Page 1

DSP56374

24-Bit Digital Signal Processor

User Guide

Document Number: DSP56374UG

Rev. 1.2

07/2007

Page 2

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064, Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software implementers to use

Freescale Semiconductor products. There are no express or implied copyright licenses granted

hereunder to design or fabricate any integrated circuits or integrated circuits based on the information

in this document.

Freescale Semiconductor reserves the right to make changes without further notice to any products

herein. Freescale Semiconductor makes no warranty, representation or guarantee regarding the

suitability of its products for any particular purpose, nor does Freescale Semiconductor assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incidental damages. “Typical” parameters

that may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating parameters,

including “Typicals”, must be validated for each cust omer application by customer’s technical exp erts.

Freescale Semiconductor does not convey any license under its patent rights nor the rights of others.

Freescale Semiconductor products are not designed, intended, or authorized for use as components

in systems intended for surgical implant into the body, or other applications intended to support or

sustain life, or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer purchase or use

Freescale Semiconductor products for any such unintended or unauthorized application, Buyer shall

indemnify and hold Freescale Semiconductor and its officers, employees, subsidiaries, affiliates, and

distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney

fees arising out of, directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale Semiconductor was

negligent regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other

product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2004–2007. All rights reserved.

Page 3

Table of Contents

Paragraph Page

Number Number

Preface i

Chapter 1

DSP56374 Overview

1.1 Introduction ...............................................................................................................................................................1-1

1.2 DSP56300 Core Description .....................................................................................................................................1-2

1.3 DSP56374 Audio Processor Architecture .................................................................................................................1-3

1.4 DSP56300 Core Functional Blocks ...........................................................................................................................1-3

1.4.1 Data ALU ............................................................................................................................................................1-3

1.4.1.1 Data ALU Registers ......................................................................................................................................1-3

1.4.1.2 Multiplier-Accumulator (MAC) ...................................................................................................................1-3

1.4.2 Address Generation Unit (AGU) ........................................................................................................................1-4

1.4.3 Program Control Unit (PCU) ..............................................................................................................................1-4

1.4.4 Internal Buses ......................................................................................................................................................1-4

1.4.5 Direct Memory Access (DMA) ...........................................................................................................................1-5

1.4.6 PLL-based Clock Oscillator ................................................................................................................................1-5

1.4.7 On-Chip Memory ................................................................................................................................................1-5

1.4.8 Off-Chip Memory Expansion .............................................................................................................................1-5

1.4.9 Power Requirements ...........................................................................................................................................1-5

1.5 Peripheral Overview ..................................................................................................................................................1-6

1.5.1 General Purpose Input/Output (GPIO) ...............................................................................................................1-6

1.5.2 Triple Timer (TEC) .............................................................................................................................................1-6

1.5.3 Enhanced Serial Audio Interface (ESAI) ............................................................................................................1-7

1.5.4 Enhanced Serial Audio Interface 1 (ESAI_1) .....................................................................................................1-7

1.5.5 Serial Host Interface (SHI) .................................................................................................................................1-7

1.5.6 Watchdog timer (WDT) ......................................................................................................................................1-7

Chapter 2

Signal/Connection Descriptions

2.1 Signal Groupings .......................................................................................................................................................2-1

2.2 Power .........................................................................................................................................................................2-1

2.3 Ground .......................................................................................................................................................................2-3

2.4 SCAN ........................................................................................................................................................................2-4

2.5 Clock and PLL ...........................................................................................................................................................2-4

2.6 Interrupt and Mode Control .......................................................................................................................................2-4

2.7 Serial Host Interface ..................................................................................................................................................2-6

2.8 Enhanced Serial Audio Interface ...............................................................................................................................2-8

2.9 Enhanced Serial Audio Interface_1 .........................................................................................................................2-12

2.10 Dedicated GPIO - Port G .........................................................................................................................................2-16

2.11 Timer .......................................................................................................................................................................2-18

2.12 JTAG/OnCE Interface .............................................................................................................................................2-19

Chapter 3

Memory Configuration

3.1 Data and Program Memory Maps .............................................................................................................................3-1

3.1.1 Reserved Memory Spaces ...................................................................................................................................3-5

3.1.2 Bootstrap CODE .................................................................................................................................................3-5

3.1.3 Dynamic Memory Configuration Switching ......................................................................................................3-5

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor TOC-1

Page 4

Table Of Contents

Paragraph Page

Number Number

3.1.4 External Memory Support ...................................................................................................................................3-5

3.1.5 DMA and Memory ..............................................................................................................................................3-5

3.1.6 Memory BLOCKS ..............................................................................................................................................3-6

3.2 Memory Patch Module ..............................................................................................................................................3-6

3.3 Internal I/O Memory Map .........................................................................................................................................3-7

Chapter 4

Core Configuration

4.1 Introduction ...............................................................................................................................................................4-1

4.2 Operating Mode Register (OMR) ..............................................................................................................................4-1

4.2.1 RESERVED - Bits 4, 5, 10 - 15 and 23 ..............................................................................................................4-1

4.3 Operating Modes .......................................................................................................................................................4-1

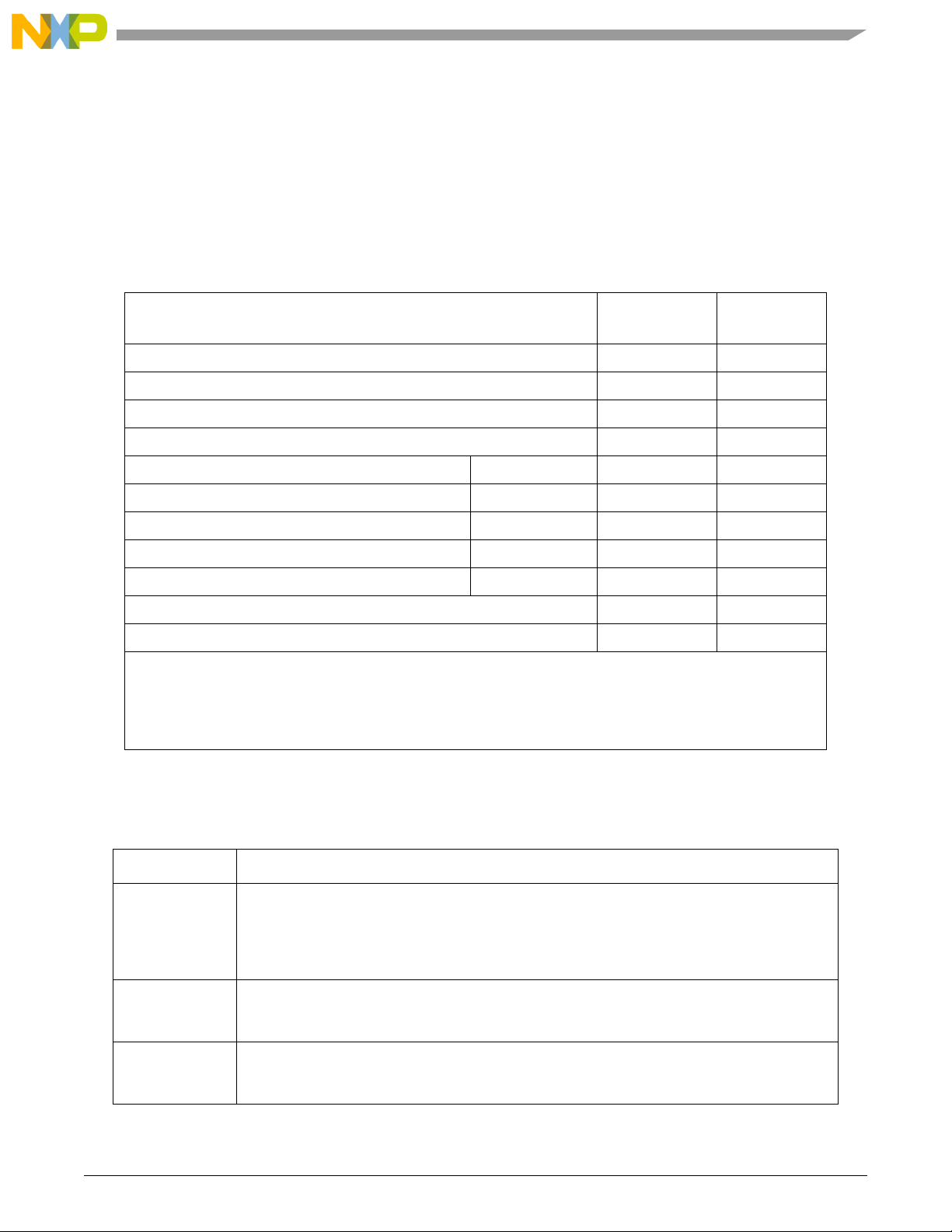

4.4 Interrupt Priority Registers ........................................................................................................................................4-3

4.5 DMA Request Sources ..............................................................................................................................................4-9

4.6 PLL Initialization ....................................................................................................................................................4-10

4.6.1 PLL Pre-Divider Factor (PD0-PD4) .................................................................................................................4-10

4.6.2 PLL Multiplication Factor (MF0-MF7) ............................................................................................................4-10

4.6.3 PLL Feedback Multiplier (OD1) ......................................................................................................................4-10

4.6.4 PLL Output Divide Factor (OD0-OD1) ............................................................................................................4-10

4.6.5 PLL Divider Factor (DF0-DF2) ........................................................................................................................4-10

4.6.6 PLL LOCK MUX (PLKM) ..............................................................................................................................4-10

4.7 Device Identification (ID) Register .........................................................................................................................4-10

4.8 JTAG Identification (ID) Register ..........................................................................................................................4-11

Chapter 5

PLL and Clock generator

5.1 Introduction ...............................................................................................................................................................5-1

5.2 PLL and Clock Signals ..............................................................................................................................................5-1

5.3 PLL Block .................................................................................................................................................................5-1

5.3.1 Frequency Predivider ..........................................................................................................................................5-2

5.3.2 Phase Detector and Charge Pump Loop Filter ....................................................................................................5-2

5.3.3 Voltage Controlled Oscillator (VCO) .................................................................................................................5-2

5.3.4 PLL DividerS ......................................................................................................................................................5-2

5.3.5 PLL Multiplication Factor (MF) .........................................................................................................................5-3

5.4 PLL Operation ...........................................................................................................................................................5-3

5.4.1 EXTAL Clock Input Division .............................................................................................................................5-3

5.4.2 PLL Frequency Multiplication ............................................................................................................................5-3

5.4.3 PLL Output Frequency (PLL Out) ......................................................................................................................5-4

5.5 Clock Generator ........................................................................................................................................................5-6

5.5.1 Low-Power Divider (LPD) .................................................................................................................................5-6

5.6 Operating Frequency (Fosc) ......................................................................................................................................5-6

5.7 PLL Programming Model .........................................................................................................................................5-7

5.8 PLL Initialization Procedure ...................................................................................................................................5-10

5.9 PLL Programming Examples ..................................................................................................................................5-11

Chapter 6

General Purpose Input/Output

6.1 Introduction ..............................................................................................................................................................6-1

6.2 Programming Model ..................................................................................................................................................6-1

DSP56374 Users Guide, Rev. 1.2

TOC-2 Freescale Semiconductor

Page 5

Table of Contents

Paragraph Page

Number Number

6.2.1 Port C and E Signals and Registers .....................................................................................................................6-1

6.2.2 Port G Signals and Registers ...............................................................................................................................6-1

6.2.2.1 Port G Control Register (PCRG) ..................................................................................................................6-1

6.2.2.2 Port G Direction Register (PRRG) ...............................................................................................................6-1

6.2.2.3 Port G Data register (PDRG) ........................................................................................................................6-2

6.2.2.4 ESAI/EXTAL clocking control ....................................................................................................................6-2

6.2.3 Port H Signals and Registers ...............................................................................................................................6-3

6.2.3.1 Port H Control Register (PCRH) ..................................................................................................................6-3

6.2.3.2 Port H Direction Register (PRRH) ...............................................................................................................6-3

6.2.3.3 Port H Data register (PDRH) ........................................................................................................................6-4

6.2.4 Timer/Event Counter Signals ..............................................................................................................................6-4

Chapter 7

Serial Host Interface

7.1 Introduction ...............................................................................................................................................................7-1

7.2 Serial Host Interface Internal Architecture ...............................................................................................................7-1

7.3 SHI Clock Generator .................................................................................................................................................7-2

7.4 Serial Host Interface Programming Model ...............................................................................................................7-2

7.4.1 SHI Input/Output Shift Register (IOSR)—Host Side .........................................................................................7-4

7.4.2 SHI Host Transmit Data Register (HTX)—DSP Side ........................................................................................7-4

7.4.3 SHI Host Receive Data FIFO (HRX)—DSP Side ..............................................................................................7-5

7.4.4 SHI Slave Address Register (HSAR)—DSP Side ..............................................................................................7-5

7.4.4.1 HSAR Reserved Bits—Bits 19, 17– 0 ..........................................................................................................7-5

7.4.4.2 HSAR I

7.4.5 SHI Clock Control Register (HCKR)—DSP Side ..............................................................................................7-5

7.4.5.1 Clock Phase and Polarity (CPHA and CPOL)—Bits 1–0 ............................................................................7-5

7.4.5.2 HCKR Prescaler Rate Select (HRS)—Bit 2 .................................................................................................7-6

7.4.5.3 HCKR Divider Modulus Select (HDM[7:0])—Bits 10–3 ............................................................................7-7

7.4.5.4 HCKR Filter Mode (HFM[1:0]) — Bits 13–12 ............................................................................................7-7

7.4.5.5 HCKR Reserved Bits—Bits 23–14, 11 ........................................................................................................7-7

7.4.6 SHI Control/Status Register (HCSR)—DSP Side ..............................................................................................7-7

7.4.6.1 HCSR Host Enable (HEN)—Bit 0 ...............................................................................................................7-7

7.4.6.1.1 SHI Individual Reset ..............................................................................................................................7-8

7.4.6.2 HCSR I

7.4.6.3 HCSR Serial Host Interface Mode (HM[1:0])—Bits 3–2 ............................................................................7-8

7.4.6.4 HCSR I

7.4.6.5 HCSR FIFO-Enable Control (HFIFO)—Bit 5 .............................................................................................7-8

7.4.6.6 HCSR Master Mode (HMST)—Bit 6 ...........................................................................................................7-8

7.4.6.7 HCSR Host-Request Enable (HRQE[1:0])—Bits 8–7 .................................................................................7-9

7.4.6.8 HCSR Idle (HIDLE)—Bit 9 .........................................................................................................................7-9

7.4.6.9 HCSR Bus-Error Interrupt Enable (HBIE)—Bit 10 .....................................................................................7-9

7.4.6.10 HCSR Transmit-Interrupt Enable (HTIE)—Bit 11 ......................................................................................7-9

7.4.6.11 HCSR Receive Interrupt Enable (HRIE[1:0])—Bits 13–12 .......................................................................7-10

7.4.6.12 HCSR Host Transmit Underrun Error (HTUE)—Bit 14 ............................................................................7-10

7.4.6.13 HCSR Host Transmit Data Empty (HTDE)—Bit 15 .................................................................................7-10

7.4.6.14 HCSR Reserved Bits—Bits 23, 18 and 16 .................................................................................................7-10

7.4.6.15 Host Receive FIFO Not Empty (HRNE)—Bit 17 ......................................................................................7-10

7.4.6.16 Host Receive FIFO Full (HRFF)—Bit 19 ..................................................................................................7-10

7.4.6.17 Host Receive Overrun Error (HROE)—Bit 20 ...........................................................................................7-11

2

C Slave Address (HA[6:3], HA1)—Bits 23–20,18 .......................................................................7-5

2

C/SPI Selection (HI2C)—Bit 1 ......................................................................................................7-8

2

C Clock Freeze (HCKFR)—Bit 4 ..................................................................................................7-8

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor TOC-3

Page 6

Table Of Contents

Paragraph Page

Number Number

7.4.6.18 Host Bus Error (HBER)—Bit 21 ................................................................................................................7-11

7.4.6.19 HCSR Host Busy (HBUSY)—Bit 22 .........................................................................................................7-11

7.5 Characteristics Of The SPI Bus ...............................................................................................................................7-11

7.6 Characteristics Of The I

7.6.1 Overview ...........................................................................................................................................................7-11

7.6.2 I2C Data Transfer Formats ................................................................................................................................7-13

7.7 SHI Programming Considerations ...........................................................................................................................7-13

7.7.1 SPI Slave Mode .................................................................................................................................................7-13

7.7.2 SPI Master Mode ..............................................................................................................................................7-14

7.7.3 I

7.7.3.1 Receive Data in I2C Slave Mode ................................................................................................................7-15

7.7.3.2 Transmit Data In I2C Slave Mode ..............................................................................................................7-15

7.7.4 I

7.7.4.1 Receive Data in I2C Master Mode ..............................................................................................................7-16

7.7.4.2 Transmit Data In I2C Master Mode ............................................................................................................7-16

7.7.5 SHI Operation During DSP Stop ......................................................................................................................7-17

7.7.6 GPIO- HREQ Signal and Registers ..................................................................................................................7-17

2

C Slave Mode .................................................................................................................................................7-14

2

C Master Mode ...............................................................................................................................................7-15

2

C Bus ...............................................................................................................................7-11

Chapter 8

Enhanced Serial Audio Interface (ESAI)

8.1 Introduction ...............................................................................................................................................................8-1

8.2 ESAI Data and Control Pins ......................................................................................................................................8-2

8.2.1 Serial Transmit 0 Data Pin (SDO0) ....................................................................................................................8-3

8.2.2 Serial Transmit 1 Data Pin (SDO1) ....................................................................................................................8-3

8.2.3 Serial Transmit 2/Receive 3 Data Pin (SDO2/SDI3) ..........................................................................................8-3

8.2.4 Serial Transmit 3/Receive 2 Data Pin (SDO3/SDI2) ..........................................................................................8-3

8.2.5 Serial Transmit 4/Receive 1 Data Pin (SDO4/SDI1) ..........................................................................................8-3

8.2.6 Serial Transmit 5/Receive 0 Data Pin (SDO5/SDI0) ..........................................................................................8-3

8.2.7 Receiver Serial Clock (SCKR) ...........................................................................................................................8-4

8.2.8 Transmitter Serial Clock (SCKT) .......................................................................................................................8-4

8.2.9 Frame Sync for Receiver (FSR) ..........................................................................................................................8-5

8.2.10 Frame Sync for Transmitter (FST) .....................................................................................................................8-6

8.2.11 High Frequency Clock for Transmitter (HCKT) ................................................................................................8-6

8.2.12 High Frequency Clock for Receiver (HCKR) .....................................................................................................8-6

8.3 ESAI Programming Model ........................................................................................................................................8-6

8.3.1 ESAI Transmitter Clock Control Register (TCCR) ............................................................................................8-6

8.3.1.1 TCCR Transmit Prescale Modulus Select (TPM7–TPM0) - Bits 7–0 .........................................................8-7

8.3.1.2 TCCR Transmit Prescaler Range (TPSR) - Bit 8 .........................................................................................8-8

8.3.1.3 TCCR Tx Frame Rate Divider Control (TDC4–TDC0) - Bits 13–9 ............................................................8-8

8.3.1.4 TCCR Tx High Frequency Clock Divider (TFP3-TFP0) - Bits 17–14 ........................................................8-8

8.3.1.5 TCCR Transmit Clock Polarity (TCKP) - Bit 18 .........................................................................................8-9

8.3.1.6 TCCR Transmit Frame Sync Polarity (TFSP) - Bit 19 ................................................................................8-9

8.3.1.7 TCCR Transmit High Frequency Clock Polarity (THCKP) - Bit 20 ...........................................................8-9

8.3.1.8 TCCR Transmit Clock Source Direction (TCKD) - Bit 21 ..........................................................................8-9

8.3.1.9 TCCR Transmit Frame Sync Signal Direction (TFSD) - Bit 22 ..................................................................8-9

8.3.1.10 TCCR Transmit High Frequency Clock Direction (THCKD) - Bit 23 ........................................................8-9

8.3.2 ESAI Transmit Control Register (TCR) .............................................................................................................8-9

8.3.2.1 TCR ESAI Transmit 0 Enable (TE0) - Bit 0 ..............................................................................................8-10

8.3.2.2 TCR ESAI Transmit 1 Enable (TE1) - Bit 1 ..............................................................................................8-10

DSP56374 Users Guide, Rev. 1.2

TOC-4 Freescale Semiconductor

Page 7

Table of Contents

Paragraph Page

Number Number

8.3.2.3 TCR ESAI Transmit 2 Enable (TE2) - Bit 2 ..............................................................................................8-10

8.3.2.4 TCR ESAI Transmit 3 Enable (TE3) - Bit 3 ..............................................................................................8-11

8.3.2.5 TCR ESAI Transmit 4 Enable (TE4) - Bit 4 ..............................................................................................8-11

8.3.2.6 TCR ESAI Transmit 5 Enable (TE5) - Bit 5 ..............................................................................................8-11

8.3.2.7 TCR Transmit Shift Direction (TSHFD) - Bit 6 .........................................................................................8-11

8.3.2.8 TCR Transmit Word Alignment Control (TWA) - Bit 7 ............................................................................8-11

8.3.2.9 TCR Transmit Network Mode Control (TMOD1-TMOD0) - Bits 9-8 ......................................................8-12

8.3.2.10 TCR Tx Slot and Word Length Select (TSWS4-TSWS0) - Bits 14-10 .....................................................8-13

8.3.2.11 TCR Transmit Frame Sync Length (TFSL) - Bit 15 ..................................................................................8-14

8.3.2.12 TCR Transmit Frame Sync Relative Timing (TFSR) - Bit 16 ...................................................................8-15

8.3.2.13 TCR Transmit Zero Padding Control (PADC) - Bit 17 ..............................................................................8-16

8.3.2.14 TCR Reserved Bit - Bits 18 ........................................................................................................................8-16

8.3.2.15 TCR Transmit Section Personal Reset (TPR) - Bit 19 ...............................................................................8-16

8.3.2.16 TCR Transmit Exception Interrupt Enable (TEIE) - Bit 20 .......................................................................8-16

8.3.2.17 TCR Transmit Even Slot Data Interrupt Enable (TEDIE) - Bit 21 ............................................................8-16

8.3.2.18 TCR Transmit Interrupt Enable (TIE) - Bit 22 ...........................................................................................8-16

8.3.2.19 TCR Transmit Last Slot Interrupt Enable (TLIE) - Bit 23 .........................................................................8-16

8.3.3 ESAI Receive Clock Control Register (RCCR) ...............................................................................................8-16

8.3.3.1 RCCR Receiver Prescale Modulus Select (RPM7–RPM0) - Bits 7–0 .......................................................8-17

8.3.3.2 RCCR Receiver Prescaler Range (RPSR) - Bit 8 .......................................................................................8-17

8.3.3.3 RCCR Rx Frame Rate Divider Control (RDC4–RDC0) - Bits 13–9 .........................................................8-17

8.3.3.4 RCCR Rx High Frequency Clock Divider (RFP3-RFP0) - Bits 17-14 ......................................................8-17

8.3.3.5 RCCR Receiver Clock Polarity (RCKP) - Bit 18 .......................................................................................8-18

8.3.3.6 RCCR Receiver Frame Sync Polarity (RFSP) - Bit 19 ..............................................................................8-18

8.3.3.7 RCCR Receiver High Frequency Clock Polarity (RHCKP) - Bit 20 .........................................................8-18

8.3.3.8 RCCR Receiver Clock Source Direction (RCKD) - Bit 21 ........................................................................8-18

8.3.3.9 RCCR Receiver Frame Sync Signal Direction (RFSD) - Bit 22 ................................................................8-19

8.3.3.10 RCCR Receiver High Frequency Clock Direction (RHCKD) - Bit 23 ......................................................8-19

8.3.4 ESAI Receive Control Register (RCR) .............................................................................................................8-19

8.3.4.1 RCR ESAI Receiver 0 Enable (RE0) - Bit 0 ..............................................................................................8-20

8.3.4.2 RCR ESAI Receiver 1 Enable (RE1) - Bit 1 ..............................................................................................8-20

8.3.4.3 RCR ESAI Receiver 2 Enable (RE2) - Bit 2.............................................................................................. 8-20

8.3.4.4 RCR ESAI Receiver 3 Enable (RE3) - Bit 3 ..............................................................................................8-20

8.3.4.5 RCR Reserved Bits - Bits 5-4, 18-17 .........................................................................................................8-20

8.3.4.6 RCR Receiver Shift Direction (RSHFD) - Bit 6 ........................................................................................8-20

8.3.4.7 RCR Receiver Word Alignment Control (RWA) - Bit 7 ...........................................................................8-21

8.3.4.8 RCR Receiver Network Mode Control (RMOD1-RMOD0) - Bits 9-8 .....................................................8-21

8.3.4.9 RCR Receiver Slot and Word Select (RSWS4-RSWS0) - Bits 14-10 .......................................................8-21

8.3.4.10 RCR Receiver Frame Sync Length (RFSL) - Bit 15 ..................................................................................8-22

8.3.4.11 RCR Receiver Frame Sync Relative Timing (RFSR) - Bit 16 ...................................................................8-22

8.3.4.12 RCR Receiver Section Personal Reset (RPR) - Bit 19 ...............................................................................8-22

8.3.4.13 RCR Receive Exception Interrupt Enable (REIE) - Bit 20 ........................................................................8-23

8.3.4.14 RCR Receive Even Slot Data Interrupt Enable (REDIE) - Bit 21 .............................................................8-23

8.3.4.15 RCR Receive Interrupt Enable (RIE) - Bit 22 ............................................................................................8-23

8.3.4.16 RCR Receive Last Slot Interrupt Enable (RLIE) - Bit 23 ..........................................................................8-23

8.3.5 ESAI Common Control Register (SAICR) .......................................................................................................8-23

8.3.5.1 SAICR Serial Output Flag 0 (OF0) - Bit 0 .................................................................................................8-23

8.3.5.2 SAICR Serial Output Flag 1 (OF1) - Bit 1 .................................................................................................8-24

8.3.5.3 SAICR Serial Output Flag 2 (OF2) - Bit 2 .................................................................................................8-24

8.3.5.4 SAICR Reserved Bits - Bits 5-3, 23-9 ........................................................................................................8-24

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor TOC-5

Page 8

Table Of Contents

Paragraph Page

Number Number

8.3.5.5 SAICR Synchronous Mode Selection (SYN) - Bit 6 .................................................................................8-24

8.3.5.6 SAICR Transmit External Buffer Enable (TEBE) - Bit 7 ..........................................................................8-24

8.3.5.7 SAICR Alignment Control (ALC) - Bit 8 ..................................................................................................8-24

8.3.6 ESAI Status Register (SAISR) ..........................................................................................................................8-25

8.3.6.1 SAISR Serial Input Flag 0 (IF0) - Bit 0 ......................................................................................................8-26

8.3.6.2 SAISR Serial Input Flag 1 (IF1) - Bit 1 ......................................................................................................8-26

8.3.6.3 SAISR Serial Input Flag 2 (IF2) - Bit 2 ......................................................................................................8-26

8.3.6.4 SAISR Reserved Bits - Bits 5-3, 12-11, 23-18 ...........................................................................................8-26

8.3.6.5 SAISR Receive Frame Sync Flag (RFS) - Bit 6 .........................................................................................8-26

8.3.6.6 SAISR Receiver Overrun Error Flag (ROE) - Bit 7 ...................................................................................8-26

8.3.6.7 SAISR Receive Data Register Full (RDF) - Bit 8 ......................................................................................8-27

8.3.6.8 SAISR Receive Even-Data Register Full (REDF) - Bit 9 ..........................................................................8-27

8.3.6.9 SAISR Receive Odd-Data Register Full (RODF) - Bit 10 .........................................................................8-27

8.3.6.10 SAISR Transmit Frame Sync Flag (TFS) - Bit 13 .....................................................................................8-27

8.3.6.11 SAISR Transmit Underrun Error Flag (TUE) - Bit 14 ...............................................................................8-27

8.3.6.12 SAISR Transmit Data Register Empty (TDE) - Bit 15 ..............................................................................8-27

8.3.6.14 SAISR Transmit Even-Data Register Empty (TEDE) - Bit 16 ..................................................................8-27

8.3.6.13 SAISR Transmit Odd-Data Register Empty (TODE) - Bit 17 ................................................................... 8-28

8.3.7 ESAI Receive Shift Registers ...........................................................................................................................8-29

8.3.8 ESAI Receive Data Registers (RX3, RX2, RX1, RX0) ....................................................................................8-30

8.3.9 ESAI Transmit Shift Registers ..........................................................................................................................8-30

8.3.10 ESAI Transmit Data Registers (TX5, TX4, TX3, TX2,TX1,TX0) ..................................................................8-30

8.3.11 ESAI Time Slot Register (TSR) .......................................................................................................................8-30

8.3.12 Transmit Slot Mask Registers (TSMA, TSMB) ...............................................................................................8-30

8.3.13 Receive Slot Mask Registers (RSMA, RSMB) ................................................................................................8-31

8.4 Operating Modes .....................................................................................................................................................8-32

8.4.1 ESAI After Reset ..............................................................................................................................................8-32

8.4.2 ESAI Initialization ............................................................................................................................................8-32

8.4.3 ESAI Interrupt Requests ...................................................................................................................................8-33

8.4.4 Operating Modes – Normal, Network and On-Demand ...................................................................................8-33

8.4.4.1 Normal/Network/On-Demand Mode Selection ..........................................................................................8-33

8.4.4.2 Synchronous/Asynchronous Operating Modes ..........................................................................................8-34

8.4.4.3 Frame Sync Selection 3 ...............................................................................................................................8-34

8.4.4.4 Shift Direction Selection ............................................................................................................................8-34

8.4.5 Serial I/O Flags .................................................................................................................................................8-34

8.5 GPIO - Pins and Registers .......................................................................................................................................8-35

8.5.1 Port C (ESAI) GPIO - Pins and Registers ........................................................................................................8-35

8.5.1.1 Port C Control Register (PCRC) ................................................................................................................8-35

8.5.1.2 Port C Direction Register (PRRC) ..............................................................................................................8-35

8.5.1.3 Port C Data register (PDRC) ...................................................................................................................... 8-36

8.5.2 Port E (ESAI_1) GPIO - Pins and Registers .....................................................................................................8-36

8.5.2.1 Port E Control Register (PCRE) .................................................................................................................8-37

8.5.2.2 Port E Direction Register (PRRE) ..............................................................................................................8-37

8.5.2.3 Port E Data register (PDRE) .......................................................................................................................8-37

8.6 ESAI Initialization Examples ..................................................................................................................................8-38

8.6.1 Initializing the ESAI Using Individual Reset ...................................................................................................8-38

8.6.2 Initializing Just the ESAI Transmitter Section .................................................................................................8-38

8.6.3 Initializing Just the ESAI Receiver Section ......................................................................................................8-38

DSP56374 Users Guide, Rev. 1.2

TOC-6 Freescale Semiconductor

Page 9

Table of Contents

Paragraph Page

Number Number

Chapter 9

Triple Timer Module

9.1 Overview ...................................................................................................................................................................9-1

9.1.1 Triple Timer Module Block Diagram .................................................................................................................9-1

9.1.2 Individual Timer Block Diagram ........................................................................................................................9-1

9.2 Operation ...................................................................................................................................................................9-2

9.2.1 Timer After Reset ...............................................................................................................................................9-2

9.2.2 Timer Initialization .............................................................................................................................................9-2

9.2.3 Timer Exceptions ................................................................................................................................................9-3

9.3 Operating Modes .......................................................................................................................................................9-3

9.3.1 Triple Timer Modes ............................................................................................................................................9-3

9.3.1.1 Timer GPIO (Mode 0) ..................................................................................................................................9-4

9.3.1.2 Timer Pulse (Mode 1) ...................................................................................................................................9-5

9.3.1.3 Timer Toggle (Mode 2) ................................................................................................................................9-7

9.3.1.4 Timer Event Counter (Mode 3) ....................................................................................................................9-9

9.3.2 Signal Measurement Modes ..............................................................................................................................9-10

9.3.2.1 Measurement Input Width (Mode 4) ..........................................................................................................9-10

9.3.2.2 Measurement Input Period (Mode 5) ..........................................................................................................9-12

9.3.2.3 Measurement Capture (Mode 6) .................................................................................................................9-13

9.3.3 Pulse Width Modulation (PWM, Mode 7) ........................................................................................................9-14

9.3.4 Watchdog Modes ..............................................................................................................................................9-16

9.3.4.1 Watchdog Pulse (Mode 9) ..........................................................................................................................9-16

9.3.4.2 Watchdog Toggle (Mode 10) .....................................................................................................................9-17

9.3.4.3 Reserved Modes .........................................................................................................................................9-18

9.3.5 Special Cases ....................................................................................................................................................9-18

9.3.6 DMA Trigger ....................................................................................................................................................9-18

9.4 Triple Timer Module Programming Model .............................................................................................................9-18

9.4.1 Prescaler Counter ..............................................................................................................................................9-18

9.4.2 Timer Prescaler Load Register (TPLR) ............................................................................................................9-19

9.4.3 Timer Prescaler Count Register (TPCR) ..........................................................................................................9-20

9.4.4 Timer Control/Status Register (TCSR) .............................................................................................................9-21

9.4.5 Timer Load Register (TLR) ..............................................................................................................................9-25

9.4.6 Timer Compare Register (TCPR) .....................................................................................................................9-25

9.4.7 Timer Count Register (TCR) ............................................................................................................................9-25

Chapter 10

Watchdog Timer Module

10.1 Introduction ............................................................................................................................................................10-1

10.2 WDT Pin ..................................................................................................................................................................10-1

10.3 WDT Operation ......................................................................................................................................................10-1

10.4 Description of Registers ..........................................................................................................................................10-2

10.4.1 Watchdog Control Register (WCR) .................................................................................................................10-2

10.4.2 Watchdog Counter & WCNTR Register ..........................................................................................................10-2

10.4.3 Watchdog Modulus Register (WMR) ..............................................................................................................10-3

10.4.4 Watchdog Service Register (WSR) ..................................................................................................................10-3

10.5 Operation in Different Modes ................................................................................................................................10-3

10.5.1 WAIT Mode .....................................................................................................................................................10-3

10.5.2 DEBUG Mode .................................................................................................................................................10-3

10.5.3 STOP MODE ....................................................................................................................................................10-3

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor TOC-7

Page 10

Table Of Contents

Paragraph Page

Number Number

Appendix A

Bootstrap Source Code

A.1 DSP56374 Bootstrap Program .................................................................................................................................A-1

A.2 Using The Serial EEPROM Boot Mode ...................................................................................................................A-5

Appendix B

Equates

Appendix C

Programmer’s Reference

C.1 Introduction ..............................................................................................................................................................C-1

C.1.1 Peripheral Addresses ..........................................................................................................................................C-1

C.1.2 Interrupt Addresses ............................................................................................................................................C-1

C.1.3 Interrupt Priorities ..............................................................................................................................................C-1

C.1.4 Programming Sheets ..........................................................................................................................................C-1

C.1.5 Internal I/O Memory Map ..................................................................................................................................C-1

C.1.6 Interrupt Vector Addresses ................................................................................................................................C-7

C.2 Interrupt Source Priorities (within an IPL) .............................................................................................................C-10

C.3 Programming Sheets ...............................................................................................................................................C-11

Appendix D

BSDL

D.1 52-pin BSDL ............................................................................................................................................................D-1

D.2 80-pin BSDL ............................................................................................................................................................D-6

DSP56374 Users Guide, Rev. 1.2

TOC-8 Freescale Semiconductor

Page 11

List of Figures

Figure Page

Number Number

1-1 DSP56374 Block Diagram ........................................................................................................................................1-1

2-1 80-pin Vdd Connections ............................................................................................................................................2-2

2-2 52-pin Vdd Connections ............................................................................................................................................2-3

3-1 Default Memory Map (MS 0) ...................................................................................................................................3-2

3-2 Memory Map (MS 1, MSW(1-0) 11) ........................................................................................................................3-2

3-3 Memory Map (MS 1, MSW(1-0) 10) ........................................................................................................................3-3

3-4 Memory Map (MS 1, MSW(1-0) 01) ........................................................................................................................3-4

3-5 Memory Map (MS 1, MSW(1-0) 00) ........................................................................................................................3-4

4-1 Interrupt Priority Register P ......................................................................................................................................4-4

4-2 Interrupt Priority Register C ......................................................................................................................................4-4

4-3 PCTL Register .........................................................................................................................................................4-10

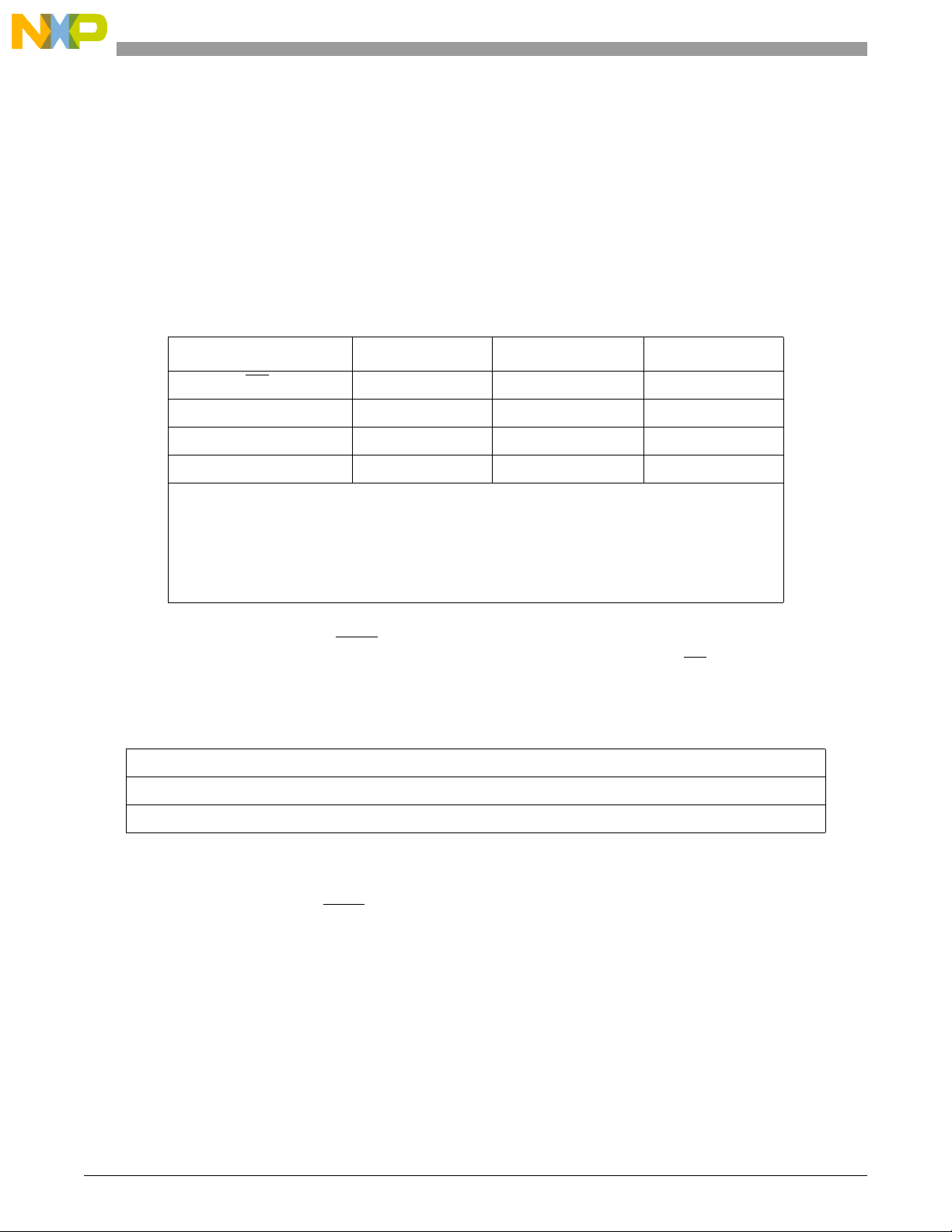

5-1 PLL Clock Generator Block Diagram .......................................................................................................................5-1

5-2 PLL Block Diagram ..................................................................................................................................................5-2

5-3 PLL Loop with One Divider when OD1=0 (FM = 2) ...............................................................................................5-4

5-4 PLL Loop with Two Dividers when OD1=1 (FM = 4) .............................................................................................5-4

5-5 PLL Out = VCO Out/2 [OD1 = 0, OD0 = 1] ............................................................................................................5-5

5-6 PLL Out = VCO Out/2 [OD1 = 1, OD0 = 0] ............................................................................................................5-5

5-7 PLL Out = VCO Out/4 [OD1 = 1, OD0 = 1] ............................................................................................................5-6

5-8 CLKGEN Block Diagram .........................................................................................................................................5-6

5-9 PLL Control (PCTL) Register ...................................................................................................................................5-7

6-1 PCRG Register ..........................................................................................................................................................6-2

6-2 PRRG Register ..........................................................................................................................................................6-2

6-3 PDRG Register ..........................................................................................................................................................6-2

6-4 PCRH Register ..........................................................................................................................................................6-4

6-5 PRRH Register ..........................................................................................................................................................6-4

6-6 PDRH Register ..........................................................................................................................................................6-4

7-1 Serial Host Interface Block Diagram ........................................................................................................................7-2

7-2 SHI Clock Generator .................................................................................................................................................7-2

7-3 SHI Programming Model—Host Side ......................................................................................................................7-3

7-4 SHI Programming Model—DSP Side .......................................................................................................................7-3

7-5 SHI I/O Shift Register (IOSR) ..................................................................................................................................7-4

7-6 SPI Data-To-Clock Timing Diagram ........................................................................................................................7-6

7-7 I

7-8 I

7-9 Acknowledgment on the I2C Bus ............................................................................................................................7-12

7-10 I

7-11 I2C Bus Protocol For Host Read Cycle ...................................................................................................................7-13

8-1 ESAI Block Diagram .................................................................................................................................................8-2

8-2 TCCR Register ..........................................................................................................................................................8-6

8-3 ESAI Clock Generator Functional Block Diagram ...................................................................................................8-7

8-4 ESAI Frame Sync Generator Functional Block Diagram .........................................................................................8-8

8-5 TCR Register ...........................................................................................................................................................8-10

8-6 Normal and Network Operation ..............................................................................................................................8-13

8-7 Frame Length Selection ...........................................................................................................................................8-15

8-8 RCCR Register ........................................................................................................................................................8-17

8-9 RCR Register ...........................................................................................................................................................8-20

8-10 SAICR Register .......................................................................................................................................................8-23

8-11 SAICR SYN Bit Operation .....................................................................................................................................8-25

2

C Bit Transfer .......................................................................................................................................................7-12

2

C Start and Stop Events ........................................................................................................................................7-12

2

C Bus Protocol For Host Write Cycle ..................................................................................................................7-13

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor LOF-1

Page 12

List of Figures

Figure Page

Number Number

8-12 SAISR Register .......................................................................................................................................................8-26

8-13 ESAI Data Path Programming Model ([R/T]SHFD=0) ..........................................................................................8-28

8-14 ESAI Data Path Programming Model ([R/T]SHFD=1) ..........................................................................................8-29

8-15 TSMA Register ........................................................................................................................................................8-30

8-16 RSMA Register .......................................................................................................................................................8-31

8-17 TSMB Register ........................................................................................................................................................8-31

8-18 RSMB Register ........................................................................................................................................................8-32

8-19 PCRC Register ........................................................................................................................................................8-36

8-20 PRRC Register ........................................................................................................................................................8-36

8-21 PDRC Register ........................................................................................................................................................8-36

8-22 PCRE Register .........................................................................................................................................................8-37

8-23 PRRE Register .........................................................................................................................................................8-37

8-24 PDRE Register ........................................................................................................................................................8-38

9-1 Triple Timer Module Block Diagram .......................................................................................................................9-1

9-2 Timer Module Block Diagram ..................................................................................................................................9-2

9-3 Timer Mode (TRM = 1) ............................................................................................................................................9-4

9-4 Timer Mode (TRM = 0) ............................................................................................................................................9-5

9-5 Pulse Mode (TRM = 1) .............................................................................................................................................9-6

9-6 Pulse Mode (TRM = 0) .............................................................................................................................................9-7

9-7 Toggle Mode, TRM = 1 ............................................................................................................................................9-8

9-8 Toggle Mode, TRM = 0 ............................................................................................................................................9-8

9-9 Event Counter Mode, TRM = 1 .................................................................................................................................9-9

9-10 Event Counter Mode, TRM = 0 ...............................................................................................................................9-10

9-11 Pulse Width Measurement Mode, TRM = 1 ...........................................................................................................9-11

9-12 Pulse Width Measurement Mode, TRM = 0 ...........................................................................................................9-11

9-13 Period Measurement Mode, TRM = 1 .....................................................................................................................9-12

9-14 Period Measurement Mode, TRM = 0 .....................................................................................................................9-13

9-15 Capture Measurement Mode, TRM = 0 ..................................................................................................................9-14

9-16 Pulse Width Modulation Toggle Mode, TRM = 1 ..................................................................................................9-15

9-17 Pulse Width Modulation Toggle Mode, TRM = 0 ..................................................................................................9-16

9-18 Watchdog Pulse Mode .............................................................................................................................................9-17

9-19 Watchdog Toggle Mode ..........................................................................................................................................9-18

9-20 Timer Module Programmer’s Model ......................................................................................................................9-19

9-21 Timer Prescaler Count Register (TPCR) .................................................................................................................9-20

10-1 Watchdog Timer Block Diagram .............................................................................................................................10-2

C-1 Status Register (SR) ...............................................................................................................................................C-12

C-2 Operating Mode Register (OMR) ...........................................................................................................................C-13

C-3 Interrupt Priority Register–Core (IPR–C) ..............................................................................................................C-14

C-4 Interrupt Priority Register – Peripherals (IPR–P) ..................................................................................................C-15

C-5 Phase Lock Loop Control Register (PCTL) ...........................................................................................................C-16

C-6 SHI Slave Address and Clock Control Registers ...................................................................................................C-17

C-7 SHI Host Control/Status Register ...........................................................................................................................C-18

C-8 ESAI Transmit Clock Control Register ..................................................................................................................C-19

C-9 ESAI Transmit Control Register ............................................................................................................................C-20

C-10 ESAI Receive Clock Control Register ...................................................................................................................C-21

C-11 ESAI Receive Control Register ..............................................................................................................................C-22

C-12 ESAI Common Control Register ............................................................................................................................C-23

C-13 ESAI Status Register ..............................................................................................................................................C-24

C-14 ESAI_1 Transmit Clock Control Register ..............................................................................................................C-25

C-15 ESAI_1 Transmit Control Register ........................................................................................................................C-26

DSP56374 Users Guide, Rev. 1.2

LOF-2 Freescale Semiconductor

Page 13

List of Figures

Figure Page

Number Number

C-16 ESAI_1 Receive Clock Control Register ...............................................................................................................C-27

C-17 ESAI_1 Receive Control Register ..........................................................................................................................C-28

C-18 ESAI_1 Common Control Register ........................................................................................................................C-29

C-19 ESAI_1 Status Register ..........................................................................................................................................C-30

C-20 Timer Prescaler Load and Prescaler Count Registers (TPLR, TPCR) ...................................................................C-31

C-21 Timer Control/Status Register ................................................................................................................................C-32

C-22 Timer Load, Compare and Count Registers ...........................................................................................................C-33

C-23 GPIO Port C ...........................................................................................................................................................C-35

C-24 GPIO Port E ............................................................................................................................................................C-36

C-25 GPIO Port G ...........................................................................................................................................................C-37

DSP56374 Users Guide, Rev. 1.2

Freescale Semiconductor LOF-3

Page 14

List of Figures

Notes

DSP56374 Users Guide, Rev. 1.2

LOF-4 Freescale Semiconductor

Page 15

List of Tables

Tab le Page

Number Number

1-1 DSP56374 Memory Switch Configurations ..............................................................................................................1-2

2-1 DSP56374 Functional Signal Groupings ..................................................................................................................2-1

2-2 Power Inputs ..............................................................................................................................................................2-1

2-3 Grounds .....................................................................................................................................................................2-3

2-4 SCAN signals ............................................................................................................................................................2-4

2-5 Clock and PLL Signals ..............................................................................................................................................2-4

2-6 Interrupt and Mode Control .......................................................................................................................................2-4

2-7 Serial Host Interface Signals .....................................................................................................................................2-6

2-8 Enhanced Serial Audio Interface Signals ..................................................................................................................2-8

2-9 Enhanced Serial Audio Interface_1 Signals ............................................................................................................2-12