Page 1

www.DataSheet4U.com

Freescale Semiconductor

Advance Information

Multiple Switch Detection

Interface with Suppressed

Wake-Up

Document Number: MC33972

Rev. 9.0, 4/2007

33972

33972A

The 33972 Multiple Switch Detection Interface with Suppressed

Wake-Up is designed to detect the closing and opening of up to 22

switch contacts. The switch status, either open or closed, is transferred

to the microprocessor unit (MCU) through a serial peripheral interface

(SPI). The device also features a 22-to-1 analog multiplexer for reading

inputs as analog. The analog input signal is buffered and provided on

the AMUX output pin for the MCU to read.

The 33972 device has two modes of operation, Normal and Sleep.

Normal mode allows programming of the device and supplies switch

contacts with pullup or pulldown current as it monitors switch change

of state. The Sleep mode provides low quiescent current, which makes

the 33972 ideal for automotive and industrial products requiring low

sleep state currents.

Features

• Designed to Operate 5.5 V ≤ V

• Switch Input Voltage Range -14 V to V

PWR

≤ 26 V

PWR

, 40 V Max

• Interfaces Directly to MPU using 3.3 V / 5.0 V SPI Protocol

• Selectable Wake-Up on Change of State

• Selectable Wetting Current (16 mA or 2.0 mA)

• 8 Programmable Inputs (Switches to Battery or Ground)

• 14 Switch-to-Ground Inputs

• Typical Standby Current - V

100 µA and VDD = 20 µA

PWR =

• Active Interrupt (INT) on Change-of-Switch State

• Pb-Free Packaging Designated by Suffix Code EW

V

BAT

V

V

BAT

BAT

SP0

SP1

SP7

SG0

SG1

SG12

33972

VPWR

VDD

WAKE

SCLK

CS

SO

INT

AMUX

V

DD

SI

DETECTION INTERFACE

EW SUFFIX (Pb-FREE)

ORDERING INFORMATION

Device

MC33972DWB/R2

MCZ33972AEW/R2

V

Power Supply

LVI

Enable

Watchdog

Reset

MULTIPLE SWITCH

DWB SUFFIX

98ARH99137A

32-PIN SOICW

Temperature

Range (T

-40°C to 125°C 32 SOICWMC33972EW/R2

DD

MCU

MOSI

SCLK

CS

MISO

INT

AN0

)

A

Package

SG13

GND

Figure 1. 33972 Simplified Application Diagram

* This document contains certain information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

Page 2

DEVICE VARIATIONS

DEVICE VARIATIONS

Table 1. Device Variations

Device Switch Input Voltage Range

33972

33972A

-14 to 38 V

-14 to 40 V

DC

DC

Reference

Location

6

6

33972

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

Page 3

SP0

SP1

SP2

SP3

SP4

SP5

SP6

SP7

SG0

SG1

SG2

SG3

SG4

SG5

SG6

SG7

SG8

SG9

SG10

SG11

SG12

SG13

V

16.0

mA

16.0

mA

V

16.0

mA

16.0

mA

V

16.0

mA

V

16.0

mA

PWR

PWR

PWR

PWR

V

V

V

V

PWR

PWR

PWR

PWR

2.0

mA

2.0

mA

2.0

mA

2.0

mA

2.0

mA

2.0

mA

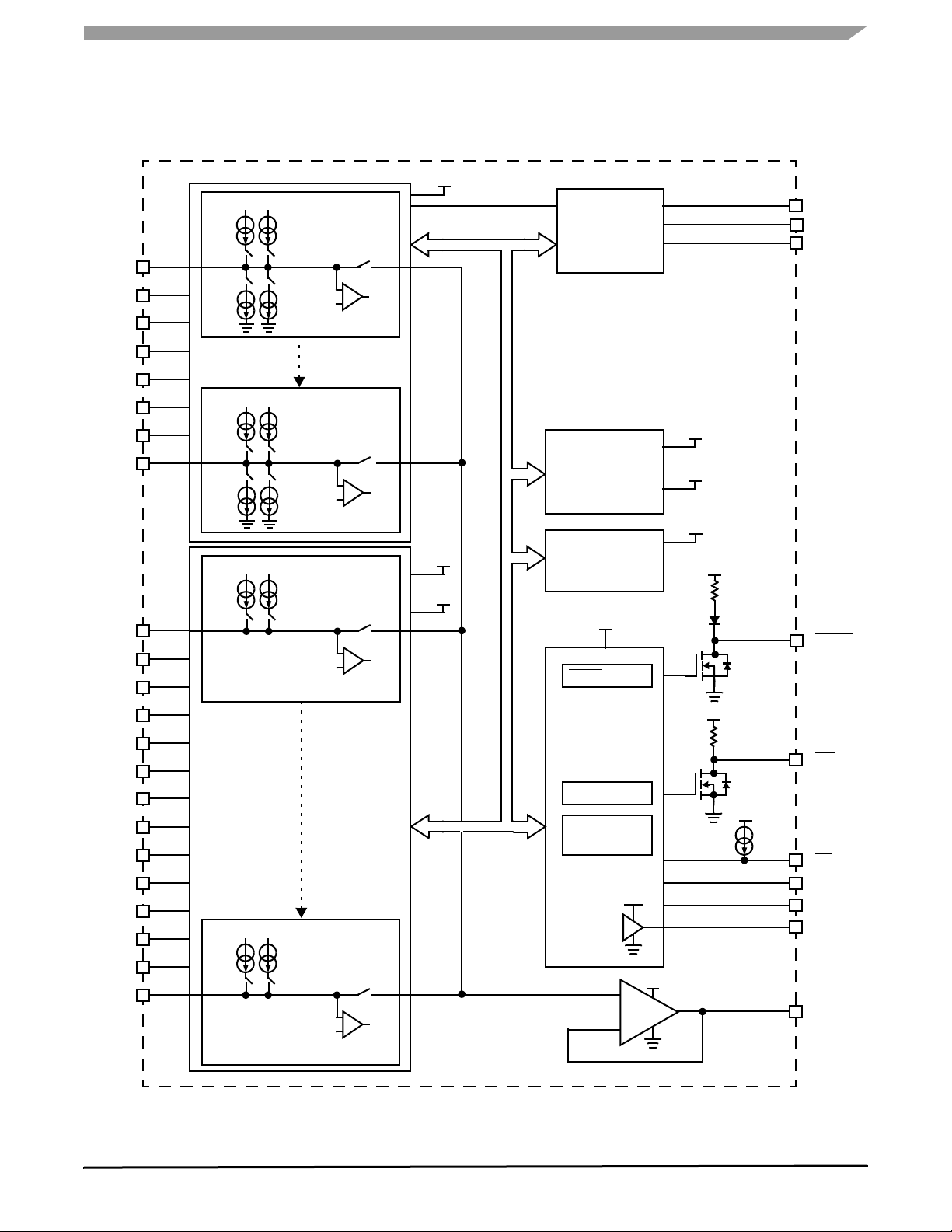

INTERNAL BLOCK DIAGRAM

5.0 V

V

PWR

PWR

4.0 V

Ref

Comparator

4.0 V

Ref

Comparator

4.0 V

Ref

Comparator

4.0 V

Ref

Comparator

+

–

+

–

+

–

+

–

SP0

To

SPI

SP7

To

SPI

SG0

To

SPI

SG13

To

SPI

5.0 V

V

V

, VDD, 5.0 V

PWR

POR

Bandgap

Sleep PWR

Oscillator

and

Clock Control

Temperature

Monitor and

Control

5.0 V

WAKE Control

SPI Interface

and Control

INT Control

MUX Interface

V

+

–

DD

V

DD

INTERNAL BLOCK DIAGRAM

VPWR

VDD

GND

5.0 V

V

PWR

5.0 V

5.0 V

125 kΩ

V

DD

125 kΩ

V

DD

40 µA

Analog Mux

Output

WAKE

INT

CS

SCLK

SI

SO

AMUX

Figure 2. 33972 Simplified Internal Block Diagram

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

Page 4

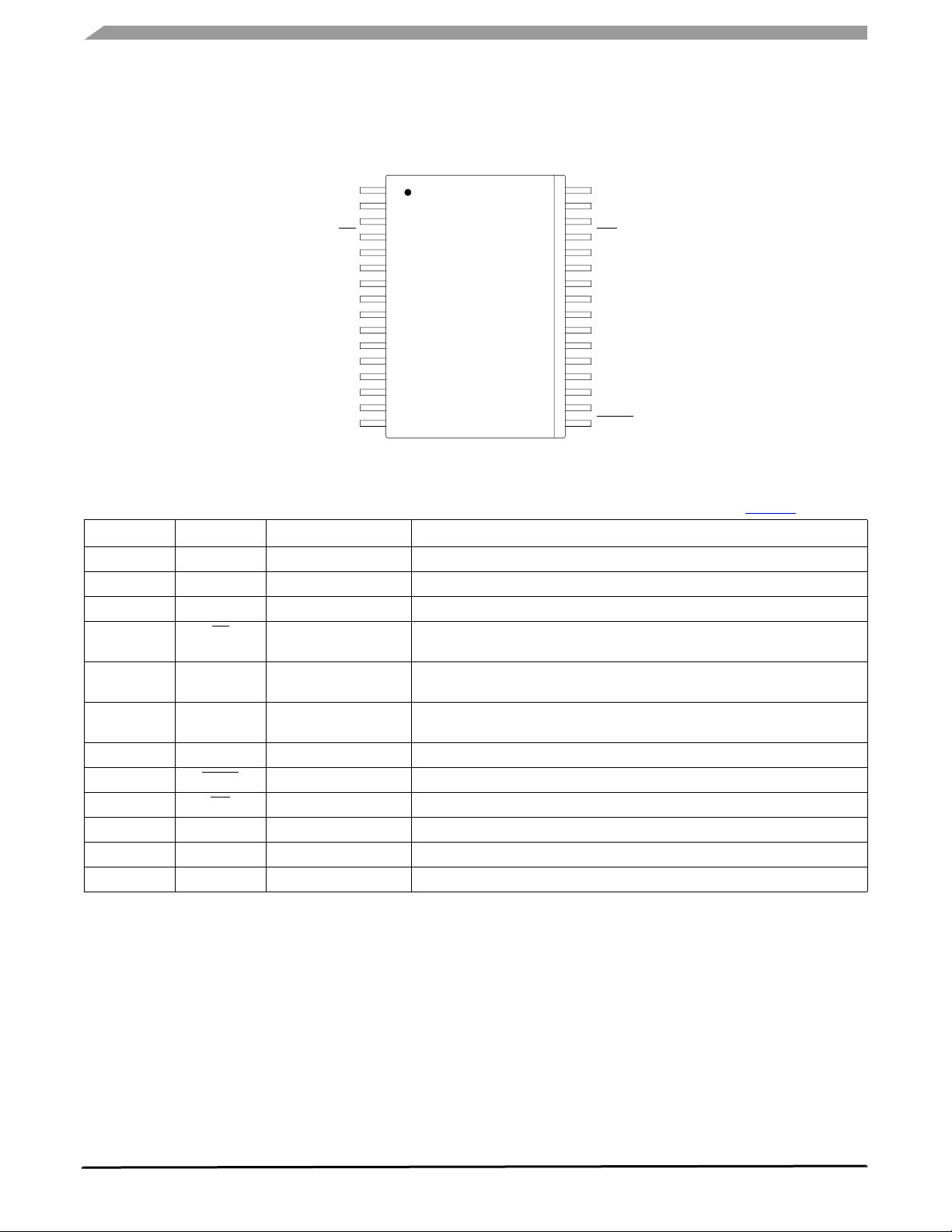

PIN CONNECTIONS

PIN CONNECTIONS

GND

SCLK

CS

SP0

SP1

SP2

SP3

SG0

SG1

SG2

SG3

SG4

SG5

SG6

VPWR

SI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SO

VDD

AMUX

INT

SP7

SP6

SP5

SP4

SG7

SG8

SG9

SG10

SG11

SG12

SG13

WAKE

Figure 3. 33972 Pin Connections

Table 2. 33972 Pin Definitions

A functional description of each pin can be found in the Functional Pin Description section beginning on page 10.

Pin Number Pin Name Formal Name Definition

1 GND Ground

2 SI SPI Slave In

3 SCLK Serial Clock

4 CS Chip Select

5 – 8

25

– 28

9 – 15,

18

– 24

SP0 – 3

SP4

– 7

SG0 – 6,

SG13

Programmable Switches

Switch-to-Ground Inputs

– 7

0

0

– 7

– 13

16 VPWR Battery Input

17 WAKE Wake-Up

29 INT Interrupt

30 AMUX Analog Multiplex Output

31 VDD Voltage Drain Supply

32 SO SPI Slave Out

Ground for logic, analog, and switch to battery inputs.

SPI control data input pin from MCU to 33972.

SPI control clock input pin.

SPI control chip select input pin from MCU to 33972. Logic [0} allows data to be

transferred in.

Programmable switch-to-battery or switch-to-ground input pins.

Switch-to-ground input pins.

Battery supply input pin. Pin requires external reverse battery protection.

Open drain wake-up output. Designed to control a power supply enable pin.

Open-drain output to MCU. Used to indicate input switch change of state.

Analog multiplex output.

3.3 / 5.0 V supply. Sets SPI communication level for SO driver.

Provides digital data from 33972 to MCU.

33972

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

Page 5

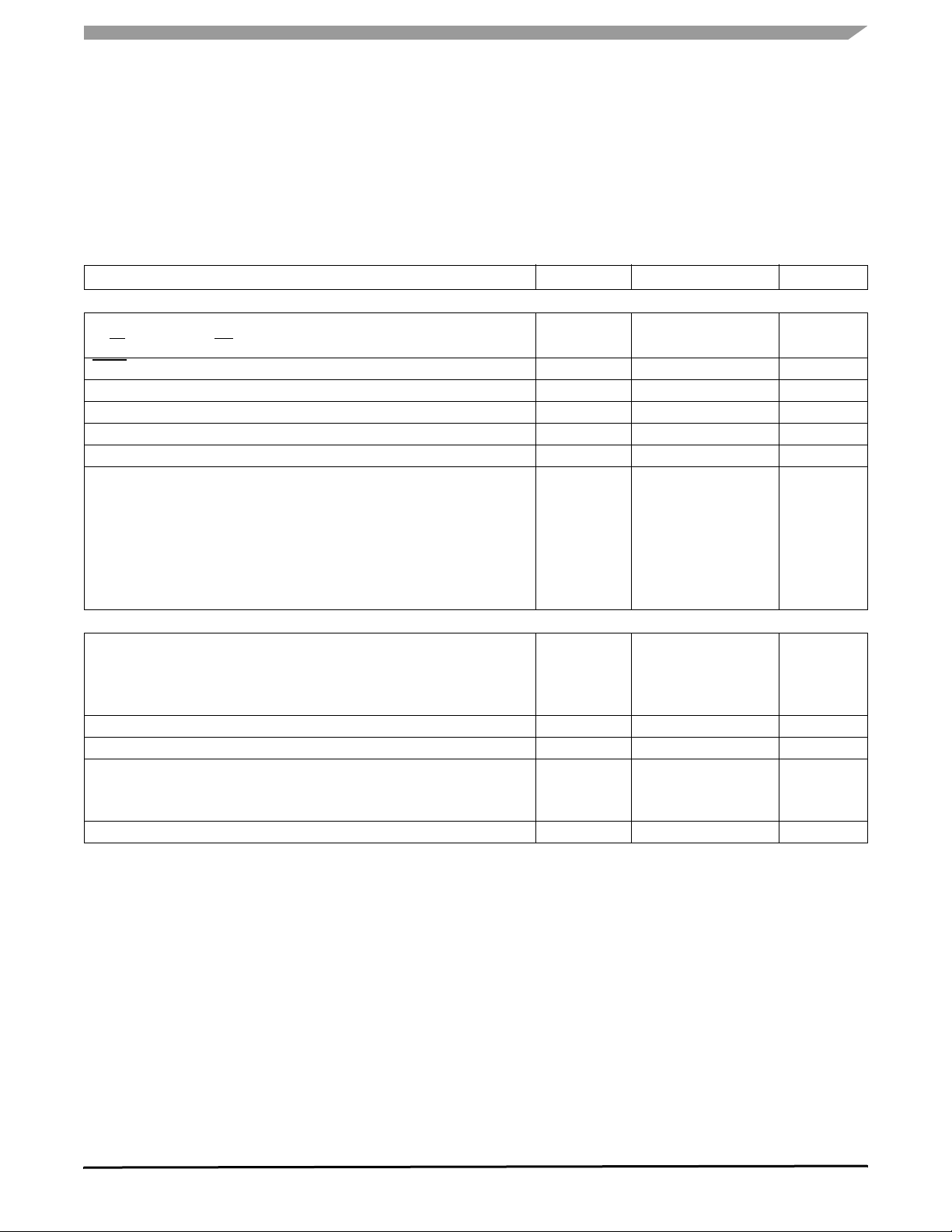

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

Table 3. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

VDD Supply Voltage

CS, SI, SO, SCLK, INT, AMUX

(1)

WAKE

VPWR Supply Voltage

(1)

VPWR Supply Voltage at -40C

(1)

(1)

Switch Input Voltage Range

Frequency of SPI Operation (VDD = 5.0 V)

ESD Voltage

Human Body Model

(3)

(2)

Applies to all non-input pins

Machine Model

– -0.3 to 7.0

– -0.3 to 40 V

– -0.3 to 50 V

– -0.3 to 45 V

– -14 to 40 V

– 6.0 MHz

V

ESD

±2000

±2000

±200

Charge Device Model

Corner Pins

Interior Pins

750

500

THERMAL RATINGS

Operating Temperature

Ambient

Junction

Case

Storage Temperature

Power Dissipation (TA = 25°C)

(4)

T

T

A

T

J

T

C

STG

P

D

- 40 to 125

- 40 to 150

- 40 to 125

- 55 to 150 °C

1.7 W

Thermal Resistance

Junction to Ambient

Junction to Lead

Peak Package Reflow Temperature During Reflow

(5), (6)

R

R

T

JA

θ

JL

θ

PPRT

74

25

Note 6.

Notes

1. Exceeding these limits may cause malfunction or permanent damage to the device.

2. ESD data available upon request.

3. ESD1 testing is performed in accordance with the Human Body Model (C

in accordance with the Machine Model (C

= 200 pF, R

ZAP

ZAP

= 0 Ω).

= 100 pF, R

ZAP

= 1500 Ω), and ESD2 testing is performed

ZAP

4. Maximum power dissipation at TJ = 150°C junction temperature with no heat sink used.

5. Pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may

cause malfunction or permanent damage to the device.

6. Freescale’s Package Reflow capability meets Pb-free requirements for JEDEC standard J-STD-020C. For Peak Package Reflow

Temperature and Moisture Sensitivity Levels (MSL),

Go to www.freescale.com, search by part number [e.g. remove prefixes/suffixes and enter the core ID to view all orderable parts. (i.e.

MC33xxxD enter 33xxx), and review parametrics.

V

°C

°C/W

°C

DC

DC

DC

DC

DC

V

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

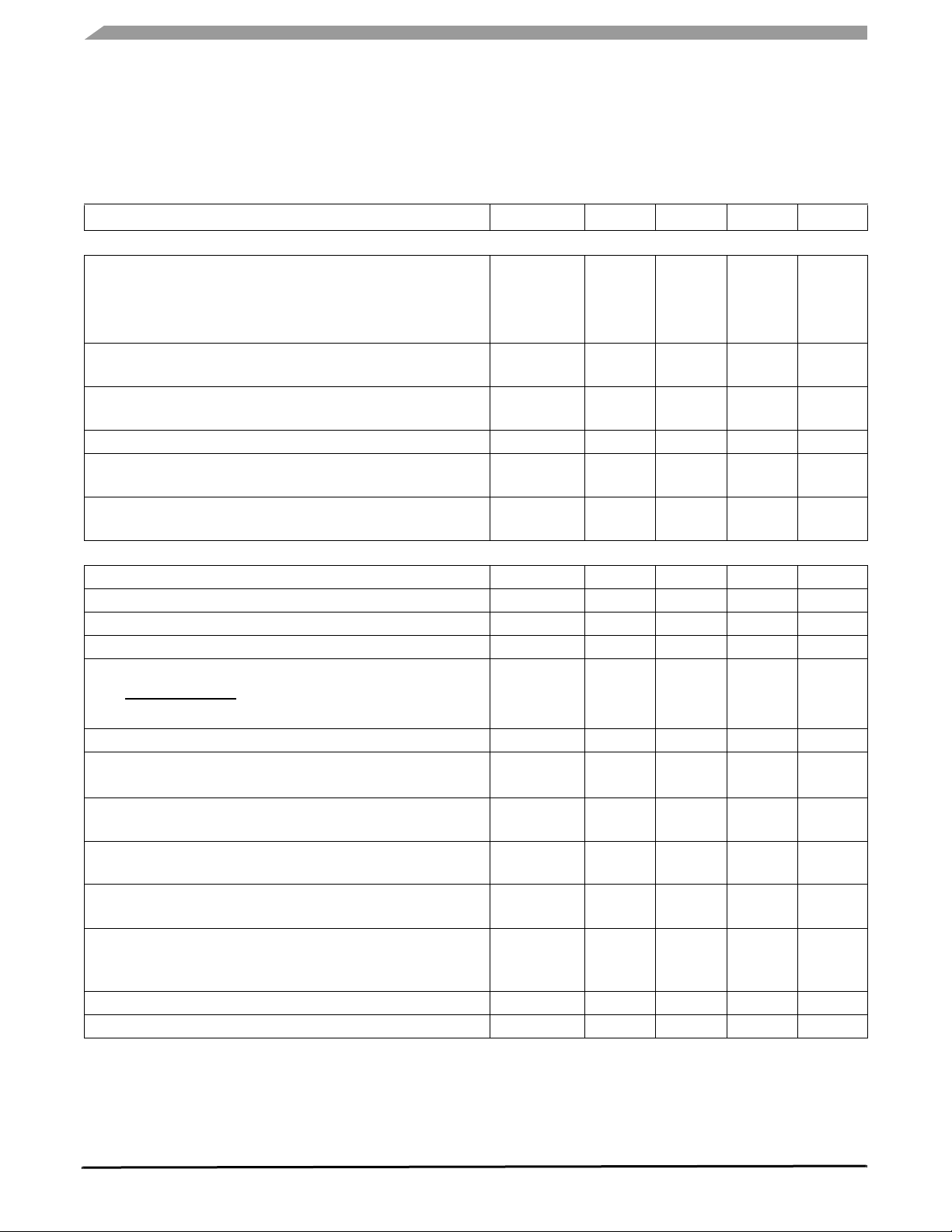

Page 6

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 4. Static Electrical Characteristics

Characteristics noted under conditions 3.1 V ≤ V

noted. Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

POWER INPUT

Supply Voltage

Supply Voltage Range Quasi-Functional

Fully Operational

Supply Voltage Range Quasi-Functional

Supply Current

All Switches Open, Normal Mode, Tri-State Disabled

Sleep State Supply Current

Scan Timer = 64 ms, Switches Open

Logic Supply Voltage

Logic Supply Current

All Switches Open, Normal Mode

Sleep State Logic Supply Current

Scan Timer = 64 ms, Switches Open

SWITCH INPUT

Pulse Wetting Current Switch-to-Battery (Current Sink)

Pulse Wetting Current Switch-to-Ground (Current Source)

Sustain Current Switch-to-Battery Input (Current Sink)

Sustain Current Switch-to-Ground Input (Current Source)

Sustain Current Matching Between Channels on Switch-to-Ground I/Os

I

SUS(MAX)

I

-

I

SUS(MIN)

SUS(MIN)

X 100

(7)

(7)

≤ 5.25 V, 8.0 V ≤ V

DD

PWR

V

PWR (QF

V

PWR (FO

V

PWR (QF

I

PWR (ON

I

PWR (SS

V

DD

I

DD

I

DD(SS

I

PULSE

I

PULSE

I

SUSTAIN

I

SUSTAIN

I

MATCH

≤ 16 V, -40°C ≤ TC ≤ 125°C, unless otherwise

)

)

)

)

)

)

5.5

8.0

26

– 2.0 4.0

40 70 100

3.1 – 5.25 V

– 0.25 0.5

– 10 20

12 15 18 mA

12 16 18 mA

1.8 2.0 2.2 mA

1.8 2.0 2.2 mA

– 2.0 4.0

= 13 V, TA = 25°C.

PWR

–

–

–

8.0

26

38/40

V

mA

µA

mA

µA

%

Input Offset Current When Selected as Analog

Input Offset Voltage When Selected as Analog

V

(SP&SGINPUTS)

to AMUX Output

Analog Operational Amplifier Output Voltage

Sink 250 µA

Analog Operational Amplifier Output Voltage

Source 250 µA

Switch Detection Threshold

33972 / 33972A

Switch Input Voltage Range

33972

33972A

Temperature Monitor

Temperature Monitor Hysteresis

(8), (9)

(9)

I

OFFSET

V

OFFSET

V

OL

V

OH

V

TH

V

T

LIM

T

LIM(HYS)

-2.0 1.4 2.0 µA

mV

-10 2.5 10

mV

– 10 30

V

V

- 0.1 – –

DD

V

3.70 4.0 4.3

IN

-14

-14

–

–

38

40

V

155 – 185 °C

5.0 10 15 °C

Notes

7. Device operational. Table parameters may be out of specification.

8. Thermal shutdown of 16 mA pullup and pulldown current sources only. 2.0 mA current source / sink and all other functions remain active.

9. This parameter is guaranteed by design but is not production tested.

33972

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

Page 7

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 4. Static Electrical Characteristics (continued)

Characteristics noted under conditions 3.1 V ≤ V

≤ 5.25 V, 8.0 V ≤ V

DD

≤ 16 V, -40°C ≤ TC ≤ 125°C, unless otherwise

PWR

noted. Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

DIGITAL INTERFACE

Input Logic Voltage Thresholds

SCLK, SI, Tri-State SO Input Current

0 V to VDD

CS Input Current

CS = V

DD

CS Pullup Current

CS = 0 V

SO High-State Output Voltage

I

SO (HIGH

= -200 µA

)

SO Low-State Output Voltage

I

SO (HIGH

= 1.6 mA

)

Input Capacitance on SCLK, SI, Tri-State SO

INT Internal Pullup Current

INT Voltage

INT = Open Circuit

INT Voltage

I

= 1.0 mA

INT

WAKE Internal Pullup Current

WAKE Voltage

WAKE = Open Circuit

WAKE Voltage

I

= 1.0 mA

WAKE

WAKE Voltage

Maximum Voltage Applied to WAKE Through External Pullup

Notes

10. Upper and lower logic threshold voltage levels apply to SI, CS, and SCLK.

11. This parameter is guaranteed by design but is not production tested.

(10)

(11)

V

INLOGIC

I

SCLK, ISI,

I

SO (TRI)

I

CS

0.8 – 2.2 V

-10 – 10

-10 – 10

I

CS

30 – 100

V

SO (HIGH

)

VDD - 0.8 – V

V

SO (LOW

)

– – 0.4

C

IN

– – 20 pF

– 15 40 100 µA

V

INT (HIGH)

VDD - 0.5 – V

V

INT (LOW)

– 0.2 0.4

I

WAKE (PU)

V

WAKE (HIGH)

20 40 100 µA

4.0 4.3 5.3

V

WAKE(LOW

)

– 0.2 0.4

V

WAKE(MAX

)

– – 40

= 13 V, TA = 25°C.

PWR

DD

DD

µA

µA

µA

V

V

V

V

V

V

V

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

Page 8

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

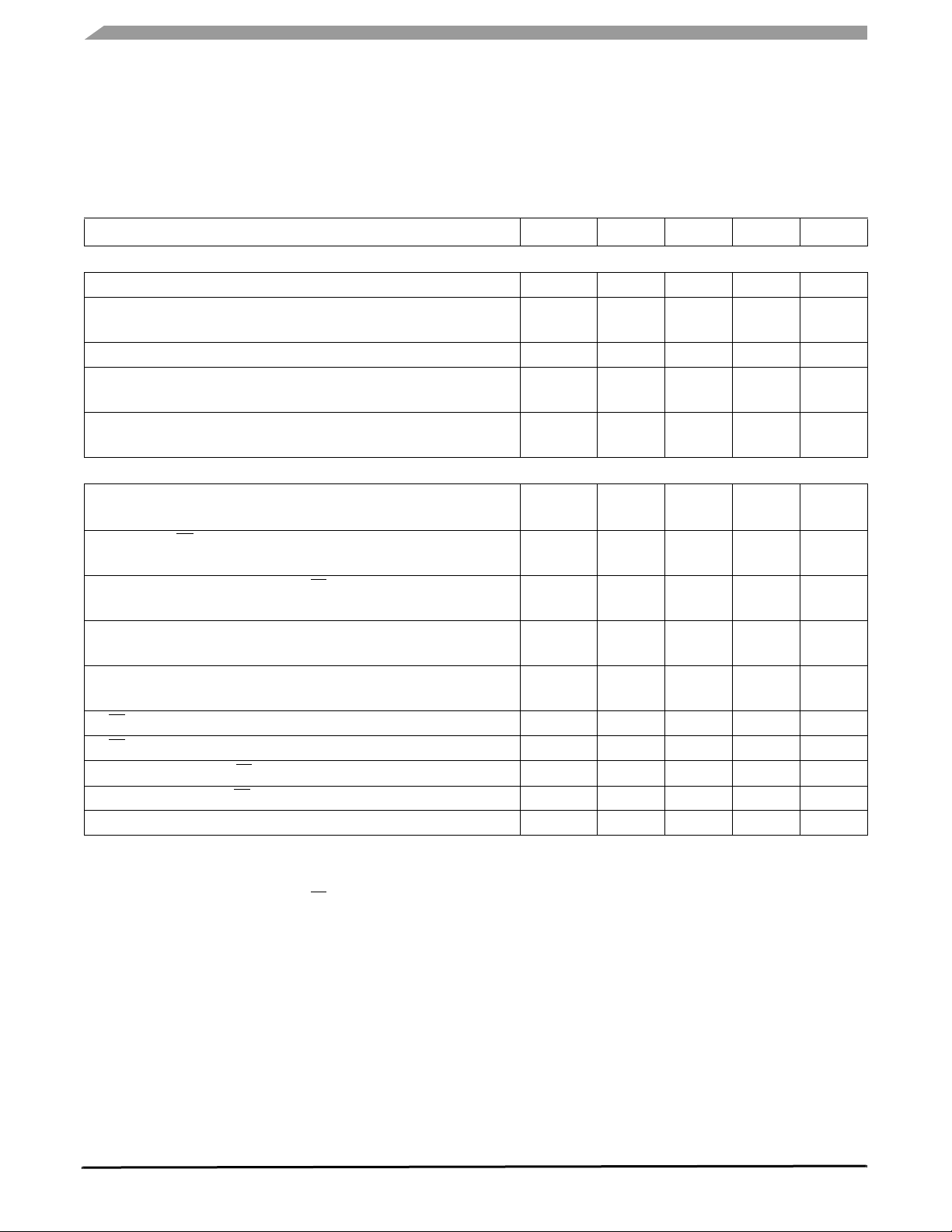

Table 5. Dynamic Electrical Characteristics

Characteristics noted under conditions 3.1 V ≤ V

noted. Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

SWITCH INPUT

Pulse Wetting Current Time

Interrupt Delay Time

Normal Mode

Sleep Mode Switch Scan Time

Calibrated Scan Timer Accuracy

Sleep Mode

Calibrated Interrupt Timer Accuracy

Sleep Mode

DIGITAL INTERFACE TIMING

Required Low-State Duration on V

V

≤ 0.2 V

PWR

Falling Edge of CS to Rising Edge of SCLK

Required Setup Time

Falling Edge of SCLK to Rising Edge of CS

Required Setup Time

SI to Falling Edge of SCLK

Required Setup Time

Falling Edge of SCLK to SI

Required Hold Time

SI, CS, SCLK Signal Rise Time

SI, CS, SCLK Signal Fall Time

Time from Falling Edge of CS to SO Low Impedance

Time from Rising Edge of CS to SO High Impedance

Time from Rising Edge of SCLK to SO Data Valid

Notes

12. These parameters are guaranteed by design. Production test equipment uses 4.16 MHz, 5.0 V SPI interface.

13. This parameter is guaranteed by design but not production tested.

14. Rise and Fall time of incoming SI, CS, and SCLK signals suggested for design consideration to prevent the occurrence of double pulsing.

15. Time required for valid output status data to be available on SO pin.

16. Time required for output states data to be terminated at SO pin.

17. Time required to obtain valid data out from SO following the rise of SCLK with 200 pF load.

(12)

(14)

(14)

PWR

for Reset

(13)

(17)

≤ 5.25 V, 8.0 V ≤ V

DD

(15)

(16)

≤ 16 V, -40°C ≤ TC ≤ 125°C, unless otherwise

PWR

t

PULSE (ON)

t

INT-DLY

15 16 20 ms

= 13 V, TA = 25°C.

PWR

– 5.0 16

t

SCAN

t

SCAN TIMER

100 200 300 µs

– – 10

t

INT TIMER

– – 10

t

RESET

– – 10

t

LEAD

100 – –

t

LAG

50 – –

t

SI (SU)

16 – –

t

SI (HOLD)

20 – –

t

R (SI)

t

F (SI)

t

SO (EN)

t

SO (DIS)

t

VALID

– 5.0 – ns

– 5.0 – ns

– – 55 ns

– – 55 ns

– 25 55 ns

µs

%

%

µs

ns

ns

ns

ns

33972

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

Page 9

TIMING DIAGRAMS

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

VPWR

VDD

WAKE

INT

CS

CS

SCLK

SI

SO

t

SO(EN)

0.2 V

DD

0.7 V

0.2 V

t

LEAD

DD

DD

0.7 V

0.2 V

0.7 V

0.2 V

DD

DD

t

SI(SU)tSI(HOLD)

DD

MSB IN

DD

t

VALID

MSB OUT LSB OUT

t

LAG

t

SO(DIS)

Figure 4. SPI Timing Characteristics

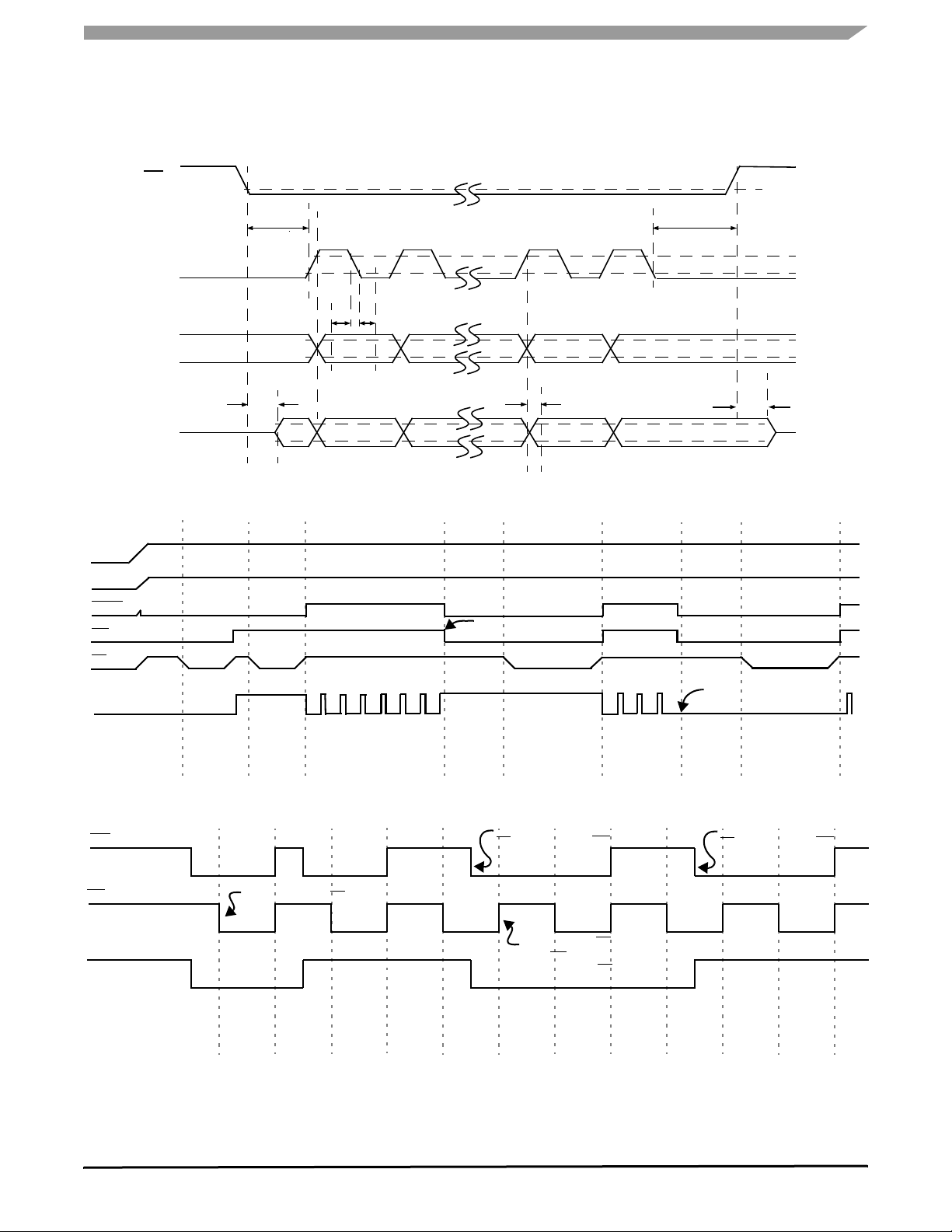

Wake-Up From Interrupt

Timer Expire

SGn

Power-Up

Normal Mode

.

INT

CS

SGn

SGn Bit in SPI Word

Tri-State

Command

(Disable

Tri-State)

Command

Sleep Sleep Mode Normal

Command

Figure 5. Sleep Mode to Normal Mode Operation

Latch switch status

on falling edge of CS

Switch

Status

Switch

Status

Command

Figure 6. Normal Mode Interrupt Operation

Mode

Switch

Status

Command

Sleep Command

Switch state change with

CS LOW generates INT

Rising edge of CS does not

clear

INT because state change

occurred while CS

Switch closed “1”

1001

Switch

Status

Command

Sleep Mode

was LOW

Wake-Up From

Closed Switch

Normal

Mode

1

Switch

Status

Command

Sleep Command

Switch state change with

CS LOW generates INT

Switch open “0”

0

Switch

Status

Command

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

Page 10

FUNCTIONAL DESCRIPTION

INTRODUCTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

The 33972 device is an integrated circuit designed to

provide systems with ultra-low quiescent sleep / wake-up

modes and a robust interface between switch contacts and a

microprocessor. The 33972 replaces many of the discrete

components required when interfacing to microprocessorbased systems while providing switch ground offset

protection, contact wetting current, and system wake-up.

The 33972 features 8-programmable switch-to-ground or

switch-to-battery inputs and 14 switch-to-ground inputs. All

FUNCTIONAL PIN DESCRIPTION

CHIP SELECT (CS)

The system MCU selects the 33972 to receive

communication using the chip select (

CS) pin. With the CS in

a logic LOW state, command words may be sent to the 33972

via the serial input (SI) pin, and switch status information can

be received by the MCU via the serial output (SO) pin. The

falling edge of

CS enables the SO output, latches the state of

the INT pin, and the state of the external switch inputs.

Rising edge of the CS initiates the following operation:

1. Disables the SO driver (high impedance)

2. INT pin is reset to logic [1], except when additional

switch changes occur during CS LOW. (See Figure 6

on page 9.)

3. Activates the received command word, allowing the

33972 to act upon new data from switch inputs.

To avoid any spurious data, it is essential the HIGH-to-

LOW and LOW-to-HIGH transitions of the

CS signal occur

only when SCLK is in a logic LOW state. Internal to the 33972

device is an active pullup to VDD on CS.

In Sleep mode the negative edge of CS (VDD applied) will

wake up the 33972 device. Data received from the device

CS wake-up may not be accurate.

during

SYSTEM CLOCK (SCLK)

The system clock (SCLK) pin clocks the internal shift

register of the 33972. The SI data is latched into the input

shift register on the falling edge of SCLK signal. The SO pin

shifts the switch status bits out on the rising edge of SCLK.

The SO data is available for the MCU to read on the falling

edge of SCLK. False clocking of the shift register must be

avoided to ensure validity of data. It is essential the SCLK pin

be in a logic LOW state whenever

For this reason, it is recommended, though not necessary,

that the SCLK pin is commanded to a logic LOW state as long

as the device is not accessed and

When the

CS is in a logic HIGH state, any signal on the SCLK

and SI pins will be ignored and the SO pin is tri-state.

CS makes any transition.

CS is in a logic HIGH state.

switch inputs may be read as analog inputs through the

analog multiplexer (AMUX). Other features include a

programmable wake-up timer, programmable interrupt timer,

programmable wake-up

/interrupt bits, and programmable

wetting current settings.

This device is designed primarily for automotive

applications but may be used in a variety of other applications

such as computer, telecommunications, and industrial

controls.

SPI SLAVE IN (SI)

The SI pin is used for serial instruction data input. SI

information is latched into the input register on the falling

edge of SCLK. A logic HIGH state present on SI will program

a one in the command word on the rising edge of the

signal. To program a complete word, 24

bits of information

CS

must be entered into the device.

SPI SLAVE OUT (SO)

The SO pin is the output from the shift register. The SO pin

remains tri-stated until the CS pin transitions to a logic LOW

state. All open switches are reported as zero, all closed

switches are reported as one. The negative transition of

CS

enables the SO driver.

The first positive transition of SCLK will make the status

24 available on the SO pin. Each successive positive

data bit

clock will make the next status data bit available for the MCU

to read on the falling edge of SCLK. The SI / SO shifting of the

data follows a first-in, first-out protocol, with both input and

output words transferring the most significant bit (MSB) first.

iNTERRUPT (INT)

The INT pin is an interrupt output from the 33972 device.

The INT pin is an open-drain output with an internal pullup to

. In Normal mode, a switch state change will trigger the

V

DD

INT pin (when enabled). The INT pin and INT bit in the SPI

register are latched on the falling edge of

MCU to determine the origin of the interrupt. When two 33972

devices are used, only the device initiating the interrupt will

have the INT

CS. The INT pin will not clear with rising edge of CS if a

of

bit set. The INT pin is cleared on the rising edge

switch contact change has occurred while

In a multiple 33972 device system with WAKE HIGH and

VDD on (Sleep mode), the falling edge of INT will place all

33972s in Normal mode.

CS. This permits the

CS was LOW.

33972

Analog Integrated Circuit Device Data

10 Freescale Semiconductor

Page 11

FUNCTIONAL DESCRIPTION

FUNCTIONAL PIN DESCRIPTION

WAKE-UP (WAKE)

The WAKE pin is an open-drain output and a wake-up

input. The pin is designed to control a power supply Enable

pin. In the Normal mode, the

WAKE pin is LOW. In the Sleep

mode, the WAKE pin is HIGH. The WAKE pin has a pullup to

the internal +

5.0 V supply.

In Sleep mode with the WAKE pin HIGH, falling edge of

WAKE will place the 33972 in Normal mode. In Sleep mode

with V

applied, the INT pin must be HIGH for negative edge

DD

of WAKE to wake up the device. If VDD is not applied to the

device in Sleep mode, INT does not affect WAKE operation.

BATTERY INPUT (VPWR)

The VPWR pin is battery input and Power-ON Reset to the

33972 IC. The VPWR pin requires external reverse battery

and transient protection. Maximum input voltage on VPWR is

V. All wetting, sustain, and internal logic current is

50

provided from the VPWR pin.

VOLTAGE DRAIN SUPPLY (VDD)

The VDD input pin is used to determine logic levels on the

microprocessor interface (SPI) pins. Current from VDD is

used to drive SO output and the pullup current for CS and INT

pins. VDD

CS or INT.

must be applied for wake-up from negative edge of

PROGRAMMABLE SWITCHES (SP0 : SP7)

The 33972 device has 8 switch inputs capable of being

programmed to read switch-to-ground or switch-to-battery

contacts. The input is compared with a 4.0

V reference.

When programmed to be switch-to-battery, voltages greater

than 4.0

V are considered closed. Voltages less than 4.0 V

are considered open. The opposite holds true when inputs

are programmed as switch-to-ground. Programming features

are defined in

Table 6 through Table 11 in the functional

Device Operation section of this datasheet beginning on

page 12. Voltages greater than the VPWR supply voltage will

source current through the SP inputs to the VPWR pin.

Transient battery voltages greater than 38/40 V must be

clamped by an external device.

SWITCH-TO-GROUND INPUTS (SG0 : SG13)

The SGn pins are switch-to-ground inputs only. The input

is compared with a 4.0 V reference. Voltages greater than

4.0 V are considered open. Voltages less than 4.0 V are

considered closed. Programming features are defined in

Table 6 through Table 11 in the functional Device Operation

section of this datasheet beginning on page 12. Voltages

greater than the VPWR supply voltage will source current

through the SG inputs to the VPWR pin. Transient battery

voltages greater than 40 V must be clamped by an external

device.

GROUND (GND)

The GND pin provides ground for the IC as well as ground

for inputs programmed as switch-to-battery inputs.

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

Page 12

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

MCU INTERFACE DESCRIPTION

The 33972 device directly interfaces to a 3.3 V or 5.0 V

microcontroller unit (MCU). SPI serial clock frequencies up to

MHz may be used for programming and reading switch

6.0

input status (production tested at 4.16

illustrates the configuration between an MCU and one 33972.

Serial peripheral interface (SPI) data is sent to the 33972

device through the SI input pin. As data is being clocked into

the SI pin, status information is being clocked out of the

device by the SO output pin. The response to a SPI

command will always return the switch status, interrupt flag,

and thermal flag. Input switch states are latched into the SO

register on the falling edge of the chip select (

Twenty-four bits are required to complete a transfer of

information between the 33972 and the MCU.

MC68HCXX

Microcontroller

MOSI SI

MISO SO

SCLK

Receive

Buffer

Parallel

Ports

Figure 7. SPI Interface with Microprocessor

Two or more 33972 devices may be used in a module

system. Multiple ICs may be SPI-configured in parallel or

serial. Figures 8 and 9 show the configurations. When using

the serial configuration, 48-clock cycles are required to

transfer data in

/ out of the ICs.

MHz). Figure 7

CS) pin.

33972

24-Bit Shift RegisterShift Register

To Logic

CS

INTINT

MC68HCXX

Microcontroller

Shift Register

Parallel

Ports

MOSI

MISO

SCLK

INT

33972

SI

SO

SCLK

CS

INT

33972

SI

SO

SCLK

CS

INT

Figure 8. SPI Parallel Interface with Microprocessor

MC68HCXX

Microcontroller

Shift Register

Parallel

Ports

MOSI

MISO

SCLK

INT

33972

SI

SO

SCLK

CS

INT

33972

SI

SO

SCLK

CS

INT

Figure 9. SPI Serial Interface with Microprocessor

33972

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

Page 13

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

POWER SUPPLY

The 33972 is designed to operate from 5.5 V to 40 V on

the VPWR pin. Characteristics are provided from 8.0

V to

16 V for the device. Switch contact currents and the internal

logic supply are generated from the VPWR pin. The VDD

supply pin is used to set the SPI communication voltage

levels, current source for the SO driver, and pullup current on

INT and CS.

VDD supply may be removed from the device to reduce

quiescent current. If VDD is removed while the device is in

Normal mode, the device will remain in Normal mode. If VDD

is removed in Sleep mode, the device will remain in Sleep

mode until wake-up input is received (

WAKE HIGH to LOW,

switch input or interrupt timer expires).

Removing VDD from the device disables SPI

communication and will not allow the device to wake up from

INT and CS pins.

POWER-ON RESET (POR)

Applying V

and place the device in Normal mode.

Default settings from Power-ON Reset via V

Command are as follows:

• Programmable Switch – Set to Switch to Battery

• All Inputs Set as Wake-Up

• Wetting Current On (16 mA)

• Wetting Current Timer On (20 ms)

• All Inputs Tri-State

• Analog Select 00000 (No Input Channel Selected)

to the device will cause a Power-ON Reset

PWR

PWR

or Reset

NORMAL AND SLEEP MODES

The 33972 has two operating modes, Normal mode and

Sleep mode. A discussion on Normal mode begins below.

A discussion on Sleep mode begins on page 18.

Normal Mode

Normal mode may be entered by the following events:

• Application of V

• Change-of-Switch State (when enabled)

PWR

to the IC

• Falling Edge of WAKE

• Falling Edge of INT (with VDD = 5.0 V and WAKE at

Logic [1])

• Falling Edge of CS (with VDD = 5.0 V)

• Interrupt Timer Expires

Only in Normal mode with VDD applied can the registers of

the 33972 be programmed through the SPI.

The registers that may be programmed in Normal mode

are listed below. Further explanation of each register is

provided in subsequent paragraphs.

•Programmable Switch Register (Settings Command )

•Wake-Up / Interrupt Register (Wake-Up / Interrupt

Command )

•Wetting Current Register (Metallic Command )

•Wetting Current Timer Register (Wetting Current Timer

Enable Command )

•Tri-State Register (Tri-State Command )

•Analog Select Register (Analog Command )

•Calibration of Timers (Calibration Command )

•Reset (Reset Command )

Figure 6, page 9, is a graphical description of the device

operation in Normal mode. Switch states are latched into the

input register on the falling edge of

CS. The INT to the MCU

is cleared on the rising edge of CS. However, INT will not

clear on rising edge of CS if a switch has closed during SPI

communication (

CS LOW). This prevents switch states from

being missed by the MCU.

PROGRAMMABLE SWITCH REGISTER

Inputs SP0 to SP7 may be programmable for switch-tobattery or switch-to-ground. These inputs types are defined

using the settings command (

for switch-to-battery, a logic [1] for the appropriate bit must be

set. To set an SPn input for switch-to-ground, a logic [0] for

the appropriate bit must be set. The MCU may change or

update the Programmable Switch Register via software at

any time in Normal mode. Regardless of the setting, when the

SPn input switch is closed a logic

Serial Output Response Register (

Table 6). To set an SPn input

[1] will be placed in the

Table 17, page 18).

Table 6. Settings Command

Settings Command Not used Battery/Ground Select

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 1 X X X X X X X X sp7 sp6 sp5 sp4 sp3 sp2 sp1 sp0

WAKE-UP / INTERRUPT REGISTER

The Wake-Up / Interrupt Register defines the inputs that

are allowed to wake the 33972 from Sleep mode or set the

INT pin LOW in Normal mode. Programming the wake-up /

interrupt bit to logic [0] will disable the specific input from

generating an interrupt and will disable the specific input from

waking the IC in Sleep mode (

wake-up /interrupt bit to logic [1] will enable the specific input

to generate an interrupt with switch change of state and will

enable the specific input as wake-up. The MCU may change

or update the Wake-Up

time in Normal mode.

Table 7). Programming the

/ Interrupt Register via software at any

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

Page 14

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

Table 7. Wake-Up / Interrupt Command

Wake-Up /Interrupt Command Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 1 0 X X X X X X X X sp7 sp6 sp5 sp4 sp3 sp2 sp1 sp0

0 0 0 0 0 0 1 1 X X sg13 sg12 sg11 sg10 sg9 sg8 sg7 sg6 sg5 sg4 sg3 sg2 sg1 sg0

WETTING CURRENT REGISTER

The 33972 has two levels of switch contact current, 16 mA

and 2.0 mA (see Figure 10). The metallic command is used

to set the switch contact current level (Table 8). Programming

the metallic bit to logic [0] will set the switch wetting current to

2.0 mA. Programming the metallic bit to logic [1] will set the

switch contact wetting current to 16 mA. The MCU may

change or update the Wetting Current Register via software

at any time in Normal mode.

Wetting current is designed to provide higher levels of

current during switch closure. The higher level of current is

designed to keep switch contacts from building up oxides that

form on the switch contact surface.

Switch Contact Voltage

16 mA Switch Wetting Current

2.0 mA Switch Sustain Current

20 ms Wetting Current Timer

Figure 10. Contact Wetting and Sustain Current

Table 8. Metallic Command

Metallic Command Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 1 0 0 X X X X X X X X sp7 sp6 sp5 sp4 sp3 sp2 sp1 sp0

0 0 0 0 0 1 0 1 X X sg13 sg12 sg11 sg10 sg9 sg8 sg7 sg6 sg5 sg4 sg3 sg2 sg1 sg0

closed switch contact. With multiple wetting current timers

disabled, power dissipation for the IC must be considered.

WETTING CURRENT TIMER REGISTER

Each switch input has a designated 20 ms timer. The timer

starts when the specific switch input crosses the comparator

threshold (4.0

current is reduced from 16 mA to 2.0 mA. The wetting current

timer may be disabled for a specific input. When the timer is

disabled, 16

V). When the 20 ms timer expires, the contact

mA of current will continue to flow through the

The MCU may change or update the Wetting Current

Timer Register via software at any time in Normal mode. This

allows the MCU to control the amount of time wetting current

is applied to the switch contact. Programming the wetting

current timer bit to logic

[0] will disable the wetting current

timer. Programming the wetting current timer bit to logic [1]

will enable the wetting current timer (

Table 9).

Table 9. Wetting Current Timer Enable Command

Wetting Current Timer Commands Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 1 1 1 X X X X X X X X sp7 sp6 sp5 sp4 sp3 sp2 sp1 sp0

0 0 0 0 1 0 0 0 X X sg13 sg12 sg11 sg10 sg9 sg8 sg7 sg6 sg5 sg4 sg3 sg2 sg1 sg0

TRI-STATE REGISTER

The tri-state command is use to set the SPn or SGn input

node as high impedance (

Register bit to logic [1], the input will be high impedance

33972

Table 10). By setting the Tri-State

regardless of the metallic command setting. The comparator

on each input remains active. This command allows the use

of each input as a comparator with a 4.0

V threshold. The

MCU may change or update the Tri-State Register via

software at any time in Normal mode.

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

Page 15

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

Table 10. Tri-State Command

Tri-State Commands Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 1 0 0 1 X X X X X X X X sp7 sp6 sp5 sp4 sp3 sp2 sp1 sp0

0 0 0 0 1 0 1 0 X X sg13 sg12 sg11 sg10 sg9 sg8 sg7 sg6 sg5 sg4 sg3 sg2 sg1 sg0

ANALOG SELECT REGISTER

The analog voltage on switch inputs may be read by the

MCU using the analog command (Table 11). Internal to the

IC is a 22-to-1 analog multiplexer. The voltage present on the

selected input pin is buffered and made available on the

AMUX output pin. The AMUX output pin is clamped to a

maximum of V

present on the input pin. After an input has been selected as

the analog, the corresponding bit in the next SO data stream

will be logic

analog, the user must also set the desired current (16

2.0 mA, or high impedance). Setting bit 6 and bit 5 to 0,0

volts regardless of the higher voltages

DD

[0]. When selecting a channel to be read as

mA,

selects the input as high impedance. Setting bit

0,1 selects 2.0 mA, and 1,0 selects 16 mA. Setting bit 6 and

5 to 1,1 in the Analog Select Register is not allowed and

bit

will place the input as an analog input with high impedance.

Analog currents set by the analog command are pullup

currents for all SGn and SPn inputs (Table 11). The analog

command does not allow pulldown currents on the SPn

inputs. Setting the current to 16 mA or 2.0 mA may be useful

for reading sensor inputs. Further information is provided in

Typical Applications section of this datasheet beginning

the

on page 20. The MCU may change or update the Analog

Select Register via software at any time in Normal mode.

6 and bit 5 to

Table 11. Analog Command

Analog Command Not used Current Select Analog Channel Select

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 1 1 0 X X X X X X X X X 16 mA 2.0 mA 0 0 0 0 0

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

Page 16

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

Table 12. Analog Channel

Bits 43210 Analog Channel Select

00000 No Input Selected

00001 SG0

00010 SG1

00011 SG2

00100 SG3

00101 SG4

00110 SG5

00111 SG6

01000 SG7

01001 SG8

01010 SG9

01011 SG10

01100 SG11

01101 SG12

01110 SG13

01111 SP0

10000 SP1

10001 SP2

10010 SP3

10011 SP4

10100 SP5

10101 SP6

10110 SP7

CALIBRATION OF TIMERS

In cases where an accurate time base is required, the user

may calibrate the internal timers using the calibration

command (

calibration command, the device expects 512 µs logic [0]

calibration pulse on the CS pin. The pulse is used to calibrate

the internal clock. No other SPI pins should transition during

Table 13). After the 33972 device receives the

this 512

frequency changes with temperature, calibration is required

for an accurate time base. Calibrating the timers has no affect

on the quiescent current measurement. The calibration

command simply makes the time base more accurate. The

calibration command may be used to update the device on a

periodic basis.

µs calibration pulse. Because the oscillator

Table 13. Calibration Command

Calibration Command Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 1 0 1 1 X X X X X X X X X X X X X X X X

33972

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

Page 17

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

RESET

The reset command resets all registers to Power-ON

Reset (POR) state. Refer to

Table 15, page 17, for POR

states or the paragraph entitled Power-ON Reset (POR) on

page 13 of this datasheet.

Table 14. Reset Command

Reset Command Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1 1 1 1 1 1 1 X X X X X X X X X X X X X X X X

SPI COMMAND SUMMARY

Table 15 below provides a comprehensive list of SPI

commands recognized by the 33972 and the reset state of

Output (SO) data for input voltages greater or less than the

threshold level. Open switches are always indicated with a

logic [0], closed switches are indicated with logic [1].

each register. Table 16 and Table 17 contain the Serial

Table 15. SPI Command Summary

MSB Command Bits Setting Bits LSBI

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Switch Status

Command

Settings Command

Bat = 1, Gnd = 0

(Default state = 1)

Wake-Up/Interrupt Bit

Wake-Up = 1

Non-Wake-Up = 0

(Default state = 1)

Metallic Command

Metallic = 1

Non-metallic = 0

(Default state = 1)

Analog Command 0 0 0 0 0 1 1 0 X X X X X X X X X

Wetting Current Timer

Enable Command

Timer ON = 1

Timer OFF = 0

(Default state = 1)

Tri-State Command

Input Tri-State = 1

Input Active = 0

(Default state = 1)

Calibration Command

(Default state –

'uncalibrated)

Sleep Command

(Refer to Sleep Mode

on page 18.)

Reset Command 0 1 1 1 1 1 1 1 X X X X X X X X X X X X X X X X

SO Response Will

Always Send

0 0 0 0 0 0 0 0 X X X X X X X X X X X X X X X X

0 0 0 0 0 0 0 1 X X X X X X X X SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

0 0 0 0 0 0 1 0 X X X X X X X X SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

0 0 0 0 0 0 1 1 X X SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

0 0 0 0 0 1 0 0 X X X X X X X X SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

0 0 0 0 0 1 0 1 X X SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

16mA02.0mA

0 0 0 0 0 1 1 1 X X X X X X X X SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

0 0 0 0 1 0 0 0 X X SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

0 0 0 0 1 0 0 1 X X X X X X X X SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

0 0 0 0 1 0 1 0 X X SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

0 0 0 0 1 0 1 1 X X X X X X X X X X X X X X X X

0 0 0 0 1 1 0 0 X X X X X X X X X X

them

int

flg

SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

flg

0 0 0 0 0

0

int

int

timer

int

timer

timer

scan

timer

scan

timer

scan

timer

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

Page 18

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

Table 16. Serial Output (SO) Bit Data

Type of Input

SP Switch to Ground SPn < 4.0 V 1

SG N/A SGn < 4.0 V 1

Input

Programmed

Switch to Ground SPn > 4.0 V 0

Switch to Battery SPn < 4.0 V 0

Switch to Battery SPn > 4.0 V 1

N/A SGn > 4.0 V 0

Table 17. Serial Output (SO) Response Register

them

SO Response Will

Always Send

int

flg

SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SG13 SG12 SG11 SG10 SG9 SG8 SG7 SG6 SG5 SG4 SG3 SG2 SG1 SG0

flg

EXAMPLE OF NORMAL MODE OPERATION

The operation of the device in Normal Mode is defined by

the states of the programmable internal control registers. A

typical application may have the following settings:

• Programmable Switch – Set to Switch-to-Ground

• All Inputs Set as Wake-Up

• Wetting Current On (16 mA)

• Wetting Current Timer On (20 ms)

• All inputs Tri-State-Disabled (comparator is active)

• Analog select 00000 (no input channel selected)

With the device programmed as above, an interrupt will be

generated with each switch contact change of state (open-toclose or close-to-open) and 16

will be source for 20 ms. The INT pin will remain LOW until

switch status is acknowledged by the microprocessor. It is

critical to understand

INT will not be cleared on the rising

edge of CS if a switch closure occurs while CS is LOW. The

maximum duration a switch state change can exist without

acknowledgement depends on the software response time to

the interrupt.

Figure 6, page 9, shows the interaction

between changing input states and the INT and CS pins.

If desired the user may disable interrupts (wake up/

interrupt command) from the 33972 device and read the

switch states on a periodic basis. Switch activation and

deactivation faster than the MCU read rate will not be

acknowledged.

The 33972 device will exit the Normal mode and enter the

Sleep mode only with a valid sleep command.

mA of contact wetting current

Voltage on

Input Pin

SO SPI Bit

SLEEP MODE

Sleep mode is used to reduce system quiescent currents.

Sleep mode may be entered only by sending the sleep

command. All register settings programmed in Normal mode

will be maintained in Sleep mode.

The 33972 will exit Sleep mode and enter Normal mode

when any of the following events occur:

• Input Switch Change of State (when enabled)

• Interrupt Timer Expire

• Falling Edge of WAKE

• Falling Edge of INT (with VDD = 5.0 V and WAKE at

Logic [1])

• Falling Edge of CS (with VDD = 5.0 V)

• Power-ON Reset (POR)

The VDD supply may be removed from the device during

Sleep mode. However removing VDD from the device in Sleep

mode will disable a wake-up from falling edge of

Note In cases where CS is used to wake the device, the

first SO data message is not valid.

The sleep command contains settings for two

programmable timers for Sleep mode, the interrupt timer and

the scan timer, as shown in

Table 18 The interrupt timer is

used as a periodic wake-up timer. When the timer expires, an

interrupt is generated and the device enters Normal mode.

Note The interrupt timer in the 33972 device may be

disabled by programming the interrupt bits to logic

Table 19 shows the programmable settings of the Interrupt

timer.

INT and CS.

[1 1 1].

Table 18. Sleep Command

Sleep Command Command Bits

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

int timer

0 0 0 0 1 1 0 0 X X X X X X X X X X

33972

int timer

int timer

scan timer

scan timer

scan timer

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

Page 19

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

Table 19. Interrupt Timer

Bits 543 Interrupt Period

000 32 ms

001 64 ms

010 128 ms

011 256 ms

100 512 ms

101 1.024 s

110 2.048 s

111 No interrupt wake-up

The scan timer sets the polling period between input

switch reads in Sleep mode. The period is set in the sleep

command and may be set to 000 (no period) to 111 (64 ms).

In Sleep mode when the scan timer expires, inputs will

behave as programmed prior to sleep command. The 33972

will wake up for approximately 125

inputs. At the end of the 125

µs and read the switch

µs, the input switch states are

compared with the switch state prior to sleep command.

When switch state changes are detected, an interrupt (when

enabled; refer to wake-up

/ interrupt command description on

page 14) is generated and the device enters Normal mode.

Without switch state changes, the 33972 will reset the scan

timer, inputs become tri-state, and the Sleep mode continues

until the scan timer expires again.

Table 20 shows the programmable settings of the Scan

timer.

Table 20. Scan Timer

Bits 210 Scan Period

000 No Scan

001 1.0 ms

010 2.0 ms

011 4.0 ms

100 8.0 ms

101 16 ms

110 32 ms

111 64 ms

Note The interrupt and scan timers are disabled in the

Normal mode.

Figure 5, page 9, is a graphical description of how the

33972 device exits Sleep mode and enters Normal mode.

Notice that the device will exit Sleep mode when the interrupt

timer expires or when a switch change of state occurs. The

falling edge of

INT triggers the MCU to wake from Sleep state.

Figure 11 illustrates the current consumed during Sleep

mode. During the 125 µs, the device is fully active and switch

states are read. The quiescent current is calculated by

integrating the normal running current over scan period plus

approximately 60

Inputs active for 125 us

Inputs active for 125 us

Inputs active for 125 us

out of 32 ms

out of 32 ms

out of 32 ms

µA.

I=V/R or 0.270V/100ohm = 2.7mA

I=V/R or 0.270V/100ohm = 2.7mA

I=V/R or 0.270V/100ohm = 2.7mA

I= V/R or 0.270 V/ 100 Ω =2.7 mA

Inputs active for

125 µs out of 32 ms

I=V/R or 6mV/100ohm = 60 uA

I=V/R or 6mV/100ohm = 60 uA

I=V/R or 6mV/100ohm = 60 uA

I=V/R or

6.0 mV/100 Ω=60 µA

Figure 11. Sleep Current Waveform

TEMPERATURE MONITOR

With multiple switch inputs closed and the device

programmed with the wetting current timers disabled,

considerable power will be dissipated by the IC. For this

reason temperature monitoring has been implemented. The

temperature monitor is active in the Normal mode only. When

the IC temperature is above the thermal limit, the temperature

monitor will do all of the following:

• Generate an interrupt.

• Force all 16 mA pullup and pulldown current sources to

revert to 2.0 mA current sources.

• Maintain the 2.0 mA current source and all other

functionality.

• Set the thermal flag bit in the SPI output register.

The thermal flag bit in the SPI word will be cleared on rising

edge of

the thermal limit. When die temperature has cooled below

thermal limit, the device will resume previously programmed

settings.

CS provided the die temperature has cooled below

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

Page 20

TYPICAL APPLICATIONS

INTRODUCTION

TYPICAL APPLICATIONS

INTRODUCTION

The 33972’s primary function is the detection of open or

closed switch contacts. However, there are many features

that allow the device to be used in a variety of applications.

The following is a list of applications to consider for the IC:

Sensor Power Supply

Switch Monitor for Metallic or Elastomeric Switches

Analog Sensor Inputs (Ratiometric)

Power MOSFET / LED Driver and Monitor

Multiple 33972 Devices in a Module System

The following paragraphs describe the applications in

detail.

SENSOR POWER SUPPLY

Each input may be used to supply current to sensors

external to a module. Many sensors such as Hall effect,

pressure sensors, and temperature sensors require a supply

voltage to power the sensor and provide an open collector or

analog output.

to supply power and interface to these types of sensors. In an

application where the input makes continuous transitions,

consider using the wake-up

the interrupt for the particular input.

VBAT

VBAT

16 mA

Hall-Effect

Sensor

Reg

X

Figure 12 shows how the 33972 may be used

/ interrupt command to disable

33972

SP0

SP1

SP7

SG0

SG1

16 2.0

mA

SG12

16 2.0

mA

SG13

V

PWRVPWR

V

PWRVPWR

mA

mA

2.5 k

Ω

V

PWR

V

WAKE

SCLK

CS

SO

INT

2.5 k

V

DD

DD

SI

Ω

MCU

MOSI

SCLK

CS

MISO

INT

IOC[7:0]

Input Capture

Timer Port

Figure 12. Sensor Power Supply

METALLIC / ELASTOMERIC SWITCH

Metallic switch contacts often develop higher contact

resistance over time owing to contact corrosion. The

corrosion is induced by humidity, salt, and other elements

that exist in the environment. For this reason the 33972

provides two settings for contacts. When programmed for

metallic switches, the device provides higher wetting current

to keep switch contacts free of oxides. The higher current

occurs for the first 20

ms of switch closure. Where longer

duration of wetting current is desired, the user may send the

wetting current timer command and disable the timer. Wetting

current will be continuous to the closed switch. After the time

period set by the MCU, the wetting current timer command

may be sent again to enable the timer. The user must

consider power dissipation on the device when disabling the

timer. (Refer to the paragraph entitled

Temperature Monitor,

page 19.)

To increase the amount of wetting current for a switch

contact, the user has two options. Higher wetting current to a

switch may be achieved by paralleling SGn or SPn inputs.

This will increase wetting current by 16

mA for each input

added to the switch contact. The second option is to simply

add an external resistor pullup to the V

supply for switch-

PWR

to-ground inputs or a resistor to ground for a switch-to-battery

input. Adding an external resistor has no effect on the

operation of the device.

Elastomeric switch contacts are made of carbon and have

a high contact resistance. Resistance of 1.0

kΩ is common.

In applications with elastomeric switches, the pullup and

pulldown currents must be reduced to prevent excessive

power dissipation at the contact. Programming for a lower

current settings is provided in the

functional Device

Operation Section beginning on page 12 under Table 8,

Metallic Command.

ANALOG SENSOR INPUTS (RATIOMETRIC)

The 33972 features a 22-to-1 analog multiplexer. Setting

the binary code for a specific input in the analog command

allows the microcontroller to perform analog to digital

conversion on any of the 22 inputs. On rising edge of

multiplexer connects a requested input to the AMUX pin. The

AMUX pin is clamped to max of VDD volts regardless of the

higher voltages present on the input pin. After an input has

been selected as the analog, the corresponding bit in the next

SO data stream will be logic

[0].

The input pin, when selected as analog, may be

configured as analog with high impedance, analog with

mA pullup, or analog with 16 mA pullup. Figure 13,

2.0

page 21, shows how the 33972 may be used to provide a

ratiometric reading of variable resistive input.

CS the

33972

Analog Integrated Circuit Device Data

20 Freescale Semiconductor

Page 21

VBAT

SP0

SP1

VBAT

SP7

SG0

SG1

I

1

2.0 mA

R

Analog Sensor

or Analog Switch

SG12

1

SG13

2.0 mA

33972

V

V

PWR

16 2.0

mA

V

V

PWR

16

mA

I

2

4.54 V to 5.02 V

Ω

2.39 k

0.1%

PWR

PWR

mA

2.0

mA

TYPICAL APPLICATIONS

INTRODUCTION

conversion may be obtained. Using the equation yields the

following:

V

PWR

V

WAKE

SCLK

CS

SO

INT

AMUX

ADC =

V

DD

DD

MCU

ADC =

I1 x R1

I2 x R2

2.0 mA x 2.0 kΩ

2.0 mA x 2.39 kΩ

ADC = 213 counts

SI

MOSI

SCLK

CS

MISO

INT

AN0

Analog

Ports

The ADC value of 213 counts is the value with 0% error

(neglecting the resistor tolerance and AMUX input offset

voltage). Now we can calculate the count value induced by

the mismatch in current sources. From a sample device the

maximum current source was measured at 2.05

minimum current source was measured at 1.99

yields 3% error in A

/ D conversion. The A / D measurement

x225

x 225

mA and

mA. This

will be as follows:

ADC =

V

R

2

REF(H)

V

REF(L)

This A / D conversion is 3% low in value. The error

1.99 mA x 2.0 kΩ

2.05 mA x 2.39 kΩ

ADC = 207 counts

x225

correction factor of 1.03 may be used to correct the value:

Figure 13. Analog Ratiometric Conversion

To read a potentiometer sensor, the wiper should be

grounded and brought back to the module ground, as

illustrated in Figure 13. With the wiper changing the

impedance of the sensor, the analog voltage on the input will

represent the position of the sensor.

Using the Analog feature to provide 2.0 mA of pullup

current to an analog sensor may induce error due to the

accuracy of the current source. For this reason, a ratiometric

conversion must be considered. Using two current sources

(one for the sensor and one to set the reference voltage to the

/ D converter) will yield a maximum error (owing to the

A

33972) of 4%.

Higher accuracy may be achieved through module level

calibration. In this example, we use the resistor values from

Figure 13 and assume the current sources are 4% from each

other. The user may use the module end-of-line tester to

calculate the error in the A / D conversion. By placing a

kΩ, 0.1% resistor in the end-of-line test equipment and

2.0

assuming a perfect 2.0 mA current source from the 33972, a

calculated A

/ D

ADC = 207 counts x 1.03

ADC = 213 counts

An error correction factor may then be stored in E2

memory and used in the A / D calculation for the specific input.

Each input used as analog measurement will have a

dedicated calibrated error correction factor.

POWER MOSFET / LED DRIVER AND MONITOR

Because of the flexible programming of the 33972 device,

it may be used to drive small loads like LEDs or MOSFET

gates. It was specifically designed to power up in the Normal

mode with the inputs tri-state. This was done to ensure the

LEDs or MOSFETs connected to the 33972 power up in the

off-state. The Switch Programmable (SP0

a source-and-sink capability, providing effective MOSFET

gate control. To complete the circuit, a pulldown resistor

should be used to keep the gate from floating during the

Sleep modes.

Figure 14, page 22, shows an application

where the SG0 input is used to monitor the drain-to-source

voltage of the external MOSFET. The 1.5

to set the drain-to-source trip voltage. With the 2.0 mA

current source enabled, an interrupt will be generated when

the drain-to-source voltage is approximately 1.0

– SP7) inputs have

kΩ resistor is used

V.

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

Page 22

TYPICAL APPLICATIONS

INTRODUCTION

VBAT

LOAD

1.5 kΩ

100 kΩ

SG0

SP0

SG13

V

V

PWR

PWR

16

mA

4.0 V Ref

V

V

PWR

PWR

16

mA

4.0 V

V

PWR

V

PWR

4.0 V Ref

Ref

2.0 mA

mA

16

mA

16 2.0

mA

2.0

mA

+

-

Comparator

2.0

mA

+

-

Comparator

+

-

Comparator

SG0

AMUX

To SPI

SG0

To SPI

SG13

To SPI

Figure 14. MOSFET or LED Driver Output

The sequence of commands (from Normal mode with

inputs tri-state) required to set up the device to drive a

MOSFET are as follows:

• wetting current timer enable command – Disable SPn

wetting current timer (refer to Table 9, page 14).

• metallic command – Set SPn to 16 mA or 2.0 mA gate

drive current (refer to Table 8, page 14).

• settings command – Set SPn as switch-to-battery (refer

Table 6, page 13).

to

• tri-state command – Disable tri-state for SPn (refer to

Table 10, page 15).

After the tri-state command has been sent (tri-state

disable), the MOSFET gate will be pulled to ground. From this

point forward the MOSFET may be turned on and off by

sending the settings command

:

• settings command – SPn as switch-to-ground

(MOSFET ON).

• settings command – SPn as switch-to-battery

(MOSFET OFF).

Monitoring of the MOSFET drain in the OFF state provides

open load detection. This is done by using an SGn input

comparator. With the SGn input in tri-state, the load will pull

up the SGn input to battery. With open load the SGn pin is

pulled down to ground through an external resistor. The open

load is indicated by a logic

[1] in the SO data bit.

The analog command may be used to monitor the drain

voltage in the MOSFET ON state. By sourcing 2.0 mA of

current to the 1.5 kΩ resistor, the analog voltage on the SGn

pin will be approximately:

V

= I

SGn

x 1.5 kΩ + V

SGn

DS

As the voltage on the drain of the MOSFET increases, so

does the voltage on the SGn pin. With the SGn pin selected

as analog, the MCU may perform the A

/ D conversion.

Using this method for controlling unclamped inductive

loads is not recommended. Inductive flyback voltages greater

than V

may damage the IC.

PWR

The SP0 : SP7 pins of this device may also be used to send

signals from one module to another. Operation is similar to

the gate control of a MOSFET.

• For LED applications a resistor in series with the LED is

recommended but not required. The switch-to-ground

inputs are recommended for LED application. To drive

the LED use the following commands:

• wetting current timer enable command – Disable SGn

wetting current timer.

• metallic command – Set SGn to 16 mA.

From this point forward the LED may be turned on and off

using the tri-state command :

• tri-state command – Disable tri-state for SGn (LED ON).

• tri-state command – Enable tri-state for SGn (LED

OFF).

These parameters are easily programmed via SPI

commands in Normal mode.

MULTIPLE 33972 DEVICES IN A MODULE SYSTEM

Connecting power to the 33972 and the MCU for Sleep

mode operation may be done in several ways. Table 21

shows several system configurations for power between the

MCU and the 33972 and their specific requirements for

functionality.

Table 21. Sleep Mode Power Supply

MCU

5.0 V 5.0 V

5.0 V 0 V

SPI control may be done in parallel or serial. However when

parallel mode is used, each device is addressed

independently (refer to

33972

V

DD

V

DD

Comments

All wake-up conditions apply. (Refer to Sleep

Mode, page 18.)

SPI wake-up is not possible.

0 V 5.0 V

Sleep mode not possible. Current from CS

pullup will flow through MCU to V

been switched off. Negative edge of

that has

DD

CS will put

33972 in Normal mode.

0 V 0 V

SPI wake-up is not possible.

Multiple 33972 devices may be used in a module system.

MCU Interface Description, page 12).

33972

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

Page 23

TYPICAL APPLICATIONS

INTRODUCTION

Therefore when sending the sleep command, one device will

enter sleep before the other. For multiple devices in a system,

it is recommended that the devices are controlled in serial (S0

from first device is connected to SI of second device). With

two devices, 48

clock pulses are required to shift data in.

When the WAKE feature is used to enable the power supply,

WAKE pins should be connected to the enable pin on the

both

power supply. The

INT pins may be connected to one

interrupt pin on the MCU or may have their own dedicated

interrupt to the MCU.

The transition from Normal to Sleep mode is done by

sending the sleep command. With the devices connected in

serial and the sleep command sent, both will enter Sleep

mode on the rising edge of

CS. When Sleep mode is entered,

the WAKE pin will be logic [1]. If either device wakes up, the

WAKE pin will transition LOW, waking the other device.

A condition exists where the MCU is sending the sleep

command (CS logic [0]) and a switch input changes state.

With this event the device that detects this input will not

transition to Sleep mode, while the second device will enter

Sleep mode. In this case two switch status commands must

be sent to receive accurate switch status data. The first

switch status command will wake the device in Sleep mode.

Switch status data may not be valid from the first switch

status command because of the time required for the input

voltage to rise above the 4.0

V input comparator threshold.

This time is dependant on the impedance of SGn or SPn

node. The second switch status command will provide

accurate switch status information. It is recommended that

software wait 10

ms to 20 ms between the two switch status

commands, allowing time for switch input voltages to

stabilize. With all switch states acknowledged by the MCU,

the sleep sequence may be initiated. All parameters for Sleep

mode should be updated prior to sending the sleep

command.

The 33972 IC has an internal 5.0 V supply from V

PWR

pin.

A POR circuit monitors the internal 5.0 V supply. In the event

of transients on the V

pin, an internal reset may occur.

PWR

Upon reset the 33972 will enter Normal mode with the

internal registers as defined in

Table 15, page 17. Therefore

it is recommended that the MCU periodically update all

registers internal to the IC.

USING THE WAKE FEATURE

The 33972 provides a WAKE output and wake-up input

designed to control an enable pin on system power supply.

While in the Normal mode, the

WAKE output is LOW,

enabling the power supply. In the Sleep mode, the WAKE pin

is HIGH, disabling the power supply. The WAKE pin has a

passive pullup to the internal 5.0

up through a resistor to V

V supply but may be pulled

supply (see Figure 16,

PWR

page 24)

When the WAKE output is not used the pin should be

pulled up to the V

supply through a resistor as shown in

DD

Figure 15, page 24.

During the Sleep mode, a switch closure will set the WAKE

pin LOW, causing the 33972 to enter the Normal mode. The

power supply will then be activated, supplying power to the

pin and the microprocessor and the 33972. The

V

DD

microprocessor can determine the source of the wake-up by

reading the interrupt flag.

COST AND FLEXIBILITY

Systems requiring a significant number of switch

interfaces have many discrete components. Discrete

components on standard PWB consume board space and

must be checked for solder joint integrity. An integrated

approach reduces solder joints, consumes less board space,

and offers wider operating voltage, analog interface

capability, and greater interfacing flexibility.

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

Page 24

TYPICAL APPLICATIONS

INTRODUCTION

VBAT

VBAT

VBAT

SP0

SP1

33972

VPWR

VDD

V

PWR

V

DD

V

Power

DD

Supply

V

DD

VBAT

VBAT

SP7

SG0

SG1

SG12

SG13

SP0

SP1

WAKE

CS

INT

SI

SO

SCLK

AMUX

Figure 15. Power Supply Active in Sleep Mode

Power

Supply

33972

V

PWR

Enable

VPWR

MC68HCXX

Microprocessor

CS

INT

MOSI

MISO

SCLK

AN0

V

DD

V

DD

V

VBAT

SP7

SG0

SG1

SG12

SG13

WAKE

VDD

CS

INT

SI

SO

SCLK

AMUX

DD

MC68HCXX

Microprocessor

CS

INT

MOSI

MISO

SCLK

AN0

Figure 16. Power Supply Shutdown in Sleep Mode

33972

Analog Integrated Circuit Device Data

24 Freescale Semiconductor

Page 25

PACKAGE DIMENSIONS

PACKAGING

PACKAGE DIMENSIONS

For the most current package revision, visit www.freescale.com and perform a keyword search using the 98A listed below.

PACKAGING

DWB SUFFIX

EW SUFFIX (Pb-FREE)

32-LEAD SOIC WIDE BODY

PLASTIC PACKAGE

98ARH99137A

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 25

Page 26

PACKAGING

PACKAGE DIMENSIONS (CONTINUED)

PACKAGE DIMENSIONS (CONTINUED)

33972

Analog Integrated Circuit Device Data

26 Freescale Semiconductor

Page 27

REVISION HISTORY

REVISION DATE DESCRIPTION OF CHANGES

4.0

5.0

6.0

7.0

8.0

9.0

2/2006

6/2006

7/2006

11/2006

12/2006

4/2007

• Converted to Freescale format

• Added PC33972A version

• Changed Figure 15, Power Supply Active in Sleep Mode

• Changed Figure 16, Power Supply Shutdown in Sleep Mode

• Updated Outline Drawing for package

• Update to the prevailing Freescale form and style.

• Added MC33972T devices.

• Updated StatiC Electrical Characteristics on page 6 with 33972T parameters.

• Changed Human Body Model parameters in Maximum Ratings table.

• Replaced Part Number MC33972TEW/R2 with MCZ33972TEW/R2

• Removed Peak Package Reflow Temperature During Reflow (solder reflow) parameter

Maximum Ratings on page 5. Added note with instructions to obtain this information

from

from www.freescale.com.

• Restated note

(6)

• Changed Part Number MCZ33972TEW/R2 with MC33972TEW/R2

• Removed all references to the 33972T device.

• Removed the MC33972TDWB/R2, MC33972TEW/R2, and PC33972AEW/R2 from the

ordering information.

• Added MCZ33972AEW/R2 to the ordering information.

REVISION HISTORY

33972

Analog Integrated Circuit Device Data

Freescale Semiconductor 27

Page 28

How to Reach Us:

Home Page:

www.freescale.com

Web Support:

http://www.freescale.com/support

USA/Europe or Locations Not Listed:

Freescale Semiconductor, Inc.

Technical Information Center, EL516

2100 East Elliot Road

Tempe, Arizona 85284

+1-800-521-6274 or +1-480-768-2130

www.freescale.com/support

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

www.freescale.com/support

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

RoHS-compliant and/or Pb-free versions of Freescale products have the functionality

and electrical characteristics of their non-RoHS-compliant and/or non-Pb-free

counterparts. For further information, see http://www.freescale.com or contact your

Freescale sales representative.

For information on Freescale’s Environmental Products program, go to http://

www.freescale.com/epp.

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license