Page 1

Freescale Semiconductor

Document Number: KT33810UG

User’s Guide

KIT33810EKEVME Evaluation Board

User’s Guide

Rev. 3.0, 5/2010

Figure 1. KT33810 Evaluation Board

Table of Contents

1 Important Notice..................................................................................................................................................... 2

2 Introduction............................................................................................................................................................. 3

3 Schematic............................................................................................................................................................... 9

4 KIT33810EKEVME Bill of Material ......................................................................................................................... 10

© Freescale Semiconductor, Inc., 2010. All rights reserved.

Page 2

Important Notice

1 Important Notice

Freescale provides the enclosed product(s) under the following conditions:

This evaluation kit is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY. It

is provided as a sample IC pre-soldered to a printed circuit board to make it easier to access inputs, outputs, and

supply terminals. This EVB may be used with any development system or other source of I/O signals by simply

connecting it to the host MCU or computer board via off-the-shelf cables. This EVB is not a Reference Design and is

not intended to represent a final design recommendation for any particular application. Final device in an application

will be heavily dependent on proper printed circuit board layout and heat sinking design as well as attention to supply

filtering, transient suppression, and I/O signal quality.

The goods provided may not be complete in terms of required design, marketing, and or manufacturing related

protective considerations, including product safety measures typically found in the end product incorporating the

goods. Due to the open construction of the product, it is the user's responsibility to take any and all appropriate

precautions with regard to electrostatic discharge. In order to minimize risks associated with the customers

applications, adequate design and operating safeguards must be provided by the customer to minimize inherent or

procedural hazards. For any safety concerns, contact Freescale sales and technical support services.

Should this evaluation kit not meet the specifications indicated in the kit, it may be returned within 30 days from the

date of delivery and will be replaced by a new kit.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes no

warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale assume any liability arising out of the application or use of any product or circuit, and specifically disclaims

any and all liability, including without limitation consequential or incidental damages. “Typical” parameters can and

do vary in different applications and actual performance may vary over time. All operating parameters, including

“Typical”, must be validated for each customer application by customer’s technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale products are not

designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other application in which the failure of the Freescale

product could create a situation where personal injury or death may occur. Should Buyer purchase or use Freescale

products for any such unintended or unauthorized application, Buyer shall indemnify and hold Freescale and its

officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Freescale was negligent

regarding the design or manufacture of the part.Freescale™ and the Freescale logo are trademarks of Freescale

Semiconductor, Inc. All other product or service names are the property of their respective owners. © Freescale

Semiconductor, Inc., 2010. All rights reserved.

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

2 Freescale Semiconductor

Page 3

2 Introduction

The KIT33810EKEVME Evaluation Board (EVB) is an easy-to-use circuit board that allows the user to exercise all

functions of the MC33810 circuit. The EVB communicates to a PC through a built in USB port. The Freescale SPIGen

program provides the User Interface to the MC33810’s SPI port and allows the user to send commands to and

receive error messages from the IC. The MC33810 contains four, low side, injector drivers and four custom ignition

IGBT drivers (which can also be configured as General Purpose MOSFET Gate drivers) . The IGBTs and the

associated current and voltage sensing circuits are included on the board to provide a complete working system,

capable of driving actual injectors and ignition coils directly.

Introduction

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

Freescale Semiconductor 3

Page 4

Introduction

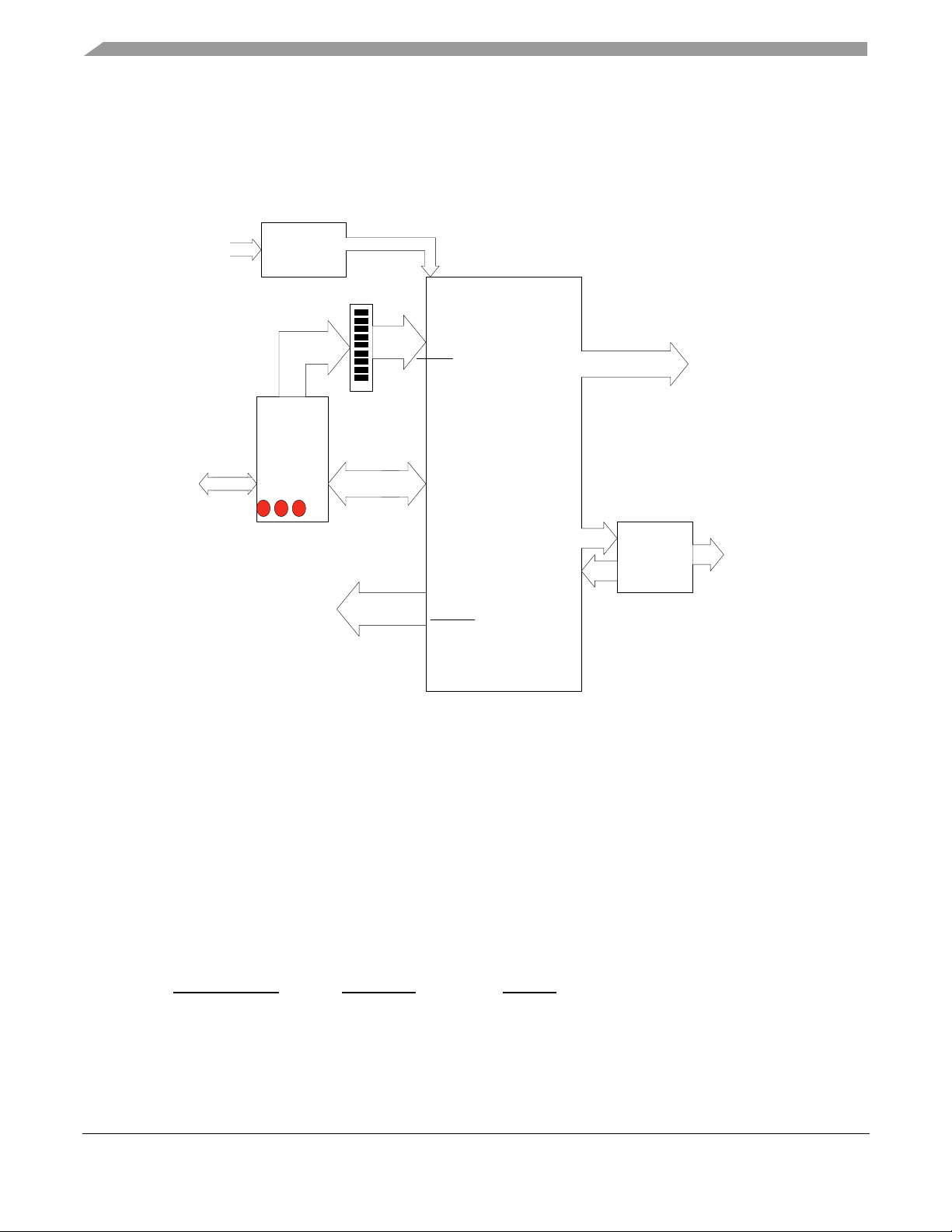

The Block Diagram for the 33811 Evaluation Board is shown below:

VBat

USB FROM/

TO PC

Voltage Regulat or and

Power Con diti oning

9 parall el

control lines

USB

To SPI

LEDs

TO MCU

Jumpers

SO, SI , CSB,

SCLK

2

VPWR,

MC33810

VDD

9

DI N1-3

GI N1- 3

OUTE N

OUT1- 3

4

Injectors

SPI

4

Por t

Spark Coils

4

GD1- 3

4

FB1-3

NOMI

3

MAXI

RSP, RSN

IGBTs (4)

And I/V Sense

6

Ignition

Ci rcu it r y

SPKDUR

Figure 1. EVB Block Diagram

The EVB consists of a 33810 Injector, Ignition Driver (IID) circuit, a USB to SPI interface, a voltage regulator and

power conditioning circuit, a set of 9 Input Jumpers, and 4 IGBTs with voltage and current sensing circuitry. All 5 volt

power required by the EVB is obtained from either the USB, MON08 connectors or the on-board 5 Volt regulator . A

5 position jumper selects which source provides the 5 volt power for VCC (and VDD).

LED DISPLAY

The LED’s are provided as a visual output device for the USB-SPI interface. As configured from the factory, LED 2

indicates when power is applied and a USB connection is established, and LED 1 and 3 are tied to the DATA0 and

CNTL0 lines, respectively, which can be toggled via the SPIGen program.

I/O JUMPER DEFINITIONS (J3)

The EVB contains nine jumpers that connect the parallel outputs of the USB SPI interface to the 33810 inputs as

follows:

USB-SPI Output 33810 Input Function

DATA0 DIN0 Injector Input 0

DATA1 DIN1 Injector Input 1

DATA2 DIN2 Injector Input 2

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

4 Freescale Semiconductor

Page 5

DATA3 DIN3 Injector Input 3

CNTL0 GIN0 Ignition Input 0

CNTL1 GIN1 Ignition Input 1

CNTL2 GIN2 Ignition Input 2

CNTL3 GIN3 Ignition Input 3

DATA4 OUTEN

If the user prefers to supply the DIN and GIN signals externally, other than from the USB-SPI Interface, the jumpers

can be removed and connections can be made to the open pins.

VCC SELECT JUMPER DEFINITIONS (JP2)

JP2 is a 5 pin, 4 position jumper that determines the source of the VCC voltage. The VCC voltage is a 5 volt supply

that is used by the USB to SPI MCU and the 33810 (VDD). The 5 volts can be supplied from three different sources:

1) An internal 5 Volt regulator connected to VBAT (12 Volts)

2) Directly from the USB Connector

3) Directly from the on board MON08 connector.

Jumper Position VCC Source

1-2 MON08 Port (used for programming the MCU)

2-3 USB Port

3-4 USB Port

4-5 Internal Voltage Regulator *

*The factory default is set to the Internal Voltage Regulator position.

Introduction

Output Enable Signal

VDD SELECT JUMPER DEFINITIONS (JP4) -

The VDD jumper is a 3 pin, two position jumper that allows the 33810 to receive 5 volt VDD power from the EVB VCC

line or to connect the 33810 VDD line to Ground to demonstrate the “Sleep Mode”. The Normal Operating Setting

(factory default) is the VDD to VCC connection, pins 1-2 shorted, pin 3 open.

When JP4 is on pins 2-3, with pin 1 open, the 33810 will be forced into the Sleep Mode. (see data sheet for more

information)

VOLTAGE REGULATOR DISCONNECT JUMPER (JP1)

The internal voltage regulator can be disconnected from VPWR to allow the 33810 I

normally connects VPWR to the input of the 5 Volt regulator.

to be measured. JP1

VPWR

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

Freescale Semiconductor 5

Page 6

Introduction

MON08 CONNECTOR

The MON08 connector is used to program the USB-SPI MCU, a MCHC908JW32. The source code for the USB-SPI

interface is included on the CD to allow reprogramming of the MCU to perform functions not included in the present

firmware. The MON08 connector consists of the following 16 pins –

Pin Number Name Description

1 NC Unused

2 GND VSS (System Gnd)

3 NC Unused

4RST Reset

5 NC Unused

6 IRQB Interrupt Request (Low active)

7 NC Unused

8 NC Unused

9 NC Unused

10 PTA0 Port A Bit 0

11 NC Unused

12 PTA1 Port A Bit 1

13 OSC 4.9152 MHz Oscillator

14 PTA2 Port A Bit 2

15 MON08_VCC +5 Volts from P & E or FSICE

16 PTC1 Port C Bit 1

This connector mates with the MON08 cable provided with the P & E Cyclone Pro or Freescale FSICEBASE

programmer.

USB CONNECTOR

A “B” type USB connector is provided to allow a standard “A to B” USB cable to interconnect the PC to the EVB. The

pinout of this connector is as follows:

Pin Number Name Description

1 +5 +5 Volts from the PC

2 D- Signal - line

3 D+ Signal + line

4 GND System ground (VSS)

OSCILLATOR JUMPER SELECTS (JP3)

A two position, three pin jumper, labeled JP3 is provided to allow the selection of the clock source for the USB-SPI

MCU.

JP3 selects the source of the MCU Oscillator (+5 volts) in accordance with the following table:

Position of Oscillator Shorting Jumper Selection Description

Pins 1 & 2 (Pin 3 open) Programming position, Clock = 4.9152 from MON08

Pins 2 & 3 (Pin 1 open) Normal operating position* Clock = 4.000 MHz crystal

*The factory default setting for JP3 is the Normal operating position. To change the programming of the MCU’s flash

RAM, this jumper must be moved to the Programming position, the VCC jumper should be set to the MON08 position

and the MON08 connector should be attached to the cable from the P & E Cyclone Pro or the Freescale FSICEBASE

unit.

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

6 Freescale Semiconductor

Page 7

SPI PORT CONNECTION PINS

The SPI port is brought out to four pins (SCLK, SI, SO, CSB) on the EVB.

Normally there is no jumpers on these pins, however to verify the proper operation of the SPI interface, the SI and

SO pins can be connected via a jumper to allow loopback testing of the USB-SPI interface. Please note that during

this loopback mode of operation, the 33810 outputs must be disabled, by setting

33810 in the Sleep Mode by Connecting JP4 to GND.

SOFTWARE DESCRIPTION

There are three main components that comprise the EVB software system.

1. The firmware that runs on the MCU is a compiled C and assembly language program, that is programmed into

the MCU flash RAM.

2. The user interface software (GUI) that sends USB messages to the EVB, and runs under Windows 2000 or

Windows XP, is called the “SPIGen” program, which is written in Visual Basic. A SPIGen “config” file for the

MC33810 is included on the CD.

3. The third piece of software is a “device driver” called spi_usbio.sys and it interfaces the SPIGen program I/O

through the Windows operating system to the USB port on the user’s PC. The device driver interfaces to the

Visual Basic program, through a special “wrapper” library called usbiocom.dll that translates the Visual Basic

COM interface, into the lower level calls in the device driver. These two pieces of software were licensed from

Thesycon, a software development company in Germany.

All of the source code that is available is provided on the Installation CD in a folder called “USB_SPI_FINAL”.

For an explanation of the SPIGen program, the user is referred to the documentation that comes with the disk for that

program.

Introduction

OUTEN to high or by placing the

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

Freescale Semiconductor 7

Page 8

Introduction

MCU SOFTWARE CODE

The software for the MCU was written in C and HC08 assembly language using the CodeWarrior version 5.0 software

integrated development environment (IDE).

Below is a listing of the source code modules and their descriptions:

main.c Beginning module, contains service loop.

main.asm Generated by CodeWarrior, used for additions to main.c written in

MC68HC908JW32.C Defines the 16 and 8 Bit Registers

constant.c Random data to fill unused flash RAM

isr.c Interrupt service routine for the timer

pll.asm Sets up the PLL using 4.00 MHz reference frequency

spi.c SPI read and write handlers and initialization routine

tb.c Initializes the time base for the JW32

timer.c Initializes the timer and PWM output (not used)

USB_descriptor.asm Defines the USB information such as VID, PID, etc.

USB_driver.c Handles USB setup, decode and interrupt service

utilities.c Misc. routines for delay and debug

The following files are include (header) files to support the above:

application.h defines some outputs and some useful macros

derivative.h Generated by CodeWarrior to define the MCU used

derivative.inc Generated by CodeWarrior for COP

global.h Some useful defines for debug

jw32_registers.h More register definitions

main_asm.h header file for main_asm.c

MC68HC908JW32.H Header file for MC68HC908JW32.C

motdef.h General purpose definitions from the old days

pll.h Header file for pll.c

spi.h Header file for spi.c

tb.h Header file for tb.c Timebase

timer.h Header file for timer.c timer initialization

usb.h Header file for USB_driver.c

usb_vars.h Header for variables used in USB_Driver.c

utilities.h Header for utilities.c

ansii.lib c library for ansii c functions

Start08.c Generated by CodeWarrior to define initialization code

Project.prm Defines interrupt and memory map

Project.map Map file generated by compile process

Burner.bbl some defines used in the programming of the JW32

assembly language.

MODIFYING AND ADDING TO THE SOFTWARE -

To modify and recompile this software, one must download a copy of the CodeWarrior software development suite

(IDE) from Freescale. The link to this software is:

http://www.freescale.com/CodeWarrior

The USB to SPI software transfers 8 bytes of data from the SPIGen.exe program, via USB, to the MCU. The

definitions of the 8 bytes can be found in the main.c program, and the actual transfer and decoding is done in the

USB_driver.c program. Comments are provided throughout the code to explain the operation of the individual

routines.

Once the code is compiled (without errors), the CodeWarrior IDE provides a means to download the binaries to the

P&E Cyclone Pro programmer, via the MON08 port to re-Flash the MCU. The documentation for this process is

contained in the CodeWarrior suite of tools and the P&E documentation.

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

8 Freescale Semiconductor

Page 9

Schematic

3 Schematic

Figure 2. Schematic

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

9 Freescale Semiconductor

Page 10

KIT33810EKEVME Bill of Material

4 KIT33810EKEVME Bill of Material

Schematic

Designation

C1 VBAT CAP ALEL 10UF 50V 20% -- CCE63X57 ROHS

C2 OSC2 CAP CERAMIC 27PF 50V NP0 0805 KEMET C0805C270J5GACTU 399-1114-2-ND

C3 OSC1 CAP CERAMIC 27PF 50V NP0 0805 KEMET C0805C270J5GACTU 399-1114-2-ND

C4 VBAT CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C5 VDD CAP TANT 10UF 10V 10% -- CASE_A ROHS VISHAY INTERTECH-

C6 VDD CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C7 VPWR CAP CER 0.1UF 50V 10% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C8 CGMXFC CAP CER 100PF 50V 10% COG 0603 ROHS AVX 06035A101KAT2A 478-3717-1-ND

C9 CGMXFC CAP CER 0.022UF 25V 10% X7R CC0603 AVX 06033C223KAT2A NA

C10 REG2.5V CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C11 REG3.3V CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C12 REG3.3V CAP TANT 10UF 10V 10% -- CASE_A ROHS VISHAY INTERTECH-

C13 VDD PLL CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C14 VR_OUT CAP TANT 10UF 10V 10% -- CASE_A ROHS VISHAY INTERTECH-

C15 VPWR CAP CER 0.1UF 50VDC 10-% X7R CC0603 VENKEL COMPANY C0603X7R500104KNE 445-1314-1-ND

C16 VDD CAP CER 0.1UF 50VDC 10-% X7R CC0603 TDK C1608X7R1H104K 445-1314-1-ND

C17 OUT_1 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C18 OUT_2 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C19 OUT_3 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C20 OUT_4 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C21 MAXI CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C22 NOMI CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C23 SPKDURB CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C24 DIN_1 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C25 DIN_2 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C26 DIN_3 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C27 GIN_0 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C28 GIN_1 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C29 GIN_2 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C30 GIN_3 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C31 DIN_0 CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C32 OUT_ENB CAP CER 0.01UF 50V 10% X7R 0805 SMEC MCCE103K2NRTF NA

C33 ACROSS R12 CAP CER 100PF 50V 5% C0G CC0805, ROHS

C34 ACROSS R13 CAP CER 10PF 50V 5% C0G CC0805 AVX 08055A100JAT2A

C35 ACROSS R14 CAP CER 10PF 50V 5% C0G CC0805 AVX 08055A100JAT2A

C36 ACROSS R15 CAP CER 10PF 50V 5% C0G CC0805 AVX 08055A100JAT2A

C37 ACROSS R16 CAP CER 10PF 50V 5% C0G CC0805 AVX 08055A100JAT2A

R1 D- RES TF 27 1/10W 1% RC0603 ROHS COMPLIANT BOURNS CR0402JW270GLF NA

R2 D+ RES TF 27 1/10W 1% RC0603 ROHS COMPLIANT BOURNS CR0402JW270GLF NA

R3 D- RES TF 1.50K 1/10W 1% RC0603 ROHS COMPLI-

R4 OSC1 OSC2 RES TF 10M 1/8W 5% RC0805, ROHS COMPLIANT BOURNS CR0805JW106ELF NA

R5 CGMXFC RES TF 2.2K 1/10W 5% RC0603 ROHS COMPLI-

R6 +5V JUMPER WIRE WITH FERRITE BEAD

Device or

Signal Name

Description Mfr. Part Nam Mfr. Part Number Digi-Key Part #

PANASONIC ECEV1HA100SP PCE3089TR-ND

COMPLIANT

293D106X9010A2TE3 NA

NOLOGY

293D106X9010A2TE3 NA

NOLOGY

293D106X9010A2TE3 NA

NOLOGY

AVX 08055A101JAT2A

COMPLIANT

BOURNS CR0603FX1501ELF NA

ANT

BOURNS CR0603JW222ELF NA

ANT

STEWARD 28L0138-40R-10 240-2439-2-ND

28L0138-40R-10

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

10 Freescale Semiconductor

Page 11

KIT33810EKEVME Bill of Material

Schematic

Designation

R7 GND JUMPER WIRE WITH FERRITE BEAD

R8 LED1 RES TF 470 1/4W 5% RC1206 ROHS COMPLIANT BOURNS CR1206JW471ELF NA

R9 LED2 RES TF 470 1/4W 5% RC1206 ROHS COMPLIANT BOURNS CR1206JW471ELF NA

R10 LED3 RES TF 470 1/4W 5% RC1206 ROHS COMPLIANT BOURNS CR1206JW471ELF NA

R11 RSN ISO RES 100 OHM 1/10W 5% 0603 SMD YAGEO RC0603JR-07100RL 311-100GRCT-ND

R12 RSP/RSN RESISTOR .020 OHM 1W 1% 2512 Panasonic ECG ERJ-M1WSF20MU P20MCT-ND

R13 COIL0 RES 36.0K OHM 1W 1% 2512 SMD Vishay/Dale CRCW251236K0FKEG CRCW251236K0FKE

R14 COIL1 RES 36.0K OHM 1W 1% 2512 SMD Vishay/Dale CRCW251236K0FKEG CRCW251236K0FKE

R15 COIL2 RES 36.0K OHM 1W 1% 2512 SMD Vishay/Dale CRCW251236K0FKEG CRCW251236K0FKE

R16 COIL3 RES 36.0K OHM 1W 1% 2512 SMD Vishay/Dale CRCW251236K0FKEG CRCW251236K0FKE

R17 FB2 RES 4.02K OHM 1/4W 1% 1206 SMD YAGEO RC1206FR-074K02L 311-4.02KFRCT-ND

R18 FB3 RES 4.02K OHM 1/4W 1% 1206 SMD YAGEO RC1206FR-074K02L 311-4.02KFRCT-ND

R19 FB0 RES 4.02K OHM 1/4W 1% 1206 SMD YAGEO RC1206FR-074K02L 311-4.02KFRCT-ND

R20 FB1 RES 4.02K OHM 1/4W 1% 1206 SMD YAGEO RC1206FR-074K02L 311-4.02KFRCT-ND

R21 RSP ISO RES 100 OHM 1/10W 5% 0603 SMD YAGEO RC0603JR-07100RL 311-100GRCT-ND

X1 VBAT MKDS 3 CONN TERM BLOCK 2POS 5MM PCB

JP1 VR INPUT 2 pin HDR 1X10 100MIL CTR LOW PROFILE

JP2 VDD SELECT 3 pin HDR 1X10 100MIL CTR LOW PROFILE

J1 USB USB B PC MOUNT FEMALE CONNECTOR ROHS

J2 SPI 4 pin HDR 1X10 100MIL CTR LOW PROFILE

J3 INPUT

J4 MON08

J5 VCC 1 pin HDR 1X10 100MIL CTR LOW PROFILE

J6 VPWR 1 pin HDR 1X10 100MIL CTR LOW PROFILE

J7 GND 1 pin HDR 1X10 100MIL CTR LOW PROFILE

J10 COIL 0-3 OUT 5 pin HDR 1X10 100MIL CTR LOW PROFILE

J11 OUT 0 - 3 4 pin HDR 1X10 100MIL CTR LOW PROFILE

J12 NOMI, MAXI,

JP1 INT. REG.

JP2 VCC SELECT 5 pin HDR 1X10 100MIL CTR LOW PROFILE

JP3 OSC SELECT 3 pin HDR 1X10 100MIL CTR LOW PROFILE

JP4 VDD SELECT 3 pin HDR 1X10 100MIL CTR LOW PROFILE

U1 VDD REG IC REG LDO 100MA 5V TO92 LM2931AZ50R ST MICROELEC-

U2 MICRO MCHC908JW32FC 8 bit USB/SPI microcontroller

Device or

Signal Name

MATRIX

Header

SPKDURB

DISC.

Description Mfr. Part Nam Mfr. Part Number Digi-Key Part #

28L0138-40R-10

ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

COMPLIANT

BREAKAWAY ROHS COMPLIANT

18 pin HDR 2X10 100MIL CTR LOW PROFILE

BREAKAWAY ROHS COMPLIANT

16 pin HDR 2X10 100MIL CTR LOW PROFILE

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

4 pin HDR 1X10 100MIL CTR LOW PROFILE

BREAKAWAY ROHS COMPLIANT

2 pin HDR 1X10 100MIL CTR LOW PROFILE

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

BREAKAWAY ROHS COMPLIANT

ROHS COMPLIANT

STEWARD 28L0138-40R-10 240-2439-2-ND

G-ND

G-ND

G-ND

G-ND

PHOENIX CONTACT 1711026 277-1022-ND

TYCO ELECTRONICS

TYCO ELECTRONICS

MOLEX/WALDOM

ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TYCO ELECTRONICS

TRONICS

FREESCALE SEMICONDUCTOR

87220-2 A26542-ND

87220-3 A26544-ND

67068-8000 WM17113-ND

87220-4 A26546-ND

9-146261-0-09 A34268-09-ND

9-146261-0-08 A34268-08-ND

87220-1 A26540-ND

87220-1 A26540-ND

87220-1 A26540-ND

87220-5 A26548-ND

87220-4 A26546-ND

87220-4 A26546-ND

87220-2 A26542-ND

87220-5 A26548-ND

87220-3 A26544-ND

87220-3 A26544-ND

LM2931AZ50R 497-4262-1-ND

MC68HC908JW32

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

11 Freescale Semiconductor

Page 12

KIT33810EKEVME Bill of Material

Schematic

Designation

U3 IID MC33810 Engine Control IC FREESCALE SEMI-

Q1 IGBT IRGS14C40L IGBTPbF 14 Amp 430 V TO-263AB

Q2 IGBT IRGS14C40L IGBTPbF 14 Amp 430 V TO-263AB

Q3 IGBT IRGS14C40L IGBTPbF 14 Amp 430 V TO-263AB

Q4 IGBT IRGS14C40L IGBTPbF 14 Amp 430 V TO-263AB

MOV-1 SURGE PRO-

D1 DIODE DIODE PWR RECT 1A 200V-- RECOVERY SMB -

LED1 LED LED RED SMT 0603 LITE ON LTST-C190KRKT 160-1436-1-ND

LED2 LED LED RED SMT 0603 LITE ON LTST-C190KRKT 160-1436-1-ND

LED3 LED LED RED SMT 0603 LITE ON LTST-C190KRKT 160-1436-1-ND

XTAL-1 OSC1 OSC2 XTAL 4.0MHZ RSN 50PPM TH CL=10PF ROHS FOX ELECTRONICS FOXSLF/040 631-1096-ND

Device or

Signal Name

TECTOR

Description Mfr. Part Nam Mfr. Part Number Digi-Key Part #

CONDUCTOR

package

package

package

package

MOV 50 VDC- ROHS COMPLIANT LITTLEFUSE V60MLA1210 F221CT-ND

ROHS COMPLIANT

INTERNATIONAL

RECTIFIER

INTERNATIONAL

RECTIFIER

INTERNATIONAL

RECTIFIER

INTERNATIONAL

RECTIFIER

ON SEMICONDUCTOR

MCZ33810EK

IRGS14C40L IGBTPbF IRGS14C40LPBF-ND

IRGS14C40L IGBTPbF IRGS14C40LPBF-ND

IRGS14C40L IGBTPbF IRGS14C40LPBF-ND

IRGS14C40L IGBTPbF IRGS14C40LPBF-ND

MURS120T3G MURS120T3GOS-ND

Freescale does not assume liability, endorse, or warrant components from external manufacturers that are referenced in circuit drawings or

tables. While Freescale offers component recommendations in this configuration, it is the customer’s responsibility to validate their application.

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

12 Freescale Semiconductor

Page 13

References

5 References

Following are URLs where you can obtain information on other Freescale products and application

solutions:

Products Links

Data Sheet MC33810 www.freescale.com/files/analog/doc/data_sheet/MC33810.pdf

Freescale’s Web Site www.freescale.com

Freescale’s Analog Web Site www.freescale.com/analog

Freescale’s Powertrain an Engine Control www.freescale.com/powertrain_and_engine_control

Freescale’s Automotive Applications www.freescale.com/automotive

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

13 Freescale Semiconductor

Page 14

Revision History

6 Revision History

REVISION DATE DESCRIPTION OF CHANGES

2.0

3.0

1/2010

5/2010

• Initial Release

• Added References Section, BOM and Revision History Section.

KIT33810EKEVME Evaluation Board User’s Guide, Rev. 3.0

14 Freescale Semiconductor

Page 15

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor China Ltd.

Exchange Building 23F

No. 118 Jianguo Road

Chaoyang District

Beijing 100022

China

+86 10 5879 8000

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or +1-303-675-2140

Fax: +1-303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and

software implementers to use Freescale Semiconductor products. There are

no express or implied copyright licenses granted hereunder to design or

fabricate any integrated circuits or integrated circuits based on the

information in this document.

Freescale Semiconductor reserves the right to make changes without further

notice to any products herein. Freescale Semiconductor makes no warranty,

representation or guarantee regarding the suitability of its products for any

particular purpose, nor does Freescale Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical” parameters that may be provided in Freescale

Semiconductor data sheets and/or specifications can and do vary in different

applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer

application by customer’s technical experts. Freescale Semiconductor does

not convey any license under its patent rights nor the rights of others.

Freescale Semiconductor products are not designed, intended, or authorized

for use as components in systems intended for surgical implant into the body,

or other applications intended to support or sustain life, or for any other

application in which the failure of the Freescale Semiconductor product could

create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended

or unauthorized application, Buyer shall indemnify and hold Freescale

Semiconductor and its officers, employees, subsidiaries, affiliates, and

distributors harmless against all claims, costs, damages, and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized

use, even if such claim alleges that Freescale Semiconductor was negligent

regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of

Freescale Semiconductor, Inc. All other product or service names

are the property of their respective owners.

© Freescale Semiconductor, Inc., 2010. All rights reserved.

KT33810UG

Rev. 3.0

5/2010

Loading...

Loading...