Page 1

Dimmable Light Ballast with

Power Factor Correction

Designer Reference Manual

M68HC08

Microcontrollers

DRM067

Rev. 1

12/2005

freescale.com

Page 2

Page 3

Dimmable Light Ballast with Power Factor Correction

Designer Reference Manual

by: Petr Frgal

Freescale Czech Systems Center

Roznov pod Radhostem, Czech Republic

To provide the most up-to-date information, the revision of our documents on the World Wide Web will be

the most current. Your printed copy may be an earlier revision. To verify that you have the latest

information available, refer to

http://www.freescale.com

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 3

Page 4

Dimmable Light Ballast with Power Factor Correction, Rev. 1

4 Freescale Semiconductor

Draft 2 for Review

Page 5

Contents

Chapter 1

Introduction

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Benefits of this Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 The MC68HC908LB8 Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

Control Theory

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Fluorescent Lamp Control Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Fluorescent Lamp Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.3 Controlling the Fluorescent Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 PFC Control Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.2 Digital Power Factor Concept — Hysteresis Current Control Mode . . . . . . . . . . . . . . . . . . 16

2.2.3 Digital Power Factor Concept — Discontinuous Conduction Mode. . . . . . . . . . . . . . . . . . . 17

2.2.4 Concept Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 3

Reference Design

3.1 Application Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Dimmable Light Ballast Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Application Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Light Ballast Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3.2 Power Factor Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3.3 Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Software Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5 Hardware Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4

Hardware Design

4.1 Hardware Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Input and PFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.3 Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 5

Page 6

Chapter 5

Software Design

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Control Algorithm Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.1 Power Factor Correction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1.1 DC-bus Voltage Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1.2 Phase Shift Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1.3 Reference Sine Wave Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1.4 Generation of Output PFC Control SIgnal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.2 Light Ballast Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.2.1 Tube Start Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.2.2 Luminance Level Control (Tube Run Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3 Software Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.1 Initialization Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.1.1 PWM Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.1.2 HRP Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3.2 Main Program Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.3 Synchronization Interrupt Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3.4 Sine Wave Generation Interrupt Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3.4.1 Fault Detection and Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4 Detailed Software Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5 Microcontroller Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1 Microcontroller Peripheral Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1.1 High Resolution PWM (HRP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1.2 Pulse-Width Modulator (PWM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1.3 Comparator Module (CM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1.4 Timer Interface Module (TIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.1.5 External Interrupt (IRQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.2 Program and Data Memory Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.5.3 I/O Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.6 Definitions of Constants and Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.6.1 System Setup Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.6.2 System Constants and Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 6

Demo Setup

6.1 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2 Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.1 Required Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.2 Building and Uploading the Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2.3 Executing the Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.2.4 Project Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix A. Schematics and Part List

A.1 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.2 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix B. References

Dimmable Light Ballast with Power Factor Correction

6 Freescale Semiconductor

Page 7

Chapter 1 Introduction

1.1 Introduction

This reference design describes the design of a fully digital dimmable light ballast with power factor

correction (PFC) control for two parallel connected fluorescent lamps.

This reference design focuses on the lamp ballast hardware and software implementation using the

Freescale MC68HC908LB8 microcontroller (MCU), which is designed specifically for light ballast

applications. This MCU includes a set of peripherals that are appropriate for light dimming and power

factor correction.

The reference design incorporates both hardware and software parts of the system including detailed

hardware descriptions and full software listings. The application uses half-bridge topology, typical for this

kind of applications. The MC68HC908LB8 MCU is well suited to this topology.

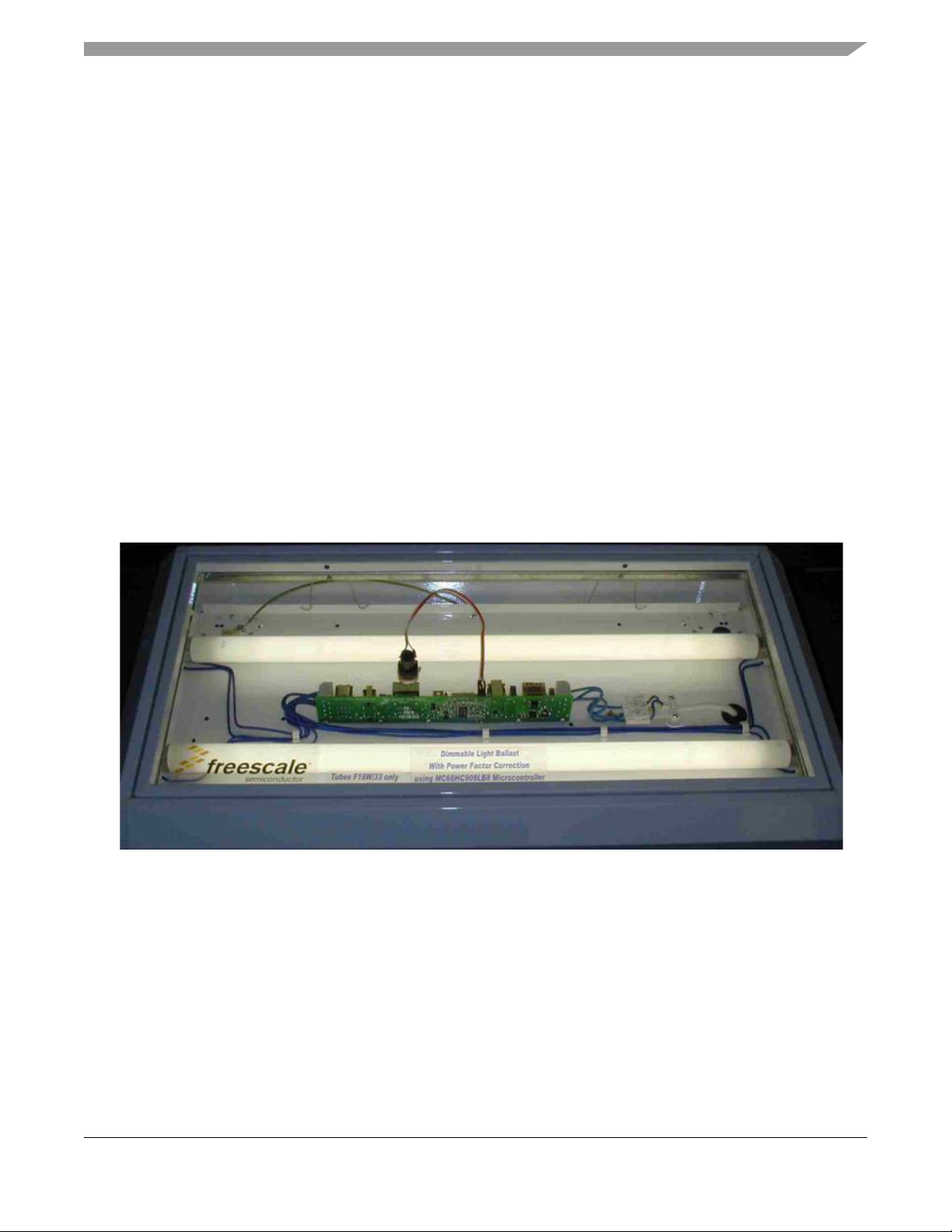

Figure 1-1. Dimmable Light Ballast with PFC Demo

1.2 Benefits of this Solution

Microcontrollers offer the advantages of low cost and attractive digital light ballast design. Using a

dedicated on-chip high resolution PWM (HRP) allows easy implementation of dimming features. PFC

improves the efficiency of the light ballast. Harmonic content of the input current for the mains supplied

equipment meets the European regulation

The advantages of the presented digital solution over standard analog solutions can be summarized as

follows:

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 7

EN 61000-3-2 and the international standard IEC 1000-3-2.

Page 8

Introduction

• Energy saving

• Ease of adapting software for different lamps

• Ease of re-programming the system behavior

• Software can simplify the hardware

• Diagnostic functions — fault state, tube end-of-life, ignition fault, tube removed

• Open to innovation

The MC68HC908LB8 is designed for light ballast applications. It contains a HRP that is assigned to

control a lamp ballast circuit using half-bridge topology. The HRP provides two complementary outputs

for controlling a half-bridge drive. Pulse Width Modulation (PWM) with constant duty cycle is used for light

ballast control. The HRP frequency can be adjusted easily by software in range 40

kHz to 120 kHz in 256

steps. Dimming levels down to 5% are possible.

The PFC circuit uses an on-chip comparator on the MC68HC908LB8. This peripheral simplifies the

dimming light ballast solution with PFC, since it eliminates the need of external components and thus

decreases the system cost.

The reference design is intended for all geographic regions, so 110V/60Hz and 230V/50Hz input voltage

supplies are supported.

The application can be debugged using the MON08 CYCLONE debug tool in monitor mode.

WARNING

Since the application runs at high voltage, it is dangerous to connect

development tools directly to the board. Therefore, it is recommended

to use an opto-isolation monitor mode board. This separate board

provides an opto-isolated interface for the MON08 debug tool, using

the MON08 standard connector. This allows the user to safely debug

or examine code in-circuit.

1.3 The MC68HC908LB8 Microcontroller

The MC68HC908LB8 is a member of the low-cost, high performance MC68HC08 Family of 8-bit MCUs.

All MCUs in the family use the enhanced MC68HC08 central processor unit (CPU08) and are available

with a variety of modules, memory sizes and types, and package types.

Standard features of microcontroller MC68HC908LB8 are:

•8 MHz internal bus frequency

• Trimmable internal oscillator:

–4.0 MHz internal bus operation

– 8-bit trim capability

– 25% untrimmed

–2% trimmed

• 8K bytes of 10K write/erase cycle typical on-chip in application programmable FLASH

with security option

• 128 bytes of on-chip random access memory (RAM)

(1)

memory

1. Non volatile memory that retains its data when the power is removed.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

8 Freescale Semiconductor

Page 9

The MC68HC908LB8 Microcontroller

• Dual channel high resolution PWM (HRP) with deadtime insertion and shutdown input to perform

light control and dimming functions for ballasts. The outputs use frequency dithering to achieve a

3.9 ns output resolution.

• Dual channel pulse width modulator module to provide power factor correction capability

• 7-channel, 8-bit successive approximation analog-to-digital converter (ADC)

• Comparator for power factor correction capability or for general-purpose use

• 7-bit keyboard interrupt

• One 16-bit, 2-channel timer interface module with one output available on port pin (PTA6) for input

capture and PWM

• 17 general-purpose input/output (I/O) pins and one input-only pin

– Three shared with HRP module

– Three shared with PWM module

– Three shared with comparator

– Seven shared with ADC module (AD[0:6])

– One shared with timer channel 0

– Two shared with OSC1 and OSC2

– One shared with reset

– Seven shared with keyboard interrupt

– One input-only pin shared with external interrupt (IRQ)

• Available packages:

– 20-pin small outline integrated chip (SOIC) package

– 20-pin plastic dual in-line package (PDIP)

• On-chip programming firmware for use with host personal computer which does not require high

voltage for entry

• System protection features:

– Optional computer operating properly (COP) reset

– Low-voltage reset

– Illegal opcode detection with reset

– Illegal address detection with reset

• Low-power design; fully static with stop and wait modes

• Standard low-power modes of operation:

– Wait mode

– Stop mode

• Master reset pin and power-on reset (POR)

• 674 bytes of FLASH programming routines in read-only memory (ROM)

• Break module (BRK) to allow single breakpoint setting during in-circuit debugging

• Internal pullup on RST pin to reduce customer system cost

• Selectable pullups on ports A and C

– Selection on an individual port bit basis

– During output mode, pullups are disengaged

• High current 10 mA sink / 10 mA source capability on all port pins

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 9

Page 10

Introduction

Dimmable Light Ballast with Power Factor Correction, Rev. 1

10 Freescale Semiconductor

Page 11

Chapter 2 Control Theory

2.1 Introduction

This chapter covers fluorescent lamp theory and two PFC concepts - discontinuous conduction mode and

hysteresis current control mode.

2.1.1 Fluorescent Lamp Control Theory

To light a low-pressure fluorescent lamp, the electronic circuit must perform the following four main

functions:

• Provide a startup voltage across the electrodes of the lamp

• Maintain a constant current when the lamp is operating in the steady state

• Ensure that the circuit will remain stable, even under fault conditions

• Comply with the applicable domestic and international regulations (PFC, THD and safety)

Most generally, light ballast topology fairly closely matches target lamps in terms of tube wattage, length,

and diameter. The digital electronic lamp ballast includes also additional features like dimming capability,

tube end-of-life, startup fault, tube removed indication, and so on. Different tubes require different

software settings; also, some hardware components may have to be adapted accordingly.

2.1.2 Fluorescent Lamp Operation

When the lamp is off, no current flows through the tubes, and the apparent impedance is nearly infinite.

When the voltage across the electrodes reaches the V

an arc is generated across the two terminals of the lamp. This behavior is depicted by the typical operating

curve shown in

Figure 2-1.

value, the gas mixture is highly ionized and

strike

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 11

Page 12

Control Theory

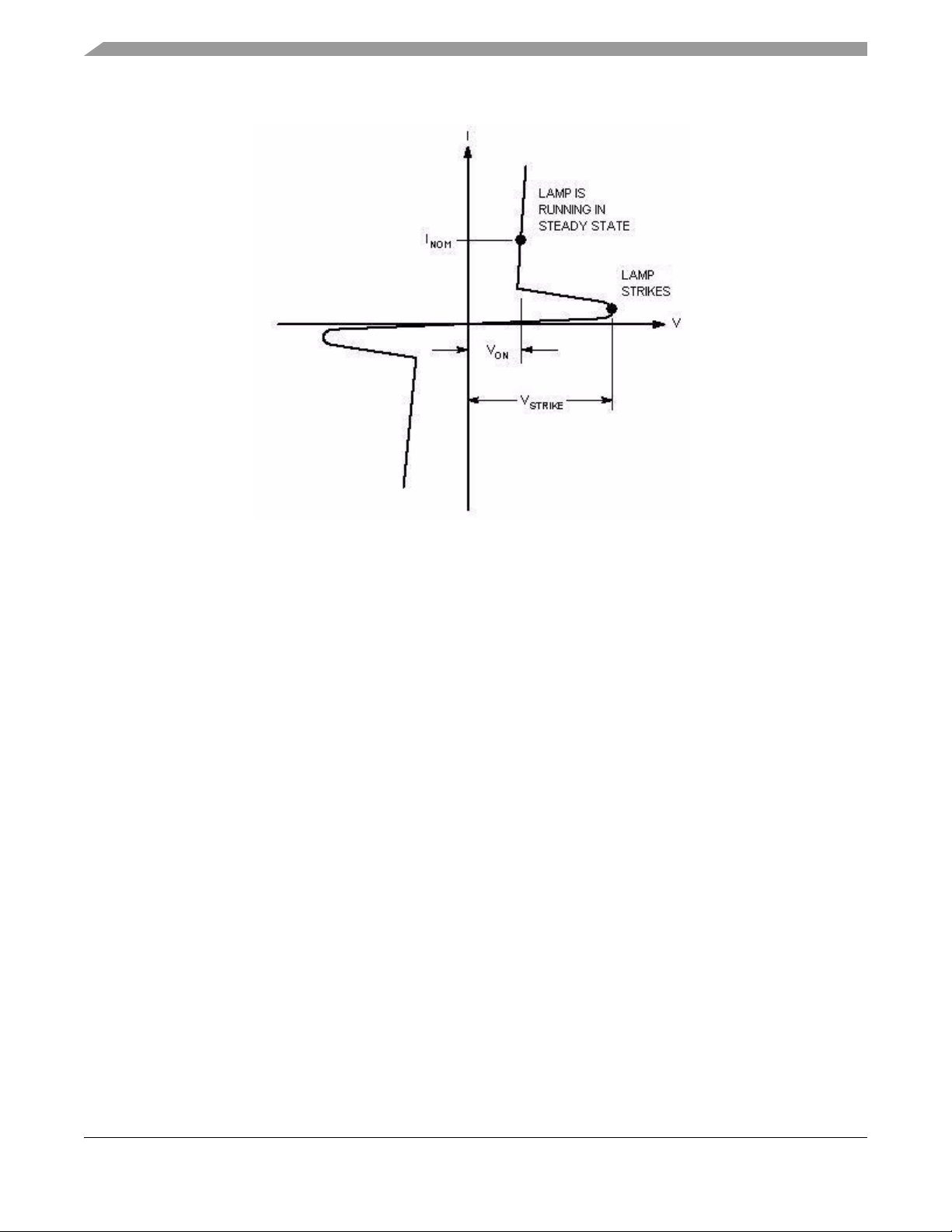

Figure 2-1. Typical Low Pressure Fluorescent Tube I/V Characteristic

The value of V

is a function of several parameters:

strike

• Gas filling mixture

• Gas pressure and temperature

• Tube length

• Tube diameter

• Temperature of electrodes: cold or hot

Typically, values of V

to the on-state voltage (V

the tube. Typically, V

are in range 500 V to 1200 V. Once the tube is on, the voltage across it drops

strike

, the magnitude of this voltage being dependent upon the characteristics of

on)

is in range 40 V to 110 V.

on

The value of Von will vary during the operation of the lamp but, in order to simplify the analysis, we will

assume, as a first approximation, that the on-state voltage is constant when the tube is running in steady

state.

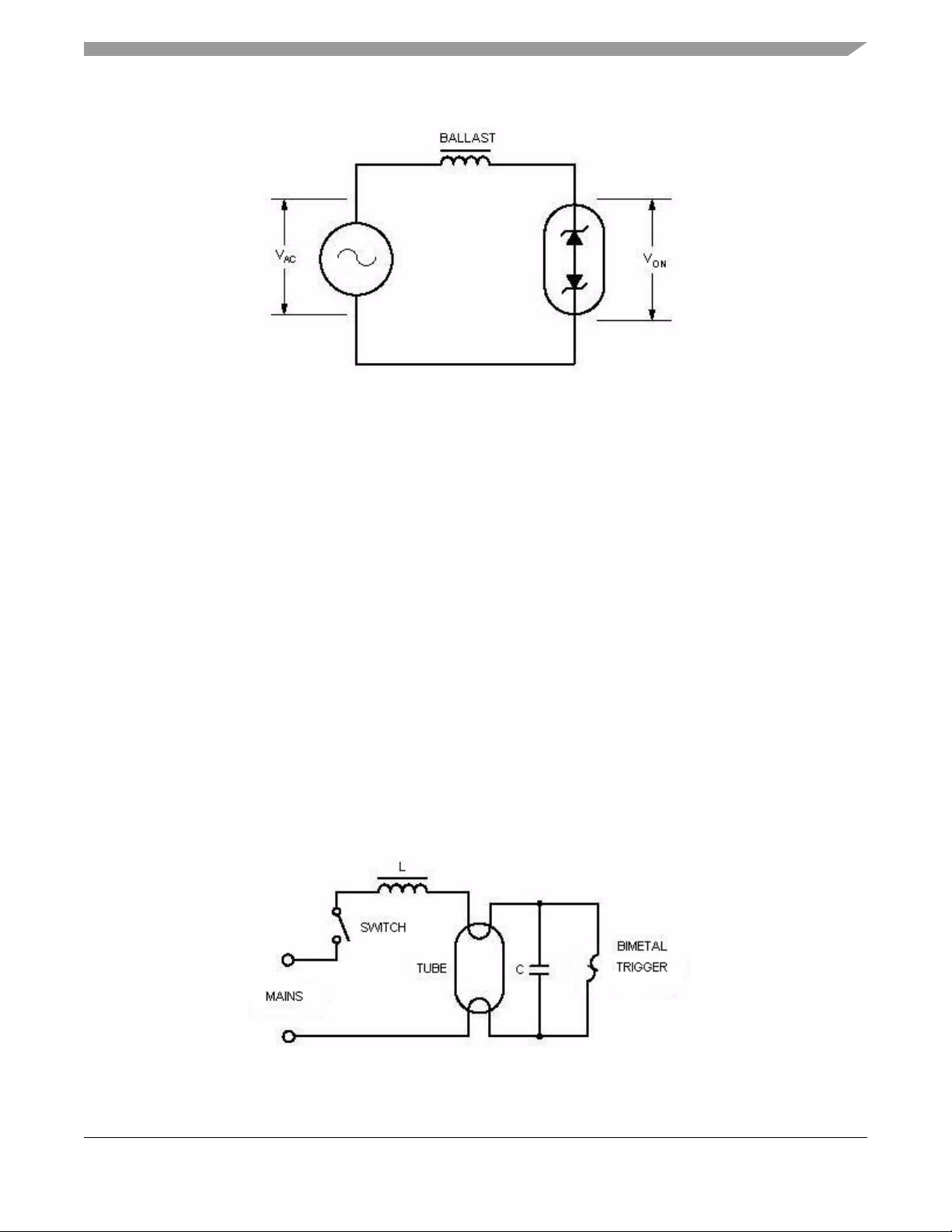

Consequently, the equivalent steady state circuit can be described by two back-to-back Zener diodes as

shown in

Figure 2-2. The startup network is far more complex, particularly during ionization of the gas.

This is a consequence of the negative impedance exhibited by the lamp when the voltage across its

electrodes collapses from V

strike

to Von.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

12 Freescale Semiconductor

Page 13

Introduction

Figure 2-2. Typical Fluorescent Tube Equivalent Circuit in Steady State

Up to now, there is no model available to describe the start up sequence of these lamps. However, since

most of the phenomena are dependent upon the steady state characteristics of the lamp, one can simplify

the analysis by assuming that the passive networks control the electrical behavior of the circuit. This

assumption is wrong during the time elapsed from V

to Von, but since this time interval is very short,

strike

the results given by the proposed simple model are accurate enough to design the converter. When a

fluorescent tube is aging, its electrical characteristics degrade from the original values, yielding less light

for the same input power, and different V

and Von voltages. A simple, low-cost electronic lamp ballast

strike

cannot optimize the overall efficiency throughout the lifetime of the tube, but the circuit must be designed

to guarantee the operation of the lamp even under worst case “end of life” conditions. As a consequence,

the converter will be slightly oversized to make sure that, after 8000 hours of operation, the system will

still drive the fluorescent tube.

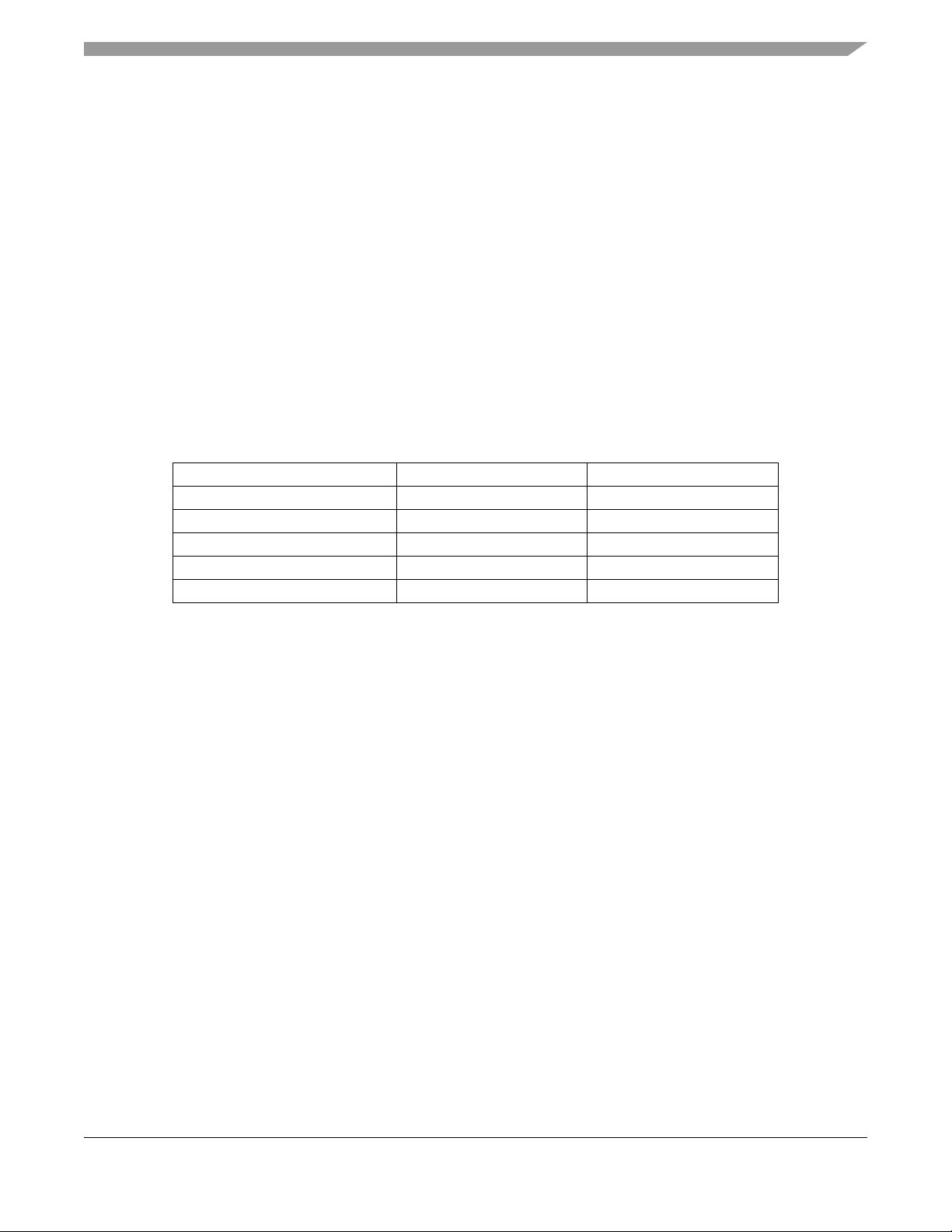

2.1.3 Controlling the Fluorescent Lamp

As already stated, both the voltage and the current must be accurately controlled to make sure that a

given fluorescent lamp operates within its specifications.

The most commonly used network is built around a large inductor, connected in series with the lamp, and

associated with a bimetallic switch generally named “the starter”.

schematic diagram for the standard, line operated, fluorescent tube control.

Figure 2-3. Standard Ballast Circuit for Fluorescent Tube

Figure 2-3 gives the typical electrical

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 13

Page 14

Control Theory

The operation of a fluorescent tube requires several components around the tube, as shown in Figure 2-3.

The gas mixture enclosed in the tube is ionized by means of a high voltage pulse applied between the

two electrodes.

To make this startup easy, the electrodes are actually made of filaments that are heated during the tube

ionization startup (i.e. increasing the electron emission), their disconnection being automatic when the

tube goes into the steady state mode. At this time, the tube impedance decreases toward its minimum

value (depending upon the tube internal characteristics), the current in the circuit being limited by the

inductance L in series with the power line. The starting element, commonly named “starter”, is an

essential part to ignite the fluorescent tube. It is made of a bimetallic contact, enclosed in a glass envelope

filled with a neon based gas mixture, and is normally in the OPEN state. When the line voltage is applied

to the circuit, the fluorescent tube exhibits a high impedance, allowing the voltage across the “starter” to

be high enough to ionize the neon mixture. The bimetallic contact gets hot, turning ON the contacts which,

in turn, will immediately de-ionize the “starter”. Therefore, the current can flow in the circuit, heating up

the two filaments. When the bimetallic contact cools down, the electrical circuit is rapidly opened, giving

a current variation in the inductance L which, in turn, generates an over-voltage according to Lenz’s law.

Since there is no synchronization with the line frequency (the switch operates on a random basis), the

circuit opens at a current level anywhere between maximum and zero.

If the voltage pulse is too low, the tube does not turn on, and the startup sequence is automatically

repeated until the fluorescent tube ionizes. At that time, the tube impedance falls to its minimum value,

yielding a low voltage drop across its end electrodes and, hence, across the switch. Since the starter can

no longer be ionized, the electrical network of the filaments remains open until the next turning on of the

circuit.

We must point out that the fluorescent tube turns off when the current is zero; this is the source of the

Hz flickering in a standard circuit. This is an important problem, which can lead to visual problems due

50

to the stroboscopic effect on any rotating machines or computer terminals.

To take care of this phenomena, the fluorescent tubes, at least those used in industrial plants, are always

set on a dual basis in a single light spreader, and are fed from two different phases (real or virtual via a

capacitor) in order to eliminate the flickering.

On the other hand, the magnetic ballast provides a very low cost solution for driving a low pressure

fluorescent tube. To overcome the flickering phenomenon and the poor startup behavior, the engineers

have endeavored to design electronic circuits to control the lamp operation at a much higher frequency.

The efficiency (Pin/Lux) of the fluorescent lamp increases significantly, as soon as the current through the

lamp runs above a few kilo Hertz.

The electronic circuits that can be used to build a fluorescent lamp controller can be divided into two main

groups:

• Single switch topology, with unipolar AC current, (unless the circuit operates in the parallel

resonant mode)

• Dual switch circuit, with a bipolar AC output current

Manufacturers of fluorescent lamps usually recommend operating the tubes with a bipolar AC current.

This avoids constantly biasing the electrodes as an anode-cathode pair, which, in turn, decreases the

expected lifetime of the lamp. In fact, when a unipolar AC current flows into the tube, the electrodes

behave like a diode and the material of the cathode side is absorbed by the electron flow, yielding a rapid

wear out of the filaments. As a consequence, all of the line operated electronic lamp ballasts are designed

with either a dual switch circuit (the only one used in Europe), or a single switch, parallel resonant

configuration (mainly used in countries with 110

V lines), providing an AC current to the tubes. A few low

Dimmable Light Ballast with Power Factor Correction, Rev. 1

14 Freescale Semiconductor

Page 15

PFC Control Theory

power, battery operated fluorescent tubes are driven with a single switch fly-back topology, but, the output

transformer is coupled to the tube by a capacitive network and the current through the lamp is alternating

current. However, the filaments (if any) cannot be automatically turned off by this simple configuration and

the global efficiency is downgraded accordingly.

Dual switch circuits are divided into two main topologies:

• Half-bridge, series resonant

• Current fed push-pull converter

The half-bridge is, by far, the most widely used in Europe (100% of the so-called “energy saving” lamps

and industrial applications are based on this topology), while the push-pull is the preferred solution in the

USA with around 80% of the electronic lamp ballasts using this scheme today.

Both of these topologies have their advantages and drawbacks, the consequence for the associated

power transistors being not at all negligible, as shown by

Table 2-1. The half-bridge topology controlled

by the dedicated MC68HC908LB8 MCU is implemented in Chapter 3. For more details about electronic

lamp ballast theory see Reference [1.].

Table 2-1. Main Characteristics of the Dual Switch Topologies

Parameters Half-bridge Push-pull

V(BR)CER 700 V

Inrush Current 3 to 4 times I nom

tsi window 2.6 – 3.6 µs 1.9 – 2.3 µs

Drive High and Low side Low side only

Intrinsic Galvanic Isolation no yes

NOTES:

1. These numbers are typical for operation on a 230 V supply.

2. I nom is the current into the transistors in steady state.

(1)

(2)

2 to 3 times I nom

1100 - 1600 V

(1)

(2)

2.2 PFC Control Theory

2.2.1 Introduction

The most practical electronic systems contain a conventional single-phase full-bridge rectifier and an

input filter capacitor. It is well known that this type of circuit draws high current peaks from the power line

and produces a high level of harmonics. High total harmonic distortion (THD) and low power factor

therefore reduce the maximum power available from the mains and the efficiency of the electricity supply

networks. The European Normative EN 61000-3-2 defines the limits of the harmonic content of the input

current for mains supplied equipment.To meet the norms, new designs require an active PFC at the input.

Many specific integrated circuit devices (ICs) are available on the market to perform power factor

correction. This approach requires additional electronic components, which increases the system cost

and complexity. On the other hand, there is a way to implement PFC control using the MCU, in addition

to the MCU’s main control tasks, such as motor control. Digital PFC allows missing out these specific ICs,

thereby reducing the system cost. Another benefit of the software implementation is the potential for easy

modifications without changing the hardware.

Two power factor correction approaches were implemented in this design, discontinuous conduction

mode and hysteresis current control mode. Each of these topologies has advantages and drawbacks.

Both topologies are described in the following.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 15

Page 16

Control Theory

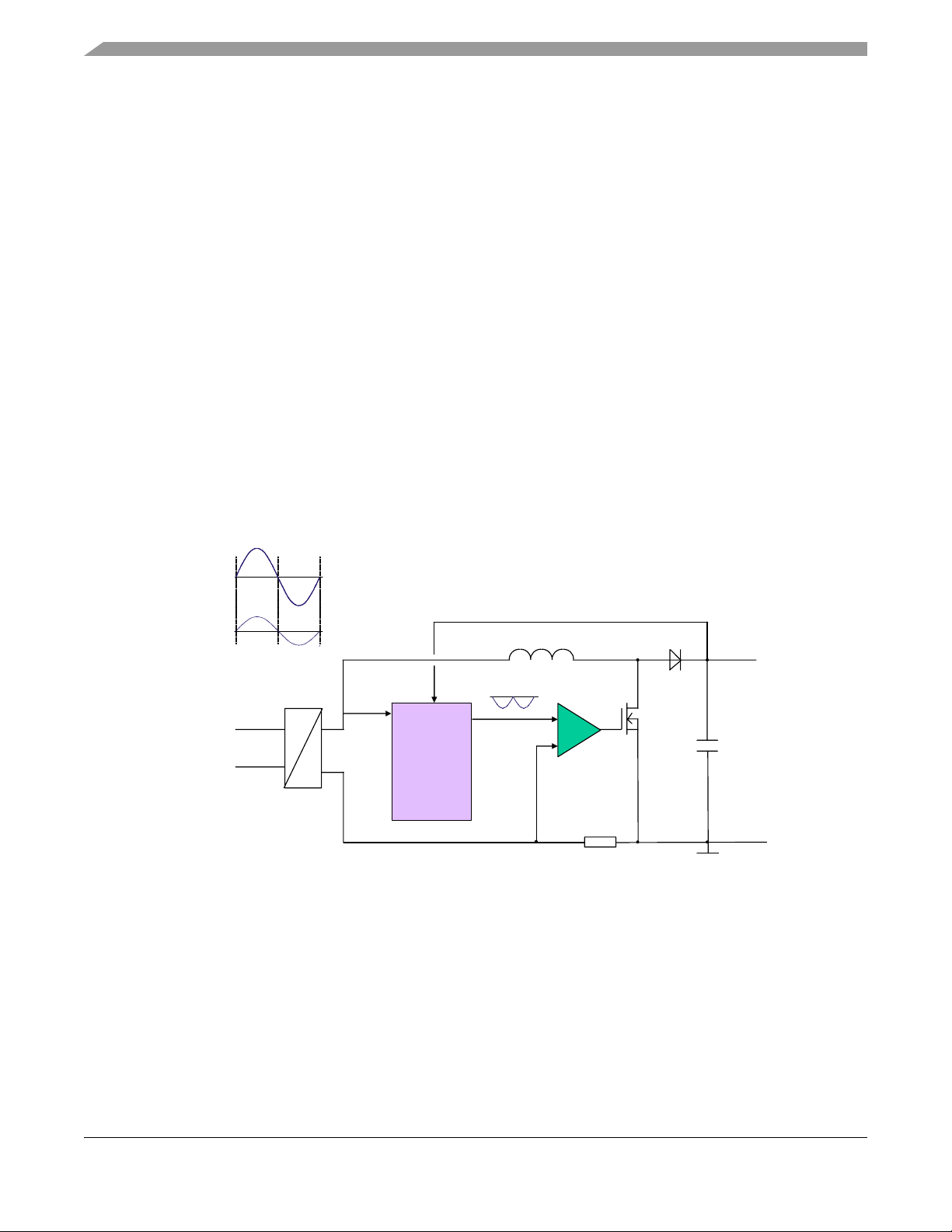

2.2.2 Digital Power Factor Concept — Hysteresis Current Control Mode

The control technique is based on hysteretic current control. The system operates in continuous

conduction mode with variable switching frequency (30–100 kHz) (see

This PFC concept is designed to have the minimum of MCU performance requirements. The basic

principles of the scheme are depicted in

Figure 2-4. The PFC control algorithm includes two control loops,

a fast one for input current control and a slow one for output voltage control. The output voltage controller

is implemented digitally using the MCU. A value proportional to the required input current is modulated by

the PWM and is taken as an input to the current control loop, which is realized by the analogue

comparator. The comparator switches the MOSFET in order to maintain the required current value.

The desired shape of the input current is a sine wave. The generated current waveform is shown in

Figure 2-8.

A hysteresis current control mode PFC concept has several drawbacks, including variable MOSFET

switching frequency, non sinusoidal input current waveform and switching under current, which causes

higher losses than other PFC topologies.

The input current harmonics content, however, complies with EN 61000-3-2 standard.

The advantages are simple control circuit, low MCU resources consumption, continuous conduction

mode operation, and low total harmonic distortion (THD).

Figure 2-5).

AC Line Voltage

AC Line Current

0

L

DC Bus

MCU

ADC

Voltage

PWM

Reference

Voltage

Comparator

+

-

Actual

Current

Current Sensing

AC

LINE

AC

DC

Zero

Crossing

IC

Figure 2-4. Hysteresis Current Control Mode Principle

+ DC BUS

MOSFET

+

GND

Dimmable Light Ballast with Power Factor Correction, Rev. 1

16 Freescale Semiconductor

Page 17

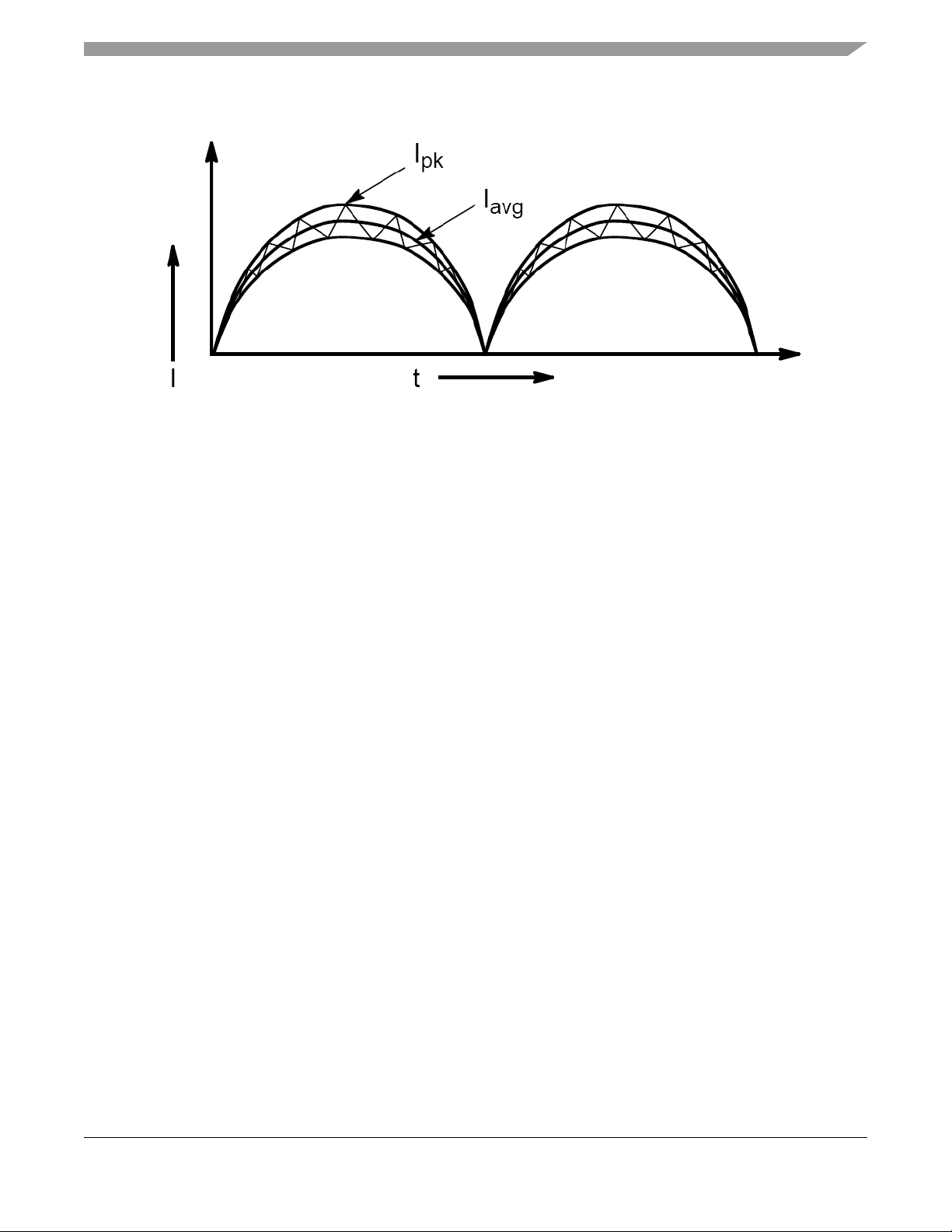

Figure 2-5. Hysteresis Current Control Mode Current Waveform

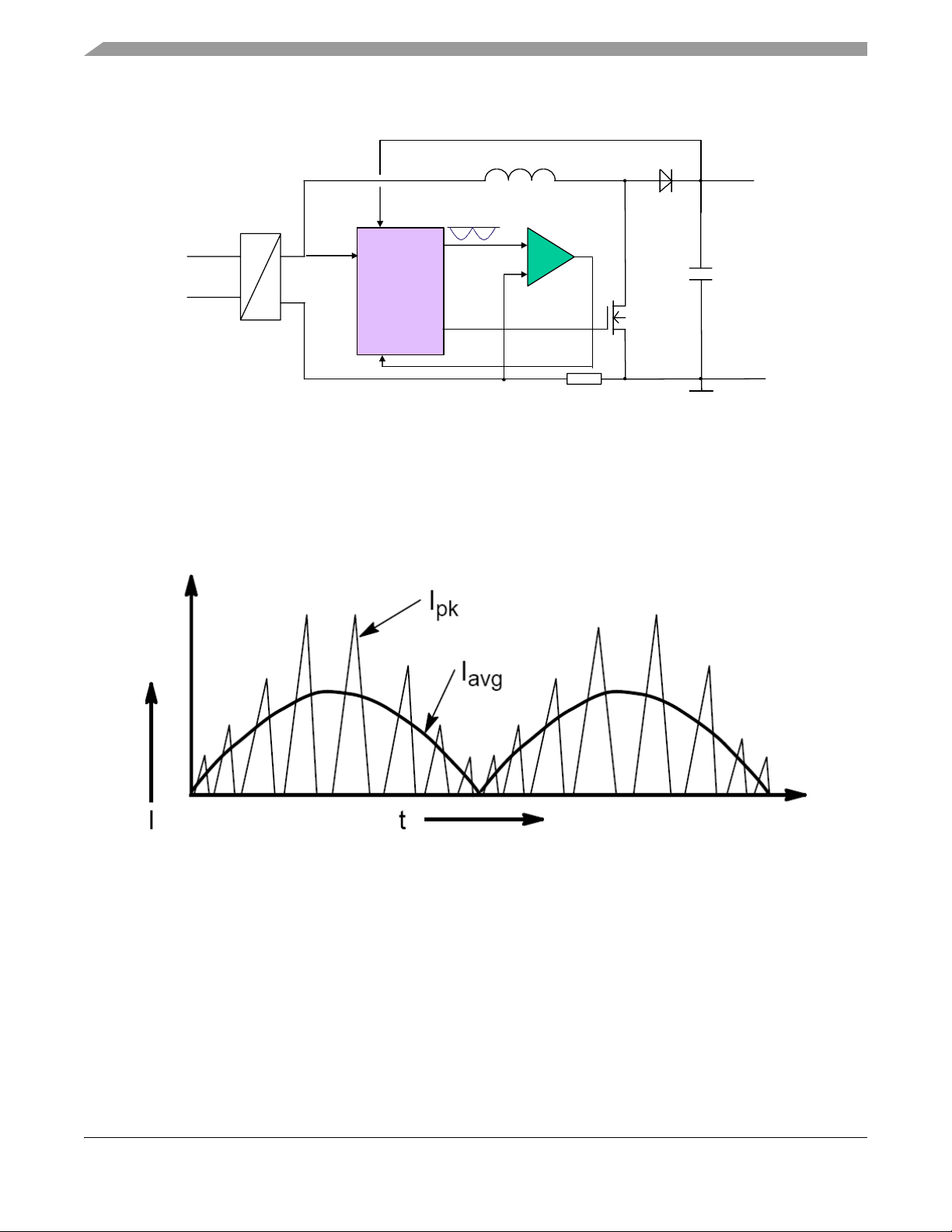

2.2.3 Digital Power Factor Concept — Discontinuous Conduction Mode

PFC Control Theory

The control technique is based on discontinuous conduction mode with a current loop with a constant

switching frequency (40 kHz) (see

Figure 2-7).

The basic principles of the scheme are depicted in Figure 2-6. The PFC control algorithm includes two

control loops, the same as the previous approach. The output voltage controller is implemented digitally

using the MCU. A value proportional to the required input current is modulated by the PWM0 and is taken

as an input to the current control loop, which is realized by the analog comparator. The comparator output

is connected to the PWM fault pin that disables the PWM output. PWM1 is used directly for switching the

MOSFET in order to maintain the required current value. PWM1 is switched off in every period where the

reference sine wave signal generated by PWM0 is higher than the actual current sensed signal on the

shunt resistor.

The desired shape of the input current is a sine wave. The generated current waveform is shown in

Figure 2-8.

The discontinuous conduction mode PFC concept has several drawbacks — higher THD than hysteresis

current control mode, non sinusoidal input current waveform, and the discontinuous conduction mode

itself. The input current harmonics content, however, complies with EN 61000-3-2 standard.

The advantages are a simple control circuit, with low MCU resource consumption, and low losses.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 17

Page 18

Control Theory

DC Bus

Voltage

L

AC

LINE

Reference

AC

DC

Zero

Crossing

ADC

IC

MCU

PWM

FAULT

PIN

Voltage

PWM0

PWM1

Actual

Current

Comparator

+

-

MOSFET

Current Sensing

Figure 2-6. Discontinuous Conduction Mode Principle

+ DC BUS

+

GND

Figure 2-7. Discontinuous Conduction Mode Current Waveform

Dimmable Light Ballast with Power Factor Correction, Rev. 1

18 Freescale Semiconductor

Page 19

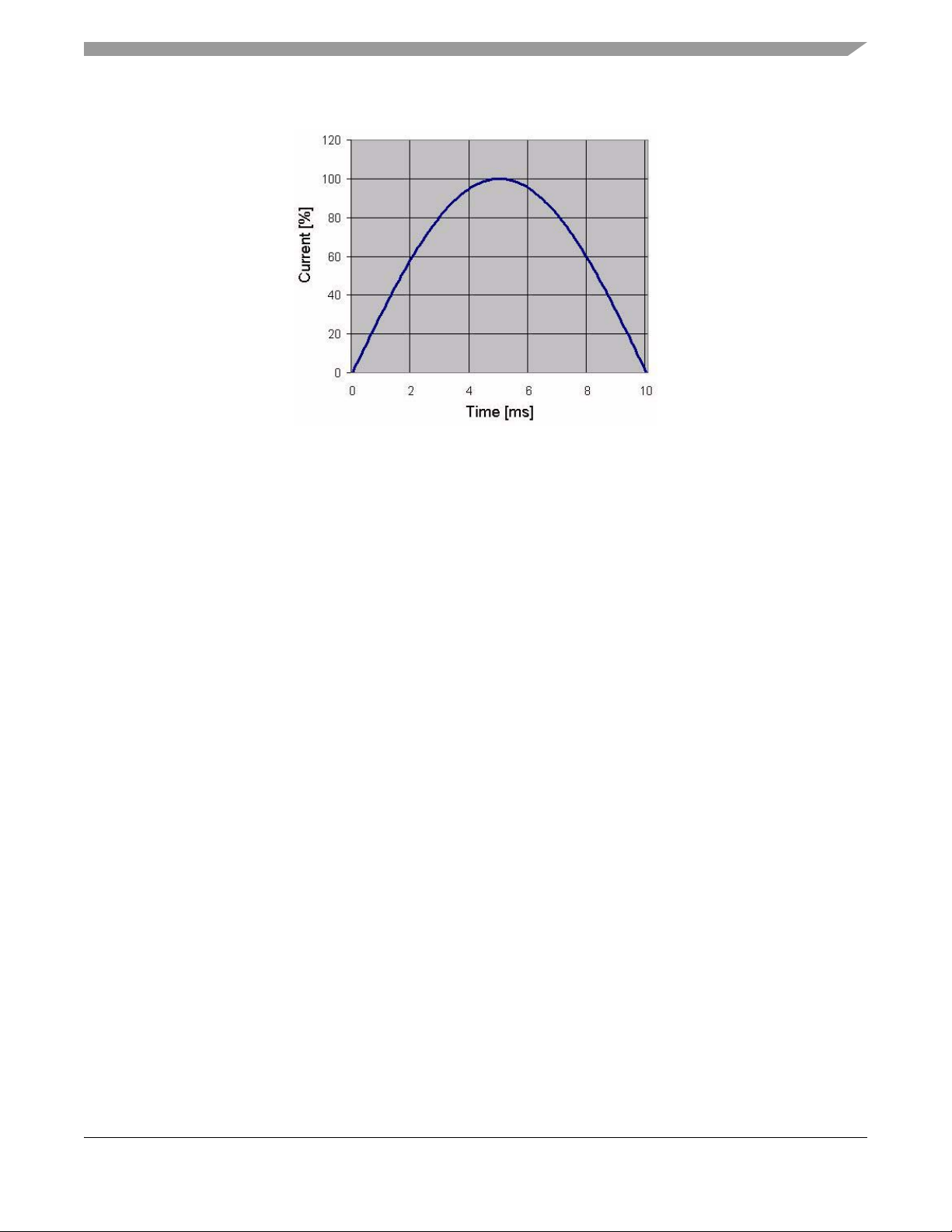

Figure 2-8. Generated Input Current Waveform

2.2.4 Concept Summary

PFC Control Theory

Both the PFC solutions can be used for applications that do not require a large portion of the MCU’s

resources, because they consume only a fraction of the MCU performance. Compared to a dedicated IC

solution, digital PFC offers high flexibility and cost reduction in the overall design, as the PFC function can

be provided within the MCU capability of the main application. Digital PFC also provides additional

benefits such as a wide range of input voltages (85

V to 265 V AC) at a constant output DC voltage.

However, hysteresis current control mode is more suitable for power above 100W, and discontinuous

conduction mode for low power consumption.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 19

Page 20

Control Theory

Dimmable Light Ballast with Power Factor Correction, Rev. 1

20 Freescale Semiconductor

Page 21

Chapter 3 Reference Design

3.1 Application Outline

The presented system is designed to control two parallel connected fluorescent lamps. The reference

design meets the following performance specification:

• Single board solution with MC68HC908LB8 microcontroller

• Supported power supply: 110V/60Hz and 230V/50Hz

•Low THD

• High power factor achieved using the PFC circuit

• Control techniques incorporating:

– Preheating

–Strike

– Run mode

• User interface (dimming level potentiometer, monitor mode interface)

• Flickering effect removal

• Lamp aging recognition

• Fault detection

– DC-bus under-voltage detection (software)

– DC-bus over-voltage detection (software)

– Ignition fault (software)

– Zero current fault (software)

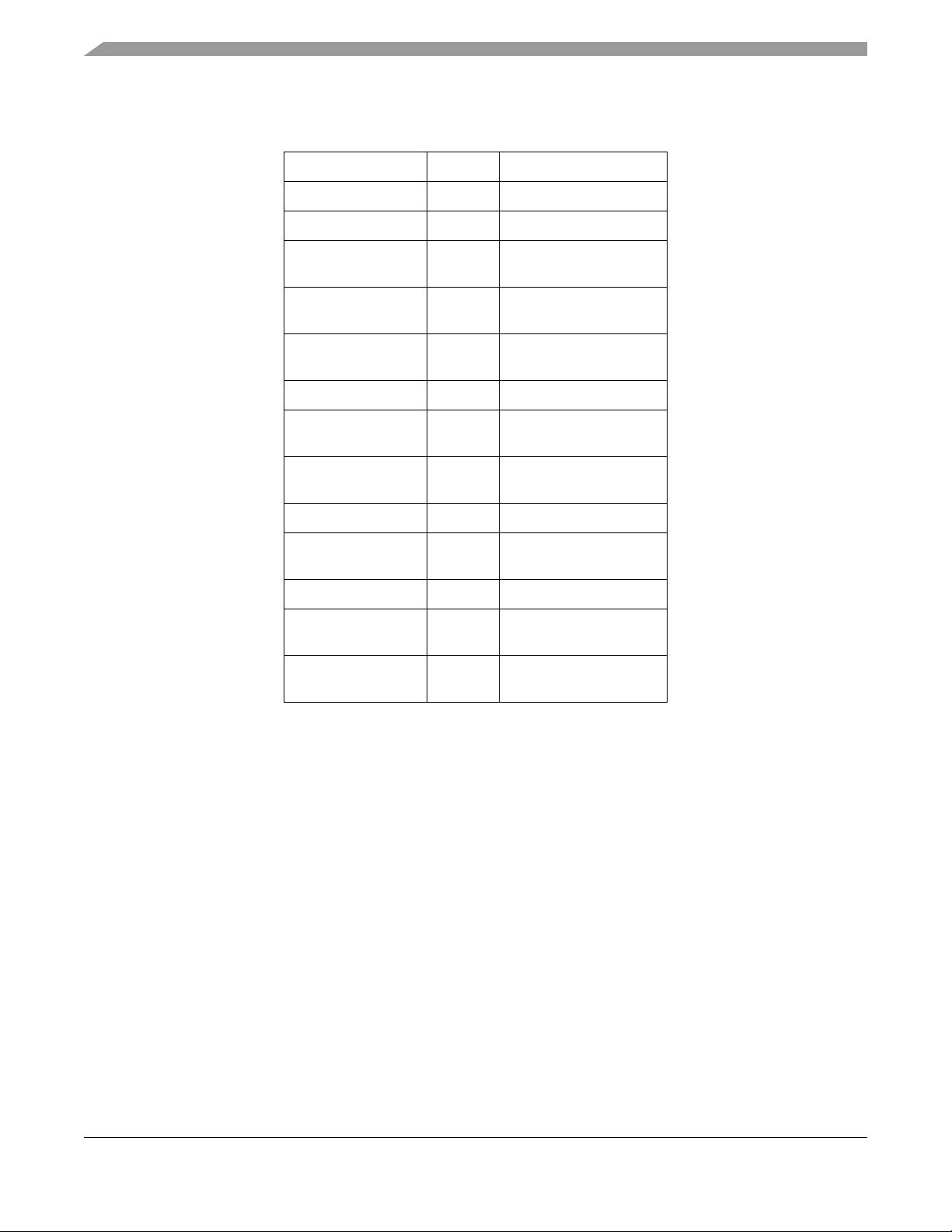

3.2 Dimmable Light Ballast Characteristics

Table 3-1 provides the basic characteristics of the Dimmable Light Ballast Demo with PFC at 25°C and

400 V DC-bus voltage.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 21

Page 22

Reference Design

Table 3-1. Light Ballast Characteristics

Parameter Unit Value

Lamp Type F18W/33

Input Power W 8...31

Input Current

(230VAC)

Preheat Output

Frequency

Preheat Output

Volt age

Preheat Time ms 900

Running Output

Frequency Range

Running Output

Voltage Range

Input AC Voltage VAC 110V/60Hz, 230/50Hz

Ambient

Temperature Range

Power Factor 0.94...0.99

Total Harmonic

Distortion

Output Ignition

Volt age

mA 40...290

kHz 86

Vpp 345

kHz 50...100

V 200...235

°C 0.50

% 5.2...24.6

Vpp 510

3.3 Application Description

The system concept is shown in Figure 3-1. The system consists of:

• Control board with MC68HC908LB8 microcontroller

• Two fluorescent lamps

The MC68HC908LB8 MCU runs the main control algorithm. According to the dimming level potentiometer

It generates output signals for the half-bridge inverter which controls the ballast circuit. It also controls

PFC. The desired dimming value is set by the potentiometer, because the human eye is more sensitive

at lower light levels. The input values from the potentiometer are converted using brightness linearization.

The HRP uses a frequency control method for dimming. It incorporates hardware that allows dithering

between two adjacent frequencies for smooth light level dimming.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

22 Freescale Semiconductor

Page 23

MAINS

MAINS

FILTER RECTIFIER

FILTER RECTIFIER

FILTER RECTIFIER

CROSSING

CROSSING

ZERO

ZERO

CONTROL BOARD

CONTROL BOARD

USER INTERFACE

USER INTERFACE

MONITOR

MONITOR

MODE

MODE

LUMINANCE

LUMINANCE

LEVEL

LEVEL

U

U

REQ

REQ

BUS VOLTAGE

BUS VOLTAGE

DC-

DC-

-

-

e

e

BRIGHTNESS

BRIGHTNESS

LINEARIZATION

LINEARIZATION

DRIVER

DRIVER

DRIVER

ACTUAL CURRENT

ACTUAL CURRENT

PWM

PWM

GENERATION

GENERATION

sineGain

sineGain

PI

PI

REGULATOR

REGULATOR

DC-BUS

DC-BUS

PFC

PFC

PFC

PWM

PWM

FILTER

FILTER

+

+

e

e

i

i

req

req

MC68HC908LB8

MC68HC908LB8

POWER

POWER

POWER

SUPPLY

SUPPLY

SUPPLY

-

-

-

-

DRIVER

DRIVER

PWM

PWM

HIGH

HIGH

RESOLUTION

RESOLUTION

PWM

PWM

f

f

PI

PI

REGULATOR

REGULATOR

i

i

act

act

Application Description

RESONANT

RESONANT

RESONANT

CIRCUIT

CIRCUIT

CIRCUIT

HALF BRIDGE

HALF BRIDGE

HALF BRIDGE

DIFFERENTIAL

DIFFERENTIAL

DIFFERENTIAL

VOLTAGE

VOLTAGE

VOLTAGE

CURRENT

CURRENT

1

1

HRP

HRP

CURRENT

CURRENT

PROCESSING

PROCESSING

e

e

TUBE 2 CURRENT

TUBE 2 CURRENT

TUBE

TUBE

FLUORESCENT LAMPS

FLUORESCENT LAMPS

Figure 3-1. Dimmable Light Ballast — System Concept

3.3.1 Light Ballast Control

The HRP provides two complementary PWM outputs for controlling a half-bridge in a light ballast

application. It uses a dithering control method to provide a high step resolution (3.9 ns) from an 8

MHz

input clock when driving inductive loads.

The High Resolution PWM Module (HRP) uses a dithering technique to increase the resolution of the

output signal.The output switches between two frequencies or duty cycles at a programmable rate. By

varying the percentage of time spent on each frequency/duty cycle, the output will appear to be at a value

between the two dithering frequencies/duty cycles when driving an inductive load.

The advantage is easy implementation of a control method for half-bridge inverter using few external

devices. The main advantage is simple performance using few instructions to perform the dithering

control algorithm.

3.3.2 Power Factor Correction

The power factor correction circuitry provides the “sinusoidal” input current by controlling the PFC switch.

In the control loop, the actual DC-bus voltage is compared with the desired one. The control error is

processed by the PI (proportional-integral) controller, which generates the amplitude of the input

“sinusoidal” current. The PWM generator generates the desired sinusoidal current profile using a PWM

technique. The digital output signal is filtered by a passive filter and the resulting analog waveform is

compared with the actual input current by an on-chip comparator. The comparator output controls directly

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 23

Page 24

Reference Design

the PFC switch in hysteresis current control mode or output is used for switch off PWM1 in DCM. Than

PWM1 signal is used directly for switching the PFC switch transistor.

3.3.3 Protection Features

During the startup phase and run phase, some erroneous states can occur. When the DC-bus voltage

does not reach the required value or is out of limits then a fault signal is generated. The DC-bus voltage

is also checked against limits in run mode. If any of the previously mentioned faults occurs, all modules

are disabled, lamps go out, and the fault diode blinks.

3.4 Software Specification

The software is written in C. The software specifications are listed in Table 3-2. A useful feature of this

application is the ability to debug software via the MON08 CYCLONE debug tool connected to JP1 header

connector. The Real-Time Debugger from Metrowerks can be used as a debug tool.

Tabl e 3-2. Software Specification

Dithering control

Control Algorithm

Target Processor MC68HC908LB8

Language C with some arithmetical functions in assembler

Compiler Metrowerks ANSI-C/C++ Compiler for HC08

MCU Oscillator Frequency 16 MHz (with default software setting)

MCU Bus Frequency 4 MHz (with default software setting)

Targeted Hardware Dimmable Light Ballast With PFC Demo Board

Current loop control

Voltage loop control

A detailed description of how to set Debugger for commutation with MON08 CYCLONE is given in

Reference [

2]. For safe debugging it is recommended use an opto-isolation board connected between the

MON08 CYCLONE and the Light Ballast Demo Board. The Opto-isolation Board user manual can be

found in Reference [

3].

3.5 Hardware Specification

The other system specifications are determined by the target hardware and lamp characteristics. The

board and its connections are shown in

This hardware set is designed for fluorescent lamp and mains voltage. The specifications for a high

voltage hardware and fluorescent lamp set are listed in

and 110 VAC mains.

Chapter 4 Hardware Design.

Table 3-1. The hardware operates on 230 VAC

Dimmable Light Ballast with Power Factor Correction, Rev. 1

24 Freescale Semiconductor

Page 25

Chapter 4 Hardware Design

4.1 Hardware Implementation

This chapter covers the system hardware implementation. The dimmable light ballast board is shown in

Figure 4-1.

Figure 4-1. Dimmable Light Ballast - Demo Board

4.2 System Modules

The light ballast system hardware is shown in the block diagram in Figure 4-2. It incorporates the

controller board, powered from AC line and fluorescent tubes. As can be seen, the controller board

contains four major parts:

• Input and PFC (Input EMI Filter, Bridge Rectifier, Boost topology PFC circuit, DC-bus Voltage,

DC-bus Sensing, Mains Zero Crossing Sensing, Comparator Circuit, Buffer Circuit)

• Inverter (Half-bridge Drive, Resonant Circuit, Output Inductance Circuity, Different Voltage

Sensing, Tube Currents Sensing)

• Microcontroller (MC68HC908LB8)

• Power Supply (Switch Mode Power Supply)

Detailed descriptions of the individual parts of the controller boards follows. Note that the reference design

includes the PCB design files and bill of materials (BOM).

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 25

Page 26

Hardware Design

Figure 4-2. Dimmable Light Ballast with Hysteresis PFC HW variation — Hardware Block Diagram

4.2.1 Input and PFC

The input and the PFC part provide the DC-bus voltage to supply the inverter. The schematic for

hysteresis current control mode is shown in

against hysteresis mode is that the gate of Q4 is connected to pin PWM1 of the MCU (see Figure A-2),

not to the output of the comparator. The input stage consists of an EMI filter and a single-phase full-bridge

rectifier. Although the PFC regulator is called an active filter, it does not suppress all harmonics. For this

reason, the EMI filter is placed at the input.

The PFC is based on the most popular non transformer isolated DC-DC boost (step-up) converter

topology. The PFC stage is built with input inductor L1, power MOSFET switch Q1, output rectifier diode

D1, and output capacitor C4. Capacitor C3 performs a filtering function. The input stage converts the

mains AC voltage, rectified by the diode bridge U1, to an output DC voltage on the output capacitor C4.

The current flowing through inductor L1 is sensed by the current sense resistor R4. There are two different

values of resistor R4, 1.5

Ω for rectified input voltage lower than half of DC-Bus voltage and 2.7Ω for higher

voltage. The voltage drop over the current sense resistor corresponds to the measured current. The

circuit, with resistors R3, R5, R7, R9, diodes D2 and D15, and capacitor C27 works as a mains

zero-crossing detector. It senses rectified mains voltage and generates zero-crossing pulses with an

amplitude of 5

volts. With the help of this detector, the microcontroller synchronizes its operation with the

mains frequency.

The DC-bus voltage sensor consists of resistors R1, R2, R6, and R8. It senses the output voltage of the

PFC, and its output is connected to the MCU AD converter. In hysteresis current control mode the output

Figure 4-3. The difference in discontinuous conduction mode

Dimmable Light Ballast with Power Factor Correction, Rev. 1

26 Freescale Semiconductor

Page 27

System Modules

signal of the comparator (Comp Out) controls the power switch Q1 through the output buffer, which

consists of transistors Q2, Q3, and Q4, resistors R10, R13, R34, R35, R36, and R37, and capacitor C7.

For discontinuous conduction mode the comparator output is disconnected from the Q4 transistor gate.

The PWM1 pin is connected to the Q4 transistor gate.

Digital PFC is driven by the MCU. The MC68HC908LB8 peripherals used for PFC are listed below:

• AD converter — channels ADC1 and ADC2

• PWM0 for generating sine wave

• comparator

• IRQ pin for zero-crossing detection

The PFC control algorithm

• converts the sensed output voltage to a digital value

• provides software PI regulator for a voltage feedback loop

• programs its PWM channel to create the pattern of the input current

• synchronizes operation with the mains frequency using mains zero-crossing detection

The control algorithm is described in 5.2 Control Algorithm Description.

DC-BUS VOLTAGE OUTPUT AND SENSING

J1

J1

PM100-INP_CONN-6

PM100-INP_CONN-6

6

6

I6

I6

5

5

I5

I5

4

4

NC

NC

3

3

I3

I3

2

2

I2

I2

1

1

I1

I1

PFC Current Sense

PFC Current Sense

INPUT EMI FILTER AND BRIDGE RECTIFIER

1 4

C1

C1

10nF 275V X2

10nF 275V X2

R14

R14

2K0

2K0

1 4

2 3

2 3

GND

GND

1

1

2

2

GND

GND

12

12

1 2

1 2

C5

C5

4n7 250/1000V Y2

4n7 250/1000V Y2

L6

L6

CMFIL2

CMFIL2

R11

R11

3K0

3K0

C8

C8

82pF

82pF

12

12

RV1

RV1

275V

275V

Comp -

COMPARATOR CIRCUIT

5V

5V

GND

GND

2.7mH

2.7mH

L1B

L1B

PFCIND3

DF1510S

4

4

AC2

AC2

3

3

AC1

AC1

12

12

R3

R3

220K

220K

1

1

R5

R5

220K

220K

2

2

1

1

R7

R7

220K

220K

2

2

C10

C10

220nF

220nF

Comp Out

150nF 275V X2

150nF 275V X2

1

1

DC+

DC+

2

2

DC-

DC-

MAINS ZERO CROSSING SENSING

12

D15

D15

R9

BAT48

BAT48

47K

GND

D2

D2

BZV55C5V6

BZV55C5V6

GND

GND

1

1

R12

R12

10K

10K

2

2

C2

U1

C2

U1

DF1510S

PFCIND3

12

12

PFC Gate

PFC Gate

1 2

1 2

R4 2R7

R4 2R7

PFC Current Sense

PFC Current Sense

Zero Detect

Zero Detect

C27

1n5

GND

C7

C7

12

12

100nF

100nF

R10

R10

6K8

6K8

GND

GND

BEQ2

BEQ2

R13

R13

620R

620R

BCQ3

BCQ3

D

G

Q4

MMBF0201

S

GND

BOOST CONVER TER

D1

D1

53

53

MURS160T3

MURS160T3

D

D

G

G

S

S

15V

15V

12

12

R35

R35

0R

0R

1

1

R34

R34

0R

0R

2

2

C

C

BC846B

BC846B

E

E

BC856B

BC856B

GND

GND

Q1

Q1

IRF820A

IRF820A

R36

R36

0R

0R

PFC Gate

PFC Gate

BUFFER CIRCUIT

10nF 630V TC356

10nF 630V TC356

R37

R37

12

12

C3

C3

0R

0R

15V/1

15V/1

GND

GND

+

+

C4

C4

22uF 450V

22uF 450V

C6

100nF

12

R1

560K

12

R2

560K

12

R6

510K

DCB Divider

12

R8

18K

GNDGND

DCB

DCB

1

2

CONN/HDR/2X1

GND

JP6

Figure 4-3. Dimmable Light Ballast — Input and PFC

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 27

Page 28

Hardware Design

4.2.2 Inverter

The power inverter generates the proper voltage for the fluorescent tubes. The power inverter consists of

two MOSFET transistors driven by a half-bridge driver. It incorporates the half-bridge, a resonant circuit,

different voltage and tube current sensing, and output inductance circuity.

The half-bridge driver IR2106 from International Rectifier is electrically connected according to the

manufacturer’s recommendations. The half-bridge is supplied from the DC-bus voltage. It is controlled by

the TOP and BOT signals from the MCU.

The half-bridge lamp resonant circuit consists of capacitor C15 and inductance L7. It provides preheating,

ignition, and running operating conditions by changing the operating frequency.

The tube voltage difference circuit consist of coils L3A, L3B, and L3D, resistors R21, R24, R22, and R151,

diode D8, and capacitor C17, and is used to sensing voltage differences between lamps. It helps to

recognize aging of the lamps.

Coils L4 and L5 and diodes D4 and D5 are for filament preheating. Diodes maintain a small offset to

remove the flickering effect. Coils L3A and L3D balance possible differences in current flow into tubes,

mainly at ignition stage. Devices R19, D7, R152, D6, C16, and R20 sense the current flow in tube 1 (and

similarly for tube 2).

For different tubes parameters, the tube currents are different. The ignition circuit formed by L3D, L3A,

and R17 balance the current. The compensation current flows through R17 until the tube currents are

equal, at which time the ignition of both tubes can be done reliably.

Tubes preheating heats the tubes to the desired temperature before startup. It decreases the wear-out

and increases the life-time and reliability in startup. Also, the voltage required for ignition is smaller.

Each tube has its own preheating circuity. Tube 1 uses L4. Tube 2 uses L5. The preheating voltage and

time is set-up in software and is controlled by the TOP and BOT signals from the HRP.

The flickering effect is caused by reducing the voltage to zero during the light ballast operation. To avoid

this, the Zener diodes D4 and D5 maintain a small voltage on both tubes at all times.

The output inductance circuity performs several important functions in the light ballast application. It helps

to ignite lamps, when tube parameters differ (due, for example, to different aging of the lamps). It removes

the flickering effect and provides filament preheating.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

28 Freescale Semiconductor

Page 29

DCB

TOP

BOT

15V/1

1 2

D3

MURA160

C13

1uF

25V

R15

IC1

1

Vcc

VB

2

HIN

HO

3

LIN

COM4LO

IR2106

Tube V o l t ag e d i f fe r e nc e

HALF BRIDGE

10R

8

7

6

Vs

5

System Modules

J2

L4C

HEAT7

43

R23

20R

0.5W

TU BE C onn ector

O11O22O33O44O55O66O77O8

6 5

L4D

L5C

HEAT7

HEAT6

R19

20R

0.5W

1 2

GND

8

56

3 4

R152

D7

MBRS140

1 2

GND

R150

0R

D10

MBRS140

TUBE CURRENTS SENSING

L5D

HEAT6

D9

BAT48

D6

BAT48

0R

C18

22nF

C16

22nF

R25

10K

Tube Current 1

R20

10K

Tube Current 2

OUTPUT INDUCTANCE CIRCUITY

C26

Q5

IRF830A

33R

C11

100nF

33R

Q6

IRF830A

D

G

S

D

G

S

GND

C17

6n8

GND

R16

R18

10nF 630V TC356

GND

RESONANT CIRCUIT

12

C28

470pF 1KV

1 3

12

C14

470pF 1KV

D8

BAT48

R22

30K

GND

L7

RES5

1mH

R151

C12

100nF 630V

1 2

12

8n2 1KV

0R

C15

GND

D4

BZG05C22

L3D DIFF8

1 8

L3A DIFF8

D5

BZG05C22

R21

3K3

R24

N/P

54

72

L3BDIFF8

2 7

L4B

HEAT7

1 2

R17 10K

L5B

HEA T6

GND

GND

27

GND

DIFFERENT VOLTAGE SENSING

Figure 4-4. Dimmable Light Ballast — Inverter

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 29

Page 30

Hardware Design

4.2.3 Microcontroller

The MC68HC908LB8 microcontroller is the core of the application. It processes the input and feedback

signals and generates appropriate control signals. The description of the pins follows.

The inverter is controlled by signals on the TOP and BOT pins of the MCU.

Signal PWM0 is used to generate a sine wave. This signal (on comparator pin V+) is compared with the

real current (on comparator pin V-) in the on-board comparator. The real current is sensed using the shunt

resistor R4. The signal from PWM0 is filtered in the RC filter comprised of R30, R31 and capacitor C9.

The output of the comparator appears on pin VOUT.

The IRQ pin is used for the zero-crossing detection circuit and for entry to the monitor mode.

The microcontroller stage incorporates two header connectors, the Luminance Level connector and the

Monitor Mode connector. The Luminance Level connector is used for the Luminance Level potentiometer

(see

Table 4-1). The Monitor Mode connector enables the MCU to enter the Monitor Mode. For Monitor

Mode, the IRQ, OSC1, PTA0, and PTA1 pins are used (see Table 4-2).

The Fault LED is connected to pin PTA5; it indicates the actual state of the application.

DC-bus shift-down voltage is sensed on pin ADC2.

Real currents through tube1 and tube2 are sensed on pins ADC3 and ADC4. The tube voltage difference

is sensed on pin ADC5.

In the discontinuous conduction mode HW variation, PWM1 pin is used directly for switching the PFC

switch transistor (see

Figure A-5). Comparator output is internally connected to the PWM fault pin. In the

hysteresis current control mode HW variation, it is not used.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

30 Freescale Semiconductor

Page 31

System Modules

TOP

BOT

Comp Comp Out

Zero Detect

R30

13K

5V

D11

R26

1K

R27

1K

R38

N/P

5V

R29

11K

R31

3K9

GND

C9

100nF

1 2

GNDGND

IC2

6

PTB0/TOP

7

PTB1/BOT

8

PTB2/FAULT

9

PTB3/PWM0

10

PTB4/PWM1

11

PTB5/V+

12

PTB6/V-

13

PTB7/VOUT/ADC6/FAULT

3

PTC0/OS C1

4

PTC1/OS C2

5

PTC2/SHTDWN/IRQ

MC68HC908LB8-CASE_751D

Serial Da ta

LED

PTA0/ADC0/KBI0

PTA1/ADC1/KBI1

PTA2/ADC2/KBI2

PTA3/ADC3/KBI3

PTA4/ADC4/KBI4

PTA5/RST/KBI5

PTA6/ADC5/TCH0/KBI6

VDD

VSS

5V

1

2

3

4

5

6

GND

CONN/HDR/6X1

JP5

R28

1K8

5V

R33

10K

R260

14

15

16

17

18

19

20

1

2

GND

0R

Serial Data

DC B Di v i d er

Tube Cur r en t 1

Tube Cur r en t 2

Tube Vol t age differe nce

C19

100nF

1 2

25V

R39

5V

1

2

3

Luminance Leve l

GND

JP2

0R

Figure 4-5. Dimmable Light Ballast — Microcontroller

NOTE

The Luminance Level potentiometer should be connected to the PCB in the

required manner. This means that if the potentiometer is in a zero position,

a 0% Luminance is required and 0V must be available on pin 2 of connector

JP2.

Table 4-1. J1 Luminance Header

Pin number Signal

1 +5V

2 PTA1

3 GND

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 31

Page 32

Hardware Design

Table 4-2. J2 Interface Header

Pin number Signal

1 +5V

2 PTC2

3 PTC0

4 PTA0

5 GND

6 PTA1

Dimmable Light Ballast with Power Factor Correction, Rev. 1

32 Freescale Semiconductor

Page 33

System Modules

4.2.4 Power Supply

The function of the switch mode power supply (SMPS) is to feed the inverter and output buffer circuit with

V and to supply the microcontroller stage by 5 V (see Table 4-3). The SMPS is supplied from the

15

DC-bus voltage. It uses the monolithic high-voltage regulator NCP1010 from ON Semiconductor

connected as recommended by the manufacturer. It can provide 15

power supply from a 15

V source, a step-down resistor R32, 5V1 Zener diode D13, and filtering capacitor

C25 are used.

22uF

35V

C20

+

1 2

DCB

GND

IC3

1

VCC

2

FB

3

DRAIN

12

C23

+

1uF

450V

NCP1010-SOT223

1 2

1nF 25V

C24

GND

4

GND

D12

MURA160

U3

4

SFH6106

TL-RAD EZK

L8

4.7mH

1

23

D14

BZV55C13

VDC @ 100 mA. To achieve a 5 V

15V 5V

12

C21

+

100uF

35V

GND GND

C22

1uF

1 2

25V

15V/1

R32

390R

GND

D13

BZV55C5V1

GND GND

Figure 4-6. Dimmable Light Ballast — Power Supply

Table 4-3. Supplied Voltages

Volt age Supply

+15V Driving stage, Output buffer circuit

+5V Microcontroller stage

C25

220nF

1 2

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 33

Page 34

Hardware Design

Dimmable Light Ballast with Power Factor Correction, Rev. 1

34 Freescale Semiconductor

Page 35

Chapter 5 Software Design

5.1 Introduction

This section describes software features and behavior of the software in all function modes. The software

is described in terms of:

• Control Algorithm Description

• Software Implementation

• Detailed Software Description

• Microcontroller Usage

• Constant and Variable Definitions

5.2 Control Algorithm Description

The application performs dimmable light ballast for fluorescent lamp control and PFC control. It uses

microcontroller built-in peripherals.

current control mode HW variation. Software block diagram for DCM HW variation is not placed because

diagram is very similar. As can be seen, the PFC Control and Light Ballast Control are separate routines.

Figure 5-1 shows the high level software block diagram for hysteresis

Figure 5-1. Dimmable Light Ballast with Hysteresis PFC HW Variation — Software Block Diagram

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 35

Page 36

Software Design

5.2.1 Power Factor Correction Control

PFC control consists of DC-bus voltage control using the PI controller, phase shift synchronization,

reference sine wave generation and generation of output PFC control signals. It also includes the

trimming of the internal oscillator frequency according to the frequency of the mains provided.

5.2.1.1 DC-bus Voltage Control

The actual value of the DC-bus voltage is sensed by the AD converter. This value is compared with the

required DC-bus value. The regulation error is then the input value for the PI regulator. The output value

from the PI regulator is the reference sine wave gain. The PWM module generates a reference sine wave

with calculated amplitude. The filtered reference sine wave is compared with the actual current using the

on-chip comparator. For the hysteresis current control mode HW variation, the output from the

comparator is the switching signal for the PFC MOSFET transistor. For the discontinuous conduction

mode HW variation, the output comparator is connected to the PWM fault pin. The PWM1 signal is directly

used for switching the PFC MOSFET transistor.

5.2.1.2 Phase Shift Synchronization

Phase shift synchronization synchronizes the generated PFC reference sine wave to the frequency of the

mains. It is realized by means of:

• Zero voltage crossing detection (zero voltage sensor)

The zero voltage crossing sensor generates a falling edge every time when the input voltage

crosses zero from positive to negative polarity.

• External interrupt

An external interrupt is triggered by the zero voltage crossing sensor. The interrupt subroutine is

used to get the content of timer TIM registers TCNTH:TCNTL for automatic microcontroller

trimming and for PFC reference sine wave amplitude gain calculation in lamp run mode.

• MCU oscillator frequency trimming

For microcontroller automatic trimming, the timer TIM is used as an interval counter. The timer is

incremented by the internal clock (divided by prescaler). Its content is cleared every

produced by the voltage zero crossing sensor. A user defined value determines what number

should be found in TIM registers TCNTH:TCNTL. On the basis of the comparison between required

and actual counter values, the content of the oscillator trim register OSCTRIM is adjusted with

ramp.

IRQ interrupt

5.2.1.3 Reference Sine Wave Generation

Reference is performed by the PWM peripheral. The software contains a sine wave table with values for

interval and maximum amplitude. The amplitude of the sine wave depends on the value of the DC-bus

voltage and it is adjusted by the PI controller every 20ms. Two different sets of PI controller parameters

are used, one for MCU startup, when the DC-bus voltage must reach the required value quickly and HRP

is not activated, and the second during standard running operation.

5.2.1.4 Generation of Output PFC Control SIgnal

The generated output PFC signal controls the PFC power MOSFET. An on-chip operational amplifier is

used in comparator mode. It compares the reference sine wave, filtered by the RC filter, with the actual

current and generates a switching signal for the PFC MOSFET transistor in the hysteresis current control

mode HW variation. In discontinuous conduction mode comparator output is used for switching off the

PWM1 signal. It works as a fault detection in fact. When the actual current sensed on the shunt resistor

Dimmable Light Ballast with Power Factor Correction, Rev. 1

36 Freescale Semiconductor

Page 37

Control Algorithm Description

is higher than the generated sine waveform, then the comparator output is in log.1 and PWM1 is switched

off. This happens every PWM period and this process is called cycle by cycle limiting. PWM1 operates at

a 40 kHz frequency with variable duty cycle. For safety reasons, the comparator is enabled when the

microcontroller is initialized and mains voltage synchronization is provided.

5.2.2 Light Ballast Control

Light Ballast Control controls the fluorescent tubes. The control process consists of two parts (modes),

tube start mode and tube run mode.

and run mode.

Figure 5-2 shows the software control time diagram during start mode

Figure 5-2. Dimmable Light Ballast — Control Time Diagram

5.2.2.1 Tube Start Mode

When the DC-bus voltage reaches the required value, the HRP is enabled at maximum ballast frequency

and kept for a set time. Then the ballast frequency is ramped down to the preheat frequency and kept for

a set time. This procedure preheats the filaments. In the next stage, the ballast frequency is ramped down

until the lamps are ignited. During the lamp ignition procedure, the frequency and tube currents are

controlled (see Reference [

4]).

5.2.2.2 Luminance Level Control (Tube Run Mode)

Luminance Level Control is active after tube ignition. The actual values of the tube currents are sensed

by the AD converter. Average value of currents is compared with required current value after luminance

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 37

Page 38

Software Design

level adjustment (brightness linearization). The regulation error is then the input value for the PI regulator.

The output value from the PI regulator is the HRP period for half bridge power stage.

Input required luminance level adjustment adapts the required luminance level to its exponential value.

This is done because of the nonlinear function dependence of luminance on the lamp current. The

transformation table is used. The table contains the required current values.

The values in the table can be calculated using the following expression.

ki

⋅

i

req

where:

•i

•i

• A is the exponential curve gain

• q is the exponential curve offset

To calculate the coefficients A and q correctly, the following values must be known.

• Minimum HRP frequency f

• Maximum HRP frequency f

• Tube current measurement range i

• Minimum required tube current i

• Maximum required tube current i

• ADC maximum value AD

• ADC minimum value AD

• Minimum required tube current value converted to ADC range i

• Maximum required tube current value converted to ADC range i

• k determines function precision

is the required current in the exponential expression used for the control algorithm calculation

reg

is the required current measured by the AD converter

regAD

Ae

reqAD

q+⋅= (EQ 5-1)

min

max

max

t

min

tmax

max

min

tADmin

tADmin

Then:

i

tADmin

i

tADmax

This is a time-consuming calculation, but it can be simplified by using the sheet “HRP_Setup” provided in

the Excel file “DLB_Setup.xls”. This file can be downloaded along with this designer reference manual.

Dimmable Light Ballast with Power Factor Correction, Rev. 1

round i

round i

i

A

----------------------------------------------------=

kAD

e

qi

tADmin

tmin

tmax

tADmaxitADmin

⋅

max

AD

AD

–

kAD

e

–

kAD

Ae

⋅–=

maximax

maximax

⋅

min

⋅

⁄ 0;⋅()=

min

(EQ 5-2)

⁄ 0;⋅()=

(EQ 5-3)

(EQ 5-4)

(EQ 5-5)

38 Freescale Semiconductor

Page 39

Software Implementation

5.3 Software Implementation

The general software implementation is illustrated in Figure 5-3. It incorporates the main routine entered

from Reset and three interrupt states. The main routine includes the initialization of the microcontroller

including PWM, HRP, ADC, and pins used in the application, and sets initial values for the PI regulator.

The infinite loop is performed as long as board remains connected to the mains and no fault conditions

are detected.

The interrupt states provide for trimming the internal oscillator, mains synchronization, reference sine

wave generation, and fault detection and processing.

OverFlow Interrupt

of Timer, Fault

Interrupt

Fault

Interrupt

Routine

done

RESET

PWM Reload Inte rrupt

done

IRQ Interrupt

done

Sinewave

Generation

Interrupt

Routine

Synchronization

Interrupt

Routine

MCU & Application

Initialization

done

Main

Infinite

Loop

Figure 5-3. Software Implementation

5.3.1 Initialization Setup

Prior to running the main program loop, the initialization setup sets the microcontroller operation mode

and peripherals. The quickest way to set and PWM is to use the auxiliary Excel sheet Reference [

achieve the required system behavior and communication with peripherals, the following registers and

initial values are set.

• Set configuration registers CONFIG1 and CONFIG2 at the beginning of the initialization; they can

be written once only after each reset.

The register CONFIG1 sets:

– long COP time-out period

– enable LVI module

– disable STOP instruction

4]. To

Dimmable Light Ballast with Power Factor Correction, Rev. 1

Freescale Semiconductor 39

Page 40

Software Design

The register CONFIG2 sets:

– internal oscillator

– IRQ interrupt enabled

– IRQPUD must be 0 to connect the internal pullup resistor between IRQ pin and Vdd.

• IRQ status and control register INTSCR sets:

– IMASK enable IRQ interrupt requests

– IRQ interrupt on falling edge only

• Analog to digital converter clock register (ADCLK)

– sets the ADC clock. ADC clock = bus clock / prescaler. The recommended value for the ADC

clock is 1

MHz.

• PWM setup — void Set_PWM(void)

The subroutine initializes PWM values, and sets 0% duty cycle on PWM.

For a better understanding of PWM setup and logic, see 5.3.1.1 PWM Setup.

• HRP setup — void Set_HRP(void)

The subroutine initializes and sets HRP registers. For a better understanding of HRP setup and

logic, see

5.3.1.2 HRP Setup.

5.3.1.1 PWM Setup

The PWM module can generate two independent PWM signals used for PFC control. These signals are

edge-aligned. PWM resolution is one clock period which is dependent on the internal bus frequency

(BUSCLK) and a programmable prescaler (PRSC0, PRSC1). Also, programmable fault protection and

PWM signal polarity controls are provided.

For the application, the PWM is set to 40 kHz, resulting in 101 levels of PWM0 at a 4 MHz bus frequency.

Because of the hardware configuration, negative polarity control of the PWM output is required.

For proper operation of the PWM module, the following registers must be set:

• PWM counter modulus registers PMODH and PMODL hold a 12-bit unsigned number that

determines the maximum count for the up-only counter. It is set to 100.

• PVAL0H and PVAL0L registers determine duty cycle value (duty cycle = PVAL0/PMOD*100). In

initialization phase this is set to 0.

• PCTL1 register controls PWM enabling/disabling, the location of the PWM Fault bit, the loading of

new modulus, prescaler, and PWM values, and the PWM correction method.

In the application, PCTL1 is set as follows:

– Fault pin is PTB7

– interrupt is enabled

– load new values active

– module enabled

• PCTL2 register controls the PWM reload frequency, PWM channel enabling/disabling, the PWM

polarity, the PWM correction method, and the PWM counter prescaler. For safety reasons, some

of these register bits are buffered. The PWM generator will not use the prescaler value until the

LDOK bit has been set and a new PWM cycle is starting. The load frequency bits are not used until

the current load cycle is complete.

In the application, PCTL2 is set as follows:

– PWM0 enabled

– PWM1 enabled

– PWM0 negative polarity control

– reload frequency bits LDFQ0 and LDFQ1 to 0 — reload every PWM cycle

Dimmable Light Ballast with Power Factor Correction, Rev. 1

40 Freescale Semiconductor

Page 41

Software Implementation

– PWM clock frequency set to BUSCLK by prescaler bits PRSC0 and PRSC1

• DISMAP is a write-once register which controls the PWM pins to be disabled if an external fault

occurs. When this register is written for the first time, it cannot be rewritten unless a reset o ccurs.

PWM0 is not disabled when an external fault appears. PWM1 is disabled if an external fault

appears.

• The FCR register controls the fault protection circuitry. A fault does not cause a CPU interrupt in

hysteresis current control mode. The fault protection circuitry operates in automatic mode for DCM

HW variation. In hysteresis current control mode operates in manual mode.

The PWM frequency is affected by the setup of the internal bus frequency, PWM modulus registers

PMODH, PMODL, and the prescaler value in the PRSC0 and PRSC1 registers. Consequently, the PWM

frequency is given by the equation:

BusFrequency

PWM Frequency

------------------------------------------------- -

Hz; Hz, -, -[]=

(EQ 5-6)

PMOD PRSC[0:1]×

According to the setting, the PWM frequency is 40 kHz.

5.3.1.2 HRP Setup

The HRP provides two complementary outputs for controlling a half-bridge in a light ballast application. It

uses a dithering control method to provide a high step resolution (< 4 ns) from an 8 MHz input clock when

driving inductive loads.

For the to operate properly, the HRP registers must be set correctly. The HRP works in variable frequency

mode with 50% duty cycle. The output frequency varies from 40 kHz up to 120 kHz, depending on the

level of dimming required. The MCU BUSCLKX2 is 8 MHz. The transistors controlling the lamp require a

deadtime of 1 µs. The deadtime must be set by software.

Four steps are required to configure the HRP:

1. Set the dithering timebase to the appropriate value

2. Set the deadtime to the appropriate value

3. Set HRPPERH:HRPPERL to select the desired frequency