Page 1

www.DataSheet4U.com

Freescale Semiconductor

Advance Information

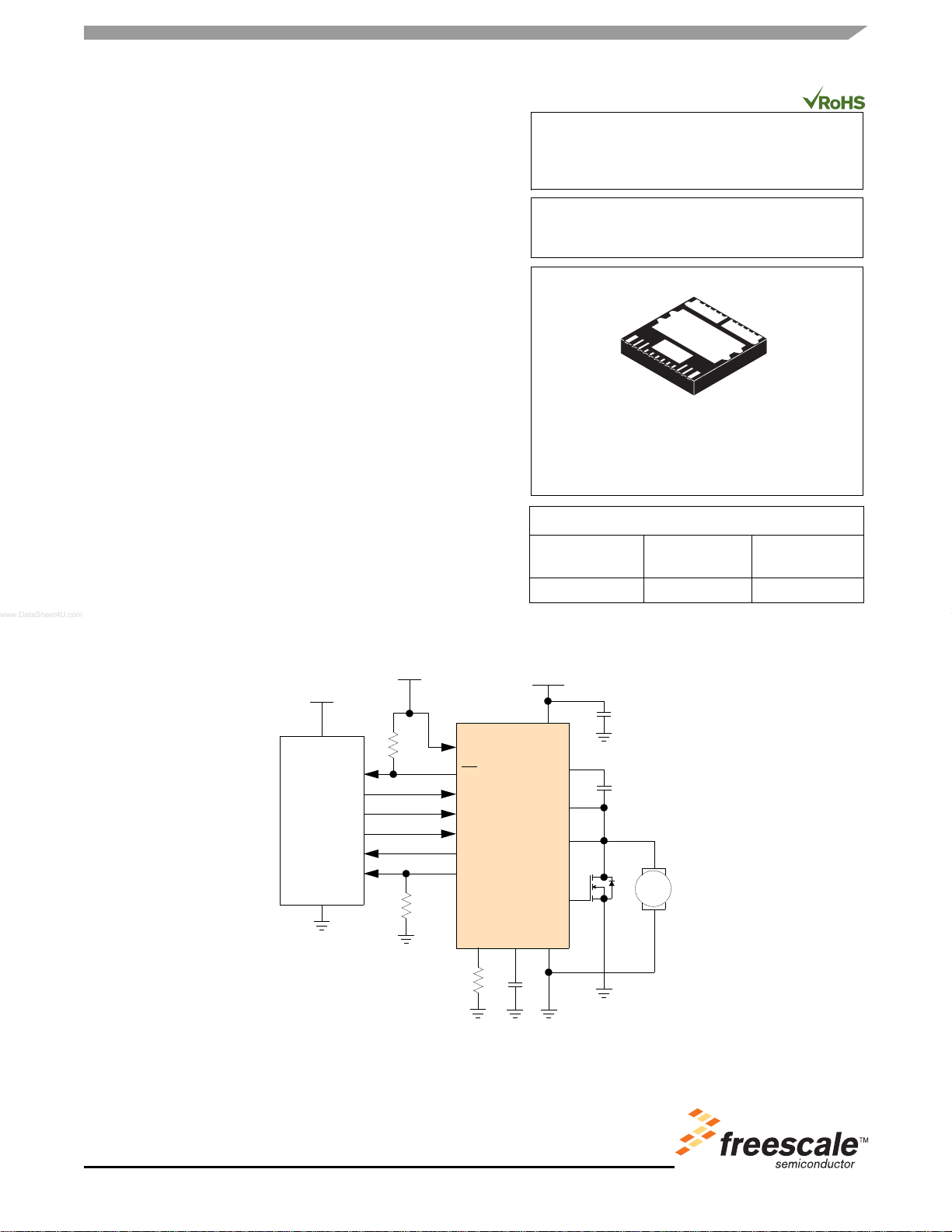

Single High-Side Switch

Document Number: MC33981

Rev. 6.0, 5/2007

(4.0 mΩ), PWM clock up to 60kHz

The 33981 is a high-frequency, self-protected 4.0 mΩ R

side switch used to replace electromechanical relays, fuses, and

discrete devices in power management applications.

The 33981 can be controlled by Pulse-Width Modulation (PWM) with

a frequency up to 60 kHz. It is designed for harsh environments, and it

includes self-recovery features. The 33981 is suitable for loads with

high in-rush current, as well as motors and all types of resistive and

inductive loads.

The 33981 is packaged in a 12 x 12 non-leaded power-enhanced

Power QFN package with exposed tabs.

Features

• Single 4.0 mΩ R

Maximum High-Side Switch

DS(ON)

• PWM Capability up to 60 kHz with Duty Cycle from 5% to 100%

• Very Low Standby Current

• Slew Rate Control with External Capacitor

• Overcurrent and Overtemperature Protection, Undervoltage

Shutdown and Fault Reporting

• Reverse Battery Protection

• Gate Drive Signal for External Low-Side N-Channel MOSFET with

Protection Features

• Output Current Monitoring

• Temperature Feedback

• Pb-Free Packaging Designated by Suffix Code PNA

DS(ON)

high-

33981B

HIGH-SIDE SWITCH

Bottom View

SCALE 1:1

PNA (Pb-Free Suffix)

98ARL10521D

16-PIN PQFN (12 X 12)

ORDERING INFORMATION

Device

MC33981BPNA/R2 - 40°C to 125°C

Temperature

Range (T

)

A

Package

16 PQFN

V

DD

V

DD

V

PWR

33981

MCU

I/O

I/O

I/O

I/O

A/D

A/D

CONF

FS

INLS

EN

INHS

TEMP

CSNS

OCLS SR GND

VPWR

CBOOT

OUT

DLS

GLS

Figure 1. 33981 Simplified Application Diagram

M

* This document contains certain information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

Page 2

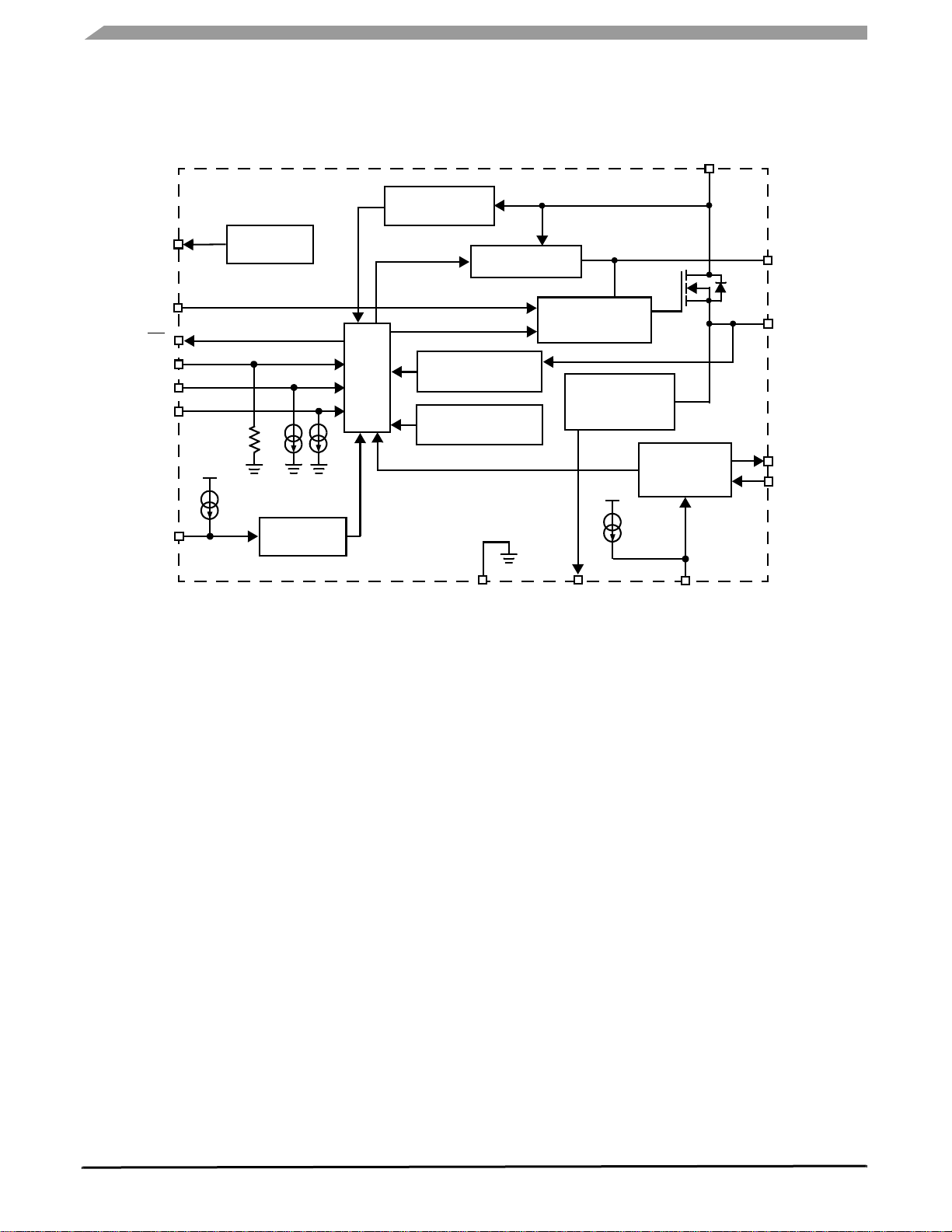

INTERNAL BLOCK DIAGRAM

TEMP

Temperature

Feedback

INTERNAL BLOCK DIAGRAM

Undervoltage

Detection

Bootstrap Supply

VPWR

CBOOT

SR

FS

EN

INHS

INLS

CONF

5.0 V

I

CONF

R

DWN

Slew Rate Control

I

DWN

Cross-

Conduction

Logic

Current

Protection

Overtemperature

Detection

GND

Figure 2. 33981 Simplified Internal Block Diagram

Gate Driver

OUT Current

Recopy

5.0 V

CSNS

Low-Side

Gate Driver

and Protection

I

OCLS

OCLS

OUT

GLS

DLS

33981

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

Page 3

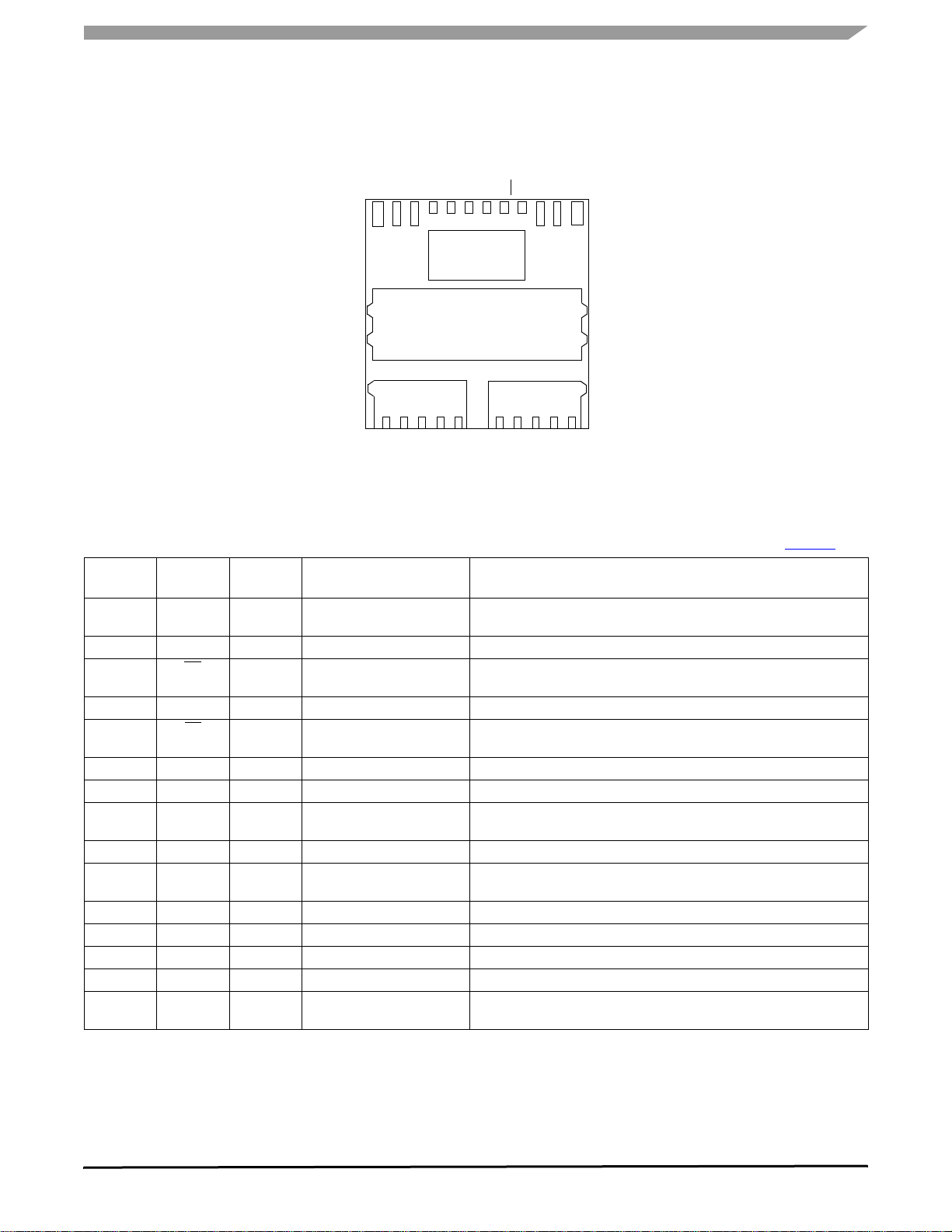

PIN CONNECTIONS

Package Transparent Top View

CBOOT

GLS

SR

DLS

CONF

OCLS

INLS

FS

INHS

TEMP

EN

PIN CONNECTIONS

CSNS

12

11

10

98765

GND

13

VPWR

14

4

OUTOUT

1

3

2

1615

Figure 3. Pin Connections

Table 1. PIN DEFINITIONS

Descriptions of the pins listed in the table below can be found in the Functional Description section located on page 12.

Pin

Number

1 CSNS Reports Output Current Monitoring

2 TEMP Reports Temperature Feedback

3EN

4 INHS Input Serial Input High Side

5FS

6 INLS Input Serial Input Low Side

7 CONF Input Configuration Input

8 OCLS Input Low-Side Overload

9 DLS Input Drain Low Side

10 GLS Output Low-Side Gate

11 SR Input Slew Rate Control

12 CBOOT Input Bootstrap Capacitor

13 GND Ground Ground

14 VPWR Input Positive Power Supply

15, 16 OUT Output Output

Pin Name

Pin

Function

Input Enable

Reports Fault Status

Formal Name Definition

(Active High)

(Active Low)

This pin is used to generate a ground-referenced voltage for the

microcontroller (MCU) to monitor output current.

This pin is used by the MCU to monitor board temperature.

This pin is used to place the device in a low-current sleep mode.

This input pin is used to control the output of the device.

This pin monitors fault conditions and is active LOW.

This pin is used to control an external low-side N-channel MOSFET.

This input manages MOSFET N-channel cross-conduction.

This pin sets the V

MOSFET.

This pin is the drain of the external low-side N-channel MOSFET.

This output pin drives the gate of the external low-side N-channel

MOSFET.

This pin controls the output slew rate.

This pin provides the high-pulse current to drive the device.

This is the ground pin of the device.

This pin is the source input of operational power for the device.

These pins provide a protected high-side power output to the load

connected to the device.

protection level of the external low-side

DS

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

Page 4

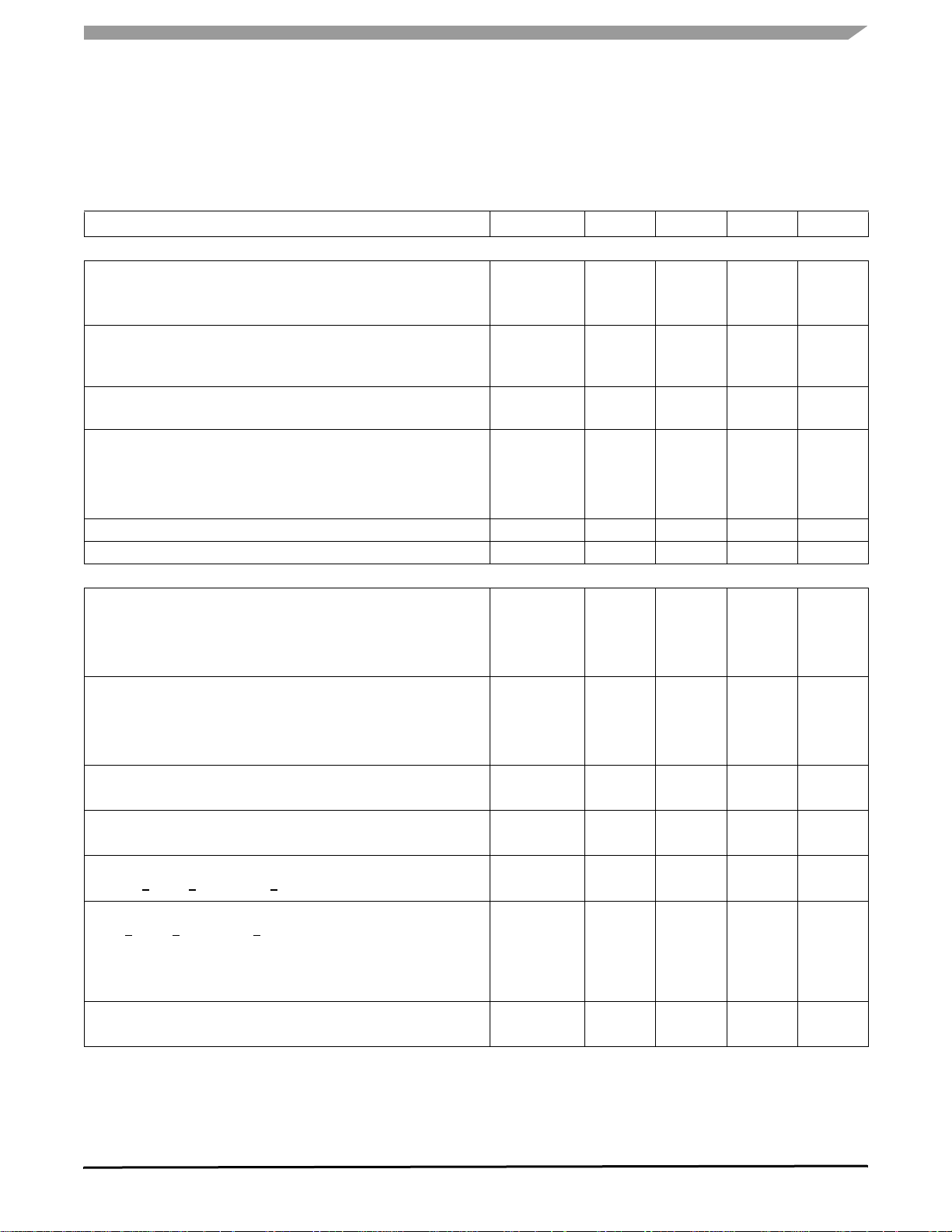

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted.

Rating Symbol Value Unit

ELECTRICAL RATINGS

Power Supply Voltage

Steady-State

Input/Output Pins Voltage

(1)

Output Voltage

Positive

Negative

(2)

Continuous Output Current

CSNS Input Clamp Current

EN Input Clamp Current

SR Voltage

C

BOOT Voltage

OCLS Voltage

Low-Side Gate Voltage

Low-Side Drain Voltage

ESD Voltage

(3)

Human Body Model (HBM)

Charge Device Model (CDM)

Corner Pins (1, 12, 15, 16)

All Other Pins (2-11, 13-14)

THERMAL RATINGS

Operating Temperature

Ambient

Junction

Storage Temperature

Thermal Resistance

(4)

Junction to Power Die Case

Junction to Ambient

Peak Pin Reflow Temperature During Solder Mounting

(5)

Notes

1. Exceeding voltage limits on INHS, INLS, CONF, CSNS, FS

, TEMP, and EN pins may cause a malfunction or permanent damage to the

device.

2. Continuous high-side output rating as long as maximum junction temperature is not exceeded. Calculation of maximum output current

using package thermal resistance is required.

3. ESD testing is performed in accordance with the Human Body Model (HBM) (C

Model (CDM), Robotic (C

ZAP

= 4.0 pF).

4. Device mounted on a 2s2p test board per JEDEC JESD51-2.

5. pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may

cause malfunction or permanent damage to the device.

V

PWR

INHS, INLS,

CONF, CSNS, FS

TEMP, EN

V

OUT

I

OUT

I

CL(CSNS)

I

CL(

EN)

V

SR

C

BOOT

V

OCLS

V

GLS

V

DLS

V

ESD

TA

TJ

T

STG

R

JC

θ

R

JA

θ

T

SOLDER

= 100 pF, R

ZAP

-16 to 41

- 0.3 to 7.0 V

,

41.0

-5.0

40.0 A

15.0 mA

2.5 mA

- 0.3 to 54.0 V

- 0.3 to 54.0 V

- 5.0 to 7.0 V

- 0.3 to 15.0 V

- 5.0 to 41.0 V

± 2000

± 750

± 500

- 40 to 125

- 40 to 150

- 55 to 150 °C

1.0

20.0

245 °C

= 1500 Ω) and the Charge Device

ZAP

V

V

V

°C

°C/W

33981

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

Page 5

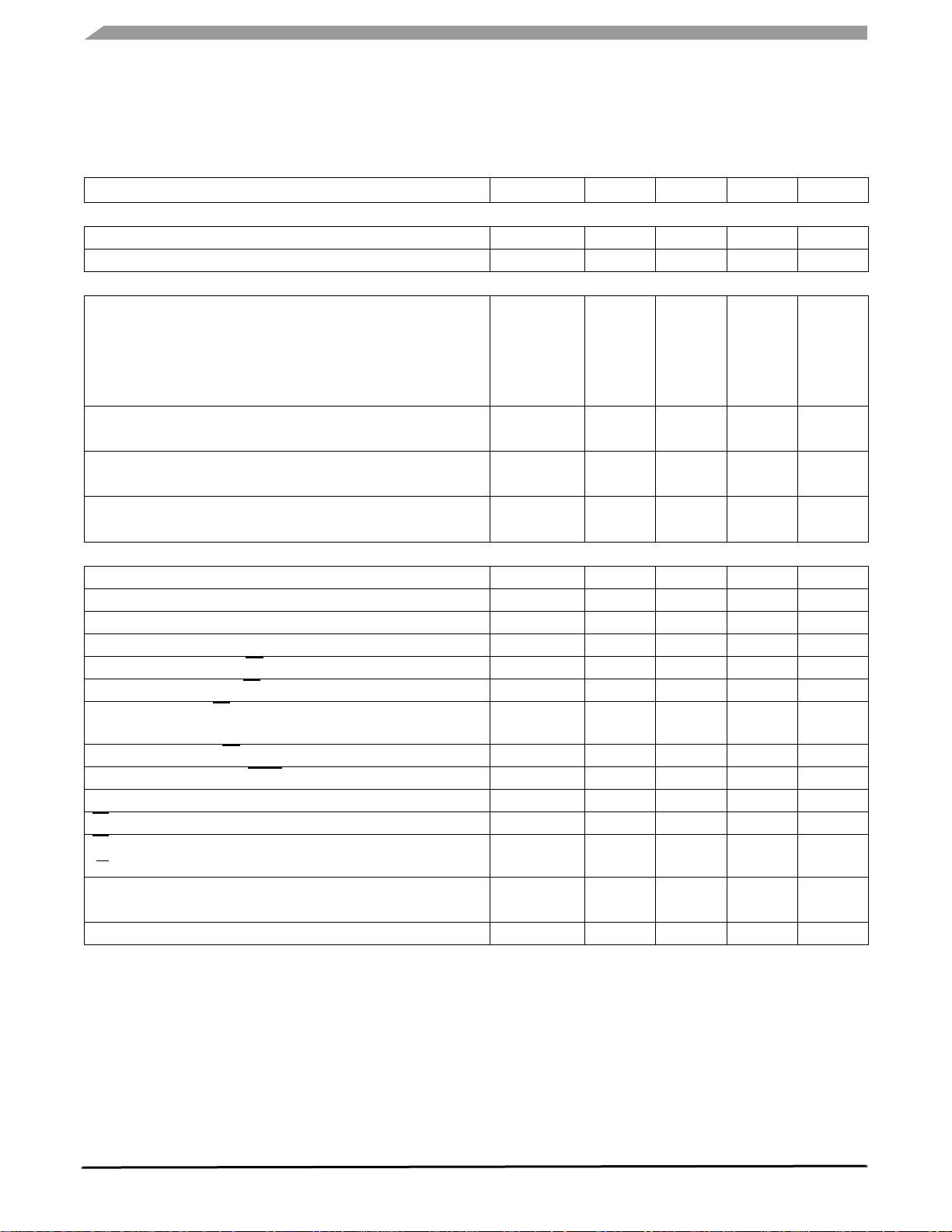

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 6.0 V ≤ V

noted reflect the approximate parameter mean at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

POWER INPUT (VPWR)

Battery Supply Voltage Range

Fully Operational

Extended

V

PWR

INHS = 1 and OUT Open

INLS = 0

V

PWR

INHS = INLS = 0, EN = 5.0 V, OUT Connected to GND

Sleep State Supply Current

(V

PWR

T

A

T

A

Undervoltage Shutdown

Undervoltage Hysteresis

POWER OUTPUT (IOUT, VPWR)

Output Drain-to-Source ON Resistance

V

PWR

V

PWR

V

PWR

Output Drain-to-Source ON Resistance (I

V

PWR

V

PWR

V

PWR

Output Source-to-Drain ON Resistance

V

PWR

Output Overcurrent Detection Level

9.0 V < V

Current Sense Ratio

9.0 V <

Current Sense Ratio (C

9.0 V <

Output Current

5.0 A

15 A, 20 A and 30 A

Current Sense Voltage Clamp

I

CSNS

Notes

6. OUT can be commanded fully on, PWM is available at room. Low Side Gate driver is available. Protections and Diagnosis are not

7. Source-Drain ON Resistance (Reverse Drain-to-Source ON Resistance) with negative polarity V

(6)

Supply Current

Supply Current

< 14 V, EN = 0 V, OUT Connected to GND)

= 25°C

= 125°C

(I

= 20 A, TA = 25°C)

OUT

= 6.0 V

= 9.0 V

= 13.0 V

= 20 A, TA = 150°C)

OUT

= 6.0 V

= 9.0 V

= 13.0 V

(I

= -20 A, TA = 25°C)

OUT

= - 12 V

< 16 V

PWR

V

< 16 V, CSNS < 4.5 V

PWR

) Accuracy

SR

V

< 16 V, CSNS < 4.5 V

PWR

= 15 mA

available. Min/max parameters are not guaranteed.

≤ 27 V, -40°C ≤ TA ≤ 125°C unless otherwise noted. Typical values

PWR

V

PWR

I

PWR(ON)

6.0

4.5

–

–

27.0

27.0

– 10.0 12.0

I

PWR(SBY)

– 10.0 12.0

I

PWR(SLEEP)

–

–

V

PWR(UV)

V

PWR(UVHYS)

R

DS(ON)25

2.0 4.0 4.5 V

0.05 0.15 0.3 V

–

–

–

R

DS(ON)150

–

–

–

(7)

R

SD(ON)

–

–

–

–

–

–

–

–

5.0

50.0

6.0

5.0

4.0

10.2

8.5

6.8

––8.0

I

OCH

75 100 125

C

SR

– 1/20000 –

C

SR_ACC

V

CL(CSNS)

-20

-15

–

–

20

15

4.5 6.0 7.0

.

PWR

V

mA

mA

µA

mΩ

mΩ

mΩ

A

–

%

V

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

Page 6

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 6.0 V ≤ V

≤ 27 V, -40°C ≤ TA ≤ 125°C unless otherwise noted. Typical values

PWR

noted reflect the approximate parameter mean at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

POWER OUTPUT (VPWR) (continued)

Overtemperature Shutdown

Overtemperature Shutdown Hysteresis

(8)

LOW SIDE GATE DRIVER (VPWR, VGLS, VOCLS)

Low-Side Gate Voltage

V

= 6.0 V

PWR

= 9.0 V

V

PWR

= 13 V

V

PWR

= 27 V

V

PWR

Low-Side Gate Sinked Current

V

GLS

= 2 V, V

PWR

= 13 V

Low-Side Gate Sourced Current

V

GLS

= 2 V, V

PWR

= 13 V

Low-Side Overload Detection Level versus Low-Side Drain Voltage

V

- V

OCLS

DLS

, (V

OCLS

≤ 4.0 ς)

CONTROL INTERFACE (CONF, INHS, INLS, EN, OCLS)

Input Logic High Voltage (CONF, INHS, INLS)

Input Logic Low Voltage (CONF, INHS, INLS)

Input Logic Voltage Hysteresis (CONF, INHS, INLS)

Input Logic Active Pulldown Current (INHS, INLS)

Enable Pull-down Resistor (EN

Enable Voltage Threshold (EN

Input Clamp Voltage (EN

I

< 2.5 mA

EN

Input Forward Voltage (EN

Input Active Pullup Current (OCLS

)

)

)

)

)

Input Active Pullup Current (CONF)

FS

Tri-State Capacitance

FS

Low-State Output Voltage

I

= -1.6 mA

FS

(8)

Temperature Feedback

T

= 25°C for V

A

Temperature Feedback Derating

PWR

= 14 V

(8)

Notes

8. Parameter is guaranteed by process monitoring but is not production tested.

T

SD

T

SDHYS

V

GLS

I

GLSNEG

I

GLSPOS

V

DS_LS

V

IH

V

IL

V

INHYS

I

DWN

R

DWN

V

EN

V

CLEN

V

F(EN)

I

OCLS p

I

CONF

C

FS

V

FSL

V

TFEED

DT

FEED

160 175 190 °C

5.0 – 20 °C

5.0

8.0

12.0

12.0

5.4

8.4

12.4

12.4

6.0

9.0

13.0

13.0

– 100 –

– 100 –

-50 – +50

3.3 – – V

– – 1.0 V

100 600 1200 mV

5.0 10 20 µA

100 200 400 kΩ

2.5 V

7.0 – 14

-2.0–-0.3V

50 100 200 µA

5.0 10 20 µA

– – 20 pF

–0.20.4

3.35 3.45 3.55

-8.5 -8.9 -9.3 mV/°C

V

mA

mA

mV

V

V

V

33981

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

Page 7

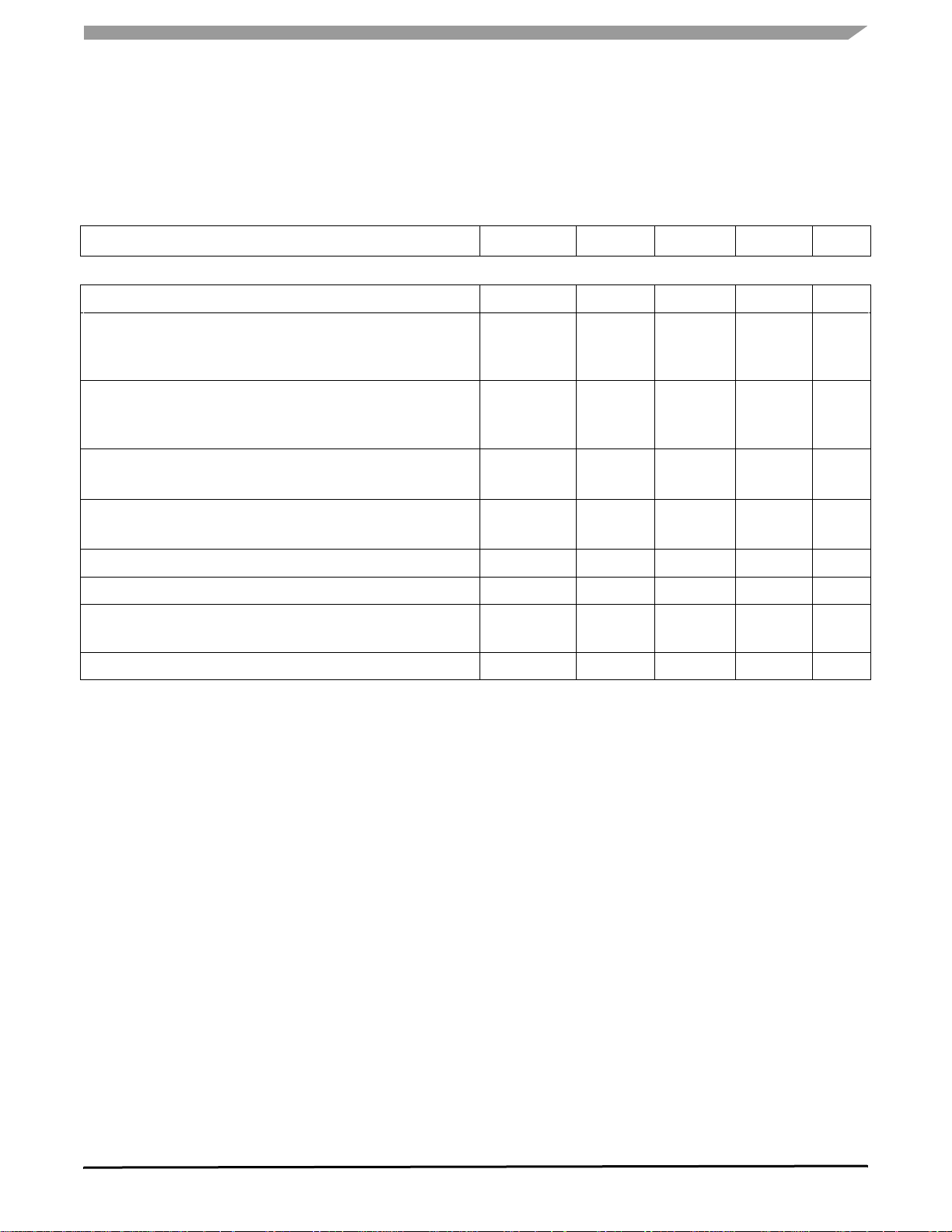

DYNAMIC ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 6.0 V ≤ V

noted reflect the approximate parameter mean at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

CONTROL INTERFACE AND POWER OUTPUT TIMING (CBOOT, VPWR)

Charge Blanking Time (CBOOT)

Output Rising Slew Rate

V

= 13 V, from 10% to 90% of V

PWR

= 5.0 Ω

R

L

Output Falling Slew Rate

V

= 13 V, from 90% to 10% of V

PWR

= 5.0 Ω

R

L

Output Turn-ON Delay Time

V

= 13 V, SR Capacitor = 4.7 nF

PWR

Output Turn-OFF Delay Time

V

= 13 V, SR Capacitor = 4.7 nF

PWR

Input Switching Frequency

Output PWM ratio @ 60kHz

Time to Reset Fault Diagnosis

(over load on high side or external low side)

Output Over Current Detection Time

Notes

9. The MC33981 can work down (~100Hz). The fault management reset can not be guaranteed with PWM frequency lower than 5kHz

(INHS=0 during 200us typ)

10. Values for CBOOT=100nF. Refer to the paragraph entitled Sleep Mode on page 13. Parameter is guaranteed by design and not

production tested.

11. Turn-ON delay time measured from rising edge of INHS that turns the output ON to V

12. Turn-OFF delay time measured from falling edge of INHS that turns the output OFF to V

13. The ratio is measured at V

(10)

SR Capacitor = 4.7 nF,

OUT,

SR Capacitor = 4.7 nF,

OUT,

(11)

(12)

(9)

(13)

= 50% V

out

without SR capacitor. The device is capable of 100% duty cycle.

PWR

≤ 27 V, -40°C ≤ TA ≤ 125°C unless otherwise noted. Typical values

PWR

t

SR

ON

R

10 25 50 µs

8.0 16 35

SR

F

8.0 16 35

t

DLYON

200 400 700

t

DLYOFF

500 1000 1500

f

PWM

R

PWM

t

RSTDIAG

– 20 60 kHz

5.0 95 %

100 200 400

t

OCH

1.0 10 20 µs

= 0.5 V with RL= 5.0 Ω resistive load.

OUT

= V

OUT

-0.5 V with RL= 5.0 Ω resistive load.

PWR

V/µs

V/µs

ns

ns

µs

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

Page 8

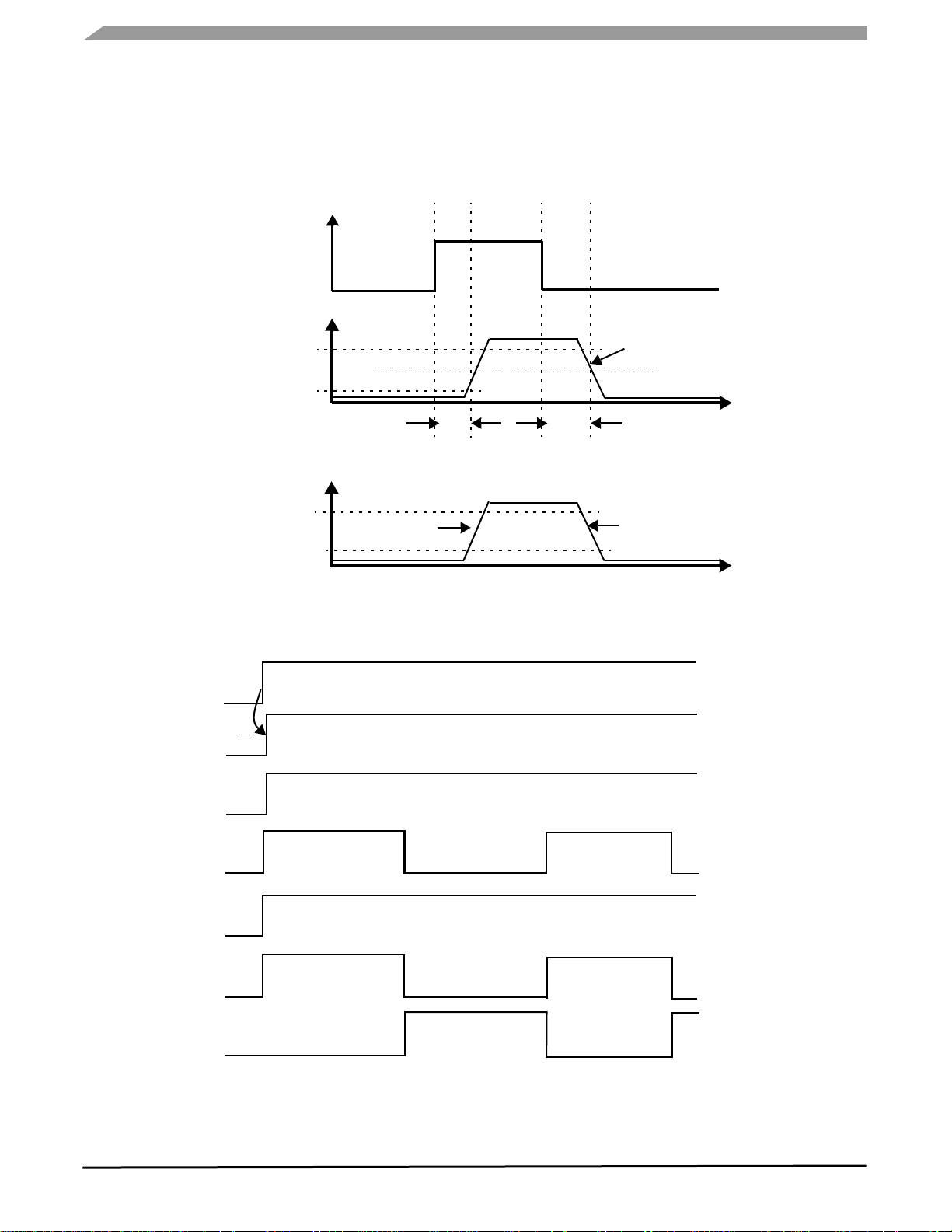

TIMING DIAGRAMS

STATIC ELECTRICAL CHARACTERISTICS

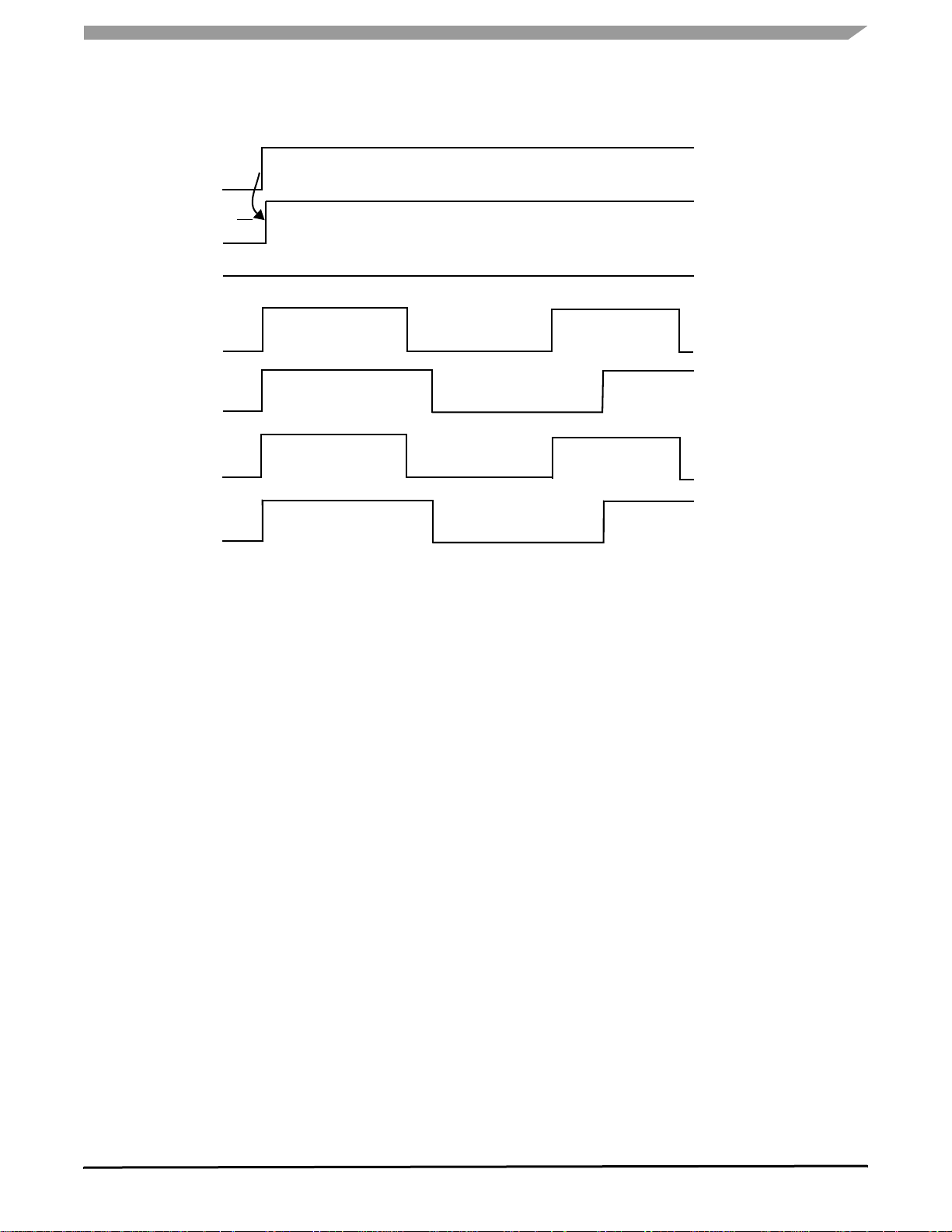

INHS

5.0 V

0.0 V

Vout

TIMING DIAGRAMS

V

PWR

90% Vout

EN

FS

- 0.5 V

0.5 V

Vout

10% Vout

t

After

ON

t

DLY(OFF)

SR

t

DLY(ON)

R

Figure 4. Time Delays Functional Diagrams

R

SR

PWM

F

50%V

PWR

5.0 V

CONF

INHS

INLS

OUT

GLS

Figure 5. Normal Mode, Cross-Conduction Management

33981

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

Page 9

EN

FS

t

ON

After

STATIC ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

CONF

INHS

INLS

OUT

GLS

High Side ON

High Side OFF

Figure 6. Normal Mode, Independent High Side a nd Low Side

0.0 V

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

Page 10

ELECTRICAL PERFORMANCE CURVES

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL PERFORMANCE CURVES

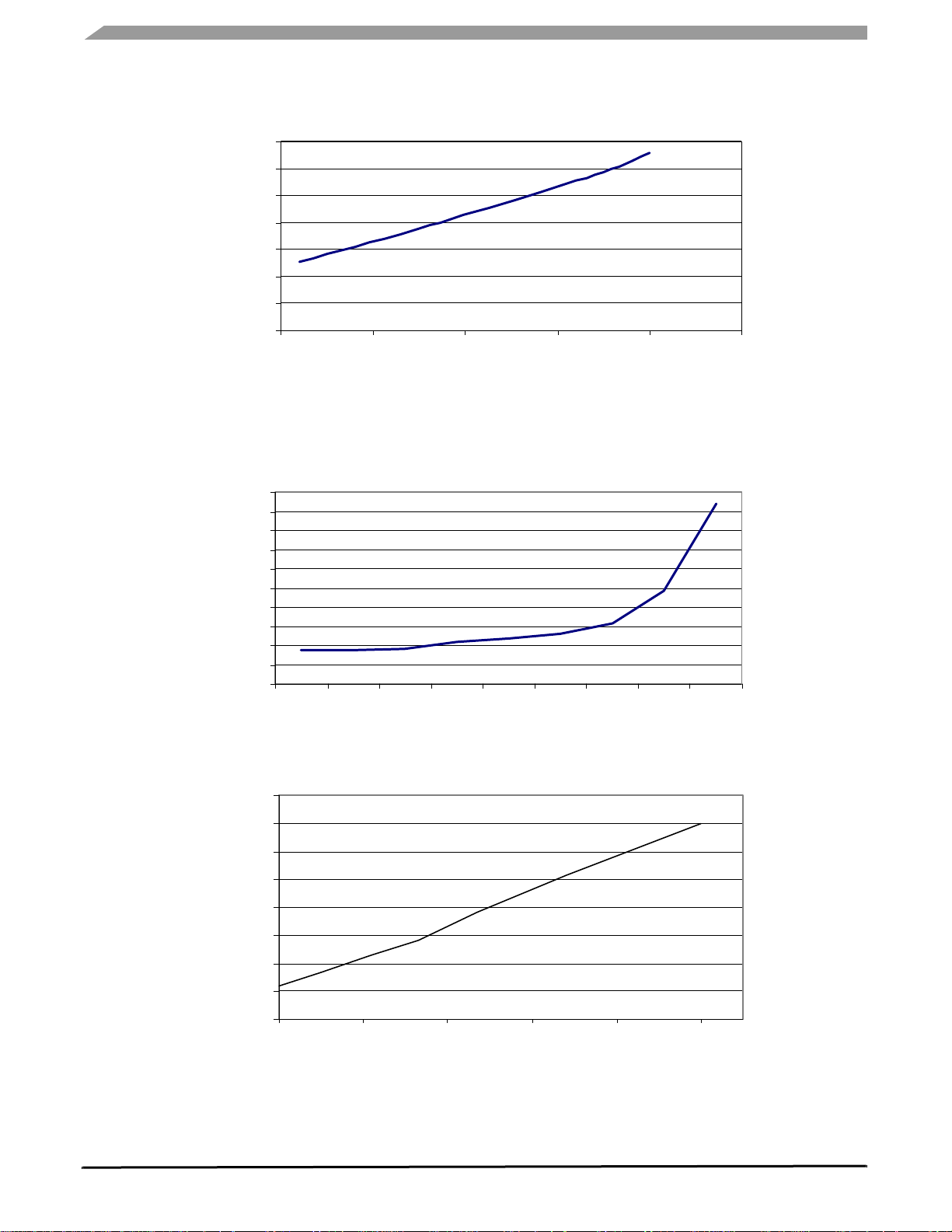

7.0

6.0

)

5.0

Ω

4.0

(m

3.0

DS(ON)

2.0

R

RdsON (mOh m)

1.0

0.0

-50 0 50 100 150 200

Temperature (°C)

Temperature (°C)

Figure 7. Typical R

vs. Temperature at V

DS(ON)

10.0

9.0

8.0

7.0

(µA)

6.0

5.0

4.0

3.0

PWR(SLEEP)

Ipwr(sleep)(µA)

I

2.0

1.0

0.0

4.5 6.0 9.0 12.0 12.5 13.0 14.0 17.0 21.0

V

Vpwr(V)

PWR

Figure 8. Typical Sleep State Supply Current vs. V

1600

1400

1200

1000

(V)

PWR

PWR

= 13 V

at 150°C

800

600

Vout Rise Time (ns)

400

200

0

0 2.0

4.0

6.0 8.0

10

SR Capacitor (nF)

Figure 9. V

33981

10 Freescale Semiconductor

Rise Time vs. SR Capacitor From 10% to 90% of V

OUT

at 25°C and V

OUT

Analog Integrated Circuit Device Data

PWR

= 13 V

Page 11

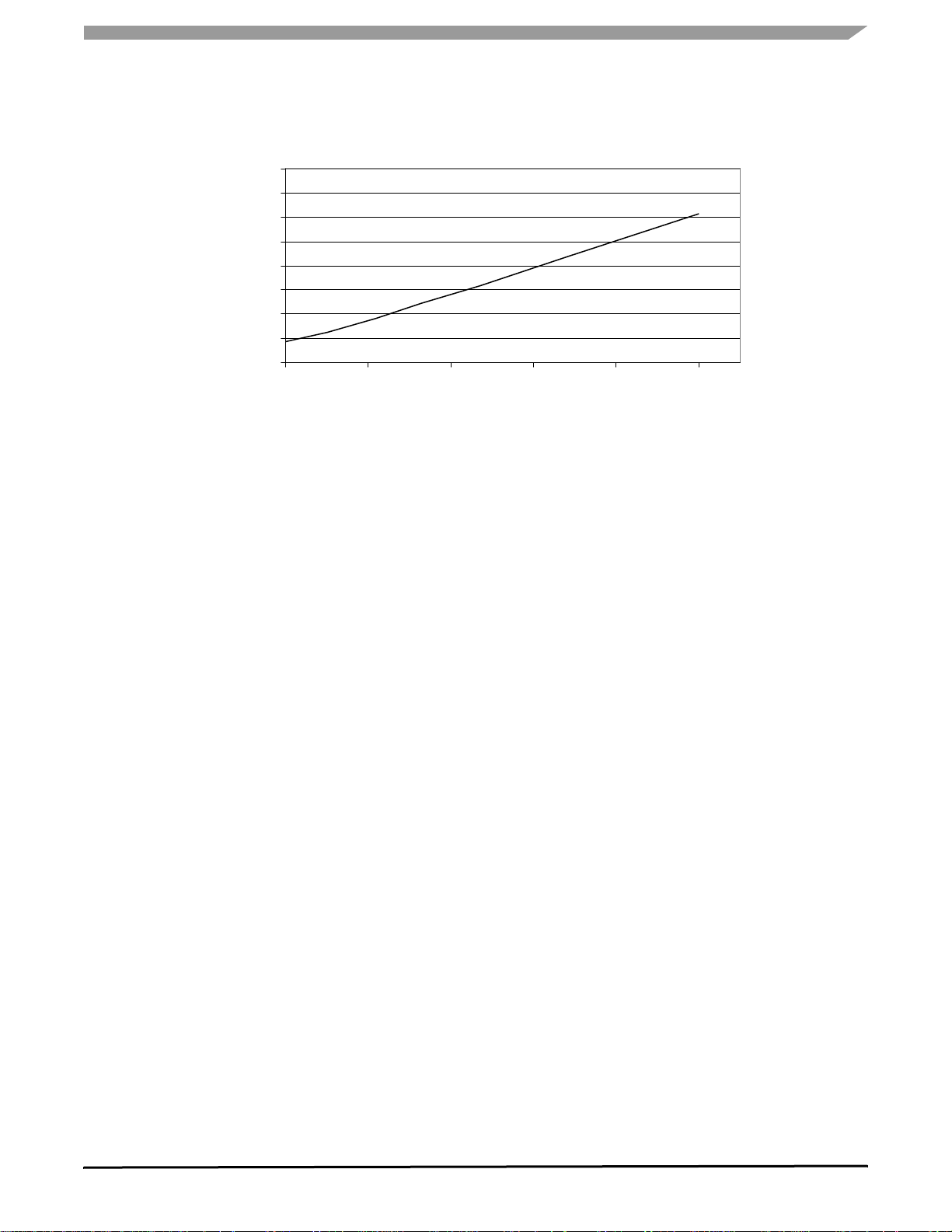

Vout Fall Time (ns)

1600

1400

1200

1000

800

600

400

200

0

0 2.0

ELECTRICAL PERFORMANCE CURVES

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL PERFORMANCE CURVES

4.0 6.0

SR Capacitor (nF)

8.0

10

Figure 10. V

Fall Time vs. SR Capacitor From 10% to 90% of V

OUT

at 25°C and V

OUT

PWR

= 13 V

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

Page 12

FUNCTIONAL DESCRIPTION

INTRODUCTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

The 33981 is a high-frequency self-protected silicon

4.0 mΩ R

electromechanical relays, fuses, and discrete devices in

power management applications. The 33981 can be

controlled by pulse-width modulation (PWM) with a frequency

up to 60 kHz. It is designed for harsh environments, and it

includes self-recovery features.

high-side switch used to replace

DS(ON)

FUNCTIONAL PIN DESCRIPTIONS

OUTPUT CURRENT MONITORING (CSNS)

This pin is used to output a current proportional to the highside OUT current and is used externally to generate a

ground-referenced voltage for the microcontroller (MCU) to

monitor OUT current.

TEMPERATURE FEEDBACK (TEMP)

This pin reports an analog value proportional to the

temperature of the GND flag (pin 13). It is used by the MCU

to monitor board temperature.

ENABLE [ACTIVE HIGH] (EN)

This is an input used to place the device in a low current

sleep mode. This pin has an active passive internal pulldown.

INPUT HIGH SIDE (INHS)

The input pin is used to directly control the OUT. This input

has an active internal pulldown current source and requires

CMOS logic levels.

FAULT STATUS (FS)

This pin is an open drain-configured output requiring an

external pullup resistor to V

When a device fault condition is detected, this pin is active

LOW.

(5.0 V) for fault reporting.

DD

INPUT LOW SIDE (INLS)

This input pin is used to directly control an external lowside N-channel MOSFET and has an active internal pulldown

current source and requires CMOS logic levels. It can be

controlled independently of the INHS depending of CONF

pin.

CONFIGURATION INPUT (CONF)

This input pin is used to manage the cross-conduction

between the internal high-side N-channel MOSFET and the

external low-side N-channel MOSFET. The pin has an active

internal pullup current source. When CONF is at 0 V, the two

The 33981 is suitable for loads with high inrush current, as

well as motors and all types of resistive and inductive loads.

A dedicated parallel input is available for an external low-side

control with protection features and cross-conduction

management.

MOSFETs are controlled independently. When CONF is at

5.0 V, the two MOSFETs cannot be on at the same time.

V

DD

LOW-SIDE OVERLOAD (OCLS)

This pin sets the VDS protection level of the external lowside MOSFET. This pin has an active internal pullup current

source. It must be connected to an external resistor.

DRAIN LOW SIDE (DLS)

This pin is the drain of the external low-side N-channel

MOSFET. Its monitoring allows protection features: low side

short protection and V

short protection.

PWR

LOW-SIDE GATE (GLS)

This pin is an output used to drive the gate of the external

low-side N-channel MOSFET.

SLEW RATE CONTROL (SR)

A capacitor connected between this pin and ground is

used to control the output slew rate.

BOOTSTRAP CAPACITOR (CBOOT)

A capacitor connected between this pin and OUT is used

to switch the OUT in PWM mode.

GROUND (GND)

This pin is the ground for the logic and analog circuitry of

the device.

POSITIVE POWER SUPPLY (VPWR)

This pin connects to the positive power supply and is the

source input of operational power for the device. The V

pin is a backside surface mount tab of the package.

PWR

OUTPUT (OUT)

Protected high-side power output to the load. Output pins

must be connected in parallel for operation.

33981

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

Page 13

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

The 33981 has 2 operating modes: Sleep and Normal

depending on EN input.

NORMAL MODE

The 33981 will go to the normal operating mode when the

EN pin is logic [1]. The INHS and INLS commands will be

SLEEP MODE

Sleep mode is the state of the 33981 when the EN is

disabled t

charge of the bootstrap capacitor.

after the EN transitions to logic [1] to enable the

ON

logic [0]. In this mode, OUT, the gate driver for the external

MOSFET, and all unused internal circuitry are off to minimize

current draw.

Table 5. Operating Modes

Condition CONF INHS INLS OUT GLS FS EN Comments

Sleep x x x x x H L

Normal L H H H H H H

Normal L L L L L H H

Normal L L H L H H H

Normal L H L H L H H

Normal H PWM H PWM PWM_bar H H

H = High level

L = Low level

x = Don’t care

PWM_bar = Opposite of pulse-width modulation signal.

Device is in Sleep mode. The OUT and low-side gate are OFF.

Normal mode. High side and low side are controlled

independently. The high side and the low side are both on.

Normal mode. High side and low side are controlled

independently. The high side and the low side are both off.

Normal mode. Half-bridge configuration. The high side is off

and the low side is on.

Normal mode. Half-bridge configuration. The high side is on

and the low side is off.

Normal mode. Cross-conduction management is activated.

Half-bridge configuration.

PROTECTION AND DIAGNOSTIC FEATURES

UNDERVOLTAGE

The 33981 incorporates undervoltage protection. In case

V

of

PWR<VPWR

supply rises to V

reset below

, the OUT is switched OFF until the power

V

(UV)

PWR

PWR

(UV)

(UV)

.

+V

PWR

. The latched fault are

(UVHYS)

offending load is removed. FS

disabled typically t ON after to enable the charge of the

bootstrap capacitor.

Overtemperature faults force the TEMP pin to 0 V.

pin transition to logic [1] will be

OVERCURRENT FAULT ON HIGH SIDE

OVERTEMPERATURE FAULT

The 33981 incorporates over temperature detection and

shutdown circuitry on OUT. Overtemperature detection also

protects the low-side gate driver (GLS pin). Overtemperature

detection occurs when OUT is in the ON or OFF state and

GLS is at high or low level.

For OUT, an over temperature fault condition results in

OUT turning OFF until the temperature falls below T

cycle will continue indefinitely until the offending load is

removed.

Figure 12, page 16 and Figure 18, page 20 show an

over temperature on OUT.

An over temperature fault on the low-side gate drive

results in OUT turning OFF and the GLS going to 0 V until the

temperature falls below T

. This cycle will continue until the

SD

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

SD

. This

The OUT pin has an overcurrent high-detection level

called I

for maximum device protection. If at any time the

OCH

current reaches this level, OUT will stay OFF and the CSNS

pin will go to 0 V. The OUT pin is reset (and the fault is

delatched) by a logic [0] at the INHS pin for at least t

RST(diag)

When INHS goes to 0 V, CSNS goes to 5.0 V.

Figure 16, page 19, the OUT pin is short-circuited to 0 V.

In

When the current reaches I

owing to internal logic circuit.

t

OCH

, OUT is turned OFF within

OCH

OVERLOAD FAULT ON LOW SIDE

This fault detection is active when INLS is logic [1]. Lowside overload protection does not measure the current

directly but rather its effects on the low-side MOSFET. When

33981

.

Page 14

FUNCTIONAL DEVICE OPERATION

PROTECTION AND DIAGNOSTIC FEATURES

V

DLS

> V

, the GLS pin goes to 0 V and the OCLS

OCLS

internal current source is disconnected and OCLS goes to

0 V. The GLS pin and the OCLS pin are reset (and the fault

is delatched) by a logic [0] at the INLS pin for at least

t

RST(diag)

. Figure 13, page 17 and Figure 14, page 18 illustrate the

behavior in case of overload on Low Side Gate driver.

When connected to an external resistor, the OCLS pin with

its internal current source sets the V

level. By changing

OCLS

the external resistance, the protection level can be adjusted

depending on low-side characteristics. A 33kΩ resistor gives

level of 3.3 V typical.

a V

DS

This protection circuitry measures the voltage between the

drain of the low side (DLS pin) and the 33981 ground (GND

pin). For this reason it is key that the low-side source, the

33981 ground, and the external resistance ground

connection are connected together in order to prevent false

error detection due to ground shifts.

The maximum OCLS voltage being 4.0V, a resistor bridge

on DLS must be used to detect a higher voltage across the

low side.

CONFIGURATION

The CONF pin manages the cross-conduction between

the internal MOSFET and the external low-side MOSFET.

With the CONF pin at 0 V, the two MOSFETs can be

independently controlled. A load can be placed between the

high side and the low side.

With the CONF pin at 5.0 V, the two MOSFETs cannot be

on at the same time. They are in half-bridge configuration as

shown in the simplified application diagram on page

1. If

INHS and INLS are at 5.0 V at the same time, INHS has

priority and OUT will be at V

. If INHS changes from 5.0 V

PWR

to 0 V with INLS at 5.0 V, GLS will go to high state as soon

as the V

of the internal MOSFET is lower than 2.0 V

GS

typically. A half-bridge application could consist in sending

PWM signal to the INHS pin and 5.0 V to the INLS pin with

the CONF pin at 5.0 V.

Figure 20, page 22, illustrates the simplified application

diagram on page

1 with a DC motor and external low side.

The CONF and INLS pins are at 5.0 V. When INHS is at

5.0 V, current is flowing in the motor. When INHS goes to 0 V,

the load current recirculates in the external low side.

BOOTSTRAP SUPPLY

Bootstrap supply provides current to charge the bootstrap

capacitor through the V

the application of power to the device to charge the bootstrap

capacitor. A typical value for this capacitor is 100 nF. An

internal charge pump allows continuous MOSFET drive.

When the device is in the sleep mode, this bootstrap supply

is off to minimize current consumption.

pin. A short time is required after

PWR

HIGH-SIDE GATE DRIVER

The high-side gate driver switches the bootstrap capacitor

voltage to the gate of the MOSFET. The driver circuit has a

low-impedance drive to ensure that the MOSFET remains

OFF in the presence of fast falling dV/dt transients on the

OUT pin.

This bootstrap capacitor connected between the power

supply and the C

pin provides the high pulse current to

BOOT

drive the device. The voltage across this capacitor is limited

to about 13 V typical.

An external capacitor connected between pins SR and

GND is used to control the slew ra te at the OU T pin.

and Figure 10, page 11 give Vout rise and fall time

page 10

Figure 9,

versus different SR capacitors.

LOW-SIDE GATE DRIVER

The low-side control circuitry is PWM capable. It can drive

a standard MOSFET with an R

frequency up to 60 kHz. The V

as low as 10.0 mΩ at a

DS(ON)

is internally clamped at

GS

12 V typically to protect the gate of the MOSFET. The GLS

pin is protected against short by a local over temperature

sensor.

THERMAL FEEDBACK

The 33981 has an analog feedback output (TEMP pin) that

provides a value in inverse proportion to the temperature of

the GND flag (pin 13). The controlling microcontroller can

“read” the temperature proportional voltage with its analogto- digital converter (ADC). This can be used to provide realtime monitoring of the PC board temperature to optimize the

motor speed and to protect the whole electronic system.

TEMP pin value is V

coefficient of DT

TFEED with a negative temperature

.

FEED

REVERSE BATTERY

The 33981 survives the application of reverse battery

voltage as low as -16 V. Under these conditions, the output’s

gate is enhanced to decrease device power dissipation. No

additional passive components are required. The 33981

survives these conditions until the maximum junction rating is

reached.

In the case of reverse battery in a half-bridge application,

a direct current passes through the external freewheeling

diode and the internal high-side.

As Figure 11

line. The proposed solution is an external N-channel low-side

with its gate tied to battery voltage through a resistor. A

high-side in the V

shows, it is essential to protect this power

line could be another solution.

PWR

33981

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

Page 15

PROTECTION AND DIAGNOSTIC FEATURES

FUNCTIONAL DEVICE OPERATION

V

DD

MCU

No current

V

PWR

GND

33981

OUT

If the DC motor module ground is disconnected from load

ground, the device protects itself and safely turns OFF the

output regardless of the output state at the time of

disconnection. A 10k resistor needs to be added between the

EN pin and the rest of the circuitry in order to ensure the

device turns off in case of ground disconnect and to prevent

exceeding this pin’s maximum ratings.

FAULT REPORTING

GROUND (GND) DISCONNECT PROTECTION

Diode

M

10.0 k

V

Ω

PWR

Figure 11. Reverse Battery Protection

Table 6. Functional Truth Table in Fault Mode

Conditions CONF INHS INLS OUT GLS FS EN TEMP CSNS OCLS Comments

Overtemperature

on OUT

Overtemperature

on GLS

Overcurrent

on OUT

Overload

on External Low-

Side MOSFET

H = High level

L = Low level

x = Don’t care

x x x L H L H L x x

x x x L L L H L x x

x H L L x L H x L x

L L H x L L H x x L

This 33981 indicates the faults below as they occur by

driving the FS pin to logic [0]:

• Overtemperature fault

• Overcurrent fault on OUT

• Overload fault on the external low-side MOSFET

The FS pin will return to logic [1] when the over

temperature fault condition is removed. The two other faults

are latched.

The 33981 is currently in fault mode.

The OUT is OFF. TEMP at 0 V

indicates this fault. Once the fault is

removed 33981 recovers its normal

mode.

The 33981 is currently in fault mode.

The OUT is OFF and GLS is at 0 V.

TEMP at 0 V indicates this fault. Once

the fault is removed 33981 recovers its

normal mode.

The 33981 is currently in fault mode.

The OUT is OFF. It is reset by a

logic [0] at INHS for at least

When INHS goes to 0 V, CSNS goes to

5.0 V.

The 33981 is currently in fault mode.

GLS is at 0 V and OCLS internal

current source is off. The external

resistance connected between OCLS

and GND pin will pull OCLS pin to 0 V.

The fault is reset by a logic [0] at INLS

for at least

t

RST(diag)

t

RST(diag)

.

.

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

Page 16

FUNCTIONAL DEVICE OPERATION

PROTECTION AND DIAGNOSTIC FEATURES

EN

CONF

INHS

INLS

OUT

GLS

FS

0.0 V

0.0 V

5.0 V

5.0 V

5.0 V

5.0 V

0.0 V

TEMP

Temperature

OUT

0.0 V

TSD

Hysteresis

Thermal Shutdown

on OUT

Figure 12. Overtemperature on Output

High Side ON

TSD

Hysteresis

Thermal Shutdown

on OUT

High Side OFF

33981

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

Page 17

PROTECTION AND DIAGNOSTIC FEATURES

FUNCTIONAL DEVICE OPERATION

EN

INLS

GLS

FS

OCLS

V

DS_LS

V

DS_LS = VOCLS

Overload on Low Side

0.0 V

Low Side OFF

0.0 V

t

RST(diag)

0.0 V

0.0 V

Case 1: Overload Removed

5.0 V

5.0 V

5.0 V

Figure 13. Overload on Low-Side Gate Drive, Case 1

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

Page 18

FUNCTIONAL DEVICE OPERATION

PROTECTION AND DIAGNOSTIC FEATURES

EN

5.0 V

INLS

OCLS

V

DS_LS

GLS

FS

0.0 V

0.0 V

Low Side OFF

t

RST(diag)

0.0 V

0.0 V

V

DS_LS = VOCLS

Case 2: Low Side Still Overloaded

Overload on Low Side

Figure 14. Overload on Low-Side Gate Drive, Case 2

33981

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

Page 19

EN

PROTECTION AND DIAGNOSTIC FEATURES

FUNCTIONAL DEVICE OPERATION

5.0 V

INHS

OUT

FS

CSNS

I

OUT

0.0 V

t

RST(diag)

0.0 V

0.0 V

VCL (CSNS)

0.0 V

I

OCH

Overcurrent on High Side

Figure 15. Overcurrent on Output

5.0 V

Fault Removed

Figure 16. High-Side Overcurrent

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

Page 20

FUNCTIONAL DEVICE OPERATION

PROTECTION AND DIAGNOSTIC FEATURES

Recirculation in Low SideCurrent in Motor

Figure 17. Cross-Conduction with Low Side

Overtemperature

INHS

TEMP

OUT

I

OUT

Figure 18. Overtemperature on OUT

33981

Analog Integrated Circuit Device Data

20 Freescale Semiconductor

Page 21

PROTECTION AND DIAGNOSTIC FEATURES

FUNCTIONAL DEVICE OPERATION

Figure 19. Maximum Operating Frequency for SR Capacitor of 4.7 nF

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

Page 22

TYPICAL APPLICATIONS

INTRODUCTION

TYPICAL APPLICATIONS

INTRODUCTION

Figure 20 shows a typical application for the 33981. A brush DC motor is connected to the output. A low-side gate driver is

used for the freewheeling phase. Typical values for external capacitors and resistors are given.

.

33981

VPWR

CBOOT

OUT

GND

V

DLS

GLS

PWR

330µF

100 nF

100 nF

M

V

PWR

V

DD

Voltage regulator

MCU

I/O

I/O

I/O

I/O

A/D

A/D

1.0 k

V

DD

33 k

SR

CONF

FS

INLS

EN

INHS

TEMP

CSNS

OCLS

Ω

1.0 k

Ω

2.2 nF

10 k

10 k

10 k

10 k

Ω

Ω

Ω

Ω

Ω

Figure 20. 33981 Typical Application Diagram

EMC AND EMI RECOMMENDATIONS

INTRODUCTION

This section relates the EMC capability for 33981, High

Frequency High-Current High-Side Switch. This device is a

self-protected silicon switch used to replace

electromechanical relays, fuses, and discrete circuits in

power management applications.

This section presents the key features of the device and its

targeted applications. The automotive standard to measure

conducted and radiated emissions is provided. Concrete

measurements on the 33981 and improvements to reduce

electromagnetic emission are described.

DEVICE FEATURES

This 33981 is a 4.0 mΩ self-protected, high-side switch

digitally controlled from a microcontroller (MCU) with

extended diagnostics, able to drive DC motors up to 60 kHz.

A bootstrap architecture has been used to provide fast

transient gate voltage in order to reach 4.0 mΩ R

maximum at room temperature. In parallel, a charge pump is

implemented to offer continuous on-state capability. This

dual current supply of the high-side MOSFET allows a duty

cycle from 5% to 100%. An external capacitor connected

between pins SR and GND is used to control the slew rate at

DS(ON)

the output and, therefore, reduce electromagnetic

perturbations.

In standard configuration, the motor current recirculation is

handled by an external freewheeling diode. To reduce global

power dissipation, the freewheeling diode can be replaced by

an external discrete MOSFET in low-side configuration . The

IC integrates a gate driver that controls and protects this

external MOSFET in the event of short circuit to battery. The

product manages the cross conduction between the internal

high side and the external low side when used in a half bridge

configuration. The two MOSFETs can be controlled

independently when the CONF pin is at 0 V. To eliminates

fuses, the device is self-protected from severe short-circuits

(100 A typical) with an innovative overcurrent strategy.

The 33981 has a current feedback for real-time monitoring

of the load current through an MCU analog/digital converter

to facilitate closed-loop operation for motor speed control.

The 33981 has an analog thermal feedback that can be

used by the MCU to monitor PC board temperature to

optimize the motor control and to protect the entire electronic

system. Therefore, an over temperature shutdown feature

protects the IC against high overload condition.

33981

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

Page 23

EMC AND EMI RECOMMENDATIONS

pp

y

m

TYPICAL APPLICATIONS

Figure 21 illustrates the typical application diagram.

Figure 21. Typical Application Diagram

APPLICATION

Engine cooling, air conditioning, and fuel pump are the

targeted automotive applications for the 33981. Conventional

solutions are designed with discrete components that are not

optimized in terms of component board size, protection, and

diagnostics. The 33981 is the right candidate to develop

lighter and more compact units.

DC motor speed adjustment allows optimization of energy

consumption by reducing supply voltage, hence the mean

voltage, applied to the motor. The commonly used control

technique is pulse wide modulation (PWM) where the

average voltage is proportional to the duty cycle. Most

applications require a PWM frequency of at least 20 kHz to

avoid audible noise. Figure 22

illustrates typical waveforms

when switching the 33981 at 20 kHz with a duty cycle of 80%.

The output voltage (OUT) and current in the motor (I

MOTOR

waveforms are represented.

OUT

Imotor (10A/div)

MC33981 OFF

MC33981 ON

Figure 22. Current and Voltage waveforms

HOW TO MEASURE ELECTROMAGNETIC

EMISSION ACCORDING TO THE CISPR25

One EMC standard in the automotive world (at system

level) is the CISPR25, edited by the International

Electrotechnical Commission. This standard describes the

measurement method to measure both conducted and

radiated emission.

CONDUCTED EMISSION MEASUREMENT

Conducted emission is the emission produced by the

device on the battery cable. The test bench is described by

CISPR25 (see Figure 23,

Test Bench for Conducted

Emission, on page 23).

The Line Impedance Stabilization Network (LISN), also

called Artificial Network (AN), in a given frequency range

(150 kHz to 108 MHz) provides a specified load impedance

for the measurement of disturbance voltages and isolates the

equipment under test (EUT) from the supply in that frequency

range.

Power Supply

BF Generator

Electrical to Optical

Converter

12V Power Supply

+

-

Contact to

Ground Plane

LISN

Load

Coaxial Cable

Spectrum Analyzer

200

+

m

200

0

Out

Non-Conductive

Material

High Side Driver Signal

Ground Plane in Copper

EUT

Figure 23. Test Bench for Conducted Emission

The EUT must operate under typical loading and other

conditions just as it must in the vehicle so maximum emission

)

state occurs. These operating conditions must be clearly

defined in the test plan to ensure that both supplier and

customer are performing identical tests.

For the testing described in this application note, the out

pin of the 33981 was connected to an inductive load (0.47 Ω

+ 1.0 mH) switching at 20 kHz with a duty cycle of 80%. The

output current was 17 A continuous.

The ground return of the EUT to the chassis must be as

short as possible. The power supply is 13.5 V.

RADIATED EMISSION MEASUREMENT

The radiated emission measurement consists of

measuring the electromagnetic radiation produced by the

equipment under test. CISPR 25 gives the schematic test

bench described in Figure 24,

Emission, on page 24.

To measure radiated emission over all frequency ranges,

several antenna types must be used:

• 0.15 MHz to 30 MHz: 1.0 m vertical monopole in vertical

polarization.

• 30 MHz to 200 MHz: a biconical antenna used in vertical

and horizontal polarization.

• 200 MHz to 1,000 MHz: a log-periodic antenna used in

vertical and horizontal polarization.

Test Bench for Radiated

Su

l

Ground

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

Page 24

TYPICAL APPLICATIONS

EMC AND EMI RECOMMENDATIONS

No SR capacitor is used. Therefore, the obtained

switching times are the maximum values. A capacitor of

1000 mF is connected between VPWR and GND.

Key

1 EUT (grounded locally if

required in test plan)

2 Test harness – –

3 Load simulator (placement

and ground connection)

4 Power supply (location

optional)

5 Artificial Network (AN) 12 Measuring instrument

6 Ground plane (bonded to

shielded enclosure)

7 Low relative permittivity

support (

ερ ≤ 1.4)

8 Biconical antenna

10 High quality double-

shielded coaxial cable

(50

Ω)

11 Bulkhead connector

13 RF absorber material

14 Stimulation and monitoring

system

Figure 24. Test Bench for Radiated Emission

EMC RESULTS AND IMPROVEMENTS

The 33981 OUT is connected to an inductive load (0.47 Ω

+ 1.0 mH) switching at 20 kHz with duty = 80%. The current

in the load was 17 A continuous.

BOARD SETUP

The initial configuration of our 33981 board is represented

in Figure 25.

Out

GND

33981

Figure 25.

33981 Initial Configuration

V

PWR

CONDUCTED MEASUREMENTS

TEST SETUP

To perform a conducted emission measurement in

accordance with the CISPR 25 standard, the test bench in

Figure 26,

developed.

Conducted Emission Test Setup, on page 24 was

Power Supply

LISN

Measurement

Point for

Conducted

Emission

EUT

Non-Conductive

Material

Load (1.0 mH + 0.47 Ω)

Optical PWM Signal

Figure 26. Conducted Emission Test Setup

EFFECTS OF SOME PARAMETERS

The conducted emissions level rise with the duty cycle.

When the duty increases the di/dt on the VPWR line is higher.

The device has to deliver more current and provide more

energy. Figure 27

on the V

PWR

level rises with the output frequency. This is due to the

increasing number of commutations.

33981

24 Freescale Semiconductor

describes the effect of duty cycle increase

current waveform. The conducted emission

Analog Integrated Circuit Device Data

Page 25

EMC AND EMI RECOMMENDATIONS

t

TYPICAL APPLICATIONS

Duty Cycle

I(t) on V

BAT

Increase

di/dt

Figure 27. VPWR Current

HOW TO REDUCE ELECTROMAGNETIC EMISSION

By adjusting the slew rate of the device during turn ON and

turn OFF with SR capacitor, the electromagnetic emissions

can be reduced.

Conductive emission tests were performed (taking care of

the board filtering and routing that have a big impact on EMC

performances).

An optimized solution was found by adding the following

external components to the initial board:

• PI filter on the V

• RC IN filter between V

series with a 100 nF capacitor

• RC Out filter between OUT and GND: a 4.7 Ω resistor

in series with a 100 nF capacitor

• Capacitor C1 of 10 nF between V

• Capacitor C2 of 10 nF between OUT and GND

• Capacitor C3 of 10 nF between OUT and V

• Capacitor SR of 3.3 nF

: 2 x 3 mF and 3.5 uH

PWR

and GND: a 2.0 Ω resistor in

PWR

PWR

and GND

PWR

di/dt

RC Out

Filter C2

RC In

Filter

C3

C1

SR

Figure 29. Enhanced Board

The chart in Figure 30

shows the spectrum of the

enhanced board and the initial board. The improvement is

appreciatively 15 dB to 20 dB in the all frequency range. The

enhanced board is now in accordance with the Class 3 limits

of the CISPR25 standard for conducted emission.

PI

Filter

C3 = 10 nF

PI filter

3.5 µH

BAT

V

3000 µF

RC In Filter

100 nF

2 Ω

OUT

33981

33891

SR

C1 = 10 nF

3.3 nF

GND

RC Out Filter

C2 = 10 nF

100 nF

4.7 Ω

Free Wheel Diode

Figure 28. 33981 with Filter

The EMC enhanced board with adapted value filter is

represented in Figure 29, Enhanced Board, on page 25.

Inductive Load

Figure 30. Conducted Emission Spectrum for 33981

RADIATED MEASUREMENTS

This test was performed in order to evaluate the

characteristic of the device relating to radiated emission.

Measurements have been done in accordance with the

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 25

Page 26

TYPICAL APPLICATIONS

POWER DISSIPATION

CISPR 25 standard as shown in Figure 31. The tested board

was the EMC enhanced board.

1.5 m Length

of Cable

Anechoic

Chamber

LISN and

Inductive Load

EUT

1 m Vertical

Monopole

Antenna

Figure 31. Radiated Emission Test Set Up

The results of these measurements are represented in

Figure 32. The enhanced board is in accordance with the

Class 3 limits of the CISPR25 standard for radiated emission.

CISPR

Class 3

Limits

33981

Emission

Figure 32. Radiated Emission Spectrum for 33981

CONCLUSION

This document explains how to measure conducted and

radiated emission in accordance with the automotive

CISPR25 standard. Measurements were performed on the

33981 in real application conditions when driving an inductive

load. An optimized filtering solution was put in place to have

the tested system in accordance with the Class 3 limits. The

same method can be used with other PC boards.

POWER DISSIPATION

INTRODUCTION

This section relates to the power dissipation capability for

33981, High Frequency High-Current High-Side Switch. This

device is a self-protected silicon switch used to replace

electromechanical relays, fuses, and discrete circuits in

power management applications.

This section presents the key features of the device and its

targeted applications. The theoretical calculations for power

dissipation and die junction temperatures are determined in

this document for inductive loads. A concrete example with

DC motor driven by the 33981 is analyzed in section DC

Motor 200 W.

DEVICE FEATURES

This 33981 is a 4.0 mΩ self-protected, high-side switch

digitally controlled from a microcontroller (MCU) with

extended diagnostics, able to drive DC motors up to 60 kHz.

A bootstrap architecture has been used to provide fast

transient gate voltage in order to reach 4.0 mΩ R

maximum at room temperature. In parallel, a charge pump is

implemented to offer continuous on-state capability. This

dual current supply of the high-side MOSFET allows a duty

cycle from 5% to 100%. An external capacitor connected

DS(ON)

between pins SR and GND is used to control the slew rate at

the output and, therefore, reduce electromagnetic

perturbations.

In standard configuration, the motor current recirculation is

handled by an external freewheeling diode. To reduce global

power dissipation, the freewheeling diode can be replaced by

an external discrete MOSFET in low-side configuration . The

IC integrates a gate driver that controls and protects this

external MOSFET in the event of short circuit to battery. The

product manages the cross conduction between the internal

high side and the external low side when used in a half bridge

configuration. The two MOSFETs can be controlled

independently when the CONF pin is at 0 V. To eliminates

fuses, the device is self-protected from severe short-circuits

(100 A typical) with an innovative overcurrent strategy.

The 33981 has a current feedback for real-time monitoring

of the load current through an MCU analog/digital converter

to facilitate closed-loop operation for motor speed control.

The 33981 has an analog thermal feedback that can be

used by the MCU to monitor PC board temperature to

optimize the motor control and to protect the entire electronic

system. Therefore, an over temperature shutdown feature

protects the IC against high overload condition.

33981

Analog Integrated Circuit Device Data

26 Freescale Semiconductor

Page 27

TYPICAL APPLICATIONS

POWER DISSIPATION

Figure 33 illustrates the typical application diagram.

Figure 33. Typical Application Diagram

APPLICATION

Engine cooling, air conditioning, and fuel pump are the

targeted automotive applications for the 33981. Conventional

solutions are designed with discrete components that are not

optimized in terms of component board size, protection, and

diagnostics. The 33981 is the right candidate to develop

lighter and more compact units.

The adjustment of the DC motor speed allows optimizing

of energy consumption. It is realized by chopping the supply

voltage, hence the mean voltage, applied to the motor. The

commonly used control technique is pulse wide modulation

(PWM) where the average voltage is proportional to the duty

cycle. Most applications require a PWM frequency of at least

20 kHz to avoid audible noise. Figure 34

waveforms when switching the 33981 at 20 kHz with a duty

cycle of 80%. The output voltage (OUT) and current in the

motor (I

) waveforms are represented.

MOTOR

illustrates typical

POWER DISSIPATION

The 33981 power dissipation is the sum of two kinds of

losses:

• On-State losses when device is fully ON,

• Switching losses when the device switches ON and

OFF.

The analysis that follows assumes an inductive load and

assumes that the current is constant in the load.

The case being considered in this paper is inductive load

and the hypothesis is that the current is constant in the load.

ON-STATE LOSSES

The mean on-state loss periods in the 33981 can be

calculated as follows:

Pon_state = a · R

DS(ON)

The critical parameter is the on resistance (R

increases with temperature. The 33981 has a maximum

R

at 25ºC of 4.0 mΩ and its deviation with temperature

DS(ON)

is only 1.7 as shown in Figure 35.

7

6

5

4

(mOhm)

3

DSON

2

R

1

0

-50 0 50 100 150 200

Figure 35. R

2

· I

where ‘a’ is the duty cycle.

OUT

Temperature (°C)

vs. Temperature

DS(ON)

DS(ON)

) that

SWITCHING LOSSES

OUT

Imotor (10A/div)

MC339 81 OFF

MC33981 ON

Figure 34. Current and Voltage waveforms

Analog Integrated Circuit Device Data

Freescale Semiconductor 27

The mean switching losses in the 33981 can be calculated

as follows:

Pswitching = (tON . F

V

PWR

where tON/t

is the turn on/off time.

OFF

. I

REQ

OUT

. V

) / 2

PWR

. I

OUT

) / 2 + (t

OFF

. F

REQ

.

The switching time is a critical parameter. The 33981

provides adjustable slew rates through an external capacitor

(SR) that slow down the rise and fall times to reduce the

electromagnetic emissions. However, this adjustment will

have an impact on power dissipation. Figure 36

positive (SR

) and negative (SRF) slew rate versus different

R

gives the

values of SR. This is illustrated in Figure 37.

33981

Page 28

TYPICAL APPLICATIONS

POWER DISSIPATION

120

100

80

60

SRr(V/µ s)

40

20

0

4.56 91427

Vbat

0

1

2.2

3.3

4.7

6.8

the freewheeling diode can be replaced by an external lowside discrete MOSFET.

The power dissipation during the recirculation phase is

calculated as follows for the diode and the low-side MOSFET

respectively:

Pdiode = (1-a) . V

. I

F

OUT

where ‘a’ is the duty cycle

. I

OUT

2

where R

Pmosfet_ls = (1-a) . R

DS(ON)_ls

is the on resistance of the low side.

DS(ON)_ls

APPLICATIONS EXAMPLES

90

80

70

60

50

40

SRf(V/µs)

30

20

10

0

4.5 6 9 14 27

Vbat

Figure 36. Positive and Negative Slew Rate

vs. SR Capacitor

0

1

2.2

3.3

4.7

6.8

EXCEL TOOL

An excel tool has been created with all the above formulas

to calculate the dissipated power and the junction

temperature knowing the application conditions. An example

of the interface is given in Figure 38

concern the load, the high-side device, the recirculation, and

the board. They are V

, DC current in the load (Imax for

PWR

100% of duty cycle), PWM frequency, 33981 R

150ºC, SR capacitor, low-side R

temperature, and thermal impedance.

Load

Vpwr

Imax

INPUTS

Frequency

R

DSON

High Side

Device (HS)

@150°C

SR

Capacitor

Low Side Characteristics

Recirculation

R

DSON

@150°C

. The parameters to enter

at 150ºC, ambient

DS(ON)

12

V

20

A

20

KHz

6.8 mOhm

0

nF

20

mOhm

DS(ON)

at

Figure 37. OUT switching vs. SR Capacitor

Board

T ambiant

15

85

°C/W

°C

Rthja

JUNCTION TEMPERATURE

The junction temperature of the 33981 can be calculated

knowing the power dissipation and the thermal

characteristics of the PC board with this formula:

= TA + (Pon_state + Pswitching). R

T

J

THJA

where TJ is the junction temperature, TA the ambient

temperature, and R

the thermal impedance junction to

THJA

ambient.

RECIRCULATION PHASE

The calculations are done with the maximum R

the 33981 and the low side. The current is also considered

constant in the load. The model taken for the V

is (0.4 + 0.01 . I

The listed conditions in Figure 38 are the ones chosen for

the entire document.

In standard configuration, the motor current recirculation is

handled by an external freewheeling diode. With the 33981,

33981

28 Freescale Semiconductor

Figure 38. Excel Tool

) Volts.

OUT

Analog Integrated Circuit Device Data

for

DS(ON)

of the diode

F

Page 29

TYPICAL APPLICATIONS

POWER DISSIPATION

DC MOTOR 200 W

A concrete example is the 33981. A 200 W DC motor, a

frequency of 20 kHz, and an ambient temperature of 85ºC are

chosen. The 33981 is evaluated using the following board.

The thermal impedance of the board is in the range of

15ºC/W.

Figure 39. 33981 Evaluation Board

POWER DISSIPATION

Figure 40 illustrates the power dissipation in the 33981.

The conditions are listed in Figure 38. Maximum power

dissipation of 3.1 W is obtained with a duty of 95%.

3.5

3.0

2.5

2.0

1.5

1.0

MC33981 Power Dissipation (W)

0.5

0

0

10 20 30 40 50 60 70 80 90 100

MC33981 Power Dissipation

Pon_state

P switching

Ptotal

Duty Cycle (%)

Figure 40. Power Dissipation (Pon and Pswitching) vs.

Duty Cycle

INFLUENCE OF SR CAPACITOR

The SR capacitor value has an impact on these switching

losses. Figure 41

illustrates the percentage of the switching

losses versus the total power dissipation for the same load

conditions as Figure 38. The higher the SR capacitor value,

the higher the switching losses. They can be more than 50%

of the total power dissipation in the 33981 with a 4.7 nF

capacitor and is a basic applications trade-off. A compromise

should be found between the power dissipation and the

electromagnetic capability (EMC) performance.

6

6

5

5

4

4

3

3

2

2

Power Dissipation (W)

Power Dissipation (W)

1

1

0

0

02.23.34.7

02.23.34.7

Pswitching

Pswitching

Pon

Pon

Csr (nF)

Csr (nF)

Figure 41. Power Switching vs. SR Capacitor

RECIRCULATION PHASE

Figure 42 illustrates the power dissipation for the two

recirculation approaches, diode or low-side MOSFET. The

power dissipation gain for the entire system when using the

low side instead of the diode can reach up to 1.5 W with a

duty cycle of 50%.

Total Board Power Dissipation

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Power Dissipation (W)

0.5

0.0

0 10 20 30 40 50 60 70 80 90 100

Ratio PWM %

Power HS

Power Diode

Power Total Board with Diode

Power LS

Power Total Board with LS

Figure 42. Total Board Power Dissipation

JUNCTION TEMPERATURE

The junction temperature of the 33981 versus duty cycle

for the condition listed in Figure 38, is given in Figure 43. The

maximum obtained junction temperature is 132ºC with a duty

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 29

Page 30

TYPICAL APPLICATIONS

POWER DISSIPATION

cycle of 95%. This value is far from the 150ºC maximum

guaranteed junction.

140.00

120.00

100.00

80.00

60.00

40.00

Junction Tempera tur e (°C)

20.00

0.00

0 10 20 30 40 50 60 70 80 90 100

Duty cycle (%)

Figure 43. Junction Temperature vs. Duty Cycle

CONCLUSION

Knowing the application conditions, this document

explained how to calculate power dissipation during on-state

and switching phases and the junction temperature for the

33981 when controlling a DC motor. A concrete example with

a 200 W DC motor was given in section DC Motor 200 W. The

same principle can be used for other DC motor and other

environmental conditions.

33981

Analog Integrated Circuit Device Data

30 Freescale Semiconductor

Page 31

SOLDERING INFORMATION

PACKAGING

PACKAGING

SOLDERING INFORMATION

The 33981 is not designed for immersion soldering. The maximum peak temperature during the soldering process should not

exceed 245oC. Pin soldering limit is for 10 seconds maximum duration. Exceeding these limits may cause malfunction or

permanent damage to the device.

PACKAGING DIMENSIONS

For the most current package revision, visit www.freescale.com and perform a keyword search using “98ARL10521D”.

PNA SUFFIX

16-PIN PQFN

PLASTIC PACKAGE

98ARL10521D

ISSUE C

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 31

Page 32

PACKAGING

PACKAGING DIMENSIONS

PNA SUFFIX

16-PIN PQFN

PLASTIC PACKAGE

98ARL10521D

ISSUE C

33981

Analog Integrated Circuit Device Data

32 Freescale Semiconductor

Page 33

ADDITIONAL DOCUMENTATION

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM (REV 2.0)

THERMAL ADDENDUM (REV 2.0)

33981

INTRODUCTION

This thermal addendum is provided as a supplement to the 33981 technical

datasheet. The addendum provides thermal performance information that may be

critical in the design and development of system applications. All electrical,

application, and packaging information is provided in the datasheet.

16-PIN

PQFN

PACKAGING AND THERMAL CONSIDERATIONS

This package is a dual die package. There are two heat sources in the package

independently heating with P1 and P2. This results in two junction temperatures,

TJ1 and TJ2, and a thermal resistance matrix with Rθ

For m, n = 1, Rθ

is the thermal resistance from Junction 1 to the reference

JA11

temperature while only heat source 1 is heating with P

For m = 1, n = 2, Rθ

is the thermal resistance from Junction 1 to the

JA12

reference temperature while heat source 2 is heating with P2. This applies to

Rθ

and Rθ

J21

respectively.

J22,

T

J1

=

T

J2

R

R

θJA11

θJA21

R

R

θJA12

θJA22

P

1

.

P

2

The stated values are solely for a thermal performance comparison of one package to another in a standardized environment.

This methodology is not meant to and will not predict the performance of a package in an application-specific environment. Stated

values were obtained by measurement and simulation according to the standards listed below.

JAmn

1

.

.

PNA SUFFIX

98ARL10521D

16-PIN PQFN

12 MM X 12 MM

Note For package dimensions, refer to

the 33981 device datasheet.

STANDARDS

Table 7. Thermal Performance Comparison

Thermal

Resistance

(1), (2)

Ρ

θJAmn

(2), (3)

Ρ

θJBmn

(1), (4)

Ρ

θJAmn

(5)

Ρ

θJCmn

Notes

1. Per JEDEC JESD51-2 at natural convection, still air

condition.

2. 2s2p thermal test board per JEDEC JESD51-7and

JESD51-5.

3. Per JEDEC JESD51-8, with the board temperature on the

center trace near the power outputs.

4. Single layer thermal test board per JEDEC JESD51-3 and

JESD51-5.

5. Thermal resistance between the die junction and the

exposed pad, “infinite” heat sink attached to exposed pad.

1 = Power Chip, 2 = Logic Chip [°C/W]

m = 1,

n = 1

22 18 41

7.0 4.0 27

62 48 81

<1.0 0.0 1.0

m = 1, n = 2

m = 2, n = 1

m = 2,

n = 2

0.2 mm spacing

between PCB pads

0.2 mm spacing

between PCB pads

Note: Recommended via diameter is 0.5 mm. PTH (plated through

hole) via must be plugged / filled with epoxy or solder mask in order

to minimize void formation and to avoid any solder wicking into the

via.

Figure 44. Surface mount for power PQFN

with exposed pads

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 33

Page 34

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM (REV 2.0)

Transparent Top View

CBOOT

SR

GLS

CONF

OCLS

DLS

INLS

FS

INHS

EN

CSNS

TEMP

98765

11

10

12

GND

13

VPWR

14

33981 Pin Connections

16-Pin PQFN

0.90 mm Pitch

12.0 mm x 12.0 mm Body

with exposed pads

4

1

3

2

A

1615

OUTOUT

Figure 45. Thermal Test Board

Device on Thermal Test Board

Material: Single layer printed circuit board

FR4, 1.6 mm thickness

Cu traces, 0.07 mm thickness

Outline: 80 mm x 100 mm board area,

including edge connector for thermal

testing

Area A: Cu heat-spreading areas on board

surface

Ambient Conditions: Natural convection, still air

Table 8. Thermal Resistance Performance

Thermal

Resistance

Ρ

θJAmn

R

JA

θ

Area A

(mm

300 47 37 73

600 43 34 70

is the thermal resistance between die junction and

1 = Power Chip, 2 = Logic Chip (°C/W)

2

066 51 84

m = 1,

)

n = 1

m = 1, n = 2

m = 2, n = 1

ambient air.

m = 2,

n = 2

This device is a dual die package. Index m indicates the

die that is heated. Index n refers to the number of the die

where the junction temperature is sensed.

33981

Analog Integrated Circuit Device Data

34 Freescale Semiconductor

Page 35

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM (REV 2.0)

90

80

70

60

50

40

R

x

θ

30

20

10

Thermal Resistance [ºC/W]

JA11

R

θ

JA22

R

=R

θ

JA12

θ

JA21

0

0 300 600

Heat spreading area A [mm²]

Figure 46. Device on Thermal Test Board R

100

10

1

Therm al Res is tance [ºC/W]

0.1

1.00E-03 1.00E -02 1.00E-01 1.00E+ 00 1.00E+ 01 1.00E+ 0 2 1.00E+03 1.00E +04

Time[s]

Figure 47. Transient Thermal Resistance R

1W Step response,Device on Thermal Test Board Area A = 600 (mm

x

θJA

θ

JA

R

θ

JA11

R

θ

JA22

R

=R

θ

JA12

θ

JA21

,

2

)

33981

Analog Integrated Circuit Device Data

Freescale Semiconductor 35

Page 36

REVISION HISTORY

REVISION HISTORY

REVISION DATE DESCRIPTION OF CHANGES

3.0

4.0

5.0

6.0

1/2006

3/2006

7/2006

5/2007

• Implemented Revision History page

• Made content updates and changes

• Converted to Freescale format

• Added Thermal Addendum

• Made minor content changes to pages 6 and 7.

• Updated to Product Preview status

• Changed Part Number from PC33981PNA to MC33981BPNA (page 1)

• Changed Electrical Characteristics, Maximum Ratings, Table 2, Maximum Ratings,

Electrical Ratings, OCLS Voltage, from “-5.0 to 5.0” to “-5.0 to 7.0” (page 4

• Changed Electrical Characteristics, Static Electrical Characteristics, Table 3, Static

Electrical Characteristics, Low Side Gate Driver (VPWR, VGLS, VOCLS), Low-Side

Overload Detection Level versus Low-Side Drain Voltage Minimum, from “-75” to “-50”

and Maximum from “+75” to “+50” (page 6).

• Changed Electrical Characteristics, Dynamic Electrical Characteristics, Table 4,

Dynamic Electrical Characteristics, Control Interface and Power Output Timing

(CBOOT, VPWR), Input Switching Frequency, Minimum from “20” to “-” and Typical from

“-” to “20” (page 7).

• Updated to Advanced status

• Changed CSNS Input Clamp Current in MAXIMUM RATINGS

• Changed Figure 11,

Reverse Battery Protection

• Removed unnecessary line in Figure 14, Overload on Low-Side Gate Drive, Case 2

• Corrected label in Figure 28, 33981 with Filter

).

33981

Analog Integrated Circuit Device Data

36 Freescale Semiconductor

Page 37

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits base d on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application o r use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheet s and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconduct or product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fee s arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

MC33981

Rev. 6.0

5/2007

Loading...

Loading...