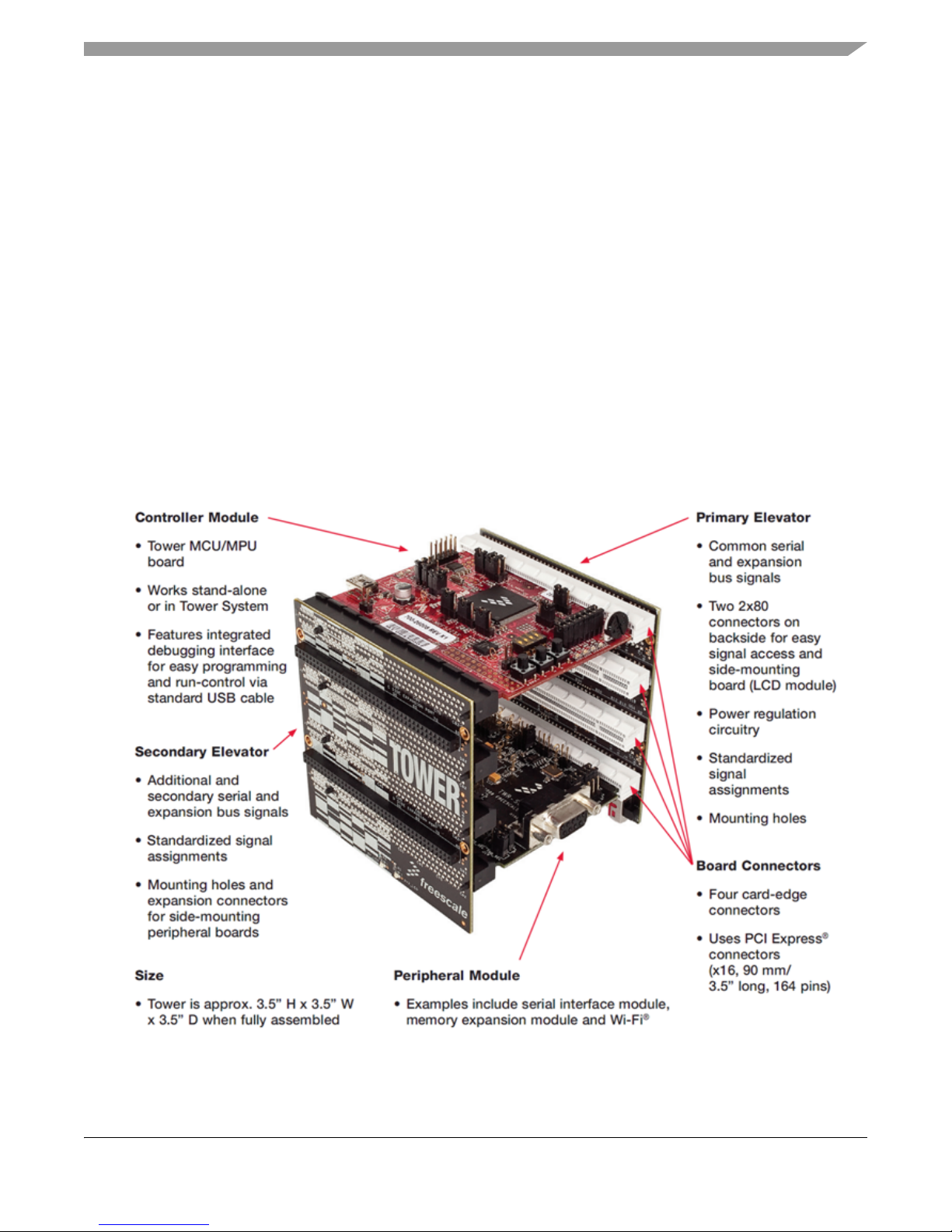

The TWR-P1025 is a Tower Controller Module compatible with the Freescale Tower System. It can

function as a stand-alone, low-cost platform for the evaluation of the QorIQ P1xxx family of

microprocessor (MPU) devices. The TWR-P1025 features the QorIQ P1025 dual core processor based on

the PowerPC® e500 core architecture.

The TWR-P1025 is available as a stand-alone product or can be combined with the Tower Elevator

Modules (TWR-ELEV) and other Tower eco-system components to create development platforms for a

wide variety of applications. Figure 1-1 shows an overview of the Freescale Tower System.

Freescale Semiconductor 1

Figure 1-1. Freescale Tower System

TWR-P1025 Hardware User Guide, Rev. 0

Page 8

TWR-P1025 Overview

1.2 Contents

The TWR-P1025 contents include:

• TWR-P1025 board

• Quick Start Guide

1.3 Features

The features of the TWR-P1025 Tower MPU Module:

• Tower compatible microprocessor module

• Dual core P1025 in a 561 TEPBGA package operating up to 533 MHz

• P1025 JTAG

•CPLD JTAG

• Three axis accelerometer (MMA8451Q)

• Two (2) user-controllable LEDs

• One (1) reset pushbutton switch

• Ten-way DIP Switch for configuration

• microSD card slot

• mini-PCIe slot

• Two (2) 10/100/1000Mbps Ethernet RJ45

• Two (2) USB2.0 Type A

• One (1) mini-USB TypeB dual UART

• 512 MB DDR3@667 MHz

• 64 MB Flash

• IEEE1588 pinned to header + DAC and VXCO (DNP option)

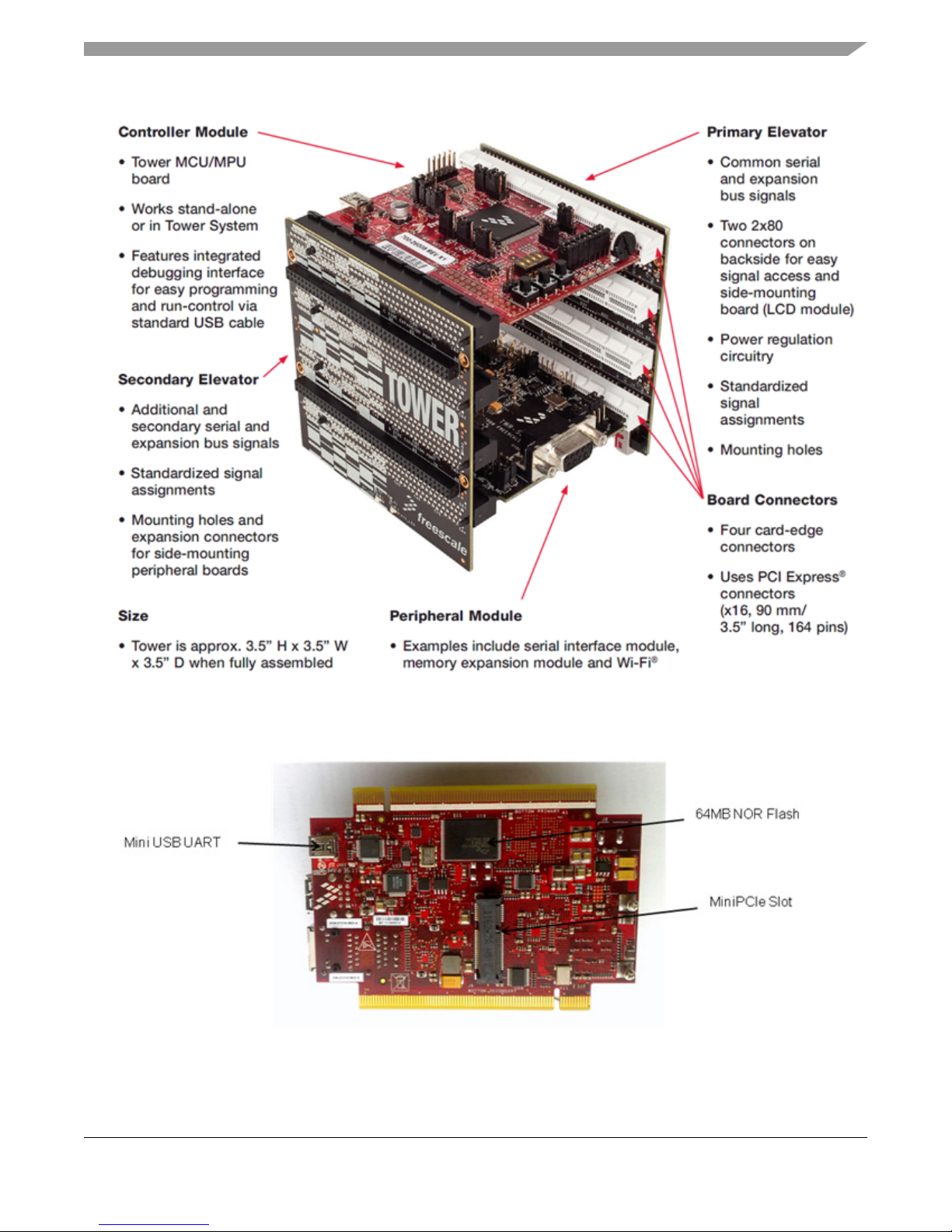

Figure 1-2 and Figure 1-3 show the TWR-P1025 with some of the key features.

2 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 9

TWR-P1025 Overview

Figure 1-2. Callouts on front side of the TWR-P1025

Figure 1-3. Callouts on back side of the TWR-P1025

TWR-P1025 Hardware User Guide, Rev. 0

Freescale Semiconductor 3

Page 10

TWR-P1025 Overview

1.4 Getting Started

Follow the printed Quick Start Guide or the interactive DVD contained in the TWR-P1025 box for

recommended get started steps.

1.5 Reference Documents

For more information on the QorIQ family, Tower System, and MPU Modules refer following documents:

• TWR-P1025-QSG: Quick Start Guide

• TWR-P1025-SCH: Schematics

• TWR-P1025-PWA: Design Package

• P1025 Reference Manual

4 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 11

Chapter 2

Power Requirements

2.1 Overview

The TWR-P1025 is designed to be externally powered through barrel connector J2 from a 5V@5A DC

supply. The barrel connector is manufactured by SWITCHCRAFT with part number RAPC722X. The

mating plug should have an inner diameter of 2.1mm and outer diameter of 5.5mm. Figure 2-1 shows the

polarity of the barrel connector.

Figure 2-1. Power Supply Barrel Connector (J2) Polarity

The 5V input is used to generate all voltages on the board. Additionally when used with TWR elevators

and other TWR peripherals, the TWR-P1025 provides 5V and 3.3V supplies.

There are several expansion options on the board that allow external boards to interface to the

TWR-P1025, such as the mini PCIe connector, USB ports and elevator expansion. As these plug in cards

have variable power requirements as well as numerous population combinations the Power capability of

the different expansion interfaces and the core board are listed in Ta bl e 2-1 . Consideration of total available

power from the external supply should be considered when adding plug-in devices or using the elevator

expansion.

Main Board 5 2.5A

MiniPCIe 3.3 1A

USB Port 1 5 0.5

USB Port 2 5 0.5

ELEVATORS 5 0.5

Freescale Semiconductor 1

Table 2-1. Power Distribution Summary

Voltage (V) Current (A) Comment

1.5 0.5

3.3 0.5

TWR-P1025 Hardware User Guide, Rev. 0

Page 12

Chapter 3

Hardware Description

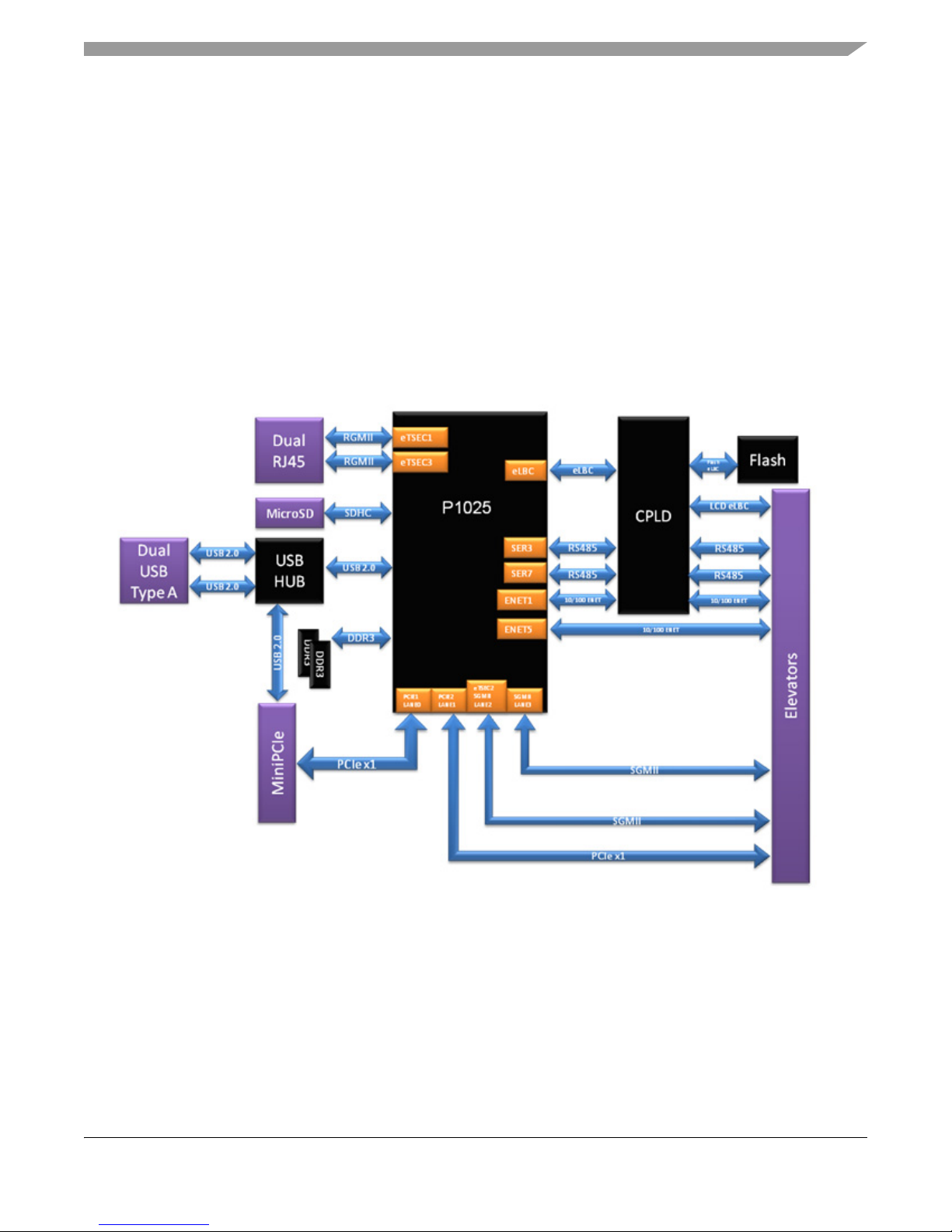

The TWR-P1025 is a Tower Controller Module featuring the P1025-a dual core e500v2 based

microprocessor in a 561 TEPBGA package with a maximum core operating frequency of 533MHz. It is

intended to be used stand-alone or in the Freescale Tower System. Power is supplied through a 5V barrel

connector. Figure 3-1 shows a block diagram of the TWR-P1025. The following sections describe the

hardware in more detail.

3.1 P1025 Microprocessor

The TWR-P1025 module features the P1025, the key features are:

• 533 MHz maximum core operating frequency

• 561 TEPBGA, 23mm x 23mm, 1.0mm pitch package

Freescale Semiconductor 1

Figure 3-1. TWR-P1025 Block Diagram

TWR-P1025 Hardware User Guide, Rev. 0

Page 13

Hardware Description

• Dual high-performance 32-bit cores, built on Power Architecture® technology:

— 32-bit e500v2 PowerPC core

— 36-bit physical addressing

— Double-precision floating-point support

— 32 Kbyte L1 instruction cache and 32 Kbyte L1 data cache for each core

— 400 MHz to 533 MHz clock frequency

• 256 Kbyte L2 cache with ECC. Also configurable as SRAM and stashing memory.

• Three 10/100/1000 Mbps enhanced three-speed Ethernet controllers (eTSECs)

— TCP/IP acceleration, quality of service, and classification capabilities

— IEEE® 1588 support

— Lossless flow control

— MII, RMII, RGMII, SGMII

• High-speed interfaces supporting various multiplexing options:

— Four SerDes upto 2.5 GHz/lane multiplexed across controllers

— Two PCI Express interfaces

— Two SGMII interfaces

• High-speed USB controller (USB 2.0)

— Host and device support

— Enhanced host controller interface (EHCI)

— ULPI interface to PHY

• Enhanced secure digital host controller (SD/MMC)

• Enhanced serial peripheral interface (eSPI)

• Integrated security engine

— Protocol support includes ARC4, 3DES, AES, RSA/ECC, RNG, single-pass SSL/TLS

— XOR acceleration

• 32-bit DDR3 SDRAM memory controller with ECC support

• Programmable interrupt controller (PIC) compliant with OpenPIC standard

• One four-channel DMA controller

• Two I2C controllers, DUART, timers

• Enhanced local bus controller (eLBC)

• QUICC Engine block

3.2 Clocking

The P1025 takes a single input clock, SYSCLK, as its primary clock source for the e500 cores and all of

the devices and interfaces that operate synchronously with the core. As shown in Figure 3-1, the SYSCLK

input (frequency) is multiplied up using a phase lock loop (PLL) to create the core complex bus (CCB)

clock (also called the platform clock). The CCB clock is used by virtually all of the synchronous system

logic, including the L2 cache, and other internal blocks such as the DMA and interrupt controller. The CCB

2 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 14

Hardware Description

clock also feeds the PLLs in the e500 core and the PLL that create clocks for the integrated flash controller.

Note that the divide-by-two CCB clock divider and the divide-by-n CCB clock divider, shown in

Figure 3-2, are located in the DDR and IFC blocks, respectively.

A SYSCLK of 66.667 MHz will be the default used for the design. The board has been designed to support

Profibus applications that require 12 Mbps baud rate with 16x oversampling. A 64 MHz oscillator provides

the necessary BRG clock for this bit rate.

The DDR memory controller complex may use the platform clock or the DDRCLK, which is multiplied

up using a separate PLL to create a unique DDR memory controller complex clock. In this case, the DDR

complex operates asynchronous with respect to the platform clock and runs at a fixed data rate of

667MTps.

The clocks for the PCI Express and SGMII interfaces are derived from a PLL in the SerDes block. This

PLL is driven by a reference clock (SD_REF_CLK/SD_REF_CLK) whose input frequency is a function

of the bit rate being used (100 MHz or 125 MHz). Note that for proper PCI Express operation, the CCB

clock frequency must be greater than 62.5 MHz.

The Ethernet blocks operate asynchronously with respect to the rest of the device. These blocks use receive

and transmit clocks supplied by their respective PHY chips, plus a 125-MHz clock input for gigabit

protocols. Data transfers are synchronized to the CCB clock internally.

Table 3- 1 and Ta ble 3- 2 describe the CCB and core platform frequency ratio selection. Ta ble 3 -3 describes

the DDRCLK input ratio to DDR controller clock ratio.

Freescale Semiconductor 3

Figure 3-2. P1025 Clocking Scheme

TWR-P1025 Hardware User Guide, Rev. 0

Page 15

Hardware Description

Two DIP switches (SW1[7:8]) select the core/QE frequencies. Three modes run at 66.667MHz SYSCLK

whereas the 4th mode is for Profibus application and uses the 64 MHz SYSCLK.

The DDR runs at a fixed x10 multiplier to DDR_CLK.

Table 3-1. P1025 CCB to SYSCLK Ratio Selection

Functional Signals Reset Configuration Name Value CCB Clock : SYSCLK Ratio

LA[29:31] No Default cfg_sys_pll[0:2] 000 4:1

001 5:1

010 6:1

Table 3-2. P1025 e500 Core 0 & 1 to CCB Clock Ratio Selection

Functional Signals Reset Configuration

Name

LBCTL, LALE,

LGPL2/LOE/LFRE

No Default

LWE0, UART_SOUT1,

READY_P1

No Default

cfg_core0_pll[0:2]

cfg_core1_pll[0:2]

Table 3-3. P1025 DDR Clock PLL Ratio

Functional Signals

TSEC_1588_CLK_OUT,

TSEC_1588_PULSE_OUT1,

TSEC_1588_PULSE_OUT2

No Default

Reset Configuration

Name

cfg_ddr_pll[0:2] 000 3:1

Val ue

000 Reserved

001 Reserved

010 1:1

011 3:2 (1.5:1)

100 2:1

101 5:2 (2.5:1)

110 3:1

111 Reserved

Value

001 4:1

010 6:1

011 8:1

e500 Core: CCB Clock

Ratio

e500 Core: CCB Clock

Ratio

4 Freescale Semiconductor

100 10:1

101 Reserved

110 Reserved

111 Synchronous mode

TWR-P1025 Hardware User Guide, Rev. 0

Page 16

Table 3-4. CPU Speed Selection

Hardware Description

CPU_SPEED

_SELECT0

SW1.7

ON ON 500 333 66.667

OFF ON 533 266 66.667

ON OFF 400 400 66.667

OFF OFF 384 384 64

CPU_SPEED_SELECT1

SW1.8

CORE(0 &1) Speed

(MHz)

QE Speed (MHz)

SYSCLK (MHz)

3.3 System Power

The TWR-P1025 is powered through a barrel connector that provides 5V to the board (and elevators if

present). All further operating voltages are generated via onboard regulators.

The power supply should be rated at 5V @5A.

3.4 Debug Interface

There are two JTAG connectors on board, one for the P1025 (J3) and another for the CPLD(J1). Both use

standard debuggers available from Freescale and Altera respectively. Pin 1 is marked on both connectors.

Refer to the relevant debug tool for operating instructions.

3.5 Accelerometer

An MMA8451Q digital accelerometer is connected to the P1025 through its second I2C interface at

address 0x1C and the accelerometers INT1 signal routed to the P1025 IRQ0.

3.6 Pushbutton and LEDs

The TWR-P1025 features one pushbutton switch connected to a reset circuit. Pressing this button initiates

the reset sequence in the CPLD and performs a HRESET sequence to the P1025 as well as resetting the

Ethernet PHYs, NOR Flash and USB circuitry.

Two LEDs are available to the user through software control. The P1025 GPIO pins, PB27 and PB31 are

routed through the CPLD to control these two LEDs.

3.7 Ethernet

The connectivity between the P1025 and the two Atheros AR8035 GETH PHYs is described in Tabl e 3-5

& Table 3-6 and illustrated in Figure 3-3.

Freescale Semiconductor 5

TWR-P1025 Hardware User Guide, Rev. 0

Page 17

Hardware Description

Figure 3-3. eTSEC connection to AR8035 PHY

Table 3-5. eTSEC1 PHY Connectivity

P1025 Signal

P1025

Pin

P1025 Pin Type

EC_GTX_CLK125 AG25 Input Osc source for TX

Description (for

RGMII mode)

AR8035

Signal

AR8035 Pin

CLK_25M NA

clock. Can be

configured to feed

eTSEC1 and

eTSEC3

TSEC1_TXD03 AC22 Output TX data bit TXD3 37

TSEC1_TXD02 AE27 Output TX data bit TXD2 36

TSEC1_TXD01 AB23 Output TX data bit TXD1 35

TSEC1_TXD00 AD25 Output TX data bit TXD0 34

TSEC1_TX_EN AD22 Output TX data

TX_CTL 32

enabled/error

TSEC1_GTX_CLK AF26 Output Inverted transmit

TX_CLK 33

clock feedback

TSEC1_RXD03 AC24 Input RX data bit RXD3 25

TSEC1_RXD02 AE23 Input RX data bit RXD2 26

TSEC1_RXD01 AG22 Input RX data bit RXD1 28

TSEC1_RXD00 AE24 Input RX data bit RXD0 29

TSEC1_RX_DV AE25 Input RX data

TSEC1_RX_CLK AE26 Input RX clock RX_CLK 31

6 Freescale Semiconductor

RX_CTL 30

valid/error

TWR-P1025 Hardware User Guide, Rev. 0

Page 18

Table 3-5. eTSEC1 PHY Connectivity (continued)

Hardware Description

P1025 Signal

EC_MDC AG19 Output Management

EC_MDIO AF19 I/O Management

P1025

Pin

P1025 Pin Type

Description (for

RGMII mode)

clock

data

AR8035

Signal

MDC 40

MDIO 39

AR8035 Pin

Table 3-6. eTSEC1 PHY Connectivity

P1025 Signal

EC_GTX_CLK125 AG25 Input Osc source for TX

TSEC3_TXD03 AE22 Output TX data bit TXD3 37

TSEC3_TXD02 AF24 Output TX data bit TXD2 36

TSEC3_TXD01 AG26 Output TX data bit TXD1 35

TSEC3_TXD00 AF21 Output TX data bit TXD0 34

TSEC3_TX_EN AD27 Output TX data

P1025

pin

P1025 Pin Type

Description (for

RGMII mode)

clock. Can be

configured to feed

eTSEC1 and

eTSEC3

enabled/error

AR8035

Signal

TX_CTL 32

AR8035 Pin

-23

TSEC3_GTX_CLK AC26 Output Inverted transmit

clock feedback

TSEC3_RXD03 AG24 Input RX data bit RXD3 25

TSEC3_RXD02 AG23 Input RX data bit RXD2 26

TSEC3_RXD01 AC20 Input RX data bit RXD1 28

TSEC3_RXD00 AC23 Input RX data bit RXD0 29

TSEC3_RX_DV AF27 I/O RX data

valid/error

TSEC3_RX_CLK AD24 Input RX clock RX_CL

EC_MDC AG19 Output Management

clock

EC_MDIO AF19 I/O Management

data

TX_CLK 33

RX_CT

L

K

MDC 40

MDIO 39

30

31

3.8 USB

The P1025 features a USB full-speed/low-speed OTG/Host/Device controller. The controller connects to

the USB3300 USB PHY with the USB D+ and D- signals from the USB3300 routed to a four-port USB

Freescale Semiconductor 7

TWR-P1025 Hardware User Guide, Rev. 0

Page 19

Hardware Description

hub. Port2 is routed to the miniPCIe connector with Ports 3 & 4 routed to a dual USB type B connector

(J5). Both ports 3 & 4 can provide 5V@500mA to peripheral USB devices.

3.9 Micro Secure Digital Card Slot (micro SDHC)

A micro Secure Digital (SD) card slot is available on the TWR-P1025 connected to the SD Host Controller

(SDHC) signals of the P1025. Refer to Table 13 "I/O Connectors and Pin Usage Table" for the SDHC

signal connection details.

3.10 Local Bus Interface

The P1025 local bus interface is used for the NOR flash and elevator Local bus expansion. The local bus

is routed to the CPLD where the LAD lines are demultiplexed.

A Spansion SP29GL512S Flash providing 64Mbytes of memory is used on the P1025 Tower Module to

provide code storage for boot and application code. Some of the connections are direct between the

P1025's GPCM controlled memory controller and the Flash device. However the data bus is multiplexed

with the address bus, therefore a latch/mux is required. Typically this would be implemented in a separate

logic device, though the board contains a CPLD that has all these signals routed to it. The latch/mux logic

is implemented in the CPLD. The CPLD also drives reset to the Flash device at power up. The interconnect

between the devices is illustrated in Figure 3-4.

Additionally a subset of the local bus is routed from the CPLD to the primary elevator. This subset is

intended to be used as interface to the TWR-LCD panel.

Figure 3-4. NOR Local Bus Connection

3.11 UART

The two P1025 UARTs are routed to the FDTI dual USB to RS232 convertor. The UART is typically used

as a terminal on a remote host to provide input and output from the devices operating system, for example,

u-boot/Linux.

8 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 20

Hardware Description

Serial connectivity for both P1025 cores is provided through the mini type B USB connector (labeled mini

USB UART in Figure 1-3). Note that the USB Drivers should be installed onto the host PC before the serial

terminal can be used. These can be downloaded from;

http://www.ftdichip.com/Drivers/VCP.htm (FT2232)

A serial terminal can be set up using a PC communication program such as hyper terminal set to 115200

Baud, 8 data bits, no parity, 1 stop bit. You should select the first COM port assigned to the USB UART

Virtual COM port.

3.12 I2C

There are two I2C buses on the P1025, I2C1 and I2C2. I2C1 is intended for Boot Sequencer operation.

I2C2 is used for peripherals. Table 3 -7 & Ta ble 3- 8 list the I2C devices attached to each bus.

Table 3-7. I2C1 Connectivity

Address Device

0x50 M24256-BWDW6TP 2K EEPROM (16-bit address)

Table 3-8. I2C2 Connectivity

Address Device

0x1C MMA8451Q 3 Axis accelerometer

0x23 GPIO expander

0x52 AT24C01B 1K Board EEPROM (8-bit address)

TBD Primary elevator

TBD miniPCIe Slot

3.13 SPI

The P1025 SPI is used to control the optional 50 MHz VXCO (DNP by default) and is also routed to the

tower primary elevator.

3.14 DDR3

512 MBytes of memory is connected to the P1025 32-bit DDR3 controller. The 512 MByte comprises of

two 128 Mbit x 32 bits x 8 banks (2-Gbit) devices (Micron MT41J128M16HA-125G).

The DDR3-SDRAM is configured with 14 row address lines, 10 column address lines, and 8 banks.

Control of each memory device is through the CS0 signal. Individual differential clocks and their

associated enable signal are routed to each memory.

Every DDR3 signal can be considered to be a member of one of four separate groups. Each group has

unique rules in terms of signal connection and signal routing. The four groups and connectivity between

controller and Memory are shown in Table 3-9 .

Freescale Semiconductor 9

TWR-P1025 Hardware User Guide, Rev. 0

Page 21

Hardware Description

Table 3-9. DDR3 Signals

Signal Group P1 Signal

Address and

Command

MA[13:0] A[13:0] A[13:0] 47 Ohm to VTT Address bus

MBA[2:0] BA[2:0] BA[2:0] 47 Ohm to VTT Bank Address

DDR3 Device 1

Signal

DDR3 Device 2

Signal

Ter min ati on/

Notes

Description

MWE WE WE 47 Ohm to VTT Write Enable

MCAS CAS CAS 47 Ohm to VTT Column Address

Strobe

MRAS RAS RAS 47 Ohm to VTT Row Address

Strobe

Control MCKE0 CKE CKE 47 Ohm to VTT Clock Enable

MCKE1 47 Ohm to VTT Clock Enable

MCS0 CS CS 47 Ohm to VTT Chip Select

MODT0 ODT ODT 47 Ohm to VTT On-Die

Te r mi n a ti o n

MODT1 47 Ohm to VTT On-Die

Te r mi n a ti o n

Data MDQS0+/- LDQS+/- ODT Data

Strobes/comple

ment

Bus

MDQS1+/- UDQS+/- ODT Data

Strobes/comple

ment

MDQS2+/- LDQS+/- ODT Data

Strobes/comple

ment

MDQS3+/- UDQS+/- ODT Data

Strobes/comple

ment

NC

MDM0 LDM ODT Data Mask

MDM1 UDM ODT Data Mask

MDM2 LDM ODT Data Mask

MDM3 UDM ODT Data Mask

MDQ[7:0] DQ[7:0] ODT Data Bus

MDQ[15:8] DQ[15:8] ODT Data Bus

MDQ[23:16] DQ[7:0] ODT Data Bus

MDQ[31:24] DQ[15:8] ODT Data Bus

10 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 22

Table 3-9. DDR3 Signals (continued)

Hardware Description

Signal Group P1 Signal

Clocks MCK0+/- MCK0+/- MCK0+/- Clock/compleme

MCK1+/- NC NC

Misc ZQ 240 Ohm to

MDIC0 Half Strength

MDIC1 Half Strength

DDR3 Device 1

Signal

RESET RESET 1.5V Tolerant Device Reset

DDR3 Device 2

The codewarrior initialization for the DDR3 controller are:

# DDR Controllers Setup

# DDR_SDRAM_CFG

reg ${DDR_CONT_GROUP}DDR_SDRAM_CFG = 0x470C0000

#CS0_BNDS

reg ${DDR_CONT_GROUP}CS0_BNDS = 0x0000001f

Signal

Ter min ati on/

Notes

VSSQ (GND)

mode 40ohm to

GND

mode 40ohm to

GVDD

Description

nt

ZQ calibration

Driver calibration

Driver calibration

#CS1_BNDS

reg ${DDR_CONT_GROUP}CS1_BNDS = 0x00000000

#CS0_CNFG

reg ${DDR_CONT_GROUP}CS0_CONFIG = 0x80014202

#CS1_CNFG

reg ${DDR_CONT_GROUP}CS1_CONFIG = 0x00000000

# TIMING_CFG_0

#reg ${DDR_CONT_GROUP}TIMING_CFG_0 = 0x00330004

reg ${DDR_CONT_GROUP}TIMING_CFG_0 = 0x00220004

# TIMING_CFG_1

#reg ${DDR_CONT_GROUP}TIMING_CFG_1 = 0x6f6b4846

reg ${DDR_CONT_GROUP}TIMING_CFG_1 = 0x5c5b6544

# TIMING_CFG_2

#reg ${DDR_CONT_GROUP}TIMING_CFG_2 = 0x0fa8c8cf

reg ${DDR_CONT_GROUP}TIMING_CFG_2 = 0x0fa880de

# TIMING_CFG_3

#reg ${DDR_CONT_GROUP}TIMING_CFG_3 = 0x00020000

reg ${DDR_CONT_GROUP}TIMING_CFG_3 = 0x00020000

# DDR_SDRAM_CFG_2

#reg ${DDR_CONT_GROUP}DDR_SDRAM_CFG_2 = 0x04401040

reg ${DDR_CONT_GROUP}DDR_SDRAM_CFG_2 = 0x04401050

Freescale Semiconductor 11

TWR-P1025 Hardware User Guide, Rev. 0

Page 23

Hardware Description

# DDR_SDRAM_MODE

#reg ${DDR_CONT_GROUP}DDR_SDRAM_MODE = 0x40461520

reg ${DDR_CONT_GROUP}DDR_SDRAM_MODE = 0x80461320

# DDR_SDRAM_MODE_2

#reg ${DDR_CONT_GROUP}DDR_SDRAM_MODE_2 = 0x8000c000

reg ${DDR_CONT_GROUP}DDR_SDRAM_MODE_2 = 0x00008000

# DDR_SDRAM_MD_CNTL

#reg ${DDR_CONT_GROUP}DDR_SDRAM_MD_CNTL = 0x00000000

reg ${DDR_CONT_GROUP}DDR_SDRAM_MD_CNTL = 0x00000000

# DDR_SDRAM_INTERVAL

#reg ${DDR_CONT_GROUP}DDR_SDRAM_INTERVAL = 0x0c300000

reg ${DDR_CONT_GROUP}DDR_SDRAM_INTERVAL = 0x09480000

# DDR_DATA_INIT

reg ${DDR_CONT_GROUP}DDR_DATA_INIT = 0xdeadbeef

# DDR_SDRAM_CLK_CNTL

reg ${DDR_CONT_GROUP}DDR_SDRAM_CLK_CNTL = 0x03000000

# TIMING_CFG_4

reg ${DDR_CONT_GROUP}TIMING_CFG_4 = 0x00220001

# TIMING_CFG_5

reg ${DDR_CONT_GROUP}TIMING_CFG_5 = 0x03402400

# DDR_ZQ_CNTL

reg ${DDR_CONT_GROUP}DDR_ZQ_CNTL = 0x89080600

# DDR_WRLVL_CNTL

#reg ${DDR_CONT_GROUP}DDR_WRLVL_CNTL = 0x8655a608

reg ${DDR_CONT_GROUP}DDR_WRLVL_CNTL = 0x8655a608

# DDR_CDR_1

reg ${DDR_CONT_GROUP}DDRCDR_1 = 0x00000000

# DDR_CDR_2

reg ${DDR_CONT_GROUP}DDRCDR_2 = 0x00000000

#delay before enable

wait 500

# DDR_SDRAM_CFG

reg ${DDR_CONT_GROUP}DDR_SDRAM_CFG = 0xc70c0000

#wait for DRAM data initialization

wait 2000

3.15 GPIO & Interrupts

Table 3-10 lists external interrupt sources of P1025.

12 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 24

Table 3-10. P1025 Interrupt Usage

IRQ Usage

0 Accelerometer

1 TSEC1

2 TSEC3

3 GPIO Expander

4 Unused (Connected to CPLD)

5 Elevator Common Interrupt (this is a logical AND

of ELEV_IRQ_[A:H] on the primary elevator.

Table 3-11. P1025 GPIO Usage

GPIO Usage

GPIO_EXPAND0 Primary elevator GPIO1

GPIO_EXPAND1 Primary elevator GPIO5

GPIO_EXPAND2 Primary elevator GPIO7

Hardware Description

GPIO_EXPAND3 Primary elevator GPIO8

GPIO_EXPAND4 Primary elevator GPIO9

GPIO_EXPAND5 Primary elevator GPIO14

GPIO_EXPAND6 Primary elevator GPIO15

GPIO_EXPAND7 Primary elevator GPIO16

GPIO_EXPAND8 Secondary elevator

GPIO27/J4.13

GPIO_EXPAND9 Secondary elevator

GPIO28/J4.15

GPIO_EXPAND10 Secondary elevator

GPIO17/J4.17

GPIO_EXPAND11 Secondary elevator

GPIO26/J4.16

GPIO_EXPAND12 Primary elevator GPIO4/J4.18

GPIO_EXPAND13 Primary elevator GPIO6/J4.20

GPIO_EXPAND14 Unused/CPLD

GPIO_EXPAND15 Unused/CPLD

CE_PB27 LED D2

CE_PB31 LED D3

Freescale Semiconductor 13

TWR-P1025 Hardware User Guide, Rev. 0

Page 25

Chapter 4

Switch Table

4.1 P1025 Jumper Table

There are several switches on the TWR-P1025 that provide configuration selection and signal isolation

(Table 4- 1). The default switch settings are shown in red.

Table 4-1. P1025 Jumper Table

Feature Settings

[OFF=1 ON=0]

S1.1 OFF

S1.2 OFF

S1.3 OFF

S1.4

S1.5

S1.6

S1.7

S1.8

ON

ON

ON

OFF

ON

OFF

ON

OFF

ON

Comments

Reserved

PCIE_HOST_AGENT Selection

P1025 is Host

P1025 is Agent

Reserved

CFG_CPU0_1_BOOT

Core0 boots, Core 1 in holdoff after reset

Both Cores run after reset

BOOT_SEQ

Boot Sequencer OFF

Boot Sequencer ON

LOCALBUS_QE_MUXSEL

local bus pins muxed with QE function as local bus in CPLD

local bus pins muxed with QE function as QE pins in CPLD

Freescale Semiconductor 1

TWR-P1025 Hardware User Guide, Rev. 0

Page 26

Switch Table

Table 4-1. P1025 Jumper Table (continued)

Feature Settings

[OFF=1 ON=0]

S1.9 OFF

S1.10

ON

OFF

ON

Comments

ETH_TDM_SEL

Ethernet1 clock routed to P1025 through CPLD

TDM Clock routed to P1025 through CPLD

PROFIBUS_MODE_SEL

normal mode - RTS inverted

debug mode – RTS connected to CTS

2 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 27

Chapter 5

Input/Output Connectors and Pin Usage Table

5.1 LED Usage

Table 5- 1 provides details on which P1025 pins are used to communicate with the LEDs, switches, and

other I/O interfaces onboard the TWR-P1025.

Table 5-1. LED Usage Table

Description Ref Color LED On LED Off

UART Activity D1 Orange Flash for Activity Off for no Activity

CPLD D2 Green User programmable User programmable

CPLD D3 Green User programmable User programmable

3V3 Power D5 Green 3V3 Power ON 3V3 Power OFF

P1025

ASLEEP

Ethernet

eTSEC1

Ethernet

eTSEC1

Ethernet

eTSEC3

Ethernet

eTSEC3

D7 Green ASLEEP Status ASLEEP Status

Left up Green ON - Link

Blink - Activity

Right up Green/Orange Orange - 1000Mbps

Green – 100Mbps

Left down Green ON – Link

Blink - Activity

Right down Green/Orange Orange - 1000Mbps

Green – 100Mbps

5.2 I/O Connectors and Pin Usage Table

Table 5- 2 provides details on I/O connector and Pin usage.

Table 5-2. I/O Connectors and Pin Usage Table

Feature Connection Port Pin Pin Function

FDTI

USB-to-serial

Bridge

VBUS J8.1 +5V In

No Link

10Mbps

No Link

10Mbps

D- J8.2 USB_Data-

D+ J8.3 USB_Data+

Freescale Semiconductor 1

TWR-P1025 Hardware User Guide, Rev. 0

Page 28

Input/Output Connectors and Pin Usage Table

Table 5-2. I/O Connectors and Pin Usage Table (continued)

Feature Connection Port Pin Pin Function

ID J8.4 N/C

G J8.5 Ground

SD Card Slot SD Data2 CN1.1 SDHC_D2

SD Data3 CN1.2 SDHC_D3

SD Command CN1.3 SDHC_CMD

VDD CN1.4 +3.3V

SD Clock CN1.5 SDHC_CLK

GND CN1.6 Ground

SD Data0 CN1.7 SDHC_D0

SD Data1 CN1.8 SDHC_D1

CD_SW CN1.9 SD Card Detect (inverted

CD_COMMON CN1.10 +3V3

polarity)

GND CN1.11 Ground

GND CN1.12 Ground

GND CN1.13 Ground

GND CN1.14 Ground

Pushbuttons SW1 (RESET) - BOARD RESET

CPU

CPU_TDO J3.1 Test Data In

JTAG/COP

- J3.2 -

CPU_TDI J3.3 Test Data Out

CPU_TRST_N J3.4 Te s t Re se t

CPU_TCLK J3.5 Tes t C LK

+3.3V J3.6 Power

CPU_TMS J3.7 Test Mode Select

CKSTP_IN_N J3.8 Checkstop In

J3.9 -

- J3.10 -

COP_SRST_N J3.11 COP Soft Reset

GND J3.12 Ground

COP_HRST_N J3.13 COP Hard Reset

- J3.14 -

2 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 29

Input/Output Connectors and Pin Usage Table

Table 5-2. I/O Connectors and Pin Usage Table (continued)

Feature Connection Port Pin Pin Function

CKSTP_OUT_N J3.15 Checkstop Out

GND J3.16 Ground

CPLD JTAG CPLD_JTAG_TCK J1.1 Te s t C L K

GND J1.2 Ground

CPLD_JTAG_TDO J1.3 Test Data Out

+3.3V J1.4 Power

CPLD_JTAG_TMS J1.5 Test Mode Select

- J1.6 -

- J1.7 -

- J1.8 -

CPLD_JTAG_TDI J1.9 Test Data In

GND J1.10 Ground

QE Serial

Expansion

GND J4.1 Ground

+3.3V J4.2 Power

SER7_RXD0 J4.3 UCC7 RXD0

SER3_RXD0 J4.4 UCC3 RXD0

SER7_TXD0 J4.5 UCC7 TXD0

SER3_TXD0 J4.6 UCC3 RXD0

SER7_RTS_B J4.7 UCC7 RTS_B

GND J4.8 Ground

SER7_CTS_B J4.9 UCC7 CTS_B

SER3_RTS_B J4.10 UCC3 RTS_B

SER7_CD J4.11 UCC7 CD

SER3_CTS_B J4.12 UCC3 CTS_B

GPIO_EXPAND8 J4.13 GPIO

SER3_CD J4.14 UCC3 CD

GPIO_EXPAND9 J4.15 GPIO

GPIO_EXPAND11 J4.16 GPIO

GPIO_EXPAND10 J4.17 GPIO

GPIO_EXPAND12 J4.18 GPIO

+5V0 J4.19 5V Power

GPIO_EXPAND13 J4.20 GPIO

Freescale Semiconductor 3

TWR-P1025 Hardware User Guide, Rev. 0

Page 30

Input/Output Connectors and Pin Usage Table

Table 5-2. I/O Connectors and Pin Usage Table (continued)

Feature Connection Port Pin Pin Function

IEEE1588 CLK_1588_HDR J7.1 1588 CLK_IN

1588_PULSE_OUT2 J7.2 1588_PULSE_OUT2

1588_PULSE_OUT1 J7.3 1588_PULSE_OUT1

1588_CLK_OUT J7.4 1588_CLK_OUT

1588_TRIGIN2 J7.5 1588_TRIGIN2

1588_ALARM_OUT1 J7.6 1588_ALARM_OUT1

1588_TRIGIN1 J7.7 1588_TRIGIN1

1588_ALARM_OUT2 J7.8 1588_ALARM_OUT2

Dual USB A1 J5.1 5V Out

A2 J5.2 USB3_DN

A3 J5.3 USB3_DP

A4 J5.4 Ground

B1 J5.5 5V Out

B2 J5.6 USB4_DN

B3 J5.7 USB4_DP

B4 J5.8 Ground

miniPCIe WAKE# P2.1 Pull up to +3.3V

+3.3V P2.2 Power

RSV P2.3 Reserved

GND P2.4 Ground

RSV P2.5 Reserved

+1.5V P2.6 Power

CLKREQ# P2.7 -

RSV P2.8 Reserved

GND P2.9 Ground

RSV P2.10 Reserved

REFCLK- P2.11 MPCIE_CLK_N

RSV P2.12 Reserved

REFCLK+ P2.13 MPCIE_CLK_P

RSV P2.14 Reserved

GND P2.15 Ground

RSV P2.16 Reserved

RSV P2.17 Reserved

4 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 31

Input/Output Connectors and Pin Usage Table

Table 5-2. I/O Connectors and Pin Usage Table (continued)

Feature Connection Port Pin Pin Function

GND P2.18 Ground

RSV P2.19 Reserved

RSV P2.20 Reserved

GND P2.21 Ground

PERST# P2.22 RST_PCIE_N

PERN0 P2.23 PCIE_RX0_N

+3.3V_AUX P2.24 Power

PERP0 P2.25 PCIE_RX0_P

GND P2.26 Ground

GND P2.27 Ground

+1.5V P2.28 Power

GND P2.29 Ground

SMBCLK P2.30 I2C_SCL

PERTN0 P2.31 PCIE_TX0_N

SMBDATA P2.32 I2C_SDA

PERTP0 P2.33 PCIE_TX0_P

GND P2.34 Ground

GND P2.35 Ground

USB_D- P2.36 USB2_DM

RSV P2.37 Reserved

USB_D+ P2.38 USB2_DP

RSV P2.39 Reserved

GND P2.40 Ground

RSV P2.41 Reserved

LED_WWAN P2.42 -

RSV P2.43 Reserved

LED_WLAN P2.44 -

RSV P2.45 Reserved

LED_WPAN P2.46 -

RSV P2.47 Reserved

+1.5V P2.48 Power

RSV P2.49 Reserved

GND P2.50 Ground

Freescale Semiconductor 5

TWR-P1025 Hardware User Guide, Rev. 0

Page 32

Input/Output Connectors and Pin Usage Table

Table 5-2. I/O Connectors and Pin Usage Table (continued)

Feature Connection Port Pin Pin Function

RSV P2.51 Reserved

+3.3V P2.52 Power

6 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 33

Chapter 6

Tower Elevator Connections

6.1 Overview

The TWR-P1025 features two expansion card-edge connectors that interface to the primary and secondary

elevator boards in a Tower system. The Primary Connector (comprised of sides A and B) is utilized by the

TWR-P1025 while the Secondary Connector (comprised of sides C and D) makes connections to the the

SER3 & 7 Serial ports as well as ENET5 RMII and three SERDES lanes. Table 14 provides the pinout for

the Primary Connector. Table 15 provides the pinout for the Secondary Connector.

Table 6-1. TWR-P1025 Primary Connector Pinout

Pin# Side B Pin# Side A

Name Usage Name Usage

B1 5V 5.0V Power A1 5V 5.0V Power

B2 GND Ground A2 GND Ground

B3 3.3V 3.3V Power A3 3.3V 3.3V Power

B4 ELE_PS_SE

NSE

B5 GND Ground A5 GND Ground

B6 GND Ground A6 GND Ground

B7 SDHC_CLK /

SPI1_CLK

B8 SDHC_D3 /

SPI1_CS1_b

B9 SDHC_D3 /

SPI1_CS0_b

B10 SDHC_CMD /

SPI1_MOSI

B11 SDHC_D0 /

SPI1_MISO

B12 ETH_COL ENET1_COL A12 ETH_CRS ENET1_CRS

B13 ETH_RXER ENET1_RX_

B14 ETH_TXCLK ENET1_TXCL

Elevator

Power Sense

ER

K

A4 3.3V 3.3V Power

A7 SCL0 I2C1_SCL

A8 SDA0 I2C1_SDA

A9 GPIO9 / CTS1 GPIO_EXPAND4

A10 GPIO8 / SDHC_led GPIO_EXPAND3

A11 GPIO7 /

SD_WP_DET

A13 ETH_MDC QE_MDC

A14 ETH_MDIO QE_MDIO

GPIO_EXPAND2

Freescale Semiconductor 1

TWR-P1025 Hardware User Guide, Rev. 0

Page 34

Tower Elevator Connections

Pin# Side B Pin# Side A

Table 6-1. TWR-P1025 Primary Connector Pinout (continued)

B15 ETH_TXEN ENET1_TXE

A15 ETH_RXCLK ENET1_RXCLK

N

B16 ETH_TXER ENET1_TXE

A16 ETH_RXDV ENET1_RX_DV

R

B17 ETH_TXD3 ENET1_TXD3 A17 ETH_RXD3 ENET1_RXD3

B18 ETH_TXD2 ENET1_TXD2 A18 ETH_RXD2 ENET1_RXD2

B19 ETH_TXD1 ENET1_TXD1 A19 ETH_RXD1 ENET1_RXD1

B20 ETH_TXD0 ENET1_TXD0 A20 ETH_RXD0 ENET1_RXD0

B21 GPIO1 / RTS1 GPIO_EXPAN

A21 SSI_MCLK

D0

B22 GPIO2 /

A22 SSI_BCLK TDMA_CLK

SDHC_D1

B23 GPIO3 CE_PB1 A23 SSI_FS TDMA_SYNC

B24 CLKIN0 ENET5_REF

A24 SSI_RXD TDMA_RXD

CLK

B25 CLKOUT1 A25 SSI_TXD TDMA_TXD

B26 GND Ground A26 GND Ground

B27 AN7 A27 AN3

B28 AN6 A28 AN2

B29 AN5 A29 AN1

B30 AN4 A30 AN0

B31 GND Ground A31 GND Ground

B32 DAC1 A32 DAC0

B33 TMR3 A33 TMR1

B34 TMR2 A34 TMR0

B35 GPIO4 GPIO_EXPAN

A35 GPIO6 GPIO_EXPAND13

D12

B36 3.3V 3.3V Power A36 3.3V 3.3V Power

B37 PWM7 A37 PWM3

B38 PWM6 A38 PWM2

B39 PWM5 A39 PWM1

B40 PWM4 A40 PWM0

B41 CANRX0 A41 RXD0 UART1_SIN

B42 CANTX0 A42 TXD0 UART1_SOUT

B43 1WIRE A43 RXD1

2 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 35

Table 6-1. TWR-P1025 Primary Connector Pinout (continued)

Pin# Side B Pin# Side A

B44 SPI0_MISO SPI0_MISO A44 TXD1

B45 SPI0_MOSI SPI0_MOSI A45 VSS

Tower Elevator Connections

B46 SPI0_CS0_b ELEV_SPI0_

A46 VDDA

CS0_b

B47 SPI0_CS1_b ELEV_SPI0_

A47 VREFA1

CS1_b

B48 SPI0_CLK SPI0_CLK A48 VREFA2

B49 GND Ground A49 GND Ground

B50 SCL1 I2C2_SCL A50 GPIO14 GPIO_EXPAND5

B51 SDA1 I2C2_SDA A51 GPIO15 GPIO_EXPAND6

B52 GPIO5 /

PTE28 A52 GPIO16 GPIO_EXPAND7

SD_CARD_D

ET

B53 USB0_DP_P

A53 GPIO17 GPIO_EXPAND10

DOWN

B54 USB0_DM_P

A54 USB0_DM

DOWN

B55 IRQ_H IRQ_H A55 USB0_DP

B56 IRQ_G IRQ_G A56 USB0_ID

B57 IRQ_F IRQ_F A57 USB0_VBUS

B58 IRQ_E IRQ_E A58 TMR7

B59 IRQ_D IRQ_D A59 TMR6

B60 IRQ_C IRQ_C A60 TMR5

B61 IRQ_B IRQ_B A61 TMR4

B62 IRQ_A IRQ_A A62 RSTIN_b ELEV_RST_IN_b

B63 EBI_ALE /

EBI_CS1_b

ELEV_LALE A63 RSTOUT_b ELEV_RST_OUT_

b

B64 EBI_CS0_b ELEV_CS1 A64 CLKOUT0 PTC3

B65 GND Ground A65 GND Ground

B66 EBI_AD15 ELEV_LAD15 A66 EBI_AD14 ELEV_LAD14

B67 EBI_AD16 ELEV_LA16 A67 EBI_AD13 ELEV_LAD13

B68 EBI_AD17 ELEV_LA17 A68 EBI_AD12 ELEV_LAD12

B69 EBI_AD18 ELEV_LA18 A69 EBI_AD11 ELEV_LAD11

B70 EBI_AD19 ELEV_LA19 A70 EBI_AD10 ELEV_LAD10

B71 EBI_R/W_b ELEV_RW A71 EBI_AD9 ELEV_LAD9

TWR-P1025 Hardware User Guide, Rev. 0

Freescale Semiconductor 3

Page 36

Tower Elevator Connections

Pin# Side B Pin# Side A

B72 EBI_OE_b ELEV_OE A72 EBI_AD8 ELEV_LAD8

B73 EBI_D7 ELEV_D7 A73 EBI_AD7 ELEV_LAD7

B74 EBI_D6 ELEV_D6 A74 EBI_AD6 ELEV_LAD6

B75 EBI_D5 ELEV_D5 A75 EBI_AD5 ELEV_LAD5

B76 EBI_D4 ELEV_D4 A76 EBI_AD4 ELEV_LAD4

B77 EBI_D3 ELEV_D3 A77 EBI_AD3 ELEV_LAD3

B78 EBI_D2 ELEV_D2 A78 EBI_AD2 ELEV_LAD2

B79 EBI_D1 ELEV_D1 A79 EBI_AD1 ELEV_LAD1

B80 EBI_D0 ELEV_D0 A80 EBI_AD0 ELEV_LAD0

B81 GND Ground A81 GND Ground

B82 3.3V 3.3V Power A82 3.3V 3.3V Power

Table 6-1. TWR-P1025 Primary Connector Pinout (continued)

Table 6-2. TWR-P1025 Primary Connector Pinout

Pin# Side B Pin# Side A

Name Usage Name Usage

D1 5V 5.0VPower C1 5V 5.0V Power

D2 GND Ground C2 GND Ground

D3 3.3V 3.3V Power C3 3.3V 3.3V Power

D4 ELE_PS_SENSE Elevator

C4 3.3V 3.3V Power

Power

Sense

D5 GND Ground C5 GND Ground

D6 GND Ground C6 GND Ground

D7 SPI2_CLK C7 I2C2_SCL

D8 SPI2_CS1_b C8 I2C2_SDA

D9 SPI2_CS0_b C9 GPIO25

D10 SPI2_MOSI C10 ULPI_STOP

D11 SPI2_MISO C11 ULPI_CLK

D12 ETH_COL C12 GPIO26 GPIO_EXPAND11

D13 ETH_RXER ENET5_RX

C13 ETH_MDC QE_MDC

_ER

D14 ETH_TXCLK C14 ETH_MDIO QE_MDIO

D15 ETH_TXEN ENET5_TXENC15 ETH_RXCL

4 Freescale Semiconductor

K

TWR-P1025 Hardware User Guide, Rev. 0

Page 37

Tower Elevator Connections

Table 6-2. TWR-P1025 Primary Connector Pinout (continued)

Pin# Side B Pin# Side A

D16 GPIO18 C16 ETH_RXDV ENET5_RX_DV

D17 GPIO19 / SDHC_D4 C17 GPIO27 /

GPIO_EXPAND8

SDHC_D6

D18 GPIO20 / SDHC_D5 C18 GPIO28 /

GPIO_EXPAND9

SDHC_D7

D19 ETH_TXD1 ENET5_TXD1C19 ETH_RXD1 ENET5_RXD1 (LWE1_b)

D20 ETH_TXD0 ENET5_TXD0C20 ETH_RXD0 ENET5_RXD0

D21 ULPI_NEXT /

USB_HS_DM

GPIO_EXPA

ND0

C21 ULPI_DATA

0 /

I2S1_MCLK

D22 ULPI_DIR /

USB_HS_DP

C22 ULPI_DATA

1 /

I2S1_DOUT

_SCK

D23 UPLI_DATA5 /

USB_HS_VBUS

CE_PB1 C23 ULPI_DATA

2 /

I2S1_DOUT

_WS

D24 ULPI_DATA6 /

USB_HS_ID

ENET5_RE

FCLK

C24 ULPI_DATA

3 /

I2S1_DIN0

D25 ULPI_DATA7 C25 ULPI_DATA

4 /

I2S1_DOUT

0

D26 GND Ground C26 GND Ground

D27 LCD_HSYNC /

C27 AN11

LCD_P24

D28 LCD_VSYNC /

C28 AN10

LCD_P25

D29 AN13 C29 AN9

D30 AN12 C30 AN8

D31 GND Ground C31 GND Ground

D32 LCD_CLK / LCD_P26 C32 GPIO29 /

SER3_CD

UART2_DC

D

D33 TMR11 C33 TMR9

D34 TMR10 C34 TMR8

Freescale Semiconductor 5

TWR-P1025 Hardware User Guide, Rev. 0

Page 38

Tower Elevator Connections

Pin# Side B Pin# Side A

Table 6-2. TWR-P1025 Primary Connector Pinout (continued)

D35 GPIO21 GPIO_EXPA

ND12

C35 GPIO30 /

UART3_DC

SER7_CD

D

D36 3.3V 3.3V Power C36 3.3V 3.3V Power

D37 PWM15 C37 PWM11

D38 PWM14 C38 PWM10

D39 PWM13 C39 PWM9

D40 PWM12 C40 PWM8

D41 CAN2_RX C41 UART2_RX

SER3_RXD0

D / TSI0

D42 CAN2_TX C42 UART2_TX

SER3_TXD0

D / TSI1

D43 LCD_CONTRAST C43 UART2_RT

SER3_RTS

S / TSI2

D44 LCD_OE / LCD_P27 SPI0_MISO C44 UART2_CT

SER3_CTS

S / TSI3

D45 LCD_D0 / LCD_P0 SPI0_MOSI C45 UART3_RX

SER7_RXD0

D / TSI4

D46 LCD_D1 / LCD_P1 ELEV_SPI0

_CS0_b

C46 UART3_TX

D / TSI5

SER7_TXD0

D47 LCD_D2 / LCD_P2 ELEV_SPI0

_CS1_b

C47 UART3_RT

S /

SER7_RTS

CAN3_RX

D48 LCD_D3 / LCD_P3 SPI0_CLK C48 UART3_CT

SER7_CTS

S /

CAN3_TX

D49 GND Ground C49 GND Ground

D50 GPIO23 I2C2_SCL C50 LCD_D4 /

GPIO_EXPAND5

LCD_P4

D51 GPIO24 I2C2_SDA C51 LCD_D5 /

GPIO_EXPAND6

LCD_P5

D52 LCD_D12 / LCD_P12 PTE28 C52 LCD_D6 /

GPIO_EXPAND7

LCD_P6

D53 LCD_D13 / LCD_P13 C53 LCD_D7 /

GPIO_EXPAND10

LCD_P7

D54 LCD_D14 / LCD_P14 C54 LCD_D8 /

LCD_P8

D55 IRQ_P / SPI2_CS2_b IRQ_H C55 LCD_D9 /

LCD_P9

6 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 39

Table 6-2. TWR-P1025 Primary Connector Pinout (continued)

Pin# Side B Pin# Side A

D56 IRQ_O / SPI2_CS3_b IRQ_G C56 LCD_D10 /

LCD_P10

D57 IRQ_N IRQ_F C57 LCD_D11 /

LCD_P11

D58 IRQ_M IRQ_E C58 I2S1_DIN_S

CK

D59 IRQ_L IRQ_D C59 I2S1_DIN_

WS

D60 IRQ_K IRQ_C C60 I2S1_DIN1

D61 IRQ_J IRQ_B C61 I2S1_DOUT

1

D62 IRQ_I IRQ_A C62 LCD_D15 /

LCD_P15

Tower Elevator Connections

D63 LCD_D18 / LCD_P18 /

SD_RX_0

ELEV_SD_

RX1_P

C63 LCD_D16 /

LCD_P16 /

SD_GND

SD_GND

D64 LCD_D19 / LCD_P19 /

SD_RXb_0

ELEV_SD_

RX1_N

C64 LCD_D17 /

LCD_P17 /

SD_GND

SD_GND

D65 GND Ground C65 GND Ground

D66 EBI_AD20 / LCD_P42 /

SD_GND

SD_GND C66 EBI_BE_32

_24_b /

ELEV_SD_TX1_P

LCD_P28 /

SD_TX_0

D67 EBI_AD21 / LCD_P43 /

SD_GND

SD_GND C67 EBI_BE_23

_16_b /

ELEV_SD_TX1_N

LCD_P29 /

SD_TXb_0

D68 EBI_AD22 / LCD_P44 /

SD_RX_1

ELEV_SD_

RX2_P

C68 EBI_BE_15

_8_b /

SD_GND

LCD_P30 /

SD_GND

D69 EBI_AD23 / LCD_P45 /

SD_RXb_1

ELEV_SD_

RX2_N

C69 EBI_BE_7_

0_b /

SD_GND

LCD_P31 /

SD_GND

D70 EBI_AD24 / LCD_P46

/ SD_GND

D71 EBI_AD25 / LCD_P47 /

SD_GND

Freescale Semiconductor 7

SD_GND C70 EBI_TSIZE0

/ LCD_P32 /

SD_TX_1

SD_GND C71 EBI_TSIZE1

/ LCD_P33 /

SD_TXb_1

TWR-P1025 Hardware User Guide, Rev. 0

ELEV_SD_TX2_P

ELEV_SD_TX2_N

Page 40

Tower Elevator Connections

Pin# Side B Pin# Side A

Table 6-2. TWR-P1025 Primary Connector Pinout (continued)

D72 EBI_AD26 / LCD_P48 /

SD_RX_2

D73 EBI_AD27 / LCD_P49 /

SD_RXb_2

D74 EBI_AD28 / LCD_P50 /

SD_GND

D75 EBI_AD29 / LCD_P51 /

SD_GND

D76 EBI_AD30 / LCD_P52 /

SD_RX_3

D77 EBI_AD31 / LCD_P53 /

SD_RXb_3

D78 LCD_D20 / LCD_P20 /

SD_GND

D79 LCD_D21 / LCD_P21 /

SD_REFCLK

ELEV_SD_

RX3_P

C72 EBI_TS_b /

LCD_P34 /

SD_GND

ELEV_SD_

RX3_N

C73 EBI_TBST_

b / LCD_P35

/ SD_GND

SD_GND C74 EBI_TA_b /

LCD_P36 /

SD_TX_2

SD_GND C75 EBI_CS4_b

/ LCD_P37 /

SD_TXb_2

C76 EBI_CS3_b

/ LCD_P38 /

SD_GND

C77 EBI_CS2_b

/ LCD_P39 /

SD_GND

SD_GND C78 EBI_CS1_b

/ LCD_P40 /

SD_TX_3

PCIE_CLK_PC79 GPIO31 /

LCD_P41 /

SD_TXb_3

SD_GND

SD_GND

ELEV_SD_TX3_P

ELEV_SD_TX3_N

SD_GND

SD_GND

D80 LCD_D22 / LCD_P22 /

SD_REFCLKb

PCIE_CLK_NC80 LCD_D23 /

LCD_P23 /

SD_GND

SD_GND

D81 GND Ground C81 GND Ground

D82 3.3V 3.3V Power C82 3.3V 3.3V Power

8 Freescale Semiconductor

TWR-P1025 Hardware User Guide, Rev. 0

Page 41

Appendix A

Revision History

This appendix provides a list of the major differences between current TWR-P1025 hardware user guide

and its previous revisions.

A.1 Version Number 0

This is initial version of the TWR-P1025 Hardware User Guide.

Freescale Semiconductor 1

TWR-P1025 Hardware User Guide, Rev. 0

Loading...

Loading...