Page 1

S08

Microcontrollers

freescale.com

LED Lighting Control Using the

MC9S08AW60

Designer Reference Manual

DRM093

Rev. 1

07/2007

Page 2

Page 3

LED Lighting Control using the MC9S08AW60

Designer Reference Manual

by: Dennis Lui, Ernest Chan

Freescale Semiconductor, Inc.

Hong Kong

To provide the most up-to-date information, the revision of our documents on the World Wide Web is the

most current. Your printed copy may be an earlier revision. To verify you have the latest information

available, refer to:

http://www.freescale.com

The following revision history table summarizes changes contained in this document. For your

convenience, the page number designators have been linked to the appropriate location.

Revision History

Date

03/2006 0 Initial release N/A

07/2007 1 Overall edits for grammar, spelling, structure, and style. N/A

Freescale Semiconductor 3

Revision

Level

Description

LED Lighting Control using the MC9S08AW60, Rev. 1

Page

Number(s)

Page 4

Revision History

LED Lighting Control using the MC9S08AW60, Rev. 1

4 Freescale Semiconductor

Page 5

Table of Contents

Chapter 1

Introduction

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 MC9S08AW60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

Hardware Description

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 DEMO9S08AW60LED Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 DEMO9S08AW60LED Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Development Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.9 User Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.1 Pushbutton Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.2 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.3 ADC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9.4 Other I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.10 LED Driving Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11 LED Driver Design Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.11.1 RGB LED Chip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.11.2 Current Sense Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.11.3 Boost Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3

Firmware Description

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 PC Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Standalone Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Firmware Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 4

Demo Setup

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Hardware and Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.2 PC Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Demo Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LED Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 5

Page 6

Table of Contents

4.3.1 Demo 1 - Demonstration Display . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.2 Demo 2 - Preset Colors Display . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.3 Demo 3 - Auto White Balance Control . . . . . . . . . . . . . . . . . . . . . 32

4.3.4 Demo 4 - PWM Output Frequency Control . . . . . . . . . . . . . . . . . . 32

4.3.5 Demo 5 - Full Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Program the MCU Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appendix A

Schematics

Appendix B

Bill of Materials

LED Control using the MC9S08AW60, Rev. 1

6 Freescale Semiconductor

Page 7

Chapter 1 Introduction

1.1 Introduction

This manual describes a reference design of a multi-color LED lighting control solution by using the

MC9S08AW60 Microcontroller.

Using a microcontroller (MCU) to control the red/green/blue (RGB) color LEDs increases system flexibility

and functionality for the next generation of lighting applications, architectural/entertainment lighting or

LCD backlighting, that require a smart and adaptive control methodology to ensure optimized color space

rendering for various display contents, excellent color contrast for realistic display scene and a consistent

color setting in manufacturing. In many cases, these new applications are controlled by a central control

unit that requires a connectivity interface that can be implemented at a low cost using MCU-based lighting

controller.

A compact light-box with more than a million display colors is implemented to demonstrate the

advantages of using MCU to control RGB color LEDs with different luminosity settings. The average

current through each color LED is controlled by an individual PWM signal generated from MCU and the

LED luminosity is almost in linear relationship with the pulse width of the driving PWM signal. The final

display color is determined on the mix of light emitted by RGB LEDs, so one of the simple methods to set

the light source in different color is changing the RGB PWM duty cycles equal to the corresponding mixing

ratio required for a particular color. In addition, a serial control protocol with user interface is also

developed as a communication link to control and monitor system parameters through a personal

computer.

All hardware schematic diagrams and firmware source codes are available as reference materials.

1.2 Features

• Apply for architectural/entertainment lighting or LCD backlighting applications

• Exceptional color mixing

• Pre-set or dynamic RGB colors

• High resolution on dimming control

• Automatic white balance tracking on dimming

• Flexible connectivity interface

• User friendly control menu

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 7

Page 8

Introduction

PWM

SCI

KBI

AW60

RGB

PWM

ADC

Button Switch

Detection

GPIO Port

RS232

Interface

To PC

Power Supply & Regulator

DC/DC

Converter

Blue LEDs

I/O Control

Red LEDs

Green LEDs

PWM

SCI

KBI

AW60

RGB

PWM

ADC

Button Switch

Detection

GPIO Port

RS232

Interface

To PC

Power Supply & Regulator

DC/DC

Converter

Blue LEDs

I/O Control

Red LEDs

Green LEDs

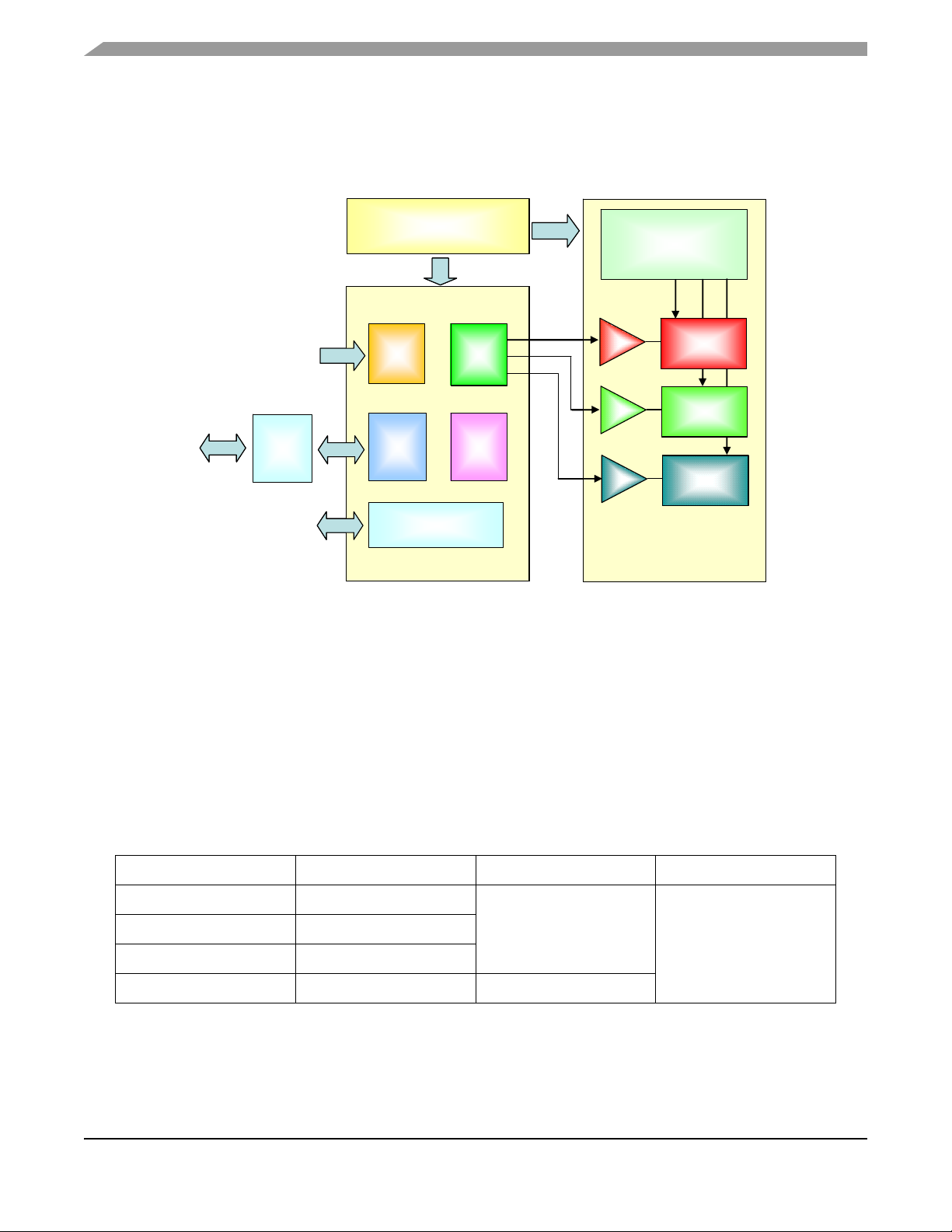

1.3 System Overview

A block diagram of the system is shown in Figure 1-1.

Figure 1-1 . System Block Diagram

1.4 MC9S08AW60

The MC9S08AW60, MC9S08AW48, MC9S08AW32, and MC9S08AW16 are members of the low-cost,

high-performance HCS08 family of 8-bit microcontroller units (MCUs). All MCUs in the family use the

enhanced HCS08 core and are available with a variety of modules, memory sizes, memory types, and

package types. Refer to Table 1-1 for memory sizes and package types.

Table 1-2 summarizes the peripheral availability per package type for the devices available in the

MC9S08AW60/48/32/16 series.

Table 1-1. Devices in the MC9S08AW60/48/32/16 Series

Device Flash RAM Package

MC9S08AW60 63,280

MC9S08AW48 49,152

MC9S08AW32 32,768

MC9S08AW16 16,384 1024

2048

64 QFP

64 LQFP

48 QFN

44 LQFP

LED Lighting Control using the MC9S08AW60, Rev. 1

8 Freescale Semiconductor

Page 9

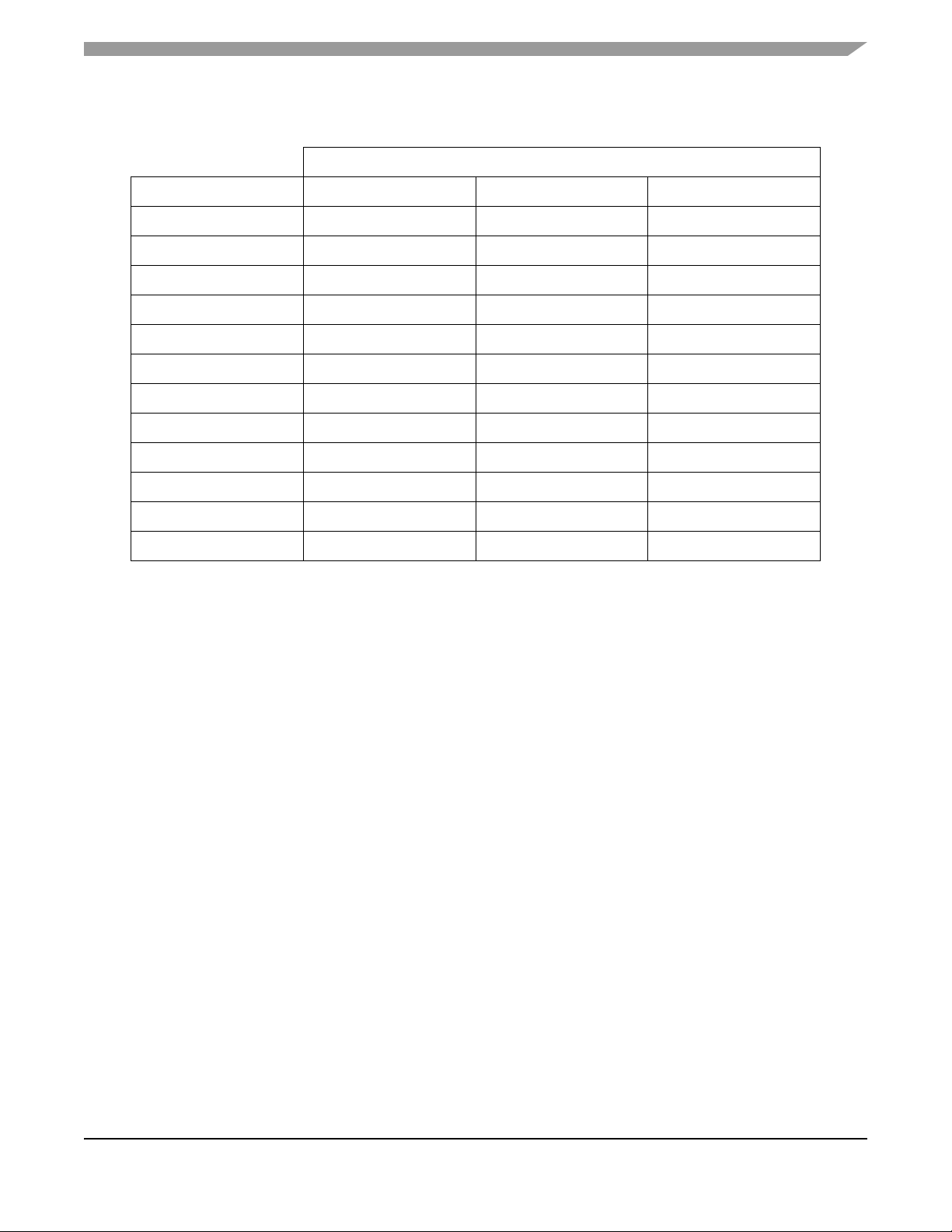

Table 1-2. Peripherals Available per Package Type

Package Options

Feature 64-Pin 48-Pin 44-Pin

ADC 16-CH 8-CH 8-CH

IIC Yes Yes Yes

IRQ Yes Yes Yes

KBI1 8 7 6

S C I 1 Ye s Ye s Ye s

S C I 2 Ye s Ye s Ye s

SPI1 Yes Yes Yes

TPM1 6-CH 4-CH 4-CH

TPM1CLK Yes No No

TPM2 2-CH 2-CH 2-CH

TPM2CLK Yes No No

MC9S08AW60

I/O Pins 54 38 34

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 9

Page 10

Introduction

LED Lighting Control using the MC9S08AW60, Rev. 1

10 Freescale Semiconductor

Page 11

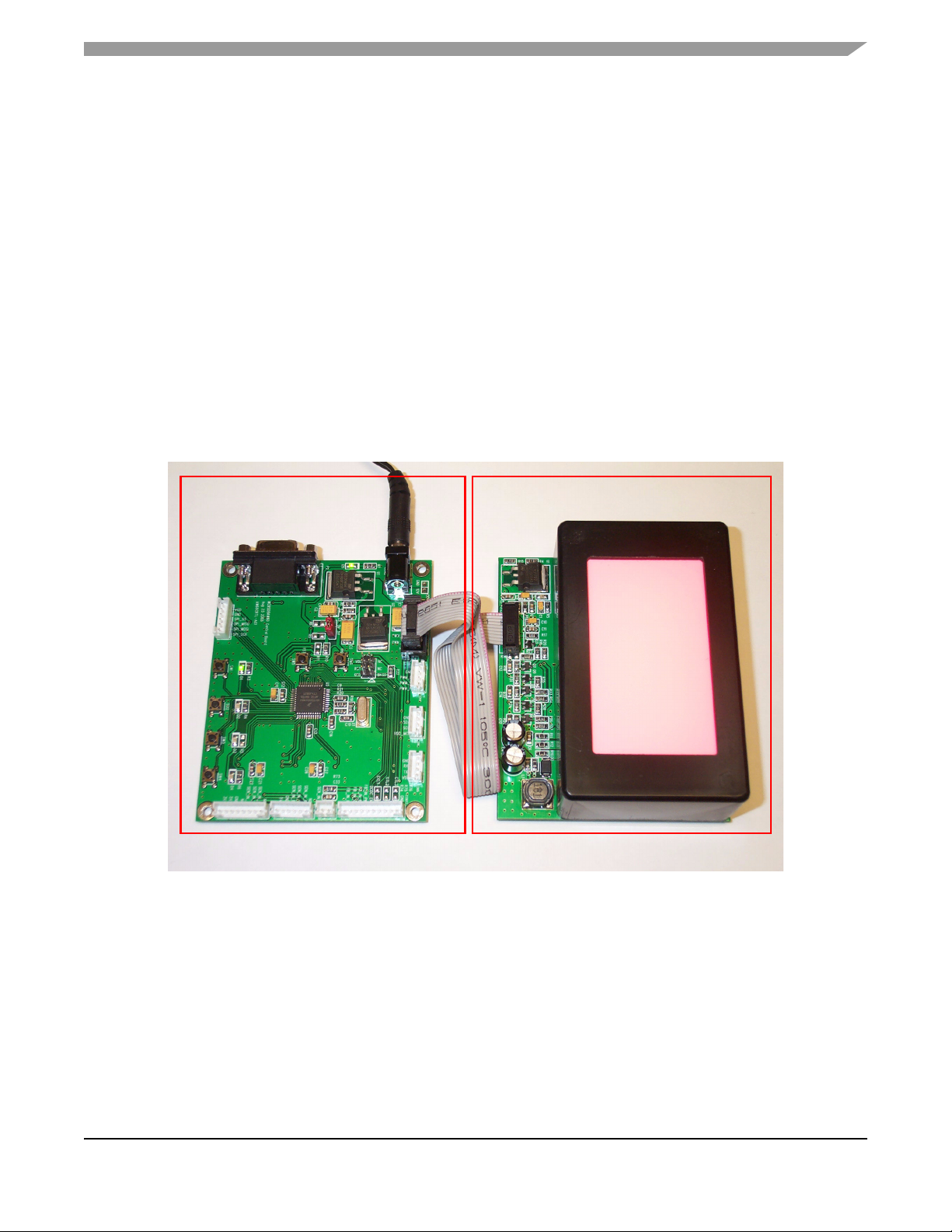

Chapter 2

AW60 Control Board

RGB LED Driving Board

Hardware Description

2.1 Introduction

The system consists of a MCU control board and a LED driving board. The MCU control board,

DEMO9S08AW60LED, is one of the demonstration boards for the Freescale MC9S08AW60. This board

allows easier developmet of code for LED control applications, architectural/entertainment lighting or LCD

backlighting. The on-board serial interface allows you to control and monitor the system status via the

RS232 serial port connection. The separated LED light-box with driving circuitries is also available as a

whole demo kit to demonstrate how to do the color mixing and see the visual effects on changing different

type of parameter settings.

Figure 2-1. Light-Box Demo

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 11

Page 12

Hardware Description

2.2 DEMO9S08AW60LED Features

• MC9S08AW60 CPU

– 44 pin LQFP package

– 20 MHz Internal Bus Frequency

– 60 Kbytes of on-chip in-circuit programmable FLASH

– 2 Kbytes of on-chip RAM

– 8-channel, 10-bit analog-to-digital converter

– Two SCI modules

– SPI module

2

–I

C module

– 6-pin keyboard interrupt (KBI) module

– 34 general-purpose input/output (I/O) pins

• External power jack for DC power supply (+12 VDC)

• Four pushbutton user switches

• Four LEDs connected to I/O port

• Master reset switch

• RGB PWM output port

• Optical sensor input port

• On-board RS-232 serial port

• 100mm x 80mm board size

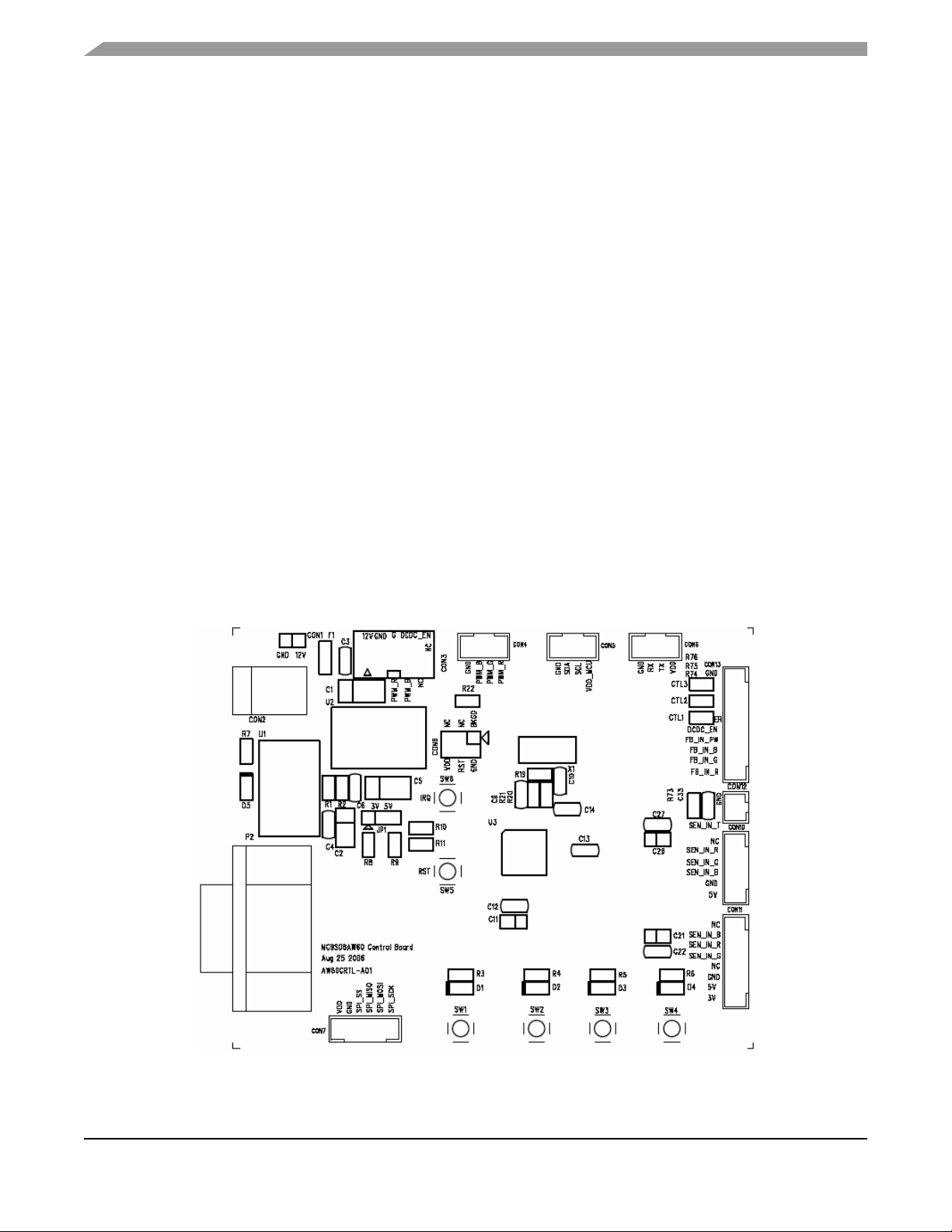

2.3 DEMO9S08AW60LED Layout

Figure 2-2. DEMO9S08AW60LED Top Side

LED Lighting Control using the MC9S08AW60, Rev. 1

12 Freescale Semiconductor

Page 13

Development Support

2.4 Development Support

Application development and debug for the MC9S08AW60 is supported through a 6-pin BDM header

(CON8). The pinout is as follows:

Table 2-1. BDM Connector (CON8) Pinout

BKGD 1 2 GND

NC 3 4 RESET

NC 5 6 V

DD

2.5 Power

The DEMO9S08AW60LED is powered externally through the barrel connector CON2. This connector is

a 2.5 mm, center positive connector. Voltage supplied through this connector should be positive 12 volts

DC. This is also the supply voltage for the LED light box.

The DEMO9S08AW60LED can be run with V

set to 5 or 3 volts. To run the board at 3V, move jumper

DD

JP1 to the 1-2, 3V position.

LED D5 turns green to let you know that power has been correctly applied to the board.

2.6 Reset Switch

The reset switch (SW5) provides a way to apply a reset to the MCU. The reset switch is connected directly

to the RESET

signal of the MCU. A 10 kΩ pullup resistor to VDD on the RESET signal allows for normal

operation. When the reset switch is pressed, the RESET signal is grounded and the MCU recognizes a

reset.

2.7 Clock Source

An on-board 16 MHz crystal (X1) is connected between the XTAL and EXTAL pins of the MCU. This offers

flexibility on clock source selection. Refer to the MC9S08AW60 data sheet for details on how to use the

internal clock generation (ICG) module to generate the system clocks for the MCU.

2.8 RS-232

An RS-232 translator provides RS-232 communication on COM connector P2. This connector is a 9-pin

Dsub right angle connector. TXD and RXD signals are routed from the MCU to the RS-232 transceiver.

Table 2-2 . RS-232 Connections

MCU Port COM Signal I/O Port Connector

PTE0/TXD1 TXD OUT P2-2

PTE1/RXD1 RXD IN P2-3

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 13

Page 14

Hardware Description

2.9 User Options

The DEMO9S08AW60LED includes various input and output devices to assist in application

development. These devices include four pushbutton switches, four LEDs, and an operational amplifier

with RC filter connected at each ADC input channel for signal amplification and filtering.

2.9.1 Pushbutton Switches

Four pushbutton switches provide momentary active low input for user applications. The table below

describes the pushbutton switch connections.

Table 2-3. Pushbutton Switches (SW1-SW4) Connections

Switch MCU Port

SW1 PTG0/KBI0

SW2 PTG1/KBI1

SW3 PTG2/KBI2

SW4 PTG3/KBI3

2.9.2 LED Indicators

Four green LED indicators (D1-D4) are provided to assist during code development. The LEDs are active

low and illuminated when a logic low signal is driven from the MCU port pin. Two of the LEDs are

connected to port A, and the other two are connected to Port C. The connections are described below:

Table 2-4. LEDs (D1-D4) Connections

LED MCU Port

D1 PTA0

D2 PTA1

D3 PTC2

D4 PTC4

2.9.3 ADC Interface

Eight operational amplifiers are provided to assist users in developing applications with feedback control

signals. For examples, the signal generated by an optical sensor in LED backlight system should be

scaled to a level matched with the ADC input range without any saturation. Each operational amplifier can

be configured as an inverting or non-inverting amplifier with variable gain setting by different resistor

connections. A RC filter is also connected at each output for noise filtering.

NOTE

The maximum operational amplifier output voltage should be limited to the

V

voltage applied to MCU to prevent any damage on input port.

DD

LED Lighting Control using the MC9S08AW60, Rev. 1

14 Freescale Semiconductor

Page 15

User Options

2.9.4 Other I/O Connectors

One user assignable and eight pre-defined I/O connectors are available to help users connect the board

into their target system.

Table 2-5. IIC Port

CON5 Signal Name Remarks

Pin 1 NC

Pin 2 SCL

Pin 3 SDA

Pin 4 GND —

Install a zero ohm resistor in the R14 footprint to

connect V

Connected to MCU PTC0/SCL1

10 kΩ pullup to V

Connected to MCU PTC1/SDA1

10 kΩ pullup to V

DD

DD

DD

Table 2-6. SCI Port

CON6 Signal Name Remarks

Pin 1 NC

Pin 2 SCI_TX Connected to MCU PTE0/TXD1

Pin 3 SCI_RX Connected to MCU PTE1/RXD1

Pin 4 GND —

Install a zero ohm resistor in the R15 footprint to

connect V

DD

Table 2-7. SPI Port

CON7 Signal Name Remarks

Pin 1 NC

Pin 2 GND —

Pin 3 SPI_SS Connected to MCU PTE4/SS1

Pin 4 SPI_MISO Connected to MCU PTE5/MISO1

Pin 5 SPI_MOSI Connected to MCU PTE6/MOSI1

Pin 6 SPI_SCK Connected to MCU PTE7/SPSCK1

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 15

Install a zero ohm resistor in the R16 footprint to

connect V

DD

Page 16

Hardware Description

Table 2-8. PWM Port

CON4 Signal Name Remarks

Pin 1 PWM R Connected to MCU PTF0/TPM1CH2

Pin 2 PWM G Connected to MCU PTF1/TPM1CH3

Pin 3 PWM B Connected to MCU PTE2/TPM1CH0

Pin 4 GND —

Table 2-9. LED Light Box Interface

CON3 Signal Name Remarks

Pin 1 & 2 12V 12V power for LED light box

Pin 3 & 4 GND —

Pin 5 PWM R Connected to MCU PTF0/TPM1CH2

Pin 6 PWM G Connected to MCU PTF1/TPM1CH3

Pin 7 PWM B Connected to MCU PTE2/TPM1CH0

Connected to MCU PTC3/TXD2

Pin 8 DCDC_EN

Pin 9 & 10 NC —

Reserved pin for DC to DC converter ON/OFF

control

Table 2-10. Sensor Interface Type A

CON10 Signal Name Remarks

Pin 1 5V Sensor supply voltage

Pin 2 GND —

Pin 3 SEN_IN_B

Pin 4 SEN_IN_G

Pin 5 SEN_IN_R

Pin 6 NC —

Sensor input (Blue), Connected to MCU

PTB2/ADP2 through operational amplifier U5B

Sensor input (Green), Connected to MCU

PTB1/ADP1 through operational amplifier U5A

Sensor input (Red), Connected to MCU

PTB0/ADP0 through operational amplifier U5D

LED Lighting Control using the MC9S08AW60, Rev. 1

16 Freescale Semiconductor

Page 17

Table 2-11. Sensor Interface Type H

CON11 Signal Name Remarks

Pin 1 3V Sensor reference voltage

Pin 2 5V Sensor supply voltage

Pin 3 GND —

Pin 4 NC —

User Options

Pin 5 SEN_IN_G

Pin 6 SEN_IN_R

Pin 7 SEN_IN_B

Pin 8 NC —

Sensor input (Green), Connected to MCU

PTB1/ADP1 through operational amplifier U5A

Sensor input (Red), Connected to MCU

PTB0/ADP0 through operational amplifier U5D

Sensor input (Blue), Connected to MCU

PTB2/ADP2 through operational amplifier U5B

NOTE

Connectors Type A and H share the same connection, so either one of the

sensor interfaces can be used for sensor input.

Table 2-12. Temperature Sensor Input

CON12 Signal Name Remarks

Pin 1 SEN_IN_T

Pin 2 GND —

10 kΩ pullup to V

PTB3/ADP3 through operational amplifier U5C

, Connected to MCU

DD

Table 2-13. User Assignable Input

CON13 Signal Name Remarks

Pin 1 FB_IN_R

Pin 2 FB_IN_G

Pin 3 FB_IN_B

Pin 4 FB_IN_PW

Pin 5 DCDC_EN

Pin 6 DCDC_ER Connected to MCU PTC5/RXD2

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 17

Connected to MCU PTD0/ADP8 through

operational amplifier U6D

Connected to MCU PTD1/ADP9 through

operational amplifier U6A

Connected to MCU PTD2/ADP10 through

operational amplifier U6B

Connected to MCU PTD3/ADP11 through

operational amplifier U6C

Connected to MCU PTC3/TXD2 and connector

CON3 pin 8

Page 18

Hardware Description

Table 2-13. User Assignable Input (Continued)

CON13 Signal Name Remarks

Pin 7 DCDC_CTL1 Connected to MCU PTF4/TPM2CH0

Pin 8 DCDC_CTL2 Connected to MCU PTF5/TPM2CH1

Pin 9 DCDC_CTL3 Connected to MCU PTE3/TPM1CH1

Pin 10 GND —

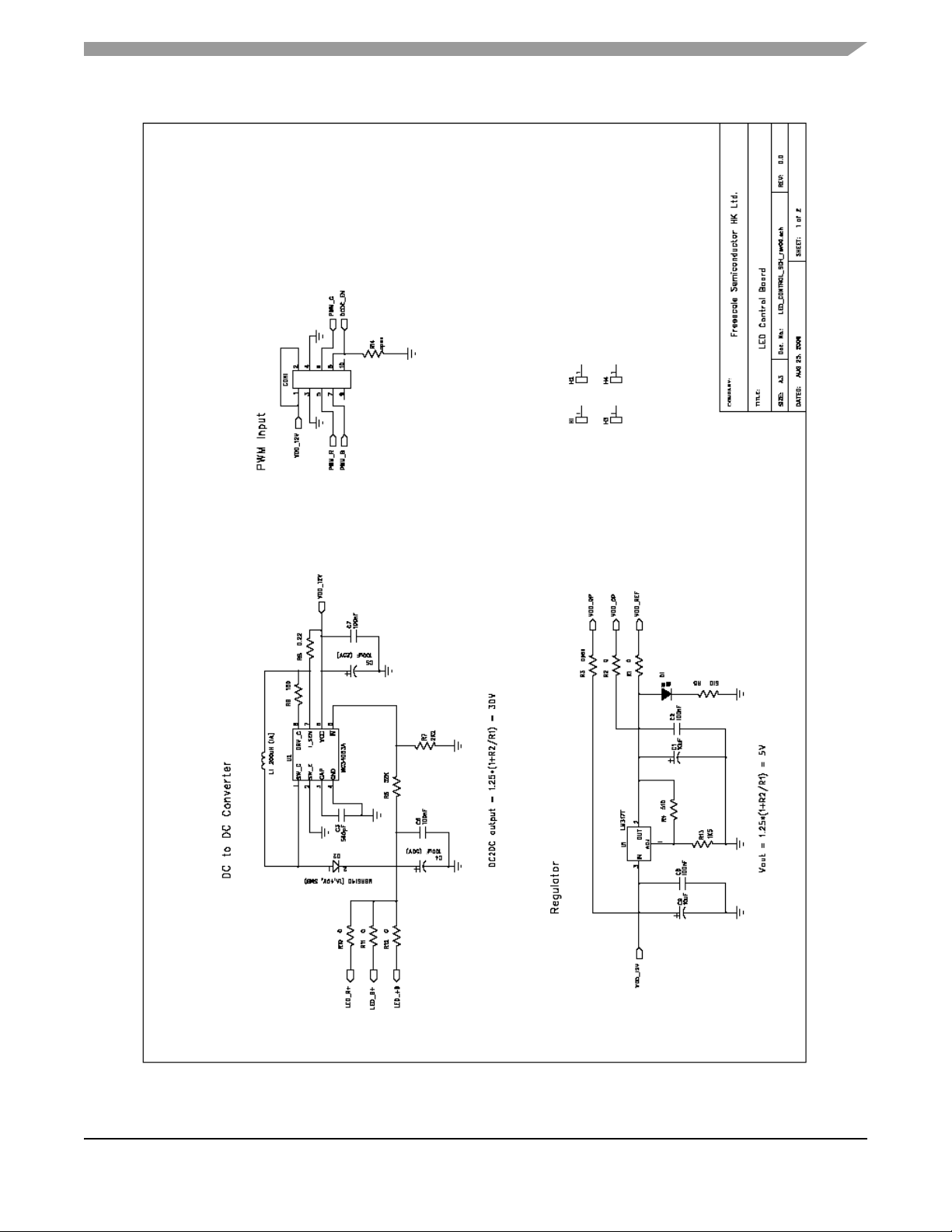

2.10 LED Driving Board

In general, LEDs have a nonlinear I-V behavior and current limitation is required to prevent the power

dissipation to exceed a maximum limit. Therefore, the ideal source for LED driving is a constant current

source. A linear type LED driver is used in this reference design and the block diagram is shown in

Figure 2-4. The major advantage of linear driver is fast turn ON and OFF response times to support high

frequency PWM dimming method and wide range control on dimming level. An integrated DC-to-DC

boost converter (MC34063) generates the high voltage required for LED driving in series and is shared

with RGB channels, but the drawback is the power loss on R channel is higher than G or B channels.

Individual DC-to-DC block should be used for each channel in power sensitive applications.

LED Lighting Control using the MC9S08AW60, Rev. 1

18 Freescale Semiconductor

Page 19

LED Driver Design Procedures

Vout = 30V

DC-to-DC

Boost

Converter

(MC34063)

V

REF

8 LEDs

Rs

Driver R

Driver G

Driver B

8 LEDs

8 LEDs

V

LED

x 8

V

DROP

V

RS

I

LED

= 50mA

Vin = 12V

R-Channel

PWM

G-Channel

PWM

B-Channel

PWM

Vout = 30V

DC-to-DC

Boost

Converter

(MC34063)

V

REF

8 LEDs

Rs

Driver R

Driver G

Driver B

8 LEDs

8 LEDs

V

LED

x 8

V

DROP

V

RS

I

LED

= 50mA

Vin = 12V

R-Channel

PWM

G-Channel

PWM

B-Channel

PWM

Eight pieces of 3-in-1 RGB LED chips connected in series are used to form the multi-color light source.

The LED chips are arranged in 2 x 4 format and each RGB LED string is driven by a separated constant

Figure 2-3. DC-to-DC Boost Converter and Linear LED Driver

current source. The average current through each RGB LED is controlled by an individual PWM signal

generated from MCU. The final output color is determined by the mix of light emitted by RGB LEDs that

are almost in linear relationship with PWM pulse width. An optical diffuser film should be placed on top of

the display window for color mixing and brightness uniformity enhancement.

2.11 LED Driver Design Procedures

This section presents guidelines for selecting external components for DC-to-DC boost converter and

linear drivers.

2.11.1 RGB LED Chip

The system is designed to drive eight pieces of RGB LED chips connected in a series. Assume the LED

current for each color is 50mA and forward voltage is 2.3V for red LED and 3.3V for green and blue LEDs.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 19

Page 20

Hardware Description

2.11.2 Current Sense Resistor

The value of the current sense resistor RS is determined by two factors: power dissipation on RS and the

reference level V

but the detection of a feedback signal in operational amplifier is more difficult.

for operational amplifier non-inverting input. Smaller RS reduces power dissipation,

REF

The voltage V

across the current sense resistor RS is directly proportional to the current I

RS

LED. In closed-loop condition, V

to the reference voltage V

Setting V

Power dissipation on R

to 1V and RS equals 20Ω, the LED current I

REF

S

divided by the current sense resistor RS.

REF

is around 50mW, I2R = (50mA)2 × 20Ω, which is reasonable compared to total

is equal to the reference level V

RS

LED

, so the LED current I

REF

is equal to 50mA.

LED

is equal

LED

through

LED power.

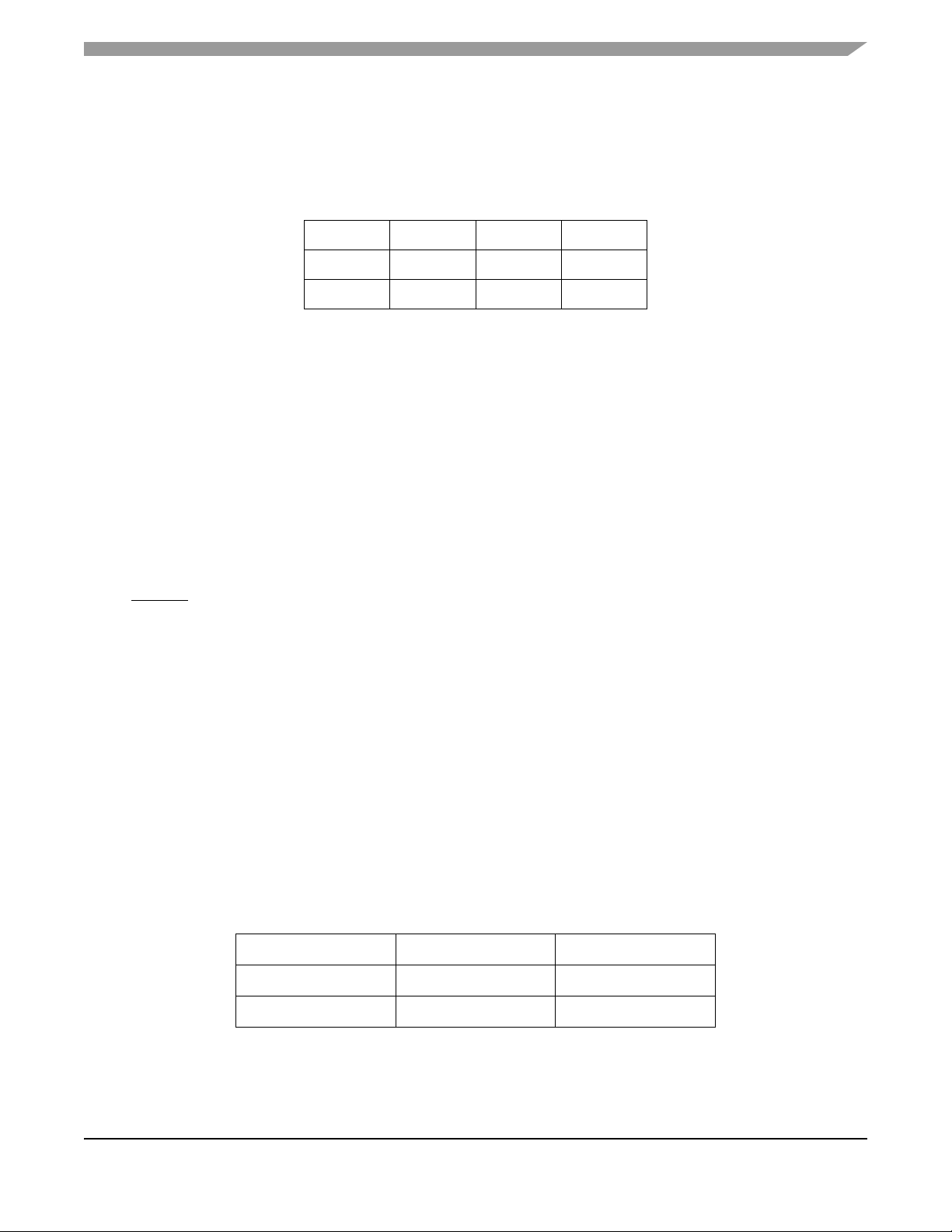

2.11.3 Boost Converter

The switching regulator MC34063 from On Semiconductor is a monolithic circuit containing the primary

functions required for DC-to-DC converters. It can be incorporated in boost converter application with

minimum number of external components.

Boost Converter Calculations:

Output voltage V

Output current Iout > 50 mA x 3

Set V

= 12 V, V

in

Refer to equations in Figure 2-4 to calculate the values for inductor and other external components.

> (V

OUT

= 30 V, and I

out

x 8) + VRS + V

LED

= 175 mA

out

(set maximum linear drop to 2 V)

DROP

LED Lighting Control using the MC9S08AW60, Rev. 1

20 Freescale Semiconductor

Page 21

LED Driver Design Procedures

Figure 2-4. Equations for Boost Converter

= Saturation voltage of the output switch.

V

sat

= Forward voltage drop of the output rectifier.

V

F

V

- Nominal input voltage.

in

V

- Desired output voltage.

out

- Desired output current.

I

out

f

- Minimum desired output switching frequency.

min

V

ripple(pp)

- Desired peak-to-peak output ripple voltage.

For further information, refer to On Semiconductor’s datasheet.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 21

Page 22

Hardware Description

LED Lighting Control using the MC9S08AW60, Rev. 1

22 Freescale Semiconductor

Page 23

Chapter 3

Display control menu through

SCI

Yes

No

Initialization

PC Control Mode

Operation?

Enable I/O for PCB button

detection

Yes

No

Valid command from PC?

Process commands and adjust PWM

output

Yes

No

Any PCB button

pressed?

Adjust PWM output according to button

event

*Standalone demo box

without PC control

Display control menu through

SCI

YesYes

No

InitializationInitialization

PC Control Mode

Operation?

Enable I/O for PCB button

detection

YesYes

No

Valid command from PC? Valid command from PC?

Process commands and adjust PWM

output

YesYes

No

Any PCB button

pressed?

Any PCB button

pressed?

Adjust PWM output according to button

event

*Standalone demo box

without PC control

Firmware Description

3.1 Introduction

The MCU firmware in this LED lighting control design is responsible for:

• Controlling timer channels for the RGB LED color PWM output

• Communicating with the host PC for receiving command and data input/output

• Operating as a standalone LED box through on board buttons

Figure 3-1 and Figure 3-2 shows the firmware flow. The LED box can operate in PC control operation

mode or standalone operation mode.

Freescale Semiconductor 23

Figure 3-1. Firmware Flow: Main Program

LED Lighting Control using the MC9S08AW60, Rev. 1

Page 24

Firmware Description

Prompt for green channel PWM input and calculate the

two remaining channels’ PWM values according to

existing color temperature

Adjust PWM width in next PWM cycle

PWM value input to one channel

Yes

Get the other two channel

values from user input

Auto White balance?

No

Prompt for green channel PWM input and calculate the

two remaining channels’ PWM values according to

existing color temperature

Adjust PWM width in next PWM cycle

Adjust PWM width in next PWM cycle

PWM value input to one channelPWM value input to one channel

Yes

Get the other two channel

values from user input

Get the other two channel

values from user input

Auto White balance?Auto White balance?

No

Figure 3-2. Firmware Flow: PWM Adjustment

3.2 PC Control Mode

Every time the MCU is powered up, the firmware detects the status of SW1. The LED lighting control box

is operated in PC control mode if SW1 is not being pressed.

In this mode, you control the LED output through the host PC. The MCU uses the serial communication

interface (SCI) module to communicate to the COM port of the host PC.

After entering this mode, the MCU sends out a number of string characters to the PC COM port. These

strings are the contents of the user interface menu displayed in the PC screen. This user interface menu

guides you on how to control the LED box by different function keys. The MCU also sends out existing

PWM control parameters to the host for display. For examples, parameters such as existing RGB PWM

output values, white balance mode, and PWM frequency are displayed. Figure 3-3 shows the PC screen

for the user control menu.

LED Lighting Control using the MC9S08AW60, Rev. 1

24 Freescale Semiconductor

Page 25

PC Control Mode

Figure 3-3. User Interface Menu

When the MCU receives a control command or PWM input data from the PC, the firmware interprets the

information to take the corresponding actions. It may update the output PWM values in next PWM duty

or delivery of the corresponding LED control parameter back to the PC. Three timer channels in the

timer 1 module are configured to edge-aligned PWM operation mode. This generates the PWM signals

for the RGB color channels.

By the proper control of the RGB channel PWM, the LED box can provide different lighting effects.

If you select the white balance mode to AUTO, the LED output gives a white color output. The firmware

retains control of the RGB PWM ratio based on the preset white color. You can adjust the output

brightness by pressing the + or − key in the host PC keyboard. Alternatively, you can input a green

channel PWM value and the firmware calculates the blue and red PWM values to give the resultant

intensity.

A demonstration display feature is available. After enabling this feature, the firmware adjusts RGB PWM

so the light box switches among different preset colors, delivery fade in and fade out lighting effects, etc.

You can also set the PWM to different frequencies. At a lower PWM frequency, such as 30 Hz, the flicking

phenomenon is more noticeable. This phenomenon can be minimized or removed by setting the PWM

frequency to a higher value.

There are examples at the end of this section showing how to control the LED box through the host PC.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 25

Page 26

Firmware Description

3.3 Standalone Mode

When the LED box is powered up with SW1 being pressed, it enters standalone mode. When compared

to the PC control mode, this standalone mode can act as a quick and simple demo that does not require

a host PC. The control of the LED light box can be done through the onboard buttons. However, the PC

control mode can have more control on the PWM output.

The functions of the buttons are as follows:

• SW6 (IRQ): Demonstration Display Enable/Disable

If SW6 is pressed, the LED box enters the demonstration display state where certain preset colors

display sequentially with some other lighting effects. The demonstration mode can be exit by

pressing SW6 again.

• SW1: Preset Colors Toggle

Whenever SW1 has been pressed and released, the LED box toggles to another preset color. The

LED1 lights up while LED2 turns off.

• SW2: Auto White Balance Control

If SW2 has been pressed, the LED box turns to auto white balance state and give a white color.

The small on board LED2 lights up while LED1 turns off, indicating an auto white balance state.

There are two preset white color with different color temperatures available for selection. To swap

between different preset color temperatures, press the SW2 button once more. The auto white

balance state can be turn off by pressing SW1.

• SW3: Decrease Brightness

The output brightness increases if SW3 has been pressed.

• SW4: Increase Brightness

The output brightness decreases if SW4 has been pressed.

• SW1+SW2: PWM Frequency Selection

The Output PWM Frequency can be changed with following steps:

1. Press and hold SW1

2. Press SW2

3. Release SW2

4. Release SW1

After performing the above action, the output PWM frequency can be changed. There are three

preset settings available, 30 Hz, 120 Hz, and 600 Hz. For examples, after changing from 30 Hz to

120 Hz using above steps, it can set the PWM to 600 Hz by applying the above steps again.

NOTE

The output brightness is changed after changing the frequency. As the

PWM output values remain the same, a change in PWM frequency modifies

the PWM duty as well.

The PWM frequency selection steps above are invalid if the LED box is

running at demonstration display state. In addition, the PWM frequency is

changed to the default value of 120 Hz after the demonstration display state

has been exited by pressing SW6.

LED Lighting Control using the MC9S08AW60, Rev. 1

26 Freescale Semiconductor

Page 27

Firmware Files

3.4 Firmware Files

Below is a list of the C files in the firmware

Main.c

• Programs entry point and determination of operation mode, i.e. PC control mode or standalone

operation mode

• System initialization

• Common functions used in different firmware modules

Menu.c

• Takes care of high level user interface communication with the PC host.

• Interprets the received PC commands or data and initiate the corresponding action. The user

interface menu contents can be modified or edited in this file.

SCI.c

• Takes care of low level SCI hardware for communication between the PC. Functions that

accessing the SCI registers are included in this file.

• String management for input and output functions used in the Menu.c

ISR.c

• Interrupt services routines for different hardware modules

• Timer 1 is used for the PWM channels for the three RGB output color

• Timer 2 is used for generating a periodical interrupt that used in the demonstration display feature

• IRQ interrupts for enabling or disabling of demonstration display in the standalone operation mode.

• KBI interrupts for on board buttons detection

• Functions for generating certain display effects are included in this file

Keyinput.c

• For operation of standalone mode without the host PC

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 27

Page 28

Firmware Description

LED Lighting Control using the MC9S08AW60, Rev. 1

28 Freescale Semiconductor

Page 29

Chapter 4 Demo Setup

4.1 Introduction

This section shows how to connect the DEMO9S08AW60LED board to your PC, run the demo program,

and how to program the board with the source code. The source code can be download from the

Freescale website.

4.2 Hardware and Software Setup

The DEMO9S08AW60LED is shipped with the demo program stored in on-chip flash memory. Use

Figure 2-2 as a guide to do the setup.

4.2.1 Hardware Setup

1. Check the jumper setting and make sure jumper JP1 on DEMO9S08AW60LED board is set to the

5V (2-3) position.

2. Connect the 2x5 pin ribbon flat cable at LED light box to connector CON3 on

DEMO9S08AW60LED board.

3. Connect a serial cable to the PC or notebook and then to the DEMO9S08AW60LED board.

4. Power up the demo through the DC jack connector CON1 on DEMO9S08AW60LED board. The

supply voltage is 12V DC and LED D5 should be on.

5. Press SW5 to reset the MCU. The LED light box demo enters PC control mode. (Make sure SW1

is not pressed during reset.)

4.2.2 PC Software Setup

1. Open up a terminal window from within Windows XP by clicking on Start → All Programs →

Accessories → Communications → HyperTerminal

2. Give your terminal connection a name (such as AW60_Control) and click the OK button.

3. In the Connect using pulldown, select the COM port you connected your serial cable to, and click

the OK button.

4. In the Port Settings window, click the OK button after entering the following settings:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

5. Make sure Echo typed characters locally is NOT selected under the ASCII Setup pop-up menu,

see Figure 4-1.

6. After configuring HyperTerminal, the LED Control Menu screen appears as shown in Figure 4-2.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 29

Page 30

Demo Setup

Figure 4-1. Echo Typed Characters Setting

LED Lighting Control using the MC9S08AW60, Rev. 1

30 Freescale Semiconductor

Page 31

Demo Examples

Figure 4-2. LED Control Menu

NOTE

Make sure the HyperTerminal window is selected all the time by moving the

mouse pointer inside the window and clicking the left mouse button (the top

color bar of the terminal window is then blue instead of grey). Otherwise, no

function key command is sent to the LED lightbox.

4.3 Demo Examples

Several examples are given here on showing how to use the LED box under the PC control.

4.3.1 Demo 1 - Demonstration Display

1. Press the reset button SW5 on DEMO9S08AW60LED board. The LED control menu screen

appears (Figure 4-2).

2. Press letter D in the PC keyboard to enter demonstration display operation.

3. In this display state, the LED light box switches among different colors automatically and delivers

other lighting effects.

NOTE

Press any other key to exit demonstration display. Press D to enter

demonstration display again.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 31

Page 32

Demo Setup

4.3.2 Demo 2 - Preset Colors Display

1. Press the tab key in the PC keyboard.

2. The output is switched to another preset color after the tab key has been pressed each time.

NOTE

You can adjust the output color any time through the control menu.

4.3.3 Demo 3 - Auto White Balance Control

1. Press F until PWM frequency is set to 120 Hz.

2. Press W to toggle to AUTO white balance control.

3. Type 2000 at line of input green. The green PWM output value should then show 2000.

4. The red and blue PWM values are adjusted automatically to keep the output at the existing color

temperature.

Note:

Pressing T can change the output to another preset color temperature.

Pressing the

intensity. Use the

+

or − key can gradually increase or decrease the output

+

or − keys from the main keyboard area instead of those

near the NUM lock key pad.

Max PWM input range is decreased if setting to a higher PWM frequency.

4.3.4 Demo 4 - PWM Output Frequency Control

1. Press W to toggle the output to AUTO mode.

2. Pressing F can switch the PWM output among different preset frequencies.

3. The flicking phenomenon is more significant at the lower frequency such as at 30 Hz. The flicking

can be removed by setting PWM to higher frequencies.

NOTE

The output brightness is changed after changing the frequency. As the

PWM output values remain the same, a change in PWM frequency modifies

the PWM duty as well.

As the frequency increases, the max allowable PWM input range

decreases because the PWM value for 100% on-duty becomes smaller.

4.3.5 Demo 5 - Full Manual Control

1. Press F until PWM frequency change to 120Hz

2. Press W to toggle the output to MANUAL mode.

3. Press R to switch to manual red channel input.

4. Type 2000 at the Input red line.

5. Press G to switch to manual green channel input.

6. Type 0000 at the Input green line.

7. Press B to switch to manual blue channel input.

8. Type 2000 at the input blue line.

9. The output color is purple. You can repeat the steps with different PWM values for different output

colors and intensities.

LED Lighting Control using the MC9S08AW60, Rev. 1

32 Freescale Semiconductor

Page 33

Program the MCU Flash

NOTE

Max PWM input range is decreased when setting to a higher PWM

frequency. With the same PWM values, increasing frequency (i.e. shorter

period) increases brightness because the PWM on-duty increases.

When typing HEX PWM input values, use only capital letters for the input

of A–F.

4.4 Program the MCU Flash

The DEMO9S08AW60LED board allows you to program the MCU flash and debug applications via the

BDM connection.

1. Download the source code file from Freescale web site, save it to your PC, and extract the files to

a working directory on your machine.

2. Open CodeWarrior HC(S)08 v5.1 and open the LED_box.mcp project file.

3. Open main.c in the sources folder by clicking the plus sign next to the sources folder and then

double clicking on main.c. This is the application code.

4. Connect the BDM cable from your development tools to the DEMO9S08AW60LED board (CON8).

5. Connect a serial cable to the PC and then to the DEMO9S08AW60LED board.

6. Power up the demo through the DC jack connector CON1 on DEMO9S08AW60LED board.

7. Open up a terminal window from within Windows XP by clicking on Start → All Programs →

Accessories → Communications → HyperTerminal

8. Give your terminal connection a name (such as AW60_Control) and click the OK button.

9. In the Connect using pulldown, select the COM port you connected your serial cable to, and click

the OK button.

10. In the Port Settings window, click the OK button after entering the following settings:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None.

11. In the Freescale CodeWarrior window, click on Debug under Project in the menu bar or press F5.

The True-Time Simulator and Real-Time Debugger interface window appears.

12. When the ICD Connection Assistant appears, click the Connect button.

13. When the Erase and Program Flash window appears, click the yes button.

14. The CPROGHCS08 Programmer window should close after the MCU flash is programmed. To run

the source code, click on Start/Continue under Run in the menu bar or click the green arrow.

4.5 Troubleshooting

1. VDD LED does not turn on

Make sure jumper JP1 is set to the 5V (2-3) position.

2. The light box does not display any color

Make sure the 2x5 pin ribbon flat cable at LED light box is installed properly to the

DEMO9S08AW60LED board.

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 33

Page 34

Demo Setup

Repeat the PC software setup procedures again.

3. Control menu contents are not correct

Make sure the COM port selection is correct.

Check the Port Settings again and make sure the configurations are correct.

4. User input does not be detected correctly

Make sure the HyperTerminal Window is being selected all the time.

When typing HEX PWM input values, use ONLY CAPITAL letter for the input of A–F.

Use the + or − keys from the main keyboard area instead of those near the NUM lock key pad.

LED Lighting Control using the MC9S08AW60, Rev. 1

34 Freescale Semiconductor

Page 35

Appendix A Schematics

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 35

Page 36

LED Lighting Control using the MC9S08AW60, Rev. 1

36 Freescale Semiconductor

Page 37

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 37

Page 38

LED Lighting Control using the MC9S08AW60, Rev. 1

38 Freescale Semiconductor

Page 39

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 39

Page 40

LED Lighting Control using the MC9S08AW60, Rev. 1

40 Freescale Semiconductor

Page 41

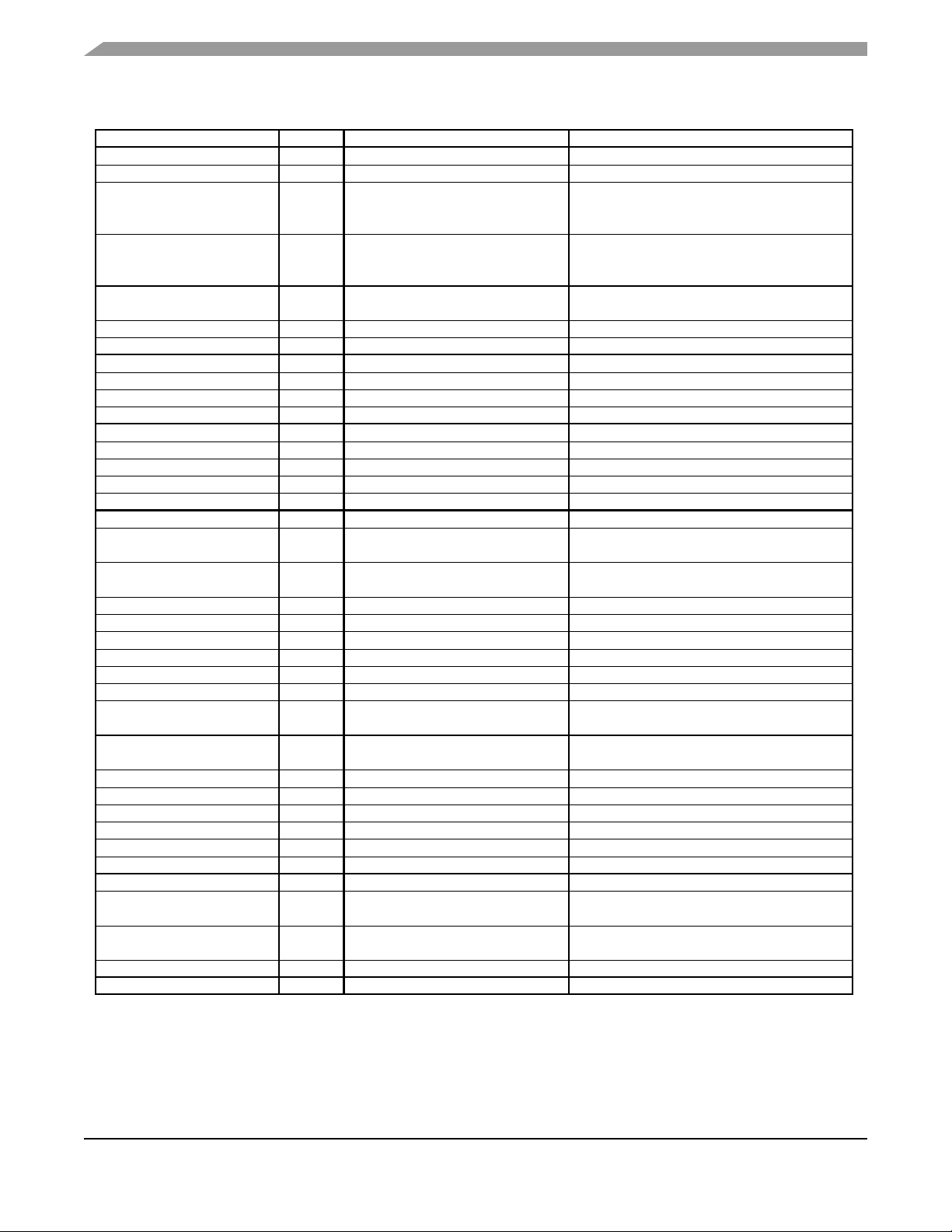

Appendix B Bill of Materials

LED Lighting Control using the MC9S08AW60, Rev. 1

Freescale Semiconductor 41

Page 42

Table 4-1 BOM for AW60 Control Board

V

SMD RESISTOR

6

1

SMD RESISTOR

25

open

R42 R46 R48 R52 R54 R58 R60 R64 R66

R70 R72 R74-76

SMD RESISTOR

22

10K

R22 R55-56 R61-62 R25-26 R67-68 R13

R73 R31

SMD RESISTOR

13

0

R21 R29 R10 R53

SMD RESISTOR

1

SMD RESISTOR

8

10

SMD CER CAPACITOR

1

SMD CER CAPACITOR

2

1

16

3

1

1

1

1

2.54mm HEADER

1

polarity) CON3

2.5mm CONNECTOR BASE

1

1x2 Pin (2.5mm Pitch) NO_POP CON1

1

1

3

1

1

1

2mm CONNECTOR BASE

1

1x10 Pin (2mm Pitch with polarity) CON13

CONNECTOR

1

CONNECTOR P2

1

6

4

1

5

1

2

DRIVER/RECEIVER

1

MAX3232CUE TSSOP16 U4

REGULATOR

1

LM317 (D2PAK) U1

1

1

Part Description

SMD RESISTOR

SMD CER CAPACITOR

SMD CER CAPACITOR

SMD TAN CAP

SMD TAN CAP

SMD TAN CAP

ECAP

ECAP

2.54mm HEADER

JUMPER

2mm CONNECTOR BASE

2mm CONNECTOR BASE

2mm CONNECTOR BASE

2mm CONNECTOR BASE

2mm CONNECTOR BASE

DB9 HORIZ FEMALE PCB

DC JACK CONNECTOR

SMD TACT SW

Plastic POST

Crystal

LED

FUSE

QUAD OP AMP

SERIAL PORT

ADJUSTABLE VOLTAGE

Quantity

alue Designators

510 R1 R3-7

820 R2

1M R19

68K R69 R27 R63 R51 R57 R39 R45 R33

100nF C4 C6-8 C12-14 C16 C22 C27

NO_POP C3

22pF C9-10

1nF C33

1uF C18-20 C15 C23-25 C17 C28-32 C34-36

10uF C11 C21 C26

47uF C2

100uF (25V) C5

22uF (50V) C1

2x3 Pin (2.54mm Pitch) CON8

2x5 Pin (2.54mm Pitch with

3 PIN (2.5mm Pitch) Short 2-3 JP1

1x2 Pin (2mm Pitch with polarity) CON12

1x4 Pin (2mm Pitch with polarity) CON4-6

1x6 Pin (2mm Pitch with polarity) CON7

1x6 Pin (2mm Pitch with polarity) CON10

1x8 Pin (2mm Pitch with polarity) CON11

DB9 HORIZ FEMALE PCB

12V DC JACK CON2

5mm x 5mm SW1-6

3-4mm Height H1-4

16MHz (3.5mm Height) X1

SMD GREEN D1-5

SMD FUSE 1A F1

LM324 (SO14 Package) U5-6

R8 R9 R11 R14-16 R28 R30 R34 R36 R40

R32 R12 R37-38 R17-18 R43-44 R49-50

R35 R23 R59 R24 R47 R65 R20 R41 R71

5 VOLT REGULATOR

MCU

42 Freescale Semiconductor

LM7805 (D2PAK) U2

MC9S08AW60CFGE (LQFP44) U3

LED Lighting Control using the MC9S08AW60, Rev. 1

Page 43

Table 4-2 BOM for LED Driving Board

y

V

5

1

1

1

1

2

1

1

1

SMD RESISTOR

9

10K

R31-32

3

6

3

4

SMD CER CAPACITOR

4

100nF C2 C7-8 C11

R

1

R

3

CAPACITOR

1

100nF (50V) C6

3

P

2

1

1

N-CHANNEL MOSFET

3

ZVN2106G (8A, 60V, SOT223) Q1 Q4 Q7

N-CHANNEL MOSFET

3

MMBF0201NL (300mA, 20V, SOT-23) Q6 Q3 Q9

P-CHANNEL MOSFET

3

NTR0202PL (400mA, 20V, SOT-23) Q2 Q5 Q8

1

P

1

REGULATOR

1

LM317M (D2PAK) U1

1

8

Plastic Box

1

100mm x 60mm (Black Color)

Board

4

PLASTIC POST

4

3-4mm Height (Paste on bottom side)

3M Diffuser Film

2

100mm x 60mm (Ref number: 3635-70)

plastic box cover

FLAT RIBBON CABLE

1

2x5 pin flat ribbon cable, 20cm length

(2.54mm pitch, one end soldering type) CON1

Part Description

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD RESISTOR

SMD CER CAPACITO

SMD CER CAPACITO

High Volt SMD CER

SMD TAN CAP

ECA

INDUCTOR Coil

LED

SMD SCHOTTKY DIODE

QUAD OP AM

ADJUSTABLE VOLTAGE

DC-TO-DC CONVERTER

OSRAM LED

Quantit

alue Designators

0 R1-2 R10-12

52K R6

2K2 R7

0.22 R8

180 R9

open R3 R14

510 R5

1K5 R13

510 R4

3K9 R19 R26 R33

1K R27-28 R21 R20 R34-35

20 R30 R16 R23

39 R36-R39

560pF C3

10nF C12-14

10uF C1 C9-10

100uF (50V) C4-5

SMD 200uH (1A) L1

SMD GREEN D1

MBRS140 (1A,40V, SMB) D2

LM324M (SO14 Package) U3

MC34063A SO8 U2

RGB LED (6-Pin SMD) U4-11

R15 R17-18 R22 R24-25 R29

with a 70mmx 40mm display

window and mount on the PCB

SCREW

Freescale Semiconductor 43

LED Lighting Control using the MC9S08AW60, Rev. 1

Use Plastic Box 's screw H1-4

Paste 2 sheets under the

Page 44

LED Lighting Control using the MC9S08AW60, Rev. 1

44 Freescale Semiconductor

Page 45

Page 46

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

RoHS-compliant and/or Pb-free versions of Freescale products have the functionality

and electrical characteristics of their non-RoHS-compliant and/or non-Pb-free

counterparts. For further information, see http://www.freescale.com or contact your

Freescale sales representative.

For information on Freescale’s Environmental Products program, go to

http://www.freescale.com/epp.

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

DRM093

Rev. 1, 07/2007

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2007. All rights reserved.

Loading...

Loading...