Page 1

Freescale Semiconductor

Technical Data Advance Information

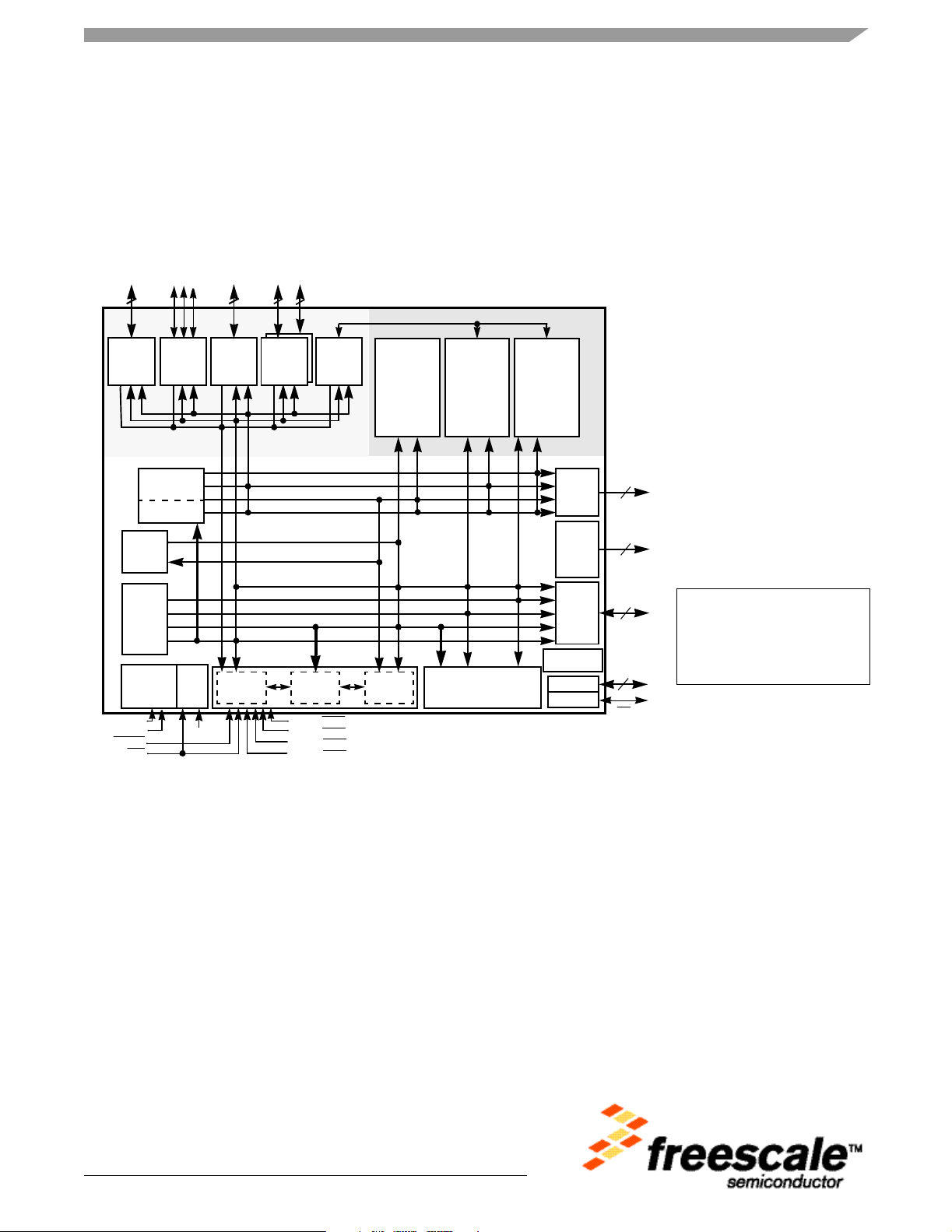

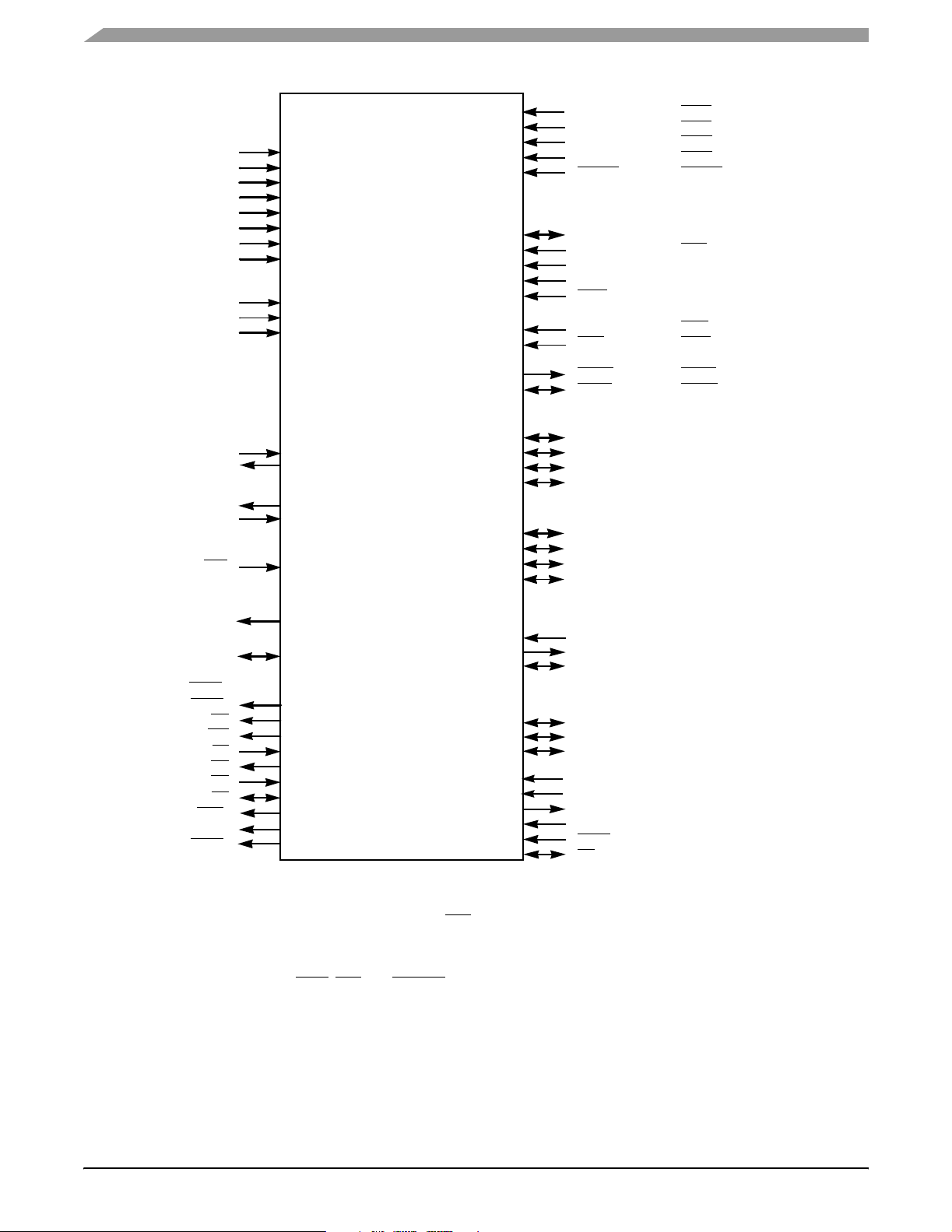

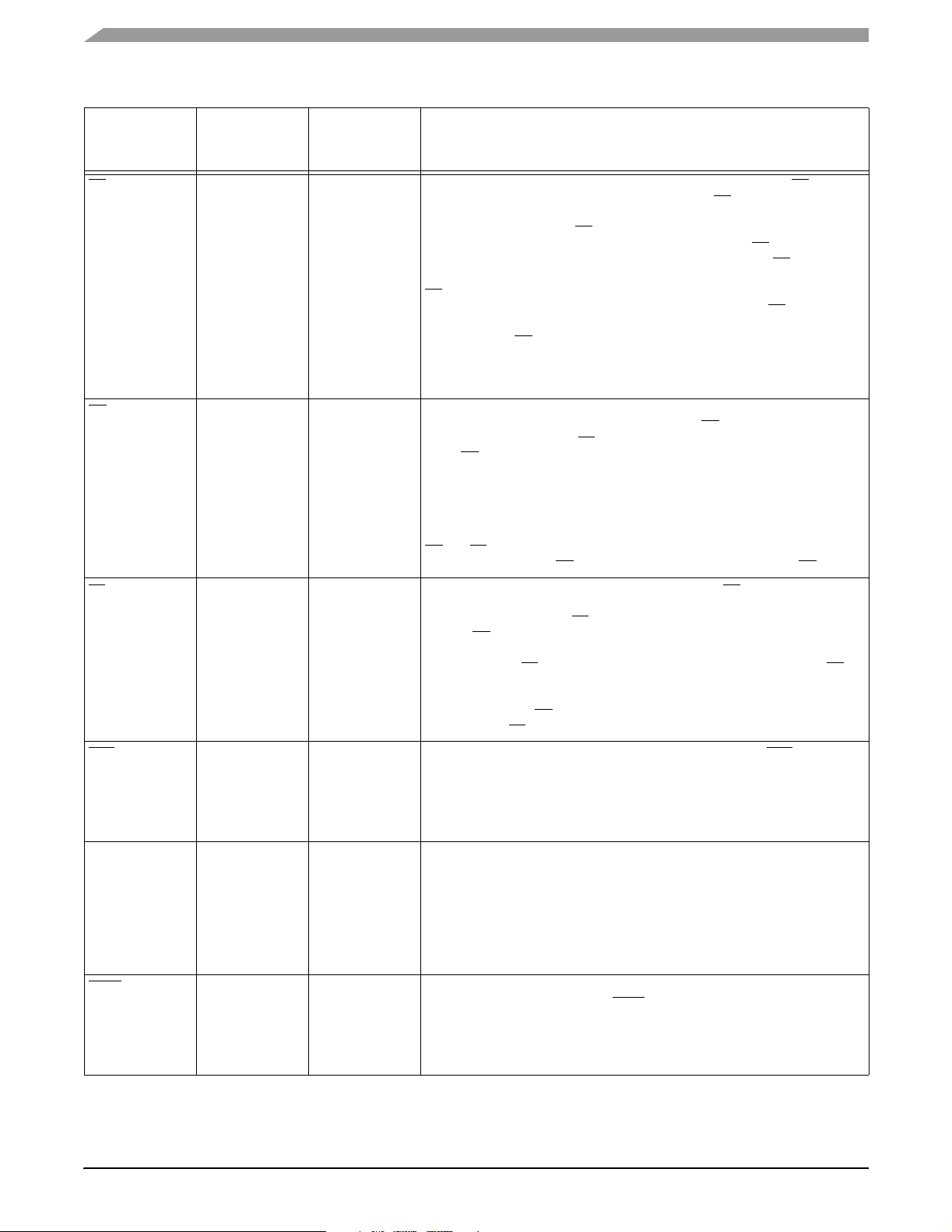

DSP56L307

24-Bit Digital Signal Processor

616

3

Generation

Six Channel

DMA Unit

ROM

Internal

Data

Bus

Switch

Clock

Tr i pl e

Timer

Address

Unit

PLL

SCI EFCOPESSIHI08

Bootstrap

Generator

EXTAL

XTAL

RESET

PINIT/NMI

PCAP

PIO_EB

Program

Interrupt

Controller

6

Peripheral

Expansion Area

Program

Decode

Controller

MODA/ IRQA

MODB /IRQB

MODC/IRQC

MODD/IRQD

Program

RAM

16 K × 24 bits

or

15 K × 24 bits

and

Instruction

Cache

1024 × 24 bits

DSP56300

Program

Address

Generator

X Data

RAM

24 K × 24 bits

YA B

PM_EB

XAB

PA B

DAB

24-Bit

Core

DDB

YDB

XDB

PDB

GDB

Data ALU

24 × 24 + 56 → 56-bit MAC

Two 56-bit Accumulators

56-bit Barrel Shifter

Memory Expansion Area

Y Data

RAM

24 K × 24 bits

XM_EB

YM_EB

I - Cache

Management

OnCE™

External

Address

Switch

External

Interface

Control

External

Switch

Powe r

JTAG

Bus

Bus

and

Data

Bus

18

Address

13

Control

24

Data

5

DE

DSP56L307

Rev. 6, 2/2005

The DSP56L307 is intended

for applications requiring a

large amount of internal

memory, such as networking

and wireless infrastructure

applications. The EFCOP

can accelerate general

filtering applications, such as

echo-cancellation

applications, correlation, and

general-purpose convolutionbased algorithms.

What’s New?

Rev. 6 includes the following

changes:

• Adds lead-free packaging and

part numbers.

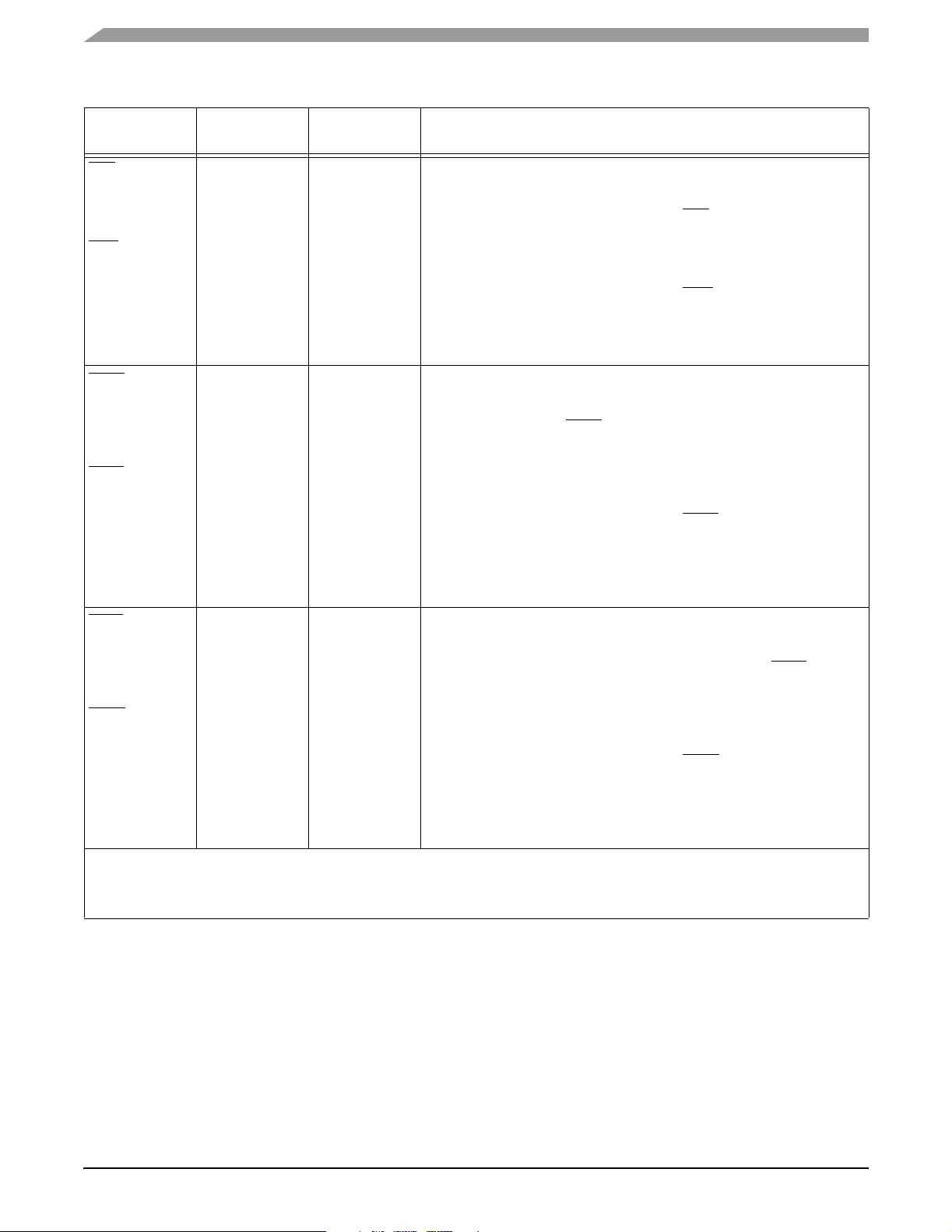

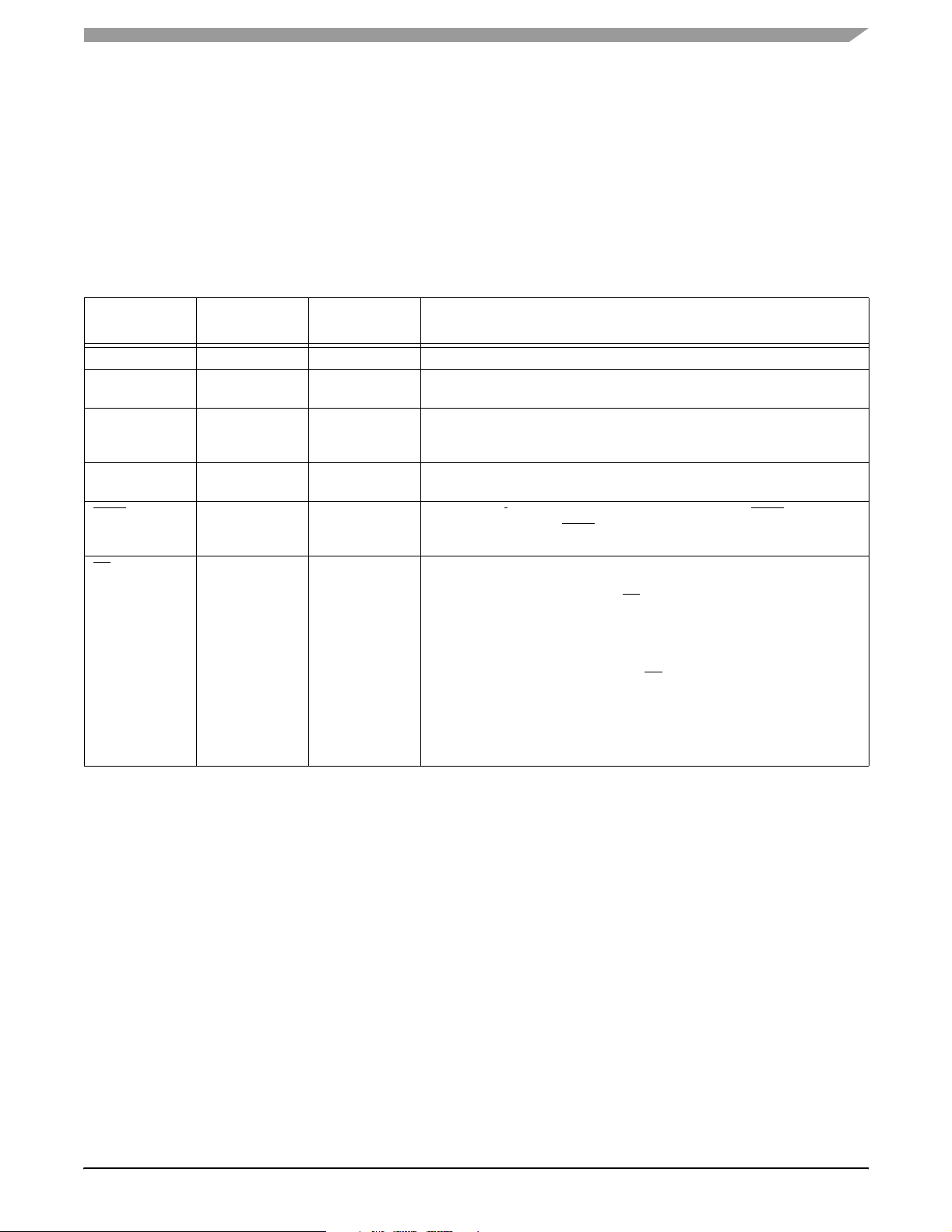

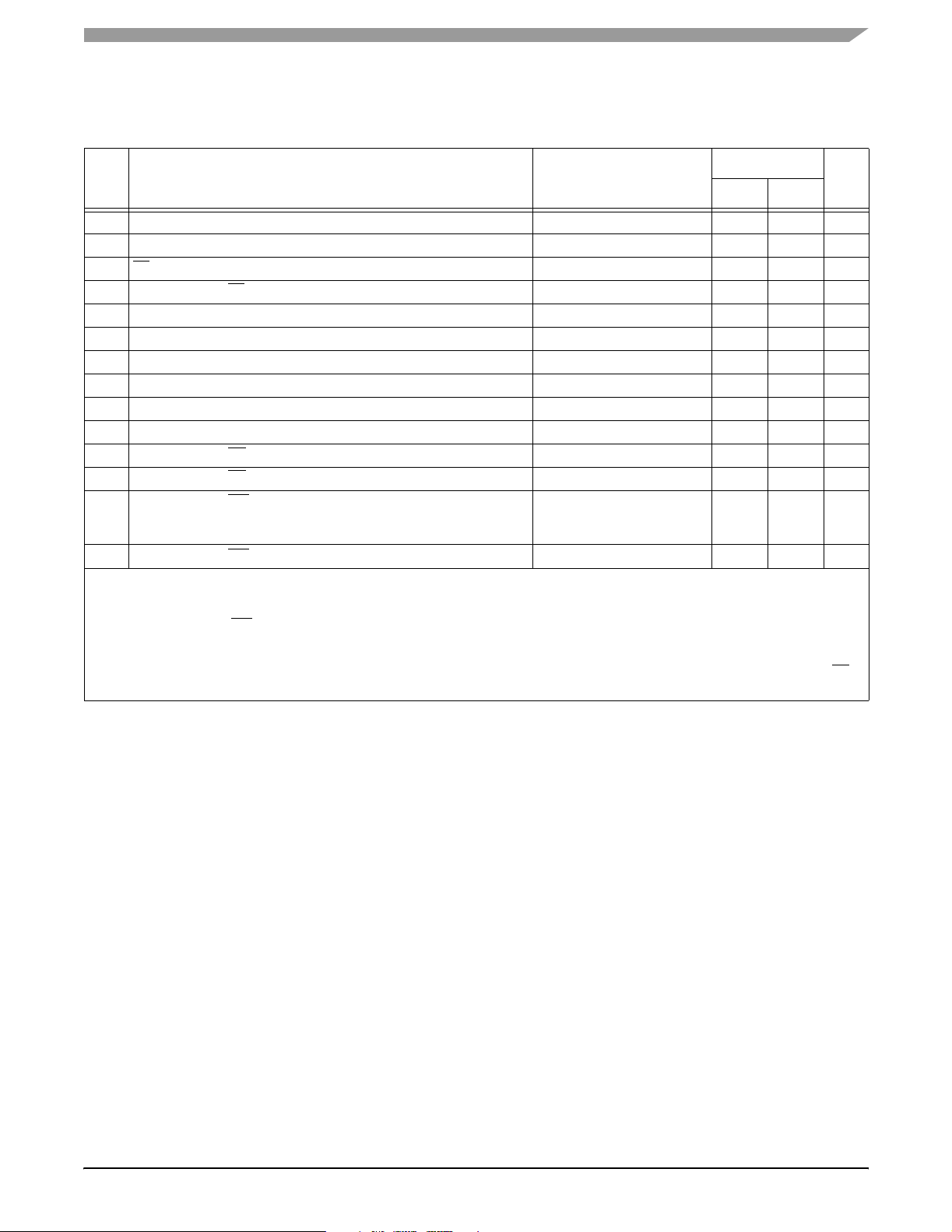

Figure 1. DSP56L307 Block Diagram

The Freescale DSP56L307, a member of the DSP56300 DSP family, supports network applications with general filtering

operations. The Enhanced Filter Coprocessor (EFCOP) executes filter algorithms in parallel with core operations, enhancing

signal quality with no impact on channel throughput or total channels supported. The result is increased overall performance.

Like the other DSP56300 family members, the DSP56L307 uses a high-performance, single-clock-cycle-per- instruction

engine (DSP56000 code-compatible), a barrel shifter, 24-bit addressing, an instruction cache, and a direct memory access

(DMA) controller (see Figure 1). The DSP56L307 performs at up to 160 million multiply-accumulates per second (MMACS),

attaining up to 320 MMACS when the EFCOP is in use. It operates with an internal 160 MHz clock with a 1.8 volt core and

independent 3.3 volt input/output (I/O) power.

Note: This document contains information on a new product. Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2001, 2005. All rights reserved.

Page 2

Table of Contents

Data Sheet Conventions .......................................................................................................................................ii

Features...............................................................................................................................................................iii

Target Applications .............................................................................................................................................iv

Product Documentation ......................................................................................................................................iv

Chapter 1 Signals/Connections

1.1 Power ................................................................................................................................................................1-3

1.2 Ground ..............................................................................................................................................................1-3

1.3 Clock .................................................................................................................................................................1-3

1.5 External Memory Expansion Port (Port A) ......................................................................................................1-4

1.6 Interrupt and Mode Control ..............................................................................................................................1-7

1.7 Host Interface (HI08) ........................................................................................................................................1-8

1.8 Enhanced Synchronous Serial Interface 0 (ESSI0) ........................................................................................1-11

1.9 Enhanced Synchronous Serial Interface 1 (ESSI1) ........................................................................................1-12

1.10 Serial Communication Interface (SCI) ...........................................................................................................1-13

1.11 Timers .............................................................................................................................................................1-14

1.12 JTAG and OnCE Interface ..............................................................................................................................1-15

Chapter 2 Specifications

2.1 Maximum Ratings.............................................................................................................................................2-1

2.2 Thermal Characteristics ....................................................................................................................................2-2

2.3 DC Electrical Characteristics ............................................................................................................................2-3

2.4 AC Electrical Characteristics ............................................................................................................................2-4

Chapter 3 Packaging

3.1 Package Description .........................................................................................................................................3-2

3.2 MAP-BGA Package Mechanical Drawing .....................................................................................................3-10

Chapter 4 Design Considerations

4.1 Thermal Design Considerations........................................................................................................................4-1

4.2 Electrical Design Considerations ......................................................................................................................4-2

4.3 Power Consumption Considerations .................................................................................................................4-3

4.4 PLL Performance Issues ...................................................................................................................................4-4

4.5 Input (EXTAL) Jitter Requirements .................................................................................................................4-5

Appendix A Power Consumption Benchmark

Data Sheet Conventions

OVERBAR

“asserted” Means that a high true (active high) signal is high or that a low true (active low) signal is low

“deasserted” Means that a high true (active high) signal is low or that a low true (active low) signal is high

Examples: Signal/Symbol Logic State Signal State Voltage

Note: Values for VIL, VOL, VIH, and VOH are defined by individual product specifications.

Indicates a signal that is active when pulled low (For example, the RESET pin is active when

low.)

PIN

PIN

PIN

PIN

True Asserted

False Deasserted

True Asserted

False Deasserted

DSP56L307 Technical Data, Rev. 6

VIL/V

VIH/V

VIH/V

VIL/V

OL

OH

OH

OL

ii Freescale Semiconductor

Page 3

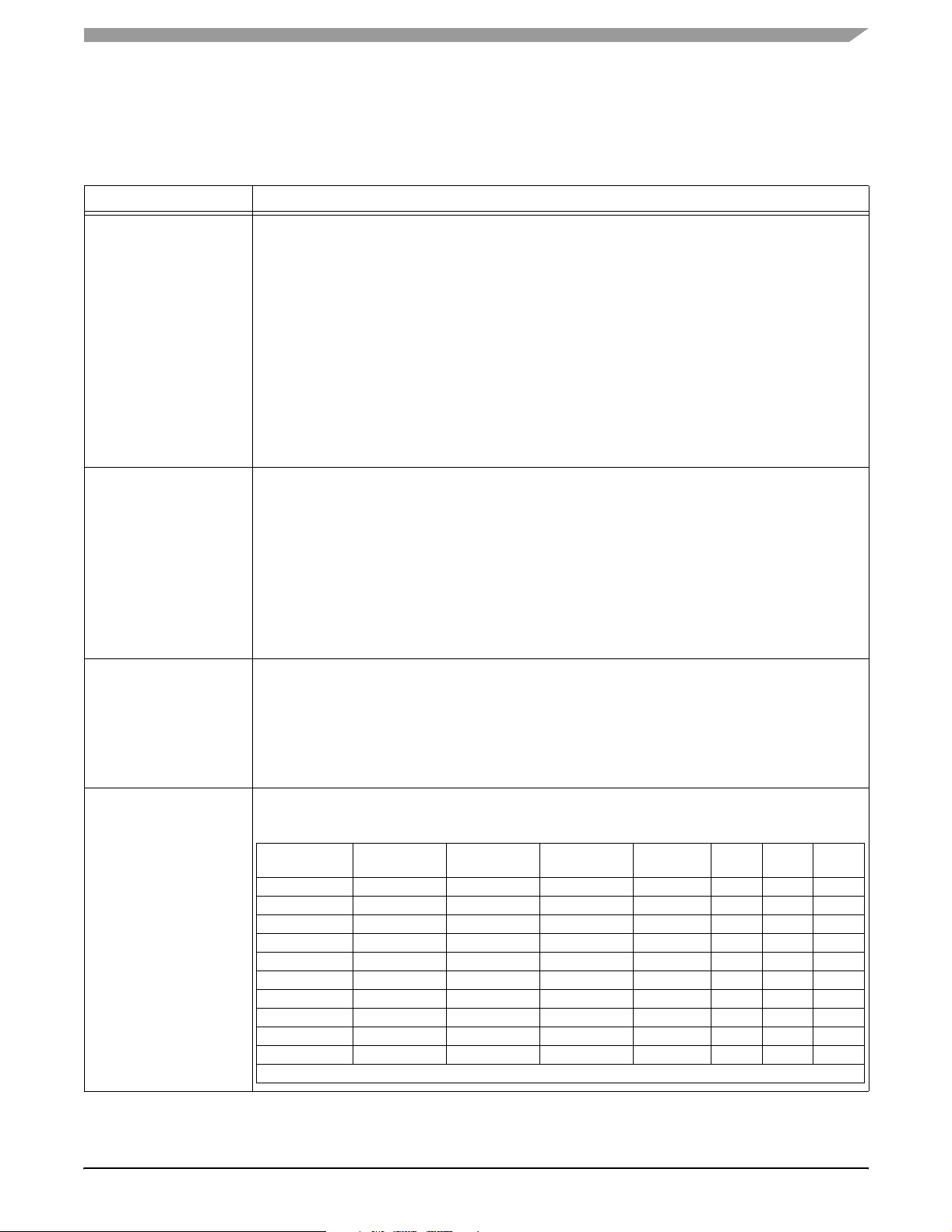

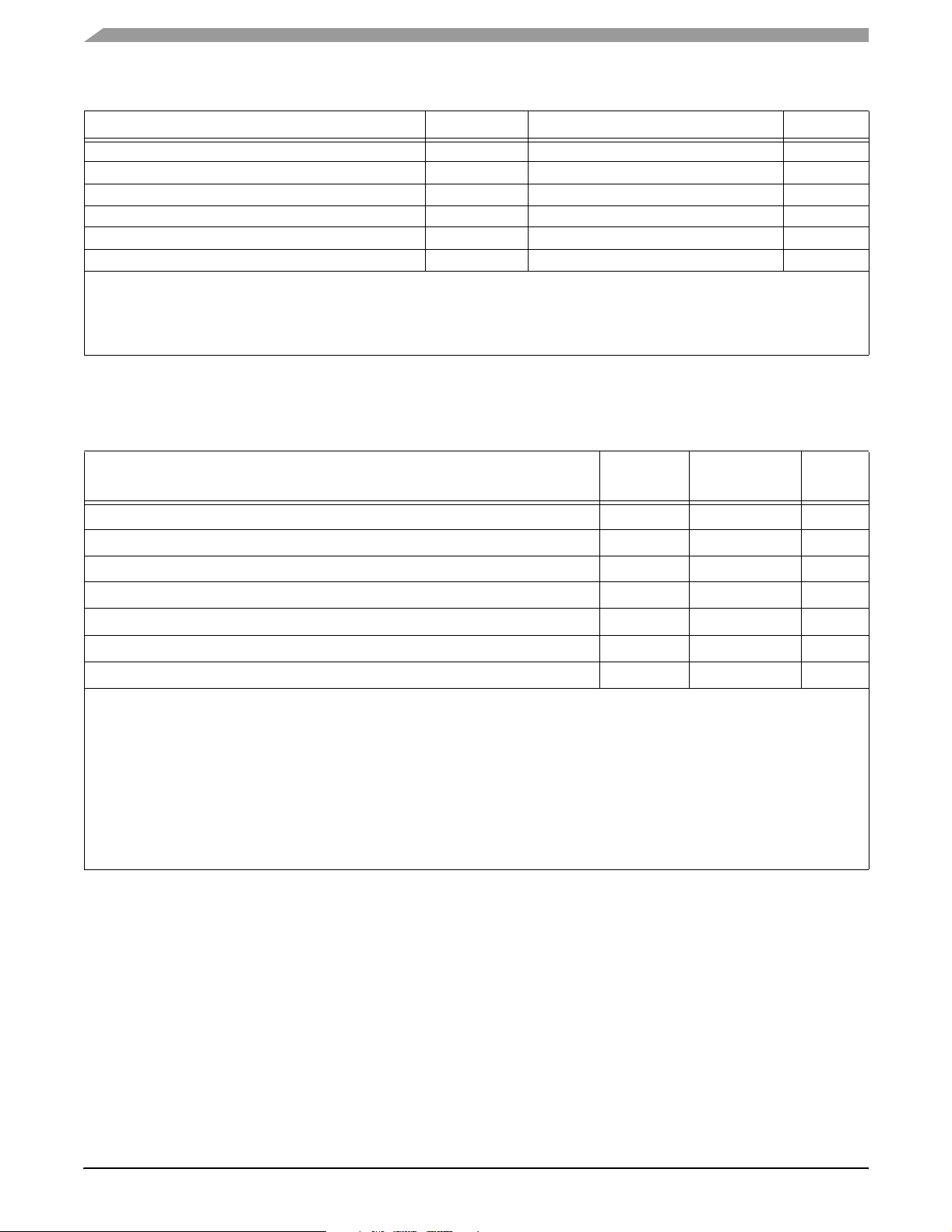

Features

:

Tabl e 1 lists the features of the DSP56L307 device.

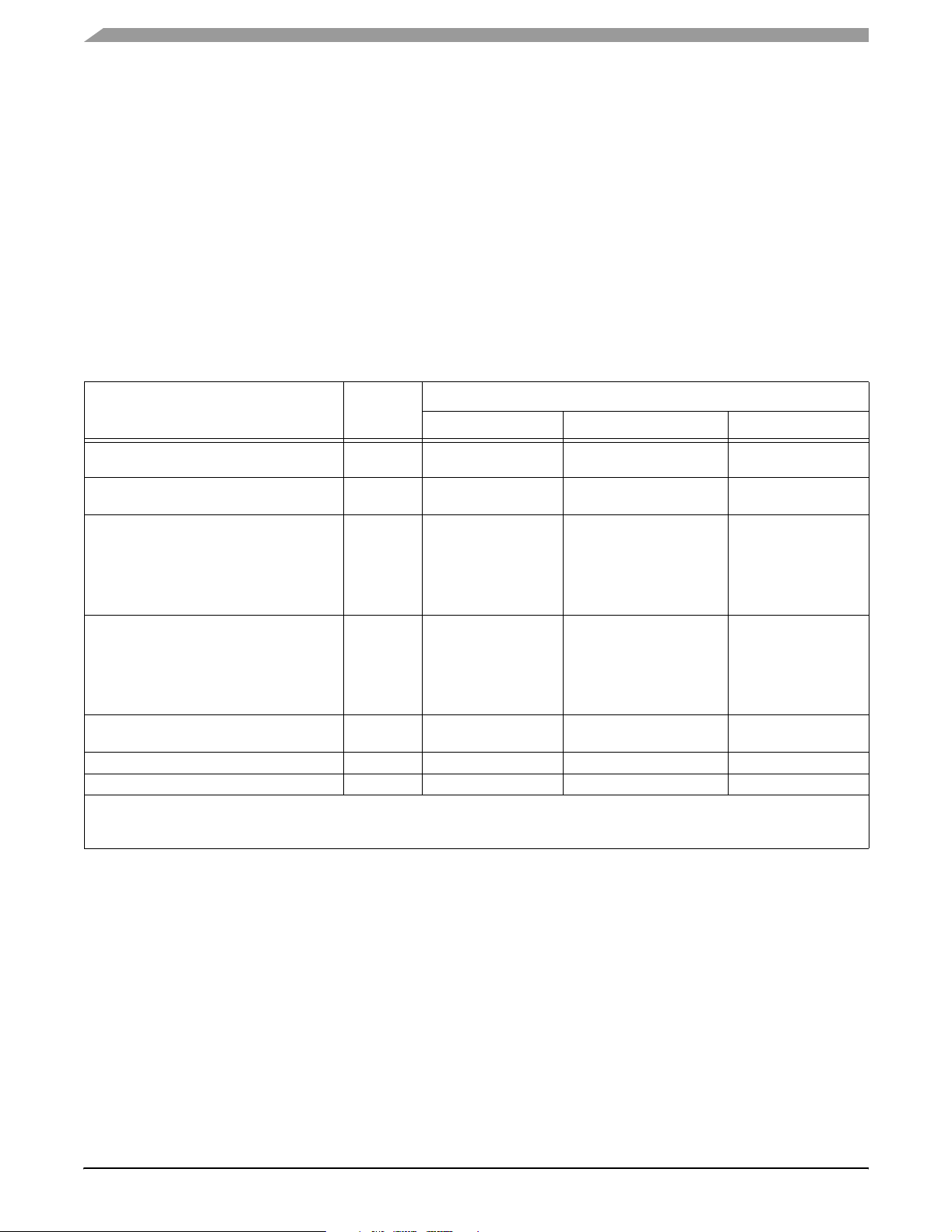

Tabl e 1 . DSP56L307 Features

Feature Description

• 160 million multiply-accumulates per second (MMACS) (320 MMACS using the EFCOP in filtering

applications) with a 160 MHz clock at 1.8 V core and 3.3 V I/O

• Object code compatible with the DSP56000 core with highly parallel instruction set

• Data arithmetic logic unit (Data ALU) with fully pipelined 24 × 24-bit parallel multiplier-accumulator (MAC),

56-bit parallel barrel shifter (fast shift and normalization; bit stream generation and parsing), conditional

ALU instructions, and 24-bit or 16-bit arithmetic support under software control

High-Performance

DSP56300 Core

Enhanced Filter

Coprocessor (EFCOP)

Internal Peripherals

Internal Memories

• Program control unit (PCU) with position-independent code (PIC) support, addressing modes optimized for

DSP applications (including immediate offsets), internal instruction cache controller, internal memoryexpandable hardware stack, nested hardware DO loops, and fast auto-return interrupts

• Direct memory access (DMA) with six DMA channels supporting internal and external accesses; one-, twoand three-dimensional transfers (including circular buffering); end-of-block-transfer interrupts; and

triggering from interrupt lines and all peripherals

• Phase-lock loop (PLL) allows change of low-power divide factor (DF) without loss of lock and output clock

with skew elimination

• Hardware debugging support including on-chip emulation (OnCE) module, Joint Test Action Group (JTAG)

test access port (TAP)

• Internal 24 × 24-bit filtering and echo-cancellation coprocessor that runs in parallel to the DSP core

• Operation at the same frequency as the core (up to 160 MHz)

• Support for a variety of filter modes, some of which are optimized for cellular base station applications:

• Real finite impulse response (FIR) with real taps

• Complex FIR with complex taps

• Complex FIR generating pure real or pure imaginary outputs alternately

• A 4-bit decimation factor in FIR filters, thus providing a decimation ratio up to 16

• Direct form 1 (DFI) Infinite Impulse Response (IIR) filter

• Direct form 2 (DFII) IIR filter

• Four scaling factors (1, 4, 8, 16) for IIR output

• Adaptive FIR filter with true least mean square (LMS) coefficient updates

• Adaptive FIR filter with delayed LMS coefficient updates

• Enhanced 8-bit parallel host interface (HI08) supports a variety of buses (for example, ISA) and provides

glueless connection to a number of industry-standard microcomputers, microprocessors, and DSPs

• Two enhanced synchronous serial interfaces (ESSI), each with one receiver and three transmitters (allows

six-channel home theater)

• Serial communications interface (SCI) with baud rate generator

• Triple timer module

• Up to 34 programmable general-purpose input/output (GPIO) pins, depending on which peripherals are

enabled

•192 × 24-bit bootstrap ROM

•192 K × 24-bit RAM total

• Program RAM, instruction cache, X data RAM, and Y data RAM sizes are programmable:

Program RAM

Size

16 K × 24-bit 0 24 K × 24-bit 24 K × 24-bit disabled disabled 0/1 0/1

15 K × 24-bit 1024 × 24-bit 24 K × 24-bit 24 K × 24-bit enabled disabled 0/1 0/1

48 K × 24-bit 0 8 K × 24-bit 8 K × 24-bit disabled enabled 0 0

47 K × 24-bit 1024 × 24-bit 8 K × 24-bit 8 K × 24-bit enabled enabled 0 0

40 K × 24-bit 0 12 K × 24-bit 12 K × 24-bit disabled enabled 0 1

39 K × 24-bit 1024 × 24-bit 12 K × 24-bit 12 K × 24-bit enabled enabled 0 1

32 K × 24-bit 0 16 K × 24-bit 16 K × 24-bit disabled enabled 1 0

31 K × 24-bit 1024 × 24-bit 16 K × 24-bit 16 K × 24-bit enabled enabled 1 0

24 K × 24-bit 0 20 K × 24-bit 20 K × 24-bit disabled enabled 1 1

23 K × 24-bit 1024 × 24-bit 20 K × 24-bit 20 K × 24-bit enabled enabled 1 1

*Includes 4 K × 24-bit shared memory (that is, memory shared by the core and the EFCOP)

Instruction

Cache Size

X Data RAM

Size*

Y Data RAM

Size*

Instruction

Cache

Switch

Mode

MSW1 MSW0

Freescale Semiconductor

DSP56L307 Technical Data, Rev. 6

iii

Page 4

Table 1. DSP56L307 Features (Continued)

Feature Description

• Data memory expansion to two 256 K × 24-bit word memory spaces using the standard external address

lines

External Memory

Expansion

Power Dissipation

Packaging

• Program memory expansion to one 256 K × 24-bit words memory space using the standard external

address lines

• External memory expansion port

• Chip select logic for glueless interface to static random access memory (SRAMs)

• Internal DRAM Controller for glueless interface to dynamic random access memory (DRAMs) up to 100

MHz operating frequency

• Very low-power CMOS design

• Wait and Stop low-power standby modes

• Fully static design specified to oper ate down to 0 Hz (dc)

• Optimized power management circuitry (instruction-dependent, peripheral-dependent, and modedependent)

• Molded array plastic-ball grid array (MAP-BGA) package in lead-free or lead-bearing versions.

Target Applications

• Wireless and wireline infrastructure applications

• Multi-channel wireless local loop systems

• DSP resource boards

• High-speed modem banks

• Packet telephony

Product Documentation

The documents listed in Table 2 are required for a complete description of the DSP56L307 device and are

necessary to design properly with the part. Documentation is available from a local Freescale distributor, a

Freescale semiconductor sales office, or a Freescale Semiconductor Literature Distribution Center. For

documentation updates, visit the Freescale DSP website. See the contact information on the back cover of this

document.

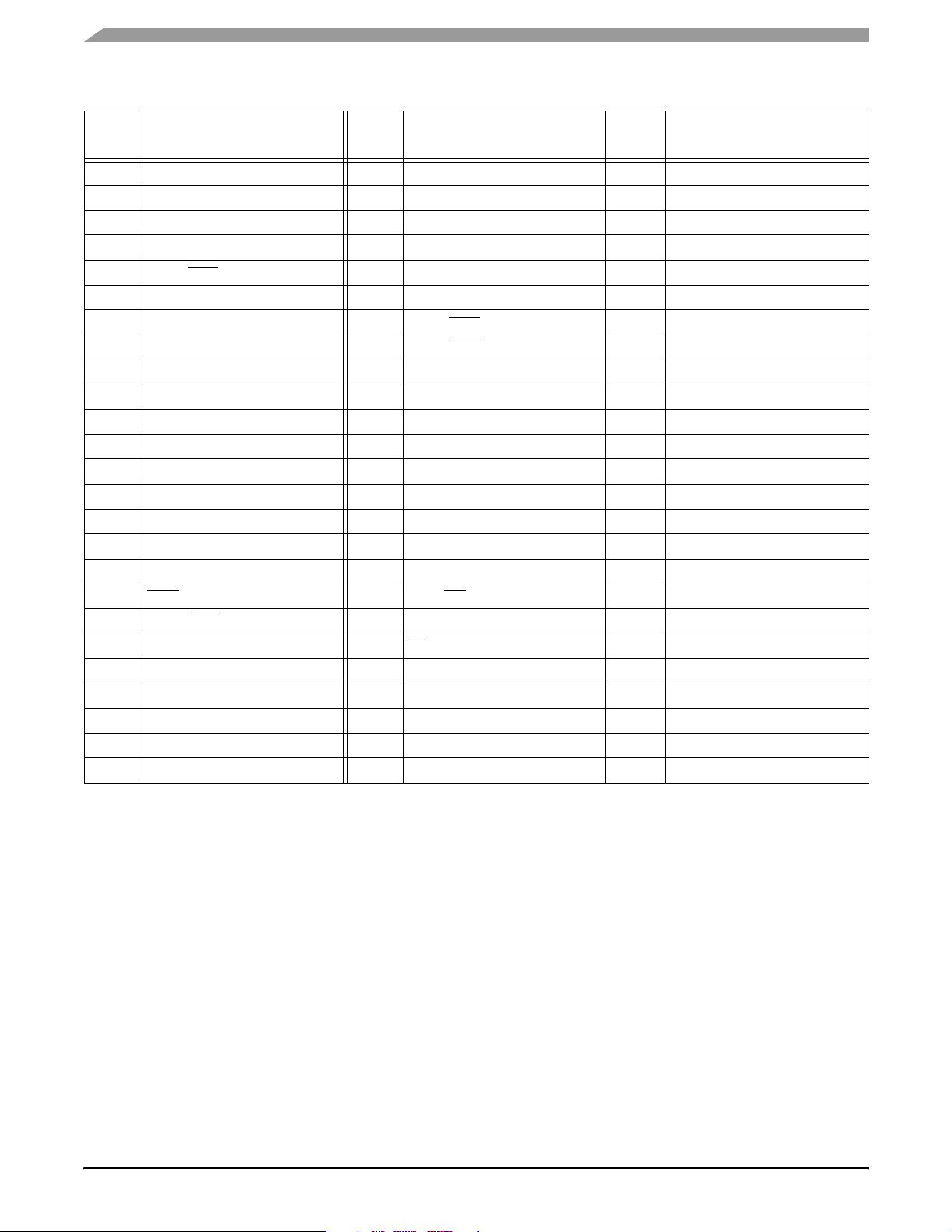

Table 2. DSP56L307 Documentation

Name Description Order Number

DSP56L307

User’s Manual

DSP56300 Family

Manual

Application Notes Documents describing specific applications or optimized device operation

Detailed functional description of the DSP56L307 memory configuration,

operation, and register programming

Detailed description of the DSP56300 family processor core and instruction set DSP56300FM

including code examples

DSP56L307UM

See the DSP56L307 product website

DSP56L307 Technical Data, Rev. 6

iv Freescale Semiconductor

Page 5

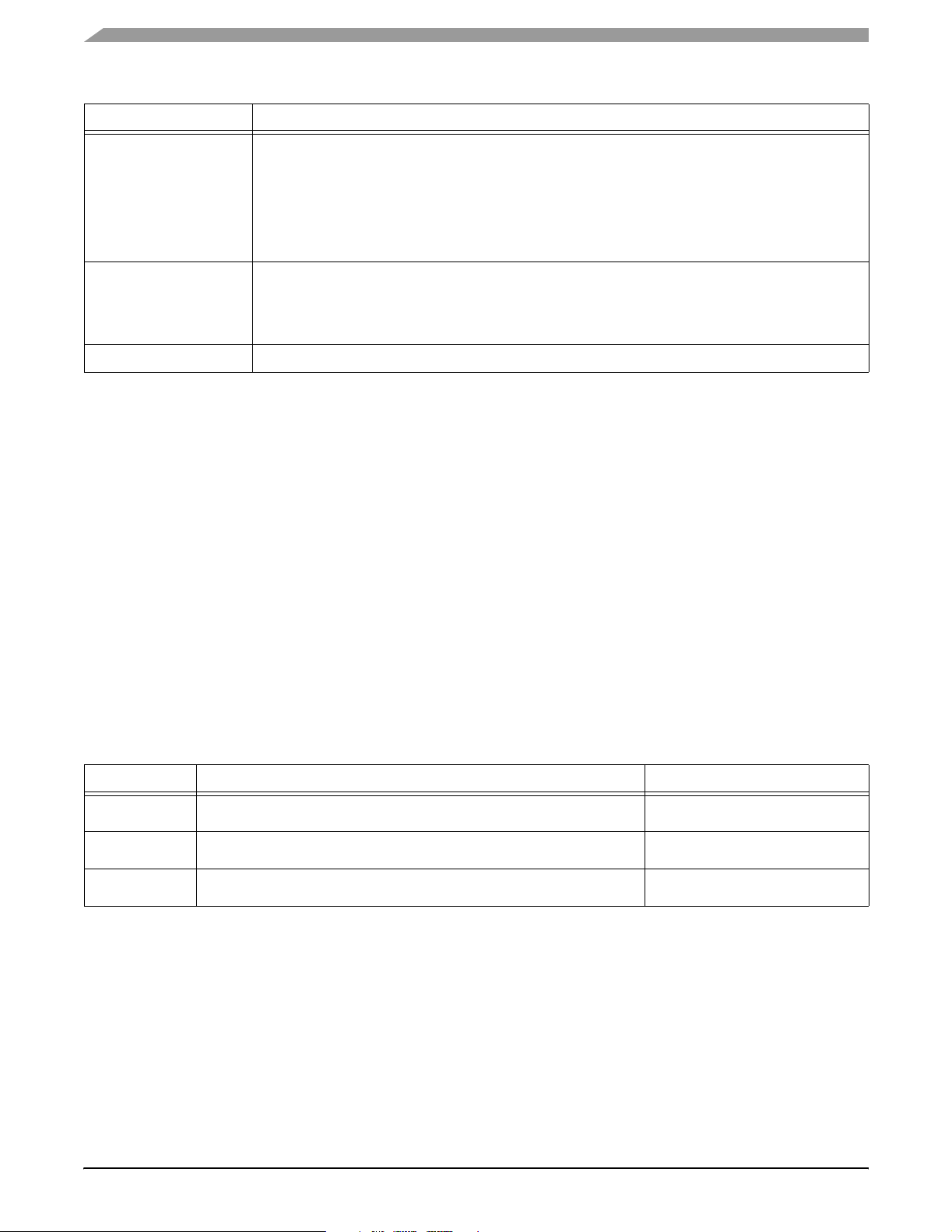

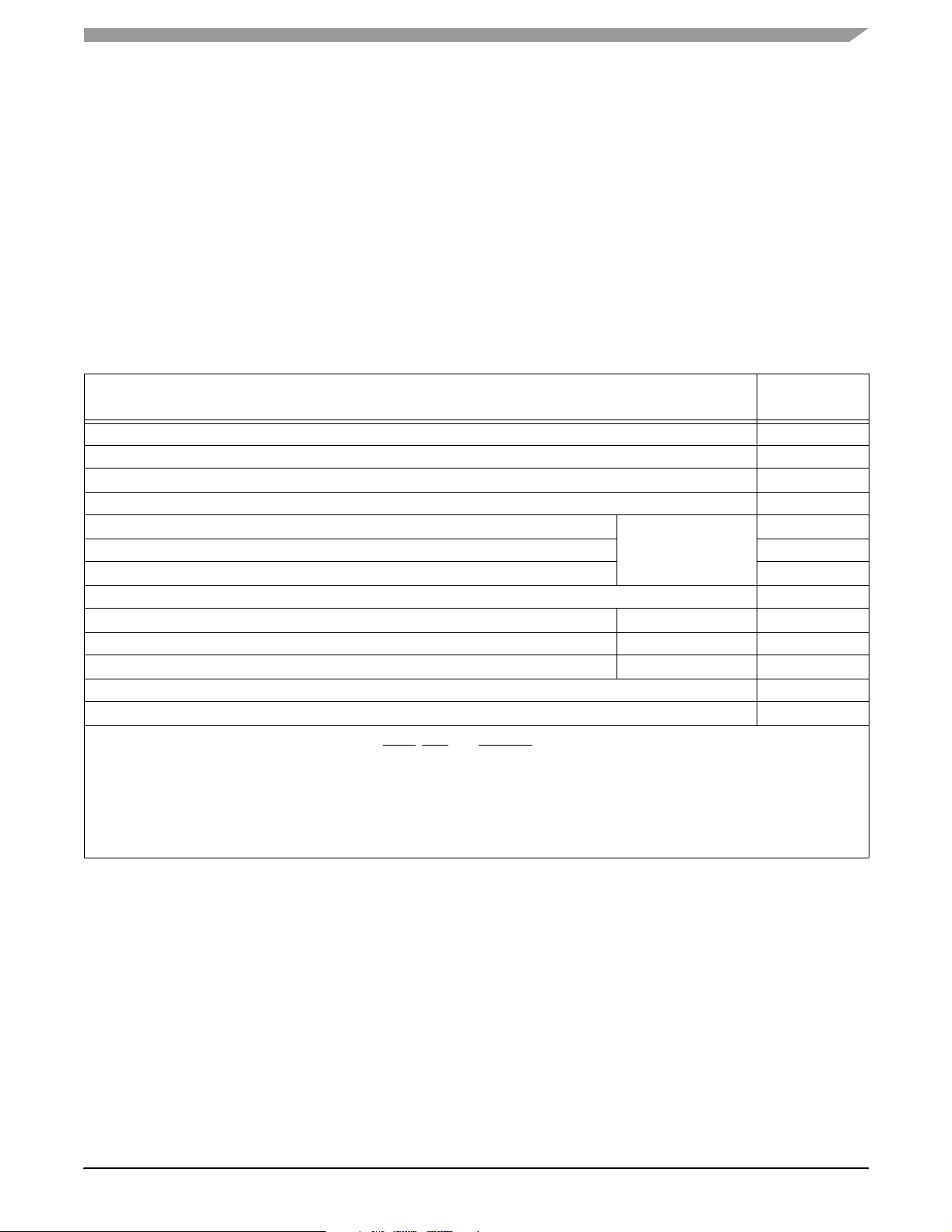

Signals/Connections 1

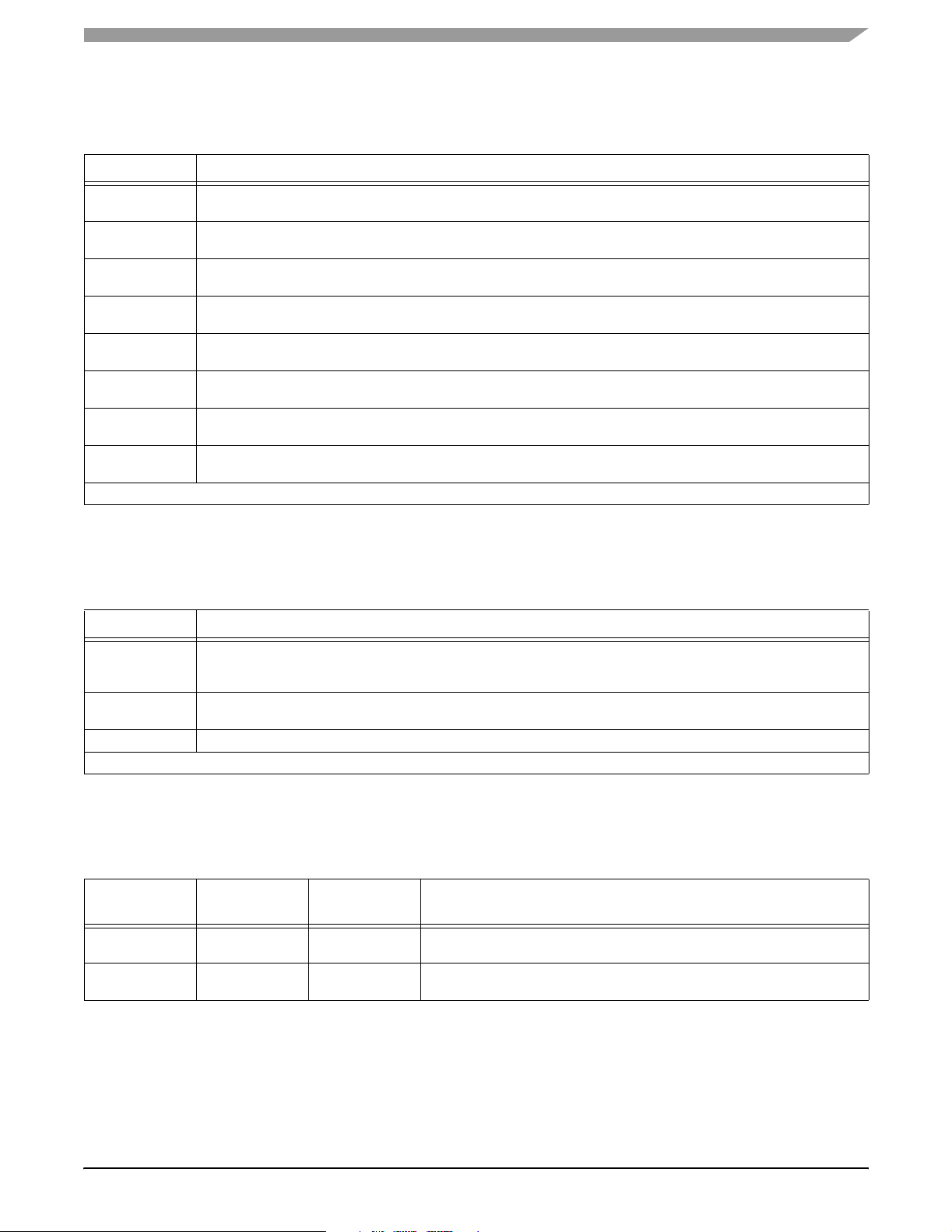

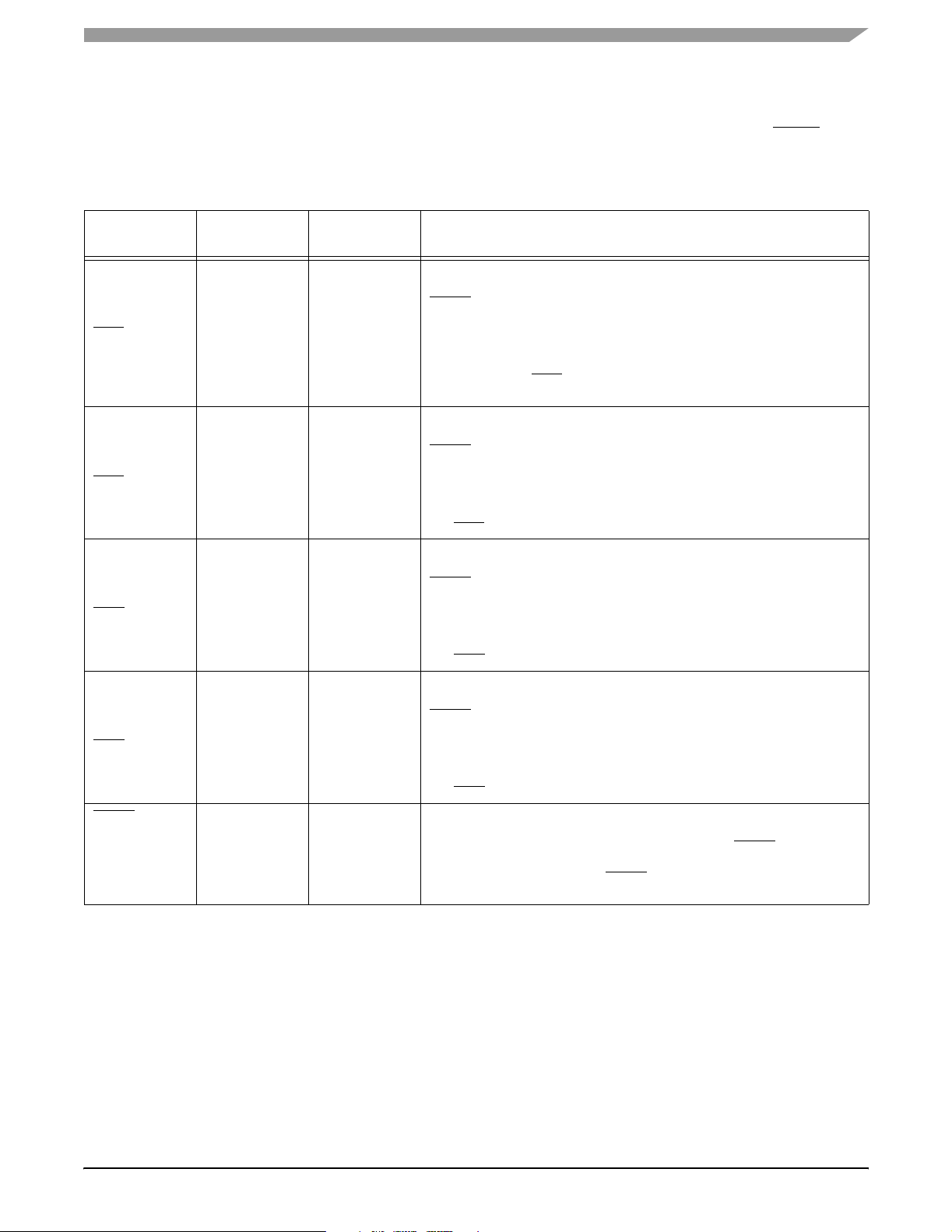

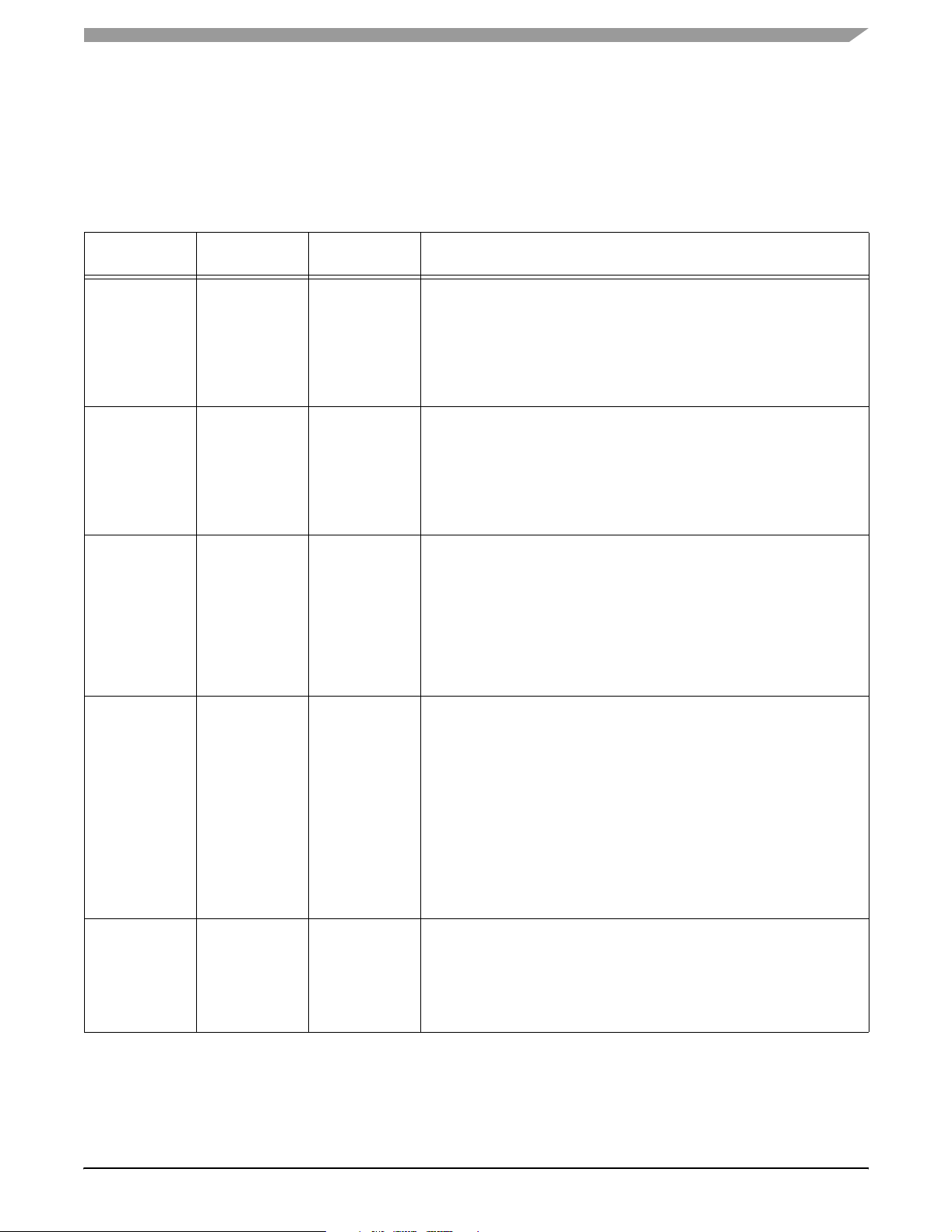

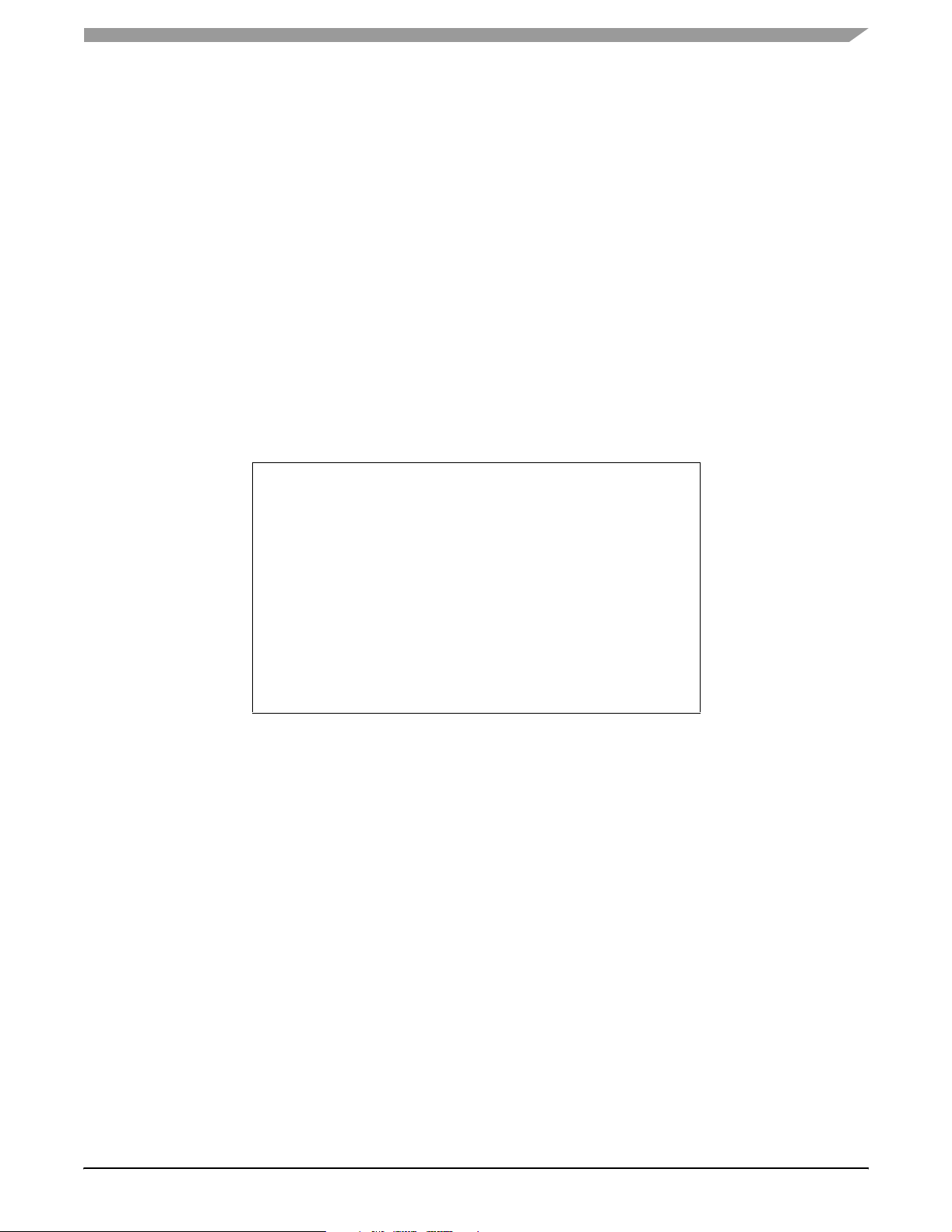

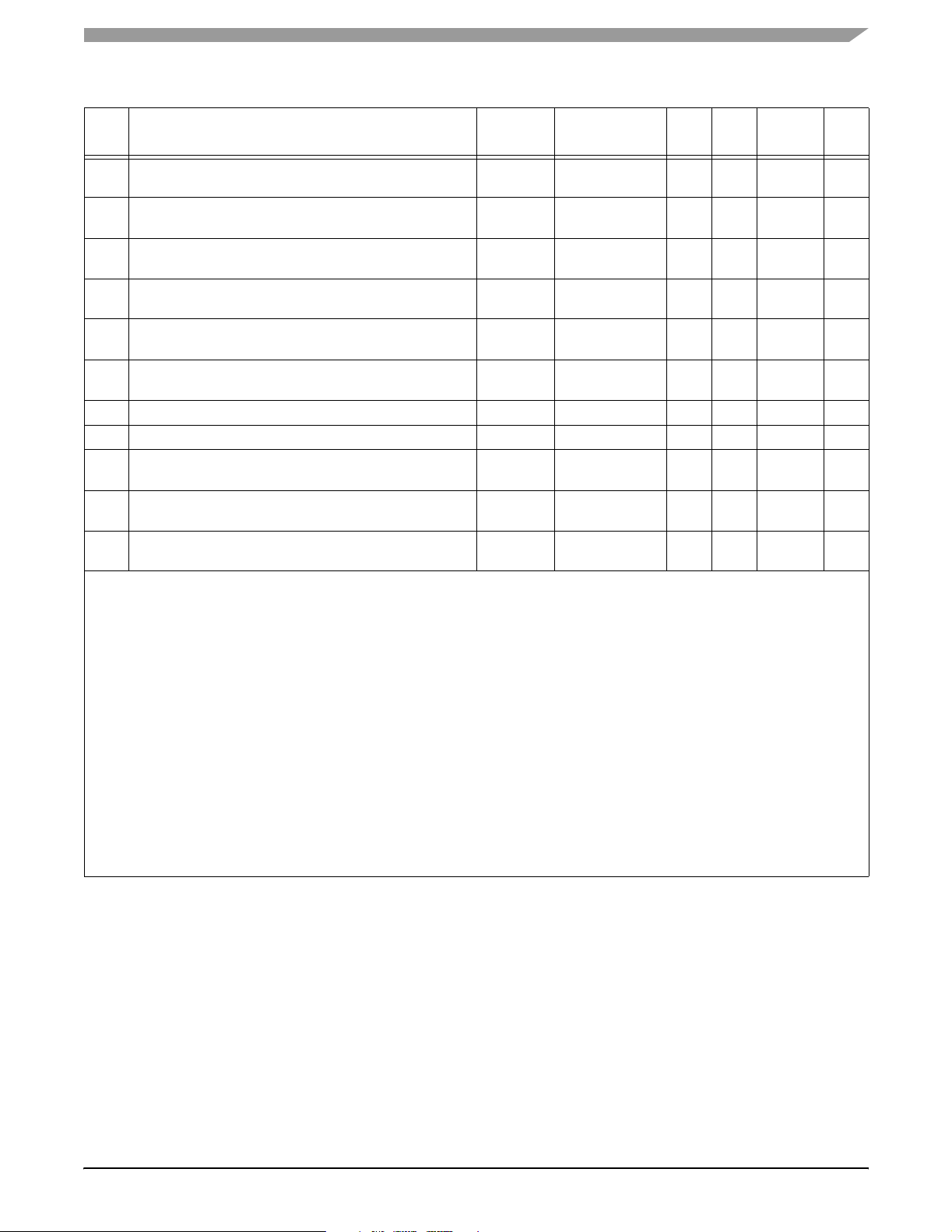

The DSP56L307 input and output signals are organized into functional groups as shown in Table 1-1 . Figure 1-1

diagrams the DSP56L307 signals by functional group. The remainder of this chapter describes the signal pins in

each functional group.

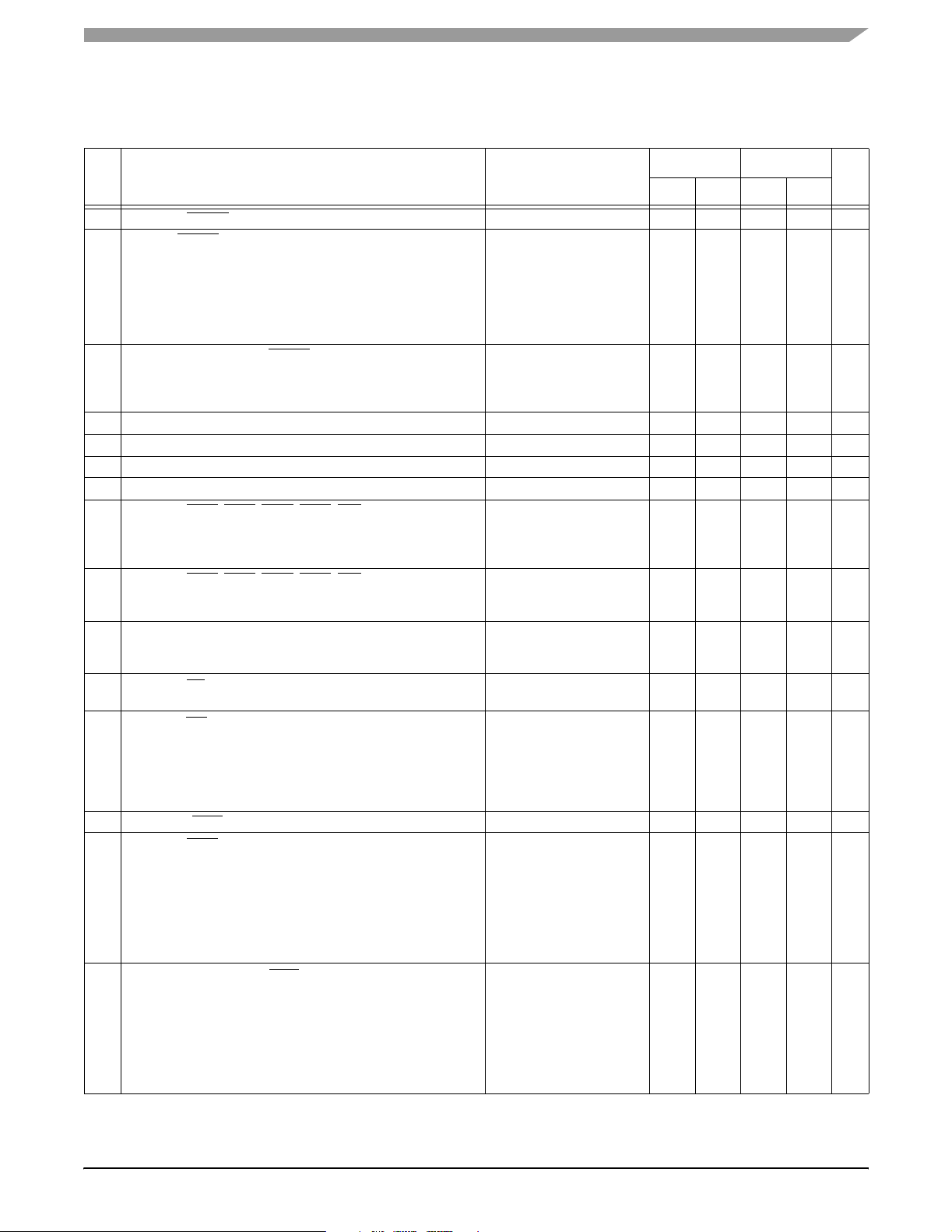

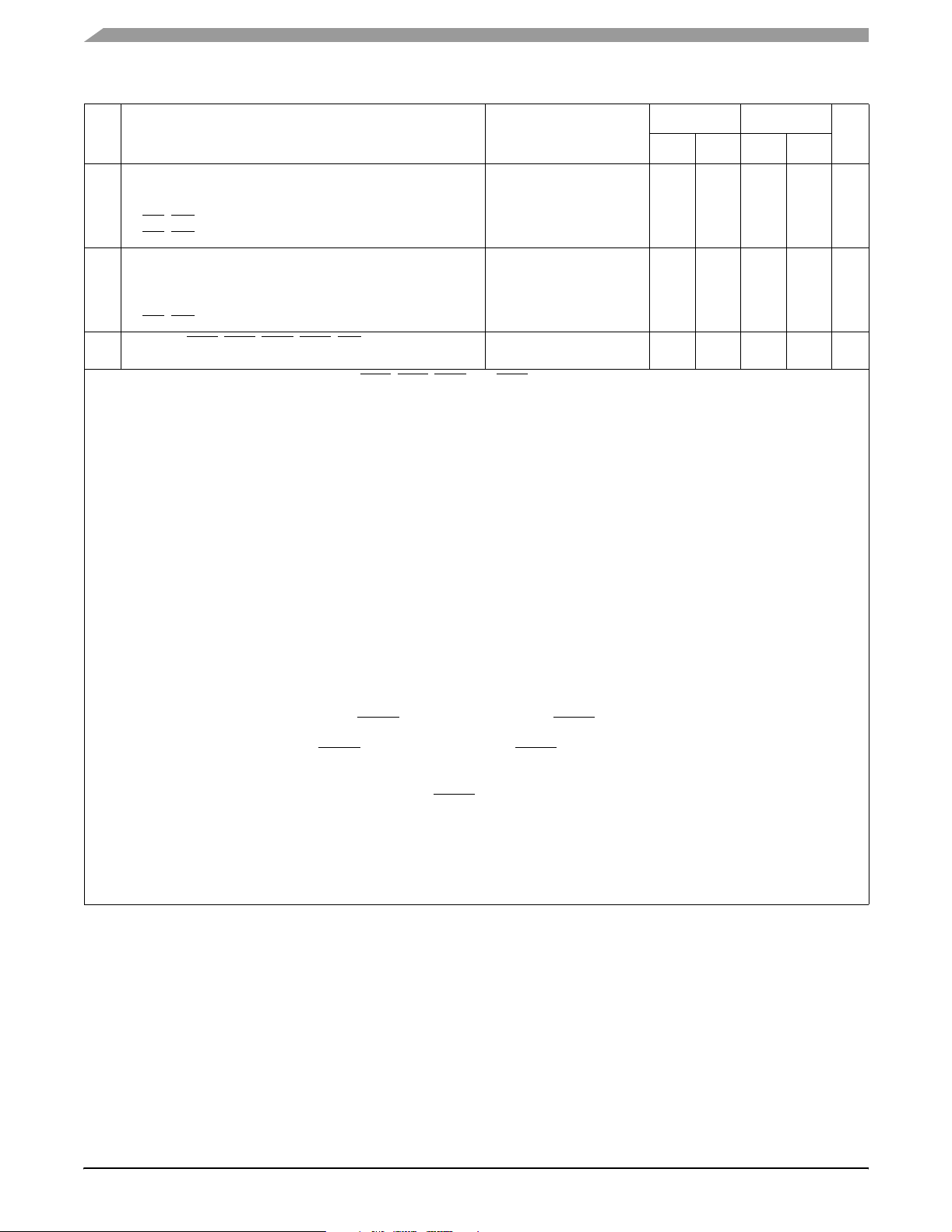

Table 1-1. DSP56L307 Functional Signal Groupings

Functional Group

Power (VCC) 20

Ground (GND) 66

Clock 2

PLL 3

Address bus

Data bus 24

Bus control 13

Interrupt and mode control 5

Host interface (HI08) Port B

Enhanced synchronous serial interface (ESSI) Ports C and D

Serial communication interface (SCI) Port E

Timer 3

OnCE/JTAG Port 6

Notes: 1. Port A signals define the external memory interface port, including the external address bus, data bus, and control signals.

The Clock Output (CLKOUT), BCLK, BCLK

supported by the DSP56L307 at operating frequencies up to 100 MHz. DRAM access is not supported above 100 MHz.

2. Port B signals are the HI08 port signals multiplexed with the GPIO signals.

3. Port C and D signals are the two ESSI port signals multiplexed with the GPIO signals.

4. Port E signals are the SCI port signals multiplexed with the GPIO signals.

5. There are 5 signal connections that are not used. These are designated as no connect (NC) in the package description (see

Chapter 3).

, CAS, and RAS[0–3] signals used by other DSP56300 family members are

Port A

1

2

3

4

Number of

Signals

18

16

12

3

Note: This chapter refers to a number of configuration registers used to select individual multiplexed signal

functionality. Refer to the DSP56L307 User’s Manual for details on these configuration registers.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-1

Page 6

Signals/Connections

After Reset

IRQA

IRQB

IRQC

IRQD

RESET

Multiplexed

Bus

HAD[0–7]

HAS

/HAS

HA8

HA9

HA10

Double DS

HRD

/HRD

HWR

/HWR

Double HR

HTRQ

/HTRQ

HRRQ

/HRRQ

Port C GPIO

PC[0–2]

PC3

PC4

PC5

Port D GPIO

PD[0–2]

PD3

PD4

PD5

Port B

GPIO

PB[0–7]

PB8

PB9

PB10

PB13

PB11

PB12

PB14

PB15

During

Reset

PINIT

V

CCP

V

CCQL

V

CCQH

V

CCA

V

CCD

V

CCC

V

CCH

V

CCS

GND

GND

GND

EXTAL

XTAL

CLKOUT

PCAP

After

Reset

NMI

DSP56L307

Power Inputs:

PLL

4

Core Logic

3

I/O

3

Address Bus

4

Data Bus

2

Bus Control

HI08

2

ESSI/SCI/Timer

Grounds:

64

PLL

PLL

Ground plane

P

P1

Interrupt/

Mode Control

Host

Interface

(HI08) Port

1

During Reset

MODA

MODB

MODC

MODD

RESET

Non-Multiplexed

Bus

8

H[0–7]

HA0

HA1

HA2

HCS/

Single DS

HRW

HDS

HCS

/HDS

Single HR

HREQ

/HREQ

HACK

/HACK

Clock

Synchronous Serial

Interface Port 0

(ESSI0)

Enhanced

4

PLL

Enhanced

Synchronous Serial

Interface Port 1

(ESSI1)

3

SC0[0–2]

SCK0

2

SRD0

STD0

3

SC1[0–2]

SCK1

2

SRD1

STD1

Port A

18

24

4

External

Address Bus

External

Data Bus

External

Bus

Control

Serial

Communications

Interface (SCI) Port

Timers

OnCE/

JTAG Port

Port E GPIO

2

TXD

SCLK

RXD

PE0

PE1

PE2

Timer GPIO

3

TIO0

TIO1

TIO2

TIO0

TIO1

TIO2

TCK

TDI

TDO

TMS

TRST

DE

A[0–17]

D[0–23]

AA0/RAS0

AA3/RAS3

CAS

BCLK

BCLK

RD

WR

TA

BR

BG

BB

–

4

4

4

4

Notes: 1. The HI08 port supports a non-multiplexed or a multiplexed bus, single or double Data Strobe (DS), and single or

double Host Request (HR) configurations. Since each of these modes is configured independently, any combination

of these modes is possible. These HI08 signals can also be configured alternatively as GPIO signals (PB[0–15]).

Signals with dual designations (for example, HAS

/HAS) have configurable polarity.

2. The ESSI0, ESSI1, and SCI signals are multiplexed with the Port C GPIO signals (PC[0–5]), Port D GPIO signals

(PD[0–5]), and Port E GPIO signals (PE[0–2]), respectively.

3. TIO[0–2] can be configured as GPIO signals.

4. CLKOUT, BCLK, BCLK

, CAS, and RAS[0–3] are valid only for operating frequencies ≤ 100 MHz.

Figure 1-1. Signals Identified by Functional Group

DSP56L307 Technical Data, Rev. 6

1-2 Freescale Semiconductor

Page 7

1.1 Power

Table 1-2. Power Inputs

Power Name Description

V

CCP

Quiet Core (Low) Power—An isolated power for the core processing logic. This input must be isolated externally from

V

CCQL

V

Quiet External (High) Power—A quiet power source for I/O lines. This input must be tied externally to all other chip

CCQH

Address Bus Power—An isolated power for sections of the address bus I/O drivers. This input must be tied externally

V

CCA

Data Bus Power—An isolated power for sections of the data bus I/O drivers. This input must be tied externally to all

V

CCD

Bus Control Power—An isolated power for the bus control I/O drivers. This input must be tied externally to all other

V

CCC

V

CCH

V

CCS

Note: The user must provide adequate external decoupling capacitors for all power connections.

PLL Power—VCC dedicated for PLL use. The voltage should be well-regulated and the input should be provided with

an extremely low impedance path to the V

all other chip power inputs.

power inputs

to all other chip power inputs,

other chip power inputs,

chip power inputs,

Host Power—An isolated power for the HI08 I/O drivers. This input must be tied externally to all other chip power

inputs,

ESSI, SCI, and Timer Power—An isolated power for the ESSI, SCI, and timer I/O drivers. This input must be tied

externally to all other chip power inputs,

except

, except

V

CCQL

V

CCQL

except

.

.

except

V

CCQL

except

V

CCQL

.

V

.

CCQL

power rail.

CC

.

except

V

CCQL

.

Power

1.2 Ground

Table 1-3. Grounds

Name Description

GND

P

GND

P1

GND Ground—Connected to an internal device ground plane.

Note: The user must provide adequate external decoupling capacitors for all GND connections.

PLL Ground—Ground-dedicated for PLL use. The connection should be provided with an extremely low-impedance

path to ground. V

package.

PLL Ground 1—Ground-dedicated for PLL use. The connection should be provided with an extremely low-impedance

path to ground.

should be bypassed to GNDP by a 0.47 µF capacitor located as close as possible to the chip

CCP

1.3 Clock

Table 1-4. Clock Signals

Signal Name Type

EXTAL Input Input External Clock/Crystal Input—Interfaces the internal crystal oscillator input

XTAL Output Chip-driven Crystal Output—Connects the internal crystal oscillator output to an external

State During

Reset

Signal Description

to an external crystal or an external clock.

crystal. If an external clock is used, leave XTAL unconnected.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-3

Page 8

Signals/Connections

1.4 PLL

Table 0-1. Phase-Locked Loop Signals

Signal Name Type

CLKOUT Output Chip-driven Clock Output—Provides an output clock synchronized to the internal core

PCAP Input Input PLL Capacitor—An input connecting an off-chip capacitor to the PLL filter.

PINIT

NMI

Input

Input

State During

Reset

clock phase.

If the PLL is enabled and both the multiplication and division factors equal one,

then CLKOUT is also synchronized to EXTAL.

If the PLL is disabled, the CLKOUT frequency is half the frequency of EXTAL.

Note: At oper ating frequencies above 100 MHz, this signal produces a lowamplitude waveform that is not usable externally by other devices.

Connect one capacitor terminal to PCAP and the other terminal to V

If the PLL is not used, PCAP can be tied to V

Input PLL Initial—During assertion of RESET, the value of PINIT is written into the

PLL enable (PEN) bit of the PLL control (PCTL) register, determining whether

the PLL is enabled or disabled.

Nonmaskable Interrupt—After RESET

instruction processing, this Schmitt-trigger input is the negative-edge-triggered

NMI request internally synchronized to CLKOUT.

Signal Description

, GND, or left floating.

CC

deassertion and during normal

CCP

1.5 External Memory Expansion Port (Port A)

.

Note: When the DSP56L307 enters a low-power standby mode (stop or wait), it releases bus mastership and tri-

states the relevant Port A signals: A[0–17], D[0–23], AA0/RAS0–AA3/RAS3, RD, WR, BB, CAS.

1.5.1 External Address Bus

Table 1-5. External Address Bus Signals

State During

Signal Name Type

A[0–17] Output Tri-stated Address Bus—When the DSP is the bus master, A[0–17] are active-high

Reset, Stop,

or Wait

Signal Description

outputs that specify the address for external program and data memory

accesses. Otherwise, the signals are tri-stated. To minimize power dissipation,

A[0–17] do not change state when external memory spaces are not being

accessed.

DSP56L307 Technical Data, Rev. 6

1-4 Freescale Semiconductor

Page 9

1.5.2 External Data Bus

Table 1-6. External Data Bus Signals

External Memory Expansion Port (Port A)

Signal Name Type

D[0–23] Input/ Output Ignored Input Last state:

State During

Reset

State During

Stop or Wait

Input

: Ignored

Output

:

Last value

Signal Description

Data Bus—When the DSP is the bus master, D[0–23] are

active-high, bidirectional input/outputs that provide the

bidirectional data bus for external program and data

memory accesses. Otherwise, D[0–23] drivers are tristated. If the last state is output, these lines have weak

keepers that maintain the last output state even when all

drivers are tri-stated.

1.5.3 External Bus Control

Table 1-7. External Bus Control Signals

State During

Signal Name Type

AA[0–3] Output Tri-stated Address Attribute—When defined as AA, these signals can be used as chip

RD

WR

TA

Output Tri-stated Read Enable—When the DSP is the bus master, RD is an active-low output that

Output Tri-stated Write Enable—When the DSP is the bus master, WR is an active-low output

Input Ignored Input Transfer Acknowledge—If the DSP56L307 is the bus master and there is no

Reset, Stop, or

Wait

Signal Description

selects or additional address lines. The default use defines a priority scheme

under which only one AA signal can be asserted at a time. Setting the AA priority

disable (APD) bit (Bit 14) of the Operating Mode Register, the priority

mechanism is disabled and the lines can be used together as four external lines

that can be decoded externally into 16 chip select signals.

is asserted to read external memory on the data bus (D[0–23]). Otherwise, RD

tri-stated.

that is asserted to write external memory on the data bus (D[0–23]). Otherwise,

the signals are tri-stated.

external bus activity, or the DSP56L307 is not the bus master, the TA

ignored. The TA

extend an external bus cycle indefinitely. Any number of wait states (1,

2. . .infinity) can be added to the wait states inserted by the bus control register

(BCR) by keeping TA

start of a bus cycle, is asserted to enable completion of the bus cycle, and is

deasserted before the next bus cycle. The current bus cycle completes one

clock period after TA

states is determined by the TA

BCR can be used to set the minimum number of wait states in external bus

cycles.

input is a data transfer acknowledge (DTACK) function that can

deasserted. In typical operation, TA is deasserted at the

is asserted synchronous to CLKOUT. The number of wait

input or by the BCR, whichever is longer. The

input is

is

To use the TA

state. A zero wait state access cannot be extended by TA

otherwise, improper operation may result.

functionality, the BCR must be programmed to at least one wait

deassertion;

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-5

Page 10

Signals/Connections

Signal Name Type

Table 1-7. External Bus Control Signals (Continued)

State During

Reset, Stop, or

Wait

Signal Description

BR Output Reset: Output

(deasserted)

State during

Stop/Wait

depends on BRH

bit setting:

• BRH = 0: Output,

deasserted

• BRH = 1:

Maintains last

state (that is, if

asserted, remains

asserted)

BG

BB

Input Ignored Input Bus Grant—Asserted by an external bus arbitration circuit when the

Input/ Output Ignored Input Bus Busy—Indicates that the bus is active. Only after BB is deasserted can the

Bus Request—Asserted when the DSP requests bus mastership. BR

deasserted when the DSP no longer needs the bus. BR

deasserted independently of whether the DSP56L307 is a bus master or a bus

slave. Bus “parking” allows BR

the bus master. (See the description of bus “parking” in the BB

description.) The bus request hold (BRH) bit in the BCR allows BR

asserted under software control even though the DSP does not need the bus.

BR

is typically sent to an external bus arbitrator that controls the priority,

parking, and tenure of each master on the same external bus. BR

only by DSP requests for the external bus, never for the internal bus. During

hardware reset, BR

state.

DSP56L307 becomes the next bus master. When BG

DSP56L307 must wait until BB

When BG

current bus cycle. This may occur in the middle of an instruction that requires

more than one external bus cycle for execution.

To ensure proper operation, the user must set the asynchronous bus arbitration

enable (ABE) bit (Bit 13) in the Operating Mode Register. When this bit is set,

BG

deassertion of an initial BG

pending bus master become the bus master (and then assert the signal again).

The bus master may keep BB

whether BR

current bus master to reuse the bus without rearbitration until another device

requires the bus. BB

driven high and then released and held high by an external pull-up resistor).

is deasserted, bus mastership is typically given up at the end of the

and BB are synchronized internally. This adds a required delay between the

is deasserted and the arbitration is reset to the bus slave

is asserted or deasserted. Called “bus parking,” this allows the

is deasserted by an “active pull-up” method (that is, BB is

to be deasserted even though the DSP56L307 is

is deasserted before taking bus mastership.

input and the assertion of a subsequent BG input.

asserted after ceasing bus activity regardless of

may be asserted or

is asserted, the

is

signal

to be

is affected

Notes: 1. See BG

CAS

BCLK Output Tri-stated Bus Clock

BCLK

Output Tri-stated Column Address Strobe—When the DSP is the bus master, CAS is an active-

low output used by DRAM to strobe the column address. Otherwise, if the Bus

Mastership Enable (BME) bit in the DRAM control register is cleared, the signal

is tri-stated.

Note: DRAM access is not supported above 100 MHz.

When the DSP is the bus master, BCLK is active when the address trace enable

(ATE) bit in the Operating Mode Register is set. When BCLK is active and

synchronized to CLKOUT by the internal PLL, BCLK precedes CLKOUT by onefourth of a clock cycle.

Note: At operating frequencies above 100 MHz, this signal produces a lowamplitude waveform that is not usable externally by other devices.

Output Tri-stated Bus Clock Not

When the DSP is the bus master, BCLK

Otherwise, the signal is tri-stated.

Note: At operating frequencies above 100 MHz, this signal produces a lowamplitude waveform that is not usable externally by other devices.

DSP56L307 Technical Data, Rev. 6

2. BB

for additional information.

requires an external pull-up resistor.

is the inverse of the BCLK signal.

1-6 Freescale Semiconductor

Page 11

Interrupt and Mode Control

1.6 Interrupt and Mode Control

The interrupt and mode control signals select the chip operating mode as it comes out of hardware reset. After RESET is

deasserted, these inputs are hardware interrupt request lines

Table 1-8. Interrupt and Mode Control

.

Signal Name Type

MODA

IRQA

MODB

IRQB

MODC

IRQC

MODD

Input

Input

Input

Input

Input

Input

Input

State During

Reset

Schmitt-trigger

Input

Schmitt-trigger

Input

Schmitt-trigger

Input

Schmitt-trigger

Input

Signal Description

Mode Select A—MODA, MODB, MODC, and MODD select one of 16 initial

chip operating modes, latched into the Operating Mode Register when the

RESET

signal is deasserted.

External Interrupt Request A—After reset, this input becomes a levelsensitive or negative-edge-triggered, maskable interrupt request input during

normal instruction processing. If the processor is in the STOP or WAIT

standby state and IRQA

state.

Mode Select B—MODA, MODB, MODC, and MODD select one of 16 initial

chip operating modes, latched into the Operating Mode Register when the

RESET

signal is deasserted.

External Interrupt Request B—After reset, this input becomes a levelsensitive or negative-edge-triggered, maskable interrupt request input during

normal instruction processing. If the processor is in the WAIT standby state

and IRQB

Mode Select C—MODA, MODB, MODC, and MODD select one of 16 initial

chip operating modes, latched into the Operating Mode Register when the

RESET

External Interrupt Request C—After reset, this input becomes a levelsensitive or negative-edge-triggered, maskable interrupt request input during

normal instruction processing. If the processor is in the WAIT standby state

and IRQC

Mode Select D—MODA, MODB, MODC, and MODD select one of 16 initial

chip operating modes, latched into the Operating Mode Register when the

RESET

is asserted, the processor exits the WAIT state.

signal is deasserted.

is asserted, the processor exits the WAIT state.

signal is deasserted.

is asserted, the processor exits the STOP or WAIT

IRQD

RESET

Input

Input Schmitt-trigger

Input

External Interrupt Request D—After reset, this input becomes a levelsensitive or negative-edge-triggered, maskable interrupt request input during

normal instruction processing. If the processor is in the WAIT standby state

and IRQD

Reset—Places the chip in the Reset state and resets the internal phase

generator. The Schmitt-trigger input allows a slowly rising input (such as a

capacitor charging) to reset the chip reliably. When the RESET

deasserted, the initial chip operating mode is latched from the MODA, MODB,

MODC, and MODD inputs. The RESET

powerup.

is asserted, the processor exits the WAIT state.

signal is

signal must be asserted after

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-7

Page 12

Signals/Connections

1.7 Host Interface (HI08)

The HI08 provides a fast, 8-bit, parallel data port that connects directly to the host bus. The HI08 supports a variety

of standard buses and connects directly to a number of industry-standard microcomputers, microprocessors, DSPs,

and DMA hardware.

1.7.1 Host Port Usage Considerations

Careful synchronization is required when the system reads multiple-bit registers that are written by another

asynchronous system. This is a common problem when two asynchronous systems are connected (as they are in the

Host port). The considerations for proper operation are discussed in Tab l e 1- 9 .

Table 1-9. Host Port Usage Considerations

Action Description

Asynchronous read of receive byte

registers

Asynchronous write to transmit byte

registers

Asynchronous write to host vector The host interface programmer must change the Host Vector (HV) register only when the Host

When reading the receive byte registers, Receive register High (RXH), Receive register Middle

(RXM), or Receive register Low (RXL), the host interface programmer should use interrupts or poll

the Receive register Data Full (RXDF) flag that indicates data is available. This assures that the data

in the receive byte registers is valid.

The host interface programmer should not write to the transmit byte registers, Transmit register High

(TXH), Transmit register Middle (TXM), or Transmit register Low (TXL), unless the Transmit register

Data Empty (TXDE) bit is set indicating that the transmit byte registers are empty. This guarantees

that the transmit byte registers transfer valid data to the Host Receive (HRX) register.

Command bit (HC) is clear. This practice guarantees that the DSP interrupt control logic receives a

stable vector.

1.7.2 Host Port Configuration

HI08 signal functions vary according to the programmed configuration of the interface as determined by the 16 bits

in the HI08 Port Control Register.

Table 1-10. Host Interface

Signal Name Type

H[0–7]

Input/Output

State During

Ignored Input Host Data—When the HI08 is programmed to interface with a non-multiplexed

Reset

1,2

host bus and the HI function is selected, these signals are lines 0–7 of the

bidirectional Data bus.

Signal Description

HAD[0–7]

PB[0–7]

1-8 Freescale Semiconductor

Input/Output

Input or Output

Host Address—When the HI08 is programmed to interface with a multiplexed

host bus and the HI function is selected, these signals are lines 0–7 of the

bidirectional multiplexed Address/Data bus.

Port B 0–7—When the HI08 is configured as GPIO through the HI08 Port

Control Register, these signals are individually programmed as inputs or outputs

through the HI08 Data Direction Register.

DSP56L307 Technical Data, Rev. 6

Page 13

Table 1-10. Host Interface (Continued)

Host Interface (HI08)

Signal Name Type

HA0

HAS

/HAS

PB8

HA1

HA8

PB9

HA2

Input or Output

Input or Output

Input

Input

Input

Input

Input

State During

Ignored Input Host Address Input 0—When the HI08 is programmed to interface with a

Ignored Input Host Address Input 1—When the HI08 is programmed to interface with a

Ignored Input Host Address Input 2—When the HI08 is programmed to interface with a

Reset

1,2

nonmultiplexed host bus and the HI function is selected, this signal is line 0 of

the host address input bus.

Host Address Strobe—When the HI08 is programmed to interface with a

multiplexed host bus and the HI function is selected, this signal is the host

address strobe (HAS) Schmitt-trigger input. The polarity of the address strobe is

programmable but is configured active-low (HAS

Port B 8—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

nonmultiplexed host bus and the HI function is selected, this signal is line 1 of

the host address (HA1) input bus.

Host Address 8—When the HI08 is programmed to interface with a multiplexed

host bus and the HI function is selected, this signal is line 8 of the host address

(HA8) input bus.

Port B 9—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

nonmultiplexed host bus and the HI function is selected, this signal is line 2 of

the host address (HA2) input bus.

Signal Description

) following reset.

HA9

PB10

HCS

HA10

PB13

HRW

HRD

PB11

/HCS

/HRD

Input

Input or Output

Input

Input

Input or Output

Input

Input

Input or Output

Host Address 9—When the HI08 is programmed to interface with a multiplexed

host bus and the HI function is selected, this signal is line 9 of the host address

(HA9) input bus.

Port B 10—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

Ignored Input Host Chip Select—When the HI08 is programmed to interface with a

nonmultiplexed host bus and the HI function is selected, this signal is the host

chip select (HCS) input. The polarity of the chip select is programmable but is

configured active-low (HCS

Host Address 10—When the HI08 is programmed to interface with a

multiplexed host bus and the HI function is selected, this signal is line 10 of the

host address (HA10) input bus.

Port B 13—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

Ignored Input Host Read/Write—When the HI08 is programmed to interface with a single-

data-strobe host bus and the HI function is selected, this signal is the Host

Read/Write

Host Read Data—When the HI08 is programmed to interface with a doubledata-strobe host bus and the HI function is selected, this signal is the HRD

strobe Schmitt-trigger input. The polarity of the data strobe is programmable but

is configured as active-low (HRD

Port B 11—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

(HRW) input.

) after reset.

) after reset.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-9

Page 14

Signals/Connections

Table 1-10. Host Interface (Continued)

Signal Name Type

HDS/HDS

HWR

/HWR

PB12

HREQ

HTRQ

PB14

HACK

/HREQ

/HTRQ

/HACK

Input or Output

Output

Output

Input or Output

Input

Input

Input

State During

Ignored Input Host Data Strobe—When the HI08 is programmed to interface with a single-

Ignored Input Host Request—When the HI08 is programmed to interface with a single host

Ignored Input Host Acknowledge—When the HI08 is programmed to interface with a single

Reset

1,2

data-strobe host bus and the HI function is selected, this signal is the host data

strobe (HDS) Schmitt-trigger input. The polarity of the data strobe is

programmable but is configured as active-low (HDS

Host Write Data—When the HI08 is programmed to interface with a doubledata-strobe host bus and the HI function is selected, this signal is the host write

data strobe (HWR) Schmitt-trigger input. The polarity of the data strobe is

programmable but is configured as active-low (HWR

Port B 12—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

request host bus and the HI function is selected, this signal is the host request

(HREQ) output. The polarity of the host request is programmable but is

configured as active-low (HREQ

programmed as a driven or open-drain output.

Transmit Host Request—When the HI08 is programmed to interface with a

double host request host bus and the HI function is selected, this signal is the

transmit host request (HTRQ) output. The polarity of the host request is

programmable but is configured as active-low (HTRQ

request may be programmed as a driven or open-drain output.

Port B 14—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

host request host bus and the HI function is selected, this signal is the host

acknowledge (HACK) Schmitt-trigger input. The polarity of the host

acknowledge is programmable but is configured as active-low (HACK

reset.

Signal Description

) following reset.

) following reset.

) following reset. The host request may be

) following reset. The host

) after

/HRRQ

HRRQ

PB15

Notes: 1. In the Stop state, the signal maintains the last state as follows:

• If the last state is input, the signal is an ignored input.

• If the last state is output, these lines have weak keepers that maintain the last output state even if the drivers are tri-stated.

2. The Wait processing state does not affect the signal state.

Output

Input or Output

Receive Host Request—When the HI08 is programmed to interface with a

double host request host bus and the HI function is selected, this signal is the

receive host request (HRRQ) output. The polarity of the host request is

programmable but is configured as active-low (HRRQ

request may be programmed as a driven or open-drain output.

Port B 15—When the HI08 is configured as GPIO through the HI08 Port Control

Register, this signal is individually programmed as an input or output through the

HI08 Data Direction Register.

DSP56L307 Technical Data, Rev. 6

) after reset. The host

1-10 Freescale Semiconductor

Page 15

Enhanced Synchronous Serial Interface 0 (ESSI0)

1.8 Enhanced Synchronous Serial Interface 0 (ESSI0)

Two synchronous serial interfaces (ESSI0 and ESSI1) provide a full-duplex serial port for serial communication

with a variety of serial devices, including one or more industry-standard codecs, other DSPs, microprocessors, and

peripherals that implement the Freescale serial peripheral interface (SPI).

Table 1-11. Enhanced Synchronous Serial Interface 0

Signal Name Type

SC00

PC0

SC01

PC1

SC02

PC2

SCK0

Input or Output

Input or Output

Input/Output

Input or Output

Input/Output

Input or Output

Input/Output

State During

Ignored Input Serial Control 0—For asynchronous mode, this signal is used for the receive

Ignored Input Serial Control 1—For asynchronous mode, this signal is the receiver frame

Ignored Input Serial Control Signal 2—The frame sync for both the transmitter and receiver

Ignored Input Serial Clock—Provides the serial bit rate clock for the ESSI. The SCK0 is a

Reset

1,2

clock I/O (Schmitt-trigger input). For synchronous mode, this signal is used

either for transmitter 1 output or for serial I/O flag 0.

Port C 0—The default configuration following reset is GPIO input PC0. When

configured as PC0, signal direction is controlled through the Port C Direction

Register. The signal can be configured as ESSI signal SC00 through the Port C

Control Register.

sync I/O. For synchronous mode, this signal is used either for transmitter 2

output or for serial I/O flag 1.

Port C 1—The default configuration following reset is GPIO input PC1. When

configured as PC1, signal direction is controlled through the Port C Direction

Register. The signal can be configured as an ESSI signal SC01 through the Port

C Control Register.

in synchronous mode, and for the transmitter only in asynchronous mode. When

configured as an output, this signal is the internally generated frame sync signal.

When configured as an input, this signal receives an external frame sync signal

for the transmitter (and the receiver in synchronous operation).

Port C 2—The default configuration following reset is GPIO input PC2. When

configured as PC2, signal direction is controlled through the Port C Direction

Register. The signal can be configured as an ESSI signal SC02 through the Port

C Control Register.

clock input or output, used by both the transmitter and receiver in synchronous

modes or by the transmitter in asynchronous modes.

Signal Description

Although an external serial clock can be independent of and asynchronous to

the DSP system clock, it must exceed the minimum clock cycle time of 6T (that

is, the system clock frequency must be at least three times the external ESSI

clock frequency). The ESSI needs at least three DSP phases inside each half of

the serial clock.

PC3

SRD0

PC4

Input or Output

Input

Input or Output

Ignored Input Serial Receive Data—Receives serial data and transfers the data to the ESSI

Port C 3—The default configuration following reset is GPIO input PC3. When

configured as PC3, signal direction is controlled through the Port C Direction

Register. The signal can be configured as an ESSI signal SCK0 through the Port

C Control Register.

Receive Shift Register. SRD0 is an input when data is received.

Port C 4—The default configuration following reset is GPIO input PC4. When

configured as PC4, signal direction is controlled through the Port C Direction

Register. The signal can be configured as an ESSI signal SRD0 through the

Port C Control Register.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-11

Page 16

Signals/Connections

Table 1-11. Enhanced Synchronous Serial Interface 0 (Continued)

Signal Name Type

STD0

PC5

Notes: 1. In the Stop state, the signal maintains the last state as follows:

• If the last state is input, the signal is an ignored input.

• If the last state is output, these lines have weak keepers that maintain the last output state even if the drivers are tri-stated.

2. The Wait processing state does not affect the signal state.

Output

Input or Output

State During

Ignored Input Serial Transmit Data—Transmits data from the Serial Transmit Shift Register.

Reset

1,2

STD0 is an output when data is transmitted.

Port C 5—The default configuration following reset is GPIO input PC5. When

configured as PC5, signal direction is controlled through the Port C Direction

Register. The signal can be configured as an ESSI signal STD0 through the Port

C Control Register.

Signal Description

1.9 Enhanced Synchronous Serial Interface 1 (ESSI1)

Table 1-12. Enhanced Serial Synchronous Interface 1

Signal Name Type

SC10

PD0

SC11

Input or Output

Input or Output

Input/Output

State During

Ignored Input Serial Control 0—For asynchronous mode, this signal is used for the receive

Ignored Input Serial Control 1—For asynchronous mode, this signal is the receiver frame

Reset

1,2

clock I/O (Schmitt-trigger input). For synchronous mode, this signal is used

either for transmitter 1 output or for serial I/O flag 0.

Port D 0—The default configuration following reset is GPIO input PD0. When

configured as PD0, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal SC10 through the Port

D Control Register.

sync I/O. For synchronous mode, this signal is used either for Transmitter 2

output or for Serial I/O Flag 1.

Signal Description

PD1

SC12

PD2

Input or Output

Input/Output

Input or Output

Port D 1—The default configuration following reset is GPIO input PD1. When

configured as PD1, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal SC11 through the Port

D Control Register.

Ignored Input Serial Control Signal 2—The frame sync for both the transmitter and receiver

in synchronous mode and for the transmitter only in asynchronous mode. When

configured as an output, this signal is the internally generated frame sync signal.

When configured as an input, this signal receives an external frame sync signal

for the transmitter (and the receiver in synchronous operation).

Port D 2—The default configuration following reset is GPIO input PD2. When

configured as PD2, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal SC12 through the Port

D Control Register.

DSP56L307 Technical Data, Rev. 6

1-12 Freescale Semiconductor

Page 17

Serial Communication Interface (SCI)

Table 1-12. Enhanced Serial Synchronous Interface 1 (Continued)

Signal Name Type

SCK1

PD3

SRD1

PD4

STD1

PD5

Notes: 1. In the Stop state, the signal maintains the last state as follows:

• If the last state is input, the signal is an ignored input.

• If the last state is output, these lines have weak keepers that maintain the last output state even if the drivers are tri-stated.

2. The Wait processing state does not affect the signal state.

Input/Output

Input or Output

Input

Input or Output

Output

Input or Output

State During

Ignored Input Serial Clock—Provides the serial bit rate clock for the ESSI. The SCK1 is a

Ignored Input Serial Receive Data—Receives serial data and transfers the data to the ESSI

Ignored Input Serial Transmit Data—Transmits data from the Serial Transmit Shift Register.

Reset

1,2

clock input or output used by both the transmitter and receiver in synchronous

modes or by the transmitter in asynchronous modes.

Although an external serial clock can be independent of and asynchronous to

the DSP system clock, it must exceed the minimum clock cycle time of 6T (that

is, the system clock frequency must be at least three times the external ESSI

clock frequency). The ESSI needs at least three DSP phases inside each half of

the serial clock.

Port D 3—The default configuration following reset is GPIO input PD3. When

configured as PD3, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal SCK1 through the Port

D Control Register.

Receive Shift Register. SRD1 is an input when data is being received.

Port D 4—The default configuration following reset is GPIO input PD4. When

configured as PD4, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal SRD1 through the

Port D Control Register.

STD1 is an output when data is being transmitted.

Port D 5—The default configuration following reset is GPIO input PD5. When

configured as PD5, signal direction is controlled through the Port D Direction

Register. The signal can be configured as an ESSI signal STD1 through the Port

D Control Register.

Signal Description

1.10 Serial Communication Interface (SCI)

The SCI provides a full duplex port for serial communication with other DSPs, microprocessors, or peripherals

such as modems.

Table 1-13. Serial Communication Interface

Signal Name Type

RXD

PE0

TXD

PE1

Input

Input or Output

Output

Input or Output

State During

Ignored Input Serial Receive Data—Receives byte-oriented serial data and transfers it to the

Ignored Input Serial Transmit Data—Transmits data from the SCI Transmit Data Register.

Reset

1,2

SCI Receive Shift Register.

Port E 0—The default configuration following reset is GPIO input PE0. When

configured as PE0, signal direction is controlled through the Port E Direction

Register. The signal can be configured as an SCI signal RXD through the Port E

Control Register.

Port E 1—The default configuration following reset is GPIO input PE1. When

configured as PE1, signal direction is controlled through the Port E Direction

Register. The signal can be configured as an SCI signal TXD through the Port E

Control Register.

Signal Description

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-13

Page 18

Signals/Connections

Table 1-13. Serial Communication Interface (Continued)

Signal Name Type

SCLK

PE2

Notes: 1. In the Stop state, the signal maintains the last state as follows:

• If the last state is input, the signal is an ignored input.

• If the last state is output, these lines have weak keepers that maintain the last output state even if the drivers are tri-stated.

2. The Wait processing state does not affect the signal state.

Input/Output

Input or Output

State During

Ignored Input Serial Clock—Provides the input or output clock used by the transmitter and/or

Reset

1,2

the receiver.

Port E 2—The default configuration following reset is GPIO input PE2. When

configured as PE2, signal direction is controlled through the Port E Direction

Register. The signal can be configured as an SCI signal SCLK through the Port

E Control Register.

Signal Description

1.11 Timers

The DSP56L307 has three identical and independent timers. Each timer can use internal or external clocking and

can either interrupt the DSP56L307 after a specified number of events (clocks) or signal an external device after

counting a specific number of internal events.

Table 1-14. Triple Timer Signals

Signal Name Type

State During

1,2

Reset

Signal Description

TIO0 Input or Output Ignored Input Timer 0 Schmitt-Trigger Input/Output— When Timer 0 functions as an

external event counter or in measurement mode, TIO0 is used as input. When

Timer 0 functions in watchdog, timer, or pulse modulation mode, TIO0 is used

as output.

The default mode after reset is GPIO input. TIO0 can be changed to output or

configured as a timer I/O through the Timer 0 Control/Status Register (TCSR0).

TIO1 Input or Output Ignored Input Timer 1 Schmitt-Trigger Input/Output— When Timer 1 functions as an

TIO2 Input or Output Ignored Input Timer 2 Schmitt-Trigger Input/Output— When Timer 2 functions as an

Notes: 1. In the Stop state, the signal maintains the last state as follows:

• If the last state is input, the signal is an ignored input.

• If the last state is output, these lines have weak keepers that maintain the last output state even if the drivers are tri-stated.

2. The Wait processing state does not affect the signal state.

external event counter or in measurement mode, TIO1 is used as input. When

Timer 1 functions in watchdog, timer, or pulse modulation mode, TIO1 is used

as output.

The default mode after reset is GPIO input. TIO1 can be changed to output or

configured as a timer I/O through the Timer 1 Control/Status Register (TCSR1).

external event counter or in measurement mode, TIO2 is used as input. When

Timer 2 functions in watchdog, timer, or pulse modulation mode, TIO2 is used

as output.

The default mode after reset is GPIO input. TIO2 can be changed to output or

configured as a timer I/O through the Timer 2 Control/Status Register (TCSR2).

DSP56L307 Technical Data, Rev. 6

1-14 Freescale Semiconductor

Page 19

JTAG and OnCE Interface

1.12 JTAG and OnCE Interface

The DSP56300 family and in particular the DSP56L307 support circuit-board test strategies based on the IEEE®

Std. 1149.1™ test access port and boundary scan architecture, the industry standard developed under the

sponsorship of the Test Technology Committee of IEEE and the JTAG. The OnCE module provides a means to

interface nonintrusively with the DSP56300 core and its peripherals so that you can examine registers, memory, or

on-chip peripherals. Functions of the OnCE module are provided through the JTAG TAP signals. For programming

models, see the chapter on debugging support in the DSP56300 Family Manual.

Table 1-15. JTAG/OnCE Interface

Signal

Name

TCK Input Input Test Cl oc k—A test clock input signal to synchronize the JTAG test logic.

TDI Input Input Test Data Input—A test data serial input signal for test instructions and data.

TDO Output Tri-stated Test Data Output—A test data serial output signal for test instructions and

TMS Input Input Test Mode Select—Sequences the test controller’s state machine. TMS is

TRST

DE

Type

Input Input Test Reset—Initializes the test controller asynchronously. TRST has an

Input/Output Input Debug Event—As an input, initiates Debug mode from an external command

State During

Reset

Signal Description

TDI is sampled on the rising edge of TCK and has an internal pull-up resistor.

data. TDO is actively driven in the shift-IR and shift-DR controller states. TDO

changes on the falling edge of TCK.

sampled on the rising edge of TCK and has an internal pull-up resistor.

internal pull-up resistor. TRST

(see EB610/D for details).

controller, and, as an open-drain output, acknowledges that the chip has

entered Debug mode. As an input, DE

executing the current instruction, save the instruction pipeline information,

enter Debug mode, and wait for commands to be entered from the debug

serial input line. This signal is asserted as an output for three clock cycles

when the chip enters Debug mode as a result of a debug request or as a result

of meeting a breakpoint condition. The DE

This signal is not a standard part of the JTAG TAP controller. The signal

connects directly to the OnCE module to initiate debug mode directly or to

provide a direct external indication that the chip has entered Debug mode. All

other interface with the OnCE module must occur through the JTAG port.

must be asserted during and after power-up

causes the DSP56300 core to finish

has an internal pull-up resistor.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 1-15

Page 20

Signals/Connections

DSP56L307 Technical Data, Rev. 6

1-16 Freescale Semiconductor

Page 21

Specifications 2

The DSP56L307 is fabricated in high-density CMOS with transistor-transistor logic (TTL) compatible inputs and

outputs.

Note: The DSP56L307 specifications are preliminary and are from design simulations, and may not be fully

tested or guaranteed. Finalized specifications will be published after full characterization and device

qualifications are complete.

2.1 Maximum Ratings

CAUTION

This device contains circuitry protecting

against damage due to high static voltage or

electrical fields; however, normal precautions

should be taken to avoid exceeding maximum

voltage ratings. Reliability is enhanced if

unused inputs are tied to an appropriate logic

voltage level (for example, either GND or V

CC

).

In the calculation of timing requirements, adding a maximum value of one specification to a minimum value of

another specification does not yield a reasonable sum. A maximum specification is calculated using a worst case

variation of process parameter values in one direction. The minimum specification is calculated using the worst

case for the same parameters in the opposite direction. Therefore, a “maximum” value for a specification never

occurs in the same device that has a “minimum” value for another specification; adding a maximum to a minimum

represents a condition that can never exist.

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 2-1

Page 22

Specifications

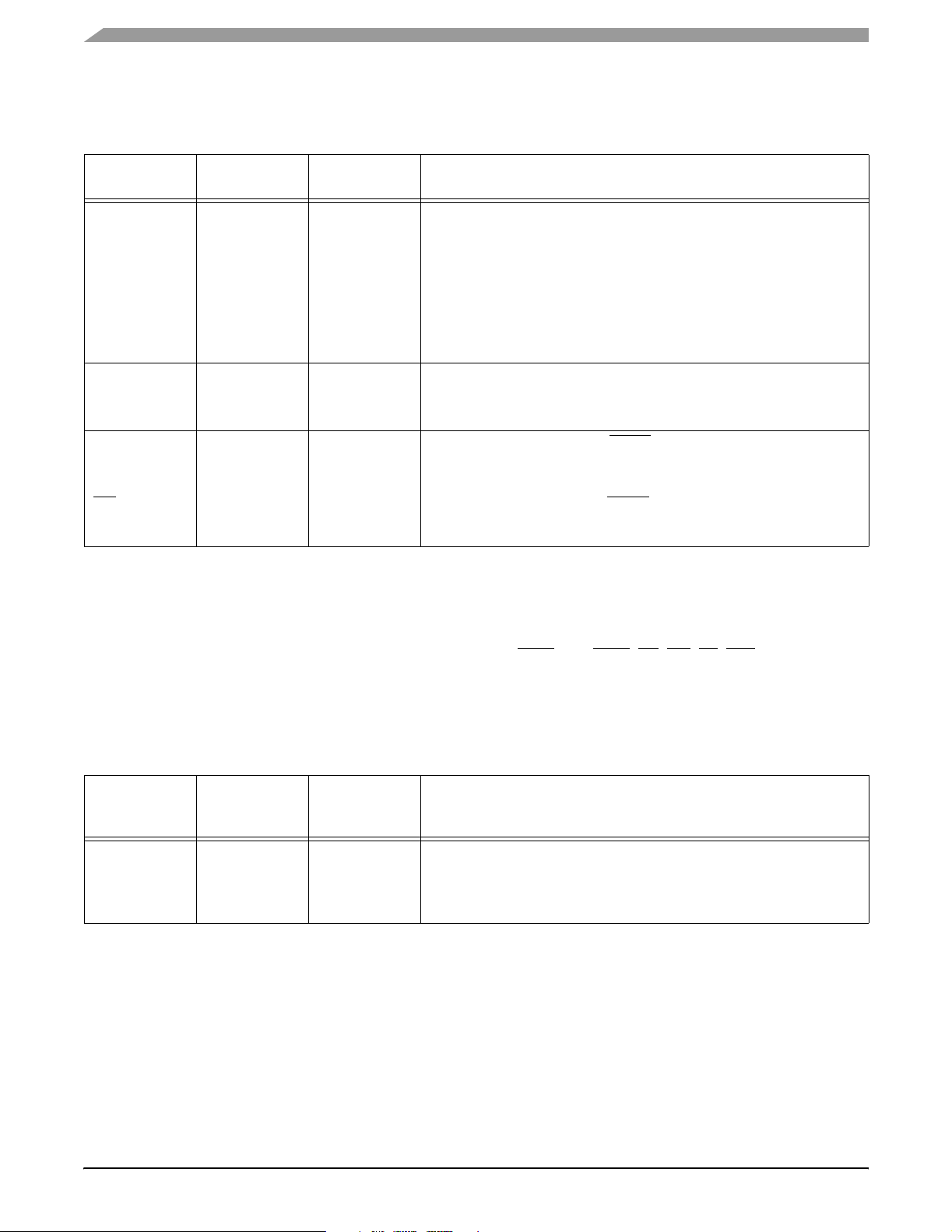

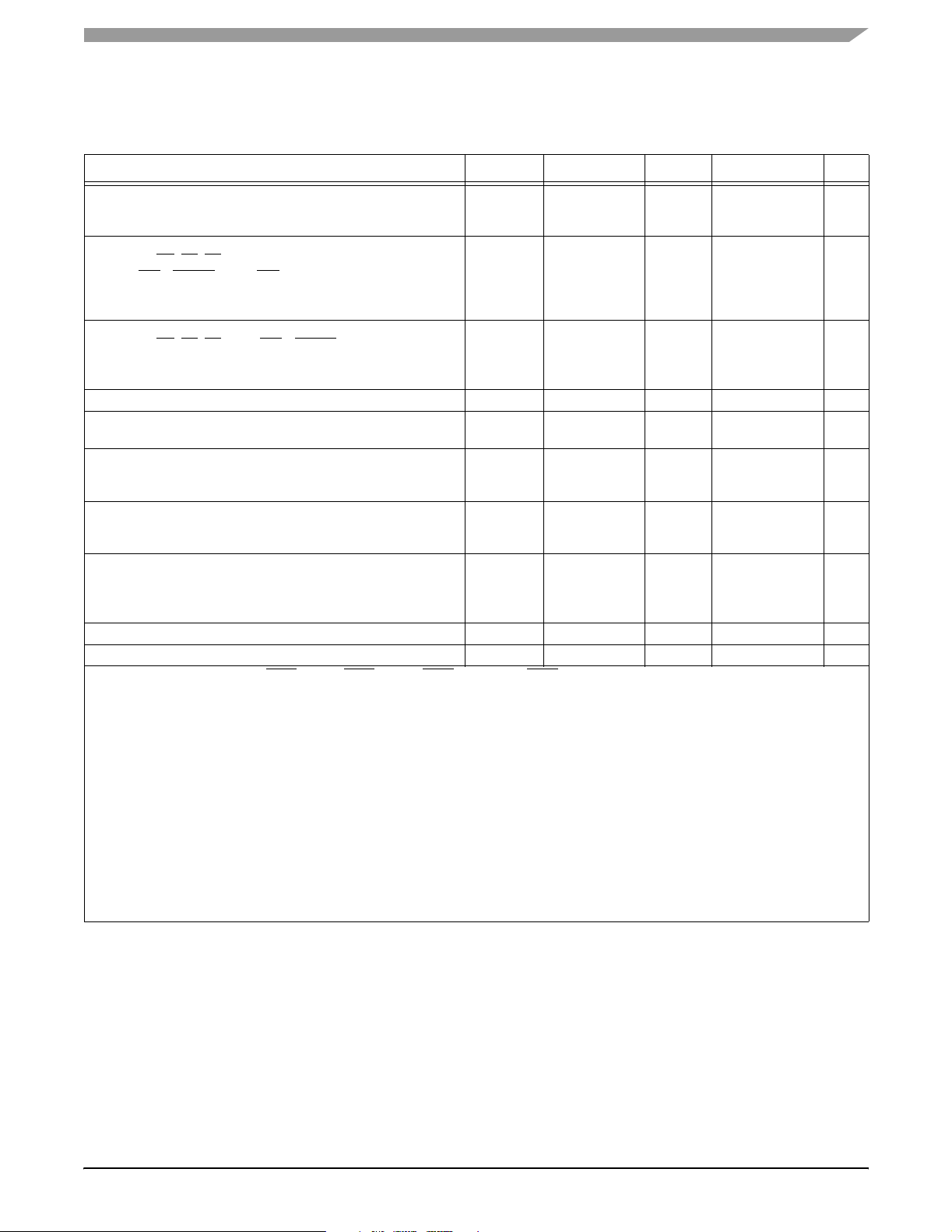

Table 2-1. Absolute Maximum Ratings

1

Rating

Symbol Value

Supply Voltage V

Input/Output Supply Voltage V

All input voltages V

Current drain per pin excluding V

and GND I 10 mA

CC

Operating temperature range T

Storage temperature T

Notes: 1. GND = 0 V, V

= 1.8 V ± 0.1 V, V

CC

= 3.3 V ± 0.3 V, TJ = –40°C to +100°C, CL = 50 pF

CCQH

2. Absolute maximum ratings are stress ratings only, and functional operation at the maximum is not guaranteed. Stress beyond

the maximum rating may affect device reliability or cause permanent damage to the device.

3. Power-up sequence: During power-up, and throughout the DSP56L307 operation, V

equal to V

voltage.

CC

2.2 Thermal Characteristics

Table 2-2. Thermal Characteristics

CC

CCQH

IN

J

STG

1, 2

–0.1 to 2.0 V

–0.3 to 4.0 V

GND – 0.3 to V

+ 0.3 V

CCQH

–40 to +100 °C

–55 to +150 °C

voltage must always be higher or

CCQH

Unit

Thermal Resistance Characteristic Symbol

Junction-to-ambient, natural convection, single-layer board (1s)

Junction-to-ambient, natural convection, four-layer board (2s2p)

Junction-to-ambient, @200 ft/min air flow, single layer board (1s)

Junction-to-ambient, @200 ft/min air flow, four-layer board (2s2p)

Junction-to-board

Junction-to-case thermal resistance

Junction-to-package-top, natural convection

4

5

6

1,2

1,3

1,3

1,3

R

R

R

R

R

R

θJA

θJMA

θJMA

θJMA

θJB

θJC

Ψ

JT

MAP-BGA

Value

47 °C/W

25 °C/W

37 °C/W

22 °C/W

15 °C/W

8 °C/W

2 °C/W

Unit

Notes: 1. Junction temperature is a function of die size, on-chip power dissipation, package thermal resistance, mounting site (board)

temperature, ambient temperature, air flow, power dissipation of other components on the board, and board thermal

resistance.

2. Per SEMI G38-87 and JEDEC JESD51-2 with the single-layer board horizontal.

3. Per JEDEC JESD51-6 with the board horizontal.

4. Thermal resistance between the die and the printed circuit board per JEDEC JESD51-8. Board temperature is measured on

the top surface of the board near the package.

5. Thermal resistance between the die and the case top surface as measured by the cold plate method (MIL SPEC-883 Method

1012.1).

6. Thermal characterization parameter indicating the temperature difference between package top and the junction temperature

per JEDEC JESD51-2.

DSP56L307 Technical Data, Rev. 6

2-2 Freescale Semiconductor

Page 23

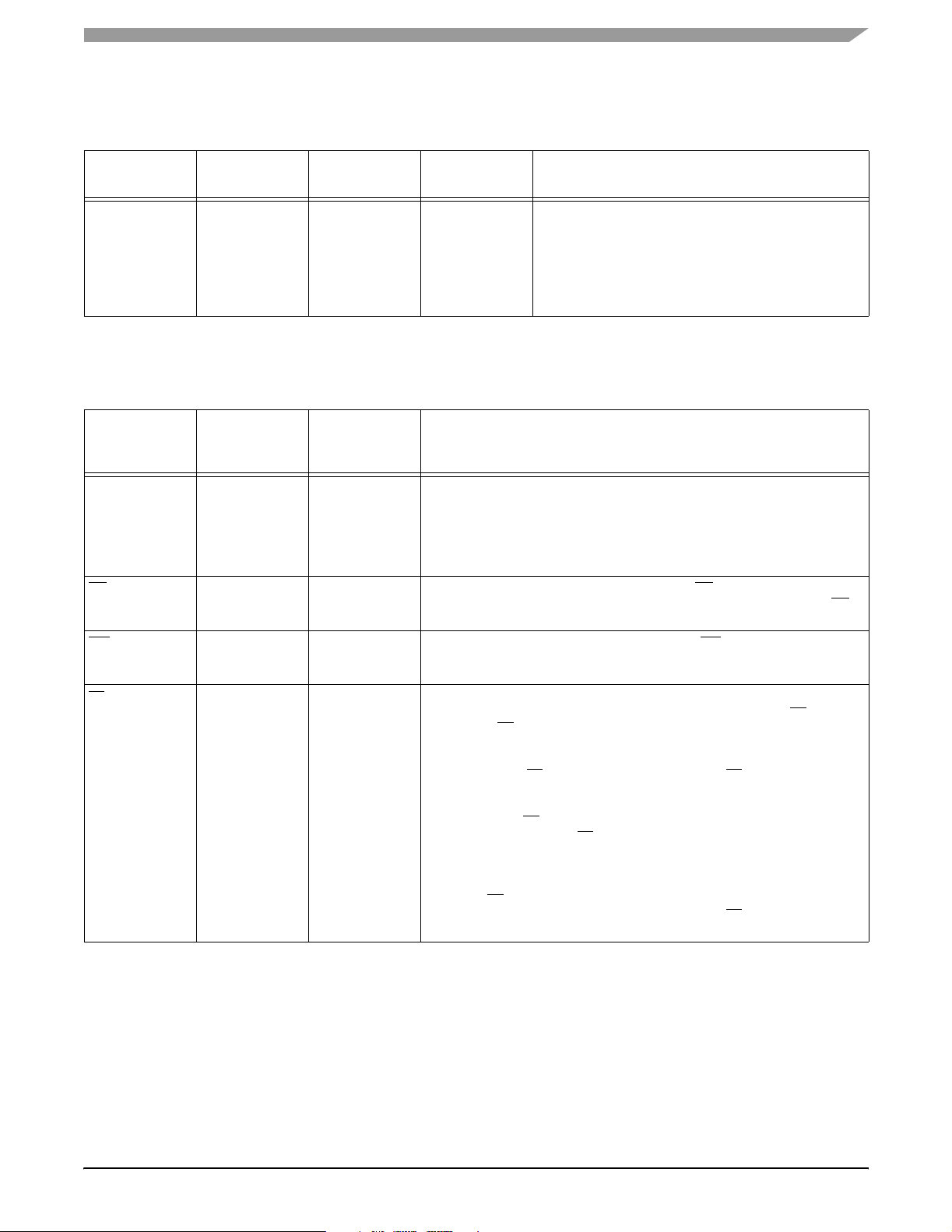

2.3 DC Electrical Characteristics

DC Electrical Characteristics

Table 2-3. DC Electrical Characteristics

7

Characteristics Symbol Min Typ Max Unit

Supply voltage:

•Core (V

•I/O (V

Input high voltage

• D[0–23], BG

• MOD/IRQ1, RESET, PINIT/NMI and all

JTAG/ESSI/SCI/Timer/HI08 pins

•EXTAL

Input low voltage

• D[0–23], BG

• All JTAG/ESSI/SCI/Timer/HI08 pins

•EXTAL

Input leakage current I

High impedance (off-state) input current

(@ 2.4 V / 0.4 V)

Output high voltage

•TTL (I

•CMOS (IOH = –10 µA)

Output low voltage

•TTL (I

•CMOS (IOL = 10 µA)

Internal supply current

• In Normal mode

• In Wait mode

• In Stop mode

PLL supply current —1 2.5mA

Input capacitance

Notes: 1. Refers to MODA/IRQA

) and PLL (V

CCQL

, V

CCA

, V

CCD

CCQH

, BB, TA

8

, BB, TA, MOD/IRQ1, RESET, PINIT

8

= –0.4 mA)

OH

= 3.0 mA, open-drain pins IOL = 6.7 mA)

OL

5,7

5

2

:

3

4

5

)

CCP

, V

, V

CCH

, and V

CCC

5

CCS

)

5,7

V

V

V

V

V

V

I

V

V

I

I

CCW

I

CCS

C

IH

IHP

IHX

IL

ILP

ILX

IN

TSI

OH

OL

CCI

IN

1.7

3.0

2.0

2.0

0.8 × V

–0.3

–0.3

–0.3

CCQH

1.8

3.3

—

—

—

—

—

—

1.9

3.6

V

CCQH

V

CCQH

V

CCQH

0.8

0.8

0.2 × V

+ 0.3

+ 0.3

CCQH

–10 — 10 µA

–10 — 10 µA

V

CC

2.4

– 0.01

—

—

—

—

—

—

—

—

—

150

7. 5

100

—

—

0.4

0.01

—

—

—

— — 10 pF

mA

mA

µA

, MODB/IRQB, MODC/IRQC, and MODD/IRQD pins.

2. Section 4.3 provides a formula to compute the estimated current requirements in Normal mode. To obtain these results, all

inputs must be terminated (that is, not allowed to float). Measurements are based on synthetic intensive DSP benchmarks (see

Appendix A

This reflects typical DSP applications. Typical internal supply current is measured with V

V

CC

3. To obtain these results, all inputs must be terminated (that is, not allowed to float). PLL and XTAL signals are disabled during

). The power consumption numbers in this specification are 90 percent of the measured results of this benchmark.

= 3.3 V,

CCQP

= 1.8 V at TJ = 100°C.

Stop state.

4. DC current in Stop mode is evaluated based on measurements. To obtain these results, all inputs not disconnected at Stop

mode must be terminated (that is, not allowed to float).

5. Periodically sampled and not 100 percent tested.

6. V

7. This characteristic does not apply to XTAL and PCAP.

8. Driving EXTAL to the low V

= 3.3 V ± 0.3 V, V

CCQH

= 1.8 V ± 0.1 V; TJ = –40°C to +100 °C, CL = 50 pF

CC

or the high V

IHX

power consumption, the minimum V

0.9 × V

and the maximum V

CCQH

value may cause additional power consumption (DC current). To minimize

ILX

should be no lower than

IHX

should be no higher than 0.1 × V

ILX

CCQH

.

V

V

V

V

V

V

V

V

V

V

V

V

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 2-3

Page 24

Specifications

2.4 AC Electrical Characteristics

The timing waveforms shown in the AC electrical characteristics section are tested with a VIL maximum of 0.3 V

and a V

the previous table. AC timing specifications, which are referenced to a device input signal, are measured in

production with respect to the 50 percent point of the respective input signal’s transition. DSP56L307 output levels

are measured with the production test machine V

Note: Although the minimum value for the frequency of EXTAL is 0 MHz, the device AC test conditions are 15

2.4.1 Internal Clocks

Internal operation frequency with PLL

enabled

Internal operation frequency with PLL

disabled

Internal clock high period

• With PLL disabled

• With PLL enabled and MF ≤ 4

• With PLL enabled and MF > 4

Internal clock low period

• With PLL disabled

• With PLL enabled and

• With PLL enabled and

Internal clock cycle time with PLL enabled T

Internal clock cycle time with PLL disabled T

Instruction cycle time I

Notes: 1. DF = Division Factor; Ef = External frequency; ET

minimum of 2.4 V for all pins except EXTAL, which is tested using the input levels shown in Note 6 of

IH

and VOH reference levels set at 0.4 V and 2.4 V, respectively.

OL

MHz and rated speed.

Table 2-4. Internal Clocks

1, 2

ET

C

—

—

ET

C

—

—

× PDF ×

C

0.51 × ETC ×

PDF × DF/MF

0.53 × ET

PDF × DF/MF

0.51 × ETC ×

PDF × DF/MF

0.53 × ET

PDF × DF/MF

Characteristics Symbol

MF ≤ 4

MF > 4

PDF = Predivision Factor; T

2. See the PLL and Clock Generation section in the

= internal clock cycle

C

Expression

Min Typ Max

f— (Ef × MF)/

(PDF × DF)

f— Ef/2 —

T

H

T

L

—ET

C

—2 × ET

C

CYC

—

0.49 × ET

PDF × DF/MF

0.47 × ET

PDF × DF/MF

0.49 × ET

PDF × DF/MF

0.47 × ET

PDF × DF/MF

= External clock cycle; MF = Multiplication Factor;

C

DSP56300 Family Manual

×

C

×

C

—

×

C

×

C

C

DF/MF

—TC—

for a detailed discussion of the PLL.

—

—

×

C

—

×

C

—

—

DSP56L307 Technical Data, Rev. 6

2-4 Freescale Semiconductor

Page 25

AC Electrical Characteristics

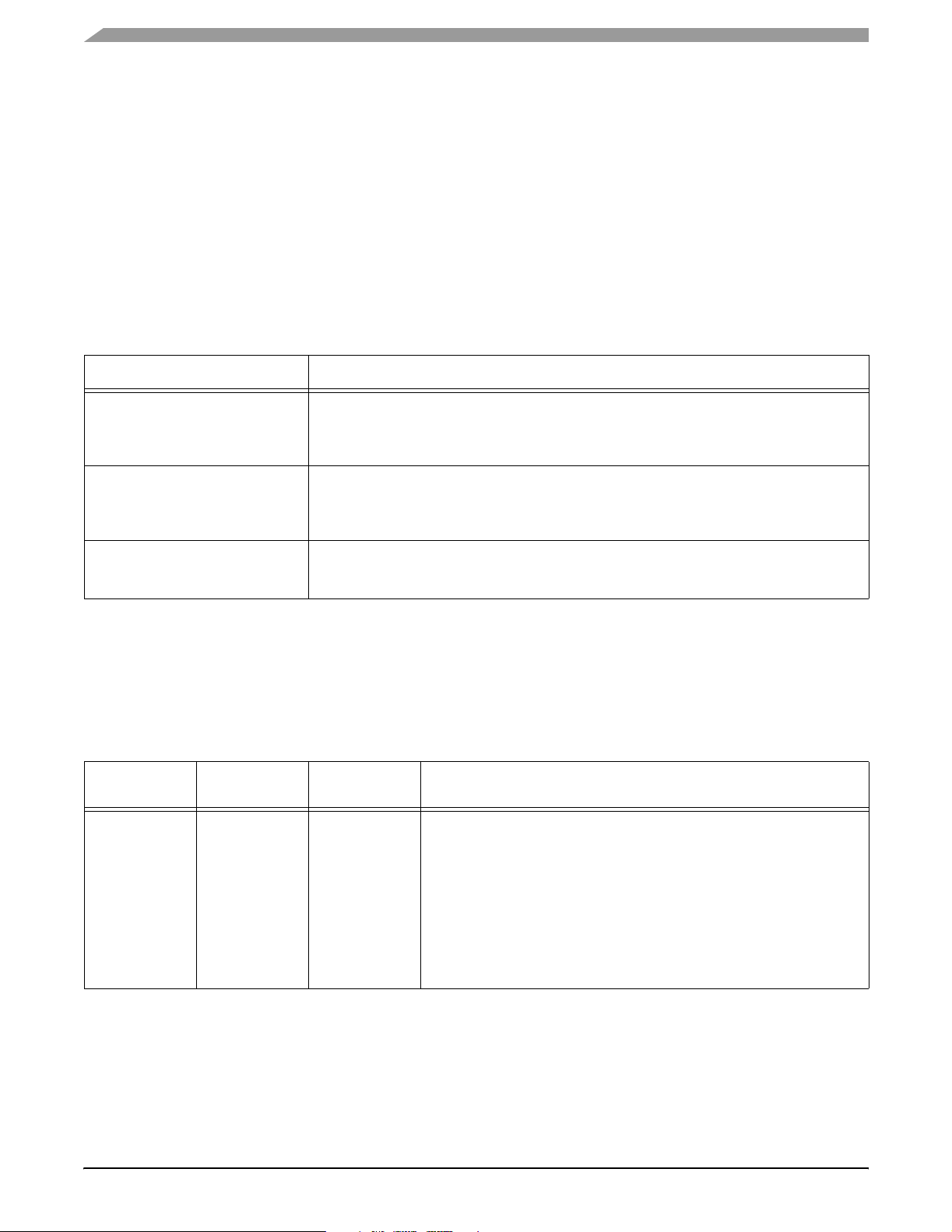

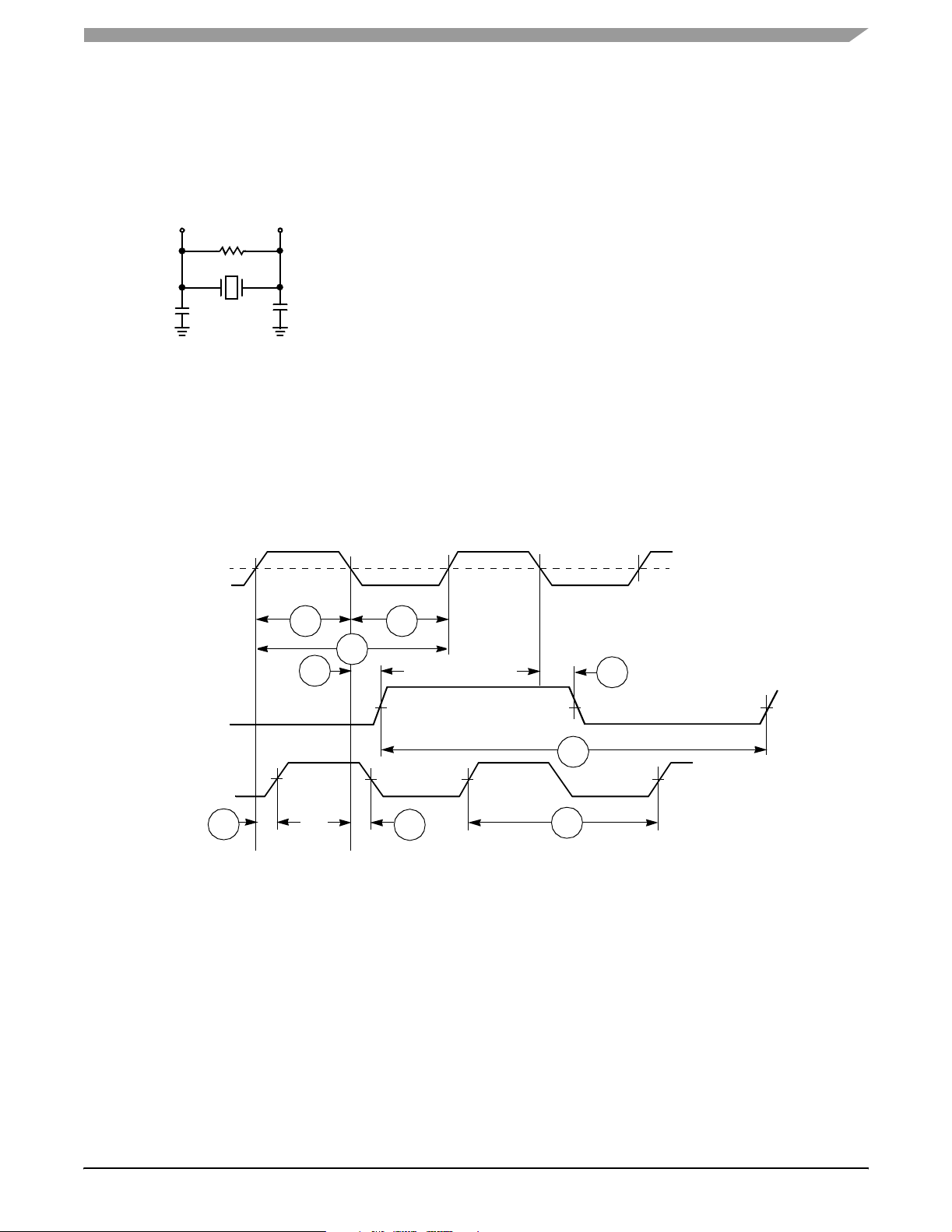

2.4.2 External Clock Operation

The DSP56L307 system clock is derived from the on-chip oscillator or is externally supplied. To use the on-chip

oscillator, connect a crystal and associated resistor/capacitor components to EXTAL and XTAL; examples are

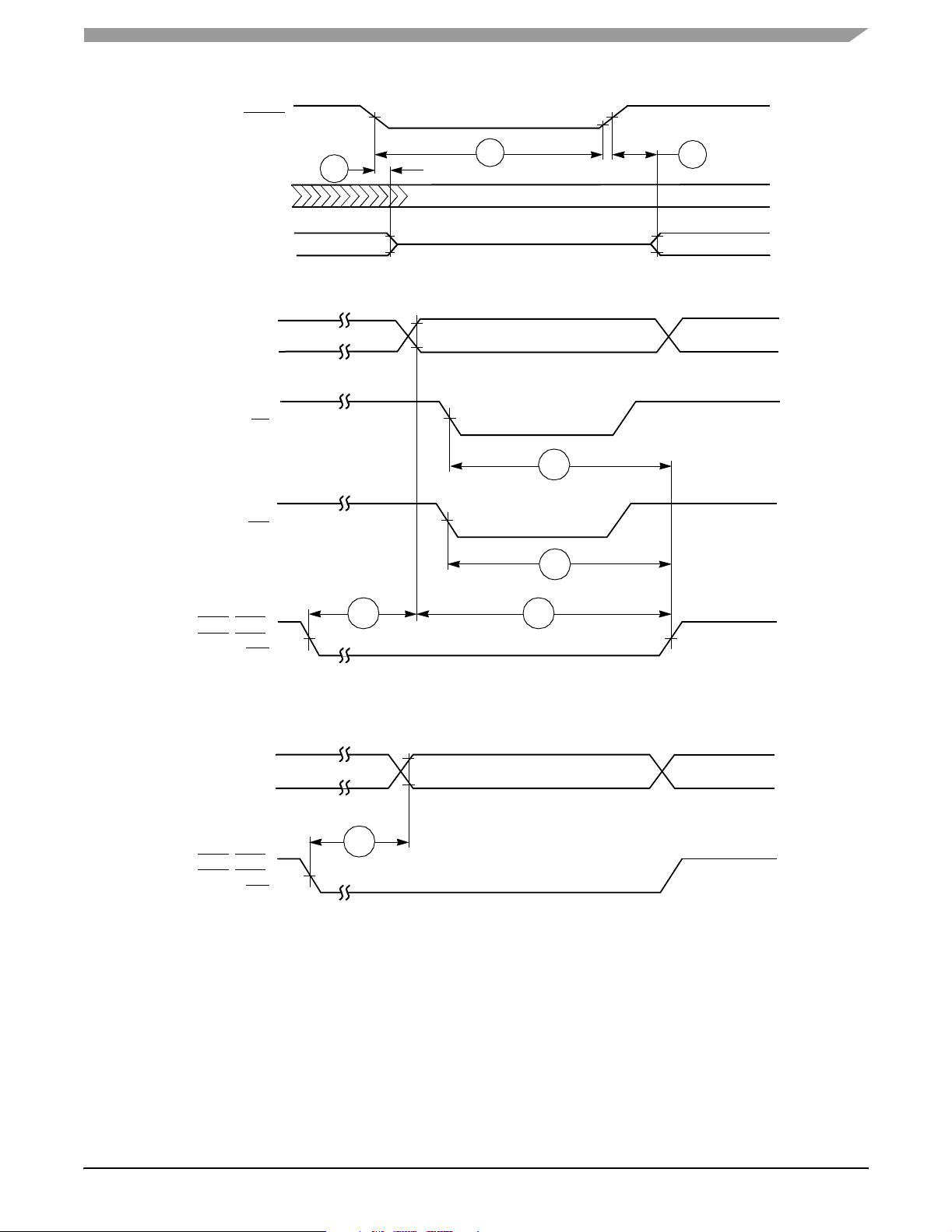

shown in Figure 2-1.

XTALEXTAL

R

C

XTAL1

Fundamental Frequency

Crystal Oscillator

Note: Make su re t hat i n

the PCTL Register:

• XTLD (bit 16) = 0

• If f

C

OSC

XTLR (bit 15) = 0

> 200 kHz,

Suggested Component Values:

f

= 4 MHz

OSC

R = 680 kΩ ± 10%

C = 56 pF ± 20%

Calculations were done for a 4/20 MHz crystal

with the following parameters:

•C

of 30/20 pF,

L

•C

of 7/6 pF,

0

• series resistance of 100/20 Ω, and

• drive level of 2 mW.

f

= 20 MHz

OSC

R = 680 kΩ ± 10%

C = 22 pF ± 20%

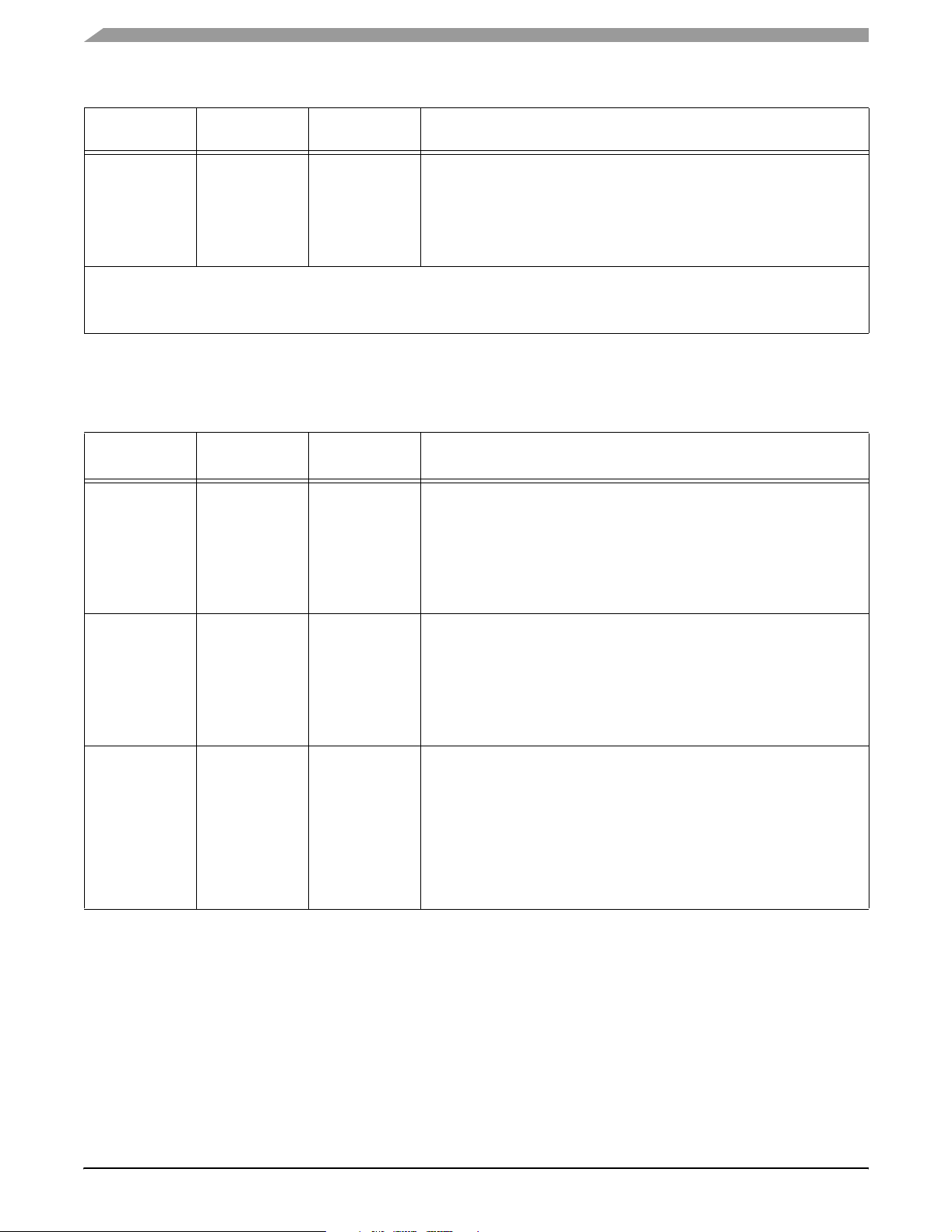

Figure 2-1. Crystal Oscillator Circuits

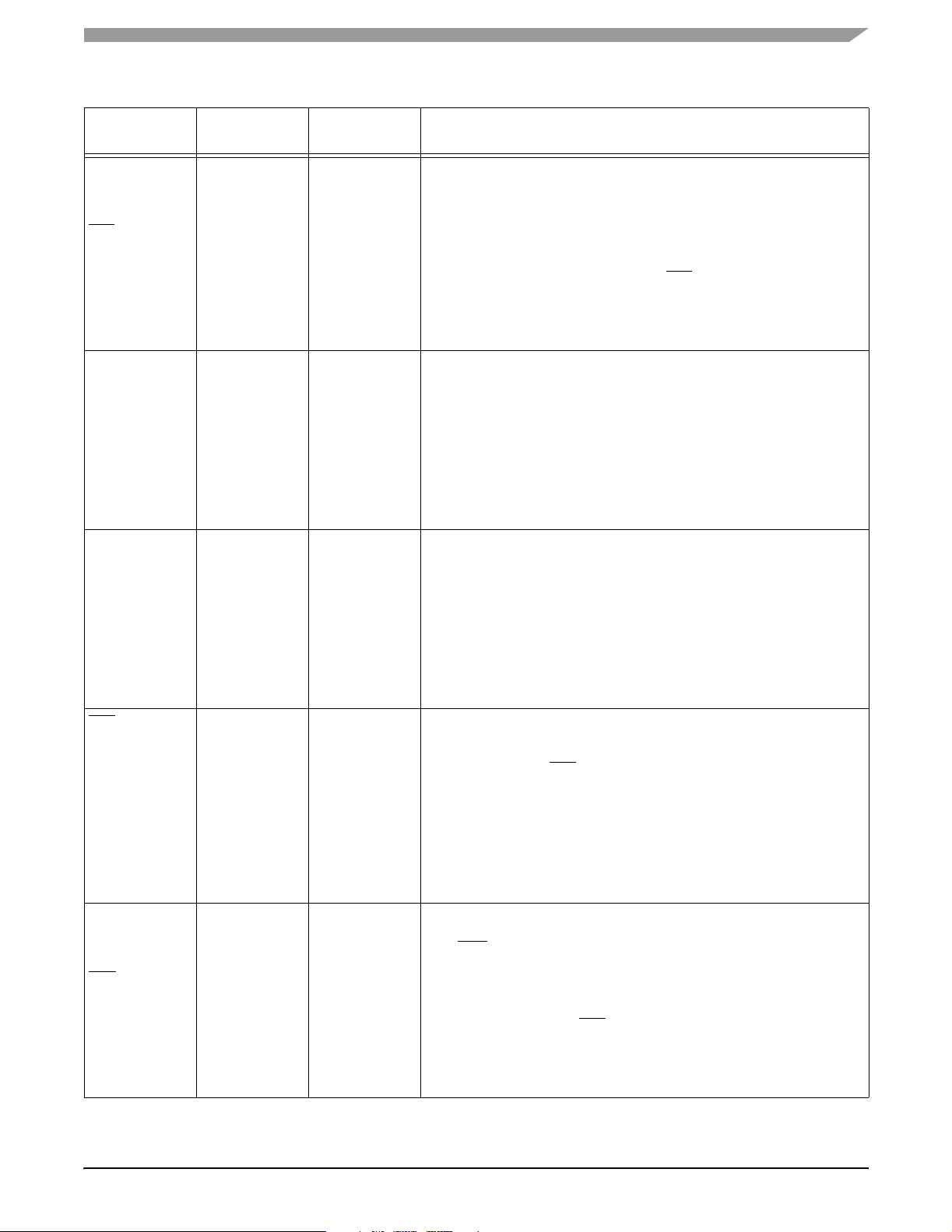

If an externally-supplied square wave voltage source is used, disable the internal oscillator circuit during bootup by

setting XTLD (PCTL Register bit 16 = 1—see the DSP56L307 User’s Manual). The external square wave source

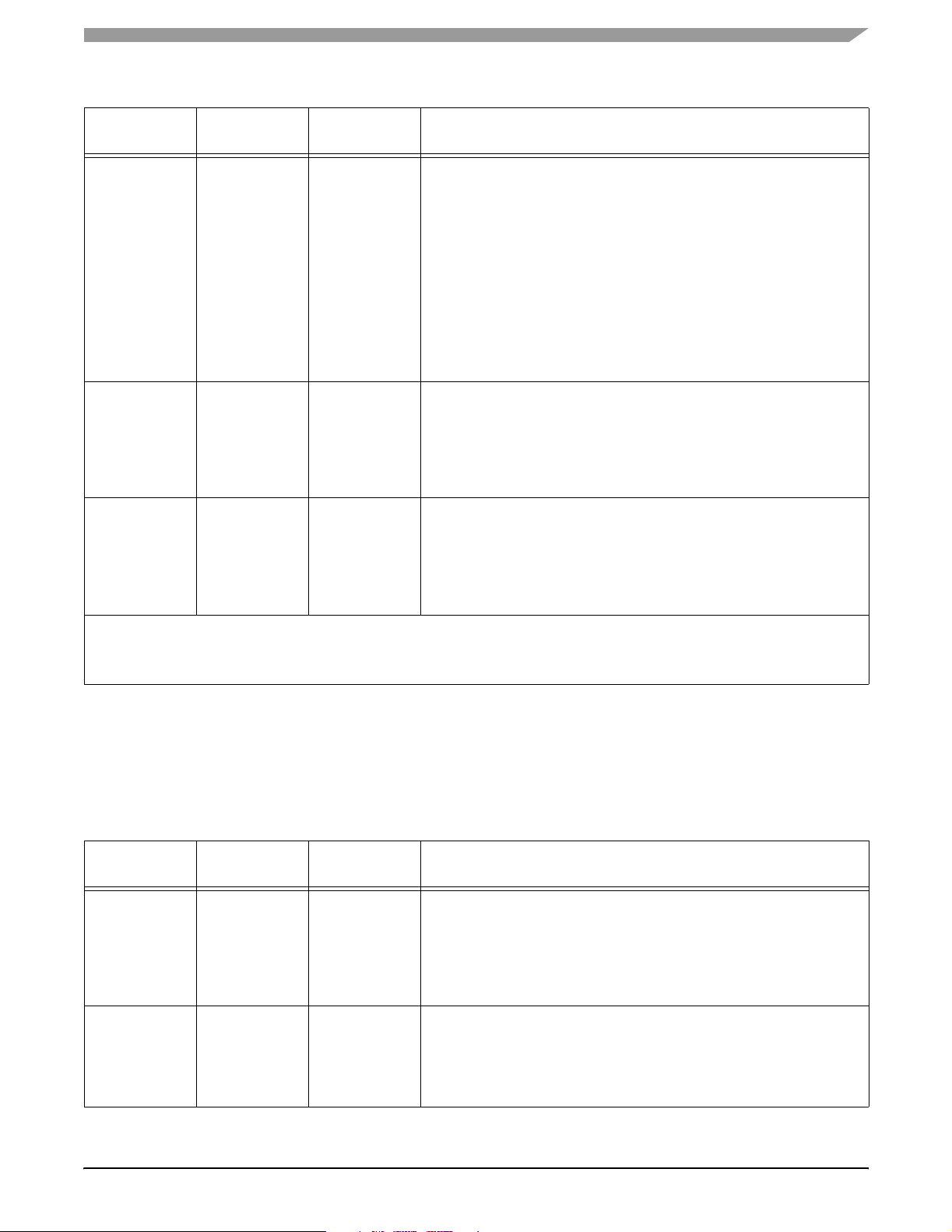

connects to EXTAL; XTAL is not physically connected to the board or socket. Figure 2-2 shows the relationship

between the

EXTAL input and the internal clock and CLKOUT.

EXTAL

CLKOUT with

PLL disabled

ET

ILX

H

2

5

V

ET

L

3

4

ET

C

Midpoint

Note: The midpoint is

0.5 (V

IHX

5

V

+ V

IHX

ILX

).

CLKOUT with

PLL enabled

6a

6b

7

7

Figure 2-2. External Clock Timing

DSP56L307 Technical Data, Rev. 6

Freescale Semiconductor 2-5

Page 26

Specifications

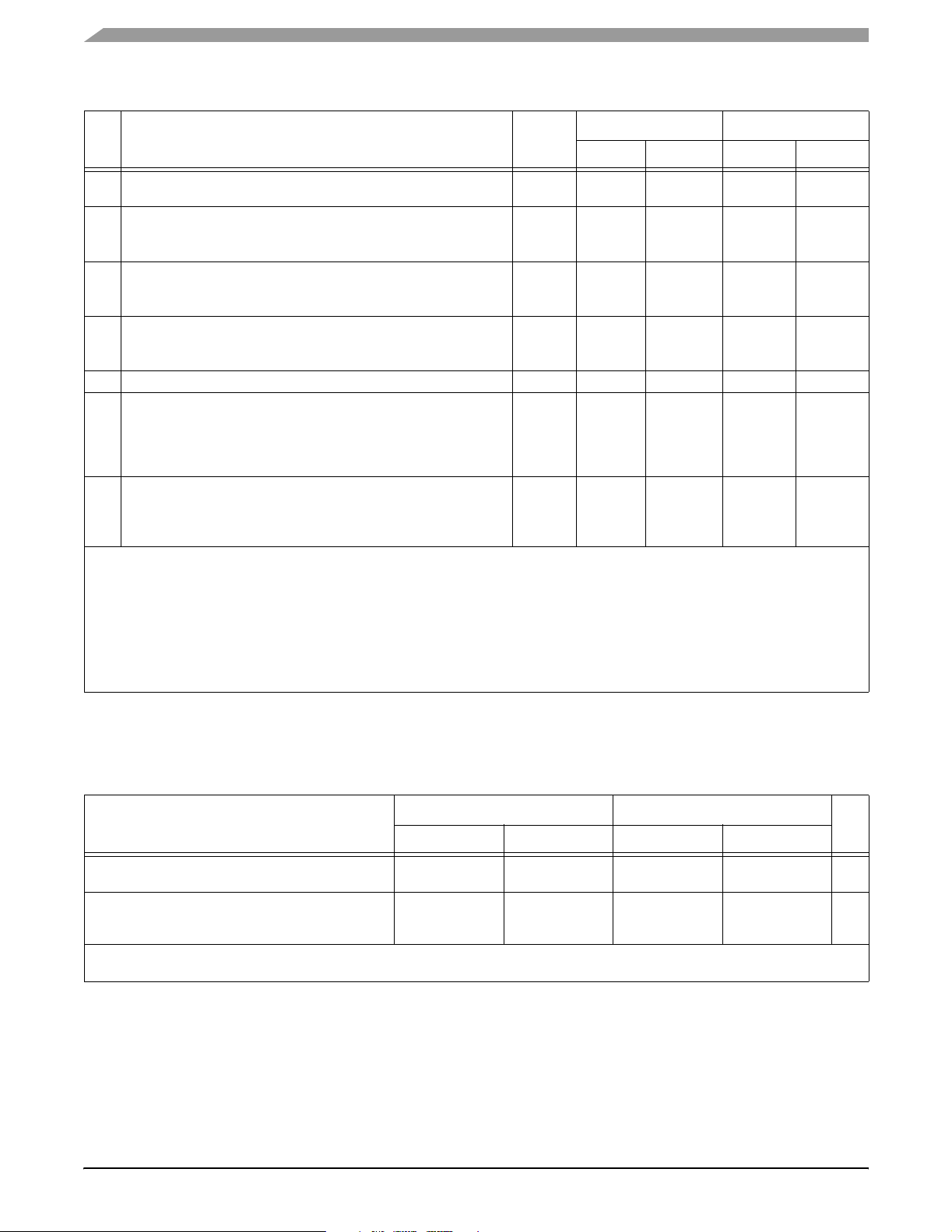

Table 2-5. Clock Operation

No. Characteristics Symbol

100 MHz 160 MHz

Min Max Min Max

1 Frequency of EXTAL (EXTAL Pin Frequency)

The rise and fall time of this external clock should be 3 ns maximum.

2 EXTAL input high

• With PLL disabled (46.7%–53.3% duty cycle6)

• With PLL enabled (42.5%–57.5% duty cycle

3 EXTAL input low

• With PLL disabled (46.7%–53.3% duty cycle6)

• With PLL enabled (42.5%–57.5% duty cycle

4 EXTAL cycle time

1, 2

1, 2

6

)

6

)

2

• With PLL disabled

• With PLL enabled

5 Internal clock change from EXTAL fall with PLL disabled 4.3 ns 11.0 ns 4.3 ns 11.0 ns

6 a.Internal clock rising edge from EXTAL rising edge with PLL enabled

(MF = 1 or 2 or 4, PDF = 1, Ef > 15 MHz)

b. Internal clock falling edge from EXTAL falling edge with PLL

enabled (MF ≤ 4, PDF ≠ 1, Ef / PDF > 15 MHz)

7 Instruction cycle time = I

CYC

= T

C

3,5

3,5

4

(see Figure 2-4) (46.7%–53.3% duty cycle)

• With PLL disabled

• With PLL enabled

Notes: 1. Measured at 50 percent of the input transition.