Page 1

© 2015 Freescale Semiconductor, Inc. All rights reserved.

Freescale Semiconductor, Inc.

Document Number: TWRK65F180MUG

User's Guide

Rev. 0

,

Contents

1 Introduction 1

1.1 Features ..................................................................... 2

1.2 Getting started ........................................................... 3

2 Contents 3

3 Hardware description 4

3.1 K65F180M microcontroller ........................................ 4

3.2 Clocking .................................................................... 5

3.3 System power ............................................................ 5

3.4 Tamper module (Dryice) and Real-Time Clock supply 6

3.5 Serial and Debug Adapter version 2 (OpenSDAv2) ..... 6

3.6 Cortex Debug connector ............................................. 7

3.7 External Bus Interface – FlexBus................................ 7

3.8 SDRAM .................................................................... 8

3.9 Accelerometer ........................................................... 8

3.10 Potentiometer, Pushbuttons, LEDs .............................. 8

3.11 General Purpose Tower Plug-in (TWRPI) socket ........ 9

3.12 Touch interface .......................................................... 9

3.13 USB interface .......................................................... 10

3.14 Secure digital card slot ............................................. 10

3.15 Ethernet and 1588 ................................ .................... 11

4 Jumper table 11

5 Input/output connectors and pin usage table 13

6 Elevator connections 14

7 References 16

8 Revision history 17

TWR-K65F180M User's Guide

Introduction

1

The K65F180M Tower MCU Module

(TWR-K65F180M) is a low-cost evaluation,

demonstration, and development board, which features

the Kinetis 180 MHz K65 low-power MCU. The

TWR-K65F180M microcontroller module can operate in

stand-alone mode or as part of the Freescale Tower

System, a modular development platform that enables

rapid prototyping and tool re-use through reconfigurable

hardware. Take your design to the next level and begin

constructing your Tower System today by visiting

freescale.com/tower for additional Tower System

microcontroller modules and compatible peripherals.

Page 2

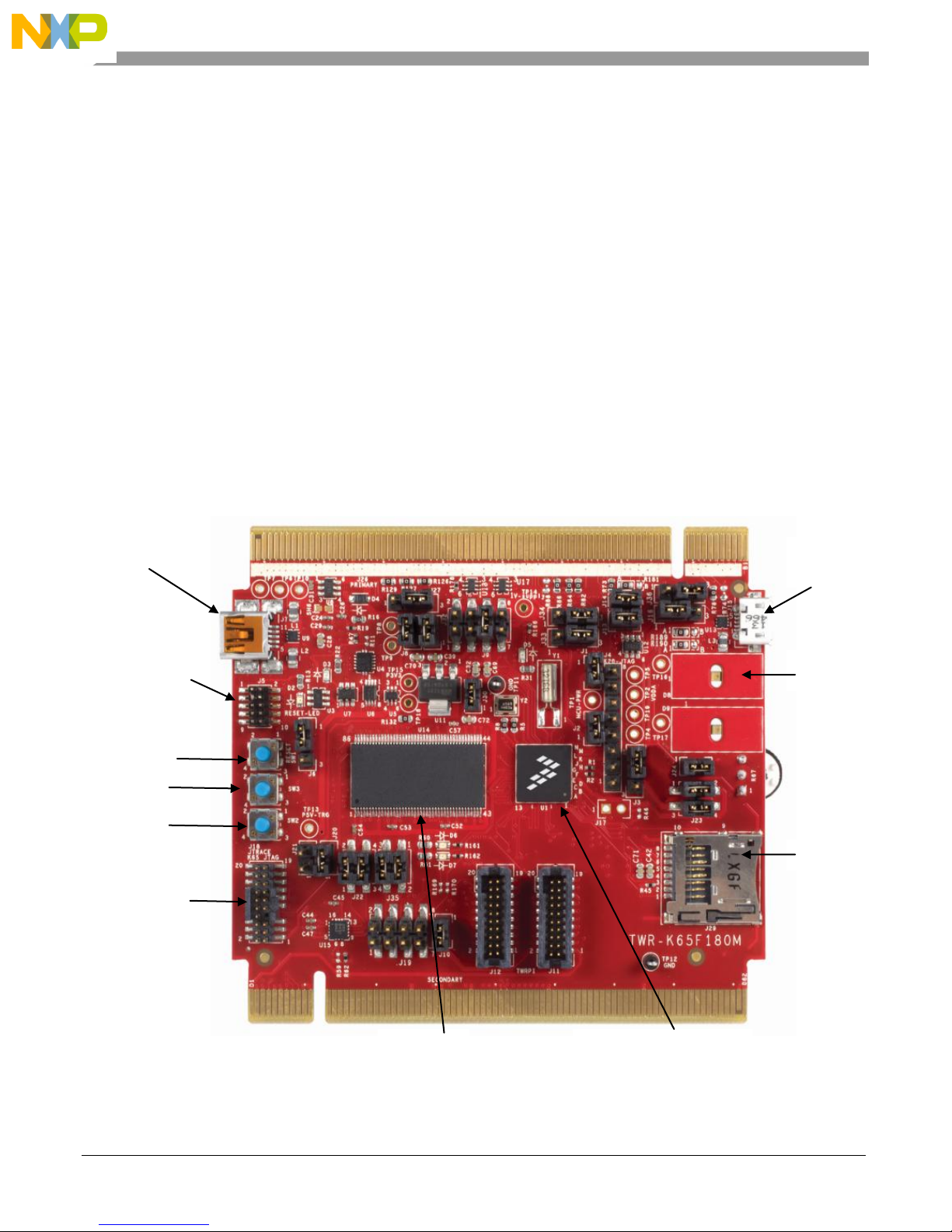

1.1 Features

OpenSDA

USB

K20 JTAG

Reset

SW3

SW2

K65 JTAG

K65

USB

Touch Pad

SD card slot

SDRAM

K65FN2M0VMI18

The following list summarizes the features of the K65F180M Tower MCU boards:

Tower compatible processor board

K20 based OPENSDA circuit

Four user-controlled status LEDs

Two Capacitive Touch Pads and two mechanical push buttons

Socket for Tower Plug-in (TWRPI, for instance a sensor board)

Standalone high speed USB host and device function

Potentiometer

SDRAM connection

MMA8451Q three-axis accelerometer

Battery holder for 20 mm lithium battery (battery diameter 20 mm, thickness 25 mm)

Board power select with 3.3 V or 1.8 V MCU operation

MicroSD card slot

OpenSDA USB

Figure 1. Front side of the TWR-K65F180M module

2 Freescale Semiconductor, Inc.

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 3

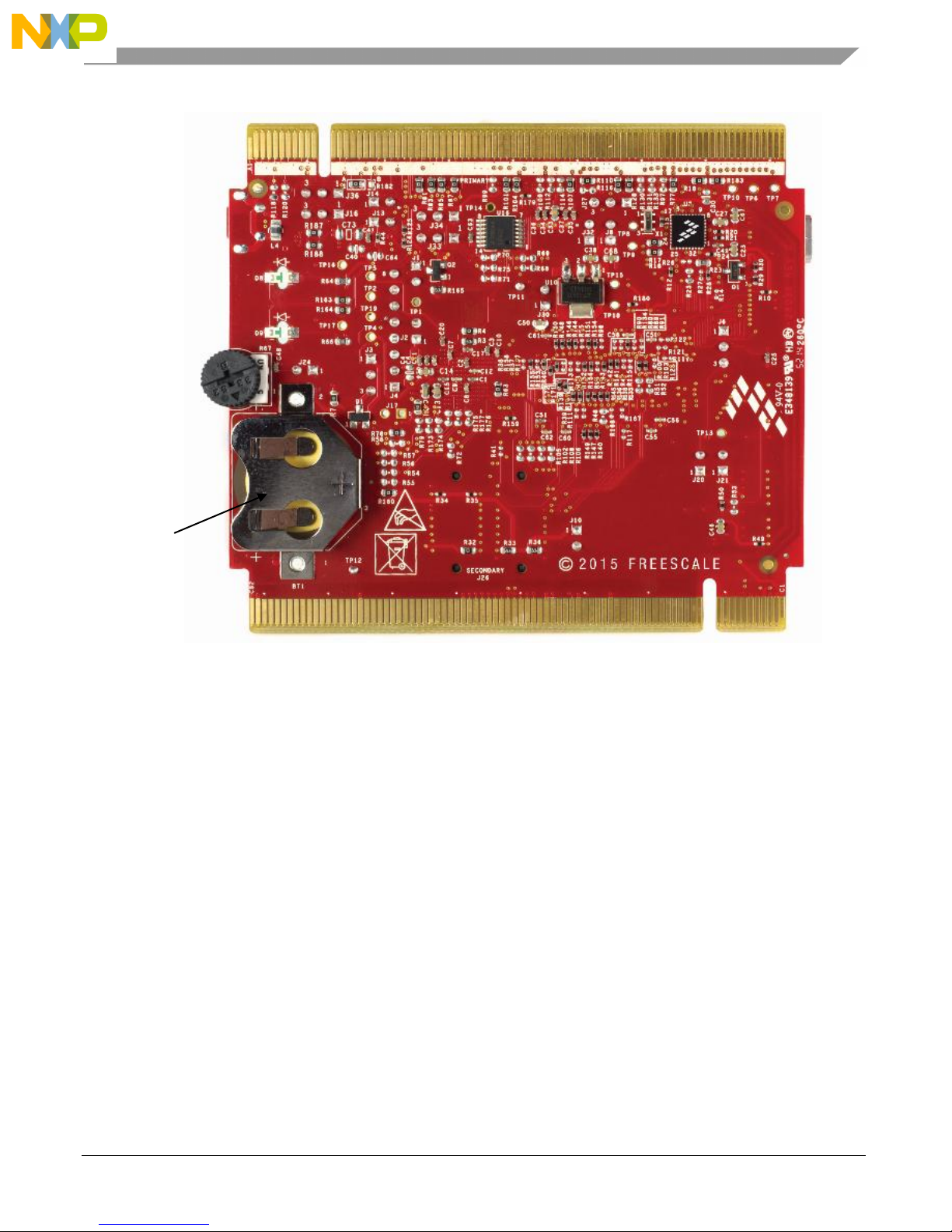

Battery

Receptacle

VBAT

Figure 2. Back side of the TWR-K65F180M module

1.2 Getting started

You can find a printed version of the Quick Start Guide in the TWR-K65F180M box that contains the

list of recommended steps for getting started.

Contents

2

The TWR-K65F180M includes:

TWR-K65F180M for board assembly

Quick Start Guide

USB A to mini-B cable for debug interface and power supply

CR2032 coin cell battery for VBAT power supply

USB A to micro-B cable for K65FN2M0VMI18 USB interface

Freescale Semiconductor, Inc. 3

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 4

Hardware description

MK20DX128VFM5

K20 MCU

Digital

Accelerometer

MMA8451Q

SDRAM

2M x 32-bit

RESET

Button

JTAG

9-PIN

JTAG

19-PIN

ENET 1588

Header

MMC-SD

Card Slot

General Purpose

Tower Plug-in

Headers

INTERRUPT

Buttons

POTENTIOMETER

5K Ohm

XTAL

8 MHz

LPC

Logic

TOUCH

Pads

Tower Elevator Expansion Connectors

I2S, SPI, I2C, ADC, USB, DAC, PWM, TMR, CAN, IRQs, GPIOs, UARTs, Flexbus, Ethernet

5 V

3.3 V

USB

MINI-B

5 V

USB

Micro-AB

5 V

3.3 V

LDO

1.8 V

LDO

TAMPER

Header

Freescale Devices

External Connectors

Interface Circuits

Power Devices

XTAL

16 MHz

GPIO

UART

SWD

FS USB

FS USB

SDHC

I2C

VBAT

JTAG

GPIO

ADC

JTAG

50 MHz

1588 TMR

HS USB

SDRAM BUS

TAMPER

RESET

LED

Yellow/Orange

Green/Blue

I2C/SPI/ADC/GPIO

sheet 8

sheet 4

XTAL

32.768 KHz

TSI

sheet 4

sheet 7

sheet 4

sheet 4

sheet 5 sheet 5

sheet 5sheet 5

sheet 5

sheet 5 sheet 5

sheet 6

sheet 6

sheet 6

sheet 6

sheet 6

sheet 7

sheet 7

sheet 7

sheet 7

sheet 4

sheet 7

BATTERY

Holder

3 V

sheet 4

MK65FN2M0VMI18

K65 MCU

RTC

3

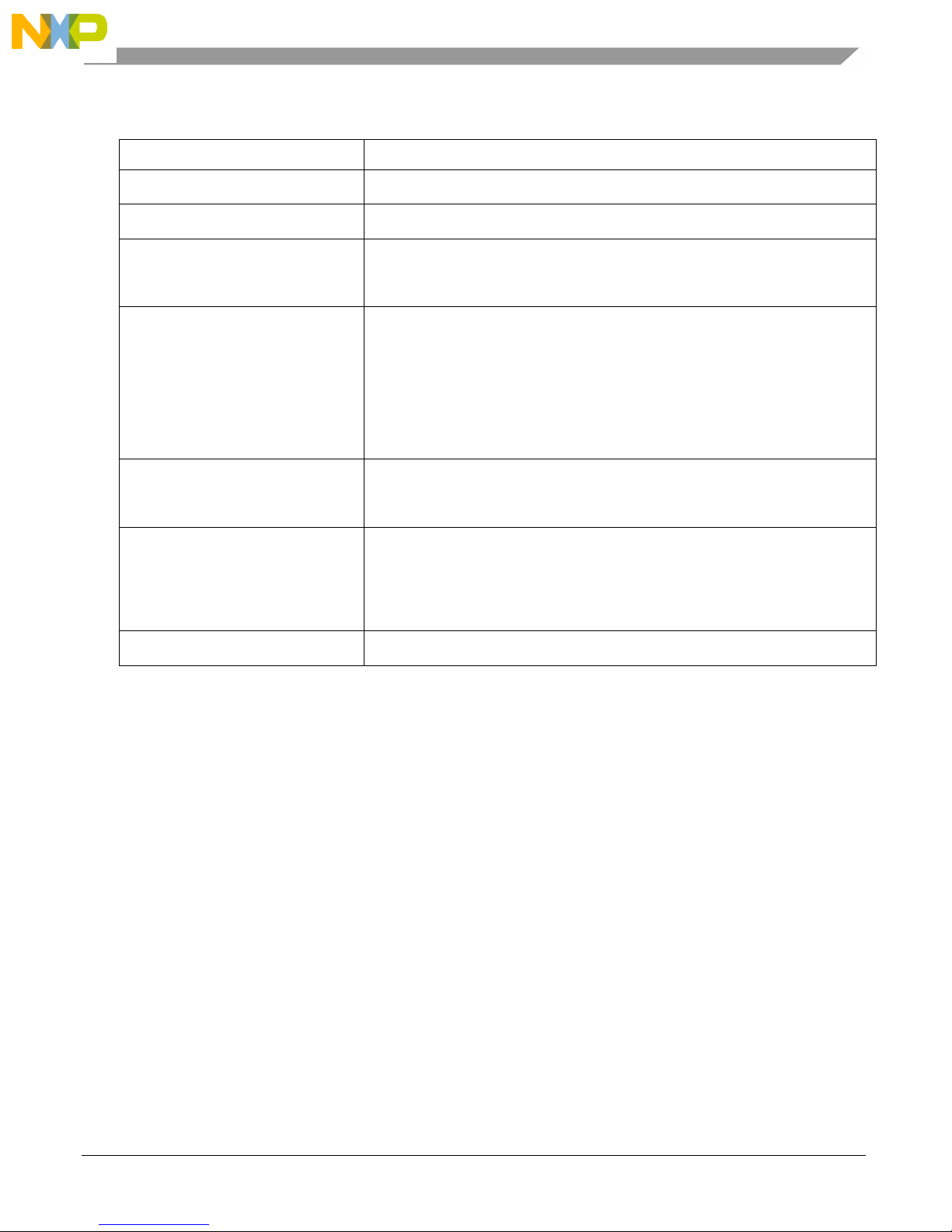

The TWR-K65F180M is a Tower MCU Module featuring the K65FN2M0VMI18 – an ARM®

Cortex®-M4F based MCU with 2 MB on-chip flash, 256 KB on-chip SRAM, SDRAM controller and

dual USB controllers in a 169 pin MAPBGA package. It has a maximum core operating frequency of

180 MHz. It is intended for use in the Freescale Tower System but can operate as a stand-alone module.

An on-board debug circuit, OPENSDA, provides the SWD debug interface and power supply input

through a single USB mini-AB connector. The following sections describe the hardware in more detail.

This figure shows a block diagram for the TWR-K65F180M.

Figure 3. TWR-K65F180M Block Diagram

3.1 K65F180M microcontroller

The TWR-K65F180M module features the K65FN2M0VMI18. The K65 microcontroller family is part

of the Kinetis portfolio of devices built around an ARM Cortex-M4F core. Refer to the K65 Family

Reference Manual (document K65P169M180SF5RMV2) for comprehensive information on the

K65FN2M0VMI18 device. The key features of K65FN2M0VMI18 are as follows.

4 Freescale Semiconductor, Inc.

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 5

Table 1. K65FN2M0VMI18 key features

Feature

Description

Performance

Up to 180 MHz ARM Cortex-M4 based core with DSP instructions and

Single Precision Floating Point unit

Memory and memory expansion

2 MB program flash memory and 256 KB RAM

FlexBus external bus interface and SDRAM controller

Analog modules

Two 16-bit SAR ADCs and two 12-bit DACs

Four analog comparators (CMP) containing a 6-bit DAC and

programmable reference input

Voltage reference 1.2 V

Communication interfaces

Ethernet controller with MII and RMII interface to external PHY and

hardware IEEE 1588 capability

USB high-, full-, and low-speed On-the-Go with on-chip high speed

transceiver

USB full-, low-speed OTG with on-chip transceiver

Two CAN, three SPI and four I2C modules

One low power UART and five standard UARTs

Secure Digital Host Controller (SDHC)

I2S module

Security

Tamper detect and secure storage

Hardware random-number generator

Supports DES, AES, SHA accelerator (CAU)

Multiple levels of embedded flash security

Timers

Four periodic interrupt timers

16-bit low-power timer

Two 16-bit low-power timer PWM modules

Two 8-channel motor control / general purpose / PWM timers

Two 2-channel quad decoder / general purpose timers

Real-time clock

Human machine interface

Low-power hardware touch sensor interface (TSI)

General-purpose input / output

3.2 Clocking

The Kinetis microcontrollers start up from an internal digitally controlled oscillator (DCO). The

software can enable one or two external oscillators if required. The external oscillator for the

Multipurpose Clock Generator (MCG) module can range from 32.768 kHz up to a 32 MHz crystal or

ceramic resonator. The external oscillator for the Real-Time Clock (RTC) module accepts a 32.768 kHz

crystal.

Two crystals are provided on-board for clocking the K65F180M device: a 16 MHz crystal as the main

oscillator to clock the MCG module and a 32.768 kHz crystal for clocking the RTC module.

The on-chip HS USB PHY requires a 12, 16, or 24 MHz crystal with the

main oscillator on EXTAL0 and XTAL0 pins.

3.3 System power

In standalone operation, the main power source for the TWR-K65F180M is derived from the 5.0 V input

from either the USB mini-B connector, J7, or the debugger header, J18, when a shunt is placed on

jumper J21. An on-board low-dropout regulator provides either 3.3 V or 1.8 V supply from the 5.0 V

Freescale Semiconductor, Inc. 5

TWR-K65F180M User's Guide, Rev. 0, 05/2015

NOTE

Page 6

input voltage based on the configuration of jumper J9. See sheet 5 of the TWR-K65F180M Schematics

OpenSDAv2

OpenSDA MCU

K20DX128Vxx5

MSD Bootloader

OpenSDAv2

Application

UART TX/RX

GPIO

Serial Terminal

File System

SWD/JTAG

LED

PWM

USB Host

IDE

GPIO/ADC

SPI, GPIO

USB

Target

Processor

nRESET

UART RX/TX

(document TWR-K65F180M-SCH) for further details.

When installed into a Tower System, the TWR-K65F180M can be powered from either an on-board

power source or from another power source in the assembled Tower System. If both the on-board and

off-board power sources are available, the TWR-K65F180M will default to the off-board power source.

The 3.3 V or 1.8 V power supplied to the MCU is routed through a jumper, J1. The jumper shunt can be

removed to allow the following:

1) Alternate MCU supply voltages to be injected.

2) Measurement of power consumed by the MCU.

3.4 Tamper module (Dryice) and Real-Time Clock supply

The Dryice tamper detection module and the Real-Time Clock (RTC) module on the K65FN2M0VMI18

have two modes of operation: system power up and system power down. During system power down,

the tamper detection module and the RTC are powered from the backup power supply (VBAT) and

electrically isolated from the rest of the MCU. The TWR-K65F180M provides a battery receptacle for a

coin cell battery that can be used as the VBAT supply. The receptacle uses standard 20 mm diameter

3 V lithium coin cell batteries.

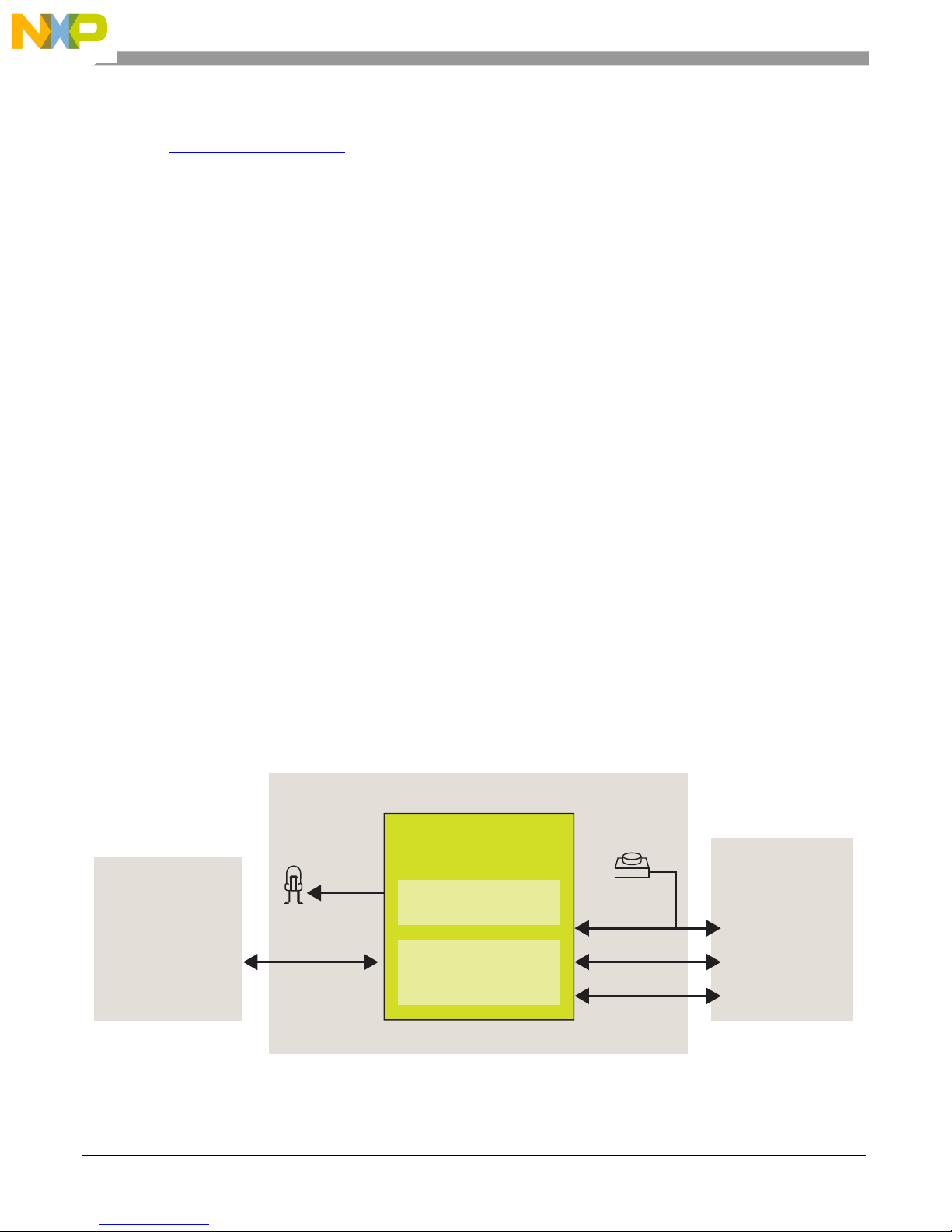

3.5 Serial and Debug Adapter version 2 (OpenSDAv2)

OpenSDAv2 is a serial and debug adapter circuit which includes an open-source hardware design, an

open-source bootloader, and debug interface software. It bridges serial and debug communications

between a USB host and an embedded target processor as shown in figure 4. The hardware circuit is

based on a Freescale Kinetis K20 family MCU with 128 KB of embedded flash and an integrated USB

controller. OpenSDAv2 comes preloaded with the CMSIS-DAP bootloader—an open-source mass

storage device (MSD) bootloader—and the CMSIS-DAP interface firmware (also known as the mbed

interface), which provides an MSD flash programming interface, a virtual serial port interface, and a

CMSIS-DAP debug protocol interface. For more information on the OpenSDAv2 software, see

mbed.org and https://github.com/mbedmicro/CMSIS-DAP.

6 Freescale Semiconductor, Inc.

Figure 4. OpenSDAv2 high-level block diagram

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 7

OpenSDAv2 is managed by a Kinetis K20 MCU built on the ARM Cortex-M4 core. The OpenSDAv2

Pin

Function

TWR-K65F180M connection

1

VTref

3.3 V MCU supply (MCU_PWR)

2

TMS/SWDIO

PTA3/UART0_RTS_b/FTM0_CH0/JTAG_MS/SWD_DIO

3

GND

GND 4 TCK/SWCLK

PTA0/UART0_CTS_b/FTM0_CH5/JTAG_CLK/SWD_CLK/EZP_CLK

5

GND

GND 6 TDO/SWO

PTA2/UART0_TX/FTM0_CH7/JTAG_DO/TRACE_SWO/EZP_DO

7

Key

—

8

TDI

PTA1/UART0_TX/FTM0_CH6/JTAG_DI/EZP_DI

9

GNDDETECT

PTA4/FTM0_CH1/MS/NMI_b/EZP_CS_b

10

nReset

RESET_b

11

Target Power

5 V supply (via J21)

12

TRACECLK

PTE0/SPI1_PCS1/UART1_TX/SDHC0_D1/TRACE_CLKOUT

13

Target Power

5 V supply (via J21)

14

TRACEDATA[0]

PTE4/SPI1_PCS0/UART3_TX/SDHC0_D3/TRACE_D0

15

GND

GND

16

TRACEDATA[1]

PTE3/SPI1_SIN/UART1_RTS_b/SDHC0_CMD/TRACE_D1

17

GND

GND

18

TRACEDATA[2]

PTE2/SPI1_SCK/UART1_CTS_b/SDHC0_DCLK/TRACE_D2

19

GND

GND

20

TRACEDATA[3]

PTE1/SPI1_SOUT/UART1_RX/SDHC0_D0/TRACE_D3

circuit includes a status LED (D3) and a pushbutton (SW1). The pushbutton asserts the Reset signal to

the K65 target MCU. It can also be used to place the OpenSDAv2 circuit into bootloader mode. SPI and

GPIO signals provide an interface to either the SWD debug port or the K20. Additionally, signal

connections are available to implement a UART serial channel. The OpenSDAv2 circuit receives power

when the USB connector J7 is plugged into a USB host.

3.6 Cortex Debug connector

The Cortex Debug connector is a 20-pin (0.05 inch) connector providing access to the SWD, JTAG, and

EzPort signals available on the K65 device. The K65 pin connections to the debug connector (J18) are

shown in this table.

Table 2. Cortex Debug connector pinout

To avoid conflict with RMII signals, trace signals are routed to the PTE

port with unpopulated 0 Ohm resistors to avoid signal conflicts with

SDHC.

3.7 External Bus Interface – FlexBus

The K65 device features a multi-function external bus interface called the FlexBus interface controller.

This is capable of interfacing with slave-only devices. The FlexBus interface is not used directly on the

TWR-K65F180M. Instead, a subset of the FlexBus is connected to the Primary Connector so that the

external bus can access devices on Tower peripheral modules. See Table 6 “Error! Reference source

not found.” and sheet 8 of the TWR-K65F180M Schematics (document TWR-K65F180M-SCH) for

more details.

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Freescale Semiconductor, Inc. 7

NOTE

Page 8

3.8 SDRAM

Default: 1-2, 3-4

(Enable Accel Interrupts)

Default: 1-2, 3-4

(Enable Accel I2C)

ACC_SA0

ACC_BYP

ACCL_INT1

ACCL_INT2

PTE19

I2C0_SCL

PTE18 I2C0_SDA

PTE27

PTE28

ACCL_SCL

ACCL_SDA

V_BRD

V_BRD

P3V3

PTE[0..28]{4,5,6,7,8}

PTE[0..28] {4,5,6,7,8}

C44

0.1uF

10%

10V

C45

0.1uF

10%

10V

J35

HDR_2X2

1 2

3 4

R59

10K

DNP

C47

0.1uF

10%

10V

J22

HDR_2X2

1 2

3 4

R62

10K

5%

C46

4.7uF

10%

10V

U15

MMA8451Q

VDDIO

1

BYP

2

VDD

14

GND15GND210GND3

12

NC3

3

NC8

8

NC13

13

NC15

15

NC16

16

INT1

11

INT2

9

SCL

4

SDA

6

SA0

7

The TWR-K65F180M board contains 64 Mb SDRAM (32-bit width) which is connected to the K65

SDRAM controller. The SDRAM signals are multiplexed with Flexbus signals. See the K65 Family

Reference Manual (document K65P169M180SF5RMV2) “Flexbus signal multiplexing” section and

“SDRAM SDR signal multiplexing” section on how to use the Flexbus and SDRAM in multiplexed

mode.

3.9 Accelerometer

An MMA8451Q digital accelerometer is connected to the K65 MCU through an I2C interface (I2C0) and

two GPIO/IRQ signals (PTE27 and PTE28). See Table 5 “Error! Reference source not found.” for

connection details.

When using Kinetis Bootloader to update K65 MCU flash firmware with an I2C interface, remove the

jumpers on J35 so I2C communication is not affected by the accelerometer connection. For information

on Kinetis Bootloader, see freescale.com/kboot.

3.10 Potentiometer, Pushbuttons, LEDs

The TWR-K65F180M features:

A potentiometer connected to an ADC input signal (ADC1_SE16/ADC0_SE22)

Two pushbutton switches (SW2 and SW3 connected to PTA4 and PTA10)

User controllable LEDs connected to GPIO signals

o Yellow LED D6 connected to PTB4

o Orange LED D7 connected to PTB5

o LED D8 connected to PTA28

o LED D9 connected to PTA29

8 Freescale Semiconductor, Inc.

Figure 5. Accelerometer connection

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 9

3.11 General Purpose Tower Plug-in (TWRPI) socket

Left-side 2x10 Connector

Right-side 2x10 Connector

Pin

Description

Pin

Description

1

5V VCC

1

GND

2

3.3 V VCC

2

GND

3

GND

3

I2C: SCL

4

3.3 V VDDA

4

I2C: SDA

5

VSS (Analog GND)

5

GND

6

VSS (Analog GND)

6

GND

7

VSS (Analog GND)

7

GND

8

ADC: Analog 0

8

GND

9

ADC: Analog 1

9

SPI: MISO

10

VSS (Analog GND)

10

SPI: MOSI

11

VSS (Analog GND)

11

SPI: SS

12

ADC: Analog 2

12

SPI: CLK

13

VSS (Analog GND)

13

GND

14

VSS (Analog GND)

14

GND

15

GND

15

GPIO: GPIO0/IRQ

16

GND

16

GPIO: GPIO1/IRQ

17

ADC: TWRPI ID 0

17

GPIO: GPIO2/UART0_RX

18

ADC: TWRPI ID 1

18

GPIO: GPIO3/ UART0_TX

19

GND

19

GPIO: GPIO4/ UART0_CTS

20

Reset

20

GPIO: GPIO5/ UART0_RTS

The TWR-K65F180M features two sockets (J11 and J12) that can accept a variety of different Tower

Plug-in modules featuring sensors, RF transceivers, and more. The General Purpose TWRPI socket

provides access to I2C, SPI, IRQs, GPIOs, timers, analog conversion signals, TWRPI ID signals, reset,

and voltage supplies. The pinout for the TWRPI Socket is defined in the following table.

Table 3. TWRPI socket pin description

3.12 Touch interface

The touch-sensing input (TSI) module of the Kinetis microcontrollers provides capacitive touch-sensing

detection with high sensitivity and enhanced robustness. Each TSI pin implements the capacitive

measurement of an electrode. There are two individual electrodes on-board the TWR-K65F180M that

simulates pushbuttons.

Freescale Semiconductor, Inc. 9

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 10

TP_LED2R

PTB18 TSI0_CH11

BRD_PAD2BRD_PAD1

PTA28

PTB19 TSI0_CH12

TP_LED1R

TP_LED2RR

TP_LED1RR

PTA29

V_BRD

V_BRD

PTB[0..23]{4,6,7,8}

PTA[0..31]{4,5,6,7,8}

R163 0

R1590

TP16

DNP

R64

1K

5%

R66

1K

5%

TP17

DNP

D8

LED_GRN + ELECTRODE

AC

1

R63

0

R164 0

D9

LED2_ELECTRODE

AC

1

Figure 6. Touch pad circuitry

default A

Place R188 very close to R190_B

USB HS

4} MCU_USB1_HS_DN{

{4} MCU_USB1_HS_DP

ELEV_USB_DN{8}

ELEV_USB_DP{8}

MCU_USB0_FS_DN {4}

MCU_USB0_FS_DP {4}

R1870

A

B

R190

0

R1880

A

B

R189

0

default A

Place R187 very close to R189_B

USB FS

3.13 USB interface

The K65FN2M0VMI18 features a high-, full-, and low-speed USB controller with on-chip HS USB

PHY, and a full-, low-speed USB controller with on-chip USB PHY. The TWR-K65F180M board

enables the USB to be host or device in standalone mode or with connection to a TWR-SER1 board in a

complete tower kit. FS USB controller DP/DM signals can be selectively routed to the MicroUSB

connector J15 or the MiniUSB connector J14 on a TWR-SER1 board by changing the 0 ohm resistor to

connect either to A or B as shown in the following schematic. This is to help reduce on-board signal

stub. The HS USB controller signal DP/DM signals can only be connected to on-board MicroUSB

connector J15.

Figure 7. USB signal routing

3.14 Secure digital card slot

A Micro SD card slot is available on the TWR-K65F180M connected to the SD host controller (SDHC)

signals of the MCU. This slot will accept standard format SD memory cards. See Table 5 “Error!

Reference source not found.” for connection details.

10 Freescale Semiconductor, Inc.

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 11

3.15 Ethernet and 1588

Jumper

Option

Setting

Description

Default

setting

J1

MCU power connection

On

Connect V_SUPPLY and V_BRD with MCU_PWR

On

Off

Disconnect V_SUPPLY and V_BRD with MCU_PWR

J2

VDD and VDDA connection

On

Connect VDD and VDDA

On

Off

Disconnect VDD and VDDA

J3

VBAT power selection

1-2

Connect VBAT to on-board 3.3 V supply from V_SUPPLY

1-2

2-3

Connect VBAT to the higher voltage between on-board 3.3 V supply

or coin cell supply

J4

Tamper signal header

2-3

Tamper signal header

2-3

J6

RESET button connection

1-2

When powering the OPENSDA MCU, bootloader mode can be

selected

1-2

2-3

When OPENSDA MCU is not powered, RESET button can be used

J8

5V power connection

On

Connect P5V_TRG_USB to input of on-board 3.3 V regulator

On

Off

Disconnect P5V_TRG_USB to on-board 3.3 V regulator

J9

Board power selection

1-2

V_SUPPLY comes from OPENSDA MCU (K20) USB regulator

5-6

3-4

V_SUPPLY comes from on-board 1.8 V regulator

5-6

V_SUPPLY comes from on-board 3.3 V regulator

7-8

V_SUPPLY comes from K65 USB regulator

J10

TWRPI power selection

On

Connect V_BRD to TWRPI connector power

On

OFF

Disconnect V_BRD to TWRPI connector power

The K65FN2M0VMI18 features a 10/100 Mbps Ethernet MAC with MII and RMII interfaces. The

TWR-K65F180M routes RMII interface signals from the K65 MCU to the primary elevator connector

which enables a connection to an external Ethernet PHY that can be found on some Tower peripheral

modules.

The reason that only RMII instead of MII interface signals are routed out is because there is

multiplexing of the Flexbus function on some of the MII signals. Routing only the RMII signals enables

Ethernet and Flexbus functions to work at the same time.

When the K65 Ethernet MAC is operating in RMII mode, synchronization of the MCU clock and the

50 MHz RMII transfer clock is important. The MCU input clock must remain in phase with the 50 MHz

clock supplied to the external PHY. According to the K65 reference manual, the RMII clock can be

selected between EXTAL and ENET_1588_CLKIN (PTE26) and because the system oscillator is

already connected with 16 MHz to allow HS USB PHY to function, the RMII clock is coming from

PTE26 and this signal is connected to CLKIN0 (B24) of the primary elevator.

Jumper table

4

There are several jumpers provided for isolation, configuration, and feature selection. See the following

table for details.

Table 4. TWR-K65F180M jumper table

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Freescale Semiconductor, Inc. 11

Page 12

Table 4. TWR-K65F180M jumper table (continued)

Jumper

Option

Setting

Description

Default

setting

J13

USB power enable connection

On

Connect PTD8 to USB power enable for MIC2005

On

OFF

Disconnect PTD8 to USB power enable for MIC2005

J14

USB over-current flag

connection

On

Connect PTD9 to USB over-current flag for MIC2005

On

OFF

Disconnect PTD9 to USB over-current flag for MIC2005

J16

USB ID connection

1-2

Connect PTD15 to USB ID pin on MicroUSB connector J15

1-2

2-3

Connect PTE10 to USB ID pin on MicroUSB connector J15

J17

Pulldown connection on

CD/DAT3 for MicroSD slot

On

Disconnect pull down resistor on CD/DAT3 pin on MicroSD slot

Off

Off

Connect pull down resistor on CD/DAT3 pin on MicroSD slot

J20

MCU reset connection on

JTAG connector

On

Connect MCU reset on pin10 of JTAG connector J18

On

Off

Disconnect MCU reset on pin10 of JTAG connector J18

J21

JTAG Power Connection

On

Connect on-board 5V supply to JTAG port (supports powering

board from external JTAG probe)

Off

Off

Disconnect on-board 5V supply from JTAG port

J22

Accelerometer INT connection

1-2

Connects INT1 from MMA8451 to PTE27

1-2

3-4

3-4

Connects INT2 from MMA8451 to PTE28

J23

K65 VREGIN selection

1-2

VREG_IN0 connected with ONBOARD_USB_VBUS

1-2

3-4

1-3

VREG_IN1 connected with ONBOARD_USB_VBUS

2-4

VREG_IN0 connected with ELEV_USB_VBUS

3-4

VREG_IN1 connected with ELEV_USB_VBUS

J24

Potentiometer connection

On

Connect potentiometer to ADC1_SE16

On

Off

Disconnect potentiometer to ADC1_SE16

J27

/RSTOUT connection

1-2

MCU reset signal connected to /RSTOUT (A63) on primary elevator

2-3

2-3

PTD10 connected to /RSTOUT (A63) on primary elevator

J30

SDRAM power connection

On

Connect V_BRD to SDRAM chip

On

Off

Disconnect V_BRD to SDRAM chip

J32

SWD clock disconnection

On

Connect SWD_CLK from OPENSDA circuit to K65 MCU to allow

debugging using OPENSDA

On

OFF

Disconnect SWD_CLK from OPENSDA circuit to K65 MCU to allow

J-Link or U-Link debug

J33

UART2 RX connection

1-2

Connect UART2_RX to elevator

2-3

2-3

Connect UART2_RX to OPENSDA UART RX

J34

UART2 TX connection

1-2

Connect UART2_TX to elevator

2-3

2-3

Connect UART2_TX to OPENSDA UART TX

J35

I2C connection with

accelerometer

1-2

Connect I2C0_SCL with accelerometer SCL

1-2

3-4

3-4

Connect I2C0_SDA with accelerometer SDA

J36

USB 5 V power connection

1-2

Connect MiniUSB connector (J7) VBUS with U12 pin 1

2-3

2-3

Connect P5V_ELEV with U12 pin 1

TWR-K65F180M User's Guide, Rev. 0, 05/2015

12 Freescale Semiconductor, Inc.

Page 13

Input/output connectors and pin usage table

Feature

Connection

Port Pin

Pin Function

OPENSDA

USB-to-serial bridge

OPENSDA RX data

PTE17

UART2_RX

OPENSDA TX data

PTE16

UART2_TX

SD Card Slot

SD clock

PTE2

SDHC0_DCLK

SD Command

PTE3

SDHC0_CMD

SD Data0

PTE1

SDHC0_D0

SD Data1

PTE0

SDHC0_D1

SD Data2

PTE5

SDHC0_D2

SD Data3

PTE4

SDHC0_D3

SD Card Detect

PTA9

PTA9

Pushbuttons

SW2 (NMI)

PTA4

PTA4

SW3 (LLWU)

PTA10

PTA10

SW1 (RESET)

RESET_b

RESET_b

Touch Pads

Touch

PTB18

TSI0_CH11

Touch

PTB19

TSI0_CH12

LEDs

D2 / Orange LED

—

RESET_b

D5 / YEL/GRN LED

—

Power on

D6 / Yellow LED

PTB4

Yellow LED

D7 / Orange LED

PTB5

Orange LED

D8

PTA28

D8 Electrode LED

D9

PTA29

D9 Electrode LED

Potentiometer

Potentiometer (R67)

—

ADC1_SE16/ADC0_SE22

Accelerometer

I2C SDA

PTE19

I2C0_SDA

I2C SCL

PTE18

I2C0_SCL

IRQ1

PTE27

PTE27

IRQ2

PTE28

PTE28

5

The table below provides details on which K65F180M pins are used to communicate with the

TWR-K65F180M sensors, LEDs, switches, and other I/O interfaces.

NOTE

Some port pins are used in multiple interfaces on-board and many are

potentially connected to off-board resources via the primary and

secondary Connectors. You must take care to avoid attempted

simultaneous usage of mutually exclusive features.

Table 5. I/O Connectors and Pin Usage Table

Freescale Semiconductor, Inc. 13

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 14

Table 5. I/O Connectors and Pin Usage Table (continued)

High Speed USB

USB VBUS Enable

PTD8

PTD8

USB Over-current flag

PTD9

PTD9

USB ID

PTD15 or PTE10

USB1_ID

ENET 1588

ENET 1588 TMR0

PTB2

ENET0_1588_TMR0

ENET 1588 TMR1

PTB3

ENET0_1588_TMR1

ENET 1588 TMR2

PTB4

ENET0_1588_TMR2

ENET 1588 TMR3

PTB5

ENET0_1588_TMR3

RTC

RTC bypass

PTA11

PTA11

General Purpose

TWRPI Socket

TWRPI AN0 (J11 Pin 8)

—

ADC0_SE16 / ADC0_SE21

TWRPI AN1 (J11 Pin 9)

—

ADC1_DP0 / ADC0_DP3

TWRPI AN2 (J11 Pin 12)

—

ADC1_DM0 / ADC0_DM3

TWRPI ID0 (J7 Pin 17)

—

ADC0_DP0 / ADC1_DP3

TWRPI ID1 (J7 Pin 18)

—

ADC0_DM0 / ADC1_DM3

TWRPI I2C SCL (J12 Pin 3)

PTE19

I2C0_SCL

TWRPI I2C SDA (J12 Pin 4)

PTE18

I2C0_SDA

TWRPI SPI MISO (J12 Pin 9)

PTD14

SPI2_SIN

TWRPI SPI MOSI (J12 Pin 10)

PTD13

SPI2_SOUT

TWRPI SPI SS (J12 Pin 11)

PTD15

SPI2_PCS1

TWRPI SPI CLK (J12 Pin 12)

PTD12

SPI2_SCK

TWRPI GPIO0 (J12 Pin 15)

PTC14

PTC14

TWRPI GPIO1 (J12 Pin 16)

PTC15

PTC15

TWRPI GPIO2 (J12 Pin 17)

PTC16

PTC16

TWRPI GPIO3 (J12 Pin 18)

PTC17

PTC17

TWRPI GPIO4 (J12 Pin 19)

PTC18

PTC18

TWRPI GPIO5 (J12 Pin 20)

PTC19

PTC19

Pin #

Side B

Pin #

Side A

Name

Usage

Name

Usage

B1

5 V

5.0 V Power

A1

5V

5.0 V Power

B2

GND

Ground

A2

GND

Ground

B3

3.3 V

3.3 V Power

A3

3.3 V

3.3 V Power

B4

ELE_PS_SENSE

Elevator Power Sense

A4

3.3 V

3.3 V Power

B5

GND

Ground

A5

GND

Ground

Elevator connections

6

The TWR-K65F180M features two expansion card-edge connectors that interface to Elevator boards in

a Tower System: the primary and secondary Elevator connectors. The pinout for the primary Elevator

Connector is provided in this table. The values in bold are either power or ground.

Table 6. TWR-K65F180M Primary Connector Pinout

14 Freescale Semiconductor, Inc.

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 15

Table 6. TWR-K65F180M Primary Connector Pinout (continued)

B6

GND

Ground

A6

GND

Ground

B7

SDHC_CLK /

SPI1_CLK

PTE2

A7

SCL0

PTE19

B8

SDHC_D3 /

SPI1_CS1_b

—

A8

SDA0

PTE18

B9

SDHC_D3 /

SPI1_CS0_b

PTE4

A9

GPIO9 / CTS1

PTD1

B10

SDHC_CMD /

SPI1_MOSI

PTE3

A10

GPIO8 / SDHC_D2

PTE5

B11

SDHC_D0 /

SPI1_MISO

PTE1

A11

GPIO7 /

SD_WP_DET

PTA9

B12

ETH_COL

—-

A12

ETH_CRS

—

B13

ETH_RXER

PTA5

A13

ETH_MDC

PTA8

B14

ETH_TXCLK

—

A14

ETH_MDIO

PTA7

B15

ETH_TXEN

PTA15

A15

ETH_RXCLK

—

B16

ETH_TXER

—

A16

ETH_RXDV

PTA14

B17

ETH_TXD3

—

A17

ETH_RXD3

—

B18

ETH_TXD2

—

A18

ETH_RXD2

—

B19

ETH_TXD1

PTA17

A19

ETH_RXD1

PTA12

B20

ETH_TXD0

PTA16

A20

ETH_RXD0

PTA13

B21

GPIO1 / RTS1

PTD0

A21

I2S0_MCLK

PTE6

B22

GPIO2 / SDHC_D1

PTE0

A22

I2S0_DOUT_BCLK

PTE12

B23

GPIO3

PTD10

A23

I2S0_DOUT_FS

PTE11

B24

CLKIN0

PTE26

A24

I2S0_RXD0

PTE7

B25

CLKOUT1

PTC3

A25

I2S0_TXD0

PTE10

B26

GND

Ground

A26

GND

Ground

B27

AN7

PTA6

A27

AN3

ADC0_SE16

B28

AN6

PTC3

A28

AN2

ADC1_DP0

B29

AN5

PTE24

A29

AN1

ADC1_DM0

B30

AN4

PTE25

A30

AN0

ADC0_SE16

B31

GND

Ground

A31

GND

Ground

B32

DAC1

DAC1_OUT

A32

DAC0

DAC0_OUT

B33

TMR3

PTD6

A33

TMR1

PTB13

B34

TMR2

PTD7

A34

TMR0

PTB12

B35

GPIO4

PTA28

A35

GPIO6

PTA29

B36

3.3 V

3.3 V Power

A36

3.3 V

3.3 V Power

B37

PWM7

—

A37

PWM3

PTD3

B38

PWM6

—

A38

PWM2

PTD2

B39

PWM5

PTD5

A39

PWM1

PTD1

B40

PWM4

PTD4

A40

PWM0

PTD0

B41

CANRX0

PTA31

A41

RXD0

PTA1

B42

CANTX0

PTA30

A42

TXD0

PTA2

B43

1WIRE

—

A43

RXD1

ELEV_UART_RX

B44

SPI0_MISO

PTD14

A44

TXD1

ELEV_UART_TX

B45

SPI0_MOSI

PTD13

A45

VSS

VSSA

B46

SPI0_CS0_b

PTD11

A46

VDDA

VDDA

B47

SPI0_CS1_b

PTD15

A47

CAN1_RX

PTE25

B48

SPI0_CLK

PTD12

A48

CAN1_TX

PTE24

B49

GND

Ground

A49

GND

Ground

B50

SCL1

PTE19

A50

GPIO14

PTA24

B51

SDA1

PTE18

A51

GPIO15

PTA25

B52

GPIO5 /

SPI0_HOLD/IO3

PTA10

A52

GPIO16

PTA26

Freescale Semiconductor, Inc. 15

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 16

Table 6. TWR-K65F180M Primary Connector Pinout (continued)

B53

USB0_DP_PDOWN

—

A53

GPIO17

PTA27

B54

USB0_DM_PDOWN

—

A54

USB0_DM

ELEV_USB_DN

B55

IRQ_H

PTE27

A55

USB0_DP

ELEV_USB_DP

B56

IRQ_G

PTE27

A56

USB0_ID

—

B57

IRQ_F

PTC11

A57

USB0_VBUS

ELEV_USB_VBUS

B58

IRQ_E

PTC11

A58

I2S0_DIN_BCLK

PTE9

B59

IRQ_D

PTC3

A59

I2S0_DIN_FS

PTE8

B60

IRQ_C

PTC3

A60

I2S0_RXD1

PTE8

B61

IRQ_B

PTE28

A61

I2S0_TXD1

PTE9

B62

IRQ_A

PTE28

A62

RSTIN_b

RESET_b

B63

EBI_ALE /

EBI_CS1_b

PTD0

A63

RSTOUT_b

Either RESET_b or PTD10

B64

EBI_CS0_b

PTD1

A64

CLKOUT0

PTA6

B65

GND

Ground

A65

GND

Ground

B66

EBI_AD15

PTB18

A66

EBI_AD14

PTC0

B67

EBI_AD16

PTB17

A67

EBI_AD13

PTC1

B68

EBI_AD17

PTB16

A68

EBI_AD12

PTC2

B69

EBI_AD18

PTB11

A69

EBI_AD11

PTC4

B70

EBI_AD19

PTB10

A70

EBI_AD10

PTC5

B71

EBI_R/W_b

PTC11

A71

EBI_AD9

PTC6

B72

EBI_OE_b

PTB19

A72

EBI_AD8

PTC7

B73

EBI_D7

PTB20

A73

EBI_AD7

PTC8

B74

EBI_D6

PTB21

A74

EBI_AD6

PTC9

B75

EBI_D5

PTB22

A75

EBI_AD5

PTC10

B76

EBI_D4

PTB23

A76

EBI_AD4

PTD2

B77

EBI_D3

PTC12

A77

EBI_AD3

PTD3

B78

EBI_D2

PTC13

A78

EBI_AD2

PTD4

B79

EBI_D1

PTC14

A79

EBI_AD1

PTD5

B80

EBI_D0

PTC15

A80

EBI_AD0

PTD6

B81

GND

Ground

A81

GND

Ground

B82

3.3 V

3.3 V Power

A82

3.3 V

3.3 V Power

References

7

The list below provides references for more information on the Kinetis family, Tower System and the

MCU modules. These can be found in the documentation section of freescale.com/TWR-K65F180M or

freescale.com/kinetis.

TWR-K65F180M Quick Start Guide (document TWR-K65F180M-QSG)

TWR-K65F180M Schematics (document TWR-K65F180M-SCH)

K65 Family Data Sheet (document K65P169M180SF5V2)

K65 Family Reference Manual (document K65P169M180SF5RMV2)

Kinetis Quick Reference User Guide (document KQRUG)

TWR-K65F180M User's Guide, Rev. 0, 05/2015

16 Freescale Semiconductor, Inc.

Page 17

Revision history

Revision number

Date

Substantive changes

0

05/2015

Initial release

8

Table 7. Revision history

Freescale Semiconductor, Inc. 17

TWR-K65F180M User's Guide, Rev. 0, 05/2015

Page 18

Document Number: TWRK65F180MUG

Rev. 0

05/2015

How to Reach Us:

Home Page:

freescale.com

Web Support:

freescale.com/support

Information in this document is provided solely to enable system and software implementers to

use Freescale products. There are no express or implied copyright licenses granted hereunder to

design or fabricate any integrated circuits based on the information in this document.

Freescale reserves the right to make changes without further notice to any products herein.

Freescale makes no warranty, representation, or guarantee regarding the suitability of its

products for any particular purpose, nor does Freescale assume any liability arising out of the

application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation consequential or incidental damages. “Typical” parameters that may

be provided in Freescale data sheets and/or specifications can and do vary in different

applications, and actual performance may vary over time. All operating parameters, including

“typicals,” must be validated for each customer application by customer's technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale

sells products pursuant to standard terms and conditions of sale, which can be found at the

following address: freescale.com/SalesTermsandConditions.

Freescale, the Freescale logo, and Kinetis are trademarks of Freescale Semiconductor, Inc., Reg.

U.S. Pat. & Tm. Off. Tower is a trademark of Freescale Semiconductor, Inc. All other product

or service names are the property of their respective owners.

ARM, ARM Powered, and Cortex are registered trademarks of ARM Limited (or its

subsidiaries) in the EU and/or elsewhere. ARM7, ARM9, ARM11 and mbed are trademarks of

ARM Limited (or its subsidiaries) in the EU and/or elsewhere. All rights reserved.

© 2015 Freescale Semiconductor, Inc.

Loading...

Loading...