Page 1

Freescale Semiconductor

123456

7

8 9 10 11 12 13

14

AVDD

GND

DVDD_IO

SCL/SPCCS

INT1/DRDY

INT2

N/C

SDO

SDA/SDI/SDO

N/C

IADDR0

N/C

GND

Technical Data

±2g/±4g/±8g Three Axis Low-g

Document Number: MMA7455L

Rev 4, 08/2008

Digital Output Accelerometer

The MMA7455L is a Digital Output (I2C/SPI), low power, low profile

capacitive micromachined accelerometer featuring signal conditioning, a low

pass filter, temperature compensation, self-test, configurable to detect 0g

through interrupt pins (INT1 or INT2), and pulse detect for quick motion

detection. 0g offset and sensitivity are factory set and require no external

devices. The 0g offset can be customer calibrated using assigned 0g registers

and g-Select which allows for command selection for 3 acceleration ranges

(2g/4g/8g). The MMA7455L includes a Standby Mode that makes it ideal for

handheld battery powered electronics.

Features

2

• Digital Output (I

• 3mm x 5mm x 1mm LGA-14 Package

• Low Current Consumption

• Self-Test for Z-Axis

• Low Voltage Operation: 2.4 V – 3.6 V

• User Assigned Registers for Offset Calibration

• Programmable Threshold Interrupt Output

• Level Detection for Motion Recognition (Shock, Vibration, Freefall)

• Pulse Detection for Single or Double Pulse Recognition

• Sensitivity (64 LSB/g @ 2g and @ 8g in 10-Bit Mode)

• Selectable Sensitivity (±2g, ±4g, ±8g) for 8-bit Mode

• Robust Design, High Shocks Survivability (5,000g)

• RoHS Compliant

• Environmentally Preferred Product

• Low Cost

C/SPI)

MMA7455L

MMA7455L: XYZ-AXIS

ACCELEROMETER

±2G/±4G/±8G

Bottom View

14 LEAD

LGA

CASE 1977-01

Top View

Typical Applications

• Cell Phone/PMP/PDA: Image Stability, Text Scroll, Motion Dialing, Tap to

Mute

• HDD: Freefall Detection

• Laptop PC: Freefall Detection, Anti-Theft

• Pedometer

• Motion Sensing, Event Recorder

ORDERING INFORMATION

Part Number Temperature Range Package Shipping

MMA7455LT

MMA7455LR1

MMA7455LR2

This document contains certain information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2007, 2008. All rights reserved.

–40 to +85°C LGA-14 Tray

–40 to +85°C LGA-14 7” Tape & Reel

–40 to +85°C LGA-14 13” Tape & Reel

Figure 1. Pin Connections

Page 2

Contents

ELECTRO STATIC DISCHARGE (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PRINCIPLE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

g-Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

LEVEL DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

$18: Control 1 (Read/Write) Setting the Detection Axes for X, Y and Z . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

$19: Control 2 (Read/Write) Motion Detection (OR Condition) or Freefall Detection (AND Condition) . . . . . . . . . . . .10

$18: Control 1 (Read/Write): Setting the threshold to be an integer value or an absolute value . . . . . . . . . . . . . . . . .10

$1A: Level Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

THRESHOLD DETECTION FOR MOTION AND FREEFALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CASE 1: Motion Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CASE 2: Motion Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CASE 3: Freefall Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CASE 4: Freefall Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

PULSE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

$18: Control 1 (Read/Write): Disable X, Y or Z for pulse detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

$19: Control 2 (Read/Write): Motion Detection (OR condition) or Freefall Detection (AND condition) . . . . . . . . . . . . .12

CASE 1: Single Pulse Motion Detection: X or Y or Z > Pulse Threshold for Time < Pulse Duration . . . . . . . . . . . . . .12

CASE 2: Freefall Detection: X and Y and Z < Pulse Threshold for Time > Latency Time . . . . . . . . . . . . . . . . . . . . . .13

CASE 3: Double Pulse Detection: X OR Y OR Z > Threshold for Pulse Duration1 < PDTime1, Latency Time, AND .14

ASSIGNING, CLEARING & DETECTING INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Clearing the Interrupt Pins: Register $17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Detecting Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

DIGITAL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

BASIC CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

REGISTER DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SOLDERING AND MOUNTING GUIDELINES FOR THE LGA ACCELEROMETER SENSOR TO A PC BOARD . . . . . . . . . .29

2

C Slave Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

I

SPI Slave Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Recommended PCB Layout for Interfacing Accelerometer to Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MMA7455L

Sensors

2 Freescale Semiconductor

Page 3

List of Figures

Pin Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

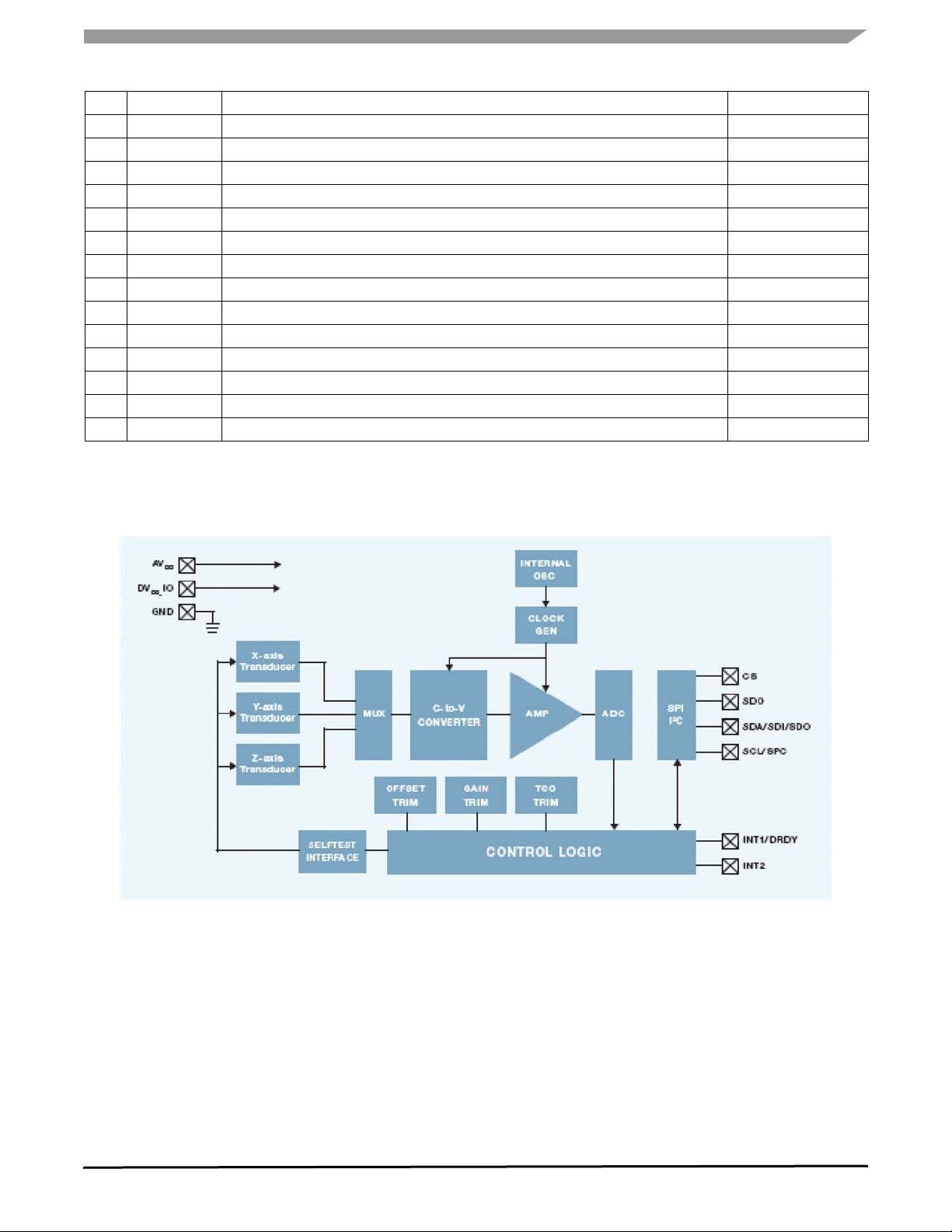

Simplified Accelerometer Functional Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Simplified Transducer Physical Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Single Pulse Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Freefall Detection in Pulse Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Double Pulse Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Single Byte Read - The Master is reading one address from the MMA7455L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Multiple Bytes Read - The Master is reading multiple sequential registers from the MMA7455L . . . . . . . . . . . . . . . . . . . . . . . . 17

Single Byte Write - The Master (MCU) is writing to a single register of the MMA7455L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Multiple Byte Writes - The Master (MCU) is writing to multiple sequential registers of the MMA7455L . . . . . . . . . . . . . . . . . . . 17

SPI Timing Diagram for 8-Bit Register Read (4 Wire Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPI Timing Diagram for 8-Bit Register Read (3 Wire Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPI timing Diagram for 8-Bit Register Write (3 Wire Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pinout Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2

C Connection to MCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

I

SPI Connection to MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Sensing Direction and Output Response at 2g Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Recommended PCB Land Pattern for the 5 x 3 mm LGA Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Incorrect PCB Top Metal Pattern Under

Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Correct PCB Top Metal Pattern Under Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Recommended PCB Land Pad, Solder Mask, and Signal Trace Near Package Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Stencil Design Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MMA7455L

Sensors

Freescale Semiconductor 3

Page 4

List of Tables

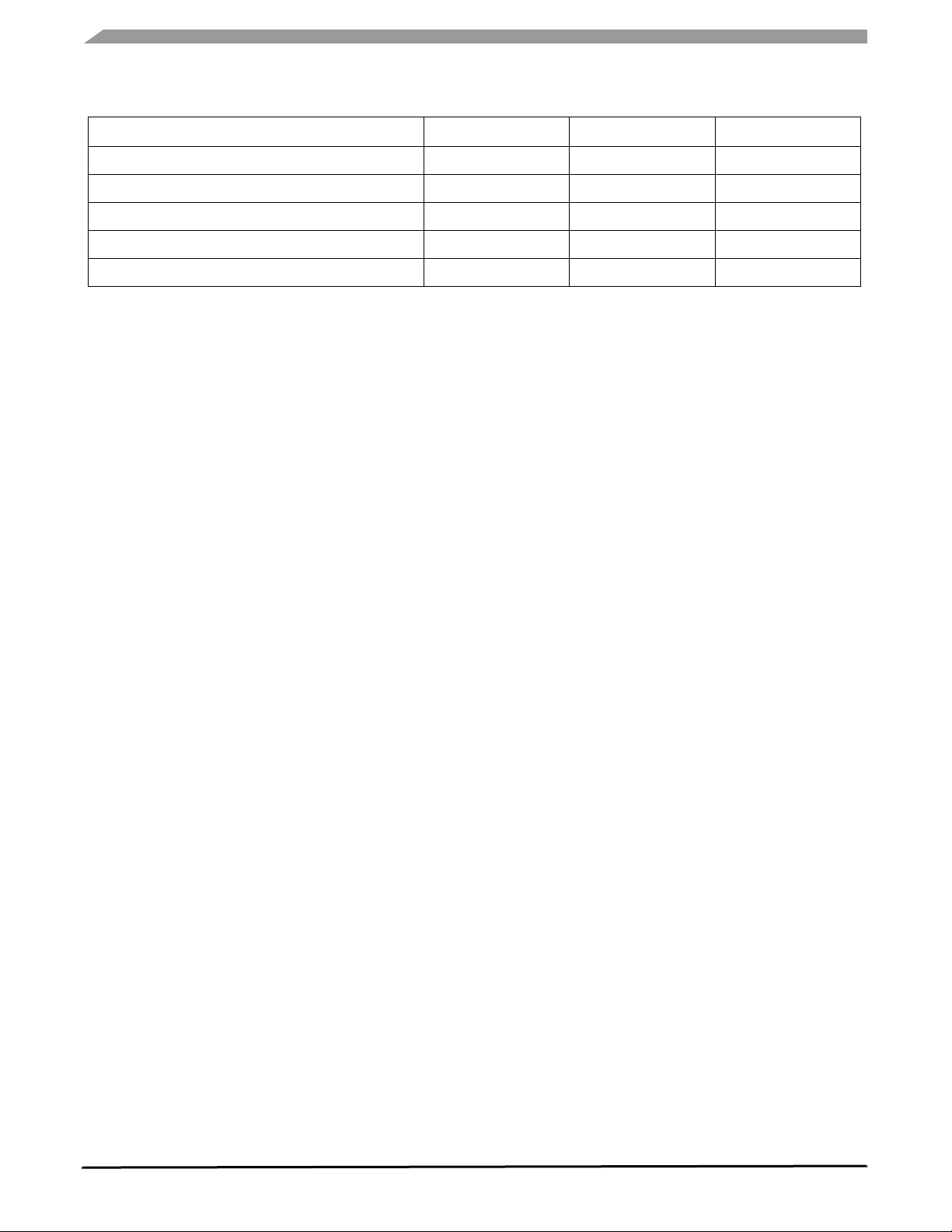

Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maximum Ratings

(Maximum ratings are the limits to which the device can be exposed without causing permanent damage.) . . . . . . . . . . . . . . .6

Operating Characteristics

Unless otherwise noted: –40°C < TA < 85°C, 2.4 V < AVDD < 3.6 V, Acceleration = 0g, Loaded output. . . . . . . . . . . . . . . . . . .7

Function Parameters for Detection

–40°C < TA < 85°C, 2.4 V < AVDD < 3.6 V, unless otherwise specified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

$16: Mode Control Register (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Configuring the g-Select for 8-bit output using Register $16 with GLVL[1:0] bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Configuring the Mode using Register $16 with MODE[1:0] bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

THOPT = 0 Absolute; THOPT = 1 Positive Negative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

$1B: Pulse Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

$1C: Pulse Duration Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

$1B: Pulse Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

$1D: Latency Time Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

$1B: Pulse Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

$1C: Pulse Duration Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

$1D: Latency Time Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

$1E: Time Window for 2nd Pulse Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

$18 Control 1 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Configuring the Interrupt settings using Register $18 with INTREG[1:0] bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

$17: Interrupt Latch Reset (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

$0A: Detection Source Register (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

User Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

$00: 10bits Output Value X LSB (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

$01: 10bits Output Value X MSB (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$02: 10bits Output Value Y LSB (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$03: 10bits Output Value Y MSB (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$05: 10bits Output Value X MSB (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$06: 8bits Output Value X (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$07: 8bits Output Value Y (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

$08: 8bits Output Value Z (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

$09: Status Register (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

$0A: Detection Source Register (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

$0D: I2C Device Address (Bit 6-0: Read only, Bit 7: Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$0E: User Information (Read Only: Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$0F: “Who Am I” Value (Read only: Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$10: Offset Drift X LSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$11: Offset Drift X MSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$12: Offset Drift Y LSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

$13: Offset Drift Y MSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

$14: Offset Drift Z LSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

$15: Offset Drift Z MSB (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

$16: Mode Control Register (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Configuring the g-Select for 8-bit output using Register $16 with GLVL[1:0] bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

$17: Interrupt Latch Reset (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

$18 Control 1 (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Configuring the Interrupt settings using Register $18 with INTREG[1:0] bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

$1A: Level Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

$1B: Pulse Detection Threshold Limit Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

$1C: Pulse Duration Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

$1D: Latency Time Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

$1E: Time Window for 2nd Pulse Value (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Acceleration vs. Output (8-bit data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

MMA7455L

Sensors

4 Freescale Semiconductor

Page 5

Table 1. Pin Descriptions

Pin # Pin Name Description Pin Status

1 DVDD_IO Digital Power for I/O pads Input

2 GND Ground Input

3 N/C No internal connection. Leave unconnected or connect to Ground. Input

4 IADDR0

2

C Address Bit 0 (optional)*

I

5 GND Ground Input

6 AVDD Analog Power Input

7CS

SPI Enable (0), I

2

C Enable (1)

8 INT1/DRDY Interrupt 1/ Data Ready Output

9 INT2 Interrupt 2 Output

10 N/C No internal connection. Leave unconnected or connect to Ground. Input

11 N/C Leave unconnected or connect to Ground. Input

12 SDO SPI Serial Data Output Output

13 SDA/SDI/SDO

14 SCL/SPC

2

C Serial Data (SDA), SPI Serial Data Input (SDI), 3-wire interface Serial Data Output (SDO)

I

2

C Serial Clock (SCL), SPI Serial Clock (SPC)

I

Open Drain/Input/Output

*This address selection capability is not enabled at the default state. If the user wants to use it, factory programming is required. If activated (pin4

on the device is active).

<$1D= 0001 1101> bit 0 is V

on pin 4

DD

<$1C=0001 1100> bit 0 is GND on pin 4. If the pin is programmed it cannot be left NC.

Input

Input

Input

Figure 1. Simplified Accelerometer Functional Block Diagram

MMA7455L

Sensors

Freescale Semiconductor 5

Page 6

Table 2. Maximum Ratings

(Maximum ratings are the limits to which the device can be exposed without causing permanent damage.)

Rating Symbol Value Unit

Maximum Acceleration (all axes) g

Analog Supply Voltage AV

Digital I/O pins Supply Voltage DV

Drop Test D

Storage Temperature Range T

max

DD

DD_IO

drop

stg

5000 g

-0.3 to +3.6 V

-0.3 to +3.6 V

1.8 m

-40 to +125 °C

ELECTRO STATIC DISCHARGE (ESD)

WARNING: This device is sensitive to electrostatic discharge.

Although the Freescale accelerometer contains internal 2000V ESD protection circuitry, extra precaution must be taken by the

user to protect the chip from ESD. A charge of over 2000 volts can accumulate on the human body or associated test equipment.

A charge of this magnitude can alter the performance or cause failure of the chip. When handling the accelerometer, proper ESD

precautions should be followed to avoid exposing the device to discharges which may be detrimental to its performance.

MMA7455L

Sensors

6 Freescale Semiconductor

Page 7

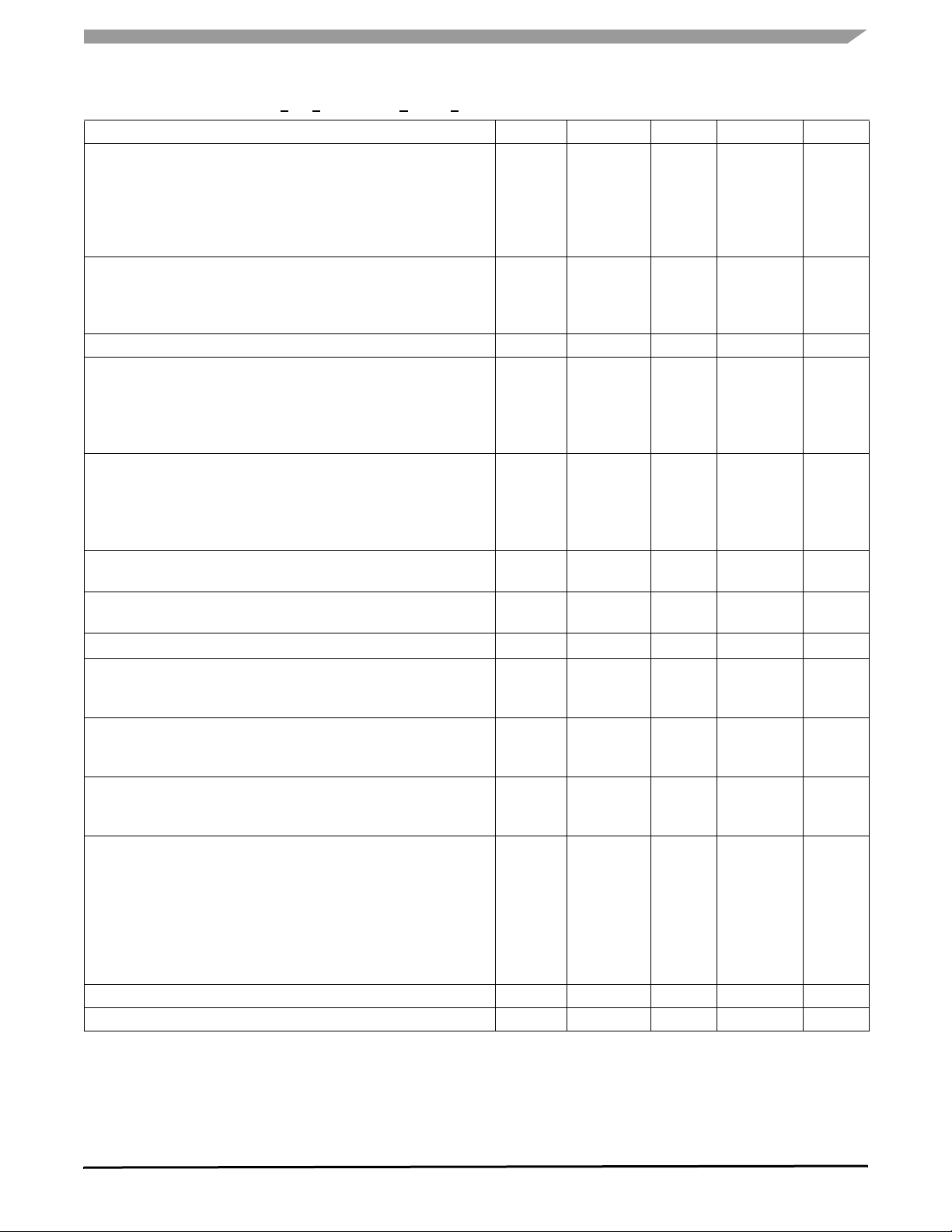

Table 3. Operating Characteristics

Unless otherwise noted: –40°C <

Analog Supply Voltage

Standby/Operation Mode

Enable Bus Mode

Digital I/O Pins Supply Voltage

Standby/Operation Mode

Enable Bus Mode

Supply Current Drain

Operation Mode

Pulse Detect Function Mode

Standby Mode (except data loading and I

Operating Temperature Range T

0g Output Signal (T

±2g range (25°C) 8bit GLVL[1:0]= 0 1

±4g range (25°C) 8bit GLVL[1:0]= 1 0

±8g range (25°C) 8bit GLVL[1:0]= 0 0

±8g range (25°C) 10bit

Sensitivity (T

±2g range (25°C) 8bit

±4g range (25°C) 8bit

±8g range (25°C) 8bit

±8g range (25°C) 10bit

Self-Test Output Response

Zout ΔST

Input High Voltage

Input Low Voltage

Internal Clock Frequency (T

SPI Frequency

DD_IO

DD_IO

< 2.4 V

> 2.4 V

DV

DV

Bandwidth for Data Measurement (User Selectable)

DFBW 0

DFBW 1

Output Data Rate

Output Data Rate is 125 Hz when 62.5 bandwidth is selected.

Output Data rate is 250 Hz when 125Hz bandwidth is selected.

Control Timing

Wait Time for I

Turn On Response Time (Standby to Normal Mode)

Turn Off Response Time (Normal to Standby Mode)

Self-Test Response Time

Sensing Element Resonant Frequency

XY

Z

Nonlinearity (2 g range) -1 — +1 %FS

Cross Axis Sensitivity -5 — +5 %

=25°C, AVDD = 2.8 V

A

=25°C, AV

A

2

DD

C/SPI ready after power on

TA < 85°C, 2.4 V < AVDD < 3.6 V, Acceleration = 0g, Loaded output.

Characteristic Symbol Min Typ Max Unit

2

C/SPI communication period)

= 2.8 V)

= 25°C, AVDD = 2.8 V) t

A

AV

DD

AV

DD

DV

DD_IO

DV

DD_IO

I

DD

I

DD

I

DD

A

V

IH

V

IL

CLK

t

su

t

ru

t

rd

t

st

f

GCELLXY

f

GCELLZ

Z

2.4

2.8

3.6

0

1.71

1.71

—

—

—

1.8

1.8

400

400

2.5

AV

DD

3.6

490

490

10

-40 25 85 °C

-21

—

—

-21

58

—

—

58

64

32

16

64

0

0

0

0

21

—

—

21

70

—

—

70

+48 +64 +80 count

0.7 x DVDD

—

—

—

—

0.35 x DVDD

140 150 160 kHz

—

—

—

—

—

—

—

—

—

—

—

—

4

8

62.5

125

125

250

1

—

—

—

6.0

3.4

—

—

—

—

—

—

—

20

20

20

—

—

count/g

count/g

count/g

count/g

V

V

V

V

μA

μA

μA

count

count

count

count

V

V

MHz

MHz

Hz

Hz

Hz

Hz

ms

ms

ms

ms

kHz

kHz

MMA7455L

Sensors

Freescale Semiconductor 7

Page 8

Table 4. Function Parameters for Detection

–40°C <

Note: The response time is between 10% of full scale VDD input voltage and 90% of the final operating output voltage.

*The bandwidth for detecting interrupts in level and pulse is 600Hz which is changed from measurement mode.

TA < 85°C, 2.4 V < AVDD < 3.6 V, unless otherwise specified

Characteristic Symbol Min Typ Max Unit

Level Detection

Detection Threshold Range 0 — FS g

Pulse Detection

Pulse detection range (Adjustable range)

Time step for pulse detection

Threshold range for pulses

Detection levels for threshold

Latency timer (Adjustable range)

Time Window (Adjustable range)

Bandwidth for detecting interrupt*

Time step for latency timer and time window

0.5

—

0

—

1

1

—

—

—

0.5

—

127

—

—

600

1

127

—

FS

—

150

250

—

—

ms

ms

g

Counts

ms

ms

Hz

ms

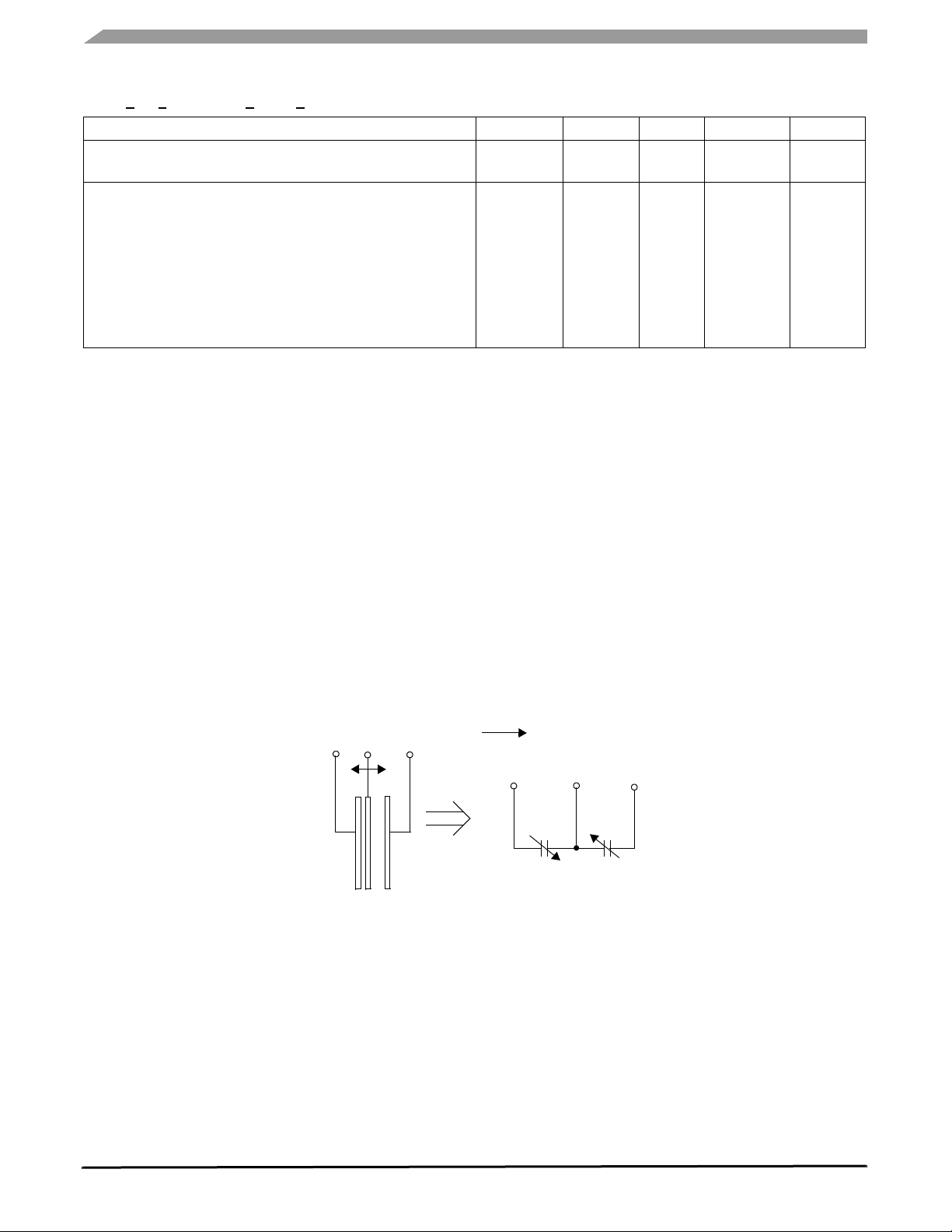

PRINCIPLE OF OPERATION

The Freescale accelerometer is a surface-micromachined integrated-circuit accelerometer. The device consists of a surface micromachined capacitive sensing cell (g-cell) and a signal conditioning ASIC contained in a single package. The sensing element

is sealed hermetically at the wafer level using a bulk micromachined cap wafer. The g-cell is a mechanical structure formed from

semiconductor materials (polysilicon) using semiconductor processes (masking and etching). It can be modeled as a set of

beams attached to a movable central mass that move between fixed beams. The movable beams can be deflected from their

rest position by subjecting the system to an acceleration (Figure 2).

As the beams attached to the central mass move, the distance from them to the fixed beams on one side will increase by the

same amount that the distance to the fixed beams on the other side decreases. The change in distance is a measure of acceleration. The g-cell beams form two back-to-back capacitors (Figure 2). As the center beam moves with acceleration, the distance

between the beams changes and each capacitor's value will change, (C = A

electric constant, and D is the distance between the beams.

The ASIC uses switched capacitor techniques to measure the g-cell capacitors and extract the acceleration data from the difference between the two capacitors. The ASIC also signal conditions and filters (switched capacitor) the signal, providing a digital

output that is proportional to acceleration.

ε/D). Where A is the area of the beam, ε is the di-

Acceleration

Figure 2. Simplified Transducer Physical Model

FEATURES

Self-Test

The sensor provides a self-test feature that allows the verification of the mechanical and electrical integrity of the accelerometer

at any time before or after installation. This feature is critical in applications such as hard disk drive protection where system integrity must be ensured over the life of the product. When the self-test function is initiated through the mode control register ($16),

accessing the “self-test” bit, an electrostatic force is applied to each axis to cause it to deflect. The Z-axis is trimmed to deflect

1g. This procedure assures that both the mechanical (g-cell) and electronic sections of the accelerometer are functioning.

MMA7455L

Sensors

8 Freescale Semiconductor

Page 9

g-Select

The g-Select feature enables the selection between 3 acceleration ranges for measurement. Depending on the values in the

Mode control register ($16), the MMA7455L’s internal gain will be changed allowing it to function with a 2g, 4g or 8g measurement

sensitivity. This feature is ideal when a product has applications requiring two or more acceleration ranges for optimum performance and for enabling multiple functions. The sensitivity can be changed during the operation by modifying the two GLVL bits

located in the mode control register.

$16: Mode Control Register (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- DRPD SPI3W STON GLVL[1] GLVL[0] MODE[1] MODE[0] Function

0 0 0 0 0 0 0 0 Default

Table 5. Configuring the g-Select for 8-bit output using Register $16 with GLVL[1:0] bits.

GLVL [1:0] g-Range Sensitivity

00 8g 16 LSB/g

01 2g 64 LSB/g

10 4g 32 LSB/g

Standby Mode

This digital output 3-axis accelerometer provides a standby mode that is ideal for battery operated products. When standby mode

is active, the device outputs are turned off, providing significant reduction of operating current. When the device is in standby

mode the current will be reduced to 2.5 µA typical. In standby mode the device can read and write to the registers with the I

2

C/

SPI available, but no new measurements can be taken in this mode as all current consuming parts are off. The mode of the device

is controlled through the mode control register by accessing the two mode bits as shown in Table 6.

Table 6. Configuring the Mode using Register $16 with MODE[1:0] bits.

MODE [1:0] Function

00 Standby Mode

01 Measurement Mode

10 Level Detection Mode

11 Pulse Detection Mode

Measurement Mode

During measurement mode, continuous measurements on all three axes enabled. The g-range for 2g, 4g, or 8g are selectable

with 8-bit data and the g-range of 8g is selectable with 10-bit data. The sample rate during measurement mode is 125 Hz with

62.5 BW filter selected. The sample rate is 250 Hz with the 125 Hz filter selected. Therefore, when a conversion is complete

(signaled by the DRDY flag), the next measurement will be ready.

When measurements on all three axes are completed, a logic high level is output to the DRDY pin, indicating “measurement data

is ready.” The DRDY status can be monitored by the DRDY bit in Status Register (Address: $09). The DRDY pin is kept high until

one of the three Output Value Registers are read. If the next measurement data is written before the previous data is read, the

DOVR bit in the Status Register will be set. Also note that in measurement mode, level detection mode and pulse detection mode

are not available.

By default all three axes are enabled. X and/or Y and/or Z can be disabled. There is a choice between detecting an absolute

signal or a positive or negative only signal on the enabled axes. There is also a choice between doing a detection for motion

where X or Y or Z > Threshold vs. doing a detection for freefall where X & Y & Z < Threshold.

MMA7455L

Sensors

Freescale Semiconductor 9

Page 10

LEVEL DETECTION

When in Level or Pulse detection mode, it is not advisable to read the XYZ measurements because this can conflict with timing.

The interrupts for level and pulse detection are at 600 Hz, while measurement mode is at 125 Hz. It is best to exit the pulse/level

mode before taking a measurement on the XYZ.

Both the Level Detection and Pulse Detection modes can trigger an interrupt. Typically one interrupt is assigned to either pulse

detection or level detection. To detect both at the same time 2 interrupts are required. The level detection mechanism has no

timers associated with it. Once a set acceleration level is reached the interrupt pin will go high and remain high until the interrupt

pin is cleared (See Assigning, Clearing & Detecting Interrupts).

By default all three axes are enabled and the detection range is 8g only. X and/or Y and/or Z can be disabled. There is a choice

between detecting an Absolute signal or a Positive or Negative only signal on the enabled axes. There is also a choice between

doing a detection for Motion where X or Y or Z > Threshold vs. doing a detection for Freefall where X& Y & Z < Threshold.

$18: Control 1 (Read/Write) Setting the Detection Axes for X, Y and Z

This allows the user to define how many axes to use for detection. All axes are enabled by default. To disable write 1.

XDA: Disable X

YDA: Disable Y

ZDA: Disable Z

D7 D6 D5 D4 D3 D2 D1 D0 Reg $18

DFBW THOPT ZDA YDA XDA INTREG[1] INTREG[0] INTPIN Function

00000000Default

$19: Control 2 (Read/Write) Motion Detection (OR Condition) or Freefall Detection (AND Condition

)

LDPL = 0: Level detection polarity is positive and detecting condition is OR for all 3 axes.

X or Y or Z > Threshold

||X|| or ||Y|| or ||Z|| > Threshold

LDPL = 1: Level detection polarity is negative detecting condition is AND for all 3 axes.

X and Y and Z < Threshold

||X|| and ||Y|| and ||Z|| < Threshold

D7 D6 D5 D4 D3 D2 D1 D0 Reg $19

-- -- -- -- -- DRVO PDPL LDPL Function

00000000Default

$18: Control 1 (Read/Write): Setting the threshold to be an integer value or an absolute value

This allows the user to set the threshold to be absolute, or to be based on the threshold value as positive or negative.

THOPT = 0 Absolute; THOPT = 1 Positive Negative

D7 D6 D5 D4 D3 D2 D1 D0 Reg $18

DFBW THOPT ZDA YDA XDA INTREG[1] INTREG[0] INTPIN Function

00000000Default

$1A: Level Detection Threshold Limit Value (Read/Write)

When an event is detected the interrupt pin (either INT1 or INT2) will go high. The interrupt pin assignment is set up in Register

$18, discussed in the Assigning, Clearing & Detecting Interrupts section. The detection status is monitored by the Detection

Source Register $0A.

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1A

LDTH[7] LDTH[6] LDTH[5] LDTH[4] LDTH[3] LDTH[2] LDTH[1] LDTH[0] Function

00000000Default

LDTH[7:0]: Level detection threshold value. If THOPT bit in Detection Control Register is “0”, it is unsigned 7 bits value and

LDTH[7] should be “0”. If THOPT bit is “1”, it is signed 8 bits value.

MMA7455L

Sensors

10 Freescale Semiconductor

Page 11

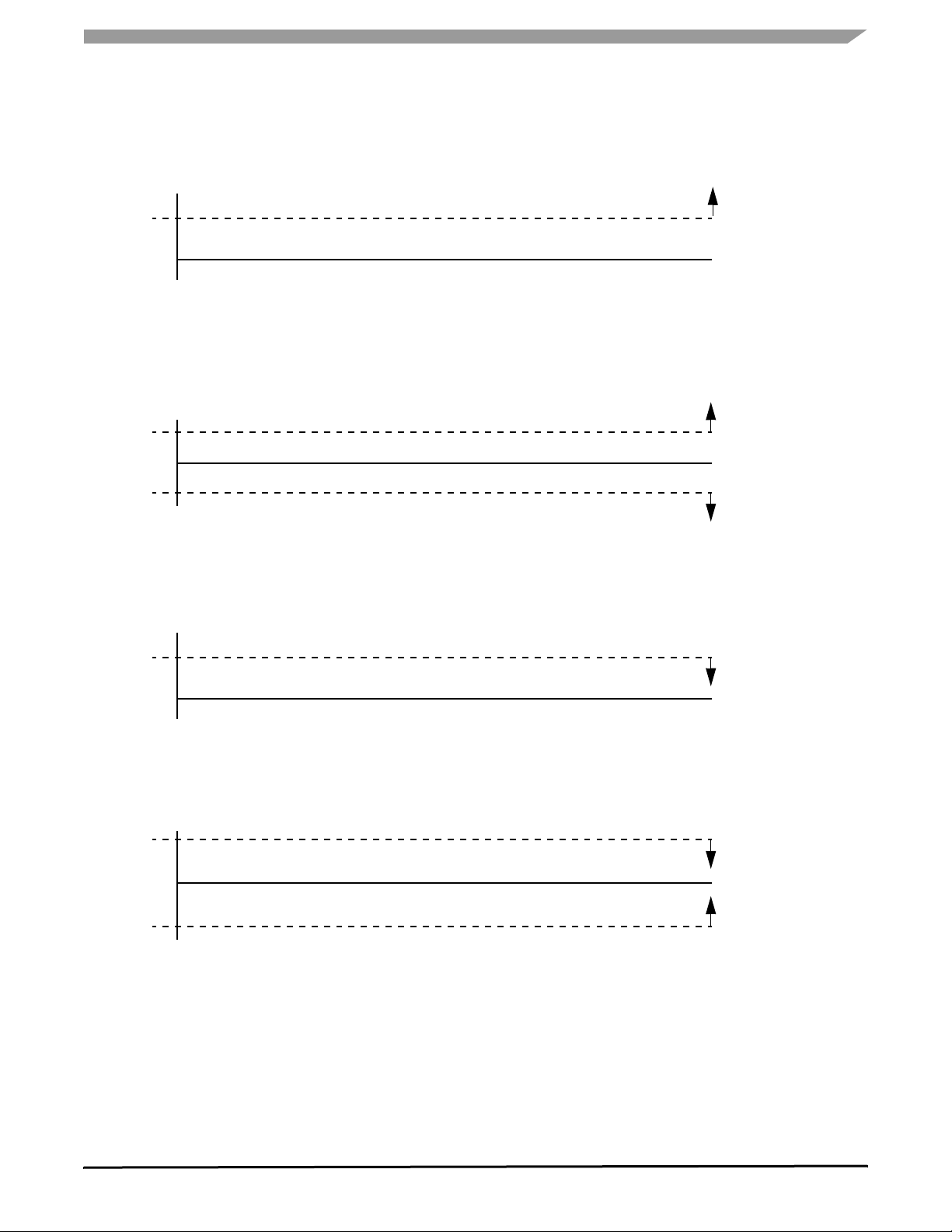

THRESHOLD DETECTION FOR MOTION AND FREEFALL CONDITIONS

CASE 1: Motion Detection

Integer Value: X >Threshold OR Y >Threshold OR Z > Threshold

Reg $18 THOPT=1; Reg 19 LDPL=0, Set Threshold to 3g, which is 47 counts (16 counts/g). Set register $1A LDTH = $2F.

TH = $2F

CASE 2: Motion Detection

Absolute: ||X|| > Threshold OR ||Y|| >Threshold OR ||Z|| > Threshold

Reg $18 THOPT=0; Reg 19 LDPL=0, Set Threshold to 3g, which is 47 counts (16 counts/g). Set register $1A LDTH = $2F.

TH = $2F

TH = $D1

CASE 3: Freefall Detection

Integer Value: X < Threshold AND Y < Threshold AND Z <Threshold

Reg $18 THOPT=1; Reg 19 LDPL=1, Set Threshold to 0.5g, which is 7 counts (16 counts/g). Set register $1A LDTH = $07

TH = $07

CASE 4: Freefall Detection

Absolute: ||X|| <Threshold AND ||Y|| < Threshold AND ||Z||< Threshold

Reg $18 THOPT=0; Reg 19 LDPL=1, Set Threshold to +/-0.5g, which is 7 counts (16 counts/g). Set register $1A LDTH = $07.

TH = $07

TH = $F9

MMA7455L

Sensors

Freescale Semiconductor 11

Page 12

PULSE DETECTION

There are two interrupt pins available for detection of level and pulse conditions. The pulse detection has several timing windows

associated with it. A single pulse and a double pulse can be detected. Also freefall can be detected. The interrupt pins can be

assigned to detect the first pulse on one interrupt and the second pulse on the other interrupt. This is explained on

Page page 15, under the Assigning, Clearing & Detecting Interrupts section.

By default all three axes are enabled and the detection range is 8g only. X and/or Y and/or Z can be disabled. There is a choice

between doing a detection for Motion detection vs. doing a detection for Freefall.

$18: Control 1 (Read/Write): Disable X, Y or Z for pulse detection

This allows the user to define how many axes to use for detection. All axes are enabled by default. To disable write 1

XDA: Disable X

YDA: Disable Y

ZDA: Disable Z.

D7 D6 D5 D4 D3 D2 D1 D0 Reg $18

DFBW THOPT ZDA YDA XDA INTREG[1] INTREG[0] INTPIN Function

00000000Default

$19: Control 2 (Read/Write): Motion Detection (OR condition) or Freefall Detection (AND condition)

PDPL

0: Pulse detection polarity is positive and detecting condition is OR 3 axes.

1: Pulse detection polarity is negative and detecting condition is AND 3 axes.

D7 D6 D5 D4 D3 D2 D1 D0 Reg $19

-- -- -- -- -- DRVO PDPL LDPL Function

00000000Default

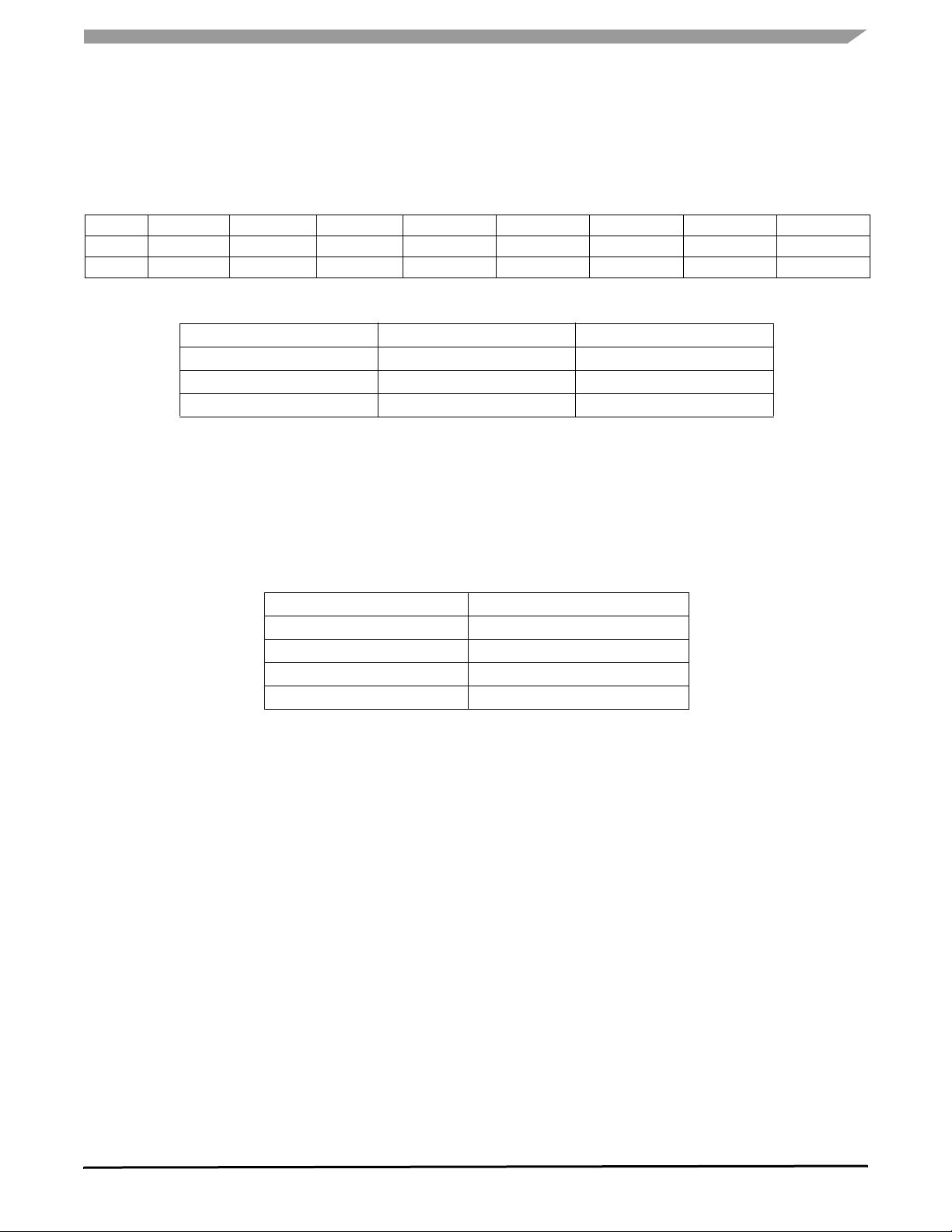

CASE 1: Single Pulse Motion Detection: X or Y or Z > Pulse Threshold for Time < Pulse Duration

For motion detection with single pulse the device must be in pulse mode. PDPL in Register $19 =0 for “OR” motion condition.

The Pulse threshold must be set in Register $1B and the pulse duration time window must also be set using Register $1C. The

pulse must be detected before the time window closes for the interrupt to trigger.

$1B: Pulse Detection Threshold Limit Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1B

PDTH[7] PDTH[6] PDTH[5] PDTH[4] PDTH[3] PDTH[2] PDTH[1] PDTH[0] Function

00000000Default

$1C: Pulse Duration Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1C

PD[7] PD[6] PD[5] PD[4] PD[3] PD[2] PD[1] PD[0] Function

00000001Default

MMA7455L

Sensors

12 Freescale Semiconductor

Page 13

G

G

th

Pulse Detec tion

Time duration

INT pin

*Note there is up to

1.6ms delay on the

interrupt signal

Single Pulse Detection ($19 PDPL=0 indicating motion detection)

Time Window for 2

nd

pulse $1E TW=0 indicating single pulse

Time

Time

Figure 3. Single Pulse Detection

CASE 2: Freefall Detection: X and Y and Z < Pulse Threshold for Time > Latency Time

For freefall detection, set in pulse mode. PDPL in Register $19 =1 for “AND” freefall condition. The Pulse threshold must be set

in Register $1B and the pulse latency time window must also be set using Register $1D. All three axes must remain below the

threshold longer than the time window for the interrupt to trigger.

$1B: Pulse Detection Threshold Limit Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1B

PDTH[7] PDTH[6] PDTH[5] PDTH[4] PDTH[3] PDTH[2] PDTH[1] PDTH[0] Function

00000000Default

$1D: Latency Time Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1D

LT[7] LT[6] LT[5] LT[4] LT[3] LT[2] LT[1] LT[0] Function

00000001Default

Figure 4. Freefall Detection in Pulse Mode

MMA7455L

Sensors

Freescale Semiconductor 13

Page 14

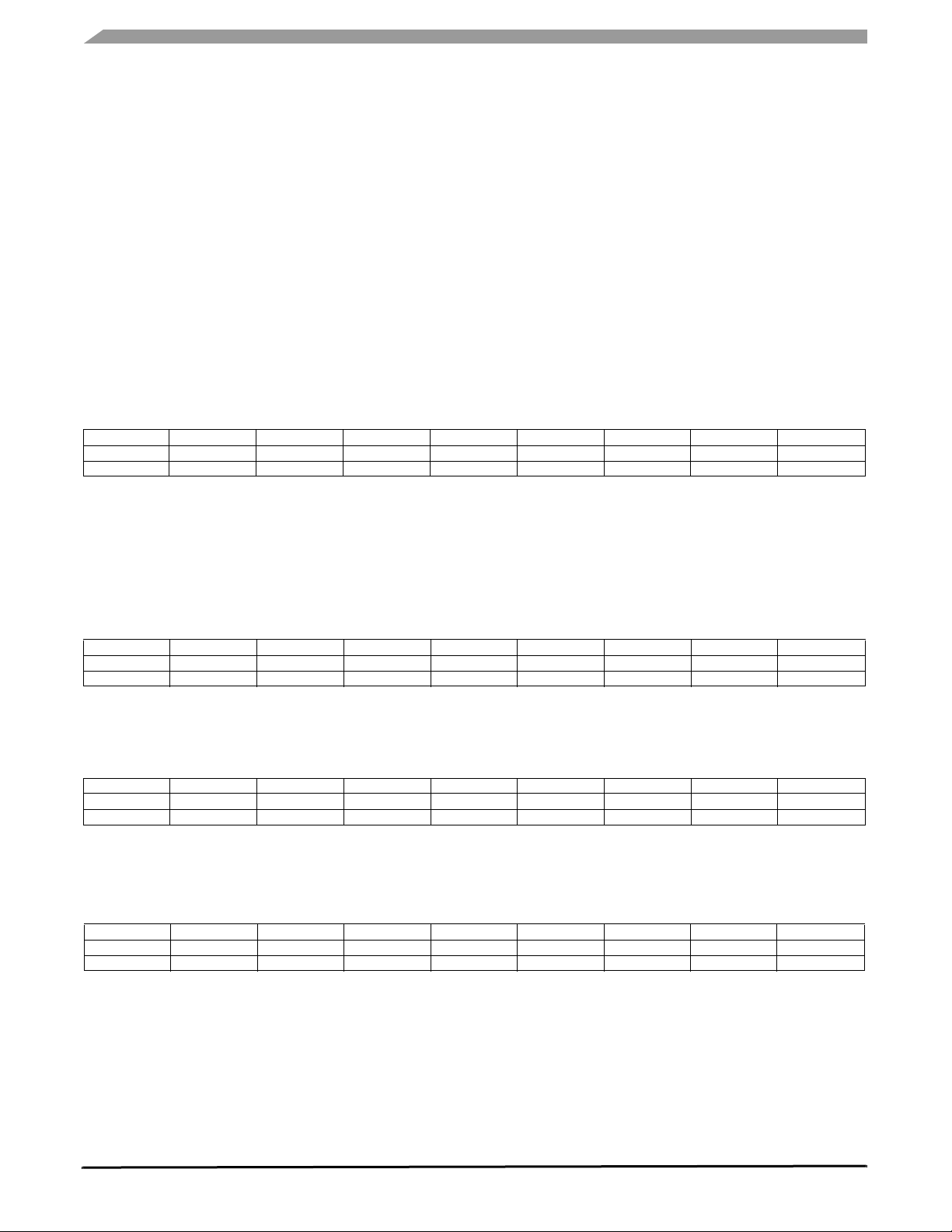

CASE 3: Double Pulse Detection: X OR Y OR Z > Threshold for Pulse Duration1 < PDTime1, Latency Time, AND

X OR Y OR Z > Threshold for Pulse Duration2 < PDTime2

For motion detection with double pulse the device must be in pulse mode. PDPL in Register $19 =0 for “OR” motion condition.

The Pulse Threshold must be set in Register $1B and the Pulse Duration Time Window must also be set using Register $1C.

Then the Latency Time (time between pulses) must be set in Register $1D and then the Second Time Window must be set in

Register $1E for the time window of the second pulse. The pulse must be detected before the time window closes for the interrupt

to trigger.

$1B: Pulse Detection Threshold Limit Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1B

PDTH[7] PDTH[6] PDTH[5] PDTH[4] PDTH[3] PDTH[2] PDTH[1] PDTH[0] Function

00000000Default

$1C: Pulse Duration Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1C

PD[7] PD[6] PD[5] PD[4] PD[3] PD[2] PD[1] PD[0] Function

00000001Default

$1D: Latency Time Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1D

LT[7] LT[6] LT[5] LT[4] LT[3] LT[2] LT[1] LT[0] Function

00000001Default

$1E: Time Window for 2nd Pulse Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $1E

TW[7] TW[6] TW[5] TW[4] TW[3] TW[2] TW[1] TW[0] Function

00000000Default

When any of the events are detected, the interrupt pin (either INT1 or INT2) will go high. The interrupt pin assignment is set

up in Register $18, discussed in the Assigning, Clearing & Detecting Interrupts section on page 15. The detection status is

monitored by the detection source register $0A.

G

G

th

INT

Pulse Detection

Time Window

Latency Time Window

nd

(2

pulse ignored here)

Double Pulse Detection ($19 PDPL=0 indicating motion detection)

Time Window for 2

nd

pulse $1E TW>0 indicating double pulse

Pulse Detection Time Window for

nd

pulse

2

Figure 5. Double Pulse Detection

Time

Time Window >0

for 2 pulse detect

*Note there is up to

1.6ms delay on the

interrupt signal

Time

MMA7455L

Sensors

14 Freescale Semiconductor

Page 15

ASSIGNING, CLEARING & DETECTING INTERRUPTS

Assigning the interrupt pins is done in Register $18. There are 3 combinations for the interrupt pins to be assigned which are

outlined below in the table for INTREG[1:0].

$18 Control 1 Register

D7 D6 D5 D4 D3 D2 D1 D0 Reg $18

DFBW THOPT ZDA YDA XDA INTREG[1] INTREG[0] INTPIN Function

00000000Default

Table 7. Configuring the Interrupt settings using Register $18 with INTREG[1:0] bits

INTREG[1:0] “INT1” Register Bit “INT2” Register Bit

00 Level detection Pulse Detection

01 Pulse Detection Level Detection

10 Single Pulse detection Single or Double Pulse Detection

00:

01: INT1 Register is detecting Pulse while INT2 is detecting Level.

10: INT1 Register is detecting a Single Pulse and INT2 is detecting Single Pulse (if 2nd Time Window = 0) or if there is a latency

time window and second time window>0 then INT2 will detect the double pulse only.

INTPIN: INT1 pin is routed to INT1 bit in Detection Source Register ($0A) and INT2 pin is routed to INT2 bit in Detection Source

Register ($0A).

INTPIN: INT2 pin is routed to INT1 bit in Detection Source Register ($0A) and INT1 pin is routed to INT2 bit in Detection Source

Register ($0A).

Note: When INTREG[1:0] =10 for the condition to detect single pulse on INT1 and either single or double pulse on INT2, INT1

register bit can no longer be cleared by setting CLR_INT1 bit. It is cleared by setting CLR_INT2 bit. In this case, setting CLR_INT2

clears both INT1 and INT2 register bits and resets the detection operation. Follow the example given for clearing the interrupts.

Clearing the Interrupt Pins: Register $17

$17: Interrupt Latch Reset (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $17

-- -- -- -- -- -- CLR_INT2 CLR_INT1 Function

00000000Default

CLR_INT1

1: Clear “INT1”

0: Do not clear “INT1”

CLR_INT2

1: Clear “INT2”

0: Do not clear “INT2”

After interrupt has triggered due to a detection, the interrupt pin (INT1 or INT2) need to be cleared by writing a logic 1. Then the

interrupt pin should be enabled to trigger the next detection by setting it to a logic 0.

This example is to show how to reset the interrupt flags

void ClearIntLatch(void)

{

IIC_ByteWrite(INTRST, 0x03);

IIC_ByteWrite(INTRST, 0x00);

}

MMA7455L

Sensors

Freescale Semiconductor 15

Page 16

Detecting Interrupts

$0A: Detection Source Register (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Reg $0A

LDX LDY LDZ PDX PDY PDZ INT2 INT1 Function

00000000Default

LDX

1: Level detection event is detected on X-axis

0: Level detection event is not detected on X-axis

LDY

1: Level detection event is detected on Y-axis

0: Level detection event is not detected on Y-axis

LDZ

1: Level detection event is detected on Z-axis

0: Level detection event is not detected on Z-axis

PDX

st

pulse is detected on X-axis

1: 1

0: 1st pulse is detected on X-axis

PDZ

st

1: 1

pulse is detected on Z-axis

st

pulse is detected on Z-axis

0: 1

INT1

1: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is detected

0: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is not detected

INT2

1: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is detected

0: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is not detected

PDY

1: 1st pulse is detected on Y-axis

st

pulse is detected on Y-axis

0: 1

DIGITAL INTERFACE

The MMA7455L has both an I2C and SPI digital output available for a communication interface. CS pin is used for selecting the

mode of communication. When CS is low, SPI communication is selected. When CS is high, I2C communication is selected.

Note: It is recommended to disable I

2

C during SPI communication to avoid communication errors between devices using a dif-

ferent SPI communication protocol. To disable I2C, set the I2CDIS bit in I2C Device Address register using SPI.

2

I

C Slave Interface

2

C is a synchronous serial communication between a master device and one or more slave devices. The master is typically a

I

microcontroller, which provides the serial clock signal and addresses the slave device(s) on the bus. The MMA7455L communicates only in slave operation where the device address is $1D. Multiple read and write modes are available. The protocol supports

slave only operation. It does not support Hs mode, “10-bit addressing”, “general call” and: ”START byte”.

SINGLE BYTE READ

The MMA7455L has an 10-bit ADC that can sample, convert and return sensor data on request. The transmission of an 8-bit

command begins on the falling edge of SCL. After the eight clock cycles are used to send the command, note that the data returned is sent with the MSB first once the data is received. Figure 6 shows the timing diagram for the accelerometer 8-bit I

2

C

read operation. The Master (or MCU) transmits a start condition (ST) to the MMA7455L, slave address ($1D), with the R/W bit

set to “0” for a write, and the MMA7455L sends an acknowledgement. Then the Master (or MCU) transmits the 10-bit address of

the register to read and the MMA7455L sends an acknowledgement. The Master (or MCU) transmits a repeated start condition

(SR) and then addresses the MMA7455L ($1D) with the R/W bit set to “1” for a read from the previously selected register. The

Slave then acknowledges and transmits the data from the requested register. The Master does not acknowledge (NAK) it received the transmitted data, but transmits a stop condition to end the data transfer.

MULTIPLE BYTES READ

The MMA7455L automatically increments the received register address commands after a read command is received. Therefore,

after following the steps of a single byte read, multiple bytes of data can be read from sequential registers after each MMA7455L

acknowledgment (AK) is received until a NACK is received from the Master followed by a stop condition (SP) signalling an end

of transmission. See Figure 7.

MMA7455L

Sensors

16 Freescale Semiconductor

Page 17

SINGLE BYTE WRITE

To start a write command, the Master transmits a start condition (ST) to the MMA7455L, slave address ($1D) with the R/W bit set

to “0” for a write, the MMA7455L sends an acknowledgement. Then the Master (MCU) transmits the 8-bit address of the register

to write to, and the MMA7455L sends an acknowledgement. Then the Master (or MCU) transmits the 8-bit data to write to the

designated register and the MMA7455L sends an acknowledgement that it has received the data. Since this transmission is complete, the Master transmits a stop condition (SP) to the data transfer. The data sent to the MMA7455L is now stored in the appropriate register. See Figure 8.

Figure 6. Single Byte Read - The Master is reading one address from the MMA7455L

Figure 7. Multiple Bytes Read - The Master is reading multiple sequential registers from the MMA7455L

Figure 8. Single Byte Write - The Master (MCU) is writing to a single register of the MMA7455L

MULTIPLE BYTES WRITE

The MMA7455L automatically increments the received register address commands after a write command is received. Therefore,

after following the steps of a single byte write, multiple bytes of data can be written to sequential registers after each MMA7455L

acknowledgment (ACK) is received. See Figure 9.

Figure 9. Multiple Byte Writes - The Master (MCU) is writing to multiple sequential registers of the MMA7455L

MMA7455L

Sensors

Freescale Semiconductor 17

Page 18

SPI Slave Interface

The MMA7455L also uses serial peripheral interface communication as a digital communication. The SPI communication is primarily used for synchronous serial communication between a master device and one or more slave devices. See Figure 15 for

an example of how to configure one master with one MMA745xL device. The MMA7455L is always operated as a slave device.

Typically, the master device would be a microcontroller which would drive the clock (SPC) and chip select (CS) signals.

The SPI interface consists of two control lines and two data lines: CS, SPC, SDI, and SDO. The CS, also known as Chip Select,

is the slave device enable which is controlled by the SPI master. CS is driven low at the start of a transmission. CS is then driven

high at the end of a transmission. SPC is the Serial Port Clock which is also controlled by the SPI master. SDI and SDO are the

Serial Port Data Input and the Serial Port Data Output. The SDI and SDO data lines are driven at the falling edge of the SPC and

should be captured at the rising edge of the SPC.

Read and write register commands are completed in 16 clock pulses or in multiples of 8, in the case of a multiple byte read/write.

SPI Read Operation

A SPI read transfer consists of a 1-bit Read/Write signal, a 6-bit address, and 1-bit don’t care bit. (1-bit R/W=0 + 6-bits address

+ 1-bit don’t care). The data to read is sent by the SPI interface during the next transfer. See Figure 10 and Figure 11 for the

timing diagram for an 8-bit read in 4 wire and 3 wire modes, respectively.

SPI Write Operation

In order to write to one of the 8-bit registers, an 8-bit write command must be sent to the MMA7455L. The write command consists

of an MSB (0=read, 1=write) to indicate writing to the MMA7455L register, followed by a 6-bit address and 1 don’t care bit.

The command should then be followed the 8-bit data transfer. See Figure 12 for the timing diagram for an 8-bit data write.

Figure 10. SPI Timing Diagram for 8-Bit Register Read (4 Wire Mode)

Figure 11. SPI Timing Diagram for 8-Bit Register Read (3 Wire Mode)

Figure 12. SPI Timing Diagram for 8-Bit Register Write (3 Wire Mode)

MMA7455L

Sensors

18 Freescale Semiconductor

Page 19

BASIC CONNECTIONS

Pin Descriptions

INT1/DRDY

INT2

N/C

N/C

SDO

SDA/SDI/SDO

Figure 13. Pinout Description

8 9 10 11 12 13

Top Vi e w

7

14

SCL/SPCCS

AVDD

GND

IADDR0

N/C

GND

123456

DVDD_IO

Table 8. Pin Descriptions

Pin # Pin Name Description

1 DVDD_IO Digital Power for I/O pads Input

2 GND Ground Input

3 N/C No internal connection. Leave

unconnected or connect to Ground.

4 IADDR0

5 GND Ground Input

6 AVDD Analog Power Input

7CS

8 INT1/DRDY Interrupt 1/ Data Ready Output

9 INT2 Interrupt 2 Output

10 N/C No internal connection. Leave

11 N/C No internal connection. Leave

12 SDO SPI Serial Data Output Output

13 SDA/SDI/SDO

14 SCL/SPC

2

I

C Address Bit 0

2

SPI Enable (0), I

unconnected or connect to Ground.

unconnected or connect to Ground.

2

C Serial Data (SDA), SPI Serial

I

Data Input (SDI), 3-wire interface

Serial Data Output (SDO)

2

I

C Serial Clock (SCL), SPI Serial

Clock (SPC)

C Enable (1)

Status

Drain/

Input/

Output

Pin

Input

Input

Input

Input

Input

Open

Input

Vdd

Vdd

VDD

GND

GND

Recommended PCB Layout for Interfacing Accelerometer to Microcontroller

Address set bit (bit 0)

Address set bit (bit 0)

Vdd_IO

Vdd_IO

10uF

10uF

0.1uF

0.1uF

10uF

10uF

0.1uF

0.1uF

VDD

Vdd

Vdd

VDD

10k?

10k?

R2

VDD

Vdd

Vdd

10k?

10k?

R1

MCU

MCU

SCL

SCL

SDA

SDA

INT2

INT2

INT1/DRDY

INT1/DRDY

2

Figure 14. I

C Connection to MCU

MMA7455L

Sensors

Freescale Semiconductor 19

Page 20

Vdd

1~10uF

Vdd_IO

1~10uF

MCU

SCL/SPC

SDA/SDI/SDO

GND

Figure 15. SPI Connection to MCU

NOTES:

1. Use a 0.1 μF and a 10 μF capacitor on AV

2. Physical coupling distance of the accelerometer to the microcontroller should be minimal.

3. PCB layout of power and ground should not couple power supply noise.

4. Accelerometer and microcontroller should not be a high current path.

5. Any external power supply switching frequency should be selected such that they do not interfere with the internal

accelerometer sampling frequency (sampling frequency). This will prevent aliasing errors.

6. Physical distance of the two GND pins (Pin2 and Pin5) tied together should be at the shortest distance.

to and DVDD_IO to decouple the power source.

DD

SDO

INT2

INT1/DRDY

CS

MMA7455L

Sensors

20 Freescale Semiconductor

Page 21

Table 9. User Register Summary

Address Name Definition Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00 XOUTL 10 bits output value X LSB XOUT[7] XOUT[6] XOUT[5] XOUT[4] XOUT[3] XOUT[2] XOUT[1] XOUT[0]

$01 XOUTH 10 bits output value X MSB -- -- -- -- -- -- XOUT[9] XOUT[8]

$02 YOUTL 10 bits output value Y LSB YOUT[7] YOUT[6] YOUT[5] YOUT[4] YOUT[3] YOUT[2] YOUT[1] YOUT[0]

$03 YOUTH 10 bits output value Y MSB -- -- -- -- -- -- YOUT[9] YOUT[8]

$04 ZOUTL 10 bits output value Z LSB ZOUT[7] ZOUT[6] ZOUT[5] ZOUT[4] ZOUT[3] ZOUT[2] ZOUT[1] ZOUT[0]

$05 ZOUTH 10 bits output value Z MSB -- -- -- -- -- -- ZOUT[9] ZOUT[8]

$06 XOUT8 8 bits output value X XOUT[7] XOUT[6] XOUT[5] XOUT[4] XOUT[3] XOUT[2] XOUT[1] XOUT[0]

$07 YOUT8 8 bits output value Y YOUT[7] YOUT[6] YOUT[5] YOUT[4] YOUT[3] YOUT[2] YOUT[1] YOUT[0]

$08 ZOUT8 8 bits output value Z ZOUT[7] ZOUT[6] ZOUT[5] ZOUT[4] ZOUT[3] ZOUT[2] ZOUT[1] ZOUT[0]

$09 STATUS Status registers -- -- -- -- -- PERR DOVR DRDY

$0A DETSRC Detection source registers LDX LDY LDZ PDX PDY PDZ INT2 INT1

$0B TOUT “Temperature output value” (Optional) TMP[7] TMP[6] TMP[5] TMP[4] TMP[3] TMP[2] TMP[1] TMP[0]

$0C (Reserved) -- -- -- -- -- -- -- --

$0D I2CAD I2C device address I2CDIS DAD[6] DAD[5] DAD[4] DAD[3] DAD[2] DAD[1] DAD[0]

$0E USRINF User information (Optional) UI[7] UI[6] UI[5] UI[4] UI[3] UI[2] UI[1] UI[0]

$0F WHOAMI “Who am I” value (Optional) ID[7] ID[6] ID[5] ID[4] ID[3] ID[2] ID[1] ID[0]

$10 XOFFL Offset drift X value (LSB) XOFF[7] XOFF[6] XOFF[5] XOFF[4] XOFF[3] XOFF[2] XOFF[1] XOFF[0]

$11 XOFFH Offset drift X value (MSB) -- -- -- -- -- XOFF[10] XOFF[9] XOFF[8]

$12 YOFFL Offset drift Y value (LSB) YOFF[7] YOFF[6] YOFF[5] YOFF[4] YOFF[3] YOFF[2] YOFF[1] YOFF[0]

$13 YOFFH Offset drift Y value (MSB) -- -- -- -- -- YOFF[10] YOFF[9] YOFF[8]

$14 ZOFFL Offset drift Z value (LSB) ZOFF[7] ZOFF[6] ZOFF[5] ZOFF[4] ZOFF[3] ZOFF[2] ZOFF[1] ZOFF[0]

$15 ZOFFH Offset drift Z value (MSB) -- -- -- -- -- ZOFF[10] ZOFF[9] ZOFF[8]

$16 MCTL Mode control -- DRPD SPI3W STON GLVL[1] GLVL[0] MOD[1] MOD[0]

$17 INTRST Interrupt latch reset -- -- -- -- -- -- CLRINT2 CLRINT1

$18 CTL1 Control 1 DFBW THOPT ZDA YDA XDA INTRG[1] INTRG[0] INTPIN

$19 CTL2 Control 2 -- -- -- -- -- DRVO PDPL LDPL

$1A LDTH Level detection threshold limit value LDTH[7] LDTH[6] LDTH[5] LDTH[4] LDTH[3] LDTH[2] LDTH[1] LDTH[0]

$1B PDTH Pulse detection threshold limit value PDTH[7] PDTH[6] PDTH[5] PDTH[4] PDTH[3] PDTH[2] PDTH[1] PDTH[0]

$1C PW Pulse duration value PD[7] PD[6] PD[5] PD[4] PD[3] PD[2] PD[1] PD[0]

$1D LT Latency time value LT[7] LT[6] LT[5] LT[4] LT[3] LT[2] LT[1] LT[0]

$1E TW Time window for 2nd pulse value TW[7] TW[6] TW[5] TW[4] TW[3] TW[2] TW[1] TW[0]

$1F (Reserved) -- -- -- -- -- -- -- --

REGISTER DEFINITIONS

$00: 10bits Output Value X LSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

XOUT [7] XOUT [6] XOUT [5] XOUT [4] XOUT [3] XOUT [2] XOUT [1] XOUT[0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 10’h000

Reading low byte XOUTL latches high byte XOUTH to allow 10-bit reads.

XOUTH should be read directly following XOUTL read.

MMA7455L

Sensors

Freescale Semiconductor 21

Page 22

$01: 10bits Output Value X MSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- -- XOUT [9] XOUT[8] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 10’h000

Reading low byte XOUTL latches high byte XOUTH to allow 10-bit reads.

XOUTH should be read directly following XOUTL read.

$02: 10bits Output Value Y LSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

YOUT [7] YOUT [6] YOUT [5] YOUT [4] YOUT [3] YOUT [2] YOUT [1] YOUT[0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 10’h000

Reading low byte YOUTL latches high byte YOUTH to allow coherent 10-bit reads.

YOUTH should be read directly following YOUTL.

$03: 10bits Output Value Y MSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- -- YOUT [9] YOUT[8] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 10’h000

Reading low byte ZOUTL latches high byte ZOUTH to allow coherent 10-bit reads.

ZOUTH should be read directly following ZOUTL.

$04: 10bits Output Value Z LSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

ZOUT [7] ZOUT [6] ZOUT [5] ZOUT [4] ZOUT [3] ZOUT [2] ZOUT [1] ZOUT[0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 10’h000

Reading low byte ZOUTL latches high byte ZOUTH to allow coherent 10-bit reads.

ZOUTH should be read directly following ZOUTL.

$05: 10bits Output Value X MSB (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- -- ZOUT [9] ZOUT[8] Function

0 0 0 0 0 0 0 0 Default

$06: 8bits Output Value X (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

XOUT[7] XOUT [6] XOUT [5] XOUT [4] XOUT [3] XOUT [2] XOUT [1] XOUT [0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 8’h00

$07: 8bits Output Value Y (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

YOUT[7] YOUT [6] YOUT [5] YOUT [4] YOUT [3] YOUT [2] YOUT [1] YOUT [0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 8’h00

MMA7455L

Sensors

22 Freescale Semiconductor

Page 23

$08: 8bits Output Value Z (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

ZOUT[7] ZOUT [6] ZOUT [5] ZOUT [4] ZOUT [3] ZOUT [2] ZOUT [1] ZOUT [0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): 0g = 8’h00

$09: Status Register (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- PERR DOVR DRDY Function

0 0 0 0 0 0 0 0 Default

DRDY

1: Data is ready

0: Data is not ready

DOVR

PERR

1: Parity error is detected in trim data. Then, self-test is disabled

0: Parity error is not detected in trim data

1: Data is over written

0: Data is not over written

$0A: Detection Source Register (Read only)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

LDX LDY LDZ PDX PDY PDZ INT2 INT1 Function

0 0 0 0 0 0 0 0 Default

LDX

1: Level detection detected on X-axis

0: Level detection not detected on X-axis

LDY

1: Level detection detected on Y-axis

0: Level detection not detected on Y-axis

LDZ

1: Level detection detected on Z-axis

0: Level detection not detected on Z-axis

PDX *Note

1: Pulse is detected on X-axis at single pulse detection

0: Pulse is not detected on X-axis at single pulse detection

PDY *Note

1: Pulse is detected on Y-axis at single pulse detection

0: Pulse is not detected on Y-axis at single pulse detection

PDZ *Note

1: Pulse is detected on Z-axis at single pulse detection

0: Pulse is not detected on Z-axis at single pulse detection

Note: This bit value is not valid at double pulse detection

INT1

1: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is detected

0: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is not detected

INT2

1: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is detected

0: Interrupt assigned by INTRG[1:0] bits in Control 1

Register ($18) and is not detected

*Note: Must define DRDY to be an output to either INT1 or

not. This is done through bit DRPD located in Register $16.

MMA7455L

Sensors

Freescale Semiconductor 23

Page 24

$0D: I2C Device Address (Bit 6-0: Read only, Bit 7: Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

I2CDIS DVAD[6] DVAD[5] DVAD[4] DVAD[3] DVAD[2] DVAD[1] DVAD[0] Function

0 0 0 1 1 1 0 1 Default

I2CDIS

2

C and SPI are available.

0: I

2

1: I

C is disabled.

DVAD[6:0]: I

2

C device address

$0E: User Information (Read Only: Optional)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

UI[7] UI[6] UI[5] UI[4] UI[3] UI[2] UI[1] UI[0] Function

0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP Default

UI2[7:0]: User information

$0F: “Who Am I” Value (Read only: Optional)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

ID[7] ID [6] ID [5] ID [4] ID [3] ID [2] ID [1] ID [0] Function

0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP 0/OTP Default

$10: Offset Drift X LSB (Read/Write)

The following Offset Drift Registers are used for setting and storing the offset calibrations to eliminate the 0g offset. Please refer

to Freescale application note AN3745 for detailed instructions on the process to set and store the calibration values.

D7 D6 D5 D4 D3 D2 D1 D0 Bit

XOFF[7] XOFF [6] XOFF [5] XOFF [4] XOFF [3] XOFF [2] XOFF [1] XOFF [0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for X-axis

Bit XOFF[7] XOFF[6] XOFF[5] XOFF[4] XOFF[3] XOFF[2] XOFF[1] XOFF[0]

Weight* 64 LSB 32 LSB 16 LSB 8 LSB 4 LSB 2 LSB 1 LSB 0.5 LSB

*Bit weight is for 8g 10bit data output. Typical value for reference only. Variation is specified in “Electrical Characteristics” section.

$11: Offset Drift X MSB (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- XOFF [10] XOFF [9] XOFF [8] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for X-axis

$12: Offset Drift Y LSB (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

YOFF[7] YOFF [6] YOFF [5] YOFF [4] YOFF [3] YOFF [2] YOFF [1] YOFF [0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for Y-axis

Bit YOFF[7] YOFF[6] YOFF[5] YOFF[4] YOFF[3] YOFF[2] YOFF[1] YOFF[0]

Weight* 64 LSB 32 LSB 16 LSB 8 LSB 4 LSB 2 LSB 1 LSB 0.5 LSB

*Bit weight is for 2g 8bit data output. Typical value for reference only. Variation is specified in “Electrical Characteristics” section.

MMA7455L

Sensors

24 Freescale Semiconductor

Page 25

$13: Offset Drift Y MSB (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- YOFF [10] YOFF [9] YOFF [8] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for Y-axis

Bit YOFF[10] YOFF[9] YOFF[8]

Weight* Polarity 256 LSB 128 LSB

*Bit weight is for 2g 8bit data output. Typical value for reference only. Variation is specified in “Electrical Characteristics” section.

$14: Offset Drift Z LSB (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

ZOFF[7] ZOFF[6] ZOFF[5] ZOFF[4] ZOFF[3] ZOFF[2] ZOFF[1] ZOFF[0] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for Z-axis

Bit ZOFF[7] ZOFF[6] ZOFF[5] ZOFF[4] ZOFF[3] ZOFF[2] ZOFF[1] ZOFF[0]

Weight* 64 LSB 32 LSB 16 LSB 8 LSB 4 LSB 2 LSB 1 LSB 0.5 LSB

*Bit weight is for 2g 8bit data output. Typical value for reference only. Variation is specified in “Electrical Characteristics” section.

$15: Offset Drift Z MSB (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- ZOFF[10] ZOFF[9] ZOFF[8] Function

0 0 0 0 0 0 0 0 Default

Signed byte data (2’s compliment): User level offset trim value for Z-axis

Bit ZOFF[10] ZOFF[9] ZOFF[8]

Weight* Polarity 256 LSB 128 LSB

*Bit weight is for 2g 8bit data output. Typical value for reference only. Variation is specified in “Electrical Characteristics” section.

$16: Mode Control Register (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- DRPD SPI3W STON GLVL[1] GLVL[0] MODE[1] MODE[0] Function

0 0 0 0 0 0 0 0 Default

Table 10. Configuring the g-Select for 8-bit output using Register $16 with GLVL[1:0] bits.

GLVL [1:0] g-Range Sensitivity

00 8g 16 LSB/g

01 2g 64 LSB/g

10 4g 32 LSB/g

GLVL [1:0]

00: 8g is selected for measurement range.

10: 4g is selected for measurement range.

01: 2g is selected for measurement range.

STON

0: Self-test is not enabled

SPI3W

0: SPI is 4 wire mode

1: SPI is 3 wire mode

DRPD

0: Data ready status is output to INT1/DRDY PIN

1: Data ready status is not output to INT1/DRDY PIN

1: Self-test is enabled

MMA7455L

Sensors

Freescale Semiconductor 25

Page 26

$17: Interrupt Latch Reset (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

-- -- -- -- -- -- CLR_INT2 CLR_INT1 Function

0 0 0 0 0 0 0 0 Default

CLR_INT1

1: Clear “INT1” and LDX/LDY/LDZ or PDX/PDY/PDZ bits in Detection Source Register ($0A) depending on

Control1($18) INTREG[1:0] setting.

0: Do not clear “INT1” LDX/LDY/LDZ or PDX/PDY/PDZ bits in Detection Source Register ($0A)

CLR_INT2

1: Clear “INT2” and LDX/LDY/LDZ or PDX/PDY/PDZ bits in Detection Source Register ($0A) depending on

Control1($18) INTREG[1:0] setting.

0: Do not clear “INT2” and LDX/LDY/LDZ or PDX/PDY/PDZ bits in Detection Source Register ($0A).

$18 Control 1 (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

DFBW THOPT ZDA YDA XDA INTREG[1] INTREG[0] INTPIN Function

00000000Default

Table 11. Configuring the Interrupt settings using Register $18 with INTREG[1:0] bits

INTREG[1:0] “INT1” Register Bit “INT2” Register Bit

00 Level detection Pulse Detection

01 Pulse Detection Level Detection

10 Single Pulse detection Single or Double Pulse Detection

01: INT1 Register is detecting Pulse while INT2 is detecting Level.

nd

10: INT1 Register is detecting a Single Pulse and INT2 is detecting Single Pulse (if 2

Time Window = 0) or if there is a latency

time window and second time window>0 then INT2 will detect the double pulse only.

INTPIN: INT1 pin is routed to INT1 bit in Detection Source Register ($0A) and INT2 pin is routed to INT2 bit in Detection Source

Register ($0A).

INTPIN: INT2 pin is routed to INT1 bit in Detection Source Register ($0A) and INT1 pin is routed to INT2 bit in Detection Source

Register ($0A).

Note: When INTREG[1:0] =10 for the condition to detect single pulse on INT1 and either single or double pulse on INT2, INT1

register bit can no longer be cleared by setting CLR_INT1 bit. It is cleared by setting CLR_INT2 bit. In this case, setting CLR_INT2

clears both INT1 and INT2 register bits and resets the detection operation.

XDA

1: X-axis is disabled for detection.

0: X-axis is enabled for detection.

YDA

1: Y-axis is disabled for detection.

0: Y-axis is enabled for detection.

ZDA

THOPT (This bit is valid for level detection only, not valid

for pulse detection)

0: Threshold value is absolute only

1: Integer value is available.

DFBW

0: Digital filter band width is 62.5 Hz

1: Digital filter band width is 125 Hz

1: Z-axis is disabled for detection.

0: Z-axis is enabled for detection.

$19: Control 2 (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

DRVO PDPL LDPL Function

0 0 0 0 0 0 0 0 Default

LDPL

0: Level detection polarity is positive and detecting condition

is OR 3 axes.

1: Level detection polarity is negative detecting condition is

AND 3 axes.

PDPL

0: Pulse detection polarity is positive and detecting condition

is OR 3 axes.

1: Pulse detection polarity is negative and detecting condition

is AND 3 axes.

MMA7455L

Sensors

26 Freescale Semiconductor

Page 27

DRVO

1: Strong drive strength on SDA/SDO pin

0: Standard drive strength on SDA/SDO pin

$1A: Level Detection Threshold Limit Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

LDTH[7] LDTH[6] LDTH[5] LDTH[4] LDTH[3] LDTH[2] LDTH[1] LDTH[0] Function

0 0 0 0 0 0 0 0 Default

LDTH[7:0]: Level detection threshold value. If THOPT bit in Detection Control Register is “0”, it is unsigned 7 bits value and

LDTH[7] should be “0”. If THOPT bit is “1”, it is signed 8 bits value.

$1B: Pulse Detection Threshold Limit Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

XPDTH PDTH[6] PDTH[5] PDTH[4] PDTH[3] PDTH[2] PDTH[1] PDTH[0] Function

0 0 0 0 0 0 0 0 Default

PDTH[6:0]: Pulse detection threshold value (unsigned 7 bits).

XPDTH: This bit should be “0”.

$1C: Pulse Duration Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

PD[7] PD[6] PD[5] PD[4] PD[3] PD[2] PD[1] PD[0] Function

0 0 0 0 0 0 0 0 Default

Min: PD[7:0] = 4’h01 = 0.5 ms

Max: PD[7:0] = 4’hFF = 127 ms

1 LSB = 0.5 ms

$1D: Latency Time Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

LT[7] LT[6] LT[5] LT[4] LT[3] LT[2] LT[1] LT[0] Function

0 0 0 0 0 0 0 0 Default

Min: LT[7:0] = 8’h01 = 1 ms

Max: LT[7:0] = 8’hFF = 255 ms

1 LSB = 1 ms

$1E: Time Window for 2nd Pulse Value (Read/Write)

D7 D6 D5 D4 D3 D2 D1 D0 Bit

TW[7] TW[6] TW[5] TW[4] TW[3] TW[2] TW[1] TW[0] Function

0 0 0 0 0 0 0 0 Default

Min: TW[7:0] = 8’h01 = 1 ms (Single pulse detection)

Max: TW[7:0] = 8’hFF = 255 ms

1 LSB = 1 ms

MMA7455L

Sensors

Freescale Semiconductor 27

Page 28

SENSING DIRECTION AND OUTPUT RESPONSE

The following figure shows sensing direction and the output response for 2g mode.

147

165432

@ +1g = $3F

X

OUT

@0g=$00

Y

OUT

@0g=$00

Z

OUT

Top View

Direction of Earth's gravity field.*

165432

147

1312111098

X

1312111098

14 7

* When positioned as shown, the Earth’s gravity will result in a positive 1g output.

@0g=$00

OUT

@ +1g = $3F

Y

OUT

@0g=$00

Z

OUT

13 12 11 10 9 8

165432

X

@0g=$00

OUT

@ -1g = $C1

Y

OUT

@0g=$00

Z

OUT

X

Y

Z

1312111098

OUT

OUT

OUT

147

@ -1g = $C1

@0g=$00

@ 0g = $00

165432

Side View

Bottom

X

OUT

Y

OUT

@ +1g = $3F

Z

OUT

Bottom

X

OUT

Y

OUT

Z

OUT

Top

@0g=$00

@0g=$00

Top

@0g=$00

@0g=$00

@ -1g = $C1

Figure 16. Sensing Direction and Output Response at 2g Mode

Table 12. Acceleration vs. Output (8-bit data)

FS Mode Acceleration Output

2g Mode -2g $80

-1g $C1

0g $00

+1g $3F

+2g $7F

4g Mode -4g $80

-1g $E1

0g $00

+1g $1F

+4g $7F

8g Mode -8g $80

-1g $F1

0g $00

+1g $0F

+8g $7F

MMA7455L

Sensors

28 Freescale Semiconductor

Page 29

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total design. The footprint for the surface mount packages must be the

correct size to ensure proper solder connection interface between the board and the package.

With the correct footprint, the packages will self-align when subjected to a solder reflow process. It is always recommended to

design boards with a solder mask layer to avoid bridging and shorting between solder pads.

SOLDERING AND MOUNTING GUIDELINES FOR THE LGA ACCELEROMETER SENSOR TO A PC BOARD

These guideline are for soldering and mounting the LGA package inertial sensors to printed circuit boards (PCBs). The purpose

is to minimize the stress on the package after board mounting. The MMA7455L digital output accelerometer uses the Land Grid

Array (LGA) package platform. This section describes suggested methods of soldering these devices to the PC board for consumer applications. Figure 17 shows the recommended PCB land pattern for the package.

Figure 17. Recommended PCB Land Pattern for the 5 x 3 mm LGA Package

MMA7455L

Sensors

Freescale Semiconductor 29

Page 30

OVERVIEW OF SOLDERING CONSIDERATIONS

Information provided here is based on experiments executed on LGA devices. They do not represent exact conditions present