Page 1

MC9S12DJ64

Device User Guide

V01.17

Covers also

MC9S12D64, MC9S12A64

DOCUMENT NUMBER

9S12DJ64DGV1/D

Original Release Date: 19 Nov. 2001

Revised: 21 May 2004

Motorola, Inc.

Motorola reserves the right to make changes without further notice to any products herein to improve reliability, function or

design. Motorola does not assume any liability arising out of the application or use of any product or circuit described herein;

neither does it convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended,

or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to

support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where

personal injury or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized

application,Buyershallindemnify andhold Motorolaand itsofficers, employees,subsidiaries, affiliates,and distributorsharmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that Motorola was

negligent regarding the design or manufacture of the part.

1

Page 2

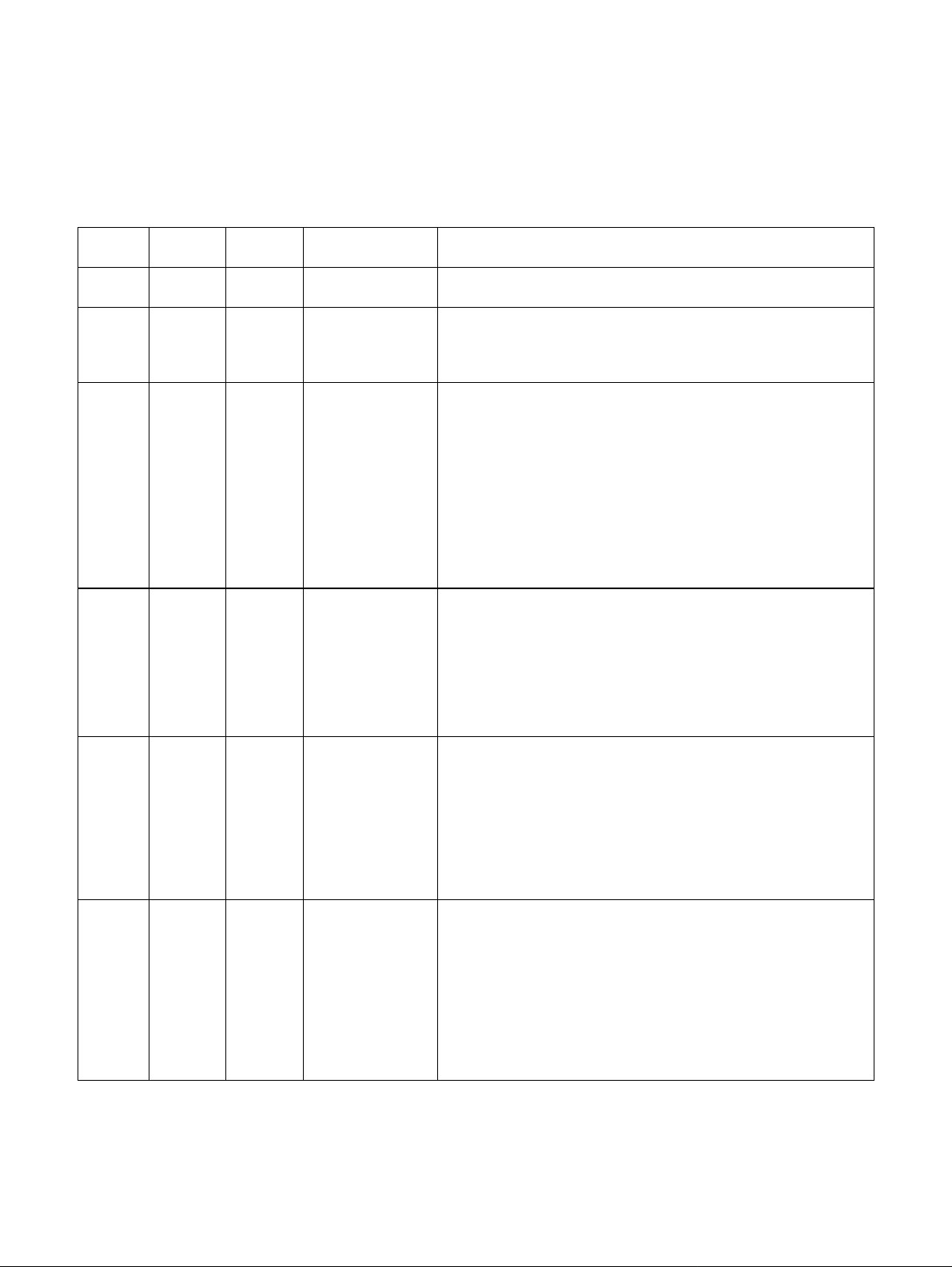

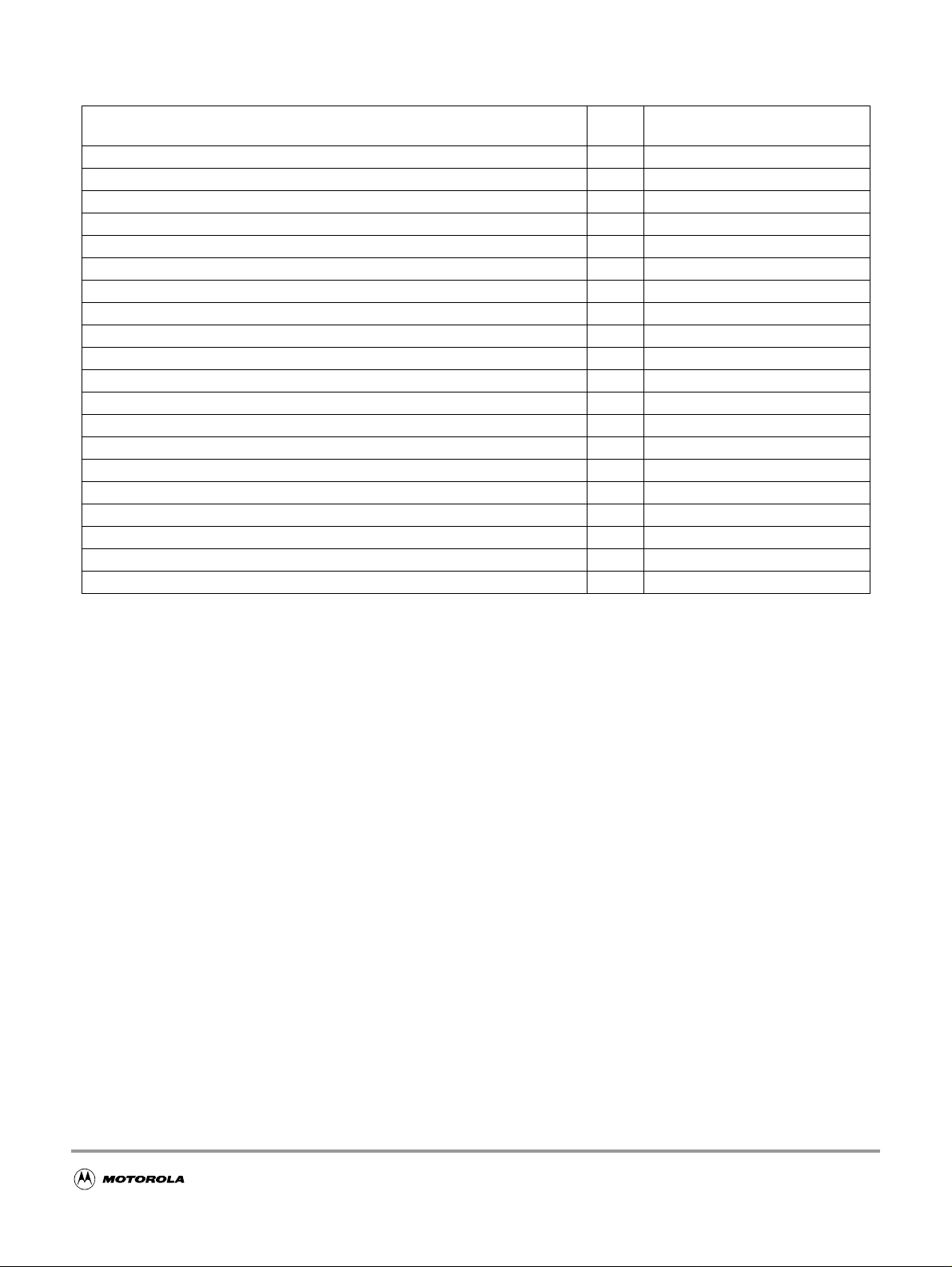

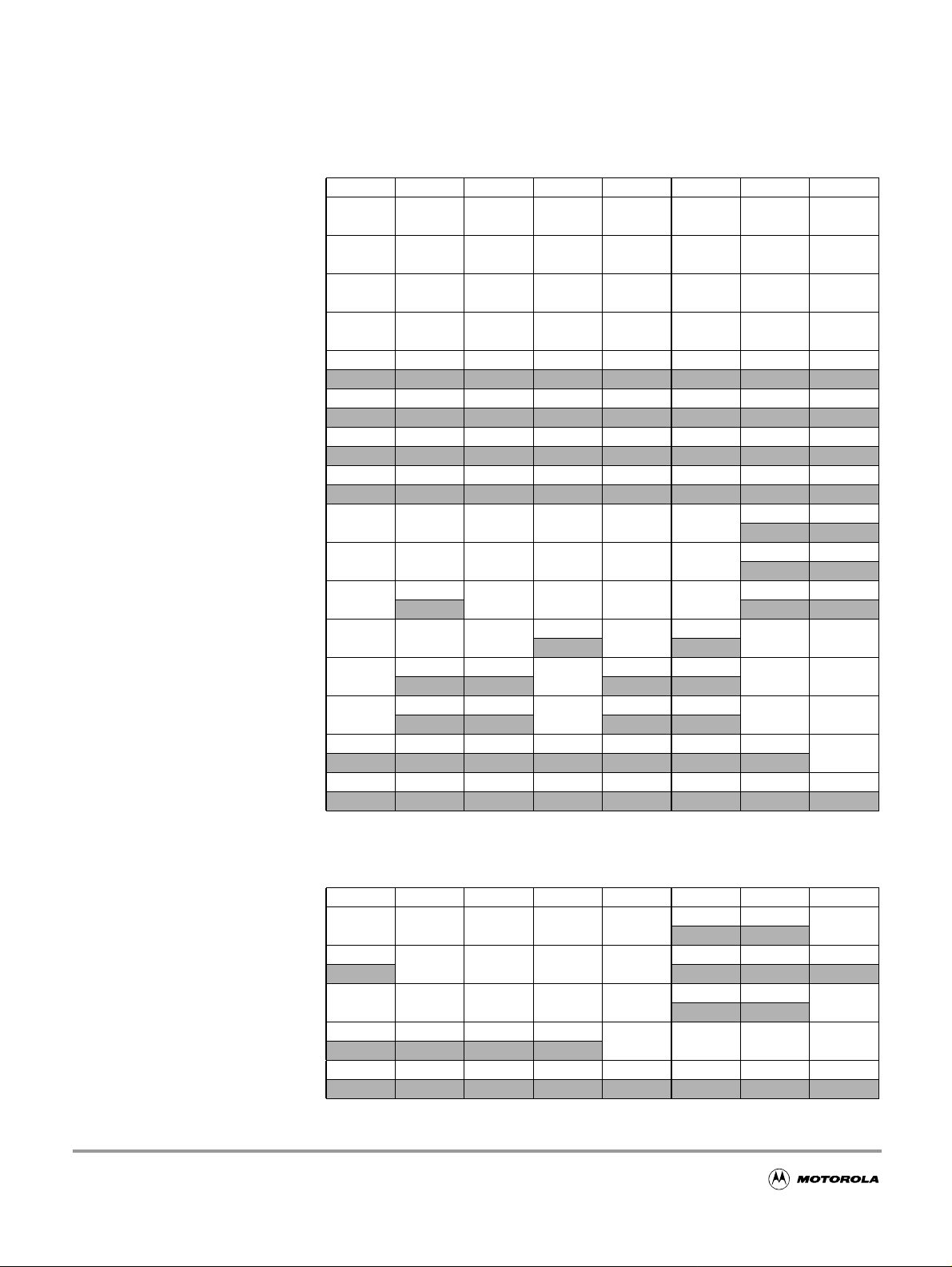

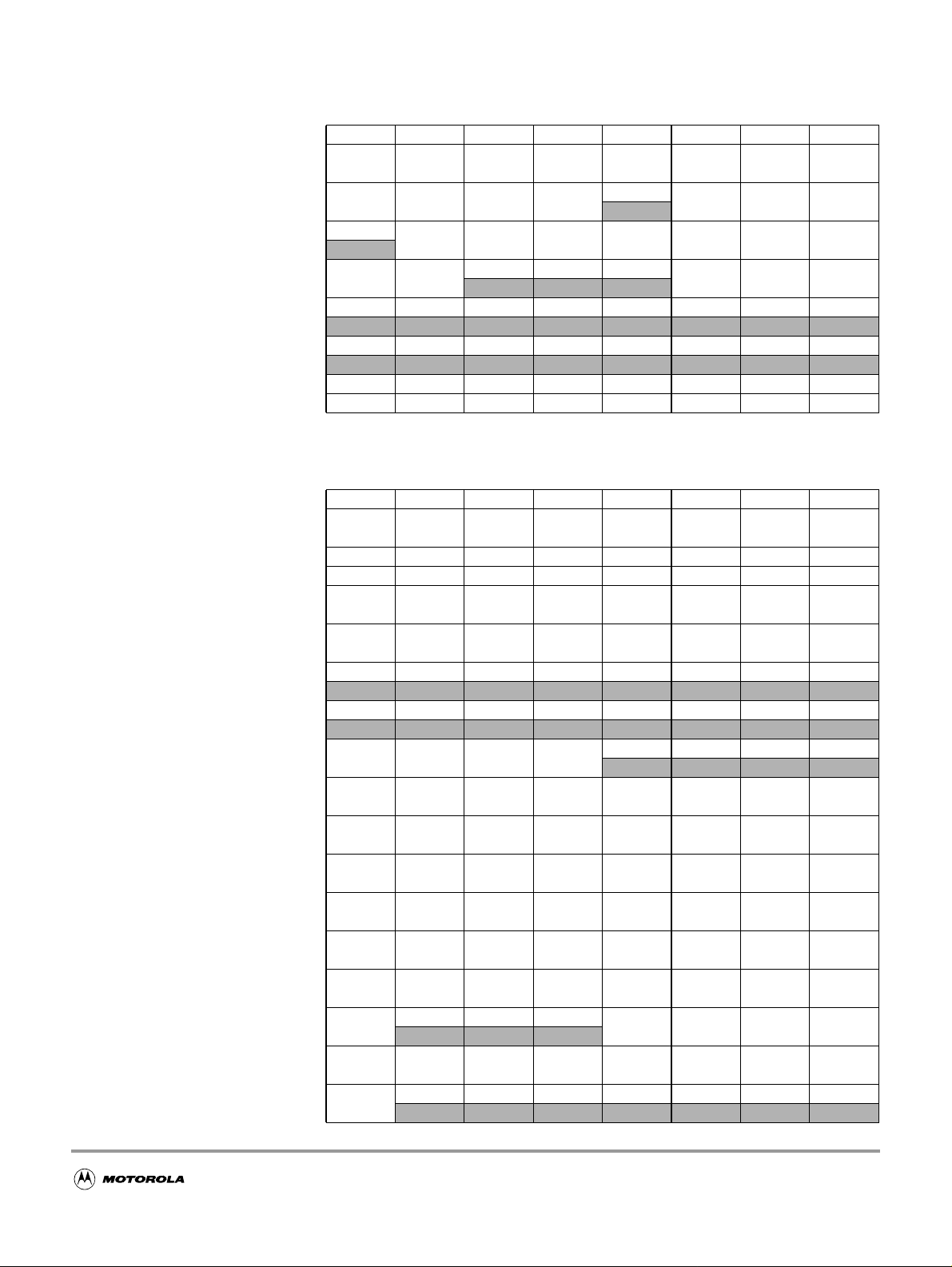

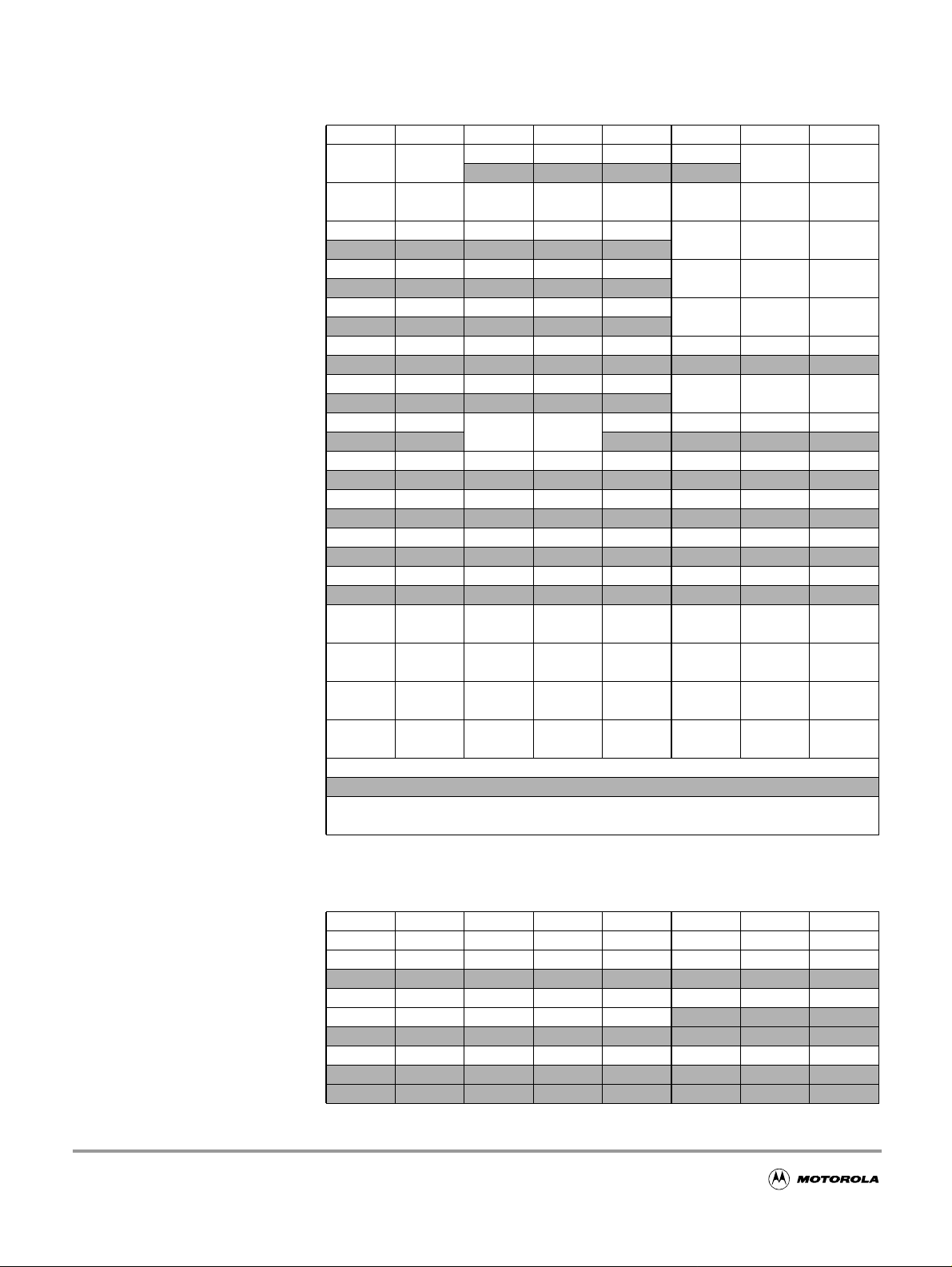

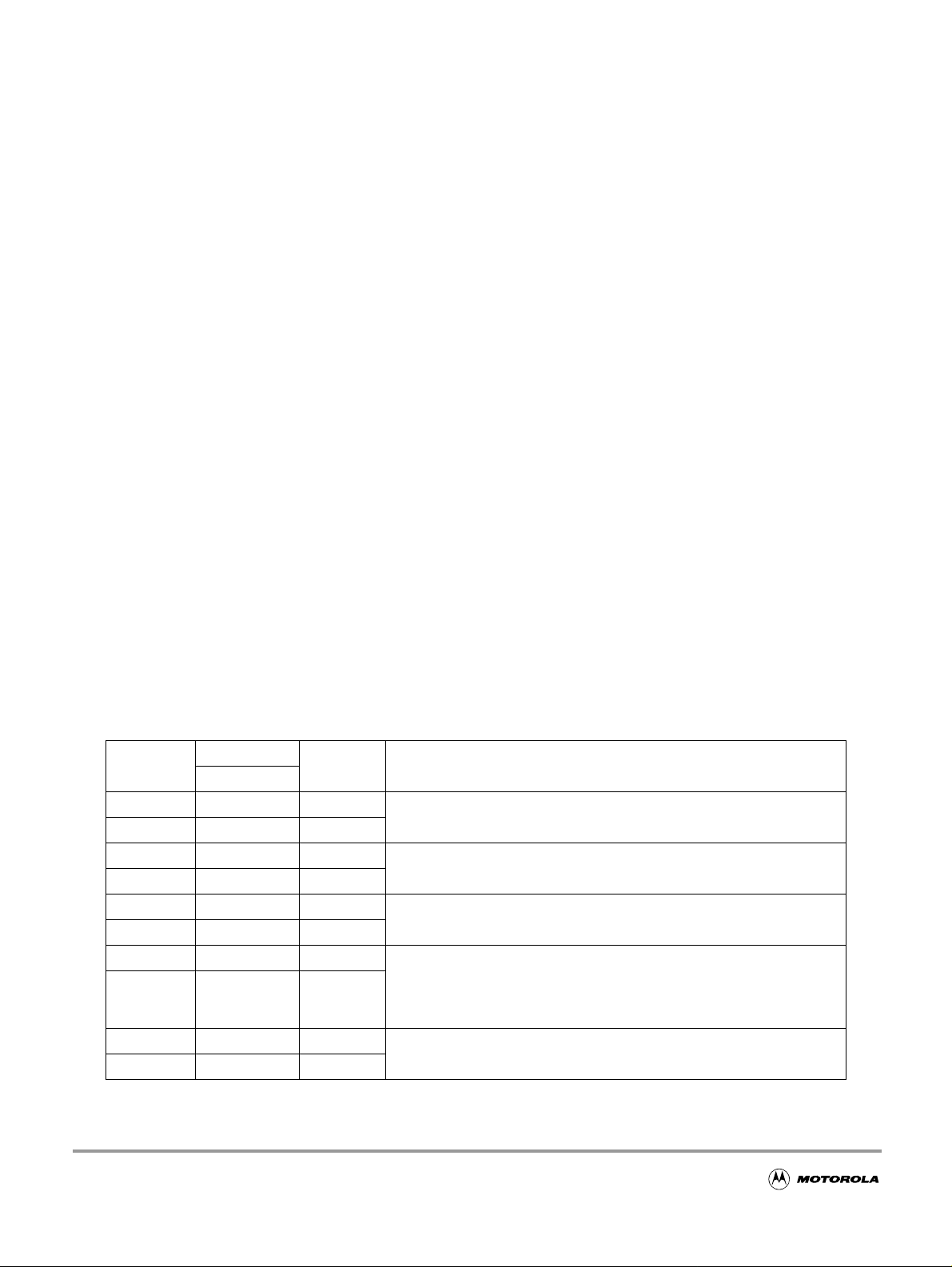

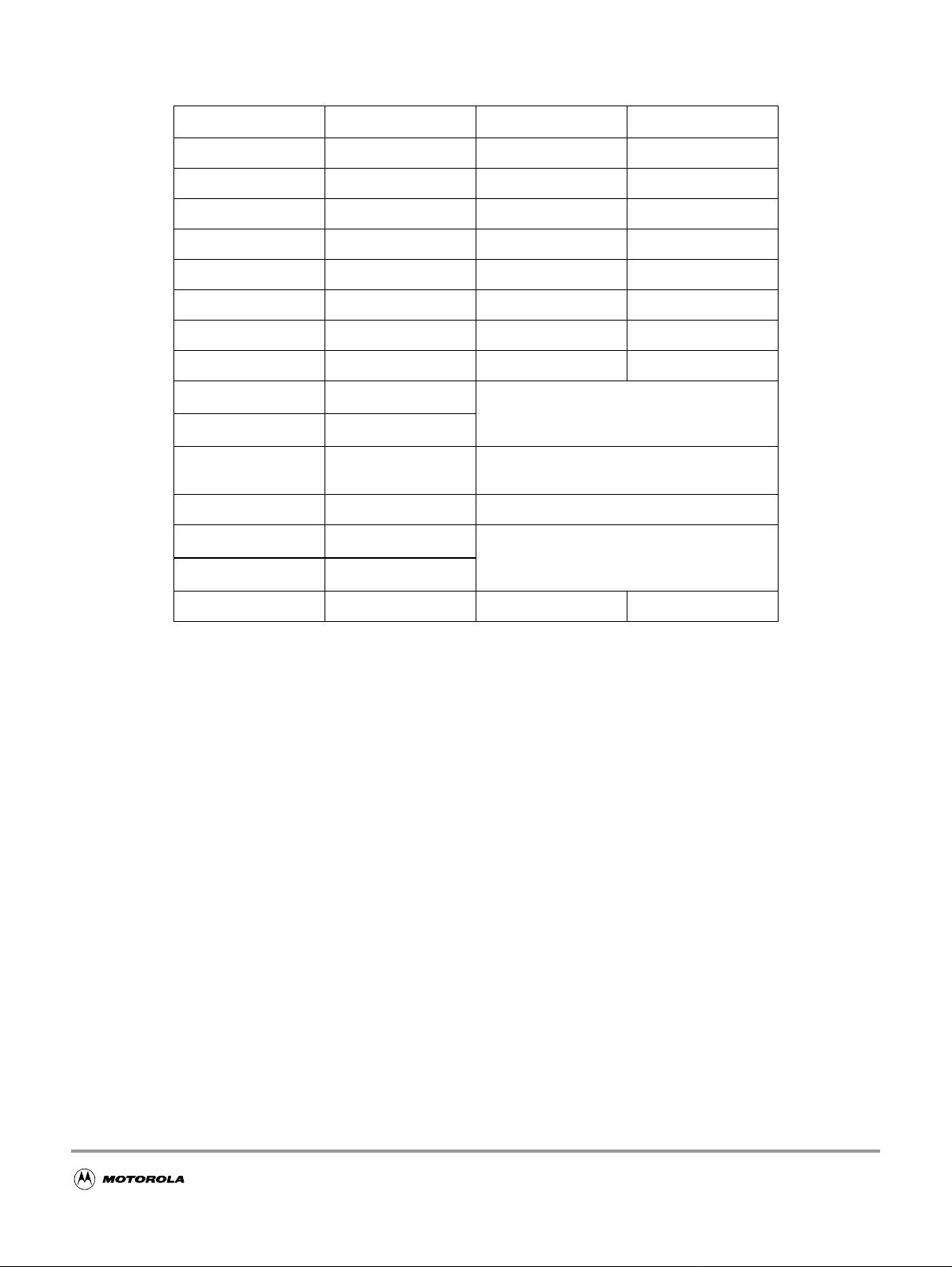

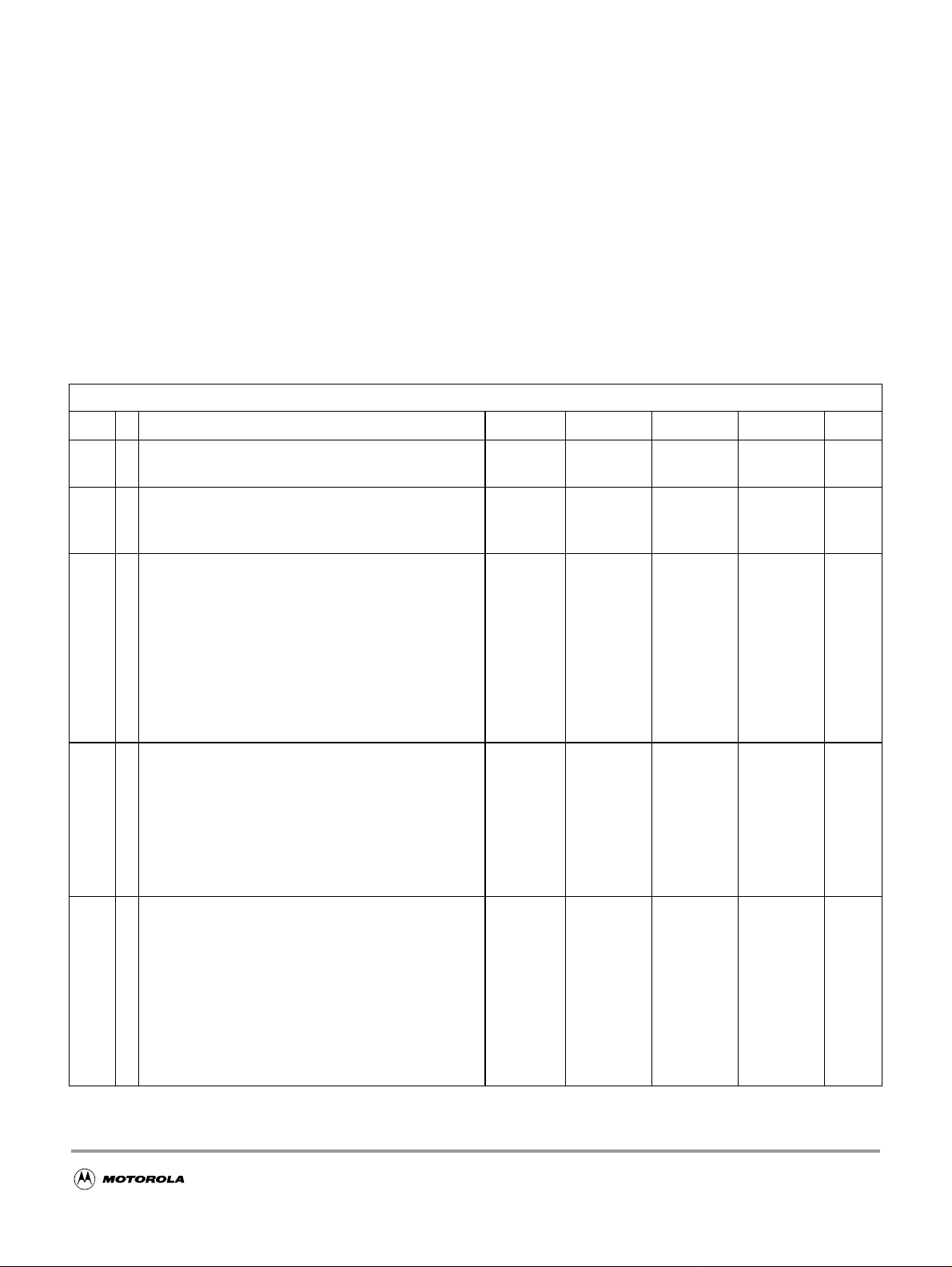

Revision History

Version

Number

V01.00

V01.01

V01.02

V01.03

V01.04

V01.05

Revision

Date

16 NOV

2001

18 FEB

2002

6 MAR

2002

4 June

2002

4 July

2002

30 July

2002

Effective

Date

19 NOV

2001

18 FEB

2002

6 MAR

2002

4 June

2002

4 July

2002

30 July

2002

Author Description of Changes

Initial version based on MC9SDP256-2.09 Version.

In table 7 I/O Characteristics" of the electrical characteristics

replaced tPULSEwith tpign andtpval inlines "Port ...Interrupt Input

Pulse filtered" and "Port ... Interrupt Input Pulse passed"

respectively.

Table "Oscillator Characteristics":removed "Oscillator start-up time

from POR or STOP" row

Table "5V I/O Characteristics": Updated

Partial Drive IOH = +–2mA and Full Drive IOH = –10mA

Table "ATD Operating Characteristics": Distinguish I

ATD blocks on

Table "ATD Electrical Characteristics": Update C

Table "Operating Conditions": Changed V

(min)

Removed Document number except from Cover Sheet

Updated Table "Document References"

Table "5V I/O Characteristics" : Corrected Input Capacitance to 6pF

Section: "Device Pinout" (112-pin and 80-pin): added in diagrams

RXCAN0 to PJ6 and TXCAN0 to PJ7

Table "PLL Characteristics": Updated parameters K

Figure "Basic PLL functional diagram": Inserted XFC pin in diagram

Enhanced section "XFC Component Selection"

Added to SectionsATD,ECT and PWM: freeze mode = active BDM

mode

Added 1L86D to Table "Assigned Part ID numbers"

Corrected MEMSIZ1 value in Table "Memory size registers"

Subsection "Device Memory Map: Removed Flash mapping from

$0000 to $3FFF.

Table "Signal Properties": Added column "Internal Pull Resistor".

Preface Table "Document References": Changed to full naming for

each block.

Table "Interrupt Vector Locations", Column "Local Enable":

Corrected several register and bit names.

Figure "Recommended PCB Layout for 80QFP: Corrected

VREGEN pin position

Thermal values for junction to board and package

BGND pin pull-up

Part Order Information

Global Register Table

Chip Configuration Summary

Modified mode of Operations chapter

Section "Printed Circuit Board Layout Proposals": added Pierce

Oscillator examples for 112LQFP and 80QFP

DD

and V

REF

to 22 pF

INS

DDPLL

1

for 1 and 2

to 2.35 V

and f

1

Page 3

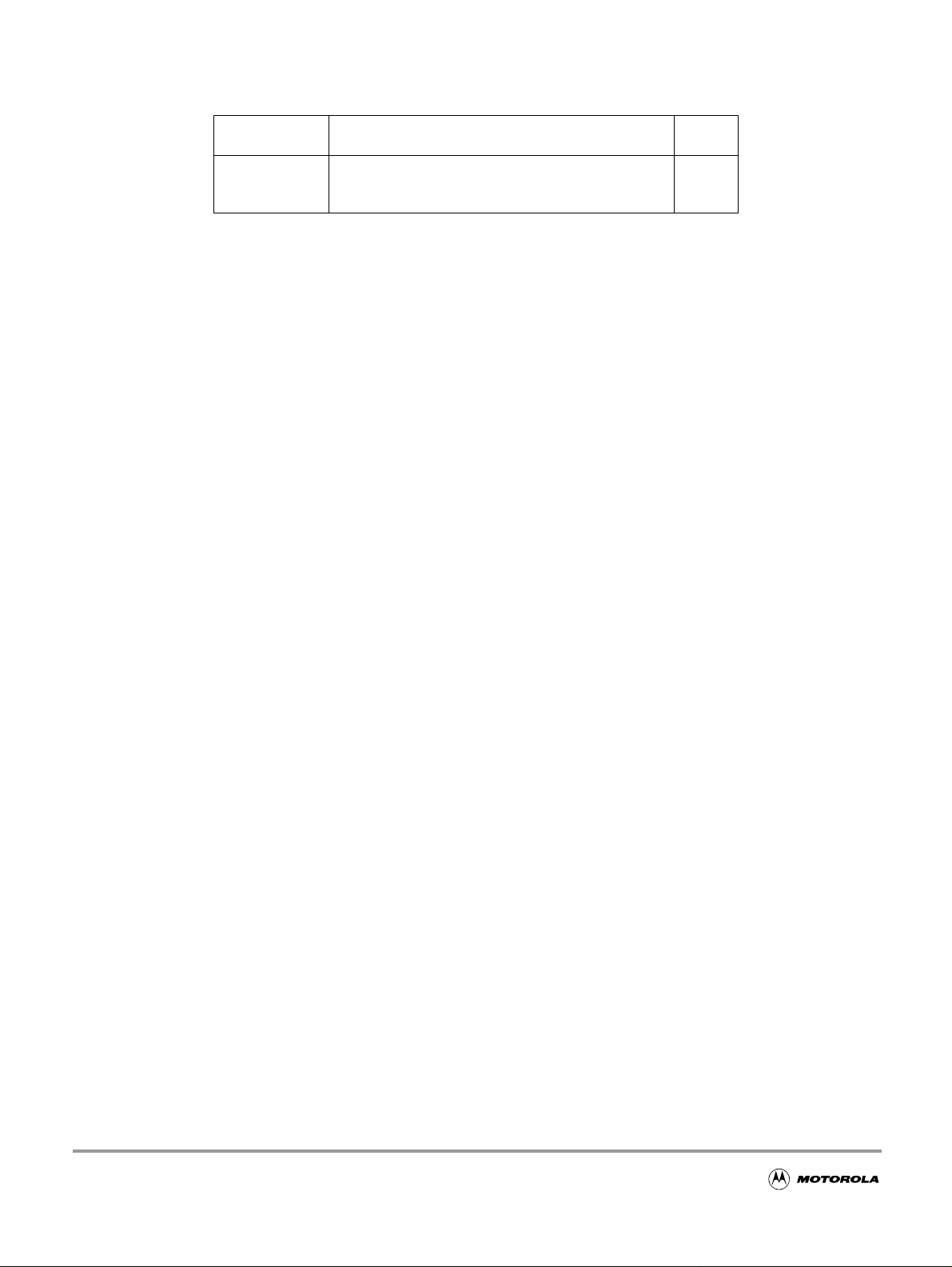

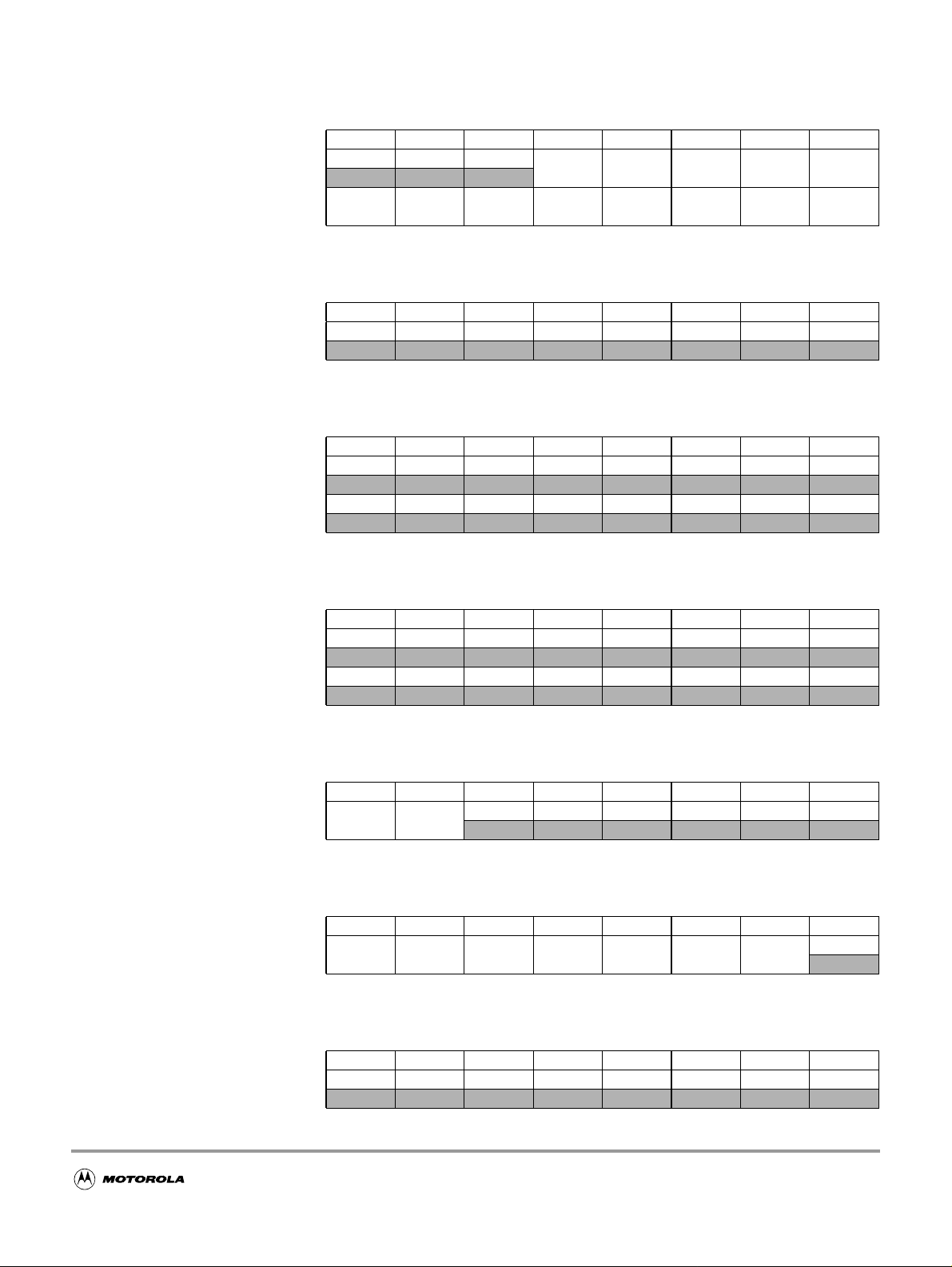

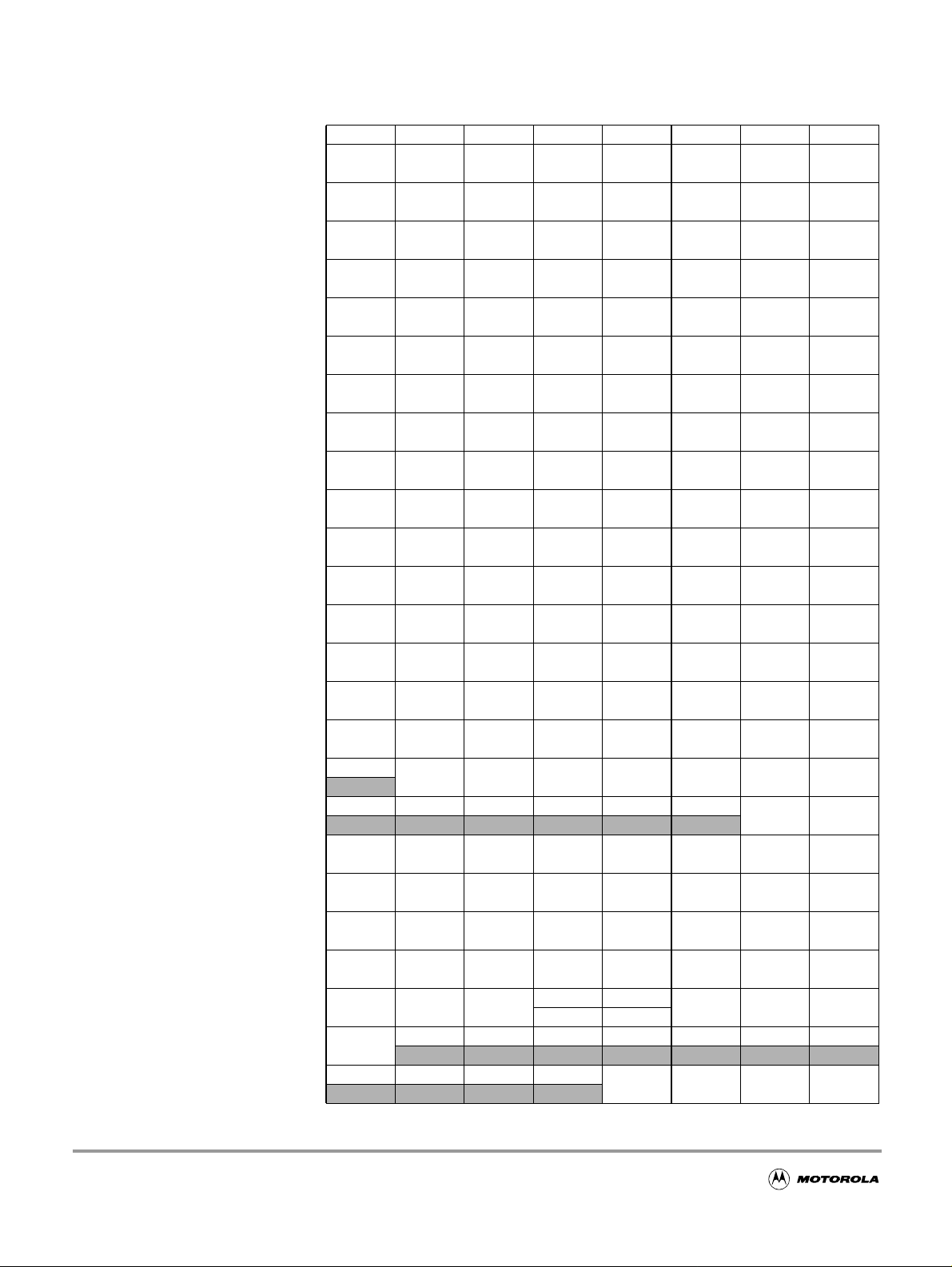

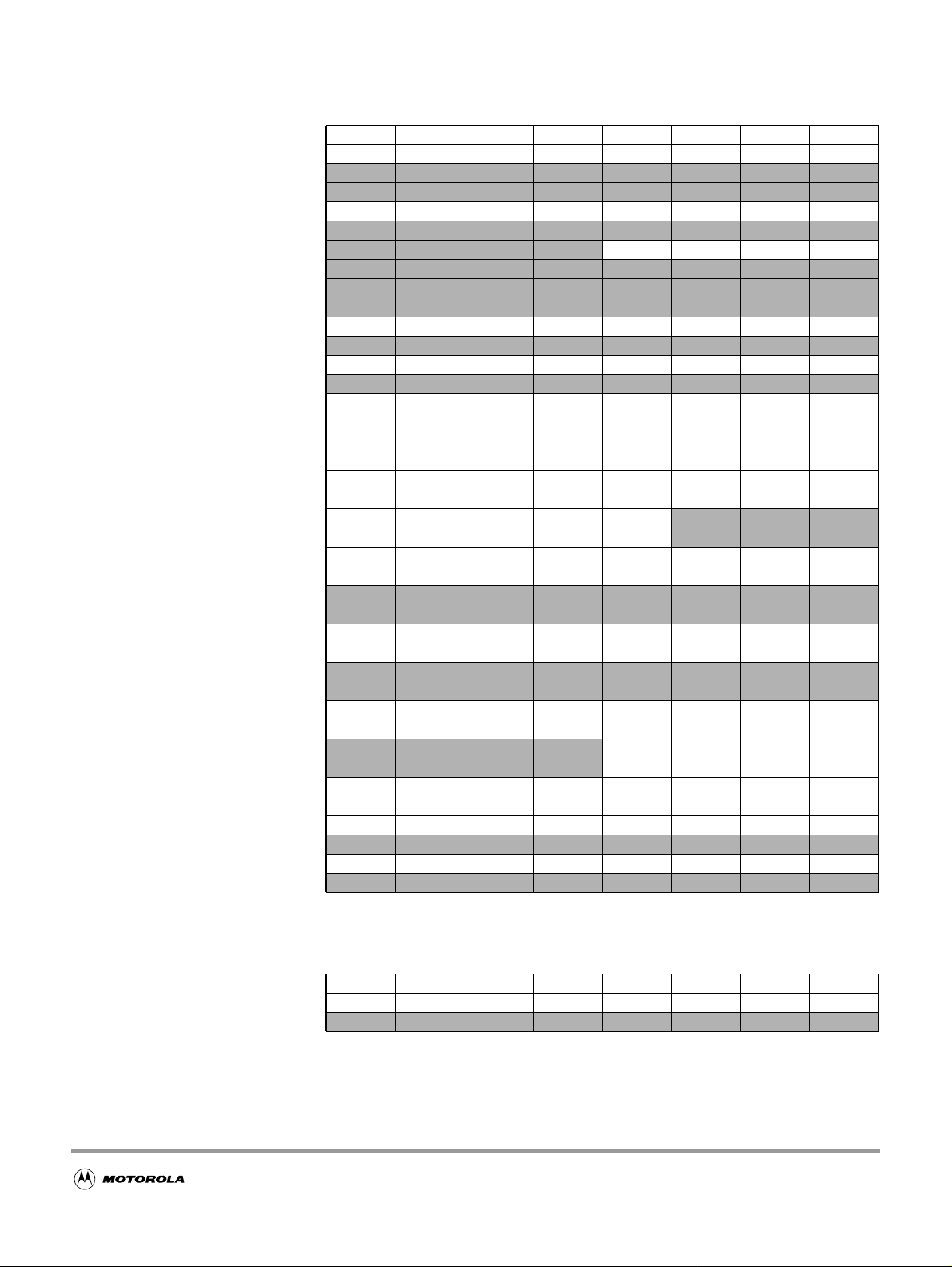

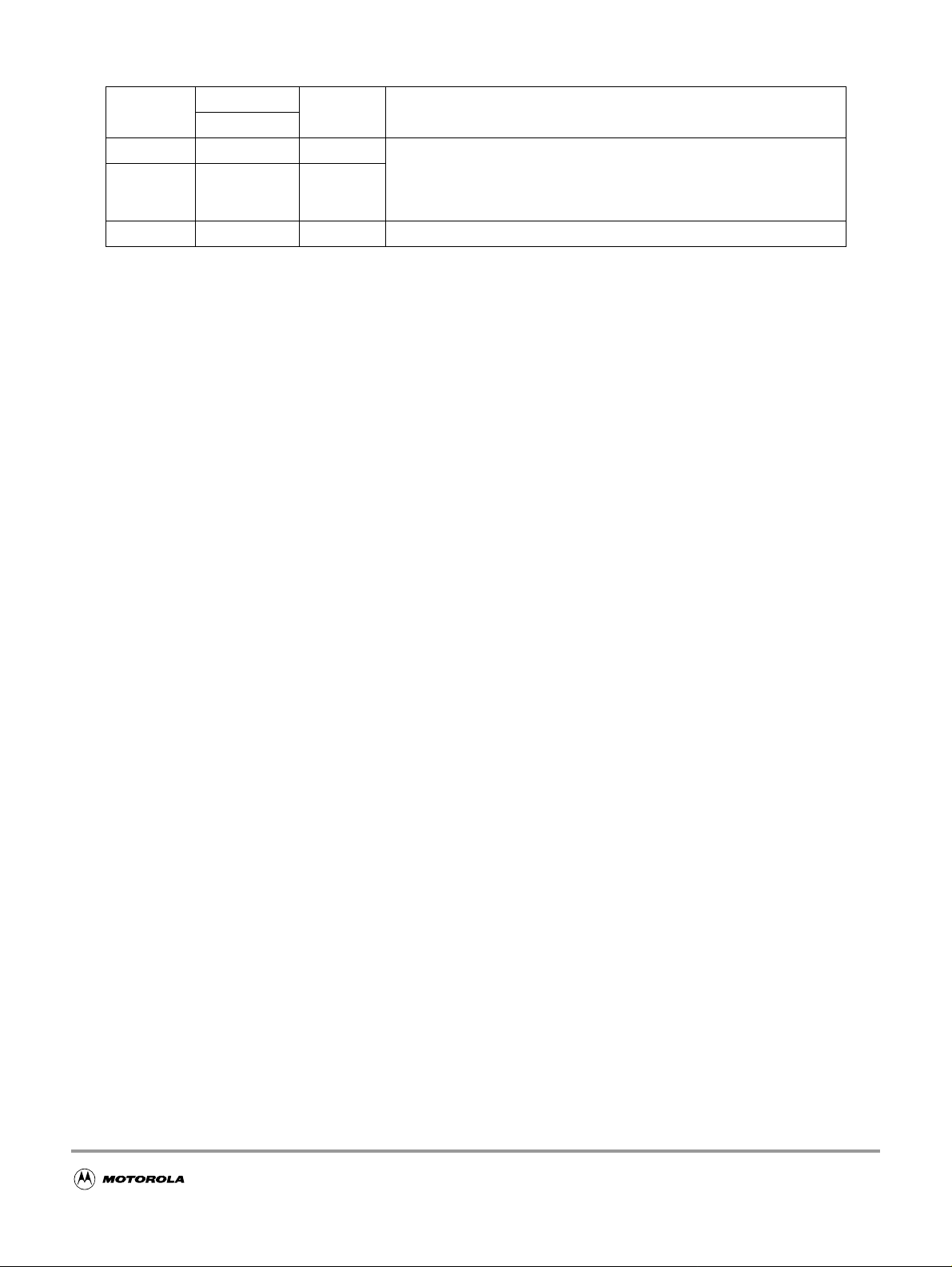

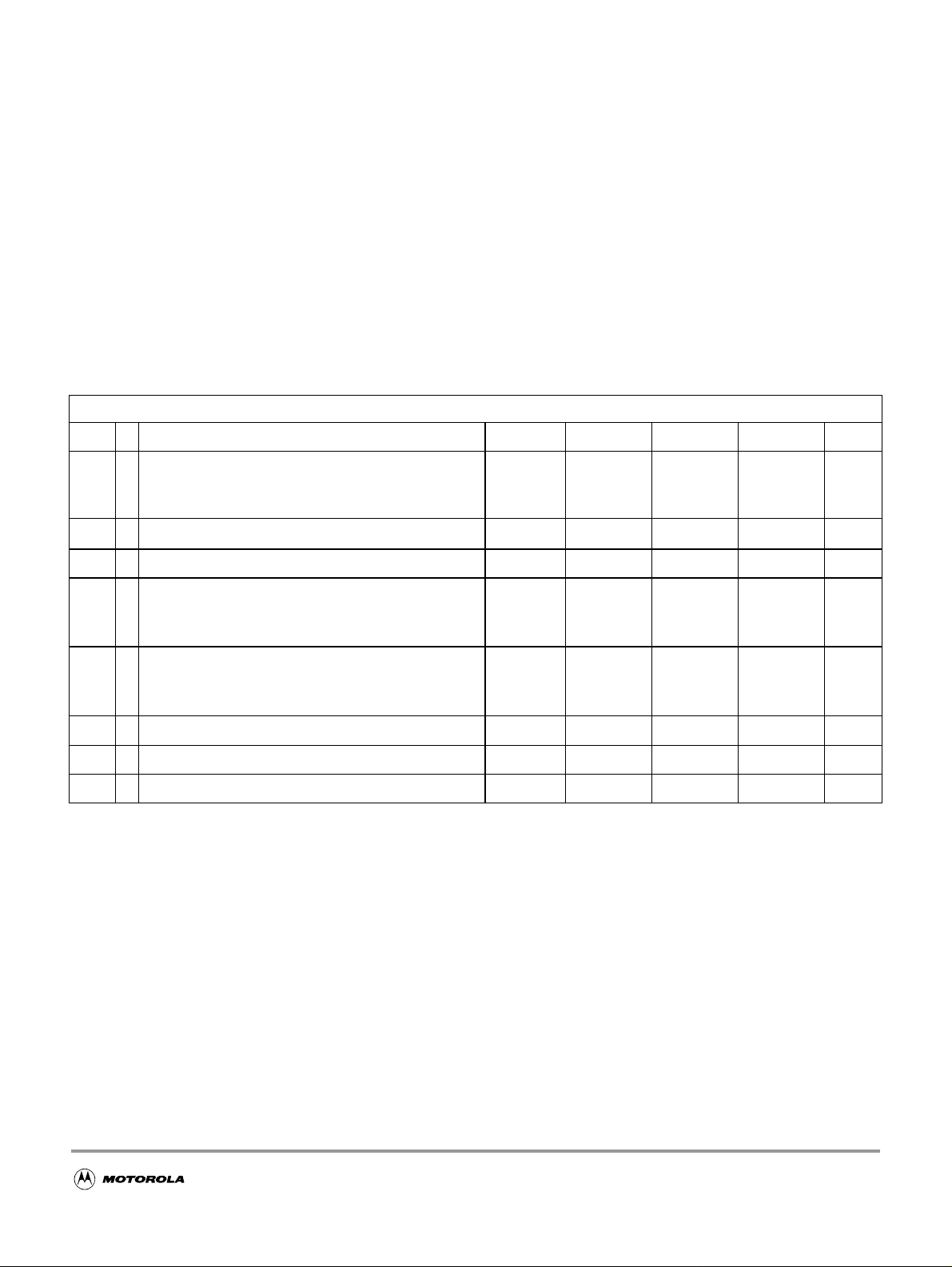

MC9S12DJ64 Device User Guide — V01.17

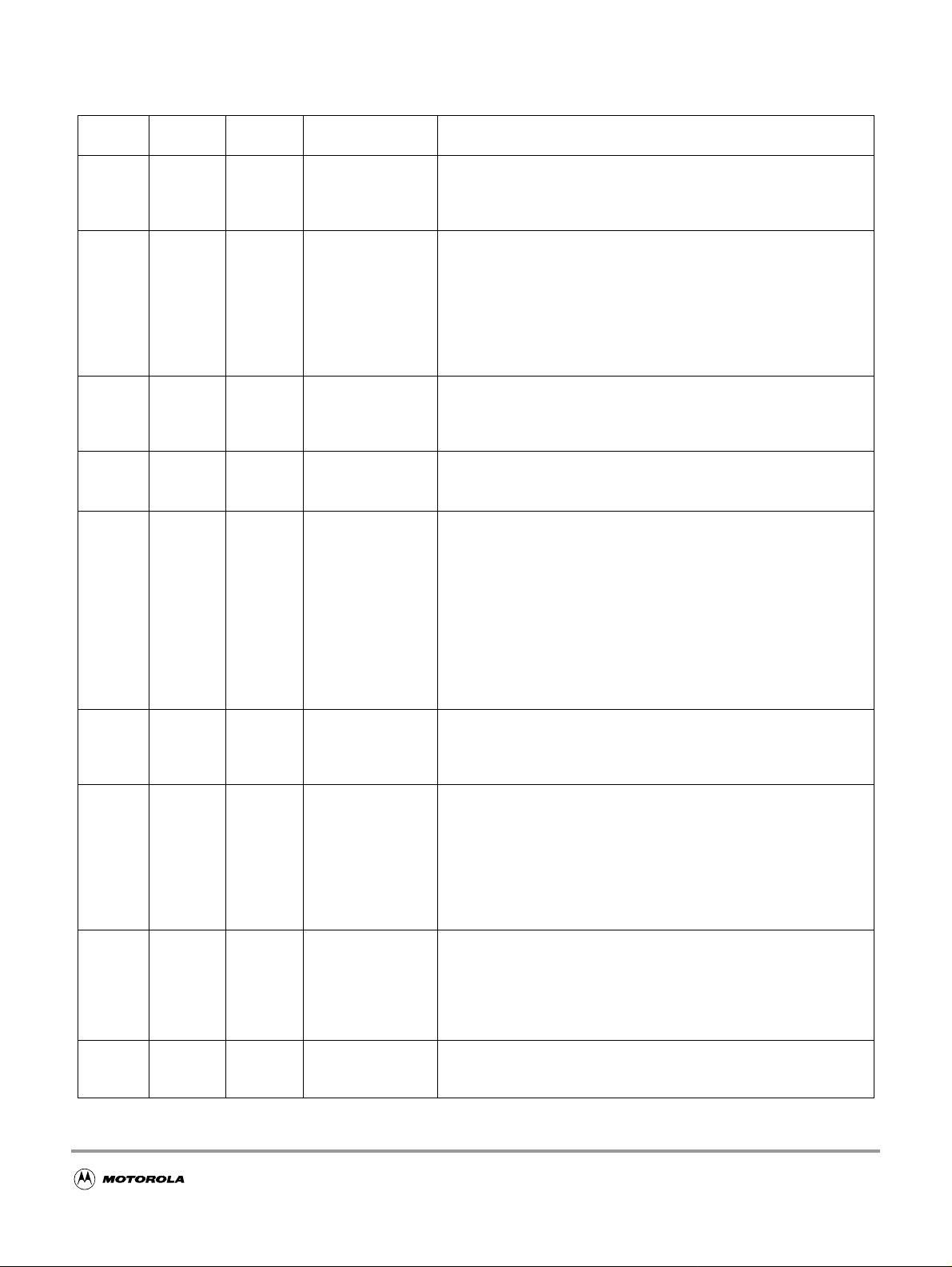

Version

Number

V01.06

V01.07

V01.08

V01.09

V01.10

V01.11

V01.12

V01.13

V01.14

Revision

Date

20 Aug.

2002

20 Sept.

2002

25 Sept.

2002

10 Oct.

2002

8 Nov.

2002

24 Jan.

2003

31 Mar.

2003

20 May

2003

10 June

2003

Effective

Date

20 Aug.

2002

20 Sept.

2002

25 Sept.

2002

10 Oct.

2002

8 Nov.

2002

24 Jan.

2003

31 Mar.

2003

20 May

2003

10 June

2003

Author Description of Changes

NVM electricals updated

Subsection "Detailed Register Map: Address corrections

Preface, Table "Document references": added OSC User Guide

New section "Oscillator (OSC) Block Description"

Electrical Characteristics:

-> Section "General": removed preliminary disclaimer

->Table "Supply Current Characteristics":

changed max Run IDD from 65mA to 50mA

changes max Wait IDD from 40mA to 30mA

changed max Stop IDD from 50uA to 100uA

Section HCS12 Core Block Description: mentioned alternate clock

of BDM to be equivalent to oscillator clock

Table "5V I/O Characteristics": Corrected Input Leakage Current to

+/- 1 uA

Section "Part ID assignment": Located on start of next page for

better readability

Added MC9S12A64 derivative to cover sheet and "Derivative

Differences" Table

Corrected in footnote of Table "PLL Characteristics": f

Renamed "Preface" section to "Derivative Differences and

Document references". Added details for derivatives missing CAN0

and/or BDLC

Table"ESD and Latch-upTest Conditions":changed pulse numbers

from 3 to 1

Table "ESD and Latch-Up Protection Characteristics": changed

parameter classification from C to T

Table "5V I/O Characteristics": removed foot note from "Input

Leakage Current"

Table " Supply Current Characteristics": updated Stop and Pseudo

Stop currents

Subsection "Detailed Register Map": Corrected several entries

Subsection "Unsecuring the Microcontroller": Added more details

Table "Operating Conditions": improved footnote 1 wording, applied

footnote 1 to PLL Supply Voltage.

Tables "SPI Master/Slave Mode Timing Characteristics: Corrected

Operating Frequency

Appendix ’NVM, Flash and EEPROM’: Replaced ’burst

programming’ by ’row programming

Table "Operating Conditions": corrected minimum bus frequency to

0.25MHz

Section "Feature List": ECT features changed to "Four pulse

accumulators ..."

Replaced references to HCS12 Core Guide by the individual

HCS12 Block guides

Table "Signal Properties" corrected pull resistor reset state for PE7

and PE4-PE2.

Table "Absolute Maximum Ratings" corrected footnote on clamp of

TEST pin.

Added cycle definition to "CPU 12 Block Description".

Added register reset values to MMC and MEBI block descriptions.

Diagram "Clock Connections": Connect Bus Clock to HCS12 Core

OSC

= 4MHz

3

Page 4

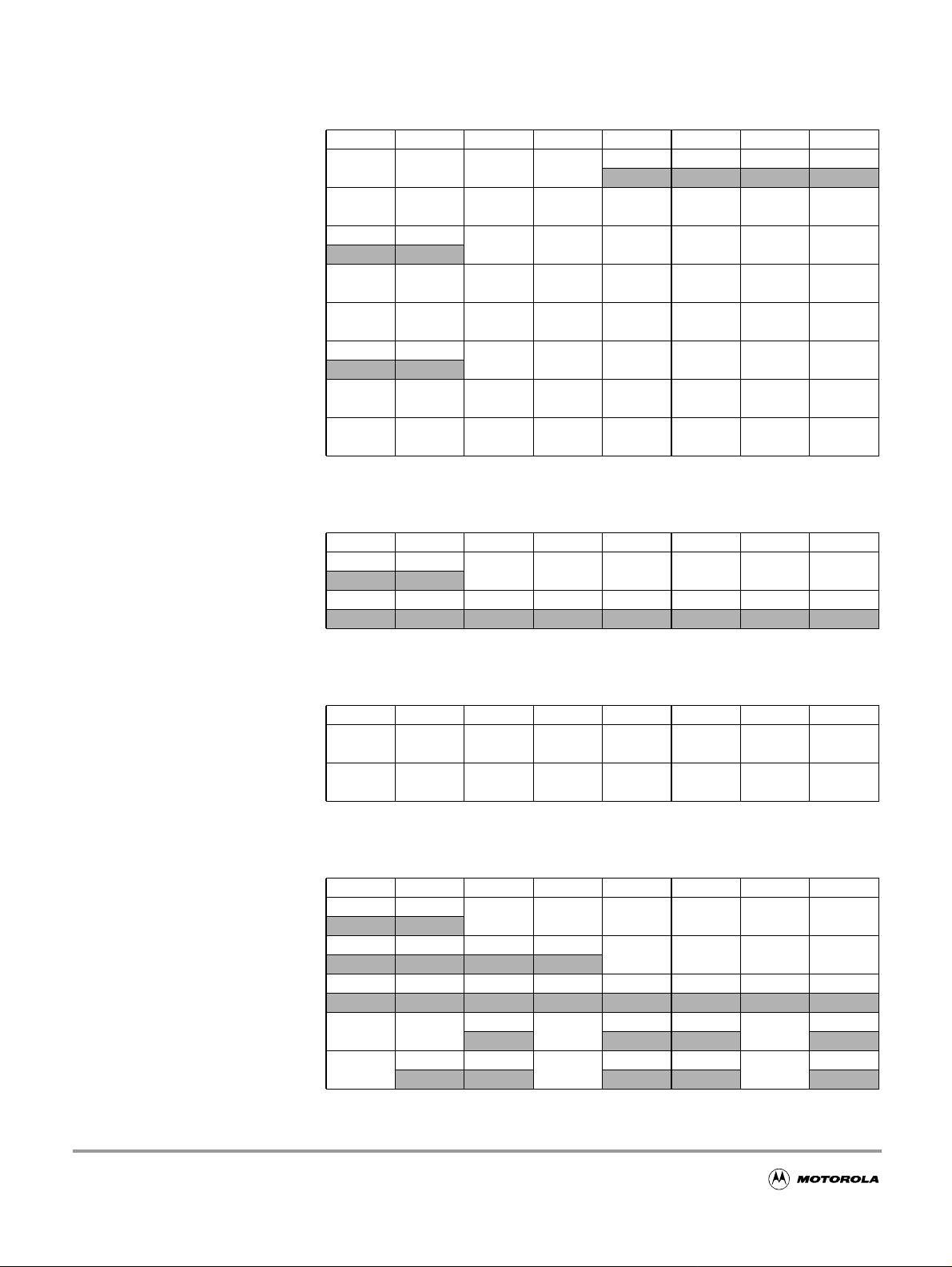

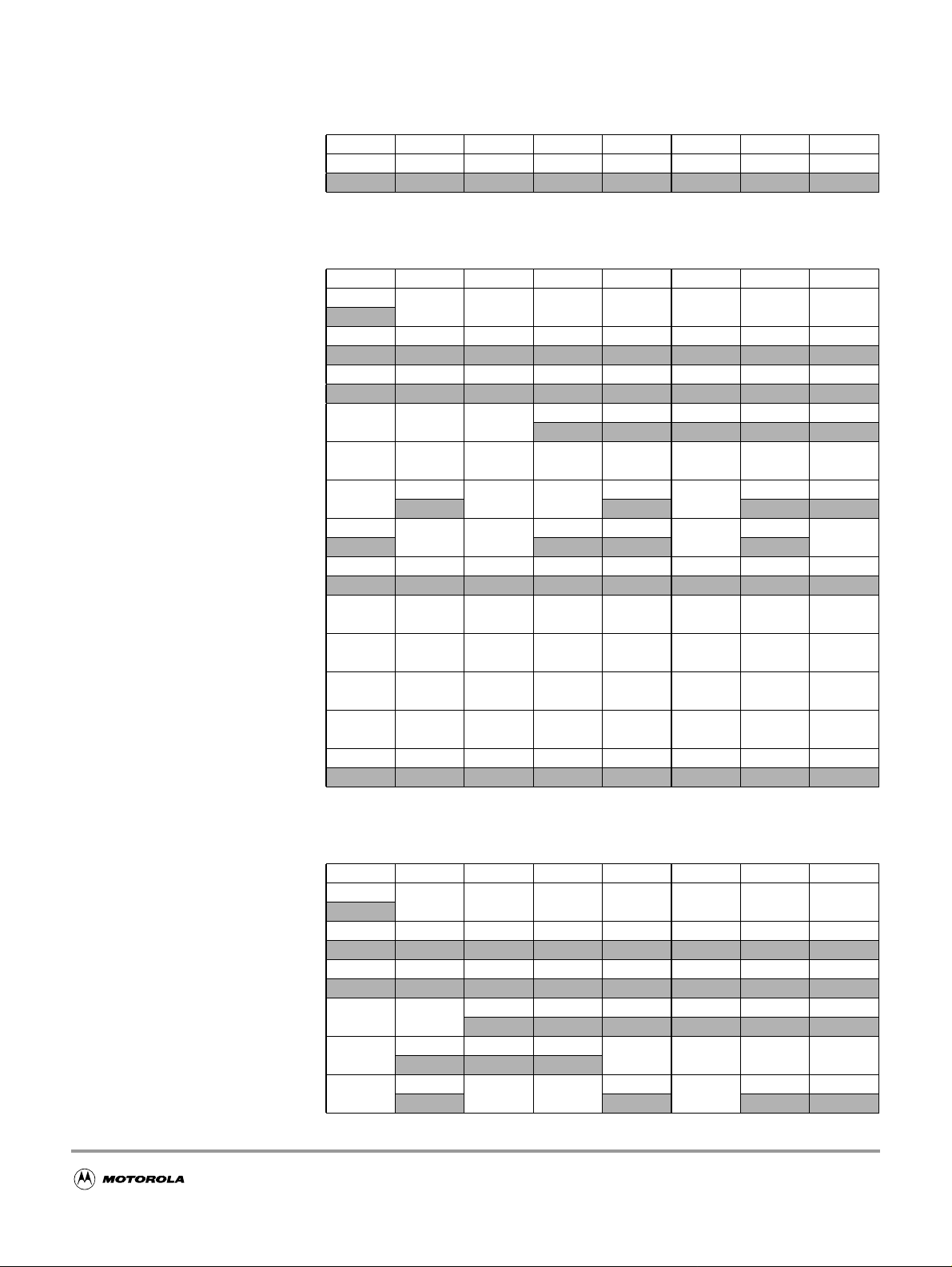

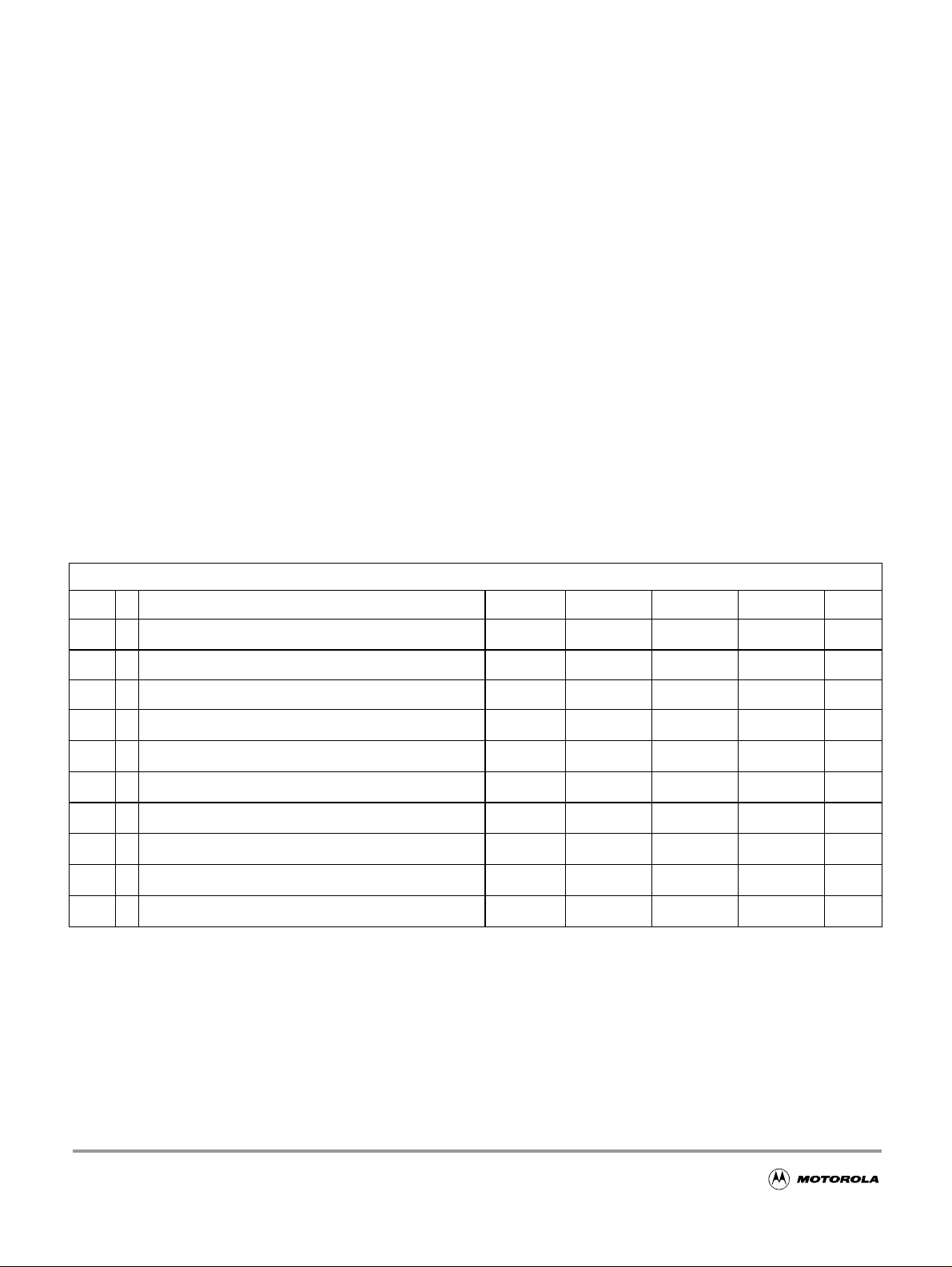

MC9S12DJ64 Device User Guide — V01.17

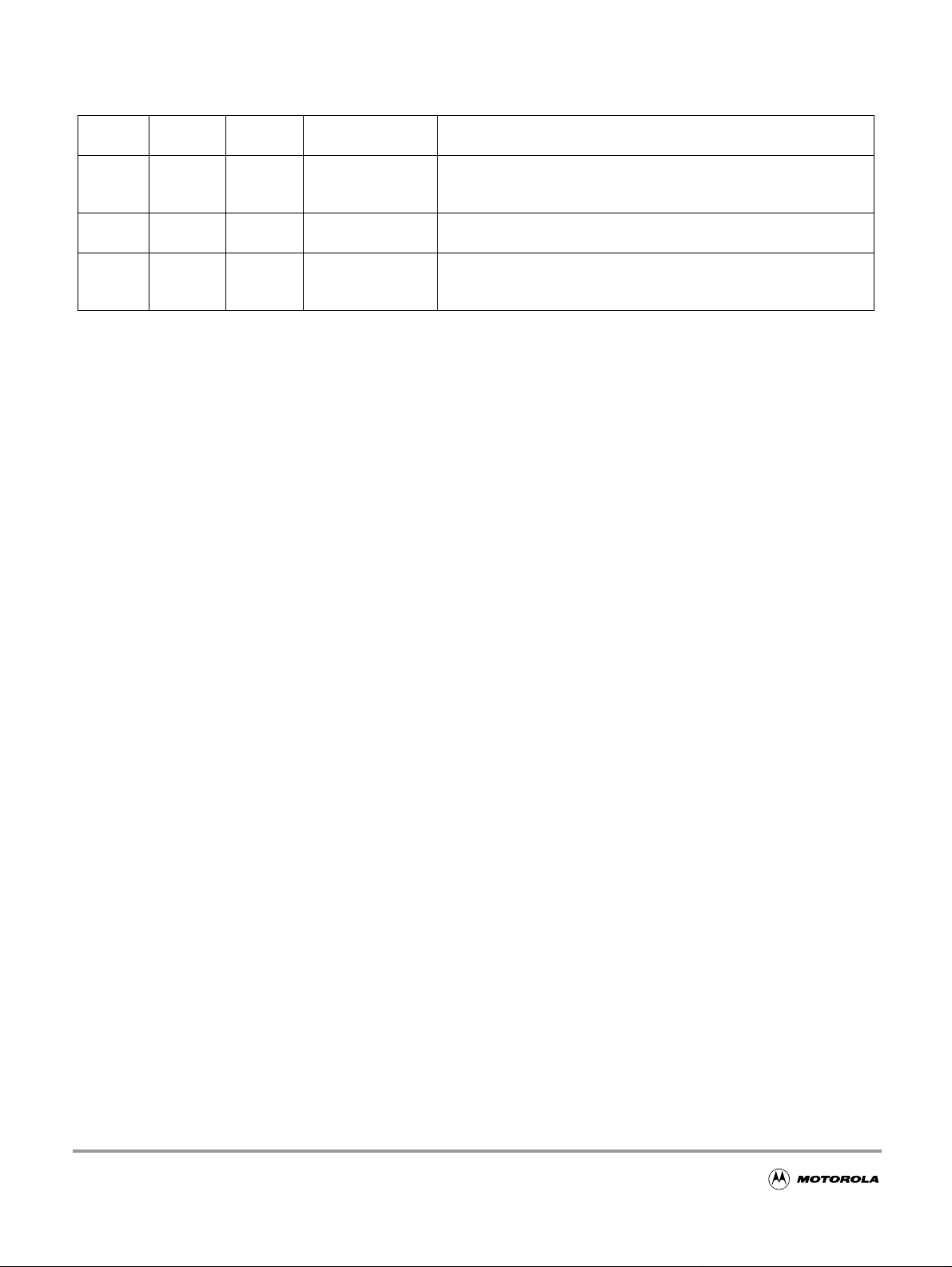

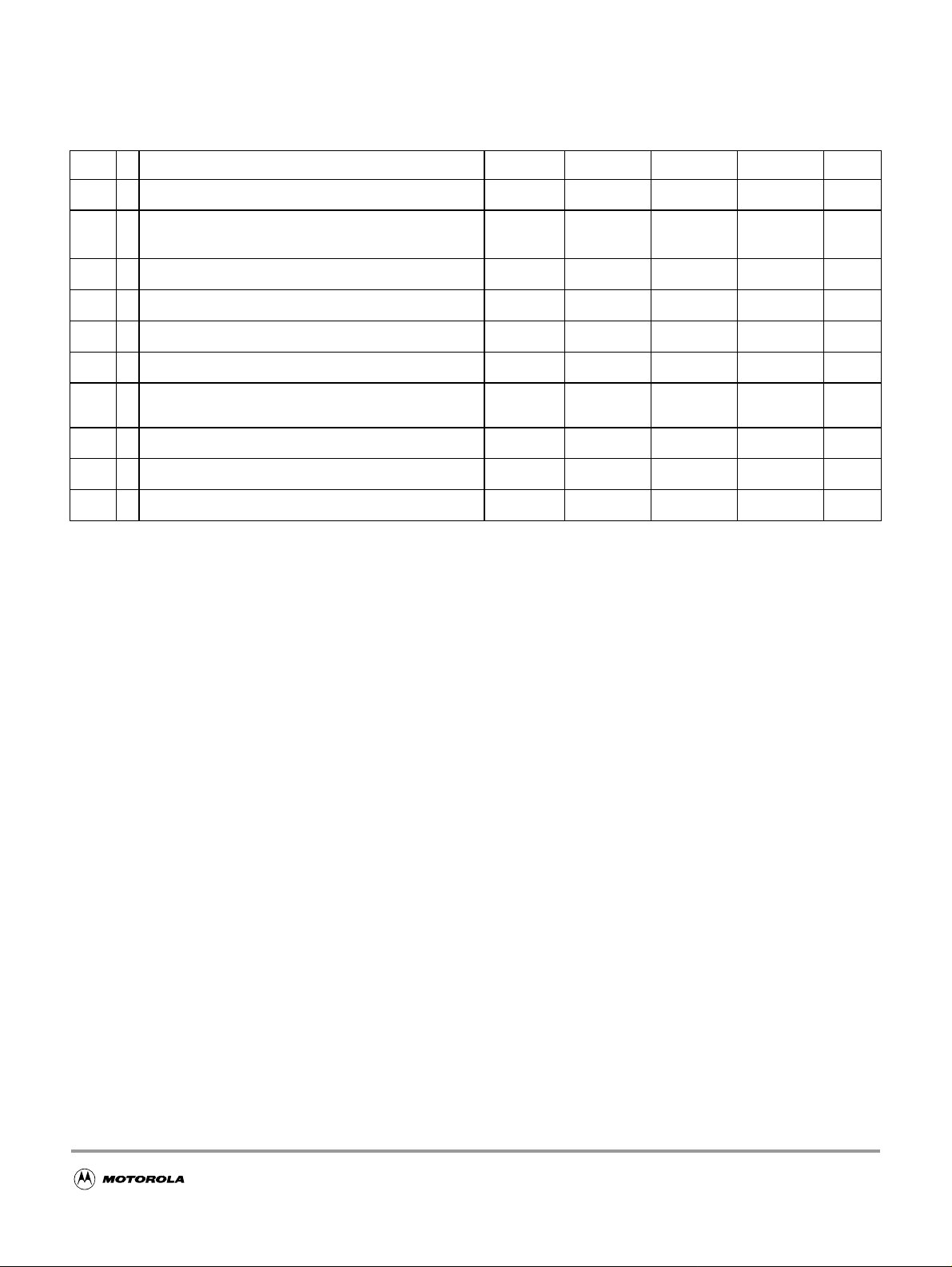

Version

Number

V01.15

V01.16

V01.17

Revision

Date

22 July

2003

24 Feb.

2004

21 May

2004

Effective

Date

22 July

2003

24 Feb.

2004

21 May

2004

Author Description of Changes

Mentioned "S12 LRAE" bootloader in Flash section

Section Document References: corrected S12 CPU document

reference

Added 3L86D maskset with corresponding Part ID

Table Oscillator Characteristics: Added more details for EXTAL pin

Added 4L86D maskset with corresponding Part ID

Table "MC9S12DJ64 Memory Mapout of Reset": corrected$1000 $3fff memory in single chip modes to "unimplemented".

4

Page 5

MC9S12DJ64 Device User Guide — V01.17

Table of Contents

Section 1 Introduction

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.3 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1.4 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1.5 Device Memory Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.5.1 Detailed Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

1.6 Part ID Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Section 2 Signal Description

2.1 Device Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.2 Signal Properties Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.3 Detailed Signal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.1 EXTAL, XTAL — Oscillator Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.2 RESET — External Reset Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.3 TEST — Test Pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.4 VREGEN — Voltage Regulator Enable Pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.5 XFC — PLL Loop Filter Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.3.6 BKGD / TAGHI / MODC — Background Debug, Tag High, and Mode Pin . . . . . . . .54

2.3.7 PAD15 / AN15 / ETRIG1 — Port AD Input Pin of ATD1 . . . . . . . . . . . . . . . . . . . . . .55

2.3.8 PAD[14:08] / AN[14:08] — Port AD Input Pins ATD1 . . . . . . . . . . . . . . . . . . . . . . . .55

2.3.9 PAD07 / AN07 / ETRIG0 — Port AD Input Pin of ATD0 . . . . . . . . . . . . . . . . . . . . . .55

2.3.10 PAD[06:00] / AN[06:00] — Port AD Input Pins of ATD0 . . . . . . . . . . . . . . . . . . . . . .55

2.3.11 PA[7:0] / ADDR[15:8] / DATA[15:8] — Port A I/O Pins . . . . . . . . . . . . . . . . . . . . . . .55

2.3.12 PB[7:0] / ADDR[7:0] / DATA[7:0] — Port B I/O Pins . . . . . . . . . . . . . . . . . . . . . . . . .55

2.3.13 PE7 / NOACC / XCLKS — Port E I/O Pin 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

2.3.14 PE6 / MODB / IPIPE1 — Port E I/O Pin 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.15 PE5 / MODA / IPIPE0 — Port E I/O Pin 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.16 PE4 / ECLK — Port E I/O Pin 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.17 PE3 / LSTRB / TAGLO — Port E I/O Pin 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.18 PE2 / R/W — Port E I/O Pin 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.19 PE1 / IRQ — Port E Input Pin 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.20 PE0 / XIRQ — Port E Input Pin 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

5

Page 6

MC9S12DJ64 Device User Guide — V01.17

2.3.21 PH7 / KWH7 — Port H I/O Pin 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.3.22 PH6 / KWH6 — Port H I/O Pin 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.23 PH5 / KWH5 — Port H I/O Pin 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.24 PH4 / KWH4 — Port H I/O Pin 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.25 PH3 / KWH3 — Port H I/O Pin 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.26 PH2 / KWH2 — Port H I/O Pin 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.27 PH1 / KWH1 — Port H I/O Pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.28 PH0 / KWH0 — Port H I/O Pin 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.29 PJ7 / KWJ7 / SCL / TXCAN0 — PORT J I/O Pin 7 . . . . . . . . . . . . . . . . . . . . . . . . . .58

2.3.30 PJ6 / KWJ6 / SDA / RXCAN0 — PORT J I/O Pin 6. . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.31 PJ[1:0] / KWJ[1:0] — Port J I/O Pins [1:0] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.32 PK7 / ECS / ROMCTL — Port K I/O Pin 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.33 PK[5:0] / XADDR[19:14] — Port K I/O Pins [5:0] . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.34 PM7 — Port M I/O Pin 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.35 PM6 — Port M I/O Pin 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.36 PM5 / TXCAN0 / SCK0 — Port M I/O Pin 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.37 PM4 / RXCAN0 / MOSI0 — Port M I/O Pin 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.3.38 PM3 / TXCAN0 / SS0 — Port M I/O Pin 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.39 PM2 / RXCAN0 / MISO0 — Port M I/O Pin 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.40 PM1 / TXCAN0 / TXB — Port M I/O Pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.41 PM0 / RXCAN0 / RXB — Port M I/O Pin 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.42 PP7 / KWP7 / PWM7 — Port P I/O Pin 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.43 PP6 / KWP6 / PWM6 — Port P I/O Pin 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.44 PP5 / KWP5 / PWM5 — Port P I/O Pin 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.45 PP4 / KWP4 / PWM4 — Port P I/O Pin 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2.3.46 PP3 / KWP3 / PWM3 — Port P I/O Pin 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.47 PP2 / KWP2 / PWM2 — Port P I/O Pin 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.48 PP1 / KWP1 / PWM1 — Port P I/O Pin 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.49 PP0 / KWP0 / PWM0 — Port P I/O Pin 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.50 PS7 / SS0 — Port S I/O Pin 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.51 PS6 / SCK0 — Port S I/O Pin 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.52 PS5 / MOSI0 — Port S I/O Pin 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.53 PS4 / MISO0 — Port S I/O Pin 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.54 PS3 / TXD1 — Port S I/O Pin 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2.3.55 PS2 / RXD1 — Port S I/O Pin 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.3.56 PS1 / TXD0 — Port S I/O Pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

6

Page 7

MC9S12DJ64 Device User Guide — V01.17

2.3.57 PS0 / RXD0 — Port S I/O Pin 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.3.58 PT[7:0] / IOC[7:0] — Port T I/O Pins [7:0] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.4 Power Supply Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.4.1 VDDX, VSSX — Power & Ground Pins for I/O Drivers . . . . . . . . . . . . . . . . . . . . . . .63

2.4.2 VDDR, VSSR — Power & Ground Pins for I/O Drivers & for Internal Voltage Regulator

63

2.4.3 VDD1, VDD2, VSS1, VSS2 — Internal Logic Power Supply Pins. . . . . . . . . . . . . . .63

2.4.4 VDDA, VSSA — Power Supply Pins for ATD0/ATD1 and VREG . . . . . . . . . . . . . . .63

2.4.5 VRH, VRL — ATD Reference Voltage Input Pins . . . . . . . . . . . . . . . . . . . . . . . . . . .64

2.4.6 VDDPLL, VSSPLL — Power Supply Pins for PLL. . . . . . . . . . . . . . . . . . . . . . . . . . .64

2.4.7 VREGEN — On Chip Voltage Regulator Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Section 3 System Clock Description

3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Section 4 Modes of Operation

4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4.2 Chip Configuration Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4.3 Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.3.1 Securing the Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.3.2 Operation of the Secured Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.3.3 Unsecuring the Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.4 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.4.1 Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.4.2 Pseudo Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.4.3 Wait . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.4.4 Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Section 5 Resets and Interrupts

5.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5.2 Vectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5.2.1 Vector Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5.3 Effects of Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.3.1 I/O pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.3.2 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Section 6 HCS12 Core Block Description

7

Page 8

MC9S12DJ64 Device User Guide — V01.17

6.1 CPU12 Block Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.1.1 Device-specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.2 HCS12 Module Mapping Control (MMC) Block Description. . . . . . . . . . . . . . . . . . . . . .75

6.2.1 Device-specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.3 HCS12 Multiplexed External Bus Interface (MEBI) Block Description . . . . . . . . . . . . . .75

6.3.1 Device-specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.4 HCS12 Interrupt (INT) Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.5 HCS12 Background Debug (BDM) Block Description . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.5.1 Device-specific information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.6 HCS12 Breakpoint (BKP) Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Section 7 Clock and Reset Generator (CRG) Block Description

7.1 Device-specific information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Section 8 Oscillator (OSC) Block Description

8.1 Device-specific information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Section 9 Enhanced Capture Timer (ECT) Block Description

Section 10 Analog to Digital Converter (ATD) Block Description

Section 11 Inter-IC Bus (IIC) Block Description

Section 12 Serial Communications Interface (SCI) Block Description

Section 13 Serial Peripheral Interface (SPI) Block Description

Section 14 J1850 (BDLC) Block Description

Section 15 Pulse Width Modulator (PWM) Block Description

Section 16 Flash EEPROM 64K Block Description

Section 17 EEPROM 1K Block Description

Section 18 RAM Block Description

Section 19 MSCAN Block Description

8

Page 9

MC9S12DJ64 Device User Guide — V01.17

Section 20 Port Integration Module (PIM) Block Description

Section 21 Voltage Regulator (VREG) Block Description

Section 22 Printed Circuit Board Layout Proposals

Appendix A Electrical Characteristics

A.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.1.1 Parameter Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.1.2 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.1.3 Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

A.1.4 Current Injection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

A.1.5 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.1.6 ESD Protection and Latch-up Immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.1.7 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.1.8 Power Dissipation and Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

A.1.9 I/O Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

A.1.10 Supply Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

A.2 ATD Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

A.2.1 ATD Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

A.2.2 Factors influencing accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

A.2.3 ATD accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

A.3 NVM, Flash and EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

A.3.1 NVM timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

A.3.2 NVM Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

A.4 Voltage Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.5 Reset, Oscillator and PLL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

A.5.1 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

A.5.2 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

A.5.3 Phase Locked Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

A.6 MSCAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

A.7 SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

A.7.1 Master Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

A.7.2 Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

A.8 External Bus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

A.8.1 General Muxed Bus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

9

Page 10

MC9S12DJ64 Device User Guide — V01.17

Appendix B Package Information

B.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

B.2 112-pin LQFP package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

B.3 80-pin QFP package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

10

Page 11

MC9S12DJ64 Device User Guide — V01.17

List of Figures

Figure 0-1 Order Partnumber Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 1-1 MC9S12DJ64 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 1-2 MC9S12DJ64 Memory Map out of Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

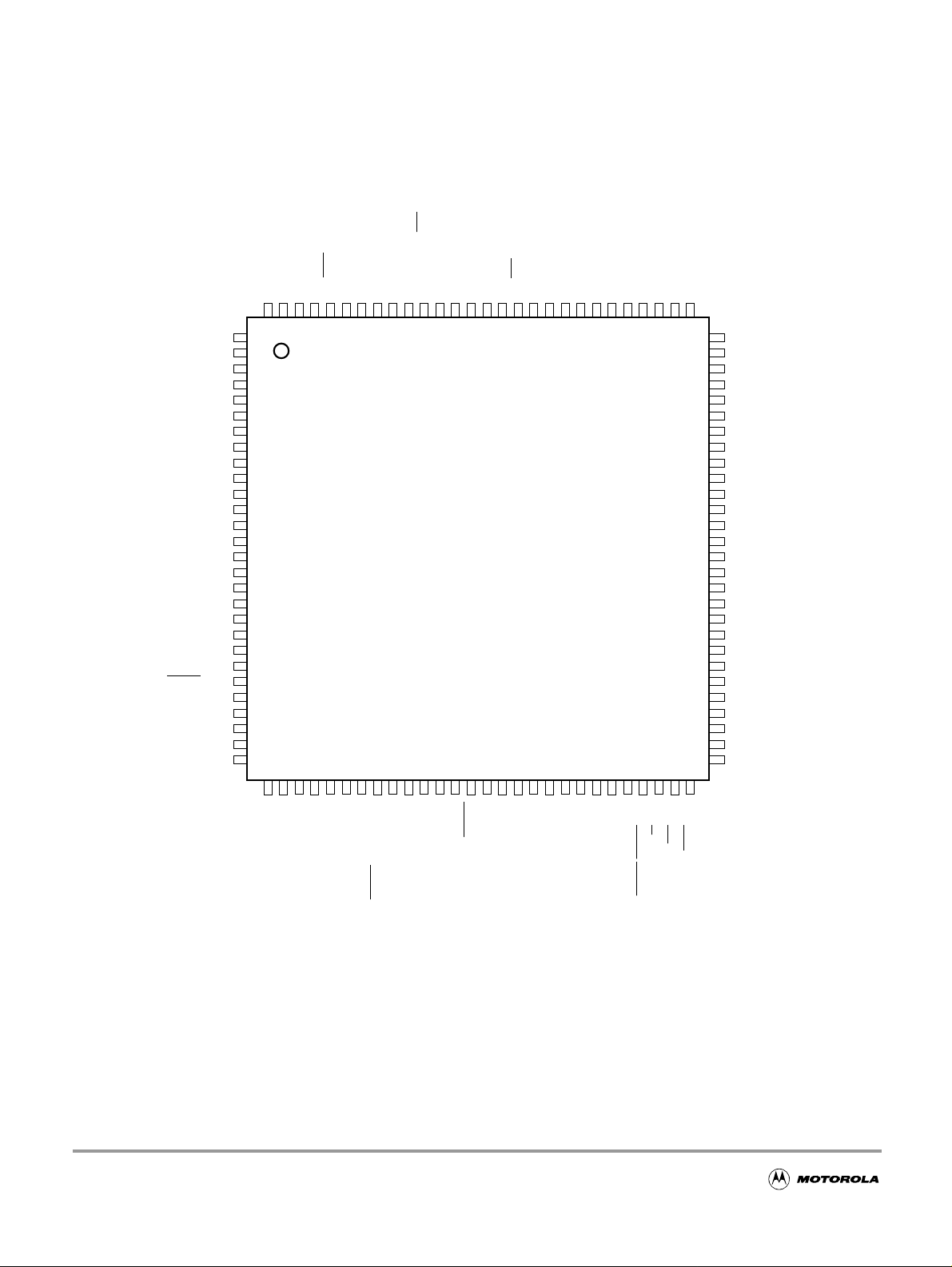

Figure 2-1 Pin Assignments in 112-pin LQFP for MC9S12DJ64 . . . . . . . . . . . . . . . . . . . . .50

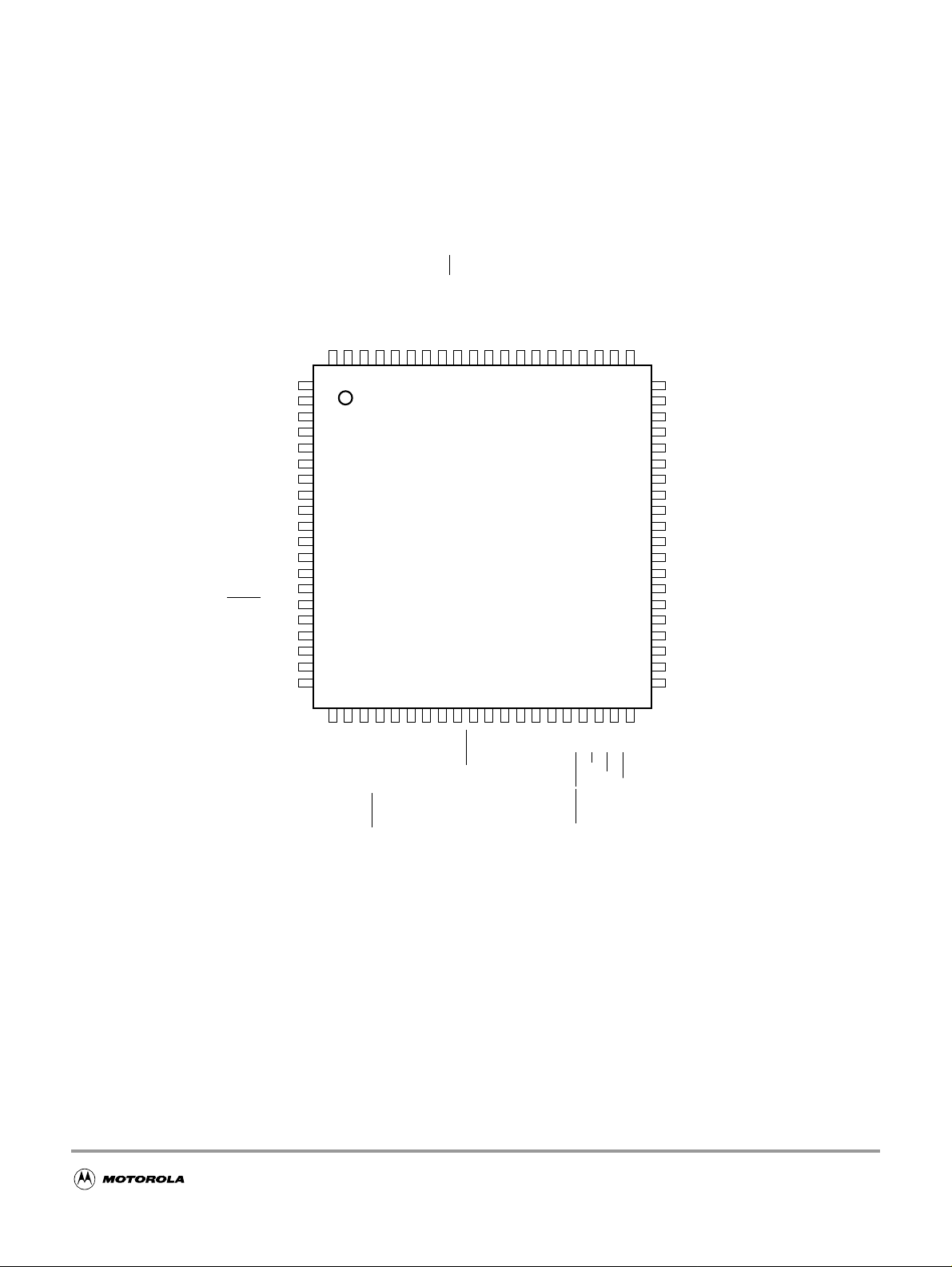

Figure 2-2 Pin Assignments in 80-pin QFP for MC9S12DJ64 . . . . . . . . . . . . . . . . . . . . . . .51

Figure 2-3 PLL Loop Filter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Figure 2-4 Colpitts Oscillator Connections (PE7=1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Figure 2-5 Pierce Oscillator Connections (PE7=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Figure 2-6 External Clock Connections (PE7=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Figure 3-1 Clock Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Figure 22-1 Recommended PCB Layout 112LQFP Colpitts Oscillator. . . . . . . . . . . . . . . . . .80

Figure 22-2 Recommended PCB Layout for 80QFP Colpitts Oscillator . . . . . . . . . . . . . . . . .81

Figure 22-3 Recommended PCB Layout for 112LQFP Pierce Oscillator . . . . . . . . . . . . . . . .82

Figure 22-4 Recommended PCB Layout for 80QFP Pierce Oscillator . . . . . . . . . . . . . . . . . .83

Figure A-1 ATD Accuracy Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure A-2 Basic PLL functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure A-3 Jitter Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure A-4 Maximum bus clock jitter approximation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure A-5 SPI Master Timing (CPHA = 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure A-6 SPI Master Timing (CPHA =1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure A-7 SPI Slave Timing (CPHA = 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure A-8 SPI Slave Timing (CPHA =1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure A-9 General External Bus Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure B-1 112-pin LQFP mechanical dimensions (case no. 987) . . . . . . . . . . . . . . . . . . 122

Figure B-2 80-pin QFP Mechanical Dimensions (case no. 841B). . . . . . . . . . . . . . . . . . . 123

11

Page 12

MC9S12DJ64 Device User Guide — V01.17

12

Page 13

MC9S12DJ64 Device User Guide — V01.17

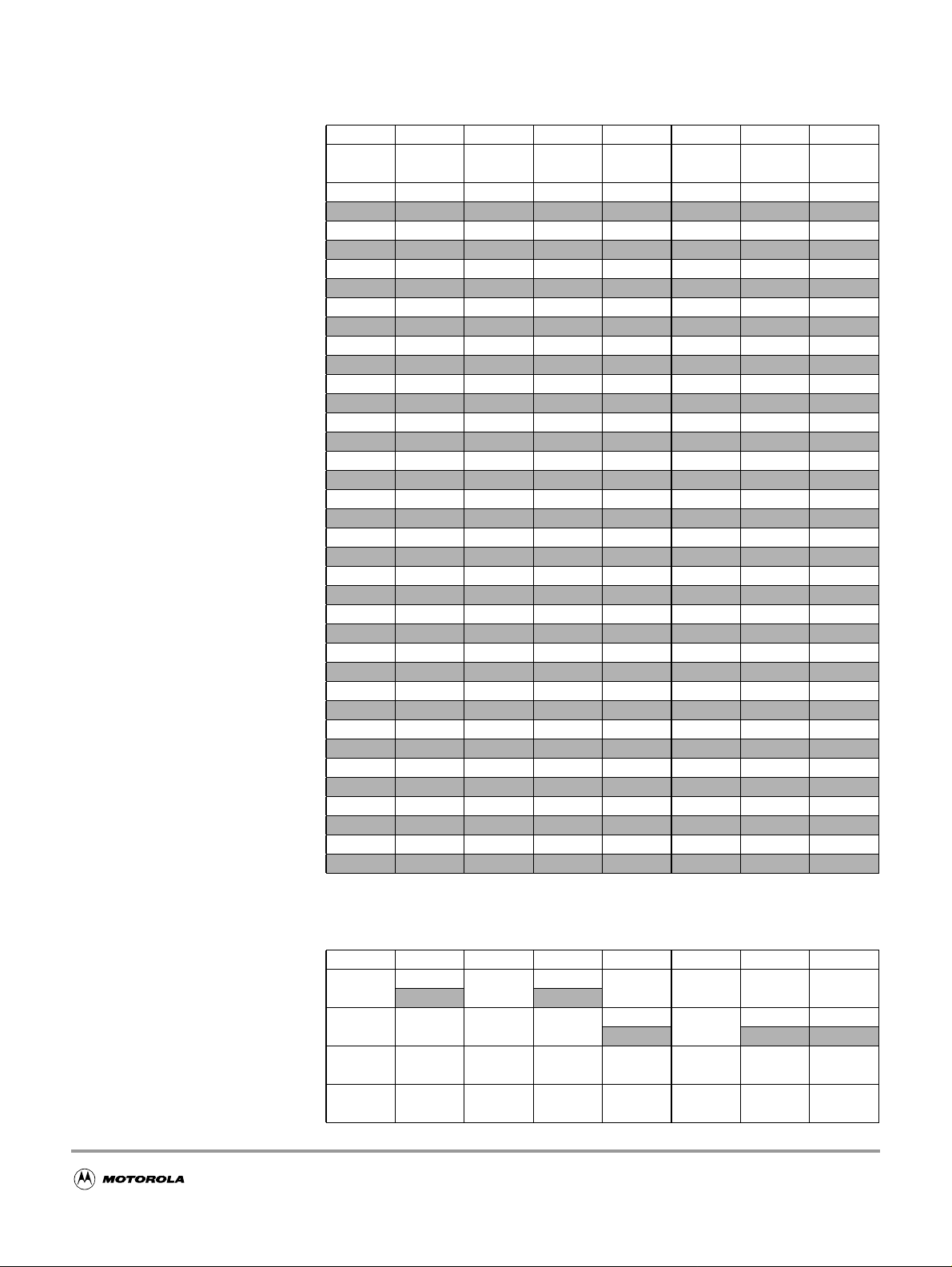

List of Tables

Table 0-1 Derivative Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table 0-2 Document References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 1-1 Device Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

$0000 - $000F MEBI map 1 of 3 (HCS12 Multiplexed External Bus Interface) ................28

$0010 - $0014 MMC map 1 of 4 (HCS12 Module Mapping Control) ...............................28

$0015 - $0016 INT map 1 of 2 (HCS12 Interrupt) ............................................................29

$0017 - $0019 Reserved ..................................................................................................29

$001A - $001B Device ID Register (Table 1-3) ................................................................29

$001C - $001D MMC map 3 of 4 (HCS12 Module Mapping Control, Table 1-4) ..............29

$001E - $001E MEBI map 2 of 3 (HCS12 Multiplexed External Bus Interface) ................29

$001F - $001F INT map 2 of 2 (HCS12 Interrupt) ............................................................29

$0020 - $0027 Reserved ..................................................................................................29

$0028 - $002F BKP (HCS12 Breakpoint) .........................................................................30

$0030 - $0031 MMC map 4 of 4 (HCS12 Module Mapping Control) ...............................30

$0032 - $0033 MEBI map 3 of 3 (HCS12 Multiplexed External Bus Interface) ................30

$0034 - $003F CRG (Clock and Reset Generator) ..........................................................30

$0040 - $007F ECT (Enhanced Capture Timer 16 Bit 8 Channels) .................................31

$0080 - $009F ATD0 (Analog to Digital Converter 10 Bit 8 Channel) ..............................34

$00A0 - $00C7 PWM (Pulse Width Modulator 8 Bit 8 Channel) .......................................35

$00C8 - $00CF SCI0 (Asynchronous Serial Interface) ......................................................37

$00D0 - $00D7 SCI1 (Asynchronous Serial Interface) ......................................................37

$00D8 - $00DF SPI0 (Serial Peripheral Interface) ............................................................37

$00E0 - $00E7 IIC (Inter IC Bus) ......................................................................................38

$00E8 - $00EF BDLC (Bytelevel Data Link Controller J1850) ..........................................38

$00F0 - $00FF Reserved ..................................................................................................39

$0100 - $010F Flash Control Register (fts64k) ................................................................39

$0110 - $011B EEPROM Control Register (eets1k) ........................................................39

$011C - $011F Reserved for RAM Control Register ........................................................40

$0120 - $013F ATD1 (Analog to Digital Converter 10 Bit 8 Channel) ..............................40

$0140 - $017F CAN0 (Motorola Scalable CAN - MSCAN) ..............................................41

Table 1-2 Detailed MSCAN Foreground Receive and Transmit Buffer Layout . . . . . . . . . . .42

$0180 - $023F Reserved ..................................................................................................43

$0240 - $027F PIM (Port Integration Module) ..................................................................44

13

Page 14

MC9S12DJ64 Device User Guide — V01.17

$0280 - $03FF Reserved ..................................................................................................46

Table 1-3 Assigned Part ID Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 1-4 Memory size registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 2-1 Signal Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Table 2-2 MC9S12DJ64 Power and Ground Connection Summary . . . . . . . . . . . . . . . . . . .62

Table 4-1 Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Table 4-2 Clock Selection Based on PE7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Table 4-3 Voltage Regulator VREGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table 5-1 Interrupt Vector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 22-1 Suggested External Component Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Table A-1 Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table A-2 ESD and Latch-up Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table A-3 ESD and Latch-Up Protection Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table A-4 Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Table A-5 Thermal Package Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Table A-6 5V I/O Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Table A-7 Supply Current Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Table A-8 ATD Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Table A-9 ATD Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Table A-10 ATD Conversion Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Table A-11 NVM Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Table A-12 NVM Reliability Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Table A-13 Voltage Regulator Recommended Load Capacitances . . . . . . . . . . . . . . . . . . .103

Table A-14 Startup Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Table A-15 Oscillator Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Table A-16 PLL Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Table A-17 MSCAN Wake-up Pulse Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Table A-18 SPI Master Mode Timing Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Table A-19 SPI Slave Mode Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Table A-20 Expanded Bus Timing Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

14

Page 15

MC9S12DJ64 Device User Guide — V01.17

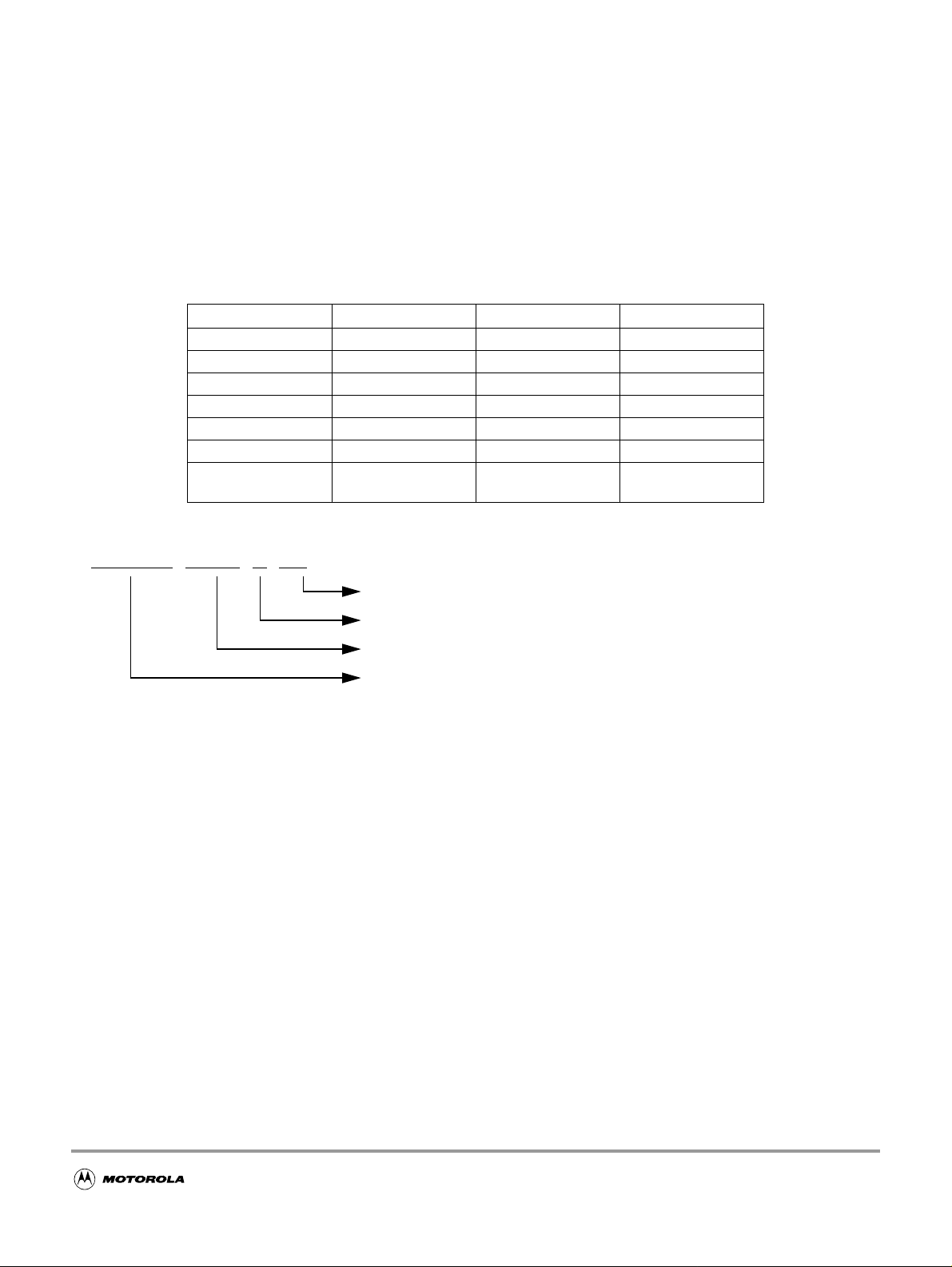

Derivative Differences and Document References

Derivative Differences

Table 0-1 shows the availability of peripheral modules on the various derivatives. For details about the

compatibility within the MC9S12D-Family refer also to engineering bulletin EB386.

Table 0-1 Derivative Differences

Generic device MC9S12DJ64 MC9S12D64 MC9S12A64

CAN0 1 1 0

J1850/BDLC 1 0 0

Packages 112LQFP, 80QFP 112LQFP, 80QFP 112LQFP, 80QFP

Mask Set L86D L86D L86D

Temp Options M, V, C M, V, C C

Package Codes PV, FU PV, FU PV, FU

Note

An errata exists

contact Sales office

An errata exists

contact Sales office

An errata exists

contact Sales office

MC9S12 DJ64 C FU

Package Option

Temperature Option

Device Title

Controller Family

Figure 0-1 Order Partnumber Example

The following items should be considered when using a derivative.

• Registers

– Do not write or read CAN0 registers (after reset: address range $0140 - $017F), if using a

derivative without CAN0 (see Table 0-1).

– Do not write or read BDLC registers (after reset: address range $00E8 - $00EF), if using a

derivative without BDLC (see Table 0-1).

• Interrupts

– Fill the four CAN0 interrupt vectors ($FFB0 - $FFB7) according to your coding policies for

unused interrupts, if using a derivative without CAN0 (see Table 0-1).

Temperature Options

C = -40˚C to 85˚C

V = -40˚C to 105˚C

M = -40˚C to 125˚C

Package Options

FU = 80QFP

PV = 112LQFP

– Fill the BDLC interrupt vector ($FFC2, $FFC3) according to your coding policies for unused

interrupts, if using a derivative without BDLC (see Table 0-1).

• Ports

15

Page 16

MC9S12DJ64 Device User Guide — V01.17

– The CAN0 pin functionality (TXCAN0, RXCAN0) is not available on port PJ7, PJ6, PM5,

PM4, PM3, PM2, PM1 and PM0, if using a derivative without CAN0 (see Table 0-1).

– The BDLC pin functionality (TXB, RXB) is not available on port PM1 and PM0, if using a

derivative without BDLC (see Table 0-1).

– Do not write MODRR1 and MODRR0 Bit of Module Routing Register (PIM_9DJ64 Block

User Guide), if using a derivative without CAN0 (see Table 0-1).

• Pins not available in 80 pin QFP package

– Port H

In order to avoid floating nodes the ports should be either configured as outputs by setting the

data direction register (DDRH at Base+$0262) to $FF, or enabling the pull resistors by writing

a $FF to the pull enable register (PERH at Base+$0264).

– Port J[1:0]

PortJpull-up resistors areenabled out ofreseton all fourpins(7:6 and1:0).Therefore care must

be taken not to disable the pull enables on PJ[1:0] by clearing the bits PERJ1 and PERJ0 at

Base+$026C.

– Port K

Port K pull-up resistors are enabled out of reset, i.e. Bit 7 = PUKE = 1 in the register PUCR at

Base+$000C. Therefor care must be taken not to clear this bit.

– Port M[7:6]

PM7:6 must be configured as outputs or their pull resistors must be enabled to avoid floating

inputs.

– Port P6

PP6 must be configured as output or its pull resistor must be enabled to avoid a floating input.

– Port S[7:4]

PS7:4 must be configured as outputs or their pull resistors must be enabled to avoid floating

inputs.

– PAD[15:8] (ATD1 channels)

Out ofresetthe ATD1 is disabledpreventingcurrent flows in the pins.Donot modify the ATD1

registers!

Document References

The Device User Guide providesinformationabouttheMC9S12DJ64 device made up of standard HCS12

blocks and the HCS12 processor core.

This document is part of the customer documentation. A complete set of device manuals also includes all

the individual Block Guides of the implemented modules. In a effort to reduce redundancy all module

specific information is located only in the respective Block Guide. If applicable, special implementation

details of the module are given in the block description sections of this document.

See Table 0-2 for names and versions of the referenced documents throughout the Device User Guide.

16

Page 17

MC9S12DJ64 Device User Guide — V01.17

Table 0-2 Document References

User Guide

HCS12 CPU Reference Manual V02 S12CPUV2/D

HCS12 Module Mapping Control (MMC) Block Guide V04 S12MMCV4/D

HCS12 Multiplexed External Bus Interface (MEBI) Block Guide V03 S12MEBIV3/D

HCS12 Interrupt (INT) Block Guide V01 S12INTV1/D

HCS12 Background Debug (BDM) Block Guide V04 S12BDMV4/D

HCS12 Breakpoint (BKP) Block Guide V01 S12BKPV1/D

Clock and Reset Generator (CRG) Block User Guide V04 S12CRGV4/D

Oscillator (OSC) Block User Guide V02 S12OSCV2/D

Enhanced Capture Timer 16 Bit 8 Channel (ECT_16B8C) Block User Guide V01 S12ECT16B8CV1/D

Analog to Digital Converter 10 Bit 8 Channel (ATD_10B8C) Block User Guide V02 S12ATD10B8CV2/D

Inter IC Bus (IIC) Block User Guide V02 S12IICV2/D

Asynchronous Serial Interface (SCI) Block User Guide V02 S12SCIV2/D

Serial Peripheral Interface (SPI) Block User Guide V02 S12SPIV2/D

Pulse Width Modulator 8 Bit 8 Channel (PWM_8B8C) Block User Guide V01 S12PWM8B8CV1/D

64K Byte Flash (FTS64K) Block User Guide V01 S12FTS64KV1/D

1K Byte EEPROM (EETS1K) Block User Guide V01 S12EETS1KV1/D

Byte Level Data Link Controller -J1850 (BDLC) Block User Guide V01 S12BDLCV1/D

Motorola Scalable CAN (MSCAN) Block User Guide V02 S12MSCANV2/D

Voltage Regulator (VREG) Block User Guide V01 S12VREGV1/D

Port Integration Module (PIM_9DJ64) Block User Guide V01 S12PIM9DJ64V1/D

Versi

on

Document Order Number

17

Page 18

MC9S12DJ64 Device User Guide — V01.17

18

Page 19

MC9S12DJ64 Device User Guide — V01.17

Section 1 Introduction

1.1 Overview

The MC9S12DJ64 microcontroller unit (MCU) is a 16-bit device composed of standard on-chip

peripherals including a 16-bit central processing unit (HCS12 CPU), 64K bytes of Flash EEPROM, 4K

bytes of RAM, 1K bytes of EEPROM, two asynchronous serial communications interfaces (SCI), one

serial peripheral interfaces (SPI), an 8-channel IC/OC enhanced capture timer, two 8-channel, 10-bit

analog-to-digital converters(ADC),an 8-channel pulse-width modulator(PWM),a digital Byte Data Link

Controller (BDLC), 29 discrete digital I/O channels (Port A, Port B, Port K and Port E), 20 discrete digital

I/O lines with interrupt and wakeup capability, a CAN 2.0 A, B software compatible modules

(MSCAN12), and an Inter-IC Bus. The MC9S12DJ64 has full 16-bit datapaths throughout. However, the

external bus can operate in an 8-bit narrow mode so single 8-bit wide memory can be interfaced for lower

cost systems. The inclusion of a PLL circuit allows power consumption and performance to be adjusted to

suit operational requirements.

1.2 Features

• HCS12 Core

– 16-bit HCS12 CPU

i. Upward compatible with M68HC11 instruction set

ii. Interrupt stacking and programmer’s model identical to M68HC11

iii.Instruction queue

iv.Enhanced indexed addressing

– MEBI (Multiplexed External Bus Interface)

– MMC (Module Mapping Control)

– INT (Interrupt control)

– BKP (Breakpoints)

– BDM (Background Debug Mode)

• CRG (low current Colpitts or Pierce oscillator, PLL, reset, clocks, COP watchdog, real time

interrupt, clock monitor)

• 8-bit and 4-bit ports with interrupt functionality

– Digital filtering

– Programmable rising or falling edge trigger

• Memory

– 64K Flash EEPROM

– 1K byte EEPROM

19

Page 20

MC9S12DJ64 Device User Guide — V01.17

– 4K byte RAM

• Two 8-channel Analog-to-Digital Converters

– 10-bit resolution

– External conversion trigger capability

• 1M bit per second, CAN 2.0 A, B software compatible module

– Five receive and three transmit buffers

– Flexible identifier filter programmable as 2 x 32 bit, 4 x 16 bit or 8 x 8 bit

– Four separate interrupt channels for Rx, Tx, error and wake-up

– Low-pass filter wake-up function

– Loop-back for self test operation

• Enhanced Capture Timer

– 16-bit main counter with 7-bit prescaler

– 8 programmable input capture or output compare channels

– Four 8-bit or two 16-bit pulse accumulators

• 8 PWM channels

– Programmable period and duty cycle

– 8-bit 8-channel or 16-bit 4-channel

– Separate control for each pulse width and duty cycle

– Center-aligned or left-aligned outputs

– Programmable clock select logic with a wide range of frequencies

– Fast emergency shutdown input

– Usable as interrupt inputs

• Serial interfaces

– Two asynchronous Serial Communications Interfaces (SCI)

– Synchronous Serial Peripheral Interface (SPI)

• Byte Data Link Controller (BDLC)

– SAE J1850 Class B Data Communications Network Interface Compatible and ISO Compatible

for Low-Speed (<125 Kbps) Serial Data Communications in Automotive Applications

• Inter-IC Bus (IIC)

– Compatible with I2C Bus standard

– Multi-master operation

– Software programmable for one of 256 different serial clock frequencies

• 112-Pin LQFP or 80 QFP package

20

Page 21

– I/O lines with 5V input and drive capability

– 5V A/D converter inputs

– Operation at 50MHz equivalent to 25MHz Bus Speed

– Development support

– Single-wire background debug™ mode (BDM)

– On-chip hardware breakpoints

1.3 Modes of Operation

User modes

• Normal and Emulation Operating Modes

– Normal Single-Chip Mode

– Normal Expanded Wide Mode

– Normal Expanded Narrow Mode

MC9S12DJ64 Device User Guide — V01.17

– Emulation Expanded Wide Mode

– Emulation Expanded Narrow Mode

• Special Operating Modes

– Special Single-Chip Mode with active Background Debug Mode

– Special Test Mode (Motorola use only)

– Special Peripheral Mode (Motorola use only)

Low power modes

• Stop Mode

• Pseudo Stop Mode

• Wait Mode

21

Page 22

MC9S12DJ64 Device User Guide — V01.17

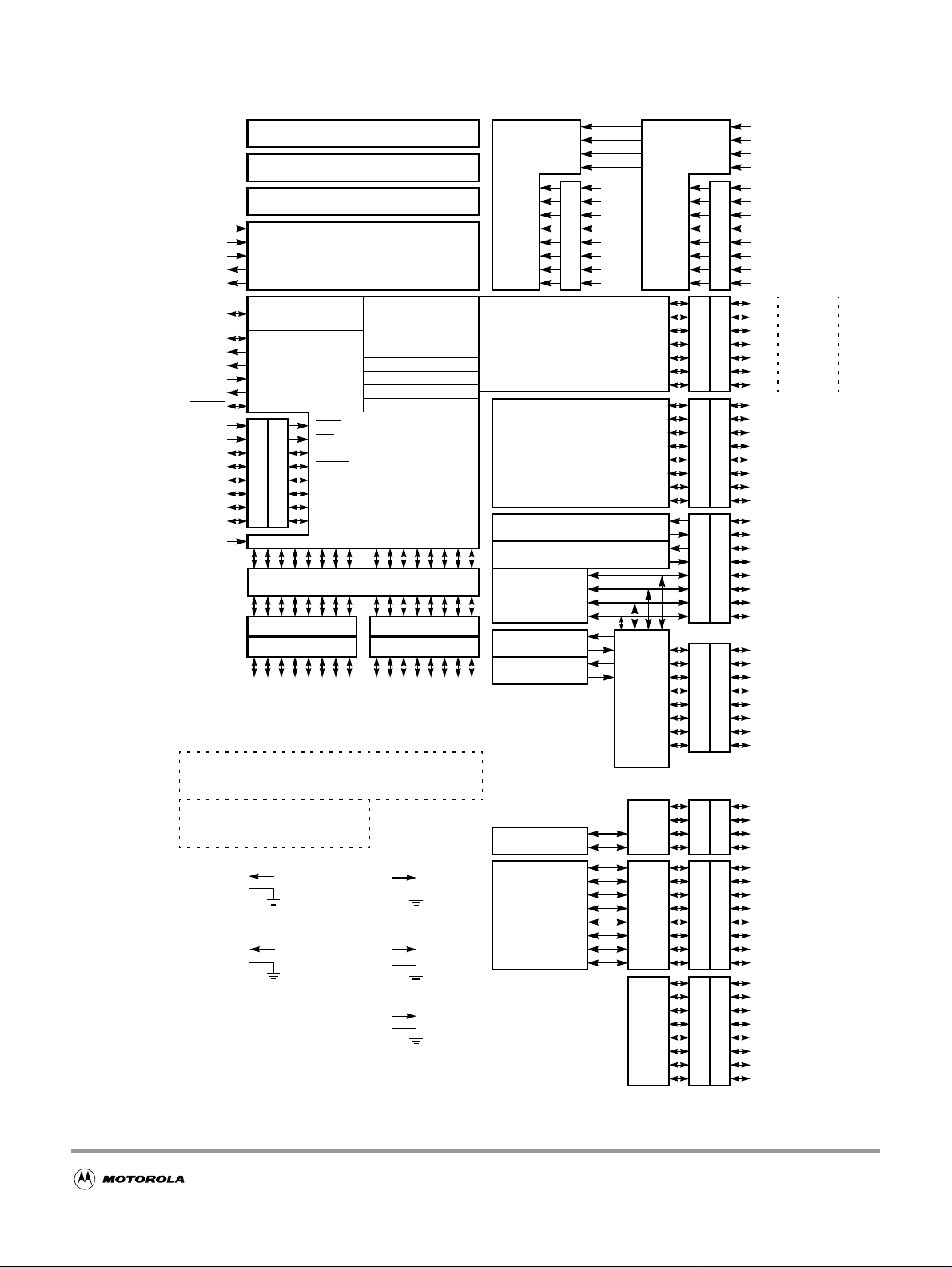

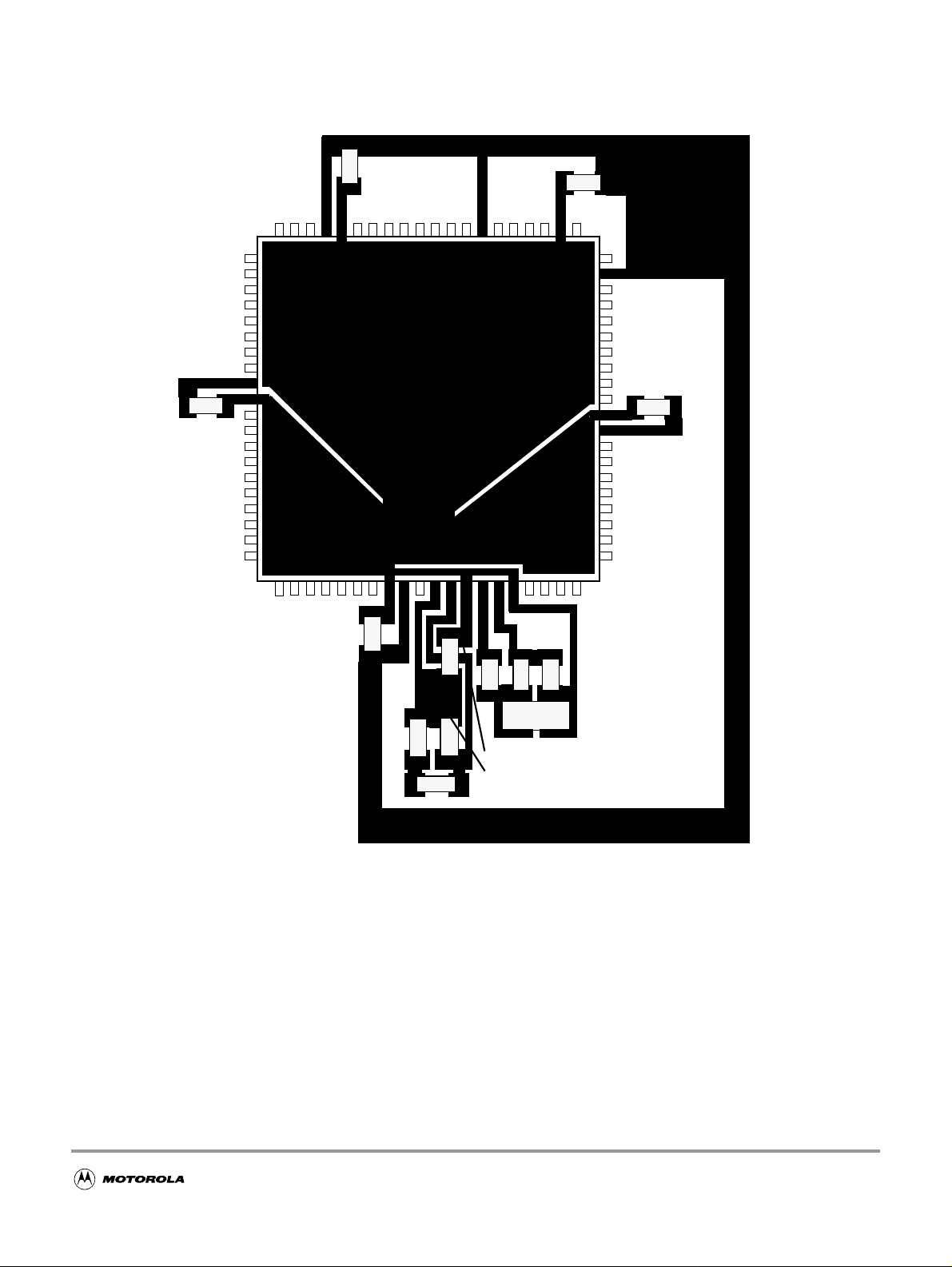

1.4 Block Diagram

Figure 1-1 shows a block diagram of the MC9S12DJ64 device.

22

Page 23

MC9S12DJ64 Device User Guide — V01.17

Figure 1-1 MC9S12DJ64 Block Diagram

VDDR

VSSR

VREGEN

VDD1,2

VSS1,2

BKGD

XFC

VDDPLL

VSSPLL

EXTAL

XTAL

RESET

PE0

PE1

PE2

PE3

PE4

PE5

PE6

PE7

TEST

Multiplexed

Wide Bus

Multiplexed

Narrow Bus

Internal Logic 2.5V

VDD1,2

VSS1,2

PLL 2.5V

VDDPLL

VSSPLL

64K Byte Flash EEPROM

4K Byte RAM

1K Byte EEPROM

Voltage Regulator

Single-wire Background

Debug Module

Clock and

Reset

PLL

Generation

Module

XIRQ

IRQ

W

R/

LSTRB

DDRE

ECLK

MODA

MODB

NOACC/

XCLKS

PTE

Multiplexed Address/Data Bus

DDRA DDRB

PTA PTB

PA4

PA3

PA2

PA1

ADDR11

ADDR10

ADDR9

DATA11

DATA10

DATA9

DATA3

DATA2

DATA1

PA0

ADDR8

DATA8

DATA0

PA7

PA6

PA5

ADDR15

ADDR14

ADDR13

DATA15

DATA14

DATA13

DATA7

DATA6

DATA5

ADDR12

DATA12

DATA4

I/O Driver 5V

VDDX

VSSX

A/D Converter 5V &

Voltage Regulator Reference

VDDA

VSSA

Voltage Regulator 5V & I/O

VDDR

VSSR

CPU12

Periodic Interrupt

COP Watchdog

Clock Monitor

Breakpoints

System

Integration

PB4

PB3

PB5

ADDR4

ADDR5

DATA4

DATA5

PB2

ADDR3

ADDR2

DATA3

DATA2

PB7

PB6

ADDR7

ADDR6

DATA7

DATA6

PB1

PB0

ADDR1

ADDR0

DATA1

DATA0

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

VRH

VRL

VDDA

VSSA

AD0

ATD0

PPAGE

Enhanced Capture

Timer

SCI0

SCI1

MISO

MOSI

SPI0

BDLC

(J1850)

CAN0

IIC

PWM

SCK

SS

RXB

TXB

RXCAN

TXCAN

SDA

SCL

PWM0

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

PWM7

ATD1

PAD00

PAD01

PAD02

PAD03

PAD04

PAD05

PAD06

PAD07

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

PIX0

PIX1

PIX2

PIX3

PIX4

PIX5

ECS

IOC0

IOC1

IOC2

IOC3

IOC4

IOC5

IOC6

IOC7

RXD

TXD

RXD

TXD

Module to Port Routing

KWJ0

KWJ1

KWJ6

KWJ7

KWP0

KWP1

KWP2

KWP3

KWP4

KWP5

KWP6

KWP7

KWH0

KWH1

KWH2

KWH3

KWH4

KWH5

KWH6

KWH7

VRH

VRL

VDDA

VSSA

DDRK

DDRT

DDRS

DDRM

DDRJ

DDRP

DDRH

AD1

PTK

PTT

PTS

PTM

PTJ

PTP

PTH

VRH

VRL

VDDA

VSSA

PAD08

PAD09

PAD10

PAD11

PAD12

PAD13

PAD14

PAD15

PK0

PK1

PK2

PK3

PK4

PK5

PK7

PT0

PT1

PT2

PT3

PT4

PT5

PT6

PT7

PS0

PS1

PS2

PS3

PS4

PS5

PS6

PS7

PM0

PM1

PM2

PM3

PM4

PM5

PM6

PM7

PJ0

PJ1

PJ6

PJ7

PP0

PP1

PP2

PP3

PP4

PP5

PP6

PP7

PH0

PH1

PH2

PH3

PH4

PH5

PH6

PH7

XADDR14

XADDR15

XADDR16

XADDR17

XADDR18

XADDR19

ECS

Signals shown in Bold are not available on the 80 Pin Package

23

Page 24

MC9S12DJ64 Device User Guide — V01.17

24

Page 25

MC9S12DJ64 Device User Guide — V01.17

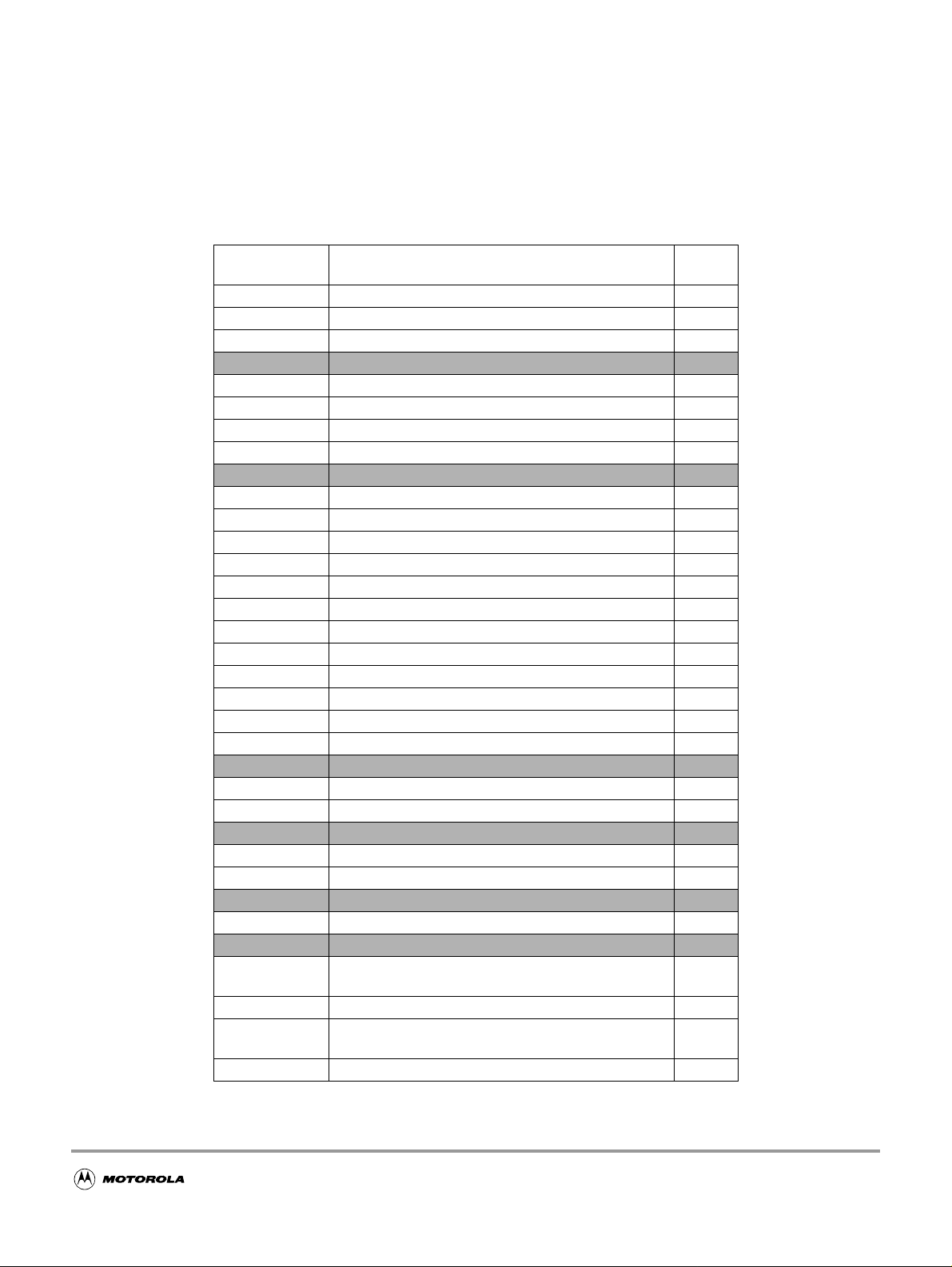

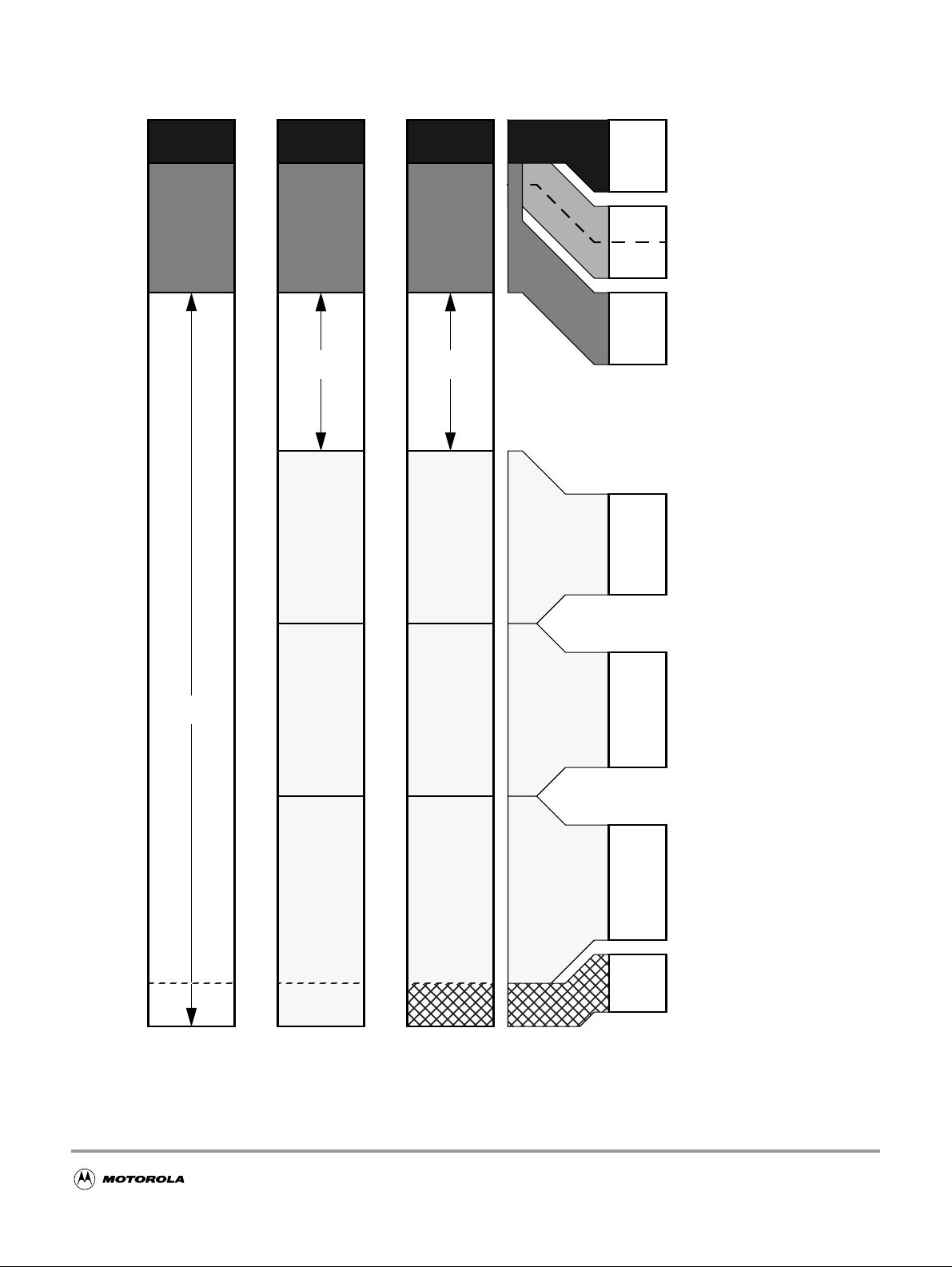

1.5 Device Memory Map

Table 1-1 and Figure 1-2 show the device memory map of the MC9S12DJ64 after reset. The 1K

EEPROM is mapped twice in a 2K address space. Note that after reset the bottom 1k of the EEPROM

($0000 - $03FF) are hidden by the register space, and the 1K $0400 - $07FF is hidden by the RAM.

Table 1-1 Device Memory Map

Address Module

$0000 - $000F HCS12 Multiplexed External Bus Interface 16

$0010 - $0014 HCS12 Module Mapping Control 5

$0015 - $0016 HCS12 Interrupt 2

$0017 - $0019 Reserved 3

$001A - $001B Device ID register (PARTID) 2

$001C - $001D HCS12 Module Mapping Control 2

$001E HCS12 Multiplexed External Bus Interface 1

$001F HCS12 Interrupt 1

$0020 - $0027 Reserved 8

$0028 - $002F HCS12 Breakpoint Module 8

$0030 - $0031 HCS12 Module Mapping Control 2

$0032 - $0033 HCS12 Multiplexed External Bus Interface 2

$0034 - $003F Clock and Reset Generator (PLL, RTI, COP) 12

$0040 - $007F Enhanced Capture Timer 16-bit 8 channels 64

$0080 - $009F Analog to Digital Converter 10-bit 8 channels (ATD0) 32

$00A0 - $00C7 Pulse Width Modulator 8-bit 8 channels (PWM) 40

$00C8 - $00CF Serial Communications Interface 0 (SCI0) 8

$00D0 - $00D7 Serial Communications Interface 0 (SCI1) 8

$00D8 - $00DF Serial Peripheral Interface (SPI0) 8

$00E0 - $00E7 Inter IC Bus 8

$00E8 - $00EF Byte Data Link Controller (BDLC) 8

$00F0 - $00FF Reserved 16

$0100- $010F Flash Control Register 16

$0110 - $011B EEPROM Control Register 12

$011C - $011F Reserved 4

$0120 - $013F Analog to Digital Converter 10-bit 8 channels (ATD1) 32

$0140 - $017F Motorola Scalable Can (CAN0) 64

$0180 - $023F Reserved 192

$0240 - $027F Port Integration Module (PIM) 64

$0280 - $03FF Reserved 384

$0000 - $07FF

$0000 - $0FFF RAM array 4096

$4000 - $7FFF

$8000 - $BFFF Flash EEPROM Page Window 16384

EEPROM array 1k Array mapped twice in the

address space

Fixed Flash EEPROM array

incl. 0.5K, 1K, 2K or 4K Protected Sector at start

Size

(Bytes)

2048

16384

25

Page 26

MC9S12DJ64 Device User Guide — V01.17

Table 1-1 Device Memory Map

Address Module

Fixed Flash EEPROM array

$C000 - $FFFF

incl. 0.5K, 1K, 2K or 4K Protected Sector at end

and 256 bytes of Vector Space at $FF80 - $FFFF

Size

(Bytes)

16384

26

Page 27

MC9S12DJ64 Device User Guide — V01.17

Figure 1-2 MC9S12DJ64 Memory Map out of Reset

$0000

$0400

$0800

$1000

$4000

Unimplemented Unimplemented

$0000

$03FF

$0000

$07FF

$0000

$0FFF

$4000

$7FFF

REGISTERS

(Mappable to any 2K

Boundary within the

first 32K)

1K Bytes EEPROM

(Mappable to any 2K

Boundary; 1K mapped two

times in the 2K address

space)

4K Bytes RAM

(Mappable to any 4K

Boundary)

16K Fixed Flash

Page $3E = 62

(This is dependant on the

state of the ROMHM bit)

$8000

$C000

$FF00

$FFFF

EXTERN

VECTORS

EXPANDED

VECTORS

NORMAL

SINGLE CHIP

VECTORS

SPECIAL

SINGLE CHIP

$8000

16K Page Window

4 x 16K Flash EEPROM

pages

$BFFF

$C000

16K Fixed Flash

Page $3F = 63

$FFFF

$FF00

BDM

(if active)

$FFFF

27

Page 28

MC9S12DJ64 Device User Guide — V01.17

1.5.1 Detailed Register Map

$0000 - $000F MEBI map 1 of 3 (HCS12 Multiplexed External Bus Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0000 PORTA

$0001 PORTB

$0002 DDRA

$0003 DDRB

$0004 Reserved

$0005 Reserved

$0006 Reserved

$0007 Reserved

$0008 PORTE

$0009 DDRE

$000A PEAR

$000B MODE

$000C PUCR

$000D RDRIV

$000E EBICTL

$000F Reserved

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 0000000

Write:

Read: 00000000

Write:

Bit 7 654321Bit 0

Bit 7 654321Bit 0

Bit 7 654321Bit 0

Bit 7 654321Bit 0

Bit 7 65432

Bit 7 6543Bit 2

NOACCE

MODC MODB MODA

PUPKE

RDPK

0

00

00

PIPOE NECLK LSTRE RDWE

PUPEE

RDPE

0

IVIS

00

00

0

Bit 1 Bit 0

00

00

EMK EME

PUPBE PUPAE

RDPB RDPA

ESTR

$0010 - $0014 MMC map 1 of 4 (HCS12 Module Mapping Control)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0010 INITRM

$0011 INITRG

$0012 INITEE

$0013 MISC

$0014 Reserved

28

Read:

Write:

Read: 0

Write:

Read:

Write:

Read: 0000

Write:

Read: 00000000

Write:

RAM15 RAM14 RAM13 RAM12 RAM11

REG14 REG13 REG12 REG11

EE15 EE14 EE13 EE12 EE11

EXSTR1 EXSTR0 ROMHM ROMON

00

000

00

RAMHAL

EEON

Page 29

MC9S12DJ64 Device User Guide — V01.17

$0015 - $0016 INT map 1 of 2 (HCS12 Interrupt)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0015 ITCR

$0016 ITEST

Read: 0 0 0

Write:

Read:

Write:

INTE INTC INTA INT8 INT6 INT4 INT2 INT0

WRINT ADR3 ADR2 ADR1 ADR0

$0017 - $0019 Reserved

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0017 -

$0019

Reserved

Read: 00000000

Write:

$001A - $001B Device ID Register (Table 1-3)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$001A PARTIDH

$001B PARTIDL

Read: ID15 ID14 ID13 ID12 ID11 ID10 ID9 ID8

Write:

Read: ID7 ID6 ID5 ID4 ID3 ID2 ID1 ID0

Write:

$001C - $001D MMC map 3 of 4 (HCS12 Module Mapping Control, Table 1-4)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$001C MEMSIZ0

$001D MEMSIZ1

Read: reg_sw0 0 eep_sw1 eep_sw0 0 ram_sw2 ram_sw1 ram_sw0

Write:

Read: rom_sw1 rom_sw0 0000pag_sw1 pag_sw0

Write:

$001E - $001E MEBI map 2 of 3 (HCS12 Multiplexed External Bus Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$001E INTCR

Read:

Write:

IRQE IRQEN

000000

$001F - $001F INT map 2 of 2 (HCS12 Interrupt)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$001F HPRIO

Read:

Write:

PSEL7 PSEL6 PSEL5 PSEL4 PSEL3 PSEL2 PSEL1

0

$0020 - $0027 Reserved

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0020 -

$0027

Reserved

Read: 00000000

Write:

29

Page 30

MC9S12DJ64 Device User Guide — V01.17

$0028 - $002F BKP (HCS12 Breakpoint)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0028 BKPCT0

$0029 BKPCT1

$002A BKP0X

$002B BKP0H

$002C BKP0L

$002D BKP1X

$002E BKP1H

$002F BKP1L

Read:

Write:

Read:

Write:

Read: 0 0

Write:

Read:

Write:

Read:

Write:

Read: 0 0

Write:

Read:

Write:

Read:

Write:

BKEN BKFULL BKBDM BKTAG

BK0MBH BK0MBL BK1MBH BK1MBL BK0RWE BK0RW BK1RWE BK1RW

BK0V5 BK0V4 BK0V3 BK0V2 BK0V1 BK0V0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

BK1V5 BK1V4 BK1V3 BK1V2 BK1V1 BK1V0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

0000

$0030 - $0031 MMC map 4 of 4 (HCS12 Module Mapping Control)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0030 PPAGE

$0031 Reserved

Read: 0 0

Write:

Read: 00000000

Write:

PIX5 PIX4 PIX3 PIX2 PIX1 PIX0

$0032 - $0033 MEBI map 3 of 3 (HCS12 Multiplexed External Bus Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0032 PORTK

$0033 DDRK

Read:

Write:

Read:

Write:

Bit 7 654321Bit 0

Bit 7 654321Bit 0

$0034 - $003F CRG (Clock and Reset Generator)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0034 SYNR

$0035 REFDV

$0036

$0037 CRGFLG

$0038 CRGINT

CTFLG

TEST ONLY

Read: 0 0

Write:

Read: 0000

Write:

Read: 00000000

Write:

Read:

Write:

Read:

Write:

RTIF PORF

RTIE

00

SYN5 SYN4 SYN3 SYN2 SYN1 SYN0

REFDV3 REFDV2 REFDV1 REFDV0

0

LOCKIF

LOCKIE

LOCK TRACK

00

SCMIF

SCMIE

SCM

0

30

Page 31

MC9S12DJ64 Device User Guide — V01.17

$0034 - $003F CRG (Clock and Reset Generator)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0039 CLKSEL

$003A PLLCTL

$003B RTICTL

$003C COPCTL

$003D

$003E

$003F ARMCOP

FORBYP

TEST ONLY

CTCTL

TEST ONLY

Read:

Write:

Read:

Write:

Read: 0

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: 00000000

Write: Bit 7 654321Bit 0

PLLSEL PSTP SYSWAI ROAWAI PLLWAI CWAI RTIWAI COPWAI

CME PLLON AUTO ACQ

RTR6 RTR5 RTR4 RTR3 RTR2 RTR1 RTR0

WCOP RSBCK

000

0

PRE PCE SCME

CR2 CR1 CR0

$0040 - $007F ECT (Enhanced Capture Timer 16 Bit 8 Channels)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0040 TIOS

$0041 CFORC

$0042 OC7M

$0043 OC7D

$0044 TCNT (hi)

$0045 TCNT (lo)

$0046 TSCR1

$0047 TTOV

$0048 TCTL1

$0049 TCTL2

$004A TCTL3

$004B TCTL4

$004C TIE

$004D TSCR2

$004E TFLG1

$004F TFLG2

Read:

Write:

Read: 00000000

Write: FOC7 FOC6 FOC5 FOC4 FOC3 FOC2 FOC1 FOC0

Read:

Write:

Read:

Write:

Read: Bit 15 14 13 12 11 10 9 Bit 8

Write:

Read: Bit 7 654321Bit 0

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

IOS7 IOS6 IOS5 IOS4 IOS3 IOS2 IOS1 IOS0

OC7M7 OC7M6 OC7M5 OC7M4 OC7M3 OC7M2 OC7M1 OC7M0

OC7D7 OC7D6 OC7D5 OC7D4 OC7D3 OC7D2 OC7D1 OC7D0

TEN TSWAI TSFRZ TFFCA

TOV7 TOV6 TOV5 TOV4 TOV3 TOV2 TOV1 TOV0

OM7 OL7 OM6 OL6 OM5 OL5 OM4 OL4

OM3 OL3 OM2 OL2 OM1 OL1 OM0 OL0

EDG7B EDG7A EDG6B EDG6A EDG5B EDG5A EDG4B EDG4A

EDG3B EDG3A EDG2B EDG2A EDG1B EDG1A EDG0B EDG0A

C7I C6I C5I C4I C3I C2I C1I C0I

TOI

C7F C6F C5F C4F C3F C2F C1F C0F

TOF

000

0000000

0000

TCRE PR2 PR1 PR0

31

Page 32

MC9S12DJ64 Device User Guide — V01.17

$0040 - $007F ECT (Enhanced Capture Timer 16 Bit 8 Channels)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0050 TC0 (hi)

$0051 TC0 (lo)

$0052 TC1 (hi)

$0053 TC1 (lo)

$0054 TC2 (hi)

$0055 TC2 (lo)

$0056 TC3 (hi)

$0057 TC3 (lo)

$0058 TC4 (hi)

$0059 TC4 (lo)

$005A TC5 (hi)

$005B TC5 (lo)

$005C TC6 (hi)

$005D TC6 (lo)

$005E TC7 (hi)

$005F TC7 (lo)

$0060 PACTL

$0061 PAFLG

$0062 PACN3 (hi)

$0063 PACN2 (lo)

$0064 PACN1 (hi)

$0065 PACN0 (lo)

$0066 MCCTL

$0067 MCFLG

$0068 ICPAR

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 0

Write:

Read: 000000

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write: ICLAT FLMC

Read:

Write:

Read: 0000

Write:

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

PAEN PAMOD PEDGE CLK1 CLK0 PAOVI PAI

PAOVF PAIF

Bit 7 654321Bit 0

Bit 7 654321Bit 0

Bit 7 654321Bit 0

Bit 7 654321Bit 0

MCZI MODMC RDMCL

MCZF

0 0 0 POLF3 POLF2 POLF1 POLF0

00

PA3EN PA2EN PA1EN PA0EN

MCEN MCPR1 MCPR0

32

Page 33

MC9S12DJ64 Device User Guide — V01.17

$0040 - $007F ECT (Enhanced Capture Timer 16 Bit 8 Channels)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0069 DLYCT

$006A ICOVW

$006B ICSYS

$006C Reserved

$006D

$006E Reserved

$006F Reserved

$0070 PBCTL

$0071 PBFLG

$0072 PA3H

$0073 PA2H

$0074 PA1H

$0075 PA0H

$0076 MCCNT (hi)

$0077 MCCNT (lo)

$0078 TC0H (hi)

$0079 TC0H (lo)

$007A TC1H (hi)

$007B TC1H (lo)

$007C TC2H (hi)

$007D TC2H (lo)

$007E TC3H (hi)

$007F TC3H (lo)

TIMTST

Test Only

Read: 000000

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 000000

Write:

Read:

Write:

Read:

Write:

Read: 0

Write:

Read: 000000

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 7 654321Bit 0

Write:

Read:

Write:

Read:

Write:

Read: Bit 15 14 13 12 11 10 9 Bit 8

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 15 14 13 12 11 10 9 Bit 8

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 15 14 13 12 11 10 9 Bit 8

Write:

Read: Bit 7 654321Bit 0

Write:

Read: Bit 15 14 13 12 11 10 9 Bit 8

Write:

Read: Bit 7 654321Bit 0

Write:

NOVW7 NOVW6 NOVW5 NOVW4 NOVW3 NOVW2 NOVW1 NOVW0

SH37 SH26 SH15 SH04 TFMOD PACMX BUFEN LATQ

PBEN

Bit 15 14 13 12 11 10 9 Bit 8

Bit 7 654321Bit 0

0000

DLY1 DLY0

TCBYP

PBOVI

PBOVF

0

0

0

33

Page 34

MC9S12DJ64 Device User Guide — V01.17

$0080 - $009F ATD0 (Analog to Digital Converter 10 Bit 8 Channel)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0080 ATD0CTL0

$0081 ATD0CTL1

$0082 ATD0CTL2

$0083 ATD0CTL3

$0084 ATD0CTL4

$0085 ATD0CTL5

$0086 ATD0STAT0

$0087 Reserved

$0088 ATD0TEST0

$0089 ATD0TEST1

$008A Reserved

$008B ATD0STAT1

$008C Reserved

$008D ATD0DIEN

$008E Reserved

$008F PORTAD0

$0090 ATD0DR0H

$0091 ATD0DR0L

$0092 ATD0DR1H

$0093 ATD0DR1L

$0094 ATD0DR2H

$0095 ATD0DR2L

$0096 ATD0DR3H

$0097 ATD0DR3L

$0098 ATD0DR4H

Read: 00000000

Write:

Read: 00000000

Write:

Read:

Write:

Read: 0

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: 0000000

Write:

Read: 00000000

Write:

Read: CCF7 CCF6 CCF5 CCF4 CCF3 CCF2 CCF1 CCF0

Write:

Read: 00000000

Write:

Read:

Write:

Read: 00000000

Write:

Read: Bit7 654321BIT 0

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

ADPU AFFC AWAI ETRIGLE ETRIGP ETRIG ASCIE

S8C S4C S2C S1C FIFO FRZ1 FRZ0

SRES8 SMP1 SMP0 PRS4 PRS3 PRS2 PRS1 PRS0

DJM DSGN SCAN MULT

SCF

Bit 7 654321Bit 0

0

ETORF FIFOR

0

0 CC2 CC1 CC0

CC CB CA

ASCIF

SC

34

Page 35

MC9S12DJ64 Device User Guide — V01.17

$0080 - $009F ATD0 (Analog to Digital Converter 10 Bit 8 Channel)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$0099 ATD0DR4L

$009A ATD0DR5H

$009B ATD0DR5L

$009C ATD0DR6H

$009D ATD0DR6L

$009E ATD0DR7H

$009F ATD0DR7L

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

Read: Bit15 14 13 12 11 10 9 Bit8

Write:

Read: Bit7 Bit6 000000

Write:

$00A0 - $00C7 PWM (Pulse Width Modulator 8 Bit 8 Channel)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00A0 PWME

$00A1 PWMPOL

$00A2 PWMCLK

$00A3 PWMPRCLK

$00A4 PWMCAE

$00A5 PWMCTL

$00A6

$00A7

$00A8 PWMSCLA

$00A9 PWMSCLB

$00AA

$00AB

$00AC PWMCNT0

$00AD PWMCNT1

$00AE PWMCNT2

$00AF PWMCNT3

PWMTST

Test Only

PWMPRSC

Test Only

PWMSCNTA

Test Only

PWMSCNTB

Test Only

Read:

Write:

Read:

Write:

Read:

Write:

Read: 0

Write:

Read:

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read:

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

PWME7 PWME6 PWME5 PWME4 PWME3 PWME2 PWME1 PWME0

PPOL7 PPOL6 PPOL5 PPOL4 PPOL3 PPOL2 PPOL1 PPOL0

PCLK7 PCLK6 PCLK5 PCLK4 PCLK3 PCLK2 PCLK1 PCLK0

PCKB2 PCKB1 PCKB0

CAE7 CAE6 CAE5 CAE4 CAE3 CAE2 CAE1 CAE0

CON67 CON45 CON23 CON01 PSWAI PFRZ

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

0

PCKA2 PCKA1 PCKA0

00

35

Page 36

MC9S12DJ64 Device User Guide — V01.17

$00A0 - $00C7 PWM (Pulse Width Modulator 8 Bit 8 Channel)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00B0 PWMCNT4

$00B1 PWMCNT5

$00B2 PWMCNT6

$00B3 PWMCNT7

$00B4 PWMPER0

$00B5 PWMPER1

$00B6 PWMPER2

$00B7 PWMPER3

$00B8 PWMPER4

$00B9 PWMPER5

$00BA PWMPER6

$00BB PWMPER7

$00BC PWMDTY0

$00BD PWMDTY1

$00BE PWMDTY2

$00BF PWMDTY3

$00C0 PWMDTY4

$00C1 PWMDTY5

$00C2 PWMDTY6

$00C3 PWMDTY7

$00C4 PWMSDN

$00C5 Reserved

$00C6 Reserved

$00C7 Reserved

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read: Bit 7 6 5 4 3 2 1 Bit 0

Write: 00000000

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

Bit 7 6 5 4 3 2 1 Bit 0

PWMIF PWMIE

PWMRSTRT

PWMLVL

0 PWM7IN

PWM7INL PWM7ENA

36

Page 37

MC9S12DJ64 Device User Guide — V01.17

$00C8 - $00CF SCI0 (Asynchronous Serial Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00C8 SCI0BDH

$00C9 SCI0BDL

$00CA SCI0CR1

$00CB SCI0CR2

$00CC SCI0SR1

$00CD SCI0SR2

$00CE SCI0DRH

$00CF SCI0DRL

Read: 0 0 0

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: TDRE TC RDRF IDLE OR NF FE PF

Write:

Read: 00000

Write:

Read: R8

Write:

Read: R7 R6 R5 R4 R3 R2 R1 R0

Write: T7 T6 T5 T4 T3 T2 T1 T0

SBR7 SBR6 SBR5 SBR4 SBR3 SBR2 SBR1 SBR0

LOOPS SCISWAI RSRC M WAKE ILT PE PT

TIE TCIE RIE ILIE TE RE RWU SBK

T8

000000

SBR12 SBR11 SBR10 SBR9 SBR8

BRK13 TXDIR

RAF

$00D0 - $00D7 SCI1 (Asynchronous Serial Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00D0 SCI1BDH

$00D1 SCI1BDL

$00D2 SCI1CR1

$00D3 SCI1CR2

$00D4 SCI1SR1

$00D5 SCI1SR2

$00D6 SCI1DRH

$00D7 SCI1DRL

Read: 0 0 0

Write:

Read:

Write:

Read:

Write:

Read:

Write:

Read: TDRE TC RDRF IDLE OR NF FE PF

Write:

Read: 00000

Write:

Read: R8

Write:

Read: R7 R6 R5 R4 R3 R2 R1 R0

Write: T7 T6 T5 T4 T3 T2 T1 T0

SBR7 SBR6 SBR5 SBR4 SBR3 SBR2 SBR1 SBR0

LOOPS SCISWAI RSRC M WAKE ILT PE PT

TIE TCIE RIE ILIE TE RE RWU SBK

T8

000000

SBR12 SBR11 SBR10 SBR9 SBR8

BRK13 TXDIR

RAF

$00D8 - $00DF SPI0 (Serial Peripheral Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00D8 SPI0CR1

$00D9 SPI0CR2

$00DA SPI0BR

$00DB SPI0SR

Read:

Write:

Read: 0 0 0

Write:

Read: 0

Write:

Read: SPIF 0 SPTEF MODF 0000

Write:

SPIE SPE SPTIE MSTR CPOL CPHA SSOE LSBFE

MODFEN BIDIROE

SPPR2 SPPR1 SPPR0

0

0

SPISWAI SPC0

SPR2 SPR1 SPR0

37

Page 38

MC9S12DJ64 Device User Guide — V01.17

$00D8 - $00DF SPI0 (Serial Peripheral Interface)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00DC Reserved

$00DD SPI0DR

$00DE Reserved

$00DF Reserved

Read: 00000000

Write:

Read:

Write:

Read: 00000000

Write:

Read: 00000000

Write:

Bit7 654321Bit0

$00E0 - $00E7 IIC (Inter IC Bus)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00E0 IBAD

$00E1 IBFD

$00E2 IBCR

$00E3 IBSR

$00E4 IBDR

$00E5 Reserved

$00E6 Reserved

$00E7 Reserved

Read:

Write:

Read:

Write:

Read:

Write: RSTA

Read: TCF IAAS IBB

Write:

Read:

Write:

Read: 0 0 0 0 0 0 0 0

Write:

Read: 00000000

Write:

Read: 00000000

Write:

ADR7 ADR6 ADR5 ADR4 ADR3 ADR2 ADR1 0

IBC7 IBC6 IBC5 IBC4 IBC3 IBC2 IBC1 IBC0

IBEN IBIE MS/

D7 D6 D5 D4 D3 D2 D1 D 0

SL TX/RX TXAK

IBAL

0SRW

00

IBIF

IBSWAI

RXAK

$00E8 - $00EF BDLC (Bytelevel Data Link Controller J1850)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

$00E8 DLCBCR1

$00E9 DLCBSVR

$00EA DLCBCR2

$00EB DLCBDR

$00EC DLCBARD

$00ED DLCBRSR

$00EE DLCSCR

$00EF DLCBSTAT

38

Read:

Write:

Read: 0 0 I3 I2 I1 I0 0 0

Write:

Read:

Write:

Read:

Write:

Read: 0

Write:

Read:

Write:

Read:

Write:

Read:

Write:

IMSG CLKS

SMRST DLOOP RX4XE NBFS TEOD TSIFR TMIFR1 TMIFR0

D7 D6 D5 D4 D3 D2 D1 D0

RXPOL

0 0

0 0 0

0 0 0 0 0 0 0 IDLE

0000

00

R5 R4 R3 R2 R1 R0

BDLCE

BO3 BO2 BO1 BO0

0 0 0 0

IE WCM

Page 39