Freescale Semiconductor

Technical Data

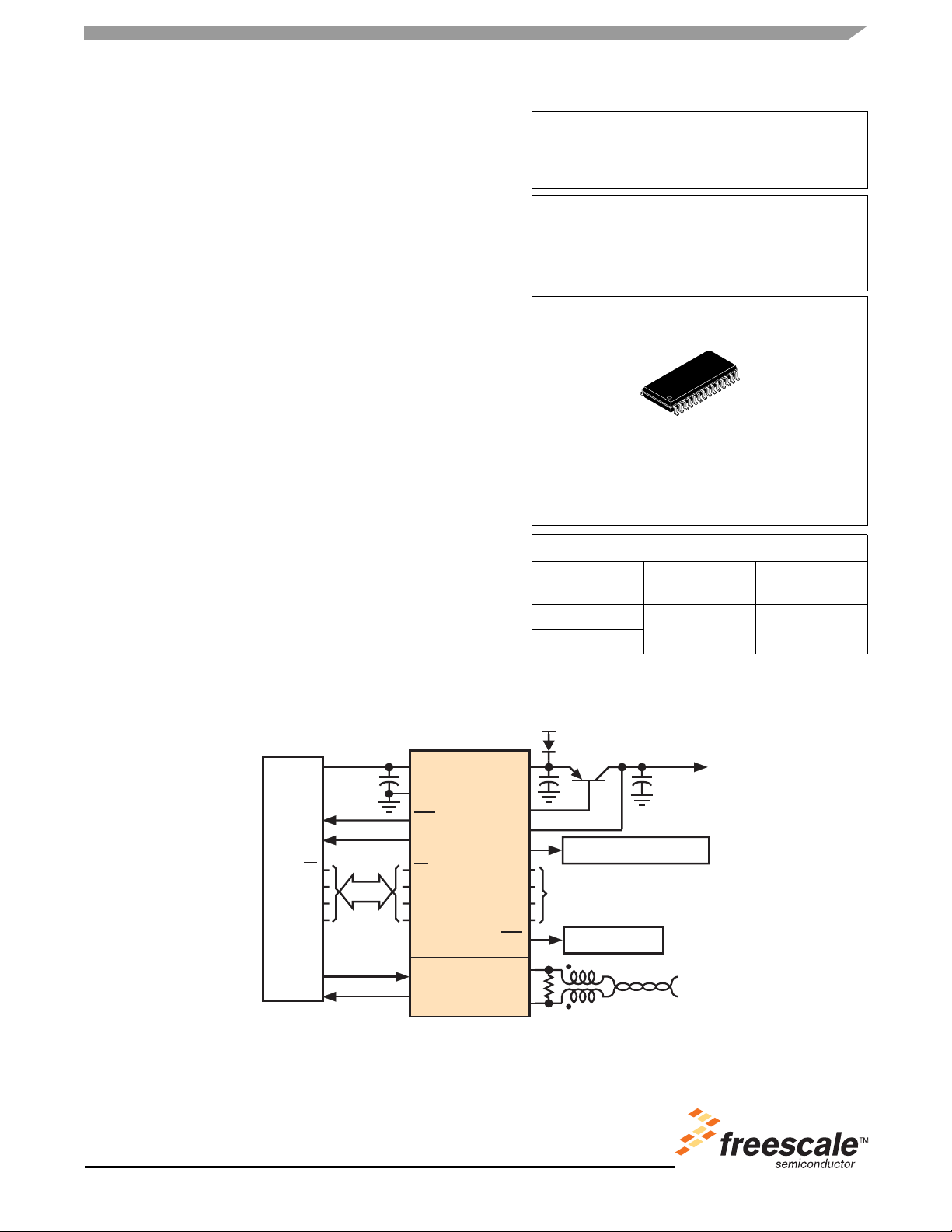

System Basis Chip with

Document Number: MC33989

Rev. 13.0, 3/2007

High-Speed CAN Transceiver

The 33989 is a monolithic integrated circuit combining many

functions used by microcontrollers (MCU) found in automotive

Engine Control Units (ECUs). The device incorporates

functions such as: two voltage regulators, four high voltage

(wake up) inputs, a 1Mbaud capable CAN physical interface,

an SPI interface to the MCU and VSUP monitoring and fault

detection circuitry. The 33989 also provides reset control in

conjunction with VSUP monitoring and the watchdog timer

features. Also, an Interrupt can be generated, for the MCU,

based on CAN bus activity as well as mode changes.

Features

•V

•V

• V2: Tracking Function of V

• Low Stand-By Current Consumption in Stop and Sleep Modes

• High-Speed 1 MBaud CAN Physical Interface

• Four External High Voltage Wake-up Inputs Associated with HS1

• 150 mA Output Current Capability for HS1 V

•V

• 40 V Maximum Transient Voltage

• Pb Free designated by suffix code EG

: Low Drop Voltage Regulator, Current Limitation,

DD1

Overtemperature Detection, Monitoring, and Reset Function

: Total Current Capability 200 mA

DD1

External Bipolar Ballast Transistor for High Flexibility in Choice of

Peripheral Voltage and Current Supply

V

Switch

BAT

Drive of External Switches Pull-Up Resistors or Relays

Failure Detection

SUP

Regulator. Control Circuitry for

DD1

Switch Allowing

BAT

33989

Device

MC33989DW/R2

MCZ33989EG/R2

V

PWR

33989

SYSTEM BASIS CHIP

WITH HIGH-SPEED CAN

DW SUFFIX

EG SUFFIX (PB-FREE)

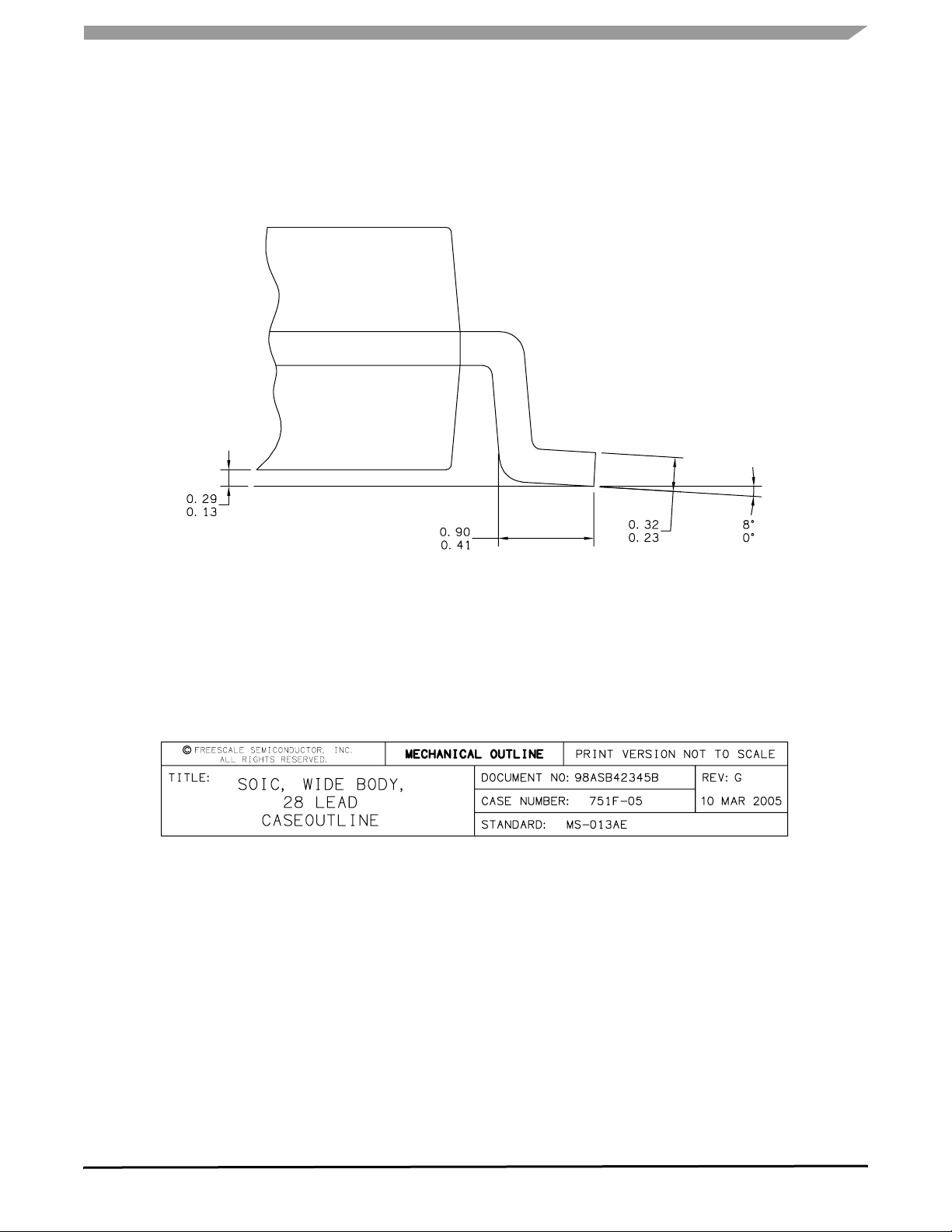

98ASB42345B

28-PIN SOICW

ORDERING INFORMATION

Temperature

Range (T

- 40°C to 125°C 28 SOICW

)

A

Package

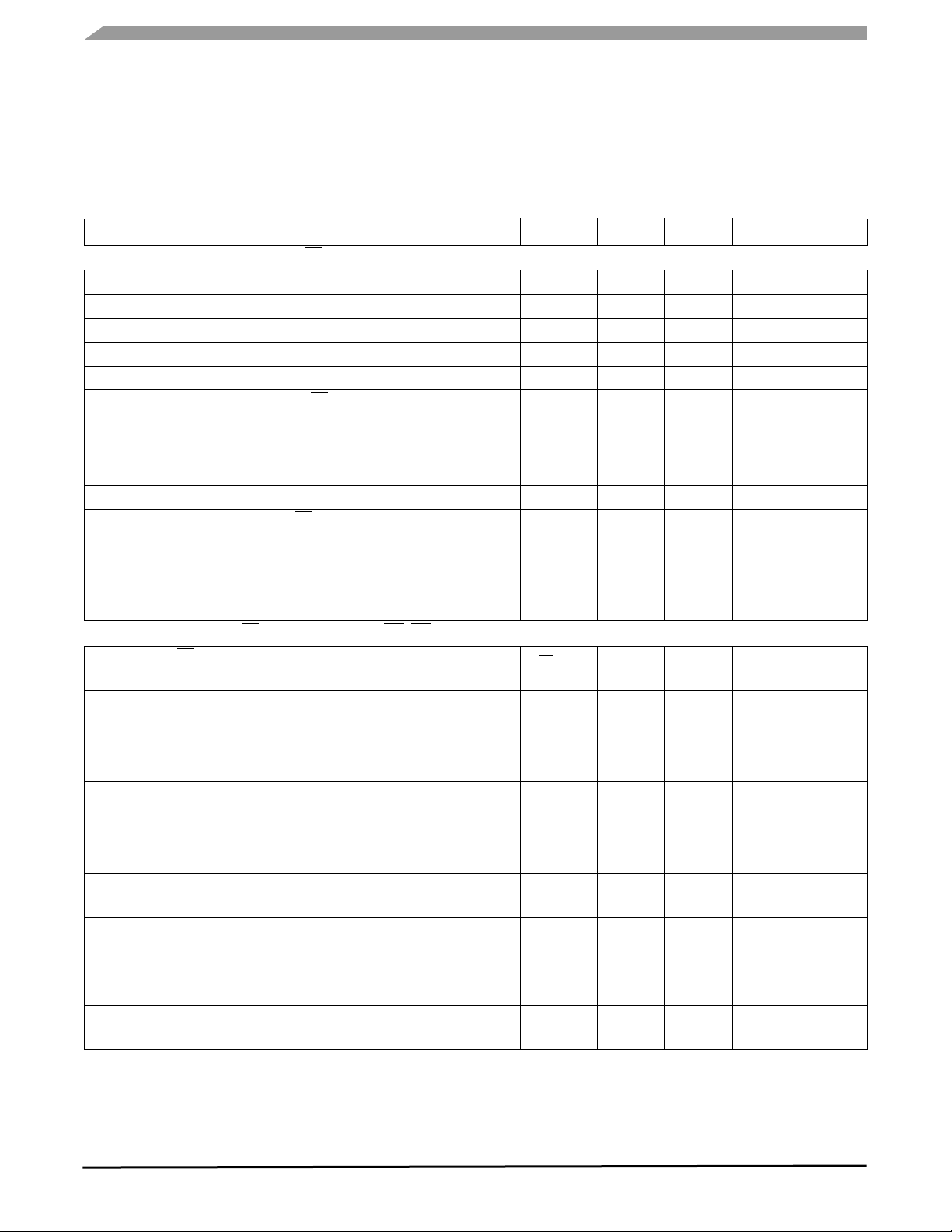

5.0 V

MCU

SCLK

MOSI

MISO

CS

SPI

VDD1

GND

RST

INT

CS

SCLK

MOSI

MISO

VSUP

V2CTRL

V2

HS1

L0

L1

L2

L3

WD

TX

RX

Figure 1. MC33989 Simplified Application Diagram

Freescale Semiconductor, Inc. reserves the right to change the detail specifications,

as may be required, to permit improvements in the design of its products.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

CANH

CANL

V2

Local Module Supply

Wake-Up Inputs

Safe Circuits

Twisted

CAN Bus

Pair

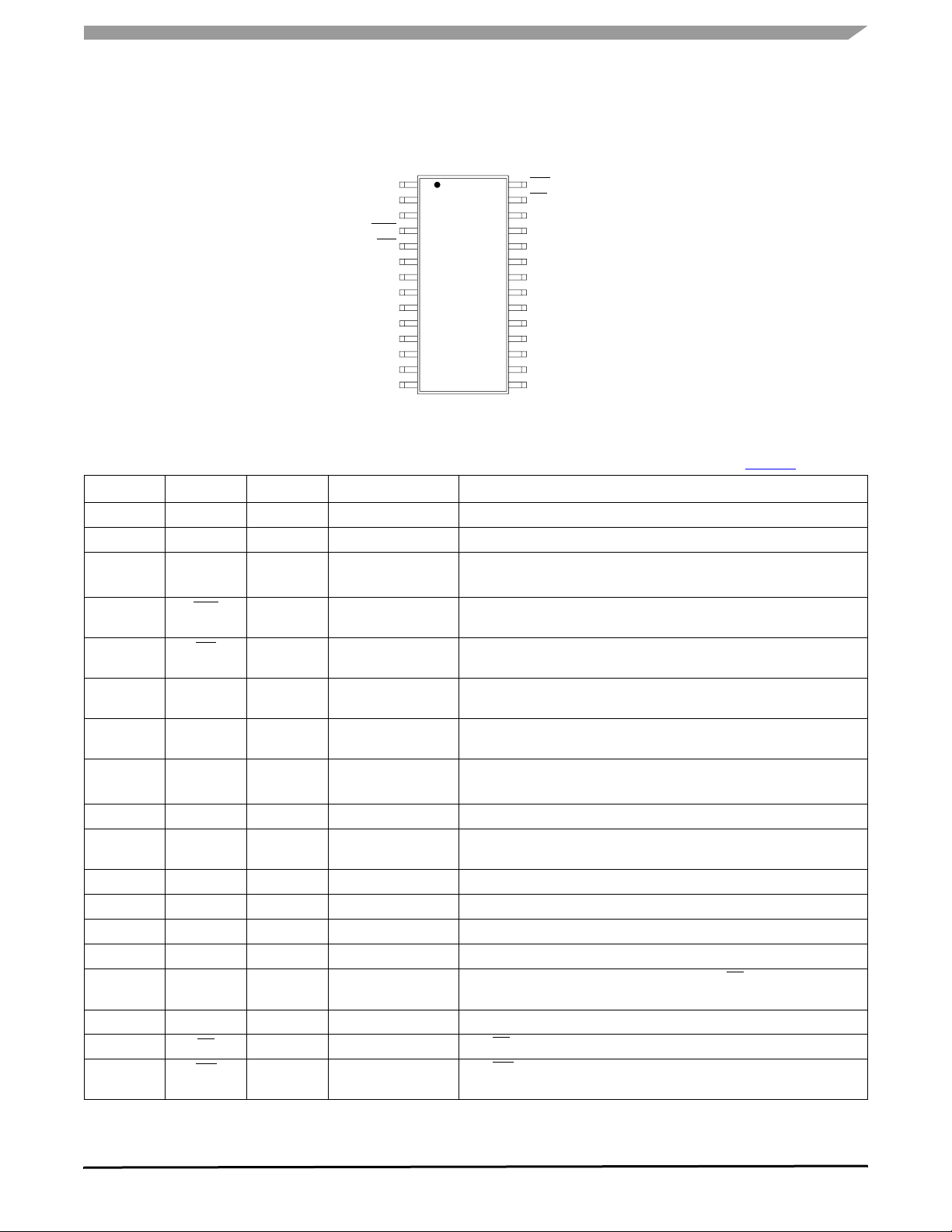

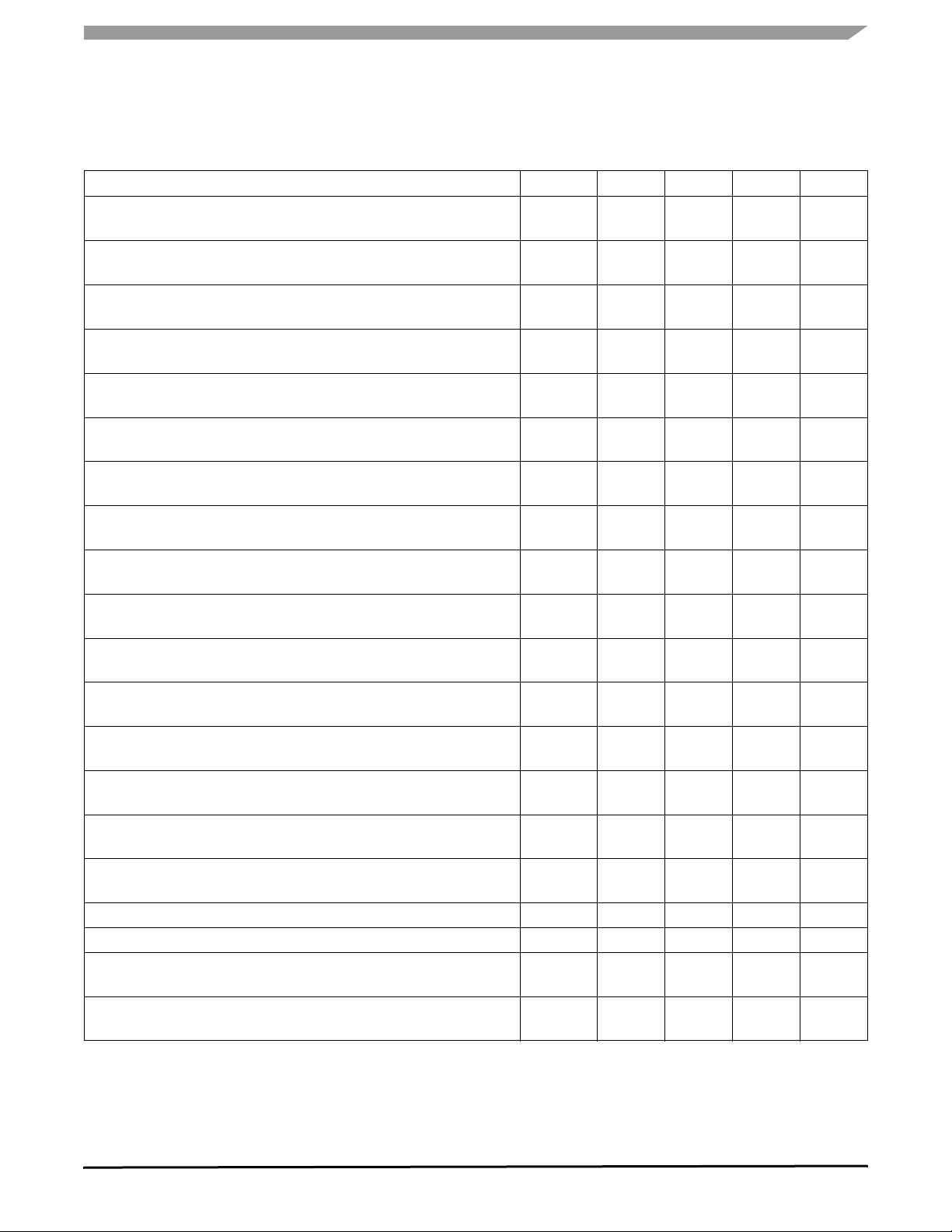

INTERNAL BLOCK DIAGRAM

VSUP

INTERNAL BLOCK DIAGRAM

VSUP Monitor Dual

Voltage Regulator

VDD1 Monitor

VDD1

HS1

L0

L1

TX

RX

CAN H

CAN L

HS1 Control

Oscillator

Interrupt

Watchdog

Programmable

Reset

Wake-Up Inputs

Mode Control

SPI

High Speed

Interface

1.0 MB/s CAN

Physical

Interface

Figure 2. 33989 Simplified Internal Block Diagram

INT

WD

RST

CS

SCLK

MOSI

MISO

GND

33989

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

PIN CONNECTIONS

PIN CONNECTIONS

RX

TX

VDD1

RST

INT

GND

GND

GND

GND

V2

V2CTRL

VSUP

HS1

L0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

WD

27

CS

26

MOSI

25

MISO

24

SCLK

23

GND

22

GND

21

GND

20

GND

19

CANL

18

CANH

17

L3

16

L2

15

L1

Figure 3. 33989 Pin Connections

Table 1. 33989 Pin Definitions

A functional description of each pin can be found in the Functional Pin Description section beginning on page 18.

Pin Number Pin Name Pin Function Formal Name Definition

1 RX Output Receive Data

2 TX Input Transmit Data

3 VDD1 Power

Output

Voltage Digital Drain

One

4 RST Output Reset

5 INT Output Interrupt

6–9

GND Ground Ground

20–23

10 V2 Input Voltage Source Two

11 V2CTRL Power

Voltage Control

Output

12 VSUP Power Voltage Supply

13 HS1 Output High Side One

14–17 L0:L3 Input Level 0: 3

22 CANH Output CAN High

23 CANL Output CAN Low

24 SCLK Input System Clock

25 MISO Output Master In/Slave Out

26 MOSI Input Master Out/Slave In

27 CS Input Chip Select

28 WD Output Watch Dog

CAN bus receive data output pin.

CAN bus transmit data input pin.

5.0 V regulator output pin. Supply pin for the MCU.

This is the device reset output pin whose main function is to reset the

MCU. This pin has an internal pullup current source to VDD.

This output is asserted LOW when an enabled interrupt condition occurs.

The output is a push-pull structure.

These device ground pins are internally connected to the package lead

frame to provide a 33989-to-PCB thermal path.

Sense input for the V2 regulator using an external series pass transistor.

V2 is also the internal supply for the CAN transceiver.

Output drive source for the V2 regulator connected to the external series

pass transistor.

Supply input pin for the 33989.

Output of the internal high-side switch. The output current is internally

limited to 150

mA.

Inputs from external switches or from logic circuitry.

CAN high output pin.

CAN low output pin.

Clock input pin for the Serial Peripheral Interface (SPI).

SPI data sent to the MCU by the 33989. When CS is HIGH, the pin is in

the high-impedance state.

SPI data received by the 33989.

The CS input pin is used with the SPI bus to select the 33989.

The WD output pin is asserted LOW if the software watchdog is not

correctly triggered.

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

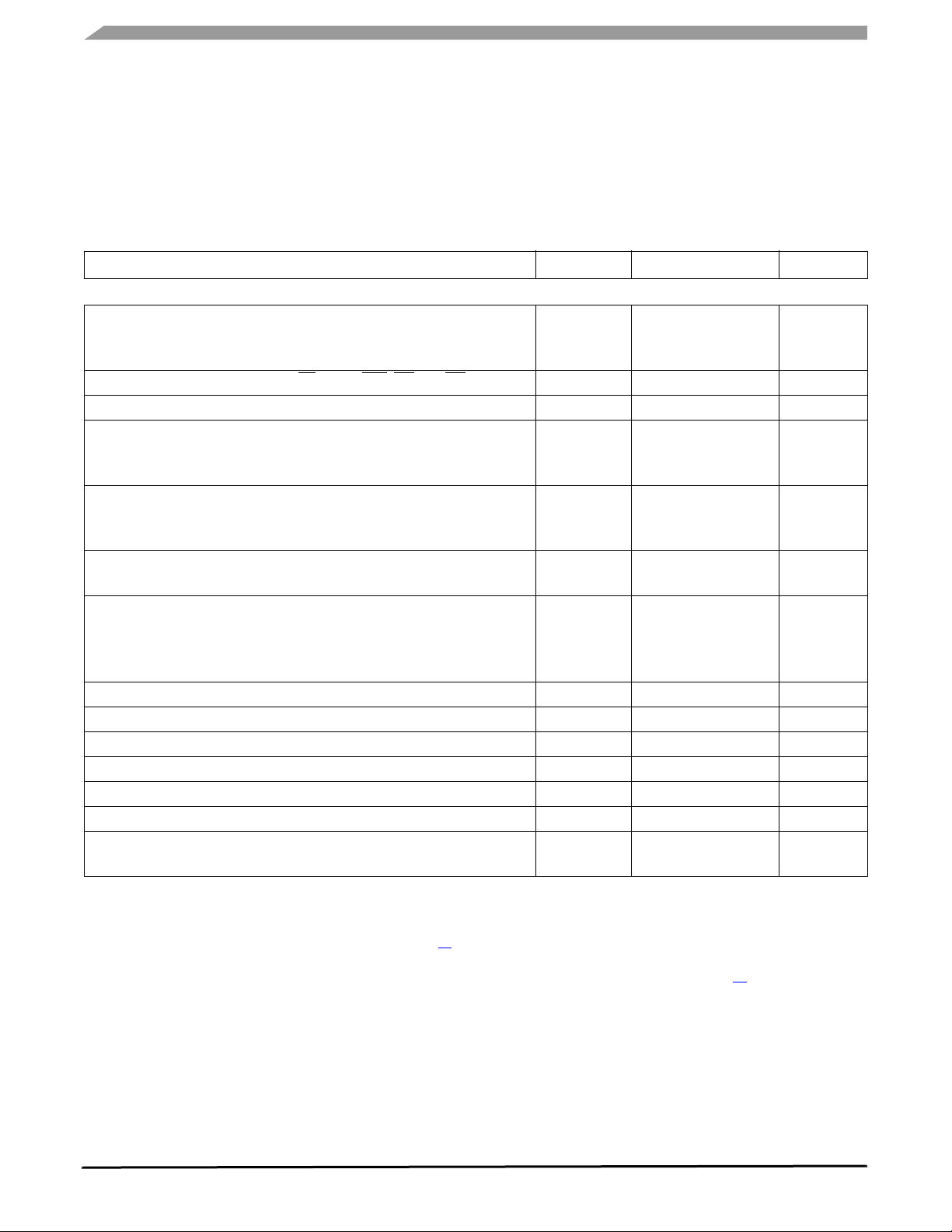

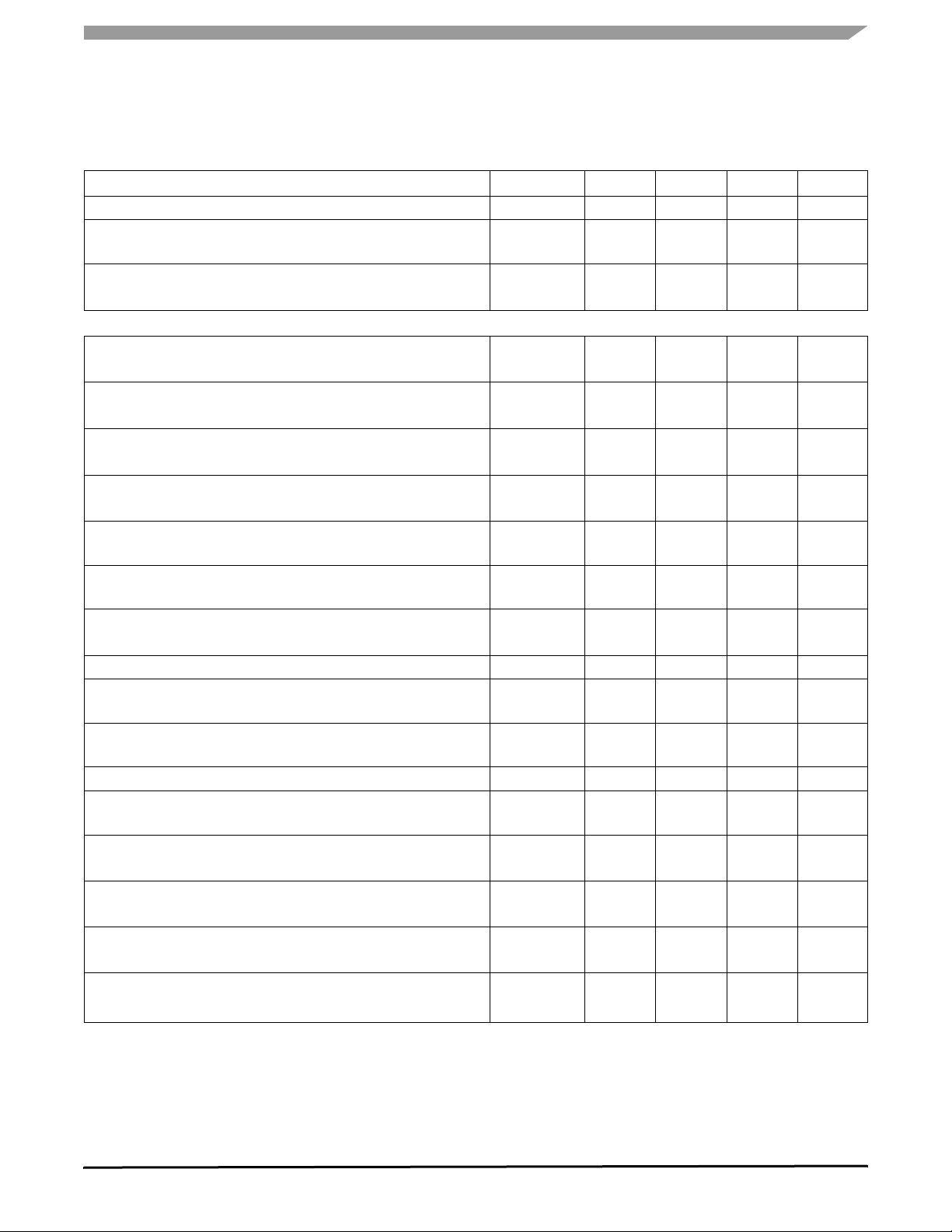

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

Power Supply Voltage at VSUP

Continuous (Steady-State)

Transient Voltage (Load Dump)

Logic Signals (RX, TX, MOSI, MISO, CS, SCLK, RST, WD, and INT)

Output Current VDD1

HS1

Voltage

Output Current

ESD Voltage, Human Body Model

(1)

HS1, L0, L1, L2, L3

All Other Pins

ESD Voltage Machine Model

All Pins Except CANH and CANL

L0, L1, L2, L3

DC Input Voltage

DC Input Current

Transient Input Voltage with External Component

(2)

CANL and CANH Continuous Voltage

CANL and CANH Continuous Current

CANH and CANL Transient Voltage (Load Dump)

CANH and CANL Transient Voltage

(5)

(4)

Logic Inputs (TX and RX)

ESD Voltage (HBM 100 pF, 1.5 k) CANL, CANH

ESD Voltage Machine Model

CANH and CANL

Notes

1. ESD1 testing is performed in accordance with the Human Body Model (C

= 0 Ω), and the Charge Device Model (CDM), Robotic (C

R

ZAP

ZAP

= 4.0pF).

2. According to ISO 7637 specification. See Table 6, page 24.

3. Load Dump test according to ISO 7637 part 1.

4. Transient test according to ISO 7637 part 1, pulses 1, 2, 3a, and 3b according to schematic in Table 17, page 35.

V

V

V

SUP

SUP

LOG

-0.3 to 27

-0.3 to 40

-0.3 to V

+ 0.3 V

DD1

I Internally Limited A

V

V

I

ESDH

-0.3 to V

SUP

+ 0.3

Internally Limited

- 4.0 to 4.0

-2.0 to 2.0

V

ESDM

±200

V

WUDC

-0.3 to 40

-2.0 to 2.0

-100 to 100

V

CANH/L

I

CANH/L

V

TRH/L

V

TRH/L

-27 to 40 V

200 mA

40 V

-40 to 40 V

V -0.5 to 6.0 V

V

ESDCH

V

ESDCM

-4.0 to 4.0 KV

-200 to 200

= 100 pF, 1.5 k), the Machine Model (MM) (C

ZAP

= 200 pF,

ZAP

V

V

A

kV

V

V

mA

V

V

33989

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

THERMAL RATINGS

Operating Junction Temperature

Storage Temperature

Ambient Temperature

Thermal Resistance Junction to GND Pins

(5)

Peak Package Reflow Temperature During Reflow

(6), (7)

R

T

T

J

T

S

T

A

J/P

Θ

PPRT

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

-40 to 150 °C

-55 to 165 °C

-40 to 125 °C

20 °C/W

Note 7.

°C

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

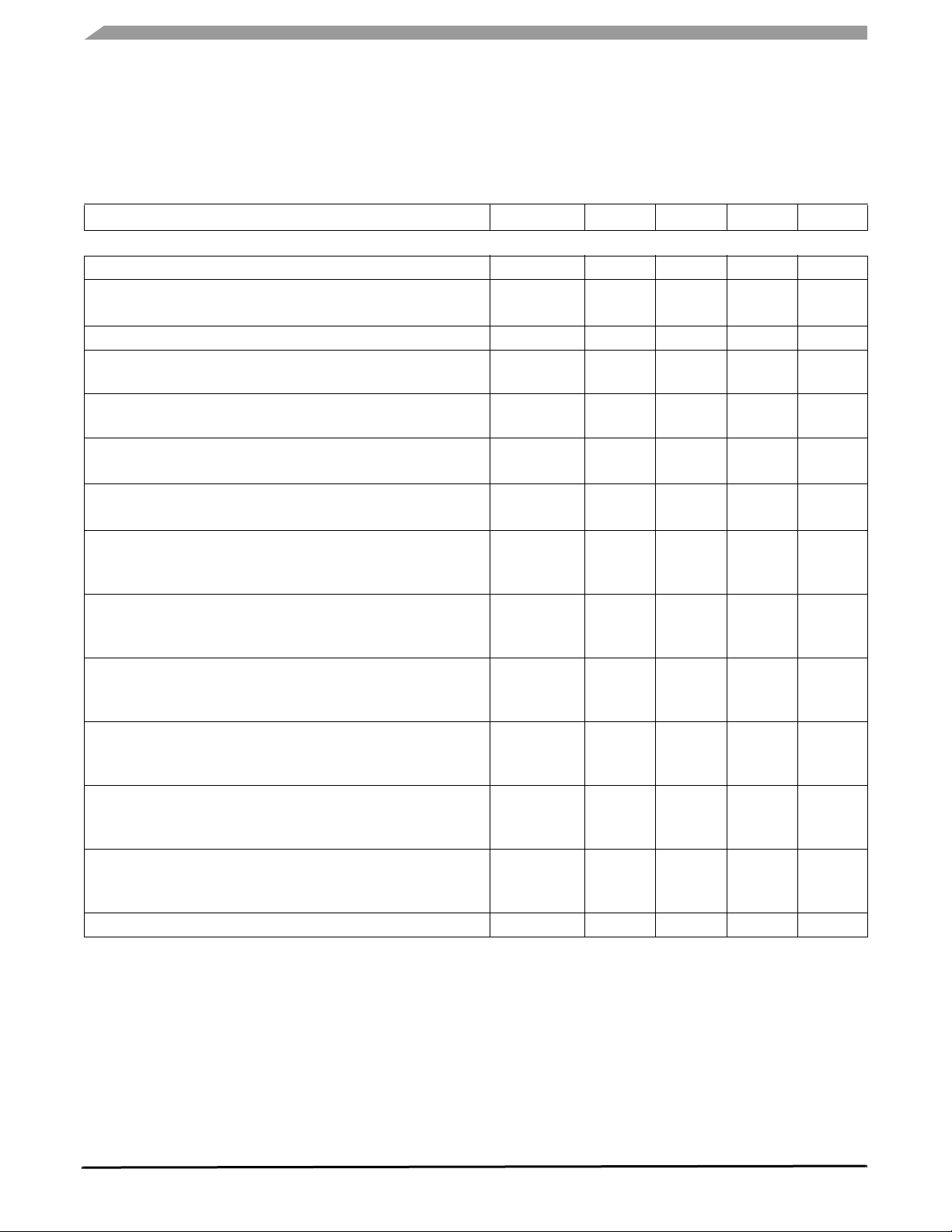

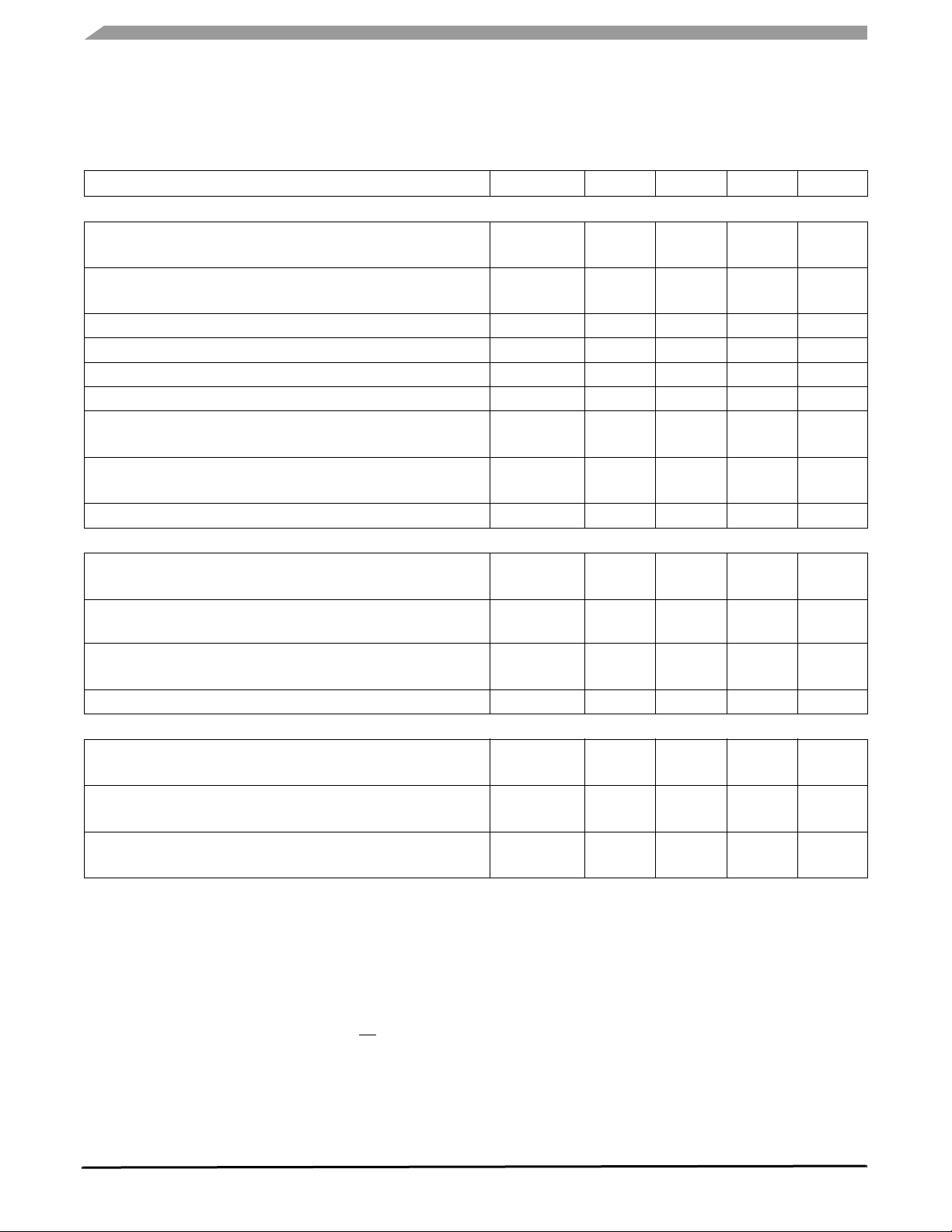

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 5.5 V ≤ V

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

POWER INPUT (VSUP)

Nominal DC Supply Voltage Range

Extended DC Voltage Range 1

Reduced Functionality

Extended DC Voltage Range 2

Input Voltage During Load Dump

Load Dump Situation

Input Voltage During Jump Start

Jump Start Situation

Supply Current in Standby Mode

I

at V

= 40 mA CAN recessive or Sleep-Disable State

OUT

DD1

Supply Current in Normal Mode

I

at V

= 40 mA CAN recessive or Sleep-Disable State

OUT

DD1

Supply Current in Sleep Mode

V

and V2 OFF, V

DD1

Sleep-Disable State

Supply Current in Sleep Mode

V

and V2 OFF, V

DD1

Sleep-Disable State

Supply Current in Sleep Mode

V

and V2 OFF, V

DD1

Sleep-Disable State

Supply Current in Stop Mode I

V

ON, V

DD1

SUP

Sleep-Disable State

Supply Current in Stop Mode I

V

ON, V

DD1

SUP

Sleep-Disable State

Supply Current in Stop Mode I

V

ON, V

DD1

SUP

Sleep-Disable State

BATFAIL Flag Internal Threshold

Notes

8. V

> 4.0 V, Reset high, Logic pin high level reduced, device is functional.

DD1

9. Device is fully functional. All functions are operating. All modes available and operating. Watchdog, HS1 turn ON turn OFF, CAN cell

operating, L0:L3 inputs operating, SPI read/write operation. Overtemperature may occur.

10. Current measured at V

11. With CAN cell in Sleep-Disable state. If CAN cell is Sleep-Enabled for wake-up, an additional 60 µA must be added to specified value.

12. Oscillator running means Forced Wake-up or Cyclic Sense of Software Watchdog is Stop mode are not activated.

(8)

(9)

(10) (11)

(10)

(10) (11)

< 12 V, Oscillator Running

SUP

(10) (11)

< 12 V, Oscillator Not Running

SUP

(10) (11)

> 12 V, Oscillator Running

SUP

V

OUT

< 12 V, Oscillator Running

OUT VDD1

< 2.0 mA

DD1

< 2.0 mA

(12)

< 12 V, Oscillator Not Running

OUT VDD1

> 12 V, Oscillator Running

SUP

< 2.0 mA

(12)

pin.

CAN in

(11)

(12)

(10) (11)

CAN in

≤ 18 V, - 40°C ≤ T

SUP

(12)

CAN in

(12)

(12)

CAN in

(10) (11)

CAN in

≤ 125°C, GND = 0 V unless otherwise noted. Typical

= 25°C under nominal conditions unless otherwise noted.

A

A

V

SUP

V

SUPEX1

5.5 — 18 V

4.5 — 5.5

V

SUPEX2

V

SUPLD

18 — 27 V

— — 40

V

SUPJS

— — 27

I

SUP(STDBY)

— 42 45

I

SUP(NORM)

— 42.5 45

I

SUP(SLEEP1)

— 72 105

I

SUP(SLEEP2)

CAN in

I

SUP(SLEEP3)

— 57 90

— 100 150

I

SUP(STOP1)

— 135 210

I

SUP(STOP2)

— 130 210

I

SUP(STOP3)

— 160 230

VBF 1.5 3.0 4.0 V

V

V

V

mA

mA

µA

µA

µA

µA

µA

µA

33989

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 5.5 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

BATFAIL Flag Hysteresis

Battery Fall Early Warning Threshold

In Normal and Standby Mode

Battery Fall Early Warning Hysteresis

In Normal and Standby Mode

POWER OUTPUT (VDD1)

VDD1 Output Voltage

I

from 2.0 to 200 mA T

DD1

VDD1 Output Voltage

I

from 2.0 to 200 mA, 4.5 V < V

DD1

Dropout Voltage

I

= 200 mA

DD1

Dropout Voltage, Limited Output Current

I

= 50 mA, 4.5 V < V

DD1

I

Output Current

DD1

Internally Limited

Junction Thermal Shutdown

Normal or Standby Modes

Junction Over Temperature Pre-Warning

V

Temperature Threshold Difference

Reset Threshold 1

Selectable by SPI. Default Value After Reset.

Reset Threshold 2

Selectable by SPI

V

DD1

Reset Delay Time

Measured at 50% of Reset Signal

Line Regulation (C at V

9.0 V V

Line Regulation (C at V

5.5 < V

Load Regulation (C at V

1.0 mA < I

Thermal Stability

V

Notes

13. With CAN cell in Sleep-Disable state. If CAN cell is Sleep-Enabled for wake-up, an additional 60 µA must be added to specified value.

14. I

15. Guaranteed by design; however, it is not production tested.

Bit Set

DDTEMP

Range for Reset Active

< 18, IDD = 10 mA

SUP

< 27 V, IDD = 10 mA

SUP

< 200 mA

IDD

= 13.5 V, 1 = -100 mA Not Tested

SUP

is the total regulator output current. VDD specification with external capacitor. Stability requirement: C > 47 µF ESR < 1.3 Ω

DD1

(tantalum capacitor). In reset, normal request, normal and standby modes. Measure with C = 47 µF Tantalum.

(13)

(13)

(14)

-40 to 125°C, 5.5 V < V

AMB

SUP

= 47 µF Tantal)

DD1

= 47 µF Tantal)

DD1

= 47 µF Tantal)

DD1

SUP

< 5.5 V

(15)

SUP

< 27 V

VBF

(HYS)

BF

EW

BF

EWH

V

DD1OUT

V

DD1OUT2

V

DD1DRP

V

DD1DRP2

I

DD1

T

SD

T

PW

T

- T

SD

PW

RST

TH1

RST

TH2

V

DDR

t

D

LR1

LR2 —

LD

THERM

S

— 1.0 — V

5.3 5.8 6.3

0.1 0.2 0.3

4.9 5.0 5.1

4.0 — —

— 0.2 0.5

— 0.1 0.25

200 285 350

160 — 200

125 — 160

20 — 40 °C

4.5 4.6 4.7

4.1 4.2 4.3

1.0 — — V

—

4.0

30

—

5.0 25

10 25

— 25 75

— 30 50

V

V

V

V

V

V

mA

°C

°C

V

V

µs

mV

mV

mV

mV

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

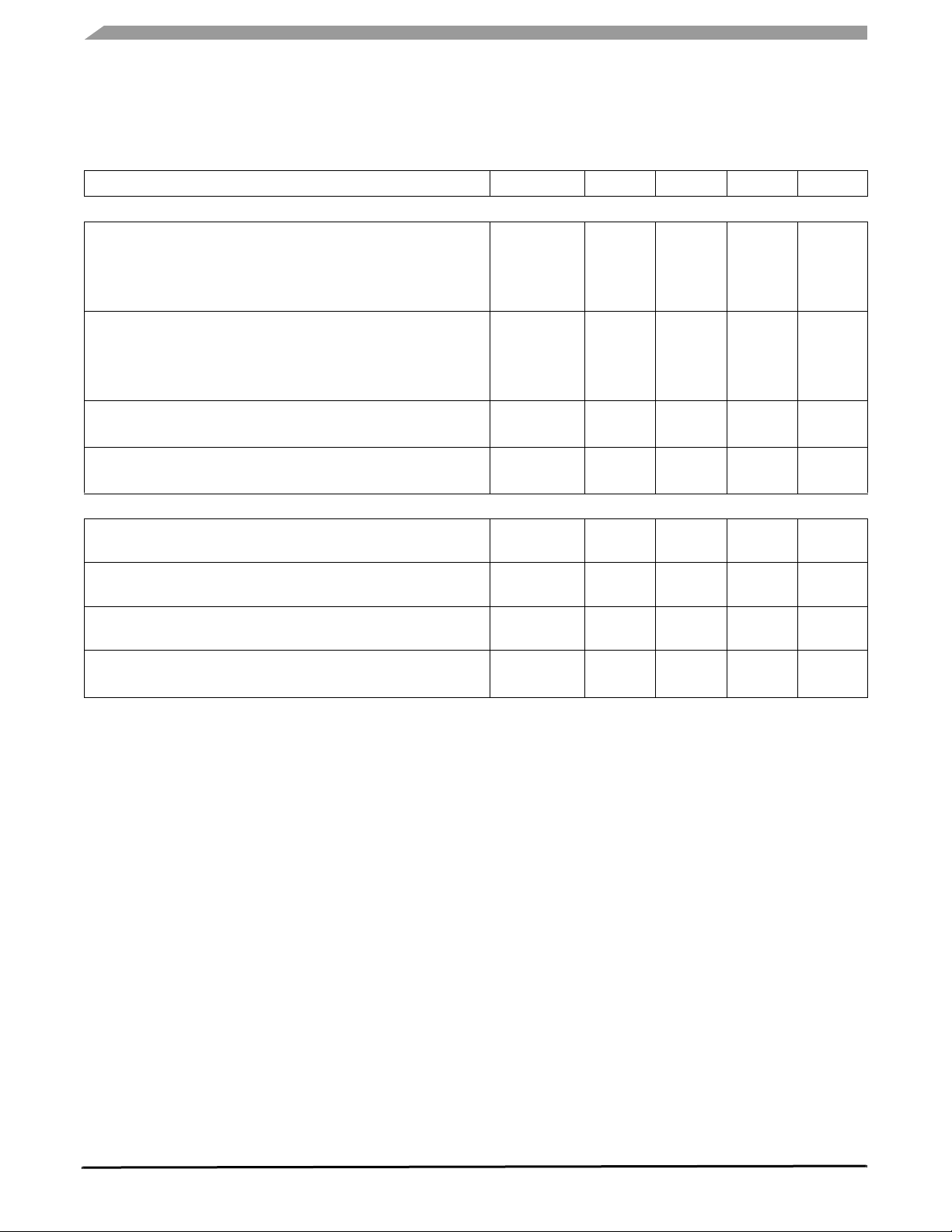

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 5.5 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

SUP

(16)

(19)

< 27 V

(17)

(18)

V

DDSTOP

V

DDSTOP2

I

DD1SWU

I

DD1DGLT

RST

STOP1

RST

STOP2

LR

LD

V

DDst-cap

V2

I2

12

CTRL

V2L

V

OL

V

OH

I

HZ

S

S

TH

4.75 5.00 5.25

4.75 5.00 5.25

10 17 25 mA

40 55 75 µs

4.5 4.6 4.7 V

4.1 4.2 4.3 V

— 5.0 25

— 15 75

— — 200 µF

0.99 1.0 1.01

200 — —

0.0 — 10

3.75 4.0 4.25 V

0.0 — 1.0

V

DD1-0.9

— V

DD1

-2.0 — 2.0

” parameter.

DDst-cap

and prevent the device to stay in

DDSWU

POWER OUTPUT (VDD1) IN STOP MODE

VDD1 Output Voltage

I

< = 2.0 mA

DD1

VDD1 Output Voltage

I

< = 10 mA

DD1

I

Stop Output Current to Wake-up SBC

DD1

I

Over Current to Wake-up Deglitcher Time

DD1

Reset Threshold

Reset Threshold

Line Regulation (C at V

5.5 V < V

< 27 V, IDD = 2.0 mA

SUP

Load Regulation (C at V

= 47 µF Tantal)

DD1

= 47 µF Tantal)

DD1

1 mA < IDD < 10 mA

Max Decoupling Capacitor at VDD1 Pin, in Stop Mode

TRACKING VOLTAGE REGULATOR (V2)

V2 Output Voltage (C at V2 = 10 µF Tantal)

I2 from 2.0 to 200 mA, 5.5 V < V

I2 Output Current (for information only)

Depending Upon External Ballast Transistor

V2 Control Drive Current Capability

Worst Case at TJ = 125°C

V2LOW Flag Threshold

LOGIC OUTPUT PIN (MISO)

(20)

Low Level Output Voltage

I

= 1.5 mA

OUT

High Level Output Voltage

I

= 250 µA

OUT

Tri-Stated MISO Leakage Current

0 V < V

MISO

< V

DD

Notes

16. If stop mode is used, the capacitor connected at VDD pin should not exceed the maximum specified by the “V

If capacitor value is exceeded, upon entering stop mode, VDD output current may exceed the I

stop mode.

17. Guaranteed by design; however, it is not production tested.

18. Guaranteed by design.

19. V2 specification with external capacitor

- Stability requirement: C > 42 µF and ESR < 1.3 Ω (Tantalum capacitor), external resistor between base and emitter required

- Measurement conditions: Ballast transistor MJD32C, C = 10 µF Tantalum, 2.2 k resistor between base and emitter of ballast transistor

20. Push/Pull structure with tri-state condition CS high.

V

V

V

mV

mV

DD1

mA

mA

V

V

µA

33989

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 5.5 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

LOGIC INPUT PINS (MOSI, SCLK, CS)

High Level Input Voltage

Low Level Input Voltage

High Level Input Current on CS

Low Level Input Current on CS

MOSI and SCLK Input Current

RESET PIN (RST)

(21)

High Level Output Current

0 < V

OUT

< 0.7 V

DD

Low Level Output Voltage (I0 = 1.5 mA)

5.5 V < V

SUP

< 27 V

Low Level Output Voltage (I0 = 0 µA

1.0 V < V

SUP

< 5.5 V

Reset Pull Down Current

V > 0.9 V

Reset Duration After V

WATCHDOG OUTPUT PIN (WD)

DD1

High

(22)

Low Level Output Voltage (I0 = 1.5 mA)

1.0 V < V

SUP

< 27 V

High Level Output Voltage (I0 = 250 µA)

INTERRUPT PIN (INT)

(22)

Low Level Output Voltage (I0 = 1.5 mA)

High Level Output Voltage (I0 = 250 µA)

HIGH SIDE OUTPUT PIN (HS1)

R

at TJ = 25°C, and I

DSON

V

> 9.0 V

SUP

R

at TA = 125°C, and I

DSON

V

> 9.0 V

SUP

R

at TA = 125°C, and I

DSON

5.5 < V

SUP

< 9.0 V

OUT

OUT

OUT

- 150 mA

- 150 mA

- 120 mA

Output Current Limitation

HS1 Overtemperature Shutdown

HS1 Leakage Current

Output Clamp Voltage at I

OUT

= -10 mA

No Inductive Load Drive Capability

Notes

21. Push/Pull structure with tri-state condition CS high.

22. Output pin only. Supply from VDD1. Structure switch to ground with pull-up current source.

V

V

I

RST

V

V

V

V

RON

RON

RON

L

O

L

V

IH

V

IL

L

IH

L

IL

L

N

I

OH

OL

OL

PDW

DUR

OL

OH

OL

OH

125-2

LIM

VT

LEAK

V

CL

25

125

0.7 V

DD1

-0.3 — 0.3 V

— V

+ 0.3 V

DD1

DD1

-100 — -20 µA

-100 — -20 µA

-10 — 10 µA

-300 -250 -150

0.0 — 0.9

0.0 — 0.9

2.3 — 5.0

3.0 3.4 4.0 ms

0.0 — 0.9

V

-0.9 — V

DD1

DD1

0.0 — 0.9 V

V

-0.9 — V

DD1

DD1

— 2.0 2.5

— — 4.5

— 3.5 5.5

160 — 500 mA

155 — 190 °C

— — 10 µA

-1.5 — -0.3

V

µA

V

V

mA

V

V

V

Ω

Ω

Ω

V

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

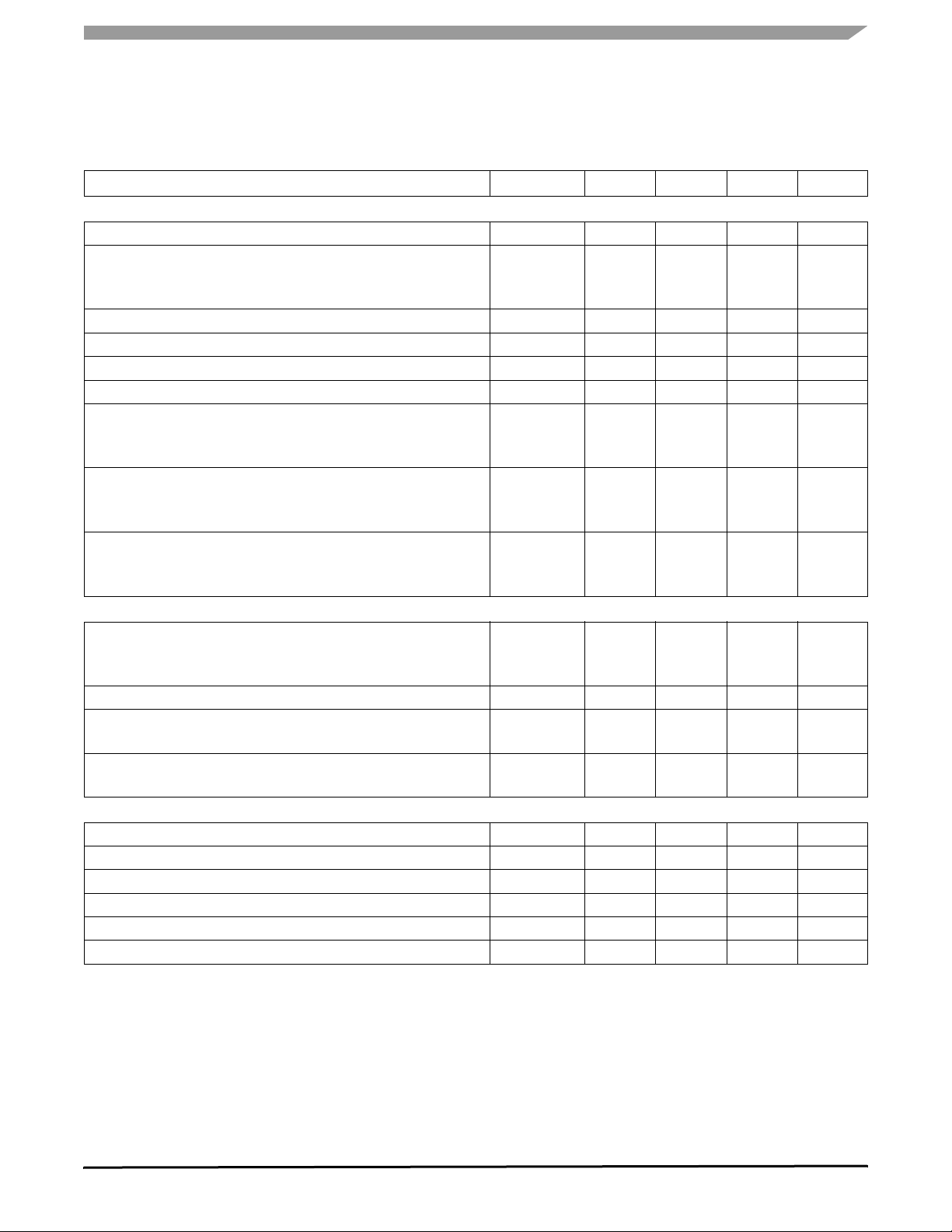

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 5.5 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

LOGIC INPUTS (L0:L3)

Negative Switching Threshold

5.5 V < V

6.0 V < V

18 V < V

SUP

SUP

SUP

< 6.0 V

< 18 V

< 27 V

Positive Switching Threshold

5.5 V < V

6.0 V < V

18 V < V

SUP

SUP

SUP

< 6.0 V

< 18 V

< 27 V

Hysteresis

5.5 V < V

SUP

< 27 V

Input Current

-0.2 V < V

IN

< 40 V

CAN SUPPLY (V2)

Supply Current Cell

Recessive State

Supply Current Cell

Dominant State without Bus Load

Supply Current Cell, CAN in Sleep State Wake-up Enable

V2 Regulator OFF

Supply Current Cell, CAN in Sleep State Wake-up Disable

V2 Regulator OFF

(23)

Notes

23. Push/Pull structure.

V

THN

V

THP

V

HYS

L

IN

I

RES

I

DOM

I

SLEEP

I

DIS

2.0

2.5

2.7

2.7

3.0

3.5

2.5

3.0

3.2

3.3

4.0

4.2

3.0

3.6

3.7

3.8

4.6

4.7

0.6 — 1.3

-10 — 10

— 1.5 3.0

— 2.0 6.0

— 55 70

— — 1.0

V

V

V

µA

mA

mA

µA

µA

33989

Analog Integrated Circuit Device Data

10 Freescale Semiconductor

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 5.5 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

CANH AND CANL

Bus Pins Common Mode Voltage

Differential Input Voltage (Common Mode Between -3.0 and 7.0 V)

Recessive State at RXD

Dominant State at RXD

Differential Input Hysteresis (RXD)

Input Resistance

Differential Input Resistance

Unpowered Node Input Current

CANH Output Voltage

TXD Dominant State

TXD Recessive State

CANL Output Voltage

TXD Dominant State

TXD Recessive State

Differential Output Voltage

TXD Dominant State

TXD Recessive State

CANH AND CANL

Output Current Capability (Dominant State)

CANH

CANL

Overtemperature Shutdown

CANL Over Current Detection

Error Reported in CANR

CANH Over Current Detection

Error Reported in CANR

TX AND RX

TX Input High Voltage

TX Input Low Voltage

TX High Level Input Current, VTX = V

DD

TX Low Level Input Current, VTX = 0 V

RX Output Voltage High, IRX = 250 µA

RX Output Voltage Low, IRX = 1.0 mA

V

CM

V

CANH-VCANL

V

HYS

R

IN

R

IND

I

CANUP

V

CANHD

V

CANHR

V

CANLD

V

CANLR

V

DIFFD

V

DIFFR

I

CANH

I

CANL

T

SHUT

I

CANL/OC

I

CANH/OC

V

IH

V

ILP

L

IH

L

IL

V

OH

V

OL

-27 — 40 V

—

900

—

—

500

—

100 — — mV

5.0 — 100 KΩ

10 — 100 KΩ

— — 1.5 mA

2.75

—

0.5

2.0

1.5

—

—

—

—

—

—

—

—

4.5

3.0

2.25

—

3.0

100

— -35

35

160 180°C — °C

60 — 200

-200 — -60

0.7 V

DD

-0.4 — 0.3 V

— VDD + 0.4 V

DD

-10 — 10 µA

-100 -50 -20 µA

VDD-1 — — V

— — 0.5 V

mV

V

V

V

mV

mA

mA

mA

V

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 7.0 V ≤ V

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

DIGITAL INTERFACE TIMING (SCLK, CS, MOSI, MISO)

SPI Operation Frequency

SCLK Clock Period

SCLK Clock High Time

SCLK Clock Low Time

Falling Edge of CS to Rising Edge of SCLK

Falling Edge of SCLK to Rising Edge of CS

MOSI to Falling Edge of SCLK

Falling Edge of SCLK to MOSI

MISO Rise Time (CL = 220 pF)

MISO Fall Time (CL = 220 pF)

Time from Falling or Rising Edges of CS to:

MISO Low Impedance

MISO High Impedance

Time from Rising Edge of SCLK to MISO Data Valid

0.2 V1 = <MISO> = 0.8 V1, CL = 200 pF

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

= 25°C under nominal conditions unless otherwise noted.

A

A

F

REQ

t

PCLK

t

WSCLKH

t

WSCLKH

t

LEAD

t

LAG

t

SISU

t

SIH

t

RSO

t

FSO

t

SOEN

t

SODIS

t

VALID

0.25 — 4.0 MHz

250 — N/A ns

125 — N/A ns

125 — N/A ns

100 — N/A ns

100 — N/A ns

40 — N/A ns

40 — N/A ns

— 25 50 ns

— 25 50 ns

—

—

—

—

50

50

— — 50

ns

ns

STATE MACHINE TIMING (CS, SCLK, MOSI, MISO, WD, INT)

Delay Between CS Low to High Transition (End of SPI Stop Command) and

Stop Mode Activation Detected by V2 OFF

(24)

Interrupt Low Level Duration

SBC in Stop Mode

Internal Oscillator Frequency

All Modes Except Sleep and Stop

(24)

Internal Low Power Oscillator Frequency

Sleep and Stop Modes

(24)

Watchdog Period 1

Normal and Standby Modes

Watchdog Period 2

Normal and Standby Modes

Watchdog Period 3

Normal and Standby Modes

Watchdog Period 4

Normal and Standby Modes

Watchdog Period Accuracy

Normal and Standby Modes

Notes

24. Guaranteed by design; however it is not production tested.

t

CS

t

O

SCF1

O

SCF2

WD

WD

WD

WD

f

1ACC

STOP

INT

1

2

3

4

µs

18 — 34

µs

7.0 10 13

kHz

— 100 —

kHz

— 100 —

ms

8.58 9.75 10.92

ms

39.6 45 50.4

ms

88 100 112

ms

308 350 392

%

-12 — 12

33989

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 7.0 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Normal Request Mode Timeout

Normal Request Modes

Watchdog Period 1 - Stop

Stop Mode

Watchdog Period 2 - Stop

Stop Mode

Watchdog Period 3 - Stop

Stop Mode

Watchdog Period 4 - Stop

Stop Mode

Stop Mode Watchdog Period Accuracy

Stop Mode

Cyclic Sense/FWU Timing 1

Sleep and Stop Modes

Cyclic Sense/FWU Timing 2

Sleep and Stop Modes

Cyclic Sense/FWU Timing 3

Sleep and Stop Modes

Cyclic Sense/FWU Timing 4

Sleep and Stop Modes

Cyclic Sense/FWU Timing 5

Sleep and Stop Modes

Cyclic Sense/FWU Timing 6

Sleep and Stop Modes

Cyclic Sense/FWU Timing 7

Sleep and Stop Modes

Cyclic Sense/FWU Timing 8

Sleep and Stop Modes

Cyclic Sense ON Time

Sleep and Stop Modes Threshold and Condition to be Added

Cyclic Sense/FWU Timing Accuracy

Sleep and Stop Modes

Delay Between SPI Command and HS1 Turn ON

Delay Between SPI Command and HS1 Turn OFF

Delay Between SPI and V2 Turn ON

(25)

(25)

(25)

Standby Mode

Delay Between SPI and V2 Turn OFF

(25)

Normal Mode

Notes

25. Delay starts at falling edge of clock cycle #8 of the SPI command and start of Turn ON or Turn OFF of HS1 or V2.

NR

TOUT

WD

1STOP

WD

2STOP

WD

3STOP

WD

4STOP

f

2ACC

CS

FWU1

CS

FWU2

CS

FWU3

CS

FWU4

CS

FWU5

CS

FWU6

CS

FWU7

CS

FWU8

t

ON

t

ACC

t

SHSON

t

SHSOFF

tS

V2ON

tS

V2OFF

308 350 392

6.82 9.75 12.7

31.5 45 58.5

70 100 130

245 350 455

-30 — 30

3.22 4.6 5.98

6.47 9.25 12

12.9 18.5 24

25.9 37 48.1

51.8 74 96.2

66.8 95.5 124

134 191 248

271 388 504

200 350 500

-30 — 30

— — 22 µs

— — 22 µs

9.0 — 22

9.0 — 22

ms

ms

ms

ms

ms

%

ms

ms

ms

ms

ms

ms

ms

ms

µs

%

µs

µs

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 7.0 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Delay Between Normal Request and Normal Mode After WD Trigger Command

Normal Request Mode

Delay Between SPI and CAN Normal Mode

SBC Normal Mode

(26)

Delay Between SPI and CAN Normal Mode

SBC Normal Mode

(26)

Delay Between CS Wake-up (CS Low to High) and SBC Normal Request Mode

(V

on and Reset High)

DD1

SBC in Stop Mode

Delay Between CS Wake-up (CS Low to High) and First Accepted API

Command

SBC in Stop Mode

Delay Between INT Pulse and First SPI Command Accepted

In Stop Mode After Wake-up

INPUT TERMINNALS (L0, L1, L2, AND L3)

Wake-up Filter Time

CAN MODULE-SIGNAL EDGE RISE AND FALL TIMES (CANH, CANL)

Dominant State Timeout

Propagation Loop Delay TX to RX, Recessive to Dominant

Slew Rate 3

Slew Rate 2

Slew Rate 1

Slew Rate 0

Propagation Delay TX to CAN

Slew Rate 3

Slew Rate 2

Slew Rate 1

Slew Rate 0

Propagation Delay CAN to RX, Recessive to Dominant

Propagation Loop Delay TX to RX, Dominant to Recessive

Slew Rate 3

Slew Rate 2

Slew Rate 1

Slew Rate 0

Propagation Delay TX to CAN

Slew Rate 3

Slew Rate 2

Slew Rate 1

Slew Rate 0

Propagation Delay CAN to RX, Dominant to Recessive

Notes

26. Guaranteed by design; however, it is not production tested.

tS

tS

tS

tW

tW

tS

1STSPI

t

t

DOUT

t

t

t

t

t

t

NR2N

CANN

CANS

CS

SPI

WUF

LRD

TRD

RRD

LDR

TDR

RDR

15 35 70

— — 10

— — 10

15 40 90

90 — N/A

20 —

N/A

8.0 20 38 µs

200 360 520 µs

70

80

100

110

20

40

60

100

140

155

180

220

65

80

120

160

210

225

255

310

110

150

200

300

30 80 140 ns

70

90

100

130

60

65

75

90

120

135

160

200

110

120

150

190

170

180

220

260

130

150

200

300

20 40 60

µs

µs

µs

µs

µs

µs

ns

ns

ns

ns

33989

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 7.0 V ≤ V

≤ 18 V, - 40°C ≤ T

SUP

≤ 125°C, GND = 0 V unless otherwise noted. Typical

A

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Non Differential Slew Rate (CANL or CANH)

Slew Rate 3

Slew Rate 2

Slew Rate 1

Slew Rate 0

t

t

t

t

SL3

SL2

SL1

SL0

4.0

3.0

2.0

1.0

19

13.5

8.0

5.0

40

20

15

10

V/µs

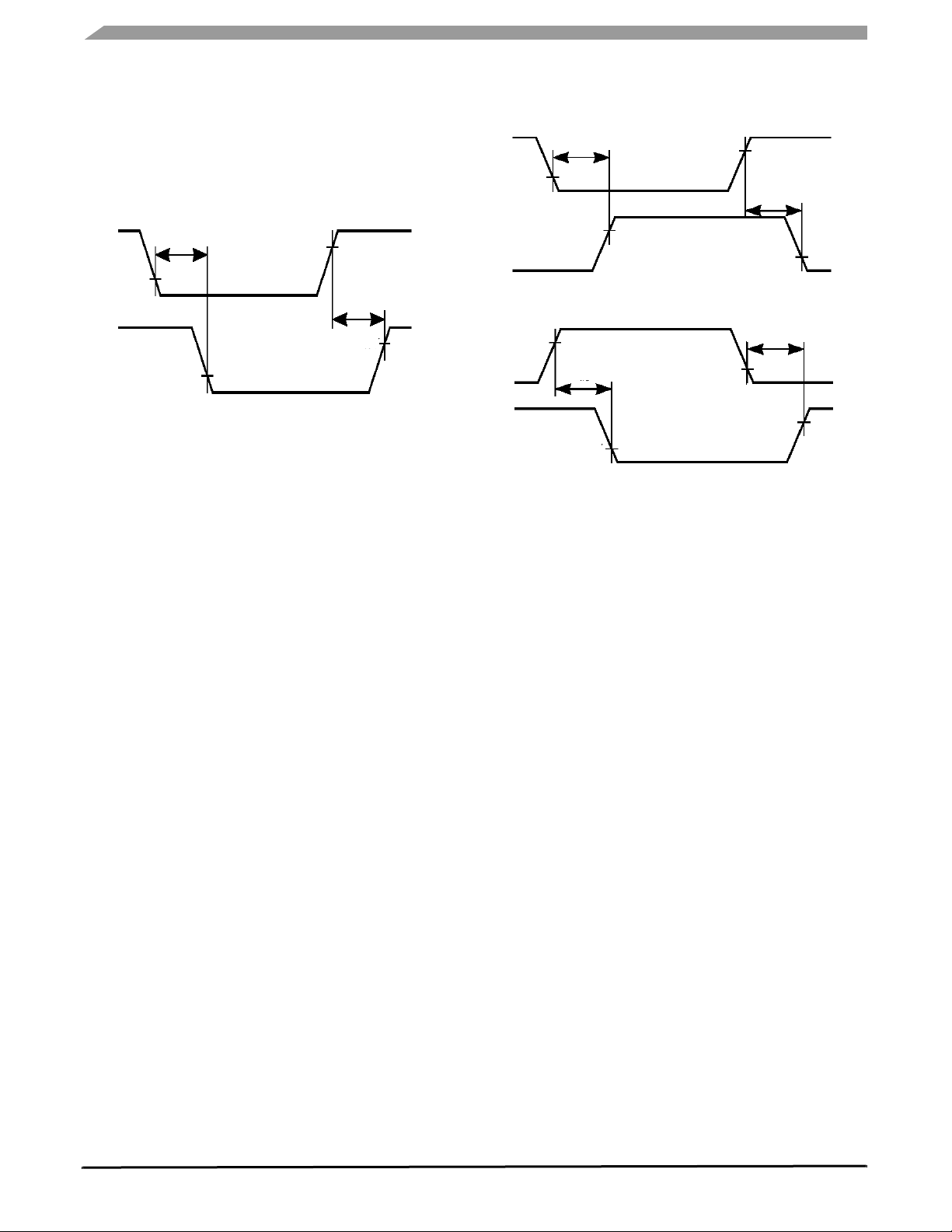

CANH

CANL

WU Receiver

Standby

Pulse Width

Filter

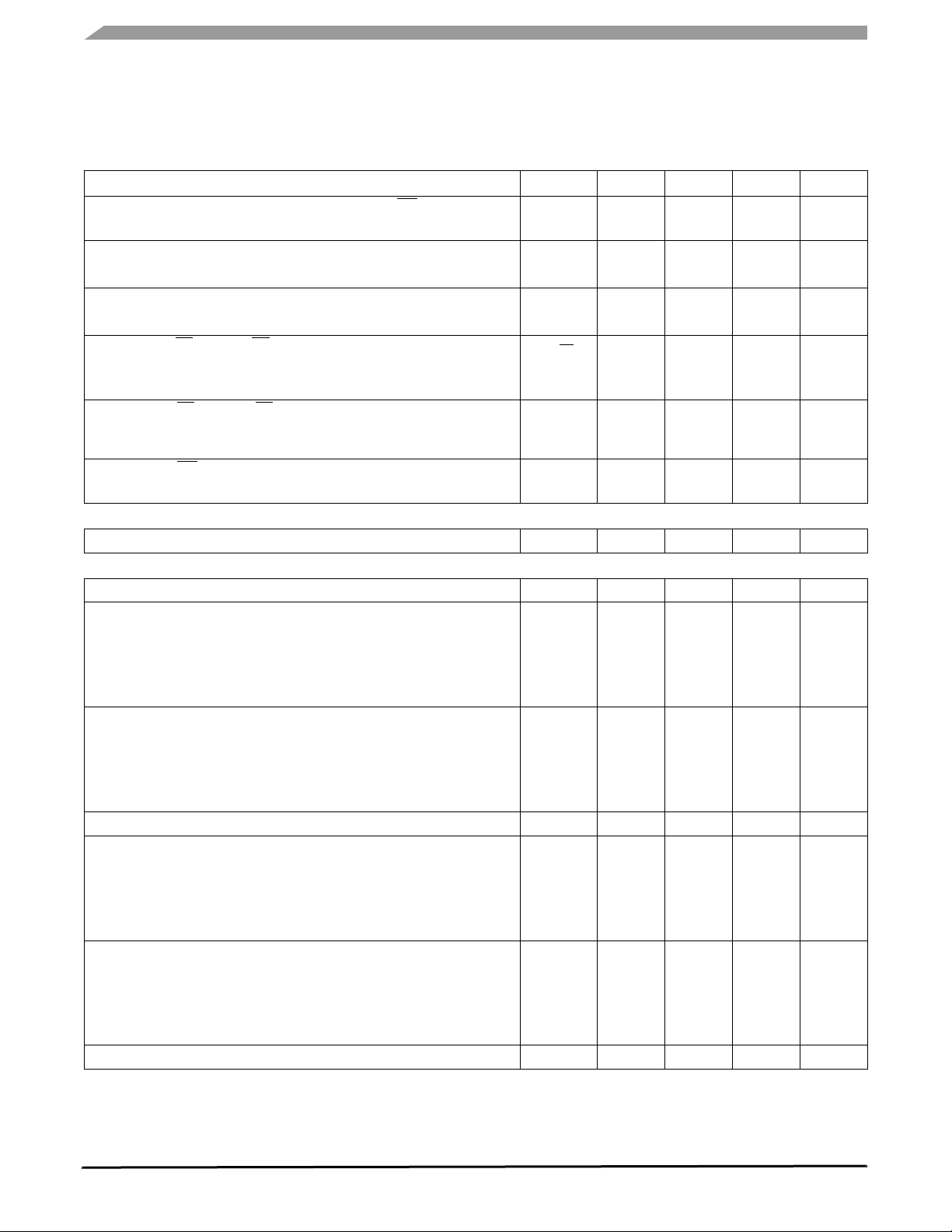

Figure 4. Wake-Up Block Diagram

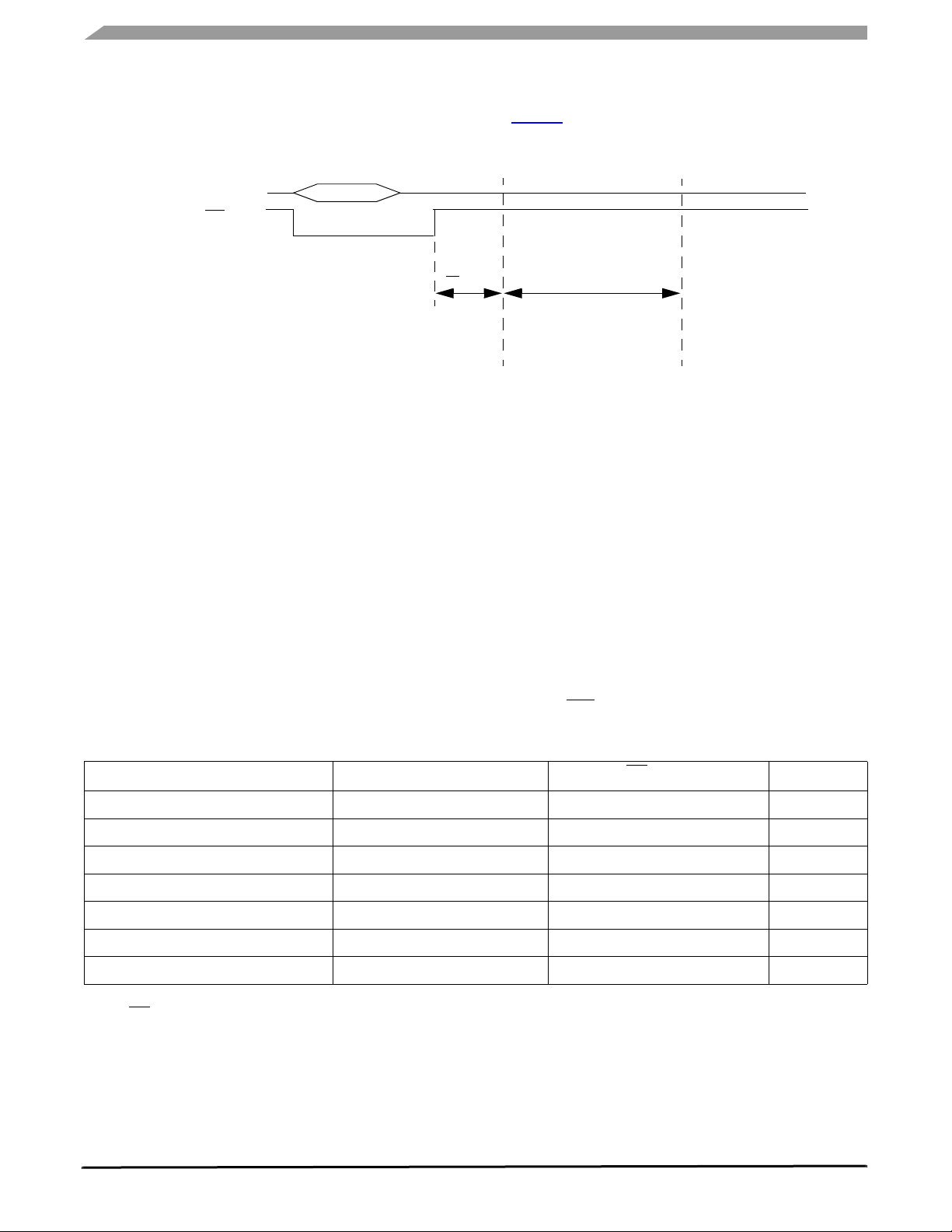

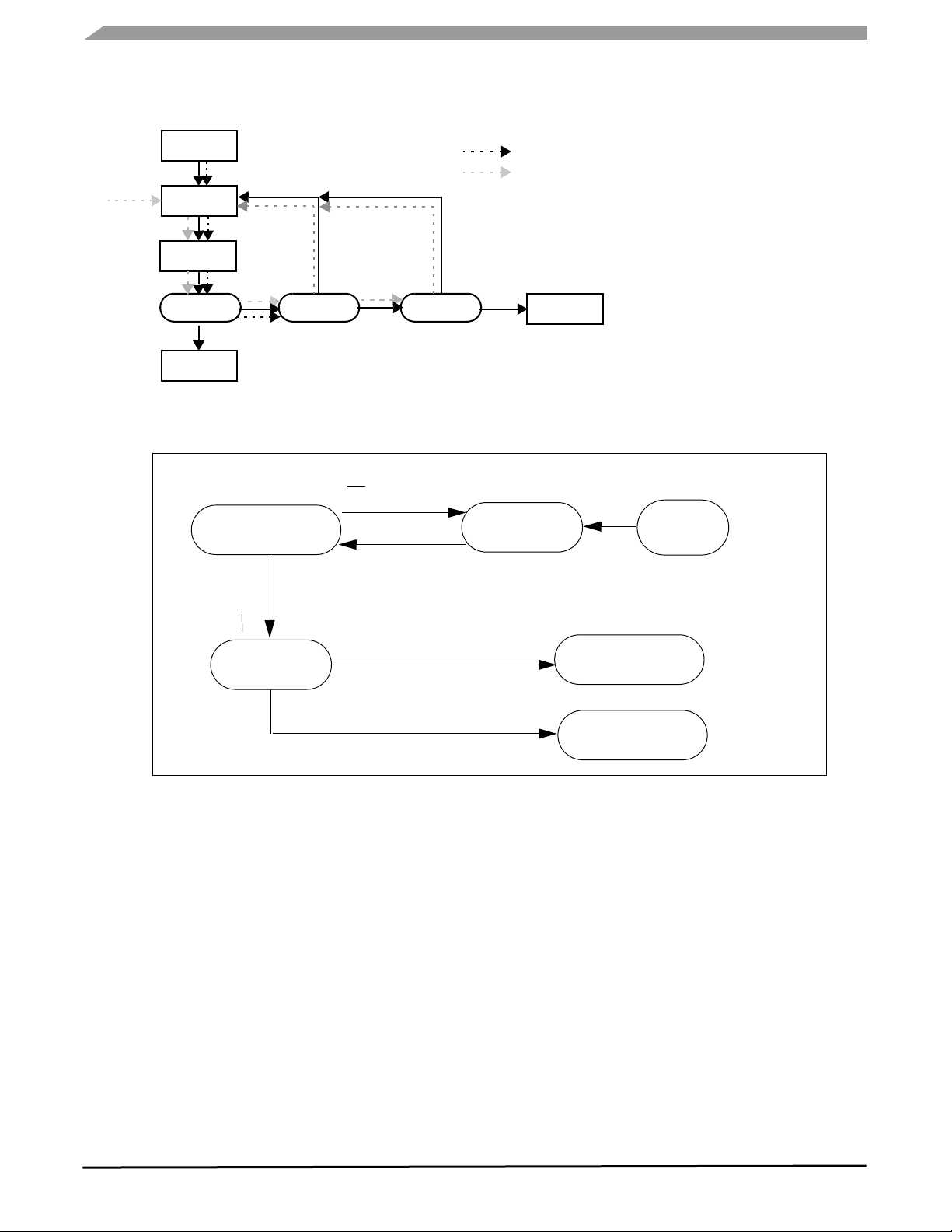

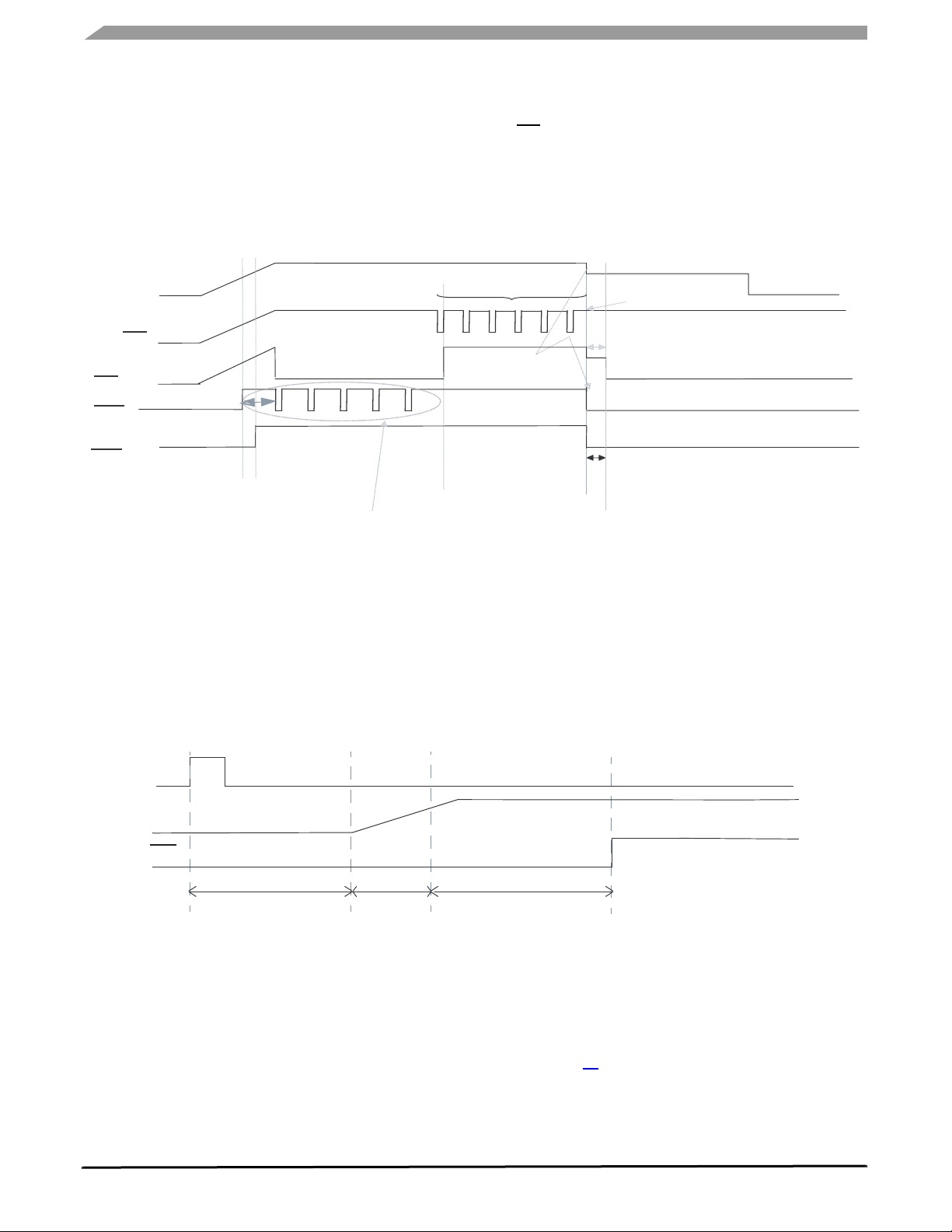

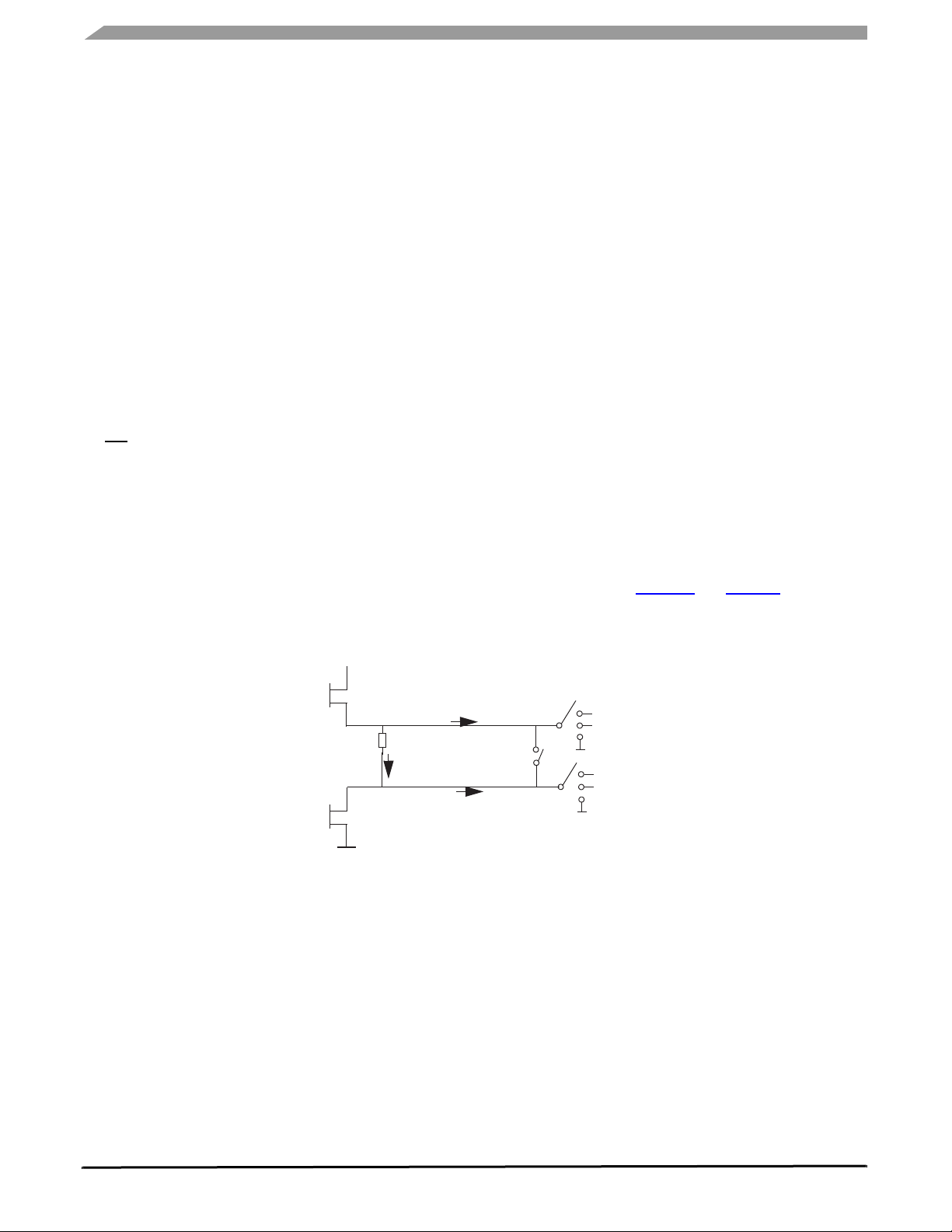

The block diagram in Figure 4 illustrates how the wake-up

signal is generated. First the CAN signal is detected by a low

consumption receiver (WU receiver). Then the signal passes

through a pulse width filter which discards the undesired

pulses. The pulse must have a width bigger than 0.5 µs and

smaller than 500 µs to be accepted. When a pulse is

discarded the pulse counter is reset and no wake signal is

generated, otherwise when a pulse is accepted the pulse

counter is incremental and after three pulses the wake signal

is asserted.

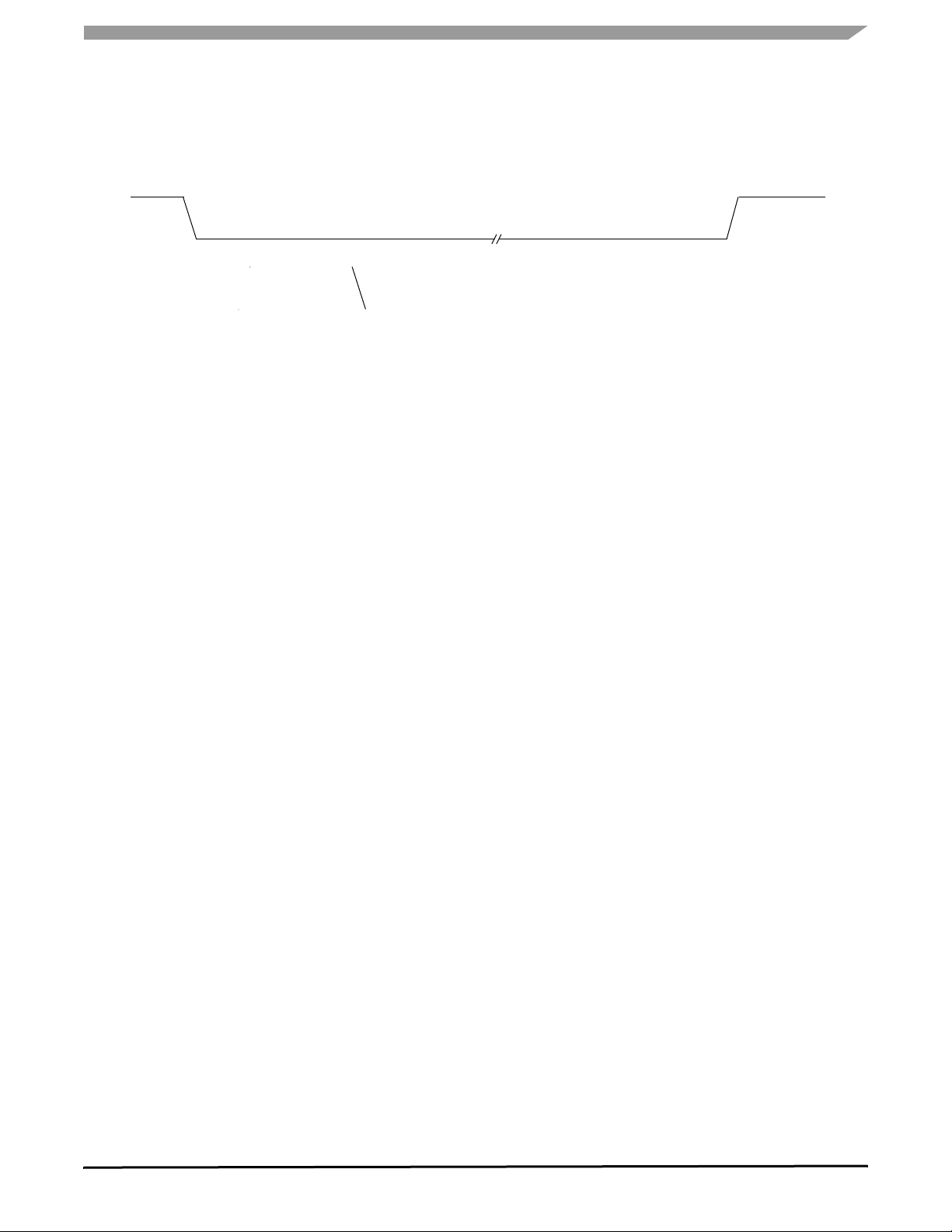

1nF

LX

10 k

GND

Note: Waveform in accordance to

ISO 7637 part1, test pulses 1, 2, 3a and 3b.

Transient Pulse

Generator

(Note)

GND

Figure 5. Transient Test Pulse for L0:L3 Inputs

Pulse OK

Narrow

Pulse

Counter

RST

+

Timeout

Generator

Latch

RST

Timeout

WU

OUT

Each one of the pulses must be spaced by no more than

500 µs. In that case the pulse counter is reset and no wake

signal is generated. This is accomplished by the wake

timeout generator. The wake-up cycle is completed (and the

wake flag reset) when the CAN interface is brought to CAN

Normal mode.

The wake-up capability of the CAN can be disabled, refer

to SPI interface and register section, CAN register.

1nF

CANH

CANL

GND

1nF

Note: Waveform in accordance to

ISO 7637 part1, test pulses 1, 2, 3a and 3b.

Transient Pulse

Generator

Figure 6. Transient Test Pulses for CANH/CANL

(Note)

GND

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

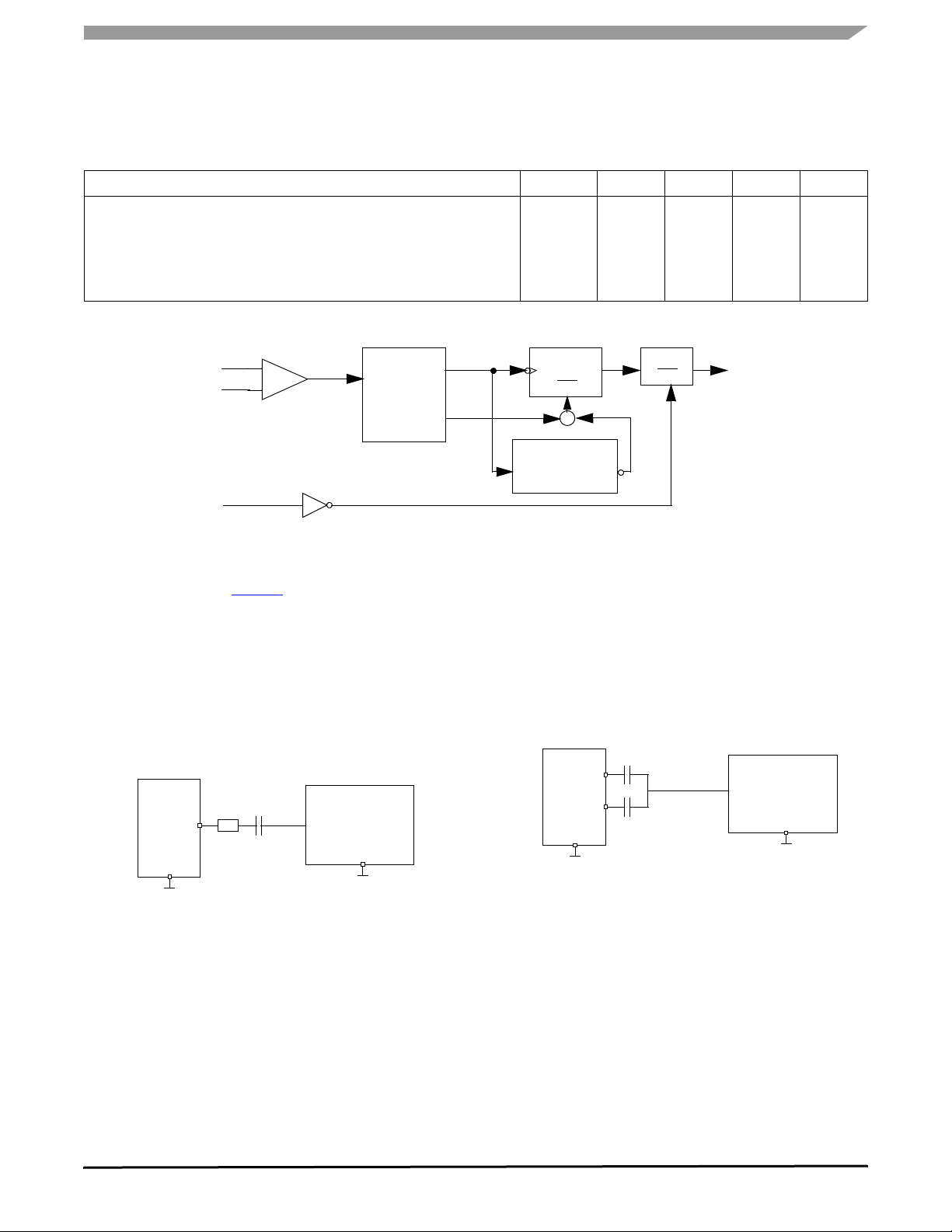

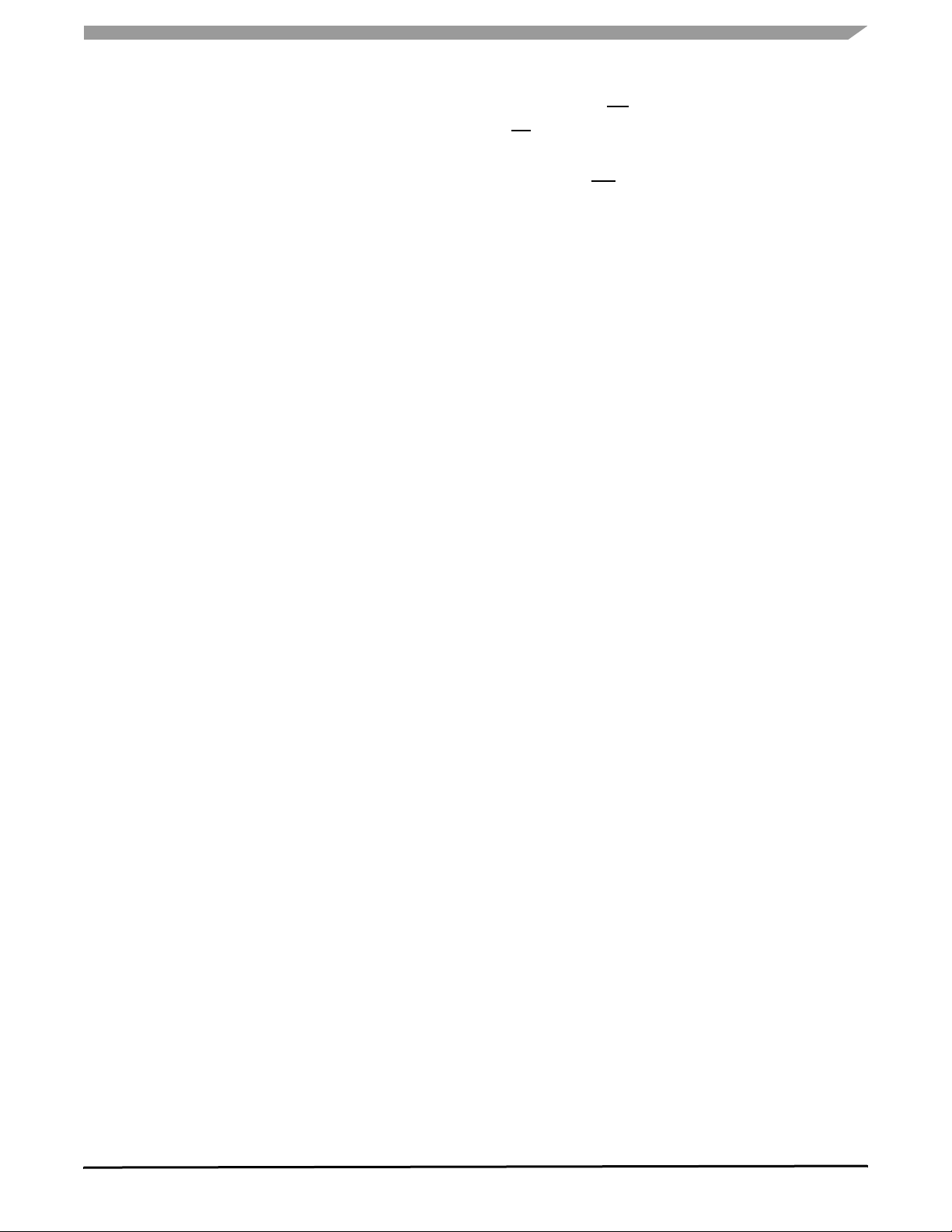

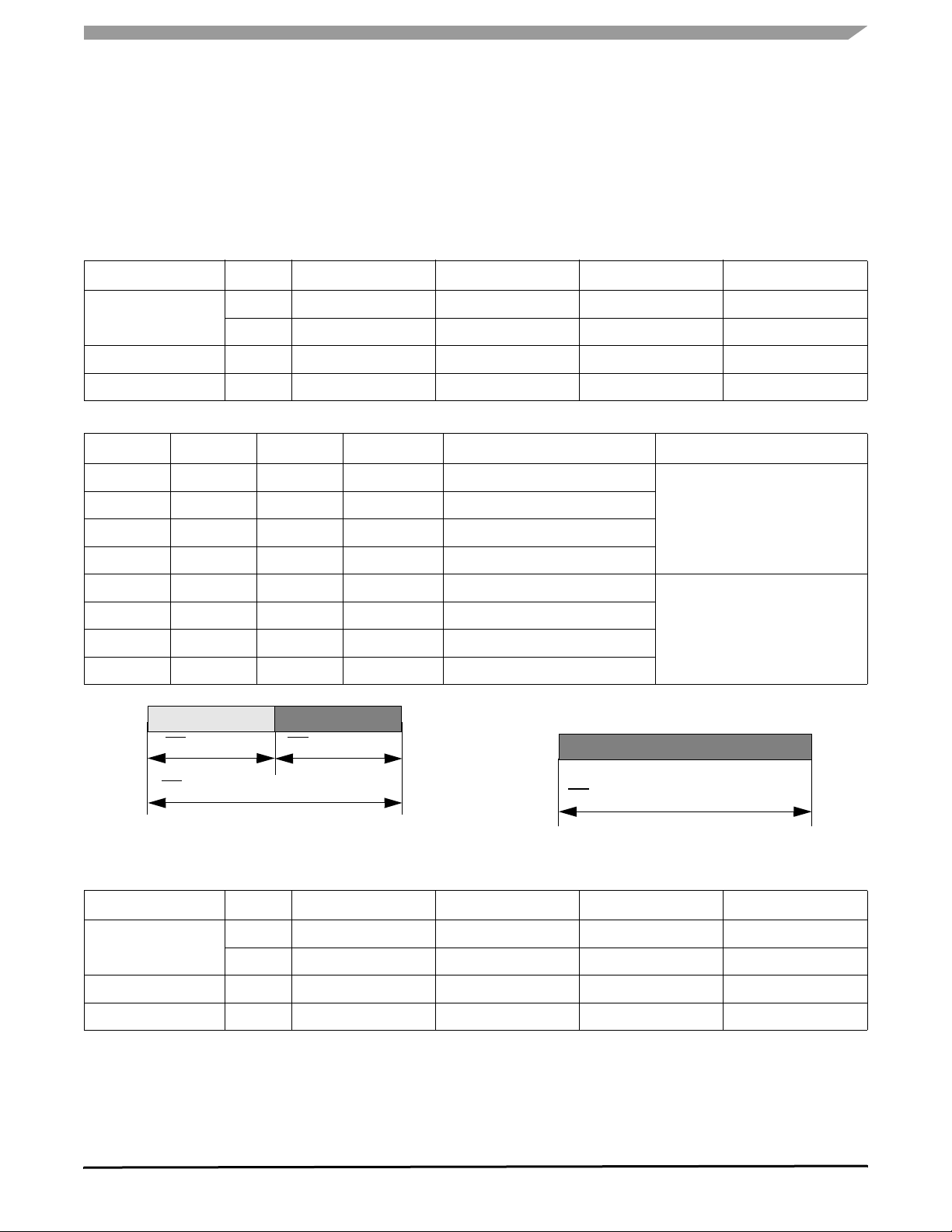

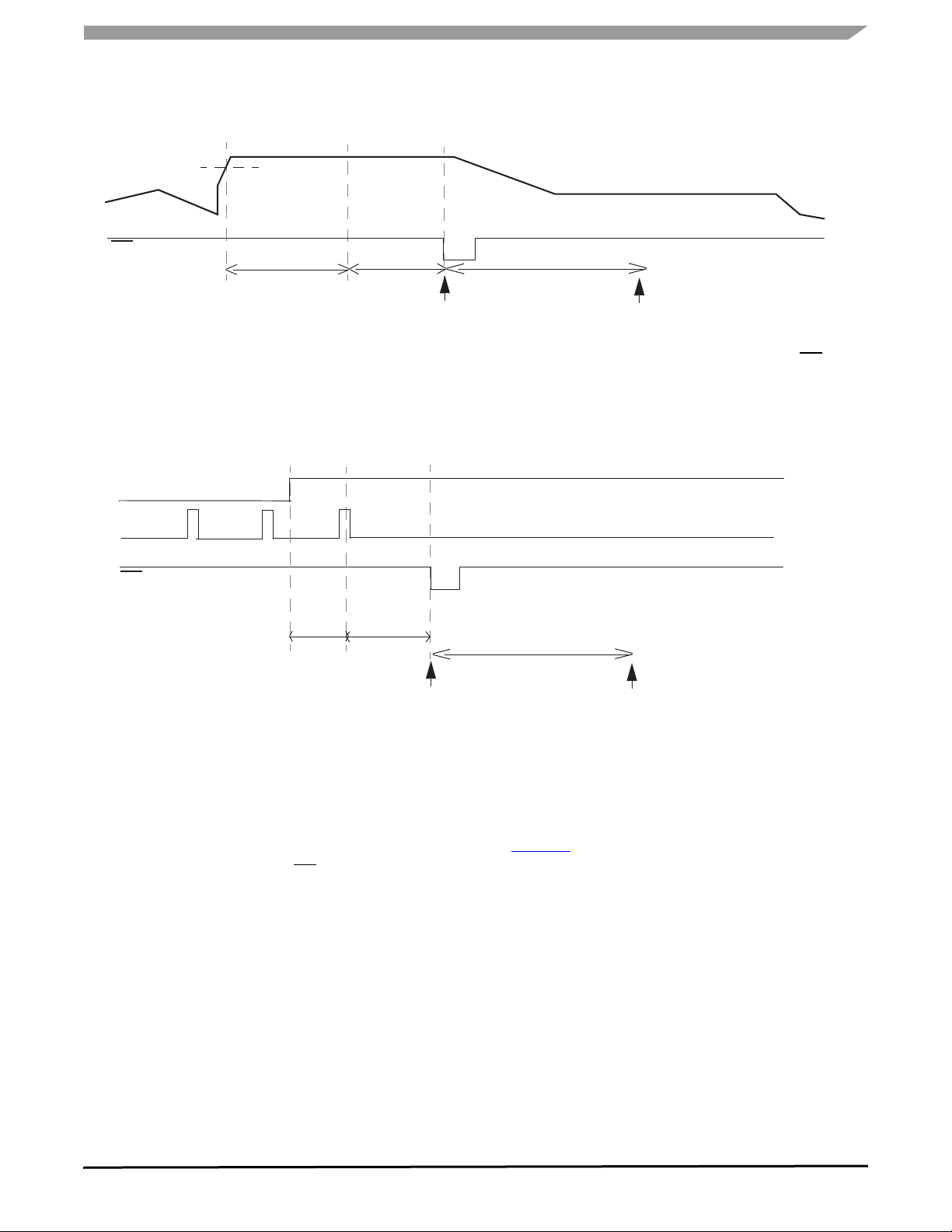

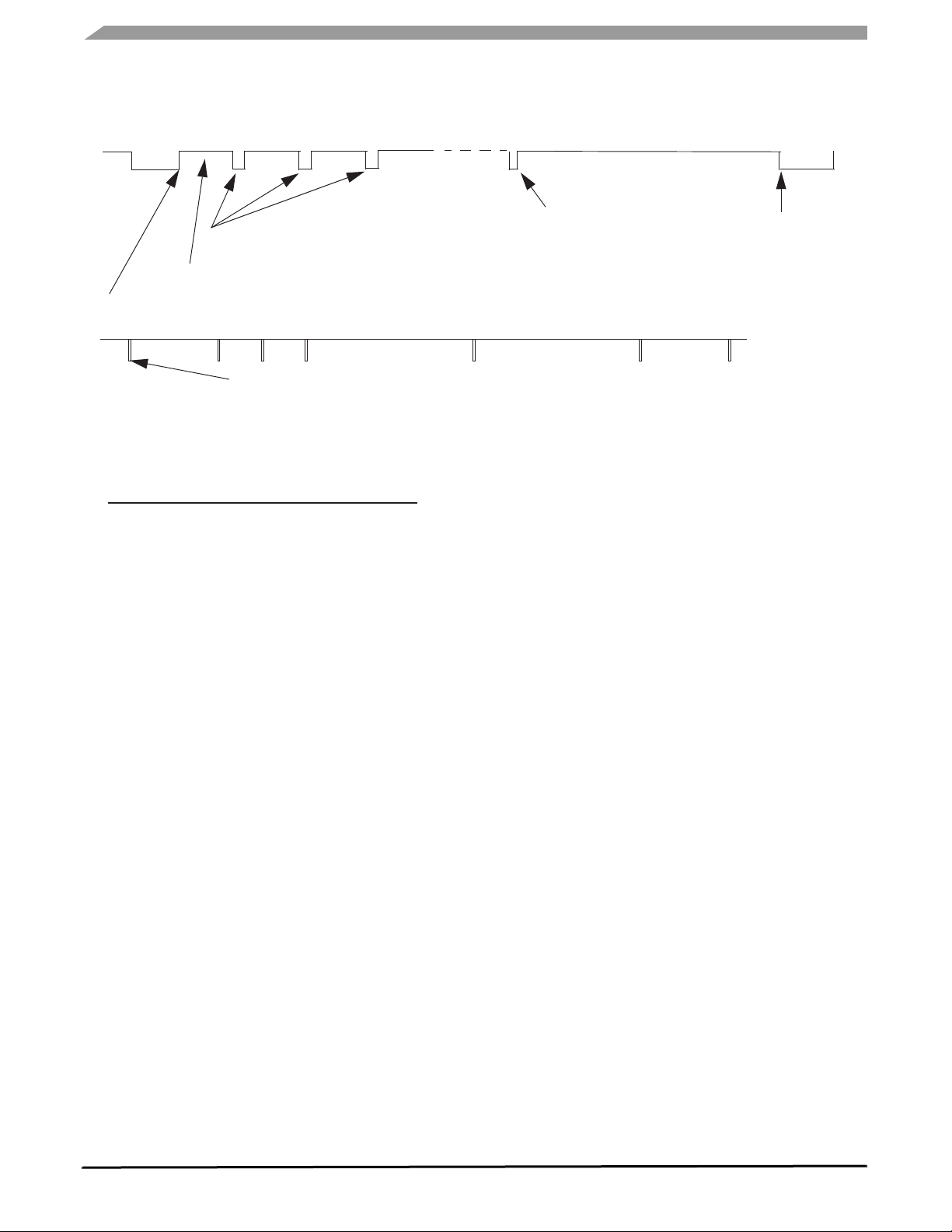

T

TX

LRD

2.0 V

0.8 V

RX

0.8 V

T

LDR

2.0 V

TX

V

V

0.8 V

DIFF

0.9 V

DIFF

T

TRD

0.9 V

T

RRD

V

DIFF

= V

CANH

2.0 V

- V

0.5 V

CANL

T

TDR

0.5 V

T

RDR

RX

0.8 V

Figure 7. Transceiver AC Characteristics

2.0 V

33989

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

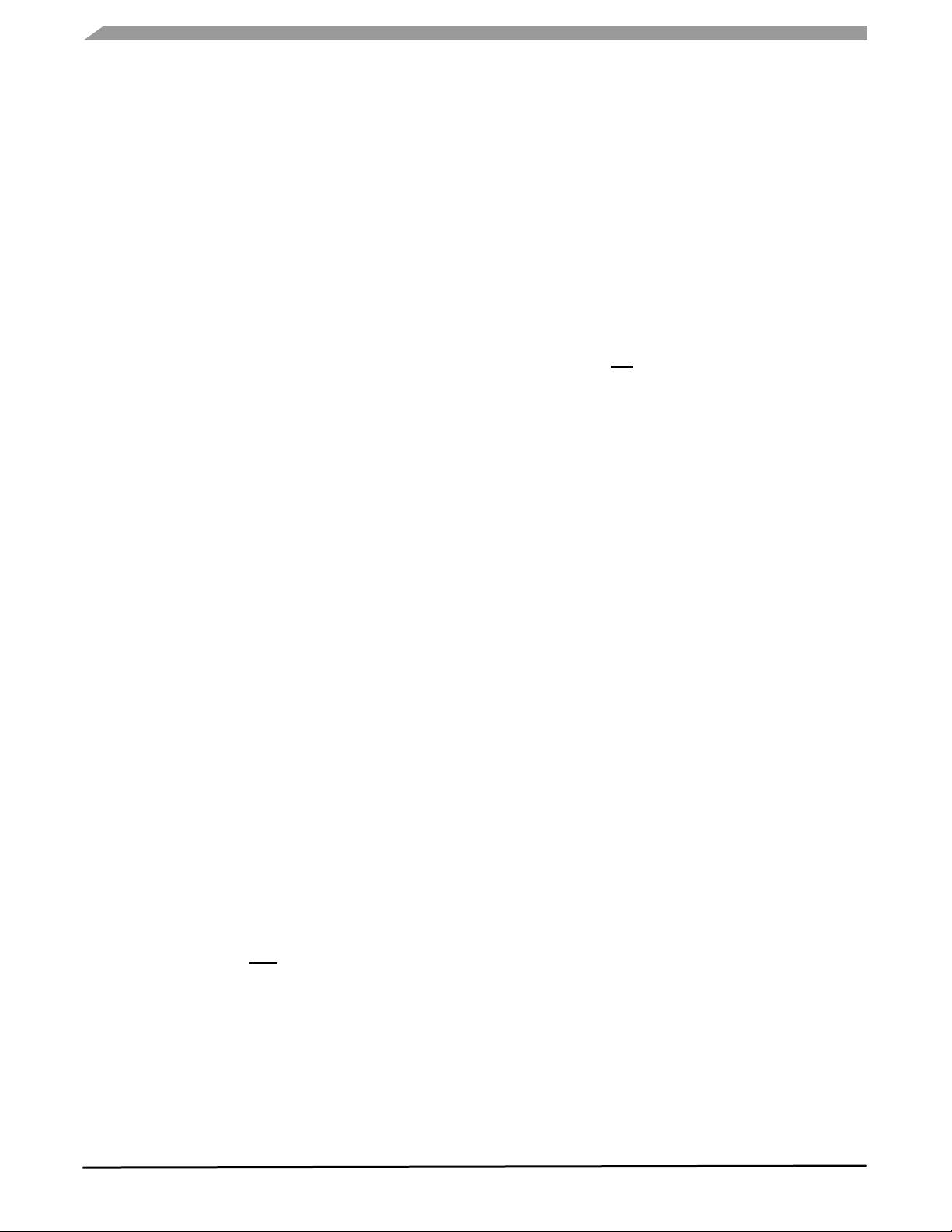

TIMING DIAGRAMS

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

Figure 8. SPI Timing Characteristics

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

FUNCTIONAL DESCRIPTION

INTRODUCTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

The 33989 is an integrated circuit dedicated to automotive

applications. Its functions include:

• One full protected voltage regulator with 200 mA total

output current capability available at V

external pin

DD1

FUNCTIONAL PIN DESCRIPTION

RECEIVE AND TRANSMIT DATA (RXD AND TXD)

The RX and TX pins (receive data and transmit data pins,

respectively) are connected to a microcontroller’s CAN

protocol handler. TXD is an input and controls the CANH and

CANL line state (dominant when TXD is LOW, recessive

when TXD is HIGH). RXD is an output and reports the bus

state (RXD LOW when CAN bus is dominant, HIGH when

CAN bus is recessive).

VOLTAGE DIGITAL DRAIN ONE (VDD1)

The VDD1 pin is the output pin of the 5.0 V internal

regulator. It can deliver up to 200 mA. This output is protected

against overcurrent and overtemperature. It includes an

overtemperature pre-warning flag, which is set when the

internal regulator temperature exceeds 130°C typical. When

the temperature exceeds the overtemperature shutdown

(170°C typical), the regulator is turned off.

VDD1 includes an undervoltage reset circuitry, which sets

the RST pin LOW when V

threshold.

is below the undervoltage reset

DD1

RESET (RST)

The Reset pin RST is an output that is set LOW when the

device is in reset mode. The

device is not in reset mode.

current source. When RST is LOW, the sink current capability

is limited, allowing

debug or software download purposes.

RST to be shorted to 5.0 V for software

RST pin is set HIGH when the

RST includes an internal pullup

INTERRUPT (INT)

The Interrupt pin INT is an output that is set LOW when an

interrupt occurs.

(INTR). When an interrupt occurs,

interrupt source is cleared.

INT output also reports a wake-up event by a 10 µs typical

pulse when the device is in Stop mode.

INT is enabled using the Interrupt Register

INT stays LOW until the

VOLTAGE SOURCE TWO (V2)

The V2 pin is the input sense for the V2 regulator. It is

connected to the external series pass transistor. V2 is also

the 5.0 V supply of the internal CAN interface. It is possible to

• Driver for an external path transistor for the V2 regulator

function

• Reset, programmable watchdog function, interrupt, and

four operational modes

• Programmable wake-up input and Cyclic Sense wake-up

• CAN high-speed physical interface

connect V2 to an external 5.0

output when no external series pass transistor is used. In this

case, the V2CTRL pin must be left open.

V regulator or to the VDD1

VOLTAGE SOURCE 2 CONTROL (V2CTRL)

The V2CTRL pin is the output drive pin for the V2 regulator

connected to the external series pass transistor.

VOLTAGE SUPPLY (VSUP)

The VSUP pin is the battery supply input of the device.

HIGH-SIDE ONE (HS1)

The HS1 pin is the internal high-side driver output. It is

internally protected against overcurrent and

overtemperature.

LEVEL 0-3 INPUTS (L0:L3)

The L0:L3 pins can be connected to contact switches or

the output of other ICs for external inputs. The input states

can be read by SPI. These inputs can be used as wake-up

events for the SBC when operating in the Sleep or Stop

mode.

CAN HIGH AND CAN LOW OUTPUTS

(CANH AND CANL)

The CAN High and CAN Low pins are the interfaces to the

CAN bus lines. They are controlled by TX input level, and the

state of CANH and CANL is reported through RX output. A

Ω termination resistor is connected between CANH and

60

CANL pins.

SYSTEM CLOCK (SCLK)

SCLK is the System Clock input pin of the serial peripheral

interface.

MASTER IN SLAVE OUT (MISO)

MISO is the Master In Slave Out pin of the serial peripheral

interface. Data is sent from the SBC to the microcontroller

through the MISO pin.

33989

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

FUNCTIONAL DESCRIPTION

FUNCTIONAL PIN DESCRIPTION

MASTER OUT SLAVE IN (MOSI)

MOSI is the Master Out Slave In pin of the serial peripheral

interface. Control data from a microcontroller is received

through this pin.

CHIP SELECT (CS)

CS is the Chip Select pin of the serial peripheral interface.

When this pin is LOW, the SPI port of the device is selected.

WATCHDOG (WD)

The Watchdog output pin is asserted LOW to flag that the

software watchdog has not been properly triggered.

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

FUNCTIONAL DEVICE OPERATION

DEVICE SUPPLY

The device is supplied from the battery line through the

VSUP pin. An external diode is required to protect against

negative transients and reverse battery. It can operate from

4.5 V and under the jump start condition at 27

Vdc. This pin

sustains standard automotive voltage conditions such as

load dump at 40 V. When V

falls below 3.0 V typical the

SUP

33989 detects it and stores the information into the SPI

register in a bit called BATFAIL. This detection is available in

all operation modes.

The device incorporates a battery early warning function,

providing a maskable interrupt when the V

voltage is

SUP

below 6.0 V typical. A hysteresis is included. Operation is

only in Normal and Standby modes. V

low is reported in

SUP

the Input/Output Register (IOR).

VDD1 VOLTAGE REGULATOR

The VDD1 Regulator is a 5.0 V output voltage with output

current capability up to 200 mA. It includes a voltage

monitoring circuitry associated with a reset function. The

VDD1 regulator is fully protected against overcurrent and

short-circuit. It has over- temperature detection warning flags

(bit V

in MCR and interrupt registers), and

DDTEMP

overtemperature shutdown with hysteresis.

V2 REGULATOR

V2 Regulator circuitry is designed to drive an external path

transistor increasing output current flexibility. Two pins are

used to achieve the flexibility. Those pins are V2 and V2

control. The output voltage is 5.0 V and is realized by a

tracking function of the VDD1 regulator. The recommended

ballast transistor is MJD32C. Other transistors can be used;

however, depending upon the PNP gain an external resistorcapacitor network might be connected. The V2 is the supply

input for the CAN cell. The state of V2 is reported in the IOR

(bit V2LOW set to 1 if V2 is below 4.5 V typical).

HS1 VBAT SWITCH OUTPUT

The HS1 output is a 2.0 Ω typical switch from the VSUP

pin. It allows the supply of external switches and their

associated pull-up or pull down circuitry, in conjunction with

the wake-up input pins, for example. Output current is limited

to 200 mA and HS1 is protected against short-circuit and has

an overtemperature shutdown (bit HS1OT in IOR and bit

HS1OT-V2LOW in

INT register). The HS1 output is controlled

from the internal register and the SPI. Because of an internal

timer, it can be activated at regular intervals in Sleep and

Stop modes. It can also be permanently turned on in Normal

or Standby modes to drive loads or supply peripheral

components. No internal clamping protection circuit is

implemented, thus a dedicated external protection circuit is

required in case of inductive load drive.

BATTERY FALL EARLY WARNING

Refer to the discussion under the heading: Device Supply.

INTERNAL CLOCK

The device has an internal clock used to generate all

timings (Reset, Watchdog, Cyclic Wake-up, Filtering Time,

etc.). Two oscillators are implemented. A high accuracy

percent) used in Normal Request, Normal and Standby

(±12

modes, and a low accuracy (±30 percent) used in Sleep and

Stop modes.

OPERATIONAL MODES

FUNCTIONAL MODES

The device has four primary operation modes:

1. Standby mode

2. Normal mode

3. Stop mode

4. Sleep mode

All modes are controlled by the SPI. An additional

temporary mode called Normal Request mode is

automatically accessed by the device after reset or wake-up

from Stop mode. A Reset (

RST) mode is also implemented.

Special modes and configuration are possible for debug and

program MCU flash memory.

STANDBY MODE

Only regulator 1 is ON. Regulator 2 is turned OFF by

disabling the V2 control pin. Only the wake-up capability of

the CAN interface is available. Other functions available are

33989

20 Freescale Semiconductor

wake-up input reading through SPI and HS1 activation. The

Watchdog is running.

NORMAL MODE

In this mode both regulators are ON. This corresponds to

the normal application operation. All functions are available in

this mode (Watchdog, wake-up input reading through SPI,

HS1 activation, CAN communication). The software

Watchdog is running and must be periodically cleared

through SPI.

STOP MODE

Regulator 2 is turned OFF by disabling the V2 control pin.

The regulator 1 is activated in a special low power mode,

allowing to deliver few mA. The objective is to maintain the

MCU of the application supplied while it is turned into power

saving condition (i.e Stop or Wait modes). In Stop mode the

device supply current from V

Analog Integrated Circuit Device Data

is very low.

BAT

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

When the application is in Stop mode (both MCU and

SBC), the application can wake-up from the SBC side (for

example: cyclic sense, forced wake-up, CAN message,

wake-up inputs and over current on VDD1), or the MCU side

(key wake-up, etc.).

Stop mode is always selected by the SPI. In Stop mode the

software Watchdog can be running or idle depending upon

selection by the SPI (RCR, bit WDSTOP). To clear the

watchdog, the SBC must be awakened by a

CS pin (SPI

wake-up). In Stop mode, SBC wake-up capability are

identical as in Sleep mode. Please refer to

Table 5.

SLEEP MODE

Regulators 1 and 2 are OFF. The current from V

reduced. In this mode, the device can be awakened internally

by cyclic sense via the wake-up inputs pins and HS1 output,

from the forced wake-up function and from the CAN physical

interface. When a wake-up occurs the SBC goes first into

reset mode before entering Normal Request mode.

SUP

pin is

RESET MODE

In this mode, the Reset (RST) pin is low and a timer is

running for a time RST

. After this time is elapsed, the SBC

DUR

enters Normal Request mode. Reset mode is entered if a

reset condition occurs (V

low, watchdog timeout or

DD1

watchdog trigger in a closed window).

NORMAL REQUEST MODE

This is a temporary mode automatically accessed by the

device after the reset mode, or after the SBC wake-up from

mode. After wake-up from the Sleep mode or after the

Stop

device power-up, the SBC enters the Reset mo de be fo re

entering the Normal Request mode. After a wake-up from the

Stop mode, the SBC enters Normal Request mode directly.

In Normal Request mode the VDD1 regulator is ON, V2 is

OFF, the reset pin is high. As soon as the device enters the

Normal Request mode an internal 350 ms timer is started.

During these 350 ms the microcontroller of the application

must address the SBC via the SPI, configuring the Watchdog

register. This is the condition for the SBC to stop the 350 ms

timer and to go into the Normal or Standby mode and to set

the watchdog timer according to configuration.

NORMAL REQUEST ENTERED AND NO WD

CONFIGURATION OCCURS

In case the Normal Request mode is entered after SBC

power-up, or after a wake-up from Stop mode, and if no

configuration occurs while the SBC is in Normal Request

mode, the SBC goes to Reset mode after the 350 ms time

period is expired before again going into Normal Request

mode. If no

WD configuration is achieved, the SBC

alternatively goes from Normal Request into reset, then

Normal Request modes etc.

In case the Normal Request mode is entered after a wake-

up from Sleep mode, and if no

WD configuration occurs while

WD

the SBC is in Normal Request mode, the SBC goes back to

Sleep mode.

APPLICATION WAKE-UP FROM SBC SIDE

When an application is in Stop mode, it can wake-up from

the SBC side. When a wake-up is detected by the SBC (for

example, CAN, Wake-up input, etc.) the SBC turns itself into

Normal Request mode and generates an interrupt pulse at

INT pin.

the

APPLICATION WAKE-UP FROM MCU SIDE

When application is in Stop mode, the wake-up event may

come from the MCU side. In this case the MCU signals to the

SBC by a low to high transition on the CS pin. Then the SBC

goes into Normal Request mode and generates an interrupt

pulse at the

INT pin.

STOP MODE CURRENT MONITOR

If the VDD1 output current exceed an internal threshold

(I

mode and generates an interrupt at the

), the SBC goes automatically into Normal Request

DD1SWU

INT pin. The interrupt

is not maskable and the interrupt register will has no flag set.

INTERRUPT GENERATION WHEN WAKE-UP

FROM STOP MODE

When the SBC wakes up from Stop mode, it first enters the

Normal Request mode before generating a pulse (10 µs

typical) on the

INT pin. These interrupts are not maskable,

and the wake-up event can be read through the SPI registers

(CANWU bit in Reset Control Register (RCR) and LCTRx bit

in Wake-Up Register (WUR). In case of wake-up from Stop

mode over current or from forced wake-up, no bit is set. After

INT pulse the SBC accept SPI command after a time

the

S1STSPI

parameter).

delay (t

SOFTWARE WATCHDOG IN STOP MODE

If Watchdog is enabled, the MCU has to wake-up

independently of the SBC before the end of the SBC

watchdog time. In order to do this the MCU must signal the

wake-up to the SBC through the SPI wake-up (

CS activation).

The SBC then wakes up and jumps into the Normal Request

mode. MCU has to configured the SBC to go to either Normal

or Standby mode. The MCU can then decide to go back again

to Stop mode.

When there is no MCU wake-up occurring within the

watchdog timing, the SBC activates the Reset pin, jumping

into the Normal Request mode. The MCU can then be

initialized.

STOP MODE ENTER COMMAND

Stop mode is entered at the end of the SPI message, and

at the rising edge of the

CS. Please refer to the t

in Dynamic Electrical Characteristics table on page 11.

Once Stop mode is entered the SBC could wake-up from

the V1 regulator over current detection. In order to allow time

for the MCU to complete the last CPU instruction, allowing

CSSTOP

data

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

FUNCTIONAL DEVICE OPERATION

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

the MCU to enter its low power mode, a deglitcher time of

typical 40 µs is implemented.

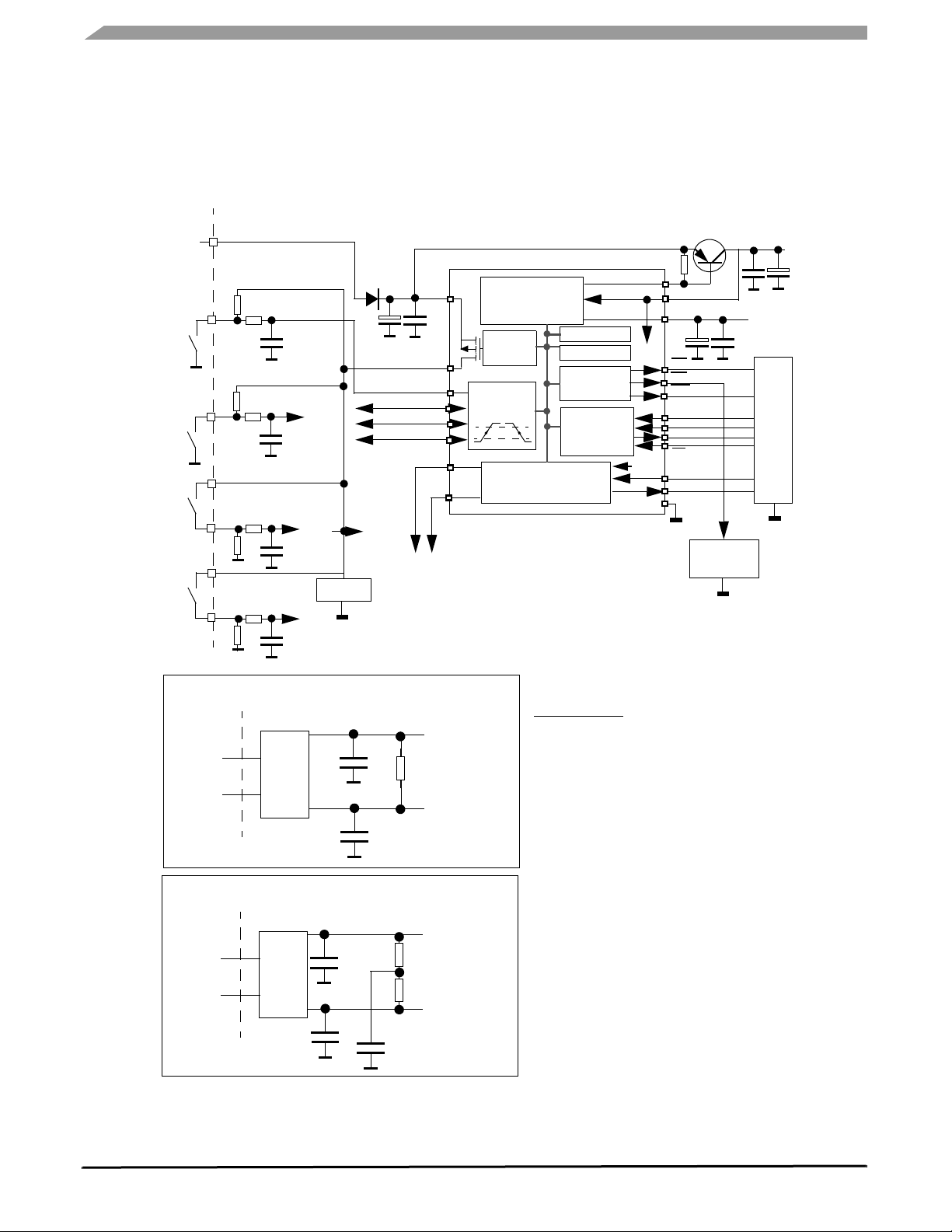

SPI Stop/ Sleep Command

SPI CS

t

SBC in Normal or Stand-by mode

Figure 9. Operation Entering Stop Mode

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

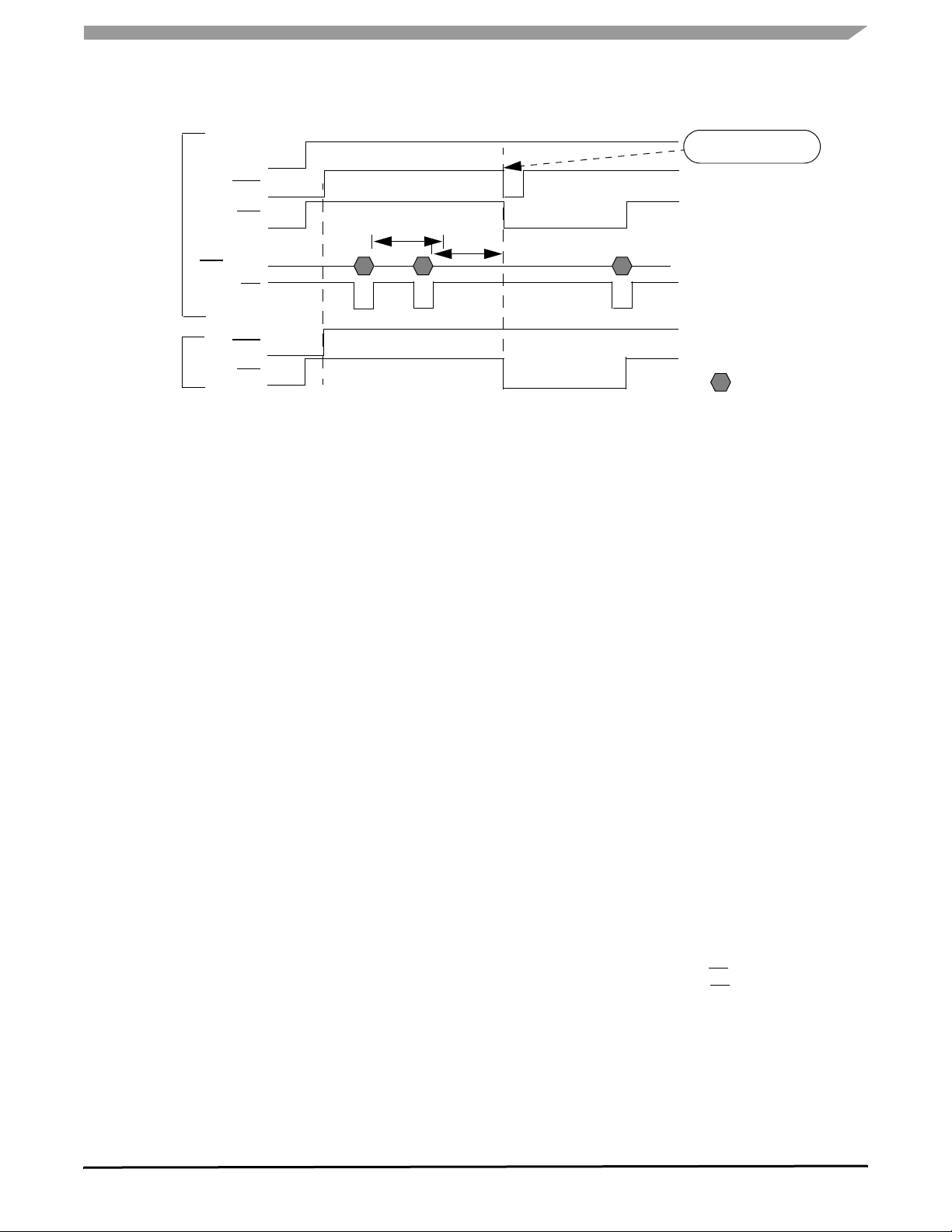

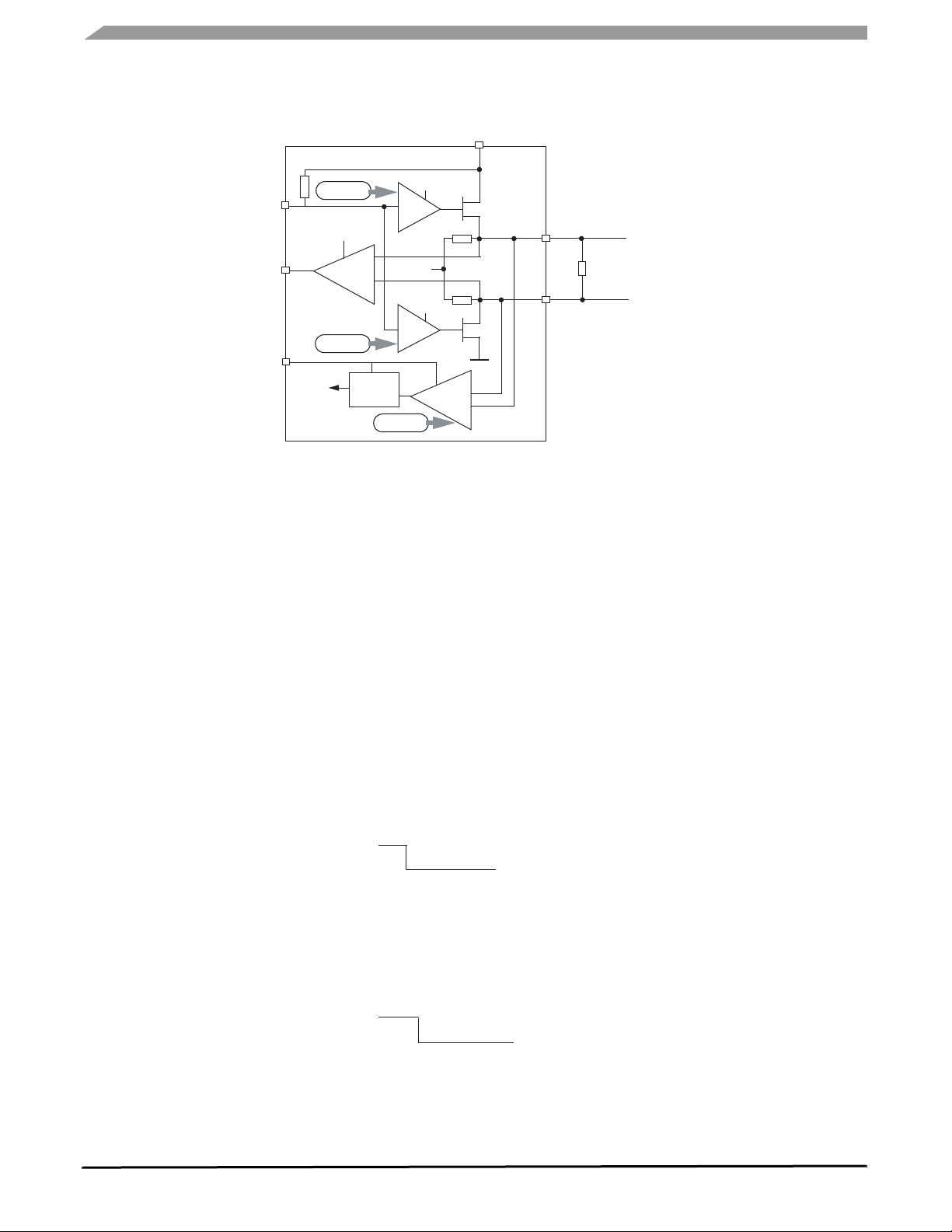

SOFTWARE WATCHDOG (SELECTABLE WINDOW

OR TIMEOUT WATCHDOG)

Software watchdog uses in the SBC Normal and Standby

modes is to monitor MCU. The Watchdog can be either

window or timeout. This is selectable by SPI (register TIM1,

bit WDW). Default is window watchdog. The period for the

watchdog is selectable from the SPI from 10 ms to 350 ms

(register TIM1, bits WDT0 and WDT1). When the window

watchdog is selected, the closed window is the first part of the

selected period, and the open window is the second part of

the period. Refer to the SPI TIM register description.

Watchdog can only be cleared within the open window time.

An attempt to clear the watchdog in the closed window will

generate a reset. Watchdog is cleared through SPI by

addressing the TIM1 register.

CS

Figure 9 indicates the operation to enter Stop mode.

STOP

I

DD1DGLT

SBC in Stop mode

no I

over I wake-up

DD1

SBC in Stop mode

with I

over I wake-up

DD1

RESET PIN DESCRIPTION

A reset output is necessary and available to reset the

microcontroller. Modes 1 and 2 are available for the reset pin

(please refer to

Reset causes when SBC is in mode 1:

•V

falling out of range — If V

DD1

threshold (parameter R

V

returns to the normal voltage.

DD1

• Power-on reset — At device power-on or at device wake-

up from Sleep mode, the reset is maintained low until V

is within its operation range.

Watchdog timeout — If watchdog is not cleared, the SBC

will pull the reset pin low for the duration of the reset time

(parameter

Table 5 for reset pin operation).

DD1

), the ret pin is pulled low until

STTH

RST

DUR)

.

falls below the reset

DD1

Table 5. Reset and Watchdog Output Operation

Events Mode WD Output Reset Output

Devices Power-up

V

Normal Watchdog Properly Triggered

DD1

V

< RST

DD1

Watchdog Timeout Reached

V

DD1

V

DD1

Watchdog Timeout Reached

Notes

27. WD stays low until the Watchdog register is properly addressed through SPI.

TH

Normal Watchdog Properly Triggered

< RST

TH

In Mode 2, the reset pin is not activated in case of

Watchdog timeout. Please refer to

Table 6 for more detail.

For debug purposes at 25°C, the Reset pin can be shorted

to 5.0 V because of its internal limited current drive capability.

33989

1 or 2 (Safe Mode) Low to High Low to High

1 High High

1 High Low

1 Low (Note) Low

2 (Safe Mode) High High

2 (Safe Mode) High Low

2 (Safe Mode) Low (Note) High

RESET AND WATCHDOG OPERATION: MODES1

AND 2

Watchdog and Reset functions have two modes of

operation:

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

FUNCTIONAL DEVICE OPERATION

1. Mode 1

2. Mode 2 (also called Safe mode)

These modes are independent of the SBC modes

(Normal, Standby, Sleep, and Stop). Modes 1 and 2 selection

is achieved through the SPI (register MCR, bit SAFE). Default

mode after reset is Mode 1.

Table 5 provides Reset and Watchdog output mode

of operation. Two modes (modes 1 and 2) are available and

can be selected through the SPI Safe bit. Default operation,

after reset or power-up, is Mode 1.

In both modes reset is active at device power-up and

wake-up.

• In mode 1–Reset is activated in case of V

DD1

fall or

watchdog not triggered. WD output is active low as soon

as reset goes low. It remains low as long as the watchdog

is not properly re-activated by the SPI.

• In mode 2–(Safe mode) Reset is not activated in case of

watchdog fault.

WD output has the same behavior as in

mode 1–The Watchdog output pin is a push-pull structure

driving external components of the application for signal

instance of an MCU wrong operation.

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

FUNCTIONAL DEVICE OPERATION

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

Table 6. Table of Operation

Mode

Voltage Regulator

HS1 Switch

Wake-up

Capabilities

(if enabled)

Reset Pin INT

Software

Watchdog

CAN Cell

Normal

Request

Normal V

HS1:Controllable

Standby V

HS1:Controllable

Stop V

(Limited Current

Capability)

HS1:OFF or Cyclic

Sleep V

HS1:OFF or Cyclic

Debug

Same as Normal — Normally High

Normal

Debug

Same as Standby — Normally High

Standby

V

:ON

DD1

V2:OFF

HS1:OFF

:ON

DD1

V2:ON

:ON

DD1

V2:OFF

:ON

DD1

V2:OFF

:OFF

DD1

V2:OFF

— Low for Reset-DUR

—

Active Low if

V

occurs (and mode 1

— Same as Normal

CAN

SPI

L0:L3

Active Low if WD

Cyclic Sense

Forced Wake-up

I

Over Current

DD1

(28)

CAN

SPI

L0:L3

Cyclic Sense

Forced Wake-up

Active Low if V

Active Low if V

— — —

Time, then High

Normally High

WD or

under voltage

DD1

If Enabled, Signal

Failure (V

DD1

Pre-

Warning Temp,

CAN, HS1)

Running Tx/Rx

selected)

Mode

Normally High

(29)

or V

Under

DD1

Voltage Occurs

Same as Normal

Mode

Signal SBC Wake-

up and

IDD > I

DD1S/WU

(Not Maskable)

Running Low Power

Running if Enabled

Not Running if

Disabled

Wake-up Capability

Low Not Active Not Running Low Power

Wake-up Capability

Same as Normal Not Running Same as Normal

DD1

Under Voltage

Occurs

Same as Standby Not Running Same as Standby

DD1

Under Voltage

Occurs

Low Power

if Enabled

if Enabled

33989

Analog Integrated Circuit Device Data

24 Freescale Semiconductor

top D(eb )-7.5g( )]TJETEMC/Span <</MCID984>>BDCBT7.98 0 0 7.981217.56 63.408 Tm0.011 Tc-0.0065 Tw(Same as Soep)TjETEMC/Span <</MCID985>>BDCBT7.98 0 0 7.98 9-6.23.63.408 Tm(Same as Soep)TjETEMC/Span <</MCID986>>BDCBT7.98 0 0 7.98 271.32 63.408 Tm0.0006 Tc-0.0002 Tw[(Nor)-4.7(m)-1(ally High)]TJ-0.9398 -1.2556 TD-0.0079 Tw[(Act)-7.2(i)4.8(ve Low if V)]TJETEMC/Span <</MCID978>>BDCBT6.36 0 0 6.36 316.082491408 Tm0.0043 Tc0 Tw(DD1)TjETEMC/Span <</MCID978>>BDCBT7.98 0 0 7.98 328.86293.46011 Tm0 Tc( )Tj-7.2632 -1.2556 TD0.0004 Tc(Under Voltage )Tj1.609 -1.2481 TD0.0046 Tc[(Occ)8.4(u)4.4(rs)]TJETEMC/Span <</MCID 89>>BDCBT7.98 0 0 7.98 46.32 63.408 Tm0.011 Tc-0.0065 Tw(Same as Soep)TjETEMC/Span <</MCID1090>>BDCBT7.98 0 0 7.98 423.96 63.408 Tm0.0004 Tc0 Tw[(No)-7.4(t Running)]TJETEMC/Span <</MCID1091>>BDCBT7.98 0 0 7.98 953.96 63.408 Tm0.011 Tc-0.0065 Tw(Same as Soep)TjETEMC/Span <</MCID1092>>BDCBT7.98 0 0 7.982715082576.8011 Tm0 TwFlash( )Tj19.732 -1.2556 TD6 Tc[Progor

ammino

ng

MODE 1

VDD1

RST

WD

SPI

WD Clear

SPI CS

Watchdog

Period

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

FUNCTIONAL DEVICE OPERATION

Watchdog Timeout

MODE 2

RST

WD

Figure 10. Reset and Watchdog Functions Diagram in Modes 1 and 2

WAKE-UP CAPABILITIES

Several wake-up capabilities are available for the device

when it is in Sleep, or Stop modes. When a wake-up has

occurred, the wake-up event is stored into the WUR or CAN

registers. The MCU can then access to the wake-up source.

The wake-up options are able to be selected through the SPI

while the device is in Normal or Standby mode and prior to

entering low power mode (Sleep or Stop mode). When a

wake-up occurs from sleep mode the device activates V

It generates an interrupt if wake-up occurs from Stop mode.

DD1

WAKE-UP FROM WAKE-UP INPUTS (L0:L3)

WITHOUT CYCLIC SENSE

The wake-up lines are dedicated to sense external switch

states and if changes occur to wake-up the MCU (in Sleep or

Stop modes). The wake-up pins are able to handle 40 V DC.

The internal threshold is 3.0 V typical and these inputs can be

used as an input port expander. The wake-up inputs state are

read through SPI (register WUR).

In order to select and activate direct wake-up from the LX

inputs, the WUR register must be configured with the

appropriate level sensitivity. Additionally, the LPC register

must be configured with 0x0 data (bits LX2HS1and

HS1AUTO are set at 0).

Level sensitivity is selected by WUR register. Level

sensitivity is configured by a pair of Lx inputs: L0 and L1 level

sensitivity are configured together while L2 and L3 are

configured together.

CYCLIC SENSE WAKE-UP (CYCLIC SENSE TIMER

AND WAKE-UP INPUTS L0, L1, L2, L3)

The SBC can wake-up upon state change of one of the

four wake-up input lines (L0, L1, L2 and L3) while the external

pull-up or pull down resistor of the switches associated to the

wake-up input lines are biased with HS1 VSUP switch. The

HS1 switch is activated in Sleep or Stop modes from an

Watchdog

Addressed

internal timer. Cyclic Sense and Forced Wake-up are

exclusive. If Cyclic Sense is enabled the forced wake-up can

not be enabled.

In order to select and activate the cyclic sense wake-up

from the Lx inputs the WUR register must be configured with

the appropriate level sensitivity, and the LPC register must be

configured with 1xx1 data (bit LX2HS1 set at 1 and bit

HS1AUTO set at 1). The wake-up mode selection (direct or

cyclic sense) is valid for all 4 wake-up inputs.

.

FORCED WAKE-UP

The SBC can wake-up automatically after a predetermined

time spent in Sleep or Stop mode. Cyclic sense and Forced

wake-up are exclusive. If Forced wake-up is enabled (FWU

bit set to 1 in LPC register) the Cyclic Sense can not be

enabled.

CAN INTERFACE WAKE-UP

The device incorporates a high-speed 1MBaud CAN

physical interface. Its electrical parameters for the CANL,

CANH, RX and TX pins are compatible with ISO 11898

specification (IS0

physical interface operation is accomplished through the SPI.

CAN modes are independent of the SBC operation modes.

The device can wake-up from a CAN message if the CAN

wake-up is enabled. Please refer to the CAN module

description for detail of wake-up detection.

11898: 1993(E)). The control of the CAN

SPI WAKE-UP

The device can wake-up by the CS pin in Sleep or Stop

modes. Wake-up is detected by the

to a high level. In Stop mode, this corresponds with the

condition where the MCU and SBC are in Stop mode; and

when the application wake-up event comes through the

MCU.

CS pin transition from low

Register

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 25

FUNCTIONAL DEVICE OPERATION

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

DEVICE POWER-UP, SBC WAKE-UP

After device or system power-up, or after the SBC wakes

up from Sleep mode, it enters into Reset mode prior to

moving into Normal Request mode.

DEBUG MODE: HARDWARE AND SOFTWARE

DEBUG WITH THE SBC

When the SBC is mounted on the same printed circuit

board as the microcontroller it supplies, both application

software and SBC dedicated routine must be debugged. The

following features allow debug of the software by allowing the

possibility of disabling the SBC internal software Watchdog

timer.

DEVICE POWER-UP, RESET PIN CONNECTED TO

VDD1

At SBC power-up the VDD1 voltage is provided, but if no

SPI communication occurs to configure the device, a reset

occurs every 350 ms. In order to allow software debug and

avoid MCU reset, the Reset pin can be connected directly to

VDD1 by a jumper.

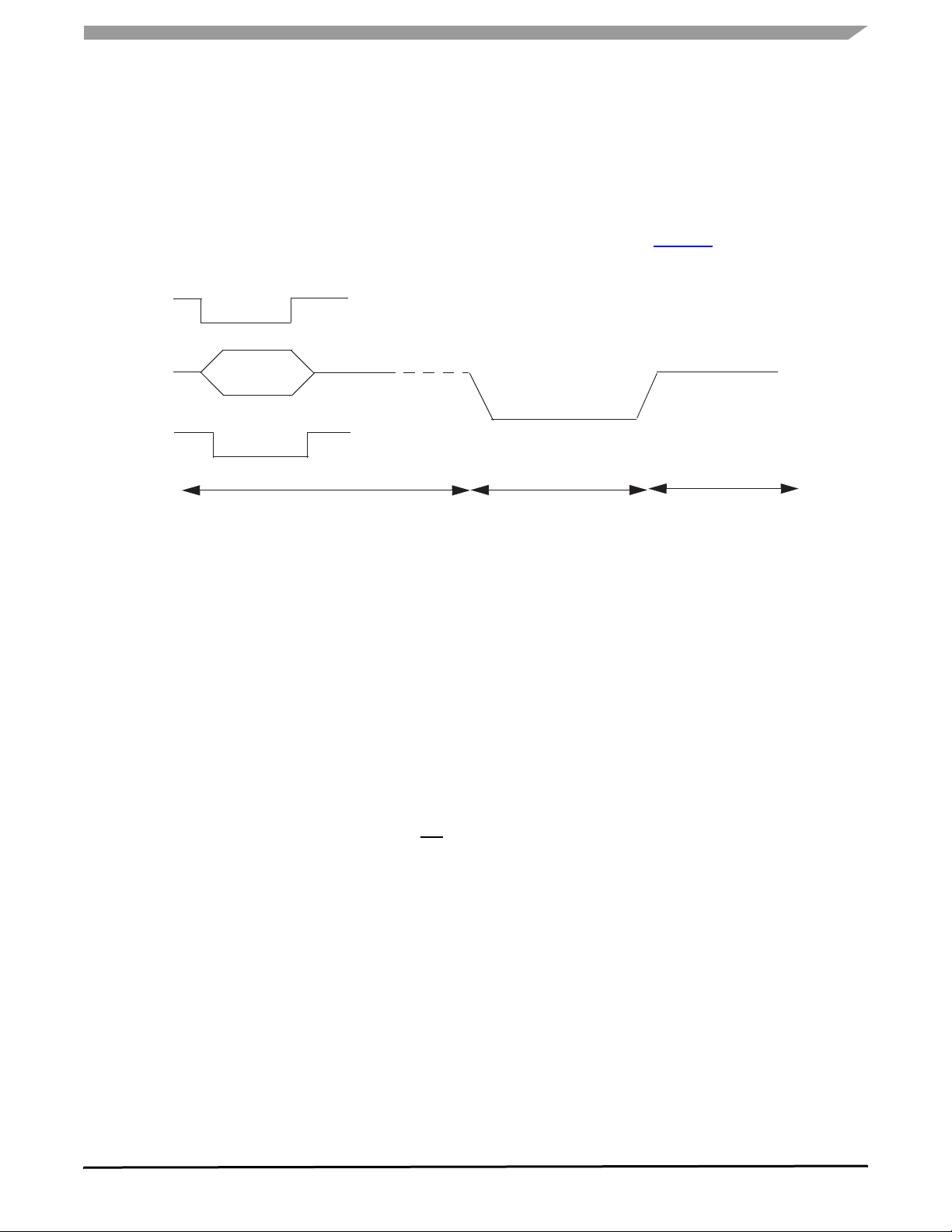

DEBUG MODES WITH SOFTWARE WATCHDOG

DISABLED THOUGH SPI (NORMAL DEBUG,

STANDBY AND STOP DEBUG)

The Watchdog software can be disabled through SPI. To

avoid unwanted watchdog disable while limiting the risk of

disabling Watchdog during SBC normal operation, the

watchdog disable must be achieved the following sequence:

• Step 1–Power down the SBC

• Step 2–Power-up the SBC (The BATFAIL bit is set,

allowing the SBC to enter Normal Request mode)

• Step 3–Write to TIM1 register allowing SBC entering

Normal mode

• Step 4–Write to MCR register with data 0000, enabling the

Debug mode. Complete SPI byte: 000 1 0000

• Step 5–Write to MCR register normal debug (0001x101)

• Step 6–To leave the Debug mode, write 0000 to MCR

register

While in Debug mode, the SBC can be used without

having to clear the

WD on a regular basis to facilitate

software and hardware debug.

At Step 2, the SBC is in Normal Request. Steps 3, 4, and

5 should be completed consecutively and within the 350 ms

time period of the Normal Request mode. If this step is not

accomplished in a timely manner, the SBC will go into Reset

mode, entering Normal Request again.

When the SBC is in Debug mode, and set in Stop Debug

or Sleep Debug, when a wake-up occurs the SBC enters

Normal Request mode for a time period of 350 ms. To avoid

the SBC generating a reset (enter Reset mode) the desired

next Debug mode (Normal Debug or Standby Debug) should

be configured within the 350 ms time period of the Normal

Request mode. For details, please refer to State Machine in

Debug mode,

Figure 16.

To avoid entering Debug mode after a power-up, first read

BATFAIL bit (MCR read) and write 0000 into MCR. Figure 15

illustrates the Debug mode enter.

VSUP

VDD1

Batfail

TIM1(Step 3)

MCR (Step5)

SPI

MCR(Step4)

Debug Mode

SPI: Read Batfail

SBC in Debug Mode, No WD

Figure 11. Debug Mode Enter

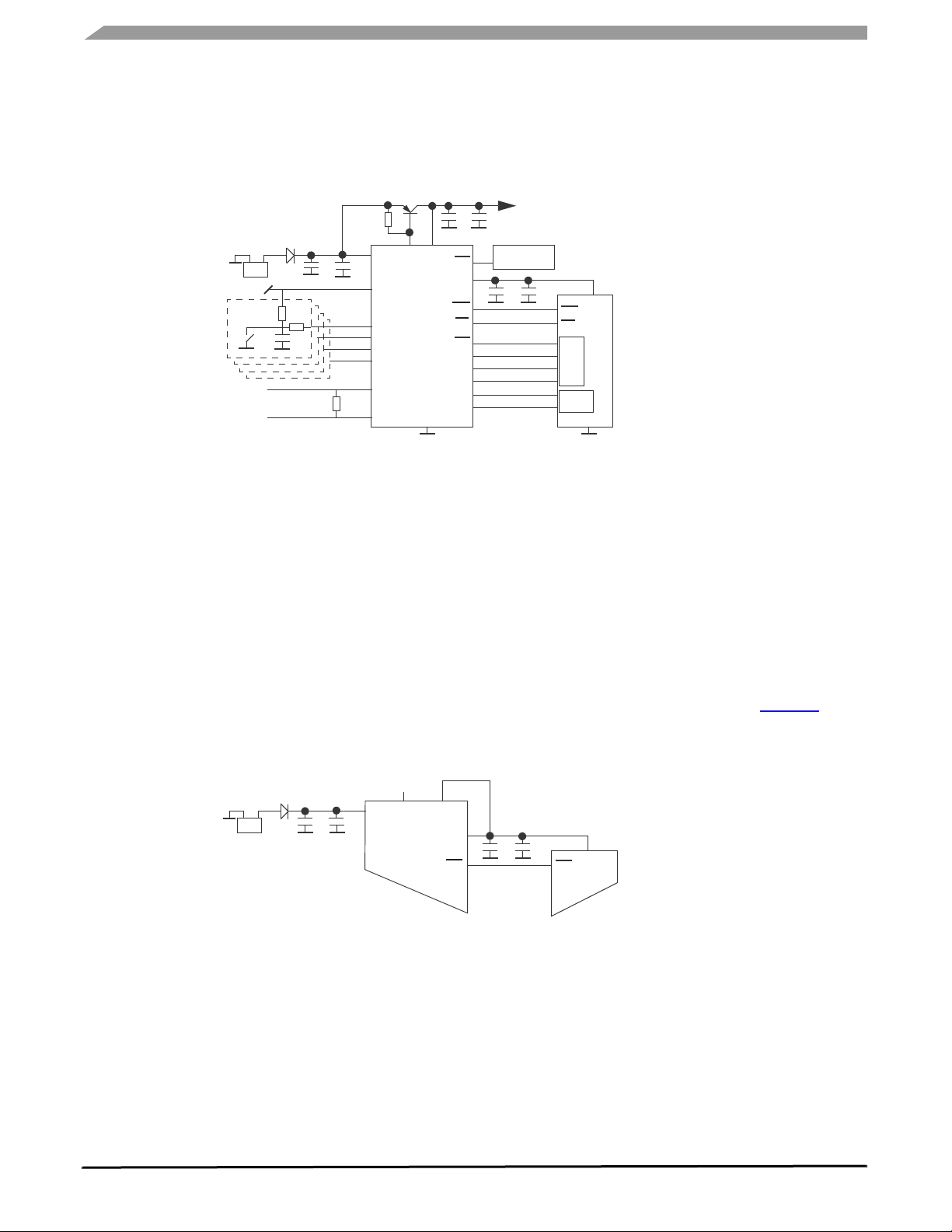

MCU FLASH PROGRAMMING CONFIGURATION

To download software into the application memory (MCU

EEPROM or Flash) the SBC capabilities allows the V

be forced by an external power supply to 5.0 V; the reset and

WD outputs by external signal sources are forced to zero or

5.0 V, both without damage. This allows, for example, supply

of the complete application board by external power supply,

DD1

to

MCR (Step6)

SBC Not in Debug Mode and WD ON

applying the correct signal to reset pins. No function of the

SBC is operating.

Due to pass transistor from VDD1 to VSUP, supplying the

device from VDD1 pin biases the VSUP pin. Therefore, V

SUP

should not be forced to a value above 5.0 V. The Reset pin is

periodically pulled low for

before being pulled to V

RST

DD1

time reset is low, the reset pin sinks 5.0 mA maximum (L

time (3.4 ms typical)

DUR

for 350 ms typical. During the

PDW

parameter).

33989

Analog Integrated Circuit Device Data

26 Freescale Semiconductor

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

FUNCTIONAL DEVICE OPERATION

VSUP (Open or > 5.0 V

SBC MCU = Flash

External supply and sources applied to V

and WD

VDD1

RST

WD

test points on application circuit board.

Figure 12. Simplified Schematic for Flash Programming

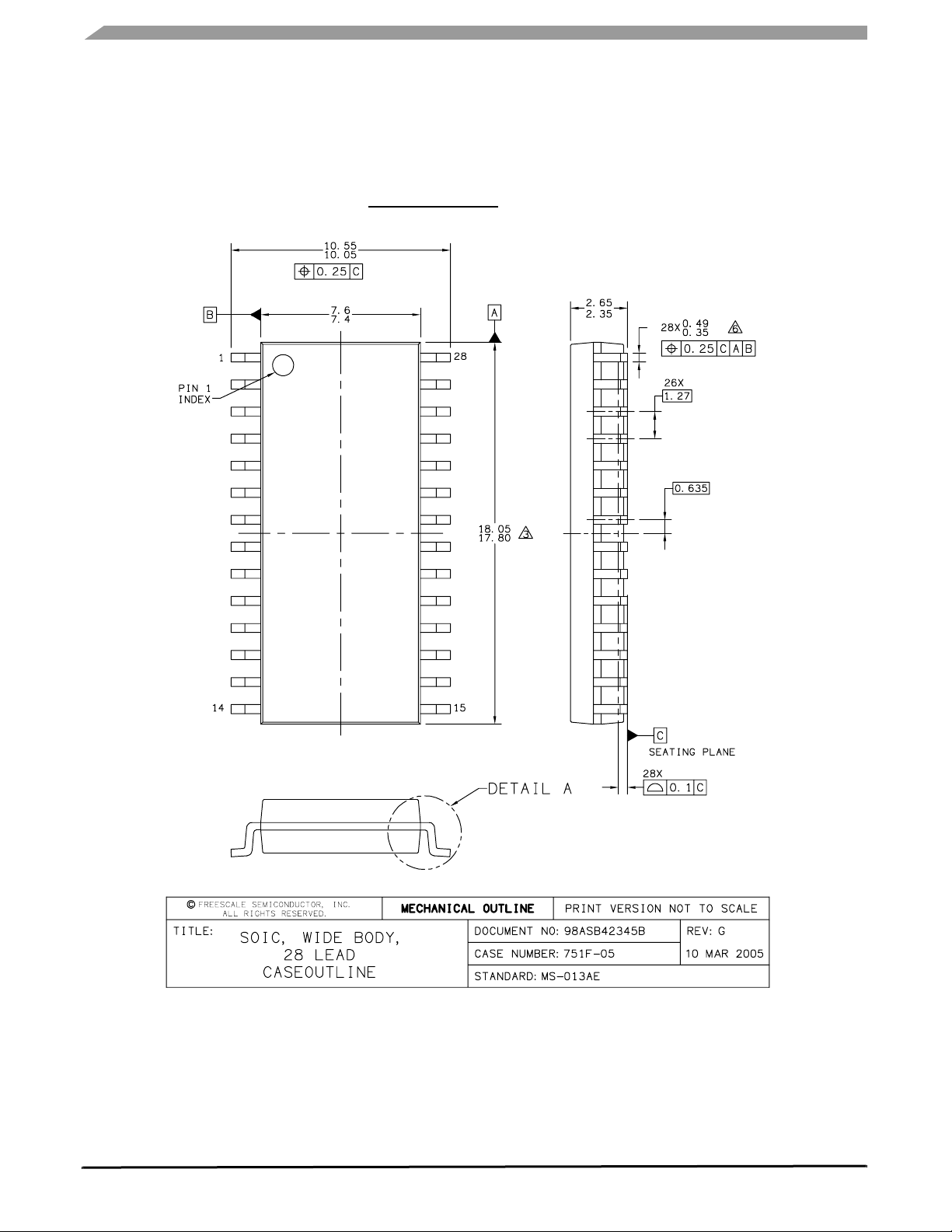

PACKAGE AND THERMAL CONSIDERATION

The device is proposed in a standard surface mount

SOIC28 package. In order to improve the thermal

performances of the SOIC28 package, eight pins are

internally connected to the lead frame and are used for heat

transfer to the printed circuit board.

WD: Timeout OR V

Reset Counter (3.4

ms) Expired

SBC Power-

Power

Down

Reset

V

Low OR WD:

:

T

i

m

e

o

DD1

Timeout 350 ms

&!Nostop

u

t

O

R

V

D

D

1

L

o

WD: Timeout OR V

W

D

w

(

3

1

0

)

1

Normal

2

Wake-up

2

Stop

DD1

Programming Bus

, RST ,

DD1

Table 6, page 24, describes the SBC operation modes.

Normal, Stand-by, and Stop Debug modes are entered

through special sequence described in the Debug mode

paragraph.

Low

DD1

WD: Timeout & Nostop

Low

4

Sto

Hi

SPI:

to

SPI: Stop & CS

Low to High

Transition

SPI: Stand-by

Trigger

& WD

3

Low

n

o

CS

&

p

ransiti

T

WD:

h

g

T

ri

g

ger

Normal

1

Stand-by

SPI: Stand-by

SPI: Normal

1

Low to High

CS

Nostop & SPI: Sleep &

Low

Nostop & SPI:

Sleep & CS

Wake-up

(V

1 2 3 4

DD1

denotes priority

High T emperature OR (V

1 Low > 100ms & V

DD1

>BFew)) & Nostop &!BA TF AIL

SUP

Sleep

STATE MACHINE DESCRIPTION:

28. Nostop = Nostop bit = 1

29. ! Nostop = Nostop bit = 0

30. BATFAIL = Batfail bit = 1

31. ! BATFAIL = Batfail bit = 0

32. V

33. V

34. V

35. WD

Over Temperature = V

DD1

low = V

DD1

low >100 ms = V

DD1

below reset threshold

DD1

DD1

thermal shutdown occurs

DD1

below reset threshold for more than 100 ms

: Trigger = TIM1 register write operation.

Figure 13. State Machine (Not Valid in Debug Modes)

Notes These two SPI commands must be sent consecutively in this sequence.

30. If WD activated.

33989

Analog Integrated Circuit Device Data

Freescale Semiconductor 27

FUNCTIONAL DEVICE OPERATION

RESET AND WATCHDOG PINS, SOFTWARE WATCHDOG OPERATIONS

Power-Up

Behavior after power-up if no trigger appears

Behavior after reset of BATFAIL if no trigger appears

Reset

Normal

Request

Yes No

NoNo

Yes

Trigger Batfail No Stop Sleep

Yes

Normal

Figure 14. Behavior at SBC Power-Up

WD: Timeout 350 ms

Normal Request

r

e

g

g

i

r

T

:

D

W

Reset Counter

(3.4 ms) Expired

SPI: MCR (0000) & Normal Debug

Reset

Normal

Power

Down

Normal Debug

SPI: MCR (0000) & Stand-by Deb ug

St and-by Debug

Figure 15. Transitions to Enter Debug Modes

33989

Analog Integrated Circuit Device Data

28 Freescale Semiconductor

Stop (1)

Wake-up

Normal Request

WD: Time-out 350 ms

Reset Counter

(3.4 ms) Expired

Reset

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

Wake-up

Sleep

R

up

-

e

R

Wa

k

Stop Debug

SPI: Stop

High Transition

SPI: Stop Debug & CS Low to

(1) If Stop mode entered, it is entered without watchdog, no matter the WDSTOP bit.

(E) Debug mode entry point (Step 5 of the Debug mode entering sequence).

(R) Represents transitions to Reset mode due to V

: Trigger

WD

SPI: Stand-by &

Stand-by

SPI: Stand-by

St and-by Debug

low.

DD1

R

R

S

P

I

:

N

o

r

m

a

l

D

e

b

SPI:

u

E

g

SPI: Stand-by Debug

SPI: Normal Debug

R

W

D

:

T

r

nd-by Debu

a

St

i

g

g

e

r

Normal

g

E

R

R

& SPI: Sleep

&!BATFAILNOSTOP

SPI: Normal Debug

Normal Debug

R

Figure 16. Simplified State Machine in Debug Modes

LOGIC COMMANDS AND REGISTERS

SPI INTERFACE AND REGISTER DESCRIPTION

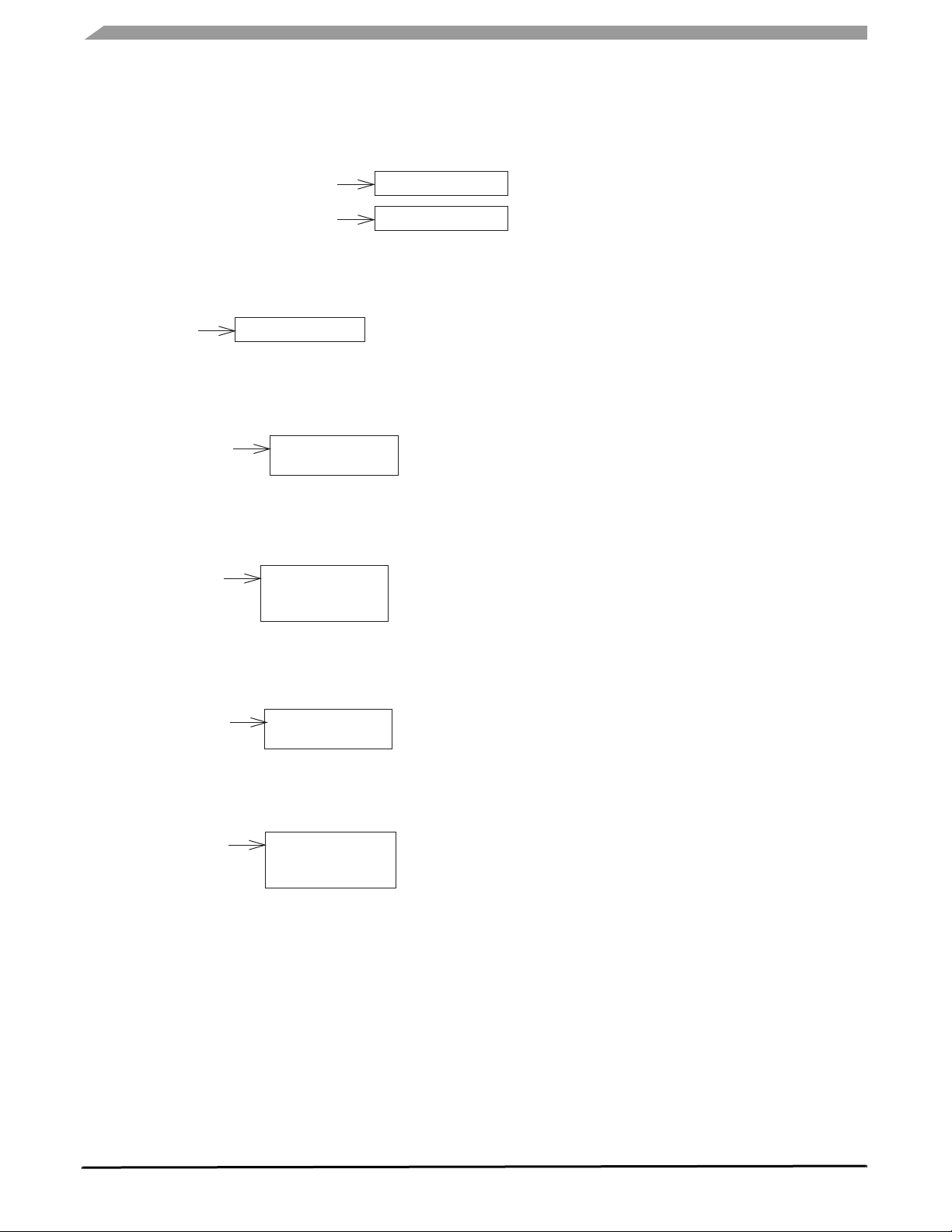

Table 7 illustrates a register, an 8-bit SPI. The first three

bits are used to identify the internal SBC register address. Bit

four is a read/write bit. The last four bits are Data Send from

MCU to SBC, or read back from SBC to MCU.

There is no significance during write operation state of

MISO.

During read operation only the final four bits of MISO have

a meaning (content of the accessed register).

The following tables describe the SPI register list, and

register bit meaning.

Registers reset value is also described along with the reset

condition. Reset condition is the condition causing the bit to

be set at the reset value.

Table 7. Data Format Description

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

A2 A1 A0 R/W D3 D2 D1 D0

Read operation: R/W Bit = 0

Write operation: R/W Bit = 1

Possible reset conditions include:

SBC Reset: Power-On Reset POR