Page 1

查询MC7445供应商

Freescale Semiconductor

Technical Data

MPC7455

RISC Microprocessor

Hardware Specifications

The MPC7455 and MPC7445 are implementations of the

PowerPC™ microprocessor family of reduced instruction set

computer (RISC) microprocessors. This document is primarily

concerned with the MPC7455; however, unless otherwise noted,

all information here also applies to the MPC7445. This document

describes pertinent electrical and physical characteristics of the

MPC7455. For functional characteristics of the processor, refer to

the MPC7450 RISC Microprocessor Family User’s Manual. To

locate any published updates for this document, refer to the

website at http://www.freescale.com.

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Comparison with the MPC7400, MPC7410,

4. General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5. Elect r ical and Thermal Characteristics . . . . . . . . . . . 10

6. Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7. Pinout Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8. Package Description . . . . . . . . . . . . . . . . . . . . . . . . . 41

9. System Design Information . . . . . . . . . . . . . . . . . . . 45

10. Document Revision History . . . . . . . . . . . . . . . . . . . 59

11. Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . 60

MPC7455EC

Rev. 4.1, 02/2005

Contents

MPC7450, MPC7451, and MPC7441 . . . . . . . . . . . . . 7

1Overview

The MPC7455 is the thir d implementation o f the fourth g eneration

(G4) microprocess ors from Freescale. The MPC7455 imple ments

the full PowerPC 32-bit architecture and is targeted at networking

and computing systems applications. The MPC7455 consists of a

processor core, a 256-Kbyte L2, and an internal L3 tag and

controller which support a glueless backside L3 cache through a

dedicated high-ba ndwidth interface. The MPC7445 is identical to

the MPC7455 except it does not support the L3 cache int erface.

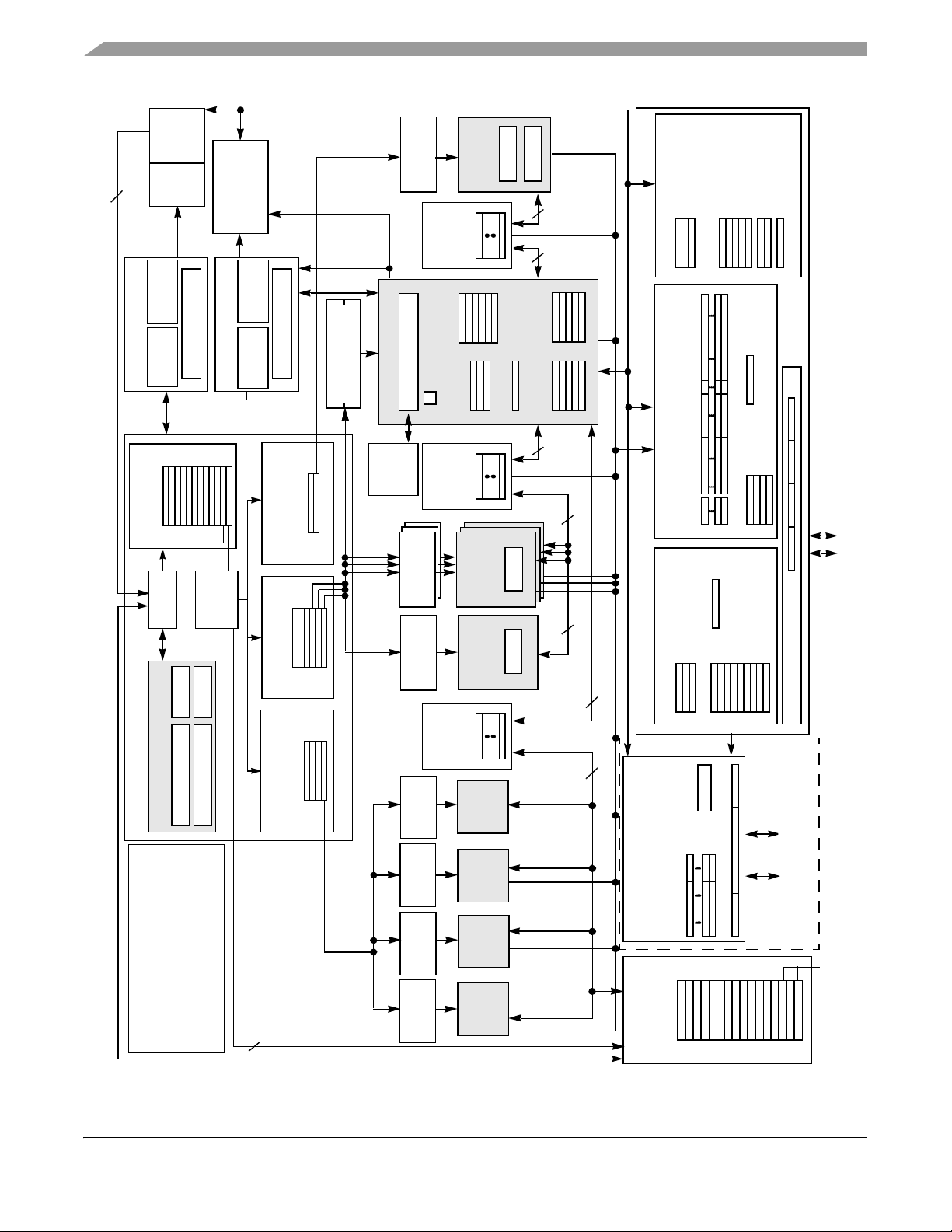

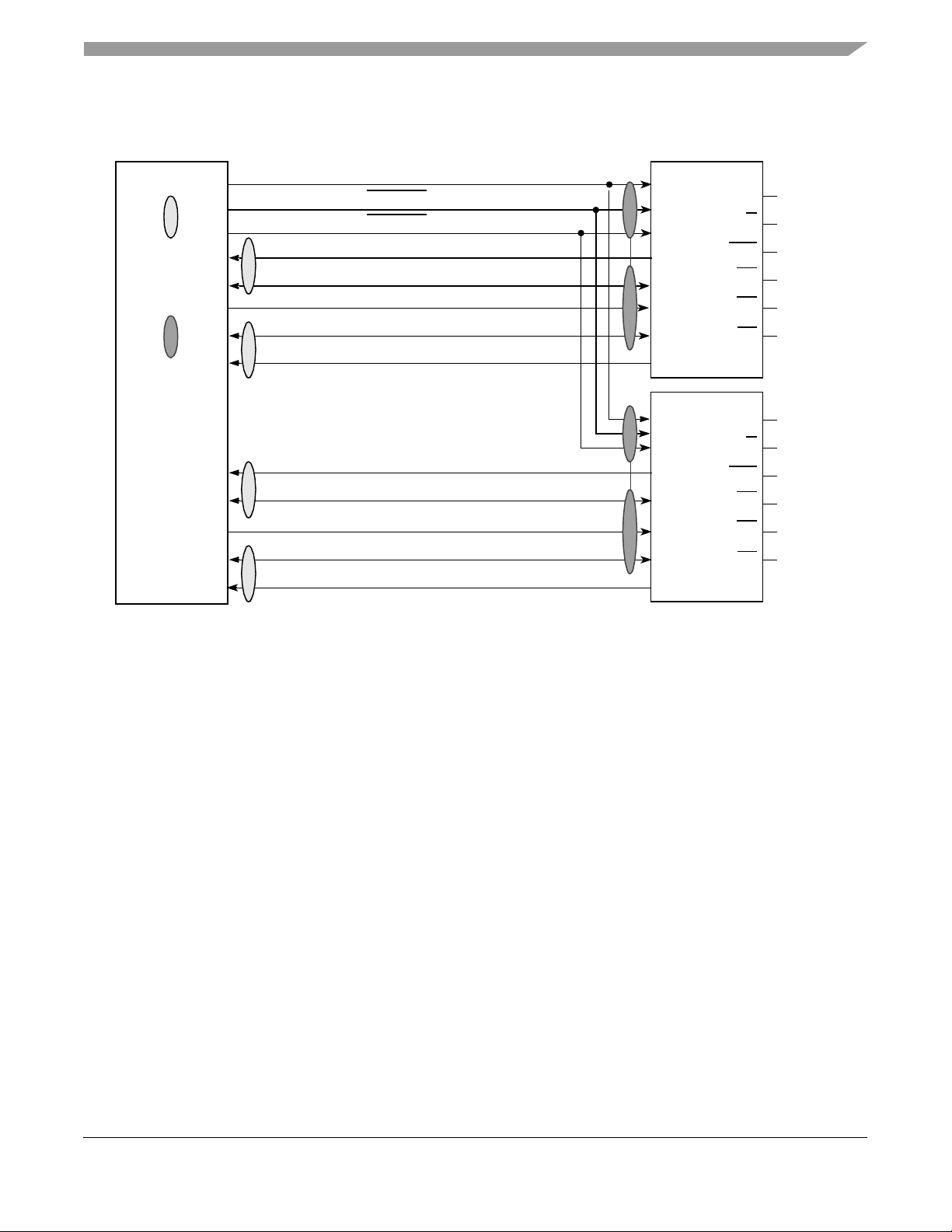

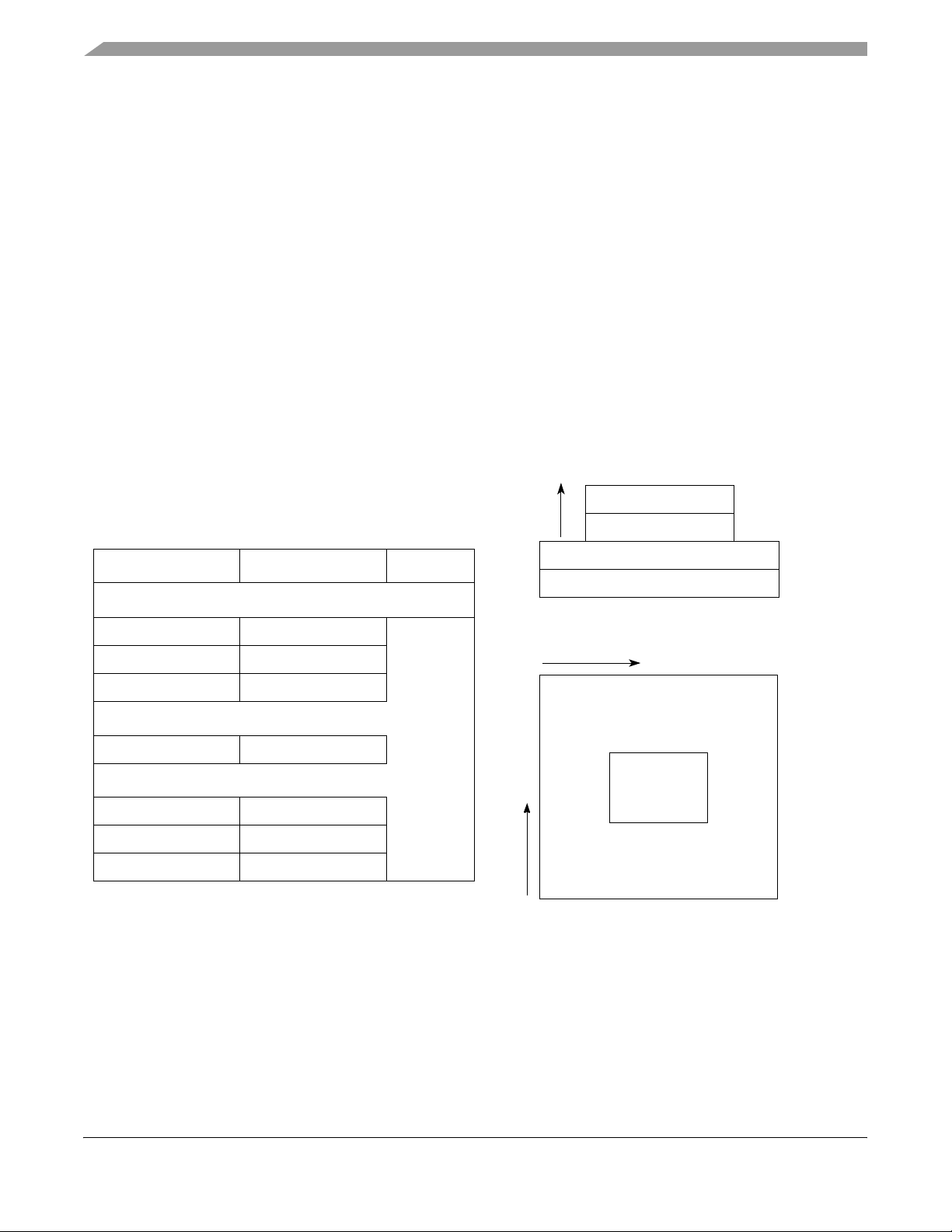

Figure 1 shows a block diagram of the MPC7455.

© Freescale Semiconductor, Inc., 2005. All rights reserved.

Page 2

Overview

I Cache

32-Kbyte

+x÷

FPSCR

Floating-

Stations (2)

D Cache

Tags

128-Bit (4 Instructions)

ITLB

128-Entry

32-Kbyte

Ta g s

DTLB

128-Entry

EA

Reservation

FPR File

PA

Point Unit

Buffers

16 Rename

FPSCR

Cacheable Store

Instruction Fetch (2)

(LSQ)

64-Bit

64-Bit

L1 Store Queue

L1 Service Queues

L1 Load Miss (5)

L1 Load Queue (LLQ)

Request (1)

Instruction MMU

Instruction Queue

Instruction Unit

Load Miss

Block 1 (32-Byte)

256-Kbyte Unified L2 Cache/Cache Controller

System Bus Interface

Stat us

Block 0 (32-Byte)

Status

Line

Ta g s

L2 Prefetch (3)

Bus Store Queue

L3CR

Stores

L1 Push

Completed

32-Bit

32-Bit

+

+

+

Memory Subsystem

32-Bit

x ÷

128-Bit128-Bit

Snoop Push/

Interventions

L2 Store Queue (L2SQ)

L1 Castouts

(4)

Push

Castout

Queue

(9)

External SRAM

36-Bit Address Bus 64-Bit Data Bus

Bus Accumulator

(1 or 2 Mbytes)

64-Bit Data

(8-Bit Parity)

Vector Touch Engine

Queue

Reservation

Reservation

Reservation

Reservation

Reservation

L1 Castout

(EA Calculation )

Stores

+

Finished

Buffers

GPR File

16 Rename

Integer

Integer

Integer

Buffers

16 Rename

Unit 2

(3)

Unit 2

Integer

Unit 2 Unit 1

FPU

Vector

Stat ion

Stat ion

Stat ion

Stations (2)

VR File

Stat ion

IBAT Array

Data MMU

SRs

(Shadow)

(12-Word)

Fetcher

Branch Processing Unit

Unit

Dispatch

LR

CTR

BTIC (128-Entry)

BHT (2048-Entry)

DBAT Array

SRs

(Original)

GPR Issue

(6-Entry/3-Issue) (4-Entry/2-Issue) (2-Entry/1-Issue )

VR Issue FPR Issue

Reservation

Load/Store Unit

Stations (2-Entry)

To u ch

Vector

Stat ion

Reservation

Stat ion

Reservation

Additional Features

• Time Base Counter/Decrementer

• Clock Multiplier

• JTAG/COP Interface

• Thermal/Power Management

96-Bit (3 Instructions)

• Performance Monitor

Stat io n

Reservation

Unit 1

Vector

Integer

Unit 2

Ve cto r

Integer

Unit

Vector

Permute

Completion Unit

L3 Cache Controller

StatusTa g s

Block 0/1 Line

Bus Accumulator

(16-Entry)

Completion Queue

18-Bit

Address

Not in

MPC7445

Completes up to three instructions per clock

Figure 1. MPC7455 Block Diagram

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

2 Freescale Semiconductor

Page 3

Features

The core is a high-performance superscalar design supporting a double-precision floating-point unit and a SIMD

multimedia unit. The memory storage subsyste m supports the MPX bus protocol and a subset of the 60x bus protocol

to main m emory a nd other system r esources. The L3 in terface supports 1 or 2 Mbytes of external SRAM for L3

cache data.

Note that the MPC7455 is footprint-compatible with the MPC7450 and MPC7451, and the MPC7445 is

footprint-co mpatible with the MPC7441.

2Features

This section summarizes features of the MPC7455 implementation of the PowerPC architecture.

Major features of the MPC7455 are as follows:

• High-performance, superscalar microprocessor

— As many as four instructions can be fetched from the instruction cache at a time

— As many as thr ee inst ruct i on s ca n be disp atch ed to the issue queu e s at a time

— As many as 12 instructions can be in the instruction queue (IQ)

— As many as 16 instructions can be at some stage of execution simultaneously

— Single-cycle execution for most instructions

— One instruction per clock cy cle thr oughput for most instructions

— Seven-stage pipeline control

• Eleven independent exec ution units and three register fil es

— Branch processing unit (BPU) features static and dynamic branch predi ction

– 128-entry (32-set, four-way set-associative) branch target instruction cache (BTIC), a cache of

branch instru ctions that ha ve been encounter ed in branc h/loop code sequ ences. If a ta rget inst ruction

is in the BTIC, it is fetched into the instruction queue a cycle sooner than it can be made available

from the instruction cache. Typically, a fetch that hits the BTIC provides the first four instructions

in the target stre am.

– 2048-entry bran ch history table (BHT) with two bits per entry for four leve ls of

prediction—not-ta ken, strongly not-taken, ta ken, and strongly taken

– Up to three outstanding spe culative branches

– Branch instructions that do not update the count register (CTR) or link register (LR) are often

removed from the instructi on stream.

– Eight-entry link register stack to predict the target address of Branch Conditional to Link Register

(bclr) instru cti ons

— Four integer units (IUs) that share 32 GPRs for integer operands

– Three identical I Us (IU1a , IU1 b, an d IU1c) can execute all integer instructions except multiply,

divide, and move to/from special-purpose register instructions

– IU2 executes misc ellaneous instruction s inc luding the CR logi cal oper ations, integer multiplica tion

and division instructions, and move to/from special-pu rpose register instructions

— Five-stag e FP U and a 32- en try FPR file

– Fully IEEE 754-1985-compliant FPU for both single- and double-precision operations

– Supports non-IEEE mode for time-critical operations

– Hardware support for de normalized numbers

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 3

Page 4

Features

– Thirty-two 64-bit FPRs for single- or double-precision operands

— Four vector units and 32-entry vector register file (VRs)

– Vector permute unit (VPU)

– Ve ctor integ er unit 1 (VIU1) handles short-latenc y AltiVec™ integer ins tructions, s uch as vect or add

instructions (vaddsbs, vaddshs, and vaddsws, for example)

– Vector integer unit 2 (VIU2) handles longer -latency AltiVec integer instruction s, suc h as vector

multiply add instruct ions (vmhaddshs, vmhraddshs, and vmladduhm, for example)

– Vector floating-point unit (VFPU)

— Three-stage load/store unit (LSU)

– Supports integer, floating-point, and vector instructi on load/store traffic

– Four-entry vector touch queue (VTQ) supports all four architected AltiVec data stream operations

– Three-cycle GPR and AltiVec load latency (byte, half -word, word, vector) with one-cycle

throughput

– Four-cyc le FPR load latency (single, double) with one-cycle throughput

– No additional delay for misaligned access within double-word boundary

– Dedicated ad der calculates effec tiv e add ress es (EA s )

– Supports store gat hering

– Performs alignmen t, nor malization, and precision conversion for floating-poi nt data

– Executes cache control and TLB instructions

– Performs alignmen t, z ero pa dding, and sign extension for integer data

– Supports hits under mis ses (multiple outstanding misses)

– Supports both big- and little-endian modes, including misaligned little-endian accesses

• Three issue queues FIQ, VIQ, and GIQ can accept as many as one, two, and three instru ctions, respect ively ,

in a cycle. Instruct io n disp a tc h requi re s the follo w ing:

— Instructions can be dis patched only from the three lowest IQ entries—IQ0, IQ1, and IQ2

— A maximum of three instructions can be dispa tched to the issue queues per clock cycle

— Space mus t be avai l abl e in the CQ fo r an instr u ction to disp at ch (t h is inclu des ins tru ct io ns tha t are

assigned a space in the CQ but not in an issue queue)

• Rename buffers

— 16 GPR rename buffers

— 16 FPR rename buffers

— 16 VR rename buffers

• Dispatch unit

— Decode/dispatch stage fully decodes each instruction

• Completion unit

— The completion unit retire s an instruction from the 16-entry comple tion queue (CQ) when all

instructions ahead of it have been completed, the instructi on has finishe d execution , and no exceptions

are pending.

— Guarantees sequentia l pr ogramming model (precise exception model)

— Monitors all dispatche d instructions and retires them in orde r

— Tracks unr esolved branches and flushes inst ructions after a mispredicted branc h

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

4 Freescale Semiconductor

Page 5

— Retires as many as three instructions per clock cycle

• Separate on-chip L1 instruction and data caches (Harvard architecture)

— 32-Kbyte, eight-way set-associative instruc tion and data caches

— Pseudo least-recently-used (PLRU) replacement algorithm

— 32-byte (eight-wor d) L1 cache block

— Physically indexed/physical tags

— Cache write-back or write-through operation programmable on a per-page or per-block basis

— Instruction cac he can provide four instructions per clock cycle; data cache can provide four words per

clock cycle

— Caches can be disabled in softwar e

— Caches can be locked in software

— MESI data cache coherency maintained in hardware

— Separate copy of data cache tags for efficient snooping

— Parity support on cache and tags

— No snooping of instruction cac he except for icbi instruction

— Data cache supports AltiVec LRU and transient instructions

— Critical double- and/or quad-word forwarding is performed as needed. Critical quad-word forwarding

is used for AltiVec loads and instruction fetches. Other accesses use critical double -word forwarding.

• Level 2 (L2) cac he interface

— On-chip, 256-Kbyte, ei ght-way set-associative unif ied instruction and data cache

— Fully pipelined to provi de 32 bytes per clock cycle to the L1 caches

— A total nine-cycle load lat en cy for an L1 data cache mis s that hits in L2

— PLRU replacement algorithm

— Cache write-back or write-through operation programmable on a per-page or per-block basis

— 64-byte, two-sectored line size

— Parity support on cache

• Level 3 (L3) cache interface (not implemented on MPC7445)

— Provides critical double-word forwarding to the requesting unit

— Internal L 3 cach e co ntr oller and tags

— External data SRAMs

— Support for 1- and 2-Mbyte L3 caches

— Cache write-back or write-through operation programmable on a per-page or per-block basis

— 64-byte (1M) or 128-byte (2M) sector ed line size

— Private memory capability for half (1-Mbyte minimum) or all of the L3 SRAM space

— Supports MSUG2 dual data rate (DDR) synchronous Burst SRAMs, PB2 pipelin ed synchronous Burst

SRAMs, and pipelined (register-register) late write synchronous Burst SRAMs

— Supports parity on cache and tags

— Configurable core-to-L3 frequency divisors

— 64-bit external L3 data bus sustains 64 bits per L3 clock cycle

Features

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 5

Page 6

Features

• Separate memory management units (MMUs) for instructions and data

— 52-bit virtual address; 32- or 36-bit physical address

— Address translation f or 4-Kbyte pages, variable-sized blocks, and 256-Mbyte segments

— Memory programmable a s write-back/write-through, caching-inhibited/caching-allowed, and m emory

coherency enforced /memory co herency not enforced on a page or block basis

— Separate IBATs and DBATs (eight each) also defined as SPRs

— Separate instruc tion and data translation lookasi de buffers (TLBs)

– Both TLBs are 128-entry, two-way set-associative, and use LRU replacement algorithm

– TLBs are hardware - or softwar e-reloa dable (that is, on a TLB miss a page table search is pe rformed

in hardware or by system software)

• Efficient data flow

— Although the VR/LSU interface is 128 bits, the L1/L2/L3 bus interface allows up to 256 bits

— The L1 data cache is fully pipelined to provide 128 bits/cycle to or from the VRs

— L2 cache is ful ly pipel in ed to pro vide 2 5 6 bits pe r proc es so r cloc k cycl e t o the L1 cac h e

— As many as eight outstanding, out-of-order, cache misses are allowed between the L1 data cache and

L2/L3 bus

— As many as 16 out-of-order transactions can be present on the MPX bus

— Store mer ging for multiple store misses to the same line. Only coherency action taken (address-only)

for store misses merge d to all 32 bytes of a cache block (no data tenure needed).

— Three-entry finish ed store queue and five-entry comple ted store queue between the LSU and the L1 data

cache

— Separate additiona l queues for eff icie nt buffe ring of outbound dat a (such as castout s and write through

stores) from the L1 data cache and L2 cache

• Multiprocessing support features include the following:

— Hardware-enforc ed, MESI cache coherency protocols for data cache

— Load/store with reserva tion instruction pair for at omic memory ref erences, semaphores, and other

multiprocessor ope rations

• Power and thermal management

— 1.3-V proces s or co re

— The following three power-saving modes are available to the system:

– Nap—Instruction fetching is halted. Only those clocks for the time base, decrementer, and JTAG

logic remain runn ing. The part goes into the doze state to snoop memory opera tions on the bus and

then back to nap using a QREQ

/QACK processor- system handshake protocol.

– Sleep—Power consump tion is f urthe r reduce d by di sabling b us snoo ping, le aving onl y the PLL in a

locked and running state. All internal functional units are disabled.

– Deep sleep—When the part is in the sleep state, the system can disable the PLL. The system can then

disable the SYSCLK source for greater system power savings. Power-on reset procedures for

restarting and relocking the PLL must be followed on exiting the deep sleep state.

— Thermal management facility provides software-controllable thermal management. Thermal

management is per formed thr ough the use of thr ee sup ervisor -le vel re gisters and an MPC7455-sp ecific

ther mal management exception.

— Instruction cache throttling provides control of instruction fetching to limit power consumption

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

6 Freescale Semiconductor

Page 7

Comparison with the MPC7400, MPC7410, MPC7450, MPC7451, and MPC7441

• Performance monitor can be used to help debug syst em designs and improve software efficiency

• In-system testabi lity and debugging features through JTAG boundary-scan capability

• Testability

— LSSD scan design

— IEEE 1149.1 JTAG interface

— Array built-in self test (ABIST)—factory test only

• Reliability and serviceability

— Parity checking on system bus and L3 cache bus

— Parity check in g on the L 2 and L3 cach e tag arrays

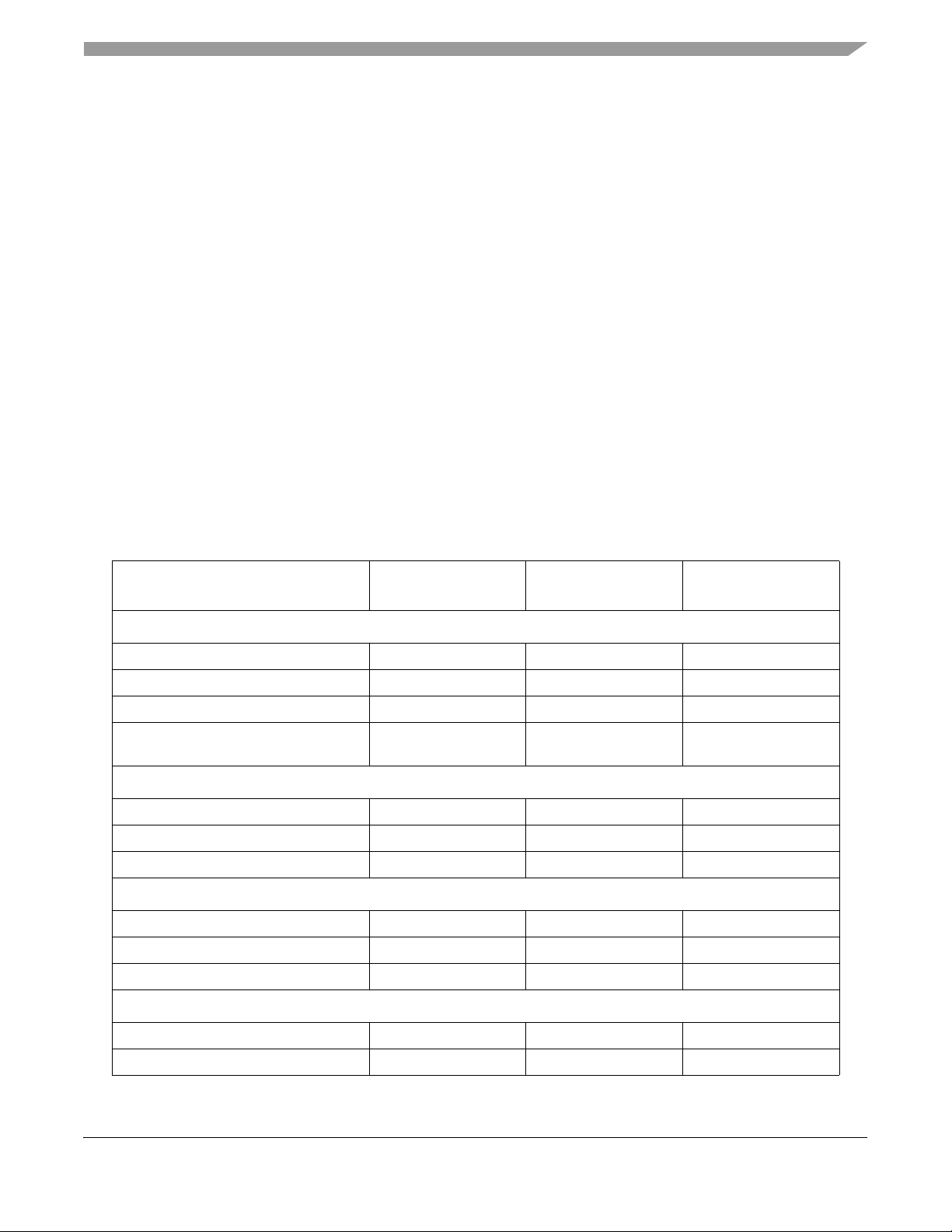

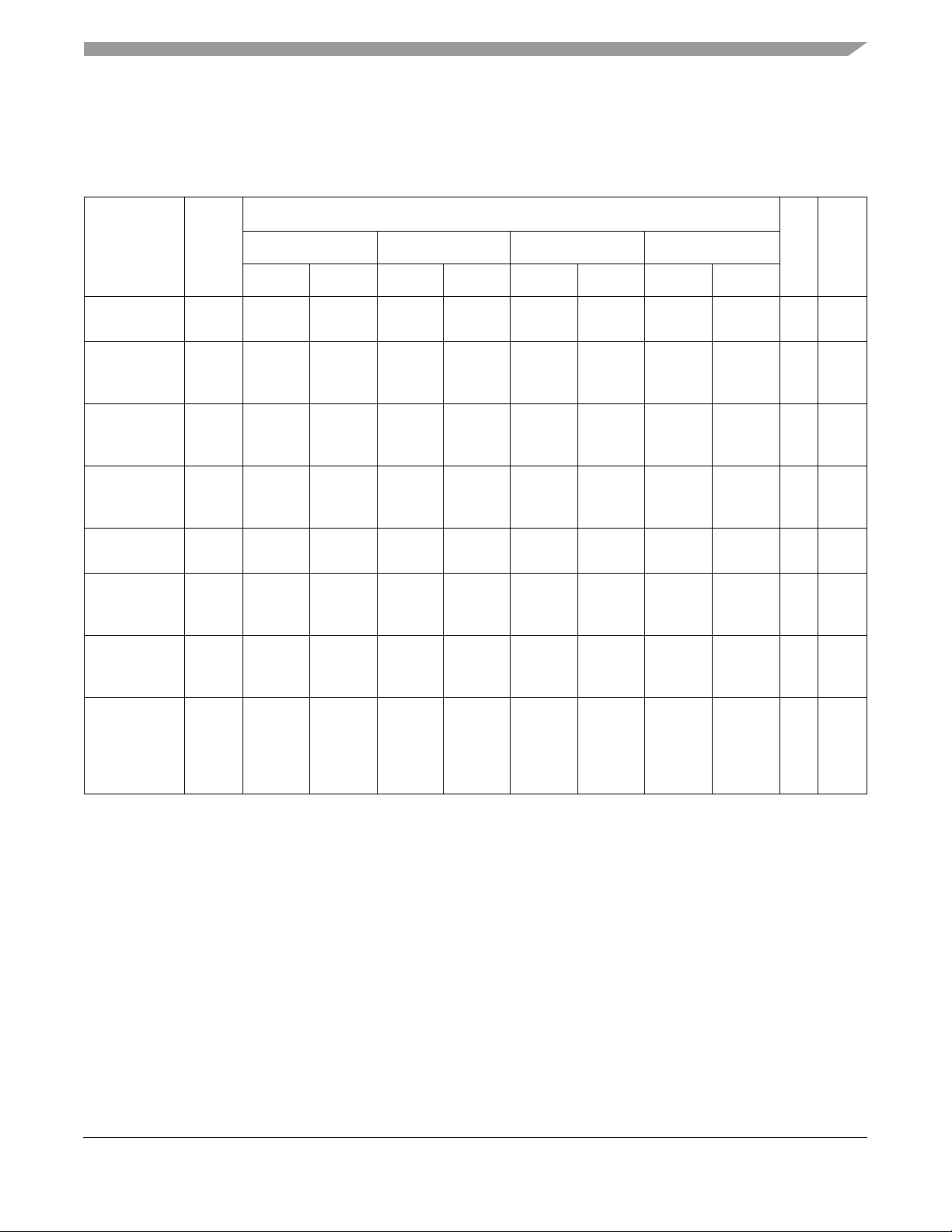

3 Comparison with the MPC7400, MPC7410, MPC7450,

MPC7451, and MPC7441

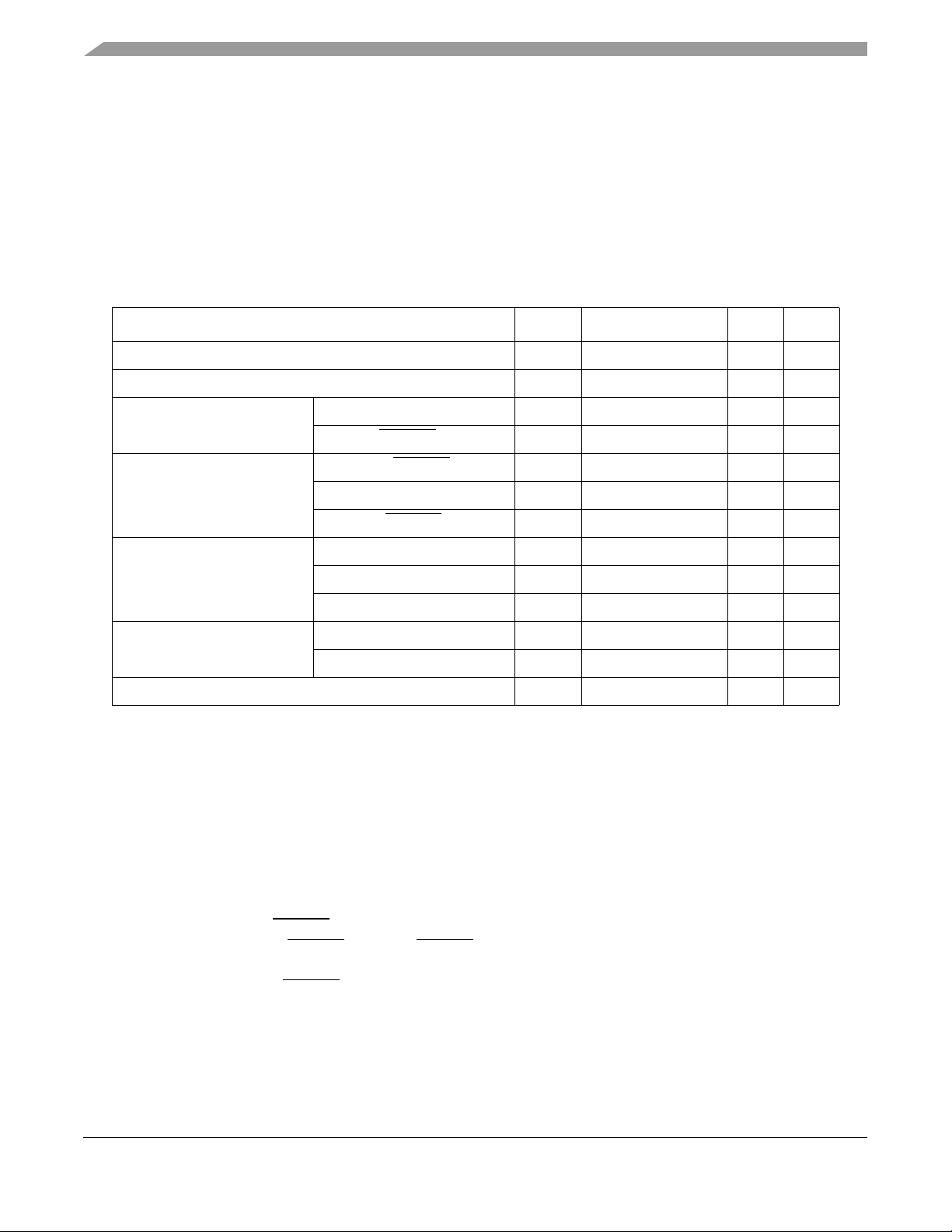

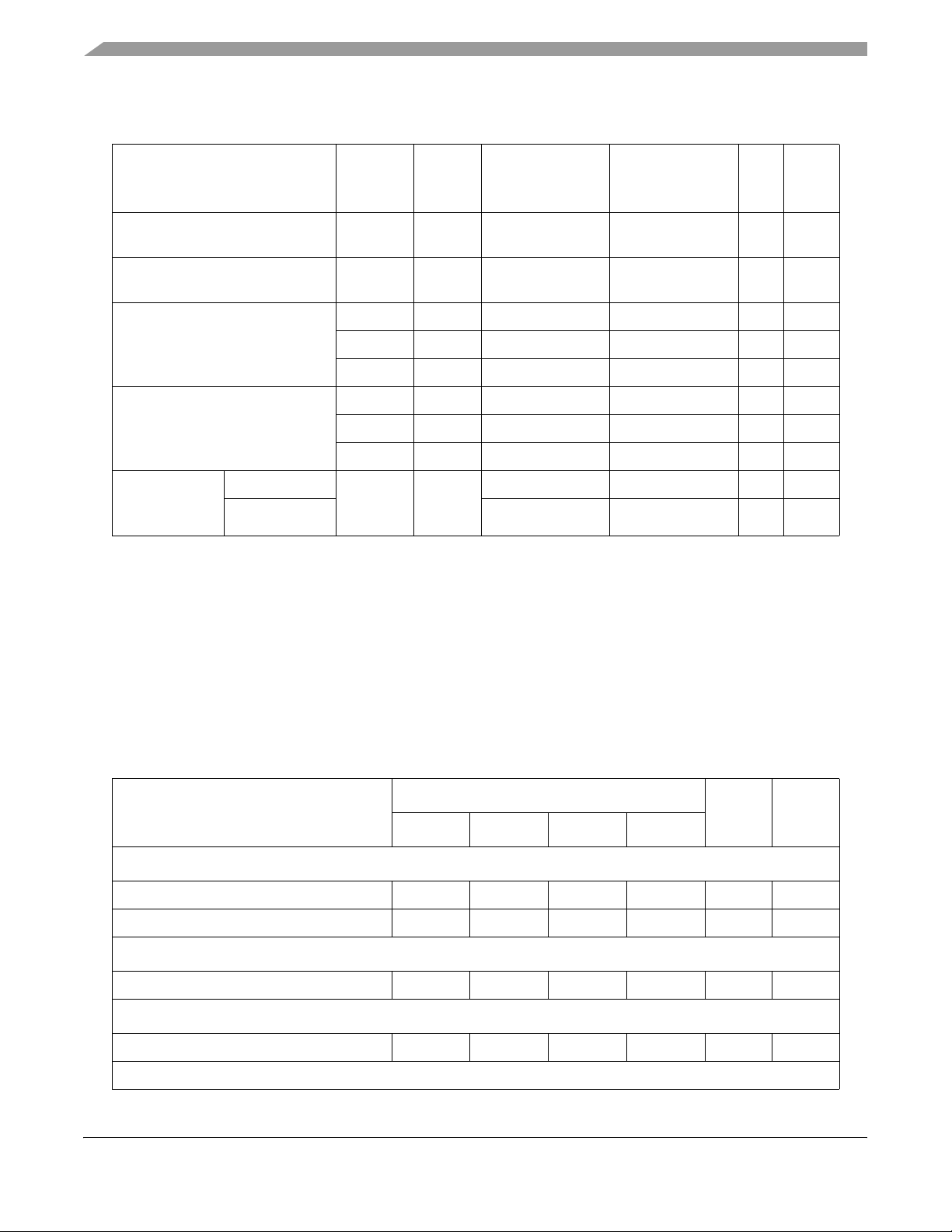

Table 1 compares the key features of the MPC7455 with the key features of the earlier MPC7400, MPC7410,

MPC7450, MPC7451, and MPC7441. To achieve a higher frequency, the number of logic levels per cycle is

reduced. Also, to achieve this higher frequency, the pipeline of the MPC7455 is extended (compared to the

MPC7400), while maintaining the same level of performance as measured by the number of instructions executed

per cycle (IPC).

Table 1. Microarchitecture Comparison

Microarchitectural Specs MPC7455/MPC7445

Basic Pipeline Functions

Logic inversions per cycle 18 18 28

Pipeline stages up to execute 5 5 3

Total pipeline stages (minimum) 7 7 4

Pipeline maximum instruction

throughput

Instruction buffer size 12 12 6

Completion buffer size 16 16 8

Renames (integer, float, vector) 16, 16, 16 16, 16, 16 6, 6, 6

Maximum Execution Throughput

SFX 332

Vector 2 (Any 2 of 4 Units) 2 (Any 2 of 4 Units) 2 (Permute/Fixed)

Scalar floating-point 1 1 1

3 + Branch 3 + Branch 2 + Branch

Pipeline Resources

MPC7450/MPC7451/

MPC7441

MPC7400/MPC7410

Out-of-Order Window Size in Execution Queues

SFX integer units 1 Entry × 3 Queues 1 Entry × 3 Queues 1 Entry × 2 Queues

Vector units In Order, 4 Queues In Order, 4 Queues In Order, 2 Queues

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 7

Page 8

Comparison with the MPC7400, MPC7410, MPC7450, MPC7451, and MPC7441

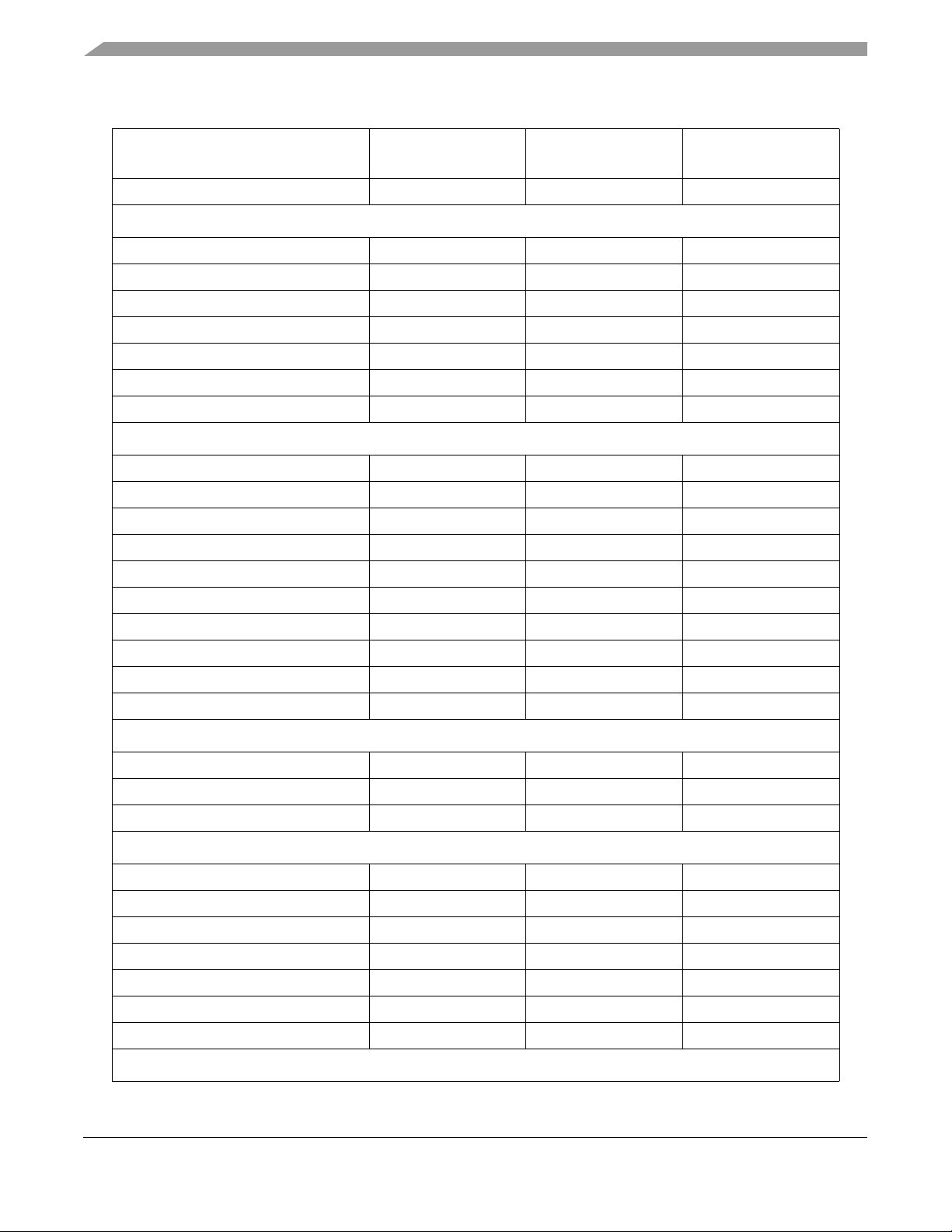

Table 1. Microarchitecture Comparison (continued)

Microarchitectural Specs MPC7455/MPC7445

MPC7450/MPC7451/

MPC7441

MPC7400/MPC7410

Scalar floating-point unit In Order In Order In Order

Branch Processing Resources

Prediction structures BTIC, BHT, Link Stack BTIC, BHT, Link Stack BTIC, BHT

BTIC size, associativity 128-Entry, 4-Way 128-Entry, 4-Way 64-Entry, 4-Way

BHT size 2K-Entry 2K-Entry 512-Entry

Link stack depth 8 8 None

Unresolved branches supported 3 3 2

Branch taken penalty (BTIC hit) 1 1 0

Minimum misprediction penalty 6 6 4

Execution Unit Timings (Latency-Throughput)

Aligned load (integer, float, vector) 3-1, 4-1, 3-1 3-1, 4-1, 3-1 2-1, 2-1, 2-1

Misaligned load (integer, float, vector) 4-2, 5-2, 4-2 4-2, 5-2, 4-2 3-2, 3-2, 3-2

L1 miss, L2 hit latency 9 Data/13 Instruction 9 Data/13 Instruction 9 (11)

1

SFX (aDd Sub, Shift, Rot, Cmp, logicals) 1-1 1-1 1-1

Integer multiply (32 × 8, 32 × 16, 32 × 32) 3-1, 3-1, 4-2 3-1, 3-1, 4-2 2-1, 3-2, 5-4

Scalar float 5-1 5-1 3-1

VSFX (vector simple) 1-1 1-1 1-1

VCFX (vector complex) 4-1 4-1 3-1

VFPU (vector float) 4-1 4-1 4-1

VPER (vector permute) 2-1 2-1 1-1

MMUs

TLBs (instruction and data) 128-Entry, 2-Way 128-Entry, 2-Way 128-Entry, 2-Way

Tablewalk mechanism Hardware + Software Hardware + Software Hardware

Instruction BATs/data BATs 8/8 4/4 4/4

L1 I Cache/D Cache Features

Size 32K/32K 32K/32K 32K/32K

Associativity 8-Way 8-Way 8-Way

Locking granularity Way Way Full Cache

Parity on I cache Word Word None

Parity on D cache Byte Byte None

Number of D cache misses (load/store) 5/1 5/1 8 (Any Combination)

Data stream touch engines 4 Streams 4 Streams 4 Streams

On-Chip Cache Features

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

8 Freescale Semiconductor

Page 9

Table 1. Microarchitecture Comparison (continued)

General Parameters

Microarchitectural Specs MPC7455/MPC7445

Cache level L2 L2 L2 tags and controller

Size/associativity 256-Kbyte/8-Way 256-Kbyte/8-Way

Access width 256 Bits 256 Bits

Number of 32-byte sectors/line 2 2

Parity Byte Byte

Off-Chip Cache Support

Cache level L3L3L2

On-chip tag logical size 1MB, 2MB 1MB, 2MB 0.5MB, 1MB, 2MB

Associativity 8-Way 8-Way 2-Way

Number of 32-byte sectors/line 2, 4 2, 4 1, 2, 4

Off-chip data SRAM support MSUG2 DDR, LW, PB2 MSUG2 DDR, LW, PB2 LW, PB2, PB3

Data path width 64 64 64

Direct mapped SRAM sizes 1 Mbyte, 2 Mbytes 1 Mbyte, 2 Mbytes 0.5 Mbyte, 1 Mbyte,

Parity Byte Byte Byte

Notes:

1. Numbers in parentheses are for 2:1 SRAM.

2. Not implemented on MPC7445 or MPC7441.

3. Private memory feature not implemented on MPC7400.

MPC7450/MPC7451/

MPC7441

2

MPC7400/MPC7410

only (see off-chip cache

support below)

2Mbytes

3

4 General Parameters

The following list provide s a summary of the general parameters of the MPC7455:

T echnology 0.18 µm CMOS, six-layer metal

2

Die size 8.69 mm × 12.17 mm (106 mm

Trans istor count 33 million

Logic design Fully-static

Packages MPC7445: Surface mount 360 ceramic ball grid array (CBGA)

MPC7455: Surface mount 483 ceramic ball gr id array (CBGA)

Core power supply 1.3 V ± 50 mV DC nominal

I/O power supply 1.8 V ± 5% DC, or

2.5 V ± 5% DC, or

1.5 V ± 5% DC (L3 interface only)

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 9

)

Page 10

Electrical and Thermal Characteristics

5 Electrical and Thermal Characteristics

This section provides the AC and DC electrical specifications and thermal c haracteristics for the MPC7455.

5.1 DC Electrical Characteristics

The tables in this section describe the MPC7455 DC electrical characteristics. Table 2 provides the absolute

maximum ratings.

Table 2. Absolute Maximum Ratings

Characteristic Symbol Maximum Value Unit Notes

1

Core supply voltage V

PLL supply voltage AV

Processor bus supply voltage BVSEL = 0 OV

BVSEL = HRESET

L3 bus supply voltage L3VSEL = ¬HRESET

or OV

DD

OVDD –0.3 to 2.7 V 3, 7

GV

L3VSEL = 0 GV

L3VSEL = HRESET

or GV

DD

GVDD –0.3 to 2.7 V 3, 10

Input voltage Processor bus V

L3 bus V

JTAG signals V

Input voltage Processor bus V

JTAG signals V

Storage temperature range T

DD

DD

–0.3 to 1.95 V 3, 6

DD

DD

DD

in

in

in

in

in

stg

–0.3 to 1.95 V 4

–0.3 to 1.95 V 4

–0.3 to 1.65 V 3, 8

–0.3 to 1.95 V 3, 9

–0.3 to OVDD + 0.3 V 2, 5

–0.3 to GVDD + 0.3 V 2, 5

–0.3 to OVDD + 0.3 V

–0.3 to OVDD + 0.3 V 2, 5

–0.3 to OVDD + 0.3 V

–55 to 150 °C

Notes:

1. Functional and tested operating conditions are given in Tab le 4. Absolute maximum ratings are stress ratings only,

and functional operation at the maximums is not guaranteed. Stresses beyond those listed may affect device

reliability or cause permanent damage to the device.

2. Caution: Vin must not exceed OV

3. Caution: OV

/GVDD must not exceed VDD/AVDD by more than 2.0 V during normal operation; this limit may be

DD

or GVDD by more than 0.3 V at any time including during power-on reset.

DD

exceeded for a maximum of 20 ms during power-on reset and power-down sequences.

4. Caution: V

/AVDD must not exceed OVDD/GVDD by more than 1.0 V during normal operation; this limit may be

DD

exceeded for a maximum of 20 ms during power-on reset and power-down sequences.

5. V

may overshoot/undershoot to a voltage and for a maximum duration as shown in Figure 2.

in

6. BVSEL must be set to 0, such that the bus is in 1.8 V mode.

7. BVSEL must be set to HRESET

8. L3VSEL must be set to ¬HRESET

or 1, such that the bus is in 2.5 V mode.

(inverse of HRESET), such that the bus is in 1.5 V mode.

9. L3VSEL must be set to 0, such that the bus is in 1.8 V mode.

10.L3VSEL must be set to HRESET

or 1, such that the bus is in 2.5 V mode.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

10 Freescale Semiconductor

Page 11

Electrical and Thermal Characteristics

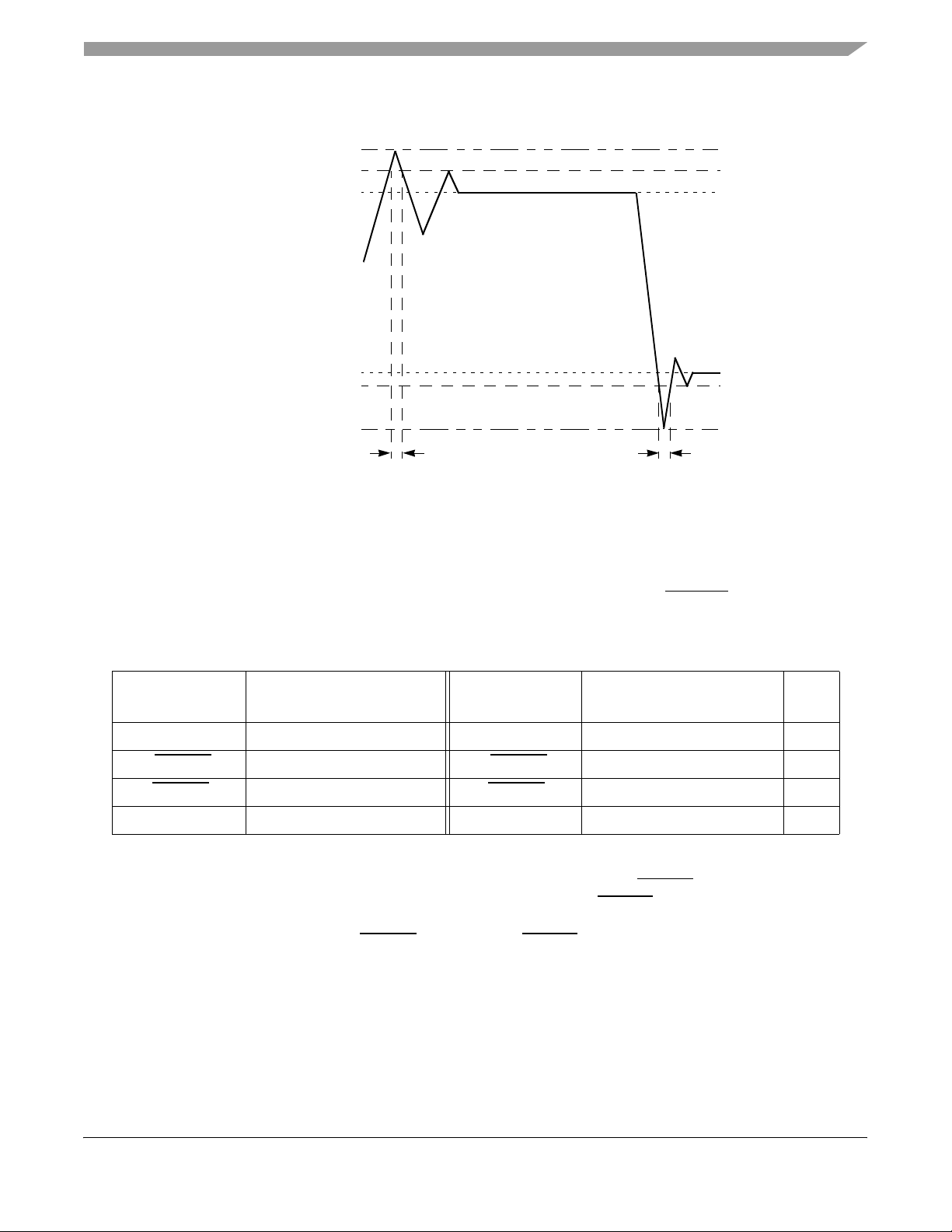

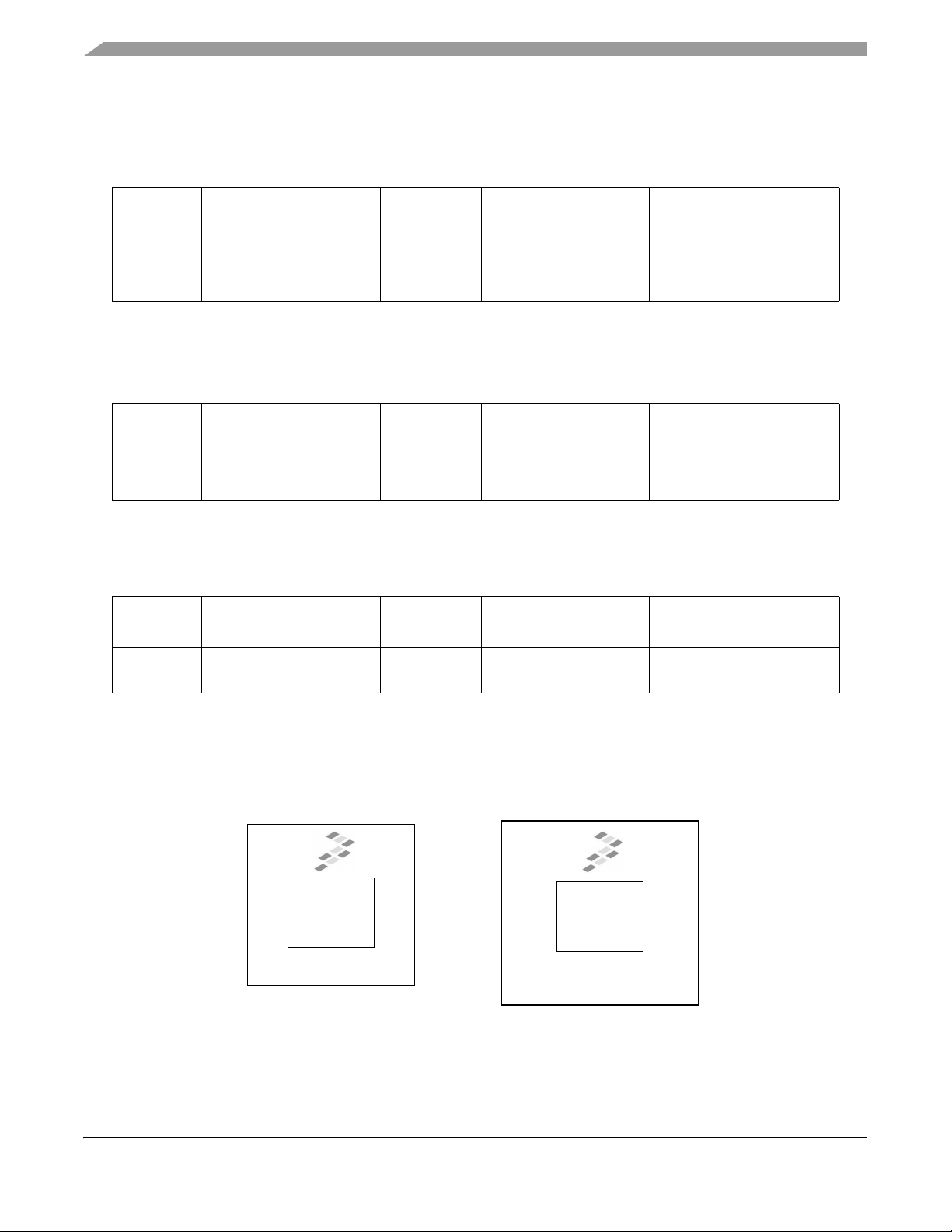

Figure 2 shows the undershoot and overshoot voltage on the MPC7455.

OVDD/GVDD + 20%

OVDD/GVDD + 5%

OVDD/GV

GND – 0.3 V

GND – 0.7 V

DD

V

V

GND

IH

IL

Not to Exceed 10%

of t

SYSCLK

Figure 2. Overshoot/Undershoot Voltage

The MPC7455 provides several I/O voltages to support both compatibility with existing systems and migration to

future systems. The MPC7455 core voltage must always be provided at nominal 1.3 V (see Table 4 f or actual

recommended core voltage ). Voltage to the L3 I/Os and processor inte rfa ce I/Os are provided through separate sets

of supply pins and may be provided at the voltages shown in Table 3. The input voltage threshold for each bus is

selected by sampling the state of the voltage select pins at the negation of the signal HRESET. The output voltage

will swing from GND to the maximum voltage applied to the OVDD or GVDD power pins.

Table 3. Input Threshold Voltage Setting

BVSEL Signal

0 1.8 V 0 1.8 V 1, 4

¬HRESET

HRESET

1 2.5 V 1 2.5 V 1

Notes:

1. Caution: The input threshold selection must agree with the OV

2. To select the 2.5-V threshold option for the processor bus, BVSEL should be tied to HRESET

change state together. Similarly, to select 2.5 V for the L3 bus, tie L3VSEL to HRESET

for selecting this mode of operation.

3. Applicable to L3 bus interface only. ¬HRESET

4. If used, pulldown resistors should be less than 250 Ω.

5. Not implemented on MPC7445.

Processor Bus Input

Threshold is Relative to:

Not Available ¬HRESET 1.5 V 1, 3

2.5 V HRESET 2.5 V 1, 2

L3VSEL Signal

/GVDD voltages supplied. See notes in Table 2.

DD

is the inverse of HRESET.

L3 Bus Input Threshold is

5

Relative to:

. This is the preferred method

Notes

so that the two signals

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 11

Page 12

Electrical and Thermal Characteristics

Table 4 provides the recommended operating conditions for the MPC7455.

Table 4. Recommended Operating Conditions

Recommended Value

Characteristic Symbol

1

Unit Notes

Min Max

Core supply voltage V

PLL supply voltage AV

Processor bus supply voltage BVSEL = 0 OV

BVSEL = HRESET

or OV

DD

OV

L3 bus supply voltage L3VSEL = 0 GV

L3VSEL = HRESET

L3VSEL = ¬HRESET

or GV

DD

GV

GV

Input voltage Processor bus V

L3 bus V

JTAG signals V

Die-junction temperature T

DD

DD

DD

DD

DD

DD

DD

in

in

in

j

1.3 V ± 50 mV V

1.3 V ± 50 mV V 2

1.8 V ± 5% V

2.5 V ± 5% V

1.8 V ± 5% V

2.5 V ± 5% V

1.5 V ± 5% V

GND OV

GND GV

GND OV

DD

DD

DD

V

V

V

0105°C

Notes:

1. These are the recommended and tested operating conditions. Proper device operation outside of these conditions

is not guaranteed.

2. This voltage is the input to the filter discussed in Section 9.2, “PLL Power Supply Filtering,” and not necessarily the

voltage at the AV

pin which may be reduced from VDD by the filter.

DD

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

12 Freescale Semiconductor

Page 13

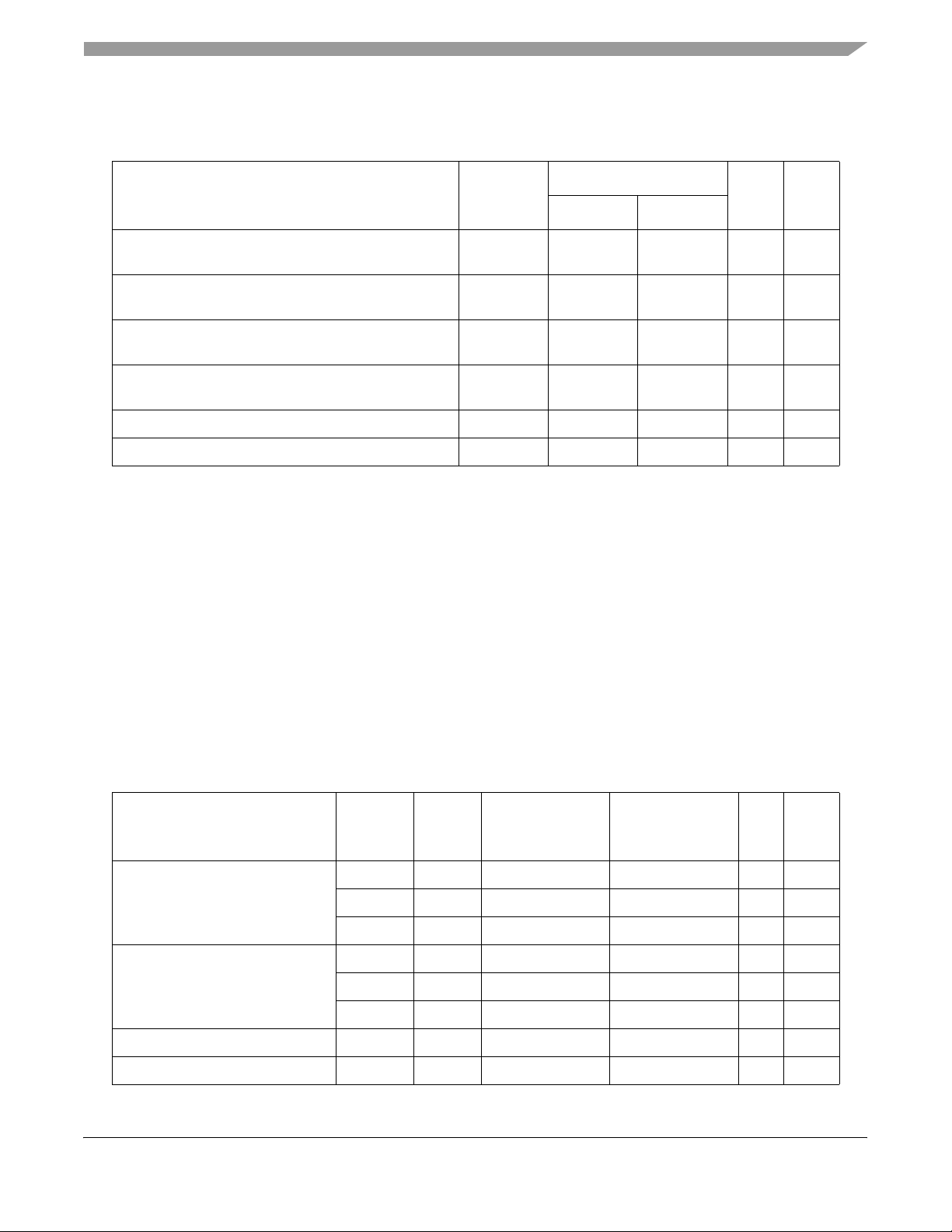

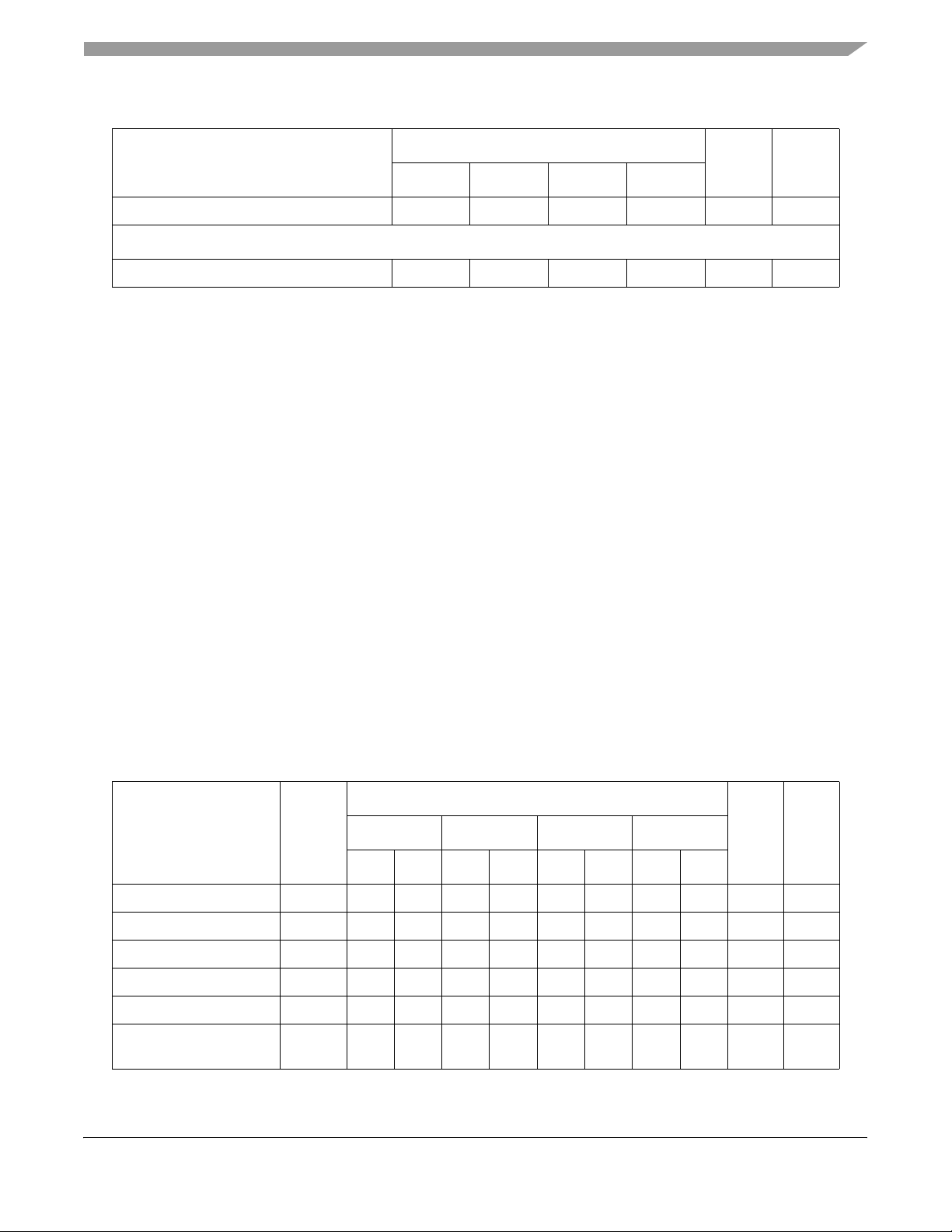

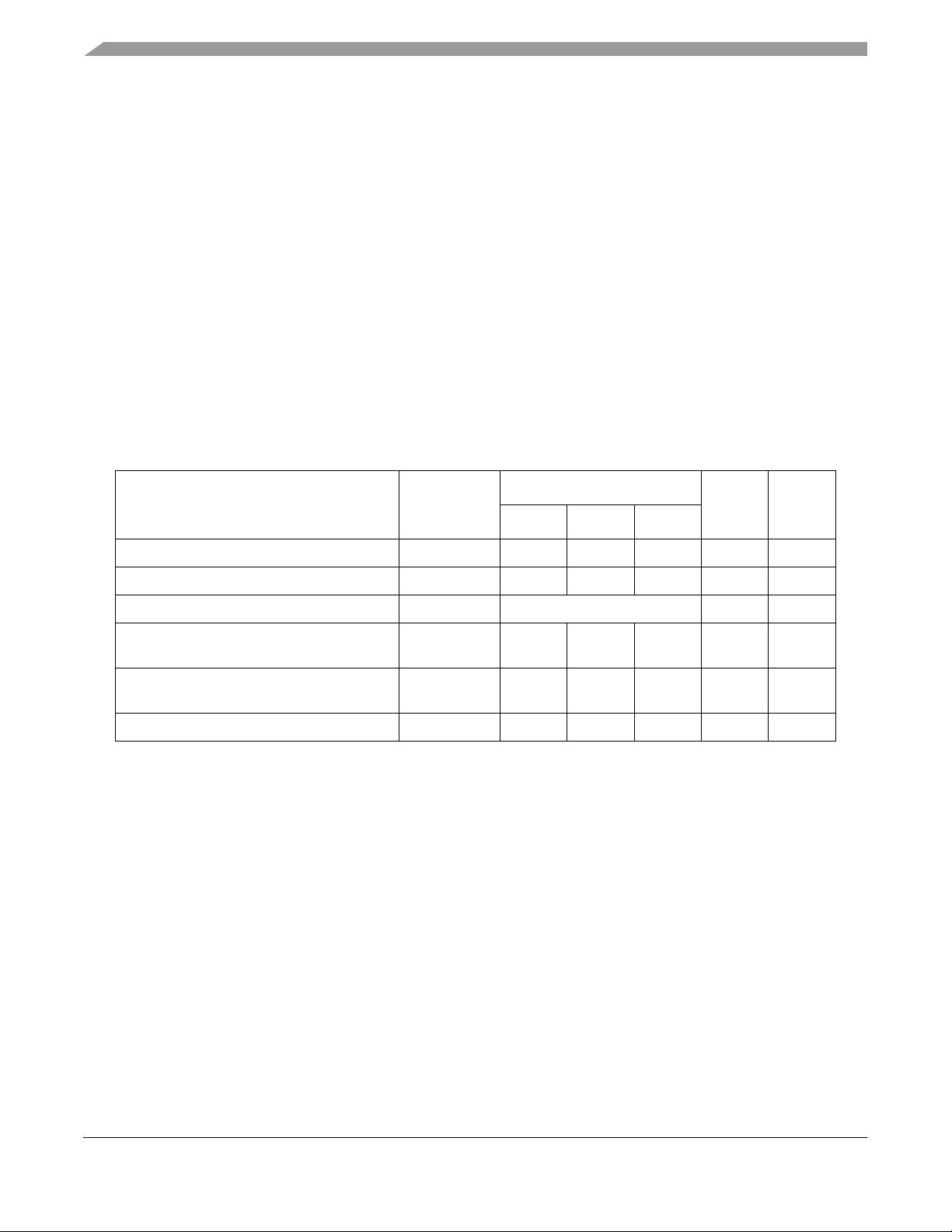

Table 5 provides the package thermal characteristics for the MPC7455.

Table 5. Package Thermal Characteristics

Characteristic Symbol

Electrical and Thermal Characteristics

6

Value

Unit Notes

MPC7445 MPC7455

Junction-to-ambient thermal resistance, natural

R

JA

θ

22 20 °C/W 1, 2

convection

Junction-to-ambient thermal resistance, natural

R

JMA

θ

14 14 °C/W 1, 3

convection, four-layer (2s2p) board

Junction-to-ambient thermal resistance, 200 ft/min

R

JMA

θ

16 15 °C/W 1, 3

airflow, single-layer (1s) board

Junction-to-ambient thermal resistance, 200 ft/min

R

JMA

θ

11 11 °C/W 1, 3

airflow, four-layer (2s2p) board

Junction-to-board thermal resistance R

Junction-to-case thermal resistance R

JB

θ

JC

θ

66°C/W4

<0.1 <0.1 °C/W 5

Notes:

1. Junction temperature is a function of on-chip power dissipation, package thermal resistance, mounting site (board)

temperature, ambient temperature, airflow, power dissipation of other components on the board, and board thermal

resistance.

2. Per SEMI G38-87 and JEDEC JESD51-2 with the single-layer board horizontal.

3. Per JEDEC JESD51-6 with the board horizontal.

4. Thermal resistance between the die and the printed-circuit board per JEDEC JESD51-8. Board temperature is

measured on the top surface of the board near the package.

5. Thermal resistance between the die and the case top surface as measured by the cold plate method

(MIL SPEC-883 Method 1012.1) with the calculated case temperature. The actual value of R

for the part is less

θJC

than 0.1°C/W.

6. Refer to Section 9.8, “Thermal Management Information,” for more details about thermal management.

Table 6 provides the DC electrical characteristics for the MPC7455.

Table 6. DC Electrical Specifications

At recommended oper ating conditions. See Ta bl e 4 .

Nominal

Characteristic

Input high voltage

(all inputs except SYSCLK)

Input low voltage

(all inputs except SYSCLK)

SYSCLK input high voltage — CV

SYSCLK input low voltage — CV

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 13

Bus

Voltage

1.5 V

1.8 V

2.5 V

1.5 V

1.8 V

2.5 V

Symbol Min Max Unit Notes

1

IH

IH

IH

IL

IL

IL

IH

IL

GVDD × 0.65 GVDD + 0.3 V 6

OVDD/GVDD × 0.65 OVDD/GVDD + 0.3 V

1.7 OVDD/GVDD + 0.3 V

–0.3 GVDD × 0.35 V 6

–0.3 OVDD/GVDD × 0.35 V

–0.3 0.7 V

1.4 OVDD + 0.3 V

–0.3 0.4 V

Page 14

Electrical and Thermal Characteristics

Table 6. DC Electrical Specifications (continued)

At recommended oper ating conditions. See Ta bl e 4 .

Nominal

Characteristic

Voltage

Bus

Symbol Min Max Unit Notes

1

Input leakage current,

V

= GVDD/OVDD + 0.3 V

in

High impedance (off-state) leakage

current, V

Output high voltage, I

Output low voltage, I

Capacitance,

V

=

in

f = 1 MHz

= GVDD/OVDD + 0.3 V

in

L3 interface — C

0 V,

All other inputs — 8.0 pF 4

= –5 mA 1.5 V

OH

5 mA 1.5 V

=

OL

—I

—I

1.8 V

2.5 V

1.8 V

2.5 V

in

TSI

OH

OVDD/GVDD – 0.45 — V

OH

OH

OL

OL

OL

in

—30µA2, 3

— 30 µA 2, 3, 5

GVDD – 0.45 — V 6

1.7 — V

—0.45V6

—0.45V

—0.7V

—9.5pF4

Notes:

1. Nominal voltages; see Table 4 for recommended operating conditions.

2. For processor bus signals, the reference is OV

while GVDD is the reference for the L3 bus signals.

DD

3. Excludes test signals and IEEE 1149.1 boundary scan (JTAG) signals.

4. Capacitance is periodically sampled rather than 100% tested.

5. The leakage is measured for nominal OV

direction (for example, both OV

and VDD vary by either +5% or –5%).

DD

/GVDD and VDD, or both OVDD/GVDD and VDD must vary in the same

DD

6. Applicable to L3 bus interface only.

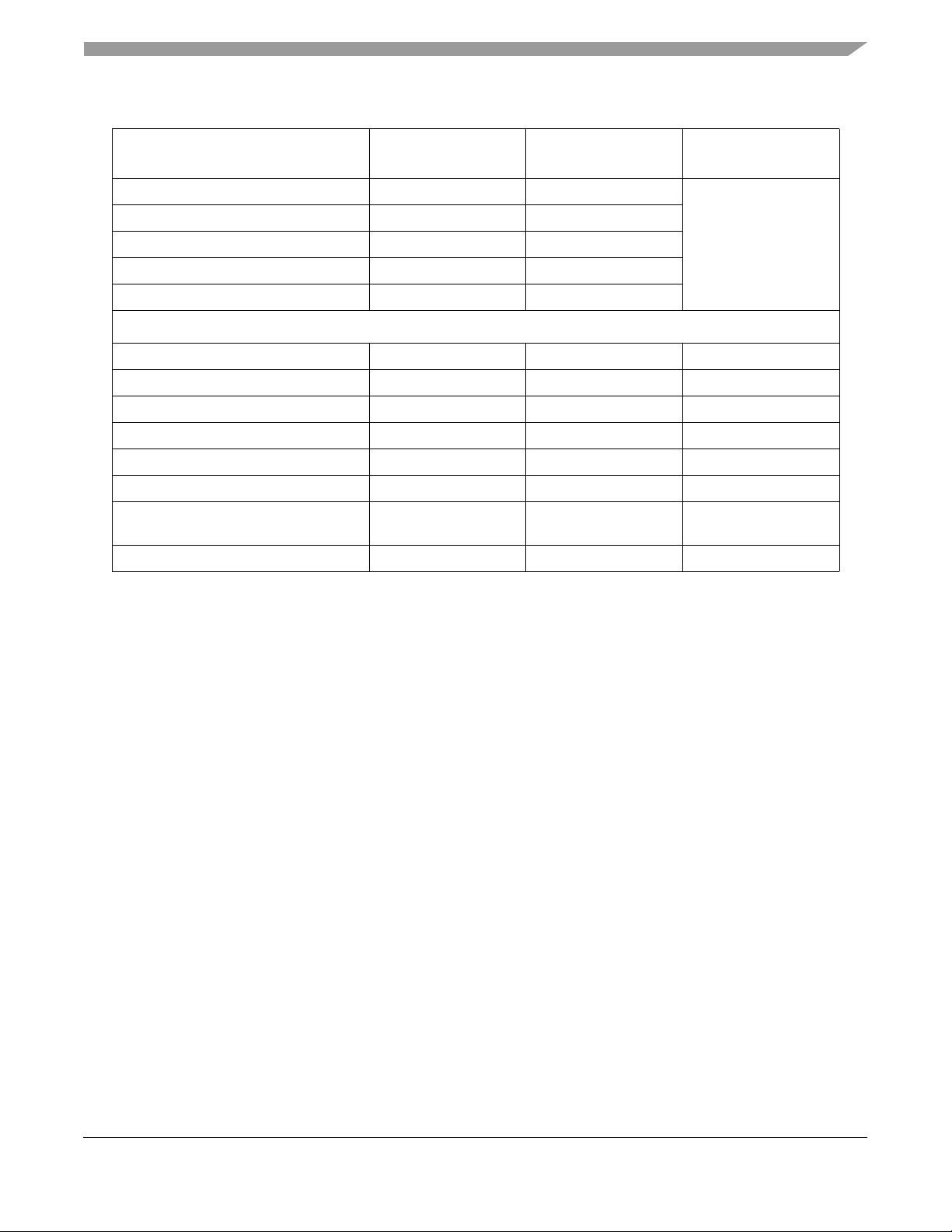

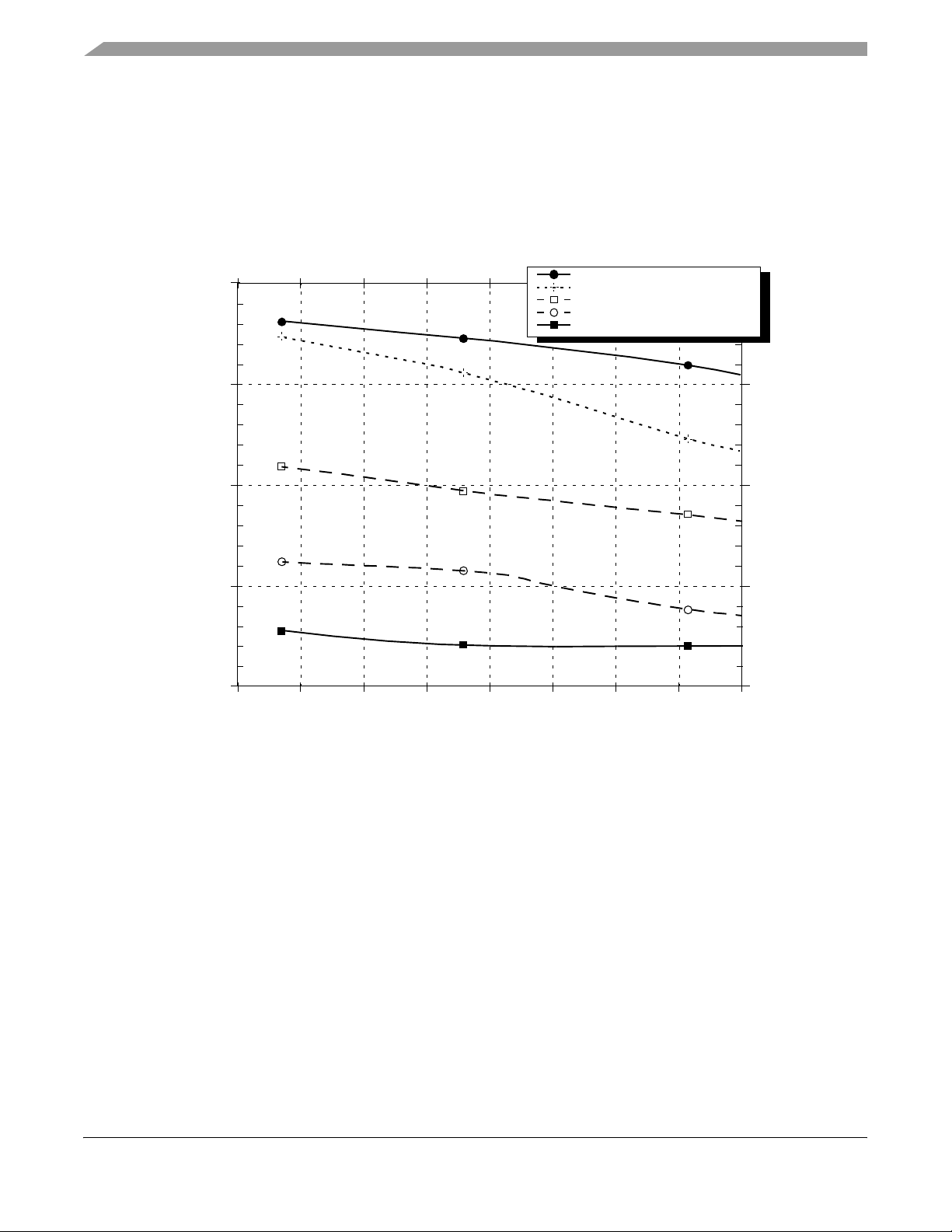

Table 7 provides the power consumption for the MPC7455.

Table 7. Power Consumption for MPC7455

Processor (CPU) Frequency

Unit Notes

733 MHz 867 MHz 933 MHz 1 GHz

Full-Power Mode

Typical 11.5 12.9 13.6 15.0 W 1, 3

Maximum 17.0 19.0 20.0 22.0 W 1, 2

Doze Mode

Typical ————W4

Nap Mode

Typical 8.0 8.0 8.0 8.0 W 1, 3

Sleep Mode

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

14 Freescale Semiconductor

Page 15

Electrical and Thermal Characteristics

Table 7. Power Consumption for MPC7455 (continued)

Processor (CPU) Frequency

Unit Notes

733 MHz 867 MHz 933 MHz 1 GHz

Typical 7.6 7.6 7.6 7.6 W 1, 3

Deep Sleep Mode (PLL Disabled)

Typical 7.3 7.3 7.3 7.3 W 1, 3

Notes:

1. These values apply for all valid processor bus and L3 bus ratios. The values do not include I/O supply power (OVDD

and GV

power. Worst case power consumption for AV

2. Maximum power is measured at nominal V

sequence of instructions which keep the execution units, with or without AltiVec, maximally busy.

3. Typical power is an average value measured at the nominal recommended V

while running a typical code sequence.

4. Doze mode is not a user-definable state; it is an intermediate state between full-power and either nap or sleep mode.

As a result, power consumption for this mode is not tested.

) or PLL supply power (AVDD). OVDD and GVDD power is system dependent, but is typically <5% of VDD

DD

< 3 mW.

DD

(see Table 4) while running an entirely cache-resident, contrived

DD

(see Table 4) and 65°C in a system

DD

5.2 AC Electrical Characteristics

This section provides the AC electrical characteristics for the MPC7455. After fabrication, functional parts are

sorted by maximum processor core frequ ency as shown in Section 5.2.1, “Clock AC Specifications,” and tested for

conformance to the AC specifications for that frequency. The processor core frequency is determined by the bus

(SYSCLK) frequency and the settings of the PLL_CFG[0:4] signals. Parts are sold by maximum processor core

frequency; see Se ction 11, “Ordering Informati on .”

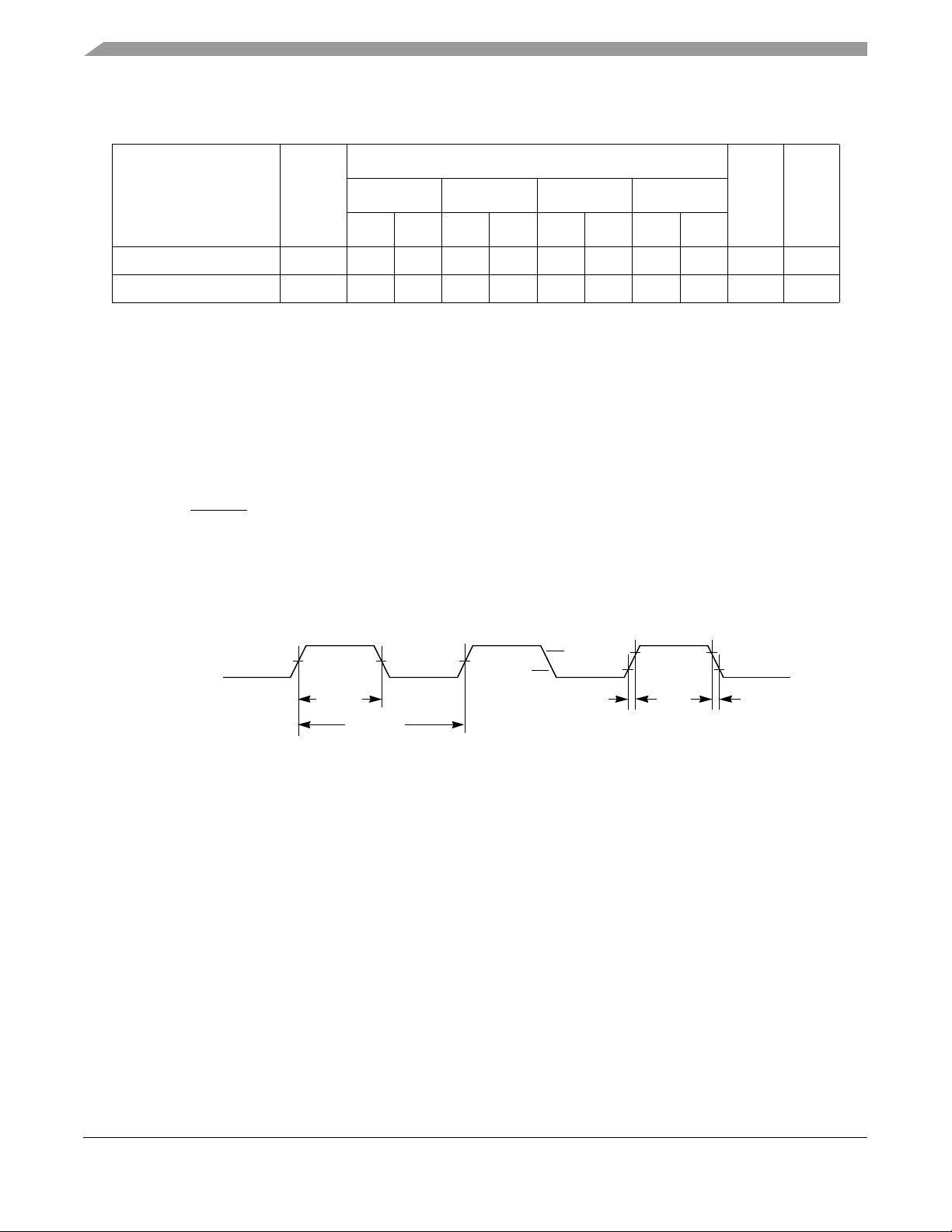

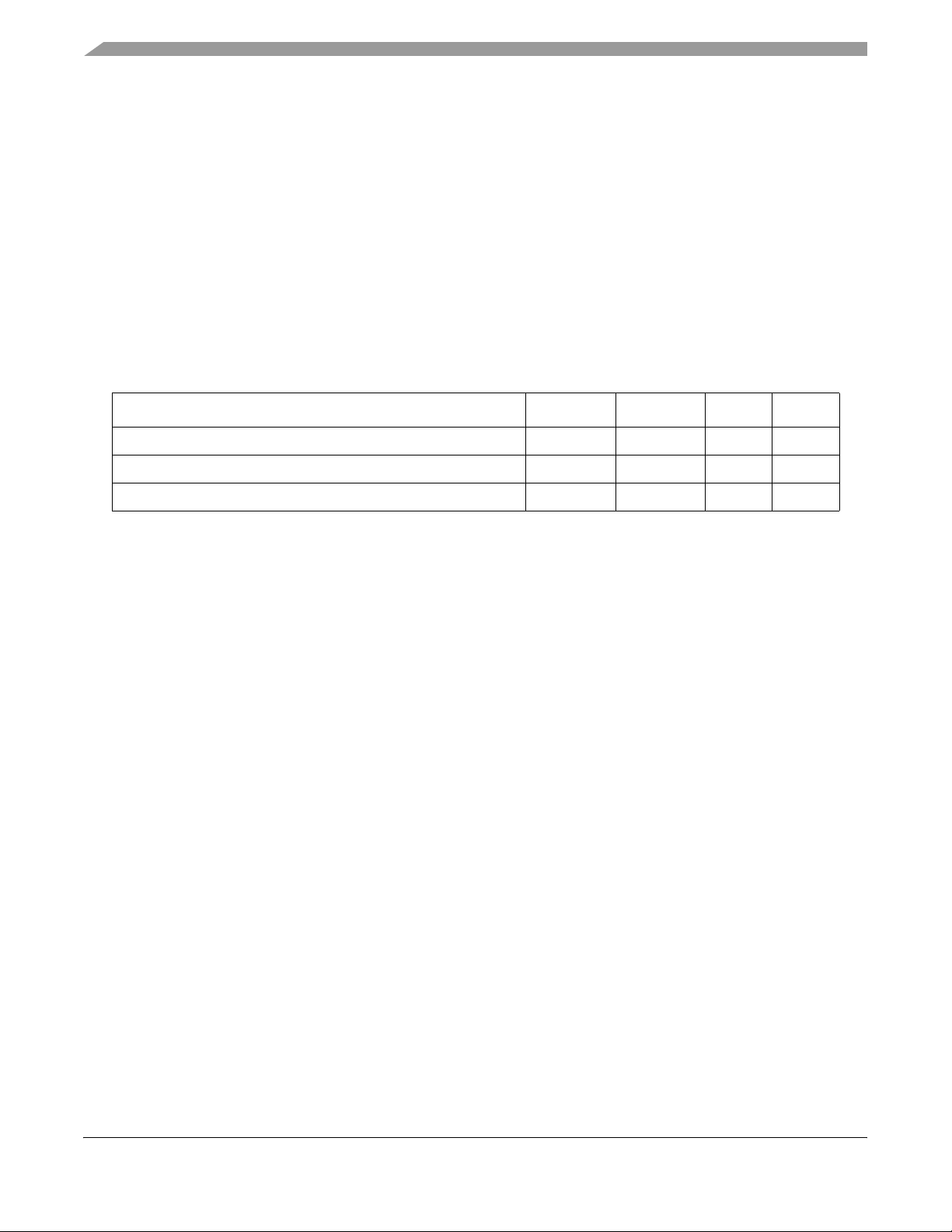

5.2.1 Clock AC Specifications

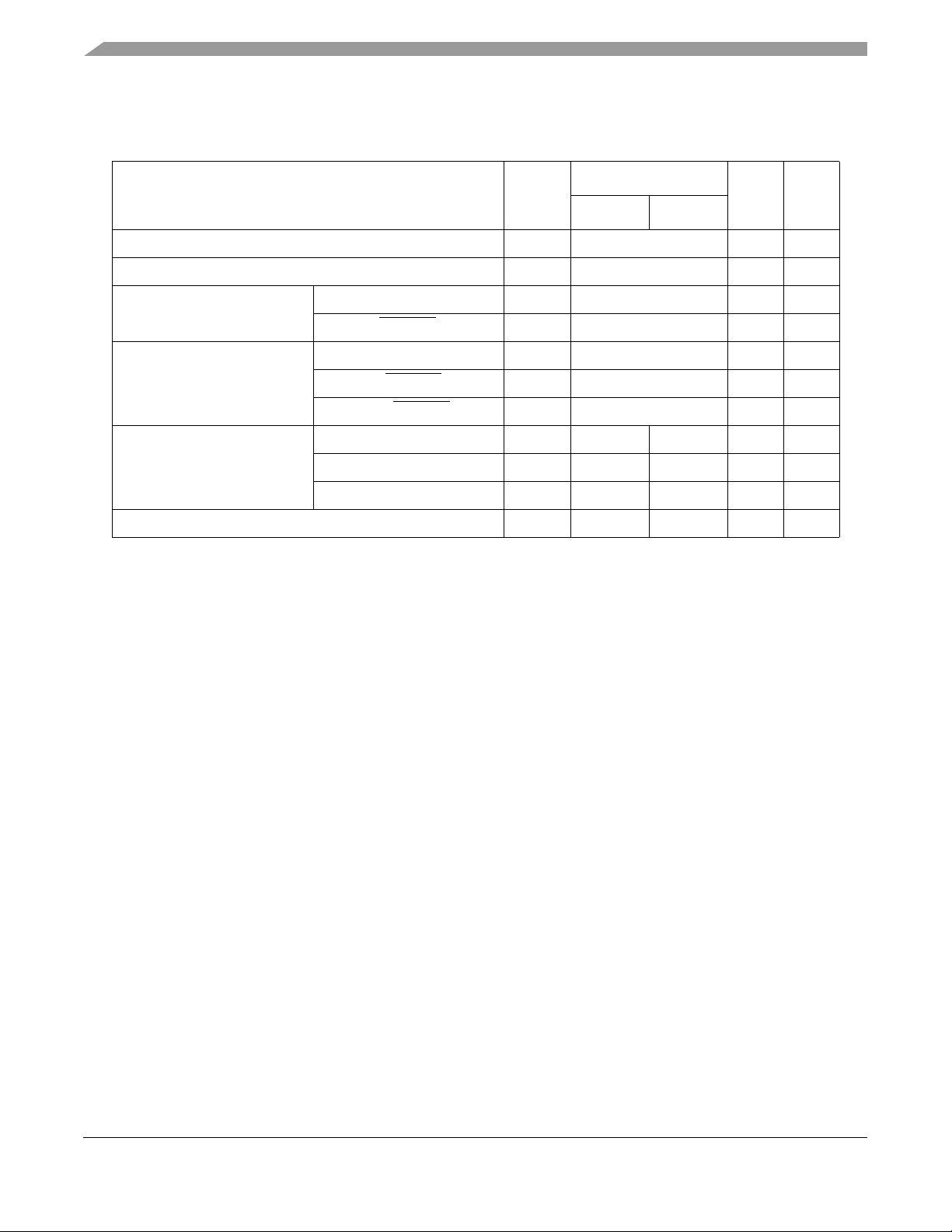

Table 8 provides the clock AC timing specifications as defined in Figure 3.

Table 8. Clock AC Timing Specifications

At recommended oper ating conditions. See Ta bl e 4 .

Maximum Processor Core Frequency

Characteristic Symbol

Processor frequency f

VCO frequency f

SYSCLK frequency f

SYSCLK cycle time t

SYSCLK rise and fall time t

SYSCLK duty cycle

measured at OV

DD

/2

t

core

VCO

SYSCLK

SYSCLK

, t

KR

KF

t

KHKL

SYSCLK

Min Max Min Max Min Max Min Max

500 733 500 867 500 933 500 1000 MHz 1

1000 1466 1000 1734 1000 1866 1000 2000 MHz 1

33 133 33 133 33 133 33 133 MHz 1

7.5 30 7.5 30 7.5 30 7.5 30 ns

—1.0—1.0—1.0—1.0 ns 2

/

40 60 40 60 40 60 40 60 % 3

Unit Notes733 MHz 867 MHz 933 MHz 1 GHz

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 15

Page 16

Electrical and Thermal Characteristics

Table 8. Clock AC Timing Specifications (continued)

At recommended oper ating conditions. See Ta bl e 4 .

Maximum Processor Core Frequency

Characteristic Symbol

Unit Notes733 MHz 867 MHz 933 MHz 1 GHz

Min Max Min Max Min Max Min Max

SYSCLK jitter — ± 150 — ± 150 — ± 150 — ± 150 ps 4, 6

Internal PLL relock time —100—100—100—100 µs5

Notes:

1. Caution: The SYSCLK frequency and PLL_CFG[0:4] settings must be chosen such that the resulting SYSCLK

(bus) frequency, CPU (core) frequency, and PLL (VCO) frequency do not exceed their respective maximum or

minimum operating frequencies. Refer to the PLL_CFG[0:4] signal description in Section 9.1, “PLL Configuration,”

for valid PLL_CFG[0:4] settings.

2. Rise and fall times for the SYSCLK input measured from 0.4 to 1.4 V.

3. Timing is guaranteed by design and characterization.

4. This represents total input jitter—short term and long term combined—and is guaranteed by design.

5. Relock timing is guaranteed by design and characterization. PLL-relock time is the maximum amount of time

required for PLL lock after a stable V

and SYSCLK are reached during the power-on reset sequence. This

DD

specification also applies when the PLL has been disabled and subsequently re-enabled during sleep mode. Also

note that HRESET

must be held asserted for a minimum of 255 bus clocks after the PLL-relock time during the

power-on reset sequence.

6. The SYSCLK driver’s closed loop jitter bandwidth should be <500 kHz at –20 dB. The bandwidth must be set low

to allow cascade connected PLL-based devices to track SYSCLK drivers with the specified jitter.

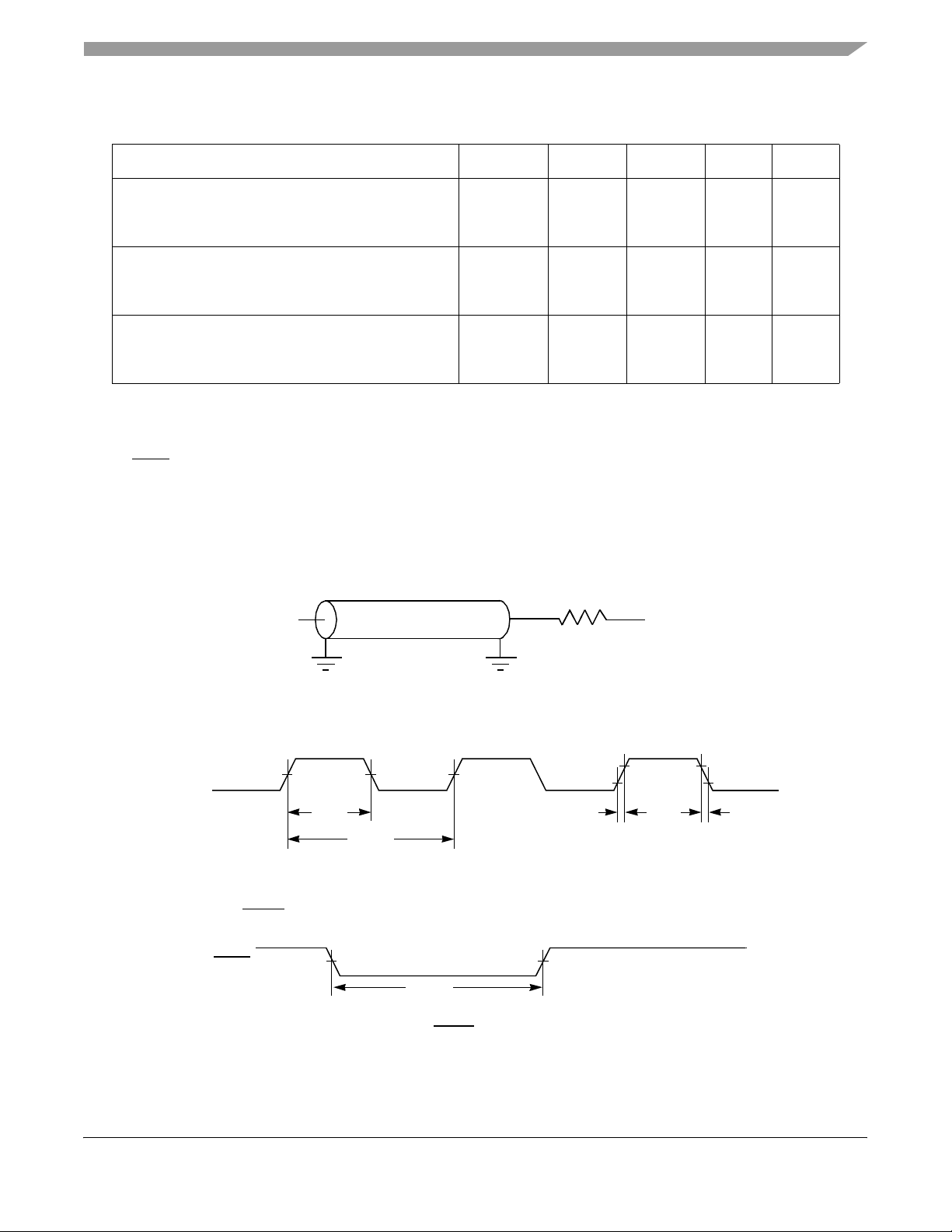

Figure 3 provides the SYSCLK input timing diagram.

SYSCLK

CV

IH

t

KR

t

KHKL

t

SYSCLK

VMVMVM

CV

IL

VM = Midpoint Voltage (OVDD/2)

Figure 3. SYSCLK Input Timing Diagram

t

KF

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

16 Freescale Semiconductor

Page 17

Electrical and Thermal Characteristics

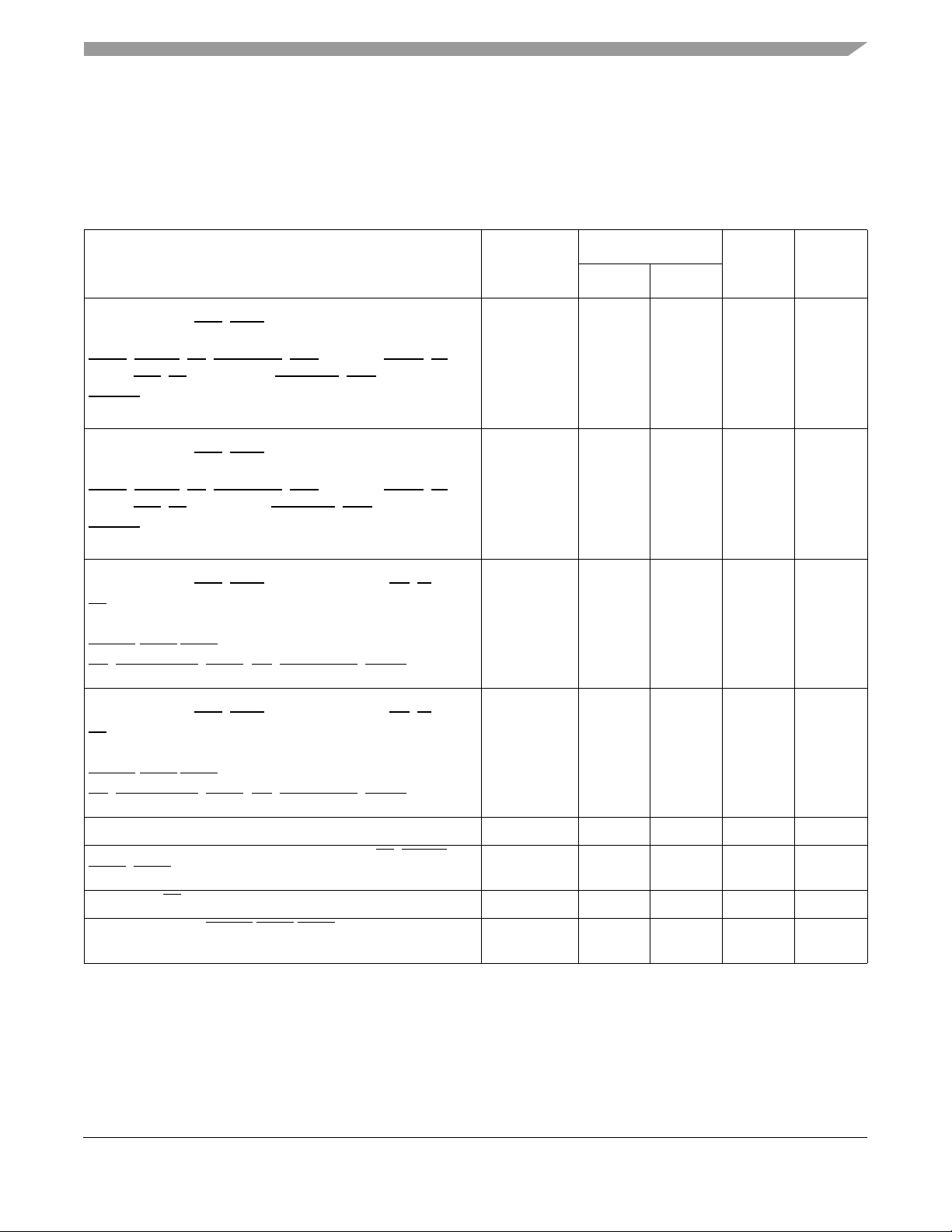

5.2.2 Processor Bus AC Specifications

Table 9 provides the processor bus AC timing specifications for the MPC7455 as defined in Figure 4 and Figure 5.

Timing spe cifications for the L3 bus are provided in Section 5.2.3, “L3 Clock AC Specifications.”

Table 9. Processor Bus AC Timing Specifications

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol

All Speed Grades

2

Min Max

1

Unit Notes

Input setup times:

A[0:35], AP[0:4], GBL

, TBST, TSIZ[0:2], TT[0:3], D[0:63],

DP[0:7]

AACK

, ARTRY, BG, CKSTP_IN, DBG, DTI[0:3], QACK, TA,

TBEN, TEA

BMODE

, TS, EXT_QUAL, PMON_IN, SHD[0:1]

[0:1], BVSEL, L3VSEL

Input hold times:

A[0:35], AP[0:4], GBL

, TBST, TSIZ[0:2], TT[0:3], D[0:63],

DP[0:7]

AACK

, ARTRY, BG, CKSTP_IN, DBG, DTI[0:3], QACK, TA,

TBEN, TEA

BMODE

, TS,EXT_QUAL, PMON_IN, SHD[0:1]

[0:1], BVSEL, L3VSEL

Output valid times:

A[0:35], AP[0:4], GBL

, TBST, TSIZ[0:2], TT[0:3], WT, CI

TS

D[0:63], DP[0:7]

/SHD0/SHD1

ARTRY

BR, CKSTP_OUT, DRDY, HIT, PMON_OUT, QREQ]

Output hold times:

A[0:35], AP[0:4], GBL

, TBST, TSIZ[0:2], TT[0:3], WT, CI

TS

D[0:63], DP[0:7]

/SHD0/SHD1

ARTRY

BR, CKSTP_OUT, DRDY, HIT, PMON_OUT, QREQ

t

AVKH

t

IVKH

t

MVKH

t

AXKH

t

IXKH

t

MXKH

t

KHAV

t

KHTSV

t

KHDV

t

KHARV

t

KHOV

t

KHAX

t

KHTSX

t

KHDX

t

KHARX

t

KHOX

2.0

2.0

2.0

0

0

0

—

—

—

—

—

0.5

0.5

0.5

0.5

0.5

—

—

—

—

—

—

2.5

2.5

2.5

2.5

2.5

—

—

—

—

—

ns

8

ns

8

ns

ns

SYSCLK to output enable t

SYSCLK to output high impedance (all except TS

SHD0

, SHD1)

SYSCLK to TS

Maximum delay to ARTRY

high impedance after precharge t

/SHD0/SHD1 precharge t

, ARTRY,

KHOE

t

KHOZ

KHTSPZ

KHARP

0.5 — ns

—3.5ns

—1t

—1t

SYSCLK

SYSCLK

3, 4, 5

3, 5,

6, 7

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 17

Page 18

Electrical and Thermal Characteristics

Table 9. Processor Bus AC Timing Specifications 1 (continued)

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol

All Speed Grades

2

Min Max

Unit Notes

SYSCLK to ARTRY/SHD0/SHD1 high impedance after

precharge

t

KHARPZ

—2t

SYSCLK

3, 5,

6, 7

Notes:

1. All input specifications are measured from the midpoint of the signal in question to the midpoint of the rising edge of the input

SYSCLK. All output specifications are measured from the midpoint of the rising edge of SYSCLK to the midpoint of the signal

in question. All output timings assume a purely resistive 50-Ω load (see Figure 4). Input and output timings are measured at

the pin; time-of-flight delays must be added for trace lengths, vias, and connectors in the system.

2. The symbology used for timing specifications herein follows the pattern of t

t

(reference)(state)(signal)(state)

for outputs. For example, t

symbolizes the time input signals (I) reach the valid state (V)

IVKH

(signal)(state)(reference)(state)

relative to the SYSCLK reference (K) going to the high (H) state or input setup time. And t

KHOV

for inputs and

symbolizes the time from

SYSCLK(K) going high (H) until outputs (O) are valid (V) or output valid time. Input hold time can be read as the time that the

input signal (I) went invalid (X) with respect to the rising clock edge (KH) (note the position of the reference and its state for

inputs) and output hold time can be read as the time from the rising edge (KH) until the output went invalid (OX).

3. t

is the period of the external clock (SYSCLK) in ns. The numbers given in the table must be multiplied by the period of

sysclk

SYSCLK to compute the actual time duration (in ns) of the parameter in question.

4. According to the bus protocol, TS

before returning to high impedance as shown in Figure 6. The nominal precharge width for TS

than the minimum t

SYSCLK

is driven only by the currently active bus master. It is asserted low then precharged high

is 0.5 × t

SYSCLK

, that is, less

period, to ensure that another master asserting TS on the following clock will not contend with the

precharge. Output valid and output hold timing is tested for the signal asserted. Output valid time is tested for precharge. The

high-impedance behavior is guaranteed by design.

5. Guaranteed by design and not tested.

6. According to the bus protocol, ARTRY

AACK

. Bus contention is not an issue because any master asserting ARTRY will be driving it low. Any master asserting it low

in the first clock following AACK

cycle after the assertion of AACK

impedance as shown in Figure 6 before the first opportunity for another master to assert ARTRY

can be driven by multiple bus masters through the clock period immediately following

will then go to high impedance for one clock before precharging it high during the second

. The nominal precharge width for ARTRY is 1.0 t

; that is, it should be high

SYSCLK

. Output valid and output

hold timing is tested for the signal asserted. The high-impedance behavior is guaranteed by design.

7. According to the MPX bus protocol, SHD0

is the same as ARTRY

, that is, the signal is high impedance for a fraction of a cycle, then negated for up to an entire cycle

(crossing a bus cycle boundary) before being three-stated again. The nominal precharge width for SHD0

t

8. BMODE

. The edges of the precharge vary depending on the programmed ratio of core-to-bus (PLL configurations).

SYSCLK

[0:1] and BVSEL are mode select inputs and are sampled before and after HRESET negation. These paramenters

and SHD1 can be driven by multiple bus masters beginning the cycle of TS. Timing

and SHD1 is 1.0

represent the input setup and hold times for each sample. These values are guaranteed by design and not tested. These

inputs must remain stable after the second sample. See Figure 5 for sample timing.

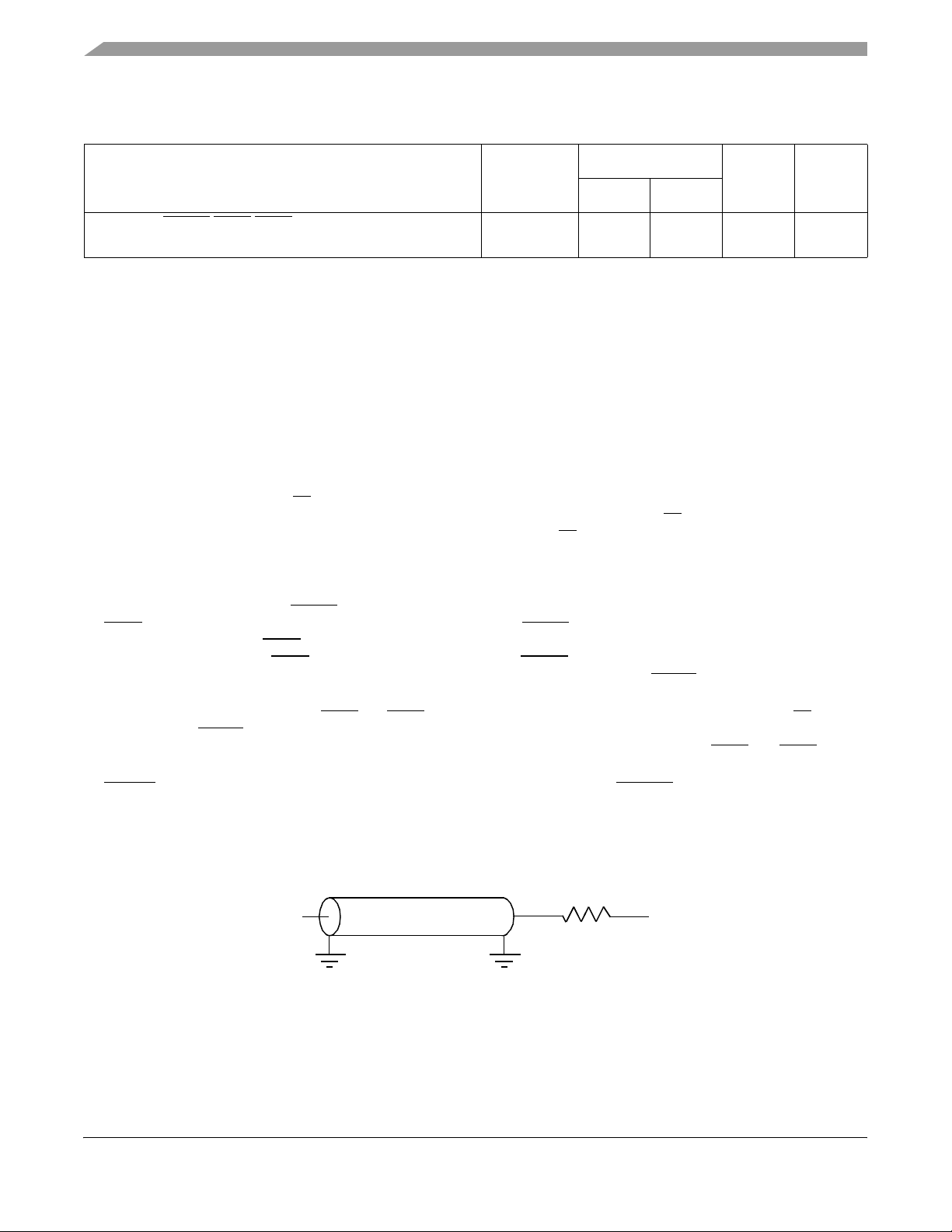

Figure 4 provides the AC test load for the MPC7455.

Output

Z0 = 50 Ω

R

= 50 Ω

L

Figure 4. AC Test Load

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

18 Freescale Semiconductor

OVDD/2

Page 19

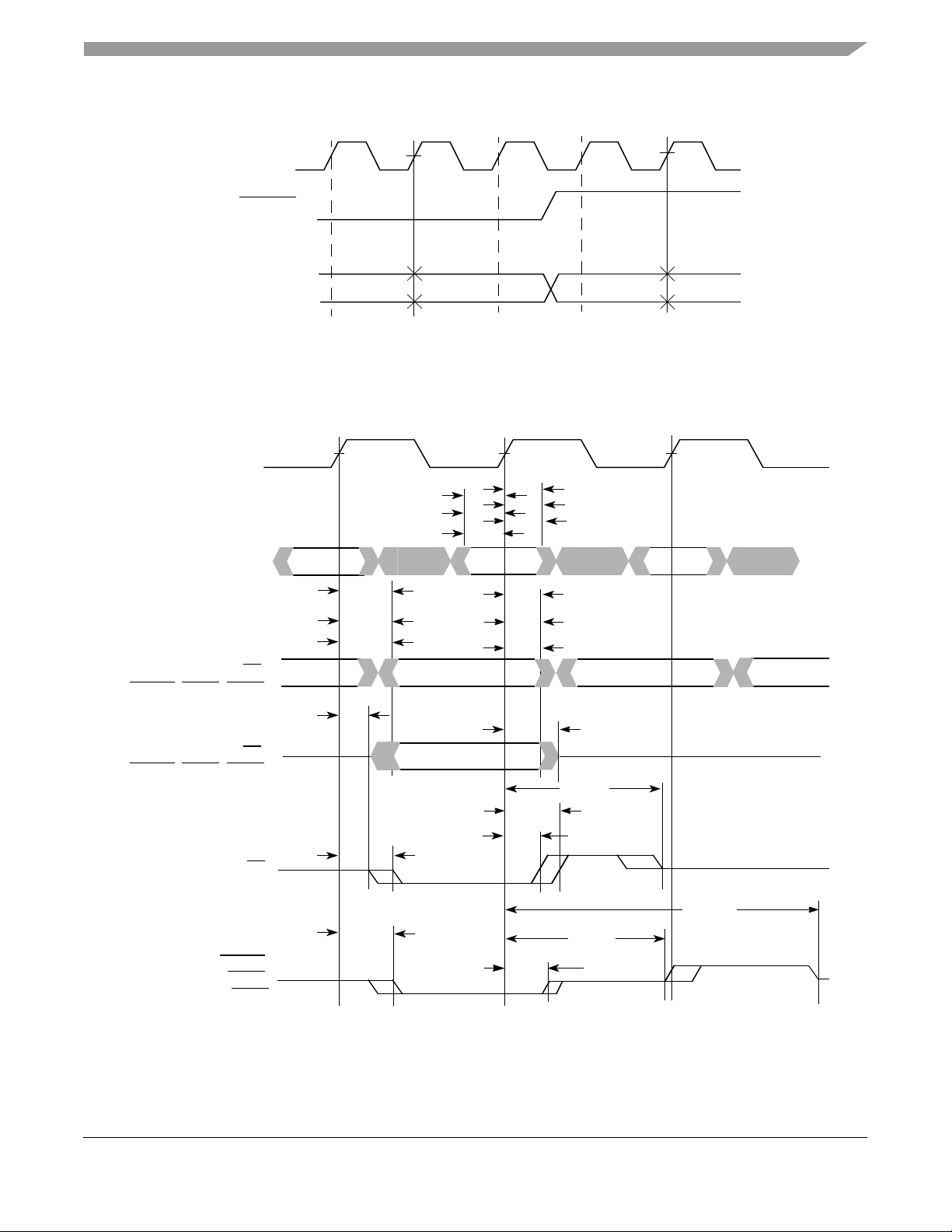

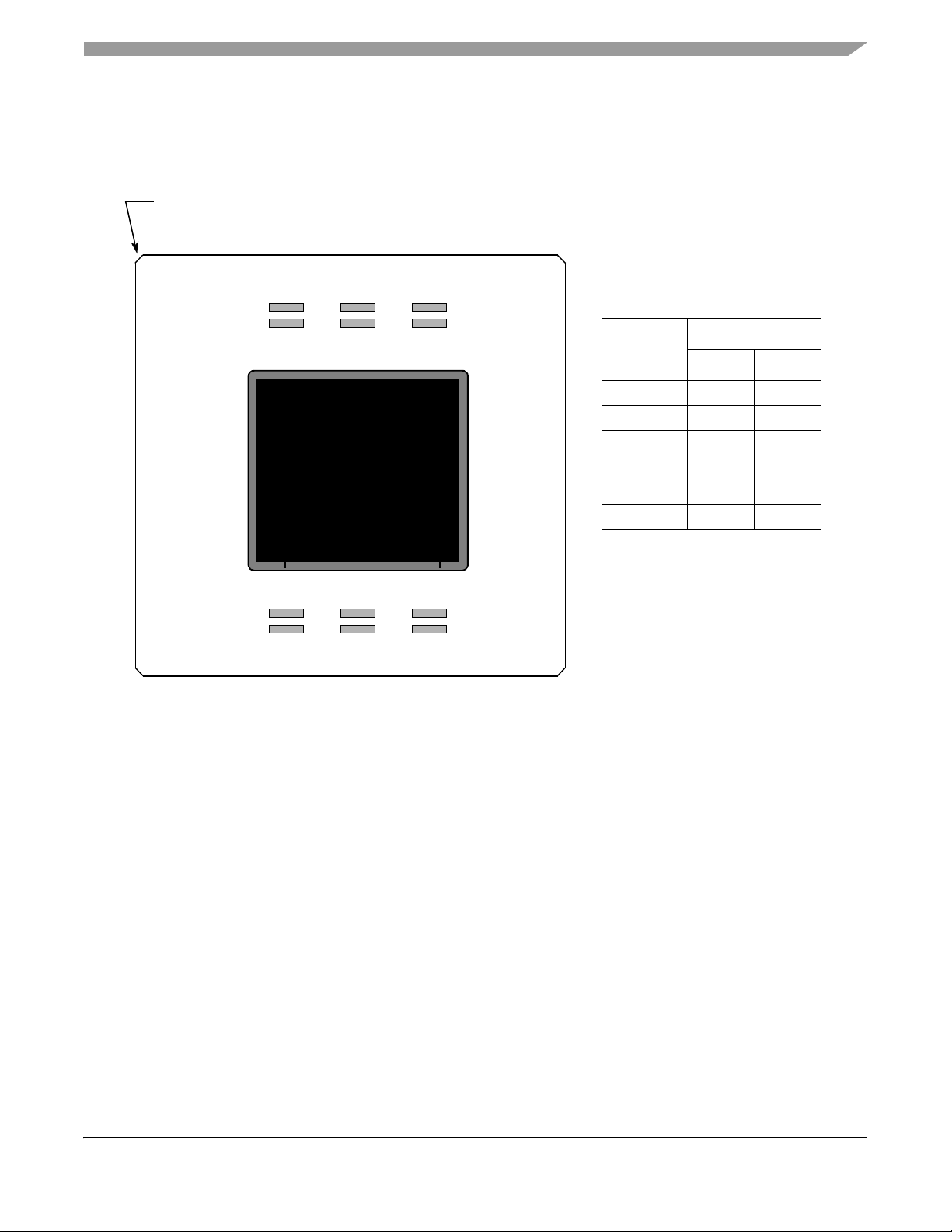

Figure 5 provides the mode select input timing diagram for the MPC7455.

Electrical and Thermal Characteristics

SYSCLK

VM

HRESET

Mode Signals

Firs t Sample Second Sample

VM = Midpoint Voltage (OVDD/2)

Figure 5. Mode Input Timing Diagram

Figure 6 provides the input/output timing diagram for the MPC7455.

SYSCLK

All Inputs

All Outputs

(Except TS,

ARTRY, SHD0, SHD1)

All Outputs

(Except TS

ARTRY, SHD0, SHD1)

TS

VM

t

AVKH

t

IVKH

t

MVKH

t

KHAV

t

KHDV

t

KHOV

t

KHOE

,

t

KHTSV

VM

t

AXKH

t

IXKH

t

MXKH

t

KHAX

t

KHDX

t

KHOX

t

KHOZ

t

KHTSPZ

t

KHTSV

t

KHTSX

VM

VM

t

KHARPZ

t

KHARV

ARTRY,

SHD0,

t

KHARP

t

KHARX

SHD1

VM = Midpoint Voltage (OV

DD

/2)

Figure 6. Input/Output Timing Diagram

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 19

Page 20

Electrical and Thermal Characteristics

5.2.3 L3 Clock AC Specifications

The L3_CLK frequency is programmed by the L3 configuration register (L3CR[6:8]) core-to-L3 divisor ratio. See

Table 18 for example core and L3 frequencies at var ious divisor s. Table 10 provides the potential range of L3_CLK

output AC timing specifications as defined in Figure 7.

The maximum L3_CLK frequency is the core frequency divided by two. Given the high core frequencies available

in the MPC7455, however, most SRAM designs will be not be a ble to operate in this mode usi ng cur rent te chnology

and, as a result, will sel ect a gr eater c ore-to-L3 div isor to provi de a long er L3_CLK perio d for re ad and write a ccess

to the L3 SRAMs. Therefore, the typical L3_CLK frequency shown in Table 10 is considered to be the practical

maximum in a typical system. The maximum L3_CLK frequency for any application of the MPC7455 will be a

function of the AC timings of the MPC7455, the AC timings for the SRAM, bus loading, and printed-circuit board

trace length, and may be greater or less tha n the value given in Table 10.

Freescale is similarly limited by system constraints and cannot perform tests of the L3 interface on a socketed part

on a functional tester at the maximum frequencies of Table 10. Therefore, functional operation and AC timing

information are test ed at core-to-L3 divisors which resul t in L3 frequencies at 200 MHz or less.

Table 10. L3_CLK Output AC Timing Specifications

At recommended oper ating conditions. See Ta bl e 4 .

All Speed Grades

Parameter Symbol

Min Typ Max

Unit Notes

L3 clock frequency f

L3 clock cycle time t

L3 clock duty cycle t

L3 clock output-to-output skew (L1_CLK0 to

L1_CLK1)

L3 clock output-to-output skew (L1_CLK[0:1]

to L1_ECHO_CLK[2:3])

L3 clock jitter — — ±50 ps 5

Notes:

1. The maximum L3 clock frequency will be system dependent. See Section 5.2.3, “L3 Clock AC Specifications,” for

an explanation that this maximum frequency is not functionally tested at speed by Freescale.

2. The nominal duty cycle of the L3 output clocks is 50% measured at midpoint voltage.

3. Maximum possible skew between L3_CLK0 and L3_CLK1. This parameter is critical to the address and control

signals which are common to both SRAM chips in the L3.

4. Maximum possible skew between L3_CLK0 and L3_ECHO_CLK1 or between L3_CLK1 and L3_ECHO_CLK3 for

PB2 or late write SRAM. This parameter is critical to the write data signals which are separately latched onto each

SRAM part by these pairs of signals.

5. Guaranteed by design and not tested. The input jitter on SYSCLK affects L3 output clocks and the L3

address/data/control signals equally and, therefore, is already comprehended in the AC timing and does not have

to be considered in the L3 timing analysis. The clock-to-clock jitter shown here is uncertainty in the internal clock

period caused by supply voltage noise or thermal effects. This must be accounted for, along with clock skew, in

any L3 timing analysis.

L3_CLK

L3_CLK

CHCL/tL3_CLK

t

L3CSKW1

t

L3CSKW2

75 250 — MHz 1

— 4.0 13.3 ns

50 % 2

— — 200 ps 3

— — 100 ps 4

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

20 Freescale Semiconductor

Page 21

The L3_CLK timing diagram is shown in Figure 7.

Electrical and Thermal Characteristics

L3_CLK0

L3_CLK1

For PB2 or Late Write:

L3_ECHO_CLK1

L3_ECHO_CLK3

VM

t

CHCL

t

L3_CLK

VM

VM

VM

VMVM

VMVM VM

VMVM VM

t

L3CR

t

L3CSKW1

t

L3CSKW2

t

L3CSKW 2

VM

VM

VM

t

L3CF

Figure 7. L3_CLK_OUT Output Timing Diagram

5.2.4 L3 Bus AC Specifications

The MPC7455 L3 interface supports three different types of SRAM: source-synchronous, double data rate (DDR)

MSUG2 SRAM, late write SRAMs, and pipeline burst (PB2) SRAMs. Each requir es a different protocol on the L3

interface and a dif fere nt routing of the L3 clock si gnals. The type of SRAM is programmed in L3CR[22: 23] and the

MPC7455 then follows the appropriate protocol for that type. The designer must connect and route the L3 signals

appropriately fo r each type of SRAM. Following are some observations about the chip-to-SRAM interface.

• The routing for the point-t o-point signals (L3_CLK[0:1], L3DATA[0:63], L3DP[0:7], and

L3_ECHO_CLK[0:3]) to a par ticular SRAM should be dela y matched. If ne cessary , t he length of tr aces can

be altered in order to intentionally skew the timing and provide additional setup or hold time margin.

• For a 1-Mbyte L3, use address bits 16:0 (bit 0 is LSB).

• No pull-up resistors are required for the L3 interface.

• For high speed operations, L3 interface address and control signals should be a ‘T’ with minimal stubs to

the two loads; data and clock signals should be point-to-point to their single load. Figure 8 shows the AC

test load for the L3 interface.

Output

Z0 = 50 Ω

R

= 50 Ω

L

GVDD/2

Figure 8. AC Test Load for the L3 Interface

In general, if rout ing is short, dela y-matched, and desi gned for incident wave reception and minimal ref lection, the re

is a high probability that the AC timing of the MPC7455 L3 interface will meet the maximum frequency operation

of appropriately chosen SRAMs. This is despite the pessimistic, guard-banded AC specifications (see Table 12,

Table 13, and Table 14), the limitations of functional testers described in Section 5.2.3, “L3 Clock AC

Specifications

,” and the uncertainty of clocks and signals which inevitably make worst-case critical path timing

analysis pes sim isti c.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 21

Page 22

Electrical and Thermal Characteristics

More specifically, certain signals within groups should be delay-matched with others in the same group while

intergroup routing is less critical. Only the address and control signals are common to both SRAMs and additional

timing margin is avail able for these signals. The double-clocked data signals are grouped with individual cloc ks as

shown in Figure 9 or Figure 11, depending on the type of SRAM. For example, for the MSUG2 DDR SRAM (see

Figure 9); L3DA TA[0:31], L3DP[0:3], a nd L3_CLK[0] f orm a closely coupled group of outputs f rom the MPC7455;

while L3DATA[0:15], L3DP[0:1], and L3_ECHO_CLK[0] form a closely coupled group of inputs.

The MPC7450 RISC Micr opr oc essor Family User’s Manual refers to logical settings called ‘sample points’ used in

the synchronization of reads from the receive FIFO. The computation of the correct value for this setting is

system-dependent and is described in the MPC7450 RISC Microprocessor Family User’s Manual. Three

specifications are used in this calculation and are given in Table 11. It is essential that all three specifications are

included in the calculations to determine the sample points, as incorrect settings can result in errors and

unpredictable beh avior. For more information, see the MPC7450 RISC Micr oprocessor Family User’s Manual.

Table 11. Sample Points Calculation Parameters

Parameter Symbol Max Unit Notes

Delay from processor clock to internal_L3_CLK t

Delay from internal_L3_CLK to L3_CLK

Delay from L3_ECHO_CLK

Notes:

1. This specification describes a logical offset between the internal clock edge used to launch the L3 address and

control signals (this clock edge is phase-aligned with the processor clock edge) and the internal clock edge used to

launch the L3_CLK

SRAM within a valid address window and provide adequate setup and hold time. This offset is reflected in the L3

bus interface AC timing specifications, but must also be separately accounted for in the calculation of sample points

and, thus, is specified here.

2. This specification is the delay from a rising or falling edge on the internal_L3_CLK signal to the corresponding rising

or falling edge at the L3CLK

3. This specification is the delay from a rising or falling edge of L3_ECHO_CLK

from the FIFO.

n

to receive latch t

n

signals. With proper board routing, this offset ensures that the L3_CLKn edge will arrive at the

n

pins.

n

output pins t

AC

CO

ECI

n

to data valid and ready to be sampled

3/4 t

3ns2

3ns3

L3_CLK

1

5.2.4.1 L3 Bus AC Specifications for DDR MSUG2 SRAMs

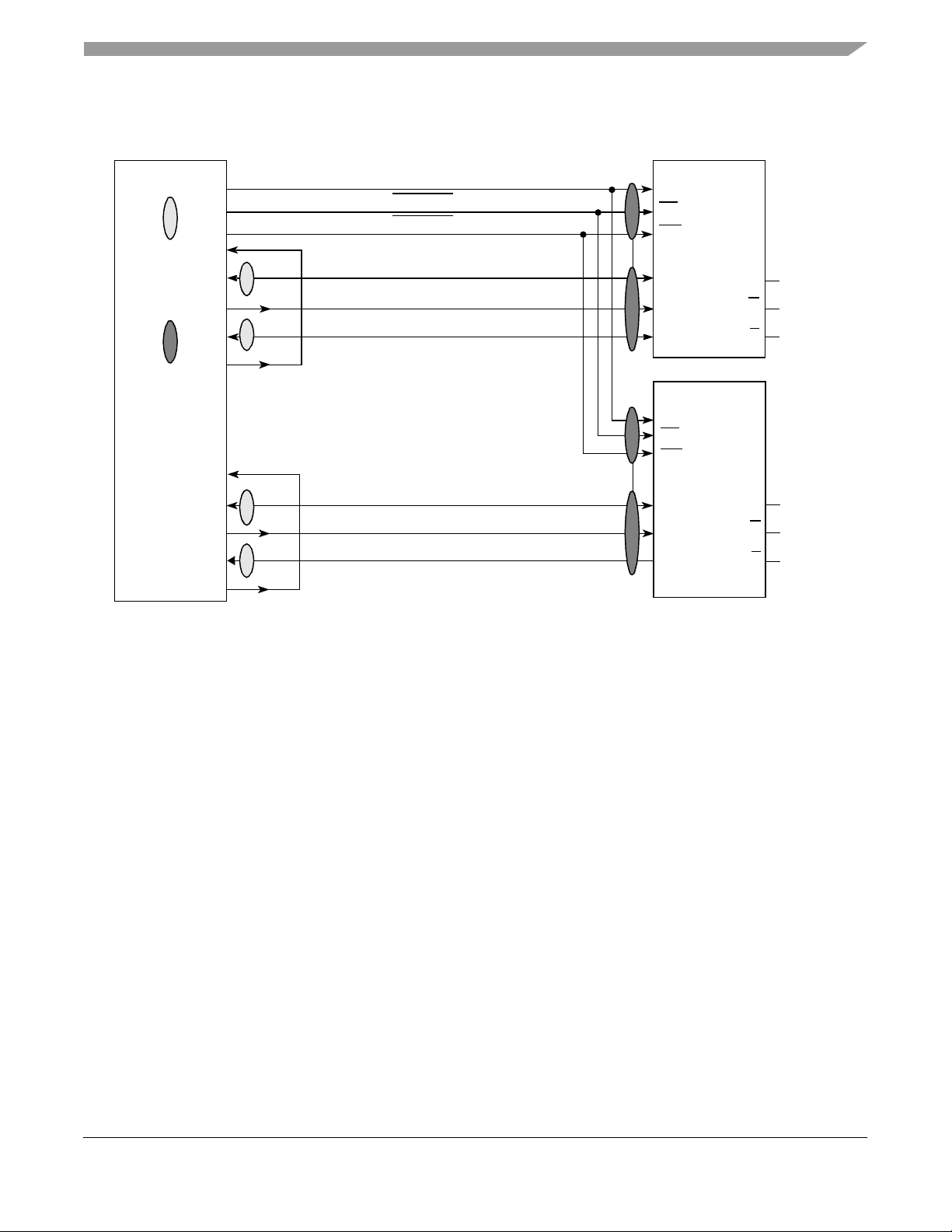

When using DDR MSUG2 SRAMs at the L3 interface, the parts should be connected as shown in Figure 9.

Outputs from the MPC7455 are actually launched on the edges of an internal clock phase-aligned to SYSCLK

(adjusted for core and L3 frequency divisors). L3_CLK0 and L3_CLK1 are this inter nal clock output with 90° phase

delay, so outputs are shown synchronous to L3_CLK0 and L3_CLK1. Output valid times are typically negative

when referenced to L3_CLKn because the data is launched one-quar ter period before L3_CLKn to provide adequate

setup time at the SRAM after the delay-matched address, control, data, and L3_CLKn signals have propagated

across the printed-wiring board.

Inputs to the MPC7455 are source-synchr onous with the CQ clock generated by the DDR MSUG2 SRAMs. These

CQ clocks are received on the L3_ECHO_CLKn inputs of the MPC7455. An internal circuit delays the incoming

L3_ECHO_CLKn signal such that it is positi oned withi n the valid da ta window a t the inter nal receiving latches. This

delayed clock is used to capture the data into these latches which comprise the receive FIFO. This clock is

asynchronous to all other processor cl ocks. This latched data is subs equently rea d out of the FIFO synchronou sly to

the processor clock. The time between writing and reading the data is set by the using the sample point settings

defined in the L3CR register.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

22 Freescale Semiconductor

Page 23

Electrical and Thermal Characteristics

Table 12 provides the L3 bus interface AC timing specifications for the configuration as shown in Figure 9,

assuming the timing relationships shown in Figure 10 and th e loading shown in Figure 8.

Table 12. L3 Bus Interface AC Timing Specifications for MSUG2

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol

L3_CLK rise

and fall time

Setup times:

Data and

parity

Input hold

times: Data

and parity

Val id times:

Data and

parity

Val id times:

All other

t

L3CR

t

L3CF

t

L3DVEH

t

L3DVEL

t

L3DXEH

t

L3DXEL

t

L3CHDV

t

L3CLDV

t

L3CH OV

outputs

Output hold

times: Data

t

L3CHDX

t

L3CLDX,

and parity

Output hold

times: All

t

L3CH OXtL3_CLK

other outputs

All Speed Grades

L3OH0 = 0, L3OH1 = 0 L3OH0 = 0, L3OH1 =1 L3OH0 = 1, L3OH1 = 0 L3OH0 = 1, L3OH1 = 1

8

Unit Notes

Min Max Min Max Min Max Min Max

,

—1.0—1.0—1.0—1.0ns1

,

– 0.1 — – 0.1 — – 0.1 — – 0.1 — ns 2, 3,

,

t

L3_CLK

+ 0.30

,

—(– t

—t

,

t

L3_CLK

– 0.40

– 0.20

/4

/4

/4

—t

/4)

L3_CLK

+ 0.60

/4

L3_CLK

+ 0.80

—t

—t

/4

L3_CLK

+ 0.30

—(– t

—t

/4

L3_CLK

– 0.60

/4

L3_CLK

– 0.40

—t

/4)

L3_CLK

+ 0.40

/4

L3_CLK

+ 0.60

—t

—t

/4

L3_CLK

+ 0.30

—(– t

—t

/4

L3_CLK

– 0.80

/4

L3_CLK

– 0.60

—t

/4)

L3_CLK

+ 0.20

/4

L3_CLK

+ 0.40

—t

—t

/4

L3_CLK

+ 0.30

—(– t

—t

/4

L3_CLK

– 1.00

/4

L3_CLK

– 0.80

—ns2, 4

/4)

L3_CLK

ns 5, 6,

+ 0.00

/4

L3_CLK

+ 0.20

ns 5, 7

—ns5, 6,

—ns5, 7

4

7

7

L3_CLK to

high

impedance:

Data and

parity

t

L3CLDZ

—t

/2 — t

L3_CLK

/2 — t

L3_CLK

/2 — t

L3_CLK

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

L3_CLK

/2 ns

Freescale Semiconductor 23

Page 24

Electrical and Thermal Characteristics

Table 12. L3 Bus Interface AC Timing Specifications for MSUG2 (continued)

At recommended oper ating conditions. See Ta bl e 4 .

+ 2.0

8

Unit Notes

/4

—t

L3_CLK

+ 2.0

/4

—ns

Parameter Symbol

L3_CLK to

high

impedance:

All other

outputs

t

L3CHOZ

All Speed Grades

L3OH0 = 0, L3OH1 = 0 L3OH0 = 0, L3OH1 =1 L3OH0 = 1, L3OH1 = 0 L3OH0 = 1, L3OH1 = 1

Min Max Min Max Min Max Min Max

—t

L3_CLK

+ 2.0

/4

—t

L3_CLK

+ 2.0

/4

t

L3_CLK

Notes:

1. Rise and fall times for the L3_CLK output are measured from 20% to 80% of GV

DD

.

2. For DDR, all input specifications are measured from the midpoint of the signal in question to the midpoint voltage of the rising

or falling edge of the input L3_ECHO_CLK

3. For DDR, the input data will typically follow the edge of L3_ECHO_CLK

n

(see Figure 10). Input timings are measured at the pins.

n

as shown in Figure 10. For consistency with other

input setup time specifications, this will be treated as negative input setup time.

4. t

/4 is one-fourth the period of L3_CLKn. This parameter indicates that the MPC7455 can latch an input signal that is

L3_CLK

valid for only a short time before and a short time after the midpoint between the rising and falling (or falling and rising) edges

of L3_ECHO_CLK

n

at any frequency.

5. All output specifications are measured from the midpoint voltage of the rising (or for DDR write data, also the falling) edge

of L3_CLK to the midpoint of the signal in question. The output timings are measured at the pins. All output timings assume

a purely resistive 50-Ω load (see Figure 8).

6. For DDR, the output data will typically lead the edge of L3_CLK

n

as shown in Figure 10. For consistency with other output

valid time specifications, this will be treated as negative output valid time.

7. t

/4 is one-fourth the period of L3_CLKn. This parameter indicates that the specified output signal is actually launched

L3_CLK

by an internal clock delayed in phase by 90°. Therefore, there is a frequency component to the output valid and output hold

times such that the specified output signal will be valid for approximately one L3_CLK period starting three-fourths of a clock

prior to the edge on which the SRAM will sample it and ending one-fourth of a clock period after the edge it will be sampled.

8. These configuration bits allow the AC timing of the L3 interface to be altered via software. L3OH0 = L2CR[12],

L30H1 = L3CR[12]. Revisions of the MPC7455 not described by this document may implement these bits differently. See

Section 11.1, “Part Numbers Fully Addressed by This Document,” and Section 11.2, “Part Numbers Not Fully Addressed by

This Document,” for more information on which devices are addressed by this document.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

24 Freescale Semiconductor

Page 25

Electrical and Thermal Characteristics

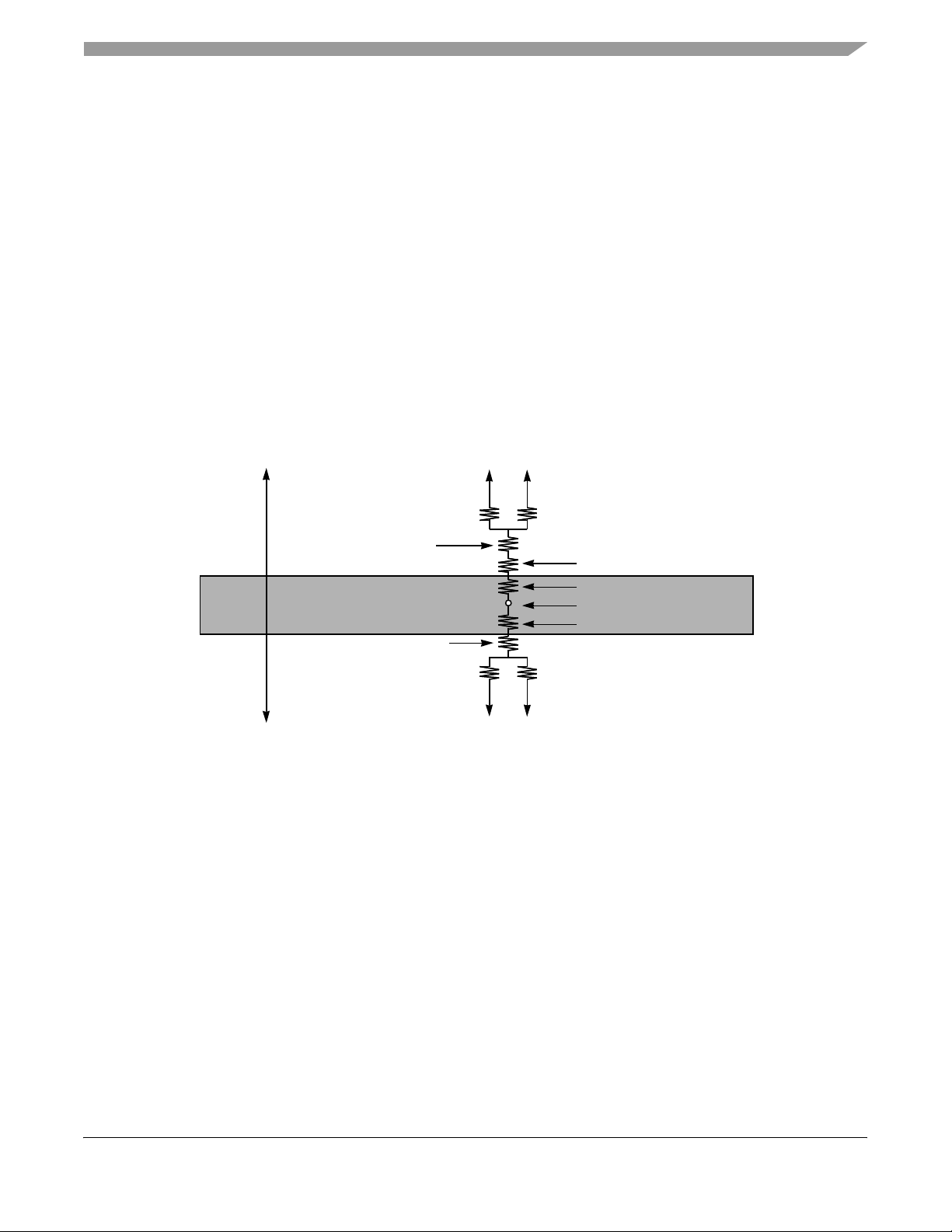

Figure 9 shows the typical connection diagram for the MPC7455 interfaced to MSUG2 SRAMs such as the

Free scal e MCM64E836.

MPC7455

Denotes

Denotes

Receive (SRAM

Receive (SRAM

to MPC7455)

to MPC7455)

Aligned Signals

Aligned Signals

Denotes

Transmit

(MPC7455 to

SRAM)

Aligned Signals

L3ADDR[17:0]

L3_CNTL

L3_CNTL[1]

L3_ECHO_CLK[0]

{L3DATA[0:15],

L3_CLK[0]

{L3DATA[16:31],

L3_ECHO_CLK[1]

L3ECHO_CLK[2]

{L3_DATA[32:47],

L3_CLK[1]

{L3DATA[48:63],

L3_ECHO_CLK[3]

[0]

L3DP[0:1]}

L3DP[2:3]}

L3DP[4:5]}

L3DP[6:7]}

SRAM 0

SA[17:0]

B1

B2

CQ

D[0:17]

CK

D[18:35]

CQ

SRAM 1

SA[17:0]

B1

B2

CQ

D[0:17]

CK

D[18:35]

CQ

B3

LBO

CQ

CQ

CK

B3

LBO

CQ

CQ

CK

G

G

GND

GND

GND

NC

NC

GV

DD

GND

GND

GND

NC

NC

GVDD/2

/2

1

1

Note:

1. Or as recommended by SRAM manufacturer for single-ended clocking.

Figure 9. Typical Source Synchronous 2-Mbyte L3 Cache DDR Interface

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 25

Page 26

Electrical and Thermal Characteristics

Figure 10 shows the L3 bus timing diagrams for the MPC7455 interfaced to MSUG2 SRAMs.

Outputs

L3_CLK[0,1]

ADDR, L3CNTL

L3DATA WRITE

Note: t

L3CHDV

and t

L3CLDV

time before the clock edge.

Inputs

L3_ECHO_CLK[0,1,2,3]

L3 Data and Data

Parity Inputs

Note: t

L3DVEH

and t

L3DVEL

time after the clock edge.

Figure 10. L3 Bus Timing Diagrams for L3 Cache DDR SRAMs

VM

t

L3CHOV

t

L3CHDV

t

L3CHDX

VM

t

L3CHOZ

t

L3CHOX

VM VM VM

t

L3CLDV

t

L3CLDZ

t

L3CLDX

VM = Midpoint Voltage (GVDD/2)

as drawn here will be negative numbers, that is, output valid time will be

VM

t

t

L3DVEH

t

L3DXEH

L3DVEL

VM = Midpoint Voltage (GV

VM

DD

/2)

VM VMVM

t

L3DXEL

as drawn here will be negative numbers, that is, input setup time will be

5.2.4.2 L3 Bus AC Specifications for PB2 and Late Write SRAMs

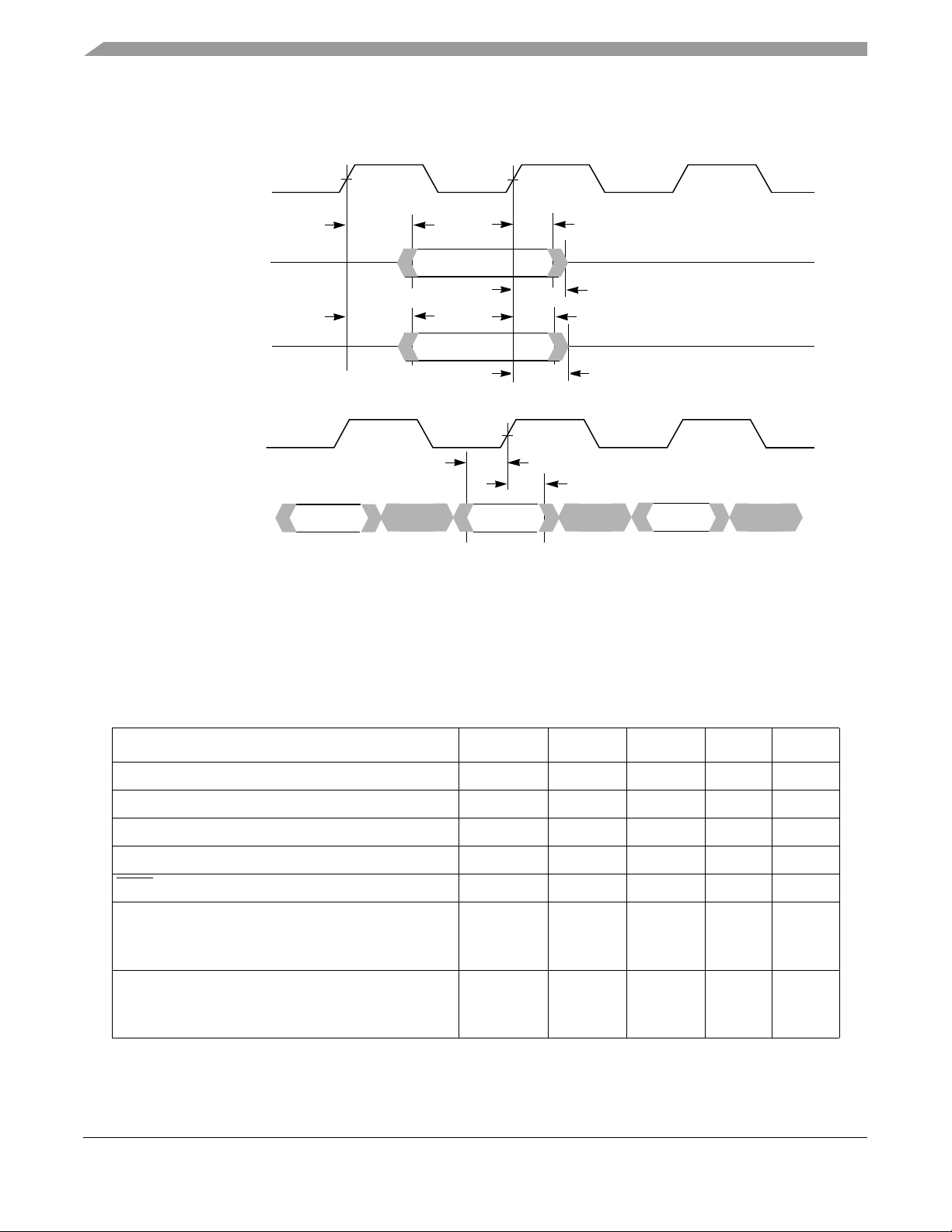

When using PB2 or late write SRAMs at the L3 interface, the parts should be connected as shown in Figure 11.

These SRAMs are synchronous to the MPC7455; one L3_CLKn signal is output to each SRAM to latch address,

control, and writ e data. Rea d data is launched by the S RAM synchronous to the delayed L3_C LKn signal it received.

The MPC7455 needs a copy of that delayed clock which launched the SRAM read data to know when the returning

data will be valid. Therefore, L3_ECHO_CLK1 and L3_ECHO_CLK3 must be routed halfway to the SRAMs and

then returned to the MPC7455 inputs L3_ECHO_CLK0 and L3_ECHO_CLK2, respectively. Thus,

L3_ECHO_CLK0 and L3_ECHO_CLK2 are phase-aligned with the input clock received at the SRAMs. The

MPC7455 will latch the incoming data on the ris ing edge of L3_ECHO_CLK0 and L3_ECHO_CLK2.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

26 Freescale Semiconductor

Page 27

Electrical and Thermal Characteristics

Table 13 provides the L3 bus inter face AC ti ming speci ficatio ns for the c onfigurat ion shown in Figure 11, assuming

the timing relationships of Figure 12 and the loading of Figure 8.

Table 13. L3 Bus Interface AC Timing Specifications for PB2 and Late Write SRAMs

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol

L3_CLK rise

and fall time

Setup times:

t

Data and

parity

Input hold

t

times: Data

and parity

Vali d times:

t

Data and

parity

Vali d t imes: All

t

L3CHOV

other outputs

Output hold

t

times: Data

and parity

Output hold

t

L3CHOXtL3_CLK

times: All other

outputs

L3OH0 = 0, L3OH1 = 0 L3OH0 = 0, L3OH1 =1 L3OH0 = 1, L3OH1 = 0 L3OH0 = 1, L3OH1 = 1

Min Max Min Max Min Max Min Max

t

,

L3CR

t

L3CF

L3DVEH

L3DXEH

L3CHDV

— 1.0 — 1.0 — 1.0 — 1.0 ns 1, 5

1.5 — 1.5 — 1.5 — 1.5 — ns 2, 5

— 0.5 — 0.5 — 0.5 — 0.5 ns 2, 5

—t

—t

L3CHDXtL3_CLK

– 0.40

– 0.40

/4

/4

/4

L3_CLK

+ 1.00

/4

L3_CLK

+ 1.00

—t

—t

—t

—t

/4

L3_CLK

– 0.60

/4

L3_CLK

– 0.60

All Speed Grades

/4

L3_CLK

—t

+ 0.80

/4

L3_CLK

—t

+ 0.80

—t

L3_CLK

– 0.80

—t

L3_CLK

– 0.80

6

L3_CLK

L3_CLK

/4

/4

/4

+ 0.60

/4

+ 0.60

—t

—t

—t

—t

/4

L3_CLK

– 1.00

/4

L3_CLK

– 1.00

Unit Notes

/4

L3_CLK

ns 3, 4, 5

+ 0.40

/4

L3_CLK

ns 4

+ 0.40

— ns 3, 4, 5

—ns4, 5

L3_CLK to

t

L3CHDZ

— 2.0 — 2.0 — 2.0 — 2.0 ns 5

high

impedance:

Data and

parity

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 27

Page 28

Electrical and Thermal Characteristics

Table 13. L3 Bus Interface AC Timing Specifications for PB2 and Late Write SRAMs (continued)

At recommended oper ating conditions. See Ta bl e 4 .

6

Unit Notes

Parameter Symbol

L3_CLK to

t

L3CHOZ

All Speed Grades

L3OH0 = 0, L3OH1 = 0 L3OH0 = 0, L3OH1 =1 L3OH0 = 1, L3OH1 = 0 L3OH0 = 1, L3OH1 = 1

Min Max Min Max Min Max Min Max

— 2.0 — 2.0 — 2.0 — 2.0 ns 5

high

impedance: All

other outputs

Notes:

1. Rise and fall times for the L3_CLK output are measured from 20% to 80% of GV

DD

.

2. All input specifications are measured from the midpoint of the signal in question to the midpoint voltage of the rising edge of

the input L3_ECHO_CLK

3. All output specifications are measured from the midpoint voltage of the rising edge of L3_CLK

n

(see Figure 10). Input timings are measured at the pins.

n

to the midpoint of the signal

in question. The output timings are measured at the pins. All output timings assume a purely resistive 50-Ω load (see

Figure 10).

4. t

/4 is one-fourth the period of L3_CLKn. This parameter indicates that the specified output signal is actually launched

L3_CLK

by an internal clock delayed in phase by 90°. Therefore, there is a frequency component to the output valid and output hold

times such that the specified output signal will be valid for approximately one L3_CLK period starting three-fourths of a clock

prior to the edge on which the SRAM will sample it and ending one-fourth of a clock period after the edge it will be sampled.

5. Timing behavior and characterization are currently being evaluated.

6. These configuration bits allow the AC timing of the L3 interface to be altered via software. L3OH0 = L2CR[12],

L30H1 = L3CR[12]. Revisions of the MPC7455 not described by this document may implement these bits differently. See

Section 11.1, “Part Numbers Fully Addressed by This Document,” and Section 11.2, “Part Numbers Not Fully Addressed by

This Document,” for more information on which devices are addressed by this document.

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

28 Freescale Semiconductor

Page 29

Electrical and Thermal Characteristics

Figure 11 shows the typical connection diagram for the MPC7455 interfaced to PB2 SRAMs, such as the Freescale

MCM63R737, or late write SRAMs, such as the Freescal e MCM63R836A.

MPC7455

L3_ADDR[16:0]

L3_CNTL

[0]

L3_CNTL[1]

Denotes

Receive (SRAM

L3_ECHO_CLK[0]

{L3_DATA[0:15],

L3_DP[0:1]}

to MPC7455)

Aligned Signals

Denotes

{L3_DATA[16:31],

L3_ECHO_CLK[1]

L3_CLK[0]

L3_DP[2:3]}

Trans mit

(MPC7455 to

SRAM)

Aligned Signals

L3_ECHO_CLK[2]

{L3_DATA[32:47],

L3_DP[4:5]}

L3_CLK[1]

{L3_DATA[48:63],

L3_DP[6:7]}

L3_ECHO_CLK[3]

Note:

1. Or as recommended by SRAM manufacturer for single-ended clocking.

Figure 11. Typical Synchronous 1-MByte L3 Cache Late Write or PB2 Interface

SRAM 0

SA[16:0]

SS

SW

DQ[0:17]

K

DQ[18:36

SRAM 1

SA[16:0]

SS

SW

DQ[0:17]

K

DQ[18:36

GND

ZZ

G

GND

1

1

ZZ

K

G

K

GVDD/2

GND

GND

GVDD/2

]

]

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

Freescale Semiconductor 29

Page 30

Electrical and Thermal Characteristics

Figure 12 shows the L3 bus timing diagrams for the MPC7455 interfaced to PB2 or late write SRAMs.

Outputs

L3_CLK[0,1]

L3_ECHO_CLK[1,3]

ADDR, L3_CNTL

L3DATA WRITE

Inputs

L3_ECHO_CLK[0,2]

Parity Inputs

L3 Data and Data

Figure 12. L3 Bus Timing Diagrams for Late Write or PB2 SRAMs

t

L3CHOV

t

L3CHDV

VM

VM = Midpoint Voltage (GV

VM

VM

t

L3DVEH

DD

t

L3CHOX

t

L3CHOZ

t

L3CHDX

t

L3CHDZ

t

L3DXEH

/2)

5.2.5 IEEE 1149.1 AC Timing Specifications

Table 14 provides the IEEE 1149.1 ( JTAG) AC timing specifications as defined in Figure 14 through Figure 17.

Table 14. JTAG AC Timing Specifications (Independent of SYSCLK)

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol Min Max Unit Notes

TCK frequency of operation f

TCK cycle time t

TCK clock pulse width measured at 1.4 V t

TCK rise and fall times t

TRST

assert time t

Input setup times:

Boundary-scan data

TMS, TDI

Input hold times:

Boundary-scan data

TMS, TDI

JR

TCLK

TCLK

JHJL

and t

TRST

t

DVJH

t

IVJH

t

DXJH

t

IXJH

0 33.3 MHz

30 — ns

15 — ns

JF

02ns

25 — ns 2

4

0

20

25

—

—

—

—

1

ns 3

ns 3

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

30 Freescale Semiconductor

Page 31

Table 14. JTAG AC Timing Specifications (Independent of SYSCLK) 1 (continued)

At recommended oper ating conditions. See Ta bl e 4 .

Parameter Symbol Min Max Unit Notes

Electrical and Thermal Characteristics

Valid times:

Boundary-scan data

TDO

Output hold times:

Boundary-scan data

TDO

TCK to output high impedance:

Boundary-scan data

TDO

t

JLDV

t

JLOV

t

JLDX

t

JLOX

t

JLDZ

t

JLOZ

4

4

TBD

TBD

3

3

20

25

TBD

TBD

19

9

ns 4

ns 4

ns 4, 5

Notes:

1. All outputs are measured from the midpoint voltage of the falling/rising edge of TCLK to the midpoint of the signal

in question. The output timings are measured at the pins. All output timings assume a purely resistive 50-Ω load

(see Figure 13). Time-of-flight delays must be added for trace lengths, vias, and connectors in the system.

2. TRST

is an asynchronous level sensitive signal. The setup time is for test purposes only.

3. Non-JTAG signal input timing with respect to TCK.

4. Non-JTAG signal output timing with respect to TCK.

5. Guaranteed by design and characterization.

Figure 13 provides the AC test load for TDO and the boundary-scan outputs of the MPC7455.

Output

Z0 = 50 Ω

R

= 50 Ω

L

OVDD/2

Figure 13. Alternate AC Test Load for the JTAG Interface

Figure 14 provides the JTAG clock input timing diagram.

TCLK

t

JHJL

t

TCLK

VM = Midpoint Voltage (OV

Figure 14. JTAG Clock Input Timing Diagram

VMVMVM

Figure 15 provides the TRST timing diagram.

TRST

VM

t

TRST

VM = Midpoint Voltage (OVDD/2)

Figure 15. TRST Timing Diagram

MPC7455 RISC Microprocessor Hardware Specifications, Rev. 4.1

DD

VM

/2)

t

JR

t

JF

Freescale Semiconductor 31

Page 32