Freescale Semiconductor

Technical Data

Single Gauge Driver

Document Number: MC33977

Rev. 2.0, 1/2007

The 33977 is a Serial Peripheral Interface (SPI) Controlled, stepper

motor gauge driver Integrated Circuit (IC). This monolithic IC consists

of a dual H-Bridge coil driver and its associated control logic. The HBridge drivers are used to automatically control the speed, direction,

and magnitude of current through the coils of a two-phase

instrumentation stepper motor, similar to an MMT-licensed AFIC 6405

of Switec MS-X156.xxx motor.

The 33977 is ideal for use in instrumentation systems requiring

distributed and flexible stepper motor gauge driving. The device also

eases the transition to stepper motors from air core motors by

emulating the damped air core pointer movement.

Features

• MMT-Licensed Two-Phase Stepper Motor Compatible

• Switec MS-X15.xxx Stepper Motor Compatible

• Minimal Processor Overhead Required

• Fully Integrated Pointer Movement and Position State Machine

with Air Core Movement Emulation

• 4096 Possible Steady State Pointer Positions

• 340° Maximum Pointer Sweep

• Maximum Acceleration of 4500°/s

2

• Maximum Pointer Velocity of 400°/s

• Analog Microstepping (12 Steps/Degrees of Pointer Movement)

• Pointer Calibration and Return to Zero (RTZ)

• Controlled via 16-Bit SPI Messages

• Internal Clock Capable of Calibration

• Low Sleep Mode Current

• Pb-Free Packaging Designated by suffix code EG

SINGLE GAUGE DRIVER

ORDERING INFORMATION

Device

MC33977DW/R2

MCZ33977EG/R2

33977

DW SUFFIX

EG SUFFIX (Pb-FREE)

98ASB42344B

24-PIN SOICW

Temperature

Range (T

- 40°C to 125°C 24 SOICW

)

A

Package

V

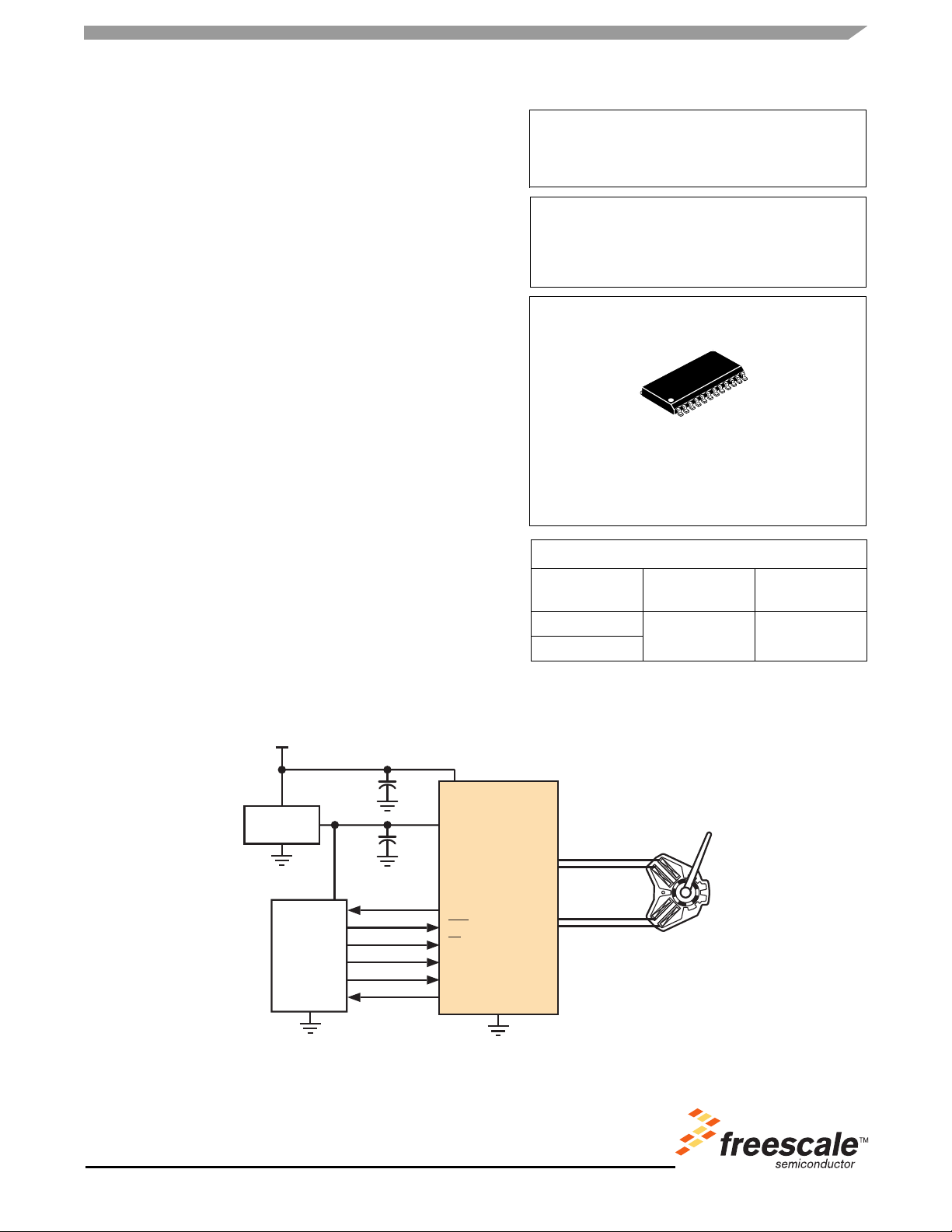

PWR

33977

V

5.0 V

DD

Regulator

MCU

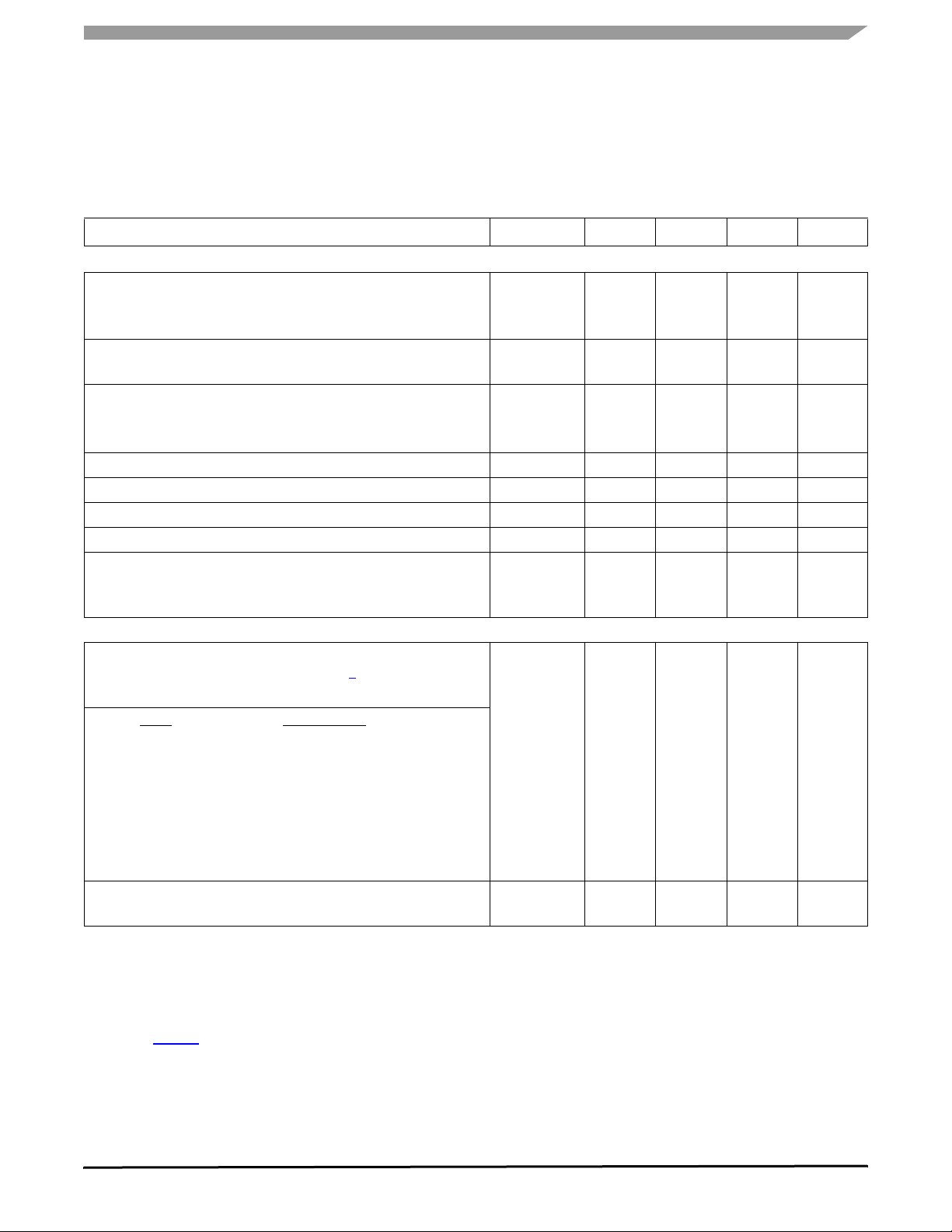

Figure 1. 33977 Simplified Application Diagram

Freescale Semiconductor, Inc. reserves the right to change the detail specifications,

as may be required, to permit improvements in the design of its products.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

VPWR

VDD

RTZ

RST

CS

SCLK

SI

SO

GND

SIN+

SIN-

COS+

COS-

Motor

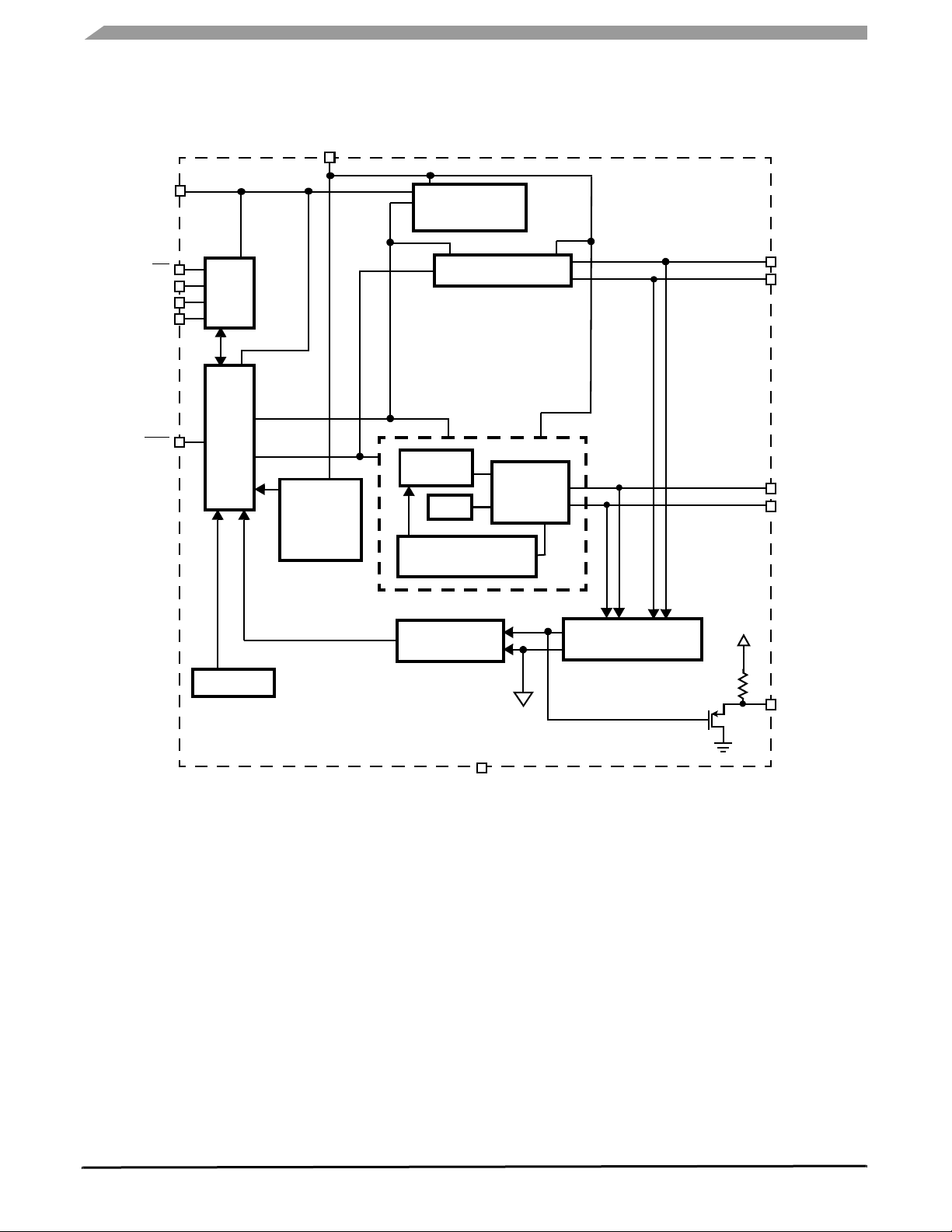

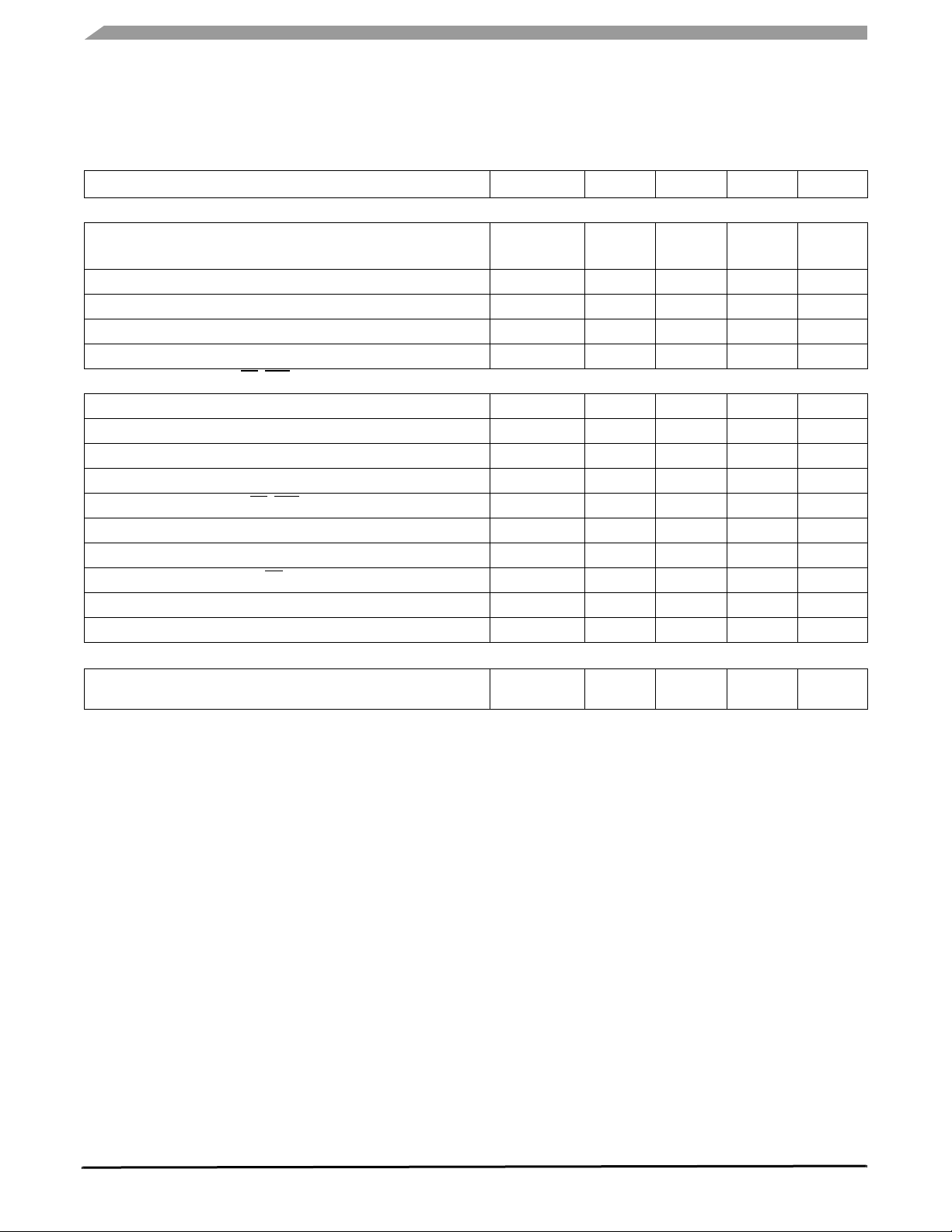

INTERNAL BLOCK DIAGRAM

INTERNAL BLOCK DIAGRAM

VPWR

VDD

CS

SCLK

SO

RST

INTERNAL

REGULATOR

COS

SPI

SI

LOGIC

UNDER

-

AND

OVERVOLTAGE

DETECT

STATE

MACHINE

ILIM

OVERTEMPERATURE

DETECT

SIGMA-DELTA

ADC

H-BRIDGE

AND

CONTROL

SIN

VDD

MULTIPLEXER

COS+

COS-

SIN+

SIN-

OSCILLATOR

AGND

GND (8)

Figure 2. 33977 Simplified Internal Block Diagram

RTZ

33977

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

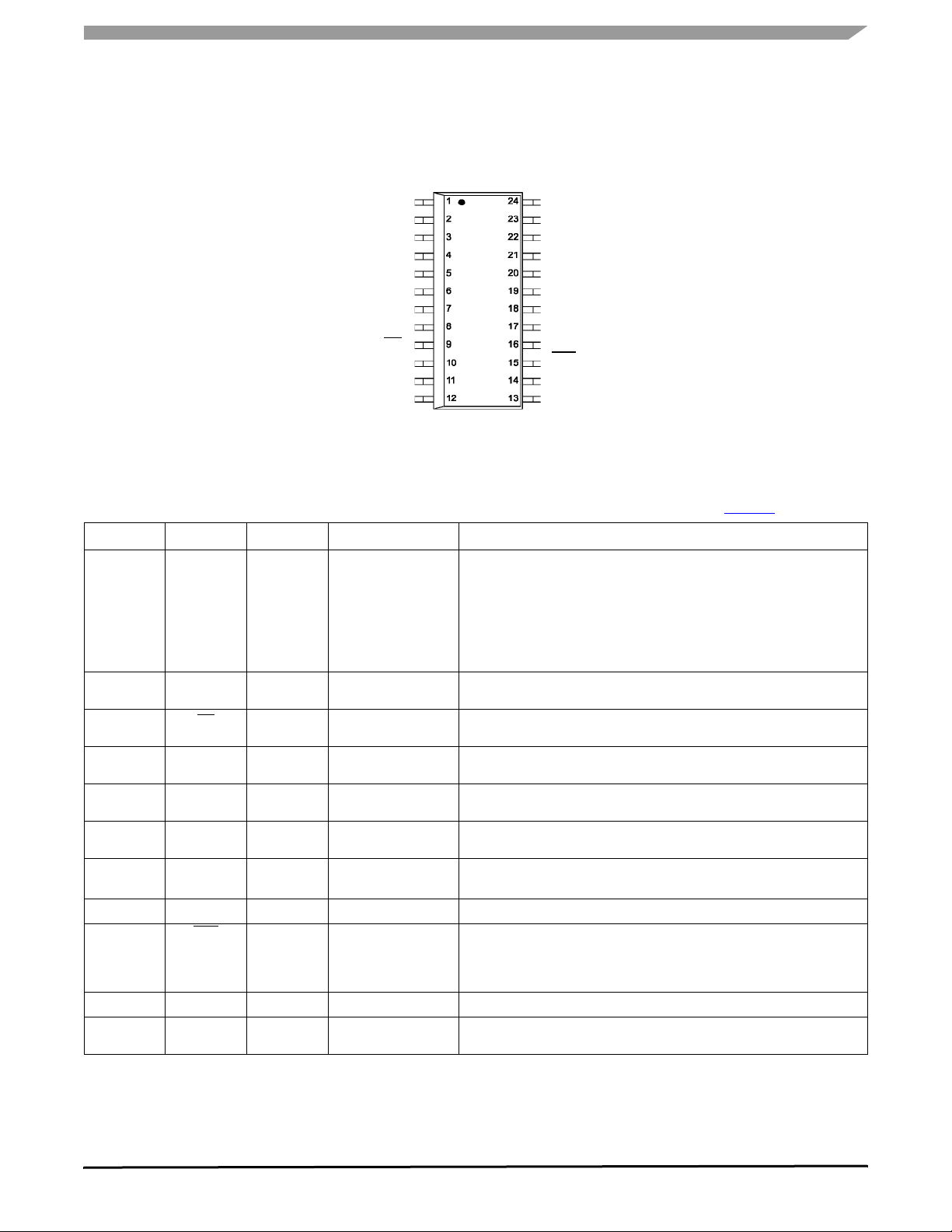

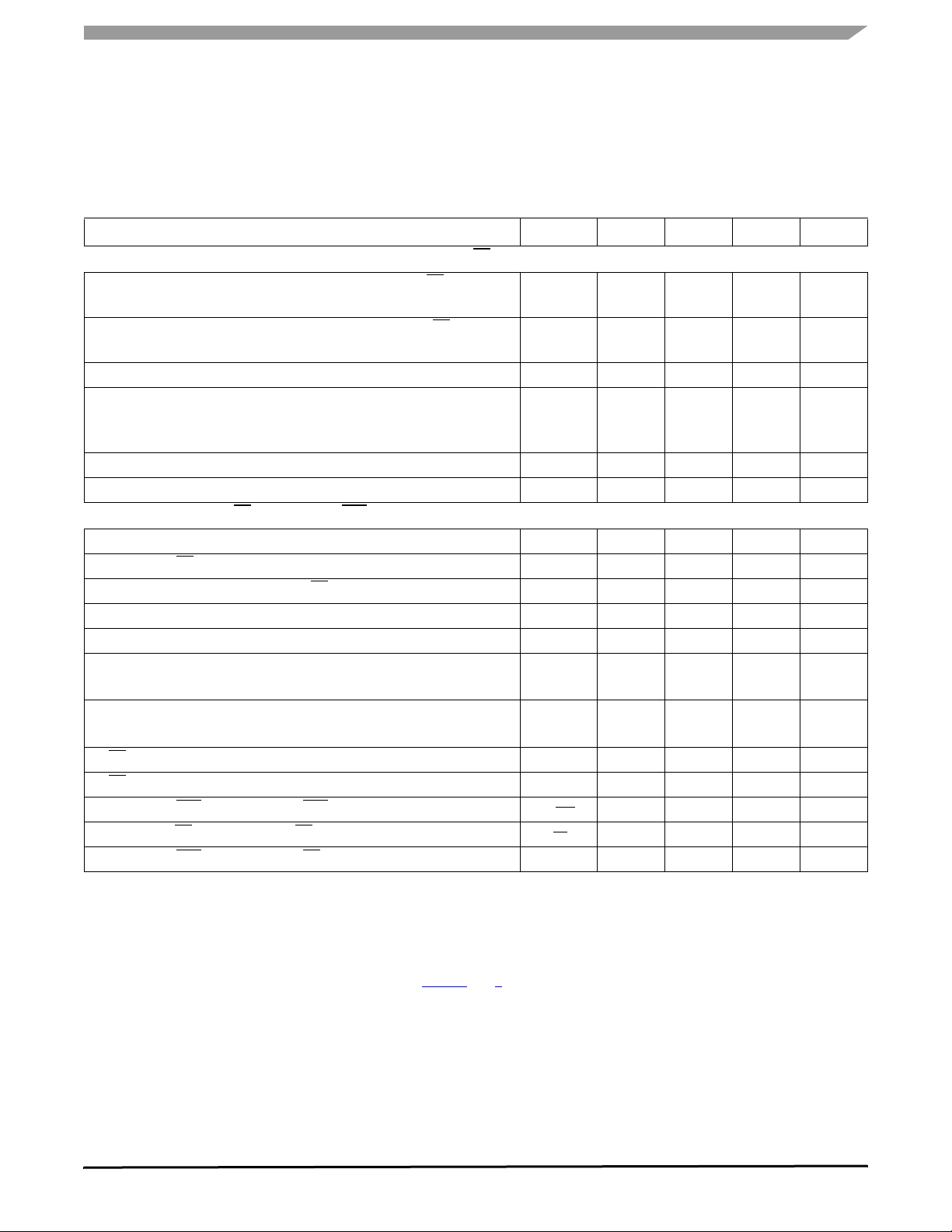

PIN CONNECTIONS

PIN CONNECTIONS

COS+

COS-

SIN+

SINGND

GND

GND

GND

CS

SCLK

SO

SI

NC

NC

NC

NC

GND

GND

GND

GND

VPWR

RST

VDD

RTZ

Figure 3. 33977 Pin Connections

Table 1. 33977 Pin Definitions

A functional description of each pin can be found in the Functional Pin Descri ption section beginning onpage 10.

Pin Pin Name Pin Function Formal Name Definition

1

2

3

4

5 to 8,

17 to 20

9

10 SCLK

11 SO

12

13 RTZ

14 VDD

15 RST

16 VPWR

21, 22, 23, 24

(MS Motor

Pin #)

COS+ (MS #4)

COS- (MS #3)

SIN+ (MS #1)

SIN- (MS #2)

GND

CS

SI

NC

Output

N/A

Input

Input

Output

Input

Multiplexed

Output

Input

Input

Input

–

H-Bridge Outputs 0 Each pin is the output of a half-bridge, designed to source or sink current.

Ground Ground pins

Chip Select This pin is connected to a chip select output of a Large Scale Integration

(LSI) Master IC and controls which device is addressed.

Serial Clock This pin is connected to the SCLK pin of the master device and acts as a

bit clock for the SPI port.

Serial Output This pin is connected to the SPI Serial Data Input pin of the Master device

or to the SI pin of the next device in a daisy chain.

Serial Input This pin is connected to the SPI Serial Data Output pin of the Master

device from which it receives output command data.

Return to Zero This is a multiplexed output pin for the non-driven coil, during a Return to

Zero (RTZ) event.

Voltage This SPI and logic power supply input will work with 5.0 V supplies.

Reset This pin is connected to the Master and is used to reset the device, or

place it into a sleep state by driving it to Logic [1]. When this pin is driven

to Logic [0], all internal logic is forced to the default state. This input has

an internal active pull-up.

Battery Voltage Power supply

No Connect These pins are not connected to any internal circuitry, or any other pin,

and may be connected to the board where convenient.

33977

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

Power Supply Voltage

Steady-State

Input Pin Voltage

SIN± COSI± Continuous Current Per Output

ESD Voltage

(1)

(2)

(3)

Human Body Model (HBM)

Machine Model (MM)

Charge Device Model (CDM)

THERMAL RATINGS

Operating Temperature

Ambient

Junction

Storage Temperature T

Thermal Resistance

Junction-to-Ambient

Junction-to-Lead

Peak Package Reflow Temperature During Reflow

(4), (5)

Notes

1. Exceeding voltage limits on Input pins may cause permanent damage to the device.

2. Output continuous output rating so long as maximum junction temperature is not exceeded. Operation at 125°C ambient temperature

will require maximum output current computation using package thermal resistances.

3. ESD testing is performed in accordance with the Human Body Model (HBM) (C

(C

ZAP

= 200 pF, R

= 0 Ω), and the Charge Device Model (CDM).

ZAP

4. Pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may

cause malfunction or permanent damage to the device.

5. Freescale’s Package Reflow capability meets Pb-free requirements for JEDEC standard J-STD-020C. For Peak Package Reflow

Temperature and Moisture Sensitivity Levels (MSL),

Go to www.freescale.com, search by part number [e.g. remove prefixes/suffixes and enter the core ID to view all orderable parts. (i.e.

MC33xxxD enter 33xxx), and review parametrics.

V

PWRSS

V

IN

I

OUTMAX

V

ESD

T

A

T

J

STG

R

ΘJA

R

ΘJL

T

PPRT

= 100 pF, R

ZAP

-0.3 to 41

-0.3 to 7.0 V

40 mA

±2000

±2000

±200

-40 to 125

-40 to 150

-55 to 150 °C

°C/W

60

20

Note 5

= 1500 Ω), the Machine Model (MM)

ZAP

V

V

°C

°C

33977

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, and - 40°C < TA< 125°C, unless otherwise noted. Typical

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

POWER INPUT (VDD)

Battery Supply Voltage Range

Fully Operational

Limited Operation

V

Supply Current

PWR

Gauge Outputs ON, No Output Loads

VPWR Supply Current (All Outputs Disabled)

Reset = Logic [0], V

Reset = Logic [0], V

Overvoltage Detection Level

Undervoltage Detection Level

Logic Supply Voltage Range (5.0 V Nominal Supply)

Under VDD Logic Reset

VDD Supply Current

Sleep: Reset Logic [0]

Outputs Enabled

POWER OUTPUT (SIN-, SIN+, COS-, COS+)

Microstep Output (Measured Across Coil Outputs)

SIN± (COS±) (Refer to Pin Definitions onpage 3)

R

= 200 Ω, PE6 = 0

OUT

Steps Pin Definitions

6, 18, 0, 12

5, 7, 17, 19 1, 11, 13, 23

4, 8, 16, 20 2, 10, 14, 22

3, 9, 15, 21 3, 9, 15, 21

2, 10, 14, 22 5, 7, 17, 19

1, 11, 13, 23 5, 7, 17, 19

0, 12 6, 18

Full Step Active Output (Measured Across Coil Outputs)

SIN± (COS±), Steps 1,3 (Pin Definitions 0 and 2)

Notes

6. Outputs and logic remain active; however, the larger coil voltage levels may be clipped. The reduction in drive voltage may result in a

loss of position control.

7. The logic will reset at some level below the specified Limited Operational minimum.

8. Outputs will disable and must be re-enabled via the PECCR command.

9. Outputs remain active; however, the reduction in drive voltage may result in a loss of position control.

10. See Figure 7.

(6), (7)

DD

DD

= 5.0 V

= 0 V

(8)

(9)

(10)

= 25°C under nominal conditions unless otherwise noted.

A

V

PWR

I

PWR

6.5

4.0

– 26

26

– 4.0 6.0

I

PWRSLP1

I

PWRSLP2

V

PWROV

V

PWRUV

V

DD

V

DDUV

I

DDOFF

I

DDON

V

ST6

V

ST5

V

ST4

V

ST3

V

ST2

V

ST1

V

ST0

V

FS

–

–

42

15

60

25

26 32 38 V

5.0 5.6 6.2 V

4.5 5.0 5.5 V

– – 4.5 V

4.82

0.94 V

0.84 V

0.68 V

0.47 V

0.23 V

0.1

–

–

ST6

ST6

ST6

ST6

ST6

40

1.0

5.3

0.97 V

0.87 V

0.71 V

0.50 V

0.26 V

0.0

ST6

ST6

ST6

ST6

ST6

65

1.8

6.0

1.0 V

0.96 V

0.8 V

0.57 V

0.31 V

0.1

ST6

ST6

ST6

ST6

ST6

4.9 5.3 6.0

V

mA

µA

µV

mA

V

V

33977

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, and - 40°C < TA< 125°C, unless otherwise noted. Typical

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

POWER OUTPUT (SIN-, SIN+, COS-, COS+) (Continued)

Microstep Full Step Output (Measured from Coil Low Side to Ground)

SIN± (COS±) I

Output Flyback Clamp

Output Current Limit (Output - V

Overtemperature Shutdown

Overtemperature Hysteresis

OUT

= 30 mA

(11)

(12)

(12)

ST6

)

CONTROL I/O (SI, SCLK, CS, RST, SO)

Input Logic High Voltage

Input Logic Low Voltage

Input Logic Voltage Hysteresis

(12)

(12)

(12)

Input Logic Pull-Down Current (SI, SCLK)

Input Logic Pull-Up Current (CS, RST)

SO High State Output Voltage (IOH = 1.0 mA)

SO Low State Output Voltage (IOL = 1.6 mA)

SO Tri-State Leakage Current (CS = 3.5 V)

Input Capacitance

SO Tri-State Capacitance

(13)

(13)

ANALOG TO DIGITAL CONVERTER (RTZ ACCUMULATOR COUNT)

ADC Gain

(12), (14)

Notes

11. Outputs remain active; however, the reduction in drive voltage may result in a loss of position control.

12. This parameter is guaranteed by design; however, it is not production tested.

13. Capacitance not measured. This parameter is guaranteed by design; however, it is not production tested.

14. Reference RTZ Accumulator (Typical) on page 30

V

V

I

LIM

T

T

HYST

V

V

V

INHYST

I

DWN

I

V

SOH

V

I

SOLK

C

C

G

ADC

LS

FB

SD

IH

IL

UP

SOL

IN

SO

0.0 0.1 0.3

– V

ST6

+ 0.5 V

+ 1.0 V

ST6

40 100 170 mA

155 – 180 °C

8.0 – 16 °C

2.0 – – V

– – 0.8 V

– 100 – mV

3.0 – 20 µA

5.0 – 20 µA

0.8 V

DD

– – V

– 0.2 0.4 V

-5.0 0.0 5.0 µA

– 4.0 12 pF

– – 20 pF

100 188 270 Counts/V/

V

ms

33977

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, and - 40°C < TA < 125°C, unless otherwise noted. Typical

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

POWER OUTPUT AND CLOCK TIMINGS (SIN+, SIN-, COS+, COS-) CS

SIN± (COS±) Output Turn ON Delay Time (Time from Rising CS

Enabling Outputs to Steady State Coil Voltages and Currents)

SIN± (COS±) Output Turn OFF Delay Time (Time from Rising CS

Disables Outputs to Steady State Coil Voltages and Currents)

Uncalibrated Oscillator Cycle Time

Calibrated Oscillator Cycle Time

Calibration Pulse = 8.0 µs, PECCR D4 = Logic [0]

Calibration Pulse = 8.0 µs, PECCR D4 = Logic [1]

Maximum Pointer Speed

Maximum Pointer Acceleration

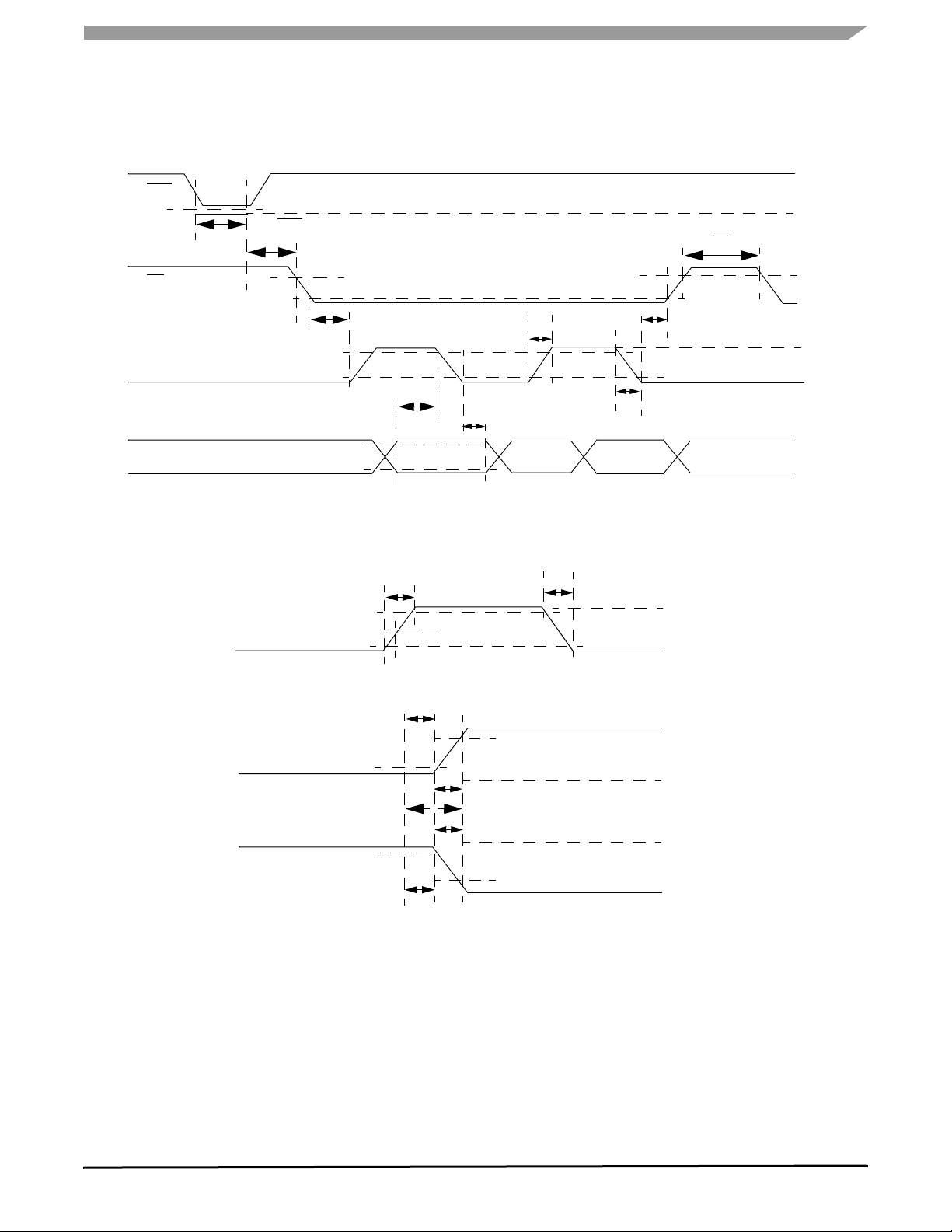

SPI INTERFACE TIMING (CS, SCLK, SO, SI, RST)

Recommended Frequency of SPI Operation

Falling Edge of CS to Rising Edge of SCLK (Required Setup Time)

Falling Edge of SCLK to Rising Edge of CS (Required Setup Time)

SI to Falling Edge of SCLK (Required Setup Time)

Falling Edge of SCLK to SI (Required Hold Time)

SO Rise Time

CL = 200 pF

SO Fall Time

CL = 200 pF

SI, CS, SCLK, Incoming Signal Rise Time

SI, CS, SCLK, Incoming Signal Fall Time

Falling Edge of RST to Rising Edge of RST (Required Setup Time)

Rising Edge of CS to Falling Edge of CS (Required Setup Time)

Falling Edge of RST to Rising Edge of CS (Required Setup Time)

Notes

15. Maximum specified time for the 33977 is the minimum guaranteed time needed from the microcontroller.

16. The minimum and maximum value will vary proportionally to the internal clock tolerance. These numbers are based on an ideally

calibrated clock frequency of 1.0 MHz. These are not 100 percent tested.

17. The 33977 shall meet all SPI interface timing requirements specified in the SPI Interface Timing section of this table, over the specified

temperature range. Digital interface timing is based on a symmetrical 50 percent duty cycle SCLK Clock Period of 33 ns. The device shall

be fully functional for slower clock speeds. Reference

18. The required setup times specified for the 33977 are the minimum time needed from the microcontroller to guarantee correct operation.

19. Rise and Fall time of incoming SI, CS, and SCLK signals suggested for design consideration to prevent the occurrence of double pulsing.

20. The value is for a 1.0 MHz calibrated internal clock. The value will change proportionally as the internal clock frequency changes.

(16)

(16)

(17)

(18)

(18)

(19)

(19)

= 25°C under nominal conditions unless otherwise noted.

A

t

(15)

(15)

(18)

(18)

DLYON

t

DLYOFF

t

CLU

t

CLC

V

MAX

A

MAX

f

SPI

t

LEAD

t

LAG

t

SISU

t

SIHOLD

t

RSO

– – 1.0

– – 1.0

0.65 1.0 1.7 µs

1.0

0.9

1.1

1.0

– – 400 °/s

– – 4500 °/s

– 1.0 2.0 MHz

167 – – ns

167 – – ns

– 25 83 ns

– 25 83 ns

– 25 50

t

FSO

– 25 50

(18)

(18), (20)

(18)

t

RSI

t

FIS

t

RST

W

t

CS

t

EN

– – 50 ns

– – 50 ns

– – 3.0 µs

– – 5.0 µs

– – 5.0 µs

Figure 4 and 5.

ms

ms

µs

1.2

1.1

ns

ns

2

33977

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, and - 40°C < TA < 125°C, unless otherwise noted. Typical

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

SPI INTERFACE TIMING (CS, SCLK, SO, SI, RST) ‘ (CONTINUED)

(24)

(22)

(23)

t

SOEN

t

SODIS

t

VALID

– – 145 ns

– 1.3 4.0 µs

ns

– 90 150

Time from Falling Edge of CS to SO Low Impedance

Time from Falling Edge of CS to SO High Impedance

Time from Rising Edge of SCLK to SO Data Valid

0.2 VDD = SO = 0.8 VDD, CL = 200 pF

Notes

21. The 33977 shall meet all SPI interface timing requirements specified in the SPI Interface Timing section of this table, over the specified

temperature range. Digital interface timing is based on a symmetrical 50 percent duty cycle SCLK Clock Period of 33 ns. The device shall

be fully functional for slower clock speeds.

22. Time required for output status data to be terminated at SO 1.0 kΩ load on SO.

23. Time required for output status data to be available for use at SO 1.0 kΩ load on SO.

24. Time required to obtain valid data out from SO following the rise of SCLK.

33977

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

RST

t

WRST

0.2 V

DD

TIMING DIAGRAMS

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

t

CS

V

IN

V

IL

CS

SCLK

SI

0.7 V

DD

SCLK

SO

Low-to-High

SO

High-to-Low

0.7 V

0.2 V

0.2 V

t

LEAD

DD

DD

0.7 V

DD

DD

t

SISU

Valid Don’t Care Valid Don’t CareDon’t Care

t

SI(HOLD)

t

RSI

Figure 4. Input Timing Switching Characteristics

t

FIS

3.5V

0.2 VDD

V

DD

0.7

t

SO(DIS)

t

SO(EN)

t

VALID

t

RSI

50%

t

RSO

t

RSO

0.7 VDD

0.2 VDD

0.7 V

1.0V

DD

t

FIS

V

IH

V

IL

t

LAG

V

OH

V

OL

V

OH

V

OL

V

OH

V

OL

V

IH

Figure 5. Valid Data Delay Time and Valid Time Waveforms

33977

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

FUNCTIONAL DESCRIPTION

FUNCTIONAL PIN DESCRIPTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

This 33977 is a single-packaged, Serial Peripheral

INterface (SPI) controlled, single stepper motor gauge driver

integrated circuit (IC). This monolithic stepper IC consists of

[deleted two per D. Mortensen] a dual output H-Bridge coil

driver [deleted plural s for accurate tense] and the

FUNCTIONAL PIN DESCRIPTION

COSINE POSITIVE (COS0+)

The H-Bridge pins linearly drive the sine and cosine coils

of a stepper motor, providing four-quadrant operation.

COSINE NEGATIVE (COS0-)

The H-Bridge pins linearly drive the sine and cosine coils

of a stepper motor, providing four-quadrant operation.

SINE POSITIVE (SIN+)

The H-Bridge pins linearly drive the sine and cosine coils

of a stepper motor, providing four-quadrant operation.

SINE NEGATIVE (SIN-)

The H-Bridge pins linearly drive the sine and cosine coils

of a stepper motor, providing four-quadrant operation.

GROUND (GND)

Ground pins.

CHIP SELECT (CS)

The pin enables communication with the master device.

When this pin is in a logic [0] state, the 33977 is capable of

transferring information to, and recei vi n g i nf ormation from,

the master. The 33977 latches data in from the Input Shift

registers to the addressed registers on the rising edge of

The output driver on the SO pin is enabled when CS is

logic [0]. When CS is logic high, signals at the SCLK and SI

pins are ignored and the SO pin is tri-stated (high

impedance).

to a logic [0] state when SCLK is logic [0].

pull-up (I

of the Static Electrical Characteristics Table.

CS will only be transitioned from a logic [1] state

CS has an internal

) connected to the pin, as specified in the section

UP

CS.

associated control logic. The dual H-Bridge driver is used to

automatically control the speed, direction, and magnitude of

current through the coils of a two-phase instrumentation

stepper motor, similar to an MMT-licensed AFIC 6405 of

Switec MS-X 156.xxx motor.

SCLK has an internal pull down (l

section of the Static Electrical Characteristics Table. When

CS is logic [1], signals at the SCLK and SI pins are ignored

and SO is tri-stated (high impedance). Refer to the data

transfer

Timing Diagrams on page 9.

), as specified in the

DWN

SERIAL OUTPUT (SO)

The SO data pin is a tri-stateable output from the Shift

register. The Status register bits are the first 16 bits shifted

out. Those bits are followed by the message bits clocked in

FIFO, when the device is in a daisy chain connection or being

sent words that are multiples of 16 bits. Data is shifted on the

rising edge of the SCLK signal. The SO pin will remain in a

high impedance state until the

state.

CS pin is put into a logic low

SERIAL INPUT (SI)

The SI pin is the input of the SPI. Serial input information

is read on the falling edge of SCLK. A 16-bit stream of serial

data is required on the SI pin, beginning with the most

significant bit (MSB). Messages that are not multiples of 16

bits (e.g., daisy chained device messages) are ignored. After

transmitting a 16-bit word, the

(logic [1]) before transmitting a new word. SI information is

ignored when

CS is in a logic high state.

CS pin must be de-asserted

RETURN TO ZERO (RTZ)

This is a multiplexed output pin for the non-driven coil,

during a Return to Zero (RTZ) event.

VOLTAGE (VDD)

The SPI and logic power supply input will work with 5.0 V

supplies.

SERIAL CLOCK (SCLK)

SCLK clocks the Internal Shift registers of the 33977

device. The SI pin accepts data into the Input Shift register on

the falling edge of the SCLK signal, while the Serial Output

pin (SO) shifts data information out of the SO Line Driver on

the rising edge of the SCLK signal. It is important that the

SCLK pin be in a logic [0] state whenever the

transition.

33977

10 Freescale Semiconductor

CS makes any

RESET (RST)

If the master decides to reset the device, or place it into a

sleep state, the

the RST pin forces all internal logic to the known default state.

This input has an internal active pull-up.

RST pin is driven to a Logic [0]. A Logic [0] on

VOLTAGE POWER (VPWR)

This is the power supply pin.

Analog Integrated Circuit Device Data

FUNCTIONAL INTERNAL BLOCK DESCRIPTION (OPTIONAL)

FUNCTIONAL INTERNAL BLOCK DESCRIPTION (OPTIONAL)

FUNCTIONAL DESCRIPTION

SPI Logic

Under and

Overvoltage

Detect

Figure 6. Functional Internal 33977 Block Illustration

SERIAL PERIPHERAL INTERFACE (SPI)

This circuitry manages incoming messages and outgoing

status data.

LOGIC

This design element includes internal logic including state

machines and message decoding.

INTERNAL REFERENCE

This design element is used for step value levels.

UNDER AND OVERVOLTAGE DETECTION

This design element detects when V

normal operating range.

is out of the

PWR

Internal

Reference

Oscillator

RTZ

H-Bridge

and Control

OSCILLATOR

The internal oscillator generates the internal clock for all

timing critical features.

H-BRIDGE AND CONTROL

This circuitry contains the output coil drivers and the

multiplexers necessary for four quadrant operation and RTZ

sequencing. This circuitry is repeated for the Sine and Cosine

coils.

• Overtemperature — Each output includes an

overtemperature sensing circuit

• ILIM — Each output is current limited

RETURN TO ZERO (RTZ)

This circuitry outputs the voltage present on the non-driven

coil during RTZ operation.

33977

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

STATE MACHINE OPERATION

The 33977 is ideal for use in instrumentation systems

requiring distributed and flexible stepper motor gauge driving.

The device also eases the transition to stepper motors from

air core motors by emulating the air core pointer movement

with little additional processor bandwidth utilization. The twophase stepper motor has maximum allowable velocities and

acceleration and deceleration. The purpose of the stepper

motor state machine is to drive the motor with the maximum

performance while remaining within the motor’s voltage,

velocity, and acceleration constraints.

A requirement of the state machine is to ensure the

deceleration phase begins at the correct time and pointer

position. When commanded, the motor [will deleted PV]

accelerates constantly to the maximum velocity, and then it

moves toward the commanded position at the maximum

velocity. Eventually, the pointer reaches the calculated

location where the movement has to decelerate, safely

slowing to a stop at the desired position. During the

deceleration phase, the motor does [will deleted PV] not

exceed the maximum deceleration.

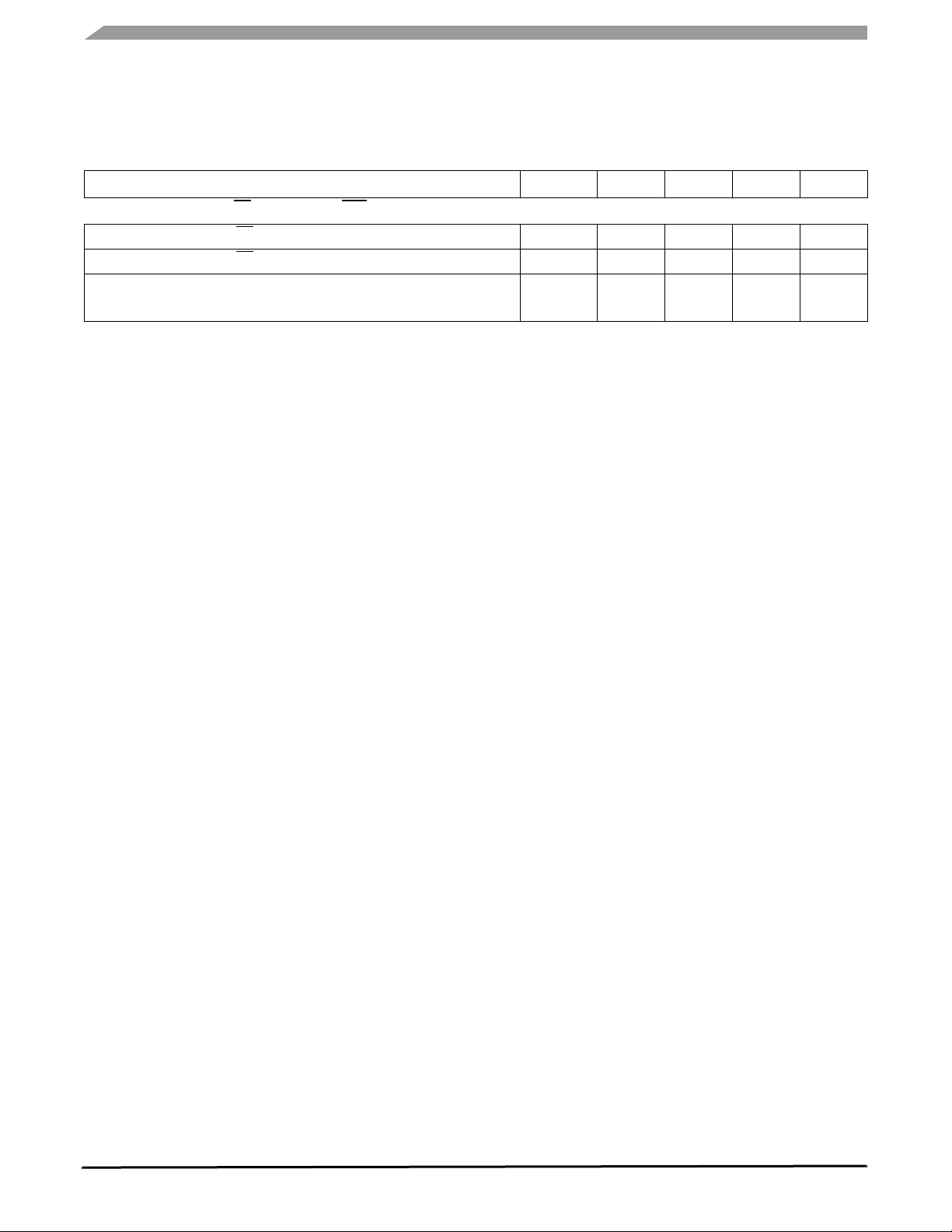

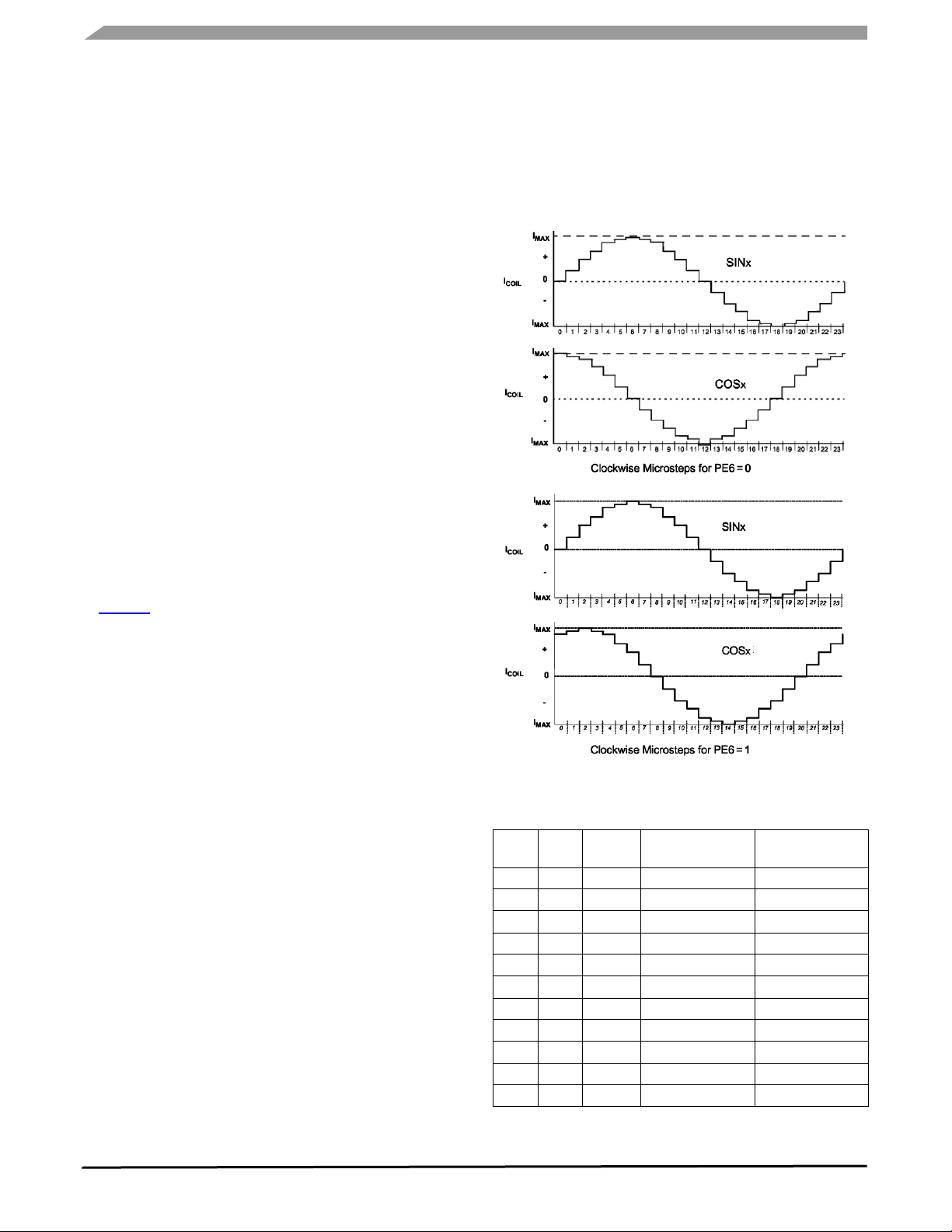

During normal operation, both stepper motor rotors are

microstepped at 24 steps per electrical revolution, illustrated

in Figure 7. A complete electrical revolution results in two

degrees of pointer movement. There is a second smaller

[parentheses removed-unnecessary] state machine in the IC

controlling these microsteps. The smaller state machine

receives clockwise or counter-clockwise index commands at

timed intervals, thereby stepping the motor in the appropriate

direction by adjusting the current in each coil. Normalized

values are provided in

Table 5.

Figure 7. Clockwise Microsteps

Table 5. Coil Step Value

33977

Step

Angle

0

1

2

3

4

5

6

7

105 0.966 -0.259 0.259

8

120 0.866 -0.5 0.0

9

135 0.707 -0.707 -0.259

10

150 0.5 -0.866 -0.500

SINE

(Angle)*

0.0 0.0 1.0 0.866

15 0.259 0.965 0.966

30 0.5 0.866 1.0

45 0.707 0.707 0.966

60 0.866 0.5 0.866

75 0.966 0.259 0.707

90 1.0 0.0 0.500

COS (Angle -30)*

PE6=0

COS (Angle -30)*

PE6=1

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

Loading...

Loading...