TWR-MCF5225X

User Manual

Rev. 1.0

Freescale Semiconductor Inc.

Contents

1 Overview ......................................................................................................................................................3

2 Reference Documents..............................................................................................................................4

3 Hardware Features...................................................................................................................................4

3.1 Clocking ..................................................................................................................................................................................4

3.2 System Power.......................................................................................................................................................................4

3.3 Debug Interface ...................................................................................................................................................................4

3.4 RS232 Interface...................................................................................................................................................................5

3.5 Elevator Connections ........................................................................................................................................................5

3.6 Mechanical Form Factor ..................................................................................................................................................5

4 Jumper Table ..............................................................................................................................................5

5 Input/Output Connectors and Pin Usage Table .............................................................................6

6 OSBDM...........................................................................................................................................................7

6.1 Bootloader Mode ................................................................................................................................................................7

Revision History

Revision Date Changes

1.0 Sept 23, 2009 Initial Release

TWR-MCF51CN User’s Manual Page 2 of 9

1 Overview

The MCF5225X Tower MCU Module (TWR-MCF5225X) is a low-cost evaluation, demonstration and

development board. The TWR-MCF5225X can operate stand-alone or as the main control board in a

Tower System with peripheral modules.

The following list summarizes the features of the TWR-MCF5225X:

• Tower compatible microcontroller module

• MCF52259 in an 144 LQFP package

• MC9S08JM60 based Open Source Debug (OSBDM) circuit

• 4 user controlled LEDs

• Four DIP Switches and two push buttons for user input

• Potentiometer

• MMA7260 three-axis accelerometer

• RS232 transceiver and 2x5 pin header

• Expansion via Primary Elevator connector

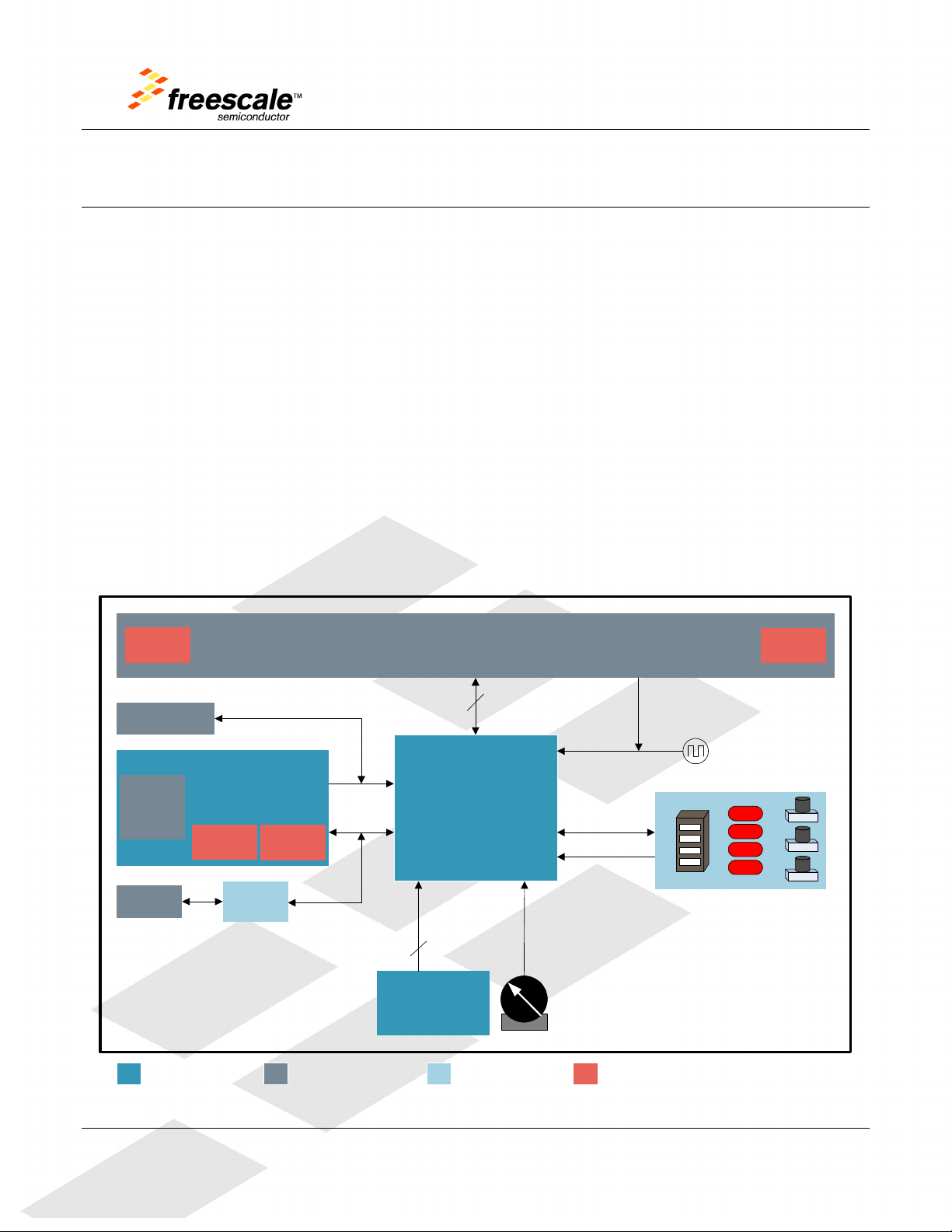

A block diagram for the TWR-MCF5225X is shown in the figure below.

Tower Elevator Expansion Connectors

SPI, I2C, ADC, USB, FEC, Timers, PWM, UARTs, IRQs, Mini-Flexbus, etc.

26-Pin BDM

Header

OSBDM

USB

Mini-AB

10-Pin

Header

Freescale Device External Connectors Interface Circuits Power

Debug, Power, SCI

5.0V

3.3V

RS232

XCVR

BDM

UART0

MCF52259

ColdFire® V2

Microcontroller

ADC

MMA7260

3-axis

Accelerometer

GPIO

Reset

C

D

A

Figure 1. TWR-MCF5225X Block Diagram

3.3V5.0V

CLOCKIN0

48 MHz

LED

LED

LED

LED

TWR-MCF51CN User’s Manual Page 3 of 9

2 Reference Documents

The documents listed below should be referenced for more information on the Freescale Tower

system and the TWR-MCF5225X. Refer to http://www.freesale.com/tower for the latest revision of all

Tower documentation.

• TWR-MCF5225X Schematics

• TWR-MCF5225X Quick Start Guide

• TWR-MCF5225X-KIT Lab Tutorial

• MCF52259 Reference Manual

• MCF52259 Data Sheet

• AN3561, USB Bootloader for the MC9S08JM60

3 Hardware Features

This section provides more details about the features and functionality of the TWR-MCF5225X.

3.1 Clocking

Two options are provided for clocking the MCF5225X device:

1. 48 MHz crystal

2. External clock input from Primary Elevator (CLOCKIN0)

Selection of the clock input is determined by the J5 jumper setting. The 48 MHz crystal option is

selected by default. Refer to Table 1 for more details.

3.2 System Power

The TWR-MCF5225X can be powered by the OSBDM circuit via the Mini-B USB connector, J17, or from

a source in an assembled Tower System. A standard USB A male to Mini-B male cable (provided) can

be used to supply power from a USB Host or powered USB Hub. Optionally, an AC to DC adapter with

a USB A female receptacle (not provided) can be used as the power source.

Power will automatically be sourced from the Elevator connector if power is available on both the

Elevator and the OSBDM.

A jumper, J4, can be used to isolate the 3.3V supply from the microcontroller. This connection can be

used to measure the power usage of the MCF5225X microcontroller.

3.3 Debug Interface

An on-board, MC9S08JM60 based Open Source BDM (OSBDM) circuit provides a debug interface to

the MCF5225X. A standard USB A male to Mini-B male cable (provided) can be used for debugging via

the USB connector, J17. Refer to Section 6 for information on other modes of operation of the

OSBDM.

TWR-MCF51CN User’s Manual Page 4 of 9

3.4 RS232 Interface

An RS232 transceiver on the TWR-MCF5225X connects to a standard 2x5 pin header (refer to Figure 2).

Selection jumpers J12 and J13 allow UART0 signals to be routed to either the RS232 transceiver or the

OSBDM circuit. Refer to Table 1 for more details.

MCF5225X

Signal Pin

No Connect 1 2 No Connect

TXD 3 4 CTS

RXD 5 6 RTS

No Connect 7 8 No Connect

GND 9 10 3.3V

MCF5225X

Signal

Figure 2. RS232 2x5 Pin Header Connections

3.5 Elevator Connections

The TWR-MCF5225X features two expansion card-edge connectors that interface to Elevator boards in

a Tower system: the Primary and Secondary Elevator connectors. The Primary Elevator connector,

comprised of sides A and B, is utilized by the TWR-MCF5225X, while the Secondary Elevator connector

only makes connections to ground (GND).

3.6 Mechanical Form Factor

The TWR-MCF5225X is designed for the Freescale Tower System and complies with the electrical and

mechanical specification as described in Freescale Tower Electromechanical Specification.

4 Jumper Table

There are several jumpers provided for isolation, configuration, and feature selection. Refer to the

following table for details. The default installed jumper settings are shown in bold.

Table 1. TWR-MCF5225X Jumper Table

Jumper

J3

J4 MCU Power Connection

J5 Clock Input Source Selection

J6 Default Clock Mode Selection

Default Clock Mode Selection

(CLKMOD1)

Option

Setting

1-2

2-3

ON

OFF

1-2

2-3

1-2

Description

Disable PLL at startup

Enable PLL at startup

Supply 3.3V to MCU

Isolate MCU from Power (connect an ammeter to

measure current)

Connect EXTAL to the on-board Crystal

Connect EXTAL to the CLKIN0 signal on the Elevator

Connector

Do not use Crystal Oscillator at startup

TWR-MCF51CN User’s Manual Page 5 of 9

Release RSTIN so it can be controlled by SW4 to initiate

(CLKMOD0)

J7 Peripheral Selection

J10

J11

J12 UART TXD0 Routing Selection

J13 UART RXD0 Routing Selection

J14 BDM / JTAG Enable Selection

J15 TCLK/PSTCLK Routing Selection

J16

J20 OSBDM Bootloader Selection

J21 RESET Select

Default Clock Mode Selection

(XTAL)

UART Hardware Flow Control

Connections

TCLK/PSTCLK/CLKOUT Routing

Selection

2-3

1-2

3-4

5-6

7-8

9-10

11-12

13-14

15-16

1-2

2-3

OFF

1-2

3-4

1-2

2-3

1-2

2-3

1-2

2-3

1-2

2-3

1-2

2-3

ON

OFF

ON

OFF

Use Crystal Oscillator at startup

Connect AN3 to Potentiometer

Connect TIN3/TOUT3/PWM6 to LED4

Connect TIN2/TOUT2/PWM4 to LED3

Connect TIN1/TOUT1/PWM2 to LED2

Connect TIN0/TOUT0/PWM0 to LED1

Connect AN2 to Accelerometor Z-access

Connect AN1 to Accelerometor Y-access

Connect AN0 to Accelerometor X-access

Bypass Crystal Oscillator at startup (if CLKMOD0 = 0)

Enable Internal Relaxation Oscillator at startup (if

CLKMOD0 = 0)

Use Crystal Oscillator at startup

Connect CTS0 to the RS232 transciever for flow control

Connect RTS0 to the RS232 transciever for flow control

Connect TXD0 to the RS232 transceiver

Connect TXD0 to the OSBDM debugger interface circuit

Connect RXD0 to the RS232 transceiver

Connect RXD0 to the OSBDM debugger interface circuit

BDM mode

JTAG mode

Connect TCLK/PSTCLK to PSTCLK for BDM mode

Connect TCLK/PSTCLK to TCLK for JTAG mode

Connect TCLK/PSTCLK/CLKOUT to TCLK/PSTCLK for

BDM/JTAG mode

Connect TCLK/PSTCLK/CLKOUT to CLKOUT0 on the

Elevator Connector

OSBDM bootloader mode (OSBDM firmware

reprogramming)

Debugger Mode

Suspend MCU in Reset state (hold RSTIN low)

reset sequences

5 Input/Output Connectors and Pin Usage Table

The following tables provides details on which MCF5225X pins are using to communicate with the

TWR-MCF5225X sensors, LEDs, switches, and other I/O interfaces.

Table 2. I/O Connectors and Pin Usage Table

TWR-MCF51CN User’s Manual Page 6 of 9

TWR-MCF5225X MCF5225X

I/O Component I/O Label Default

SW2-1 DDATA0

Dip Switch

Push Button

LED

Accelerometer

MMA7260QT

Potentiometer POT AN3

RS232

ICL3232

USB↔Serial

SW2-2 DDATA1

SW2-3 DDATA2

SW2-4 DDATA3

SW1 GPT0

SW3 GPT1

SW4 RSTI

LED1 DTIN0 DTOUT0 PWM0 PTC0

LED2 DTIN1 DTOUT1 PWM2 PTC1

LED3 DTIN2 DTOUT2 PWM4 PTC2

LED4 DTIN3 DTOUT3 PWM6 PTC3

X_OUT AN0

Y_OUT AN1

Z_OUT AN2

232_RXD URXD0

232_TXD UTXD0

CTS UCTS0

RTS URTS0

T_RXD1 URXD0

T_TXD1 UTXD0

Alt 1 Alt 2 Alt 3

PWM1 PTA0

PWM3 PTA1

USB_VBUSE PUA3

USB_VBUSD PUA2

GPIO

GPIO

GPIO

GPIO

PAN0

PAN1

PAN2

PAN3

PUA1

PUA0

PUA1 OSBDM

PUA0

Note:

Refer to Chapter 15, General Purpose I/O Module, in MCF5225X Reference Manual to

configure pin to appropriate alternate function.

6 OSBDM

An on-board, MC9S08JM60 based Open Source BDM (OSBDM) circuit provides a debug interface to

the MCF5225X. The MC9S08JM60 is a USB-enabled microcontroller with an 8-bit HC9S08 core. The

OSBDM circuit provides a USB-to-debug interface that allows run-control and debugging of the

MCF5225X target device. The USB drivers required to communicate with the OSBDM are provided in

development tools such as Freescale CodeWarrior. This single USB connection can also be used to

power the TWR-MCF5225X stand-alone or in a fully assembled Tower System.

6.1 Bootloader Mode

The MC9S08JM60 device used in the OSBDM circuit is preprogrammed with OSBDM debugger

firmware and a USB Bootloader. The bootloader mode can be used to update the OSBDM debugger

firmware if an update becomes available. Jumper J20 determines which application will run following a

power-on reset. If Bootloader Mode is chosen (jumper shunt on J20), the bootloader will be executed,

TWR-MCF51CN User’s Manual Page 7 of 9

allowing in-circuit reprogramming of the JM60 flash memory via USB. Refer to Application Note

AN3561 on the Freescale website (http://www.freescale.com) for details on the USB Bootloader.

The USB Bootloader communicates with a GUI application running on a host PC. The GUI application

can be found on the Freescale website; search keyword “JM60 GUI”. Refer to section 2.5 and 3.3 of

AN3561 for details on installing and running the application.

Note:

The JM60 GUI Installer should be run before connecting the OSBDM in Bootloader

Mode to a host USB port. Otherwise, the JM60 USB device will not be recognized and

the proper drivers will not be loaded.

TWR-MCF51CN User’s Manual Page 8 of 9

Freescale™ and the Freescale logo are trademarks of

Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners.

© Freescale Semiconductor, Inc. 2009. All rights reserved.

TWR-MCF51CN User’s Manual Page 9 of 9

Loading...

Loading...