Page 1

Freescale Semiconductor

User’s Guide

Document Number: MPC8313ERDBUG

Rev. 4, 02/2009

PowerQUICC™ MPC8313E Reference

Design Board (RDB)

The MPC8313E reference design board (RDB) is a system

featuring the PowerQUICC™ II Pro processor, which

includes a built-in security accelerator. This low-cost,

high-performance system solution consists of a printed

circuit board (PCB) assembly plus a s oft ware board support

package (BSP) distributed in a CD image. This BSP enables

the fastest possible time-to-market for development or

integration of applications including printer engines,

broadband gateways, no-new-wires home adapters/access

points, and home automation boxes.

This document describes the hardware features of the board

including specifications, block diagram, connectors,

interfaces, and hardware straps. It also describes the board

settings and physical connections needed to boot the

MPC8313E RDB. Finally, it considers the software shipped

with the platform.

When you finish reading this document, you should:

• Be familiar with the board layout

• Understand the default board configuration and your

board configuration options

• Know how to get started and boot the board

Contents

1. MPC8313E RDB Hardware . . . . . . . . . . . . . . . . . . . . 2

2. Board-Level Functions . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Connectors, Jumpers, Switches, and LEDs . . . . . . . 19

4. Micro-Jumper/Resistor Options for eTSEC1 . . . . . . 27

5. MPC8313E RDB Board Configuration . . . . . . . . . . 38

6. Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7. MPC8313E RDB Software . . . . . . . . . . . . . . . . . . . . 46

8. Frequently Asked Questions (FAQs) . . . . . . . . . . . . 47

9. Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

WARNING

This is a class A product. In a domestic

environment this product may cause radio

interference, in which case the user may

be required to take adequate measures.

• Know about the software and further documentation

that supports the board

© Freescale Semiconductor, Inc., 2008. All rights reserved.

Page 2

MPC8313E RDB Hardware

Use this manual in conjunction with the following documents:

• MPC8313E PowerQUICC™ II Pro Integrated Communications Processor Family Reference

Manual (MPC8313ERM)

• MPC8313E PowerQUICC II Pro Processor Hardw are Specifications (MPC8313EEC)

• “Hardware and Layout Design Considerations for DDR Memory Interfaces” (AN2582)

NOTE

The normal function of the product may be disturbed by strong

electromagnetic interference. If so, simply reset the product to resume

normal operation by following the instructions in the manual. If normal

function does not resume, use the product in another location.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy. If it is

not installed and used in accordance with the instruction manual, it may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in

which case the user will be require d to co rr ect the interference at his or her

own expense.

1 MPC8313E RDB Hardware

This section covers the features, block diagram, specifications, and mechanical data of the MPC8313E

RDB.

1.1 Features

The board features are as follows:

• CPU: Freescale MPC8313E running at 333/166 MHz; CPU/coherent system bus (CSB)

• Memory subsystem:

— 128 Mbyte unbuffered DDR2 SDRAM discrete devices

— 8 Mbyte flash single-chip memory

— 32 Mbyte NAND flash memory

— 256 Kbit M24256 serial EEPROM

— SD connector to interface with the SD memory card in SPI mode

• Interfaces:

— 10/100/1000 BaseT Ethernet ports:

™

– eTSEC1, RGMII: five 10/100/1000 BaseT RJ-45 interfaces using Vitesse

switch, or selectable one 10/100/1000 BaseT RJ-45 interface using Marvell

in REVC board

VSC7385 L2

™

88E1111 PHY

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

2 Freescale Semiconductor

Page 3

MPC8313E RDB Hardware

– eTSEC2, selectable RGMII or SGMII: one 10/100/1000 BaseT RJ-45 interface using

Marvell 88E1111 PHY

— USB 2.0 port: high-speed host/device

— USB interface: selectable on-chip PHY or external ULPI PHY interface by SMSC USB3300

USB PHY

— PCI: 32-bit PCI interface running at up to 66 MHz

– One 32-bit 3.3 V PCI slot connected to PCI bus

– One 32-bit 3.3 V miniPCI slot connected to PCI bus

— Dual UAR T ports:

– DUART interface: supports two UARTs up to 115200 bps for console display

• Board connectors:

— LCD connectors by GPIO

— ATX power supply connector

— JTAG/COP for debugging

• IEEE Std. 1588™ signals for test and measurement

• Real-time clock and thermal sensor on I2C bus

• Programmable LEDs for debug use

• 6-layer PCB routing (4-layer signals, 2-layer power and ground)

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 3

Page 4

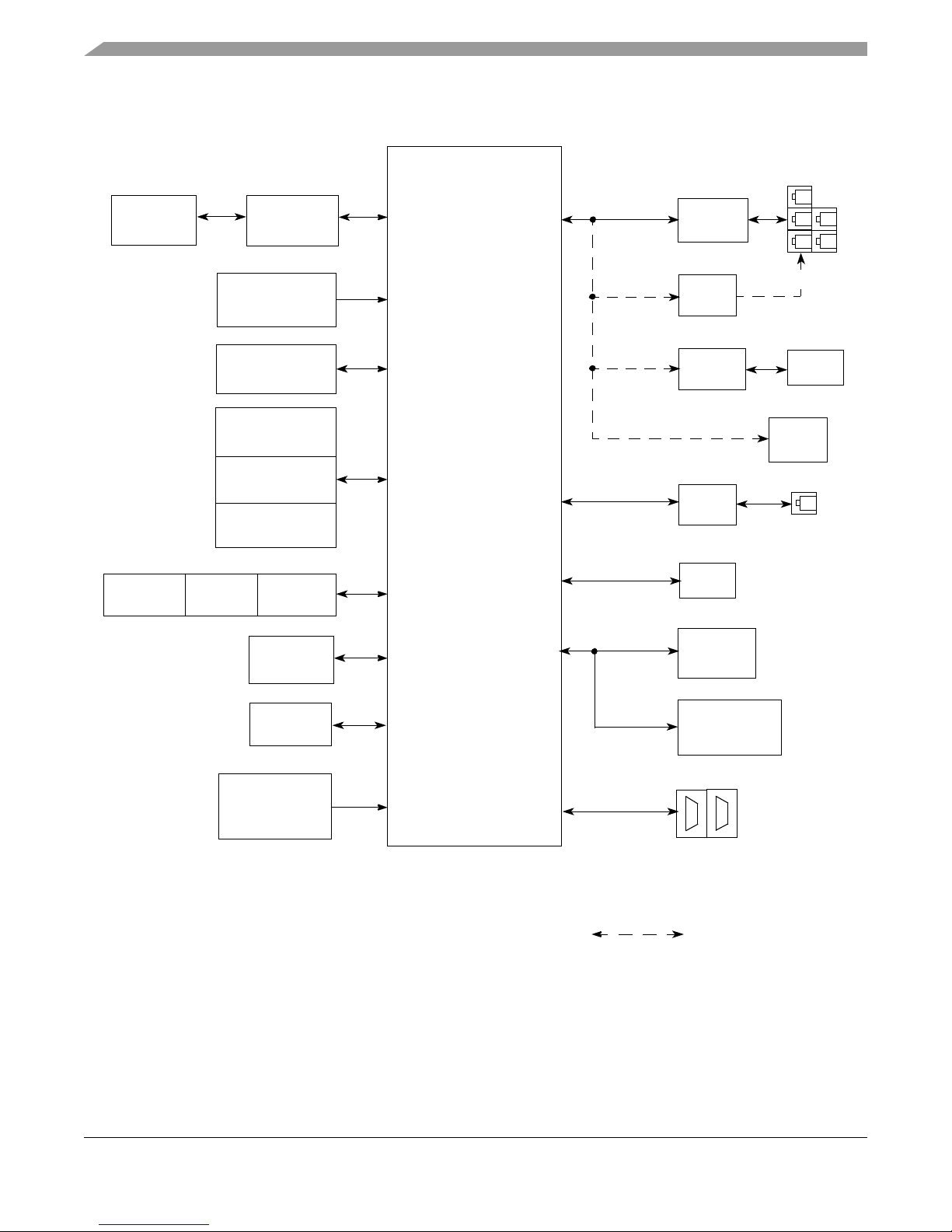

MPC8313E RDB Hardware

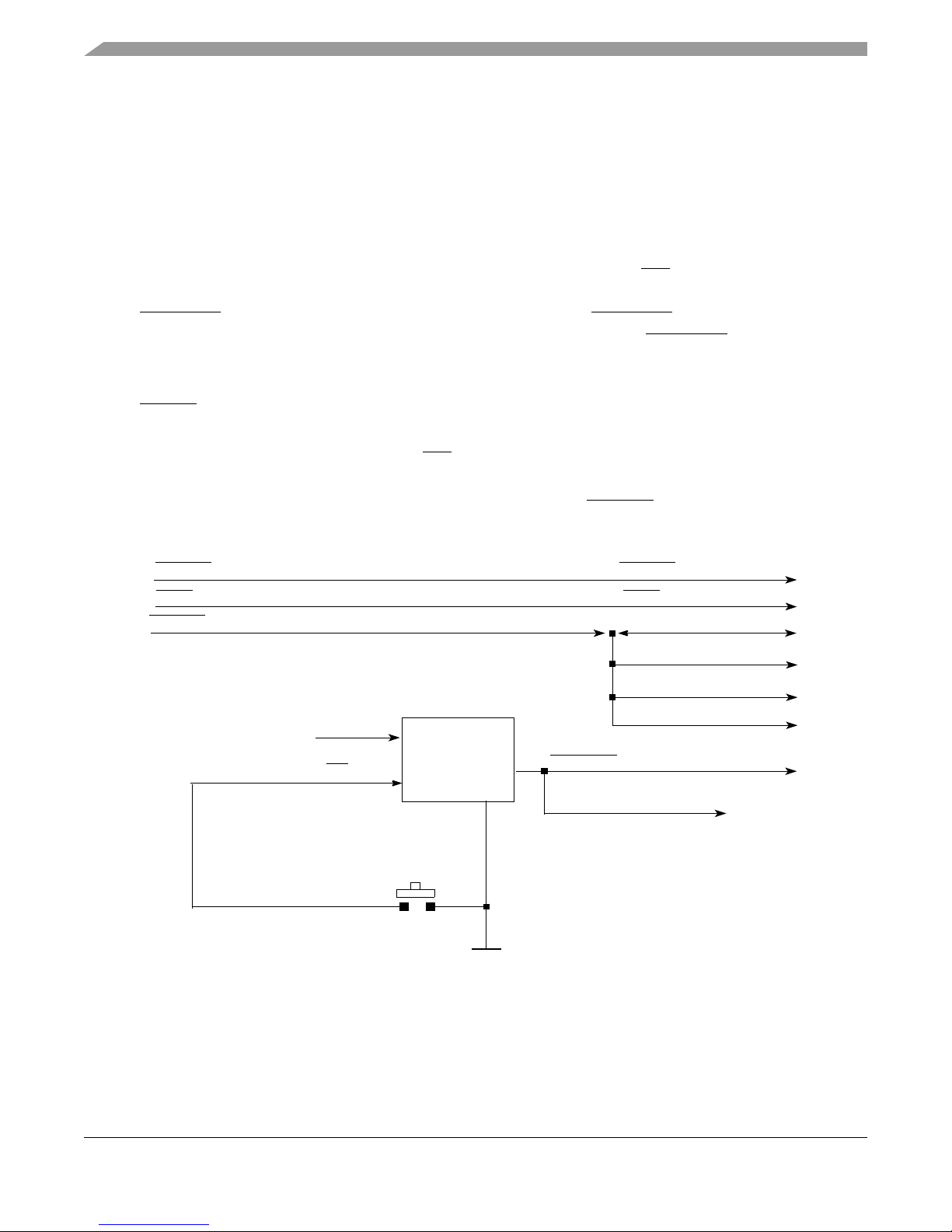

MPC8313E

eTSEC1

Vitesse

L2 Switch

RGMII/

ULPI/

SMSC

USB PHY

IEEE1588

eTSEC2

Marvell

PHY

RGMII/SGMII

Clock, pulse, etc.

On-Chip

USB

Dual

UART

USB

mini-AB

USB

mini-AB

SPI

SD card

33/66 MHz

3.3 V 32-Bit

PCI Slot

3.3 V 32-Bit

miniPCI Slot

PCI Bus

System Clock

and USB Clock

128 Mbyte

DDR2

8 Mbyte NOR

Flash Memory

32-Bit DDR2

Bus

32 Mbyte NAND

Flash Memory

LEDs/status

Buffers

16-Bit Local

Bus

DAC for

IEEE1588

Clock (optional)

I2C Bus

Real-Time

Clock

Thermal

Sensor

GPIO

LCD

Connectors

JTAG/COP

Header

JTAG/COP

Power Su pp ly

with Low Power

Mode

Te st

Points

: selected by resistor options

---NOTE---

EEPROM

Marvell

PHY

RGMII/SGMII

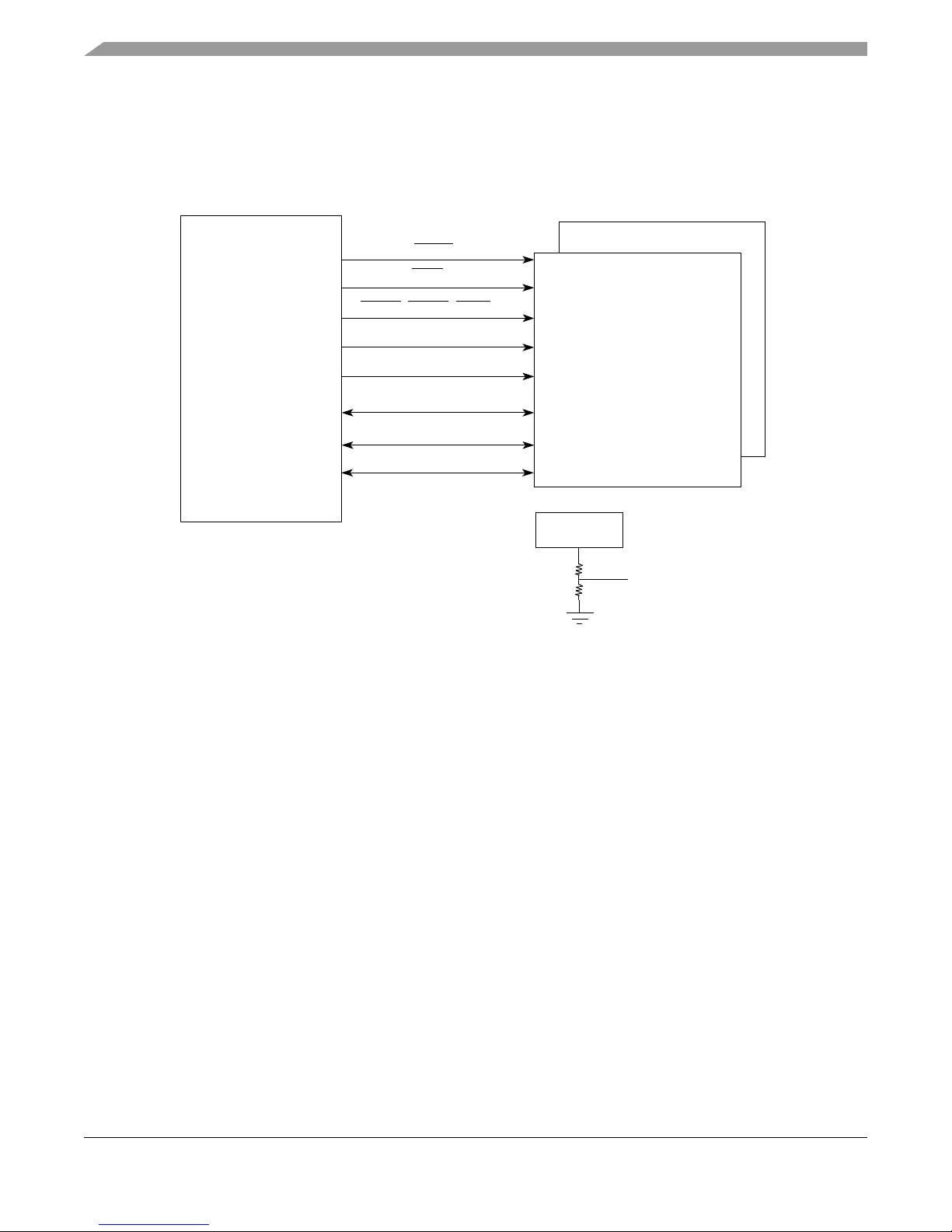

Figure 1 shows the MPC8313E RDB block diagram.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

4 Freescale Semiconductor

Figure 1. MPC8313E RDB Block Diagram

Page 5

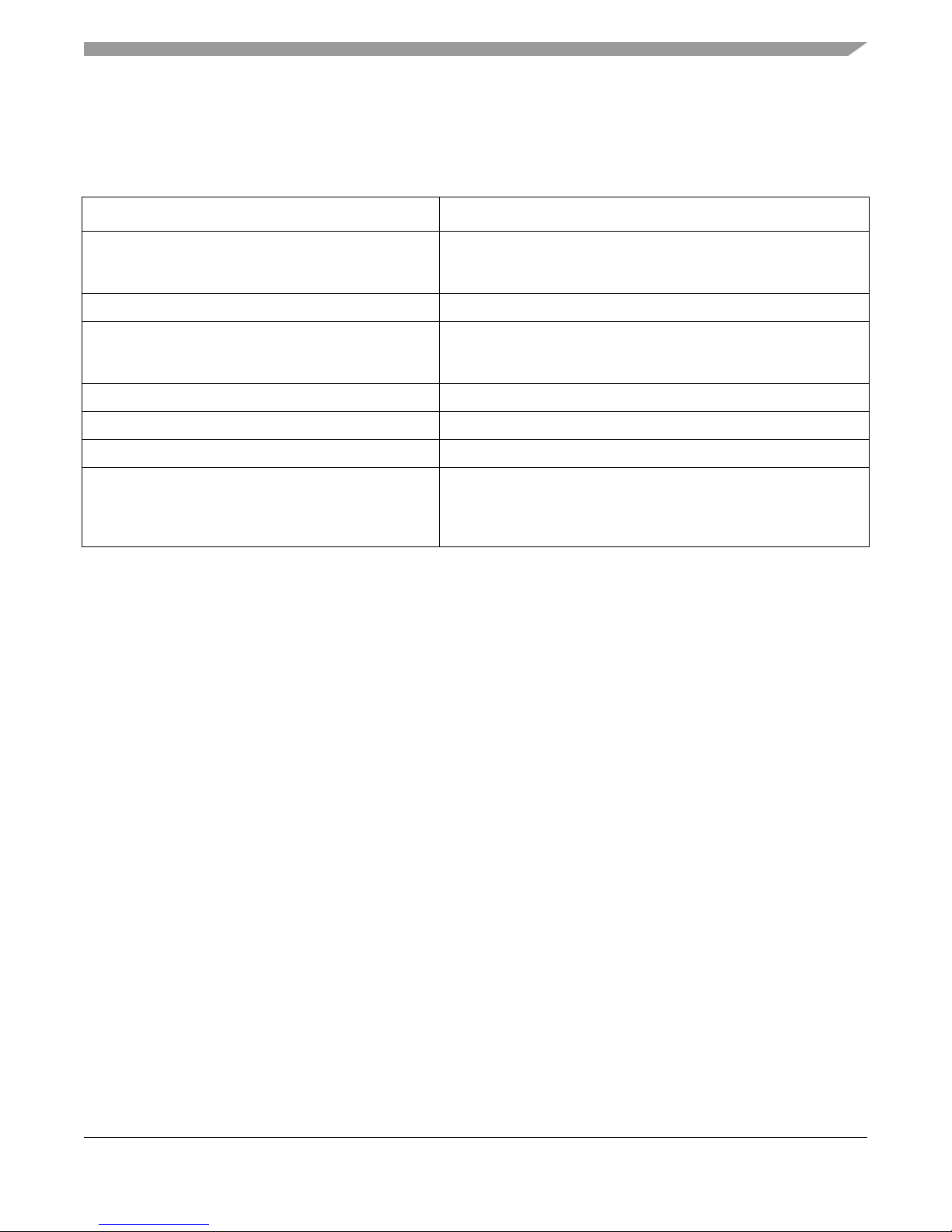

1.2 Specifications

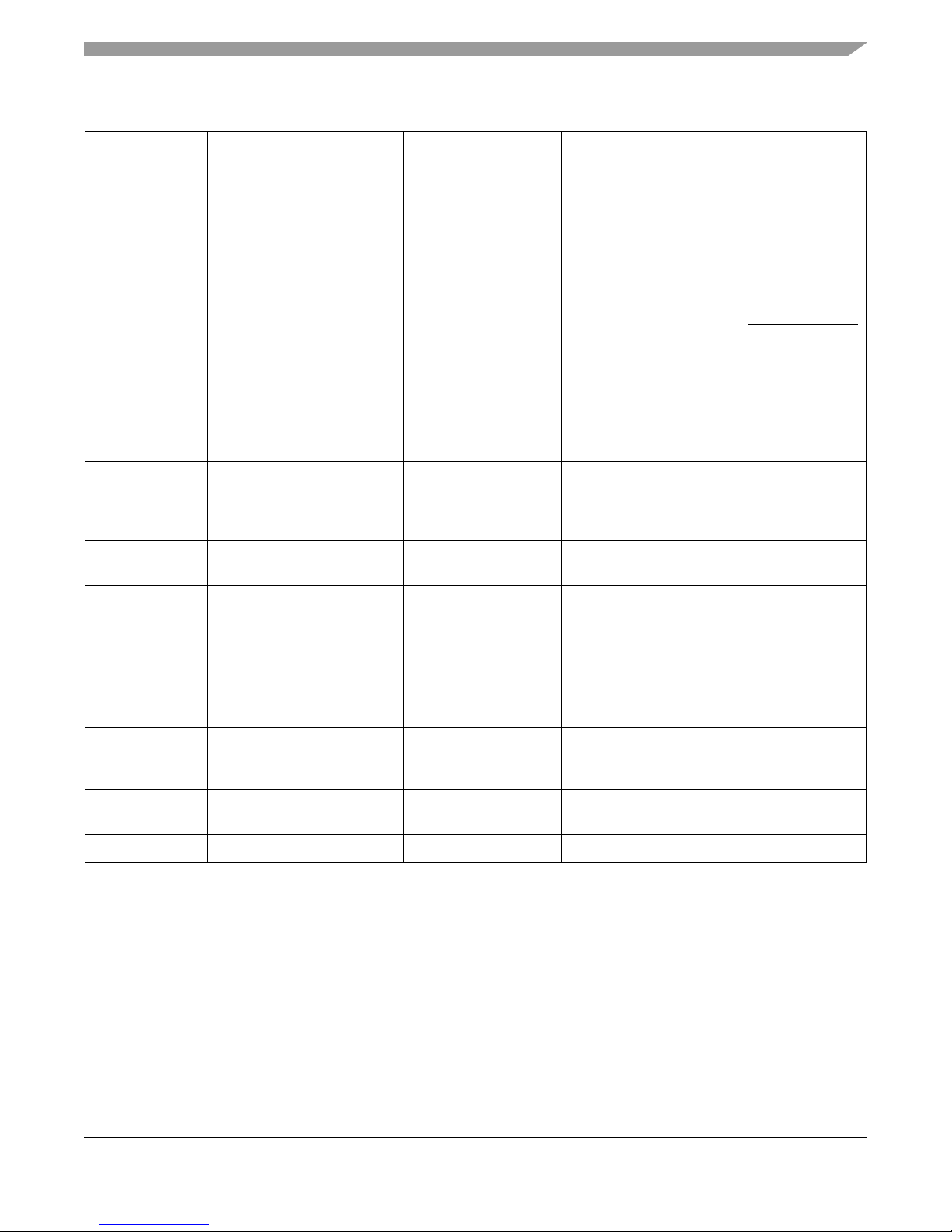

Table 1 lists the specifications of the MPC8313E RDB.

Table 1. MPC8313E-RDB Specifications

Characteristics Specifications

Power requirements (without add-on card): Typical Maximum

12 V DC 0A 0 A

5.0 V DC1 mA1.5 A

Communication processor MPC8313E running at 266 MHz

MPC8313E RDB Hardware

Addressing: Total address range

Flash memory (local bus)

DDR2 SDRAM

Operating temperature 0

Storage temperature –25

Relative humidity 5% to 90% (noncondensing)

PCB dimensions:

Length

Width

Thickness

4 Gbyte (32 address lines)

8 Mbyte with one chip-select

128 Mbyte DDR2 SDRAM

o

C to 70o C (room temperature)

o

C to 85oC

6693 mil (REVA and REVB) or 7692 mil (REVC)

6693 mil

62 mil

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 5

Page 6

MPC8313E RDB Hardware

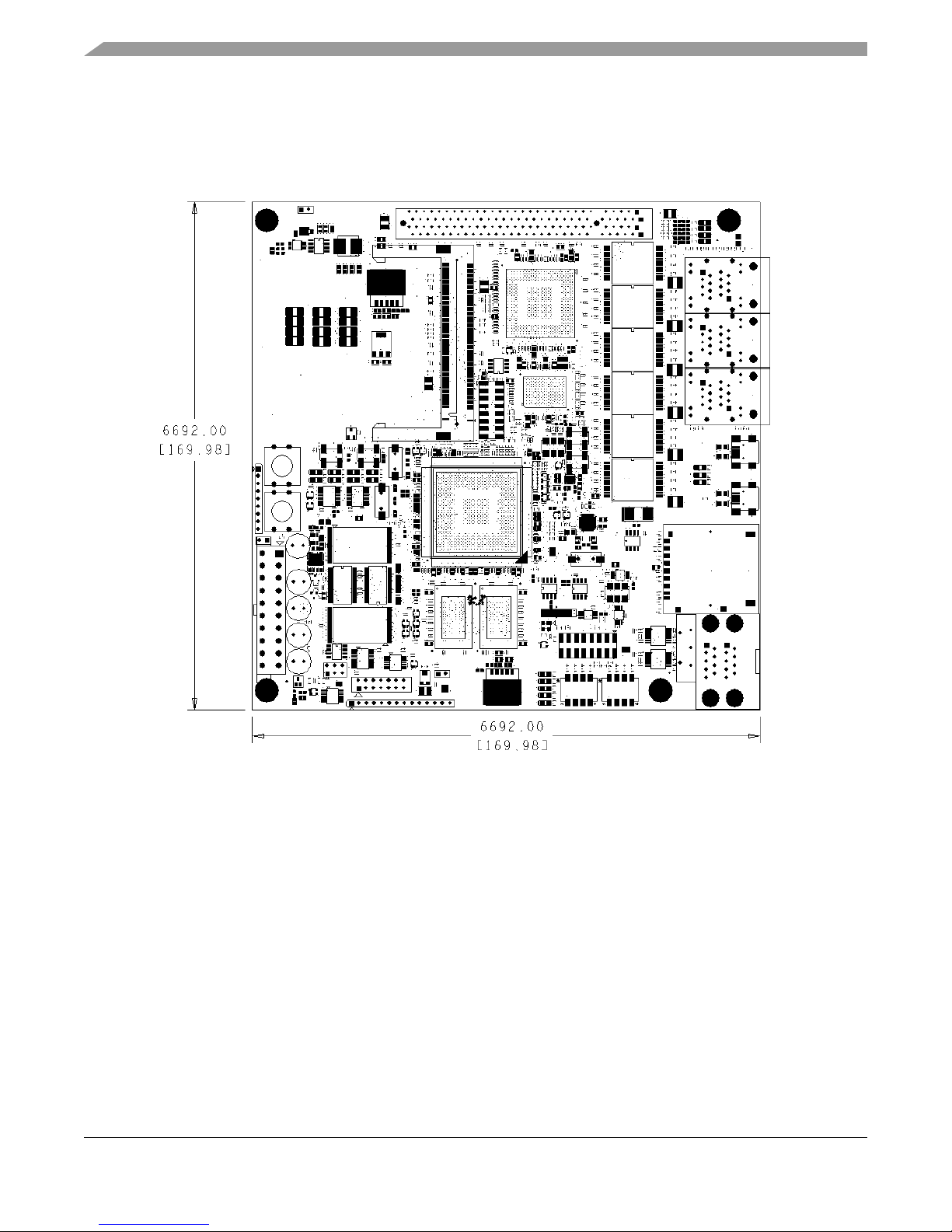

1.3 Mechanical Data

Figure 2 shows the MPC8313E RDB REVAx and REVB dimensions (in mil and [mm]). The board

measures 170 mm × 170 mm (6693 mil × 6693 mil) for integration in a mini-ITX chassis.

Figure 2. Dimensions of the MPC8313E RDB (REVAx and REVB)

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

6 Freescale Semiconductor

Page 7

Board-Level Functions

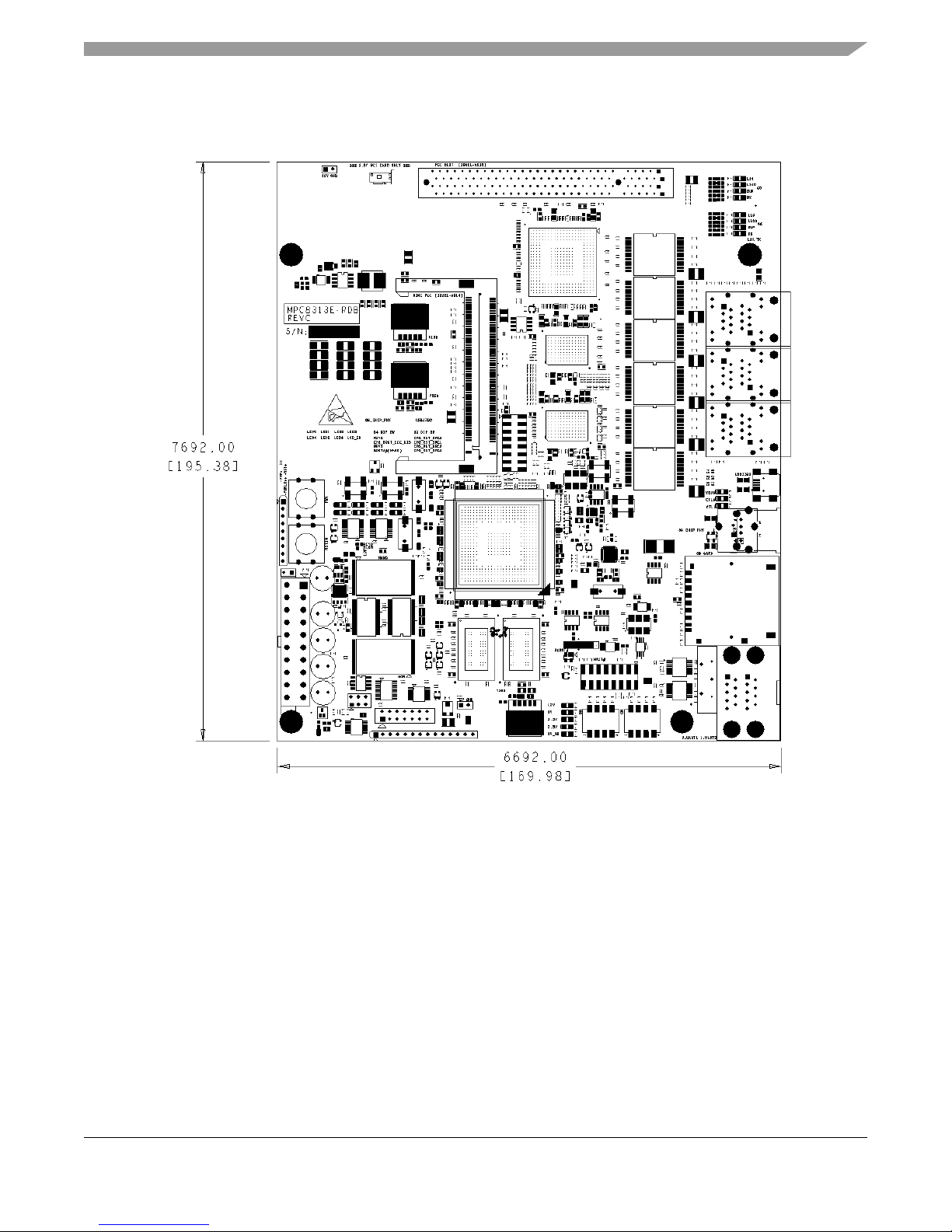

Figure 3 shows the MPC8313E RDB Rev C dimensions (in mil and [mm]). The board measures

195 mm × 170 mm (7692 mil × 6693 mil).

Figure 3. Dimensions of the MPC8313E RDB (REVC)

2 Board-Level Functions

The board-level functions are reset, external interrupts, clock distribution, DDR SDRAM controller, local

bus controller, I2C interfaces, SD memory card interface, USB interface, eTSEC1 10/100/1000 BaseT

interface, dual RS-232 ports, PCI bus, and COP/JTAG.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 7

Page 8

Board-Level Functions

MAX811

3.3 V

MR

Push Button

GND

HRESET from COP

SRESET

from COP

TRST

from COP

SRESET

to MPC8313E

TRST

to MPC8313E

PORESET

to MPC8313E

NOR FLASH

L2 Switch

MPC8313E

Reset config logic

Marvell PHY

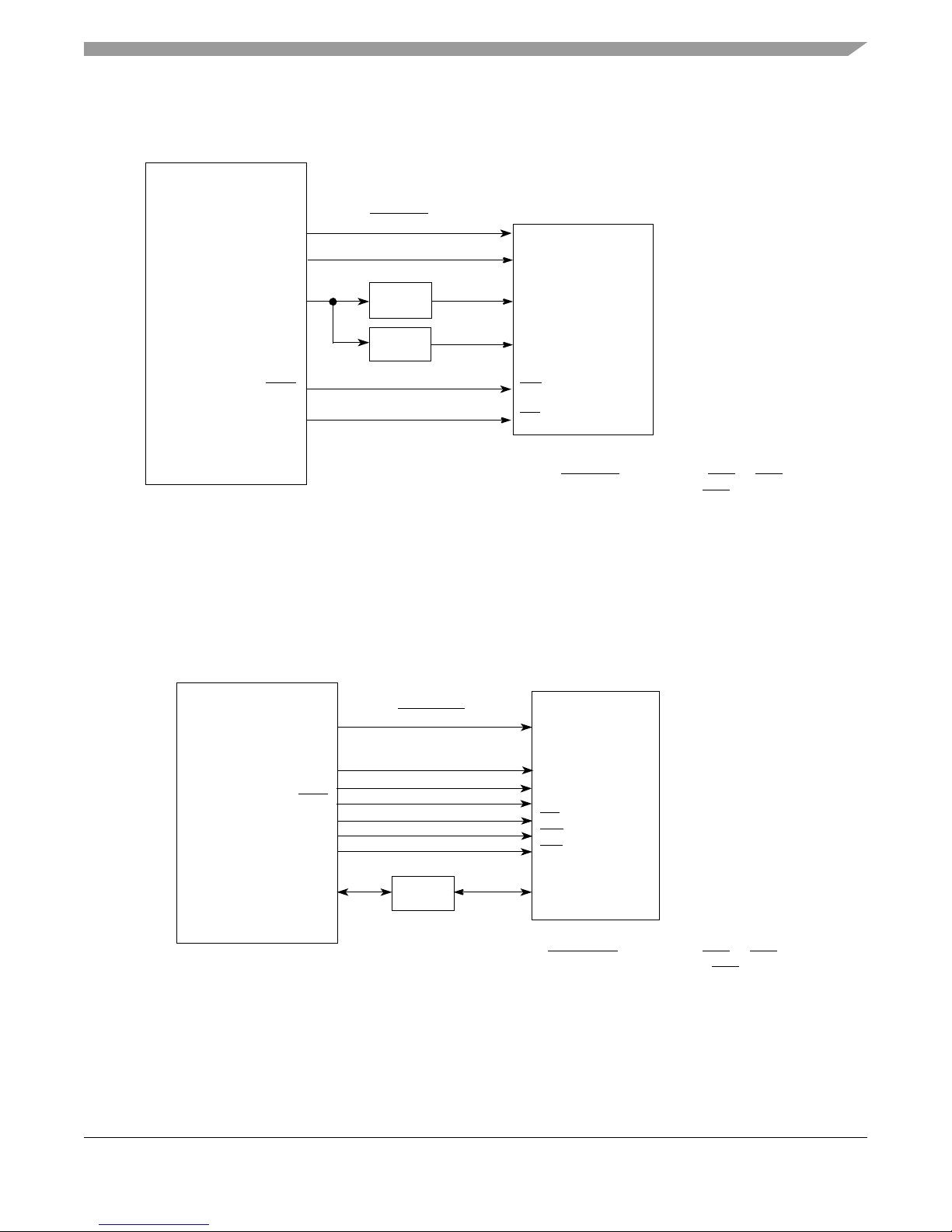

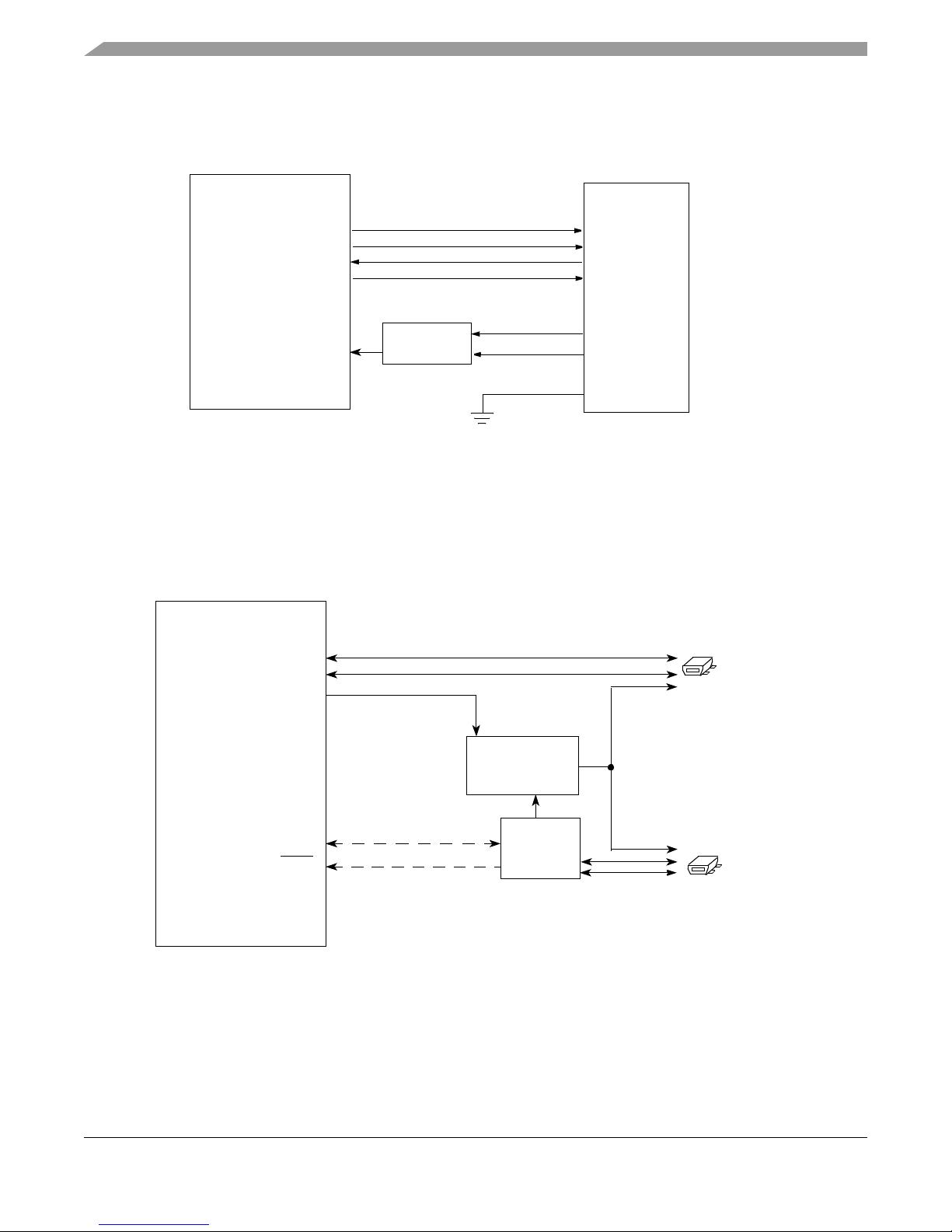

2.1 Reset and Reset Configurations

The MPC8313E RDB reset module generates a single reset to the MPC8313E and other peripherals on the

board. The reset unit provides power-on reset, hard reset, and soft reset signals in compliance with the

MPC8313E hardware specification.

Figure 4 shows the reset circuitry. Note the following:

• Hard reset is generated either by the COP/JTAG port or the MPC8313E.

• Power-on reset is generated by the Maxim MAX811 device. When MR is deasserted and 3.3 V is

ready , the MAX81 1 internal timeout guarantees a minimum reset active time of 150 ms before

PORESET is deasserted. This circuitry guarantees a 150 ms PORESET pulse width after 3.3 V

reaches the right voltage level, which meets the specification of the PORESET input of

MPC8313E.

• COP/JTAG port reset provides convenient hard-reset capability for a COP/JT AG controller. The

RESET line is available at the COP/JT AG port connector. The COP/JTAG controller can directly

generate the hard-reset signal by asserting this line low.

• Push button reset interfaces using the MR signal with debounce capability to produce a manual

master reset of the RDB.

• Soft reset is generated by the COP/JT AG port. Assertion of SRESET causes the MPC8313E to

abort all current internal and external transactions and set most registers to their default values.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

8 Freescale Semiconductor

Figure 4. Reset Circuitry of the MPC8313E

Page 9

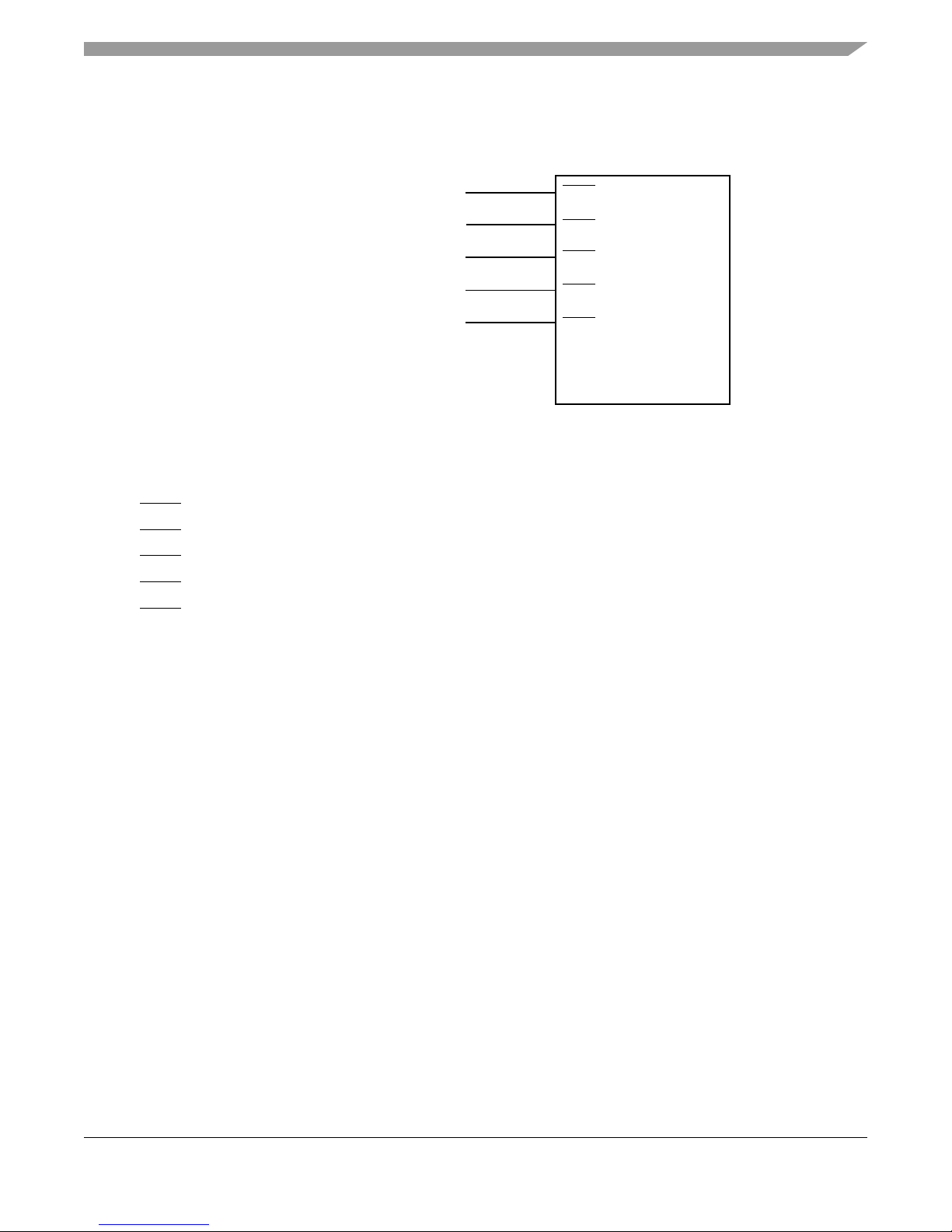

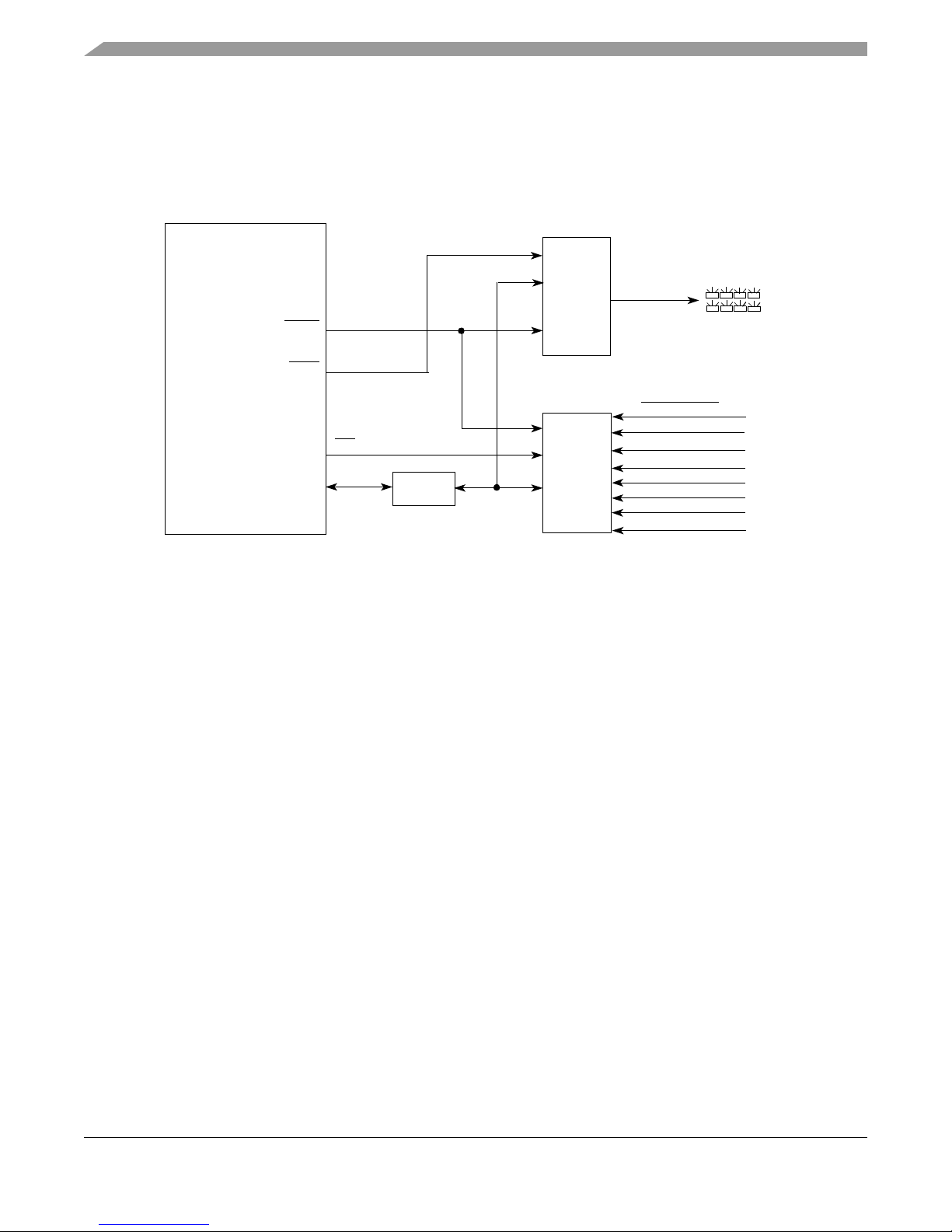

2.2 External Interrupts

IRQ0

IRQ2

IRQ3

IRQ4

MPC8313E

SD Card

IRQ1

PCI slot (AD15) INTA

Mini PCI (AD14) INTA and PCI slot (AD15) INTB

L2 Switch and ULPI external USB PHY (optional)

Marvell PHY, RTC (optional) and LM75 (optional)

Figure 5 shows the external interrupts to the MPC8313E.

Figure 5. MPC8313E Interrupts

The following are descriptions of the interrupt signals shown in Figure 5:

• All external interrupt signals are pulled up by 4.7 KΩ resistors.

•IRQ0 is connected to SD Card

Board-Level Functions

•IRQ1 is connected to PCI slot INTA.

•IRQ2 is connected to and shared by the PCI slot’s INTB and the mini PCI slot INTA.

•IRQ3 is connected to the L2 switch as well as to an external USB PHY (by an optional resistor).

•IRQ4 is connected to the Marvell GBE PHY as well as to RTC and LM75 (by an optional resistors).

Freescale Semiconductor 9

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 10

Board-Level Functions

MPC8313E

LCLKx (NC)

local bus

PLL

DDR

PLL

PCI

DIV

66.666 MHz

OSC

CLKIN

33/66 MHz

33/66 MHz

Mini PCI Slot

PCI Slot

OCCR

2

PCI_SYNC_OUT

PCI_SYNC_IN

System

PLL

M66EN

33/66 MHz

CFG_CLKIN_DIV

NC

48 MHz

OSC

25 MHz

OSC

USB

CLKIN

L2 Switch

GBE PHY

GTX_CLK125

SD_REF_CLK

50 MHz OSC/

50 MHz VCXO

IEEE1588

TMR CLK

0

1

2

ULPI USB

GND GND

24 MHz

Crystal

PHY

Real-Time

GND GND

32.768 KHz

Crystal

Clock

DDR2 SDRAM

CLK

MCK

MCK#

133 MHz

PLL

125 MHz

LVD S

OSC

125MHz

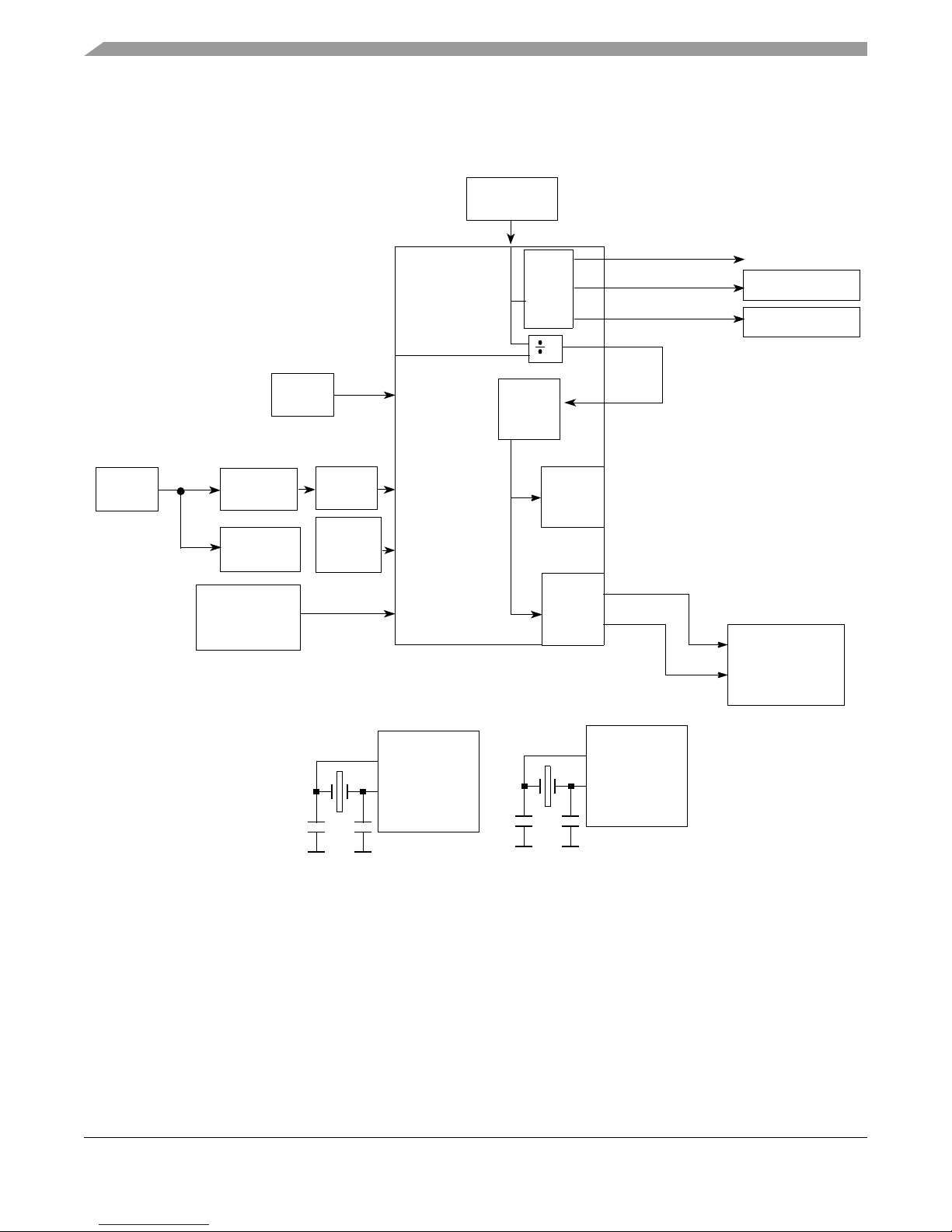

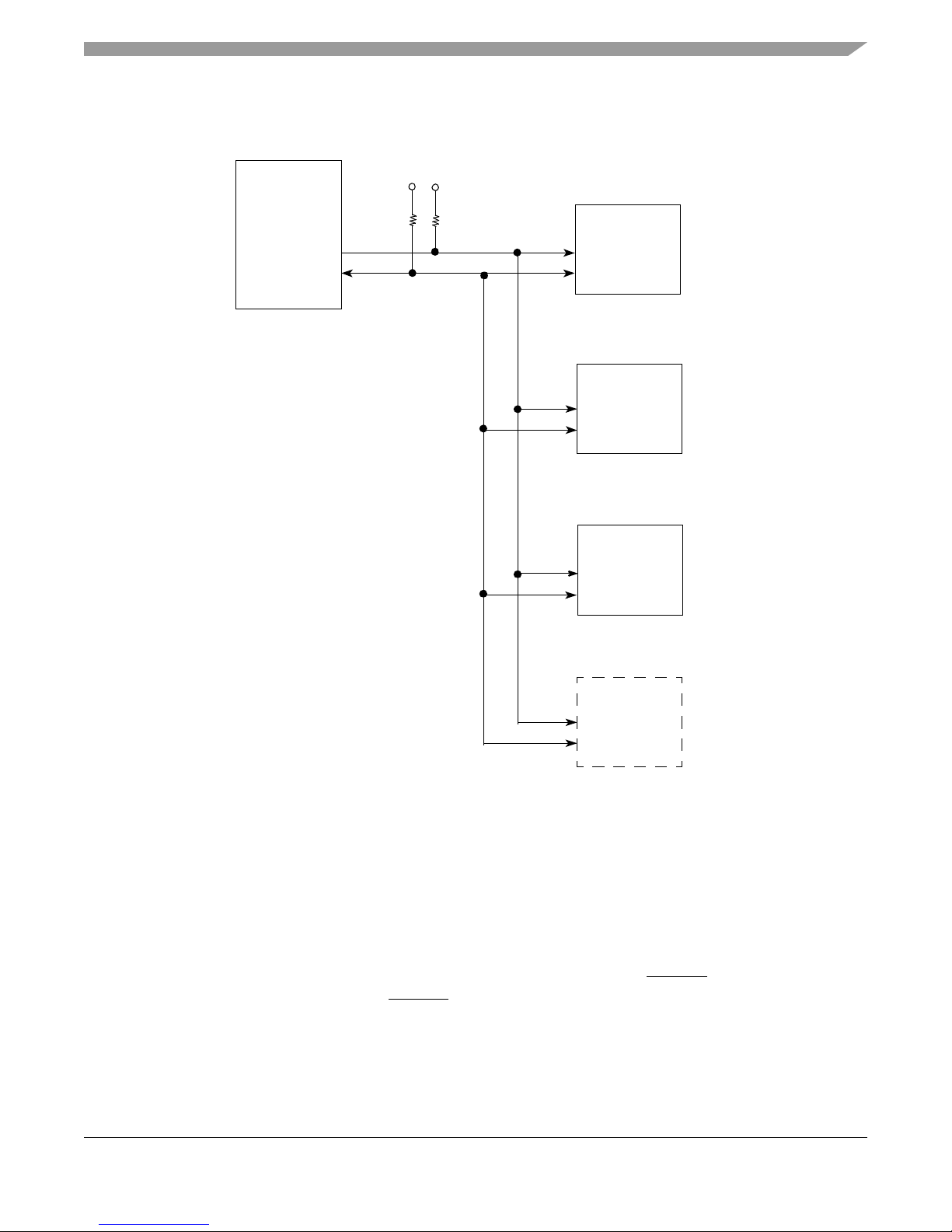

2.3 Clock Distribution

Figure 6 and Table 2 show the clock distribution on the MPC8313E RDB.

Figure 6. MPC8313E-RDB Clock Scheme

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

10 Freescale Semiconductor

Page 11

Board-Level Functions

Table 2. Clock Distribution

Clock Frequency Module Generated by Description

66.666 MHz MPC8313E CLKIN 66.666 MHz oscillator The MPC8313E uses CLKIN to generate the

PCI_SYNC_OUT clock signal, which is fed back

on the board through the PCI_SYNC_IN signal

to the internal system PLL. From the power-on

reset configuration, the CSB clock is generated

by the internal PLL and is fed to the e300 core

PLL for generating the e300 core clock. The

CFG_CLKIN_DIV

whether CLKIN or CLKIN/2 is driven on the

PCI_SYNC_OUT signal. The CFG_CLKIN_DIV

is tied to the M66EN input pin.

133 MHz DDR2 SDRAM MPC8313E The DDR memory controller is configured to use

the 2:1 mode CSB to DDR for the DDR interface

(DDR266). The local bus clock uses 1:1 local to

CSB clock, which is configured by hard reset

configuration or SPMR register.

configuration input selects

33/66 MHz PCI 32-bit slot and MiniPCI

slot

25 MHz L2 Switch and GBE PHY 25 MHz oscillator The 25 MHz oscillator provides the clock for the

125 MHz eTSEC clock GBE PHY with PLL

48 MHz USB clock 48 MHz oscillator 48 MHz is provided for on-chip USB PHY of

50 MHz IEEE1588 Clock (TMR_CLK) 50 MHz oscillator/50

24 MHz ULPI external USB PHY 24 MHz crystal 24 MHz crystal is used by the ULPI external

32.768 KHz Real-time clock 32.768 KHz crystal 32.768 KHz crystal is used by the real-time clock

MPC8313E The PCI module uses the PCI_SYNC_IN as its

clock source. The trace length of the

PCI_SYNC_IN to PCI_SYNC_OUT signal is

matched with all PCI clocks on the RDB.

L2 switch and the GBE PHY

The GTX_CLK125 and SERDES (SGMII) clocks

(REVC), or

125 MHz oscillators

(REVB), or

GBE PHY (REVAx)

MHz VCXO

are provided by external oscillators (or by GBE

PHY in REVAx and REVC boards).

MPC8313E

50 MHz is used by the IEEE 1588 module. It can

be an ordinary oscillator or VCXO controlled by

SPI DAC.

USB PHY

2.4 DDR2 SDRAM Controller

The MPC8313E processor uses DDR2 SDRAM as the system memory. The DDR2 interface uses the

SSTL2 driver/receiver and 1.8 V power. A Vref 1.8 V/2 is needed for all SSTL2 receivers in the DDR2

interface. For details on DDR2 timing design and termination, refer to the Freescale application note

entitled “Hardware and Layout Design Considerations for DDR Memory Interfaces” (AN2582). Signal

integrity test results show this design does not require terminating resistors (series resistor (R

termination resistor (R

)) for the discrete DDR2 devices used. DDR2 supports on-die termination; the

T

DDR2 chips and MPC8313E are connected directly. The interface is 1.8 V provided by an on-board

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 11

) and

S

Page 12

Board-Level Functions

DDR2 Device (512 Mbit, 16-Bit)

MPC8313E

DDR2

Controller

DDR2 Device (512 Mbit, 16-Bit)

MCS0

MCK, MCK, MCKE

MRAS

, MCAS, MWE

MDM[0:3], MDQS[0:3]

A[0:14], BA[0:2]

MDQ[0:31]

ODT

VREF

1.8 V Reg

VREF

voltage regulator. VREF, which is half the interface voltage, or 0.9 V, is provided by a voltage divider of

1.8 V for voltage tracking and low cost. The MPC8313E provides a pair of clock pins, which are connected

and shared by the two DDR2 devices.

Figure 7 shows the DDR2 SDRAM controller connection.

2.5 Local Bus Controller

The MPC8313E local bus controller has a 26-bit LAD[0–15] and LA[16–25] address that consists of

16-bit data multiplex bus and control signals. The local bus speed is up to 133 MHz. T o interface with the

standard memory device, an address latch must provide the address signals. The LALE is used as the

latching signal. To reduce loading of the high speed local bus interface, a data buffer for all low-speed

devices is attached to the memory controller. The followings modules are connected to the local bus:

2.5.1 NOR Flash Memory

Through the general-purpose chip-select machine (GPCM), the MPC8313E RDB provides 8 Mbyte of

flash memory using a chip-select signal. The flash memory is used with the 16-bit port size. Figure 8

Figure 7. DDR2 SDRAM Connection

• 8 Mbyte NOR flash memory

• 32 Mbyte NAND flash memory

• LED/status buffer s

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

12 Freescale Semiconductor

Page 13

Board-Level Functions

MPC8313E

eLBC

Controller

NOR

Flash 16-Bit

NOR_CS

*NOTE: NOR_CS

can be either CS0 or CS1

by DIP switch option, default is CS0

Latch

Buffer

LA[24:16]

A[0:8]

A[9:21]

LBA[15:3]

LAD[15:0]

DQ[0:15]

LBD[15:0]

WE

OE

WE0

GPL2

MPC8313E

eLBC

Controller

NAND

Flash 8-Bit

NAND_CS

*NOTE: NAND_CS

can be either CS0 or CS1

by DIP switch option; the default is CS1

CLE

ALE

WE

RE

R/B

WP

GPL0

GPL1

WE0

GPL2

GPL4

GPL3

LAD[0:7] IO[7:0]

*Buffer

LBD0-7

shows the hardware connections for the flash memory . The starting address for the 8 M byte flash memory

is 0xFE00_0000 to 0xFE7F_FFFF.

2.5.2 NAND Flash Memory

The MPC8313E has native support for NAND Flash memory through its NAND Flash control machine

(FCM). The MPC8313E RDB implements an 8-bit NAND Flash with 32 Mbyte in size. Figure 9 shows

the NAND Flash connection.

Freescale Semiconductor 13

Figure 8. NOR Flash Connection

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Figure 9. NAND Flash Connection

Page 14

Board-Level Functions

MPC8313E

eLBC

Controller

WE0

GPL2

LAD[0:7]

Buffer

LCS3

LCX373

LCX245

8x LEDs

Write Buffer

Read Buffer

SD_INSERT

SD_PROTECT

RSVD0

BOOT0

RSVD1

M66EN

REV0

REV1

LBD[0:7]

OE

2.5.3 LED/Status Buffers

The MPC8313E RDB has an 8-bit read/write buffer . The read buffer returns information on M66EN, board

revision, boot device (NOR or NAND), and SD card status. The write buffer controls eight LEDs on the

board for status or debug indication. Figure 10 shows the hardware connection of the buffers.

2.6 I2C Interfaces

The MPC8313E has two I2C interfaces. On the MPC8313E RDB, I2C1 is used as master mode. It is

connected to the following three devices as shown in Figure 11.

It may also be connected to the DAC AD5301 at addres s 0x0C, whose optional nature is represented in

Figure 11 by the dashed line.

The connection of the I

the reset configuration word of the MPC8313E, as well as to store the configuration registers’ values and

user program if the MPC8313E boot sequencer is enabled. By default, the EEPROM is not used and the

hard reset configuration words are loaded from local bus flash memory. For details about how to program

Figure 10. LED/Status Buffers

• Serial EEPROM M24256 at address 0x50.

• Real-time clock DS1339U at address 0x68.

• Thermal sensor LM75 at address 0x48.

2

C bus is shown in Figure 11. The M24256 serial EEPROM can be used to store

14 Freescale Semiconductor

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 15

Board-Level Functions

I2C1-SCL

I2C EEROM

M24256

MPC8313E

SCL

SDA

I2C1-SDA

I

2

C Address = 0x50

I2C RTC

DS1339U

SCL

SDA

I

2

C Address = 0x68

I2C Sensor

LM75

SCL

SDA

I

2

C Address = 0x48

3.3 V

I2C DAC (Optional)

AD5301

SCL

SDA

I

2

C Address = 0x0C

the reset configuration word value i n I2C EEPROM and the boot se quencer mode, refer to the MPC8313E

reference manual.

Figure 11. I2C Connection

2.7 SD Memory Card Interface

An SD memory card interface connects directly to the SPI bus of the MPC8313E. SD data mode and SDIO

mode are not supported. The SPI mode is the only SD operating mode supported by this connection. Hot

insertion and removal is not supported. See Figure 12 for the hardware connection.

For REVB boards, the SD card chip select signal is changed from GPIO31(SPISEL) to GPIO13(LA8)

because when using SPI as master mode, SPISEL

device select signal). In this case, another GPIO pin should be used. GPIO13 is implemented on this board

as an example.

cannot be set as GPIO (which is supposed to be used for

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 15

Page 16

Board-Level Functions

MPC8313E

CS

DIN

DOUT

SCLK

INSERT

CONTACT

PROTECT

SD_CS

SPIMOSI

SPIMISO

SPICLK

SD_INSERT

SD_CONTACT

SD_PROTECT

LA8 (GPIO13)

SPIMOSI

SPIMISO

SPICLK

SD Memory Card Socket

Status Read

Buffer

Local Bus

MPC8313E

USB-DP

USB-DM

USB mini-AB

On-Chip

USB PHY

ULPI external

USB PHY Interface

USB3300

USB PHY

USB VBUS

Power Supply

USB mini-AB

USB-VBUS

Control

Control

**ULPI

IRQ3

**NOTE: Because ULPI is multiplexed with eTSEC1 RGMII, by default

on-chip PHY is used. A change of resistor option is needed to use

the external USB PHY interface.

OR

Power down before inserting or removing the SD memory card.

2.8 USB Interface

CAUTION

Figure 12. SD Memory Card Connection

MPC8313E supports a USB 2.0 high speed host/device i nterface through its on-chip USB PHY or external

ULPI USB PHY. The MPC8313E R DB s upports both options. By default, the on- chip USB PHY is used.

Figure 13 shows the USB connections.

Figure 13. USB Connections

16 Freescale Semiconductor

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 17

Board-Level Functions

VSC7385

MPC8313E

RGMII

eTSEC1

Local Bus

LCS2#, GPCM 8bit data

RJ-45 ports

L2 switch

MPC8313E

RGMII

eTSEC2

88E1111

GBE PHY

SGMII

RJ-45 Port

NOTE: By default, RGMII is used and SGMII is optional

MDC, MDIO

MDIO PHY

Address = 4

2.9 eTSEC1 10/100/1000 BaseT Interface

eTESC1 is set to operate in RGMII mode. It connects to a VSC7385 5-port L2 switch, as shown in

Figure 14.

Figure 14. RGMII Interface Connection for L2 Switch

2.10 eTSEC2 10/100/1000 BaseT Interface

eTESC2 can be set to operate in RGMII mode (default) or SGMII mode. Figure 15 shows the hardware

connection for eTSEC.

Figure 15. eTSEC2 Connection

Freescale Semiconductor 17

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 18

Board-Level Functions

MPC8313E

UART1

RXD

RTS

TXD

CTS

UART2

RXD

RTS

TXD

CTS

MAX3232

TXD

RXD

CTS

RX

TX

TX

DO

DI

DI

RTS

Female DB-9

RS-232

Serial

Por t

RX

DO

3

7

8

2

MAX3232

TXD

RXD

CTS

RX

TX

TX

DO

DI

DI

RTS

Female DB-9

RS-232

Serial

Por t

RX

DO

3

7

8

2

MPC8313E

32Bit PCI

PCI-AD[0:31]

PCI-CBE[0:3]

PCI-REQ0

PCI-GNT0

PCI-CTRL

32Bit 3.3 V

PCI Slot

32-Bit 3.3 V

MiniPCI Slot

PCI-REQ1

PCI-G NT1

[AD14]

[AD15]

2.11 Dual RS-232 Ports

Dual RS-232 ports are supported on the RDB. Figure 16 illustrates the serial port connection using a

MAX3232 3.3 V RS-232 driver to interface with a 9-pin D type female connector . Thi s serial connection

runs at up to 115.2 Kbps.

Figure 16. RS-232 Debug Ports Connection

2.12 PCI Bus

The 32-bit PCI interface connects to a 32-bit 3.3 V PCI slot and a miniPCI slot (see Figure 17).

18 Freescale Semiconductor

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Figure 17. PCI Bus Connection

Page 19

Connectors, Jumpers, Switches, and LEDs

PC

MPC8313E RDB

P1

USB

Emulator

USB Port

COP Port

TDI

Pull-up

TCK

TMS

SRESET

HRESET

CKSTP_OUT

GND

TRST

Pull-up

CKSTP_IN

NC

NC

NC

GND

1

TDO

2.13 COP/JTAG Port

The common on-chip processor (COP) is part of the MPC8313E JTAG module and is implemented as a

set of additional ins tructions and logi c. This por t can connect to a dedicated emulator for extensive system

debugging. Several third-party emulators in the market can connect to the host computer through the

Ethernet port, USB port, parallel port, RS-232, and so on. A typical setup using a USB port emulator is

shown in Figure 18.

Figure 18. Connecting MPC8313E-RDB to a USB Emulator

The 16-pin generic header connector carries the COP/JTAG signals and the additional signals for system

debugging. The pinout of this connector is shown in Figure 19.

Figure 19. MPC8313E RDB COP Connector

3 Connectors, Jumpers, Switches, and LEDs

Table 3 summarizes the connectors, jumpers, switches, and LEDs on the MPC8313E RDB and provides

the number of the section/page on which each is discussed. The rest of this section discusses each of these

in the order of its appearance in the table.

Table 3. Connectors, Jumpers, Switches, and LEDs

Reference Description Section/Page

Freescale Semiconductor 19

P1 14-pin COP/JTAG connector 3.1/Page 21

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Connectors

Page 20

Connectors, Jumpers, Switches, and LEDs

Table 3. Connectors, Jumpers, Switches, and LEDs (continued)

Reference Description Section/Page

P2 3.3 V PCI Slot [IDSEL - AD15] 3.2/Page 21

P3 MiniPCI Slot [IDSEL - AD14] 3.3/Page 22

P4 USB mini-AB Connector (on-chip PHY) 3.4/Page 22

P5 RJ-45 LAN connectors Enet4 (top), Enet5 (bottom). See Figure 23 3.5/Page 23

P6 RJ-45 LAN connectors Enet2 (top), Enet3 (bottom). See Figure 23

P7 RJ-45 LAN connectors Enet0 (top), Enet1 (bottom). See Figure 23

P8 USB mini-AB Connector (external ULPI USB PHY) 3.4/Page 22

P9 ATX type power supply connector. The board can be powered by an ATX power supply or

—

the power supply bundled with the mini-ITX case.

P10 IEEE 1588 connector (Optional) 3.9/Page 25

P11 Dual UART connector. UART1 (top), UART2 (bottom) 3.6/Page 24

U44 SD memory card socket 3.7/Page 24

BT1 RTC battery holder, CR2032 type. The real-time clock on the RDB requires a battery when

—

the board is powered off. When placing or replacing the battery, take care to ensure that the

polarity is correct.

J20 Connector for chassis connection (power on, power LED, reset) —

J21 LCD connector 3.8/Page 24

J22 LCD connector

J23 LCD backlight connector. A 2-pin header (J23) is provided for LCD backlight power. Pin1 is

—

5 V and pin 2 is GND.

J24 MCU programming connector. J24 is used for MCU programming on the RDB. It is reserved. —

Jumpers

J19 Open (Default)—Power ON controlled by switch; Close—Power is always ON —

Switches

S1 System reset button. Resets the MPC8313E RDB. (PORESET

button reset switch on the RDB to cause a power-on reset (PORESET

). Press once on the push

) to the board.

—

S2 Power ON button. Press once to power ON/OFF. —

S3 DIP switch. Selects the reset configuration source (RST_CFG_SRC) for the MPC8313E. 3.10/Page 26

S4 DIP switch. Board revision indicator and boot device selector. 3.11/Page 26

D6 Enet5 Link 10 —

D7 Enet5 Link 100 —

D8 Enet5 Duplex —

D9 Enet5 RX —

D12 USB VBUS —

D10 On-chip USB PHY CTL0 —

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

20 Freescale Semiconductor

LEDs

Page 21

Connectors, Jumpers, Switches, and LEDs

Table 3. Connectors, Jumpers, Switches, and LEDs (continued)

Reference Description Section/Page

D11 On-chip USB PHY CTL1 —

D16 12-V Indicator —

D15 5-V Indicator —

D14 3.3-V Indicator —

D17 2.5-V Indicator —

D13 5-V standby indicator —

D3 Programmable LED0 (Red) 3.12/Page 27

D5 Programmable LED1 (Yellow)

D2 Programmable LED2 (Green)

D1 Programmable LED3 (Green)

D22 Programmable LED4 (Green)

D21 Programmable LED5 (Green)

D20 Programmable LED6 (Green)

D4 Programmable LED7/LCD_EN (Green)

3.1 COP Connector (P1)

The COP connector allows the user to connect a COP/JTAG-based debugger to the MPC8313E RDB for

debugging. Table 4 lists the pin assignments of the COP connector.

Table 4. COP Connector Pin Assignments

Pin Signal Pin Signal

1 TDO 2 GND

3 TDI 4 TRST

5QREQ 6 VDD_SENSE

7 TCK 8 CKSTP_IN

9TMS 10 NC

11 SRESET

13 HRESET

15 CKSTP_OUT 16 GND

12 NC

14 NC

3.2 PCI Slot (P2)

The MPC8313E RDB has one 32-bit 3.3-V PCI expansion slot (P2) for an expansion card. The slot

connects AD15 for its device select signal. Only the 3.3-V PCI card is supported. Turn OFF power during

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 21

Page 22

Connectors, Jumpers, Switches, and LEDs

PCI Slot

5 V Key

Match

3.3 V Key

Here

Front Panel

ATX p owe r

Connector

M

i

n

i

P

C

I

C

a

r

d

1

.

I

n

s

e

r

t

2. Press down

insertion and removal of the PCI card. As Figure 20 shows, 3.3-V PCI cards can be identified by the key

position on the PCI card.

Figure 20. 3.3 V Key on a Typical 3.3 V PCI Card

3.3 MiniPCI Connector (P3)

There is a MiniPCI connector (P3) on the RDB. The slot connects to AD14 for its device select signal.

Figure 21 shows how to install a MiniPCI card.

3.4 USB Connectors (P4, P8)

There are two USB connectors on the MPC8313E RDB . One connects to the on-chip PHY of the

MPC8313E, and the other connects to the external ULPI USB PHY. Either can be enabled at a time. The

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

22 Freescale Semiconductor

Figure 21. Installation of MiniPCI Card

Page 23

Connectors, Jumpers, Switches, and LEDs

USB LEDs:

CTL1

CTL0

VBUS

for external

ULPI USB PHY

for on-chip

PHY

G0

G1

G2

G3

G4

G5

USB mini-AB

USB Type A

RX

Duplex

Link100

Link10

G5 LEDsLink1000

TX

A

B

A

B

A

B

A

B

A

B

A: Link/Activity 1000

B: Link/Activity 10/100

G0-G4 LEDs:

selection between the two requires modification of micro-jumpers/resistor options as discussed later. By

default, the on-chip PHY USB is used. Figure 22 shows the USB connectors in front panel.

Figure 22. USB Connectors

3.5 Ethernet Connectors (P5, P6, P7)

The MPC8313E RDB has six Ethernet ports (RJ-45). The first five ports (G0–G4) are supported by

eTSEC1 (L2 switch), and the last port (G5) is supported by eTSEC2 (GBE PHY). Figure 23 shows the

G0–G5 mapping viewing from the front panel.

Freescale Semiconductor 23

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Figure 23. Ethernet Connectors

Page 24

Connectors, Jumpers, Switches, and LEDs

UART1

UART2

SD Memory

1GB

Card

3.6 RS-232 UART Connector (P11)

Serial interfaces are available at connector P11. It is a double deck RS-232 female connector. The upper

port is UART1 and the lower port is UART2. By default, UAR T 1 is used. Figure 24 shows the RS-232

UART connector front view.

.

Figure 24. RS-232 UART Connectors

3.7 SD Memory Card Socket (U44)

An SD card socket (U44) for SD memory card installation is located next to the UART connector of the

board. Figure 25 shows how to install a compact flash card.

3.8 LCD Connectors (J21, J22)

T wo headers (J21, J22) are provided for LCD connections. They use the MPC8313E GPIO interface. Both

headers carry the same set of GPIO signal pins, but they are different physically. J21 is single row of

1 × 14, and J22 is double row of 2 × 7. Table 5 shows the mapping.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

24 Freescale Semiconductor

Figure 25. Installation of SD Card

Table 5. LCD Connector Pin Assignment

Pin Number Description

1GND

25V

3 5 V to –5 V variable

4GPIO2

5GPIO3

6GPIO1

Page 25

Connectors, Jumpers, Switches, and LEDs

TSEC_TMR_PP1

TSEC_TMR_PP2

TSEC_TMR_PP3

GND

GND

GND

TSEC_TMR_GCLK

TSEC_TMR_ALARM1

TSEC_TMR_ALARM2

TSEC_TMR_TRIG1

TSEC_TMR_TRIG2

TSEC_TMR_TRIG2

GND

TSEC_TMR_CLK

1

3.3 V

by TSEC1 PHY)

3.3 V

(Optional if not used

by TSEC1 PHY)

(Optional if not used

Table 5. LCD Connector Pin Assignment (continued)

Pin Number Description

7 Pull-down

8 Pull-down

9 Pull-down

10 Pull-down

11 GPIO7

12 GPIO6

13 GPIO5

14 GPIO4

3.9 IEEE 1588 Connector (Optional)

A header (P10) is provided for IEEE 1588 signals connection. It is double r ow of 2 × 8 header connector.

The pinout of this connector is shown in Figure 26.

Figure 26. IEEE 1588 Connector (Optional)

Freescale Semiconductor 25

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 26

Connectors, Jumpers, Switches, and LEDs

1

2

3

4

ON

CFG_RST_SRC0

0

1

CFG_RST_SRC1

CFG_RST_SRC2

CFG_RST_SRC3

1

2

3

4

ON

0

1

RSVD

REV1

BOOT1

(NAND)

CFG_BOOT_ECC_DIS

3.10 DIP Switch S3

DIP switch S3 selects the reset configuration source (RST_CFG_SRC) for the MPC8313E. Figure 27

shows the factory default configuration of S3.

Figure 27. DIP Switch S3

Check the MPC8313E reference manual for the meaning of the CFG_RST_SRC combination. By default,

the DIP switch is set to all ON, meaning CFG_RST_SRC[0..3] = 0000. In this case, the hardware reset

configuration is loaded from local bus NOR flash memory.

3.11 DIP Switch S4

DIP switch S4 on the RDB is shown in Figure 28, with the factory default configuration.

RSVD is reserved. When software options are implemented, their values can be read from a buffer on the

board. CFG_BOOT_ECC_DIS switch is OFF by default to disable booting with ECC by driving HIGH to

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

26 Freescale Semiconductor

Figure 28. DIP Switch S4

Page 27

Micro-Jumper/Resist or Options for eTSEC1

LED0 LED1

LED2

(Red) (Yellow)

(Green)

LED3

(Green)

LED4

(Green)

LED5

(Green)

LED6

(Green)

LED7/LCD_EN

(Green)

the signal LB_POR_CFG_BOOT_ECC_DIS (TSEC1_MDC) during power on reset (REVB and REVC

only . REVAx is a reserved switch (RSVD0)). REV1 represents bit 1 of the revision number. T ogether with

REV0 (implemented by resistor option; the default is 0), REV[0..1] shows the revision number, which is

01 by default. The values can be read from a buffer on the RDB. BOOT1 selects the boot device on the

RDB. By default, BOOT1 is set, so chip-select 0 (CS0) is connected to the NOR Flash. CS1 is connected

to the NAND Flash memory. If BOOT1 is cleared, CS0 is connected to NAND Flash memory, and CS1 is

connected to NOR Flash memory.

3.12 RDB Programmable LEDs

Eight programmable LEDs give status indication and debug information. Figure 29 shows the diagram.

Figure 29. Programmable LEDs

An 8-bit write register on the RDB turns the LEDs on and off. The LEDs are arranged so that the most

significant bit represents LED0 and least significant bit represents LED7; that is, LED[0..7]. A write of

0x00 turns on all LEDs, and 0xFF turns off all LEDs.

4 Micro-Jumper/Resistor Options for eTSEC1

The eTSEC1 RGMII, ULPI USB, and IEEE 1588 signals are multiplexed on the MPC8313E. The

MPC8313E RDB supports switching among the three interfaces using micro-jumpers (REVA boards) or

resistor options (REVA1 or later boards).

NOTE

For IEEE 1588 support, use the same setting as for the eTS EC1 RGMII. In

this case, a 50 MHz clock would be provided for the IEEE 1588 TMR_CLK

pin.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 27

Page 28

Micro-Jumper/Resistor Options for eTSEC1

4.1 For REVA Boards

Figure 30 shows the micro-jumper locations.

Figure 30. REVA Micro-jumper Locations

By default the REVA boards are shipped with the following settings:

Setup 1:

• eTSEC1, RGMII

• eTSEC2, RGMII

The corresponding micro-jumper settings are shown in Table 6.

Table 6. Default Micro-jumper Settings for REVA

Jumper Setting Jumper Setting Jumper Setting Jumper Setting

J13 1-2 J7 1-2 J5 open J18 2-3

J12 1-2 J9 1-2 J1 open

J16 1-2 J6 1-2 J2 open

J15 1-2 J8 1-2

J17 1-2 J3 1-2

J14 1-2 J4 1-2

J11 open

J10 1-2

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

28 Freescale Semiconductor

Page 29

Micro-Jumper/Resist or Options for eTSEC1

There are alternative sett i ngs f or RE VA boar ds:

Setup 2:

• eTSEC1, USB DR with external ULPI USB PHY (USB3300)

• eTSEC2, SGMII (remove R87, C275; connect 125 MHz clock from R181 to SGMII SCLK)

The corresponding micro-jumper settings are shown in Table 7.

Table 7. Alternative Micro-jumper Settings for REVA (Setup 2)

Jumper Setting Jumper Setting Jumper Setting Jumper Setting

J13 open J7 2-3 J5 2-3 J18 1-2

J12 open J9 2-3 J1 2-3

J16 open J6 2-3 J2 2-3

J15 open J8 2-3

J17 open J3 2-3

J14 2-3 J4 2-3

J11 2-3

J10 2-3

Setup 3:

• eTSEC1, USB DR with external ULPI USB PHY (USB3300)

• eTSEC2, RGMII

The corresponding micro-jumper settings are shown in Table 8.

Table 8. Alternative Micro-jumper Settings for REVA (Setup 3)

Jumper Setting Jumper Setting Jumper Setting Jumper Setting

J13 open J7 2-3 J5 2-3 J18 1-2

J12 open J9 2-3 J1 2-3

J16 open J6 2-3 J2 2-3

J15 open J8 2-3

J17 open J3 2-3

J14 2-3 J4 2-3

J11 2-3

J10 2-3

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 29

Page 30

Micro-Jumper/Resistor Options for eTSEC1

Setup 4

• eTSEC1, RGMII

• eTSEC2, SGMII (remove R87, C275; connect 125 MHz clock from R181 to SGMII SCLK)

The corresponding micro-jumper settings are shown in Table 9.

Table 9. Alternative Micro-jumper Settings for REVA (Setup 4)

Jumper Setting Jumper Setting Jumper Setting Jumper Setting

J13 1-2 J7 1-2 J5 open J18 2-3

J12 1-2 J9 1-2 J1 open

J16 1-2 J6 1-2 J2 open

J15 1-2 J8 1-2

J17 1-2 J3 1-2

J14 1-2 J4 1-2

J11 open

J10 1-2

Because the eTSEC1 Ethernet switch PHY on the RDB supports only RGMII, the eTSEC1 SGMII is not

supported. The micro-jumper settings listed only matter for the eTSEC1 pin connections. They have

nothing to do with switching between eTSEC2 RGMII and SGMII. The settings of eTSEC2 SGMII are

provided as a reference.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

30 Freescale Semiconductor

Page 31

Micro-Jumper/Resist or Options for eTSEC1

4.2 REVA1 to REVA4 Boards

For REVA1 or later boards, the micro-jumpers are replaced by resistor options for easier modifi cati on.

Figure 31 shows the resistor locations. Table 10 shows the default configuration.

Setup 1:

• eTSEC1, RGMII

• eTSEC2, RGMII

Figure 31. Locations of Resistor Options on REVA1 or Later Boards

Table 10. Default Resistor Options for REVA1 to REVA4

Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R258 short R267 open R276 short R285 open

R259 open R268 short R277 open R286 short

R260 short R269 open

R261 open

R262 short R271 open R280 short R289 open

R263 open R272 short R281 open R290 short

R264 short R273 open

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

R270 short R279 open R288 short

R278 short R287 open

R282 short R291 open

Freescale Semiconductor 31

Page 32

Micro-Jumper/Resistor Options for eTSEC1

Table 10. Default Resistor Options for REVA1 to REVA4 (continued)

Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R265 open R274 short R283 open R293 short

R266 short R275 open R284 short R292 open

Figure 32 shows the graphical representation for Setup 1.

Figure 32. Default Resistor Options for REVA1

Table 11 shows the alternative configuration.

Setup 2:

• eTSEC1, USB DR with external ULPI USB PHY (USB3300)

• eTSEC2, SGMII

Table 11. Setup 2 Resistor Options for REVA1

Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R258 open R267 short R276 open R285 short

R259 short R268 open R277 short R286 open

R260 open R269 short

R261 short

R262 open R271 short R280 open R289 short

R263 short R272 open R281 short R290 open

R264 open R273 short

R265 short

R266 open R275 short R284 open R292 short

R270 open R279 short R288 open

R274 open R283 short R293 open

R278 open R287 short

R282 open R291 short

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

32 Freescale Semiconductor

Page 33

Figure 33 shows the graphical representation for Setup 2.

Figure 33. Setup 2 Resistor Options for REVA1

Table 12 shows the alternative configuration.

Micro-Jumper/Resist or Options for eTSEC1

Setup 3:

• eTSEC1, USB DR with external ULPI USB PHY (USB3300)

• eTSEC2, RGMII

Table 12. Setup 3 Resistor Options for REVA1

Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R258 open R267 short R276 open R285 short

R259 short R268 open R277 short R286 open

R260 open R269 short

R261 short

R262 open R271 short R280 open R289 short

R263 short R272 open R281 short R290 open

R264 open R273 short

R265 short

R266 open R275 short R284 open R292 short

R270 open R279 short R288 open

R274 open R283 short R293 open

R278 open R287 short

R282 open R291 short

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 33

Page 34

Micro-Jumper/Resistor Options for eTSEC1

Figure 34 shows the graphical representation for Setup 3.

Figure 34. Setup 3 Resistor Options for REVA1

Table 13 shows the alternative configuration.

Setup 4:

• eTSEC1, RGMII

• eTSEC2, SGMII

Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R258 short R267 open R276 short R285 open

R259 open R268 short R277 open R286 short

R260 short R269 open

R261 open

R262 short R271 open R280 short R289 open

R263 open R272 short R281 open R290 short

R264 short R273 open

R265 open

R266 short R275 open R284 short R292 open

Table 13. Setup 4 Resistor Options for REVA1

R278 short R287 open

R270 short R279 open R288 short

R282 short R291 open

R274 short R283 open R293 short

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

34 Freescale Semiconductor

Page 35

Micro-Jumper/Resist or Options for eTSEC1

Figure 35 shows the graphical representation for Setup 4.

Figure 35. Setup 4 Resistor Options for REVA1

Because the eTSEC1 Ethernet switch PHY on the RDB supports only RGMII, the eTSEC1 SGMII is not

supported on the RDB. The resistor options listed only matter for the eTSEC1 pin connections. They have

nothing to do with switching between eTSEC2 RGMII and SGMII. They are listed for reference. The

switch between eTSEC2 RGMII and SGMII does not require hardware modification on the RDB.

4.3 REVB Boards

For REVB boards, three more resistor options (R311–R313) are added to route three IEEE 1588 signals

to the IEEE 1588 connector.

All other resistor options are the same as on the REVA1 to REVA4 boards.

Table 14 shows how to populate the resistors if these three optional signals are used.

Table 14. Resistor Options for REVB Using Three Optional IEEE 1588 Signals

Signal Resistor Setting Resistor Setting Resistor Setting

TSEC_TMR_TRIG2/TSEC1_RX_ER/ULPI1_DIR R311 short R266 open R267 open

TSEC_TMR_ALARM1/TSEC1_RX_ER/ULPI1_CLK R312 short R280 open R281 open

TSEC_TMR_PP3/TSEC1_RX_ER/ULPI1_STP R313 short R284 open R285 open

4.4 REVC Boards

For REVC boards, 22 more resistor options (R31 1–R313) are added to route eTSEC2 RGMII signals either

to L2 Switch or Marvell 88E1111 PHY. All other resistor options are the same as on the REVB boards.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 35

Page 36

Micro-Jumper/Resistor Options for eTSEC1

Table 15 shows how to populate the resistors if routing eTSEC2 RGMII signals to L2 Switch.

Setup 1:

eTSEC1, RGMII signals to L2 Switch

Table 15. Setup 1 Resistor Options for REVC

Resistor Setting Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R118 short R346 open R336 short R370 short R360 short

R342 open R123 short R337 open R352 short R361 open

R119 short R347 open

R343 open

R120 short R331 open R340 short R355 open R365 short

R344 open R332 short R341 open R356 short R364 open

R121 short R333 open

R345 open

R122 short R335 open R346 open R359 open - -

R330 short R339 open R354 short R363 open

R334 short R350 short R358 short R367 open

R338 short R353 open R362 short

R345 open R357 open R366 short

Figure 36 shows the graphical representation for Setup 1.

Figure 36. Setup 2 Resistor Options for REVC

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

36 Freescale Semiconductor

Page 37

Table 16 shows the alternative configuration.

Setup 2:

• eTSEC1, RGMII signals to PHY

Table 16. Setup 2 Resistor Options for REVC

Resistor Setting Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R118 open R346 open R336 short R370 short R360 short

R342 short R123 short R337 open R352 short R361 open

Micro-Jumper/Resist or Options for eTSEC1

R119 open R347 short

R343 short

R120 open R331 short R340 open R355 short R365 open

R344 short R332 open R341 short R356 open R364 short

R121 open R333 short

R345 short

R122 open R335 short R346 short R359 short - -

R330 open R339 short R354 open R363 short

R334 open R350 open R358 open R367 short

R338 open R353 short R362 open

R345 short R357 short R366 open

Figure 37 shows the graphical representation for Setup 2.

Figure 37. Setup 2 Resistor Options for REVC

Table 17 shows the alternative configuration.

Setup 3:

• eTSEC1, SGMII signals to PHY

Table 17. Setup 3 Resistor Options for REVC

Resistor Setting Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R118 open R346 open R336 short R370 short R360 short

R342 short R123 short R337 open R352 short R361 open

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 37

Page 38

MPC8313E RDB Board Configuration

Table 17. Setup 3 Resistor Options for REVC (continued)

Resistor Setting Resistor Setting Resistor Setting Resistor Setting Resistor Setting

R119 open R347 short R338 open R353 short R362 open

R343 short

R120 open R331 short R340 open R355 short R365 open

R344 short R332 open R341 short R356 open R364 short

R121 open R333 short

R345 short

R122 open R335 short R346 short R359 short - -

R330 open R339 short R354 open R363 short

R345 short R357 short R366 open

R334 open R350 open R358 open R367 short

Figure 38 shows the graphical representation for Setup 3.

Figure 38. Setup 2 Resistor Options for REVC

5 MPC8313E RDB Board Configuration

This section describes the operational frequency and configuration options of the MPC8313E RDB.

5.1 PCI Operating Frequency

An M66EN input pin determines the frequency of the PCI interface. On the MPC8313E RDB, the M66EN

signal level is determined by the PCI agent card connected to the miniPCI or PCI slot. If a 33 MHz-only

card is inserted, the M66EN signal is driven to 0 by the PCI agent card according to the PCI specification.

However, it is pulled to 1 if it can perform at 66 MHz. By default, the MPC8313E RDB runs its PCI

interfaces at 66 MHz unless a 33-MHz PCI card is inserted.

5.2 Reset Configuration Word

The reset configuration word (RCW) controls the clock ratios and other basic device functions such as PCI

host or agent mode, boot location, and endian mode. The reset configuration word is divided into reset

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

38 Freescale Semiconductor

Page 39

MPC8313E RDB Board Configuration

configuration word lower (RCWL) and reset configuration word higher (RCWH) and is loaded from the

local bus during the power-on or hard reset flow. The default RCW low bit setting is 0x6204_0000. The

default RCW high bit setting is 0xA060_7800. The RCW is located at the lowest 64 bytes of the boot flash

memory, which is 0xFE00_0000 if the default memory map is used.

Table 18 shows the default RCW in the flash memory.

Table 18. Default RCW in Flash Memory

Address

FE000000: 62626262 62626262 04040404 04040404

FE000010: 00000000 00000000 00000000 00000000

FE000020: A0A0A0A0 A0A0A0A0 60606060 60606060

FE000030: 78787878 78787878 00000000 00000000

The RCW definitions are shown in Figure 39 and Figure 40.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Field LBCM DDRCM — SPMF — COREPLL

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Field —

Figure 39. Reset Configuration Word Low (RCWL) Bit Settings

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Field PCIHOST — PCIABR — COREDIS BMS BOOTSEQ SWEN ROMLOC RLEXT —

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Field TSEC1M TSEC2M — TLE LALE —

Figure 40. Reset Configuration Word High (RCWH) Bit Settings

Table 19. RCWL Bit Descriptions

Bits Name Meaning Description

0 LBCM Local bus clock mode Local Bus Controller Clock: CSB_CLK

0: Default Ratio 1:1

1 Ratio 2:1

1 DDRCM DDR SDRAM clock

mode

DDR Controller Clock: CSB_CLK

0 Ratio 1:1

1: Default Ratio 2:1

2–3 — Reserved Must be set to 10

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 39

Page 40

MPC8313E RDB Board Configuration

Table 19. RCWL Bit Descriptions (continued)

Bits Name Meaning Description

4–7 SPMF[0–3] System PLL

multiplication factor

0000 Reserved

0001 Reserved

0010 (Default) 2:1

0011 3:1

0100 4:1

0101 5:1

4–7 SPMF[0–3] System PLL

multiplication factor

0110 6:1

0111-1111 Reserved

8 — Reserved Must be cleared.

9–15 COREPLL

[0–6]

Value coreclk: csb_clk VCO divider

nn 0000 0 PLL bypassed PLL bypassed

00 0001 0 1:1 2

01 0001 0 1:1 4

10 0001 0 1:1 8

00 0001 1 1.5:1 2

01 0001 1 1.5:1 4

10 0001 1 1.5:1 8

00 0010 0 (Default) 2:1 2

9–15 COREPLL

[0–6]

01 0010 0 2:1 4

10 0010 0 2:1 8

00 0010 1 2.5:1 2

01 0010 1 2.5:1 4

10 0010 1 2.5:1 8

00 0011 0 3:1 2

01 0011 0 3:1 4

10 0011 0 3:1 8

16–31 — Reserved. Must be cleared.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

40 Freescale Semiconductor

Page 41

MPC8313E RDB Board Configuration

Table 20. Reset Configuration Word High (RCWH) Bit Descriptions

Bits Name Meaning Description

0 PCIHOST PCI host mode 0 PCI agent

1: Default PCI host

1 Reser ved — Must be cleared

2 PCIARB PCI1 arbiter 0 PCI arbiter disabled

1: Default PCI arbiter enabled

3 Reser ved — Must be cleared

4 COREDIS Core disable mode 0: Default e300 enabled

1 e300 disabled

5 BMS Boot memory

space

6–7 BOOTSEQ Boot sequencer

configuration

8 SWEN Software watchdog

enable

9–11 ROMLOC Boot ROM

interface location

12–13 RLEXT Boot ROM

location extension

0: Default 0x0000_0000–0x007F_FFFF

1 0xFF80_0000–0xFFFF_FFFF

00: Default Boot sequencer is disabled

01 Boot sequencer load configuration from I

2

C

10 Boot sequencer load configuration from EEPROM

11 Reserved

0: Default Disabled

1 Enabled

000 DDR2 SDRAM

001 PCI

010,011, 100 Reserved

101 Local bus GPCM, 8 bits

110: Default Local bus GPCM, 16 bits

111 Reserved

00: Default Legacy mode

01 NAND Flash mode

10,11 Reserved

14-15 Reserved — Must be cleared

16-18 TSEC1M TSEC1 Mode 000 MII mode

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 41

001 RMII mode

011:Default RGMII mode

101 RTBI mode

110 SGMII mode

010,100,111 Reserved

Page 42

MPC8313E RDB Board Configuration

Table 20. Reset Configuration Word High (RCWH) Bit Descriptions (continued)

Bits Name Meaning Description

19-21 TSEC2M TSEC2 Mode 000 MII mode

001 RMII mode

011:Default RGMII mode

101 RTBI mode

110 SGMII mode

010,100,111 Reserved

22-27 Reserved — Must be cleared

28 TLE True little endian 0: Default Big-endian mode

1 True little endian mode

29 LALE Local Bus ALE

signal timing

30-31 Reserved — Must be cleared

0: Default Normal LALE timing

1 LALE is negated 1/2 lbc_controller_clk earlier.

5.3 Power Supply

The MPC8313E RDB requires a power supply from the A TX power connector. The ATX supply connector

directly provides 12-V, 5-V, and 3.3-V voltages. Core voltage, DDR2 voltage, RGMII voltage, and

PHY-specific voltages are provided by either switching or linear regulated depending on the voltage drop

and current consumption requirement. MPC8313E power-down mode is supported. A regulator that can

be shut down is implemented for this purpose.

The MPC8313E does not require the core supply voltage and IO supply voltages to be applied in any

particular order. However, during the power ramp up, before the power supplies are stable, there may be

an interval when the IO pins are actively driven. After the power is stable, as long as PORESET is asserted,

most IO pins are three-stated. To minimize the time that IO pins are actively driven, apply core voltage

before IO voltage and assert PORESET before the power supplies fully ramp up.

Table 21 shows the power supply table.

Table 21. Power Supply Usage Summary

Voltage Usage Budget Solution

1 V shutdownable VDD, AVDD1 <1 A MIC1510ETB+ regulator (3 A) with tracking

1 V VDDC <10 A MIC1953EUB+ switching

1.2 V VSC7385, 88E1111 1.75 A + 0.4 A MIC37302 LDO (3 A)

1.8 V DDR2 0.5 A + DDR chip x2pcs MIC37302 LDO (3 A)

2.5 V RGMII 0.2 A + 0.2 A + 0.2 A MIC39100-2.5WS (1 A)

3.3 V General IO Variable Direct from ATX Power

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

42 Freescale Semiconductor

Page 43

Getting Started

Table 21. Power Supply Usage Summary

Voltage Usage Budget Solution

5 V Switching power, PCI cards 0.5–1 A Direct from ATX Power

12 V None Nil Direct from ATX Power

5.4 Chip-Select Assignments and Memory Map

Table 22 shows an example memory map on the MPC8313E RDB for U-Boot in NOR Flash memory.

Table 22. Example Memory Map, Local Access Window, and Chip-Select Assignments

Address Range Target Interface

0x0000_0000–0x07FF_FFFF DDR2 MCS0# DDR SDRAM (128 Mbyte) 32

0x8000_0000–0x9FFF_FFFF PCI Nil PCI memory space (512 Mbyte) 32

0xE000_0000–0xE00F_FFFF Internal bus Nil IMMR (1 Mbyte) —

0xE200_0000–0xE20F_FFFF PCI Nil PCI I/O space (1 Mbyte) 32

0xE280_0000–0xE280_7FFF NAND Controller LCS1# NAND Flash window (32Kbyte) 8

0xF000_0000–0xF001_FFFF Local bus LCS2# VSC7385 (128Kbyte) 8

0xFA00_0000–0xFA00_7FFF Local bus LCS3# Read/write buffer (32Kbyte) 8

0xFE00_0000–0xFE7F_FFFF Local bus LCS0# Boot Flash (8 Mbyte) 16

Chip-Select

Line

Device Name Port Size (Bits)

6 Getting Started

This section describes how to boot the MPC8313E RDB. The on-board flash memory is preloaded with a

flash image from the factory. Before powering up the board, verify that all the on-board DIP switches and

jumpers are set to the factory defaults according to the settings listed in Section 6.1, “Board Jumper

Settings,” and make all external connections as described in Section 6.2, “Externa l Cable Connections.”

CAUTION

A void touching areas of integrated circuitry and connectors; static discharge

can damage circuits.

Only the 3.3-V PCI Card is supported. T urn OFF power during insertion and

removal of a PCI card.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 43

WARNING

Page 44

Getting Started

Pin 1

P8

D12

P1

D6

COP Connector

S2

S1

J20

D16

P11

J19

S4

J23

J22

J24

J21

U44

S3

1234

ON

1234

ON

D3

D22

D5

D2

D1

D21

D20

D4

MPC8313E

P3

P2

P5

P6

P7

D15

D14

D17

D13

D7

D8

D9

D10

D11

P4

PCI Slot [IDSEL-AD15]

miniPCI Slot [IDSEL-AD14]

CFG_RST_SRC0

CFG_RST_SRC1

CFG_RST_SRC2

CFG_RST_SRC3

RSVD

CFG_BOOT_ECC_DIS

REV1

BOOT1# (NAND)

VBUS

CTL0

CTL1

LCD Connector

LCD Backlight

LCD Connector

MCU

Connector

Power On

Button,

Reset Button

Programmable

LED0-7

Micro-jumper/resistor option area

for RGMII/ULPI/IEEE1588 selection

MPC8313E-RDB

S/N:

IEEE 1588 Conne ctor (Optional)

P10

and L2 Switch/PHY selection

6.1 Board Jumper Settings

Figure 41 shows the top view of the MPC8313E RDB with pin 1 marked for each reference. There are two

DIP switches (S3, S4) and one jumper (J19). Their default settings are listed in Table 23.

Figure 41. MPC8313E-RDB Top View

Table 23. Default DIP Switch and Jumper Setting

Reference Default Setting

S3 0000 (all ON)

S4 1111 (all OFF)

J19 open (no jumper)

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

44 Freescale Semiconductor

Page 45

Getting Started

PC

G0

G1

G2

G3

G4

G5

A

B

A

B

A

B

A

B

A

B

CAT-5 cable to

one of the ports (lowerright-most is eTSEC2, other

five are eTSEC1)

Straight-through 9-conductor

serial cable, M-F (upper

port for UART1 default;

lower por t for UART2)

6.2 External Cable Connections

Do not turn on power until all cables are connected and the serial port is configured as described in

Section 6.3, “Serial Port Configuration (PC).” C onnect the serial port of the MPC8313E RDB system and

the personal computer using an RS-232 cable as shown in Figure 42.

Figure 42. External Connections

6.3 Serial Port Configuration (PC)

Before powering up the MPC8313E RDB, configure the serial port of the attached computer with the

following values:

• Data rate: 115200 bps

• Number of data bits: 8

• Parity: None

• Number of Stop bits: 1

• Flow Control: Ha rd wa re /N on e

6.4 Power Up

An ATX-type power connector (P9) should be used to supply necessary DC power to the MPC8313E

RDB. It can be provided by an ATX-type power supply or from a mini-ITX case.

WARNING

Turn off the main power for the ATX power supply/mini-ITX case before

the power connector is attached.

Freescale Semiconductor 45

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Page 46

MPC8313E RDB Software

Power up the power supply. A few seconds after power up, the U-Boot prompt => should be received by

the serial terminal program as shown here:

U-Boot 1.x.x (FSL Development) (Date - time) MPC83XX

Clock configuration:

Coherent System Bus: xxx MHz

Core: yyy MHz

Local Bus Controller: xxx MHz

Local Bus: yy MHz

DDR: xxx MHz

…

Hit any key to stop autoboot: 0

=>

NOTE

The normal function of the product may be disturbed by strong

electromagnetic interference. If so, simply reset the product to resume

normal operation by following the instructions in the manual. If normal

function does not resume, use the product in another location.

7 MPC8313E RDB Software

A board support package (BSP) is pre-installed on the MPC8313E RDB. This BSP consists of a bootloader

(U-Boot), a generic PowerPC Linux-based system, and an associated file system. U-Boot, the Linux

kernel, and the file system reside in the on-board flash memory. At power up, the Linux system runs on

the MPC8313E RDB.

The MPC8313E RDB BSP generation takes advantage of a tool called the Linux Target Image Builder

(LTIB). LTIB is a suite of tools that leverages existing open source configuration scripts and source code

packages and bundles them into a single BSP-generation package. The source code packages include boot

loaders and Linux kernel sources as well as many user-space source code packages to build a complete

BSP. L TI B also provides compiler packages required to build the BSP. Freescale developers use LTIB to

create BSPs for a multitude of Freescale development targets. LTIB leverages as many BSP elements as

possible for all Freescale-supported targets, and it offers the flexibility to customize components that

require platform-specific modifications.

The MPC8313E RDB BSP release package contains a file named

MPC8313E RDB-<yyyymmdd>.iso. This file

is an ISO image that can be burned to a CD-ROM or mounted directly from your hard disk. Note that

<yyyymmdd> is the release creation date. The LTIB installation script that installs all necessary packages on

a host Linux PC and allows you to modify the BSP and packages within the BSP is in the

/ltib-MPC8313E-RDB

subdirectory within the ISO image.

This ISO image contains a file called Readme.txt that describes how to generate and install the BSP on the

MPC8313E RDB hardware platform.

ISO image also contains

Release Notes.txt, which describes changes to the current BSP version versus

Readme.txt contains the latest information for each BSP release. The

earlier releases. To rebuild the BSP package or to add application software, carefully follow th e

instructions in Readme.txt. Th is file contains details on how to build, run, and install the BSP. It guides the

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

46 Freescale Semiconductor

Page 47

Frequently Asked Questions (FAQs)

user to achieve a successful re-installation of the BSP on the MPC8313E RDB. This ISO image contains

the following documents as well:

• MPC8313ERDBUG.pdf. This user's guide document in PDF format.

MPC8313E-RDB_schematic.pdf. The platform schematic in PDF format.

•

•

SEC2SWUG.pdf. User's guide for the driver software of the security engine. This document details the

driver software interface to boost the throughput performance of security applications such as

IPSec.

• LtibFaq.pdf. Frequently asked questions for LTIB, which is a us eful document desc ribing how to

use LTIB to build the ISO image.

For more information on the MPC8313E RDB, visit the Freescale website listed on the back cover of this

document. To run demonstrations or to acquire details of Freescale third-party applications for this

MPC8313E RDB, contact your local Freescale sales office.

8 Frequently Asked Questions (FAQs)

Here are some commonly asked questions and their respective answers.

8.1 What are the differences among RDB revisions?

There are five revisions of the RDB, which are REVA, REVA1, REVA2, REVA3, REVA4, REVB and

REVC. Table 24 lists and describes these revisions.

Table 24. MPC8313E-RBD Revisions

Revision Description

REVA There are two major issues on the REVA board:

• On-chip PHY USB signals (DP, DM) are swapped. To use the USB, use a USB cable that swaps the signals

(the cable is attached in the REVA package).

• NAND flash memory cannot be used as a boot device.

REVA1 Fixes both major issues on the REVA board. The boot-from-NAND on the REVA1 RDB has been verified.

However, on the current BSP preloaded on REVA1 RDB, NAND flash memory is empty, so it is also not

bootable. Booting from NAND flash memory will be supported in a future release of the BSP.

Software for REVA and REVA1 differs only in the OR1[BCTLD] register setting for NAND flash memory. That

is, REVA OR1[BCTLD] is 1; while REVA1 OR1[BCTLD] is 0.

REVA2 A minor update from REVA1 for mass production. It updates the silkscreen and adds a 12-V fan connector

(J25) and resistor loading for ATX power.

Software can be shared without modification between REVA1 and REVA2.

REVA3 Fixes the PMC register issue mentioned in Section 8.5, “Power management control (PMC) registers cannot

be accessed?”

Because of a processor erratum, a 166 MHz CSB frequency should be used. For this reason, some REVA3

and all later boards have 33 MHz instead of 66 MHz as the clock input (check your board U15 oscillator

marking). The CORE/CSB/DDR frequency setting is 333/166/333 MHz. However, there are two drawbacks:

• PCI bus can run at up to only 33 MHz

• PCI/mini-PCI card can run at 66 MHz (has its M66EN pulled up) and should be used. Even the PCI bus on

the RDB runs at only 33 MHz. Otherwise, the PCI frequency is further divided and it becomes 16.6 MHz.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 47

Page 48

Frequently Asked Questions (FAQs)

Table 24. MPC8313E-RBD Revisions

Revision Description

REVA4 Fixes the second drawback point of REVA3.

REVB • Added GTX_CLK125 sourced from external 125 MHz oscillator.

• Added an optional IEEE 1588 connector (P10).

• Added three more resistor options (R311–R313) to route 3 IEEE 1588 signals that only available in eTSEC1

to the IEEE 1588 connector.

• Changed S4 to support LB_POR_CFG_BOOT_ECC_DIS.

• Changed SD chip select signal from SPISEL

REVC • Added a Marvell 88E1111 PHY. Phy address assigned to 0x3. Use same IRQ3# as L2 Switch.

• Added resistor option for RGMII signals route to either to L2 Switch or Marvell 88E1111 PHY.

• Added SGMII support for eTSEC1 if using the added Marvell 88E1111 PHY. (SGMII for eTSEC2 already

supported.)

• Added PLL CY23EP05SXC-1 U86 to PHY gerneated 125 MHz clock.

• Changed default TSEC1_GTX_CLK125 clock source to PLL CY23EP05SX-1 instead of external 125 MHZ

oscillator.

• Changed U36 1A linear regulator MIC39100-2.5WS to 3A MIC37302WR for higher 2.5V power consumption

by additional PHY.

• Changed default DAC to 16-bit SPI controlled MAX5203BEUB+ (U47).

(GPIO31) to GPIO13.

8.2 What should I do if the flash (NOR flash) image on the RDB is

accidentally erased?

You should set the RDB to use a hardcoded reset configuration and reprogram the flash memory by

debugger (for example, CodeWarrior debugger + USBTAP). T o use a hardcoded reset configuration, set

DIP switch S3 as OFF-ON-OFF-OFF (1011). On the other hand, if there is a reset configuration in NAND

Flash or the I2C EEPROM, you may want to use either one as a hard reset configuration source.

Alte rnat iv ely, some RE VA3 and all later boards have the I2C EEPROM bootloader programmed. It can be

used to reprogram the NOR Flash memory without a debugger. The procedure is as follows:

1. Power off the board and set DIP switch S3 as ON-OFF-ON-ON (0100).

2. Connect the board to Kermit (a UART terminal program; the other terminal program does not

work at this mode). Kermit can be downloaded from http://kermit.wwarthen.com/Download.htm.

3. Set the baud rate in Kermit as 38400 bps (for a 66 MHz clock-in RDB) or 19200 bps (for a 33

MHz clock-in RDB).

4. Power on the board and you should see the following in Kermit:

Hello and welcome to I2C BOOTLOADER

## Ready for binary (kermit) download

5. Go to Kermit → Send and select the u-boot image binary to be written into flash memory .

6. Wait for the file transfer and flash programming until you see

7. Power off the board and set DIP switch S3 back to ON-ON-ON-ON (0000).

8. Power on the board and you should see a running u-boot.

success in the Kermit window.

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

48 Freescale Semiconductor

Page 49

Revision History

8.3 What is the hardware setting for boot from NAND Flash?

Set DIP switch S4 as OFF-OF F-OFF-ON (1 1 10) and set DIP swit ch S3 as ON-ON-ON-OFF (0001). Note

that there is no boot image on NAND flash memory with the default shipment.

8.4 Some ATX power supplies do not work with the RDB?

Some ATX power supplies may need a large 5-V loading to stabilize the 3.3-V output; otherwise, you may

observe the 3.3 V lowered to around 2.9 V–3 V. The consequence can be a periodic reset by the on-board

voltage monitoring circuit. For a workaround, you may take one of the following actions:

• Add a 5-V loading to the power supply, for example, attach a hard disk drive.

• Change to another ATX power supply that does not require a large 5-V loading.

• Use the power supply provided with the RDB package.

Starting from revision REVA2, a resistor loading for 5 V is added. It should work better with the ATX

power supply that requires large 5-V loading. If there is still a problem, simply apply one of the

workarounds presented here.

8.5 Power management control (PMC) registers cannot be

accessed?

The PMC registers range from IMMR + 0x0B00 to IMMR + 0x0BFF . When this area is accessed in u-boot,

the RDB hangs up. It appears that the PMC block is related to the JT AG interface; TRST must not be pulled

down for normal operation of the PMC block. Possible workarounds are as follows:

• Attach a debugger to drive TRST high during normal operation.

• Remove the pull-down resistor (R37) for TRST. Although this tested on some RDBs without any

problem, it violates the hardware specification. If it does not work on your RDB, use another

workaround.

• This problem is fixed in REVA3

9 Revision History

Table 25 provides a revision history for this document.

Table 25. Document Revision History

Rev.

Number

0 2/2007 Initial public release.

1 4/2007 Replaced a faulty table of contents and restructured sections of the document for clarity.

2 4/2007 Added information to Section 8, Frequently Asked Questions (FAQs)

Date Substantive Change(s)

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 49

Page 50

Revision History

Table 25. Document Revision History (continued)

Rev.

Number

Date Substantive Change(s)

3 3/2008 • Added GTX_CLK125 sourced from external 125 MHz oscillator.

• Added an optional IEEE 1588 connector (P10).

• Added three more resistor options (R311–R313) to route three IEEE 1588 signals that are

only available in eTSEC1 to the IEEE 1588 connector.

• Changed S4 to support LB_POR_CFG_BOOT_ECC_DIS.

• Changed SD chip select signal from SPISEL(GPIO31) to GPIO13.

4 8/2008 • Added a Marvell 88E1111 PHY. Phy address assigned to 0x3. Use same IRQ3# as L2

Switch.

• Added resistor option for RGMII signals route to either to L2 Switch or Marvell 88E1111

PHY.

• Added SGMII support for eTSEC1 if using the added Marvell 88E1111 PHY. (SGMII for

eTSEC2 already supported.)

• Added PLL CY23EP05SXC-1 U86 to PHY gerneated 125 MHz clock.

• Changed default TSEC1_GTX_CLK125 clock source to PLL CY23EP05SX-1 instead of

external 125 MHZ oscillator.

• Changed U36 1A linear regulator MIC39100-2.5WS to 3A MIC37302WR for higher 2.5V

power consumption by additional PHY.

• Changed default DAC to 16-bit SPI controlled MAX5203BEUB+ (U47).

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

50 Freescale Semiconductor

Page 51

THIS PAGE INTENTIONALLY LEFT BLANK

Revision History

PowerQUICC™ MPC8313E Reference Design Board (RDB), Rev. 4

Freescale Semiconductor 51

Page 52

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or

+1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku

Tokyo 153-0064

Japan

0120 191014 or

+81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor

Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

+1-800 441-2447 or

+1-303-675-2140

Fax: +1-303-675-2150

LDCForFreescaleSemiconductor

@hibbertgroup.com