Page 1

Freescale Semiconductor

Technical Data

MC13211/212/213/214

Document Number: MC1321x

Rev. 0.0, 03/2006

MC1321x

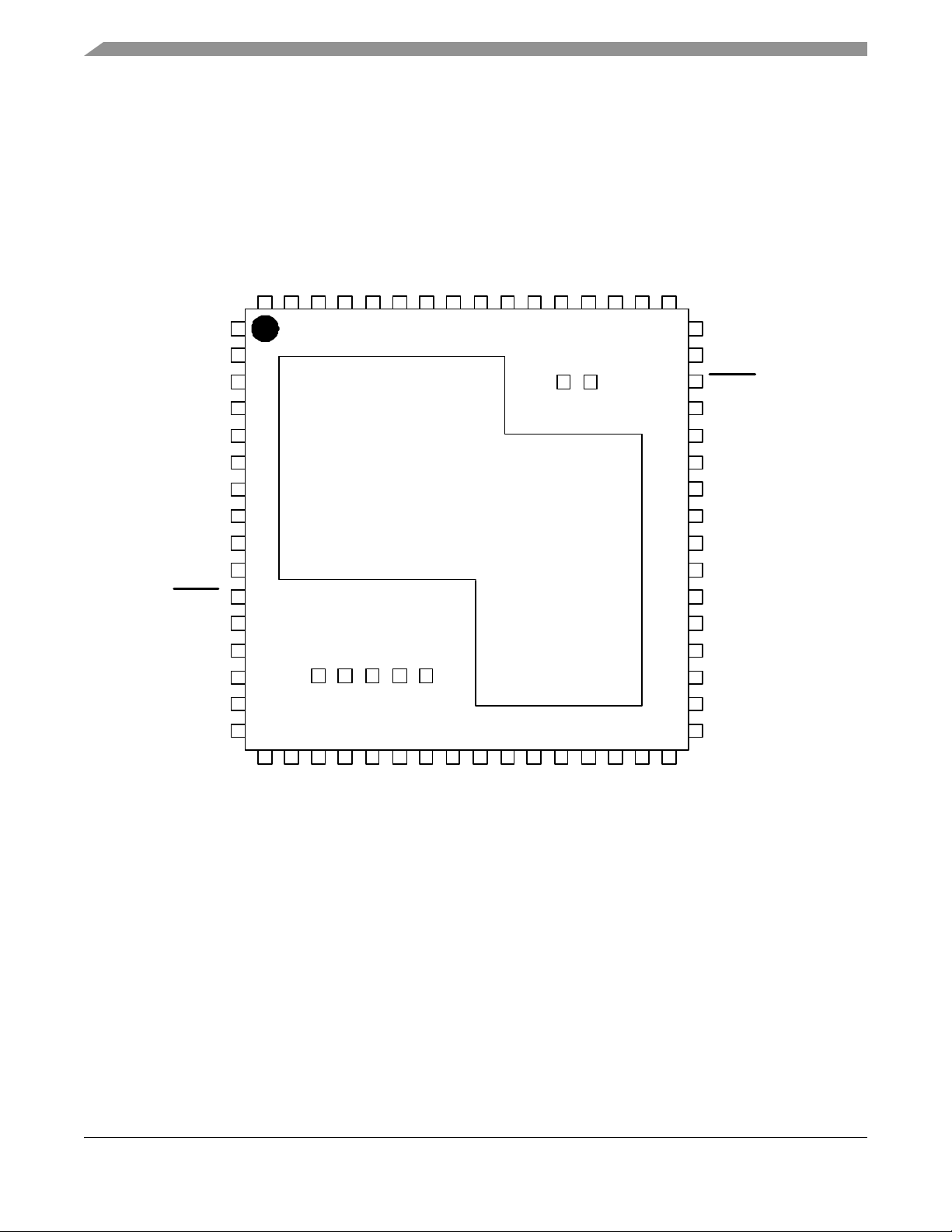

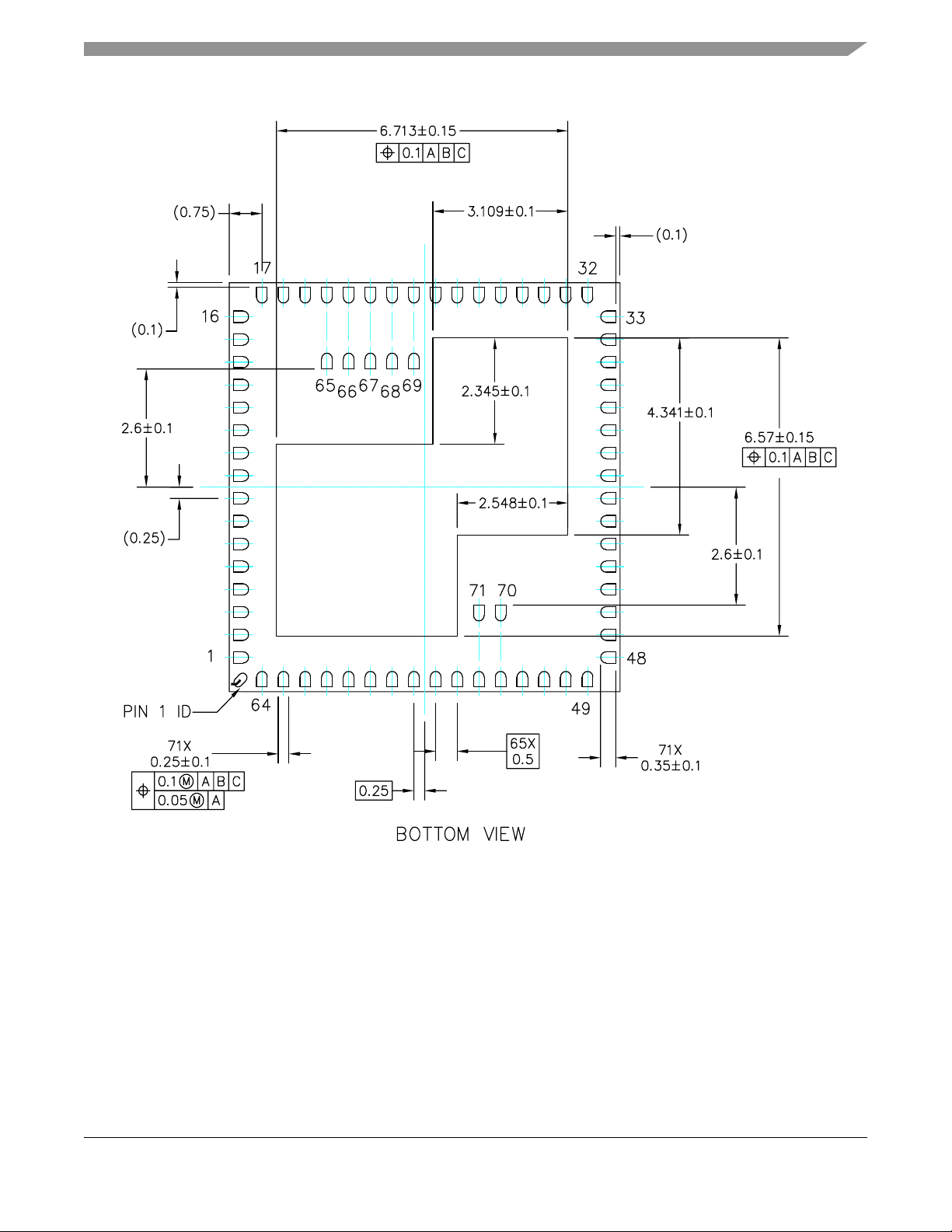

Package Information

Case 1664-01

71-pin LGA [9x9 mm]

ZigBee™- Compliant Platform -

2.4 GHz Low Power Transceiver

for the IEEE

®

802.15.4 Standard

plus Microcontroller

1 Introduction

The MC1321x family is Freescale’s second-generation

ZigBee platform which incorporates a low power 2.4

GHz radio frequency transceiver and an 8-bit

microcontroller into a single 9x9x1 mm 71-pin LGA

package. The MC1321x solution can be used for wireless

applications from simple proprietary point-to-point

connectivity to a complete ZigBee mesh network. The

combination of the radio and a microcontroller in a small

footprint package allows for a cost-effective solution.

The MC1321x contains an RF transceiver which is an

802.15.4-compliant radio that operates in the 2.4

IEEE

GHz ISM frequency band. The transceiver includes a

low noise amplifier, 1mW nominal output power, PA

with internal voltage controlled oscillator (VCO),

integrated transmit/receive switch, on-board power

supply regulation, and full spread-spectrum encoding

and decoding.

Ordering Information

Device Device Marking Package

MC13211

MC13212

MC13213

MC13214

1

See Table 1 for more details.

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 MC1321x Pin Assignment and Connections 8

3 MC1321x Serial Peripheral Interface (SPI) . 14

4 IEEE 802.15.4 Modem . . . . . . . . . . . . . . . . . . 16

5 MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 System Electrical Specification . . . . . . . . . 46

7 Application Considerations . . . . . . . . . . . . . 63

8 Mechanical Diagrams . . . . . . . . . . . . . . . . . . 68

1

1

1

1

13211 LGA

13212 LGA

13213 LGA

13214 LGA

The MC1321x also contains a microcontroller based on

the HCS08 Family of Microcontroller Units (MCU) and

can provide up to 60KB of flash memory and 4KB of

RAM. The onboard MCU allows the communications

Freescale reserves the right to change the detail specificatio ns as may be required to permit improvements in the design of i ts

products.

© Freescale Semiconductor, Inc., 2005, 2006. All rights reserved.

Page 2

stack and also the application to reside on the same system-in-package (SIP). The MC1321x family is

organized as follows:

• The MC13211 has 16KB of flash and 1KB of RAM and is an ideal solution for low cost,

proprietary applications that require wireless point-to-point or star network connectivity. The

MC13211 combined with the Freescale Simple MAC (SMAC) provides the foundation for

proprietary applications by supplying the necessary source code and application examples to get

users started on implementing wireless connectivity.

• The MC13212 contains 32K of flash and 2KB of RAM and is intended for use with the Freescale

fully compliant 802.15.4 MAC. Custom networks based on the 802.15.4 standard MAC can be

implemented to fit user needs. The 802.15.4 standard supports star, mesh and cluster tree

topologies as well as beaconed networks.

• The MC13213 contains 60K of flash and 4KB of RAM and is also intended for use with the

Freescale fully compliant 802.15.4 MAC where larger memory is required. In addition, this device

can support ZigBee applications that use a stack from 3rd party vendors.

• The MC13214 is a fully compliant ZigBee platform. The MC13214 contains 60K of flash and 4KB

of RAM and uses the Figure 8 Wireless ZigBee Stack (Z-stack) software. Applications can be

added to develop fully certified ZigBee products.

Applications include, but are not limited to, the following:

• Residential and commercial automation

— Lighting control

— Security

— Access control

— Heating, ventilation, air-conditioning (HVAC)

— Automated meter reading (AMR)

• Industrial Control

— Asset tracking and monitoring

— Homeland security

— Process management

— Environmental monitoring and control

—HVAC

— Automated meter reading

• Health Care

— Patient monitoring

— Fitness monitoring

MC13211/212/213/214 Technical Data, Rev. 0.0,

2 Freescale Semiconductor

Page 3

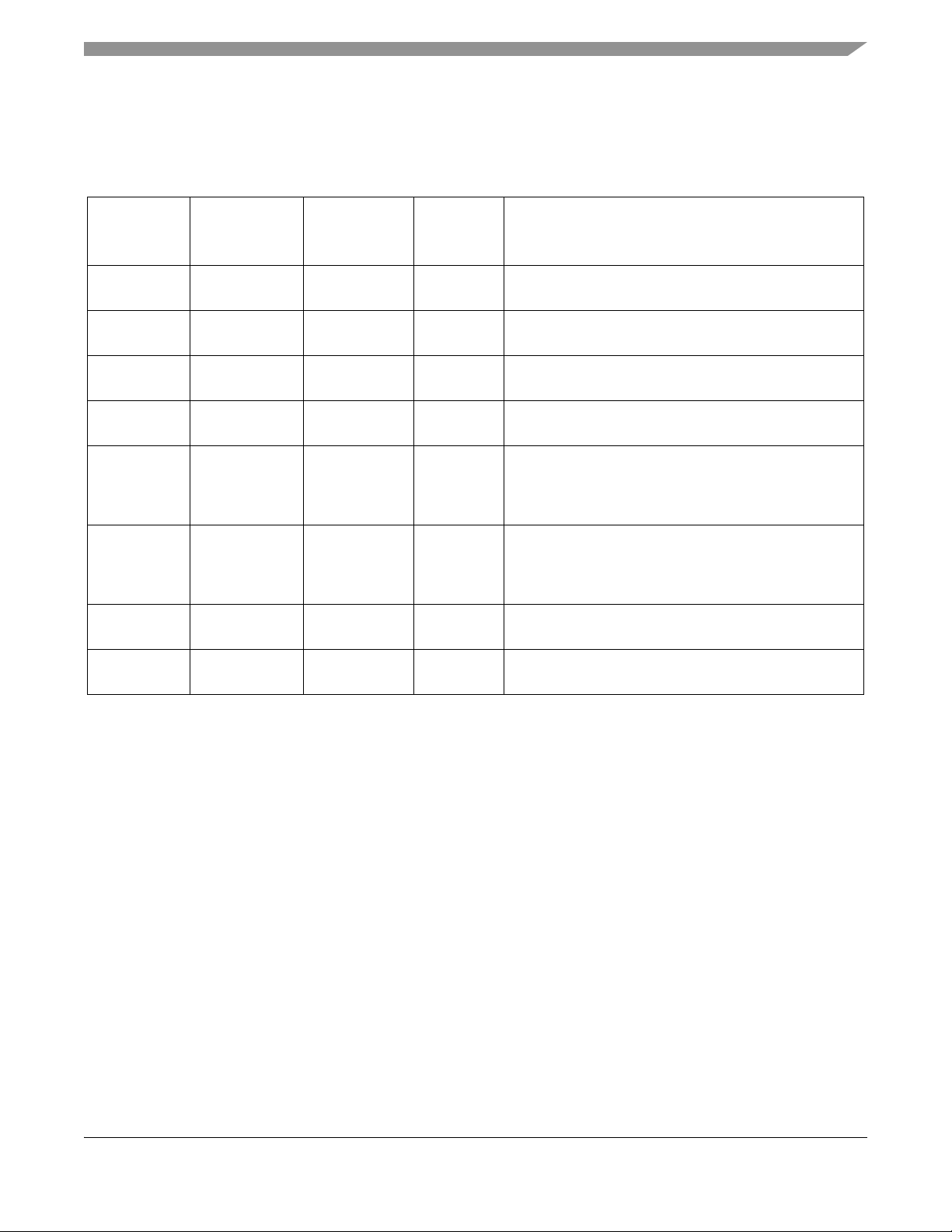

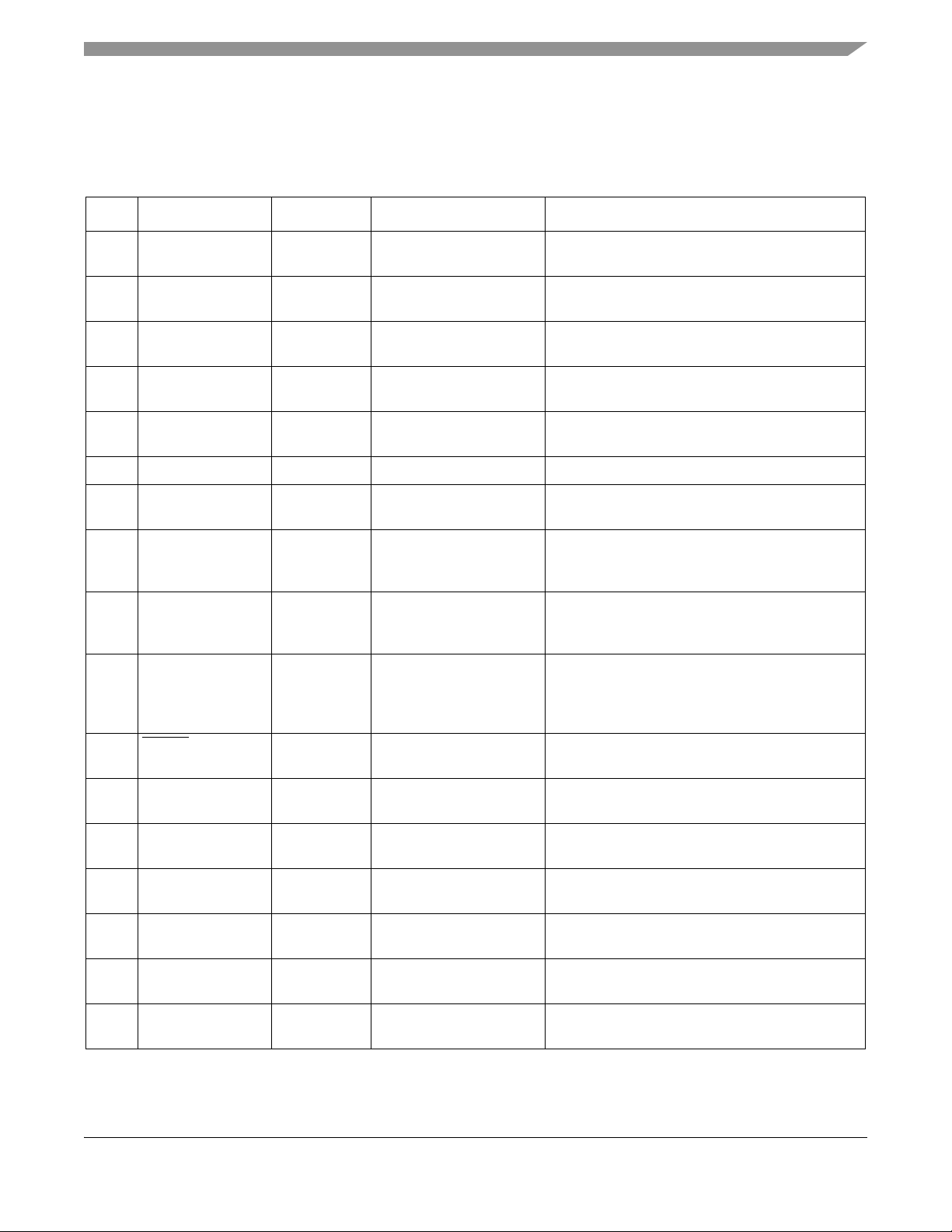

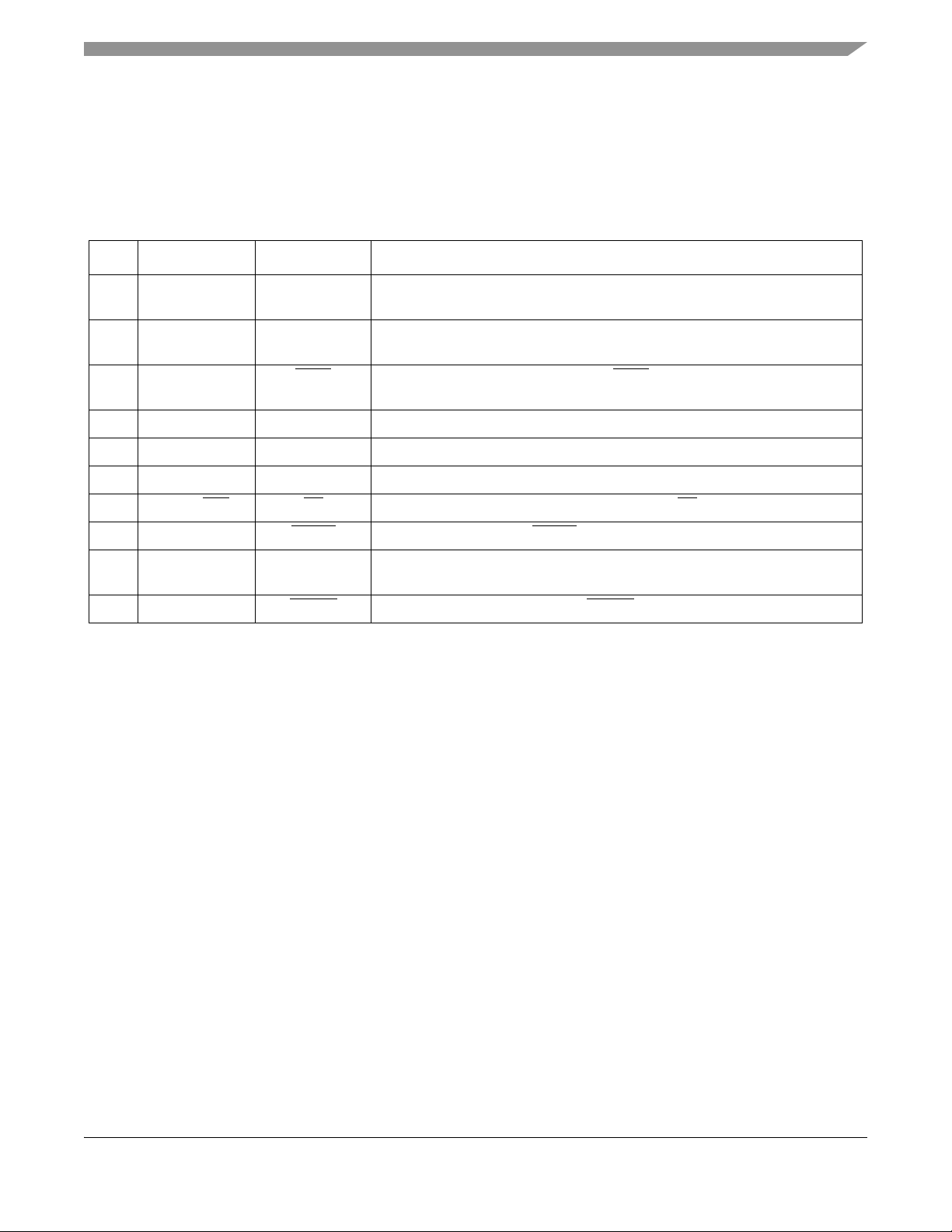

1.1 Ordering Information

Table 1 provides additional details about the MC1321x family.

Table 1. Orderable Parts Details

Operating

Device

MC13211 -40° to 85° C LGA 1KB RAM,

MC13211R2 -40° to 85° C LGA

MC13212 -40° to 85° C LGA 2KB RAM,

MC13212R2 -40° to 85° C LGA

MC13213 -40° to 85° C LGA 4KB RAM,

MC13213R2 -40° to 85° C LGA

MC13214 -40° to 85° C LGA 4KB RAM,

MC13214R2 -40° to 85° C LGA

Temp Ran ge

(TA.)

Package

Tape and Reel

Tape and Reel

Tape and Reel

Tape and Reel

Memory

Options

16KB Flash

1KB RAM,

16KB Flash

32KB Flash

2KB RAM,

32KB Flash

60KB Flash

4KB RAM,

60KB Flash

60KB Flash

4KB RAM,

60KB Flash

Description

Intended for proprietary applications and Freescale

Simple MAC (SMAC)

Intended for proprietary applications and Freescale

Simple MAC (SMAC)

Intended for IEEE 802.15.4 compliant applications and

Freescale 802.15.4 MAC

Intended for IEEE 802.15.4 compliant applications and

Freescale 802.15.4 MAC

Intended for IEEE 802.15.4 compliant applications and

Freescale 802.15.4 MAC.

Also supports ZigBee applications that use a stack from a

3rd party vendor.

Intended for IEEE 802.15.4 compliant applications and

Freescale 802.15.4 MAC.

Also supports ZigBee applications that use a stack from a

3rd party vendor.

Intended for full ZigBee compliant applications using the

F8 Wireless Z-Stack

Intended for full ZigBee compliant applications using the

F8 Wireless Z-Stack

1.2 General Platform Features

• IEEE 802.15.4 standard compliant on-chip transceiver/modem

— 2.4GHz

— 16 selectable channels

— Programmable output power

• Multiple power saving modes

• 2V to 3.4V operating voltage with on-chip voltage regulators

• -40°C to +85°C temperature range

• Low external component count

• Supports single 16 MHz crystal clock source operation or dual crystal operation

• Support for SMAC, IEEE 802.15.4, and ZigBee software

• 9mm x 9mm x 1mm 71-pin LGA

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 3

Page 4

1.3 Microcontroller Features

• Low voltage MCU with 40 MHz low power HCS08 CPU core

• Up to 60K flash memory with block protection and security and 4K RAM

— MC13211: 16KB Flash, 1KB RAM

— MC13212: 32KB Flash, 2KB RAM

— MC13213: 60KB Flash, 4KB RAM

— MC13214: 60KB Flash, 4KB RAM with ZigBee Z-stack

• Low power modes (Wait plus Stop2 and Stop3 modes)

• Dedicated serial peripheral interface (SPI) connected internally to 802.15.4 modem

• One 4-channel and one 1-channel 16-bit timer/pulse width modulator (TPM) module with

selectable input capture, output capture, and PWM capability.

• 8-bit port keyboard interrupt (KBI)

• 8-channel 8-10-bit ADC

• Two independent serial communication interfaces (SCI)

• Multiple clock source options

— Internal clock generator (ICG) with 243 kHz oscillator that has +/-0.2% trimming resolution

and +/-0.5% deviation across voltage.

— Startup oscillator of approximately 8 MHz

— External crystal or resonator

— External source from modem clock for very high accuracy source or system low-cost option

• Inter-integrated circuit (IIC) interface.

• In-circuit debug and flash programming available via on-chip background debug module (BDM)

— Two comparator and 9 trigger modes

— Eight deep FIFO for storing change-of-flow addresses and event-only data

— Tag and force breakpoints

— In-circuit debugging with single breakpoint

• System protection features

— Programmable low voltage interrupt (LVI)

— Optional watchdog timer (COP)

— Illegal opcode detection

• Up to 32 MCU GPIO with programmable pullups

MC13211/212/213/214 Technical Data, Rev. 0.0,

4 Freescale Semiconductor

Page 5

1.4 RF Modem Features

• Fully compliant IEEE 802.15.4 transceiver supports 250 kbps O-QPSK data in 5.0 MHz channels

and full spread-spectrum encode and decode

• Operates on one of 16 selectable channels in the 2.4 GHz ISM band

• -1 dBm to 0 dBm nominal output power, programmable from -27 dBm to +3 dBm typical

• Receive sensitivity of <-92 dBm (typical) at 1% PER, 20-byte packet, much better than the IEEE

802.15.4 specification of -85 dBm

• Integrated transmit/receive switch

• Dual PA ouput pairs which can be programmed for full differential single-port or dual-port

operation that supports an external LNA and/or PA.

• Three low power modes for increased battery life

• Programmable frequency clock output for use by MCU

• Onboard trim capability for 16 MHz crystal reference oscillator eliminates need for external

variable capacitors and allows for automated production frequency calibration

• Four internal timer comparators available to supplement MCU timer resources

• Supports both packet data mode and streaming data mode

• Seven GPIO to supplement MCU GPIO

1.5 Software Features

Freescale provides a wide range of software functionality to complement the MC1321x hardware. There

are three levels of application solutions:

1. Simple proprietary wireless connectivity.

2. User networks built on the IEEE 802.15.4 MAC standard.

3. ZigBee-compliant network stack.

1.5.1 Simple MAC (SMAC)

• Small memory footprint (about 3 Kbytes typical)

• Supports point-to-point and star network configurations

• Proprietary networks

• Source code and application examples provided

1.5.2 IEEE 802.15.4-Compliant MAC

• Supports star, mesh and cluster tree topologies

• Supports beaconed networks

• Supports GTS for low latency

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 5

Page 6

1.5.3 ZigBee-Compliant Network Stack

• Supports ZigBee 1.0 specification

• Supports star, mesh and tree networks

• Advanced Encryption Standard (AES) 128-bit security

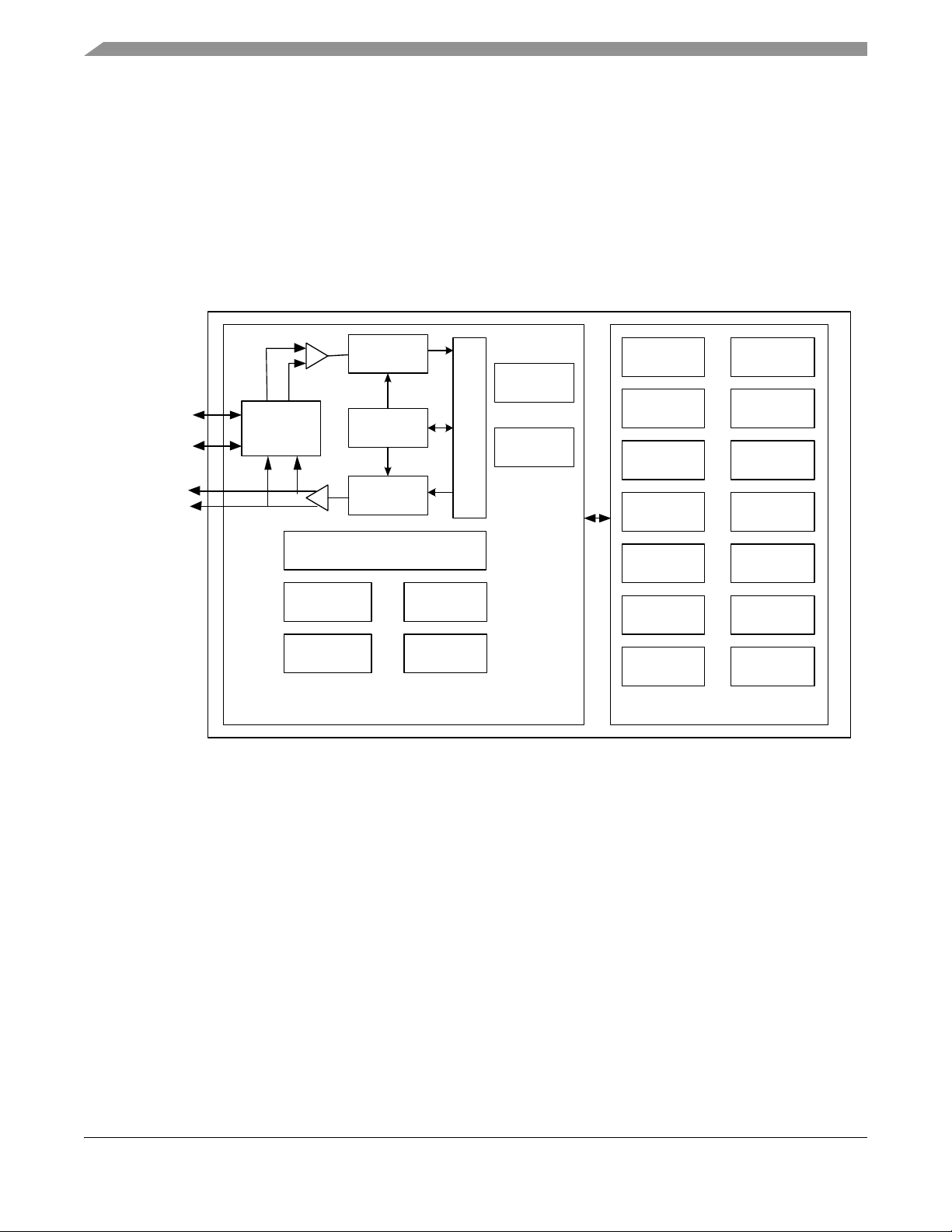

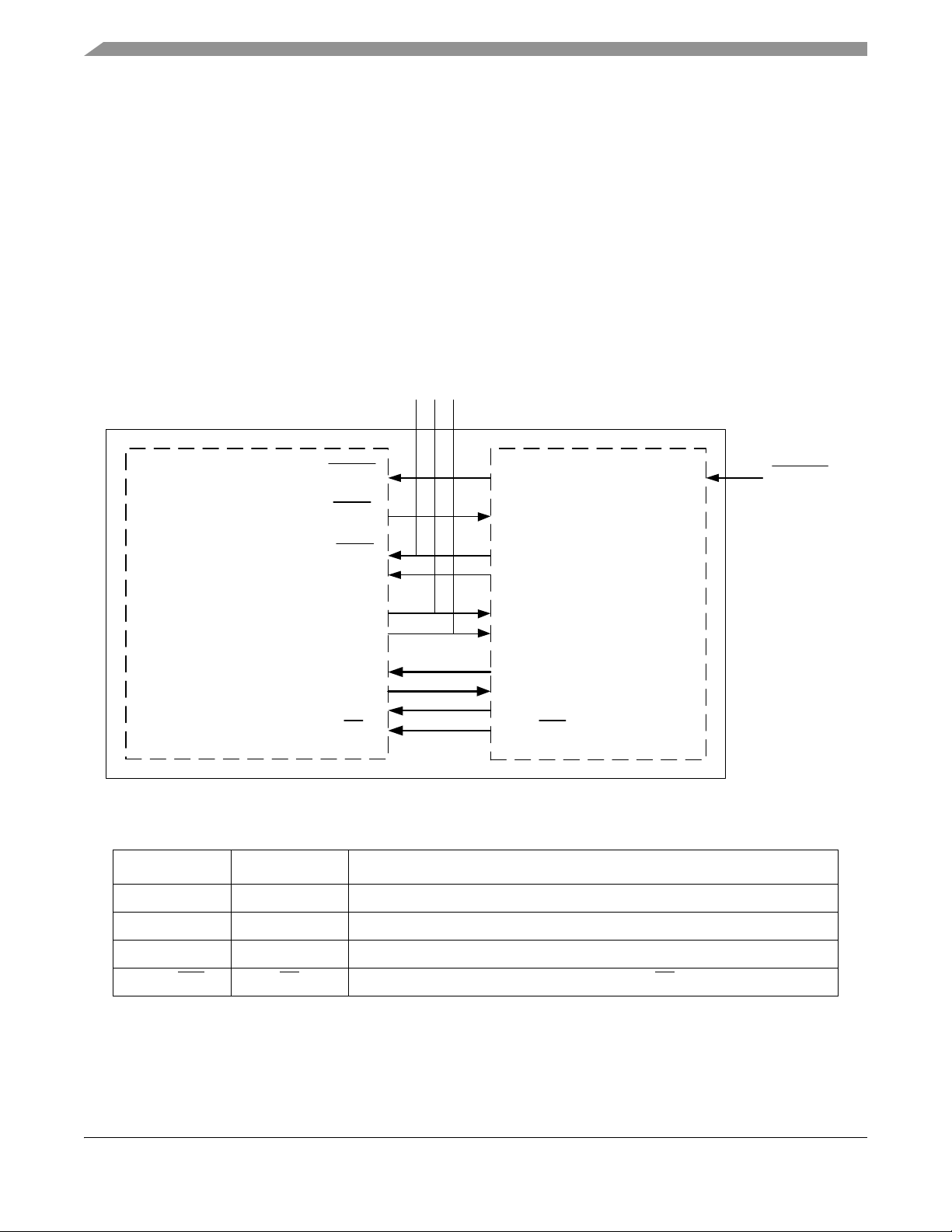

1.6 System Block Diagram

Figure 1 shows a simplified block diagram of the MC1321x solution.

RIN_P(PAO_P)

RIN_M(PAO_M)

PAO_P

PAO_M

Analog Receiver

Transmit/Receive

Switch

IRQ Arbiter RAM Arbiter

Power Management Voltage Regulators

Frequency

Generator

Analog Transmitter

Buffer RAM

Figure 1. MC1321x System Level Block Diagram

HCS08 CPU

RFIC Timers

16-60 KB

Flash Memory

Digital

Digital Control

Transceiver

Logic

1-4 KB RAM

Dedicated

SPI

Low Voltage Detect

Keyboard Interrupt

Internal Clock

Generator

Background

Debug Module

8 Channel

10 Bit ADC

2x SCI

I2C

1 Channel & 4

Channel 16-bit

Timers

COP

Up to 32 GPIO

802.15.4 M odem H CS08 M CU

MC13211/212/213/214 Technical Data, Rev. 0.0,

6 Freescale Semiconductor

Page 7

1.7 System Clock Configuration

The MC321x device allows for a wide array of system clock configurations:

• Pins are provided for a separate external clock source for the CPU. The external clock source can

by derived from a crystal oscillator or from an external clock source

• Pins are provided for a 16 MHz crystal for the modem clock source (required)

• The modem crystal oscillator frequency can be trimmed through programming to maintain the tight

tolerances required by IEEE 802.15.4

• The modem provides a CLKO programmable frequency clock output that can be used as an

external source to the CPU. As a result, a single crystal system clock solution is possible

• Out of reset, the MCU uses an internally generated clock (approximately 8-MHz) for start-up. This

allows recovery from stop or reset without a long crystal start-up delay

• The MCU contains an internal clock generator (which can be trimmed) that can be used to run the

MCU for low power operation. This internal reference is approximately 243 kHz

MC 1321X

802.15.4 MODEM HCS08 M CU

XTAL1 XTAL2 CLKO

EXTAL XTAL

27

16MHz

Figure 2. MC1321x Single Crystal System Clock Structure

28 10

98

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 7

Page 8

2 MC1321x Pin Assignment and Connections

Figure 3 shows the MC1321x pinout.

PTA3/KBI1P3

PTA4/KBI1P4

PTA5/KBI1P5

PTA6/KBI1P6

PTA7/KBI1P7

VDDAD

PTG0/BKGD/MS

PTG1/XTAL

PTG2/EXTAL

CLKO

RESET

PTC0/TXD2

PTC1/RXD2

PTC2/SDA1

PTC3/SCL1

PTC4

PTB6/AD1P6

PTA2/KBI1P2

1

16

63 62 61 60 59 58 57 56 55 54 53 52 51 50

2

3

4

5

6

7

8

9

10

11

12

13

14

15

18 19 20 21 22 23 24 25 26 27 28 29 30 31

17

PTC5

PTC6

VREF L

TEST

65

66

PTC7

PTE0/TXD1

PTA0/KBI1P0

PTA1/KBI1P1

PTB7/AD1P7

VREFH

MC1321x

Flag opening

67 68

VDDD

PTE1/RXD1

PTB5/AD1P5

69

VDDINT

GPIO5

PTB4/AD1P4

PTB3/AD1P3

GPIO6

GPIO7

PTB1/AD1P1

PTB2/AD1P2

PTB0/AD1P0

71 70

TEST

XTAL1

XTAL2

VDDLO2

PTD7/TPM2CH4

VDDLO1

PTD6/TPM2CH3

PTD5/TPM2CH2

4964

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

VDDVCO

VBATT

PTD4/TPM2CH1

PTD2/TPM1CH2

ATTN

VDD

GPIO1

GPIO2

GPIO3

GPIO4

SM

PAO_M

PAO_P

NC

RFIN_P

RFIN_M

CT_Bias

VDDA

Figure 3. Preliminary MC1321x Pinout

MC13211/212/213/214 Technical Data, Rev. 0.0,

8 Freescale Semiconductor

Page 9

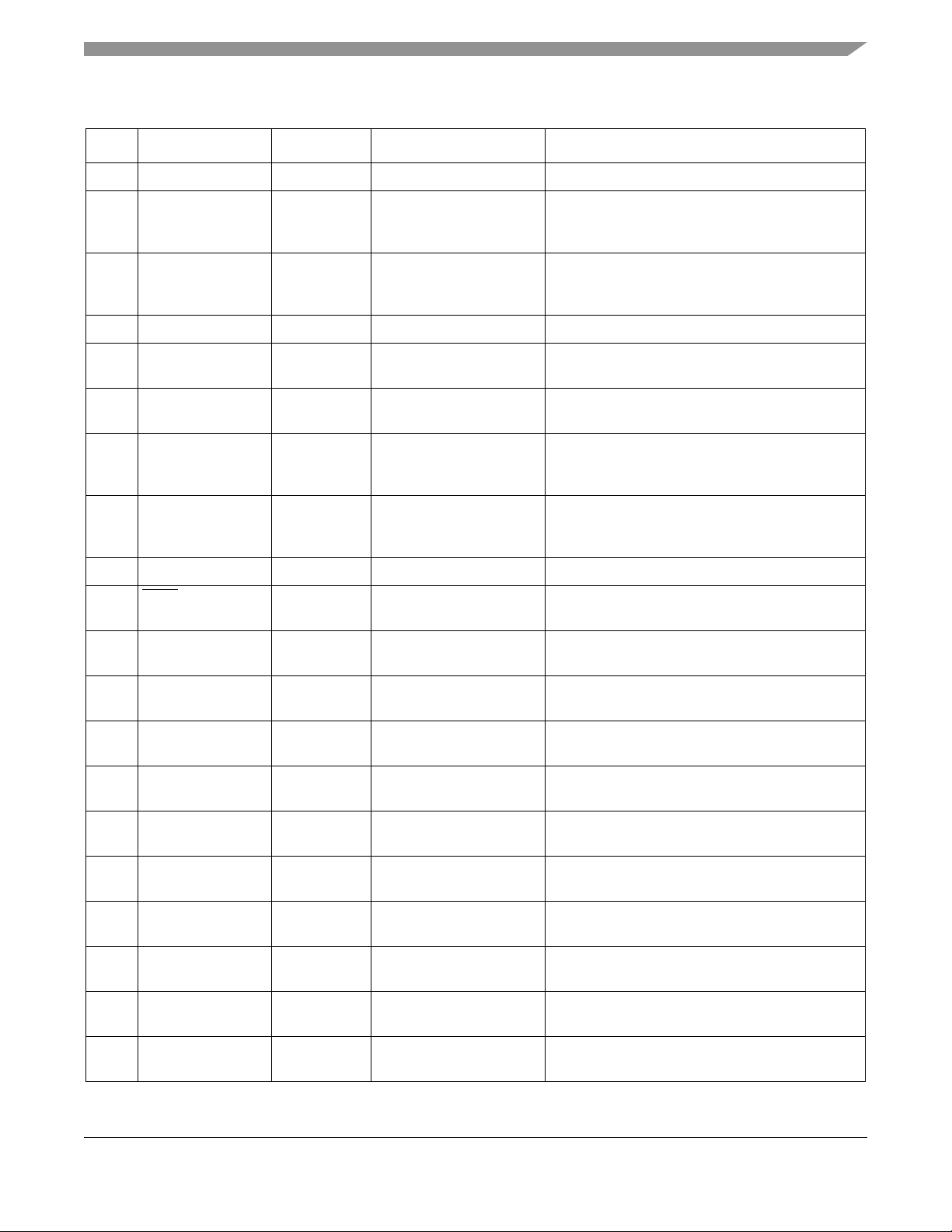

2.1 Pin Definitions

Table 2 details the MC1321x pinout and functionality.

Table 2. Pin Function Description

Pin # Pin Name Type Description Functionality

1 PTA3/KBI1P3 Digital

Input/Output

2 PTA4/KBI1P4 Digital

Input/Output

3 PTA5/KBI1P5 Digital

Input/Output

4 PTA6/KBI1P6 Digital

Input/Output

5 PTA7/KBI1P7 Digital

Input/Output

6 VDDAD Power Input MCU power supply to ATD Decouple to ground.

7 PTG0/BKGND/MS Digital

Input/Output

8 PTG1/XTAL Digital

Input/Output/

Output

9 PTG2/EXTAL Digital

Input/Output/

Input

10 CLKO Digital Output Modem Clock Output Programmable frequencies of:

MCU Port A Bit 3 /

Keyboard Input Bit 3

MCU Port A Bit 4 /

Keyboard Input Bit 4

MCU Port A Bit 5 /

Keyboard Input Bit 5

MCU Port A Bit 6 /

Keyboard Input Bit 6

MCU Port A Bit 7 /

Keyboard Input Bit 7

MCU Port G Bit 0 /

Background / Mode Select

MCU Port G Bit 1 / Crystal

oscillator output

MCU Port G Bit 2 / Crystal

oscillator input

PTG0 is output only . Pin is I/O when used as BDM

function.

Full I/O when not used as clock source.

Full I/O when not used as clock source.

16 MHz, 8 MHz, 4 MHz, 2 MHz, 1 MHz, 62.5 kHz,

32.786+ kHz (default),

and 16.393+ kHz.

11 RESET Digital

Input/Output

12 PTC0/TXD2 Digital

Input/Output

13 PTC1/RXD2 Digital

Input/Output

14 PTC2/SDA1 Digital

Input/Output

15 PTC3/SCL1 Digital

Input/Output

16 PTC4 Digital

Input/Output

17 PTC5 Digital

Input/Output

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 9

MCU reset. Active low

MCU Port C Bit 0 / SCI2

TX data out

MCU Port C Bit 1/ SCI2 RX

data in

MCU Port C Bit 1/ IIC bus

data

MCU Port C Bit 1/ IIC bus

clock

MCU Port C Bit 4

MCU Port C Bit 5

Page 10

18 PTC6 Digital

Input/Output

MCU Port C Bit 6

19 PTC7 Digital

Input/Output

20 PTE0/TXD1 Digital

Input/Output

21 PTE1/RXD1 Digital

Input/Output

22 VDDD Power Output Modem regulated output

23 VDDINT Power Input Modem digital interface

24 GPIO5 Digital

Input/Output

25 GPIO6 Digital

Input/Output

26 GPIO7 Digital

Input/Output

27 XTAL1 Input Modem crystal reference

28 XTAL2 Input/Output Modem crystal reference

MCU Port C Bit 7

MCU Port E Bit 0 / SCI1 TX

data out

MCU Port E Bit 1/ SCI1 RX

data in

supply voltage

supply

Modem General Purpose

Input/Output 5

Modem General Purpose

Input/Output 6

Modem General Purpose

Input/Output 7

oscillator input

oscillator output

Decouple to ground.

2.0 to 3.4 V. Decouple to ground. Connect to

Battery.

Connect to 16 MHz crystal and load capacitor.

Connect to 16 MHz crystal and load capacitor. Do

not load this pin by using it as a 16 MHz source.

Measure 16 MHz output at CLKO, programmed for

16 MHz.

29 VDDLO2 Power Input Modem LO2 VDD supply Connect to VDDA externally.

30 VDDLO1 Power Input Modem LO1 VDD supply Connect to VDDA externally.

31 VDDVCO Power Output Modem VCO regulated

supply bypass

32 VBATT Power Input Modem voltage regulators’

input

33 VDDA Power Output Modem analog regulated

65 RFIN_ RF Input

(Output)

34 CT_Bias RF Control

Output

35 RFIN_M RF Input

(Output)

MC13211/212/213/214 Technical Data, Rev. 0.0,

10 Freescale Semiconductor

Modem RF input/output

supply output

(i).8((i).8ive)]TJET1 sc350.82 132.36ml556.8 132.36 l556.8 033.86 l350.82 033.86 lfBT9 0 0 9 353.82 241.32 Tm0 sc-0.002 Tc-0.0025 Tw[(W)-4.8(hen )-6.7(use)-5.8(d)0.8( w)-6.5(i)0.2(th i)-6.5(n)0.8(ternal)-6.5( T)-4.5(/)2.5(R)-6.5( swi)-6.5(t)2.5(ch, )-6.7(th)-5.8(is i)-6.5(s)-2( a )]TJT*-0.0019 Tc0.0041 Tw[(bi)-6.4(0 Tctioan)-5.7nal(RF)-4.4( )6.7ponted nted Li

Modem bias

voltage/control signal for

RF external components

Modem RF input/output

negative

Decouple to ground.

Decouple to ground. Connect to Battery.

Decouple to ground. Connect to directly VDDLO1

and VDDLO2 externally and to PAO_P and

PAO_M through a bias network.

When used with internal T/R switch, provides

ground reference for RX and VDDA reference for

TX. Can also be used as a control signal with

external LNA, antenna switch, and/or PA.

When used with internal T/R switch, this is a

bi0 TctioanRF ted nted Li

Page 11

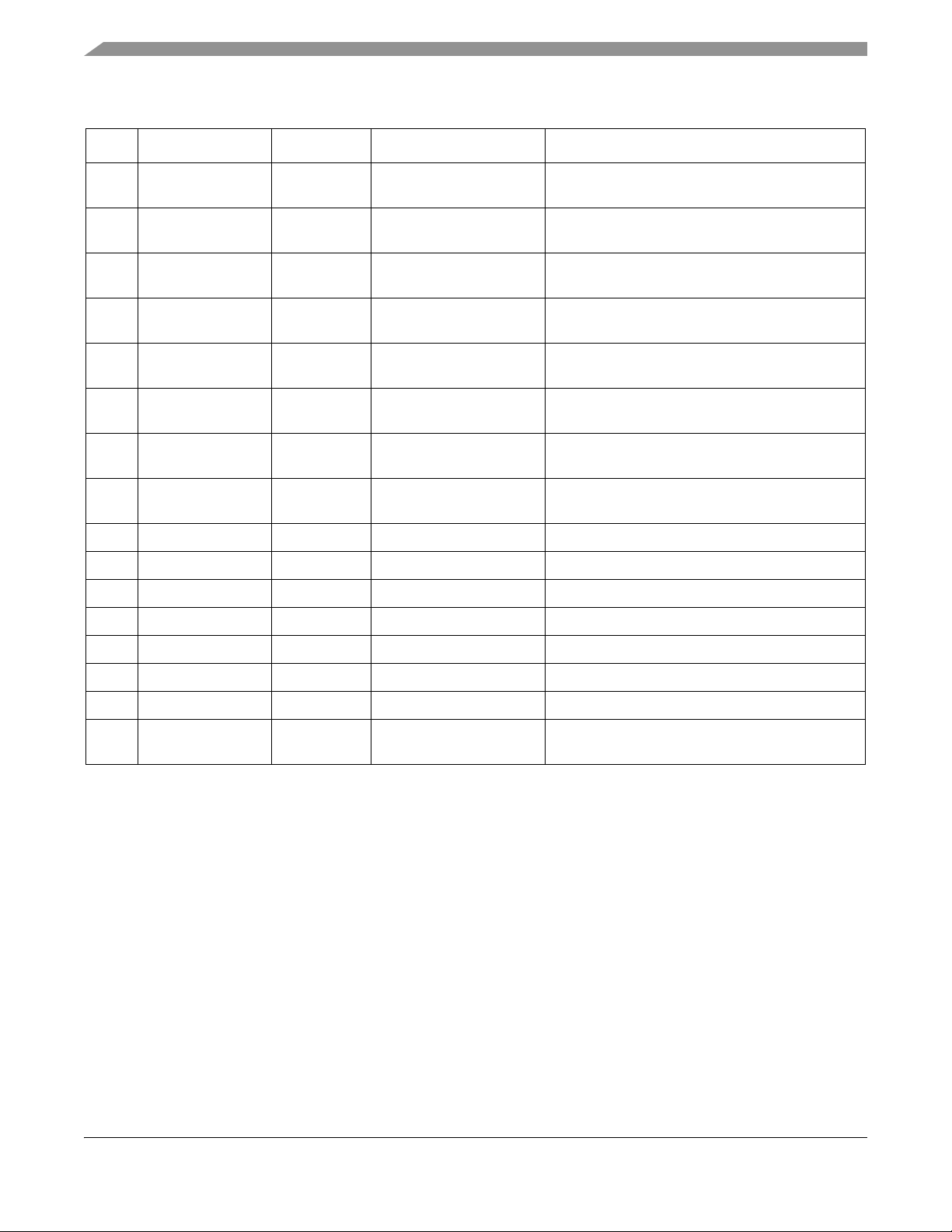

Table 2. Pin Function Description (continued)

Pin # Pin Name Type Description Functionality

37 NC Not used May be grounded or left open

38 PAO_P RF Output Modem power amplifier

RF output positive

39 PAO_M RF Output Modem power amplifier

RF output negative

40 SM Input Test Mode pin Must be grounded for normal operation

41 GPIO4 Digital

Input/Output

42 GPIO3 Digital

Input/Output

43 GPIO2 Test Point MCU Port E Bit 6 / Modem

44 GPIO1 Test Point MCU Port E Bit 7 / Modem

45 VDD Power Input MCU main power supply Decouple to ground.

46 ATTN Test Point MCU Port D Bit 0 / Modem

47 PTD2/TPM1CH2 Digital

Input/Output

Modem General Purpose

Input/Output 4

Modem General Purpose

Input/Output 3

General Purpose

Input/Output 2

General Purpose

Input/Output 1

attention input

MCU Port D Bit 2 / TPM1

Channel 2

Open drain. Connect to VDDA through a bias

network when used with external balun. Not used

when internal T/R switch is used.

Open drain. Connect to VDDA through a bias

network when used with external balun. Not used

when internal T/R switch is used.

Internally connected pins. When gpio_alt_en,

Register 9, Bit 7 = 1, GPIO2 functions as a “CRC

Valid” indicator.

Internally connected pins. When gpio_alt_en,

Register 9, Bit 7 = 1, GPIO1 functions as an “Out of

Idle” indicator.

Internally connected pins.

48 PTD4/TPM2CH1 Digital

Input/Output

49 PTD5/TPM2CH2 Digital

Input/Output

50 PTD6/TPM2CH3 Digital

Input/Output

51 PTD7/TPM2CH4 Digital

Input/Output

52 PTB0/AD1P0 Input/Output MCU Port B Bit 0 / ATD

53 PTB1/AD1P1 Input/Output MCU Port B Bit 1 / ATD

54 PTB2/AD1P2 Input/Output MCU Port B Bit 2 / ATD

55 PTB3/AD1P3 Input/Output MCU Port B Bit 3 / ATD

56 PTB4/AD1P4 Input/Output MCU Port B Bit 4 / ATD

MC13211/212/213/214 Technical Data, Rev. 0.0,

MCU Port D Bit 4 / TPM2

Channel 1

MCU Port D Bit 5 / TPM2

Channel 2

MCU Port D Bit 6 / TPM2

Channel 3

MCU Port D Bit 7 / TPM2

Channel 4

analogChannel 0

analog Channel 1

analog Channel 2

analog Channel 3

analog Channel 4

Freescale Semiconductor 11

Page 12

Table 2. Pin Function Description (continued)

Pin # Pin Name Type Description Functionality

57 PTB5/AD1P5 Input/Output MCU Port B Bit 5 / ATD

analog Channel 5

58 PTB6/AD1P6 Input/Output MCU Port B Bit 6 / ATD

analog Channel 6

59 PTB7/AD1P7 Input/Output MCU Port B Bit 7 / ATD

analog Channel 7

60 VREFH Input MCU high reference

voltage for ATD

61 VREFL Input MCU low reference

voltage for ATD

62 PTA0/KBI1P0 Digital

Input/Output

63 PTA1/KBI1P1 Digital

Input/Output

64 PTA2/KBI1P2 Digital

Input/Output

65 TEST Test Point For factory test Do not connect

66 TEST Test Point For factory test Do not connect

67 TEST Test Point For factory test Do not connect

68 TEST Test Point For factory test Do not connect

69 TEST Test Point For factory test Do not connect

70 TEST Test Point For factory test Do not connect

71 TEST Test Point For factory test Do not connect

FLAG VSS Power input External package flag.

MCU Port A Bit 0 /

Keyboard Input Bit 0

MCU Port A Bit 1 /

Keyboard Input Bit 1

MCU Port A Bit 2 /

Keyboard Input Bit 2

Connect to ground.

Common VSS

MC13211/212/213/214 Technical Data, Rev. 0.0,

12 Freescale Semiconductor

Page 13

2.2 Internal Functional Interconnects

The MCU provides control for the 802.15.4 modem. The required interconnects between the devices are

routed onboard the SiP. In addition, the signals are brought out to external pads primarily for use as test

points. These signals can be useful when writing and debugging software.

Table 3. Internal Functional Interconnects

Pin # MCU Signal Modem Signal Description

43 PTE6 GPIO2 Modem GPIO2 output acts as “CRC Valid” status indicator for Stream Data

Mode to MCU.

44 PTE7 GPIO1 Modem GPIO1 output acts as “Out of Idle” status indicator for Stream Data

Mode to MCU.

46 PTD0 ATTN

PTE5/SPSCK1 SPICLK MCU SPI master SPI clock output drives modem SPICLK slave clock input.

PTE4/MOSI1 MOSI MCU SPI master MOSI output drives modem slave MOSI input

PTE3/MISO1 MISO Modem SPI slave MISO output drives MCU master MISO input

PTE2/SS1

IRQ M_IRQ Modem interrupt request M_IRQ output drives MCU IRQ input

PTD1 RXTXEN MCU Port D Bit 1 drives the RXTXEN input to the modem to enable TX or RX

PTD3 M_RST MCU Port D Bit 3 drives the reset M_RST input to the modem.

CE MCU SPI master SS output drives modem slave CE input

MCU Port D Bit 0 drives the attention (ATTN) input of the modem to wake

modem from Hibernate or Doze Mode.

or CCA operations.

NOTE

T o use the MCU and modem signals as described in Table 3, the MCU needs

to be programmed appropriately for the stated function.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 13

Page 14

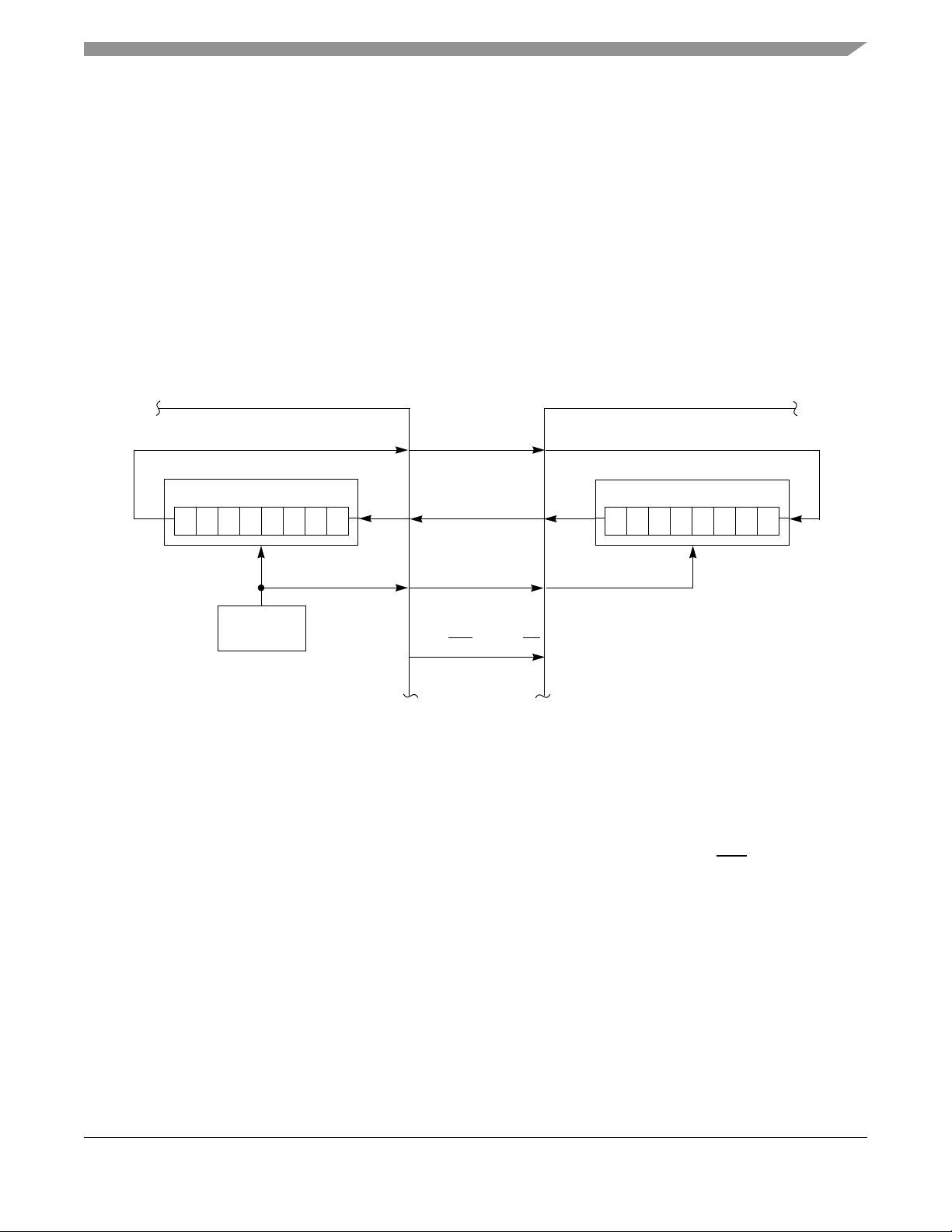

3 MC1321x Serial Peripheral Interface (SPI)

The MC1321x modem and CPU communicate primarily through the onboard SPI command channel.

Figure 4 shows the SiP internal interconnects with the SPI bus highlighted. The MCU has a single SPI

module that is dedicated to the modem SPI interface. The modem is a slave only and the MCU SPI must

be programmed and used as a master only. Further, the SPI performance is limited by the modem

constraints of 8 MHz SPI clock frequency, and use of the SPI must be programmed to meet the modem

SPI protocol.

3.1 SiP Level SPI Pin Connections

The SiP level SPI pin connections are all internal to the device. Figure 4 shows the SiP interconnections

with the SPI bus highlighted.

MC1321x

M_RST PTD3

M_IRQ

ATTN

RXTXEN

MODEM MCU

MCU Signal Modem Signal Description

GPIO1/Out_of_Idle

GPIO2/CRC_Valid

MOSI

MISO

SPICLK

CE PTE2/SS1

Figure 4. MC1321x Internal Interconnects Highlighting SPI Bus

Table 4. MC1321x Internal SPI Connections

474443

IRQ

PT D0

PT D1

PT E7

PT E6

PTE4/MOSI1

PTE3/MISO1

PTE5/SPSCK1

11

RESET

PTE5/SPSCK1 SPICLK MCU SPI master SPI clock output drives modem SPICLK slave clock input.

PTE4/MOSI1 MOSI MCU SPI master MOSI output drives modem slave MOSI input

PTE3/MISO1 MISO Modem SPI slave MISO output drives MCU master MISO input

PTE2/SS1 CE MCU SPI master SS output drives modem slave CE input

MC13211/212/213/214 Technical Data, Rev. 0.0,

14 Freescale Semiconductor

Page 15

3.2 SPI Features

• MCU bus master

• Modem bus slave

• Programmable SPI clock rate; maximum rate is 8 MHz

• Double-buffered transmit and receive at MCU

• Serial clock phase and polarity must meet modem requirements (MCU control bits

• Slave select programmed to meet modem protocol

3.3 SPI System Block Diagram

Figure 5 shows the SPI system level diagram.

MCU (MASTER)

SPI SHIFTER

7 6 5 4 3 2 1 0

CLOCK

GENERATOR

MOS1

MISO1

SPSCK1

PTE2/SS1

Figure 5. SPI System Block Diagram

MOSI

MISO

SPICLK

CE

MODEM (SLAVE)

SPI SHIFTER

7 6 5 4 3 2 1 0

Figure 5 shows the SPI modules of the MCU and modem in the master-slave arrangement. The MCU

(master) initiates all SPI transfers. During a transfer, the master shifts data out (on the MOSI pin) to the

slave while simultaneously shifting data in (on the MISO pin) from the slave. Although the SPI interface

supports simultaneous data exchange between master and slave, the modem SPI protocol only uses data

exchange in one direction at a time. The SPSCK signal is a clock output from the master and an input to

the slave. The slave device must be selected by a low level on the slave select input (SS1 pin).

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 15

Page 16

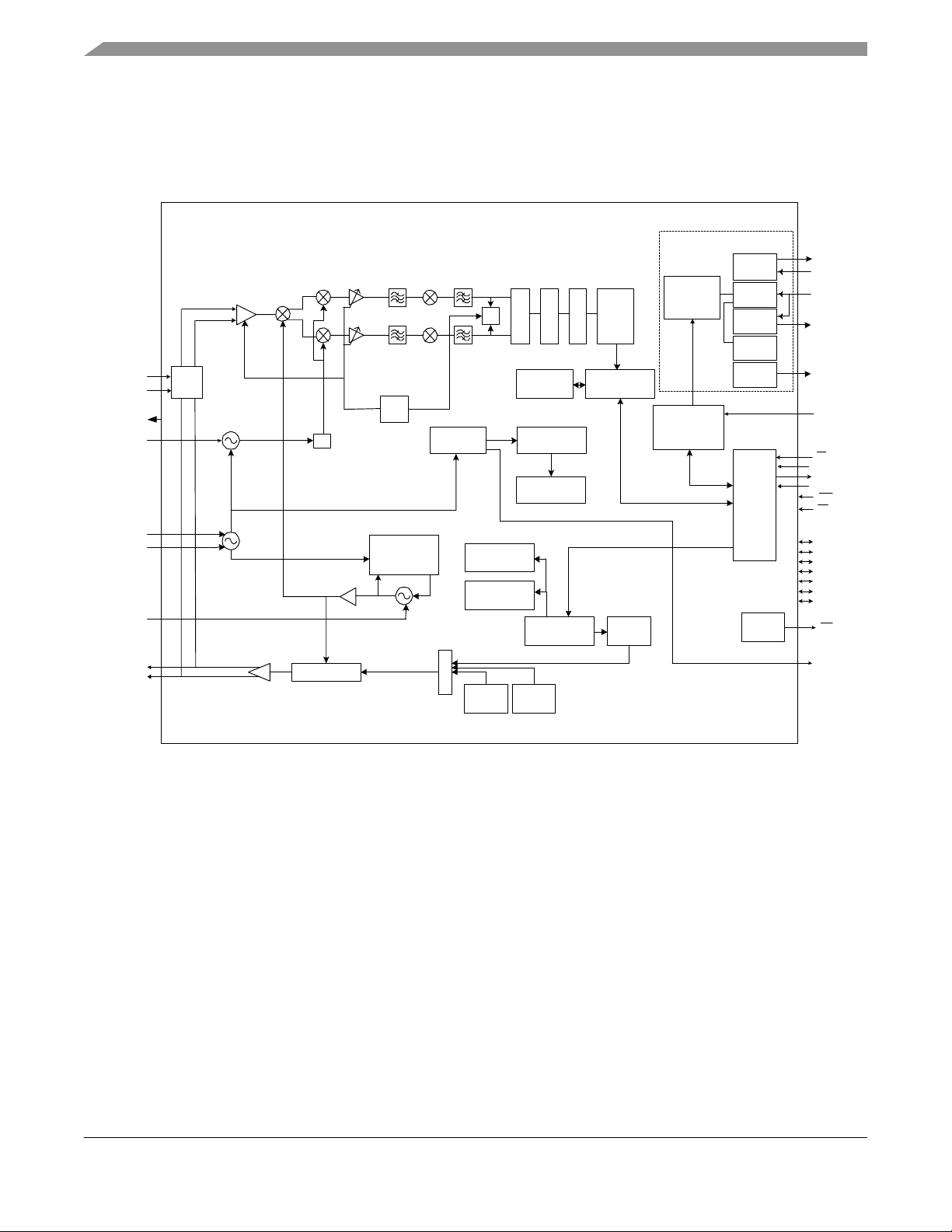

4 IEEE 802.15.4 Modem

4.1 Block Diagram

2nd IF Mix er

IF = 1 MHz

RFIN_P

(PAO_P)

RFIN_M

(PAO_M)

T / R

LNA

1st IF Mi x er

IF = 65 MHz

CT_Bias

VDD LO2 ÷4

XTAL1

XTAL2

VDDLO1

PAO_P

PAO_M

256 MHz

Crystal

Oscillator

16 MHz

PA

Phase Shift Modulator

PMA

Decimation

Filter

AGC

Synthesizer

Baseband

Mixer

2.45 GHz

VCO

Matched

Filter

Programmable

Prescaler

MUX

CCA

Transmit

Packet RAM 2

Transmit

Packet RAM 1

FCS

Generation

DCD

Receive

Packet R AM

24 Bit Event Timer

4 Programmable

Timer Com parators

Transmit RAM

Header

Generation

Correlator

Arbiter

Symbol

Synch & Det

Receive RAM

Packet

Processor

Arbiter

Symbol

Generation

Power-Up

Control

Logic

Sequence

Manager

(Control Logic)

Analog

Regulator VBATT

Digital

Regulator L

Digital

Regulator H

Crystal

Regulator

VCO

Regulator

SERIAL

PERIPHERAL

IRQ

Arbiter

INTERFACE

VDDINT

VDDD

VDDVCO

(SPI)

VDDA

RXTXEN

CE

MOSI

MISO

SPICLK

ATTN

RST

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

IRQ

CLKO

Figure 6. 802.15.4 Modem Block Diagram

MC13211/212/213/214 Technical Data, Rev. 0.0,

16 Freescale Semiconductor

Page 17

4.2 Data Transfer Modes

The 802.15.4 modem has two data transfer modes:

1. Packet Mode — Data is buffered in on-chip RAM

2. Streaming Mode — Data is processed word-by-word

The Freescale 802.15.4 MAC software only supports the streaming mode of data transfer . For proprietary

applications, packet mode can be used to conserve MCU resources.

4.3 Packet Structure

Figure 7 shows the packet structure of the 802.15.4 modem. Payloads of up to 125 bytes are supported.

The 802.15.4 modem adds a four-byte preamble, a one-byte Start of Frame Delimiter (SFD), and a

one-byte Frame Length Indicator (FLI) before the data. A Frame Check Sequence (FCS) is calculated and

appended to the end of the data.

4 bytes 1 byte 1 byte 125 bytes maximum 2 bytes

Preamble SFD FLI P ayload Data FCS

Figure 7. 802.15.4 modem Packet Structure

4.4 Receive Path Description

In the receive signal path, the RF input is converted to low IF In-phase and Quadrature (I & Q) signals

through two down-conversion stages. A Clear Channel Assessment (CCA) can be performed based upon

the baseband energy integrated over a specific time interval. The digital back end performs Differential

Chip Detection (DCD), the correlator “de-spreads” the Direct Sequence Spread Spectrum (DSSS) Offset

QPSK (O-QPSK) signal, determines the symbols and packets, and detects the data.

The preamble, SFD, and FLI are parsed and used to detect the payload data and FCS (which are stored in

RAM in Packet Mode). A two-byte FCS is calculated on the received data and compared to the FCS value

appended to the transmitted data, which generates a Cyclical Redundancy Check (CRC) result. A

parameter of received energy during the reception called the Link Quality Indicator is measured over a 64

µs period after the packet preamble and stored in an SPI register.

If the 802.15.4 modem is in Packet Mode, the data is stored in RAM and processed as an entire packet.

The MCU is notified that an entire packet has been received via an interrupt.

If the 802.15.4 modem is in streaming mode, the MCU is notified by a recurring interrupt on a

word-by-word basis.

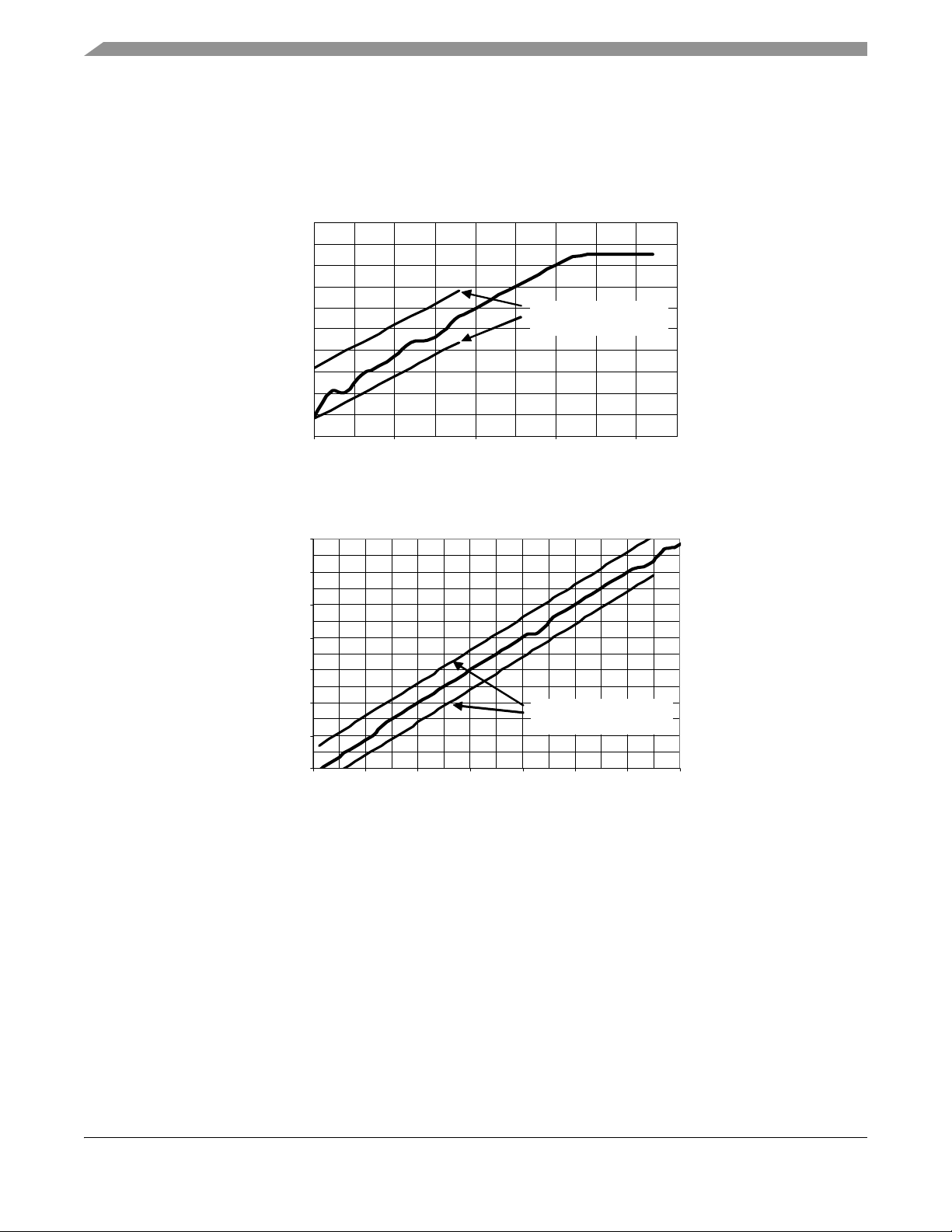

Figure 8 shows CCA reported power level versus input power. Note that CCA reported power saturates at

about -57 dBm input power which is well above IEEE 802.15.4 Standard requirements. Figure 9 shows

energy detection/LQI reported level versus input power.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 17

Page 18

NOTE

For both graphs, the required IEEE 802.15.4 Standard accuracy and range

limits are shown. A 3.5 dBm offset has been programmed into the CCA

reporting level to center the level over temperature in the graphs.

-50

-60

-70

-80

-90

Reported Power Level (dBm)

-100

-90 -80 -70 -60 -50

Input Power (dBm)

802.15.4 Accura cy

and range Requirements

Figure 8. Reported Power Level versus Input Power in Clear Channel Assessment Mode

-15

-25

-35

-45

-55

-65

Reported Power Level (dBm)

-75

802.15.4 Accur ac y

and Range Requirements

-85

-85 -75 -65 -55 -45 -35 -25 -15

Input Power Level (dBm)

Figure 9. Reported Power Level Versus Input Power for Energy Detect or Link Quality Indicator

4.5 Transmit Path Description

For the transmit path, the TX data that was previously written to the internal RAM is retrieved (packet

mode) or the TX data is clocked in via the SPI (stream mode), formed into packets per the 802.15.4 PHY,

spread, and then up-converted to the transmit frequency.

If the 802.15.4 modem is in packet mode, data is processed as an entire packet. The data is first loaded into

the TX buffer. The MCU then requests that the modem transmit the data. The MCU is notified via an

interrupt when the whole packet has successfully been transmitted.

MC13211/212/213/214 Technical Data, Rev. 0.0,

18 Freescale Semiconductor

Page 19

In streaming mode, the data is fed to the 802.15.4 modem on a word-by-word basis with an interrupt

serving as a notification that the 802.15.4 modem is ready for more data. This continues until the whole

packet is transmitted.

In both modes, a two-byte FCS is calculated in hardware from the payload data and appended to the packet.

This done without intervention from the user.

4.6 Functional Description

4.6.1 802.15.4 Modem Operational Modes

The 802.15.4 modem has a number of operational modes that allow for low-current operation. Transition

from the Off to Idle mode occurs when M_RST is negated. Once in Idle, the SPI is active and is used to

control the IC. Transition to Hibernate and Doze modes is enabled via the SPI. These modes are

summarized, along with the transition times, in Table 5. Current drain in the various modes is listed in

Table 8, DC Electrical Characteristics.

Table 5. 802.15.4 Modem Mode Definitions and Transition Times

Mode Definition

Off All IC functions Off, Leakage only. M_RST asserted. Digital outputs are tri-stated

including IRQ

Hibernate Crystal Reference Oscillator Off. (SPI not functional.) IC Responds to ATTN. Data

is retained.

Doze Crystal Reference Oscillator On but CLKO output available only if Register 7, Bit 9

= 1 for frequencies of 1 MHz or less. (SPI not functional.) Responds to ATTN and

can be programmed to enter Idle Mode through an internal timer comparator.

Idle Crystal Reference Oscillator On with CLKO output available. SPI active.

Receive Crystal Reference Oscillator On. Receiver On. 144 µs from Idle

Transmit Crystal Reference Oscillator On. Transmitter On. 144 µs from Idle

Transition Time

To or From Idle

10 - 25 ms to Idle

7 - 20 ms to Idle

(300 + 1/CLKO) µs to Idle

4.6.2 Serial Peripheral Interface (SPI)

The MCU directs the 802.15.4 modem, checks its status, and reads/writes data to the device through the

4-wire SPI port. The transceiver operates as a SPI slave device only. A transaction between the host and

the 802.15.4 modem occurs as multiple 8-bit bursts on the SPI. The modem SPI signals are:

1. Chip Enable (CE) - A transaction on the SPI port is framed by the active low CE input signal. A

transaction is a minimum of 3 SPI bursts and can extend to a greater number of bursts.

2. SPI Clock (SPICLK) - The host drives the SPICLK input to the 802.15.4 modem. Data is clocked

into the master or slave on the leading (rising) edge of the return-to-zero SPICLK and data out

changes state on the trailing (falling) edge of SPICLK.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 19

Page 20

NOTE

For the MCU, the SPI clock format is the clock phase control bit CPHA = 0

and the clock polarity control bit CPOL = 0.

3. Master Out/Slave In (MOSI) - Incoming data from the host is presented on the MOSI input.

4. Master In/Slave Out (MISO) - The 802.15.4 modem presents data to the master on the MISO

output.

Although the SPI port is fully static, internal memory , timer and interrupt arbiters require an internal clock

(CLK

), derived from the crystal reference oscillator, to communicate from the SPI regis ters to internal

core

registers and memory.

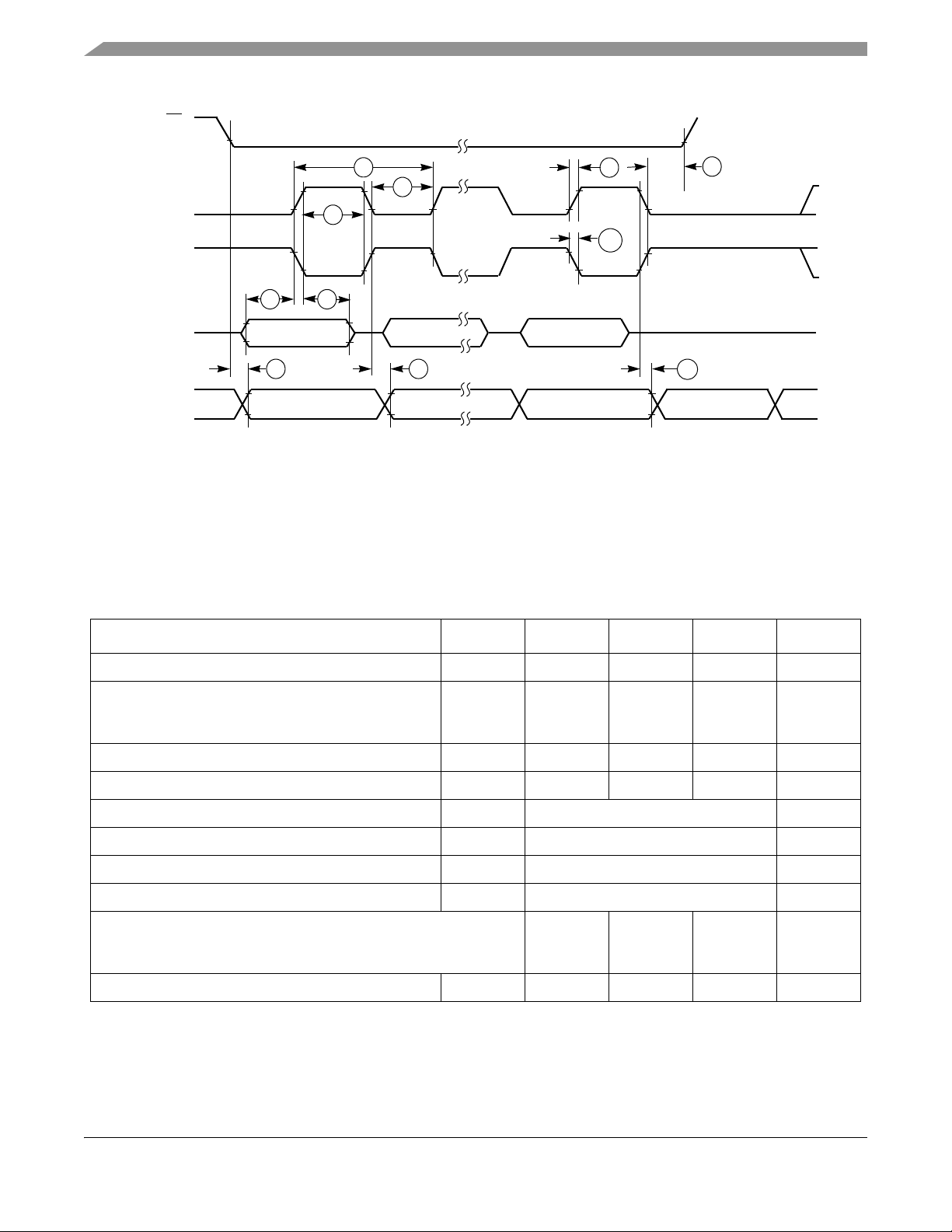

4.6.2.1 SPI Burst Operation

The SPI port of the MCU transfers data in bursts of 8 bits with most significant bit (MSB) first. The master

(MCU) can send a byte to the slave (transceiver) on the MOSI line and the slave can send a byte to the

master on the MISO line. Although an 802.15.4 modem transaction is three or more SPI bursts long, the

timing of a single SPI burst is shown in Figure 10. The maximum SPI clock rate is 8 Mhz from the MCU

because the modem is limited by this number.

1

Figure 10. SPI Single Burst Timing Diagram

MC13211/212/213/214 Technical Data, Rev. 0.0,

20 Freescale Semiconductor

Page 21

4.6.2.2 SPI Transaction Operation

Although the SPI port of the MCU transfers data in bursts of 8 bits, the 802.15.4 modem requires that a

complete SPI transaction be framed by CE, and there will be three (3) or more bursts per transaction. The

assertion of CE to low signals the start of a transaction. The first SPI burst is a write of an 8-bit header to

the transceiver (MOSI is valid) that defines a 6-bit address of the internal resource being accessed and

identifies the access as being a read or write operation. In this context, a write is data written to the 802.15.4

modem and a read is data written to the SPI master . The following SPI bursts will be either the write data

(MOSI is valid) to the transceiver or read data from the transceiver (MISO is valid).

Although the SPI bus is capable of sending data simultaneously between master and slave, the 802.15.4

modem never uses this mode. The number of data bytes (payload) will be a minimum of 2 bytes and can

extend to a larger number depending on the type of access. After the final SPI burst, CE is negated to high

to signal the end of the transaction.

An example SPI read transaction with a 2-byte payload is shown in Figure 11.

CE

Clock Burst

SPICLK

MISO

MOSI

Valid

Header Read data

Figure 11. SPI Read Transaction Diagram

Valid Valid

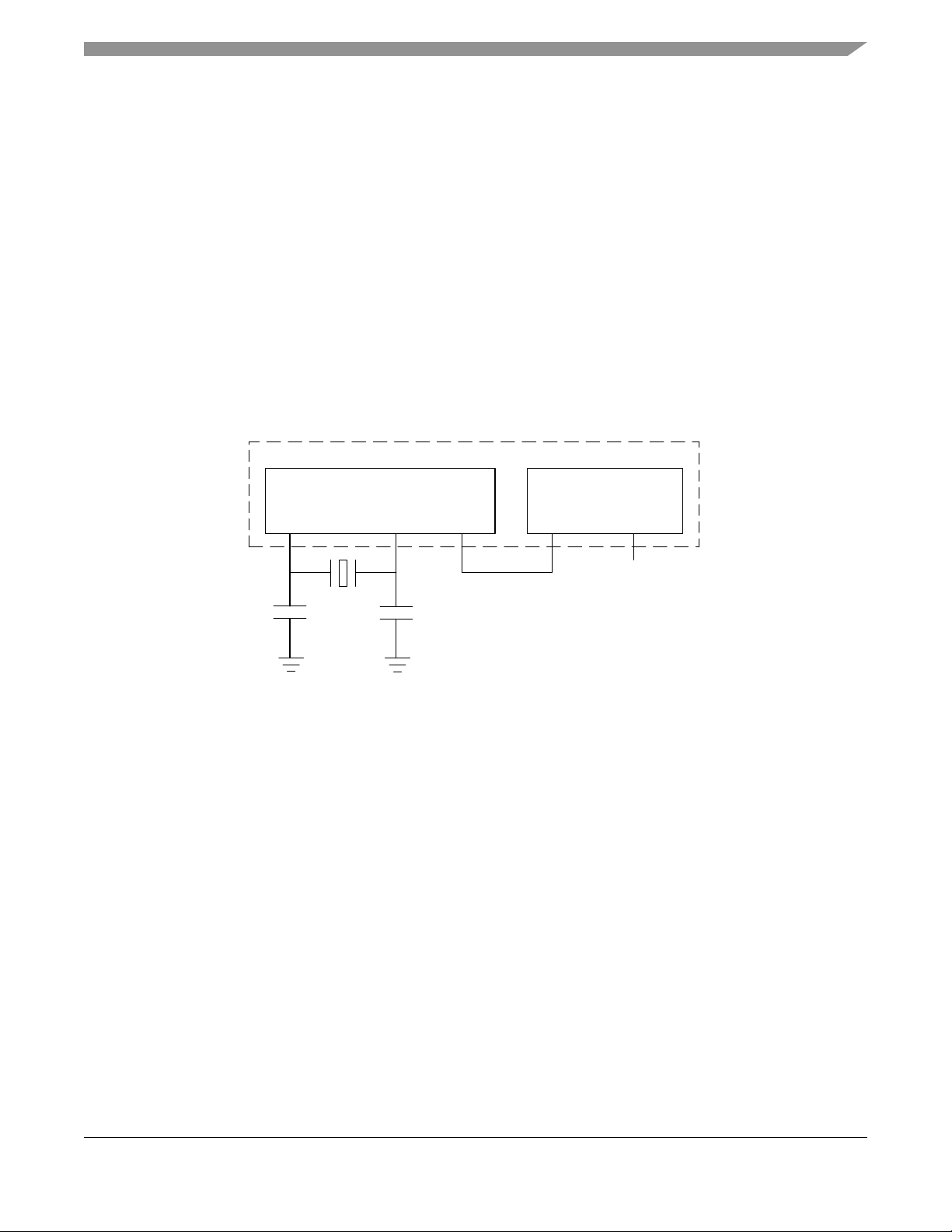

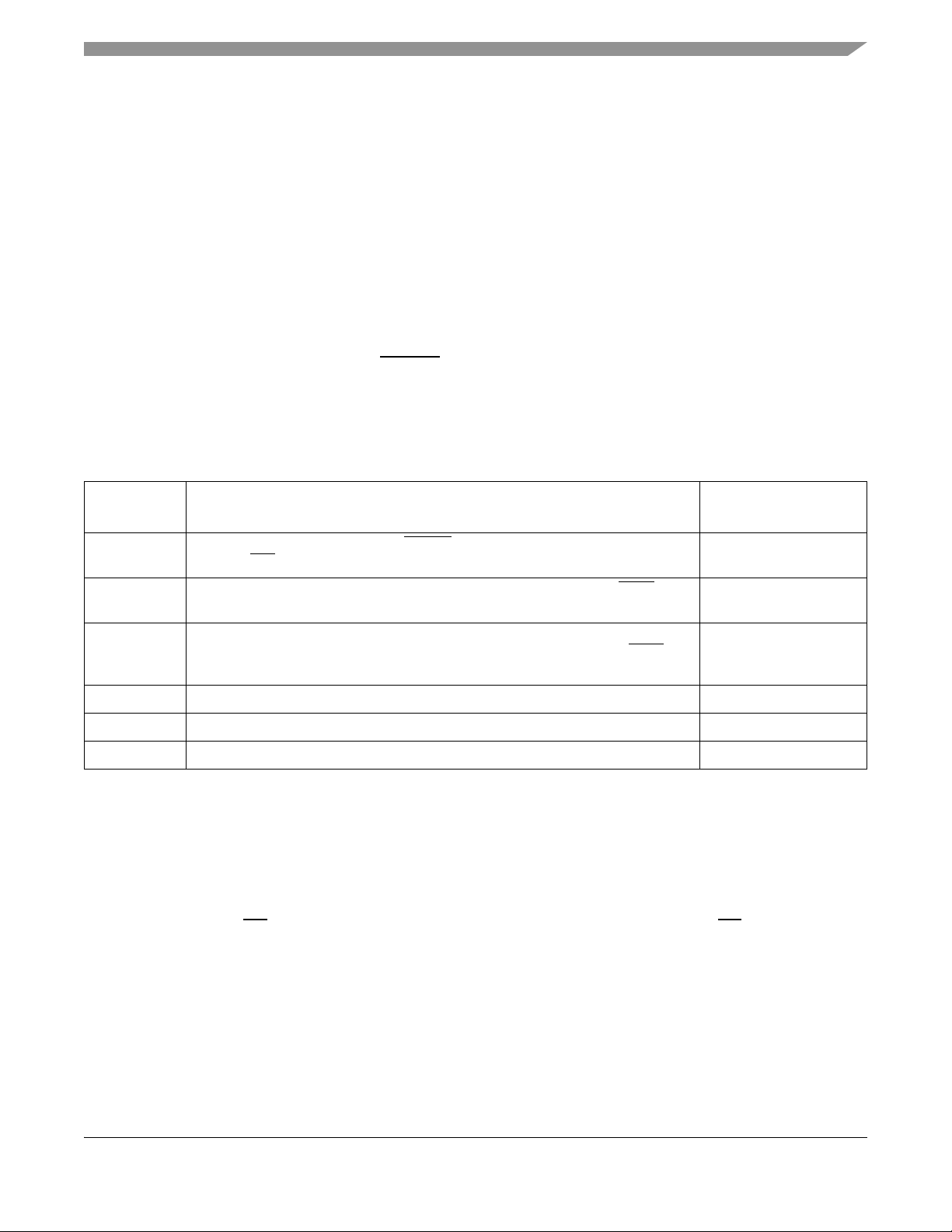

4.7 Modem Crystal Oscillator

The modem crystal oscillator uses the following external pins as shown in Figure 12.

1. XTAL1 - reference oscillator input.

2. XTAL2 - reference oscillator output. Note that this pin should not be loaded as a reference source

or to measure frequency; instead use CLKO to measure or supply 16 MHz.

MC1321X

802.15.4 MODEM

XTAL1 XTAL2 CLKO

27

28 10

16MH z

Figure 12. Modem Crystal Oscillator

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 21

Page 22

The IEEE 802.15.4 Standard requires that several frequency tolerances be kept within ± 40 ppm accuracy.

This means that a total offset up to 80 ppm between transmitter and receiver will still result in acceptable

performance. The primary determining factor in meeting this specification is the tolerance of the crystal

oscillator reference frequency. A number of factors can contribute to this tolerance and a crystal

specification will quantify each of them:

1. The initial (or make) tolerance of the crystal resonant frequency itself.

2. The variation of the crystal resonant frequency with temperature.

3. The variation of the crystal resonant frequency with time, also commonly known as aging.

4. The variation of the crystal resonant frequency with load capacitance, also commonly known as

pulling. This is affected by:

a) The external load capacitor values - initial tolerance and variation with temperature.

b) The internal trim capacitor values - initial tolerance and variation with temperature.

c) Stray capacitance on the crystal pin nodes - including stray on-chip capacitance, stray package

capacitance and stray board capacitance; and its initial tolerance and variation with

temperature.

Freescale has specified that a 16 MHz crystal with a <9 pF load capacitance is required. The 802.15.4

modem does not contain a reference divider, so 16 MHz is the only frequency that can be used. A crystal

requiring higher load capacitance is prohibited because a higher load on the amplifier circuit may

compromise its performance. The crystal manufacture r defines the load capacitance as that total external

capacitance seen across the two terminals of the crystal. The oscillator amplifier c onfiguration used in the

802.15.4 modem requires two balanced load capacitors from each terminal of the crystal to ground. As

such, the capacitors are seen to be in series by the crystal, so each must be <18 pF for proper loading.

The modem uses the 16 MHz crystal oscillator as the reference oscillator for the system and a

programmable warp capability is provided. It is controlled by programming CLKO_Ctl Register 0A, Bits

15-8 (xtal_trim[7:0]). The trimming procedure varies the frequency by a few hertz per step, depending on

the type of crystal. The high end of the frequency spectrum is set when xtal_trim[7:0] is set to zero. As

xtal_trim[7:0] is increased, the frequency is decreased. Accuracy of this feature can be observed by

varying xtal_trim[7:0] and using a spectrum analyzer or frequency counter to track the change in

frequency of the crystal signal. The reference oscillator frequency can be measured at the CLKO contact

by programming CLKO_Ctl Register 0A, Bits 2-0, to value 000.

MC13211/212/213/214 Technical Data, Rev. 0.0,

22 Freescale Semiconductor

Page 23

0

0 50 100 150 200 250 300

-100

-200

-300

-400

-500

-600

-700

Frequency Decrease (Hz)

-800

-900

xtal_t r i m[ 7:0] ( decim al )

Figure 13. Crystal Frequency Variation vs. xtal_trim[7:0]

Figure 13 shows typical oscillator frequency decrease versus the value programmed in xtal_trim[7:0].

4.8 Radio Usage

The MC1321x RF analog interface has been designed to provide maximum flexibility as well as low

external part count and cost. An on-chip transmit/receive (T/R) switch with bias switch (CT_Bias) can be

used for a simple single antenna interface with a balun. Alternately, separate full differential RFIN and

PAO outputs can be utilized for separate RX and TX antennae or external LNA and PA designs.

Figure 14 shows three possible configurations for the transceiver radio RF usage.

1. Figure 14A shows a single antenna configuration in which the MC1321x internal T/R switch is

used. The balun converts the single-ended antenna to differential signals that interface to the

RFIN_x (PAO_x) pins of the radio. The CT_Bias pin provides the proper bias point to the balun

depending on operation, that is, CT_Bias is at VDDA voltage for transmit and is at ground for

receive. The internal T/R switch enables the signal to an onboard LNA for receive and enables the

onboard PAs for transmit.

2. Figure 14B shows a single antenna configuration with an external low noise amplifier (LNA) for

greater range. An external antenna switch is used to multiplex the antenna between receive and

transmit. An LNA is in the receive path to add gain for greater receive sensitivity. Two external

baluns are required to convert the single-ended antenna switch signals to the differential signals

required by the radio. Separate RFIN and P AO signals are provided for connection with the baluns,

and the CT_Bias signal is programmed to provide the external switch control. The polarity of the

external switch control is selectable.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 23

Page 24

3. Figure 14C shows a dual antenna configuration where there is a RX antenna and a TX antenna. For

the receive side, the RX antenna is ac-coupled to the differential RFIN inputs and these capacitors

along with inductor L1 form a matching network. Inductors L2 and L3 are ac-coupled to ground to

form a frequency trap. For the transmit side, the TX antenna is connected to the differential PAO

outputs, and inductors L4 and L5 provide dc-biasing to VDDA but are ac isolated.

VDD

RFIN_P (PAO_P)

Balun

Bypass

L1

RFI N_M (PAO_M)

CT_Bias

MC1321x

PAO_P

PAO_M

14A) Using Onboard T/R Switch

RX Antenna

L1

TX Antenna

L2 L3

Bypass Bypass

VDDA

Ant

Sw

LNA

Balun

Balun

Bypass

VDDA

Bypass

RFIN_P (PAO_P)

L1

RFIN_M (PAO_M)

(Ant Sw C tl)

PAO_P

PAO_M

14B) Using External Antenna Switch With LNA

RFIN_P (PAO_P)

RFIN_M (PAO_M)

MC1321x

MC1321x

CT_Bias

L4 L5

CT_Bias

PAO_P

PAO_M

14C) Using Dual Antennae

Figure 14. Using the MC1321x with External RF Components

MC13211/212/213/214 Technical Data, Rev. 0.0,

24 Freescale Semiconductor

Page 25

5MCU

5.1 MCU Block Diagram

RESET

VDDAD

VSSAD

VREFH

VREFL

IRQ

MCU CORE

CPUBDC

MCU SYSTEM CONTROL

RESETS AND INTERRUPTS

MODES OF OPERATION

POWER MANAGEMENT

RTI

IRQ LVD

USER FLASH

(61,268 BYTES MAX)

USER RAM

(4096 BYTES MAX)

10-BIT

ANALOG-TO-DIGITAL

CONVERTER (ATD1)

INTERNAL CLOCK

GENERATOR (ICG)

LOW-POWER OSCILLATOR

COP

INTERNAL BUS

DEBUG

MODULE (DBG)

8-BIT KEYBOARD

INTERRUPT MODULE (KBI1)

IIC MODULE (IIC)

SERIAL COMMUNICATIONS

INTERFACE MODULE (SCI1)

SERIAL COMMUNICATIONS

INTERFACE MODULE (SCI2)

1-CHANNEL TIMER/PWM

MODULE (TPM1)

4-CHANNEL TIMER/PWM

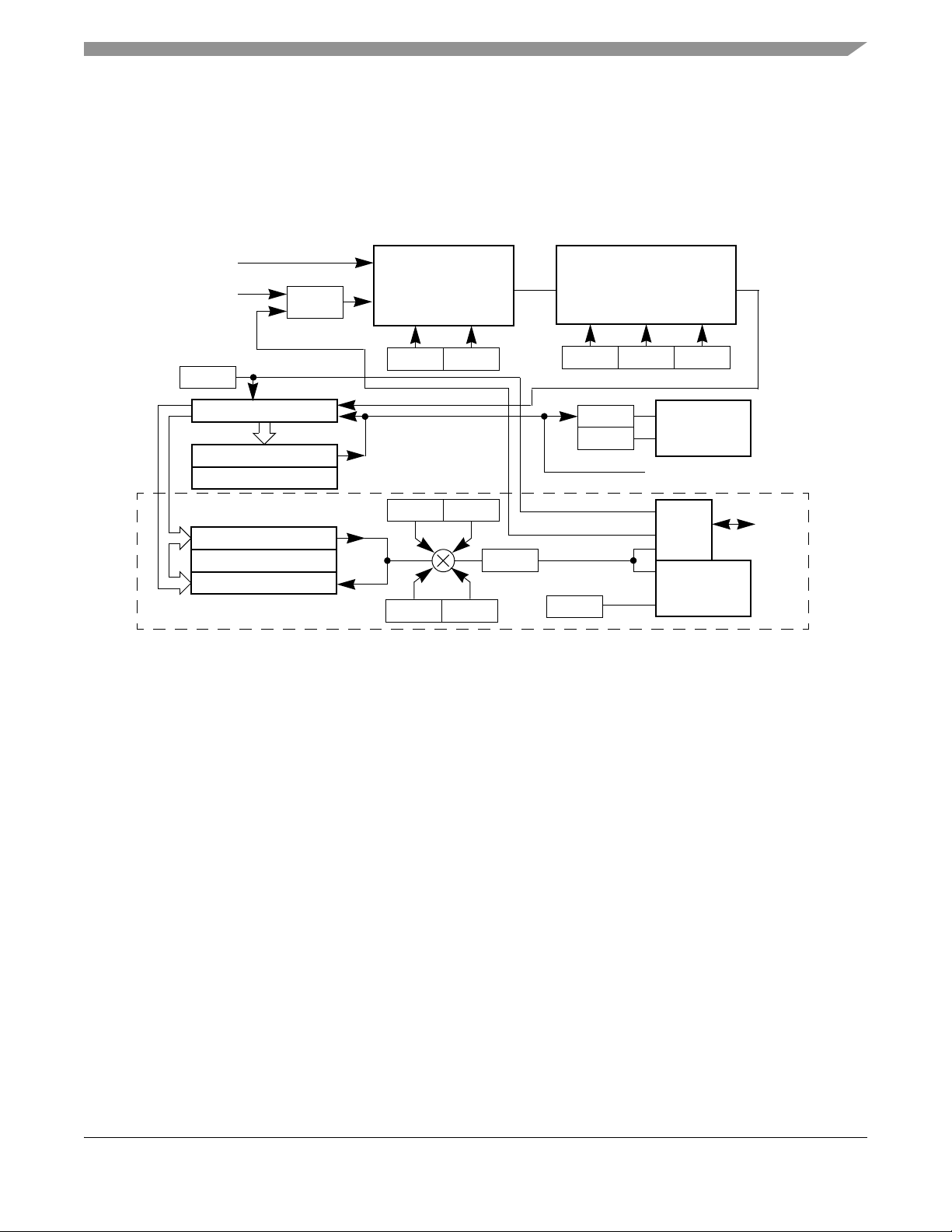

MODULE (TPM2)

DEDICATED SERIAL

PERIPHERAL INTERFACE

MODULE (SPI)

8

PORT A

8

PORT B

PORT C

PORT D

PORT E

See Note 1.

PORT F

PTA7/KBI1P7–

PTA0/KBI1P0

PTB7/AD1P7–

PTB0/AD1P0

PTC7

PTC6

PTC5

PTC4

PTC3/SCL1

PTC2/SDA1

PTC1/RxD2

PTC0/TxD2

PTD7/TPM2CH4

PTD6/TPM2CH3

PTD5/TPM2CH2

PTD4/TPM2CH1

PTD3

PTD2/TPM1CH2

PTD1

PTD0

PTE7

PTE6

PTE5/SPSCK

PTE4/MOSI

PTE3/MISO

PTE2/SS

PTE1/RxD1

PTE0/TxD1

VDD

VSS

Notes

1. All Port F and Port G signals are present on the MCU,

2.

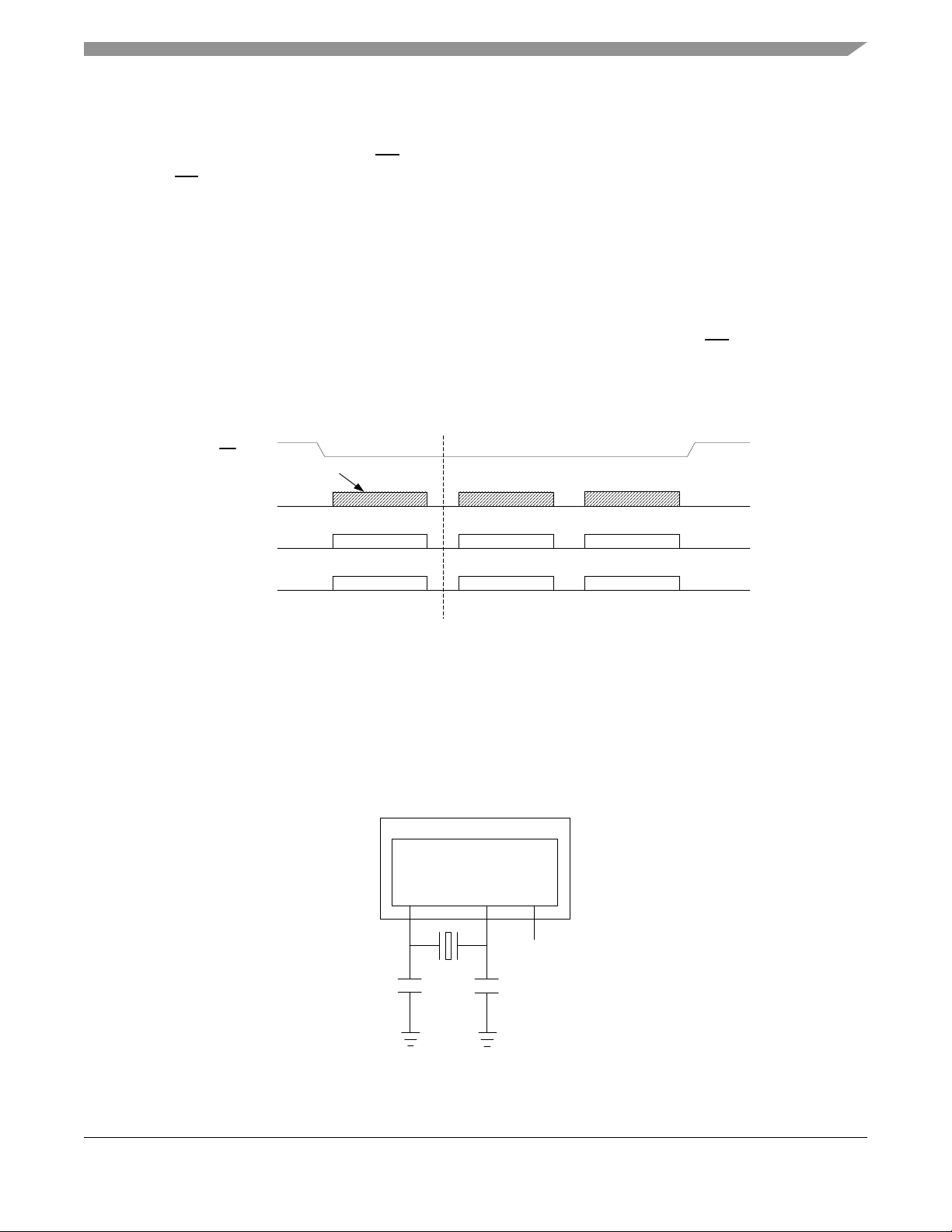

VOLTAGE

REGULATOR

but only the signals used by the MC1321x are designated.

For lowest power operation, all unused I/O should be programmed

as outputs during initialization.

Timer channels are limited as noted due to use of Port D I/O for

internal signals.

See Note 1.

PORT G

PTG2/EXTAL

PTG1/XTAL

PTG0/BKGD/MS

Figure 15. MCU Block Diagram

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 25

Page 26

5.2 MCU Modes of Operation

The MCU has multiple operational modes to facilitate maximum system performance while also providing

low-power modes. In the MC1321x, the MCU can use the following modes:

•Run

•Wait

• Stop2

• Stop3

NOTE

The MCU can also be programmed for Stop1 mode, but this mode IS NOT

USABLE. The reset to the modem function is controlled by an MCU GPIO

and the GPIO state must be maintained during the MCU “stop” condition.

Stop1 mode does not control I/O states as required during modem power

down condition.

5.2.1 Run Mode

This is the normal operating mode for the HCS08. This mode is selected when the BKGD/MS pin is high

at the rising edge of reset. In this mode, the CPU executes code from internal memory with execution

beginning at the address fetched from memory at $FFFE:$FFFF after reset.

5.2.2 Wait Mode

W ait Mode is entered by executing a WAIT instruction. Upon execution of the WAIT instruction, the CPU

enters a low-power state in which it is not clocked. The I bit in CCR is cleared when the CPU enters the

wait mode, enabling interrupts. When an interrupt request occurs, the CPU exits the wait mode and

resumes processing, beginning with the stacking operations leading to the interrupt service routine.

While the MCU is in Wait Mode, there are some restrictions on which background debug commands can

be used. Only the BACKGROUND command and memory-access-with-status commands are available

when the MCU is in wait mode. The memory-access-with-status commands do not allow memory access,

but they report an error indicating that the MCU is in either stop or wait mode. The BACKGROUND

command can be used to wake the MCU from Wait Mode and enter active background mode.

5.2.3 Stop 2

The Stop2 Mode provides very low standby power consumption and maintains the contents of RAM and

the current state of all of the I/O pins. Stop2 can be entered only if the LVD circuit is not enabled in Stop

Modes (either LVDE or LVDSE not set).

Before entering Stop2 Mode, the user must save the contents of the I/O port registers, as well as any other

memory-mapped registers they want to restore after exit of Stop2, to locations in RAM. Upon exit of

Stop2, these values can be restored by user software before pin latches are opened.

MC13211/212/213/214 Technical Data, Rev. 0.0,

26 Freescale Semiconductor

Page 27

When the MCU is in Stop2 Mode, all internal circuits that are powered from the voltage regulator are

turned off, except for the RAM. The voltage regulator is in a low-power standby state, as is the ATD. Upon

entry into Stop2, the states of the I/O pins are latched. The states are held while in Stop2 Mode and after

exiting Stop2 Mode until a 1 is written to PPDACK in SPMSC2.

Exit from Stop2 is performed by asserting either of the wake-up pins: RESET or IRQ, or by an RTI

interrupt. IRQ is always an active low input when the MCU is in Stop2, regardless of how it was

configured before entering Stop2.

Upon wake-up from Stop2 Mode, the MCU will start up as from a power-on reset (POR) except pin states

remain latched. The CPU will take the reset vector. The system and all peripherals will be in their default

reset states and must be initialized.

After waking up from Stop2, the PPDF bit in SPMSC2 is set. This flag may be used to direct user code to

go to a Stop2 recovery routine. PPDF remains set and the I/O pin states remain latched until a 1 is written

to PPDACK in SPMSC2.

To maintain I/O state for pins that were configured as general-purpose I/O, the user must restore the

contents of the I/O port registers, which have been saved in RAM, to the port registers before writing to

the PPDACK bit. If the port registers are not restored from RAM before writing to PPDACK, then the

register bits will assume their reset states when the I/O pin latches are opened and the I/O pins will switch

to their reset states.

For pins that were configured as peripheral I/O, the user must reconfigure the peripheral module that

interfaces to the pin before writing to the PPDACK bit. If the peripheral module is not enabled before

writing to PPDACK, the pins will be controlled by their associated port control registers when the I/O

latches are opened.

A separate self-clocked source (approximately 1 kHz) for the real-time interrupt allows a walk-up from

Stop2 or Stop3 Modes with no external components. When RTIS2:RTIS1:RTIS0 = 0:0:0, the real-time

interrupt function and this 1-kHz source are disabled. Power consumption is lower when the 1-kHz source

is disabled, but in that case the real-time interrupt cannot wake the MCU from stop.

5.2.4 Stop3

Upon entering the Stop3 Mode, all of the clocks in the MCU, including the oscillator itself, are halted. The

ICG is turned off, the ATD is disabled, and the voltage regulator is put in standby. The states of all of the

internal registers and logic, as well as the RAM content, are maintained. The I/O pin states are not latched

at the pin as in Stop2. Instead they are maintained by virtue of the states of the internal logic driving the

pins being maintained.

Exit from Stop3 is performed by asserting RESET

interrupt. The asynchronous interrupt pins are the IRQ or KBI pins.

If Stop3 is exited by means of the RESET pin, then the MCU will be reset and operation will resume after

taking the reset vector. Exit by means of an asynchronous interrupt or the real-time interrupt will result in

the MCU taking the appropriate interrupt vector.

, an asynchronous interrupt pin, or through the real-time

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 27

Page 28

A separate self-clocked source (approximately1 kHz) for the real-time interrupt allows a wake up from

Stop2 or Stop3 Modes with no external components. When RTIS2:RTIS1:RTIS0 = 0:0:0, the real-time

interrupt function and this 1-kHz source are disabled. Power consumption is lower when the 1-kHz source

is disabled, but in that case the real-time interrupt cannot wake the MCU from stop.

5.3 MCU Memory

As shown in Figure 16, on-chip memory in the MC1321x series of MCUs consists of RAM, FLASH

program memory for non-volatile data storage, plus I/O and control/status registers. The registers are

divided into three groups:

• Direct-page registers ($0000 through $007F)

• High-page registers ($1800 through $182B)

• Nonvolatile registers ($FFB0 through $FFBF)

DIRECT PAGE REGISTERS

RAM

4096 BYTES

FLASH

1920 BYTES

HIGH PAGE REGISTERS

FLASH

59348 BYTES

$0000

$007F

$0080

$107F

$1080

$17FF

$1800

$182B

$182C

DIRECT PAGE REGISTERS

RAM

2048 BYTES

UNIMPLEMENTED

3968 BYTES

HIGH PAGE REGISTERS

UNIMPLEMENTED

26580 BYTES

FLASH

32768 BYTES

$0000

$007F

$0080

$087F

$0880

$17FF

$1800

$182B

$182C

$7FFF

$8000

DIRECT PAGE REGISTERS

RAM 1024 BYTES

UNIMPLEMENTED

4992 BYTES

HIGH PAGE REGISTERS

UNIMPLEMENTED

42964 BYTES

FLASH

$0000

$007F

$0080

$047F

$0480

$17FF

$1800

$182B

$182C

$BFFF

$C000

16384 BYTES

$FFFF

MC13213/214 MC13212

$FFFF

MC13211

$FFFF

Figure 16. MC1321X Memory Maps

MC13211/212/213/214 Technical Data, Rev. 0.0,

28 Freescale Semiconductor

Page 29

5.4 MCU Internal Clock Generator (ICG)

The ICG provides multiple options for MCU clock sources. This block along with the ability to provide

the MCU clock form the modem offers a user great flexibility when making choices between cost,

precision, current draw , and performance. As seen in Figure 17, the ICG consists of four functional blocks.

• Oscillator Block — The Oscillator Block provides means for connecting an external crystal or

resonator. Two frequency ranges are software selectable to allow optimal start-up and stability.

Alternatively , the oscillator block can be used to route an external square wave to the MCU system

clock. External sources such as the modem CLKO output can provide a low cost source or a very

precise clock source. The oscillator is capable of being configured for low power mode or high

amplitude mode as selected by HGO.

• Internal Reference Generator — The Internal Reference Generator consists of two controlled

clock sources. One is designed to be approximately 8 MHz and can be selected as a local clock for

the background debug controller. The other internal reference clock source is typically 243 kHz

and can be trimmed for finer accuracy via software when a precise timed event is input to the MCU.

This provides a highly reliable, low-cost clock source.

• Frequency-Locked Loop — A Frequency-Locked Loop (FLL) stage takes either the internal or

external clock source and multiplies it to a higher frequency . Status bits provide information when

the circuit has achieved lock and when it falls out of lock. Additionally , this block can monitor the

external reference clock and signals whether the clock is valid or not.

• Clock Select Block — The Clock Select Block provides several switch options for connecting

different clock sources to the system clock tree. ICGDCLK is the multiplied clock frequency out

of the FLL, ICGERCLK is the reference clock frequency from the crystal or external clock source,

and FFE (fixed frequency enable) is a control signal used to control the system fixed frequency

clock (XCLK). ICGLCLK is the clock source for the background debug controller (BDC).

The module is intended to be very user friendly with many of the features occurring automatically without

user intervention.

5.4.1 Features

Features of the ICG and clock distribution system:

• Several options for the MCU primary clock source allow a wide range of cost, frequency, and

precision choices:

— 32 kHz–100 kHz crystal or resonator

— 1 MHz–16 MHz crystal or resonator

— External clock supplied by modem CLKO or other source

— Internal reference generator

• Defaults to self-clocked mode to minimize startup delays

• Frequency-locked loop (FLL) generates 8 MHz to 40 MHz (for bus rates up to 20 MHz). When

using modem CLKO as external source, maximum FLL frequency is 32 MHz (16 MHz bus rate)

with CLKO = 16 MHz or maximum FLL frequency is 40 MHz (20 MHz bus rate) with CLKO =

4 MHz.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 29

Page 30

— Uses external or internal clock as reference frequency

• Automatic lockout of non-running clock sources

• Reset or interrupt on loss of clock or loss of FLL lock

• Digitally-controlled oscillator (DCO) preserves previous frequency settings, allowing fast

frequency lock when recovering from stop3 mode

• DCO will maintain operating frequency during a loss or removal of reference clock. When FLL is

engaged (FEE or FEI) loss of lock or loss of clock adds a divide-by-2 to ICG to prevent

over-clocking of the system.

• Post-FLL divider selects 1 of 8 bus rate divisors (/1 through /128)

• Separate self-clocked source for real-time interrupt

• Trimmable internal clock source supports SCI communications without additional external

components

• Automatic FLL engagement after lock is acquired

• Selectable low-power/high-gain oscillator modes

5.4.2 Modes of Operation

This section provides a high-level description only.

• Mode 1 — Off

The output clock, ICGOUT, is static. This mode may be entered when the STOP instruction is

executed.

• Mode 2 — Self-clocked (SCM)

Default mode of operation that is entered out of reset. The ICG’ s FLL is open loop and the digitally

controlled oscillator (DCO) is free running at a frequency set by the filter bits.

• Mode 3 — FLL engaged internal tio.000Spera.00039may be eno..2(sm-i-the digitall.3(d)Tj-p5-thc1 Ttstatic. 8.29unning )Tj17.375 0 TD-0.0000.0002 Tis sde ofarew[(gris fr0004cations)Tj4-1.415 TD-0.0012a114ly-co150.m0.0ipl2-i-thck. Whe8.53n is

MC13211/212/213/214 Technical Data, Rev. 0.0,

30 Freescale Semiconductor

Page 31

— FLL engaged external locked is a state which occurs when the FLL detects that the DCO is

locked to a multiple of the internal reference.

Figure 17 is a top-level diagram that shows the functional organization of the internal clock generation

(ICG) module.

EXTAL

ICG

DCO

ICGDCLK

CLOCK

SELECT

OUTPUT

CLOCK

SELECT

FIXED

CLOCK

SELECT

/R

FFE

ICGLCLK

ICGOUT

XTAL

VDD

VSS

OSCILLATOR (OSC)

WITH EXTERNAL REF

SELECT

TYP 243 kHz

INTERNAL

REFERENCE

GENERATORS

IRG

8 MHz

RG

ICGERCLK

FREQUENCY

REF

SELECT

LOCKED

LOOP (FLL)

LOSS OF LOCK

AND CLOCK DETECTOR

ICGIRCLK

LOCAL CLOCK FOR OPTIONAL USE WITH BDC

Figure 17. ICG Block Diagram

5.5 Central Processing Unit (CPU)

The HCS08 CPU is fully source- and object-code-compatible with the M68HC08 CPU. Several

instructions and enhanced addressing modes were added to improve C compiler efficiency and to support

a new background debug system which replaces the monitor mode of earlier M68HC08 microcontrollers

(MCU).

5.5.1 CPU Features

Features of the CPU include:

• Object code fully upward-compatible with M68HC05 and M68HC08 Families

• All registers and memory are mapped to a single 64-Kbyte address space

• 16-bit stack pointer (any size stack anywhere in 64-Kbyte address space)

• 16-bit index register (H:X) with powerful indexed addressing modes

• 8-bit accumulator (A)

• Many instructions treat X as a second general-purpose 8-bit register

• Seven addressing modes:

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 31

Page 32

— Inherent — Operands in internal registers

— Relative — 8-bit signed offset to branch destination

— Immediate — Operand in next object code byte(s)

— Direct — Operand in memory at 0x0000–0x00FF

— Extended — Operand anywhere in 64-Kbyte address space

— Indexed relative to H:X — Five submodes including auto increment

— Indexed relative to SP — Improves C efficiency dramatically

• Memory-to-memory data move instructions with four address mode combinations

• Overflow, half-carry, negative, zero, and carry condition codes support conditional branching on

the results of signed, unsigned, and binary-coded decimal (BCD) operations

• Efficient bit manipulation instructions

• Fast 8-bit by 8-bit multiply and 16-bit by 8-bit divide instructions

• STOP and WAIT instructions to invoke low-power operating modes

5.5.2 Programmer’s Model and CPU Registers

Figure 18 shows the five CPU registers. CPU registers are not part of the memory map.

16-BIT INDEX REGISTER H:X

H

15

STACK POINTER

15

PROGRAM COUNTER

CONDITION CODE REGISTER

7

ACCUMULATOR

INDEX REGISTER (LOW)INDEX REGISTER (HIGH)

87

70

0

A

X

0

SP

0

PC

CCR

CV11HINZ

CARRY

ZERO

NEGATIVE

INTERRUPT MASK

HALF-CARRY (FROM BIT 3)

TWO’S COMPLEMENT OVERFLOW

Figure 18. CPU Registers

MC13211/212/213/214 Technical Data, Rev. 0.0,

32 Freescale Semiconductor

Page 33

5.6 Parallel Input/Output

The MC1321x HCS08 has seven I/O ports which include a total of 56 general-purpose I/O signals (one of

these pins, PTG0, is output only). The MC1321x family does not use all the these signals as denoted in

Figure 15. Port F and part of port G are not utilized. The MC1321x family makes use of the remaining I/O

as pinned-out I/O or as internally dedicated signal for communication with the 802.15.4 modem.

As stated above port F and part of port G are not utilized. These signals and any unused IO should be

programmed as outputs during initialization for lowest power operation. Many of these pins are shared

with on-chip peripherals such as timer systems, various communication ports, or keyboard interrupts.

When these other modules are not controlling the port pins, they revert to general-purpose I/O control. For

each I/O pin, a port data bit provides access to input (read) and output (write) data, a data direction bit

controls the direction of the pin, and a pullup enable bit enables an internal pullup device (provided the pin

is configured as an input), and a slew rate control bit controls the rise and fall times of the pins.Parallel I/O

features include:

• A total of 32 general-purpose I/O pins in seven ports (PTG0 is output only)

• High-current drivers on port C

• Hysteresis input buffers

• Software-controlled pullups on each input pin

• Software-controlled slew rate output buffers

• Eight port A pins shared with KBI1

• Eight port B pins shared with ATD1

• Eight high-current port C pins shared with SCI2 and IIC1

• Eight port D pins shared with TPM1 and TPM2

• Eight port E pins shared with SCI1 and SPI1

• Eight port G pins shared with EXTAL, XTAL, and BKGD/MS

NOTE

Not all port G signals and no port F signals are bonded out, but are present

in the MCU hardware (see Figure 15). These port I/O signals should be

programmed as outputs set to the low state.

5.7 MCU Peripherals

5.7.1 Modem Dedicated Serial Peripheral Interface (SPI) Module

The HCS08 provides one serial peripheral interface (SPI) module which is connected within the SiP to the

modem SPI port. The four pins associated with SPI functionality are shared with port E pins 2–5. When

the SPI is enabled, the direction of pins is controlled by module configuration.

The MCU SPI port is used only in master mode on the MC1321x family. The user must program the SPI

module for the proper characteristics as listed in the features below and also program the SS

the proper use to support the modem transaction protocol for the modem CE

signal.

signal to have

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 33

Page 34

5.7.1.1 SPI Features

Features of the SPI module use include:

• Used in master mode only

• Programmable transmit bit rate (maximum usable rate is 8 MHz with modem)

• Double-buffered transmit and receive

• Serial clock phase and polarity option must be programmed to CPHA = 0 and CPOL = 0

• Programmable slave select output to support modem SPI protocol

• MSB-first data transfer

5.7.1.2 SPI Module Block Diagram

Figure 19 is a block diagram of the SPI module. The central element of the SPI is the SPI shift register.

Data is written to the double-buffered transmitter (write to SPI1D) and gets transferred to the SPI shift

register at the start of a data transfer. After shifting in a byte of data, the data is transferred into the

double-buffered receiver where it can be read (read from SPI1D). Pin multiplexing logic controls

connections between MCU pins and the SPI module.

When the SPI is configured as a master, the clock output is routed to the SPSCK pin, the shifter output is

routed to MOSI, and the shifter input is routed from the MISO pin.

SPE

ENABLE

SPI SYSTEM

LSBFE

BUS RATE

CLOCK

MSTR

SHIFT

OUT

SHIFT

DIRECTION

SPIBR

CLOCK GENERATOR

MASTER/SLAVE

MODE SELECT

PIN CONTROL

M

S

Tx BUFFER (WRITE

M

SPI SHIFT REGISTER

Rx BUFFER (READ)

Rx BUFFER

SHIFT

CLOCK

CLOCK

LOGIC

MODE FAULT

DETECTION

FULL

SPRF

MODF

SHIFT

IN

Tx BUFFER

EMPTY

SPTEF

SPTIE

SPIE

SPC0

BIDIROE

MASTER CLOCK

SLAVE CLOCK

MOD-

SSOE

S

M

S

MASTER/

SLAVE

SPI

INTERRUPT

REQUEST

Figure 19. Modem Dedicated SPI Block Diagram

MOSI

MISO

SPSCK

SS

Connected onboard SiP

MOSI

MISO

MODEM

SPICLK

CE

SPI

PORT

MC13211/212/213/214 Technical Data, Rev. 0.0,

34 Freescale Semiconductor

Page 35

5.7.2 Keyboard Interrupt (KBI) Module

The HCS08 has one KBI module with eight keyboard interrupt inputs that share port A pins.

The KBI module allows up to eight pins to act as additional interrupt sources. Four of these pins allow

falling-edge sensing while the other four can be configured for either rising-edge sensing or falling-edge

sensing. The sensing mode for all eight pins can also be modified to detect edges and levels instead of only

edges.

This on-chip peripheral module is called a keyboard interrupt (KBI) module because originally it was

designed to simplify the connection and use of row-column matrices of keyboard switches. However, these

inputs are also useful as extra external interrupt inputs and as an external means of waking up the MCU

from stop or wait low-power modes.

5.7.3 KBI Features

The keyboard interrupt (KBI) module features include:

• Keyboard interrupts selectable on eight port pins:

— Four falling-edge/low-level sensitive

— Four falling-edge/low-level or rising-edge/high-level sensitive

— Choice of edge-only or edge-and-level sensitivity

— Common interrupt flag and interrupt enable control

— Capable of waking up the MCU from stop3 or wait mode

5.7.3.1 KBI Block Diagram

Figure 20 shows the block diagram for the KBI module.

KBIP0

KBIPE0

KBIP3

VDD

KBIMOD

CLR

DQ

CK

KBIP4

KBEDG4

KBIPn

KBEDGn

KBIPE3

1

0

S

KBIPE4

1

0

S

KBIPEn

Figure 20. KBI Block Diagram

KBACK

RESET

KEYBOARD

INTERRUPT FF

STOP

BUSCLK

SYNCHRONIZER

STOP BYPASS

KBIE

KBF

KEYBOARD

INTERRUPT

REQUEST

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 35

Page 36

5.7.4 Timer/PWM (TPM) Module Introduction

The HCS08 includes two independent Timer/PWM (TPM) modules which support traditional input

capture, output compare, or buffered edge-aligned pulse-width modulation (PWM) on each channel. A

control bit in each TPM configures all channels in that timer to operate as center-aligned PWM functions.

In each of these two TPMs, timing functions are based on a separate 16-bit counter with prescaler and

modulo features to control frequency and range (period between overflows) of the time reference. This

timing system is ideally suited for a wide range of control applications, and the center-aligned PWM

capability on the 3-channel TPM extends the field of applications to motor control in small appliances.

The use of the fixed system clock, XCLK, as the clock source for either of the TPM modules allows the

TPM prescaler to run using the oscillator rate divided by two (ICGERCLK/2). This clock source must be

selected only if the ICG is configured in either FBE or FEE mode. In FBE mode, this selection is redundant

because the BUSCLK frequency is the same as XCLK. In FEE mode, the proper conditions must be met

for XCLK to equal ICGERCLK/2. Selecting XCLK as the clock source with the ICG in either FEI or SCM

mode will result in the TPM being non-functional.

5.7.4.1 TPM Features

The timer system in the MC1321x family MCU includes a 1-channel TPM1 and a separate 4-channel

TPM2. Timer system features include:

• A total of 5 channels:

— Each channel may be input capture, output compare, or buffered edge-aligned PWM

— Rising-edge, falling-edge, or any-edge input capture trigger

— Set, clear, or toggle output compare action

— Selectable polarity on PWM outputs

• Each TPM may be configured for buffered, center-aligned pulse-w idth modulation (CPWM) on all

channels

• Clock source to prescaler for each TPM is independently selectable as bus clock, fixed system

clock, or an external pin

• Prescale taps for divide by 1, 2, 4, 8, 16, 32, 64, or 128

• 16-bit free-running or up/down (CPWM) count operation

• 16-bit modulus register to control counter range

• Timer system enable

• One interrupt per channel plus terminal count interrupt

MC13211/212/213/214 Technical Data, Rev. 0.0,

36 Freescale Semiconductor

Page 37

5.7.4.2 TPM Block Diagram

The TPM uses one input/output (I/O) pin per channel, TPMxCHn where x is the TPM number (for

example, 1 or 2) and n is the channel number (for example, 1–4). The TPM shares its I/O pins with

general-purpose I/O port pins. Figure 21 shows the structure of a TPM. Some MCUs include more than

one TPM, with various numbers of channels.

BUSCLK

XCLK

TPM1) EXT CLK

CPWMS

MAIN 16-BIT COUNTER

16-BIT COMPARATOR

TPM1MODH:TPM1MODL

CHANNEL 1

16-BIT COMPARATOR

TPM1C1VH:TPM1C1VL

16-BIT LATCH

SYNC

CLOCK SOURCE

SELECT

OFF, BUS, XCLK, EXT

CLKSB

COUNTER RESET

ELS1B

MS1B MS1A

CLKSA

ELS1A

PRESCALE AND SELECT

DIVIDE BY

1, 2, 4, 8, 16, 32, 64, or 128

PS2 PS1 PS0

TOF

TFIE

CH1F

CH1IE

Figure 21. TPM Block Diagram

5.7.5 Serial Communications Interface (SCI) Module

INTERRUPT

LOGIC

PORT

LOGIC

INTERRUPT

LOGIC

TPM1CH1

The HCS08 includes two independent serial communications interface (SCI) modules — sometimes called

universal asynchronous receiver/transmitters (UAR T s). Typically, these systems are used to connect to the

RS232 serial input/output (I/O) port of a personal computer or workstation, and they can also be used to

communicate with other embedded controllers.

A flexible, 13-bit, modulo-based baud rate generator supports a broad range of standard baud rates beyond

115.2 kbaud. Transmit and receive within the same SCI use a common baud rate, and each SCI module

has a separate baud rate generator.

This SCI system offers many advanced features not commonly found on other asynchronous serial I/O

peripherals on other embedded controllers. The receiver employs an advanced data sampling technique

that ensures reliable communication and noise detection. Hardware parity, receiver wakeup, and double

buffering on transmit and receive are also included.

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 37

Page 38

5.7.5.1 SCI Features

Features of SCI module include:

• Full-duplex, standard non-return-to-zero (NRZ) format

• Double-buffered transmitter and receiver with separate enables

• Programmable baud rates (13-bit modulo divider)

• Interrupt-driven or polled operation:

— Transmit data register empty and transmission complete

— Receive data register full

— Receive overrun, parity error, framing error, and noise error

— Idle receiver detect

• Hardware parity generation and checking

• Programmable 8-bit or 9-bit character length

• Receiver walk-up by idle-line or address-mark

MC13211/212/213/214 Technical Data, Rev. 0.0,

38 Freescale Semiconductor

Page 39

5.7.5.2 SCI Block Diagrams

The SCI allows full-duplex, asynchronous, NRZ serial communication among the MCU and remote

devices, including other MCUs. The SCI comprises a baud rate generator, transmitter, and receiver block.

The transmitter and receiver operate independently, although they use the same baud rate generator.

During normal operation, the MCU monitors the status of the SCI, writes the data to be transmitted, and

processes received data. Figure 22 and Figure 23 show the SCI transmitter and receiver block diagrams.

INTERNAL BUS

(WRITE-ONLY)

SCID – Tx BUFFER

1 ¥ BAUD

RATE CLOCK

ENABLE

H 8 7 6 5 4 3 2 1 0 L

PARITY

GENERATION

11-BIT TRANSMIT SHIFT REGISTER

STOP

SHIFT DIRECTION

SHIFT ENABLE

TRANSMIT CONTROL

PREAMBLE (ALL 1s)

START

LSB

BREAK (ALL 0s)

SCI CONTROLS TxD1

TxD1 DIRECTION

LOOP

CONTROL

TO RECEIVE

DATA IN

TO TxD1 PIN

TO TxD1

PIN LOGIC

Figure 22. SCI Transmitter

MC13211/212/213/214 Technical Data, Rev. 0.0,

Freescale Semiconductor 39

Page 40