Page 1

Freescale Semiconductor

User’s Guide

Small Engine Reference Design User Manual

Featuring the MC33812 and MC9S12P128

Document Number: KT33812ECUUG

Rev. 3.0, 11/2009

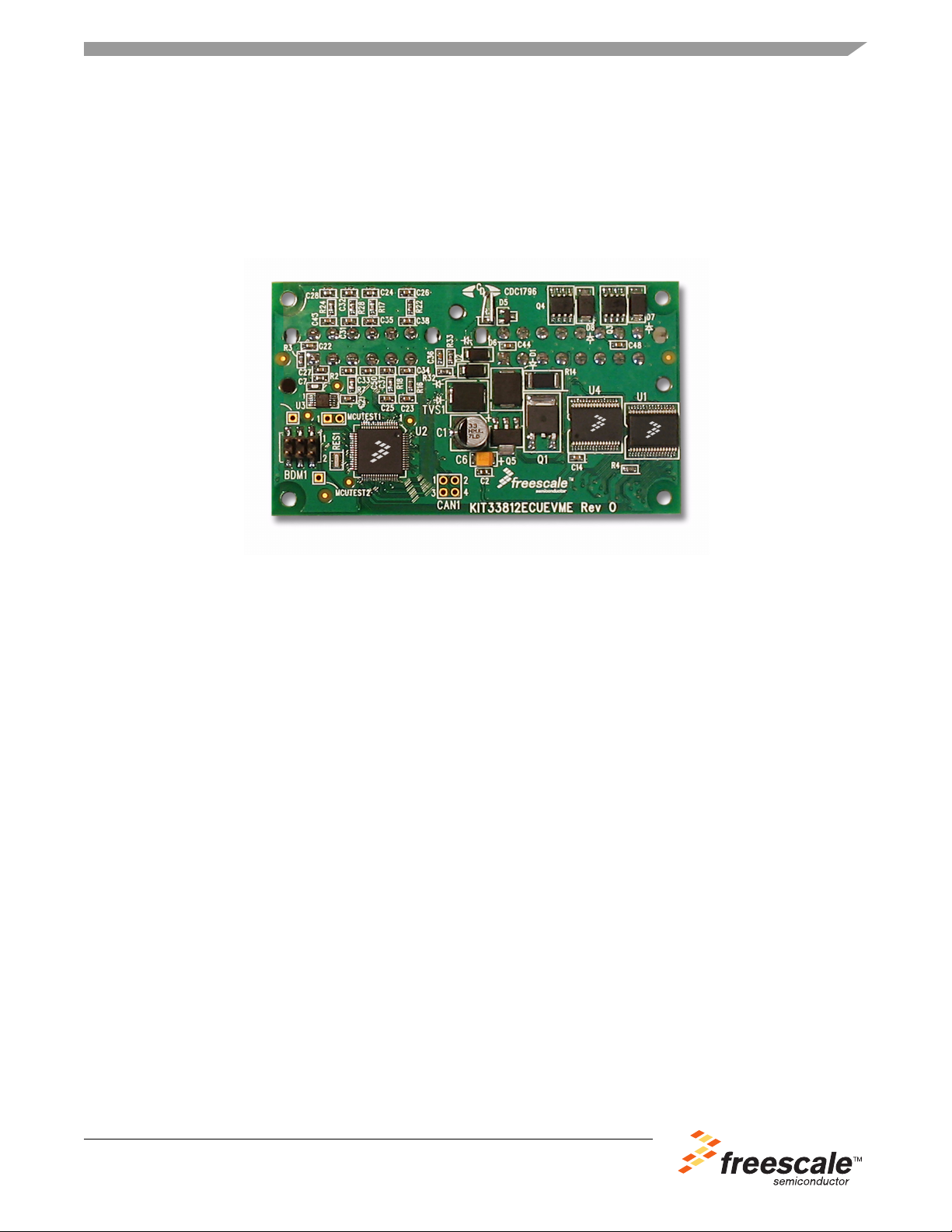

Figure 1. KIT33812ECUEVME Evaluation Board

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Application Development. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Application Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8 System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9 Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

10 Appendix A: Hardware Reference Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11 Appendix B: Software Reference Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

12 Appendix C: Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

13 Appendix D: References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

© Freescale Semiconductor, Inc., 2009. All rights reserved.

Page 2

Introduction

1 Introduction

Welcome to the Freescale Small Engine Reference Design Kit. This product was designed to be a

complete solution for the electronic control of a small engine. Small engines are defined as a one or two

cylinder engine for use in anything from a motorbike to a lawn mower to a generator. While the decision

was made to address a one-cylinder engine specifically, this design is extremely useful for a two-cylinder

engine with little or no modification. Freescale's concept of creating an engine control kit is intended to

enable a market ranging from garage hobbyist to seasoned Tier 1 Powertrain Engineer using Freescale

products.

Through the use of this kit, you can create an engine controller specific to a small engine application.

Engine control is a discipline that requires intimate knowledge and experience in Chemical, Mechanical,

and Electrical Engineering. For those familiar with mechanical control of an engine through a carburetor,

the use of this reference design kit can help to advance your knowledge in the electrical area and provide

a jump-start for a successful adoption of electrical engine controls to meet new emissions standards.

Providing a kit such as this is intended to make semiconductor products from Freescale easier to use.

The user is responsible for providing all input signals, output loads as well as the completed system

design and development. This kit should serve as a starting point for the development of an application

specific engine controller for a small engine. Example software and documentation are provided to assist

in successful design and implementation. It is recommended to have the following skills and experience:

embedded C-language programming, analog and digital circuit design and schematic analysis,

microcontroller programming, fuel injection system debugging and calibration, and engine test

environment experience. Additionally, there is further benefit to experience using the CodeWarrior

Development Studio and the Freescale S12(X) microcontroller Units (MCUs). The User Reference

Manual provides exercises and references to additional information to reduce the learning curve for

inexperienced users.

Freescale's goal is to enable the small engine market. To clarify this point, the hardware included in this

kit can readily be configured and reprogrammed to run an engine. However, it lacks the application

specific hardening (EMC, ESD, and environmental areas for example) and implementation optimization

that make it a production ready module for any specific application. Further, the free example application

software provided is a starting point capable of running an engine. It does not apply any advanced control

strategy capable of addressing the pollution concerns and regulations facing the small engine industry.

To do this would become application specific to an engine and could not be and should not be

implemented by a semiconductor supplier as it is deeply outside their area of expertise. The example

application software does show how to use the key functionality in the Freescale products that the kit is

based on, which speeds up the development process by showing a working example.

The contents of this kit will save many months of work, even for experienced powertrain engineers just

looking to evaluate Freescale products. A system has been created based on a one-cylinder closed-loop

engine controller using integrated technology while being cost-effective for the small engine market.

Example software is provided that can be customized to run an actual engine that has electronic fuel

injection. Documentation is provided to aid in going through the process of developing an application.

Finally, information on modifying the design to support the adaptation of the small engine reference

design to your application goals.

Small Engine Reference Design User Manual, Rev. 3.0

2 Freescale Semiconductor

Page 3

2 Getting Started

2.1 Exploring the Contents of KIT33812ECUEVME

Included in this kit are the essential components to develop an engine control application for small

engines. Development is centered on the use of a Windows based PC and the Electronic Control Unit

(ECU) contained in this kit.

kit are: ECU, wire harness, documentation DVD, Freescale CodeWarrior for the S12(X) (contained on

DVD), USB BDM Tool, and USB cable. Please refer to the packing list for any additional components that

may be included in the kit. If contents are missing, use the included warranty card or contact your local

Freescale Support Team.

Software Development on PC

Figure 2 shows a picture of the key kit contents. The key components of the

USB Connection to ECU

Documentation DVD

Including CodeWarrior

and example application

Small Engine ECU

code

Getting Started

Wire harness for

connection to EFI

System

Your Engine

Figure 2. Contents of Kit KIT33812ECUEVME

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 3

Page 4

Getting Started

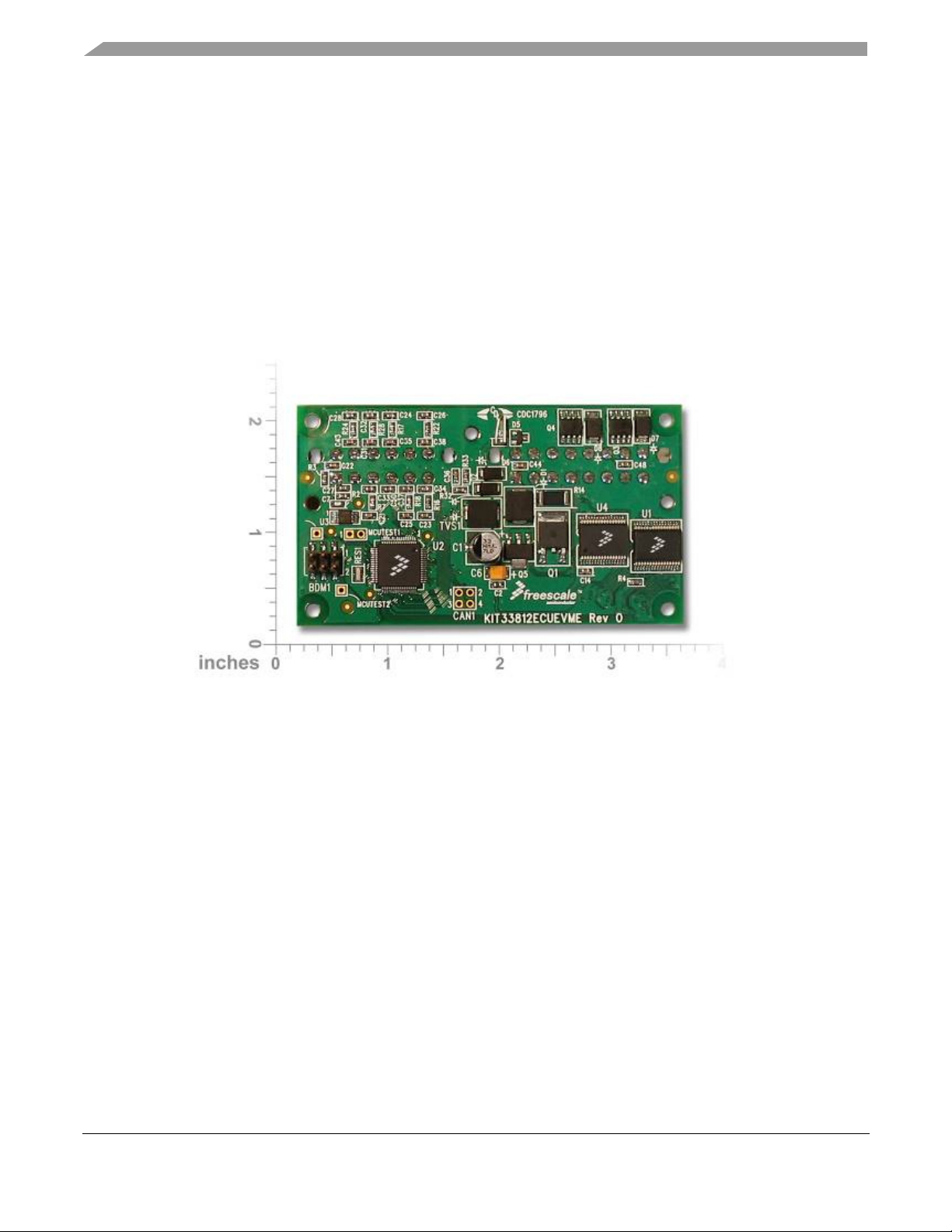

2.2 Electronic Control Unit (ECU)

This is the Small Engine Reference Design hardware. It is a one-cylinder engine controller based on the

Freescale MC9S12P128 microcontroller, MC33812 Small Engine Integrated Circuit, and MC33880

Configurable Octal Serial Switch. The unit will run from a 12

a fuel injector, inductive ignition coil, relays, incandescent lamps, and LEDs. The ECU also takes inputs

from switches and sensors, such as Engine Stop switch, manifold air pressure, engine temperature, and

variable reluctance sensors. Application software will be run on this unit containing your engine control

strategy. While the unit is not designed to be a production module specific to any engine, it is intended to

have the same look and feel. This resulted the small, business card sized form factor and minimal

provision for expansion.

V battery and control engine loads such as

Figure 3. ECU Included in KIT33812ECUEVME

Small Engine Reference Design User Manual, Rev. 3.0

4 Freescale Semiconductor

Page 5

2.3 ECU Wire Harness

To provide a physical connection to the electronic fuel injection system, a wired connection to the controls

and sensors of the system is required. As a starting point, a basic wire harness is included in the kit along

with the components to fully populate the connectors. The basic wire harness allows power to be applied

to the module and a minimal set of loads. Later in this manual, there is documentation that will discuss

the process of interfacing the signals of the engine to the ECU. Addition connectors can be easily

obtained through known electronic component supplies. Exact part numbers are made available in the

bill of materials (BOM) for the ECU.

Getting Started

Figure 4. ECU Wiring Harness

2.4 Documentation DVD/CD

The documentation media contains electronic copies of all relevant information for creating and using this

kit, including this User Manual. Documentation includes various support tools, such as spreadsheet tools,

and design files including schematics and Gerber output files. These can be accessed through the

graphical application that is automatically launched or by using Windows Explorer as a more direct

navigation of the contents. As information may be updated, always reference www.freescale.com for the

latest relevant information.

Figure 5. Small Engine Reference Design Documentation DVD/CD

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 5

Page 6

Getting Started

2.5 Freescale CodeWarrior for the S12(X)

All software for the ECU is developed using this application, which is included on the DVD. This is done

as a convenience as it is a large program to download. It is recommended to check for the latest version

and updates at www.freescale.com. Example software is tested using the 5.0 release of the S12(X)

product. This version does not require any updates or patches at the time development, however it is

recommended to maintain this software through updates as available. The CodeWarrior Development

Studio is an integrated development environment that provides a common interface for working with the

various tools needed for building software. It comes in various levels of product for various types of

MCUs. The example software allows the use of the Special Edition Product which is free for use. As your

application grows and further features of the product are required, upgraded licenses can be purchased

to meet your needs. The primary function of the CodeWarrior application is to compile software, program

the ECU, and then control the execution of the software through the integrated debugger.

Figure 6. Screen shot of Freescale CodeWarrior for the S12(X)

Small Engine Reference Design User Manual, Rev. 3.0

6 Freescale Semiconductor

Page 7

2.6 USB BDM Tool

Connection from the Windows PC to the ECU is performed by the USB to BDM Tool. This tool is powered

through USB and interfaces with the CodeWarrior application. The link to the ECU is through a 6 pin

ribbon cable that goes from the USB BDM Tool to the Background Debug Module (BDM) header on the

ECU. Through the BDM connection, the CodeWarrior application can use the BDM tool to communicate,

program, and control the S12 microcontroller on the ECU. While tool gets its power from the USB port

on the PC, it does not power the ECU. This separation is important as it provides a level of isolation from

the engine system to the development PC. Initial kits may include the P&E Multilink as the USB to BDM

Tool. Normal production kits will make use of the TBDML. It is important to know which tool you are using

so that the proper connection is selected when using CodeWarrior.

Getting Started

Figure 7. Example USB BDM Tool for Connection to PC

2.7 Additional Recommended Hardware

In addition to this kit, various pieces of equipment are recommended to perform application development

work for software validation and testing. These are commonly found in most electronics labs:

•12 V, 10 A DC power supply

• 100 MHz (minimum) 4 channel oscilloscope

• Soldering iron

• Grounded electrostatic matt

• Windows XP (required) PC

•12 V relays

• Potentiometers

• Switches.

Having all of these items will allow testing and debugging of the system.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 7

Page 8

System Setup

3 System Setup

Now that the contents of the small engine reference design have been described, the focus will shift to

the complete development system. This includes the contents of this kit and the fuel injected engine as

a system. At a high level, system setup contains the following steps:

• Definition of interface between ECU and Engine

• Creation of simulated engine environment

• Installation and verification of software development environment

• Engine load and sensor validation

• Migration plan towards real engine hardware

To accomplish these steps, several exercises will be described to help take you through this critical

phase. These exercises include, getting started with Freescale CodeWarrior, and creating a known

reference system. Additionally, suggestions for further training will be provided based on using Freescale

products and the system level setup.

your engine. This system incorporates the interface from the PC to the actual engine. The user must

provide the engine loads for electronic fuel injection including fuel injector, inductive ignition coil, relays,

and other relevant components. Signals from VRS, MAP, switches, and other inputs must also be

provided along with the actual engine itself.

Figure 2 shows the components of this kit and a placeholder for

3.1 Definition of interface between ECU and Engine

The first step in using this kit is to determine how it will connect to your engine system. As mentioned, the

engine must be fuel injected. If you are converting an engine from mechanical (carburetor) to electronic

control, this must be done before or in parallel with using this kit. The ECU is designed around a

one-cylinder engine, however, it can be adapted to work with a two-cylinder engine. The requirements for

two-cylinder operation are: a) ignition coil must be a dual output or twin coil, b) wasted-spark strategy is

acceptable for application. This means that a twin coil, capable of driving two separate spark plugs from

a single input, can be used to fire every engine revolution (in a four-stroke engine) to produce two spark

events, one in the desired cylinder and one in the second (wasted) cylinder. If this can be tolerated in the

system, fuel control can be provided individually to each cylinder through the INJOUT and ROUT1

signals.

To aid in the connection from the ECU to the engine, a worksheet is provided. Using Load Worksheet.xls,

available on the documentation DVD, connection to the engine can be defined. This Excel spreadsheet

contains the full list of connections and suggested functionality for each pin of the ECU. Matching up the

various controls, sensors, and inputs on the engine to the ECU should take into account voltage ranges

and current capabilities. If there is doubt to the connection, use the schematic and Hardware Design

Reference Manual found in Appendix A to for in-depth analysis of the circuits behind each ECU level pin.

The design goal of a cost-efficient design does not allow for a system to include all possible system

configurations. The signals available reflect essential controls for one-cylinder, closed-loop engine

control, highlighting the integration of the MC33812 Small Engine IC. Essential functionality should be

considered first, such as the direct controls for fuel and spark. System controls such as the fuel pump or

voltage regulator should be secondary concern as they can be externally controlled and do not require

precise timing execution.

Small Engine Reference Design User Manual, Rev. 3.0

8 Freescale Semiconductor

Page 9

System Setup

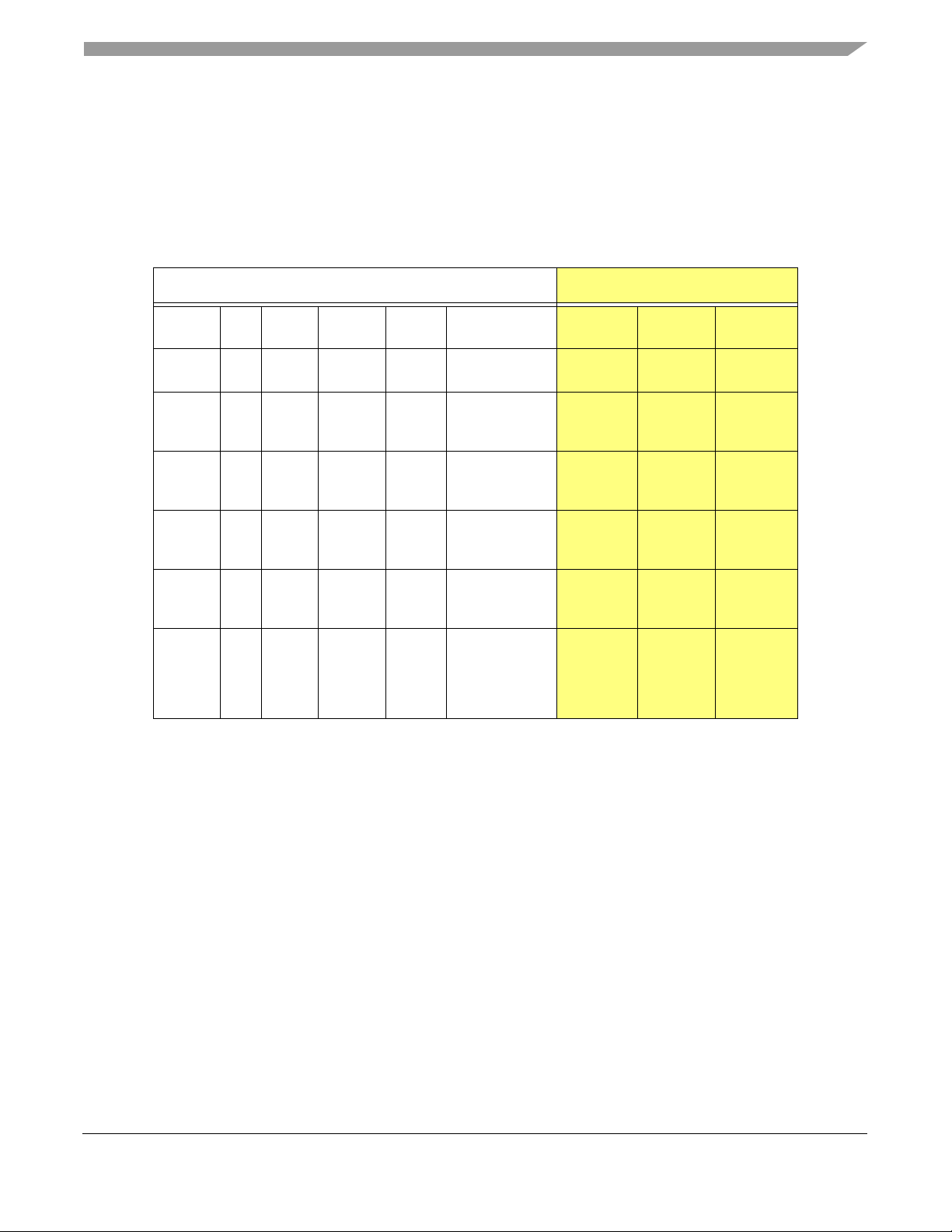

By filling in the information under the “Target Engine System” column, see yellow highlight in Engine Load

Worksheet - Target System Identification Column in Yellow, each connection to the ECU can be defined.

In the actual worksheet, signals of the ECU are color coded to identify similar functionality. From this

completed worksheet, the wire harness from the engine to the ECU can be made. Materials for the AMP

brand connectors of the ECU are included to get this process started.

Engine Load Worksheet - Target System Identification Column in Yellow

KIT33812ECUEVME Reference Design Target Engine System

Connector Pin Signal

Name

1VPWRPower

2 ISO9141 Input /

3 COIL 0-Vbat Spark control of

4 GND 0V Module level

5 GND 0V Module level

6 TPMD 0-Vbat H-bridge control

Signal

Type

Input

Output

Voltage

Range

13.6V System power

0-Vbat Bi-directional com-

Recommended

Functionality

from 12V battery

munication pin for

diagnostics

digital ignition system

ground reference,

return path of Vbat

ground reference,

return path of Vbat

for 4-phase stepper motor for idle

speed air speed

control

Connector

Pin

Wire Color Functional

Exercise 1: Complete the Load Worksheet for your target engine system.

Description

1. Open “Load Worksheet.xls” and bring the “Instructions” sheet to the front by clicking on this tab.

2. Collect information such as wiring diagrams and schematics for the engine system to be run.

3. Use the engine system information to define how each signal of the ECU is going to be connected to the engine.

This includes a definition of an existing pin on a connector, wire color and type, and the functionality associated

with the system. This table will also be useful for configuring the software.

4. Repeat this exercise for creating a simulated engine environment.

Creation of simulated engine environment

Before the simulated environment can be created, the ECU must have a viable power source. As the ECU

is designed to work in a real engine system, it is required to have a 12

capable of generating 12

V at 1.0 A is a good starting point for the ECU alone. Depending on the loads

V power source. A power supply

that will be connected to the ECU, a much larger power supply may be required with high current. A good

starting point for working with a full featured system is a 12

loads may be greater, 10

A is generally large enough since the high current loads of ignition and injectors

V, 10 A power supply. While the total system

are not typically on simultaneously.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 9

Page 10

System Setup

The best and safest way to begin developing an application for engine control is to work with a simulated

engine system. This reduces risk and development time by not having to focus on fuel related safety

concerns when trying to solve complex applications issues that arise. Developing with a simulated engine

system engine begins by selecting components that are similar or identical to the actual components on

the engine. For many of the loads, these can be the exact same components. In some cases, loads can

be replaced by a lesser expensive relay or a light. Relays work well for high power loads with dynamic

operating frequencies such as ignition and injectors. In those cases, the sound of the relay actuation is

beneficial to validate behavior during low speed testing. Other loads work better with lights or LEDs.

These are more simple loads that are simply controlled as on or off for long periods of time. Some loads

will require the actual load to test, such as an idle speed motor.

Perhaps the most challenging part of the system to simulate is engine position. Two core technologies

are used to sense engine position: variable reluctance sensors (VRS) and Hall Effect sensors. The

majority of production engines use a VRS for engine position. The advantage with the VRS is cost, while

a Hall Effect sensor provides a cleaner output signal. Both types are supported on the ECU. The default

configuration is for VRS. Use the schematic to identify the components to remove and populate for using

a Hall Effect sensor.

With respect to creating a simulated engine environment, engine position is the fundamental element.

Simulating the rotation of the engine can be done in two ways, virtual and physical simulation. A virtual

simulation involves a digital re-creation of the spinning crankshaft signal. This is best done by reproducing

a Hall Effect Sensor type of output, but there are options for a VRS. Using a different ECU, such as a

basic development board for a Freescale MCU, software can be written to create a the missing tooth

output pattern that is produced by a rotating engine using a Hall Effect Sensor. Such programs have

already been written for varying degrees of Freescale MCUs. The TOOTHGEN function is a part of a

library of functions for the MPC55xx products that have the eTPU peripheral.(ref1) Using a development

tool for such a product can allow the creation of a simulated engine position signal. For a VRS, options

for a virtual simulation include a combination of PC software with simple custom hardware. Do it yourself

(DIY) web sites, such as those for the Mega Squirt products, provide detailed instructions for building your

own circuit and provide PC software that can control the generation of the VRS signal based on a

simulated signal. (ref2)

While the concept of a virtual simulated engine position signal is very attractive, it lacks fundamental

characteristics that come with actual crankshaft of an engine. Since a virtual signal is typically generated

by a digital computer, it usually does not account for the real world imperfections of an engine.

Specifically, the timing pulses produced by a virtual signal are perfect. While this is a good on paper or

visually on a screen, the imperfections in the motion due to production tolerance and jerk associated with

cylinder compression lead to a rotation pattern that is not perfect. As a step in the right direction, a

physical simulated engine position signal can be used. This type of setup can take advantage of VRS or

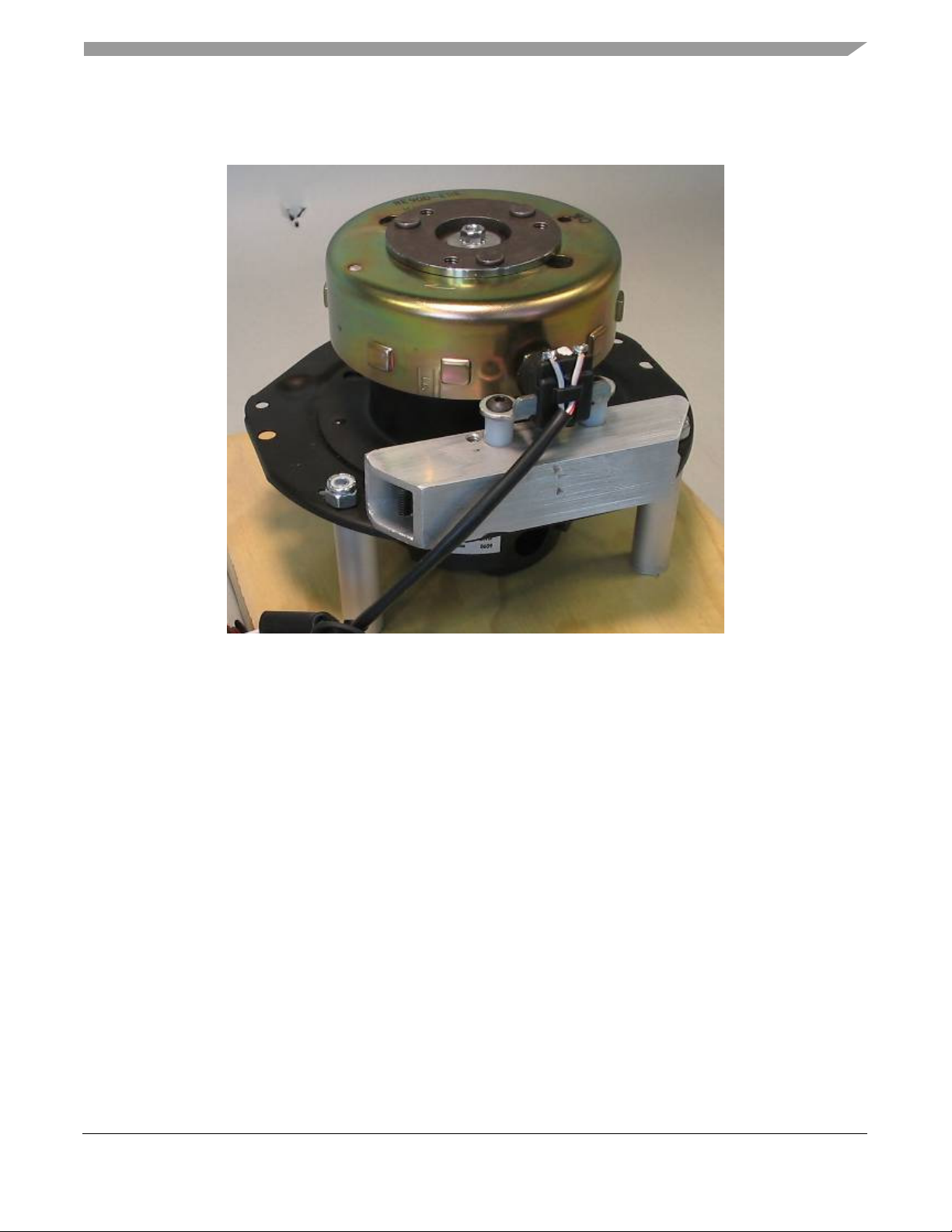

Hall Effect Sensors and produce a signal that has more realistic characteristics to a real engine. A simple

and effective way to make a physical simulation is to mount an engine flywheel containing the position

teeth to a small electric motor. This creates a tool known as a spin bench. Using an electric motor and the

actual flywheel allows simple control of the engine speed while adding real world conditions for changes

in the actual time between position teeth. While the strong variations related to compression and

combustion are not present, the spin bench does allow transitions to and from a stopped engine and

provide teeth that are representative of the actual engine that the application is being developed for.

Figure 8 shows an example of a spin bench using a production flywheel and VRS from a small motorbike.

Small Engine Reference Design User Manual, Rev. 3.0

10 Freescale Semiconductor

Page 11

System Setup

Figure 8. Spin Bench Example for Creating a

Physical Simulated Engine Position Signal

Exercise 2: Creating a reference platform for a simulated engine environment

1. Open Load Worksheet.xls and bring the “Reference System Load Worksheet” to the front.

2. Obtain components listed. Generic component specifications are listed.

3. Additionally, a simulation for engine position will be required. Create this using any of the examples described in

this section. Verify the simulated engine position signal is being properly generated. For this reference platform

to work, a 12 minus 1 signal must be generated. This means 12 equally spaced teeth with one missing tooth

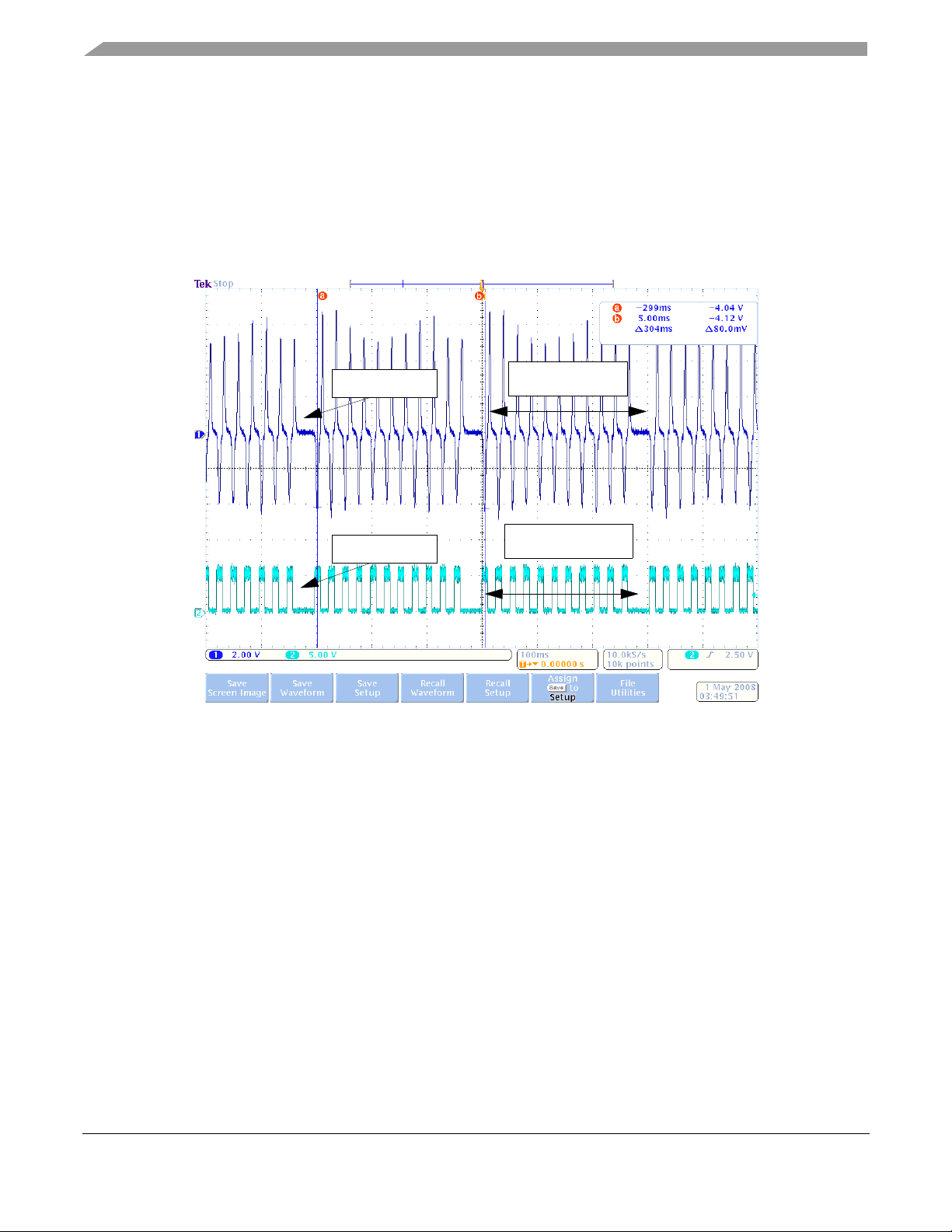

representing a gap. See Figure 9 for oscilloscope trace of 12 minus 1 signal.

4. Create a wire harness to connect reference components to the ECU. Include specifications of wire color and pin

number as applicable. This will aid in debugging and later development.

5. Connect the wire harness to the ECU.

6. Place the Engine Stop Switch in the active position, which is a short to ground.

7. Apply power. Verify connections are correct by noting that power supply is drawing less than 500mA of current

and no components of the ECU are generating large amounts of heat. If any component is hot, remove power

and verify connections.

8. Verify that no relays should be active. This should be audible when power is applied if a relay was activated. If

relay activates on power on, verify Engine Stop Switch position and relay connections.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 11

Page 12

System Setup

9. Move Engine Stop Switch to passive (12 V) position. This should activate the ROUT1 relay for 3 seconds then

10. Start engine position simulation through Hall Effect or VRS. Keep RPM to about 500RPM. Relay connected to

deactivate the relay. Audibly this will be heard by two clicks. If connections are good and relay is not actuating,

verify signal on P1-9 (ISO9141) is low (0 V). If this is not low, then ECU does not have application code and will

require programming.

COIL should be turning on and off each rotation and be audibly heard. This indicates that a good engine position

signal is getting to the MCU and it is able to process and control the loads.

Missing Tooth

Missing Tooth

VRS Tooth Signal

(12 minus 1)

Hall Effect Tooth

Signal (12 minus 1)

Figure 9. Graphical Representation of 12 Minus 1 Tooth Pattern on Oscilloscope

Installation and Verification of Software Development Environment

All application software for the ECU is developed using the Freescale CodeWarrior for S12(X) integrated

development environment (IDE). Version 5.0 is the latest at creation of this manual and is included on the

DVD included with the KIT33812ECUEVME. To install CodeWarrior, save then launch the installation

application from a temporary location on a Windows based PC or directly launch the installation

application. No specific instructions are recommended beyond the default settings shown in the on

screen menus. If other versions of the CodeWarrior product are on the PC, this will not overwrite any

information as each version is a separate product and installation. For step by step confirmation of the

installation process and a quick tutorial on getting started, refer to the CodeWarrior Quickstart Guide

included on the Documentation DVD/CD. Further information relative to CodeWarrior can be found at

www.freescale.com/training. This link has a search feature allowing refinement of high level training

topics. Two training topics that will aid in the use of this kit are learning C programming

(http://www.freescale.com/webapp/sps/site/training_information.jsp?code=TP_C_PROGRAMMING&fsr

ch=1) and the Virtual lab for the S12XE

(http://www.freescale.com/webapp/sps/site/virtual_lab_information.jsp?code=VLAB_EVB9S12XEP100

&fsrch=1). Additional resources for working with CodeWarrior include the various user manuals that are

installed with CodeWarrior.

Small Engine Reference Design User Manual, Rev. 3.0

12 Freescale Semiconductor

Page 13

System Setup

Once you have installed the CodeWarrior application and become familiar with its operation through the

virtual lab, the software development environment can be validated.

Software Development Environment Validation Exercise

1. Create a new project in CodeWarrior for the MC9S12P128 MCU using the Project Wizard that appears when

CodeWarrior is launched. Create the project using default settings but be sure to include the

included with your kit

2. Once you have the project created, verify the integrity of the empty software project by doing a build.

3. Once successful, connect the ECU to your 12 V power source using your simulated load harness.

4. Next, connect the PC to the USB BDM tool. Installation will be required if this is the first connection to the PC,

follow on screen menu and install driver automatically.

5. Connect the BDM ribbon cable to the BDM header on the ECU, note the location of Pin 1 as the red wire on the

cable and number 1 near the header.

6. Press the debug control in CodeWarrior to download the empty software project to the ECU. Follow the on

screen menus to connect and program the ECU, as performed in the Virtual Lab for the S12XE.

7. Press the “GO” arrow and allow execution for a few seconds before pressing “HALT”. The source window should

show the processor stuck in an infinite FOR loop. This verifies that the ECU is working and the software

environment has been created allowing programming and development.

as the target connection.

USB BDM tool

As a final piece towards a complete development environment, a build of the example software will verify

if all of the tools discussed this far are working on your system.

System Setup Validation Exercise

1. Save the example application software by copying the folder “Example Scooter Application” from the DVD. This

is a CodeWarrior project that contains a working application that runs a 50cc scooter engine

2. Open “My _Engine_Project.mcp” in the saved folder through CodeWarrior.

3. Build the project.

4. Program the ECU by providing power and clicking debugger per previous exercise.

5. Run the application using the green “GO” button.

6. Stimulate the application by running the engine position simulation and using the Engine Stop Switch. Operation

should be identical to simulated engine environment test performed above.

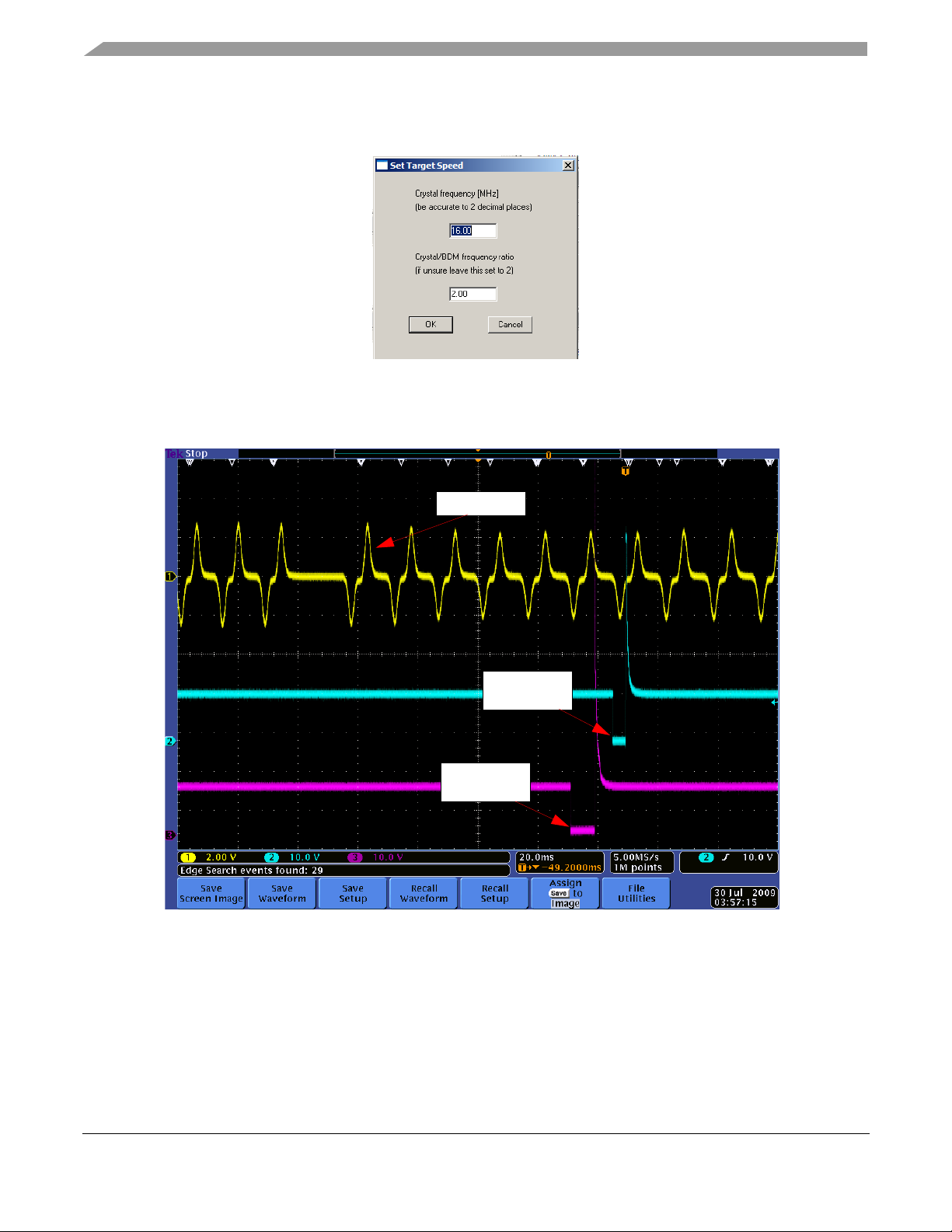

Note: When using the TBDML as a BDM tool, the BDM communication speed must be manually changed

when the MCU switches between internal and external oscillator settings. The example application

switches from internal to external oscillator and it is necessary to change the BDM speed to 8MHz as

shown in

Figure 10. This setting is found in the TBDML HCS12 drop down menu in the debugger

window. If you do not have this drop down menu, you do not have the proper connection selected in

Codewarrior.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 13

Page 14

System Setup

7. Verify control signals for VRS, COIL, and INJOUT match those shown in Figure 11 using an oscilloscope.

Figure 10. Changing the BDM Communication Setting for TBDML

VRS Input

Fuel on

INJOUT

Spark on

COIL

Figure 11. Control Signals for Reference System Validation Exercise

Congratulations! This is a significant step towards creating your own engine controller. A safe and

effective development environment has been created allowing you to create your own application for

small engines. As the next sections progress, the focus will be mainly on the C-language source code

used in the example application. It is recommended to be experienced in the C programming language

to continue.

Small Engine Reference Design User Manual, Rev. 3.0

14 Freescale Semiconductor

Page 15

4 Application Development

There are three paths that can be taken using the Small Engine Reference Design for application

development: 1) Ground up custom code can be written. 2) The example applications can be modified.

3) A ground up application can be written using the low level drivers and operating system used in the

example applications. If a ground up software project is selected, it may be beneficial to use various

aspects of the example application for working with the S12 MCU and the other various components in

the design. The example application will also be a benefit when using the low level drivers as it serves as

an example for using these pieces of code. At the very least, customizing of the example application will

be required. This section will focus on customizing the example application to a specific engine.

4.1 Example Application Architecture Overview

The example application is designed to run a one or two cylinder engine using a hybrid operating system.

A hybrid operating system is important to engine control as all engine control events are based on the

rotation (angle domain) of the engine and user control processing and data collection must be performed

periodically (time domain). Additionally, the example application reduces complexity through a hardware

abstraction layer (HAL). Through the HAL, software complexity is reduced by using application level

signal names instead of native control names for the MCU. The combination of these two software

techniques produces an example that is configurable through a single header file and reduces user

implemented code to three main functions.

Application Development

User functions are split into three main activities. In Data_Management(), all data is collected and

processed in the system. This includes analog and digital information and any filter functions that are to

be performed. Engine_Management() is called to calculate raw fuel and spark parameters for running the

engine. This includes table look up of hard data values based on current engine RPM and load as well

as factoring in fuel and spark modifiers. In User_Management(), the engine control strategy is run. It

includes interpretations of user control inputs and control strategies for loads. The primary goal of the

User Management function is to handle user controls, determine fuel modifiers, and calculate engine

load. Each of these functions are performed at various rates and configured through the Application

Definitions.h header file. These functions do not directly control the engine fuel and spark events. These

are performed by low level functions that react to the rotation of the engine through the engine position

data. The low level engine control events use the latest parameters passed to fuel and spark controllers

by the user functions. Additional information is provided in Software Reference Manual found in Appendix

B.

4.2 Configuring the Application

The first step in working with the example software is to configure the code to be generated through the

Application Definitions.h file. In this file are definitions used to conditionally compile code based on the

user defined system. This is done to create an application that only uses the memory required for the

specific application, demonstrate flexible software design through conditional compiling, and create a

framework for a custom implementation using various types of hardware. The file is designed to be simple

and allow decisions to which definitions to select by using the completed Load Worksheet, discussed

earlier, and knowledge of the application.

While the software provides a signal abstraction layer, configuration of the low level software must be

performed through an application header file, “Application Definitions.h”. This file defines what signals are

used in system and provides parameters that lead to conditionally compiled code. Example of configuring

the software is provided in the demo application. The header file gives you detailed description on how

to choose what options you want in your system. Configuring the system through the application header

file is done by modifying system parameters by adding or removing specific lines through the comment

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 15

Page 16

Application Development

directive of the C programming language. The following examples goes through various definitions found

in the application header file and show possibilities for configuration. It is important to keep in mind the

limitations of the hardware as the software incorporates functionality beyond what is found on the

reference design hardware.

Example: Configuring the number of cylinders.

//How many cylinders? Choose one.

#define ONE_CYLINDER

//#define TWO_CYLINDER

To change this application from one cylinder to two cylinders, modify the lines as follows:

//How many cylinders? Choose one.

//#define ONE_CYLINDER

#define TWO_CYLINDER

Other configuration of the application header file will require modifying parameters that are numerical in

nature. Each value must be customized to your application. Default values are provided but may not be

relevant.

Example: Configuring maximum RPM of engine.

//Set the maximum RPM for engine rotation

#define RPM_MAX 10000

This parameter can be modified to reduce the maximum RPM from 10 KRPM to 500 RPM as follows:

//Set the maximum RPM for engine rotation

#define RPM_MAX 500

For system signals that are configurable, multiple definitions are required. Only if the signal is used do

any of the associated parameters need to be defined.

Example: Removing definition of an analog signal.

//Oxygen Sensor(O2)

//Define the signal for the system to enable functionality.

#define O2

//Define for O2 filter algorithm selection. Only average is

//available.

//Leave undefined for using raw data only.

#define AVERAGE_FILTER_O2

//Data collection periodic rate can be from 1 - 255ms.

#define O2_DATA_COLECTION_RATE 16

/* O2 data buffer size */

#define O2_BUFFER_SIZE 16

In this example, if the Oxygen Sensor is not used, then all pound defines should be changed to comments

as follows:

//Oxygen Sensor(O2)

//Define the signal for the system to enable functionality.

//#define O2

//Define for O2 filter algorithm selection. Only average is

//available.

//Leave undefined for using raw data only.

//#define AVERAGE_FILTER_O2

//Data collection periodic rate can be from 1 - 255ms.

//#define O2_DATA_COLECTION_RATE 16

/* O2 data buffer size */

//#define O2_BUFFER_SIZE 16

Small Engine Reference Design User Manual, Rev. 3.0

16 Freescale Semiconductor

Page 17

Application Development

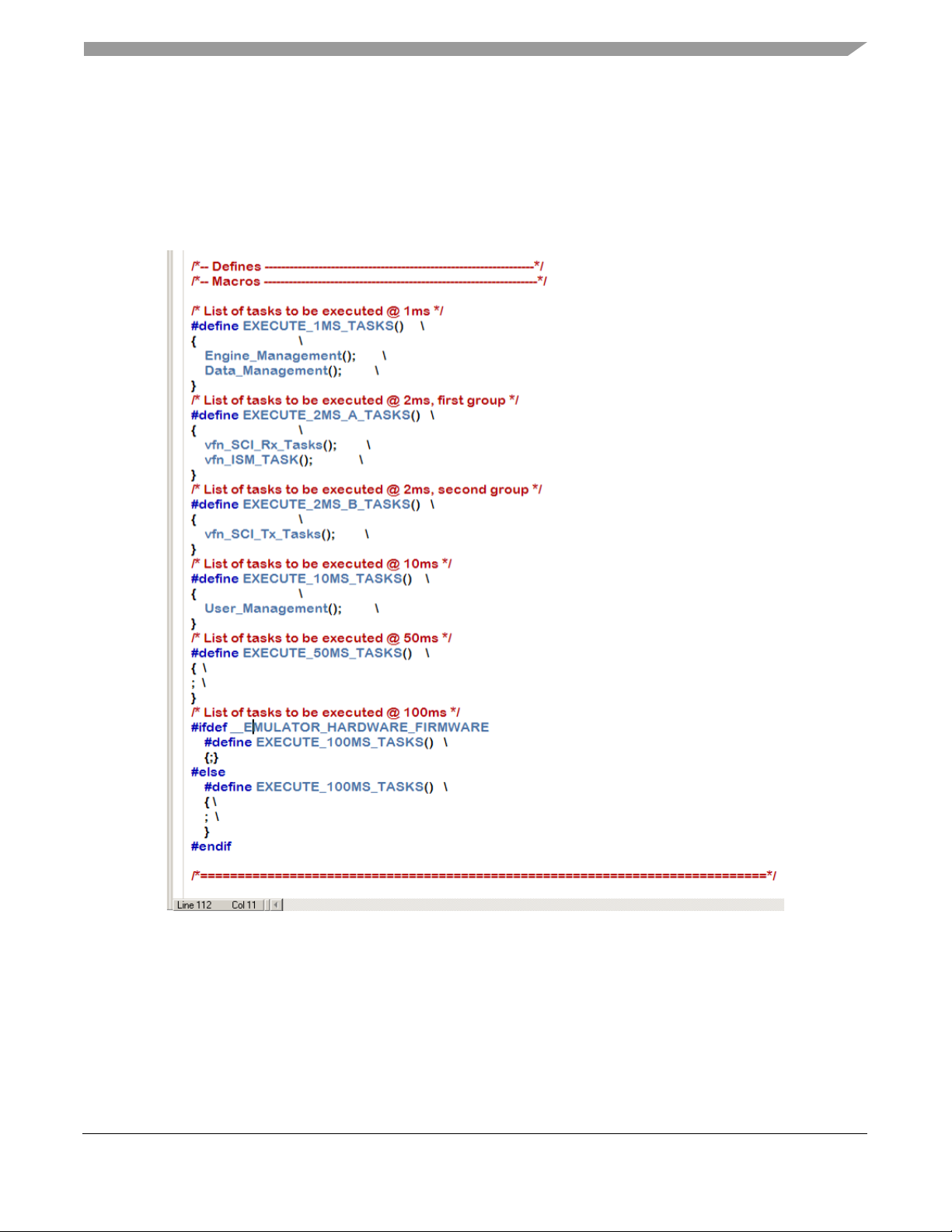

One additional configuration is provided outside the Application Definitions.h file. This is the configuration

of the time domain scheduler of the operating system. Configuration of the timing for the tasks is done in

the Tasks.h file. As seen in

Figure 12, the various tasks are configured by placing function calls in the

desired task time. While this is an easy way to implement a variety of time based tasks, this simple

scheduler does not guarantee task execution time. It is recommended to perform timing analysis using

simulation and instrumented software as a part of the application development process.

Figure 12. Definition of Tasks in Tasks.h File

To configure the task timing, edit the definitions shown in Figure 12 using the exact syntax found in the

file.

Example: Modifying Task Times

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 17

Page 18

Application Development

In this example, the default task scheduler found in the example application will be modified to show how

to slow down the execution of User_Management() and add a custom function to be run every 1ms called

Heartbeat().

1. Open the example application using CodeWarrior.

2. Open the file “Tasks.h”.

3. Find the definition section containing the 10 ms tasks.

4. Select the line containing the function call “User_Management()”. Cut this line from the code.

5. Place the User Management task by copying it into the space for 100 ms tasks.

6. In the 1.0 ms task section add a line containing the function call “Heartbeat()” and follow syntax shown for other

tasks

When complete the code shown in Figure 12 should look exactly like the code shown in Figure 13 below.

Figure 13. Modifications of Tasks.h from Example Exercise

Small Engine Reference Design User Manual, Rev. 3.0

18 Freescale Semiconductor

Page 19

4.2.1 Fuel and Spark Data Tables

As a means to input data used for fuel and spark values, an Application Map Tool based on a spreadsheet

is provided. This tool provides the essential functionality for translating fuel and spark data tables into

content that can be placed into the example software. Specific engine management data can be placed

into the tool using engineering units. This table is then converted to microcontroller units in a C-source

friendly format. Map table sizes can be adjusted to meet application requirements. The Application Map

tool is identified as “Map Tool.xls”. Additionally, reference for an example map is provided in “Scooter

Map.xls”. This provides an example of a completed map as used in the example application.

4.2.2 Modifying Table Sizes

As a first step, the table size should be customized to accommodate the performance and data

requirements. This is accomplished by adjusting the number of load points and RPM points in the table.

In the empty map provided (Map Tool.xls), this is done by changing number of and content of the load

row (green) and the RPM column (yellow) values. Both the number of load and RPM values directly

impact the size of the table and speed at which the table look up is performed.

While more data points gives you better tuning ability, it will increase the size of the application and

increase the worst case time to perform the table look up. Another factor used for sizing the tables is

available data. If a legacy map is used then the simplest starting point is to directly reuse this map. If a

new map is to be created by empirical data through testing, a smaller map is the best starting point.

Application Development

Fuel and spark maps are independent of each other and the load and RPM points must be customized

for both sets of data. Using the “Fuel Engineering Units (ms)” and the “Spark Engineering Units (BTDC)”

worksheets, enter the desired number of points and values for each point for the load row and RPM

column. Load is input as a percentage from 0 to 100% in ascending order, left to right. RPM is input from

0 to your max RPM in ascending order, top to bottom.

When determining your max RPM, you should consider the performance of the engine as well as the

resolution of the software. For the example application software, a fundamental timing unit is 1.6

means that the highest resolution between RPM measurements is 1.6us. However, RPM, or engine

speed, is determined from the tooth period measurements on the engine's flywheel. This means is that

while the engine is rotating at a given RPM, the measurement taken is at a fraction of this rate.

For example, at 6000 RPM, an engine completes one rotation every 10 ms. The engine controller

monitors position of the engine through the teeth on the flywheel. Each engine will have a specific number

of teeth. For this example the engine has 12 teeth. The result is that the engine controller will measure

the time between two teeth at 6000

will provide a measurement of 520 (really 520.8 but quantization results in 520).

At 6000 RPM, there is not much sensitivity due to the 1.6 μs timing unit as there is a count of 520.

However, as the RPM and number of teeth increases so does the sensitivity. This concept is important to

understand and also is relevant for low RPM conditions as well. At low RPM maximum time that can be

measured is 104.5

ms. For the 12 tooth engine example, this would correspond to 47 RPM.

RPM as 833 μs. Looking at our fundamental timing unit, the software

4.2.3 Configuring Data Translation

Before entering any data, the parameters used to translate engineering units to MCU units must be

properly set. This must be done on two worksheets: “Fuel MCU Units (Tics & Counts)” and “Spark MCU

Units (BTDC & Tics).” At the top of these two worksheets are five parameters that each must customized

to each engine system.

μs. This

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 19

Page 20

Application Development

Use the Min. Load value to change what the minimum voltage reading is for load. For a throttle position

based load, this is typically the closed throttle position. For a MAP sensor based load, this is the voltage

produced by the MAP sensor at a minimum operating pressure.

Figure 14.

In the Max Load field, change the value to what the maximum voltage reading is for load. The same

concepts apply as for Min. Load only this is at a minimum condition.

Figure 15.

For the ADC ref field, input what the reference voltage is for the analog measurement. The Small Engine

Reference Design uses 5.0 V as the reference and this should not be changed.

Small Engine Reference Design User Manual, Rev. 3.0

20 Freescale Semiconductor

Page 21

Application Development

Figure 16.

Depending on the software configuration, analog data is collected as 8, 10, or 12 bits. Make sure this field

matches how the software is configured.

Figure 17.

The final field that must be completed is the Number of teeth. This is the number of teeth on the flywheel

as used for synchronization and engine speed measurement. Use the total number of teeth including

missing teeth as the spacing is the important characteristic. For example, an engine may have a 12 minus

one tooth configuration, meaning 12 equally spaced teeth and one of the teeth is removed for

synchronization. In this case the relevant number is 12.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 21

Page 22

Application Development

Figure 18.

4.2.4 Entering Map Data

Each combination of load and RPM value creates a unique data point that can be accessed by the

software during execution. The data for fuel and spark maps are input into the “Fuel Engineering Units

(ms)” and the “Spark Engineering Units (BTDC)” input worksheets, respectively. As data is entered in

these two worksheets, it is translated on the “Fuel MCU Units (Tics & Counts)” and the “Spark MCU Units

(BTDC & Tics)” output worksheets. These two output worksheets contain the same data as the input

worksheets only translated based on the MCU and software configuration.

Small Engine Reference Design User Manual, Rev. 3.0

22 Freescale Semiconductor

Page 23

Application Development

Figure 19. Completed Input Table for Fuel Map Data Example

An example of using this tool is provided and is the actual maps used by the demo software running a

scooter engine. This serves as a reference and should not be considered a starting point for any engine

without validation. Validated maps from other fuel management systems can be directly input into this tool

if in the same format.

4.2.5 Exporting Map Data

Once the fuel and spark maps are completely filled, it is necessary to export the data to a file format that

is C-source code friendly and can be placed into the example application. This is accomplished by saving

the worksheets labeled as “Fuel Export Data” and “Spark Export Data” in a comma delimited format and

performing limited modification to the saved file. Once the data is then saved in this new format, it can be

copied and pasted into the Sea Breeze Emulator Software.

4.2.6 Map Data Export Process

1. Complete fuel and spark map data entry per above desciption.

2. Select the “Fuel Map Export Data” as the active worksheet.

3. Verify the table values match with the values of “Fuel MCU Units (Tics & Counts)”.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 23

Page 24

Application Development

4. With “Fuel Map Export Data” active, save the file as a comma delimited file with the extension <my fuel

map>.csv. This will put the active worksheet into a file that contains only the fuel data separated by commas.

When saving this file as a “.csv”, many warnings will be presented. Most of these warnings will indicate that the

new file format does not support multiple worksheets. Read these warnings and select the option that saves the

active worksheet and continues with the operation.

5. The “.csv” file will need one specific alteration. Open the fuel map <my fuel map>.csv using a text based editor,

such as WordPad. At the end of each row of data, add a comma after the last data value, excluding the last row.

Save the file. The data can now be copied and pasted into the Application Map.c file of the Sea Breeze Emulator

Software in the fuel data array. Choose the array that fits your data type as configured in the map tool and the

application header file.

6. Repeat steps 1 through 5 for spark map data.

Additionally, information regarding the size of the table and the actual values of for each of the load and

RPM values must be put into the Application Map.c file. The same process used for the table data can be

used for the load and RPM values using specific export tabs and above procedure provided. The number

of load and RPM points for the fuel and spark arrays must be put into the Application Map.h file. It is up

to the user to ensure the table is sized properly for the data that is input into the actual map. Errors in the

size of the data tables or the data used for each load or RPM value will result in an improper table look

up procedure, which may result in random data used to create fuel and spark events. Use the demo

application as a guide if there is doubt in your procedure.

4.2.7 Working with the Example Application

The demo application is based on a simple application state machine (ASM) for engine control. This state

machine executes in the User_Management() task and can be found in the User_Management.c file. A

combination of user controls and engine operating parameters are used to control the states of the

application. The five states of the ASM are: INIT, STOP, START, RUN, and OVERRUN. A function call is

provided for transitioning to each state. This allows a more controlled engine operating mode when

changing states.

Description of User Management States

INIT

This state provides a known configuration of the User Management task and should be configured as the

initial state using User_Management_Init(). Variables for User Management should be initialized and any

essential activity that is necessary to be performed prior to operating in any other state should be done

in the INIT state. Once this activity completes, the ASM should transition to the STOP state where the

periodic activity begins. Optionally, if a major system error occurred, the user may find it necessary to

return to this state.

STOP

In this state, the engine has been decided to be stopped from rotating or running. System inputs such as

switches would typically cause the application to enter the STOP state. The application should configure

any outputs or controllers to match this request to stop the engine and remain in this state until the inputs

reflect going to an active engine state.

START

As provision for a slowly rotating engine or in preparation for the engine to begin rotating, the START state

allows the application to initialize engine controls for an active mode. This state is maintained as long as

the engine stays below a minimum speed, identified in the User Management header file as the stall

speed. Additionally, the same system inputs that allowed the exit of the STOP state must be present or a

transition to the STOP state would occur.

Small Engine Reference Design User Manual, Rev. 3.0

24 Freescale Semiconductor

Page 25

Application Development

RUN

Once a minimum engine speed has been obtained and the correct system inputs have been applied, the

RUN state represents the normal operating state of the application for a rotating or running engine. The

engine control strategy is to be implemented in this state. System inputs must be maintained to keep the

engine in the RUN state and the engine speed must be above the stall speed but below the maximum

speed, identified in the User’s Management header file as over speed.

OVERRUN

As a special case for an active engine, the OVERRUN state provides a way to limit the engine speed.

This can be implemented by changing the engine control outputs through variables or through disabling

specific engine control outputs. System inputs for an active engine state must be maintained to prevent

the ASM from going to the STOP state.

Additionally the engine speed must be reduced below a specific value. This parameter is adjusted in the

User Management header file as over speed recovery.

The true performance of the Small Engine Reference Design can only be shown in a real application.

Through development using a real engine, testing can be performed that addresses real system issues

with an engine control application. Using a real production scooter as a test platform demonstrates the

capabilities of the hardware and software beyond documentation. For this purpose, a demonstration

application using the 50cc EFI motorbike was selected. By retrofitting the engine controller with the Small

Engine Reference Design, a basic engine management application is demonstrated.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 25

Page 26

System Overview

e

e

5 System Overview

Design for the ECU is centered on an EFI system capable of closed-loop control for a one cylinder engine

using known loads. This system includes essential inputs and outputs for an application that is emissions

sensitive.

6 analog channels and one digital input. The names of these signals are suggestions for use but may be

changed based on application demands. Additionally, a special input is used for the crankshaft sensor.

This is for a VRS using 2 pins but can be adapted to use a Hall Effect type of interface. A total of 10

outputs are available, each with specific functionality in mind. In most cases these outputs are oversized.

This allows the drivers to be flexible to a broad range of loads. One special output is provided as a system

reference voltage available for sensors drawing small amounts of current. Further detail of ECU design

is covered in the Hardware Reference Manual found in Appendix A.

Figure 20 shows the high level signals of the Small Engine Reference Design. Inputs include

Tilt

Engine Stop Switch

Engine Stop Switch

Cranksh aft Se nsor

Cranksh aft Se nsor

Tilt

TPS

TPS

ATEMP

ATEMP

ETEMP

ETEMP

MAP

MAP

O2

O2

Battery

Battery

DIAG

DIAG

MC33812

MC33812

Reference

Reference

Design

Design

Malfunction Indicator

Malfunction Indicator

Relay

Relay

O2 Heater

O2 Heater

Idle Speed Motor (A)

Idle Speed Motor (A)

Idle Speed Motor(B )

Idle Speed Motor(B )

Idle Speed Motor(C )

Idle Speed Motor(C )

Idle S peed Motor( D)

Idle S peed Motor( D)

Ignition Coil

Ignition Coil

Fuel Injector

Fuel Injector

Fuel Pump

Fuel Pump

Ground

Ground

Sensor Reference

Sensor Reference

Figure 20. Module Level Signals of the Small Engine Reference Design.

Acceler ator

Acceler ator

Position

Position

I/O or ADC

Manifo ld pre ssure

Manifo ld pre ssure

Ignition Sw itch

Ignition Sw itch

Crankshaft

Crankshaft

angle

angle

BAT

BATBAT

I/O or ADC

ADC

ADC

Mux

Mux

Power

Power

Power

Power

Suppl y

Suppl y

VRS i nput

VRS i nput

ISO9141

ISO9141

MCU

MCU

SPI & Parallel

SPI & Parallel

SPI Wat chdog

SPI Wat chdog

SMARTMOS

SMARTMOS

I/O

I/O

SPI & I/O

SPI & I/O

Switched Outputs

Switched Outputs

BDM

BDM

Injector

Injector

Ignition

Ignition

H-Bridge

H-Bridge

(1) d.c. motor

(1) d.c. motor

(2) stepper

(2) stepper

Fuel

Fuel

Pump

Pump

and Programming

and Programming

Fu el

Fu el

Injector

Injector

Figure 21. System Block Diagram for the Scooter Engine Control

Development

Development

Ports

Ports

Bipo lar coil driv

Bipo lar coil driv

Small Engine Reference Design User Manual, Rev. 3.0

26 Freescale Semiconductor

Page 27

6 Application Overview

The scooter demo application uses the same simple state machine that described above. Complexity of

the application is limited to an Alpha N engine management strategy with system modifier parameters.

Engine management strategy uses table look up for fuel and spark parameters based on throttle position

and engine speed. Although table look up is restricted to exact values on the table, interpolation between

points is can be easily implemented through custom code. Once the table look up value has been

obtained for fuel and spark, various modifier values can used to obtain the final value used by the fuel

and spark controllers.

These fuel and spark modifiers are determined and managed by the User Management task. The

example application only uses two modifiers in the application but provides the framework for an

advanced algorithm. These variables are maintained in the User Management task but are added to the

table look up base value in a low level function. This action is performed in u16Calc_Fuel_Pulse_Width(),

which is used by the Engine Management task. Additionally, two fuel variables are available for tuning

that let you directly control the fuel pulse output when a fuel event is scheduled. These two variables are

Fuel_Cut and Fuel_Add and have companion variables for spark, referenced as Spark_Advance and

Spark_Retard. These direct fuel and spark modifiers are extremely useful for coarse and fine tuning of

the engine without the complexity of multiple modifiers.

For starting conditions, a fuel modifier value, FM_MSTART, adds additional fuel to the base look up table

value. When in the START state, a calibration value of MSTART is used. When the engine speed

increases to the RUN state, the FM_MSTART fuel modifier is decayed at a specific rate,

MSTART_Decay_Timeout, based on execution of the User Management task. The amount of the decay

is set by MSTART_Decay. Both values are sent in the User Management header file. This working

example shows how others can be used in a more advanced implementation.

Application Overview

For transient operation, the fuel modifier FM_MACCEL is used. Parameters associated with the transient

fuel detection are found in the user management header file. Tip in and tip out can be detected and

individually handled. Thresholds based on ADC count changes between new TPS_Filtered data values

can be configured along with decay size and rates. Transient fuel operation is intended to emulate the

accelerator pump functionality of a carburetor.

This application also demonstrates active load control through time-outs. The example that is used is the

fuel pump. When the application state machine is in the STOP state, the application must be ready to

begin starting the engine at anytime. As a strategy, pressurizing the fuel system is best done before any

attempt to fuel the engine is made. As a result, the fuel pump is turned on in the STOP state. However, if

the fuel pump was left on unconditionally, the battery would be discharged quickly. To prevent this, a

time-out is used so that the fuel pump is turned off after 3 seconds in the STOP state. This parameter is

defined in the User Management header file as FUEL_PUMP_TIMEOUT and the fuel pump activity is

controlled by the Fuel_Pump_Controller(). This simple routine is provided to show how time based

management of the loads can be done using engine operating states.

For a four-stroke engine, the process is a 720 degree cycle. Additional synchronization techniques must

be performed to transfer the low level processes from a two-stroke to a four-stroke operating mode. For

a one cylinder engine, a simple technique can be done to eliminate the need of an additional camshaft

sensor. If the system uses manifold absolute pressure (MAP), measurements can be performed to

determine if the engine is in a compression or exhaust stroke. This requires looking for a specific

signature of the MAP signal. This must be done at the low level. To do this, a toothed based MAP data

collection process is selected in the application header file. Specific teeth for collecting data are defined.

Signature detection is implemented in the Crank_State_ISR() in the SYNCHRONIZED state in

Crank_Sensing.c file. This signature detection algorithm can be easily customized. Implementation using

a cam sensor is also easily accommodated for as a simple flag enables the transition from the two-stroke

mode to four-stroke mode.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 27

Page 28

Application Overview

In the application state machine, clear areas are defined to implement engine strategy. A simple example

is provided based on using an Alpha N engine control strategy. The software is not intended to show an

optimized strategy, however it is designed to provide a starting point for development of an engine

management application that is modular and can be successful in running an engine. Thorough

understanding and optimization are required when applying this software to any engine application.

Updating Low Level Code

There are no committed support plans for the example application software. It is recommended to

continue the customizing of the software down to the lowest level if it is to be used beyond a

demonstration purpose. This would include correction of errors for compilations and operation as well as

application hardening of software both at the application level and microcontroller level. In event of a

significant low level driver update or third party software addition, low level code can be updated in two

different ways.

Method 1: Using the new software project containing the new low level driver code, copy in the contents

of the user functions. These include User_Management(), Engine_Management(), Data_Management(),

and Application Map data. Include any custom definitions in the header files as well.

Method 2: Import new driver files on an individual basis. For specific file updates, copy and overwrite the

specific file and header file of interest into the project directory folder structure. Be sure to do a clean build

by removing all object code as well as back up the project before overwriting files. Additional

dependencies may need to be considered as new code could make use of other new code not found in

the replaced file.

6.1 Application Testing

Before going to a real system with your application, extensive testing is recommended to ensure that any

engine control signals, specifically fuel and spark, meet your timing requirements and the application

provides the desired high level operation and user control. This is best achieved with the simulated

system set up previously. Once the application is validated at the bench level, it may be necessary to

reduce system functionality and test basic operation when migrating to real engine hardware. Data

collection, load control, and system start/stop conditions can be easily tested without the engine running.

Additional testing can be performed with fuel and spark controls physically disabled which provides an

opportunity for analysis of the rotating engine with no combustion events. Control signals for fuel and

spark can then be verified using the actual loads in preparation for calibration of engine control

parameters.

Testing the application can be done in real-time using the Hi-wave debugger built into the CodeWarrior

IDE. This tool allows non-intrusive debugging through the microcontroller’s BDM pin while the processor

is running. Using the Hi wave debugger will allow you to set breakpoints, step though code, view and

modify software variables, and directly control the registers of the S12X microcontroller. Assistance

learning the debugger can be found in the Virtual Lab mentioned in previous sections. Through the use

of calibration variables that are able to be modified using the debugger, testing can be performed to find

working values for system control parameters.

One of the most difficult aspects to master is the angle based operation of the engine. It may take many

iterations of software building and testing to get the timing right for the delivery of the fuel and spark

pulses. Some of this confusion may come from the generic implementation of the example application.

The crankshaft state machine that synchronizes to the rotation of the engine, through the teeth pulses on

the crankshaft, uses the missing tooth as the definition of top dead center or 0 degrees. The first tooth

after the missing tooth gap is then tooth 1. This is not always the case and an offset will need to be created

to compensate for specific engine implementation. In the example application, the missing tooth gap is

actually at bottom dead center. This creates an offset of 6 teeth (12 minus 1 wheel defined) that must be

Small Engine Reference Design User Manual, Rev. 3.0

28 Freescale Semiconductor

Page 29

Application Overview

accounted for. The end result in this case is the top dead center must be defined as tooth 7, creating an

offset of 180 degrees.

Once this is compensated for in the application, adjustment of the timing for fuel and spark is handled by

the application maps. It may be necessary to create a test map for fuel and spark to verify timing is being

properly controlled. Small test maps help provide useful validation tools. Test maps with all the same data

are good for basic timing validation. Progressive value maps provide a way to validated table look up is

performed as expected.

In the example application, one of the most important calibration variables is the MSTART. This is a fuel

modifier variable that adds additional time to the fuel pulse when the application is in the START state.

Proper setting of this variable will depend on the engine and fuel injector used, as well as atmospheric

conditions. With the debugger open and the application running, it is possible to adjust the MSTART value

between starting attempts to adjust the amount of extra fuel is added during startup. This is a delicate

process and leads to the art of engine calibration. As calibration is performed, it is important to get back

to a steady state before testing a new value. Specifically for MSTART, it is difficult as the failure to start

and run the engine can leave the engine cylinder with raw fuel and easily foul the spark plug.

As development of your application progresses, it will need to incorporate features for performance and

safety. It is advised to balance hard testing with simulation exercises. This is a necessary step in the

development process that should account for worst case code execution. Independent exercises for RAM

utilization and execution timing should be considered so that bandwidth of the system is not at 100%,

which can easily result in poor engine operation or runaway code due to stack overflow. This leaves room

for addition unforeseen complexity that can only come code execution on the real system.

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 29

Page 30

Schematic

7 Schematic

REV:

C

7

Date

1

of

1

1

SHEET

Revisions

Original Release

O

Rev Description

ABC

2

28125 Cabot Drive, Suite 100

Novi, MI 48377

Detroit Automotive Technology Center

TITLE:

Date:

3

KIT33812ECUEVME

DWG. NO.

GEDABV:

GEDTTL:

KIT33812ECUEVME

B

SIZE

10/14/2009

10/14/2009

Date:

2

Wednesday, October 14, 2009

LAST MODIFIED=

10/14/2009

Date:

3

CDC Technologies, Inc.

CDC Technologies, Inc. CDC1920

Designer: Ref:

Drawn by:

4

5

Jesse Beeker

Jesse Beeker

Quality:

Approved:

4

5

Table of Contents

Microcomputer Circuit

Input Filters and Level Shifters

Input Conditioner, Voltage Regulator, Drivers5

Throttle Position Motor, H-Bridges, or LS Drivers6

4

D D

ISO9141 Interface and IO Connector

7

1. UNLESS OTHERWISE SPECIFIED:

RESISTANCE VALUES ARE IN OHMS.

RESISTORS ARE 1/10 W, ±1% or 1/8W, ±5%.

CAPACITANCE VALUES ARE IN MICROFARADS, ±10% or ±20%.

4. SPECIAL SIGNAL USAGE:

_B DENOTES - ACTIVE-LOW SIGNAL

5. INTERPRET DRAWING IAW ANSI SPECIFICATIONS,

CURRENT REVISION, WITH THE EXCEPTION OF LOGIC BLOCK

C C

B B

<> OR [] DENOTES - VECTORED SIGNALS

SYMBOLOGY.

2. INTERRUPTED LINES CODED WITH THE SAME LETTER OR

3. DEVICE TYPE NUMBER IS FOR REFERENCE ONLY. THE

LETTER COMBINATIONS ARE ELECTRICALLY CONNECTED.

NUMBER VARIES PER MANUFACTURER.

POLARIZED CAPACITORS ARE TANTALUM.

A A

NOTES:

Block Diagram

2

3

1 TITLE & REVISION STATUS

Small Engine Reference Design User Manual, Rev. 3.0

30 Freescale Semiconductor

Page 31

Schematic

C

BWednesday, October 14, 2009

Rev

Size

73

of

1

2

GND

16V

10%

GND

16V

10%

KIT33812ECUEVME

Drawing Title:

Ref:

Date:

Drawn by:

Designer:

CDC Tech, Inc. 1 0/14/2009

GND

Detroit Automotive Technology Center

28125 Cabot Drive, Suite 100

Novi, MI 48377

2

INJFLT SH 5

IGNFLT SH 5

ETEMP_F SH 4

TPS_F SH 4

VPWR_F SH 4

39

AN0938AN08

MC9S12P128

PJ0

WDRFSHSH 5

R55

AN08

37

10K 1%

1/10W

RELFLT SH 5

33

PA336PA235PA134PA0

16

VRSOUTSH 5

123456

ENGSTOP_FSH 4

GND

XIRQ

IRQ

PJ2

XTAL

EXTAL

VSSPLL

VSS3

VDDR

RESET

VDDX2

VSSX2

PE4

PE7

PB7

PB6

PB5

1/10W

R58 10K 1%

1

MCUTEST2

HDR

16V

C17 0 .22uF

10%

1

2

MCUTEST1

GND

RES1

GND

8 MHz

1 3

C40

0.1uF

C19

0.1uF

+5V

1/10W

R57 10K 1%

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

PE7

1

MCUTEST3

ATEMP_F SH 4

O2IN_F SH 4

MAP_F SH 4

IN5 SH 6

RXDB SH 5

MISO SH 6

TXDB SH 5

SCLK SH 6

IN6 SH 6

MOSI SH 6

CSB SH 6

C51

0.1uF

10%

16V

+5V

3

4

CAN1

MA02-2SM

GND

1 2

3 4

GND

C20

+5V

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

0.1uF

10%

16V

GND

TILTSW_F SH 4

C41

0.1uF

10%

16V

47

48

VRH

ANO746ANO645ANO544ANO443ANO342ANO241ANO140ANO0

VDDA

VSSAVRL

RXD0

TXD0

PS2

PS3

TEST

SCK0

MOSI0

SS0

MISO0

TXCAN0

RXCAN0

VSSX1

VDDX1

PP7

PP5

U2

PP31PP22PP13PP04IOC0/PT05IOC1/PT16IOC2/PT27IOC3/PT38PJ09PJ110IOC4/PT411IOC5/PT512IOC6/PT613IOC7/PT714MODC/BKGD15PBO

INJINSH 5

RIN1SH 5

O2HINSH 5

LAMPINSH 5

ENSH 6

RIN2SH 5

IGNINSH 5

+5V

KIT33812ECUEVME

Microcomputer

Page Title:

Document Number:

Date:

10/14/2009

CDC1920

Approved:

Quality: Date:

CDC Tech, Inc.

Jesse Beeker

Jesse Beeker 10/14/2009

1

Date: Sheet

2

3

4

BDM1

MA03-2SM

C42

100pF

10%

R48

GND

10K 1%

+5V

B B

AN08

PJ0

PE7

C39

0.22uF

10%

16V

GND

5

1/10W

R49 10K 1%

+5V

GND

16V

C18

10%

0.22uF

Only populate C18, C39

and R49, if S12XS family

is used for U2.

D D

C C

C8

0.1uF

10%

16V

+5V

50V

1/10W

RESETBSH 5

GND

Place C17, C18, C19, C20, C39,

C40, C41, C42, R48, R55, and RES1

close to U2 pins.

A A

5

Small Engine Reference Design User Manual, Rev. 3.0

Freescale Semiconductor 31

Page 32

Schematic

C

BWednesday, October 14, 2009

Rev

Size

74

of

1

Novi, MI 48377

KIT33812ECUEVME

Drawing Title:

Date:

Drawn by:

CDC Tech, Inc. 10/14/2009

Detroit Automotive Technology Center

28125 Cabot Drive, Suite 100

SH 3

SH 3

SH 3

MAP_F SH 3MAPSH 7

TPS_F

ATEMP_F SH 3

ETEMP_F

O2IN_F SH 3

ENGSTOP_F

6.8K

R47

5%

1/10W

2

3

R7 3.1K1% 1/10W

R51

10K 1%

1/10W

C28

C26

C25

C24

C23

C21

C43

R22 31.6K 1% 1/10W

R24 16K 5% 1/10W

R16 16K 5% 1/10W

R17 16K 5% 1/10W

R18 16K 5% 1/10W

C38

0.1uF

0.01uF

0.01uF

0.1uF

0.01uF

0.01uF

0.01uF

0.01uF

GND

10%

16V

10%

100V

10%

100V

10%

16V

10%

100V

10%

100V

10%

100V

10%

100V

D2

VPWR

R32 15K 5%

BAS716

VPWR_F SH 3

TILTSW_F SH 3

C32

0.01uF

10%

100V

GND

R39

4.99K1%1/10W

C36

0.01uF

10%

100V

6.8K

R33

5%

1/10W

C31

0.01uF

10%

100V

R28 15K 5%

1/10W

1/10W

TILTSWSH 7

2 1

1

KIT33812ECUEVME

Input Filters and Level Shifters

Page Title:

Document Number:

Date: Sheet

Ref:

Date:

10/14/2009

CDC1920

2

Designer:

Approved:

Quality: Date:

CDC Tech, Inc.

Jesse Beeker

Jesse Beeker 10/14/2009

3

C37

0.01uF