Quick Start Guide

TWR-MECH

Mechatronics Board

TOWER SYSTEM

Quick Start Guide

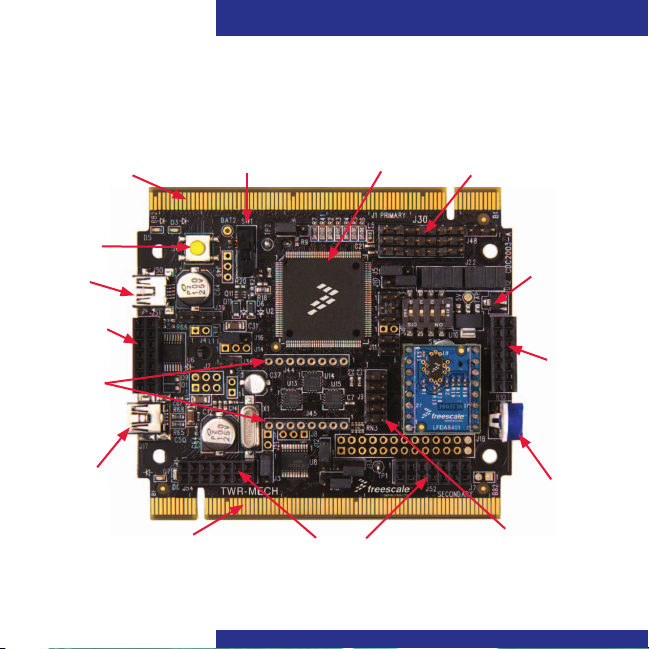

Get to Know the Tower Mechatronics Board

Primary

Connector

SW4

(Reset)

USB

OTG

Touch Panel

Socket

Daughter

Card

Sockets

Debug

USB

2

Secondary

Connector

On/Off Switch

Touch Panel Sockets

MCF52259

Connectors for

Up to Eight Servos

5V Supply

Touch

Panel

Socket

Potentiometer

RS232

Port

TOWER SYSTEM

How to Use the Mechatronics Robot

The Freescale robot (FSLBOT) kit

operates with the Tower mechatronics

(TWR-MECH) board to create an easy-to-

use mechatronics development and

demonstration platform. It is designed

specifically to be used and programmed

with StickOS

users can take programming to new levels

of functionality with the use of CodeWarrior

and Freescale’s Tower System.

®

BASIC. More advanced

TWR-MECH BOARD

Freescale Tower System

The TWR-MECH board is part of the Freescale Tower

System, a modular development platform that enables

rapid prototyping and tool re-use through reconfigurable

hardware. Take your design to the next level and begin

constructing your Tower System today.

3

Quick Start Guide

Step-by-Step Installation Instructions for StickOS

StickOS BASIC is a programming

language and an IDE. It’s specifically

designed to allow those with little or no

programming experience to get up and

running quickly with the TWR-MECH

board. It also provides complex

functionality such as vision filters and

face tracking.

Install StickOS

1

1. Open an Internet browser of your

choice and navigate to

freescale.com/mechbot

2. Select the “Download” tab. Scroll

through the list of downloads and select

FSLBOT_StickOS_IDE. Click “Download”

and save the file to an easily accessible

place on your computer.

3. Decompress the downloaded file.

4

TOWER SYSTEM

Connect the USB Cable

2

1. Plug the included FSLBOT USB cable

into the computer and into the left rear

mini-USB port on the board (labeled

USB OTG).

2. The “Found New Hardware Wizard” will

appear. Choose “Install” from a list or

specific location (Advanced). Click “Next.”

Configure Drivers

3

with Windows® XP

1. Ensure “Search for the best driver in

these locations” is selected. Also, the

“Include this location in the search” box

should be checked. Click “Browse” and

navigate to the folder of the recently

downloaded file. Click “OK,” followed

by “Next.”

5

Quick Start Guide

2. The hardware wizard will install the

needed files to run the Freescale

TWR-MECH.

6

3. Once the hardware wizard has finished,

click “Finish” to complete the installation.

Additional Resources

For more information, visit

freescale.com/mechbot.

Join the online Tower community at

towergeeks.org.

TOWER SYSTEM

Installation Instructions for CodeWarrior

Install CodeWarrior

1

• Downloadandinstallthelatestversion

of CodeWarrior for ColdFire V2 from

freescale.com.

• DownloadtheCodeWarriorsamplecode

for the Freescale mechatronics robot. This

can be found on the Freescale website

on the right hand side of the TWR-MECH

page under “Featured Software.”

Connect the USB Cable

2

Connect the USB cable to the PC and the

other end to the J17 on the TWR-MECH

board, also labeled “DEBUG.”

Configure Drivers

3

Allow PC to automatically configure drivers

if needed. If you have driver problems, please

see the TWR-MECH driver installation guide

located in the sample code folder mentioned

above, or visit pemicro.com/osbdm.

Launch Software

4

Launch CodeWarrior for ColdFire V2.

Close the startup box, and click “File >

Open” to open the sample code.

The file path is: TWR_MECH_FSLBOT_

Cadewarrior_Sample_CODE/ mcf5225x_

SC_FreeBot/build/cw/twr-mcf5225x/TWR

_Mechatronics_MCF5225X_base.mcp.

You are now ready to start programming

with CodeWarrior.

Note: On/Off switch must be in “On”

position for the servos to activate.

Additional Resources

Please see the related documents provided

in the sample code folder, and visit

freescale.com for more information.

7

Quick Start Guide

TWR-S08PT60 Default Jumper Options

The following is a list of all jumper options. The default installed jumper settings are

shown in white text within the violet boxes

Jumper Option Setting Description

Default Clock Mode

J3

Selection (CLKMOD1)

MCU Power

J4

Connection

Clock Input Source

J5

Selection

Default Clock Mode

J6

Selection (CLKMOD0)

Potentiometer

J7

Selection

Serial Flash

J8

Programming Mode

Default Clock Mode

J10

Selection (XTAL)

8

.

1-2 Disable PLL at startup

2-3 Enable PLL at startup

On

Cut-Trace

Cut-Trace

Cut-Trace

Supply 3.3V to MCU

Isolate MCU from power (connect an ammeter to

Off

measure current)

1-2 Connect EXTAL to the on-board crystal

Connect EXTAL to the CLKIN0 signal on the elevator

2-3

connector

1-2 Do not use crystal oscillator at startup

2-3 Use crystal oscillator at startup

On

Connect AN6 to potentiometer

Isolate AN6 from potentiometer

O

1-2

Pull RCON high, allow normal reset behavior

Pull RCON low, as exiting reset give EzPort access to

2-3

flash memory for programming by external device

1-2 Bypass crystal oscillator at startup (if CLKMOD0 = 0)

Enable internal relaxation oscillator at startup

2-3

(if CLKMOD0 = 0)

Off Use crystal oscillator at startup

TOWER SYSTEM

TWR-MECH Jumper Options (continued)

Jumper Option Setting Description

UART Hardware Flow

J11

Control Connections

UART TXD0 Routing

J12

Selection

UART RXT0 Routing

J13

Selection

BDM/JTAG Enable

J14

Selection

TCLK/PSTCLK

J15

Routing Selection

TCLK/PSTCLK/

J16

CLKOUT Routing

Selection

OSBDM Bootloader

J20

Selection

J21 RESET Select

1-2 Connect CTS0 to the RS232 transceiver for flow control

3-4 Connect RTS0 to the RS232 transceiver for flow control

1-2 Connect TXD0 to the RS232 transceiver

2-3 Connect TXD0 to the OSBDM debugger interface circuit

1-2 Connect RXD0 to the transceiver

2-3 Connect RXD0 to the OSBDM debugger interface circuit

1-2

Cut-Trace

Non-Pop

Non-Pop

BDM mode

2-3 JTAG mode

1-2 Connect TCLK/PSTCLK to PSTCLK for BDM mode

2-3 Connect TCLK/PSTCLK to TCLK for JTAG

Connect TCLK/PSTCLK/CLKOUT to TCLK/PSTCLK for

1-2

BDM/JTAG mode

Connect TCLK/PSTCLK/CLKOUT to CLKOUT0 on the

2-3

elevation connector

OSBDM bootloader mode (OSBDM firmware

On

reprogramming)

Off

Debugger mode

On Suspend MCU in reset state (hold RSTIN low)

Off

Release RSTIN so it can be controlled by SW4 to initiate

reset sequences

9

Quick Start Guide

TWR-MECH Jumper Options (continued)

Jumper Option Setting Description

1-2 Connect SERVO_1 PWM signal to servo plug

3-4 Connect SERVO_2 PWM signal to servo plug

5-6 Connect SERVO_3 PWM signal to servo plug

Servo Motor

J22

Signal Selection

Touch Sensor

J40

Interrupt Select

Universal Sensor No. 1

J41

Interrupt No. 1 Select

Universal Sensor No. 1

J42

Interrupt No. 2 Select

Universal Sensor No. 1

J43

Interrupt No. 3 Select

J49 Battery Selection

10

7-8 Connect SERVO_4 PWM signal to servo plug

9-10 Connect SERVO_5 PWM signal to servo plug

11-12 Connect SERVO_6 PWM signal to servo plug

13-14 Connect SERVO_7 PWM signal to servo plug

15-16 Connect SERVO_8 PWM signal to servo plug

On

Cut-Trace

Cut-Trace

Connect IRQ_TOUCH to IRQ7_b to use touch

sensor interrupt

Off Isolate IRQ7_b from touch sensor

On Connect AN0 to IRQ1_b to sense interrupt signal

Off Isolate AN0 from IRQ1_b to measure analog signal

Connect AN1 to IRQ3_b/FEC_MDIO to sense

On

interrupt signal

Isolate AN1 from IRQ3_b/FEC_MDIO to measure analog

Off

signal

Connect AN2 to IRQ5_b/FEC_MDC to sense interrupt

On

signal

Isolate AN2 from IRQ5_b/FEC_MDC to measure analog

Off

signal

1-2

Connect SW1 to BAT1 for 4x AA cells

2-3 Connect SW1 to BAT2 for 7.2V external battery pack

TOWER SYSTEM

11

Quick Start Guide

For more information, visit

freescale.com/Tower

Join the online Tower community at

towergeeks.org

Freescale, the Freescale logo, CodeWarrior and ColdFire are trademarks

or registered trademarks of Freescale Semiconductor, Inc., Reg. U.S. Pat.

& Tm. Off. All other product or service names are the property of their

respective owners. © 2011 Freescale Semiconductor, Inc.

Doc Number: TWRMECHQSG REV1 Agile Number: 926-27081 REV B

Loading...

Loading...