Page 1

Tower KW2xDxxx Hardware

Reference Manual

Document Number: TWR-KW2xDxxxHWRM

Rev. 0.2

10/2013

Page 2

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

Information in this document is provided solely to enable system and software implementers to use

Freescale Semiconductor products. There are no express or implied copyright licenses granted

hereunder to design or fabricate any integrated circuits or int egrated circuits based on the informa tion

in this document.

Freescale Semiconductor reserves the right to make changes without furt her notice to any product s

herein. Freescale Semiconductor makes no warranty, representation or guarantee regarding the

suitability of its products for any particular purpose, nor does Freescale Semiconductor assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incident al damages. “Typical” parameters

that may be provided in Freescale Semiconductor data sheet s and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating parameters,

including “Typicals”, must be vali dated for each customer application by customer’s technical

experts. Freescale Semiconductor does not convey any l icense und er it s paten t rights no r the right s

of others. Freescale Semiconductor products are not designed, intended, or authorized for use as

components in systems intended for surgical implant into the body, or other applications intended to

support or sustain life, or for any other applicatio n in which the failure of the Freescale Semiconductor

product could create a situation where personal injury or death may occur. Should Buyer purchase

or use Freescale Semiconductor products for any such unintended or unauthorized application,

Buyer shall indemnify and hold Freescale Semiconductor and its officers, employees, subsidiaries,

affiliates, and distributors harmless against all claims, costs, damages, and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other

product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2013. All rights reserved.

Page 3

Contents

Chapter 1

Safety Information

1.1 FCC Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.2 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.3 Exposure Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.4 Antenna Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Regulatory Approval For Canada (IC RSS 210) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 26 PART 5 – Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Electrostatic Discharge Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Disposal Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2

TWR-KW2xDxxx Development Platform Overview and Description

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Software and Driver Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3

TWR-KW2xDxxx

3.1 TWR-KW2xDxxx Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 PCB Board Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Form Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.3 Board Level Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.1 RF Performance and Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.2 Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.3 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.4 TWR-KW2xDxxx Peripheral Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.4.1 Serial FLASH (SPI Interface). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.4.2 TWRPI Connectors J9 and J10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.2.4.3 Jumper Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.2.4.4 MKW24D512 USB Supply (J6) - TWR-MK24D512 Board Only . . . . . . . . . . . . . . . 3-12

3.2.4.5 MKW21D256 (Non-USB) UART2 Support - TWR-MK21D256 Board Only . . . . . . 3-12

3.3 Schematic, Board Layout, and Bill of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.3.1 Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Chapter 4

PCB Manufacturing Specifications

4.1 Single PCB Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Panelization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Tower MKW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor iii

Page 4

4.4 Solder Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Silk Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.6 Electrical PCB Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.7 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.8 Hole Specification/Tool Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.9 File Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Tower MKW2xDxxx Hardware Reference Manual, Rev. 0.2

iv Freescale Semiconductor

Page 5

About This Book

This manual describes Freescale’s TWR-KW2xDxxx development platform hardware. The

TWR-KW2xDxxx is an IEEE® 802.15.4 compliant evaluation environment based on the Freescale

MKW2xDxxx device. The MKW2xDxxx family is Freescale's latest generation ZigBee™ platform,

which incorporates a complete low power 2.4 GHz radio frequency transceiver and a Kinetis family low

power, mixed-signal ARM Cortex™-M4 MCU into a single package. This family of products is targeted

to meet the higher performance requirements of ZigBee Pro and ZigBee IP based applications, especially

Smart Energy and Commercial Building Automation. This product is a cost-effective solution that matches

or exceeds competitive solutions.

Audience

This manual is intended for system designers.

Organization

This document is organized into the following chapters.

Chapter 1 Safety Information — Highlights some of the FCC requirements.

Chapter 2 TWR-KW2xDxxx Development Platform Overview and Description — Provides

an overview of the boards that comprise the TWR-KW2xDxxx development

platform.

Chapter 3 TWR-KW2xDxxx — This chapter details the TWR-KW21D256 and

TWR-KW24D512 evaluation boards.

Chapter 4 PCB Manufacturing Specifications — This chapter provides the specifications

used to manufacture the various TWR-KW2xDxxx printed circuit boards (PCBs).

Revision History

The following table summarizes revisions to this document since the previous release (Rev. 0.0).

Revision History

Location Revision

Entire document First public release

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor v

Page 6

Definitions, Acronyms, and Abbreviations

The following list defines the acronyms and abbreviations used in this document.

ADC Analog to Digital Converter

AES Advanced Encryption Standard

CTS Clear to Send

DAC Digital to Analog Converter

I2C Inter-Integrated Circuit is a multi-master serial computer bus

ISM Industrial Scientific Medical 2.4 GHz radio frequency band

JTAG Joint Test Action Group

LGA Land Grid Array

MAC Media Access Controller

MCU Microcontroller Unit

PCB Printed circuit board

PiP Platform in Package

PWM Pulse-width modulation

RCM Remote Control Module

REM Remote Extender Board

RTS Request to Send

SMA Connector SubMiniature version “A” connector

SoC System on Chip

SPI Serial Peripheral Interface

SSI Synchronous Serial Interface

TACT Switch A switch that provides a slight “snap” or “click” to the user to indicate function.

TELCO Telephone Company

TWR Tower System

USB Universal Serial Bus

VCP Virtual Com Port

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

vi Freescale Semiconductor

Page 7

Chapter 1

Safety Information

1.1 FCC Guidelines

This equipment is for use by developers for evaluation purposes only and must not be incorporated into

any other device or system. This device may not be sold to the general public. Integrators will be

responsible for reevaluating the end product (including the transmitter) and obtaining a separate FCC

authorization.

FCC approval of this device only covers the original configuration of this device as supplied. Any

modifications to this product, including changes shown in this manual, may violate the rules of the Federal

Communications Commission and Industry Canada and make operation of the product unlawful.

1.1.1 Labeling

FCC labels are physically located on the back of the board.

1.1.2 Operating Conditions

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause undesired

operation.

1.1.3 Exposure Limits

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment.

The antenna(s) used for this equipment must be installed to provide a separation distance of at least 8

inches (20cm) from all persons.

1.1.4 Antenna Restrictions

An intentional radiator shall be designed to ensure that no antenna other than that furnished by the

responsible party shall be used with the device. The use of a permanently attached antenna or of an

antenna that uses a unique coupling to the intentional radiator shall be considered sufficient to comply with

the provisions of this Section. The manufacturer may design the unit so that a broken antenna can be

replaced by the user, but the use of a standard antenna jack or electrical connector is prohibited. This

requirement does not apply to carrier current devices or to devices operated under the provisions of

Sections 15.211, 15.213, 15.217, 15.219, or 15.221. Further , this requirement does not apply to intentional

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 1-1

Page 8

Safety Information

radiators that must be professionally installed, such as perimeter protection systems and some field

disturbance sensors, or to other intentional radiators which, in accordance with Section 15.31(d), must be

measured at the installation site. However, the installer shall be responsible for ensuring that the proper

antenna is employed so that the limits in this Part are not exceeded.

1.2 Regulatory Approval For Canada (IC RSS 210)

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions:

1. This device may not cause interference, and

2. This device must accept any interference, including interference that may cause undesired

operation of the device.

1.2.1 26 PART 5 – Appendix

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes:

1. l'appareil ne doit pas produire de brouillage, et

2. l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d'en compromettre le fonctionnement.

1.3 Electrostatic Discharge Considerations

Although damage from electrostatic discharge (ESD) is much less common on these devices than on early

CMOS circuits, normal handling precautions should be used to avoid exposure to static discharge.

Qualification tests are performed to ensure that these devices can withstand exposure to reasonable levels

of static without suffering any permanent damage.

All ESD testing is in conformity with the JESD22 Stress Test Qualification for Commercial Grade

Integrated Circuits. During the device qualification ESD stresses were performed for the human body

model (HBM), the machine model (MM) and the charge device model (CDM).

All latch-up test testing is in conformity with the JESD78 IC Latch-Up Test.

When operating or handling the development boards or components, Freescale strongly recommends

using at least the grounding wrist straps plus any or all of the following ESD dissipation methods:

• Flexible fabric, solid fixed size, or disposable ESD wrist straps

• Static control workstations, static control monitors and table or floor static control systems

• Static control packaging and transportation materials and environmental systems

1.4 Disposal Instructions

This product may be subject to special disposal requirements. For product disposal instructions, refer to

www.freescale.com/productdisposal.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

1-2 Freescale Semiconductor

Page 9

Chapter 2

TWR-KW2xDxxx Development Platform Overview and

Description

2.1 Introduction

The TWR-KW2xDxxx development platform is an evaluation environment based on the Freescale

MKW21D256 or MKW24D512 SIP devices (MKW2xDxxx).

The MKW2xDxxx device family is Freescale's latest generation ZigBee™ platform which incorporates a

complete low power 2.4 GHz radio frequency transceiver and a Kinetis family low power, mixed-signal

ARM Cortex™-M4 MCU into a single package. Additionally, the MKW2xDxxx comprising of a a 2.4

GHz Industrial, Scientific, and Medical (ISM) and Medical Body Area Network (MBAN) transceiver are

intended for the IEEE® 802.15.4 Standard.

Freescale supplements the MKW2xDxxx with tools and software that include hardware evaluation and

development boards, software development IDE and applications, drivers, custom PHY usable with

Freescale’s IEEE 802.15.4 compatible MAC.

The TWR-KW2xDxxx development platform comprises two boards:

• Tower — TWR-KW21D256 — this board contains the MKW21D256 device with 32 MHz

reference oscillator crystal, RF circuitry including antenna, and supporting circuitry. The board is

a standalone, with a software stack to implement an IEEE 802.15.4 Standard platform solution. The

following list summarizes the features of the TWR-KW21D256 board.

— Provides compact reference design for device footprint and RF layout.

— Provides pre-designed MKW21D256 hardware (device and function).

— Provides access to the MKW21D256 set of GPIO/Alternate port functions.

— Provides target MCU Cortex 20-pin (0.05”) JTAG debug port.

— Provides a Mini USB Type B coupled with OpenSDA use as debug interface, serial

communication and power supply (J13, Cortex 10-pin (0.05”) JTAG port for OpenSDA

updates).

• Tower — TWR-KW24D512 — this board contains the MKW24D512 device with 32 MHz

reference oscillator crystal, RF circuitry including antenna, and supporting circuitry. The board is

a standalone, with a software stack to implement an IEEE 802.15.4 Standard platform solution. The

following list summarizes the features of the TWR-KW24D512 board.

— Provides compact reference design for device footprint and RF layout.

— Provides pre-designed MKW24D512 hardware (device and function).

— Provides access to the MKW24D512 set of GPIO/Alternate port functions.

— Provides MCU JTAG Cortex 20-pin (0.05”) JTAG debug port.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 2-1

Page 10

TWR-KW2xDxxx Development Platform Overview and Description

— Provides a Mini USB Type B coupled with OpenSDA used as debug interface, serial

communication and power supply (J13, Cortex 10-pin (0.05”) JTAG port for OpenSDA

updates)

— The TWR-KW24D512 also provides a Micro USB T ype AB used as serial communication and

power supply.

Whether the TWR-KW2xDxxx is used in a simple standalone application or in combination with another

reference platform, Freescale provides a complete software development environment called the Freescale

BeeKit Wireless Connectivity Toolki t (BeeKit). BeeKit is a comprehensive codebase of wireless

networking libraries, application templates, and sample applications. A wide range of software

functionality are available to complement the TWR-KW2xDxxx platform and these are provided as

codebases within BeeKit.

2.2 Features

The TWR-KW2xDxxx development platform is built around Freescale’s concept of a standalone Tower

System Modular Development Platform that contains either the MKW21D256 device or the

MKW24D512 device and all necessary I/O connections for use as a self-contained board or for connection

to an application, but also has the capability to connect with the Tower System.

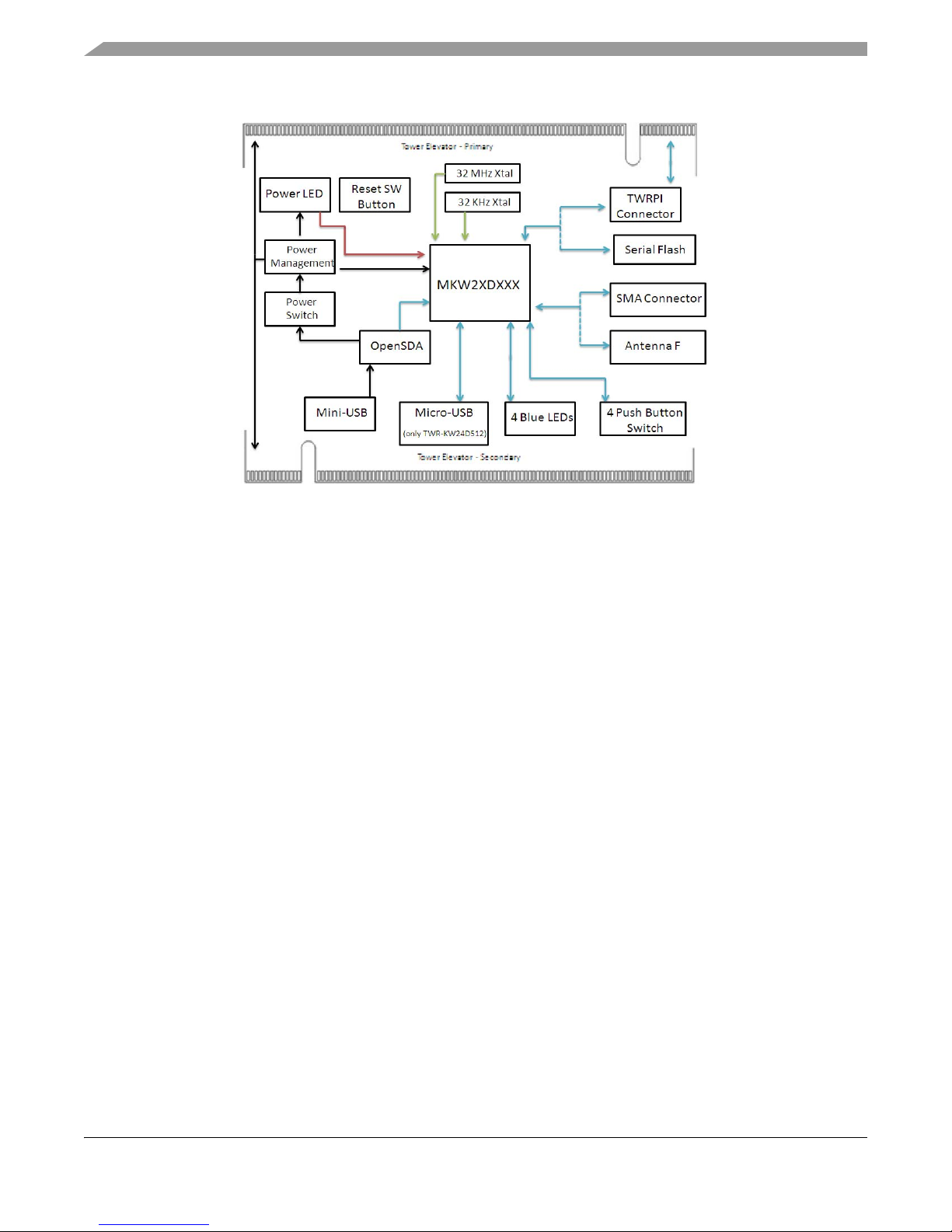

Figure 2-1 shows the TWR-KW2xDxxx development platform:

Figure 2-1. TWR-KW2XDXXX Development Platform

The TWR-KW2xDxxx development platform includes the following Features:

• Freescale’s low-power MKW21D256 or MKW24D512 SIP ZigBee™ platform device

• Fully compliant IEEE 802.15.4 Standard 2006 transceiver supports 250 kbps O-QPSK data in 5.0

MHz channels and full spread-spectrum encode and decode.

• Full IEEE 802.15.4 compliant wireless node; ZigBee capable with Freescale’ s BeeS tack software

stack.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

2-2 Freescale Semiconductor

Page 11

TWR-KW2xDxxx Development Platform Overview and Description

• Reference design area with small footprint, low cost RF node

— Differential input/output port used with external balun for single port operation

— Low external component count

— Programmable output power from –30 dBm to +8 dBm at the SMA connector.

— Receiver sensitivity: –100 dBm, typical (@1% PER for 20 byte payload packet) at the SMA

connector

• Integrated PCB inverted F-type antenna and SMA RF port

• Selectable power sources

• 32 MHz reference oscillator

• 32 kHz reference oscillator

• Pre-certified 2.4 GHz frequency band of operation (ISM)

• Programmable frequency clock output (CLK_OUT)

• External Serial flash for Over-the-air Programming (OTP) support

• General purpose TWRPI connector

•Interfaces:

— SPI, UART, and I2C interface configurations

— ADC and GPIO configurations

• Integrated open-standard serial and debug interface (OpenSDA)

• Supports full speed USB 2.0 (TWR-KW24D512 only)

• Cortex 20-pin (0.05”) JTAG debug port for target MCU

• Cortex 10-pin (0.05”) JTAG port for OpenSDA updates

• 4 blue LED indicators

• 4 push button switches

Figure 2-2 shows a simplified block diagram of the Freescale TWR-KW2XDXXX system.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 2-3

Page 12

TWR-KW2xDxxx Development Platform Overview and Description

Figure 2-2. Simplified TWR-KW2xDxxx Block Diagram

2.3 Software and Driver Considerations

It is a good idea to install the BeeKit Wireless Connectivity Toolkit package found under Software and

Tools at the following URL before proceeding to use the TWR boards:

• www.freescale.com\zigbee

When users first connect a TWR-KW2xDxxx based platform to a PC, they may be prompted to install

drivers. If BeeKit is installed and this occurs, do not allow Windows to automatically search for and install

the drivers. Instead, select manual installation and steer Windows to the following directory:

C:\Program Files\Freescale\Drivers

Follow the instructions as they appear on the screen to complete driver installation.

NOTE

If installing the BeeKit software package to another drive or directory,

indicate the Drivers directory created by the installer in the custom location

where BeeKit was installed.

If BeeKit is not installed, note the following:

• The boards use the OpenSDA to USB converter, Virtual COM Port (VCP) driver for Windows.

• Download the appropriate driver and follow the instructions to complete driver installation.

— www.pemicro.com/opensda and download the Windows USB Drivers

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

2-4 Freescale Semiconductor

Page 13

Chapter 3

TWR-KW2xDxxx

3.1 TWR-KW2xDxxx Overview

The TWR-KW2xDxxx is an evaluation board based on the Freescale MKW2xDxxx device. The

TWR-KW2xDxxx provides a platform to evaluate the TWR-KW2xDxxx SIP IC, develop software and

applications. The core device is accompanied by the 32 MHz reference oscillator crystal, RF circuitry

including PCB F-type antenna (or SMA), and supporting circuitry.

This basic board is intended as the core PCB for TWR-KW2xDxxx evaluation and application

development and can be used in the following modes:

• Simple standalone evaluation platform

• Daughtercard to other Development Platform boards (Tower System)

• Mothercard to an application specific dauhtercard, could be a TWRPI card.

3.1.1 PCB Board Features

The TWR-KW2xDxxx provides the following features:

• Freescale’s Tower System form factor

• 4-Layer metal, 0.062 inch thick FR4 board

• LGA footprint and power supply bypass

• Printed metal F-Antenna (and SMA)

• 32 MHz reference oscillator crystal

• 32.768 kHz crystal provided for optional timing oscillator.

• Standard Tower TWRPI daughter card mounting interface

— 20-Pin primary connector

— 20-Pin secondary connector

— Can provide main supply voltage to board

3.1.2 Form Factor

Figure 3-1 shows the TWR-KW2xDxxx connector and header locations.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-1

Page 14

TWR-KW2xDxxx

Figure 3-1. TWR-KW2xDxxx Connector and Header Details

The TWR-KW2xDxxx incorporates the following general headers.

Headers J9 and J10:

• Both headers have standard 0.05in / 1.27 mm pin spacing

• J9 and J10 are 20-pin

• Both are pin headers mounted on the T op side of the board and are intended to plug into matching

receptacles on the TWRPI standard.

Headers J17 and J18:

• Both headers have standard 0.10in / 2.54 mm pin spacing

• J17 and J18 are 3x4-pin

• Both are pin headers mounted on the Top side of the board and are intended to have the capability

for SPI/TWR_Elevator Selector (J17) and UART1/TWR_Elevator Selector (J18).

Headers J19, J20, J21, and J24:

• Headers have standard 0.10in / 2.54 mm pin spacing

• J19, J20, J21, and J24 are 3-pin

• 19, J20, J21, and J24 are pin headers mounted on the Top side of the board and are intended to

select between UART0/LED.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-2 Freescale Semiconductor

Page 15

Figure 3-2 shows a footprint of the TWR-KW2xDxxx with the location of the IO Headers.

TWR-KW2xDxxx

Figure 3-2. TWR-KW2xDxxx T op Side (Component Side) Footprint

3.1.3 Board Level Specifications

Table 3-1. TWR-KW2xDxxx Specifications

Parameter Units Notes/Conditions

MIN TYP MAX

General

Size (PCB: X, Y) 90 x 80.6

3.54 x 3.175mminches

Layer build (PCB) 1.57

0.062

Dielectric material (PCB) FR4

Power

Current consumption

Transmit

Receive

18

20

18

20

mm

inches

mA

4-Layer

*Board level measured at J2.

Radio TX (Nominal power)

MCU

Radio RX mode

MCU

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-3

Page 16

TWR-KW2xDxxx

Table 3-1. TWR-KW2xDxxx Specifications (continued)

Parameter Units Notes/Conditions

Temperature

Operating temperature (see note) -40 +25 +70 °C • Operating temperature is limited to +70

°C due to switches. Basic circuit is good

for a maximum temperature of +85 °C.

Storage temperature -30 +25 +70 °C

RF

All 16 channels in the2450 MHz band

802.15.4 Frequency range 2405 2480 MHz

RF Receiver

Saturation (maximum input level) +10 dBm

Sensitivity for 1% packet error rate (PER)

-100 dBm

(+25 °C)

RF Transmitter

RF Power Output -32 +10 dBm Programmable in 2dB steps

2nd harmonic <-50 <-40 dBm Measured with output power set to nominal

(0 dBm) and temperature @ 25°C. Trap filter

is needed.

3rd harmonic <-50 <-40 dBm Measured with output power set to nominal

(0 dBm) and temperature @ 25°C. Trap filter

is needed.

Regulatory Approval

FCC Product is approved accordingly to the FCC

part 15 standard

CE (ETSI) Product is approved accordingly to the EN

300 328 V1.7.1 (2006-10) standard

CE (EMC) Product is approved accordingly to the EN

301 489-1 V1.6.1 (2005-09) and EN 301

489-17 V1.2.1 (2002-08) standards

Safety

UL Product is approved accordingly to the IEC

Environment

RoHS Product complies with the EU Directive

WEEE Product complies with the EU Directive

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-4 Freescale Semiconductor

60950-1 and EN 60950-1, First Edition

standards

2002/95/EC of 27 January 2003

2002/95/EC of 27 January 2003

Page 17

TWR-KW2xDxxx

3.2 Functional Description

The TWR-KW2xDxxx is built around Freescale’ s MKW2XDXXX 56-pin LGA platform and is intended

as a simple evaluation platform and as a building block for application development. The 4-layer board

provides the MKW2XDXXX with its required RF circuitry , 32 MHz reference oscillator crystal and power

supply bypassing. The layout for this base level functionality can be used as a reference layout by the user

target board.

3.2.1 RF Performance and Considerations

TWR-KW2xDxxx transceiver includes a 1mW nominal output power, PA with internal voltage controlled

oscillator (VCO), integrated transmit/receive switch, on-board power supply regulation, and full

spread-spectrum encoding and decoding. Key specifications for MKW2XDXXX are:

• Nominal output power is 0 dBm, with +10 dBm max

• Programmable output power from –30 dBm to +10 dBm (measured at the package pin)

• Frequency range is 2360 to 2480 MHz (Includes both ISM and MBAN bands)

• Receiver sensitivity: –102 dBm, typical (@1% PER for 20 byte payload packet, measured at the

package pin)

• Differential bidirectional RF input/output port with integrated transmit/receive switch

The TWR-KW2xDxxx utilizes a minimum number of components while providing good RF performance:

• Uses a minimum number of RF marching components and external 50:50 balun.

• “F” printed metal antenna for a small footprint, low cost design.

An external 50 (unbal): 50(bal) balun connects a single-ended 50-ohm port to the differential RF port of

the MKW2XDXXX radio. The layout has provision for out-of-band signal suppression (components L5

and C19) if required.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-5

Figure 3-3. TWR-KW2xDxxx RF Circuitry

Page 18

TWR-KW2xDxxx

3.2.2 Clocks

The TWR-KW2xDxxx provides two clocks:

• 32 MHz Reference Oscillator - Figure 3-4 shows the external 32 MHz external crystal Y1. This

mounted crystal must meet the MKW2XDXXX specifications. The IEEE 802.15.4 Standard

requires that the frequency be accurate to less that +/-40 ppm.

— Capacitors C21 and C22 provide the bulk of the crystal load capacitance. Onboard trim

capacitors can be programmed to center the frequency. At 25°C, it is desired to have the

frequency accurate to +/-10 ppm or less to allow for temperature variation.

— To measure the 32 MHz oscillator frequency, signal CLK_OUT (PTA18) can optionally be

programmed to provide a buffered output clock signal

— The TWR-KW2xDxxx has provision for injecting an external 32 MHz clock source as an

alternative to use of the onboard crystal:

– The crystal Y1 should be removed

– C20 must be mounted

– The ex ternal 32 MHz source is connected to 2-pin header J5; the frequency accuracy of the

external source must meet the +/-40 ppm of the IEEE 802.15.4

Figure 3-4. 32 MHz Reference Oscillator Circuit

• Optional 32.768 kHz Crystal Oscillator - Provision is also made for a secondary 32.768 kHz crystal

Y2 as shown in Figure 3-5. This oscillator can be used for a low power accurate time base.

— The module comes provided with the 32.768 kHz crystal.

— Load capacitors C23 and C24 provide the entire crystal load capacitance; there is no onboard

trim capacitance.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-6 Freescale Semiconductor

Page 19

Figure 3-5. 32.768 kHz Optional Oscillator Circuit

3.2.3 Power Management

The TWR-KW2xDxxx power management circuit is shown in Figure 3-6.

TWR-KW2xDxxx

Figure 3-6. TWR-KW2xDxxx Power Management Circuit

The TWR-KW2xDxxx has the flexibility to be powered in several configurations:

• Board can be supplied through the mini USB type B connector (J15) which provides P5V_USB to

J1 1-2.

• Board can be supplied through the micro USB AB (J6) (TWR-KW24D512 only) providing

P5V_KW24_USB to J27 1-2 and VOUT33 to J3 2-3.

• Board can be supplied through the TWR System Elevator headers which provides either

3.3V_ELEV or 5V_ELEV to header J1 3-4 or J1 5-6 respectively.

• Board can be supplied from an external DC supply in the following ways:

— Connect an USB battery adaptor capable of suppling 1.8 to 5.5 VDC to the micro USB AB (J6)

(TWR-KW24D512 only)

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-7

Page 20

TWR-KW2xDxxx

— An external unregulated supply up to 5.5VDC can be supplied to V_EXT header J28 making

use of the onboard 3.3 V LDO regulator

Header J2 provides the means to supply either the MCU, the radio and LED circuits. Current

measurements can be made by inserting a current meter in place of a designated jumper. Connections

configurations are described in Table 3-2.

Table 3-2. Power Distribution Header J2

Supply

Designation

V_LED 1 - 2 Supply voltage to power indicator LED

V_MCU 3 - 4 Supply voltage to MKW2xDxxx

V_RF 5 - 6 Supply voltage to MKW2xDxxx

Header

Pins

Description

• Normally jumpered

• Jumper used to enable LEDs on board

• Leave open for lowest power

• Usage: Measure LED current

• Normally jumpered

• Supplies only the MKW2xDxxx MCU

• Usage: Measure or supply MCU current

• Normally jumpered

• Supplies only the MKW2xDxxx transceiver

• Usage: Measure or supply radio current

3.2.4 TWR-KW2xDxxx Peripheral Functions

The TWR-KW2xDxxx includes the TWRPI general purpose peripheral function to assist in implementing

targeted applications. The TWR-KW2xDxxx board also has alternate port functions routed to the elevator

interface where off board tower system peripherals can be used if desired.

3.2.4.1 Serial FLASH (SPI Interface)

Component U13 is an AT45DB161E-SSHD 16 Mbit (2 Mbyte) serial Flash memory with SPI interface.

The memory is useful for over-the-air programming (OTAP) and for storage of non-volatile system data

or parameters. Figure 3-7 shows the memory circuit.

• Memory power supply is V_MCU

• Discrete pullup resistors for the SPI port are provided

• The SPI can be shared with another peripheral with the TWRPI J10 connector — an additional IO

signal would be required as a chip enable (CS or SS) for the peripheral. The normal SPI_SS and

the second chip select should NOT be active at the same time.

• The SPI Write Protect and Reset signals have discrete pullup resistors for control if required. The

resistors are DNP.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-8 Freescale Semiconductor

Page 21

TWR-KW2xDxxx

Figure 3-7. AT45DB161E-SSHD 16Mbit Serial FLASH memory

3.2.4.2 TWRPI Connectors J9 and J10

The two connectors J9 and J10 are 50 mil pin headers mounted on the front (component side) supporting

the standard TWRPI general purpose connector. The primary header J9 and secondary header J10 are

20-pin and mounted physically in such a manner as to prevent reverse insertion of any TWRPI card into

the motherboard receptacle (see Figure 3-1., “TWR-KW2xDxxx Connector and Header Details”).

• V_MCU provides the TWRPI connector its supply voltage

— Depending on power supply configuration, this voltage may supply the TWRPI card from the

TWR-KW2xDxxx. See Section 3.2.3, “Power Management”.

— Peripherals IO to the TWR-KW2xDxxx and the TWRPI card supply should use this same

voltage avoiding potential damage.

The pin definitions for the primary header J9 and the secondary header J10 are shown in Table 3-3.,

“TWRPI 20 Pin Primary Connector” and Table 3-4., “TWRPI 20 Pin Secondary Connector” respectively.

Table 3-3. TWRPI 20 Pin Primary Connector

Header

Pin

Number

1 5V_ELEV 5V VDD supply to board

2 V_MCU 3V3 VDD supply to board

3 GND Module ground

4 V_MCU 3V3 VDD supply to board

5 GND VSS (GND) board ground

6 GND VSS (GND) board ground

7 GND VSS (GND) board ground

8 PTE0_TWRPI ADC: Analog 0

TWR-MKW24D512 Pin Name Description

9 PTD1 ADC: Analog 1

10 GND VSS (GND) board ground

11 GND VSS (GND) board ground

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-9

Page 22

TWR-KW2xDxxx

Table 3-3. TWRPI 20 Pin Primary Connector

Header

Pin

TWR-MKW24D512 Pin Name Description

Number

12 PTE1_TWRPI ADC: Analog 2

13 GND VSS (GND) board ground

14 GND VSS (GND) board ground

15 GND GND board ground

16 GND GND board ground

17 PTE2_TWRPI ADC: TWRPI ID 0

18 PTE3_TWRPI ADC: TWRPI ID 1

19 GND GND board ground

20 RESET_B RESET

Table 3-4. TWRPI 20 Pin Secondary Connector

Header Pin

Number

TWR-KW24D512 Pin Name Description

1 GND Board ground

2 GND Board ground

3PTD2I2C: SCL

4PTD3I2C: SDA

5 GND Board ground

6 GND Board ground

7 GND Board ground

8 GND Board ground

9 PTB17_TWRPI SPI:MISO Master Input Slave Output

10 PTB16_TWRPI SPI:MOSI Master Output Slave Input

11 PTB10_TWRPI SPI: SS Slave Select

12 PTB11_TWRPI SPI:CLK R_SClock

13 GND Board ground

14 GND Board ground

15 GPIO1 GPIO: GPIO0/IRQ

16 GPIO2 GPIO; GPIO1/IRQ

17 PTE17/UART2_RX UART_RX or GPIO2

18 PTE16/UART2_TX UART_TX or GPIO3

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-10 Freescale Semiconductor

Page 23

Table 3-4. TWRPI 20 Pin Secondary Connector

TWR-KW2xDxxx

Header Pin

Number

19 PTE18/UART2_CTS U ART_CTS or GPIO4/TIMER

20 PTE19/UAR T2_RTS UART_RTS or GPIO5/TIMER

TWR-KW24D512 Pin Name Description

3.2.4.3 Jumper Connectors

The TWR-KW2xDxxx development platform incorporates several headers which allow different MCU

port configurations assisting in the implementation of target applications. (see Figure 3-1.,

“TWR-KW2xDxxx Connector and Header Details”).

• SPI0 TWRPI / TWR_ELEV Select (J17).

— The TWR-KW2xDxxx has the capability to support a SPI for TWRPI boards - to configure,

shunt J17 pin 2-3 (SPI0_PCS), pin 5-6 (SPI0_SCK), 8-9 (SPI0_MOSI), and pin 11-12

(SPI0_MISO). See Figure 3-8., “TWR-KW24D512 Schematic”.

— The TWR-KW2xDxxx has the capability to support a TWR_ELEV with another TWR System

- to configure, shunt J17 pin 1-2 (SPI0_PCS), pin 4-5 (SPI0_SCK), 7-8 (SPI0_MOSI), and pin

10-11 (SPI0_MISO). See Figure 3-8., “TWR-KW24D512 Schematic”.

• UART1 / ADC TWRPI Select (J18).

— The TWR-KW2xDxxx has the capability to support a ADC for TWRPI boards - to configure,

shunt J18 pin 2-3 (ADC0_DM1), pin 5-6 (ADC0_DP1), 8-9 (ADC0_SE11), and pin 11-12

(ADC_SE10). See Figure 3-8., “TWR-KW24D512 Schematic”.

— The TWR-KW2xDxxx has the capability to support an UART1 connection trough

TWR_ELEV with another TWR System - to configure, shunt J17 pin 1-2 (UART1_TX), pin

4-5 (UART1_RX), 7-8 (UART1_CTS), and pin 10-11 (UART1_RTS). See Figure 3-8.

• UART0 / LED Select (J19/ J20/ J21/ J24).

— The TWR-KW2xDxxx has the capability to support the Blue LEDs on board - to configure,

shunt J19 pin 2-3 (P TD4_LED), J20 pin 2-3 (PTD5_LED), J21 pin 2-3 (PTD6_LED), and J24

pin 2-3 (PTD7_LED). See Figure 3-8., “TWR-KW24D512 Schematic”.

— The TWR-KW2xDxxx has the capability to support an UART0 connection trough

TWR_ELEV with another TWR System - to configure, shunt J19 pin 1-2 (UAR T0_RTS), J20

pin 1-2 (UART0_CTS), J21 pin 1-2 (UART0_Rx), and J24 pin 1-2 (UART0_TX). See

Figure 3-8., “TWR-KW24D512 Schematic”.

3.2.4.4 MKW24D512 USB Supply (J6) - TWR-MK24D512 Board Only

The MKW2xDxxx device has an on-board USB port which is configured to provide both power and serial

communication with the target MCU. (see Figure 3-1., “TWR-KW2xDxxx Connector and Header

Details”). The following jumpers allow the USB functionality:

• USB Select - Micro USB AB (J6).

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-11

Page 24

TWR-KW2xDxxx

— Shunt J27 to supply 5VDC to the MKW2xDxxx device (U3 pin 24, VREGIN) through the

Micro USB AB connector, This supplies the on-board USB regulator with then provides 3.3

VDC supply (U3 pin 23, VOUT33). See Figure 3-8., “TWR-KW24D512 Schematic”.

— Shunt J3 2-3 to supply power to the MKW2xDxxx device. See Figure 3-8., “TWR-KW24D512

Schematic”.

3.2.4.5 MKW21D256 (Non-USB) UART2 Support - TWR-MK21D256 Board Only

The MKW21D256 device does not support the USB interface and instead makes use of UART2 port

functionality . In this case, resistors are placed configuring UART2 use for both the TWRPI connector and

TWR elevator interface. (see Figure 3-1., “TWR-KW2xDxxx Connector and Header Details”).

• UART2/Non USB Select

— J27 is open, shunt J3 1-2, supply voltage required though power management configuration.

See Figure 3-8., “TWR-KW24D512 Schematic”, and Section 3.2.3, “Power Management”.

— The following resistors are placed: R84, R85, R86 and R87, keep as DNP, C27 and C28. See

Figure 3-8., “TWR-KW24D512 Schematic”.

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-12 Freescale Semiconductor

Page 25

TWR-KW2xDxxx

Tower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-13

3.3 Schematic, Board Layout, and Bill of Material

Figure 3-8. TWR-KW24D512 Schematic

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

3.3V BUCK/BOOST REGULATOR

TO USE TPS63000,

REPLACE RESISTORS WITH

THE FOLLOWING VALUES:

R1 = 100 OHM, R2 = 1.24M

AND POPULATE R5.

OUTPUT VOLTAGE WILL BE 3.6V

POWER SELECTOR

POWER ON

LED VOLTAGE

MCU VOLTAGE

RF VOLTAGE

Power Switch

SCH-27845

SEE NOTE C

External Voltage

P5V_USB

V_MAIN

V_REG

VCC

V_LED

V_MCU

V_RF

V_LED

3V3_ELEV

5V_ELEV

VREG_IN

VREG_IN

V_EXT

V_EXT

V_MAIN

VOUT33

VOUT33

VOUT33_SW

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

POWER SUPPLY

48

X ______

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

POWER SUPPLY

48

X ______

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

POWER SUPPLY

48

X ______

TP12

Q1

SI2305

1

32

D2

MBR0520LT1G

A C

TP10

J3

HDR TH 1X3

1

2

3

J1

HDR 2X3

1 2

3 4

65

TP2TP1

TP507

J28

HDR 1X2

1

2

R7

4.7K

R4 0R9

10K

TL3TL1 TL2

R6 0

C1

10UF

SW5

DPDT SWITCH

2

1

3

6

4

5

J2

HDR 2X3

1 2

3 4

65

R8 0

C4

0.1UF

TP4

U1

TPS63001

EN

6

GND

9

L14L2

2

PS/SYNC

7

VOUT1VIN

5

VINA

8

FB

10

PGND

3

PPAD

11

L1 3.3uH

1 2

C2

10UF

TP6

TP5

D4

GREEN

AC

R1

0

C3

10UF

TP9

TP7

R2

0

TP3

D1

MBR0520LT1G

A C

TP11

R10

330

D3

MBR0520LT1G

A C

R5

200K

DNP

Page 26

Tower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-14 Freescale Semiconductor

TWR-KW2xDxxx

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

32MHz XTAL

32kHz XTAL

XTAL_32M

XTAL_32K

HARMONIC TRAP

SCH-27845

USB / Non-USB SELECTOR

MKW24 (USB)

USB HOST

SEE NOTE A

SEE NOTE B

VBAT

EXTAL_32

RST_TGTMCU_B

XTAL_32M

EXTAL_32M

XTAL_32

Z_RF_N

Z_RF_P

XTAL_32

XTAL_32M_R

XTAL_32MEXTAL_32M

EXTAL_32K

CLK_OUT

EXTAL_32

RF_ANTRF_50

VDD_PA

VDD_IF

VDD_RF VDD_RF VDD_IF VDD_PA

VDD_REGD

VDD_REGD

P5V_K24_USB

KW24_USB_DP

K24_USB_SHLD

KW24_USB_DN PTE17/UART2_RX/USB_DN

PTE16/UART2_TX/USB_DP

PTE18/UART2_CTS/VOUT33

PTE19/UART2_RTS/VREGINP5V_KW24_USB

CLK_OUT

V_MCU

V_MCU

V_MCU

V_RF

V_MCU

GND

VOUT33_SW

PTC4

PTC6

PTC7

PTC5

PTD1

PTD4

PTD5

PTD6

PTD7

PTE0

PTE1

PTE16/UART2_TX/USB_DP

PTA1

PTA3

PTA4

PTA2

PTA0

GPIO2

GPIO1

RST_TGTMCU_B

PTE16/UART2_TX/USB_DP

PTE17/UART2_RX

PTE18/UART2_CTS

PTE16/UART2_TX

PTE17/UART2_RX/USB_DN

PTE18/UART2_CTS/VOUT33

PTE19/UART2_RTS/VREGIN

PTE19/UART2_RTS

PTE17/UART2_RX/USB_DN

PTE18/UART2_CTS/VOUT33

PTE19/UART2_RTS/VREGIN

PTE2

PTE3

PTE4

PTD3

PTD2

PTA19

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

MICROCONTROLLER

58

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

MICROCONTROLLER

58

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

MICROCONTROLLER

58

___ ___

X

R86 0

DNP

U3

MKW24D512V

VDD_MCU

20

VDDA

25

VREFH

26

VREFL

27

VSSA

28

VBAT_MCU

32

VDD_MCU

38

VBAT2_RF

42

VDD_REGD

43

VDD_PA

52

VDD_IF

53

VDD_RF

54

GND_PA363GND_PA148GND_PA2

51

EXTAL_32M

1

TAMPER0/RTC_WAKEUP

29

XTAL32

30

EXTAL32

31

RESET

41

RX_SWITCH

46

TX_SWITCH

47

RF_OUTP

49

RF_OUTN

50

XTAL_32M

56

GPIO1

2

GPIO2

3

PTA0/JTAG_TCLK/SWD_CLK/EZP_CLK/UART0_CTS/UART0_COL/FTM0_CH5

33

PTA1/JTAG_TDI/EZP_DI/UART0_RX/FTM0_CH6

34

PTA2/JTAG_TDO/TRACE_SWO/EZP_DO/UART0_TX/FTM0_CH7

35

PTA3/JTAG_TMS/SWD_DIO/UART0_RTS/FTM0_CH0

36

PTA4/LLWU_P3/NMI/EZP_CS/FTM0_CH1

37

PTA18/EXTAL0/FTM0_FLT2/FTM_CLKIN0

39

PTA19/XTAL0/FTM1_FLT0/FTM_CLKIN1/LPTMR0_ALT1

40

PTC4/LLWU_P8/SPI0_PCS0/UART1_TX/FTM0_CH3/CMP1_OUT

4

PTC5/LLWU_P9/SPI0_SCK/LPTMR0_ALT2/I2S0_RXD0/CMP0_OUT

5

PTC6/LLWU_P10/CMP0_IN0/SPI0_SOUT/PDB0_EXTRG/I2S0_RX_BCLK/I2S0_MCLK

6

PTC7/CMP0_IN1/SPI0_SIN/USB_SOF_OUT/I2S0_RX_FS

7

PTD1/ADC0_SE5B/SPI0_SCK/UART2_CTS

8

PTD2/LLWU_P13/SPI0_SOUT/UART2_RX/I2C_SCL/GPIO4_BSM_DATA

9

PTD3/SPI0_SIN/UART2_TX/I2C_SDA/GPIO5_BSM_CLK

10

PTD4/LLWU_P14/MADC0_SE21/SPI0_PCS1/UART0_RTS/FTM0_CH4/EWM_IN/GPIO_BSM_FRAME

11

PTD5/ADC0_SE6B/SPI0_PCS2/UART0_CTS/UART0_COL/FTM0_CH5/EWM_OUT

12

PTD6/LLWU_P15/ADC0_SE7B/SPI0_PCS3/UART0_RX/FTM0_CH6/FTM0_FLT0

13

PTD7/MADC0_SE22/CMT_IRO/UART0_TX/FTM0_CH7/FTM0_FLT1

14

PTE0/MADC0_SE10/SPI1_PCS1/UART1_TX/MTRACE_CLKOUT/I2C1_SDA/RTC_CLKOUT

15

PTE1/LLWU_P0/MADC0_SE11/SPI1_SOUT/UART1_RX/MTRACE_D3/I2C1_SCL/SPI1_SIN

16

USB0_DP

21

USB0_DM

22

VOUT33

23

VREGIN

24

PTE2/LLWU_P1/MADC0_DP1/SPI1_SCK/UART1_CTS/MTRACE_D2

17

PTE3/MADC0_DM1/SPI1_SIN/UART1_RTS/MTRACE_D1/SPI1_SOUT

18

PTE4/LLWU_P2/SPI1_PCS0/MTRACE_D0

19

EP_GND164EP_GND2

65

NC_57

57

NC_58

58

NC_59

59

NC_60

60

NC_61

61

NC_62

62

VBAT_RF

55

ANT_A

44

ANT_B

45

C44

5pF

R85 0

DNP

U10

12

J5

HDR 1X2

1

2

5VD-D+IDG

MICRO USB AB 5

J6

1

2

3

4

S2

5

S1

S3S4

C43

1000pF

R87 0

DNP

U11

12

C27

2.2UF

TP26

C14

0.1UF

C19

1.8pF

U12

12

TP25

R780

R13 0

Z1

2400MHz 50OHM

5

1

6

2

3

4

C46

1000pF

TP27

L4

330 OHM

1 2

L5

2.2nH

12

TP21

R82 0

C50

1.0UF

C28

0.1UF

R12

1.0M

TP22

C45

10PF

C13

0.1UF

R790

Y1

32MHZ

1 4

32

C8

5pF

R83 0

DNP

R14 0

J27

HDR 1X2 TH

1

2

Y2

32.768KHZ

21

C48

47PF

DNP

C7

0.33UF

L2 0

C21

12PF

R33 33

D15

MSS1P3L

A C

C9

1000pF

C36

0.1UF

DNP

C35

47PF

DNP

1

J4

SMA

R800

C17

10PF

R34 33

C42

0.1UF

D14

MSS1P3L

AC

L8

330 OHM

12

C10

5pF

ANT1

F_Antenna

C16

0.33UF

C23

12PF

C47

5pF

C11

1000pF

C20

10PF

DNP

C22

12PF

C25

1PF

C18

10PF

DNP

R15 0

C24

12PF

C15

33PF

R810

R840DNP

C12

0.1UF

L3 0

Page 27

TWR-KW2xDxxx

Tower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-15

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

SWITCHING GPIO

LEDS

PIN FUNCTIONS USEDNET NAMES

PIN FUNCTIONS USEDNET NAMES

Default: 1-2

(Remove to measure

TWRPI current)

GENERAL PURPOSE

TWRPI

SPI0 TWRPI/TWR_ELEV Select

UART0/LED Select

UART1/ADC TWRPI/TWR_ELEV_Select

SCH-27845

NET NAMES PIN FUNCTIONS USED

NET NAMES PIN FUNCTIONS USED

SPI FLASH

SPI FLASHSPI FLASH

SPI FLASH

ADC0_DP0

SPI0_SIN_(MISO)PTB17 SPI0_SOUT_(MOSI)

RST_TGTMCU_B

TWRPI_ID1 ADC0_DM0

ADC1_DP0/ADC0_DP3

GPT_VDA

SPI0_SCK

GPT_VBRD

SPI0_PCS0PTB10

SPI0_PCS0_TWRPI

SPI0_SIN_(MISO)_TWRPI

SPI0_SCK_TWRPI

SPI0_SOUT_(MOSI)_TWRPI

ADC0_SE10

ADC0_DM1

ADC0_SE11

UART1_CTS

UART1_RTS

ADC0_DP1

UART1_TX

UART1_RX

UART0_CTSUART0_RTS

UART1_TX/MADC0_SE10

UART1_RX/MADC0_SE11

UART1_CTS/ADC0_DP1

UART1_RTS/ADC0_DM1

UART0_RX UART0_TX

SPI0_SCK

SPI0_PCS0

SPI0_SOUT

SPI0_SIN

V_LED

V_MCUV_MCU

V_MCU V_MCUV_MCU

5V_ELEV

V_MCU

V_MCU

V_MCU

PTD4_LED

PTD5_LED

PTD6_LED

PTD7_LED

PTC4

PTC5

PTC6

PTC7

PTE2_TWRPI

PTE3_TWRPI

RST_TGTMCU_B

PTE1_TWRPI

PTD3

PTB16_TWRPI

PTB11_TWRPI

GPIO2

PTE19/UART2_RTS

PTD2

PTB17_TWRPI

PTB10_TWRPI

GPIO1

PTE18/UART2_CTS

PTD1

PTE0_TWRPI

PTE17/UART2_RX

PTE16/UART2_TX

PTB10_TWRPI

PTB17_TWRPI

PTB11_TWRPI

PTC5

PTC4_A

PTC5_A

PTC7

PTC6

PTC4

PTC6_A

PTC7_A

PTB16_TWRPI

PTE0_TWRPI

PTE3_TWRPI

PTE1_TWRPI

PTE3

PTE2

PTE2_TWR

PTE3_TWR

PTE2_TWRPI PTD4_LED PTD5_LED

PTD4_TWR PTD5_TWR

PTE0_TWR

PTE1_TWR

PTD5PTD4

PTE0

PTE1

PTD6_LED

PTD6_TWR

PTD6

PTD7_LED

PTD7_TWR

PTD7

PTB17_TWRPI

PTB16_TWRPI

PTB11_TWRPI

PTB10_TWRPI

PTA19

PTE4

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

PERIPHERALS

68

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

PERIPHERALS

68

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

PERIPHERALS

68

___ ___

X

R21

4.7K

D5

BLUE

AC

TP502

R22

4.7K

J8

HDR 1X2 TH

1

2

D6

BLUE

AC

R553

10.0K

DNP

D7

BLUE

AC

R566

0

DNP

R563

10.0K

D8

BLUE

AC

R554

10.0K

DNP

R19

390

R20

0

R23

10.0K

R565

10.0K

J19

HDR TH 1X3

123

R555

10.0K

DNP

J9

CON_2X10

1 2

3 4

65

7 8

9 10

11 12

13 14

15 16

17 18

19 20

SW3 PB switch

1 4

2 3

J10

CON_2X10

1 2

3 4

65

7 8

9 10

11 12

13 14

15 16

17 18

19 20

R18

390

U13

AT45DB161E-SSHD

SCK

2

VCC

6

WP

5

RESET

3

GND

7

CS

4

SI

1

SO

8

R24

10.0K

J17

HDR 3X4

147

10

528

11

369

12

R16

390

SW4 PB switch

1 4

2 3

J20

HDR TH 1X3

123

R17

390

TP500

TP14

SW1 PB switch

1 4

2 3

TP15

J21

HDR TH 1X3

123

R564

0

DNP

J18

HDR 3X4

147

10

528

11

369

12

TP16

TP504

SW2 PB switch

1 4

2 3

TP17

TP506

TP501

J24

HDR TH 1X3

123

R552

10.0K

DNP

Page 28

Tower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-16 Freescale Semiconductor

TWR-KW2xDxxx

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

PIN FUNCTIONS USED NET NAMES

JTAG / SWD CONNECTOR

SCH-27845

TARGET MCU

INTERFACE

SIGNALS

PU/PD LOGIC:

SERIAL INTERFACE

IS ALWAYS RESET

WHEN USB PORT

IS DISCONNECTED

OpenSDA INTERFACE

OpenSDA INTERFACE JTAG CONNECTOR

SPARE 74HC125 buffer

KEY - PIN 7

Default: no shunt

(Disconnect Target Power)

DEBUGGER

TX

RX

CTS

RTS

MANUAL

RESET

RST_TGTMCU_B

JTAG_TCLK/SWD_CLK/EZP_CLK PTA0

JTAG_TMS/SWD_DIO PTA3

SDA_RST

TC_EXTAL_TP

TC_XTAL_TP

SDA_SWD_OE_B

UART1_RX_TGTMCU

UART1_TX_TGTMCU

SDA_EXTAL

SDA_XTAL

TC_SDA_USB_ID_TP

SWD_DIO_TGTMCU

SDA_USB_CONN_DP

SDA_USB_CONN_DN

SDA_SPI0_SOUT

SDA_USBSHIELD

P5V0_SDA_USB_CONN_VBUS

SDA_USB_VOUT33

SDA_JTAG_TCLK

SDA_JTAG_TDI

SDA_JTAG_TDO

SDA_JTAG_TMS

UART1_TX_TGTMCU

UART1_RX_TGTMCU

SDA_SPI0_SCK

SDA_LED

SDA_SPI0_SIN

SDA_LED_R

SDA_RST

SDA_JTAG_TCLK

SDA_JTAG_TDI

SDA_JTAG_TDO

SDA_JTAG_TMS

TC_74125_SPARE_O_TPTC_74125_SPARE_I_TP

PTA2JTAG_TDO/TRACE_SWO/EZP_DO

PTA1JTAG_TDI/EZP_DI

VTRG_FAULT_B

POWER_EN

VTRG_ENPOWER_EN

VTRG_FAULT_B

PTA4 EZP_CS_B EZP_CSR_B

TGT_PWR

UART1_CTS_TGTMCU

UART1_RST_TGTMCU

TRACE_CLKOUT

TRACE_D0

TRACE_D3

TRACE_D2

TRACE_D1

UART1_CTS_TGTMCU

UART1_RST_TGTMCU

SDA_SWD_EN

SWD_CLK_TGTMCU

RESET_B

RSTR

SDA_USB_DP

SDA_USB_DN

V_MCU

GND

GND

GND

GND

GND

GND

GND

GND

P5V_SDA

GND GND

GND

GND

SDA_USB_VOUT33

P5V_SDA

SDA_USB_VOUT33

SDA_USB_VOUT33

GNDGND

GND

SDA_USB_VOUT33

P5V_SDA

SDA_USB_VOUT33

GND

SDA_USB_VOUT33

SDA_USB_VOUT33

P5V_SDA

P5V_USB

SDA_USB_VOUT33

5V_ELEV

V_MCUV_MCU

P5V_USB

SDA_USB_VOUT33

V_LED

SDA_USB_VOUT33

V_MCU

SDA_USB_VOUT33

V_MCU

SDA_USB_VOUT33

RST_TGTMCU_B4,7,8

PTA0

PTA3

RESET_B

PTE0_TWR

PTE1_TWR

PTA3

PTA0

PTA2

PTA1

ELE_PS_SENSE8

PTA4

PTE2_TWR

PTE3_TWR

PTE0

PTE4

PTE3

PTE2

PTE1

RST_TGTMCU_B

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

OpenSDA

78

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

OpenSDA

78

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

OpenSDA

78

___ ___

X

D9

ORANGE

AC

TP101

U14

TXS0101

VCCA

1

GND

2

A3B

4

OE

5

VCCB

6

R560

10K

GND2

GND1

Y3

8MHZ

1 2

34

R110

10.0K

U4C

74LVC125ADB

98

10

R94 0

TP509

TP102

R90 1.0K

TP105

TP103

R26

10.0K

R46

330

D12 MSS1P3L

A C

C33

0.1UF

TP510

R104

220

R91 1.0K

R108

10.0K

DNP

L7

330 OHM

1 2

R112

27K

DNP

TP511

R88 1.0K

R25

10.0K

R562

100K

J30

HDR 1X2

1

2

R106

27K

R109

15K

R27 0

DNP

C49

1.0UF

R92 1.0K

R111 1K

J12

HDR 1X2 TH

1

2

TP512

R551 1.0K

U8

GSOT05C-GS08

1

2

3

C30

22PF

DNP

Q2

MMBT2484L

2 3

1

U4B

74LVC125ADB

5 6

4

D13

MSS1P3L

A C

PK20DX128VFM5

U6

VDD1

1

VSS1

2

VDDA

7

VSSA

8

VBAT

11

JTAG_TCLK/SWD_CLK/EZP_CLK/TSI0_CH1/PTA0/UART0_CTS/UART0_COL/FTM0_CH5

12

JTAG_TDI/EZP_DI/TSI0_CH2/PTA1/UART0_RX/FTM0_CH6

13

JTAG_TDO/TRACE_SWO/EZP_DO/TSI0_CH3/PTA2/UART0_TX/FTM0_CH7

14

JTAG_TMS/SWD_DIO/TSI0_CH4/PTA3/UART0_RTS/FTM0_CH0

15

NMI/EZP_CS/TSI0_CH5/PTA4/FTM0_CH1/LLWU_P3

16

EXTAL0/PTA18/FTM0_FLT2/FTM_CLKIN0

17

XTAL0/PTA19/FTM1_FLT0/FTM_CLKIN1/LPTMR0_ALT1

18

ADC0_SE8/TSI0_CH0/PTB0/I2C0_SCL/FTM1_CH0/FTM1_QD_PHA/LLWU_P5

20

ADC0_SE9/TSI0_CH6/PTB1/I2C0_SDA/FTM1_CH1/FTM1_QD_PHB

21

ADC0_SE4B/CMP1_IN0/TSI0_CH15/PTC2/SPI0_PCS2/UART1_CTS/FTM0_CH1/I2S0_TX_FS

23

CMP1_IN1/PTC3/SPI0_PCS1/UART1_RX/FTM0_CH2/I2S0_TX_BCLK/LLWU_P7

24

PTC4/SPI0_PCS0/UART1_TX/FTM0_CH3/CMP1_OUT/LLWU_P8

25

PTC5/SPI0_SCK/LPTMR0_ALT2/I2S0_RXD0/CMP0_OUT/LLWU_P9

26

CMP0_IN0/PTC6/SPI0_SOUT/PDB0_EXTRG/I2S0_RX_BCLK/I2S0_MCLK/LLWU_P10

27

CMP0_IN1/PTC7/SPI0_SIN/USB_SOF_OUT/I2S0_RX_FS

28

PTD4/SPI0_PCS1/UART0_RTS/FTM0_CH4/EWM_IN/LLWU_P14

29

ADC0_SE6B/PTD5/SPI0_PCS2/UART0_CTS/UART0_COL/FTM0_CH5/EWM_OUT

30

ADC0_SE7B/PTD6/SPI0_PCS3/UART0_RX/FTM0_CH6/FTM0_FLT0/LLWU_P15

31

PTD7/CMT_IRO/UART0_TX/FTM0_CH7/FTM0_FLT1

32

VREGIN

6

VOUT33

5

USB0_DM

4

USB0_DP

3

EXTAL32

10

XTAL32

9

RESET

19

ADC0_SE15/TSI0_CH14/PTC1/SPI0_PCS3/UART1_RTS/FTM0_CH0/I2S0_TXD0/LLWU_P6

22

EPAD

33

VCC

GND

U4A

74LVC125ADB

2 3

14

1

7

R95

0

TP108

J29

HDR 1X2

1

2

C34

18PF

DNP

U4D

74LVC125ADB

12 11

13

R51 33

TP100

TP107

R52

4.7K

U7

MIC2005-0.8YM6

VOUT

6

CSLEW

5

ENABLE3GND

2

VIN

1

FAULT

4

TP106

R100

10K

C26

1.0UF

C31

22PF

DNP

C29

0.1UF

TP508

R89 1.0K

R105

10K

R93 1.0K

J11

HDR_19P

1 2

3 4

65

8

9 10

11 12

13 14

15 16

17 18

19 20

C32

2.2UF

J13

HDR 2X5

1 2

3 4

65

7 8

9 10

D16

CDSQR400B

AC

SW6

PB switch

14

23

R50 33

L6

330 OHM

1 2

5VD-D+IDG

CONN USB MINI-B

J15

1

2

3

4

S2

5

S1

S3S4

R107

10K

TP104

D11LED GREEN

AC

Page 29

TWR-KW2xDxxx

Tower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-17

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

SCH-27845

ADC0_SE8PTB0

ADC0_SE9PTE1

3V3_ELEV

5V_ELEV

3V3_ELEV

5V_ELEV

3V3_ELEV

5V_ELEV

5V_ELEV

3V3_ELEV

ELE_PS_SENSE

PTC4

PTC5

PTC6

PTC7

PTD1

PTC6_A

PTD2

PTD3

PTC7_A

PTD4

PTD4_TWR

PTD5_TWR

PTD6_TWR

PTD6_TWR

PTE0_TWR

PTE3_TWR

PTE2_TWR

PTD2

PTD3

PTD2

PTD3

PTD3

PTD2

PTB17_TWRPI

PTB17_TWRPI

PTB16_TWRPI

PTB16_TWRPI

PTB10_TWRPI

PTB10_TWRPI

PTB11_TWRPI

PTB11_TWRPI

PTE3_TWRPI

PTE1_TWRPI

PTE0

PTE1_TWR

PTE3_TWR

PTE2_TWR

PTC4_A

PTC5_A

PTE1_TWR

PTE0_TWR

PTD6_TWR

PTD7_TWR

PTE18/UART2_CTS

PTE19/UART2_RTS

PTE17/UART2_RX

GPIO1

GPIO2

PTD2

PTE16/UART2_TX

RST_TGTMCU_B

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

TOWER CONNECTORS

88

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

TOWER CONNECTORS

88

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

C

TWR- KW24D512

C

Thursday, August 22, 2013

TOWER CONNECTORS

88

___ ___

X

R5610

DNP

R720 DNP

R740 DNP

R660 DNP

R770 DNP

SECONDARYPCI EXPRESS TOWER SYSTEM

J16B

5V_3

D1

GND_17

D2

3.3V_8

D3

ELE_PS_SENSE_2

D4

GND_18

D5

GND_19

D6

SPI2_CLK

D7

SPI2_CS1

D8

SPI2_CS0

D9

SPI2_MOSI

D10

SPI2_MISO

D11

ETH_COL_2

D12

ETH_RXER_2

D13

ETH_TXCLK_2

D14

ETH_TXEN_2

D15

GPIO18

D16

GPIO19/SDHC_D4

D17

GPIO20/SDHC_D5

D18

ETH_TXD1_2

D19

ETH_TXD0_2

D20

ULPI_NEXT/USB_HS_DM

D21

ULPI_DIR/USB_HS_DP

D22

UPLI_DATA5/USB_HS_VBUS

D23

ULPI_DATA6/USB_HS_ID

D24

ULPI_DATA7

D25

GND_20

D26

LCD_HSYNC/LCD_P24

D27

LCD_VSYNC/LCD_P25

D28

AN13

D29

AN12

D30

GND_21

D31

LCD_CLK/LCD_P26

D32

TMR11

D33

TMR10

D34

GPIO21

D35

3.3V_9

D36

PWM15

D37

PWM14

D38

PWM13

D39

PWM12

D40

CAN2_RX

D41

CAN2_TX

D42

LCD_CONTRAST

D43

LCD_OE/LCD_P27

D44

LCD_D0/LCD_P0

D45

LCD_D1/LCD_P1

D46

LCD_D2/LCD_P2

D47

LCD_D3/LCD_P3

D48

GND_22

D49

GPIO23

D50

GPIO24

D51

LCD_D12/LCD_P12

D52

LCD_D13/LCD_P13

D53

LCD_D14/LCD_P14

D54

IRQ_P/SPI2_CS2

D55

IRQ_O/SPI2_CS3

D56

IRQ_N

D57

IRQ_M

D58

IRQ_L

D59

IRQ_K

D60

IRQ_J

D61

IRQ_I

D62

LCD_D18/LCD_P18/SD_RX_0+

D63

LCD_D19/LCD_P19/SD_RX_0-

D64

GND_23

D65

EBI_AD20/LCD_P42/SD_GND

D66

EBI_AD21/LCD_P43/SD_GND

D67

EBI_AD22/LCD_P44/SD_RX_1+

D68

EBI_AD23/LCD_P45/SD_RX_1-

D69

EBI_AD24/LCD_P46/SD_GND

D70

EBI_AD25/LCD_P47/SD_GND

D71

EBI_AD26/LCD_P48/SD_RX_2+

D72

EBI_AD27/LCD_P49/SD_RX_2-

D73

EBI_AD28/LCD_P50/SD_GND

D74

EBI_AD29/LCD_P51/SD_GND

D75

EBI_AD30/LCD_P52/SD_RX_3+

D76

EBI_AD31/LCD_P53/SD_RX_3-

D77

LCD_D20/LCD_P20/SD_GND

D78

LCD_D21/LCD_P21/SD_REFCLK+

D79

LCD_D22/LCD_P22/SD_REFCLK-

D80

GND_24

D81

3.3V_10

D82

5V_4

C1

GND_25

C2

3.3V_11

C3

3.3V_12

C4

GND_26

C5

GND_27

C6

I2C2_SCL

C7

I2C2_SDA

C8

GPIO25

C9

ULPI_STOP

C10

ULPI_CLK

C11

GPIO26

C12

ETH_MDC_2

C13

ETH_MDIO_2

C14

ETH_RXCLK_2

C15

ETH_RXDV_2

C16

GPIO27/SDHC_D6

C17

GPIO28/SDHC_D7

C18

ETH_RXD1_2

C19

ETH_RXD0_2

C20

ULPI_DATA0/I2S1_MCLK

C21

ULPI_DATA1/I2S1_DOUT_SCK

C22

ULPI_DATA2/I2S1_DOUT_WS

C23

ULPI_DATA3/I2S1_DIN0

C24

ULPI_DATA4/I2S1_DOUT0

C25

GND_28

C26

AN11

C27

AN10

C28

AN9

C29

AN8

C30

GND_29

C31

GPIO29/UART2_DCD

C32

TMR9

C33

TMR8

C34

GPIO30/UART3_DCD

C35

3.3V_13

C36

PWM11

C37

PWM10

C38

PWM9

C39

PWM8

C40

UART2_RXD/TSI0

C41

UART2_TXD/TSI1

C42

UART2_RTS/TSI2

C43

UART2_CTS/TSI3

C44

UART3_RXD/TSI4

C45

UART3_TXD/TSI5

C46

UART3_RTS/CAN3_RX

C47

UART3_CTS/CAN3_TX

C48

GND_30

C49

LCD_D4/LCD_P4

C50

LCD_D5/LCD_P5

C51

LCD_D6/LCD_P6

C52

LCD_D7/LCD_P7

C53

LCD_D8/LCD_P8

C54

LCD_D9/LCD_P9

C55

LCD_D10/LCD_P10

C56

LCD_D11/LCD_P11

C57

I2S1_DIN_SCK

C58

I2S1_DIN_WS

C59

I2S1_DIN1

C60

I2S1_DOUT1

C61

LCD_D15/LCD_P15

C62

LCD_D16/LCD_P16/SD_GND

C63

LCD_D17/LCD_P17/SD_GND

C64

GND_31

C65

EBI_BE_32_24/LCD_P28/SD_TX_0+

C66

EBI_BE_23_16/LCD_P29/SD_TX_0-

C67

EBI_BE_15_8/LCD_P30/SD_GND

C68

EBI_BE_7_0/LCD_P31/SD_GND

C69

EBI_TSIZE0/LCD_P32/SD_TX_1+

C70

EBI_TSIZE1/LCD_P33/SD_TX_1-

C71

EBI_TS/LCD_P34/SD_GND

C72

EBI_TBST/LCD_P35/SD_GND

C73

EBI_TA/LCD_P36/SD_TX_2+

C74

EBI_CS4/LCD_P37/SD_TX_2-

C75

EBI_CS3/LCD_P38/SD_GND

C76

EBI_CS2/LCD_P39/SD_GND

C77

EBI_CS1/LCD_P40/SD_TX_3+

C78

GPIO31/LCD_P41/SD_TX_3-

C79

LCD_D23/LCD_P23/SD_GND

C80

GND_32

C81

3.3V_14

C82

PRIMARYPCI EXPRESS TOWER SYSTEM

J16A

5V_1

B1

GND_1

B2

3.3V_1

B3

ELE_PS_SENSE_1

B4

GND_2

B5

GND_3

B6

SDHC_CLK/SPI1_CLK

B7

SDHC_D3/SPI1_CS1

B8

SDHC_D3/SPI1_CS0

B9

SDHC_CMD/SPI1_MOSI

B10

SDHC_D0/SPI1_MISO

B11

ETH_COL_1

B12

ETH_RXER_1

B13

ETH_TXCLK_1

B14

ETH_TXEN_1

B15

ETH_TXER

B16

ETH_TXD3

B17

ETH_TXD2

B18

ETH_TXD1_1

B19

ETH_TXD0_1

B20

GPIO1/UART1_RTS

B21

GPIO2/SDHC_D1

B22

GPIO3

B23

CLKIN0

B24

CLKOUT1

B25

GND_4

B26

AN7

B27

AN6

B28

AN5

B29

AN4

B30

GND_5

B31

DAC1

B32

TMR3

B33

TMR2

B34

GPIO4

B35

3.3V_2

B36

PWM7

B37

PWM6

B38

PWM5

B39

PWM4

B40

CAN0_RX

B41

CAN0_TX

B42

1WIRE

B43

SPI0_MISO/IO1

B44

SPI0_MOSI/IO0

B45

SPI0_CS0

B46

SPI0_CS1

B47

SPI0_CLK

B48

GND_6

B49

I2C1_SCL

B50

I2C1_SDA

B51

GPIO5/SPI0_HOLD/IO3

B52

RSRV_B53

B53

RSRV_B54

B54

IRQ_H

B55

IRQ_G

B56

IRQ_F

B57

IRQ_E

B58

IRQ_D

B59

IRQ_C

B60

IRQ_B

B61

IRQ_A

B62

EBI_ALE/EBI_CS1

B63

EBI_CS0

B64

GND_7

B65

EBI_AD15

B66

EBI_AD16

B67

EBI_AD17

B68

EBI_AD18

B69

EBI_AD19

B70

EBI_R/W

B71

EBI_OE

B72

EBI_D7

B73

EBI_D6

B74

EBI_D5

B75

EBI_D4

B76

EBI_D3

B77

EBI_D2

B78

EBI_D1

B79

EBI_D0

B80

GND_8

B81

3.3V_3

B82

5V_2

A1

GND_9

A2

3.3V_4

A3

3.3V_5

A4

GND_10

A5

GND_11

A6

I2C0_SCL

A7

I2C0_SDA

A8

GPIO9/UART1_CTS

A9

GPIO8/SDHC_D2

A10

GPIO7/SD_WP_DET

A11

ETH_CRS

A12

ETH_MDC_1

A13

ETH_MDIO_1

A14

ETH_RXCLK_1

A15

ETH_RXDV_1

A16

ETH_RXD3

A17

ETH_RXD2

A18

ETH_RXD1_1

A19

ETH_RXD0_1

A20

I2S0_MCLK

A21

I2S0_DOUT_SCK

A22

I2S0_DOUT_WS

A23

I2S0_DIN0

A24

I2S0_DOUT0

A25

GND_12

A26

AN3

A27

AN2

A28

AN1

A29

AN0

A30

GND_13

A31

DAC0

A32

TMR1

A33

TMR0

A34

GPIO6

A35

3.3V_6

A36

PWM3

A37

PWM2

A38

PWM1

A39

PWM0

A40

UART0_RX

A41

UART0_TX

A42

UART1_RX

A43

UART1_TX

A44

VSSA

A45

VDDA

A46

CAN1_RX

A47

CAN1_TX

A48

GND_14

A49

GPIO14

A50

GPIO15

A51

GPIO16/SPI0_WP/IO2

A52

GPIO17

A53

USB0_DM

A54

USB0_DP

A55

USB0_ID

A56

USB0_VBUS

A57

I2S0_DIN_SCK

A58

I2S0_DIN_WS

A59

I2S0_DIN1

A60

I2S0_DOUT1

A61

RSTIN

A62

RSTOUT

A63

CLKOUT0

A64

GND_15

A65

EBI_AD14

A66

EBI_AD13

A67

EBI_AD12

A68

EBI_AD11

A69

EBI_AD10

A70

EBI_AD9

A71

EBI_AD8

A72

EBI_AD7

A73

EBI_AD6

A74

EBI_AD5

A75

EBI_AD4

A76

EBI_AD3

A77

EBI_AD2

A78

EBI_AD1

A79

EBI_AD0

A80

GND_16

A81

3.3V_7

A82

R650

DNP

R730 DNP

R600

R670DNP

R620DNP

R590DNP

R700 DNP

R750DNP

R630

R640

DNP

R680DNP

R580 DNP

R710 DNP

R610DNP

R760DNP

R690DNP

Page 30

TWR-KW2xDxxx

Figure 3-9. TWR-KW24D512 Reference Board PCB Component Location (Top View)

Figure 3-10. TWR-KW24D512 Reference Board PCB Test Points

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

3-18 Freescale Semiconductor

Page 31

TWR-KW2xDxxx

Figure 3-11. TWR-KW24D512 Reference Board PCB Layout (Top View)

Figure 3-12. TWR-KW24D512 Reference Board PCB Layout (Bottom View)

T ower KW2xDxxx Hardware Reference Manual, Rev. 0.2

Freescale Semiconductor 3-19

Page 32

TWR-KW2xDxxx

3.3.1 Bill of Materials

Table 3-5. Bill of Materials (Common parts for all frequency bands) (Sheet 1 of 6)

Item Qty Reference Value Description Mfg. Name Mfg. Part Number

1 1 ANT1 F_Antenna PCB F ANTENNA, NO PART

ORDER

2 1 D16 CDSQR400BDIODE SW 0.1A 80V SOD-923F COMCHIP

TECHNOLOGY CO.

3 3 C1,C2,C3 10UF CAP CER 10UF 10V 10% X7R

0805

46C4,C12,C1

3,C14,C29,

C42

5 2 C7,C16 0.33UF CAP CER 0.33UF 6.3V 10% X5R

64C8,C10,C4

4,C47

7 5 R108,R552

,R553,R55

4,R555

DNP

84C9,C11,C4

3,C46

9 1 C15 33PF CAP CER 33PF 50V 5% C0G 0402 VENKEL COMPANY C0402C0G500-330JN

10 2 C18,C20,

DNP

0.1UF CAP CER 0.1UF 16V 10% X7R

0402

0402

5pF CAP CER 5PF 16V 5% C0G

CC0402

10.0K RES MF 10.0K 1/16W 1%

AEC-Q200 0402

1000pF CAP CER 1000PF 50V 5% C0G

0402

10PF CAP CER 10PF 50V 5% C0G

040210PF

Murata GRM21BR71A106KE

Kemet C0402C104K4RAC

Murata GRM155R60J334KE0

SMEC MCCA050J0NOTF

VISHAY

INTERTECHNOLOGY

MURATA GRM1555C1H102JA0

AVX 04025A100JAT2A

CDSQR400B

51L

1D

CRCW040210K0FKE

D

1D

E

11 2 C17,C45 10PF CAP CER 10PF 50V 5% C0G

040210PF

12 1 C19 1.8pF CAP CER 1.8PF 50V 0.25PF C0G

0402

13 4 C21,C22,C

23,C24

14 1 C25 1PF CAP CER 1PF 50V 5% C0G 0402 MURATA GRM1555C1H1R0CA

15 3 C26,C49,C501.0UF CAP CER 1.0UF 10V 10% X5R