Page 1

Freescale Semiconductor, Inc.

© Freescale Semiconductor, Inc., 2013. All rights reserved.

User’s Guide

Document Number: KTXSWITCH4UG

Rev. 1.0, 11/2013

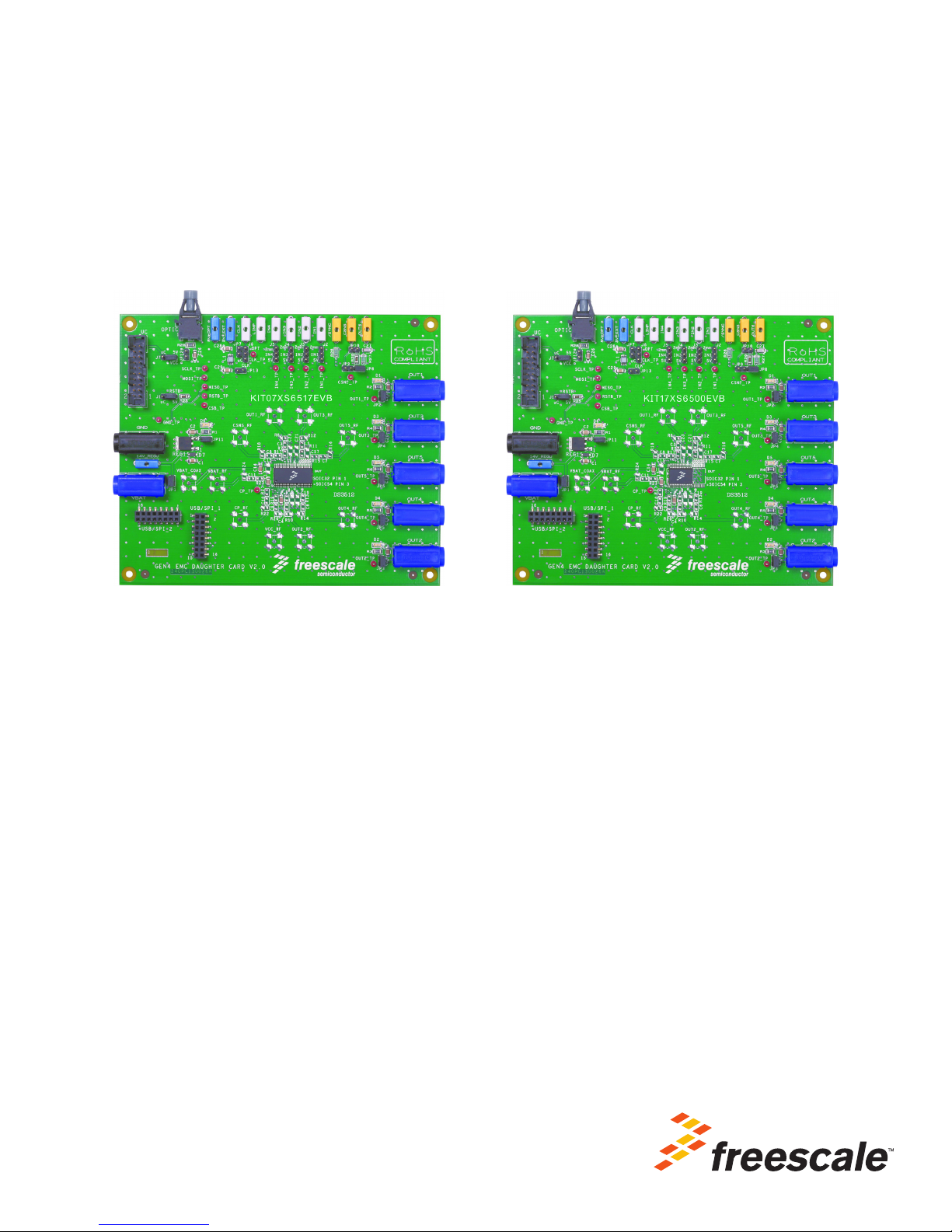

eXtreme Switch Gen4 Evaluation Board

Featuring the MC07XS6517 and MC17XS6500 Penta High Side Switch

Figure 1. eXtreme Switch Gen4 Evaluation Boards

Contents

1 Kit Contents/Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Jump Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Important Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 Evaluation Board Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 MC07XS6517 and MC17XS6500 Device Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

7 Accessory Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9 Evaluation Board Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 Installing SPIGen Freeware on your Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

11 Setting Up and Using the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

12 Evaluation Board Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

13 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

14 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

15 Bill of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

16 References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

17 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 2

Kit Contents/Packing List

Jump Start Your Design

1 Kit Contents/Packing List

• Assembled and tested evaluation board/module in anti-static bag.

• Warranty card

2Jump Start

•Go to www.freescale.com/analogtools

• Locate your kit

• Review your Tool Summary Page

• Look for

• Download documents, software and other information

2 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 3

3 Important Notice

Freescale provides the enclosed product(s) under the following conditions:

This evaluation kit is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES

ONLY. It is provided as a sample IC pre-soldered to a printed circuit board to make it easier to access inputs,

outputs, and supply terminals. This evaluation board may be used with any development system or other

source of I/O signals by simply connecting it to the host MCU or computer board via off-the-shelf cables. This

evaluation board is not a Reference Design and is not intended to represent a final design recommendation

for any particular application. Final device in an application will be heavily dependent on proper printed circuit

board layout and heat sinking design as well as attention to supply filtering, transient suppression, and I/O

signal quality.

The goods provided may not be complete in terms of required design, marketing, and or manufacturing related

protective considerations, including product safety measures typically found in the end product incorporating

the goods. Due to the open construction of the product, it is the user's responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. In order to minimize risks associated with the

customers applications, adequate design and operating safeguards must be provided by the customer to

minimize inherent or procedural hazards. For any safety concerns, contact Freescale sales and technical

support services.

Should this evaluation kit not meet the specifications indicated in the kit, it may be returned within 30 days from

the date of delivery and will be replaced by a new kit.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes

no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor

does Freescale assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages.

“Typical” parameters can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typical”, must be validated for each customer application by customer’s

technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale products are

not designed, intended, or authorized for use as components in systems intended for surgical implant into the

body, or other applications intended to support or sustain life, or for any other application in which the failure

of the Freescale product could create a situation where personal injury or death may occur.

Should Buyer purchase or use Freescale products for any such unintended or unauthorized application, Buyer

shall indemnify and hold Freescale and its officers, employees, subsidiaries, affiliates, and distributors

harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

use, even if such claim alleges that Freescale was negligent regarding the design or manufacture of the

part.Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other product or

service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2013

Important Notice

Freescale Semiconductor, Inc. 3

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 4

Introduction

4 Introduction

This evaluation board demonstrates the capability of the latest eXtreme Switch Gen4 family. This family offers

new combinations of output channels as well as a selection of Rdson values. All devices are

footprint-compatible; therefore, they can all be evaluated using this evaluation board.

This evaluation board can be used to evaluate either the MC07XS6517 or the MC17XS6500 which are both

12

V penta high side devices that feature integrated control with high flexibility, and high number of protection

and diagnostic functions. These devices are designed for low-voltage automotive lighting applications and can

drive a wide range of sources, including HIB ballasts and LEDs.

Programming, control and diagnostics are accomplished using a 16-bit SPI interface, which makes possible a

large array of configurations, diagnostics and protection features. For example, see below:

• Configuration: Output slew rates, PWM frequency with prescaler, output phasing, current sense precision,

etc.

• Protection and diagnostics: under/overvoltage, thermal warning, overcurrent, open load, SPI fail, etc.

These devices also provide analog feedback of the IC's temperature, battery voltage or selectable-channel

current sensing with high precision.

The five channels can be controlled individually by external clock signal or in fail safe mode by using direct inputs

(available for OUT1 through OUT4). This fail-safe mode operation happens whenever communication with the

external microcontroller is lost (due to watchdog time-out) and all protection as well as control remains

operational.

5 Evaluation Board Features

This evaluation board consists of either an MC07XS6517 or MC17XS6500 IC in SOIC 54 or 32 pins with

exposed pads.

This board can control

• Five separate 28 W bulbs

• Three separate 55 W HID ballasts

• Five separate LED modules

• Five separate loads of other types

Device can be driven by the 16-bit SPI using KITUSBSPI with SPIGen software or with direct input signals in

Fail safe mode operation. It also offers the possibility to apply an external clock in order to drive outputs in PWM

operation.

6 MC07XS6517 and MC17XS6500 Device Features

MC07XS6517 and MC17XS6500 are smart + power ICs intended for lighting application. The devices supports

the following functions:

• Five protected high side switches

–3*7 mOhms + 2*17 mOhms for the MC07XS6517

–5*17 mOhms for the MC17XS6500

• Operating voltage range from 6.0 V to 18 V with sleep current < 5.0 µA.

• 16-bit 5.0 V SPI control, programming and status reporting with daisy chain capability

• PWM module using external clock with programmable slew rates (to satisfy EMC requirements), 8-bit

flexibility for duty cycle and output delay management.

• Smart overcurrent shutdown, severe short circuit detection, overtemperature protections, output short to

battery, undervoltage or overvoltage reporting, etc.

• Open load detection in On or Off state, available for bulbs and LEDs

• Analog temperature and voltage feedback, so current with selectable ratio is optimized for LEDs modules

4 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 5

Freescale analog ICs are manufactured using the SMARTMOS process, a combinational BiCMOS

manufacturing flow that integrates precision analog, power functions and dense CMOS logic together on a

single cost-effective die. All power channels are integrated using LFet45V technology.

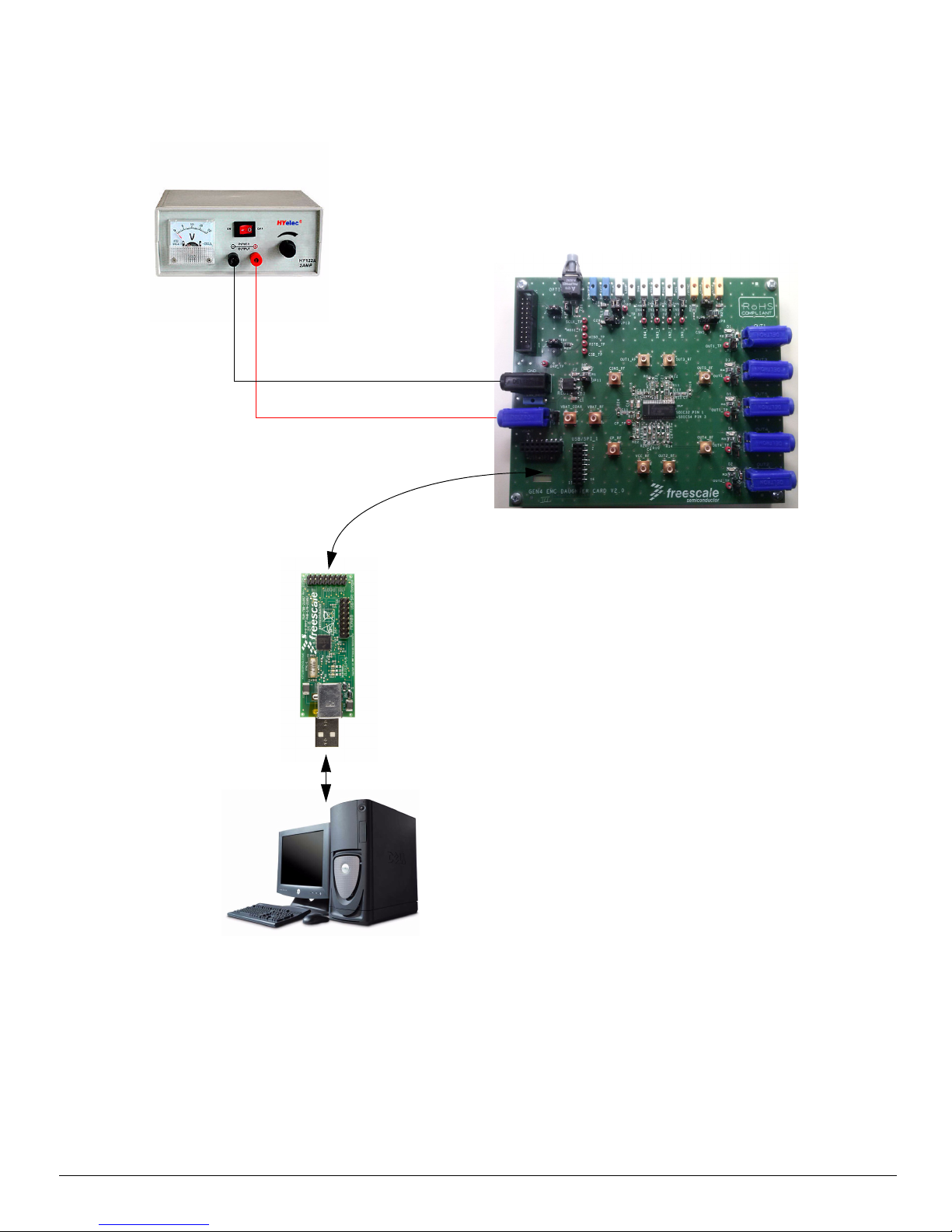

7 Accessory Interface Board

The eXtreme Switch Gen4 Evaluation board may be used with the KITUSBSPIDGLEVME interface dongle

(shown below), which provides a USB-to-SPI interface. This small board makes use of the USB and SPI ports

built into Freescale’s MC68HC908JW32 microcontroller. The main function provided by this dongle is to allow

Freescale evaluation boards that have an SPI port to communicate with a PC through its USB port.

Accessory Interface Board

Figure 2. KITUSBSPIDGLEVME Interface Dongle

8 Required Equipment

Minimum equipment required:

• Minimum equipment required for optimal use:

• DC Power supply 30 V/40 A

• Clock signal generator 0-100 kHz

• Computer with an available USB port, running Windows XP or higher

• KITUSBSPIDGLEVME interface board

• Latest version of SPIGen software (available through www.freescale.com/analogtools)

• Typical loads (lamps)

Freescale Semiconductor, Inc. 5

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 6

Evaluation Board Configuration

GND

+12 V

eXtreme Switch Gen4

Evaluation Board

USB/SPI Dongle

(KITUSBSPIDGLEVME)

16-Pin SPI Ribbon

Cable

Power Supply

9 Evaluation Board Configuration

Figure 3. eXtreme Switch Gen4 Evaluation Board plus KITUSBSPIDGLEVME Board Setup

6 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 7

Installing SPIGen Freeware on your Computer

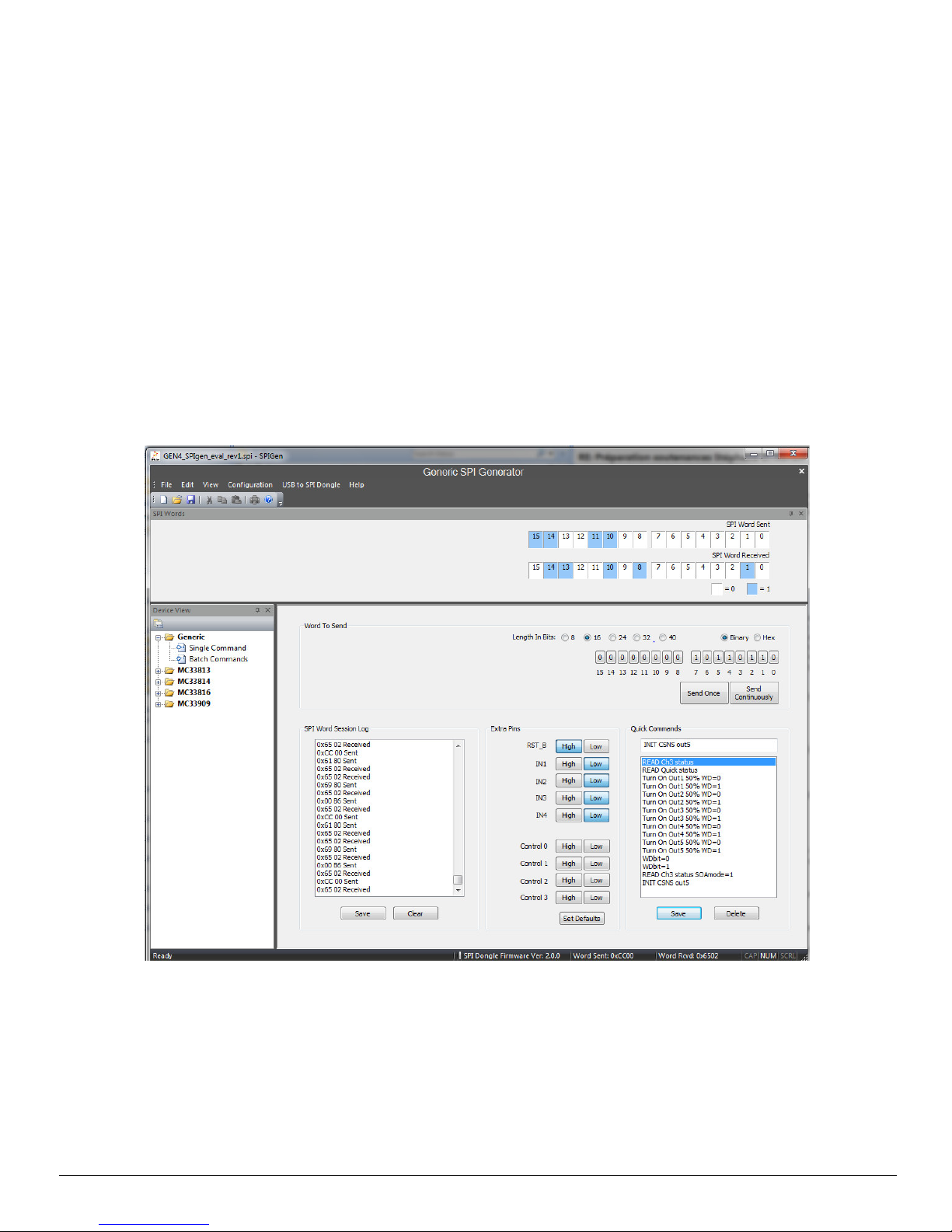

10 Installing SPIGen Freeware on your Computer

The latest version of SPIGen is designed to run on any Windows 8, Windows 7, Vista or XP-based operating

system. To install the software, go to

open the corresponding Tool Summary Page. Look for “Jump Start Your Design”. Download to your computer

desktop the SPIGen software as well as the associated configuration file.

Run the install program from the desktop. The Installation Wizard will guide you through the rest of the process.

To use SPIGen, go to the Windows Start menu, then Programs, then SPIGen, and click on the SPIGen icon.

The SPIGen Graphic User Interface (GUI) will appear. Go to the file menu in the upper left hand corner of the

GUI, and select “Open”. In the file selection window that appears, set the “Files of type:” drop-down menu to

“SPIGen Files (*.spi)”. (As an exceptional case, the file name may have a .txt extension, in which case you

should set the menu to “All Files (*.*)”.) Next, browse for the configuration file you saved on your desktop earlier

and select it. Click “Open”, and SPIGen will create a specially configured SPI command generator for your

evaluation board.

The GUI is shown in Figure 4. The text at the top is the name of the configuration file loaded. The left side panel

displays folders that group user interfaces. The process of loading the configuration file has assigned a list of

“Extra Pins” as well as a list “Quick Commands”, all of which are board-specific.

www.freescale.com/analogtools and select your kit. Click on that link to

Freescale Semiconductor, Inc. 7

Figure 4. SPIGen GUI

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 8

Setting Up and Using the Hardware

11 Setting Up and Using the Hardware

In order to perform the demonstration examples, first set up the evaluation board hardware and software as

follows:

1. Ready the computer and install the latest available version of SPIGen GUI. Then connect the cable

between this interface board and computer. Finally, plug this interface board into the eXtreme Switch Gen4

Evaluation Board.

2. Attach a DC power supply (without turning on the power) to evaluation board’s Vpwr-Gnd connectors and

attach loads to the KIT07XS6517EVBE board. Plug the USB/SPI interface dongle (KITUSBSPIDGLEVME)

directly into the evaluation board.

3. Use as many output terminals as desired.

4. Launch SPIGen and load the GEN4_SPIgen_eval_rev1.spi configuration file obtained from the Jump Start

download.

5. Turn on the power supply with the correct voltage and verify that EVB is supplied correctly by observing the

D6 LEDs with JP1 and JP11 closed. J1 and J7 have to be set either to the Vcc or the µC position. Set all

the LED jumpers, JP2 to JP6, to outputs pins; set the "Extra Pin" RST_B (if J1 in uC position) to high on

the SPIGen GUI and then do the following verification:

6. Click on the "Extra Pins" button INx. The corresponding OUTx LED should turn on.

7. Click on the "Send Once" button. The 'SPI Word Received' at the top of the screen should answer

something different from 0x0000.

Once the steps above are all accomplished, then you are ready to proceed with the remaining examples.

11.1 SPIGen Software information

On the left side of the "device view", you have two options:

• "Single Command": The screen displays 16 bits from the SP interface, so the user can configure them easily

in binary or hexadecimal. You will also find at the top, the corresponding status of SI and SO bits and on

bottom left, the "SPI Word Session Log". Extra pins are also available for configuration.

• "Batch Commands" allows the user to create a specific function using commands that already exist.

Note:

• Some commands and batches of commands are already set up in the GEN4_SPIgen_eval_rev1.spi file.

You may create and save your own command for specific purposes.

• Gen4 devices need a WD toggle on bit D11 to stay in normal mode. The interface board

KITUSBSPIDGLEVME is not able to generate and take into account WD bit status. Therefore, when doing

your own sequence, you may take this into account, and use the "Send Continuously" button.

8 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 9

Evaluation Board Hardware Description

Device Under Test

Add SOIC32 pin 1 marking:

corresponds to pin3 of SOIC54

Capacitors layout placement:

- C22, C24, C20, C18, C16: near banana

- C23, C25, C21, C19, C17: near DUT pi

- C12, C13, C14, C15: near DUT

AGND

AGND AGND

AGND

AGND

AGND

AGND

AGND

AGND

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

CSNS

/SYNC

IN4

IN3

IN2

IN1

LIMP

CLK

MISO

MOSI

SCLK

CSB

RSTB

Vcc CP

Vcc

Vbat

C13

0.1UF

R265.0K

DUT

T07D17

IN1

47

IN2

48

IN3

49

IN4

50

CLK

52

LIMP

51

CS

5

SCLK

6

MOSI

7

MISO

9

RST

4

GND_111GND_2

44

VCC

8

CP

3

VBAT

55

OUT1_1

42

OUT1_2

43

OUT2_1

12

OUT2_2

13

OUT3_1

39

OUT3_2

40

OUT3_3

41

OUT4_1

14

OUT4_2

15

OUT4_3

16

OUT5_1

28

OUT5_2

29

OUT5_3

30

OUT5_4

31

OUT5_5

32

OUT5_6

33

OUT5_7

34

OUT5_8

35

OUT5_9

36

OUT5_10

37

OUT5_11

38

OUT6

10

CSNS

45

SYNC

46

NC_1

1

NC_2

2

NC_17

17

NC_18

18

NC_19

19

NC_20

20

NC_21

21

NC_22

22

NC_23

23

NC_24

24

NC_25

25

NC_26

26

NC_27

27

NC_53

53

NC_54

54

C20

0.022UF

JP8

12

C25

1000PF

C21

1000PF

C18

0.022UF

C14

0.1UF

C19

1000PF

C16

0.022UF

C15

1000PF

C17

1000PF

C22

0.022UF

R27

5.0K

C12

0.1UF

C24

0.022UF

C23

1000PF

12 Evaluation Board Hardware Description

This evaluation board has the capability to demonstrate the functionality of either the MC07XS6517 or

17XS6500 IC, when either of those devices is mounted on the board as a Device Under Test. Below are shown

the DUT connections on the board. The labels displayed in red are accessible to a PC running SPIGen software.

12.1 LED Display

The following LEDs are provided as visual output devices for the KIT07XS6517EVBE evaluation board:

1. {LED Dx} indicates when the corresponding Outputx is On

2. {LED D6} indicates that Vcc is supplied by the on-board regulator

12.2 Test Point Definitions

Freescale Semiconductor, Inc. 9

Each test point of the board has a label showing its corresponding signal.

Figure 5. Device Under Test Signals

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 10

Evaluation Board Hardware Description

Output power connections

+12V

supply

KITUSBSPIDGLEVME Interface

Dongle

Spare

connector

for μC

Device I/Os

5V

ext

sup

CLK

opt

12.3 Input Signal Definitions

The MC07XS6517 and MC17XS6500 ICs both have special input signals that are used to control certain outputs

or functions inside the circuit. These signals are:

1. {INx} {Control of the corresponding OUTx}

2. {LIMP} {Force the IC into fail-safe mode operation when High}

3. {CLK} {To provide an external clock for PWM}

4. {RSTB} {Wakes up the device}

5. {VCC} {Allows SPI communication}

12.4 Output Signal Definitions

MC07XS6517 and MC17XS6500 ICs have six output signals that are used to connect loads (OUT1 to OUT5)

or an additional smart power device (OUT6).

12.5 Evaluation Board Connectors

Figure 6. Connector Designations

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

10 Freescale Semiconductor, Inc.

Page 11

12.5.1 USB/SPI Dongle Connector

USB/SPI dongle connector mates with the 16-conductor flat cable that connects to the USB/SPI Dongle

(KITUSBSPIDGLEVME).

This is a 16 pin, 0.1" center, dual-row connector that is designed to interface directly to the USB/SPI Dongle unit.

The USB/SPI dongle connector consists of the following 16 pins.

Table 1. USB/SPI Dongle Pin Description

Evaluation Board Hardware Description

Pin

Number

1 CSB SPI signal, Chip Select Bar

2 CNTL2 NC

3 SO SPI signal, Serial Out

4 CNTL1 NC

5 SI SPI signal, Serial In

6 CNTL0 CNTL0, connected to LIMP

7 SCLK SPI signal, Serial Clock

8 DATA4 DATA4 connected to IN4

9 CNTL3 NC

10 DATA3 DATA4 connected to IN3

11 VDD +5.0 Volt VDD from USB

12 DATA2 DATA4 connected to IN2

13 +3.3V

14 DATA1 DATA4 connected to IN1

15 GND Signal Ground

16 DATA0 DATA0, connected to RST_B

Note:

1. This connection is unused for this evaluation board.

Name Description

+3.3 V from USB (not used)

(1)

Freescale Semiconductor, Inc. 11

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 12

Evaluation Board Hardware Description

12.6 Jumper Definitions

The following table defines the evaluation board jumper positions and explains their functions. (The default

settings are shown in bold.)

Table 2. Jumper Table

Jumper Description Setting Connection

J1, J7 /RSTB & Vcc connection to 5 V 1-2 Connected to 5 V regulator

J2-J5 IN1-IN4 connection to 5 V 1-2 Connected to white banana IN1-IN4

J6 CLK connection 1-2 Connected to white banana CLK

JP1 5 V regulator connection 1-2 Connect Vbat to regulator Vin

JP2-JP6 Witness LED of each output status 1-2 Connect the output to LED trough resistor

2-3 Connected to SPIgen connector

2-3 Connected to 5 V regulator

2-3 Connected to CON2x10

JP7 External Clock via optical interface 1-2 Connect J6(2-3) to optical interface

JP8 CSNS load connection 1-2 Connect CSNS to 5k resistor

JP9 CSNS external connection 1-2 Route CSNS externally through banana

JP10 CSNS filtered external connection 1-2 Route filtered CSNS signal externally through

banana

JP11 5 V supply witness LED 1-2 Connect regulator output to LED through

resistor

JP12 Optical interface 5 V connection 1-2 Connect optical interface to 5 V regulator

JP13 Filtered Vcc connection 1-2 Connect IC’s VCC to a PI-filtered 5 V supply

12 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 13

13 Schematic

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Jumpers Device Under Test

CLK optical interface

Add SOIC32 pin 1 marking:

corresponds to pin3 of SOIC54

Capacitors layout placement:

- C22, C24, C20, C18, C16: near banana plug

- C23, C25, C21, C19, C17: near DUT pin

- C12, C13, C14, C15: near DUT

AGND

AGND AGND

AGND

AGND

AGND

AGND

AGND

5V

5V

5V

5V

5V

5V

AGND

AGND

5V

AGND

AGND

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

CSNS

/SYNC

IN4

IN3

IN2

IN1

LIMP

CLK

MISO

MOSI

SCLK

CSB

RSTB

Vcc CP

RSTB_uC

RSTB

IN1_2mm

IN1

IN2

IN2_2mm

IN3_2mm

IN3

IN4_2mm

IN4

CLK_uC

CLK CLK_2mm

CLK_opt

5V_uC

Vcc

Vcc

CSNS_2mm

CSNS

CLK_opt

5V_opt

5V_filter

Vbat

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Device Under Test

12

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Device Under Test

12

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Device Under Test

12

___ ___

X

C26

0.1UF

C13

0.1UF

R265.0K

R29

1.0K

DUT

T07D17

IN147IN248IN349IN4

50

CLK52LIMP

51

CS5SCLK6MOSI7MISO

9

RST

4

GND_1

11

GND_2

44

VCC

8

CP

3

VBAT

55

OUT1_142OUT1_243OUT2_112OUT2_213OUT3_139OUT3_240OUT3_341OUT4_114OUT4_215OUT4_316OUT5_128OUT5_229OUT5_330OUT5_431OUT5_532OUT5_633OUT5_734OUT5_835OUT5_9

36

OUT5_1037OUT5_11

38

OUT6

10

CSNS

45

SYNC

46

NC_11NC_22NC_1717NC_1818NC_1919NC_2020NC_2121NC_2222NC_2323NC_2424NC_2525NC_2626NC_2727NC_5353NC_54

54

C20

0.022UF

Optic

AFBR-2529Z

NC_4

4

VCCR

3

VEER

2

DATA_OUT

1

NC_5

5

NC_8

8

JP10

1 2

JP8

12

C25

1000PF

J3 HDR_1X3

1

2

3

C21

1000PF

C18

0.022UF

C27

0.01UF

C14

0.1UF

C19

1000PF

C16

0.022UF

J7 HDR_1X3

1

2

3

R28

2.7

C15

1000PF

C17

1000PF

C22

0.022UF

R25

1.0K

R27

5.0K

JP9

1 2

J5 HDR_1X3

1

2

3

C12

0.1UF

JP13

1 2

JP12

1 2

J2 HDR_1X3

1

2

3

C24

0.022UF

J4 HDR_1X3

1

2

3

C23

1000PF

J6 HDR_1X3

1

2

3

JP7

1 2

J1 HDR_1X3

1

2

3

Schematic

Figure 7. Evaluation Board Schematic, Part 1

Freescale Semiconductor, Inc. 13

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 14

Schematic

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Banana Connectors Vcc generation Outputs LEDs

Adaptation Networks

μC Interface

Test Points

KITUSBSPIDGLEVME: Rev 2.1

150Ohm trace needed

between resistor and

DUT pin

Route OUTx_TP as sense

AGND

AGND

AGND AGND

AGND

5V

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND AGND

OUT1 OUT2

OUT3 OUT4

OUT5

IN1_2mm IN2_2mm

IN3_2mm IN4_2mm

LIMP

CSNS_2mm

CLK_2mm

OUT2

OUT3

OUT4

OUT5

OUT1

OUT1

OUT2

OUT3

OUT4

OUT5

CSNS

Vcc

CP

Vbat

SCLK

MISO

CLK_uC

CSNS_Sync

RSTB_uC

IN2

IN3

IN4

IN1

LIMP

CSB

MOSI

5V_uC

OUT1

OUT2

OUT3

OUT4

OUT5

CP

CSB

MISO

MOSI

SCLK

5V_uC

LIMP

IN4

IN3

IN2

IN1

RSTB_uC

OUT6

IN1

IN2

IN3

IN4

CLK

CSB

SCLK

MOSI

MISO

RSTB

/SYNC

CSNS

5V_ext

5V_opt

5V_ext 5V_filter

Vbat

Vbat

Vbat

Drawing Title:

Size Document Number Rev

Date: Sheet

of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Interface

22

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Interface

22

___ ___

X

Drawing Title:

Size Document Number Rev

Date: Sheet of

Page Title:

ICAP Classification: FCP: FIUO: PUBI:

SCH-XXXXX PDF: SPF-XXXXX 2.0

BOSS EMC Daughter Board

A4

Monday, April 15, 2013

Interface

22

___ ___

X

5V_ext

BANANA BLUE

1

OUT2

CONN BANANA BLUE

1

2

Vbat

CONN BANANA BLUE

1

2

R7 120

IN4

BANANA WHITE

1

JP11

1 2

GND_TP

TEST POINT

1

CSNS

BANANA YELLOW

1

OUT1

CONN BANANA BLUE

1

2

1

CP_RF

CON_1_SMB

1

OUT5_RF

CON_1_SMB

C5 0.0068uF

C28

1uF

JP2

1 2

LIMP

BANANA WHITE

1

/SYNC

BANANA YELLOW

1

IN1

BANANA WHITE

1

IN1_TP

TEST POINT

1

1

CSNS_RF

CON_1_SMB

1

OUT1_RF

CON_1_SMB

R12 49.9

USB/SPI_1

NPPC082KFMS-RC

1 2

3 4657 8

9 10

11 12

13 14

15 16

R11 120

MISO_TP

TEST POINT

1

CSB_TP

TEST POINT

1

OUT5_TP

TEST POINT

1

R1

470

CLK

BANANA WHITE

1

R5 10K

CSNS_TP

TEST POINT

1

R3 10K

L1 4.7UH

1 2

C4 0.0068uF

D5

GREEN

A C

OUT4_TP

TEST POINT

1

C1

0.33UF

VIN VOUT

GND

Reg1

L7805CDT

1

4

3

C7 0.0068uF

MOSI_TP

TEST POINT

1

1

OUT3_RF

CON_1_SMB

R10 49.9

D4

GREEN

A C

IN2

BANANA WHITE

1

IN2_TP

TEST POINT

1

C11 0.0068uF

R2 10K

R9 120

D3

GREEN

A C

JP3

1 2

GND

CONN BANANA BLACK 2

1

2

R8 49.9

R24 49.9

uC

CON_2X10

1 2

3 4657 8

9 10

11 12

13 14

15 16

17 18

19 20

D2

GREEN

A C

D1

GREEN

A C

IN4_TP

TEST POINT

1

R23 120

OUT6

BANANA YELLOW

1

D6

GREEN

AC

CLK_TP

TEST POINT

1

1

OUT2_RF

CON_1_SMB

R6 10K

1

Vbat_coax

CON_1_SMB

1

OUT4_RF

CON_1_SMB

JP4

1 2

C9 0.0068uF

14V_Regu

BANANA BLUE

1

RSTB_TP

TEST POINT

1

R20 49.9

5V_opt

BANANA BLUE

1

IN3_TP

TEST POINT

1

IN3

BANANA WHITE

1

OUT1_TP

TEST POINT

1

1

Vbat_RF

CON_1_SMB

C29

0.33UF

C2

0.1UF

USB/SPI_2

NPPC082KFMS-RC

1 2

3 4657 8

9 10

11 12

13 14

15 16

R19 120

JP6

1 2

C10 0.0068uF

SCLK_TP

TEST POINT

1

JP1

1 2

D7

CMMR1U-02

A C

CP_TP

TEST POINT

1

OUT5

CONN BANANA BLUE

1

2

C8 0.0068uF

C6 0.0068uF

R22 49.9

R14 49.9

R21 120

R16 49.9

OUT4

CONN BANANA BLUE

1

2

OUT3_TP

TEST POINT

1

R18 49.9

R4 10K

1

Vcc_RF

CON_1_SMB

OUT3

CONN BANANA BLUE

1

2

R17 120

R13 120

OUT2_TP

TEST POINT

1

R15 120

JP5

1 2

C3 0.0068uF

14 Freescale Semiconductor, Inc.

Figure 8. Evaluation Board Schematic, Part 2

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 15

14 Board Layout

14.1 Assembly Layer Top

Board Layout

Freescale Semiconductor, Inc. 15

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 16

Board Layout

14.2 Top Layer Routing

16 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 17

14.3 Inner Layer 1 Routing

Board Layout

Freescale Semiconductor, Inc. 17

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 18

Board Layout

14.4 Inner Layer 2 Routing

18 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 19

14.5 Bottom Layer Routing

Board Layout

Freescale Semiconductor, Inc. 19

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 20

Board Layout

14.6 Drill Location

20 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 21

Bill of Material

15 Bill of Material

Qty Schematic Label Value Description Package

Integrated Circuits

Freescale MC07XS6517EK or

1 DUT

1 Optic Avago AFBR-2529Z,IC RCVR 50MBD 3.3/5V 20MA TH hfbr_1521

Inductors

1 L1 4.7µH IND CHK 4.7UH@1MHZ 650mA 20% SMD 1210

Freescale MC17XS6500EK

Diodes

1 D7 DIODE RECT 1A 200V SOD-123F

LEDs

6 D1, D2, D3, D4, D5, D6 LED GRN SGL 20mA SMT SMD 1206

Capacitors

54-pin SOICEP or

32-pin SOICEP

2 C1, C29 330nF CAP CER 0.33µF 50V 10% X7R SMD 1206

1 C2 100nF CAP CER 0.1µF 50V 10% X7R SMD1206

9 C3...C11 6.8nF CAP CER 0.0068µF 50V 10% X7R SMD0805

4 C12, C13, C14, C26 100nF CAP CER 0.1µF 200V 10% X7R SMD1206

6 C15, C17, C19, C21, C23, C25 1nF CAP CER 1000pF 2000V +80%/-20% X7R SMD1206

5 C16, C18, C20, C22, C24 22nF CAP CER 0.022µF 50V 5% X7R SMD1206

1 C27 10nF CAP CER 0.01µF 100V 5% X7R SMD1206

1 C28 1µF CAP CER 1µF 50V 10% X7R SMD 1206

Regulator

1 Reg1 5V IC VREG 5V 1.5A 35V DPAK to252_dpak_st

Resistors

1 R1 470 RES MF 470 OHM 1/4W 5% SMD 1206

5 R2, R3, R4, R5, R6 10k RES MF 10K 1/4W 5% SMD 1206

R7, R9, R11, R13, R15, R17, R19, R21,

9

9

R23

R8, R10, R12, R14, R16, R18, R20, R22,

R24

120 RES MF 120 OHM 1/8W 5% SMD 0805

49.9 RES MF 49.9 OHM 1/8W 1% SMD 0805

1 R25 1.0k RES MF 1.0K 1/4W 5% SMD 1206

2 R26, R27 5.0k RES MF 5.00K 1/4W 0.1% SMD 1206

1 R28 2.70 RES MF 2.70 OHM 1/4W 1% SMD 1206

1 R29 1.0k RES MF 1.00K 1/4W 1% SMD 1206

Freescale Semiconductor, Inc. 21

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 22

Bill of Material

Qty Schematic Label Value Description Package

Switches, Connectors, Jumpers and Test Points

6 CLK, IN1-IN4, LIMP CON 1 BANANA RA TH -- 203H AG WHITE

CLK_TP, CP_TP, CSB_TP, CSNS_TP,

GND_TP, IN1_TP, IN2_TP, IN3_TP,

IN4_TP, MISO_TP, MOSI_TP,

OUT1_TP, OUT2_TP, OUT3_TP,

OUT4_TP, OUT5_TP, RSTB_TP,

18

2 5V_EXT, 5V_OPT, 14V_Regu CON 1 BANANA RA TH -- 203H AG BLUE

3 /SYNC, CSNS, OUT6 CON 1 BANANA RA TH -- 203H AG YELLOW

6 VBAT, OUT1...OUT5

1 GND

13 JP1...13 CON 2 JUMPER MALE 2.54MM

SCLK_TP

TEST POINT RED PAD C100-55T TH

CON 1X2 BANANA RA TH 15.3MM SP 488H AG BLUE

197L

CON 1X2 BANANA RA TH 15.3MM SP 488H AG BLACK

197L

7 J1...J7 HDR 1X3 TH 100MIL SP 374H AU

CP_RF, CSNS_RF, OUT1_RF,

OUT2_RF, OUT3_RF, OUT4_RF,

OUT5_RF,VBAT_RF, VBAT_COAX,

10

2 USB/SPI_1, USB/SPI_2 HDR 2X8 SKT SMT 100MIL CTR 305H AU

Note: Freescale does not assume liability, endorse, or warrant components from external manufacturers that are referenced in circuit drawings or tables.

While Freescale offers component recommendations in this configuration, it is the customer’s responsibility to validate their application.

VCC_RF

UC CON 2X10 PLUG SHRD TH 100MIL CTR 380H AU HDR210_4w

CON 1 COAX SMB SMT -- 291H AU con_smb_6p3sq

22 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 23

16 References

Following are URLs where you can obtain information on related Freescale products and application solutions:

References

Freescale.com

Support Pages

MC07XS6517

Product Summary Page

MC17XS6500

Product Summary Page

KITUSBSPIDGLEVME

Tool Summary Page

SPIGen

Tool Summary Page

Analog Home Page http://www.freescale.com/analog

Automotive Home Page http://www.freescale.com/automotive

http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=MC07XS6517

http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=MC17XS6500

http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=KITUSBSPIDGLEVME

http://www.freescale.com/files/soft_dev_tools/software/device_drivers/SPIGen.html

16.1 Support

Visit www.freescale.com/support for a list of phone numbers within your region.

16.2 Warranty

Visit www.freescale.com/warranty for a list of phone numbers within your region.

URL

Freescale Semiconductor, Inc. 23

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 24

Revision History

17 Revision History

Revision Date Description of Changes

1.0

11/2013 • Initial Release

24 Freescale Semiconductor, Inc.

KTXSWITCH4UG User’s Guide Rev. 1.0 11/2013

Page 25

How to Reach Us:

Home Page:

freescale.com

Web Support:

freescale.com/support

Information in this document is provided solely to enable system and software implementers to use Freescale

products. There are no express or implied copyright licenses granted hereunder to design or fabricate any integrated

circuits based on the information in this document.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes no

warranty, representation, or guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale assume any liability arising out of the application or use of any product or circuit, and specifically disclaims

any and all liability, including without limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale data sheets and/or specifications can and do vary in different applications, and actual

performance may vary over time. All operating parameters, including “typicals,” must be validated for each customer

application by customer’s technical experts. Freescale does not convey any license under its patent rights nor the

rights of others. Freescale sells products pursuant to standard terms and conditions of sale, which can be found at the

following address: freescale.com/SalesTermsandConditions.

Freescale and the Freescale logo are trademarks of Freescale Semiconductor, Inc., Reg. U.S. Pat. & Tm. Off.

SMARTMOS is a trademark of Freescale Semiconductor, Inc. All other product or service names are the property of

their respective owners.

© 2013 Freescale Semiconductor, Inc.

Document Number: KTXSWITCH4UG

Rev. 1.0

11/ 2013

Loading...

Loading...