Page 1

Freescale Semiconductor

User’s Guide

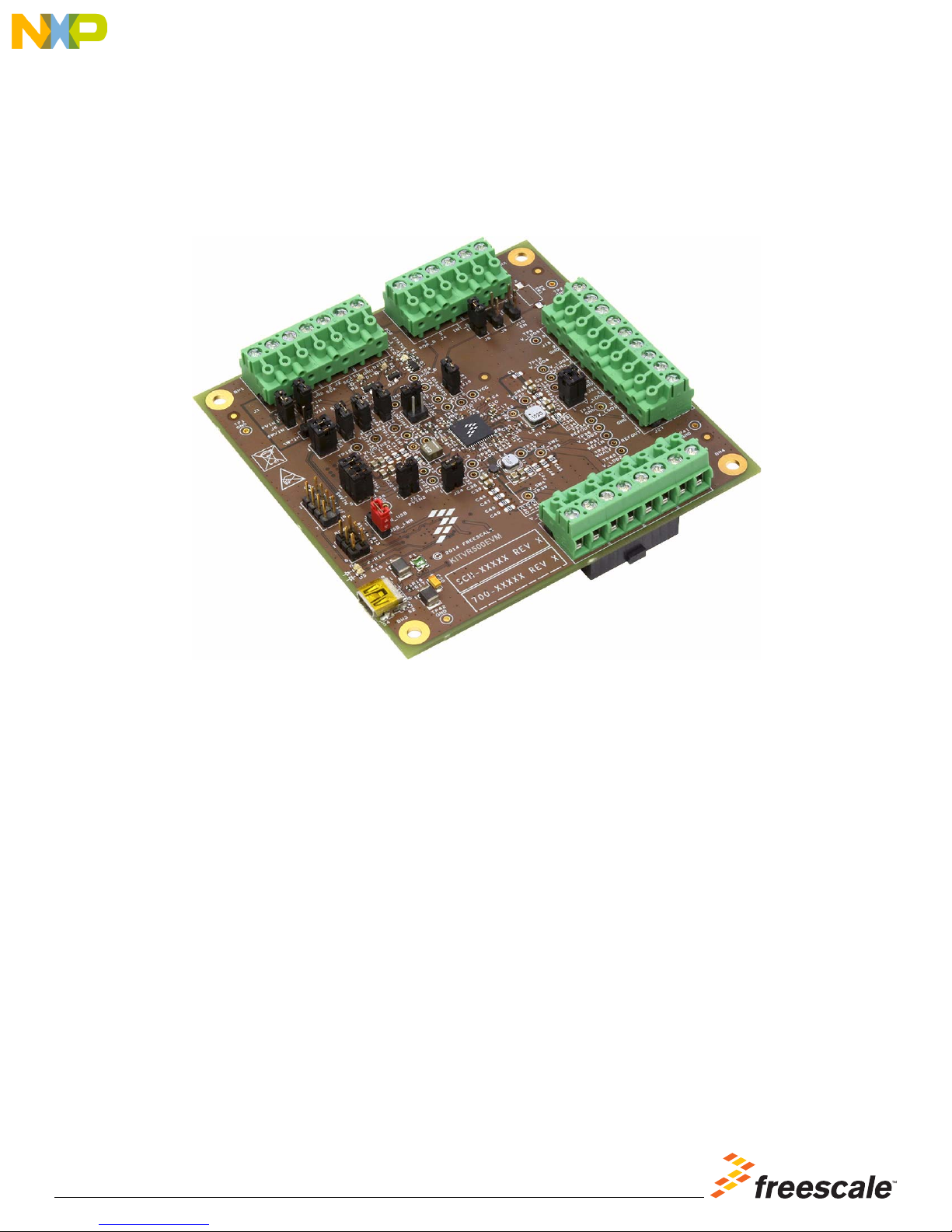

KITVR500EVM Evaluation Board

Document Number: KTVR500UG

Rev. 1.0, 8/2014

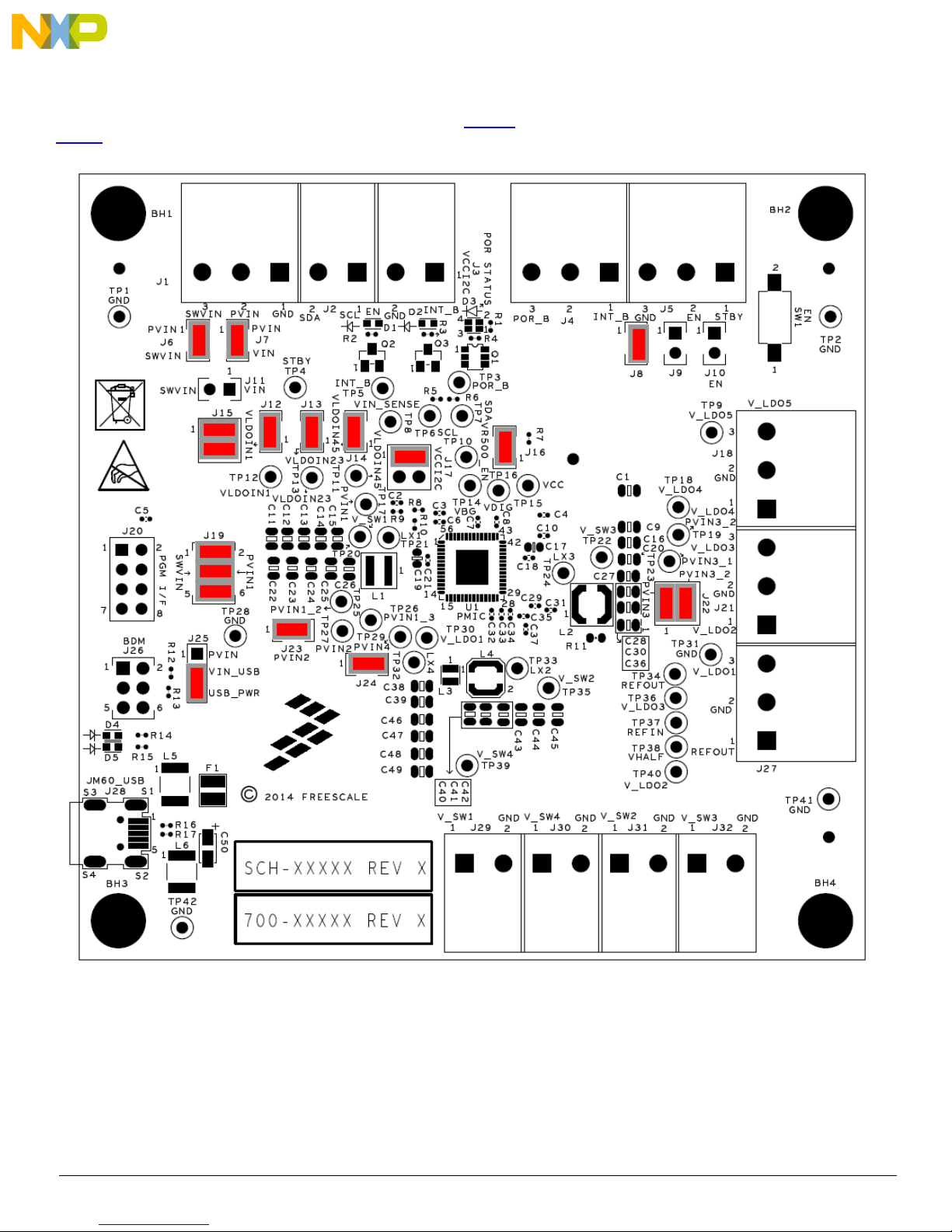

Figure 1. KITVR500EVM

Contents

1 Important Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Getting to Know the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Installing the GUI and Setting up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Board Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

© Freescale Semiconductor, Inc., 2014. All rights reserved.

Page 2

Important Notice

1 Important Notice

Freescale provides the enclosed product(s) under the following conditions:

This evaluation kit is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY.

It is provided as a sample IC pre-soldered to a printed circuit board to make it easier to access inputs, outputs, and

supply terminals. This evaluation board may be used with any development system or other source of I/O signals

by simply connecting it to the host MCU or computer board via off-the-shelf cables. This evaluation board is not a

Reference Design and is not intended to represent a final design recommendation for any particular application.

Final device in an application will be heavily dependent on proper printed circuit board layout and heat sinking

design as well as attention to supply filtering, transient suppression, and I/O signal quality.

The goods provided may not be complete in terms of required design, marketing, and or manufacturing related

protective considerations, including product safety measures typically found in the end product incorporating the

goods. Due to the open construction of the product, it is the user's responsibility to take any and all appropriate

precautions with regard to electrostatic discharge. In order to minimize risks associated with the customers

applications, adequate design and operating safeguards must be provided by the customer to minimize inherent or

procedural hazards. For any safety concerns, contact Freescale sales and technical support services.

Should this evaluation kit not meet the specifications indicated in the kit, it may be returned within 30 days from the

date of delivery and will be replaced by a new kit.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes no

warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters

can and do vary in different applications and actual performance may vary over time. All operating parameters,

including “Typical”, must be validated for each customer application by customer’s technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale products are not

designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other application in which the failure of the Freescale

product could create a situation where personal injury or death may occur.

Should the Buyer purchase or use Freescale products for any such unintended or unauthorized application, the

Buyer shall indemnify and hold Freescale and its officers, employees, subsidiaries, affiliates, and distributors

harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges Freescale was negligent regarding the design or manufacture of the part.Freescale™ and the

Freescale logo are trademarks of Freescale Semiconductor, Inc. All other product or service names are the property

of their respective owners.© Freescale Semiconductor, Inc. 2014

2 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 3

Getting Started

Jump Start Your Design

2 Getting Started

2.1 Kit Contents/Packing List

The KITVR500EVM contents include:

• Assembled and tested evaluation board/module in anti-static bag.

• Warranty card and Technical support brochure

2.2 Jump Start

Freescale’s analog product development boards help to easily evaluate Freescale products. These tools support analog mixed signal and

power solutions including monolithic ICs using proven high-volume SMARTMOS mixed signal technology, and system-in-package devices

utilizing power, SMARTMOS and MCU dies. Freescale products enable longer battery life, smaller form factor, component count reduction,

ease of design, lower system cost and improved performance in powering state of the art systems.

•Go to www.freescale.com/analogtools

• Locate your kit

• Review your Tool Summary Page

• Look for

• Download documents, software and other information

Once the files are downloaded, review the user guide in the bundle. The user guide includes setup instructions, BOM and schematics.

Jump start bundles are available on each tool summary page with the most relevant and current information. The information includes

everything needed for design.

2.3 Required Equipment and Software

To use this kit, you need:

• Power supply:

• Output voltage range from 3.1 to 4.5 V

• Current capability from 3.0 to 5.0 A (current requirement is dependent on output loading)

• Supply to board connection cables (capable of withstanding up to 5.0 A current)

• USB (male) to mini USB (male) communication cable

• USB-enabled computer

• Multimeter is recommended

2.4 System Requirements

The kit requires the following to function properly with the software:

• Windows XP or Windows 7 operating system

• VR500_GUI_REV_1.1.zip: Graphical User Interface (GUI) for KITVR500EVM

Freescale Semiconductor, Inc. 3

KTVR500UG Rev. 1.0 8/2014

Page 4

Getting to Know the Hardware

3 Getting to Know the Hardware

3.1 Board Overview

The KITVR500EVM evaluation board allows full evaluation capability of the 34VR500 PMIC for the QorlQ LS102x family of application

processors. It provides access to all output voltage rails as well as control and signal pins through terminal block connectors for an easier

out-of-the-box evaluation experience. A single terminal block connector for the input power supply allows the user to supply the board with

an external DC power supply to fully evaluate the performance of the device.

3.2 Board Features

The board features are as follows:

• Input voltage operation range from 3.1 to 4.5 V

• Output voltage supplies accessible through detachable terminal blocks

• Four buck converters

• Five general purpose LDO regulators

• One DDR memory termination voltage reference

• On/off push button support

• Hardware configuration flexibility through various jumper headers and resistors

• Integrated USB to I2C programming interface for full control/configuration

• Onboard PMIC control through the I2C register map

• On board connectors for interfacing with future evaluation/debug tools

• Compact form factor (4 x 4 in2)

3.3 Device Features

This evaluation board features the following Freescale products:

Table 1. Features

Device Description Features

• Four buck converters

Multi-output DC/DC Regulator for QorIQ LS1

MC34VR500

MC9S08JM60 8-bit USB Cost-Effective JM MCUs

Family of Communications Processors

• Five general purpose linear regulators

• Programmable output voltage, sequence, and timing

• DDR termination reference voltage

• Power control logic with processor interface and event detection

• Individually programmable ON, OFF, Standby, and Sleep modes

• 8-bit HCS08 Central Processing Unit (CPU)

• Up to 24 MHz internal bus (48 MHz HCS08 core) frequency offering 2.7

to 5.5 V across temperature range of -40 °C to +85 °C

• Support for up to 32 peripheral interrupt/reset sources

• On-chip Memory

• Up to 60 k flash read/program/erase over the full operating voltage and

temperature

• Up to 4.0 k RAM

• 256 Byte USB RAM

• Support for up to 32 peripheral interrupt/reset sources

4 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 5

3.4 Board Description

LDO’s

outputs

Buck regulators

outputs

Power

supply

Logic and

monitoring outputs

PC

interface

via the

USB bus

Power

Management

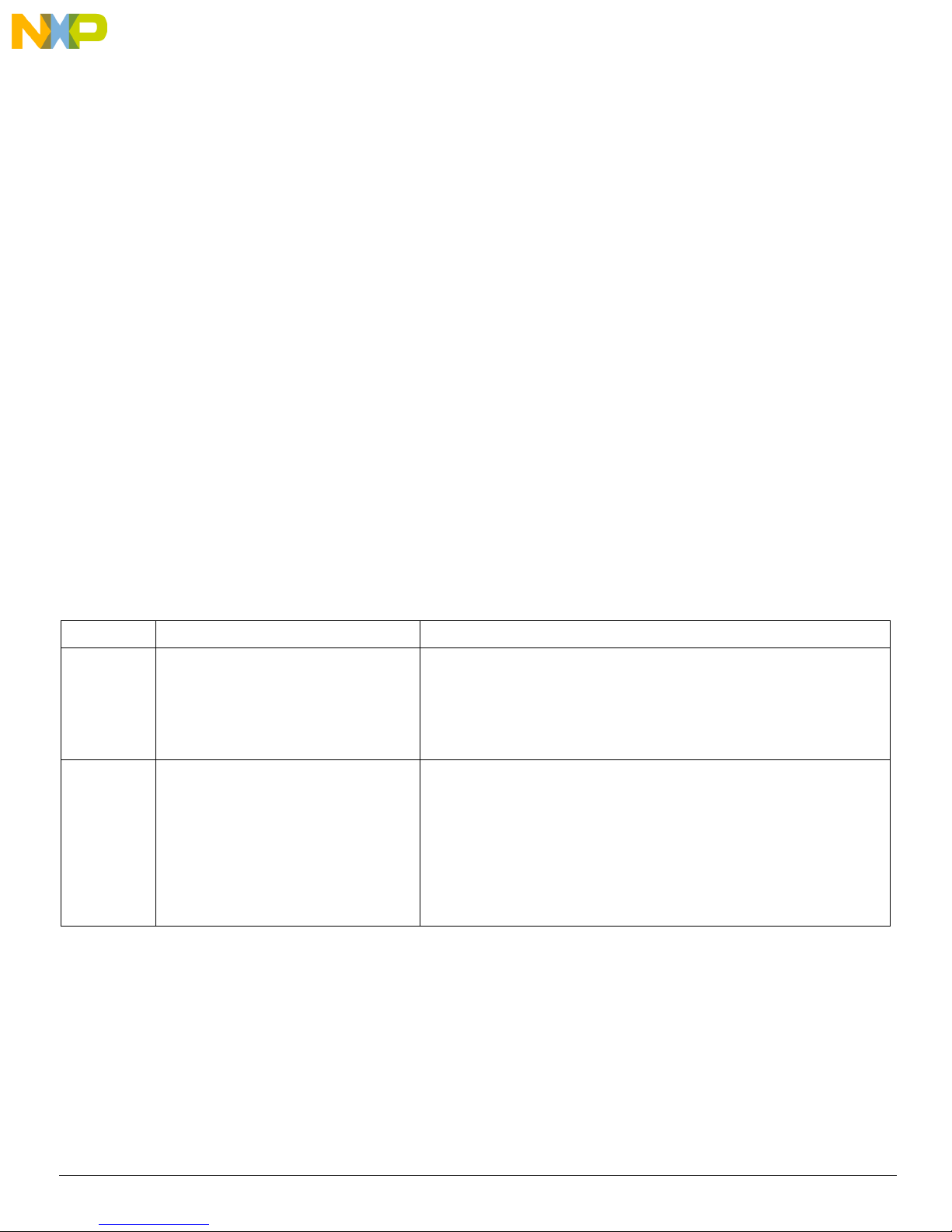

Figure 2 describes the main blocks of the KITVR500EVM.

Getting to Know the Hardware

Table 2. Board Description

Name Summary Description

Power Supply Main power supply connection (3.1 to 4.5 V)

Logic and monitoring outputs I2C, INTB, EN, PORB and STBY connections for monitoring

LDO’s outputs LDO1, 2, 3, 4, 5 REFOUT output connections (can be used to connect a load)

Buck regulators outputs SW1, 2, 3, 4 output connections (can be used to connect a load)

PC Interface To be connected to the PC running the GUI

Figure 2. Board Description

Freescale Semiconductor, Inc. 5

KTVR500UG Rev. 1.0 8/2014

Page 6

Getting to Know the Hardware

KITVR500EVM

3.5 Jumper Description

Verify that the jumpers are placed in the right position as shown in Figure 3. For a detailed description of the jumper functionality, refer to

Table 3.

Figure 3. Default Jumper Configuration Diagram

6 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 7

Table 3. Jumper Description

Jumper Default Description

Getting to Know the Hardware

J6 Closed

J7 Closed Shorts PVIN to VIN. Allows one to isolate or connect the 34VR500 logic input supply to PVIN net. (debugging option)

J8 Closed Short EN to the MCU

J9 Open Short to pull STBY to PVIN voltage supply

J10 Open Short to hold EN pin low

J11 Open

J12, J13, J14 Closed Short to connect VLDOIN to VIN

J15 Closed Short to connect SCL and SDA to the MCU

J16 Closed Short to connect EN to PVIN

J17 1 - 2

J19, J23, J24

J22

J25 2 - 3

Closed

1 - 2

3 - 4

Shorts PVIN and SWVIN. Allows supply isolation to provide more accurate efficiency readings on the switching

supplies

Shorts SWVIN to VIN. Allows one to isolate or connect the 34VR500 logic input supply to SWVIN net. (debugging

option)

VCCI2C Supply selector

• 1-2: Connect VCCI2C to 3V3 LDO

• 3-4: Connect VCCI2C to SW2 output

Buck regulators input power path isolation

Short these jumpers to allow PVINx to be powered from the SWVIN supply

Buck regulators input power path isolation

Control Interface input supply selector

• 1-2: Enables PVIN node as the input supply source for the control interface

• 2-3: Enables USB power as the input supply source for the control interface

3.6 Connectors and Terminal Blocks Description

Table 4 presents pin connection for each header present on the KITVR500EVM.

Table 4. Terminal Blocks Descriptions

Terminal Block Function Pin definition

J1 Main Input Supply

J2 I²C Signals

J3 VCCI2C

J4 Interfacing 1

J5 Interfacing 2

J18 LDO4 / LDO5

J21 LDO2 / LDO3

J27 REFOUT / LDO1

J29 SW1

Pin 1 – GND

Pin 2 – PVIN

Pin 3 – SWVIN

Pin 1 – SCL

Pin 2 – SDA

Pin 1 – VCCI2C

Pin 2 – GND

Pin 1 – INT_B

Pin 3 – POR_B

Pin 1 – STBY

Pin 2 – EN

Pin 3 – GND

Pin 1 – LDO4 Output

Pin 2 – GND

Pin 3 – LDO5 Output

Pin 1 – LDO2 Output

Pin 2 – GND

Pin 3 – LDO3 Output

Pin 1 – REFOUT Output

Pin 2 – GND

Pin 3 – LDO1 Output

Pin 1 – SW1 Output

Pin 2 – GND

Freescale Semiconductor, Inc. 7

KTVR500UG Rev. 1.0 8/2014

Page 8

Getting to Know the Hardware

Table 4. Terminal Blocks Descriptions (continued)

J30 SW4

J31 SW2

J32 SW3

Table 5. Connector Description

Connector Function Pin definition

J20 Debug Port 1 Debugging connector for future development tools

J26 BDM Connector

J28 Mini USB Connector

J33 Debug Port 2 Debugging connector for future development tools

J34 Debug Port 3 Debugging connector for future development tools

J35 Debug Port 4 Debugging connector for future development tools

Pin 1 – SW4 Output

Pin 2 – GND

Pin 1 – SW2 Output

Pin 2 – GND

Pin 1 – SW3 Output

Pin 2 – GND

Pin 1 - BKGD_JM60

Pin 2 - GND

Pin 3 - NC

Pin 4 - RST_JM60

Pin 5 - NC

Pin 6 - USB_PWR

Pin 1 - VBUS

Pin 2 - DPin 3 - D+

Pin 4 - NC

Pin 5 - GND

Chassis - GND

3.6.1 LDO Input Supply Source Selection

It is possible to modify the LDO input supply sources by removing the Jumpers J12, J13, J14, J17 and connecting another power supply,

as one of the buck converters outputs.

LDO INPUT SENSE POINTS

TP11

TP13

DNP

C33

1.0UF

C35

0.1UF

C37

0.1UF

VHALF

TP12

DNP

TP37

REFIN

TP38

VHALF

C63

1.0UF

DNP

DNP

VLDOIN1

VLDOIN23

VLDOIN45

17

27

40

30

29

U1B

VLDOIN1

VLDOIN23

VLDOIN45

REFIN

VHALF

LDO

REF

REG

MC34VR500V1ES

LDO1

LDO2

LDO3

LDO4

LDO5

REFOUT

V_LDO1

18

V_LDO2

26

V_LDO3

28

V_LDO4

39

V_LDO5

41

31

REFOUT

VIN

J12

2

1

HDR 1X2 TH

J13

2

1

HDR 1X2 TH

J14

1

2

HDR 1X2 TH

Default:

1-2 shunt

V_SW3

VLDOIN45 VLDOIN23 VLDOIN1

DNP

C54

1.0UF

0

R11

REFIN

C31

1.0UF

Figure 4. LDO Schematic Configuration

LDO OUTPUT SENSE POINTS

TP30

V_LDO1 V_LDO2 V_LDO3 V_LDO4 V_LDO5

DNP

C62

4.7uF

TP34

REFOUT

DNP

C29

1.0UF

TP40

DNP

C32

2.2UF

REFOUT

TP36

DNP

C34

4.7uF

TP18

DNP

C10

2.2UF

TP9

DNP

C4

2.2UF

V_LDO1 V_LDO2

V_LDO3 V_LDO4

V_LDO5

8 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 9

Getting to Know the Hardware

VIN_SENSE

VDIG

VBG

VCC

LCSADS

Default:

1-2 shunt

Default:

1-2 shunt,

3-4 shunt.

POR_B STBY

INT_B

VR500_EN

Default:

1-2 shunt

Default:

No shunt

Default:

No shunt

Default:

1-2 shunt

VIN

VCC

VBIAS

VBG

VDIG

VCCI2C

I2C_S CL

I2C_S DA

MCU_SDA

MCU_SCL

STBY

INT_ B

POR_B

EN

VR500_EN

VIN

V_SW2

VCCI2C

VCCI2C

PVIN

3V3

PVIN

MCU_SCL3,5

MCU_SDA3,5

STBY 3

INT_ B 3

POR_B 3

EN 3,5

J16

HDR 1X2 TH

1 2

SW1

FSMSM

DNP

12

TP4

DNP

C8

0.47uF

TP6

DNP

TP16

DNP

R7

1M

C51

1.0UF

Control

MC34VR500V1ES

U1A

ICTEST1

5

INT

1

POR

3

SCL

54

SDA

53

STBY

4

VDIG

51

VBG

52

VCCI2C

55

ICTEST2

47

EN

56

VCC

49

VIN

50

VBIAS

43

TP10

DNP

J9

HDR 1X2 TH

1 2

TP14

DNP

J15

HDR 2X2

1 2

3

4

C3

1.0UF

DNP

TP15

DNP

TP8

DNP

R10

10.0K

R6

4.7K

R8

10.0K

R9

100K

C52

1.0UF

R5

4.7K

J10

HDR 1X2 TH

1 2

C53

0.22uF

TP7

DNP

C2

1.0UF

C7

1.0UF

J17

HDR 2X2

1 2

3

4

C6

0.1UF

TP5

DNP

TP3

DNP

J8

HDR 1X2 TH

12

Figure 5. Logic and Core Supplies Schematic

Freescale Semiconductor, Inc. 9

KTVR500UG Rev. 1.0 8/2014

Page 10

Getting to Know the Hardware

STBY

INTB

PORB

SW1

LDO1

SW2

SW4

LDO2

REFOUT

LDO3

SW3

LDO4

LDO5

VCC

VDIG

VBG

EN

Table 6. LDO Input Supply Configuration Chart

Input Pin Input options

VLDOIN1

VLDOIN23

VLDOIN45

REFIN

VCCI2C

Input supply for LDO1:

J12 Closed: VIN

J12 Open: User's choice

Input supply for LDO2 and LDO3:

J13 Closed: VIN

J13 Open: User's choice

Input supply for LDO4 and LDO5:

J14 Closed: VIN

J14 Open: User's choice

Input supply for REFOUT:

R11 = V_SW3

R11 removed: User's choice

Input supply for VCCI2C:

1 - 2: 3V3

3 - 4: V_SW2

3.6.2 Test point

All test points are clearly marked on the evaluation board. Figure 6 shows the location of various test points of interest during evaluation.

Figure 6. Key Test Point Locations

KTVR500UG Rev. 1.0 8/2014

10 Freescale Semiconductor, Inc.

Page 11

Getting to Know the Hardware

VIN_SENSE

VDIG

VBG

VCC

LCSADS

Default:

1-2 shunt

Default:

1-2 shunt,

3-4 shunt.

POR_B STBY

INT_B

VR500_EN

Default:

1-2 shunt

Default:

No shunt

Default:

No shunt

Default:

1-2 shunt

VIN

VCC

VBIAS

VBG

VDIG

VCCI2C

I2C_S CL

I2C_S DA

MCU_SDA

MCU_SCL

STBY

INT_ B

POR_B

EN

VR500_EN

VIN

V_SW2

VCCI2C

VCCI2C

PVIN

3V3

PVIN

MCU_SCL3,5

MCU_SDA3,5

STBY 3

INT_ B 3

POR_B 3

EN 3,5

J16

HDR 1X2 TH

1 2

SW1

FSMSM

DNP

12

TP4

DNP

C8

0.47uF

TP6

DNP

TP16

DNP

R7

1M

C51

1.0UF

Control

MC34VR500V1ES

U1A

ICTEST1

5

INT

1

POR

3

SCL

54

SDA

53

STBY

4

VDIG

51

VBG

52

VCCI2C

55

ICTEST2

47

EN

56

VCC

49

VIN

50

VBIAS

43

TP10

DNP

J9

HDR 1X2 TH

1 2

TP14

DNP

J15

HDR 2X2

1 2

3

4

C3

1.0UF

DNP

TP15

DNP

TP8

DNP

R10

10.0K

R6

4.7K

R8

10.0K

R9

100K

C52

1.0UF

R5

4.7K

J10

HDR 1X2 TH

1 2

C53

0.22uF

TP7

DNP

C2

1.0UF

C7

1.0UF

J17

HDR 2X2

1 2

3

4

C6

0.1UF

TP5

DNP

TP3

DNP

J8

HDR 1X2 TH

12

3.7 Miscellaneous Components

3.7.1 Power on Push Button

A footprint for a normally open, momentary push-button is provided at the EN terminal to allow a momentary low state by pressing the

push button. J8 allows isolation of the EN terminal from the MCU GPIO controlling this pin.

Freescale Semiconductor, Inc. 11

Figure 7. Power on Circuit

KTVR500UG Rev. 1.0 8/2014

Page 12

Getting to Know the Hardware

ROTACI

DNI NWODTUHS

ROTACI

DNI TPURRETNI

INT_B

EN

INT _B

EN

PVIN

PVIN

3B

_

TNI 5,3NE

R2

200 OHM

Q2

FDV302P

1

3 2

D1

LED Red

AC

Q3

FDV302P

1

3 2

D2

LED Red

AC

R3

200 OHM

3.7.2 PMIC LED Indicators

LED indicators are provided to notify the PMIC status to the user. Figure 8 shows the PMIC status LEDs D2 and D4, and a Reserved

LED indicator D3, that allows for an external rework connection to the transistor gate if any given signal debug is required.

RESET INDICATOR

PVIN

3

POR_B

POR_B

3

1

Q1

G

G

FDC6327C

2

S

4

D

6

D

200 OHM

5

S

PVIN

R1

R4

200 OHM

13

D3

LED_RED-GRN

POR_B

Red

Grn

4 2

Table 7 describes the meaning of the LED state.

Table 7. LED State Description

LED Description

Interrupt Notification

D2

D3

D1

ON = PMIC has detected an unmasked interrupt

OFF = No interrupt detected

PORB Notification

Green = PMIC is in regulation and operating properly

Red = PMIC is out of regulation

Reserved debug LED

ON = Q3 gate (R84 pad) is low

OFF = Q3 gate (R84 pad) is high or floating

Figure 8. PMIC Status Indicators

12 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 13

Installing the GUI and Setting up the Hardware

4 Installing the GUI and Setting up the Hardware

4.1 Installing the GUI Interface

The new “driverless” environment allows automatically detecting and recognizing the board connected through the USB port, enabling the

specific features and controls for each board.

1. Create a directory on your PC as follows: C:\Freescale\KITVR500GUI

2. Extract the KITVR500GUI.zip file into that directory.

3. Launch the "setup.exe" program.

4. When the following popup dialog appears, click the “Install” button.

Figure 9. KITVR500EVM Installation Window

Freescale Semiconductor, Inc. 13

KTVR500UG Rev. 1.0 8/2014

Page 14

Installing the GUI and Setting up the Hardware

4.2 Configuring the Hardware

The KITVR500EVM operates with a single power supply from 3.1 to 4.5 V and is controlled via USB with help of an integrated USB-I2C

communication bridge. By applying the input voltage supply, the KITVR500EVM powers up according to the default power-up sequence

(34VR500V1) described in the MC34VR500 Data Sheet.

Connect the power supply and the USB communication cables as shown in Figure 10. Multimeter is optional but it is recommended in

order to accurately verify that each one of the output supplies is providing the correct voltage level.

The KITVR500EVM allows the selection of SW2 regulator output or an external 3.3 V LDO

output as the VCCI2C/I2C pull-up supply. By default, the 3.3 V LDO regulator is the source

for the VDDIO supply (J17 = 1–2). If the SW2 regulator is to be set below 3.0 V then make

sure the 3.3 V LDO output is connected to VCCI2C.

14 Freescale Semiconductor, Inc.

Figure 10. KITVR500EVM Board Setup

Note:

KTVR500UG Rev. 1.0 8/2014

Page 15

Installing the GUI and Setting up the Hardware

4.2.1 Step-by-step Instructions for Setting up the Hardware using GUI

To perform the demonstration examples, the following connections and setup must be performed:

1. Connect the power supply to J1, PVIN, and GND pins.

2. Switch on the power supply with a voltage set up between 3.1 and 4.5 V.

3. Connect the mini USB cable to J28 and to the computer.

4. Launch the VR500GUI, the description on how to use the GUI is provided in KTVR500SWUG

Figure 11. KITVR500GUI

The main features of the KITVR500GUI are:

• Automatic detection of the KITVR500EVM

• Read/write access to the 34VR500 PMIC

• Intuitive interface for controlling the 34VR500

• Monitoring all interrupts manually or continuously

• Scrip editor for prototyping, test emulation, or customized operation of the 34VR500 device

• Saving and recalling customized scripts files

KTVR500UG Rev. 1.0 8/2014

Freescale Semiconductor, Inc. 15

Page 16

Schematic

VIN_SENSE

VDIG

VBG

VCC

LCSADS

Default:

1-2 shunt

Default:

1-2 shunt,

3-4 shunt.

POR_B STBY

INT_B

VR500_EN

Default:

1-2 shunt

Default:

No shunt

Default:

No shunt

Default:

1-2 shunt

VIN

VCC

VBIAS

VBG

VDIG

VCCI2C

I2C_S CL

I2C_S DA

MCU_SDA

MCU_SCL

STBY

INT_ B

POR_B

EN

VR500_EN

VIN

V_SW2

VCCI2C

VCCI2C

PVIN

3V3

PVIN

MCU_SCL3,5

MCU_SDA3,5

STBY 3

INT_ B 3

POR_B 3

EN 3,5

J16

HDR 1X2 TH

1 2

SW1

FSMSM

DNP

12

TP4

DNP

C8

0.47uF

TP6

DNP

TP16

DNP

R7

1M

C51

1.0UF

Control

MC34VR500V1ES

U1A

ICTEST1

5

INT

1

POR

3

SCL

54

SDA

53

STBY

4

VDIG

51

VBG

52

VCCI2C

55

ICTEST2

47

EN

56

VCC

49

VIN

50

VBIAS

43

TP10

DNP

J9

HDR 1X2 TH

1 2

TP14

DNP

J15

HDR 2X2

1 2

3

4

C3

1.0UF

DNP

TP15

DNP

TP8

DNP

R10

10.0K

R6

4.7K

R8

10.0K

R9

100K

C52

1.0UF

R5

4.7K

J10

HDR 1X2 TH

1 2

C53

0.22uF

TP7

DNP

C2

1.0UF

C7

1.0UF

J17

HDR 2X2

1 2

3

4

C6

0.1UF

TP5

DNP

TP3

DNP

J8

HDR 1X2 TH

12

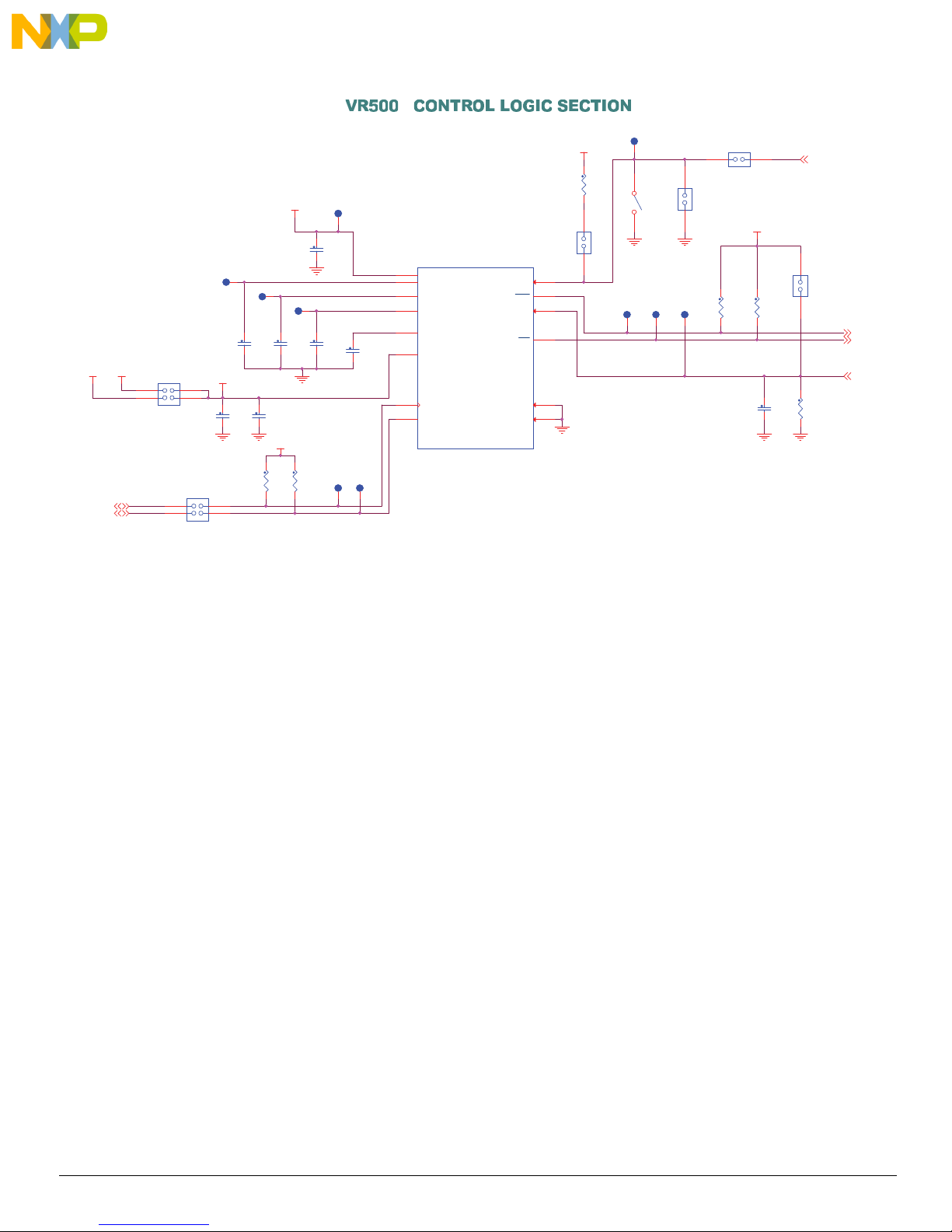

5 Schematic

LDO INPUT SENSE POINTS

TP11

TP13

DNP

C33

1.0UF

C35

0.1UF

C37

0.1UF

VHALF

TP12

DNP

TP37

REFIN

TP38

VHALF

C63

1.0UF

DNP

DNP

VLDOIN1

VLDOIN23

VLDOIN45

17

27

40

30

29

U1B

VLDOIN1

VLDOIN23

VLDOIN45

REFIN

VHALF

LDO

REF

REG

MC34VR500V1ES

LDO1

LDO2

LDO3

LDO4

LDO5

REFOUT

V_LDO1

18

V_LDO2

26

V_LDO3

28

V_LDO4

39

V_LDO5

41

31

REFOUT

VIN

J12

2

1

HDR 1X2 TH

J13

2

1

HDR 1X2 TH

J14

1

2

HDR 1X2 TH

Default:

1-2 shunt

V_SW3

VLDOIN45 VLDOIN23 VLDOIN1

DNP

C54

1.0UF

0

R11

REFIN

C31

1.0UF

LDO OUTPUT SENSE POINTS

TP30

V_LDO1 V_LDO2 V_LDO3 V_LDO4 V_LDO5

DNP

C62

4.7uF

TP34

REFOUT

DNP

C29

1.0UF

TP40

DNP

C32

2.2UF

REFOUT

TP36

DNP

C34

4.7uF

TP18

DNP

C10

2.2UF

TP9

DNP

C4

2.2UF

V_LDO1 V_LDO2

V_LDO3 V_LDO4

V_LDO5

16 Freescale Semiconductor, Inc.

Figure 12. Evaluation Board Schematic, Part 1

KTVR500UG Rev. 1.0 8/2014

Page 17

Schematic

VR500 - CONTROL SIGNALS

TERMINAL BLOCK SECTION

GND

EN

STBY

POR_B

INT _B

5,3

NE

3Y

BT

S

POR_B3

3B_

TNI

J4

SUB_TB_3X1

1

2

3

J5

SUB_TB_3X1

1

2

3

ROTACI

DNI NWODTUHS

ROTACI

DNI TPURRETNI

INT_B

EN

INT _B

EN

PVIN

PVIN

3B

_

TNI 5,3NE

R2

200 OHM

Q2

FDV302P

1

3 2

D1

LED Red

AC

Q3

FDV302P

1

3 2

D2

LED Red

AC

R3

200 OHM

RESET INDICATOR

POR_B

POR_B

PVIN

PVIN

POR_B

3

Red

Grn

D3

LED_RED-GRN

4 2

13

R4

200 OHM

G

D

S

G

S

D

Q1

FDC6327C

2

6

1

5

4

3

R1

200 OHM

VR500 - LDO & REFOUT O/P HEADER SECTION

V_LDO1

V_LDO2

V_LDO3

V_LDO4

V_LDO5

REFOUT

V_LDO1 V_LDO2 V_LDO3 V_LDO4

V_LDO5 REFOUT

J34

CON_2X10

1

2

3 4

65

7 8

9 10

11 12

13 14

15 16

17 18

19 20

SWVIN

PVIN

GND

SUB_TB_3X1

J1

SWVIN PVIN SWVIN

3

2

1

Main Input supply to the board

VR500 Swithcing Regulator input

VR500 Main chip supply &

Supply

PVIN -

SWVIN -

VIN -

Input supply for LDO.

J6

HDR 1X2 TH

Default:

1 2

1-2 shunt

Input Terminal Block J1 pin 2

Input Terminal Block J1 pin 3

(or)

Feed the power from PVIN

by shunting the head er J6.

Feed the power from PVIN

by shunting the head er J7

(or)

Feed the power from SWVIN

by shunting the head er J11.

Default:

No shunt

J11

12

HDR 1X2 TH

Input Source

VIN

1 2

J7

HDR 1X2 TH

Default:

1-2 shunt

3,5

MCU_SCL

MCU_SDA3,5

I2C Terminal Blocks

MCU_SCL

MCU_SDA

1

2

VCCI2C

1

VCCI2C

2

GND

J2

SUB_TB_2X1

J3

SUB_TB_2X1

Freescale Semiconductor, Inc. 17

Figure 13. Evaluation Board Schematic, Part 2

KTVR500UG Rev. 1.0 8/2014

Page 18

Schematic

GND GND GND GND GND GND

GROUND TEST POINTS

TP31

DNP

TP42

DNP

TP28

DNP

TP2

DNP

TP1

DNP

TP41

DNP

3YBTS

VR500 - CONTROL/I2C SIGNALS HEADER

J33

STBY EN

V_LDO1

1

3 4

7 8

9

11 12

13

15 16

17 18

19 20

CON_2X10

REFOUT

2

INT _B

65

POR_B

10

VCCI2C

MCU_SCL

14

MCU_SDA

PVIN

SWVIN

VR500 - LDO & REFOUT O/P

TERMINAL BLOCK SECTION

J27

REFOUT

GND

V_LDO1

1

2

3

SUB_TB_3X1

EN 3,5

INT _B 3

POR_B 3

MCU_SCL 3,5

MCU_SDA 3,5

REFOUT= DDR memory reference

voltage,10 mA.

VCCI2C

V_LDO1= 0.80 to 1.55 V, 250 mA

PVIN SWVIN

V_LDO3 V_LDO2

V_LDO5 V_LDO4

V_LDO2

GND

V_LDO3

V_LDO4

GND

V_LDO5

J21

1

2

3

SUB_TB_3X1

J18

1

2

3

SUB_TB_3X1

V_LDO2 = 1.8 to 3.3 V, 100 mA

V_LDO3 = 1.8 to 3.3 V, 350 mA

V_LDO4 = 1.8 to 3.3 V, 100 mA

V_LDO5 = 1.8 to 3.3 V, 200 mA

MOUNTING HOLES

MTG

BH1

MTG

BH3

Figure 14. KITVR500EVM LDO/Control Schematic Part 3

BH4

MTG

BH2

MTG

18 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 19

PVIN1_1 PVIN1_2PVIN1_3

Default:

1-2 shunt,

3-4 shunt,

5-6 shunt.

LX1

6.0A

V_SW1

PVIN2

Default:

1-2 shunt

2.4A

LX2

FB1

FB2

V_SW2

PVIN3_1 PVIN3_2

Default:

1-2 shunt,

3-4 shunt.

2.65A

LX3

FB3

V_SW3

PVIN4

Default:

1-2 shunt

2.0A

LX4

FB4

V_SW4

PVIN1_1

PVIN1_2

PVIN1_3

LX1

V_SW1

PVIN2 LX2

V_SW2

PVIN3_2

PVIN3_1

LX3

V_SW3

PVIN4 LX4

V_SW4

SWVIN

V_SW1

SWVIN

V_SW2

SWVIN

V_SW3

SWVIN

V_SW4

C25

22UF

C64

4.7uF

TP27

DNP

TP23

DNP

C61

0.1UF

C21

0.1UF

C9

22UF

C22

22UF

C30

22UF

J19

HDR 2X3

1

2

3 4

6

5

C57

0.1UF

TP19

DNP

C59

0.1UF

C47

22UF

DNP

L1 1uH

1

2

TP39

DNP

L4 1uH

1 2

C66

4.7uF

C58

4.7uF

TP20

DNP

TP24

DNP

C13

22UF

DNP

C24

22UF

C48

22UF

DNP

C36

22UF

DNP

C15

22UF

DNP

C12

22UF

C42

22UF

DNP

C14

22UF

DNP

C46

22UF

DNP

C27

22UF

DNP

C40

22UF

L2 1uH

1

2

TP25

DNP

TP33

DNP

C39

22UF

C65

0.1UF

C43

22UF

DNP

TP22

DNP

C56

4.7uF

C11

22UF

TP21

DNP

C41

22UF

TP26

DNP

TP35

DNP

J24

HDR 1X2 TH

1 2

C49

22UF

DNP

C26

22UF

DNP

C20

22UF

DNP

C23

22UF

C55

0.1UF

C60

4.7uF

L3 1UH

1

2

TP17

DNP

C45

22UF

DNP

J23

HDR 1X2 TH

1 2

C38

22UF

C1

22UF

DNP

C18

0.1UF

TP32

DNP

TP29

DNP

C44

22UF

DNP

J22

HDR 2X2

1

2

3 4

SW2

SW3

SW4

SW1

MC34VR500V1ES

U1C

PVIN1_3

12

SGND1

14

FB3

38

PVIN3_2

37

LX3_2

36

DNC4

33

PVIN3_1

34

LX3_1

35

SGND3

32

FB4

19

PVIN4

20

DNC6

44

DNC7

45

DNC8

46

PVIN1_1

7

LX1_1

8

PVIN1_2

10

LX1_2

9

FB1

13

LX1_3

11

DNC2

6

FB2

25

LX2

22

LX4

21

EPGND57SGND2

15

DNC1

2

DNC5

42

DNC3

16

SGND4

48

PVIN2_1

23

PVIN2_2

24

C19

4.7uF

C16

22UF

C28

22UF

C17

4.7uF

VR500-SWITHCING REGULATOR O/P

TERMINAL BLOCK SECTION

SW1

0.625 to 1.875 V

4.5 A (M ax. Peak)

SW3

0.625 to 1.975 V ,

2.5 A (M ax. Peak)

SW4

1.0 A

operates in VTT mode

provide DDR termination

at 50% of SW3

SW2

0.625 to 1.975V ,

1.0 A (M ax. Peak)

V_SW1

V_SW2

V_SW3

V_SW4

J32

SUB_TB_2X1

1

2

J29

SUB_TB_2X1

1

2

J31

SUB_TB_2X1

1

2

J30

SUB_TB_2X1

1

2

VR500-SWITHCING REGULATOR O/P HDR

V

VOUT = 1.242 X ( (R2/R1) + 1) = 3.3V

R2 = ((VOUT/1.242) -1) X R1

LDO REGULATOR 3.3 V

Layout Note :

Place this LDO section

on the bottom s ide of the PCB.

R1

R2

VIN_USB

LD0_3V3_EN

3V3

LDO_3V3_ADJ

3V3

VIN_USB

3V3

3V3

LD0_3V3_EN

5

R21 12.0K

R22

20K

U3

MIC5205

IN

1

GND

2

ADJ

4

EN

3

OUT

5

C79

1.0UF

C71

470PF

+

C80

2.2UF

C74

2.2uF

DNP

Schematic

Freescale Semiconductor, Inc. 19

Figure 15. KITVR500EVM Switching Regulators Schematic

V_SW4

V_SW2

_SW3

3,5

KTVR500UG Rev. 1.0 8/2014

V_SW1

V_SW1

V_SW4

V_SW2

V_SW3

J35

1 2

3 4

5

7

9

11 12

13 14

15 16

17 18

19 20

CON_2X10

PROGRAMMING INTERFACE

J20

1

MCU_SDA

51OIPG

MCU_SDA

GPIO1

3

7

HDR 2X4

V_SW1

6

8

10

V_SW1

V_SW4

V_SW2

V_SW4

V_SW2

V_SW3

V_SW3

3V3

C5

2

3V3

MCU_SCL

4

65

EN

8

GPIO2

0.1UF

MCU_SCL 3,5

EN 3,5

GPIO2 5

Page 20

Schematic

Default:

2-3 shunt

Ohm

90

Ohm

90

USB SECTION

USB_GND

VUSB

VUSB_L

USB_DN

USB_DP JM60_USB_DP

JM60_USB_DN

USB_PWR

USB_PWR

PVIN

VIN_USB

JM60_USB_DN 5

JM60_USB_DP 5

R16 33

R17 33

L5

HI1812V101R-10

1

2

J25

HDR 1X3

123

GDI+D-DSUBV

USB-MiniB

J28

1

2

3

4

S2

5

S1

S3S4

+

C50

10UF

L6

HI1812V101R-10

1

2

F1

0.5A

12

C73

0.1uF

ESD PROTECTION

ID1

IDO

MCU_SCL

MCU_SDA

D6

ESD9L5.0ST5G

ESD9L5.0ST5G

A C

Layout Note :

Place the ESD diodes on

the bottom si de of the PCB.

5,3NE

MCU_SCL

3,5

C72

MCU_SDA3,5

0.1uF

51OIPG

52OIPG

D7

A C

R20 0

R19 0

RST_JM60_B

BKGD_JM60

ESD9L5.0ST5G

D8

A C

EN

ID1

IDO

MCU_SCL

MCU_SDA

LED INDICATORS

USB_PWR USB_PWR

Y1

12MHz

AC

D5

LED Red

R15

470

C67

12PF

C68

12PF

AC

D4

LED Green

D9

ESD9L5.0ST5G

A C

PTD0GPIO1

PTD1GPIO2

C70

0.1uF

U2

24

PTA0

25

PTA5

26

PTB0/MISO2/ADP0

27

PTB1/MOSI2/ADP1

28

PTB2/SPSCK2/ADP2

29

PTB3/SS2/ADP3

30

PTB4/KBIP4/ADP4

31

PTB5/KBIP5/ADP5

44

PTC0/SCL

45

PTC1/SDA

46

PTC2

47

PTC3/TxD2

1

PTC4

48

PTC5/RxD2

32

PTD0/ADP8/ACMP+

33

PTD1/ADP9/ACMP-

36

PTD2/KBIP2/ACMPO

37

PTD7

2

IRQ/TPMCLK

3

RESET

40

BKGD/MS

MC9S08JM60CGTE

C69

0.1uF

17

34

VDD

PTE2/TPM1CH0

PTE3/TPM1CH1

VDDAD/VREFH

PTF0/TPM1CH2

PTF1/TPM1CH3

PTF4/TPM2CH0

PTF5/TPM2CH1

VSS

VSSAD/VREFL

VSSOSC

GND

18

35

43

49

C76

0.1uF

PTE0/TxD1

PTE1/RxD1

PTE4/MISO1

PTE5/MOSI1

PTE6/SPSCK1

PTE7/SS1

PTF6

PTG0/KBIP0

PTG1/KBIP1

PTG2/KBIP6

PTG3/KBIP7

PTG4/XTAL

PTG5/EXTAL

VUSB33

USBDN

USBDP

VIN_USB

+

C78

10UF

Layout Note :

Place this JM60 MCU

on the bottom si de of the PCB.

9

10

11

LD0_3V3_EN

12

LED_GRN_ON

13

LED_RED_ON

14

15

16

4

5

6

7

8

22

23

38

39

41

42

21

VUSB33

19

20

LD0_3V3_EN 5

VUSB33

C77

0.47UF

VUSB33

R14

470

LED_GRN_ON

LED_RED_ON

XTAL_JM60

EXTAL_JM60

+

C75

4.7UF

CRYSTAL SECTION

12

GND2

R18

GND1

1M

3 4

Layout Note :

Place the crstal section on the

bottom side of the PCB as close

as possible to the JM60 MCU.

BKGD_JM60

20 Freescale Semiconductor, Inc.

Figure 16. KITVR500EVM Control/programming Interface Schematic

BDM PROGRAMMER

USB_PWR USB_PWR

R12

4.7K

J26

1 2

3 4

HDR 2X3

65

USB_PWR

RST_JM60_B

R13

4.7K

KTVR500UG Rev. 1.0 8/2014

R24

R23

1.5K

1.5K

DNP

DNP

90

Ohm

JM60_USB_DN

JM60_USB_DP

JM60_USB_DN 5

JM60_USB_DP 5

Page 21

6 Board Layout

KITVR500EVM

6.1 Silkscreen

Board Layout

Freescale Semiconductor, Inc. 21

KTVR500UG Rev. 1.0 8/2014

Page 22

Board Bill of Materials

7 Board Bill of Materials

Table 8. Bill of Materials

Item Qty Schematic Label Value Description Part Number

Active Components

11U1

21U2

31U3

4 1 Y1 12 MHz

Mounting Hole

54

Capacitors

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Diodes

25

3 D1,D2,D5 LED Red LED RED SGL 30MA 0603 SML-LXFM0603SIC-TR

26

1 D3

BH1,BH2,BH3,BH4

C1,C13,C14,C15,C20,C

26,C27,C36,C42,C43,C4

16

4,C45,C46,C47,C48,C49

C2,C7,C29,C31,C33,C5

9

1,C52,C54,C63

1 C3 1.0 F CAP CER 1.0 F 10V 10% X5R 0402 CC0402KRX5R6BB105

3 C4,C10,C32 2.2 F CAP CER 2.2 F 6.3 V 20% X5R 0402 C0402C225M9PACTU

C5,C6,C18,C21,C35,C3

11

7,C55,C57,C59,C61,C65

1 C8 0.47 F CAP CER 0.47 F 16 V 10% X5R 0402 C1005X5R1C474K

C9,C11,C12,C16,C22,C

23,C24,C25,C28,C30,C3

14

8,C39,C40,C41

C17,C19,C56,C58,C60,

7

C64,C66

2 C34,C62 4.7 F CAP CER 4.7 F 6.3 V 20% X5R 0402 C0402X5R6R3-475MNP

2 C50,C78 10 F CAP TANT 10 F 16 V 10% -- 3216-18 TAJA106K016R

1 C53 0.22 F CAP CER 0.22 F 16 V 10% X7R 0402 GRM155R71C224KA12D

2 C67,C68 12 PF CAP CER 12 PF 25 V 5% C0G 0402 CC0402JRNPO8BN120

5 C69,C70,C72,C73,C76 0.1 F CAP CER 0.1 F 16 V 10% X5R 0402 C1005X5R1C104K

1 C71 470 PF CAP CER 470 PF 50 V 5% COG 0603 06035A471JAT2A

1 C74 2.2 F CAP CER 2.2 F 16 V 10% X5R 0603 GRM188R61C225KE15D

1 C75 4.7 F CAP TANT 4.7 F 10 V 10% -- 3216-18 T491A475K010AT

1 C77 0.47 F CAP CER 0.47 F 16V 10% X7R 0603 C0603C474K4RAC

1 C79 1.0 F CAP CER 1.0 F 16 V 10% X5R 0603 C1608X5R1C105K

1 C80 2.2 F

(1)

Freescale IC POWER MANAGEMENT

COMMUNICATION -0.3-4.8 V QFN56

Freescale IC MCU 8-bit 48 MHZ 60 KB

FLASH 2.7-5.5V QFN48

Micrel IC LIN VREG LDO 1.5-15 V 150

MA 2.5-16 V SOT23-5

Aker XTAL 12 MHZ 12PF -- 3.2X2.5MM

SMT

MOUNTING HOLE 0.130 INCH, no part

to order

22 F CAP CER 22 F 10 V 20% X5R 0805 LMK212BJ226MG-T

1.0 F CAP CER 1.0 F 10 V 10% X5R 0402 CC0402KRX5R6BB105

0.1 F CAP CER 0.1 F 10 V 10% X5R 0402 C0402C104K8PAC

22 F CAP CER 22 F 10 V 20% X5R 0805 LMK212BJ226MG-T

4.7 F CAP CER 4.7 F 10 V 10% X5R 0603 LMK107BJ475KA-T

CAP TANT ESR=1.800 OHMS 2.2 F

10 V 10% 3216-18

LED_RED-GR

N

LED DUAL GRN/RED 30MA SMT LTST-C195KGJRKT

MC34VR500V1ES

MC9S08JM60CGTE

MIC5205YM5

C3E-12.000-12-3030-R

TPSA225K010R1800

Assy

Opt

(3)

(3)

(3)

(3)

(2)

(2)

(3)

(2)

22 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 23

Board Bill of Materials

Table 8. Bill of Materials

(1)

(continued)

Item Qty Schematic Label Value Description Part Number

27

1 D4 LED Green LED GRN SGL 30MA SMT 0603 SML-LXFM0603SUGCTR

28

4 D6,D7,D8,D9

ESD9L5.0ST5GDIODE TVS ESD PROT ULT LOW

CAP 5-5.4V SOD-923

ESD9L5.0ST5G

Resistors

29

30

31

32

33

34

35

36

37

38

39

40

4 R1,R2,R3,R4 200 RES MF 200 1/10W 1% 0402 ERJ2RKF2000X

4 R5,R6,R12,R13 4.7 K RES MF 4.7 K 1/16W 1% 0402 RK73H1ETTP4701F

2 R7,R18

2 R8,R10

1.0 M

10 K

RES MF 1.0 M 1/16W 1% AEC-Q200

0402

RES MF 10 K 1/16W 1% AEC-Q200

0402

CRCW04021M00FKED

CRCW040210K0FKED

1 R9 100 K RES MF 100 K 1/16W 5% 0402 RK73B1ETTP104J

1 R11 ZERO RES MF ZERO 1/10W 1% 0603 MC0603SAF0000T5E

2 R14,R15 470 RES MF 470 1/16W 1% 0402 CR-02FL6--470R

2 R16,R17 33 RES MF 33 1/16W 1% 0402 CR-02FL6---33R

2 R19,R20 ZERO RES MF ZERO 1/10W -- 0402 ERJ-2GE0R00X

1 R21 12 K RES MF 12 K 1/10W 1% 0603 RK73H1JTTD1202F

1 R22 20 K RES MF 20 K 1/10W 5% 0603 CR0603-JW-203ELF

2 R23,R24

1.5 K

RES MF 1.5 K 1/16W 5% 0402 CRCW04021K50JNED

Inductors

41

42

43

44

45

1 L1 1 H

1 L2 1 H

1 L3 1 H

1 L4 1 H

2 L5,L6

HI1812V101R10

Coilcraft IND PWR 1 H@100 KHz 6 A

20% SMT

Coilcraft IND PWR 1 H@100 KHZ

2.65 A 20% SMT

TDK IND PWR 1 H@1 MHZ 2 A 30%

SMT

Coilcraft IND PWR 1 H@100 KHZ 2.4

A 30% SMT

IND FER 100 @100 MHZ 8 A 25%

SMD/1812

XAL4020-102MEC

LPS5015-102MLC

VLS252010T-1R0N

LPS4012-102NLC

HI1812V101R-10

Switches, Connectors, Jumpers, and Test Points

46

1 F1

0.5 A

FUSE PLYSW 0.5A 13.2V SMT MICROSMD050F-2

SUBASSEMBLY HDR 1X3 TH 197MIL

47

6 J1,J4,J5,J18,J21,J27

SUB_TB_3X1

374H SN 138L + CON 1X3 PLUG TB

210-80542,211-79574

TH 5MM 449H

SUBASSEMBLY HDR 1X2 TH 197MIL

48

6 J2,J3,J29,J30,J31,J32

SUB_TB_2X1

374H SN 138L + CON 1X2 PLUG TB

210-80539,211-79573

TH 5MM 449H

49 12

50 3

51 2

52 1

53 1

54 1

J6,J7,J8,J9,J10,J11,J12,

J13,J14,J16,J23,J24

J15,J17,J22

J19,J26

J20

J25

J28

HDR 1X2 TH

HDR 2X2

HDR 2X3

HDR 2X4

HDR 1X3

USB-MiniB

HDR 1X2 TH 100MIL SP 339H AU 118L 210-91-02GB01

HDR 2X2 TH 100MIL CTR 340H SN

105L

HDR 2X3 TH 100MIL CTR 335H AU

95L

HDR 2X4 TH 100MIL CTR 425H AU

310L

5-146258-2

TSW-103-07-S-D

TSW-104-16-G-D

HDR 1X3 TH 100MIL SP 340H AU 118L M20-9990345

CON 5 USB MINI-B RA SHLD SKT

SMT 31MIL SP AU

675031340

Assy

Opt

(2)

(3)

(3)

(3)

(3)

Freescale Semiconductor, Inc. 23

KTVR500UG Rev. 1.0 8/2014

Page 24

Board Bill of Materials

Table 8. Bill of Materials

Item Qty Schematic Label Value Description Part Number

55 3

56 1

57 2

58 1

59 42

Notes

1. Freescale does not assume liability, endorse, or warrant components from external manufacturers are referenced in circuit drawings or tables.

While Freescale offers component recommendations in this configuration, it is the customer’s responsibility to validate their application.

2. Do not populate

3. Critical components. For critical components, it is vital to use the manufacturer listed.

J33,J34,J35

Q1

Q2,Q3

SW1

TP1,TP2,TP3,TP4,TP5,

TP6,TP7,TP8,TP9,TP10,

TP11,TP12,TP13,TP14,

TP15,TP16,TP17,TP18,

TP19,TP20,TP21,TP22,

TP23,TP24,TP25,TP26,

TP27,TP28,TP29,TP30,

TP31,TP32,TP33,TP34,

TP35,TP36,TP37,TP38,

TP39,TP40,TP41,TP42

(1)

(continued)

CON_2X10

FDC6327C

FDV302P

FSMSM

TEST POINT

RED

CON 2X10 SKT SMT 100MIL CTR

390H AU

TRAN MOSFET DUAL N & P

CHANNEL 2.5V S-SOT6

TRAN PMOS SW 120MA 25V SOT23 FDV302P

SW SPST PB 12V 50MA SMT 1437566-4

TEST POINT RED 40 MIL DRILL 180

MIL TH 109L

SSW-110-22-F-D-VS-N

FDC6327C

5000

Assy

Opt

(2)

(2)

24 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 25

8 References

Following are URLs where you can obtain information on related Freescale products and application solutions:

References

Freescale.com

Support Pages

KITVR500EVM Tool Summary Page

MC34VR500 Product Summary Page http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=MC34VR500

KTVR500SWUG Software User Guide

Description URL

http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=KITVR500EVM

http://cache.freescale.com/files/analog/doc/user_guide/KTVR500SWUG.pdf

8.1 Support

Visit www.freescale.com/support for a list of phone numbers within your region.

8.2 Warranty

Visit www.freescale.com/warranty for a list of phone numbers within your region.

Freescale Semiconductor, Inc. 25

KTVR500UG Rev. 1.0 8/2014

Page 26

Revision History

9 Revision History

Revision Date Description of Changes

1.0

8/2014 • Initial Release

26 Freescale Semiconductor, Inc.

KTVR500UG Rev. 1.0 8/2014

Page 27

How to Reach Us:

Home Page:

freescale.com

Web Support:

freescale.com/support

Information in this document is provided solely to enable system and software implementers to use Freescale products.

There are no express or implied copyright licenses granted hereunder to design or fabricate any integrated circuits based

on the information in this document.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes no

warranty, representation, or guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale data sheets and/or specifications can and do vary in different applications, and actual performance

may vary over time. All operating parameters, including “typicals,” must be validated for each customer application by

customer’s technical experts. Freescale does not convey any license under its patent rights nor the rights of others.

Freescale sells products pursuant to standard terms and conditions of sale, which can be found at the following address:

freescale.com/SalesTermsandConditions.

Freescale and the Freescale logo are trademarks of Freescale Semiconductor, Inc., Reg. U.S. Pat. & Tm. Off.

SMARTMOS is a trademark of Freescale Semiconductor, Inc. All other product or service names are the property of their

respective owners.

© 2014 Freescale Semiconductor, Inc.

Document Number: KTVR500UG

Rev. 1.0

8/2014

Loading...

Loading...