Freescale Semiconductor

Technical Data

Electric Field Imaging Device

Document Number: MC33794

Rev 9, 11/2006

The MC33794 is intended for applications where noncontact sensing of

objects is desired. When connected to external electrodes, an electric field is

created.,The MC33794 is intended for use in detecting objects in this electric

field. The IC generates a low-frequency sine wave. The frequency is adjustable

by using an external resistor and is optimized for 120 kHz. The sine wave has

very low harmonic content to reduce harmonic interference.

The MC33794 also contains support circuits for a microcontroller unit (MCU)

to allow the construction of a two-chip E-field system.

Features

• Supports up to 9 Electrodes and 2 References or Electrodes

• Shield Driver for Driving Remote Electrodes Through Coaxial Cables

• +5.0 V Regulator to Power External Circuit

• ISO-9141 Physical Layer Interface

• Lamp Driver Output

• Watchdog and Power-ON Reset Timer

• Critical Internal Nodes Scaled and Selectable for Measurement

• High-Purity Sine Wave Generator Tunable with External Resistor

Typical Applications

• Occupant Detection Systems

• Appliance Control Panels and Touch Sensors

• Linear and Rotational Sliders

• Spill Over Flow Sensing Measurement

• Refrigeration Frost Sensing

• Industrial Control and Safety Systems Security

• Proximity Detection for Wake-Up Features

• Touch Screens

• Garage Door Safety Sensing

• Liquid Level Sensing

MC33794

ELECTRIC FIELD

IMAGING DEVICE

EK SUFFIX

54-LEAD SOICW-EP

CASE 1390-02

ORDERING INFORMATION

Device Name Temperature Range (TA)

MC33794EK/R2 -40°C to 85°C 1390-02 54 SOICW-EP

© Freescale Semiconductor, Inc., 2006. All rights reserved.

Package

Drawing

Package

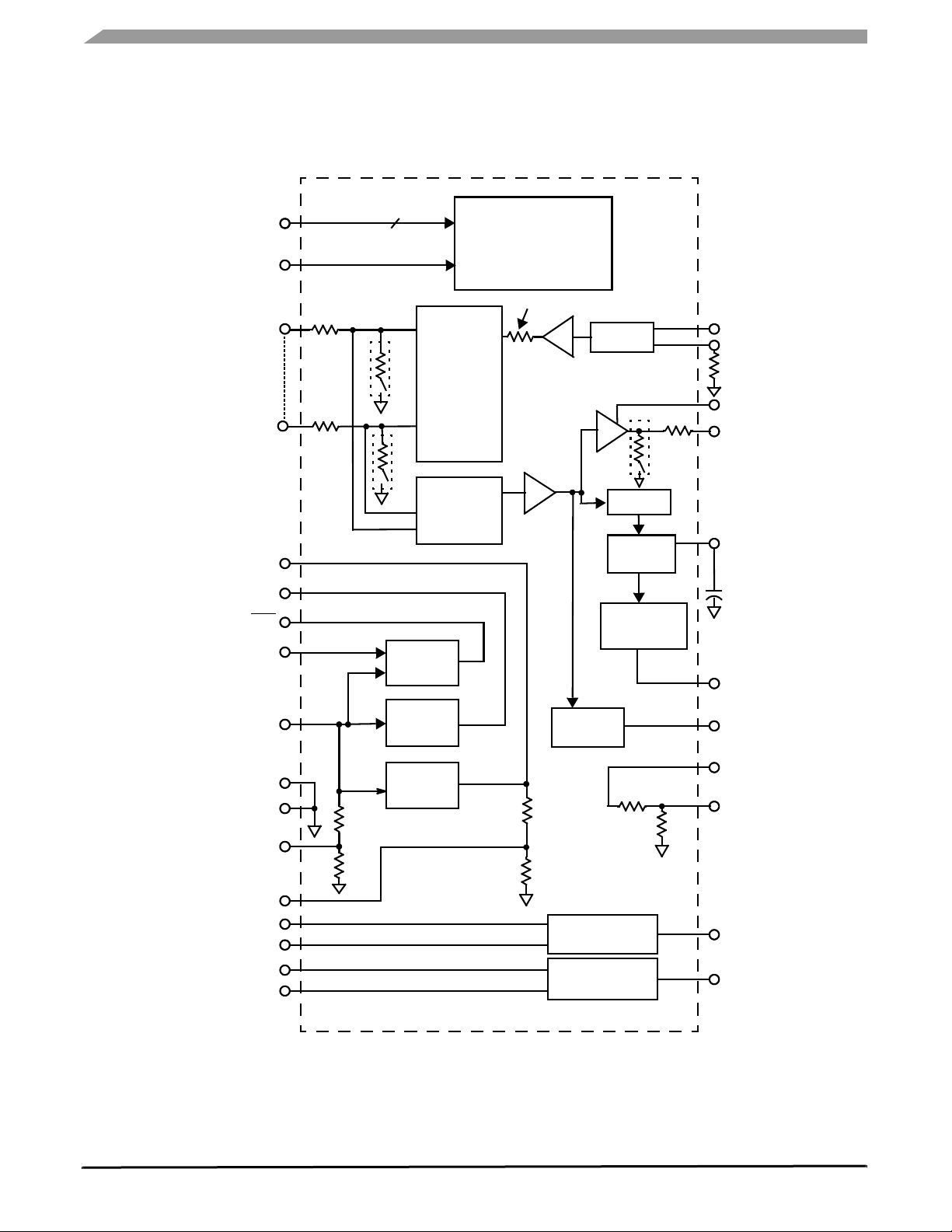

INTERNAL BLOCK DIAGRAM

A,B,C,D

TEST

E1–E9

REF_A*, REF_B*

* REF_A and REF_B are

not switched to ground

when not selected.

WD_IN

V

DD

V

CC

RST

2.8 kΩ

2.8 kΩ

4

700 Ω*

700 Ω*

POR/

WD

MUX

OUT

MUX

IN

CONTROL

LOGIC

22 k

Ω (Nominal)

OSC

RECT

LPF

GAIN AND

OFFSET

150

300 Ω

CLK

R_OSC

39 kΩ

SHIELD_EN

Ω

SHIELD

LP_CAP

10 nF

LEVEL

V

V

PWR

AGND

GND and HEAT SINK

PWR_MON

MON

V

DD

_

LAMP_GND

LAMP_CTRL

ISO_OUT

ISO_IN

CC

REG

V

DD

REG

ATTN

LAMP CKT

ISO-9141

SIGNAL

LAMP_SENSE

LAMP_MON

LAMP_OUT

ISO-9141

(Note: All Resistor Values are Nominal)

Figure 1. Simplified Functional Block Diagram

MC33794

Sensors

2 Freescale Semiconductor

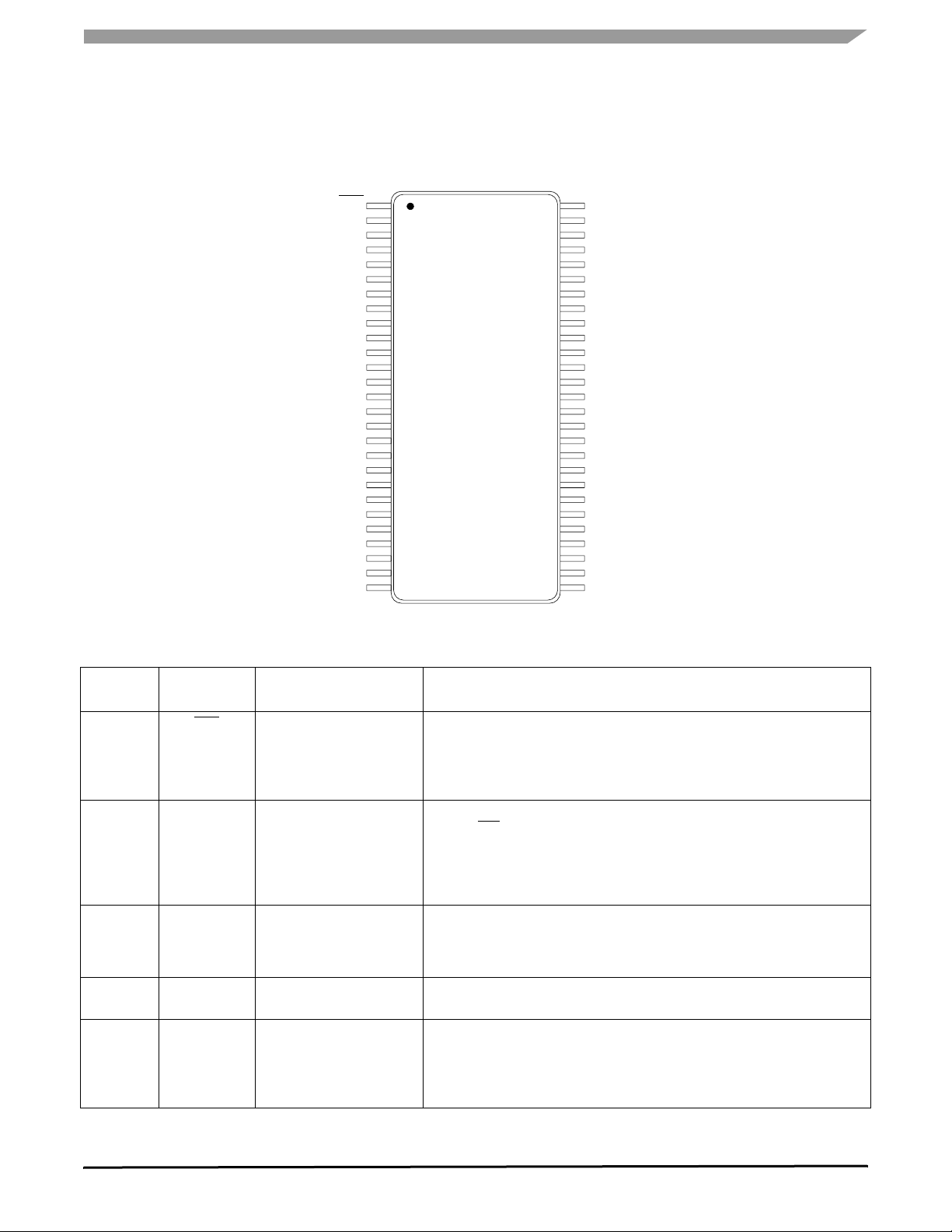

SOICW-EP TERMINAL CONNECTIONS

RST

WD_IN

NC

LAMP_GND

NC

LAMP_OUT

NC

LAMP_SENSE

LAMP_MON

SHIELD_EN

SIGNAL

LEVEL

PWR_MON

LP_CAP

R_OSC

NC

NC

NC

NC

CLK

MON

V

DD

_

V

DD

V

PWR

1

2

3

4

5

6

7

8

9

10

11

D

12

C

13

B

14

A

15

16

17

18

19

20

21

22

23

24

25

26

27

Figure 2. SOICW-EP Terminal Connections

Table 1. SOICW-EP TERMINAL FUNCTION DESCRIPTION

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

LAMP_CTRL

ISO-9414

NC

ISO_IN

NC

NC

NC

ISO_OUT

REF_B

REF_A

E9

E8

E7

E6

E5

E4

E3

E2

E1

TEST

NC

NC

GND

NC

SHIELD

AGND

V

CC

Terminal

Terminal

Name

Formal Name Definition

1 RST Reset

2 WD_IN Watchdog In

3, 5, 7,

NC No connect

20–23, 31,

33, 34,

48– 50, 52

4 LAMP_GND Lamp Ground

6 LAMP_OUT Lamp Driver

This output is intended to generate the reset function of a typical MCU. It has a

delay for Power-ON Reset, level detectors to force a reset when V

out-of-range high or low, and a watchdog timer that will force a reset if WD_IN

REG is

CC

is not asserted at regular intervals. Timing is derived from the oscillator and will

change with changes in the resistor attached to R_OSC.

This terminal must be asserted and deserted at regular interval in order to

prevent

RST from being asserted. By having the MCU program perform this

operation more often the allowed time, a check that the MCU is running and

executing its program is assured. If this doesn’t occur, the MCU will be reset. If

the watchdog function is not desired, this terminal may be connected to CLK to

prevent a reset from being issued.

These terminals may be used at some future date and should be left open.

This is the ground for the current from the lamp. The current into LAMP_OUT

flows out through this terminal.

This is an active low output capable of sinking current of a typical indicator lamp.

One end of the lamp should be connected to a positive supply (for example,

battery voltage) and the other side to this terminal. The current is limited to

prevent damage to the IC in the case of a short or surge during lamp turn-on or

burn-out.

MC33794

Sensors

Freescale Semiconductor 3

Table 1. SOICW-EP TERMINAL FUNCTION DESCRIPTION (continued)

Terminal

Terminal

Name

Formal Name Definition

8 LAMP_SENSE Lamp Sense

9 LAMP_MON Lamp Monitor

10 SHIELD_EN Shield Driver

11–14 A, B, C, D Selector Inputs

15 SIGNAL Undetected Signal

16 LEVEL Detected Level

17 PWR_MON Power Monitor

This terminal is normally connected to the LAMP_OUT terminal. The voltage at

this terminal is reduced and sent to LAMP_MON so the voltage at the lamp

terminal is brought into the range of the analog-to-digital converter (ADC) in the

MCU.

This terminal is connected through a voltage divider to the LAMP_SENSE

terminal. The voltage divider scales the voltage at this terminal so that battery

voltage present when the lamp is off is scaled to the range of the MCU ADC.

With the lamp off, this terminal will be very close to battery voltage if the lamp is

not burned out and the terminal is not shorted to ground. This is useful as a lamp

check.

This terminal is used to enable the shield signal. The shield is disabled when

SHIELD_EN is a logic low (ground)

These input terminals control which electrode or reference is active. Selection

values are shown in Table 5, Electrode Selection, page 10

. These are logic level

inputs.

This is the undetected signal being applied to the detector. It has a DC level with

the low radio frequency signal superimposed on it. Care must be taken to

minimize DC loading of this signal. A shift of DC will change the center point of

the signal and adversely affect the detection of the signal.

This is the detected, amplified, and offset representation of the signal voltage on

the selected electrode. Filtering of the rectified signal is performed by a capacitor

attached to LP_CAP.

This is connected through a voltage divider to V

voltage so it will fall within the range of the ADC on the MCU.

. It allows reduction of the

PWR

18 LP_CAP Low-Pass Filter Capacitor

19 R_OSC Oscillator Resistor

24 CLK Clock

25 V

26 V

27 V

28 V

MON VDDMonitor

DD

_

DD

PWR

CC

VDD Capacitor

Positive Power Supply

5.0 V Regulator Output

29 AGND Analog Ground

30 SHIELD Shield Driver

A capacitor on this terminal forms a low pass filter with the internal series

resistance from the detector to this terminal. This terminal can be used to

determine the detected level before amplification or offset is applied. A 10 nF

capacitor connected to this terminal will smooth the rectified signal. More

capacitance will increase the response time.

A resistor from this terminal to circuit ground determines the operating frequency

of the oscillator. The MC33794 is optimized for operation around 120 kHz.

This terminal provides a square wave output at the same frequency as the

internal oscillator. The edges of the square wave coincide with the peaks

(positive and negative) of the sine wave.

This is connected through an internal voltage divider to V

reduction of the voltage so it will fall within the range of the ADC on the MCU.

REG. It allows

DD

A capacitor is connected to this terminal to filter the internal analog regulated

supply. This supply is derived from V

through internal V

PWR

DD

REG.

12 V power applied to this terminal will be converted to the regulated voltages

needed to operate the part. It is also converted to 5.0 V (internal V

8.5 V (internal V

REG) to power the MCU and external devices.

DD

This output terminal requires a 47 µF capacitor and internal V

a regulated 5.0 V for the MCU and for internal needs of the MC33794.

REG) and

CC

REG provides

CC

This terminal is connected to the ground return of the analog circuitry. This

ground should be kept free of transient electrical noise like that from logic

switching. Its path to the electrical current return point should be kept separate

from the return for GND.

This terminal connects to cable shields to cancel cable capacitance.

MC33794

Sensors

4 Freescale Semiconductor

Table 1. SOICW-EP TERMINAL FUNCTION DESCRIPTION (continued)

Terminal

32 GND Ground

35 TEST Test Mode Control

36–44 E1–E9 Electrode Connections

45, 46 REF_A,

47 ISO_OUT ISO-9141 Output

51 ISO_IN ISO-9141 Input

53 ISO-9141 ISO-9141 Bus

54 LAMP_CTRL Lamp Control

Terminal

Name

REF_B

(E10, E11)

Formal Name Definition

Reference Connections

(Or as additional electrodes)

This terminal and metal backing is the IC power return and thermal radiator /

conductor.

This terminal is normally connected to circuit ground. There are special

operating modes associated with this terminal when it is not at ground.

These are the electrode terminals. They are connected either directly or through

coaxial cables to the electrodes for measurements. When not selected, these

outputs are grounded through the internal resistance.

These terminals can be individually selected to measure a known capacitance

value. Unlike E1-E9, these two inputs are not grounded when not selected.

This terminal translates ISO-9141 receive levels to 5.0 V logic levels for the

MCU.

This terminal accepts data from the MCU to be sent over the ISO-9141

communications interface. It translates the 5.0 V logic levels from the MCU to

transmit levels on the ISO-9141 bus.

This terminal connects to the ISO-9141 bus. It provides the drive and detects

signaling on the bus and translates it from the bus level to logic levels for the

MCU.

This signal is used to control the lamp driver. A high logic level turns on the lamp.

MC33794

Sensors

Freescale Semiconductor 5

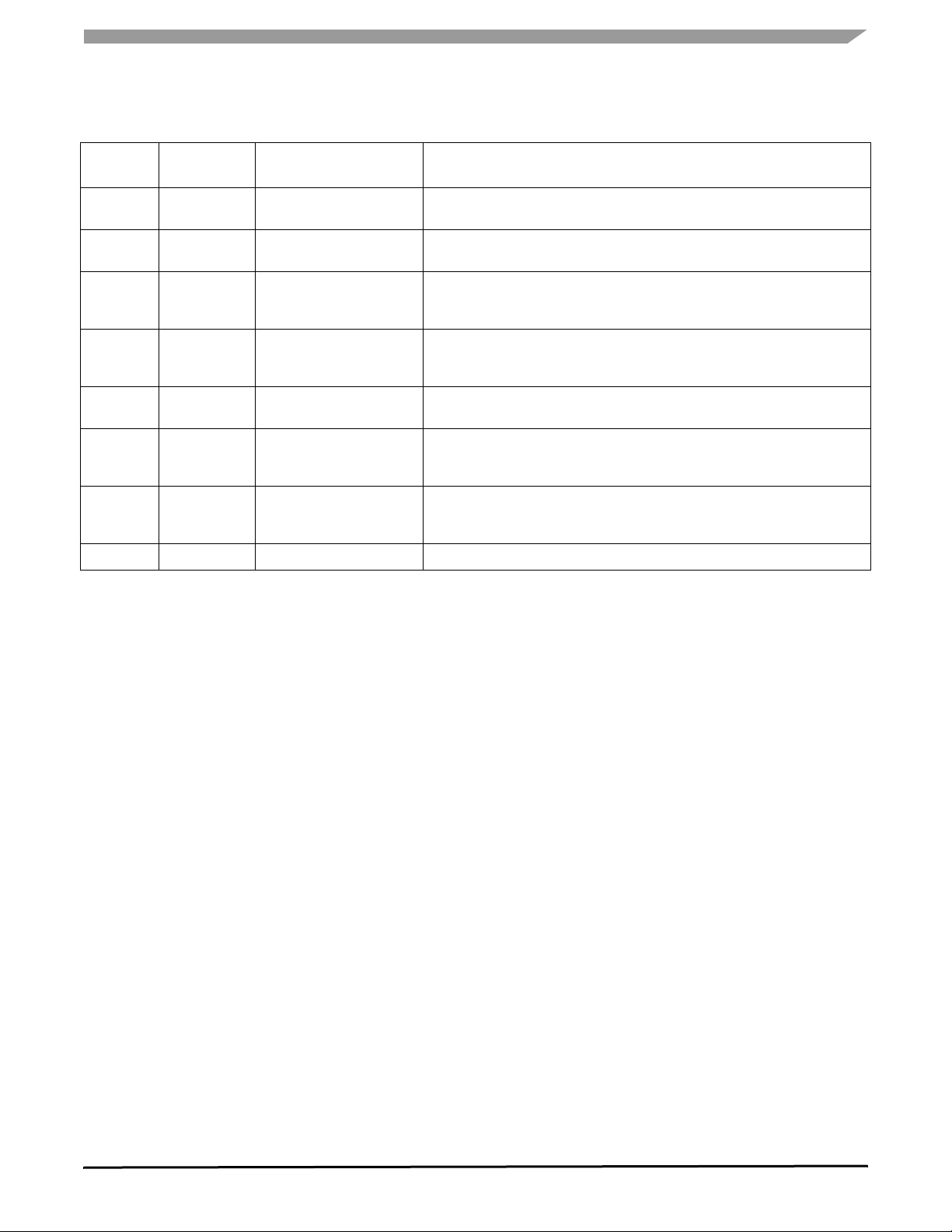

MAXIMUM RATINGS

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Rating Symbol Value Unit

Peak VPWR Voltage

Double Battery

1 Minute Maximum T

= 30°C

A

V

PWRPK

V

DBLBAT

40 V

26.5

ESD Voltage

Human Body Model

Machine Model

(1)

(2)

Storage Temperature

Operating Ambient Temperature

Operating Junction Temperature

Thermal Resistance

Junction-to-Ambient

Junction-to-Case

Junction-to-Board

(3)

(4)

(5)

Lead Soldering Temperature (for 10 Seconds)

V

V

T

ESD1

ESD2

STG

T

A

±2000

±200

-55 to 150 °C

-40 to 85 °C

TJ -40 to 150 °C

R

θ

R

θ

R

θ

T

SOLDER

JA

JC

JB

260 °C

41

0.2

3.0

°C/W

Notes

1. ESD1 performed in accordance with the Human Body Model (C

2. ESD2 performed in accordance with the Machine Model (C

ZAP

= 200 pF, R

ZAP

= 100 pF, R

ZAP

= 1500 Ω).

ZAP

= 0 Ω).

3. Junction temperature is a function of on-chip power dissipation, package thermal resistance, mounting site (board) temperature,

ambient temperature, air flow, power dissipation of other components on the board, and board thermal resistance. In accordance with

SEMI G38-87 and JEDEC JESD51-2 with the single layer board horizontal.

4. Indicates the average thermal resistance between the die and the case top surface as measured by the cold plate method

(MILSPEC 883 Method 1012.1) with the cold plate temperature used for the case temperature.

5. Thermal resistance between the die and the printed circuit board per JEDEC JESD51-8. Board temperature is measured on the top

surface of the board near the package.

V

V

MC33794

Sensors

6 Freescale Semiconductor

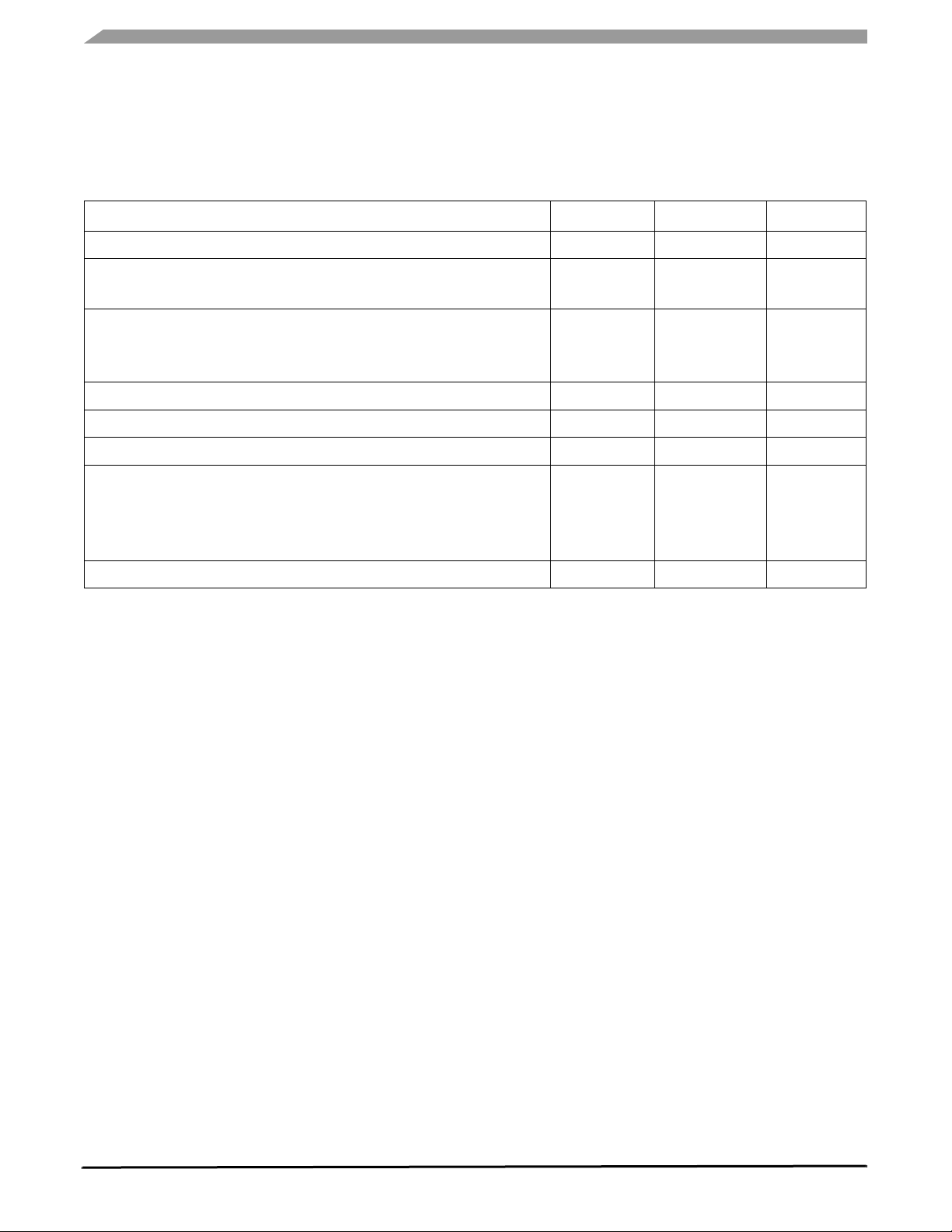

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 9.0 V ≤ VPWR ≤ 18 V, -40°C ≤ TA ≤ 85°C unless otherwise noted. Typical values noted

reflect the approximate parameter means at T

to GND unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Voltage Regulators

= 25°C under normal conditions unless otherwise noted. Voltages are relative

A

5.0 V Regulator Voltage

7.0 V ≤ V

≤ 18 V, 1.0 mA ≤ IL ≤ 75 mA, C

PWR

FILT

= 47 µF

Analog Regulator Voltage

9.0 V ≤ V

PWR

≤ 18 V, C

FILT

= 47 µF

Out-of-Range Voltage Detector (Terminal name VCC)

5.0 V Low Voltage Detector

5.0 V High Voltage Detector

5.0 V Out-of-Range Voltage Detector Hysteresis

ISO-9141 Communications Interface

Input Low Level

Input High Level

Input Hysteresis

Output Low

Output High

(6)

(6)

(6)

(6)

(6)

Output Breakdown

= 20 mA

I

OUT

Output Resistance

I

= 40 mA

OUT

V

CC

4.75 5.0 5.25

V

ANALOG

8.075 8.5 8.925

V

4.0 4.52 4.72 V

LV5

V

5.26 5.55 5.83 V

HV5

VIF

VIF

VIF

VIF

VIF

V

VIF

RIF

HYS5

INLO

INHI

INHYS

OLO

OHI

Z

ON

– 0.05 – V

0.30 0.33 – V/V

– 0.53 0.7 V/V

– 0.2 – V/V

– – 0.2 V/V

0.8 – – V/V

40

–

– 58 –

V

V

V

–

Ω

Current Limit

Sinking Current with V

Output Propagation Delay

Out to ISO-9141, C

LOAD

OUT

= 20 pF

< 0.3 V

PWR

IN

IIF

TIF

LIM

DLY

60 90

120

– – 8.0

mA

µs

ISO In

Logic Output Low

I

= 1.0 mA

SINK

Logic Output Pull-Up Current

V

= 0 V

OUT

Input to Output Propagation Delay

ISO-9141 to ISO_IN, R

18 V

= 10 kΩ, CL = 470 pF, 7.0 V ≤ VPWR ≤

L

VIF

TIF

IIF

OLO

PU

DLY

V

– – 1.0

µA

100 – –

µs

– – 5.4

Notes

6. Ratio to V

PWR

MC33794

Sensors

Freescale Semiconductor 7

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 9.0 V ≤ VPWR ≤ 18 V, -40°C ≤ TA ≤ 85°C unless otherwise noted. Typical values noted

reflect the approximate parameter means at T

= 25°C under normal conditions unless otherwise noted. Voltages are relative

A

to GND unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Electrode Signals

Total Variance Between Electrode Measurements

All C

LOAD

= 15 pF

Electrode Maximum Harmonic Level Below Fundamental

5.0 pF ≤ C

LOAD

≤ 100 pF

(7)

(8)

ELV

EL

VAR

HARM

–

– 3.0

–

-20

–

%

dB

Electrode Transmit Output Range

5.0 pF ≤ C

LOAD

≤ 100 pF

Receive Input Voltage Range

Grounding Switch on Voltage

I

= 1.0 mA

SW

EL

TXV

1.0 – 8.0

RXV 0 – 9.0 V

SW

VON

– – 5.0

Shield Driver

Shield Driver Output Level

0pF ≤ C

LOAD

≤ 500 pF

Shield Driver Input Range

Grounding Switch on Voltage

(9)

SD

TXV

1.0 – 8.0

SDIN 0 – 9.0 V

SW

– – 1.5 V

VON

Logic I/O

CMOS Logic Input Low Threshold

Logic Input High Threshold

Voltage Hysteresis

Input Current

V

= V

CC

IN

VIN = 0 V

V

0.3 – – V

THL

V

THH

V

– 0.06 – V

HYS

– – 0.7 V

IIN

10

-5.0

–

–

Signal Detector

V

V

V

CC

CC

CC

µA

50

5.0

Detector Output Resistance

LP_CAP to LEVEL Gain

LP_CAP to LEVEL Offset

DET

A

REC

V

RECOFF

RO

– 50 – kΩ

3.6 4.0 4.4 A

-3.3 -3.0 -2.7 V

V

Notes

7. Verified by design. Not tested in production.

8. Verified by design and characterization. Not tested in production.

9. Current into grounded terminal under test = 1.0 mA.

MC33794

Sensors

8 Freescale Semiconductor

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 9.0 V ≤ VPWR ≤ 18 V, -40°C ≤ TA ≤ 85°C unless otherwise noted. Typical values noted

reflect the approximate parameter means at T

= 25°C under normal conditions unless otherwise noted. Voltages are relative

A

to GND unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Lamp Driver

On Resistance

I

= 400 mA

IN

Current Limit

V

= 1.0 V

OUT

On-Voltage

I

= 400 mA

OUT

Breakdown Voltage

I

= 100 µA, Lamp Off

OUT

Voltage Monitors

LAMP_MON to LAMP_SENSE Ratio

PWR_MON to V

V

MON to VDD Ratio

DD

_

PWR

Ratio

Supply

Quiescent supply current

= 14 V

(10)

V

PWR

(11)

Notes

10. Verified by design and characterization. Not tested in production.

11. No external devices connected to internal voltage regulators.

RLD

DSON

ILD

VLDON

VLDZ

LMP

PWR

V

DD_MON

I

pwr

– 1.75 3.5

LIM

0.7 – 1.7

– – 1.4

40

0.1950 0.20524 0.2155 V/ V

MON

0.2200 0.2444 0.2688 V/V

MON

–

–

0.45 0.5 0.55 V/ V

_ 7.0 _ mA

Ω

A

V

V

MC33794

Sensors

Freescale Semiconductor 9

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 9.0 V ≤ VPWR ≤ 18 V, -40°C ≤ TA ≤ 85°C unless otherwise noted. Typical values noted

reflect the approximate parameter means at T

to GND unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

OSC

(12), (13)

OSC Frequency Stability

OSC Center Frequency

R_OSC = 39 kΩ

Harmonic Content

(12)

2nd through 4th Harmonic Level

5th and Higher

Shield Driver

Shield Driver Maximum Harmonic level below Fundamental

10 pF ≤ C

LOAD

≤ 500 pF

Shield Driver Gain Bandwidth Product

Measured at 120 kHz

POR

(12)

= 25°C under normal conditions unless otherwise noted. Voltages are relative

A

f

– – 10 %

STAB

f

OSC

– 120 –

(12)

OSCH

SD

ARM

HARM

–

–

–

–

-20

-60

– -20 –

SD

GBW

–4.5 –

kHz

dB

dB

MHz

POR Time-Out Period

Watchdog

Watchdog Time-Out Period

Watchdog Reset Hold Time

Lamp Driver

Short Circuit to Battery Survival Time

Notes

12. Verified by design and characterization. Not tested in production.

13. Does not include errors in external reference parts.

ELECTRODE SELECTION

Table 5. Electrode Selection

TERMINAL/SIGNAL D C B A

Source (internal)

E1

E2

E3

E4

E5

E6

E7

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1 1 1

t

PER

t

WDPER

t

WDHLD

3.0 – – ms

t

SCB

9.0 – 50 ms

50 68 250 ms

9.0 – 50 ms

Table 5. Electrode Selection (continued)

TERMINAL/SIGNAL D C B A

E8

E9

REF_A

REF_B

Internal OSC

Internal OSC after 22 kΩ

Internal Ground

Reserved

1 0 0 0

1 0 0 1

1 0 1 0

1 0 1 1

1 1 0 0

1 1 0 1

1 1 1 0

1 1 1 1

MC33794

Sensors

10 Freescale Semiconductor

FUNCTIONAL DESCRIPTION

INTRODUCTION

The MC33794 is intended for use in detecting objects

using an electric field. The IC generates a low radio

frequency sine wave. The frequency is set by an external

resistor and is optimized for 120 kHz. The sine wave has very

low harmonic content to reduce potential interference at

higher harmonically related frequencies. The internal

generator produces a nominal 5.0 V peak-to-peak output that

is passed through an internal resistor of about 22 kΩ. An

internal multiplexer routes the signal to one of 11 terminals

under control of the ABCD input terminals. A receiver

multiplexer simultaneously connected to the selected

electrode routes its signal to a detector, which converts the

sine wave to a DC level. This DC level is filtered by an

external capacitor and is multiplied and offset to increase

sensitivity. All of the unselected electrode outputs are

grounded by the device. The current flowing between the

selected electrode and the other grounded electrodes plus

other grounded objects around the electrode causes a

BLOCK DIAGRAM COMPONENTS

Refer to Figure 1, MC33794 Internal Block Diagram,

, for a graphic representation of the block diagram

page 2

information in this section.

OSC

This section generates a high purity sine wave. The center

frequency is controlled by a resistor attached to R_OSC. The

normal operating frequency is around 120 kHz. A square

wave version of the frequency output is available at CLK.

Timing for the Power-ON Reset and watchdog (POR/WD)

circuit are derived from this oscillator’s frequency.

MUX OUT

This circuit directs the output of the sine wave to one of

nine possible electrode outputs or two reference terminals.

All unused terminals are automatically grounded (except the

two reference terminals). The selected output is controlled by

the ABCD inputs.

ELECTRODES E1-E9

These are the electrode terminals. They are connected

either directly or through coaxial cables to the electrodes for

measurements. Every electrode has a 2.8K (

in series with the external pad and the internal electronics.

Only one of these electrodes can be selected at a time for

capacitance measurement. All of the other unselected

electrodes are switched to ground by an internal switch that

has an internal on-resistance of approximately 700

signal at the selected electrode terminal is routed to the

shield driver amplifier by an internal switch. All of the coaxial

cable shields should be isolated from ground and connected

SHIELD.

± 20%) resistor

Ω. The

voltage drop across the internal resistance. Objects brought

into or out of the electric field change the current and resulting

voltage at the IC terminal, which in turn reduces the voltage

at LP_CAP and LEVEL.

A shield driver is included to minimize the effect of

capacitance caused by using coaxial cables to connect to

remote electrodes. By driving the coax shield with this signal,

the shield voltage follows that of the center conductor,

significantly reducing the effective capacitance of the coax

and maintaining sensitivity to the capacitance at the

electrode.

The MC33794 is made to work with and support a

microcontroller. It provides two voltage regulators, a PowerON-reset/out-of-range voltage detector, watchdog circuit,

lamp driver and sense circuit, and a physical layer ISO-9141

communications interface.

REF_A & REF_B ELECTRODES

These terminals can be individually selected like E1

through E9. Unlike E1 through E9, these terminals are not

grounded when not selected. Both terminals have a 2.8K

± 20%) resistor in series with the external pad and the

(

internal electronics. The purpose of these terminals is to

allow known capacitors to be measured. By using capacitors

at the low and high end of the expected range, absolute

values for the capacitance on the electrodes can be

computed. These terminals can be used for electrodes E10

and E11 with the only difference is that these two electrodes

will not be grounded when not selected.

SHIELD DRIVE

This circuit provides a buffered version of the returned AC

signal from the electrode. Since it nearly has the same

amplitude and phase as the electrode signal, there is little or

no potential difference between the two signals thereby

cancelling out any electric field. In effect, the shield drives

and isolates the electrode signal from external virtual

grounds. A common application is to connect the Shield Drive

to the shield of a coax cable used to connect an electrode to

the corresponding electrode terminal. Another typical use is

to drive a ground plane that is used behind an array of touch

sensor electrodes in order to cancel out any virtual grounds

that could attenuate the AC signal.

MUX IN

This circuit connects the selected electrode, reference, or

one of two internal nodes to an amplifier/detector. The

selection is controlled by the ABCD inputs and follows the

driven electrode/reference when one is selected.

MC33794

Sensors

Freescale Semiconductor 11

RECT

The rectifier circuit detects the level from MUX IN by

offsetting the midpoint of the sine wave to zero volts and

inverting the waveform when it is below the midpoint. It is

important to avoid DC loading of the signal, which would

cause a shift in the midpoint voltage of the signal.

LPF

The rectified sine wave is filtered by a low pass function

formed by an internal resistance and an external capacitance

attached to LP_CAP. The nominal value of the internal

resistance is 50 k

selected to provide filtering of noise while still allowing the

desired settling time for the detector output. A 10 nF

capacitor would allow 99% settling in less than 5.0 ms. In

practice, it is recommended you wait at least 1.5 ms after

selecting an electrode before reading LEVEL.

Ω. The value of the external capacitor is

GAIN AND OFFSET

This circuit multiplies the detected and filtered signal by a

gain and offsets the result by a DC level. This results in an

output range that covers 1.0 V to 4.0 V for capacitive loading

of the field in the range of 10 pF to 100 pF. This allows higher

sensitivity for a digital-to-analog converter with a 0 V-to-5.0 V

input range.

ATTN

This circuit passes the undetected signal to SIGNAL for

external use.

SHIELD_EN

A logic low on this input disables the shield drive. The

purpose of doing this is to be able to detect that the shield

signal is not working or the connection to the coax shields is

broken. If either of these conditions exists, there will be little

or no change in the capacitance measured when the

SHIELD_EN is changed. If the SHIELD output is working and

properly connected, the capacitance of the coax will not be

cancelled when this terminal is asserted and the measured

capacitance will appear to change by approximately the

capacitance between the center conductor and the shield in

the coax.

(with appropriate current setting resistor) is connected to a

positive voltage source and the other is connected to

LAMP_OUT, and LAMP_GND is connected to ground, the

lamp will light. This circuit provides current limiting to prevent

damage to itself in the case of a shorted lamp or during a

high-surge condition typical of an incandescent lamp

burnout.

LAMP_GND should always be connected to ground even

if the lamp circuit is not used.

ISO-9141

This circuit connects to an ISO-9141 bus to allow remote

communications. ISO_IN is data from the bus to the MCU

and ISO_OUT is data to drive onto the bus from the MCU.

POR/WD

This circuit is a combined Power-ON Reset and watchdog

timer. The RST output is held low until a certain amount of

time after the V

minimum operating threshold. If VCC falls below the level at

any time, RST is pulled low again and held until the required

time after V

also included, which will force a reset if VCC rises above a

maximum voltage. The watchdog function also can force RST

low if too long an interval is allowed to pass between positive

transitions on WD_IN.

REG output (VCC) has remained above a

CC

has returned high. An over voltage circuit is

CC

INTERNAL VCC REGULATOR

This circuit converts an unregulated voltage from VIN to a

regulated 5.0 V source, which is used internally and available

for other components requiring a regulated voltage source.

INTERNAL VDD REGULATOR

This is a regulator for analog devices that require more

than 5.0 V. This is used by the device and some current is

available to operate op-amps and other devices. By having

this higher voltage available, some applications can avoid the

need for a rail-to-rail output amplifier and still achieve the 0 Vto-5.0 V output for a digital-to-analog converter input.

V

DD_MON

allows a 0.0 V-to-5.0 V ADC to measure VDD. Normal value

for V

is a divided output from internal VDD REG, which

is 8.5 Volts.

DD

LAMP CKT

This section controls the operation of the LAMP_OUT

terminal. When LAMP_CTRL is asserted, LAMP_OUT is

pulled to LAMP_GND. If one side of an indicator lamp or LED

CONTROL LOGIC

This contains the logic that decodes and controls the

MUXes and some of the test modes

APPLICATION INFORMATION

The MC33794 is intended to be used where an object’s

size and proximity are to be determined. This is done by

placing electrodes in the area where the object will be. The

proximity of an object to an electrode can be determined by

the increase in effective capacitance as the object gets closer

to the electrode and modifies the electric field between the

MC33794

12 Freescale Semiconductor

electrode and surrounding electrically common objects. The

shape and size of an object can be determined by using

multiple electrodes over an area and observing the

capacitance change on each of the electrodes. Those that

don’t change have nothing near them, and those that do

change have part of the object near them.

Sensors

A “capacitor” can be formed between the driving electrode

and the object, each forming a “plate” that holds the electric

charge. Capacitance is directly proportional to the area of the

electrode plates. Doubling the area doubles the capacitance.

Capacitance is also directly proportional to the dielectric

constant of the material between the plates. Air typically has

a dielectric constant of 1 (unity) whereas water can have a

dielectic constant of 80 (which means the capacitance is

roughly 80 times larger). Plastics and glass that are

commonly used in touch panel applications have dielectric

constants greater than unity. A third consideration is that

capacitance is inversely proportional to the distance between

the plates. Doubling the distance between the two plates will

reduce capacitance by four. This property can be exploited in

cases where small distances need to be measured.

From the above, it can be seen that increased detection

sensitivity is a function of the plate size, the dielectric

constant of the material between the plates, and the distance

between them.

The voltage measured at LEVEL is an inverse function of

the capacitance between the electrode being measured and

the surrounding electrodes and other objects in the electric

field surrounding the electrode. Increasing capacitance

results in decreasing voltage. The value of series resistance

Ω) was chosen to provide a nearly linear relationship at

(22 k

120 kHz over a range of 10 pF to 100 pF.

The measured value may change with any change in

frequency, series resistance, driving voltage, the dielectric

constant of the capacitor, or detector sensitivity. These can

change with temperature and time. There are several ways to

compensate for these changes. One method uses the

REF_A and REF_B capacitors. Another method may use

long term averages to set a baseline value.

Using REF_A and REF_B, a typical measurement

algorithm would start by measuring the voltage for two known

value capacitors (attached to REF_A and REF_B). The value

of these capacitors would be chosen to be near the minimum

and maximum values of capacitance expected to be seen at

the electrodes. These reference voltages and the known

capacitance values are then used with the electrode

measurement voltage to determine the capacitance seen by

the electrode. This method can be used to detect short- and

long-term changes due to objects in the electric field and

significantly reduce the effect of temperature-and timeinduced changes.

Another approach is to run long term averaging of the

electrode values. Long term, in this case, may mean several

seconds. These long term averages are then used as a set

point so that short term changes in the field intensity can be

reliably determined. This is typically the method used for

touch panel applications.

The MC33794 does not contain an ADC. It is intended to

be used with an MCU that contains one. Offset and gain have

been added to the MC33794 to maximize the sensitivity over

the range of 0 pF to 100 pF. An 8-bit ADC can resolve around

0.4 pF of change and a 10-bit converter around 0.1 pF.

Higher resolution results in more distant detection of smaller

objects. Due to the relatively slow data access requirements

(approximately 2 ms per electrode), digital over-sampling

techniques can be used to extend the resolution of 8- or 10bit converters by 2 or 3 bits.

DC loading on the electrodes should be avoided. A typical

situation where this might occur is if moisture gets in direct

contact between electrodes, or between an electrode and

ground or shield drive. The signal is generated with a DC

offset that is more than half the peak-to-peak level. This

keeps the signal positive above ground at all times. The

detector uses this voltage level as the midpoint for detection.

All signals below this level are inverted and added to all

signals above this level. Loading of the DC level will cause

some of the positive half of the signal to be inverted and

added and will change the measurement.

If it is not possible to assure that the electrodes will always

have a high DC resistance to ground source, a series

capacitor of about 10 nF should be connected between the IC

electrode terminals and the electrodes. This capacitor will

block DC bias voltages to the detector. Note that it is also

advisable to add a DC blocking capacitor in series with the

Shield Driver output as well.

MC33794

Sensors

Freescale Semiconductor 13

EXAMPLE APPLICATION DIAGRAM

+9 to +18 V

47

VCC

Analog_IN

Analog_IN

Analog_IN

Analog_IN

MCU

ISO_Tx

ISO_Rx

Watchdog

Reset

GPx

Electrode Select

Shield Disable

µF

10 nF

Indicator

Lamp

(Optional)

(Optional)

(Optional)

0.1

µF

LAMP_OUT

LP_CAP

LEVEL

VDD

PWR_MON

LAMP_MON

LAMP_SENSE

ISO_IN

ISO_OUT

WD_IN

RST

LAMP_CTRL

LAMP_GND

TEST

4

A, B, C, D

SHIELD_EN

R_OSC AGND

V

MON

_

PWR

33794

VCC

VDD

ISO-9141

SIGNAL

REF_A

REF_B

SHIELD

GND

E1

E2

E9

47 µF

Monitor (Optional)

100 pF

10 k

1

2

9

Ω

10 pF

ISO-9141 Bus

Field

Electrodes

39 k

Ω

Figure 3. Example Application Diagram

MC33794

Sensors

14 Freescale Semiconductor

PACKAGE DIMENSIONS

PAGE 1 OF 3

EK SUFFIX

CASE 1390-02

ISSUE C

MC33794

Sensors

Freescale Semiconductor 15

PACKAGE DIMENSIONS

PAGE 2 OF 3

EK SUFFIX

CASE 1390-02

ISSUE C

PAGE 2 OF 3

MC33794

Sensors

Freescale Semiconductor 16

PACKAGE DIMENSIONS

PAGE 1 OF 3

EK SUFFIX

CASE 1390-02

ISSUE C

PAGE 3 OF 3

PAGE 3 OF 3

MC33794

Sensors

Freescale Semiconductor 17

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2006. All rights reserved.

MC33794

Rev 9

11/2006

RoHS-compliant and/or Pb-free versions of Freescale products have the functionality and electrical

characteristics of their non-RoHS-compliant and/or non-Pb-free counterparts. For further

information, see http:/www.freescale.com or contact your Freescale sales representative.

For information on Freescale’s Environmental Products program, go to http://www.freescale.com/epp.

Loading...

Loading...