Page 1

TWR-LCD

User’s Manual

Rev. 1.3

Freescale Semiconductor Inc.

Page 2

Contents

1 Overview ...................................................................................................................................................... 3

2 Reference Documents .............................................................................................................................. 4

3 Hardware Features ................................................................................................................................... 4

3.1 Power Supply ....................................................................................................................................................................... 4

3.2 LCD Display / Controller ................................................................................................................................................. 5

3.2.1 Communication Mode ...................................................................................................................................................................... 5

3.2.2 MCU Selection ...................................................................................................................................................................................... 5

3.2.3 Resistive Touch Overlay .................................................................................................................................................................. 6

3.3 MicroSD Card ........................................................................................................................................................................ 7

3.4 5-way Navigation Switch ................................................................................................................................................. 8

3.5 Mini-B USB Connection .................................................................................................................................................... 8

3.6 Bootloader ............................................................................................................................................................................. 9

3.6.1 Obtaining the S19 file ........................................................................................................................................................................ 9

3.6.2 Using the Bootloader ........................................................................................................................................................................ 9

3.7 Elevator Connections ..................................................................................................................................................... 10

4 Jumper Table ........................................................................................................................................... 12

4.1 Mechanical Form Factor ............................................................................................................................................... 13

TWR-LCD User’s Manual Page 2 of 13

Page 3

LCD Display

Tower Primary Side Expansion Ports

(Sides A and B)

External Connectors

Interface Component Power

5.0V

microSD

Card

Socket

Freescale Device

mini-B USB

Recepticle

5.0V

SPI1, IRQ, GPIO

SPI1, KBI, GPIO

USB (DP/DN)

External Bus

Interface (EBI)

SPI0

SPI2

LCD Display Controller

Resistive

Touch Panel

Analog

Analog

I

2

C

5-Way Navigation

Switch

Power Regulation

3.3V15.5V

Core

Voltage

Backlight

Driver

Piezo

PWM PWM

MCF51JM

ColdFire® V1

Microcontroller

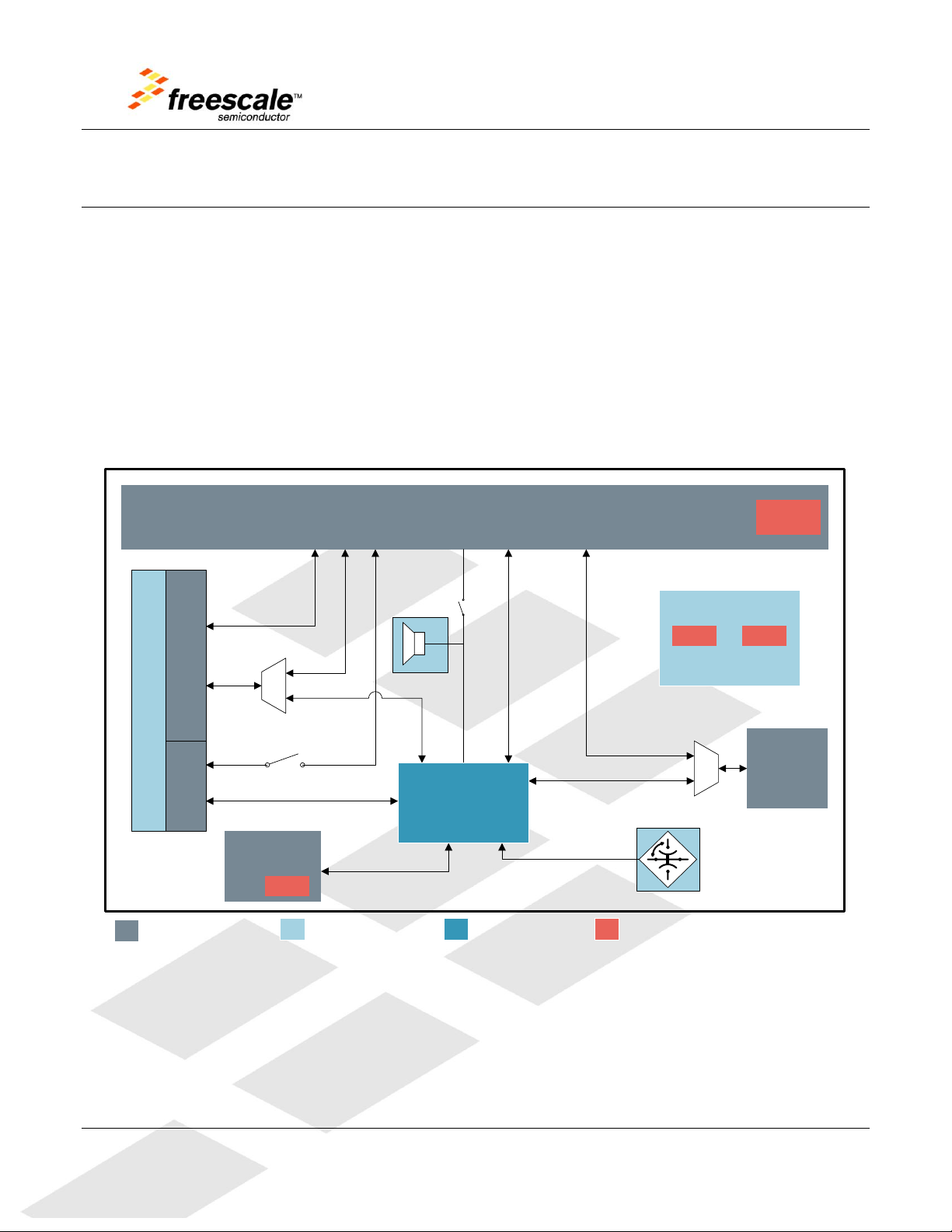

1 Overview

The Tower LCD Module (TWR-LCD) adds a side mounting TFT QVGA Display to the Freescale Tower

System. It can be used with a wide variety of Tower Processor Modules through a SPI and/or external

bus interface (EBI).

The TWR-LCD features a 3.2” QVGA TFT LCD Display with touch sensitive overlay, 5-way navigation

control, MicroSD Card slot, dedicated MCF51JM microcontroller, and a Piezo Buzzer for audible

feedback. The LCD Display Controller is accessible to the dedicated MCF51JM microcontroller through

the SPI. The LCD Display Controller is also accessible to any capable Tower MCU module utilizing

either the SPI or the EBI. A block diagram for the TWR-LCD is shown in the figure below.

TWR-LCD User’s Manual Page 3 of 13

Figure 1 - TWR-LCD Block Diagram

Page 4

Figure 2 - Tower System with TWR-LCD

2 Reference Documents

The documents listed below should be referenced for more information on the Freescale Tower

system and the TWR-LCD. Refer to http://www.freescale.com/tower for the latest revision of all

Tower documentation.

TWR-LCD Schematics

TWR-LCD Quick Start Guide

Truly TFT2N0451-E LCD Module Specification

3 Hardware Features

This section provides more details about the features and functionality of the TWR-LCD.

3.1 Power Supply

The TWR-LCD can be powered as a standalone device from the Mini-B USB connector. The TWR-LCD

can also be powered from a source in an assembled Tower System via the 5.0V supply on the TWRELEV Side Expansion Port. When attached to a Tower Elevator board, it is required that the board be

externally powered from the Elevator board; additionally the USB connector on the TWR-LCD can still

be used to communicate over USB to the on-board MCF51JM MCU. On-board power regulation will

provide the necessary core voltage (3.3V) and backlight driver voltage (15.5V).

TWR-LCD User’s Manual Page 4 of 13

Page 5

SW1-DIP1

(PS2)

SW1-DIP 2

(PS0)

Description

OFF

ON

Enables SPI communication mode to the LCD Display; can be

driven by SPI0 on the Primary Elevator or by the on-board

MCF51JM, selectable by JM/ELE (SW1-DIP3)

ON

OFF

Enables EBI (16b mode) communication to the LCD Display

This interface is only accessible from the Tower Elevator MCU

ON

ON

Enables EBI (8b mode) communication to the LCD Display

This interface is only accessible from the Tower Elevator MCU

JM/ELE

(SW1-DIP3)

ON

Enables SPI connection from SPI0 of Primary Elevator Connector

OFF

Enables SPI connection from on-board MCF51JM MCU

3.2 LCD Display / Controller

The TWR-LCD features a Truly Semiconductor 3.2” TFT LCD with an analog resistive touch overlay.

3.2.1 Communication Mode

The LCD utilizes a 240 RGB x 320 QVGA display controller. The display controller is accessible to the

on-board MCF51JM MCU through SPI. The controller is also accessible to any compatible Tower MCU

module through SPI or the External Bus Interface (EBI) via the primary Tower Side Expansion Ports.

Use SW1-DIP1 and DIP2 to configure the desired interface mode (SPI or EBI). Refer to Section 4 for

more configuration details.

Table 1 - LCD Communication Mode Settings

3.2.2 MCU Selection

The LCD can be controlled by either the on-board MCF51JM MCU or a compatible Tower MCU

Module.

Use SW1-DIP3 to specify which MCU has access to the display controller. Refer to Section 4 for more

configuration details.

Table 2 - Display Driver MCU Selection

Setting the JM/ELE (SW1-DIP3) configuration switch to the “Off” position will isolate the SPI signals

from the Tower MCU allowing a direct connection between the on-board MCF51JM MCU and the LCD

display controller.

Setting the JM/ELE configuration switch to the “On” position will cause both the on-board MCF51JM

MCU and Tower MCU SPI signals to be simultaneously connected to the LCD display controller. It is

required that on-board MCF51JM MCU firmware detect the status of the JM/ELE signal and tri-state

the on-board MCF51JM MCU SPI signals.

TWR-LCD User’s Manual Page 5 of 13

Page 6

SPI CS SEL

(SW1-DIP5)

ON

Select SPI0 CS1 as the chip-select for LCD SPI interface

OFF

Select SPI0 CS0 as the chip-select for LCD SPI interface

TP SEL

(SW1-DIP6)

ON

Disables MCF51JM connection to the LCD Touch Panel

Use SW5 to enable ADC connection from Primary Elevator Connector

OFF

Enables MCF51JM connection to the LCD Touch Panel

Ensure that all switches on SW5 DIP are OFF

If utilizing a Tower MCU module to drive the SPI to the LCD display controller, use SW1-DIP5 to specify

the desired SPI chip select.

Table 3 - Tower MCU SPI CS Selection

3.2.3 Resistive Touch Overlay

The TWR-LCD display features an integrated analog resistive touch panel. The panel can be access by

either the on-board MCF51JM MCU or a compatible Tower MCU module. The selection of which MCU

interfaces the Touch Panel is independent of which MCU is driving the LCD display controller

(designated by JM/ELE).

Use SW1-DIP6 to specify which MCU has access to the resistive touch panel. Refer to Section 4 for

more configuration details.

Table 4 - Resistive Touch MCU Selection

Setting the TP SEL (SW1-DIP6) configuration switch to the “Off” position will indicate to the on-board

MCF51JM MCU that it is the interfacing MCU to the touch panel’s analog signals.

Setting the TP SEL configuration switch to the “On” position will indicate to the on-board MCF51JM

MCU that the tower MCU Module is the interfacing MCU to the touch panel’s analog signals. It is

required that on-board MCF51JM MCU firmware detect the status of the To SEL signal and tri-state

the respective on-board MCF51JM MCU ADC signals.

SW5 is used to isolate the touch panel’s analog signals from the Tower Elevator Side Expansion Port.

This ensures correct isolation of the analog signals when the on-board MCF51JM MCU is used. SW5DIP[4:1] should all be set to the “Off” position if the on-board MCF51JM MCU is being used to

interface the resistive touch panel.

TWR-LCD User’s Manual Page 6 of 13

Page 7

SW5-DIP 1

Touch Panel

Isolation (XPLS)

ON

Connects AN4 (TWR-ELEV) to XPLS Touch Panel Signal

OFF

Disconnects AN4 from Touch Panel

SW5-DIP 2

Touch Panel

Isolation (XMNS)

ON

Connects AN5 (TWR-ELEV) to XMNS Touch Panel Signal

OFF

Disconnects AN5 from Touch Panel

SW5-DIP 3

Touch Panel

Isolation (YMNS)

ON

Connects AN6 (TWR-ELEV) to YMNS Touch Panel Signal

OFF

Disconnects AN6 from Touch Panel

SW5-DIP 4

Touch Panel

Isolation (YPLS)

ON

Connects AN7 (TWR-ELEV) to YPLS Touch Panel Signal

OFF

Disconnects AN7 from Touch Panel

ELE uSD

(SW1-DIP4)

ON

MicroSD is connected to the SPI1 of Primary Elevator Connector

OFF

MicroSD is connected to the on-board MCF51JM MCU

Elevator

Pin #

Name

Group

Description

I/O

B7

SDHC_CLK / SPI1_CLK

SDHC / SPI 1

SDHC or SPI Clock

O

B9

SDHC_D3 / SPI1_CS0_b

SDHC / SPI 1

SDHC Chip Select / Data or SPI Chip Select

O

B10

SDHC_CMD / SPI1_MOSI

SDHC / SPI 1

SDHC Command or SPI Master Out / Slave In

O

B11

SDHC_D0 / SPI1_MISO

SDHC / SPI 1

SDHC Data or SPI Master In / Slave Out

I

B22

GPIO2 / SDHC_D1

GPIO / SDHC

General Purpose I/O or SDHC Data

I/O

A10

GPIO8 / SDHC_D2

GPIO / SDHC

General Purpose I/O or SDHC Data

I/O

Table 5 - Resistive Touch Analog Isolation Settings

3.3 MicroSD Card

The Tower System defines a Secure Digital interface as shown in 0. The SD Card interface is

multiplexed over the SPI1 signals and two GPIOs such that the host can communicate with the SD

memory card in the SD Card slot using the SPI mode or the one- or four-bit SD mode.

The MicroSD Card slot is accessible to either the on-board MCF51JM MCU or a compatible Tower MCU

Module. Use SW1 –DIP4 to select which MCU has access to the MicroSD Card slot. Refer to Section 4

for more configuration details.

Table 6 - MicroSD Card Slot MCU Selection

Setting the EuSD (SW1-DIP4) configuration switch to the “Off” position will isolate the SD signals from

the Tower MCU allowing a direct connection between the on-board MCF51JM MCU and the MicroSD

Card slot.

Setting the EuSD configuration switch to the “On” position will cause both the on-board MCF51JM

MCU and Tower MCU SD signals to be simultaneously connected to the MicroSD Card slot. It is

required that on-board MCF51JM MCU firmware detects the status of the EuSD signal and tri-state the

on-board MCF51JM MCU SD signals.

Table 7 - Tower System SD Card Interface Pinout

TWR-LCD User’s Manual Page 7 of 13

Page 8

Navigation Direction

Tower Elevator Connection

Up (North)

GPIO7 (Pin A11)

Down (South)

GPIO8 (Pin A10)

Right (East)

GPIO5 (Pin B52)

Left (West)

GPIO1 (Pin B21)

Select (Center)

GPIO9 (Pin A9)

The SD Card Detect signal is connected to KBI7 on the on-board MCF51JM MCU and, if configured via

EuSD (SW1-DIP4), IRQ_H on the Primary Tower Elevator. This will allow the host controller to monitor

the presence of an SD memory card. To ensure that he SD Card Detect is handled properly, the

MCF51JM must configure the SD Card Detect GPIO/KBI (PTG3 / KBIP7) as an internal pull-up. This is

done by setting the appropriate register values for PTEPE (PTGPE3=1) for GPIO and additionally KBI1ES

(KBEDG7=0) for KBI functionality. Refer to the MCF51JM128 Reference Manual, Section 9, for

additional details. The SD Card Detect signal must be configured as an internal pull-up regardless of

which host MCU is accessing the MicroSD Card slot.

3.4 5-way Navigation Switch

The TWR-LCD features a 5-way Navigation Switch. This switch will allow user interaction with the

TWR-LCD providing a method to indicate Up (North), Down (South), Right (East), Left (West), and

Select (Center). The corresponding directional signals are connected to the on-board MCF51JM MCU.

It is intended that the on-board MCF51JM MCU firmware either respond directly to the Navigation

Switch or relay the signal detection to the Tower MCU module through the I2C interface.

It is possible to connect the 5-way Navigation Switch directly to the Tower Elevator by making a

hardware modification to the TWR-LCD.

The following resister will should to be populated to create a direct connection to the Tower Elevator:

R19, R22, R23, R24, R26, R28, R29, R32, R41, R44

The resisters are intentionally unpopulated in the final design to ensure maximum compatibility with

additional Freescale Tower MCU and Peripheral Modules.

Populating these resisters will enable to following connections:

Refer to the “Optional Nav Switch Connections to Elevator” section within the TWR-LCD schematics for

additional details.

3.5 Mini-B USB Connection

The TWR-LCD features a Mini-B USB connection on the lower right corner of the module. The USB

connector is used to provide power to the TWR-LCD module when operating in stand-alone mode (not

TWR-LCD User’s Manual Page 8 of 13

Page 9

connected to the tower system). The USB data signals are connected to the on-board MCF51JM MCU

allow a connection to exist between a host device and the TWR-LCD.

In Boot Loader mode, if the USB cable is connected to a host PC, the TWR-LCD will enumerate as a

Mass Storage Device. If an appropriate compiled binary (.s19) file is placed in the root directory of the

enumerated storage drive, the TWR-LCD will parse the binary file and reprogram the main application

running on the TWR-LCD. Refer to Section 3.6 for more details.

3.6 Bootloader

The TWR-LCD includes a USB bootloader that allows simple “drag and drop” reprogramming. This

section will describe how to use the bootloader.

3.6.1 Obtaining the S19 file

The bootloader accepts srecord or S19 files that it uses to program the board. In the example

projects this file can be found in the <project directory>/bin/ folder and will end in an “.s19” file

extension. This file will get overwritten every time the project is compiled.

To create an S19 file, click on the “Standard Settings…” button on your project, and look for the

Linker category. Select “ColdFire Linker” and make sure that the “Generate S-Record File” option is

checked. Also make sure that the “Max S-Record Length” field is set to 32.

3.6.2 Using the Bootloader

Connect the on-board USB connector to a Windows computer using the included mini-B to A USB

cable and press reset while holding down the BTLD push button.

The badge board will then enumerate as a Mass Storage Device. Inside the newly added storage

device, there will be an empty file named “READY.TXT”.

Copy and paste the S19 file into the enumerated drive. Upon successful programming, you will

hear two beeps from the board and the S19 file will appear on the removable drive.

TWR-LCD User’s Manual Page 9 of 13

Page 10

TWR-LCD Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B1

5V

5V Power

X A1

5V

5V Power

X B2

GND

Ground

X A2

GND

Ground

X B3

3.3V

A3

3.3V

B4

ELE_PS_SENSE

A4

3.3V

B5

GND

Ground

X A5

GND

Ground

X B6

GND

Ground

X A6

GND

Ground

X B7

SDHC_CLK / SPI1_CLK

uSD Clock

X X A7

SCL0

X

B8

SDHC_D3 / SPI1_CS1_b

A8

SDA0

X

B9

SDHC_D3 / SPI1_CS0_b

uSD Chip Select / Data3

X X A9

GPIO9 / CTS1

B10

SDHC_CMD / SPI1_MOSI

uSD MOSI / Command

X X A10

GPIO8 / SDHC_D2

uSD Data2

X X B11

SDHC_D0 / SPI1_MISO

uSD MISO / Data0

X X A11

GPIO7 / SD_WP_DET

B12

ETH_COL

A12

ETH_CRS

B13

ETH_RXER

A13

ETH_MDC

B14

ETH_TXCLK

A14

ETH_MDIO

B15

ETH_TXEN

A15

ETH_RXCLK

B16

ETH_TXER

A16

ETH_RXDV

B17

ETH_TXD3

A17

ETH_RXD3

B18

ETH_TXD2

A18

ETH_RXD2

B19

ETH_TXD1

A19

ETH_RXD1

B20

ETH_TXD0

A20

ETH_RXD0

B21

GPIO1 / RTS1

A21

SSI_MCLK

B22

GPIO2 / SDHC_D1

SD Data1

X X A22

SSI_BCLK

B23

GPIO3

A23

SSI_FS

B24

CLKIN0

A24

SSI_RXD

B25

CLKOUT1

A25

SSI_TXD

B26

GND

Ground

X A26

GND

B27

AN7

Touch Panel YPLS

X X A27

AN3

Reset or power cycle to TWR-LCD to execute the new application.

For additional information regarding using and creating the TWR-LCD Bootloader refer to the TWRLCD Lab Guide Document.

3.7 Elevator Connections

The TWR-LCD features two 80-pin connectors that interface to the Side Expansion Ports on the

Primary Elevator board in a Tower System. The Primary Elevator Side Expansion Port connectors,

comprised of sides A and B, are utilized by the TWR-LCD. The table below provides the pinout for the

Primary Elevator Connector. An “X” in the “Used” column indicated that there is a connection from

the TWR-LCD to that pin on the Elevator connector. An “X” in the “Jmp” column indicates that a

jumper is available that can configure or isolate the connection from the Elevator connector.

Table 8 - TWR-LCD Primary Elevator Expansion Pinout

TWR-LCD User’s Manual Page 10 of 13

Page 11

TWR-LCD Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B28

AN6

Touch Panel XMNS

X X A28

AN2

B29

AN5

Touch Panel YMNS

X X A29

AN1

B30

AN4

Touch Panel XPLS

X X A30

AN0

B31

GND

Ground

X A31

GND

Ground

X B32

DAC1

A32

DAC0

B33

TMR3

A33

TMR1

B34

TMR2

A34

TMR0

B35

GPIO4

A35

GPIO6

B36

3.3V

A36

3.3V

B37

PWM7

A37

PWM3

B38

PWM6

A38

PWM2

B39

PWM5

A39

PWM1

B40

PWM4

A40

PWM0

Piezo Buzzer

X X B41

CANRX0

A41

RXD0

B42

CANTX0

A42

TXD0

B43

1WIRE

A43

RXD1

B44

SPI0_MISO

LCD SPI MISO

X X A44

TXD1

B45

SPI0_MOSI

LCD SPI MOSI

X X A45

Analog VDD

B46

SPI0_CS0_b

LCD SPI Chip Select

X X A46

Analog VSS

B47

SPI0_CS1_b

LCD SPI Chip Select

X X A47

Analog Vref

B48

SPI0_CLK

LCD SPI Clock

X X A48

Analog Vref

B49

GND

Ground

X A49

GND

B50

SCL1

A50

GPIO14

B51

SDA1

A51

GPIO15

B52

GPIO5 / SD_CARD_DET

A52

GPIO16

B53

USB0_DP_PDOWN

A53

GPIO17

B54

USB0_DM_PDOWN

A54

USB0_DM

B55

IRQ_H

SD Detect

X X A55

USB0_DP

B56

IRQ_G

A56

USB0_ID

B57

IRQ_F

A57

USB0_VBUS

B58

IRQ_E

A58

TMR7

B59

IRQ_D

A59

TMR6

B60

IRQ_C

A60

TMR5

B61

IRQ_B

A61

TMR4

B62

IRQ_A

A62

RSTIN_b

B63

EBI_ALE / EBI_CS1_b

A63

RSTOUT_b

Reset X

B64

EBI_CS0_b

LCD EBI Chip Select

X X A64

CLKOUT0

B65

GND

Ground

X A65

GND

Ground

X B66

EBI_AD15

LCD EBI

X A66

EBI_AD14

LCD EBI

X B67

EBI_AD16

LCD EBI

X A67

EBI_AD13

LCD EBI

X B68

EBI_AD17

A68

EBI_AD12

LCD EBI

X B69

EBI_AD18

A69

EBI_AD11

LCD EBI

X

B70

EBI_AD19

A70

EBI_AD10

LCD EBI

X

B71

EBI_R/W_b

LCD EBI R/W_b

X A71

EBI_AD9

LCD EBI

X B72

EBI_OE_b

A72

EBI_AD8

LCD EBI

X

TWR-LCD User’s Manual Page 11 of 13

Page 12

TWR-LCD Primary Connector

Pin

Name

Usage

Used

Jmp

Pin

Name

Usage

Used

Jmp

B73

EBI_D7

A73

EBI_AD7

LCD EBI

X B74

EBI_D6

A74

EBI_AD6

LCD EBI

X B75

EBI_D5

A75

EBI_AD5

LCD EBI

X B76

EBI_D4

A76

EBI_AD4

LCD EBI

X B77

EBI_D3

A77

EBI_AD3

LCD EBI

X B78

EBI_D2

A78

EBI_AD2

LCD EBI

X B79

EBI_D1

A79

EBI_AD1

LCD EBI

X B80

EBI_D0

A80

EBI_AD0

LCD EBI

X

Configuration

Settings

Option

Setting

Description

SW1

DIP 1 / DIP 2

PS2 / PS0

DIP 1

(PS2)

DIP 2

(PS0)

OFF

OFF

Not a valid setting

*OFF*

*ON*

Enables SPI communication mode to the LCD Display; can be driven by

SPI0 on the Primary Elevator or by the on-board MCF51JM, selectable by

JM/ELE (SW1-DIP3)

ON

OFF

Enables EBI (16b mode) communication to the LCD Display

This interface is only accessible from the Tower Elevator MCU

ON

ON

Enables EBI (8b mode) communication to the LCD Display

This interface is only accessible from the Tower Elevator MCU

DIP 3

JM/ELE

ON

Enables SPI connection from SPI0 of Primary Elevator Connector

*OFF*

Enables SPI connection from on-board MCF51JM MCU

DIP 4

ELE uSD

ON

MicroSD is connected to the SPI1 of Primary Elevator Connector

*OFF*

MicroSD is connected to the on-board MCF51JM MCU

DIP 5

SPI CS SEL

ON

Select SPI0 CS1 as the chip-select for LCD SPI interface

*OFF*

Select SPI0 CS0 as the chip-select for LCD SPI interface

DIP 6

TP SEL

ON

Disables MCF51JM connection to the LCD Touch Panel

Use SW5 to enable ADC connection from Primary Elevator Connector

*OFF*

Enables MCF51JM connection to the LCD Touch Panel

Ensure that SW5 DIP[4:1] are OFF

DIP 7

LCD BL

ON

Enables LCD Backlight

OFF

Disables LCD Backlight

DIP 8

ELE PWM0

ON

Piezo Buzzer is controlled by PWM0 of Primary Elevator Connector and

on-board MCF51JM

*OFF*

Piezo Buzzer is controlled by on-board MCF51JM only

4 Jumper Table

There are several configuration switches provided for isolation, configuration, and feature selection.

Refer to the following table for details. The default installed dip switch settings are shown in *bold*.

Table 9 - TWR-LCD Configuration Table

TWR-LCD User’s Manual Page 12 of 13

Page 13

Configuration

Settings

Option

Setting

Description

SW2

5-way Nav

5-way

Navigation

Switch

North (Up)

Indicates "North" signal to onboard MCU

East (Right)

Indicates "East" signal to onboard MCU

South (Down)

Indicates "South" signal to onboard MCU

West (Left)

Indicates "West" signal to onboard MCU

Center (Enter)

Indicates "Center" signal to onboard MCU

SW5

DIP 1

Touch Panel

Isolation

(XPLS)

ON

Connects AN4 of Primary Elevator Connector to XPLS Touch Panel Signal

*OFF*

Disconnects AN4 from Touch Panel

DIP 2

Touch Panel

Isolation

(XMNS)

ON

Connects AN5 of Primary Elevator Connector to XMNS Touch Panel Signal

*OFF*

Disconnects AN5 from Touch Panel

DIP 3

Touch Panel

Isolation

(YMNS)

ON

Connects AN6 of Primary Elevator Connector to YMNS Touch Panel Signal

*OFF*

Disconnects AN6 from Touch Panel

DIP 4

Touch Panel

Isolation

(YPLS)

ON

Connects AN7 of Primary Elevator Connector to YPLS Touch Panel Signal

*OFF*

Disconnects AN7 from Touch Panel

Freescale™ and the Freescale l ogo are trademarks of

Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners.

© Freescale Semiconductor, Inc. 2009. All rights reserved.

4.1 Mechanical Form Factor

The TWR-LCD is designed for the Freescale Tower System as a side mounting peripheral and complies

with the electrical and mechanical specification as described in Freescale Tower Electromechanical

Specification.

TWR-LCD User’s Manual Page 13 of 13

Loading...

Loading...