Page 1

Freescale Semiconductor

Advance Information

Dual Gauge Driver Integrated

Document Number: MC33970

Rev. 3.0, 1/2007

Circuit with Improved Damping

Algorithms

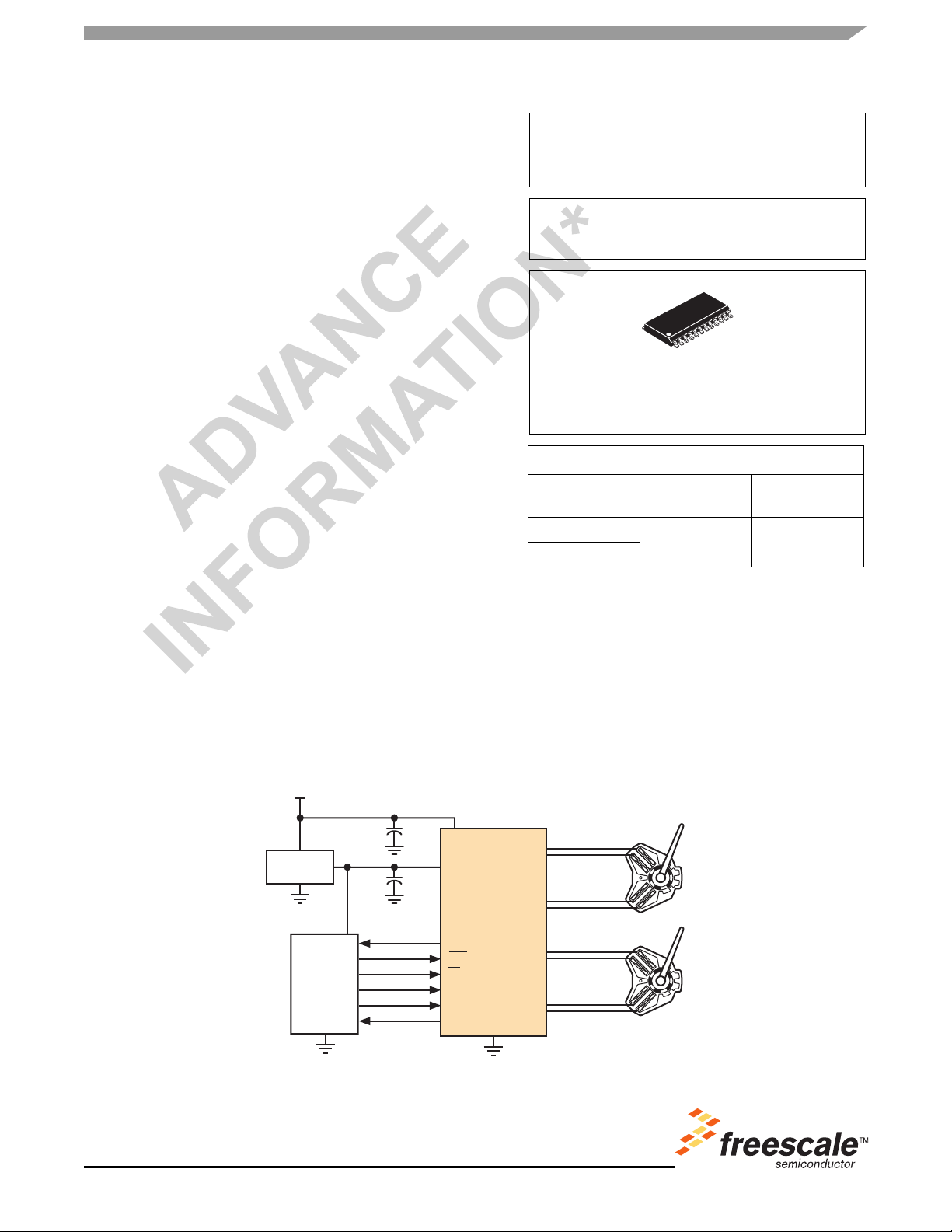

This 33970 is a single-packaged, Serial Peripheral Interface (SPI)

controlled, dual step motor gauge driver integrated circuit (IC). This

monolithic IC consists of four dual output H-Bridge coil drivers and the

associated control logic. Each pair of H-Bridge dri ve rs is used to

automatically control the speed, direction, and magnitude of current

through the two coils of a two-phase instrumentation step motor,

similar to an MMT-licensed AFIC

The 33970 is ideal for use in automotive instrumentation systems

requiring distributed and flexible step motor gauge driving. The

device also eases the transition to step motors from air core motors

by emulating the air core pointer movement with little additional

processor bandwidth utilization.

Features

• MMT-Licensed Two-Phase Step Motor Compatible

• Minimal Processor Overhead Required

• Fully Integrated Pointer Movement and Position State Machine

with Air Core Movement Emulation

• 4096 Possible Steady State Pointer Positions

• 340° Maximum Pointer Sweep

• Fixed Maximum Acceleration and Deceleration of 4500°/s2

• Maximum Pointer Velocity of 400°/s

• Analog Microstepping (12 Steps/Degree of Pointer Movement)

• Pointer Calibration and Return to Zero

• SPI-Controlled 16-Bit Word

• Calibratable Internal Clock

• Low Sleep Mode Current

• Backward Compatible with MC33991

• Improved Pointer Movement, Diagnostics, and Return to Zero (RTZ)

• Pb-Free Packaging Designated by Suffix Code EG

6405.

IMPROVED GAUGE DRIVER

ORDERING INFORMATION

Device

MC33970DW/R2

MCZ33970EG/R2

33970

INTEGRATED CIRCUIT

DW SUFFIX

EG SUFFIX (Pb-FREE)

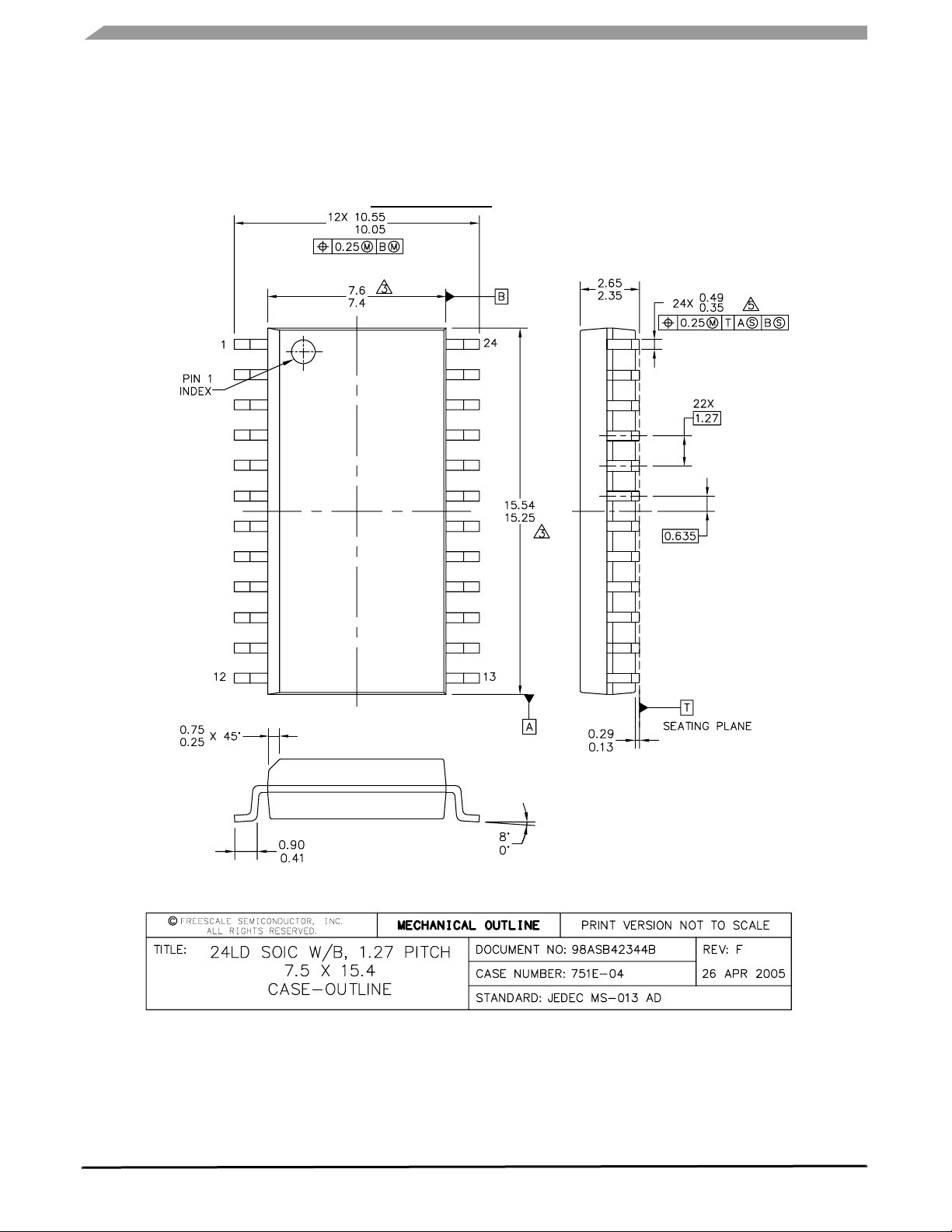

98ASB42344B

24-PIN SOICW

Temperature

Range (T

-40°C to 125°C 24 SOICW

)

A

Package

V

PWR

33970

V

5.0 V

Regulator

DD

MCU

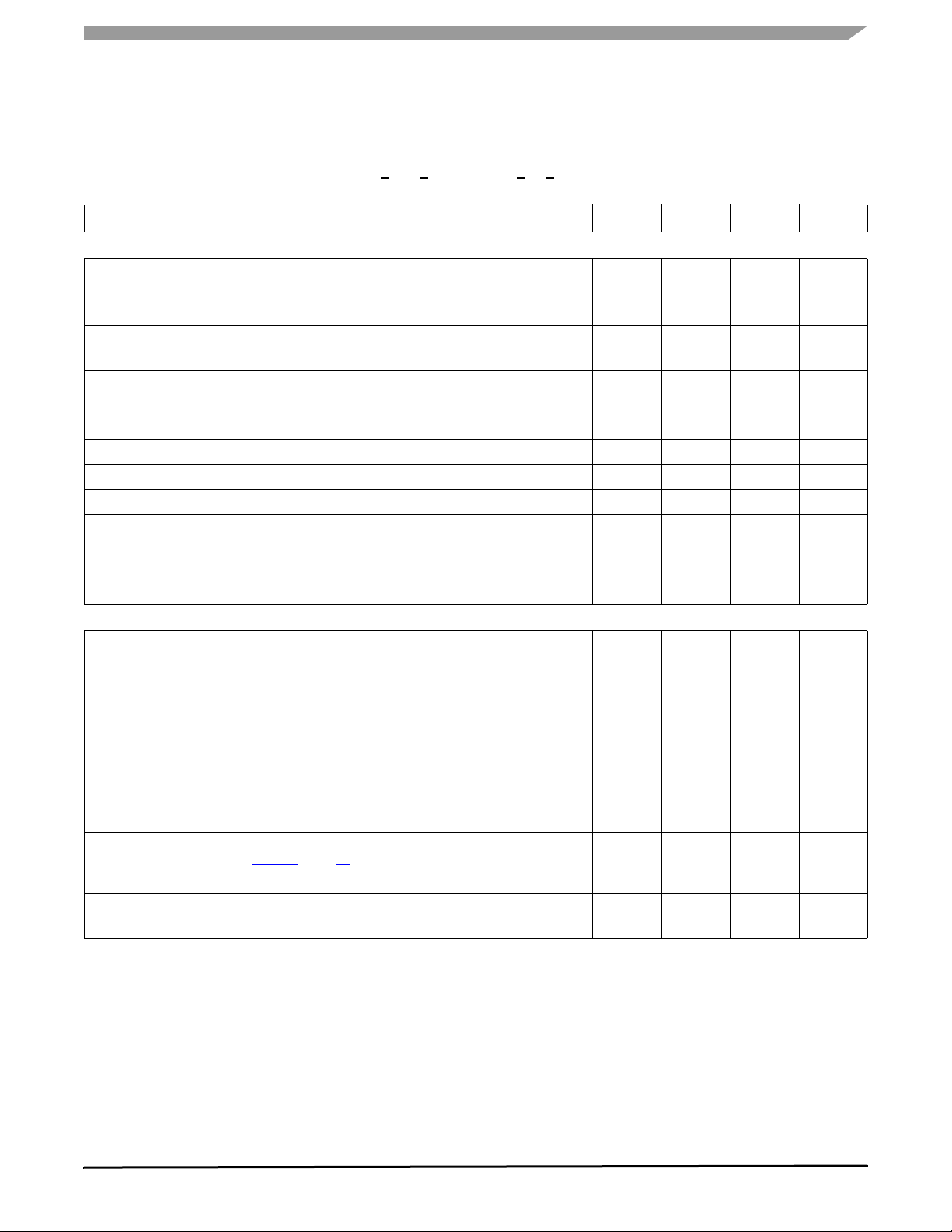

Figure 1. 33970 Simplified Application Diagram

* This document contains certain information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2007. All rights reserved.

VPWR

VDD

RTZ

RST

CS

SCLK

SI

SO

SIN0+

SIN0-

Motor 0

COS0+

COS0-

SIN1+

SIN1-

Motor 1

COS1+

COS1-

GND

Page 2

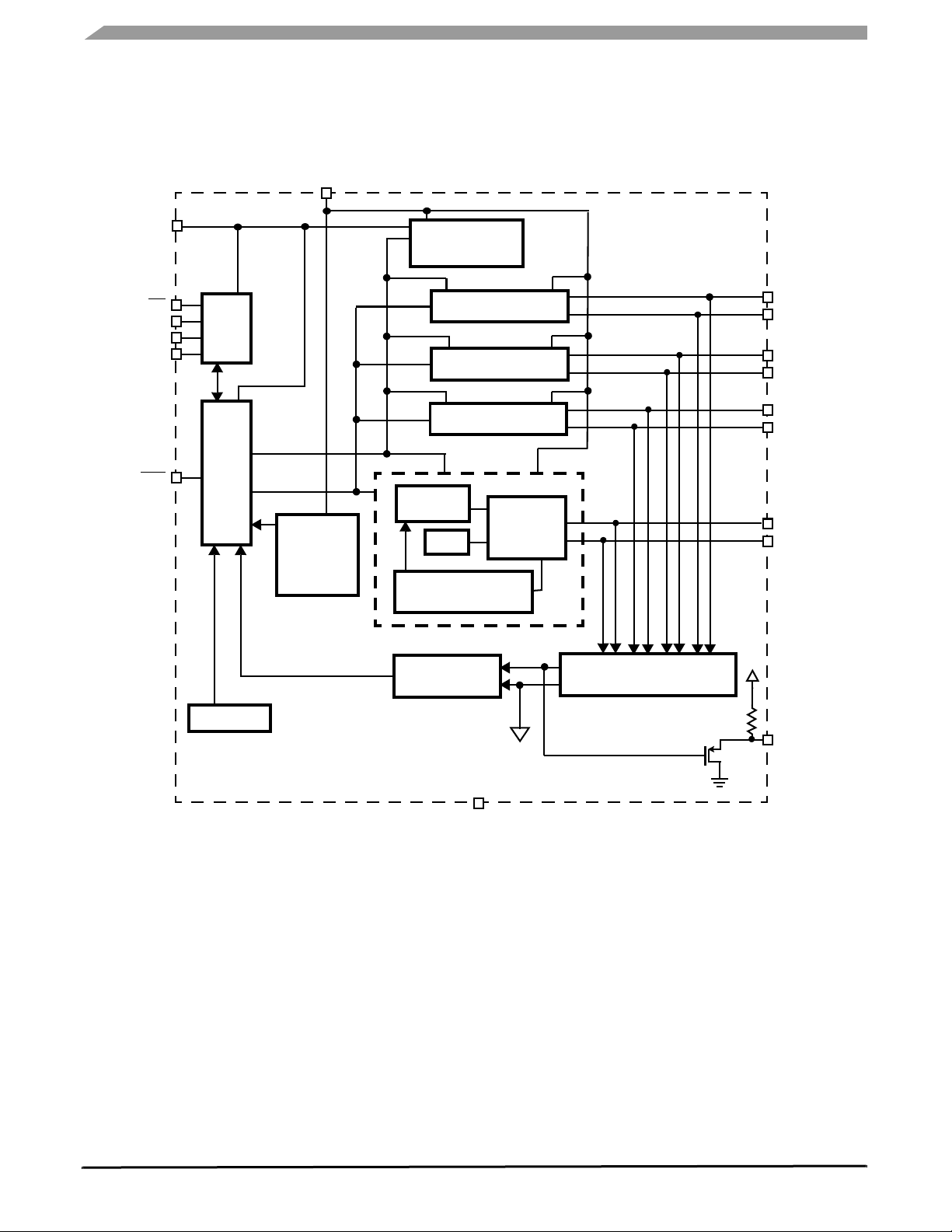

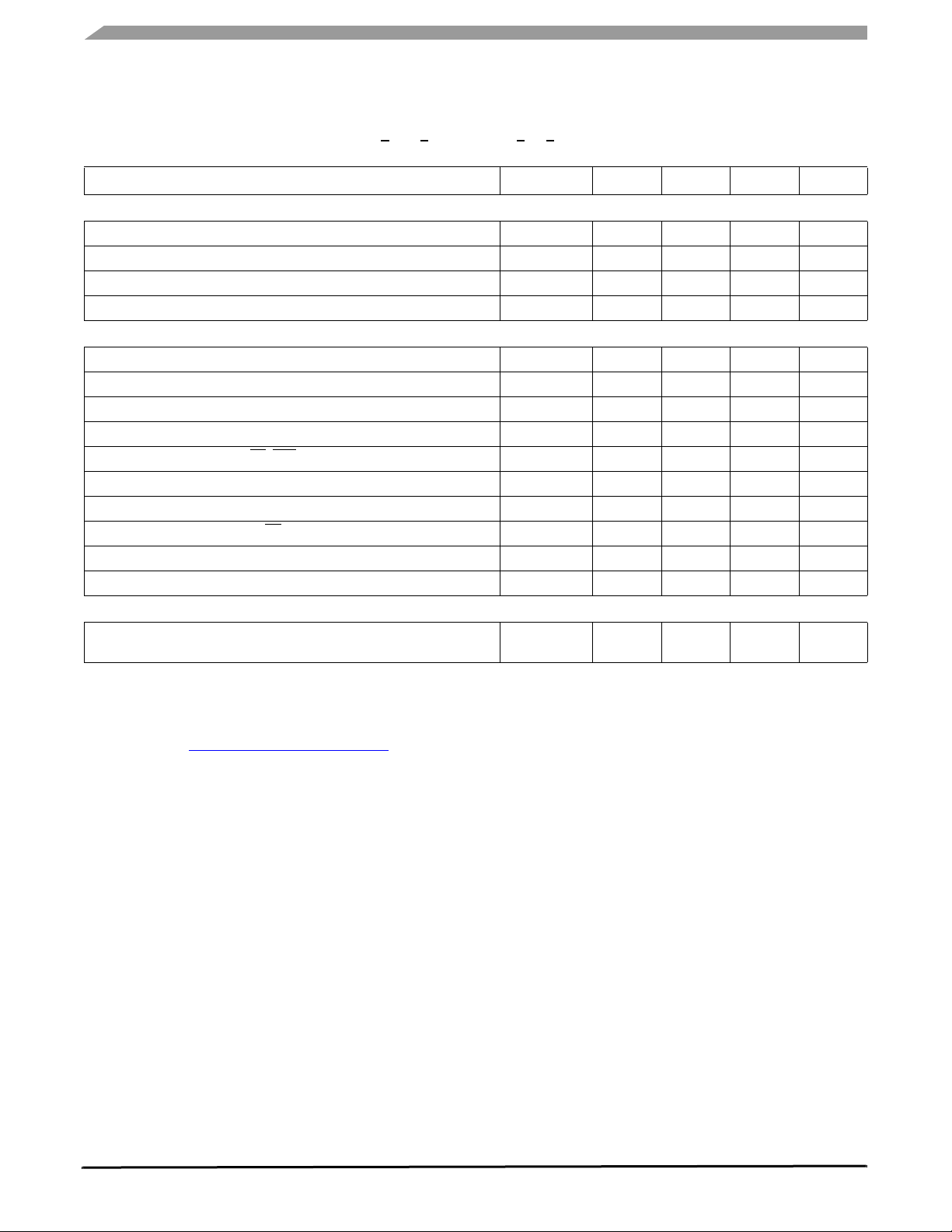

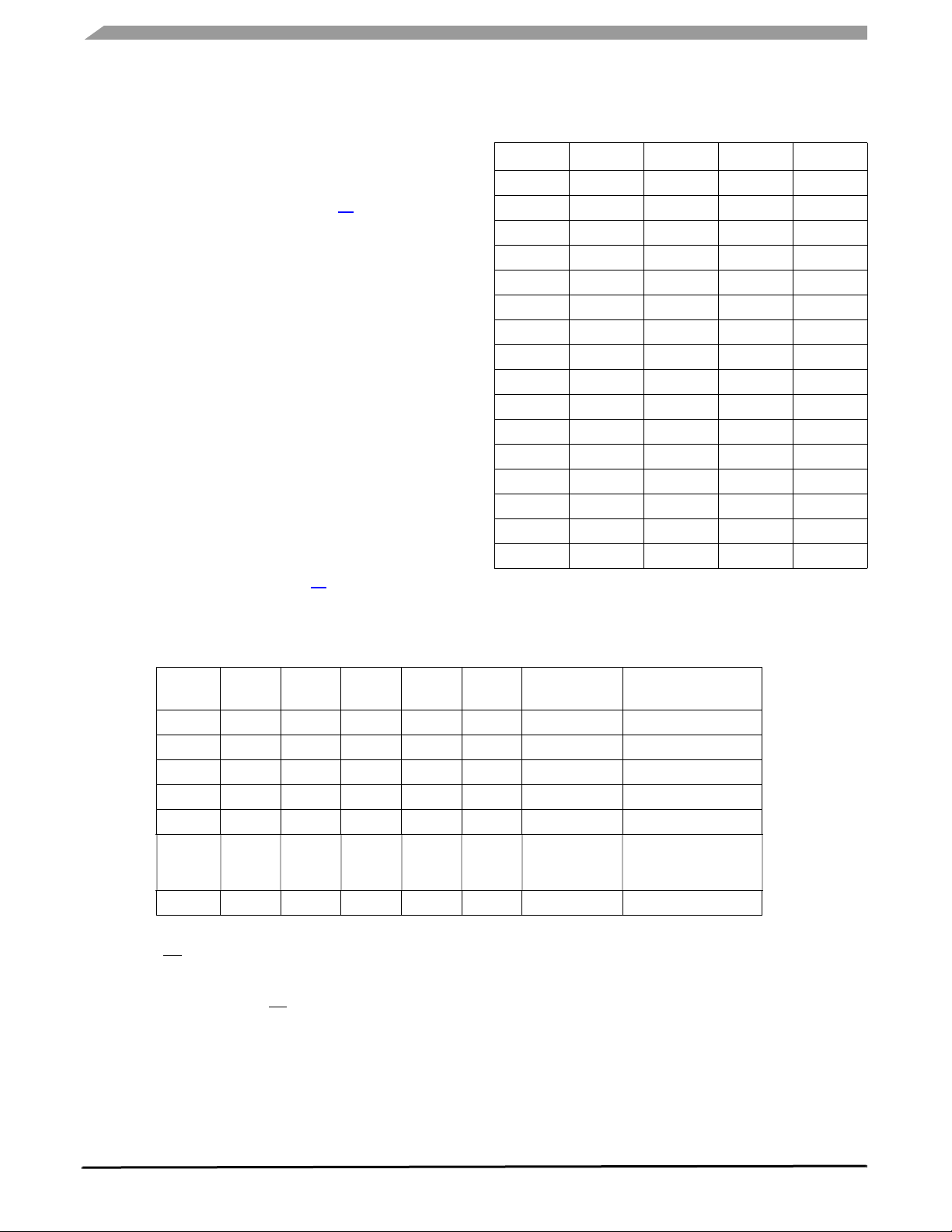

INTERNAL BLOCK DIAGRAM

INTERNAL BLOCK DIAGRAM

VPWR

VDD

CS

SCLK

SO

RST

INTERNAL

REGULATOR

COS0

SPI

SI

LOGIC

STATE

MACHINE

UNDER

-

AND

OVERVOLTAGE

DETECT

ILIM

OVERTEMPERATURE

DETECT

SIGMA-DELTA

ADC

SIN0

COS1

H-BRIDGE

AND

CONTROL

SIN1

MULTIPLEXER

COS0+

COS0-

SIN0+

SIN0-

COS1+

COS1-

SIN1+

SIN1-

VDD

OSCILLATOR

AGND

GND (8)

RTZ

Figure 2. 33970 Simplified Internal Block Diagram

33970

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

Page 3

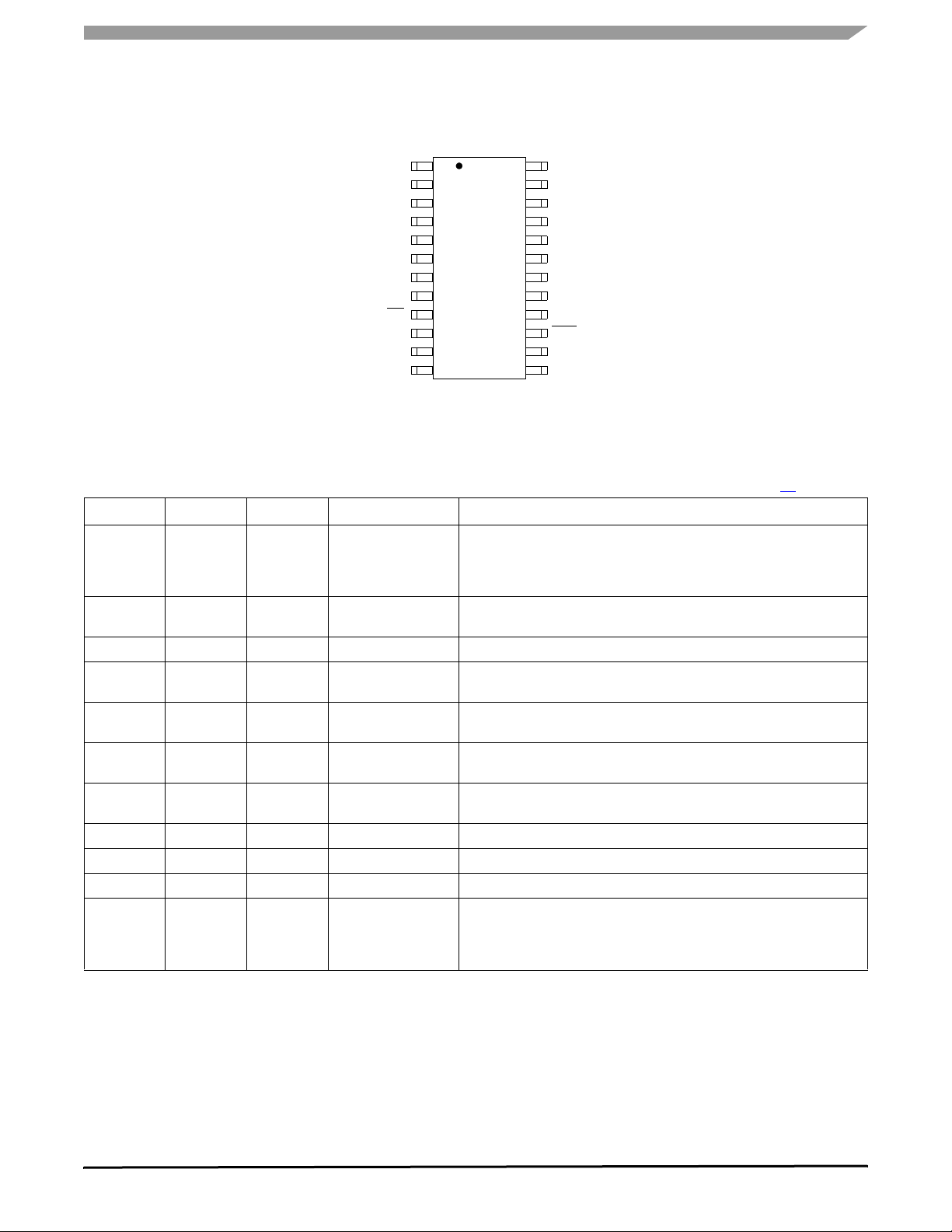

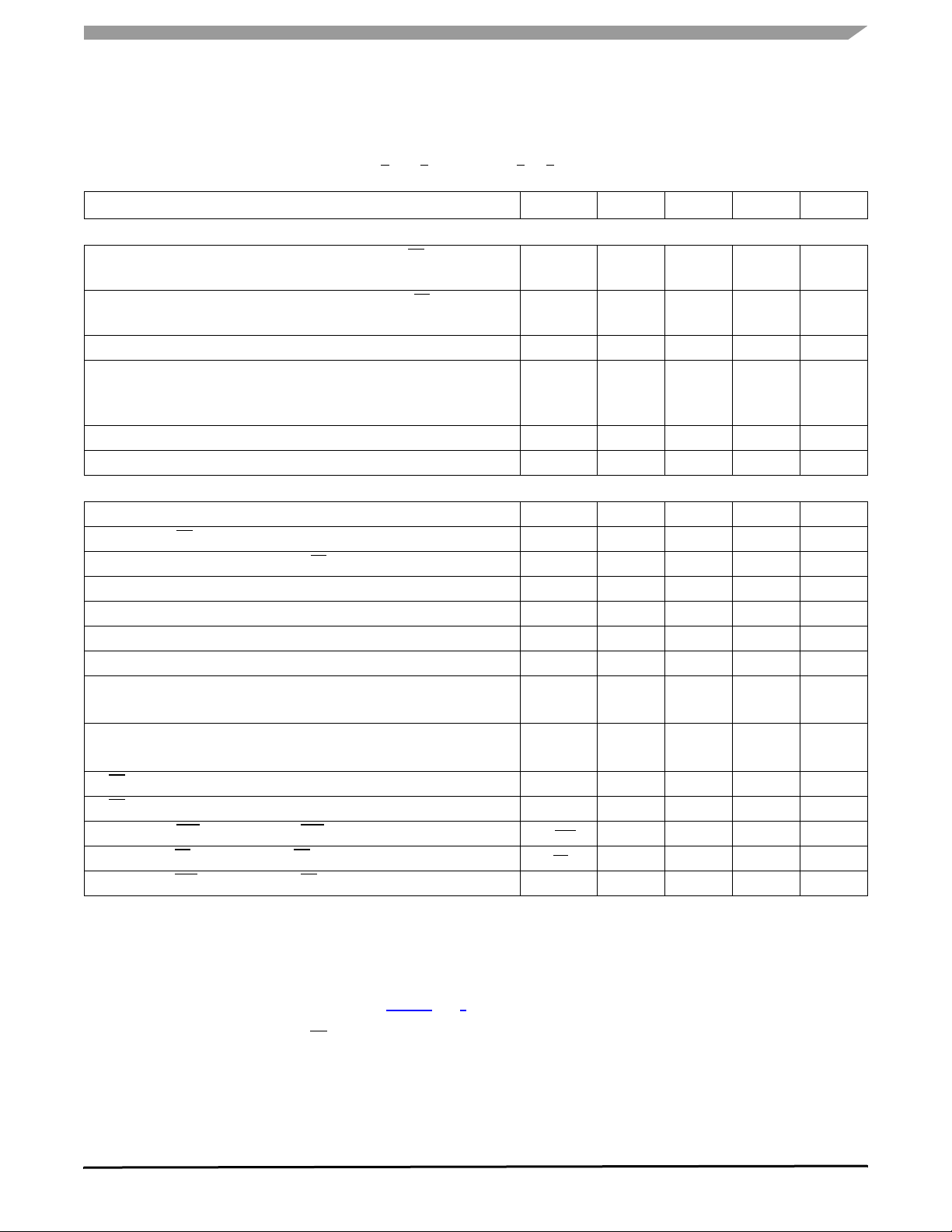

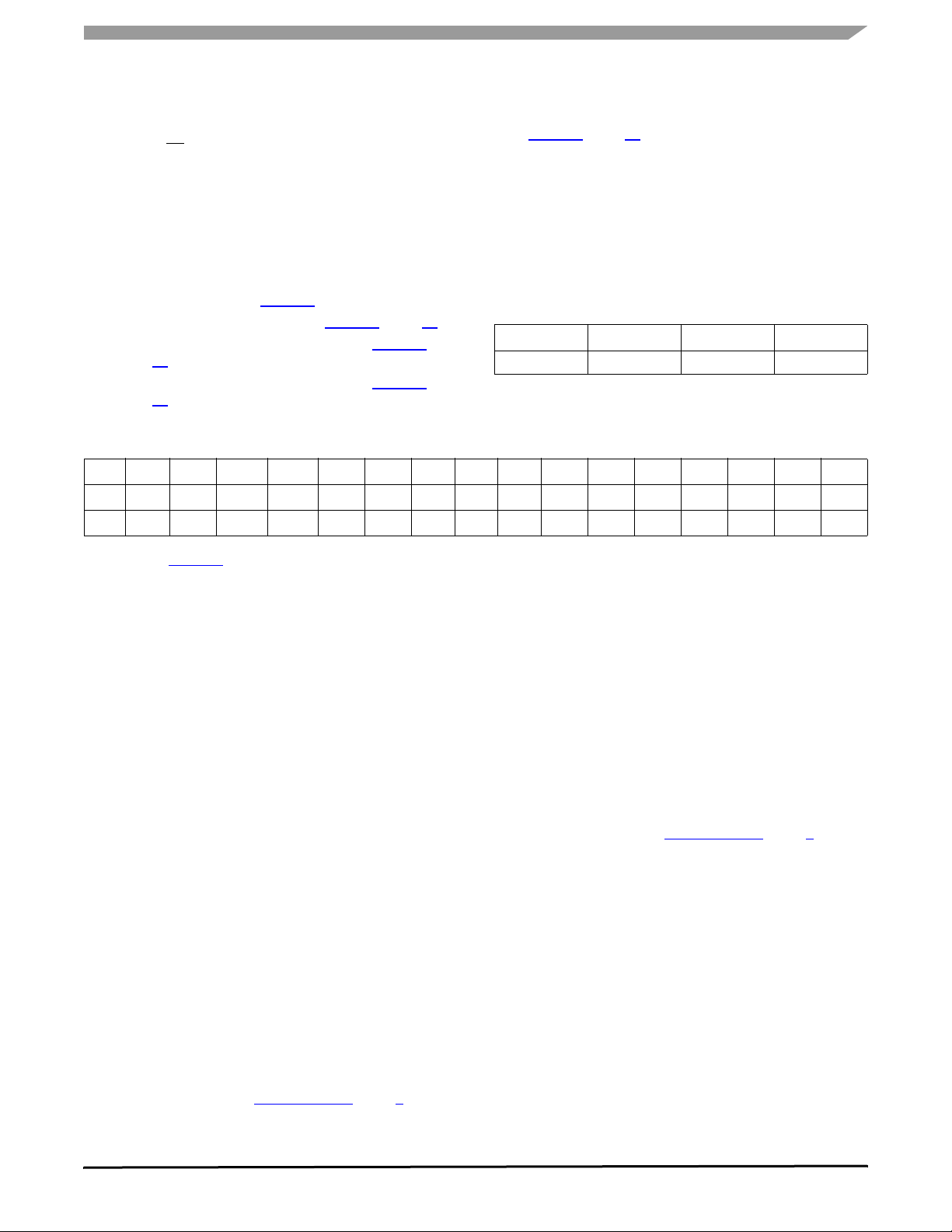

PIN CONNECTIONS

PIN CONNECTIONS

COS0+

COS0-

SIN0+

SIN0-

GND

GND

GND

GND

CS

SCLK

SO

1

2

3

4

5

6

7

8

9

10

11

SI

12

24

23

22

21

20

19

18

17

16

15

14

13

COS1+

COS1SIN1+

SIN1GND

GND

GND

GND

VPWR

RST

VDD

RTZ

Figure 3. 33970 Pin Connections

Table 1. 33970 Pin Definitions

A functional description of each pin can be found in the Functional Pin Description section beginning on page 10.

Pin Number Pin Name Pin Function Formal Name Definition

1

2

3

4

5 – 8,

17–

20

9 CS Input Chip Select

10 SCLK Input Serial Clock

11 SO Output Serial Output

12 SI Input Serial Input

13 RTZ Output Multiplexed Output

14 VDD Input Voltage

15 RST Input Reset

16 VPWR Input Battery Voltage

21

22

23

24

COS0+

COS0−

SIN0+

SIN0−

GND Ground Ground

SIN1−

SIN1+

COS1−

COS1+

Output H-Bridge Outputs 0

Output H-Bridge Outputs 1

Each pin is the output pin of a half bridge, designed to source or sink

current.

These pins serve as the ground for the source of the low-side output

transistors as well as the logic portion of the device.

This pin is connected to a chip select output of a LSI IC.

This pin is connected to the SCLK pin of the master device and acts as a

bit clock for the SPI port.

This pin is connected to the SPI Serial Data Input pin of the master

device, or to the SI pin of the next device in a daisy chain.

This pin is connected to the SPI Serial Data Output pin of the master

device from which it receives output command data.

This is a multiplexed output pin, for the non-driven coil, during a Return to

Zero (RTZ) event.

This SPI and logic power supply input will work with 5.0 V supplies.

This input has an internal active pull-up.

Power supply.

Each of these pins are the output pin of a half bridge, designed to source

or sink current.

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

Page 4

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

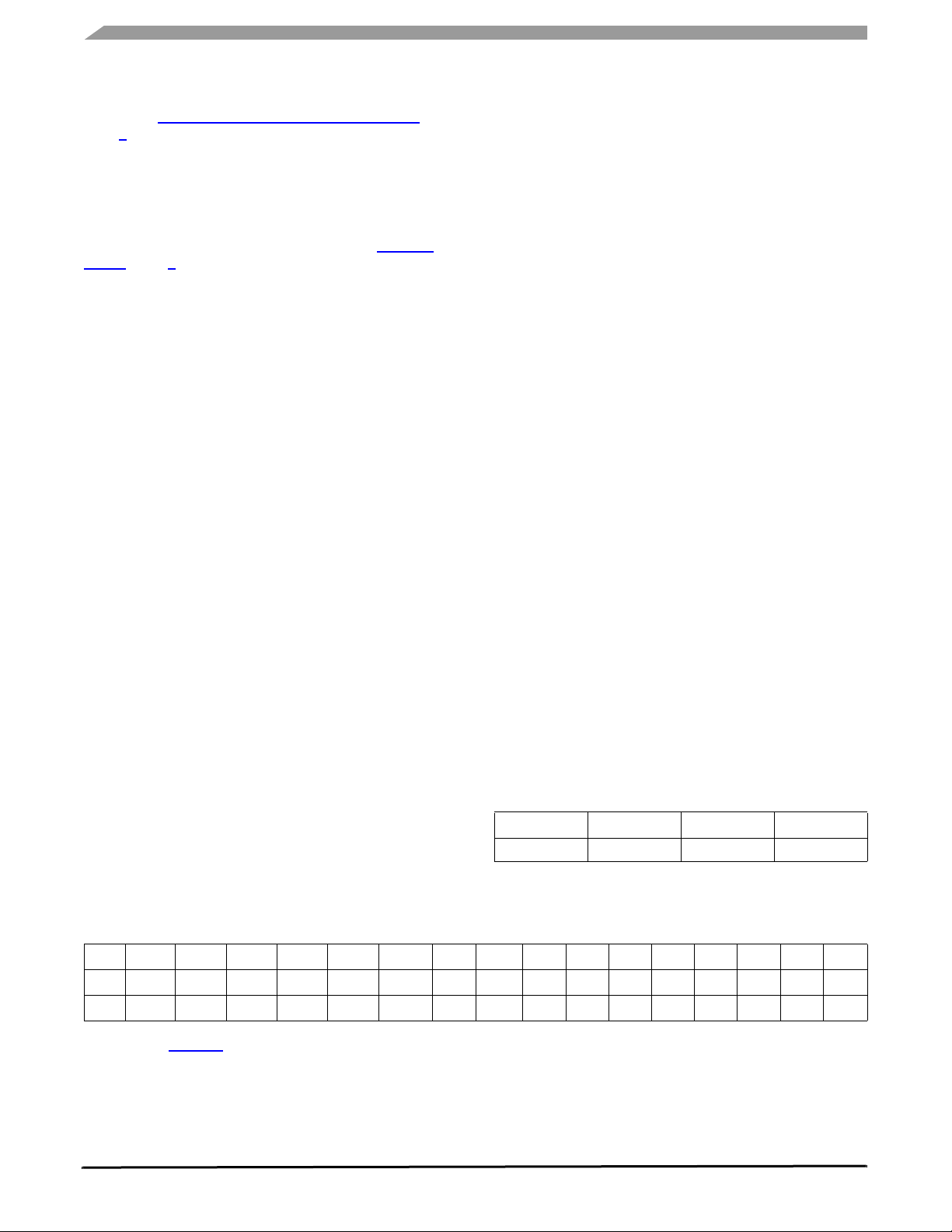

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

Power Supply Voltage

Steady State

Input Pin Voltage

SIN +/- COS +/- Continuous Per Output Current

ESD Voltage

(1)

(2)

(3)

Human Body Model

Machine Model

THERMAL RATINGS

Storage Temperature

Operating Junction Temperature

Thermal Resistance

Junction to Ambient

Junction to Lead

THERMAL RESISTANCE

Peak Package Reflow Temperature During Reflow

(4), (5)

Notes

1. Exceeding voltage limits on Input pins may cause permanent damage to the device.

2. Output continuous output rating so long as maximum junction temperature is not exceeded. Operation at 125°C ambient temperature

will require maximum output current computation using package thermal resistances.

3. ESD1 testing is performed in accordance with the Human Body Model (C

accordance with the Machine Model (C

= 200 pF, R

ZAP

ZAP

= 0 Ω).

4. Pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may

cause malfunction or permanent damage to the device.

5. Freescale’s Package Reflow capability meets Pb-free requirements for JEDEC standard J-STD-020C. For Peak Package Reflow

Temperature and Moisture Sensitivity Levels (MSL),

Go to www.freescale.com, search by part number [e.g. remove prefixes/suffixes and enter the core ID to view all orderable parts. (i.e.

MC33xxxD enter 33xxx), and review parametrics.

V

PWR(SUS)

I

OUTMAX

= 100 pF, R

ZAP

V

V

T

R

R

T

V

IN

ESD1

ESD2

STG

T

J

JA

θ

JL

θ

PPRT

-0.3 to 41

-0.3 to 7.0 V

40 mA

±2000

±200

-55 to 150 °C

-40 to 150 °C

°C/W

60

20

Note 5

= 1500 Ω), ESD2 testing is performed in

ZAP

V

V

°C

33970

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

Page 5

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, -40°C < TA < 125°C, GND = 0 V unless otherwise noted. Typical

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

POWER INPUT

Supply Voltage Range

Fully Operational

Limited Operational

VPWR Supply Current

Gauge 1 and 2 Outputs ON, No Output Loads

VPWR Supply Current (All Outputs Disabled)

Reset = Logic [0], VDD = 5.0 V

Reset = Logic [0], VDD = 0 V

Overvoltage Detection Level

Undervoltage Detection Level

Logic Supply Voltage Range (5.0 V Nominal Supply)

Under VDD Logic Reset

VDD Supply Current

Sleep: Reset Logic [0]

Outputs Enabled

POWER OUTPUTS

Microstep Output (Measured Across Coil Outputs)

SIN0,1, ± (COS0,1, ±) (refer to Table 1)

R

= 200 Ω

OUT

Steps 6, 18 (0, 12)

Steps 5, 7, 17, 19 (1, 11, 13, 23)

Steps 4, 8, 16, 20 (2, 10, 14, 22)

Steps 3, 9, 15, 21 (3, 9, 15, 21)

Steps 2, 10, 14, 22 (4, 8,16, 20)

Steps 1, 11, 13, 23 (5, 7, 17, 19)

Steps 0, 12 (6, 18)

Full Step Active Output (Measured Across Coil Outputs)

SIN0, 1, ± (COS0, 1, ±) (see Figure 9, page 23)

Steps 1, 3 (0, 2)

Microstep, Full Step Output (Measured from Coil Low Side to Ground)

SIN0, 1, ± (COS0, 1, ±), I

Notes

6. Outputs and logic remain active; however, the larger coil voltage levels may be clipped. The reduction in drive voltage may result in a

loss of position control.

7. The logic will reset at some level below the specified Limited Operational minimum.

8. Outputs will disable and must be re-enabled via the PECCR command.

9. Outputs remain active; however, the reduction in drive voltage may result in a loss of position control.

(6), (7)

OUT

(8)

(9)

= 30 mA

= 25°C under nominal conditions unless otherwise noted.

A

V

PWR

I

PWR(ON)

6.5

4.0

–

–

26

26

– 4.0 6.0

I

PWSLP1

I

PWRSLP2

V

PWROV

V

PWRUV

V

DD

V

DDUV

I

DD(OFF)

I

DD(ON)

V

ST6

V

ST5

V

ST4

V

ST3

V

ST2

V

ST1

V

ST0

V

FS

–

–

42

15

60

25

26 32 38 V

5.0 5.6 6.2 V

4.5 5.0 5.5 V

– – 4.5 V

4.82

0.94 V

0.84 V

0.68 V

0.47 V

0.23 V

-0.1

–

–

ST6

ST6

ST6

ST6

ST6

40

1.0

5.3

0.97 V

0.87 V

0.71 V

0.50 V

0.26 V

0.0

ST6

ST6

ST6

ST6

ST6

65

1.8

6.0

1.0 V

0.96 V

0.8 V

0.57 V

0.31 V

0.1

ST6

ST6

ST6

ST6

ST6

4.9 5.3 6.0

V

LS

0.0 0.1 0.3

V

mA

µA

µA

mA

V

V

V

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

Page 6

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, -40°C < TA < 125°C, GND = 0 V unless otherwise noted. Typical

values noted reflect the approximate parameter means at T

Characteristic Symbol Min Typ Max Unit

POWER OUTPUTS (continued)

Output Flyback Clamp

Output Current Limit (Output = VST6)

Overtemperature Shutdown

Overtemperature Hysteresis

CONTROL I/O

Input Logic High Voltage

Input Logic Low Voltage

Input Logic Voltage Hysteresis

Input Logic Pull Down Current (SI, SCLK)

Input Logic Pull-Up Current (CS, RST)

SO High-State Output Voltage (IOH = 1.0 mA)

SO Low-State Output Voltage (IOL = -1.6 mA)

SO Tri-State Leakage Current (CS ≥ 3.5 V)

Input Capacitance

SO Tri-State Capacitance

ANALOG TO DIGITAL CONVERTER (RTZ ACCUMULATOR COUNT)

ADC Gain

(10), (13)

Notes

10. This parameter is guaranteed by design; however, it is not production tested.

11. VDD = 5.0 V.

12. Capacitance not measured. This parameter is guaranteed by design; however, it is not production tested.

13. Reference Figure 8, RTZ Accumulator (Typical)

(10)

(10)

(10)

(11)

(11)

(10)

(12)

(12)

= 25°C under nominal conditions unless otherwise noted.

A

V

FB

I

LIM

OT

OT

HYST

V

IH

V

IL

V

IN(HYST)

I

DWN

I

UP

V

SOH

V

SOL

I

SOLK

C

IN

C

SO

G

ADC

SD

– V

+ 0.5 V

ST6

+ 1.0 V

ST6

40 100 170 mA

155 – 180 °C

8.0 – 16 °C

2.0 – – V

– – 0.8 V

– 100 – mV

3.0 – 20 µA

5.0 – 20 µA

0.8 V

DD

– – V

– 0.2 0.4 V

-5.0 0 5.0 µA

– 4.0 12 pF

– – 20 pF

100 188 270 Counts/V/

ms

33970

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

Page 7

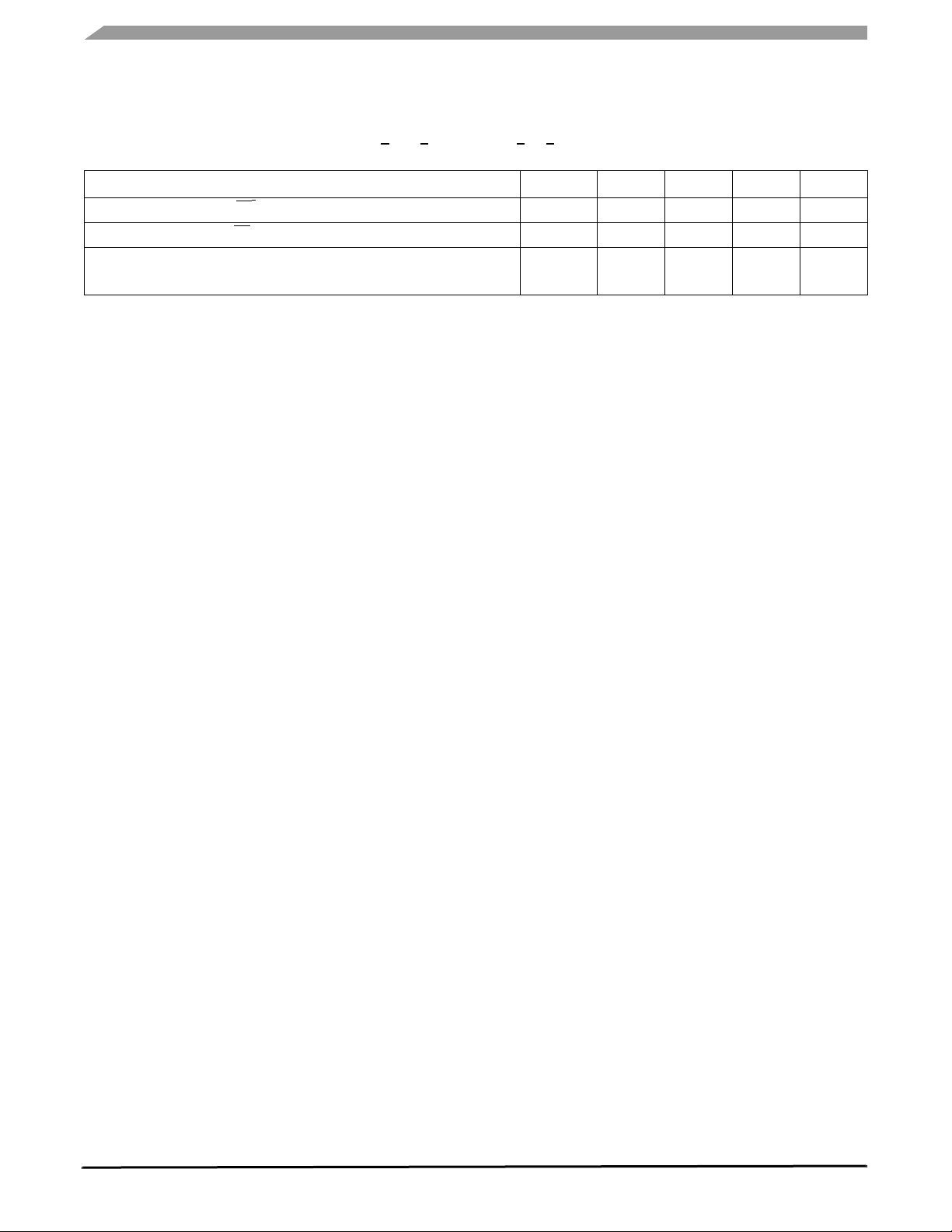

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, -40°C < TA < 125°C, GND = 0 V unless otherwise noted. Typical

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

POWER OUTPUT AND CLOCK TIMINGS

SIN, COS Output Turn ON Delay Time (Time from Rising CS Enabling

Outputs to Steady State Coil Voltages and Currents)

SIN, COS Output Turn OFF Delay Time (Time from Rising CS Disables

Outputs to Steady State Coil Voltages and Currents)

(14)

(14)

Uncalibrated Oscillator Cycle Time

Calibrated Oscillator Cycle Time

Cal Pulse = 8.0 µs, PECCR D4 = Logic [0]

Cal pulse = 8.0 µs, PECCR D4 = Logic [1]

Maximum Pointer Speed

Maximum Pointer Acceleration

SPI INTERFACE TIMING

(15)

(15)

(16)

Recommended Frequency of SPI Operation

Falling Edge of CS to Rising Edge of SCLK (Required Setup Time)

Falling Edge of SCLK to Rising Edge of CS (Required Setup Time)

SI to Falling Edge of SCLK (Required Setup Time)

(17)

Required High State Duration of SCLK (Required Setup Time)

Required Low State Duration of SCLK (Required Setup Time)

Falling Edge of SCLK to SI (Required Hold Time)

(17)

(17)

(17)

(17)

(17)

SO Rise Time

CL = 200 pF

SO Fall Time

CL = 200 pF

SI, CS, SCLK, Incoming Signal Rise Time

SI, CS, SCLK, Incoming Signal Fall Time

Falling Edge of RST to Rising Edge of RST (Required Setup Time)

Rising Edge of CS to Falling Edge of CS (Required Setup Time)

Rising Edge of RST to Falling Edge of CS (Required Setup Time)

(18)

(18)

(17)

(17), (19)

(17)

Notes

14. Maximum specified time for the 33970 is the minimum guaranteed time needed from the microcontroller.

15. The minimum and maximum value will vary proportionally to the internal clock tolerance. These numbers are based on an ideally

calibrated clock frequency of 1.0

MHz. These are not 100 percent tested.

16. The device shall meet all SPI interface timing requirements specified in the SPI Interface Timing section of this table, over the temperature

range specified. Digital interface timing is based on a symmetrical 50 percent duty cycle SCLK Clock Period of 333 ns. The device shall

be fully functional for slower clock speeds. See

Figure 4 and 5.

17. The maximum setup time specified for the 33970 is the minimum time needed from the microcontroller to guarantee correct operation.

18. Rise and Fall time of incoming SI, CS, and SCLK signals suggested for design consideration to prevent the occurrence of double pulsing.

19. The value is for a 1.0 MHz calibrated internal clock. The value will change proportionally as the internal clock frequency changes

t

DLY (ON)

t

DLY (OFF)

t

CLU

t

CLC

V

MAX

A

MAX

f

SPI

t

LEAD

t

LAG

t

S

ISU

t

WSCLKH

t

WSCLKL

t

SI

(HOLD)

t

R

SO

t

F

SO

t

RSI

t

F

SI

t

W

RST

t

CS

t

EN

ms

– – 1.0

ms

– – 1.0

0.65 1.0 1.7 µs

µs

1.0

0.9

1.1

1.0

1.2

1.1

– – 400 °/s

– – 4500 °/s

– 1.0 3.0 MHz

– 50 167 ns

– 50 167 ns

– 25 83 ns

– – 167 ns

– – 167 ns

– 25 83 ns

ns

– 25 50

ns

– 25 50

– – 50 ns

– – 50 ns

– – 3.0 µs

– – 5.0 µs

– – 5.0 µs

2

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

Page 8

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 4.75 V < VDD < 5.25 V, -40°C < TA < 125°C, GND = 0 V unless otherwise noted. Typical

values noted reflect the approximate parameter means at TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

(22)

(20)

(21)

t

SO(EN)

t

SO(DIS)

t

VALID

– – 145 ns

– 1.3 4.0 µs

– 65 105

Time from Falling Edge of CS to SO Low Impedance

Time from Rising Edge of CS to SO High Impedance

Time from Rising Edge of SCLK to SO Data Valid

0.2 V

≤ SO ≥ 0.8 VDD, CL = 200 pF

DD

Notes

20. Time required for output status data to be terminated at SO. 1.0 kΩ load on SO

21. Time required for output status data to be available for use at SO. 1.0 kΩ load on SO.

22. Time required to obtain valid data out from SO following the rise of SCLK.

ns

33970

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

Page 9

RST

CS

SCLK

SI

t

WRST

0.7 V

0.2 V

DD

0.2 V

DD

t

EN

0.7 V

t

LEAD

DD

DD

0.7 V

0.2 V

DD

DD

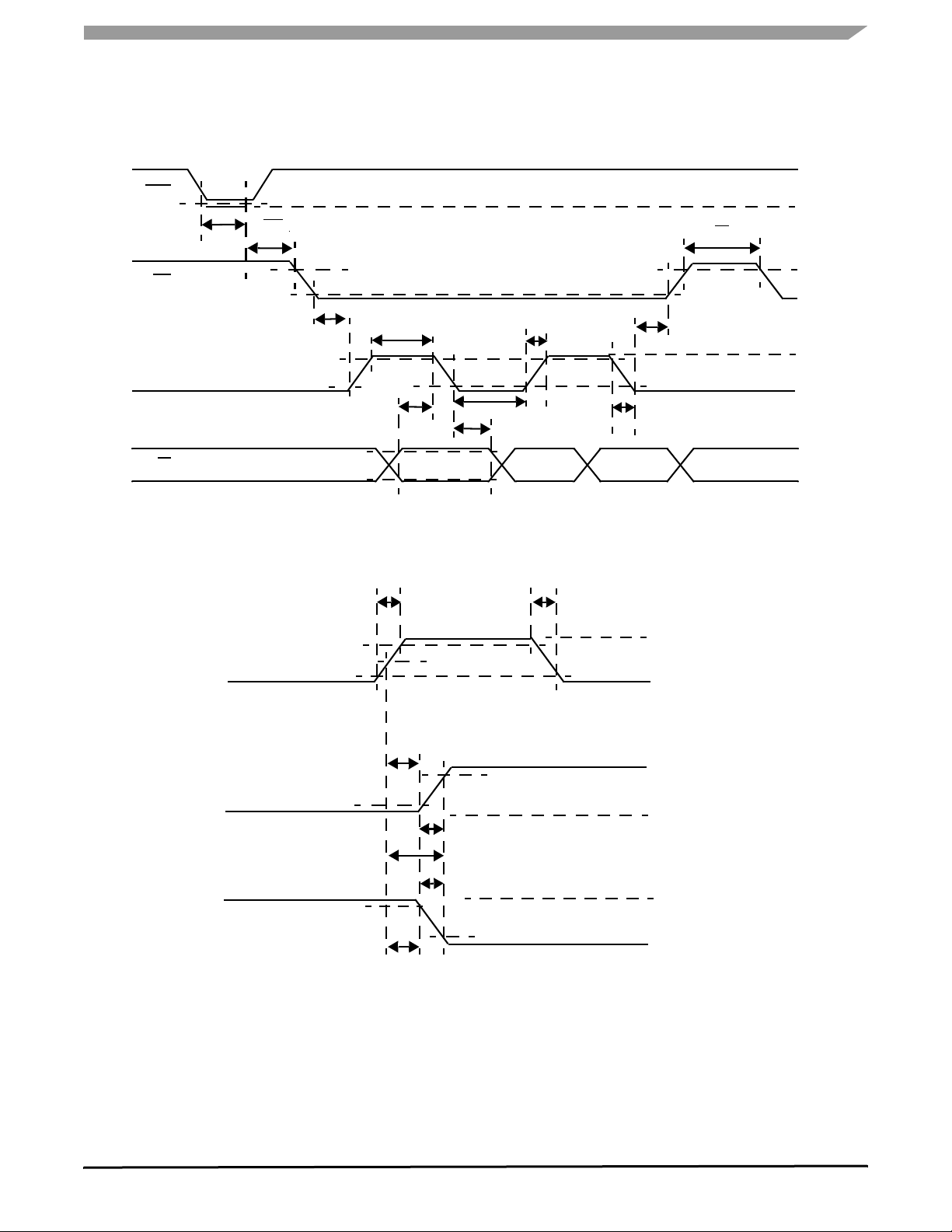

TIMING DIAGRAMS

t

WSCLKh

t

LEAD

t

WSCLKl

t

SI(HOLD)

ELECTRICAL CHARACTERISTICS

0.7 V

DD

t

RSI

t

FSI

t

LAG

TIMING DIAGRAMS

t

CS

V

IN

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

Don’t CareValidValid Don’t CareDon’t Care

V

IL

SCLK

SO

Low-to-High

SO

High-to-Low

Figure 4. Input Timing Switching Characteristics

0.7 V

0.2 V

DD

t

FSI

1.0 V

DD

3.5 V

0.2 V

0.7 V

t

SO(EN)

DD

t

DD

t

SO(DIS)

t

RSI

VALID

50%

t

RSO

t

FSO

V

OH

V

OL

V

OH

V

OL

V

OH

V

OL

Figure 5. Valid Data Delay Time and Valid Time Waveforms

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

Page 10

FUNCTIONAL DESCRIPTION

INTRODUCTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

This 33970 is a single-packaged, Serial Peripheral

Interface (SPI) controlled, dual step motor gauge driver

integrated circuit (IC). This monolithic IC consists of four dual

output H-Bridge coil drivers and the associated control logic.

Each pair of H-Bridge drivers is used to automatically control

the speed, direction, and magnitude of current through the

two coils of a two-phase instrumentation step motor, similar

to an MMT-licensed AFIC

6405.

FUNCTIONAL PIN DESCRIPTION

H-Bridge Outputs 0 (COS0+, COS0-, SIN0+, SIN0-)

Each pin is the output pin of a half bridge, designed to

source or sink current. The H-Bridge pins linearly drive the

sine and cosine coils of two separate step motors to provide

four-quadrant operation.

GROUND (GND)

These pins serve as the ground for the source of the lowside output transistors as well as the logic portion of the

device. They also help dissipate heat from the device.

CHIP SELECT (CS)

The CS pin enables communication with the master

device. When this pin is in a logic [0] state, the 33970 is

capable of transferring information to, and receiving

information from, the master. The 33970 latches data in from

the Input Shift registers to the addressed registers on the

rising edge of

when CS is logic [0]. When CS is logic high, signals at the

SCLK and SI pins are ignored and the SO pin is tri-stated

(high impedance).

state to a logic

internal pull-up (lUP) connected to the pin, as specified in the

section of the Static Electrical Characteristics table entitled

CONTROL I/O, which is found on page 6.

CS. The output driver on the SO pin is enabled

CS will only be transitioned from a logic [1]

[0] state when SCLK is a logic [0]. CS has an

SERIAL CLOCK (SCLK)

SCLK clocks the Internal Shift registers of the 33970

device. The Serial Input (SI) pin accepts data into the Input

Shift register on the falling edge of the SCLK signal, while the

Serial Output pin (SO) shifts data information out of the SO

Line Driver on the rising edge of the SCLK signal. It is

important that the SCLK pin be in a logic [0] state whenever

CS makes any transition. SCLK has an internal pull down

the

), as specified in the section of the Static Electrical

(l

DWN

Characteristics table entitled

on page 6. When CS is logic [1], signals at the SCLK and SI

pins are ignored and SO is tri-stated (high impedance). Refer

to the data transfer timing diagrams in

on page 12.

CONTROL I/O, which is found

Figure 6 and Figure 7

The 33970 is ideal for use in automotive instrumentation

systems requiring distributed and flexible step motor gauge

driving. The device also eases the transition to step motors

from air core motors by emulating the air core pointer

movement with little additional processor bandwidth

utilization.

SERIAL OUTPUT (SO)

The SO data pin is a tri-stateable output from the Shift

register. The Status register bits are the first 16 bits shifted

out. Those bits are followed by the message bits clocked in

FIFO, when the device is in a daisy chain connection or being

sent words that are multiples of 16 bits. Data is shifted on the

rising edge of the SCLK signal. The SO pin will remain in a

high impedance state until the

state.

CS pin is put into a logic low

SERIAL INPUT (SI)

The SI pin is the input of the Serial Peripheral Interface

(SPI). Serial Input (SI) information is read on the falling edge

of SCLK. A 16-bit stream of serial data is required on the SI

pin, beginning with the most significant bit (MSB). Messages

that are not multiples of 16 bits (e.g., daisy chained device

messages) are ignored. After transmitting a 16-bit word, the

CS pin must be de-asserted (logic [1]) before transmitting a

new word. SI information is ignored when CS is in a logic high

state.

Multiplexed Output (RTZ)

This is a multiplexed output pin, for the non-driven coil,

during a Return to Zero (RTZ) event.

Voltage (VDD)

This SPI and logic power supply input will work with 5.0 V

supplies.

RESET (RST)

If the master decides to reset the device, or place it into a

sleep state, the

RST pin will force all internal logic to the known default

the

state. This input has an internal active pull-up.

RST pin is driven to a logic [0]. A logic [0] on

BATTERY VOLTAGE (VPWR)

Power supply.

33970

Analog Integrated Circuit Device Data

10 Freescale Semiconductor

Page 11

FUNCTIONAL DESCRIPTION

FUNCTIONAL PIN DESCRIPTION

H-BRIDGE OUTPUTS 1 (SIN1-, SIN1+, COS1-,

COS1+)

Each of this pins is the output pin of a half bridge, designed

to source or sink current. The H-Bridge pins linearly drive the

sine and cosine coils of two separate step motors to provide

four-quadrant operation.

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

Page 12

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

FUNCTIONAL DEVICE OPERATION

OPERATIONAL MODES

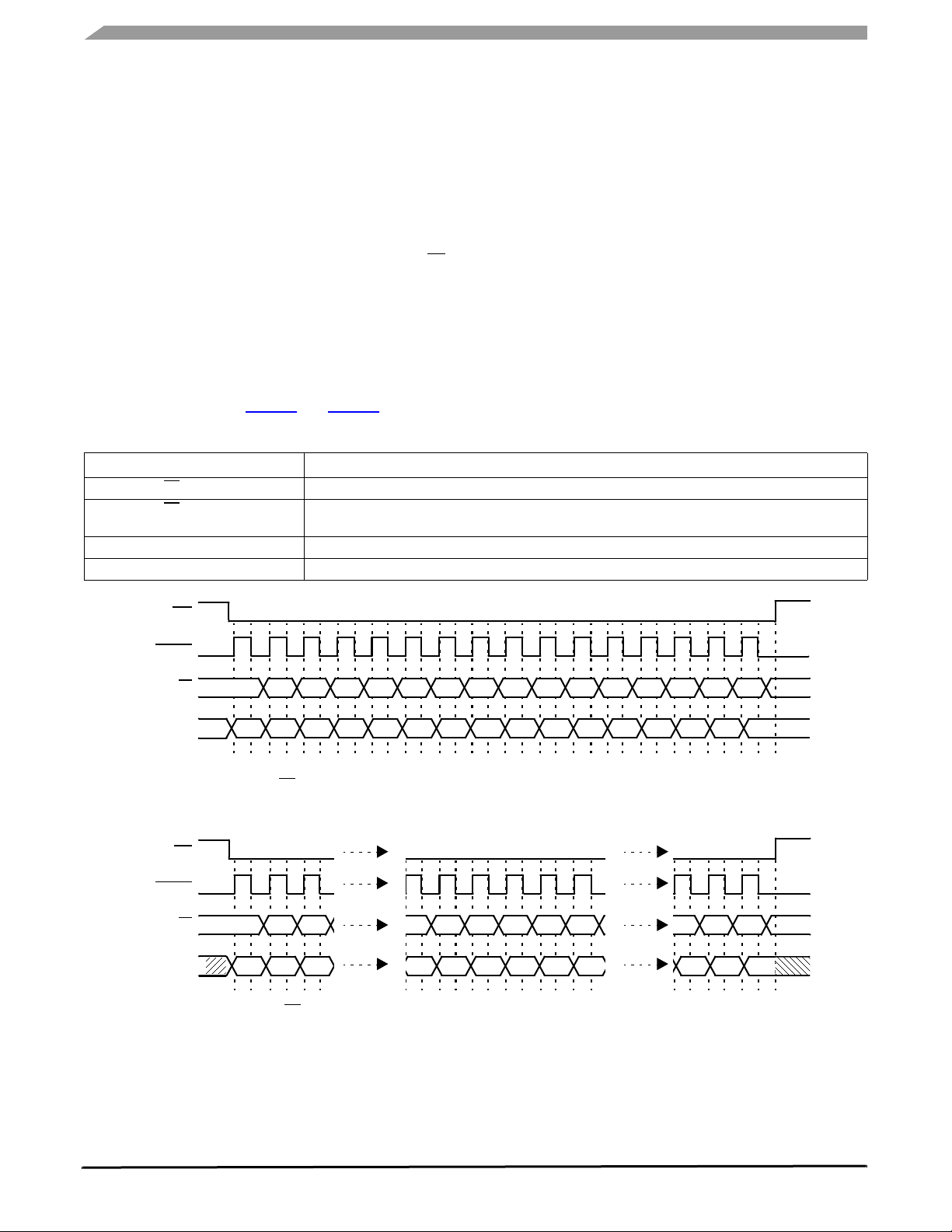

SPI PROTOCOL DESCRIPTION

The SPI interface has a full-duplex, three-wire

synchronous, 16-bit serial synchronous interface data

transfer and four I/O lines associated with it: Chip Select (

CS),

Serial Clock (SCLK), Serial Input (SI), and Serial Output

LOGIC COMMANDS AND REGISTERS

This section provides a description of the 33970 SPI behavior. To follow the explanations below, refer to Table 5 and to the

timing diagrams shown in Figure 6 and Figure 7.

Table 5. Data Transfer Timing

Pin Description

CS (1-to-0)

CS (0-to-1)

SO

SI

SO pin is enabled.

33970 configuration and desired output states are transferred and executed according to the data in

the Shift registers.

Will change state on the rising edge of the SCLK pin signal.

Will accept data on the falling edge of the SCLK pin signal.

(SO). The SI/SO pins of the 33970 follow a first in/first out

(D15/D0) protocol with both input and output words

transferring the most significant bit first. All inputs are

compatible with 5.0 V CMOS logic levels.

CS

SCLK

SI

SO

Note SO is tri-stated when CS is logic [1].

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1

Output shift register is loaded here.

Figure 6. Single 16-Bit Word SPI Communication

CS

SCLK

SI

SO

1. SO is tri-stated when

Notes

2. D15, D14, D13, ..., and D0 refer to the first 16 bits of data into the 33970.

3. D15*, D14*, D13*, ..., and D0* refer to the most recent entry of program data into the 33970.

4. OD15, OD14, OD13, ..., and OD0 refer to the first 16 bits of fault and status data out of the 33970.

D15 D14 D13 D12 D11 D2 D1 D0 D15*D14*D13*D4 D3 D2*D1

OD15 OD14 OD13 OD12 OD11 OD2 OD1 OD0 D15 D14 D13 OD4 OD3 D2 D1

CS is logic [1].

D0

OD0

D0

*

*

D0

Figure 7. Multiple 16-Bit Word SPI Communication

33970

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

Page 13

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

DATA INPUT

The Input Shift register captures data at the falling edge of

the SCLK clock. The SCLK clock pulses exactly 16

times only

inside the transmission windows (CS in a logic [0] state). By

the time the CS signal goes to logic [1] again, the contents of

the Input Shift register are transferred to the appropriate

internal register, to the address contained in bits 15:13. The

minimum time

CS should be kept high depends on the

internal clock speed. That data is specified in the SPI

INTERFACE TIMING section of the Static Electrical

Characteristics, which is found on

page 7. It must be long

enough so the internal clock is able to capture the data from

the Input Shift register and transfer it to the internal registers.

DATA OUTPUT

At the first rising edge of the SCLK clock, with the CS at

[0], the contents of the selected Status Word register

logic

are transferred to the Output Shift register. The first 16 bits

clocked out are the status bits. If data continues to clock in

before the

CS transitions to a logic [1], the device begins to

shift out the data previously clocked in FIFO after the CS first

transitioned to logic [0].

COMMUNICATION MEMORY MAPS AND

REGISTER DESCRIPTIONS

The 33970 device is capable of interfacing directly with a

microcontroller via the 16-bit SPI protocol described and

specified below. The device is controlled by the

microprocessor and reports back status information via the

SPI. This section provides a detailed description of all

registers accessible via serial interface. The various registers

control the behavior of this device.

A message is transmitted by the master beginning with the

MSB (D15) and ending with the LSB (D0). Multiple messages

can be transmitted in succession to accommodate those

applications where daisy chaining is desirable, or to confirm

transmitted data, as long as the messages are all multiples of

bits. Data is transferred through daisy-chained devices, as

16

illustrated in Figure 7, page 12. If an attempt is made to latch

in a message smaller than 16 bits wide, it is ignored.

The 33970 uses six registers to configure the device,

control the state of the four H-bridge outputs, and determine

the type of status information that is clocked back to the

master. The registers are addressed via D15:D13 of the

incoming SPI word (refer to

Table 6).

MODULE MEMORY MAP

Various registers of the 33970 SPI module are addressed

by the three MSBs of the 16-bit word received serially.

Functions to be controlled include:

• Individual gauge drive enabling

• Power-up/down

• Internal clock calibration

• Gauge pointer position and velocity

• Gauge pointer zeroing

• Air core motor movement emulation

• Status information

Status reporting includes:

• Individual gauge overtemperature condition

• Battery overvoltage

• Battery undervoltage

• Pointer zeroing status

• Internal clock status

• Confirmation of coil output changes that should result in

pointer movement

• Real time pointer position information

• Real time pointer velocity step information

• Pointer movement direction

• Command pointer position status

• RTZ accumulator value

Table 6 provides the registers available to control the

above functions.

Table 6. Module Memory Map

Address

[15:13]

000 Power, Enable, Calibration,

and Configuration Register

001 Maximum Velocity Register VELR Page 15

010 Gauge 0 Position Register POS0R Page 15

011 Gauge 1 Position Register POS1R Page 15

100 Gauge Return to 0 Register RTZR Page 16

101 Gauge Return to 0

110 Not Used – –

111 Reserved for Test – –

Register Name See Page

PECCR Page 13

RTZCR Page 17

Configuration

Register

REGISTER DESCRIPTIONS

The following section describes the registers, their

addresses, and their impact on device operation.

Address 000 — Power, Enable, Calibration, and

Configuration Register (PECCR)

The Power, Enable, Calibration, and Configuration

Register is illustrated in

33970 using this register allows the master to

(1)

independently enable or disable the output drivers of the

two-gauge controllers, (2)

(3) disable the air core emulation, (4) select the direction of

the pointer movement during pointer positioning and zeroing,

configure the device for the desired status information to

(5)

be clocked out into the SO pin, or (6) send a null command

for the purpose of reading the status bits. This register is also

used to place the 33970 into a low current consumption

mode.

Each of the gauge drivers can be enabled by writing a

[1] to their assigned address bits, PE0 and PE1

logic

respectively. This feature could be used to disable a driver if

Table 7, page 14. A write to the

calibrate the internal clock,

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

Page 14

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

it is failing or is not being used. The device can be placed into

a standby current mode by writing a logic [0] to both PE0 and

PE1. During this state, most current consuming circuits are

biased off. When in the Standby mode, the internal clock will

remain ON.

The internal state machine utilizes a ROM table of step

times defining the duration that the motor will spend at each

microstep as it accelerates or decelerates to a commanded

position. The accuracy of the acceleration and velocity of the

motor is directly related to the accuracy of the internal clock.

Although the accuracy of the internal clock is temperature

independent, the non-calibrated tolerance is +70% to -35%.

The 33970 was designed with a feature allowing the internal

clock to be software calibrated to a tighter tolerance of ±10%,

using the

CS pin and a reference time pulse provided by the

microcontroller.

Calibration of the internal clock is initiated by writing a

logic [1] to PE3. The calibration pulse, which must be 8.0 µs

for an internal clock speed of 1.0 MHz, will be sent on the CS

pin immediately after the SPI word is sent. No other SPI lines

will be toggled. A clock calibration will be allowed only if the

gauges are disabled or the pointers are not moving, as

indicated by status bits MOV0 and MOV1. Additional details

are provided in the

INTERNAL CLOCK CALIBRATION

section, beginning on page 26.

Some applications may require a guaranteed maximum

pointer velocity and acceleration. Guaranteeing these

maximums requires that the nominal internal clock frequency

fall below 1.0

clock will always be below 1.0

MHz. The frequency range of the calibrated

MHz if bit PE4 is logic [0] when

initiating a calibration command, followed by an 8.0 µs

reference pulse. The frequency will be centered at 1.0 MHz if

bit PE4 is logic

[1].

Some applications may require a slower calibrated clock

due to a lower motor gear reduction ratio. Writing a logic [1]

to bit PE2 will slow the internal oscillator by one-third. Slowing

the clock accommodates a longer calibration pulse without

overrunning the internal counter— a con d i ti on de si g ne d to

generate a CAL fault indication. For example, calibration for

a clock frequency of 667

kHz would require a calibration

pulse of 12 µs. Unless the internal oscillator is slowed by

writing PE2 to logic [1], a 12 µs calibration pulse may overrun

the counter and generate a CAL fault indication.

Some applications may require faster pointer positioning

than is provided with the air core motor emulation feature.

This feature is enabled with the device that is in the default

mode. Writing logic

[1] to bit PE5 will disable the air core

emulation and provide a constant acceleration and

deceleration at the maximum rate.

Bit D6 is logic [0] during a PECCR commands.

The default Pointer Position 0 (PE7 = 0) will be the farthest

counter-clockwise position. A logic [1] written to bit PE7 will

change the location of the position 0, for the Gauge selected

by bit PE8, to the farthest clockwise position. A change in

position 0 of only one, or both, of the two coils can be

accomplished by using bits PE8 and PE7. Performing an RTZ

will always move the pointer to position

0. Exercise care

when writing to PECCR bits PE8 and PE7 in order to prevent

accidental changes of the position 0 locations.

Bits PE11:PE8 determine the content of the bits clocked

out of the SO pin. When bit PE11 is at logic

[0], the clocked

out bits will provide device status. If a logic [1] is written to bit

PE11, the bits clocked out of the SO pin, depending upon the

state of bits PE10:PE8, provides either:

• Accumulator information and detection status during

the RTZ (PE10 logic [0])

• Real time pointer position location at the time CS goes

low (PE10 logic [1] and PE9 logic [0]), or

• The real time step position of the pointer as described

in the velocity

Table 21, page 24 (PE10, PE9, and PE8

logic [1]).

Additional details are provided in the SO Communication

section beginning on page 18.

If bit PE12 is logic [1] during a PECCR command, the state

of PE11:PE0 is ignored. This is referred to as the null

command and can be used to read device status without

affecting device operation.

Table 7. Power, Enable, Calibration, and Configuration Register (PECCR)

Address 000

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

The bits in Table 7 are write-only.

PE12 (D12) — Null Command for Status Read

• 0 = Disable

• 1 = Enable

PE11 (D11) — Status Select bit. This bit selects the

information clocked out of the SO pin.

• 0 = Device Status (the logic states of PE10, PE9, and

33970

– – – – – – – – – – – – –

PE12 PE11 PE10 PE9 PE8 PE7 0 PE5 PE4 PE3 PE2 PE1 PE0

• 1 = RTZ Accumulator Value, Gauge 0 or 1 Pointer

position, or Gauge 0 and 1 Velocity ramp position

(depending upon the logic states of PE10, PE9, and

PE8)

PE10 (D10) — RTZ Accumulator or Pointer Status Select

bit. This bit is recognized only when PE11 = 1.

• 0 = RTZ Accumulator Value and status

PE8 don’t cares)

• 1 = Pointer Position or Speed

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

Page 15

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

PE9 (D9) — Pointer Position or Pointer Speed Select bit.

This bit is recognized only if PE11 and PE10 = 1.

• 0 = Gauge 0 or Gauge 1 Pointer Position

• 1 = Gauge 0 and Gauge 1 Pointer Speed

PE8 (D8) — Pointer Position Gauge Select bit. Also the

Position 0 of the selected gauge is determined by the PE7

selection. This bit is recognized only if PE11 and PE10 = 1

and PE9 = 0.

• 0 = Gauge 0 position

• 1 = Gauge 1 position

PE7 (D7) — Position 0 Location Select bit. This bit

determines the Position 0 of the gauge selected by PE8. RTZ

direction will always be to the position 0.

• 0 = Position 0 is the most CCW (counterclockwise)

position

• 1 = Position 0 is the most CW (clockwise) position

PE6 (D6) — This bit must be transmitted as logic [0] for

valid PECCR commands.

PE5 (D5) — Air Core Motor Emulation bit. This bit is

enabled or disabled (acceleration and deceleration is

constant if disabled).

• 0 = Enable

• 1 = Disable

PE4 (D4) — Clock Calibration Frequency Selector

• 0 = Maximum f =1.0 MHz (for 8.0 µs calibration pulse)

• 1 = Nominal f =1.0 MHz (for 8.0 µs calibration pulse)

PE3 (D3) — Clock Calibration Enable bit. This bit enables

or disables the clock calibration.

• 0 = Disable

•1 = Enable

PE2 (D2) — Oscillator Adjustment

•0 = t

CLU

• 1 = 0.66 x t

CLU

PE1 (D1) — Gauge 1 Enable bit. This bit enables or

disables the output driver of Gauge 1.

• 0 = Disable

•1 = Enable

PE0 (D0) — Gauge 0 Enable bit. This bit enables or

disables the output driver of Gauge 0.

• 0 = Disable

•1 = Enable

Address 001 — Maximum Velocity Register (VELR)

The Gauge Maximum Velocity Register is used to set a

maximum velocity for each gauge (refer to

Table 8). Bits

V7:V0 contain a position value from 1– 225 that is

representative of the velocity position value described in

Table 21, page 24. The table value becomes the maximum

velocity until it is changed to another value. If a maximum

value is chosen greater than the maximum velocity in the

acceleration table, the maximum table value becomes the

maximum velocity. If the motor is turning at a speed greater

than the new maximum, the motor immediately moves down

the velocity ramp until the speed falls equal to or below it.

Velocity for each motor can be changed simultaneously or

independently by writing V8 and/or V9 to a logic

V12:V10 must be at logic

[0] for valid VELR commands.

[1]. Bits

Table 8. Maximum Velocity Register (VELR)

Address 001

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

The bits in Table 8 are write-only.

V12:V10 (D12:D10) — These bits must be transmitted as

logic

V9 (D9) — Gauge 1 Velocity. Specifies whether the

maximum velocity determined in the V7: V0 field will apply to

Gauge 1.

• 0 = Velocity does not apply to Gauge 1

• 1 = Velocity applies to Gauge 1

V8 (D8) — Gauge 0 Velocity. Specifies whether the

maximum velocity specified in the V7: V0 field will apply to

Gauge 0.

• 0 = Velocity does not apply to Gauge 0

• 1 = Velocity applies to Gauge 0

– – – – – – – – – – – – –

0 0 0 V9 V8 V7 V6 V5 V4 V3 V2 V1 V0

V7:V0 (D7:D0) — Maximum Velocity. Specifies the

Table 21. This velocity will

[0] for valid VELR commands

maximum velocity position from

remain the maximum of the intended gauge until changed by

command. Velocities can range from position 1 (00000001)

to position 225 (11111111).

Addresses 010 and 011 — Gauge 0/1 Position Registers

(POS0R, POS1R)

Gauge 0 Position Register (SI Addresses 010) bits

11: P0 0 are written to when communicating the desired

P0

pointer positions, and Gauge 1 Position Register (SI Address

011) bits P1

11: P1 0 are written to when communicating the

desired pointer positions. Commanded positions can range

from 0 to 4095. The D12 bit must be at logic

[0] for valid

POS0R and POS1R commands.

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

Page 16

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

Table 9. Gauge 0 Position Register (POS0R)

Address 010

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

– – – – – – – – – – – – –

0 P0 11 P0 10 P0 9 P0 8 P0 7 P0 6 P0 5 P0 4 P0 3 P02 P01 P0 0

The bits in Table 9 are write-only.

P0 12 (D12) — This bit must be transmitted as logic [0] for

valid commands.

P0 11:P0 0 (D11:D0) — Desired pointer position of

Gauge 0. Pointer positions can range from 0

(000000000000) to position 4095 (111111111111). For a

step motor requiring 12

microsteps per degree of pointer

movement, the maximum pointer sweep is 341.25°.

.

Table 10. Gauge 1 Position Register (POS1R)

Address 011

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

The bits in Table 10 are write-only.

P1 12 (D12) — This bit must be transmitted as logic [0] for

valid commands.

P1 11:P1 0 (D11:D0) — Desired pointer position of

Gauge 1. Pointer positions can range from 0

(000000000000) to position 4095 (111111111111). For a

step motor requiring 12

movement, the maximum pointer sweep is 341.25°

(4095 ÷ 12).

– – – – – – – – – – – – –

0 P1 11 P1 10 P1 9 P1 8 P1 7 P1 6 P1 5 P1 4 P1 3 P1 2 P1 1 P1 0

driven coil is integrated and its results are stored in an

accumulator.

A logic [1] written to bit RZ1 enables a Return to Zero for

Gauge 0 if RZ0 is logic [0], and Gauge 1 if RZ0 is logic [1],

respectively. Similarly, a logic [0] written to bit RZ1 disables a

0 when RZ0 is logic [0], and

microsteps per degree of pointer

Return to Zero for Gauge

Gauge 1 when RZ0 is logic [1], respectively.

Bits D12:D5 and D3:D2 must be at logic [0] for valid RTZR

commands.

Bit RZ4 is used to enable an unconditional RTZ event. A

Address 100 — Gauge Return to Zero Register (RTZR)

Gauge Return to Zero Register (RTZR) (refer to Table 11)

is written to return the gauge pointers to the zero position.

During an RTZ event, the pointer is returned to zero using full

steps, where only one coil is driven at any point in time. The

[0] results in a typical RTZ event, automatically

logic

providing a Stop when a stall condition is detected. A logic [1]

will result in RTZ movement, causing a Stop if a logic [0] is

written to bit RZ0. This feature is useful during development

and characterization of RTZ requirements.

back electromotive force (EMF) signal present on the non-

Table 11. Return to Zero Register (RTZR)

Address 100

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

The register bits in Table 11 are write-only.

RZ12:RZ5 (D12:D5) — These bits must be transmitted as

logic

RZ4 (D4) — This bit is used to enable an unconditional

RTZ event.

• 0 = Automatic Return to Zero

• 1 = Unconditional Return to Zero

– – – – – – – – – – – – –

0 0 0 0 0 0 0 0 RZ4 0 RZ2 RZ1 RZ0

RZ3 (D3) — This bit must be transmitted as logic [0] for

valid commands.

[0] for valid commands.

RZ2 (D2) — Return to Zero Direction bit. This bit is used to

properly sequence the integrator, depending upon the

desired zeroing direction.

• 0 = Return to Zero will occur in the CCW direction

= 0)

(PE7

• 1 = Return to Zero will occur in the CW direction

(PE7

= 1)

33970

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

Page 17

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

RZ1 (D1) — Return to Zero Direction. This bit commands

the selected gauge to return the pointer to zero position.

• 0 = Return to Zero Disabled

• 1 = Return to Zero Enabled

RZ0 (D0) — Gauge Select: Gauge 0/Gauge 1. This bit

selects the gauge to be commanded.

• 0 = Selects Gauge 0

• 1 = Selects Gauge 1

Address 101 — Gauge Return to Zero Configuration

Register

Gauge Return to Zero Configuration Register (RTZCR) is

used to configure the Return to Zero Event (refer to

Table 12). It is written to modify the step time, or rate; at

which the pointer moves during an RTZ event. Also, the

integration blanking time, which is the time immediately

following the transition of a coil from a driven state to an open

state in the RTZ mode, is adjustable with this command.

Finally, this command is used to adjust the threshold of the

RTZ integration register.

The values used for this register should be selected during

development to optimize the RTZ for each application.

Selecting an RTZ step rate resulting in consistently

successful zero detections depends on a clear understanding

of the motor characteristics. Specifically, resonant

frequencies exist due to the interaction between the motor

and the pointer. This command allows movement of the RTZ

pointer speed away from these frequencies. Also, some

motors require a significant amount of time for the pointer to

settle to a steady state position when moving from one full

step position to the next. Consistent and accurate integration

values require the pointer be stationary at the end of the full

step time.

Bits RC3:RC0, RC12:RC11, and RC4 determine the time

spent at each full step during an RTZ event. Bits RC3:RC0

are used to select a

(1111) in increments of 4.096 ms (refer to

∆t ranging from 0 ms (0000) to 61.44 ms

Table 13). The ∆t

is multiplied by the factor M, which is defined by bits

RC12:RC11. The product is then added to the blanking time,

selected using bit RC4, to generate the full step time. The

multiplier selected with RC12:RC11 will be 1

4

(10) as illustrated in the equations below. Note that the

(00), 2 (01), or

RC12:RC11 value of 8 (11) is not recommended for use in a

product design application, because of the potential for an

RTZ accumulator internal overflow, due to the long time step.

The blanking time is either 512

.

µs when RC4 is logic [0], or

Table 12. RTZCR SI Register Assignment

µs when it is logic [1].The full step time is generated

768

using the following equations:

When D3:D0 (RC3:RC0) ≠ 0000

Full Step (t) = ∆t x M + blanking (t)(1)

When D3:D0 (RC3:RC0) = 0000

Full Step (t) = blanking (t) + 2.048 ms(2)

Note In equation (2), a 2.048 ms offset is added to the full

step time when the RC:3:RC0 = 0000. The full step time

default value after a logic reset is 12.80 ms

(RC12:RC11

= 00, RC4 = 0, and RC3:RC0 = 0011).

If there are two full steps per degree of pointer movement,

the pointer speed is 1/(FullStep

x 2) deg/s.

Detecting pointer movement is accomplished by

integrating the EMF present in the non-driven coil during the

RTZ event. The integration circuitry is implemented using a

Sigma-Delta converter resulting in the placement of a value

in the 15-bit RTZ accumulator at the end of each full step. The

value in the RTZ accumulator represents the change in flux

and is compared to a threshold. Values above the threshold

indicate a pointer is moving. Values below the threshold

indicate a stalled pointer, thereby resulting in the cessation of

the RTZ event.

The RTZ accumulator bits are signed and represented in

two’s complement. After a full step of integration, a sign bit of

0 is the indicator of an accumulator exceeding the decision

threshold of 0, and the pointer is assumed to still be moving.

Similarly, if the sign bit is logic [1] after a full step of

integration, the accumulator value is negative and the pointer

is assumed to be stopped. The integrator and accumulator

are initialized after each full step. If the PECCR command is

written to clock out the RTZ accumulator values via the SO,

the OD14 bit corresponds to the sign bit of the RTZ

accumulator.

Accurate pointer stall detection depends on a correctly

preloaded accumulator for specific gauge, pointer, and full

step combinations. Bits RC10:RC5 are used to offset the

initial RTZ accumulator value, properly detecting a stalled

motor. The initial accumulator value at the start of a full step

of integration is negative. If the accumulator was correctly

preloaded, a free-moving pointer will result in a positive value

at the end of the integration time, and a stalled pointer will

result in a negative value. The preloaded values associated

with each combination of bits RC10:RC5 are illustrated in

Table 14. The accumulator should be loaded with a value

resulting in an accumulator MSB to a logic [1] when the motor

is stalled. For the default mode, after a power-up or any reset,

the 33970 device sets the accumulator value to -1.

Address 101

Bits D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Read

Write

– – – – – – – – – – – – –

RC12 RC11 RC10 RC9 RC8 RC7 RC6 RC5 RC4 RC3 RC2 RC1 RC0

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

Page 18

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

The bits in Table 12 are write-only.

RC12:RC11 (D12:D11) — These bits, along with RC3:RC0

(D3:D0) and RC4 (D4), determine the full step time and,

therefore, the rate at which the pointer will move during an

RTZ event. The values of D12:D11 determine the multiplier

(M) is used in equation (1) (refer to

page 17).

RC12:RC11 = M

• 00 = 1

• 01 = 2

• 10 = 4

• 11 = 8 (Not to be used for design)

RC10:RC5 (D10:D5) — These bits determine the value

preloaded into the RTZ integration accumulator to adjust the

detection threshold. Values range from -1 (00000000) to 1099 (11111111) as shown in

Table 14.

RC4 (D4) — This bit determines the RTZ blanking time

(blanking (t)).

• 0 = 512 µs

• 1 = 768 µs

RC3:RC0 (D3:D0) — These bits, along with RC12:RC11

(D12:D11) and RC4 (D4), determine the time variables used

to calculate the full step times with equations (1) or (2)

illustrated above. RC3:RC0 determines the

∆t time. The ∆t

values range from 0 (0000) to 61.440 ms (1111) and are

shown in Table 13. The default ∆t is 0 (0011).

Note Equation (2) (refer to page 17) is only used to

calculate the full step time if RC3:RC0 = 0000. Use

equation (1) for all other combinations of RC3:RC0.

Table 13. RTZCR Full Step Time

RC3 RC2 RC1 RC0 ∆t (ms)

0 0 0 0 0

0 0 0 1 4.096

0 0 1 0 8.192

0 0 1 1 12.288

0 1 0 0 16.384

0 1 0 1 20.480

0 1 1 0 24.576

0 1 1 1 28.672

1 0 0 0 32.768

1 0 0 1 36.864

1 0 1 0 40.960

1 0 1 1 45.056

1 1 0 0 49.152

1 1 0 1 53.248

1 1 1 0 57.344

1 1 1 1 61.440

Table 14. RTZCR Accumulator Offset

RC10 RC9 RC8 RC7 RC6 RC5

0 0 0 0 0 0 0 -1

0 0 0 0 0 1 1 -17

0 0 0 0 1 0 2 -33

0 0 0 0 1 1 3 -49

0 0 0 1 0 0 4 -65

.

.

.

1 1 1 1 1 1 63 -1009

.

.

.

.

.

.

.

.

.

.

.

.

SO Communication

When the CS pin is pulled low, the internal status register,

as configured with the PECCR command bits PE11:PE8, is

loaded into the output register and the data is clocked out

MSB (OD15) first. Following a

CS transition 0 to 1, the device

determines if the shifted-in message was of a valid length (a

valid message length is one that is greater than 0 bits and a

multiple of 16 bits), and if so, latches the incoming data into

the appropriate registers.

.

.

.

Preload Value

(PV)

.

.

.

Initial Accumulator

Value = (-16

x PV) -1

.

.

.

At this time, the SO pin is tri-stated and the status register

is now able to accept new status information. Fault status

information will be latched and held until the Device Status

Output register is selected and it is clocked out via the SO. If

the message length was determined to be invalid, the fault

information will not be cleared and will be transmitted again

during the next valid SPI message. Pointer status information

bits (e.g., pointer position, velocity, and commanded position

status) will always reflect the real time state of the pointer.

33970

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

Page 19

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

Any bits clocked out of the SO pin after the first 16 are

representative of the initial message bits clocked into the SI

pin since the CS pin first transitioned to a logic [0]. This

feature is useful for daisy-chaining devices as well as

message verification.

As described above, the last valid write to bits PE11:PE8

of the PECCR command determines the nature of the status

5. Gauge 1 and 2 Pointer Velocity Status (refer to

Table 19, page 22)

Once a specific status type is selected, it will not change

until either the PECCR command bits PE11:PE8 (D11:D8)

are written to select another or the device is reset. Each of the

Status types and the PECCR bit necessary to select them are

described below.

data that is clocked out of the SO pin.

There are five different types of status information

available:

1. Device Status (refer to Table 15 below)

Device Status Information

Most recent valid PECCR command resulting in the

Device Status output:

2. RTZ Accumulator Status (refer to Table 16, page 20)

3. Gauge 0 Pointer Position Status (refer to Table 17,

page 21)

4. Gauge 1 Pointer Position Status (refer to Table 18,

D11 D10 D9 D8

0 x x x

x = Don’t care.

page 21)

Table 15. Device Status Output Register

Bits OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1 OD0

Read

DIR1 DIR0 0POS1 0POS0 CMD1 CMD0 OV UV CAL OVUV MOV1 MOV0 RTZ1 RTZ0 OT1 OT0

Write

pointer is moving.

pointer is moving.

– – – – – – – – – – – – – – – –

The bits in Table 15 are read-only bits.

DIR1 (OD15) — This bit indicates the direction Gauge 1

overvoltage event will automatically disable the driver

outputs. Because the pointer may not be in the expected

position, the master may want to re-calibrate the pointer

• 0 = Toward position 0

• 1 = Away from position 0

DIR0 (OD14) — This bit indicates the direction Gauge 0

• 0 = Toward position 0

• 1 = Away from position 0

position with an RTZ command after the voltage returns to a

normal level. For an overvoltage event, both gauges must be

re-enabled as quickly as this flag returns to logic

state machine will continue to operate properly as long as

is within the normal range.

V

DD

• 0 = Normal range

• 1 = Battery voltage exceeded V

PWROV

[0]. The

0POS1 (OD13) — This bit indicates the configured Position

0 for Gauge 1.

• 0 = Farthest CCW

•1 = Farthest CW

0POS0 (OD12) — This bit indicates the configured Position

0 for Gauge 0.

• 0 = Farthest CCW

•1 = Farthest CW

CMD1 (OD11) — This bit indicates whether Gauge 1 is at

the most recently commanded position.

• 0 = At commanded position

• 1 = Not at commanded position

CMD0 (OD10) — This bit indicates whether Gauge 0 is at

the most recently commanded position.

• 0 = At commanded position

• 1 = Not at commanded position

OV (OD9) — Overvoltage Indication. A logic [1] on this bit

indicates V

voltage exceeded the upper limit of V

PWR

PWROV

since the last SPI communication (refer to the Static Electrical

Characteristics table under

POWER INPUT, page 5). An

UV (OD8) — Undervoltage Indication. A logic 1] on this bit

indicates the V

voltage fell below V

PWR

PWRUV

since the last

SPI communication (refer to the Static Electrical

Characteristics table under

POWER INPUT, page 5). An

undervoltage event is just flagged; however, at some voltage

level below 4.0

V, the outputs turn OFF and the state

machine resets. Because the pointer may not be in the

expected position, the master may want to re-calibrate the

pointer position with an RTZ command after the voltage

returns to a normal level. For an undervoltage event, both

gauges may need to be re-enabled as quickly as this flag

returns to logic

properly as long as V

[0]. The state machine will continue to operate

is within the normal range.

DD

• 0 = Normal range

• 1 = Battery voltage fell below V

PWRUV

CAL (OD7) — Calibrated Clock out of Specification. A

[1] on this bit indicates the clock count calibrated to a

logic

value outside the expected range given the tolerance

specified by t

in the Dynamic Electrical Characte ri sti cs

CLC

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

Page 20

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

table under POWER OUTPUT AND CLOCK TIMINGS,

page 7.

• 0 = Clock within spec

• 1 = Clock out of spec

OVUV (OD6) — Undervoltage or Overvoltage Indication. A

logic [1] on this bit indicates the V

below the V

since the last SPI communication (refer to

PWRUV

the Static Electrical Characteristics table under

voltage fell to a level

PWR

POWER

INPUT, page 5). An undervoltage event is just flagged, while

an overvoltage event automatically disables the drive

outputs. Because the pointer may not be in the expected

position, the master may want to re-calibrate the pointer with

an RTZ command after the voltage returns to normal level.

For an overvoltage event, both gauges must be re-enabled

as soon as this flag returns to logic

[0]. The state machine will

continue to operate properly as long as VDD is within the

normal range.

• 0 = Normal range

• 1 = Battery voltage fell below V

V

PWROV

PWRUV

or exceeded

MOV1 (OD5) — This bit identifies Gauge 1 Movement

since last SPI communication. A logic [1] on this bit indicates

the Gauge 1 pointer position changed since the last SPI

command. This information allows the master to confirm the

pointer is moving as commanded.

• 0 = Gauge 1 position has not changed since the last SPI

command

• 1 = Gauge 1 pointer position has changed since the last

SPI command

MOV0 (OD4) — Gauge 0 Movement Since last SPI

Communication. A logic [1] on this bit indicates the Gauge 0

pointer position has changed since the last SPI command.

This information allows the master to confirm the pointer is

moving as commanded.

• 0 = Gauge 0 position has not changed since the last SPI

command

• 1 = Gauge 0 pointer position has changed since the last

SPI command

RTZ1 (OD3) — RTZ1 Is Enabled or Disabled. A logic [1] on

this bit indicates Gauge 1 is in the process of returning to the

zero position as requested with the RTZ command. This bit

will continue to indicate a logic [1] until the SPI message

following a detection of the zero position, or the RTZ feature

is commanded OFF using the RTZ message.

• 0 = Return to Zero disabled

• 1 = Return to Zero enabled successfully

RTZ0 (OD2) — RTZ0 Is Enabled or Disabled. A logic [1] on

this bit indicates Gauge 0 is in the process of returning to the

zero position as requested with the RTZ command. This bit

continues to indicate a logic [1] until the SPI message

following a detection of the zero position, or the RTZ feature

is commanded OFF using the RTZ message.

• 0 = Return to Zero disabled

• 1 = Return to Zero enabled successfully

OT1 (OD1) — Gauge 1 Junction Overtemperature. A

logic [1] on this bit indicates that the coil drive circuitry

dedicated to drive Gauge 1 has exceeded the maximum

allowable junction temperature since the last SPI

communication and that Gauge

1 has been disabled. It is

recommended that the pointer be re-calibrated using the RTZ

command after re-enabling the gauge using the PECCR

command. This bit remains logic

[1] until the gauge is

enabled.

• 0 = Temperature within range

• 1 = Gauge 1 maximum allowable junction temperature

condition has been reached

OT0 (OD0) — Gauge 0 Junction Overtemperature. A

logic [1] on this bit indicates that the coil drive circuitry

dedicated to drive Gauge 0 has exceeded the maximum

allowable junction temperature since the last SPI

communication and that Gauge

0 has been disabled. It is

recommended that the pointer be re-calibrated using the RTZ

command after re-enabling the gauge using the PECCR

command. This bit remains logic

[1] until the gauge is re-

enabled.

• 0 = Temperature within range

• 1 = Gauge 0 maximum allowable junction temperature

condition is reached

RTZ Accumulator Status Information

Most recent valid PECCR command resulting in the RTZ

Accumulator status output:

D11 D10 D9 D8

1 0 x x

x = Don’t care.

Table 16. RTZ Accumulator Status Output Register

Bits OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1 OD0

Read

Write

on this bit indicates that the Gauge is in the process of

returning to the zero position as requested with the RTZ

33970

RTZ ACC14 ACC13 ACC12 ACC11 ACC10 ACC9 ACC8 ACC7 ACC6 ACC5 ACC4 ACC3 AC2C ACC1 ACC0

– – – – – – – – – – – – – – – –

The bits in Table 16 are read-only bits.

RTZ (OD15) — RTZ Bit Is Enabled or Disabled. A logic [1]

command. This bit will continue to indicate a logic [1] until the

SPI message following a detection of the zero position, or the

RTZ feature is commanded OFF using the RTZ message.

• 0 = Return to Zero disabled

Analog Integrated Circuit Device Data

20 Freescale Semiconductor

Page 21

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

• 1 = Return to Zero enabled successfully

ACC14:ACC0 (OD14:OD0) — These 15 bits are from the

RTZ accumulator. They represent the integrated signal

present on the non-driven coil during an RTZ event. These

bits are logic [0] after power-on reset, or after the

RST pin

transitions from logic [0] to [1]. After an RTZ event, they will

represent the last RTZ accumulator result before the RTZ

was stopped. ACC14 is the MSB and is the sign bit used for

zero detection.

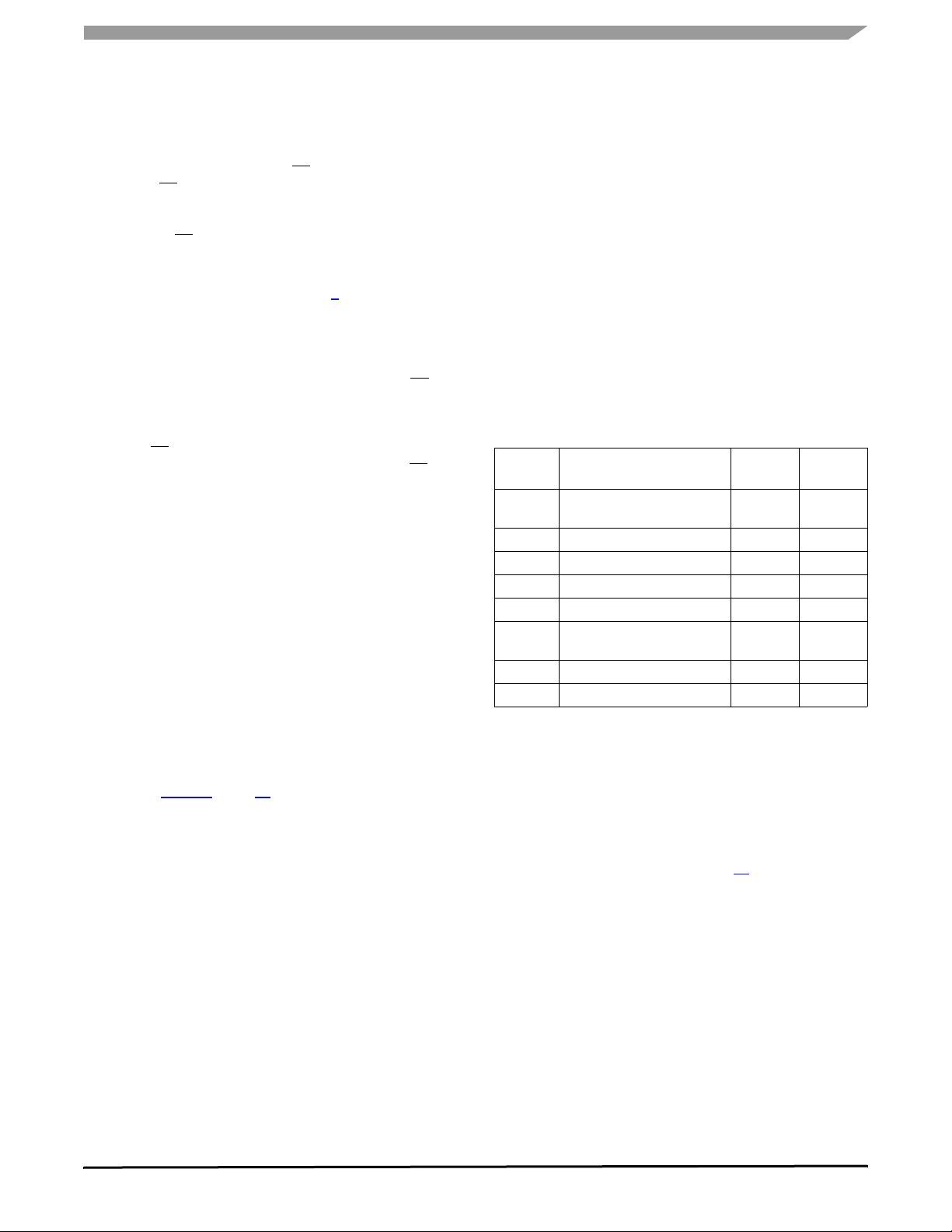

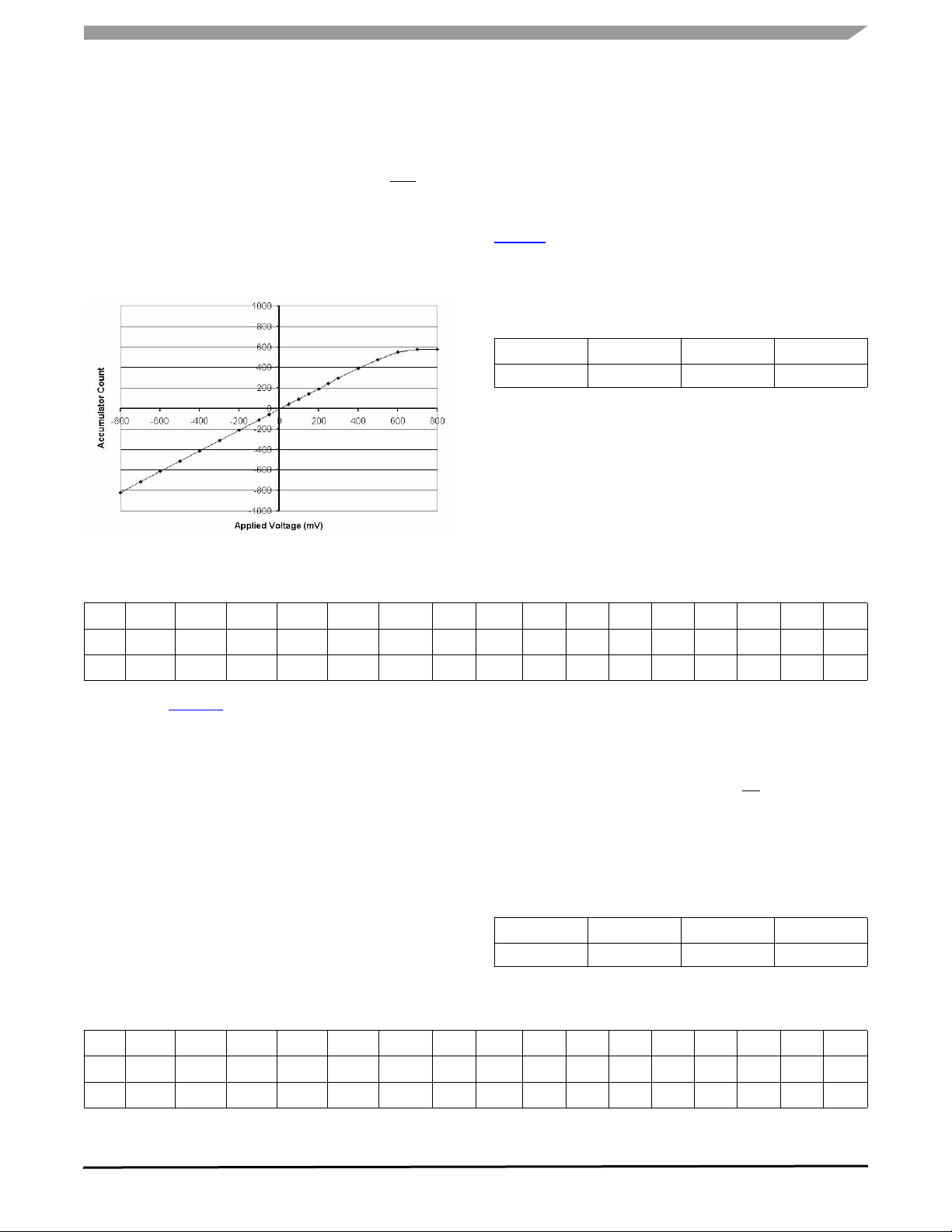

Figure 8. RTZ Accumulator (Typical)

The analog-to-digital converter's linear input range covers

the expected magnitude of motor back e.m.f. signals, which

is_usually less than 500mV. Input signals greater than this

will not cause any damage (the circuit is connected to the

motor H-Bridge drivers, and thus is exposed to the full

magnitude of the drive voltages), but may cause some small

loss of linearity. A typical plot of output vs. input is shown in

Figure 8 for 4ms step times.

Gauge 0 Pointer Position Status Information

Most recent valid PECCR command resulting in the

Gauge 0 Pointer Position status output:

D11 D10 D9 D8

1 1 0 0

Table 17. Gauge 0 Pointer Position Status Output Register

Bits OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1 OD0

Read

ENB0 DIR0 DIRC0 CMD0 POS11 POS10 POS9 POS8 POS7 POS6 POS5 POS4 POS3 POS2 POS1 POS0

Write

enabled.

moving.

direction of the most recent pointer movement is toward the

– – – – – – – – – – – – – – – –

The bits in Table 17 are read-only bits.

ENB0 (OD15) — This bit indicates whether Gauge 0 is

CMD0 (OD12) — This bit indicates whether Gauge 0 is at

the most recently commanded position.

• 0 = At commanded position

• 0 = Disabled

• 1 = Enabled

DIR0 (OD14) — This bit indicates the direction Gauge 0 is

• 1 = Not at commanded position

POS11:POS0 (OD11:OD0) — These 12 bits represent the

actual position of the pointer at the time CS transitions to a

logic [0].

• 0 = Toward position 0

• 1 = Away from position 0

DIRC0 (OD13) — This bit is used to determine whether the

Gauge 1 Pointer Position Status Information

Most recent valid PECCR command resulting in the

1 Pointer Velocity status output:

Gauge

last commanded position or away from it.

• 0 = Direction of the pointer movement is toward the

commanded position

D11 D10 D9 D8

1 1 0 1

• 1 = Direction of the pointer movement is away from the

commanded position

Table 18. Gauge 1 Pointer Position Status Output Register

Bits OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1 OD0

Read

ENB1 DIR1 DIRC1 CMD1 POS11 POS10 POS9 POS8 POS7 POS6 POS5 POS4 POS3 POS2 POS1 POS0

Write

– – – – – – – – – – – – – – – –

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

Page 22

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

The bits in Table 18 are read-only bits.

ENB1 (OD15) — This bit indicates if Gauge 1 is enabled.

• 0 = Disabled

• 1 = Enabled

DIR1 (OD14) — This bit indicates the direction Gauge 1

pointer is moving.

• 0 = Toward position 0

• 1 = Away from position 0

DIRC1 (OD13) — This bit determines if the direction of the

most recent pointer movement is toward, or away from, the

last commanded position.

• 0 = Direction of the pointer movement is toward the

commanded position

• 1 = Direction of the pointer movement is away from the

commanded position

CMD1 (OD12) — This bit indicates if Gauge 1 is at the most

recently commanded position.

• 0 = At commanded position

• 1 = Not at commanded position

POS11:POS0 (OD11:OD0) — These 12 bits represent the

actual position of the pointer at the time CS transitions to a

[0].

logic

Gauge 0 and 1 Pointer Velocity Status Information

Most recent valid PECCR command resulting in the

Gauge 0 and 1 Pointer Velocity status output:

D11 D10 D9 D8

1 1 1 x

x = Don’t care.

Table 19. Gauge 0 and 1 Pointer Velocity Status Output Register

Bits OD15 OD14 OD13 OD12 OD11 OD10 OD9 OD8 OD7 OD6 OD5 OD4 OD3 OD2 OD1 OD0

Read

Write

velocity position value (refer to Table 21, page 24) indicating

the actual velocity of Gauge 1 pointer at the time CS

transitions to a logic

velocity position value (refer to Table 21) indicating the

actual velocity of Gauge 0 pointer at the time CS transitions

to a logic

1V7 1V6 1V5 1V4 1V3 1V2 1V1 1V0 0V7 0V6 0V5 0V4 0V3 0V2 0V1 0V0

– – – – – – – – – – – – – – – –

The bits in Table 19 are read-only bits.

1V7:1V0 (OD15:OD8) — These eight bits represent the

A requirement of the state machine is to ensure the

deceleration phase begins at the correct time and pointer

position. When commanded, the motor will accelerate

constantly to the maximum velocity, then move toward the

[0].

0V7:0V0 (OD7:OD0) — These eight bits represent the

commanded position. Eventually, the pointer will reach the

calculated location where the movement has to decelerate,

slowing safely to a stop at the desired position. During the

deceleration phase, the motor will not exceed the maximum

[0].

deceleration.

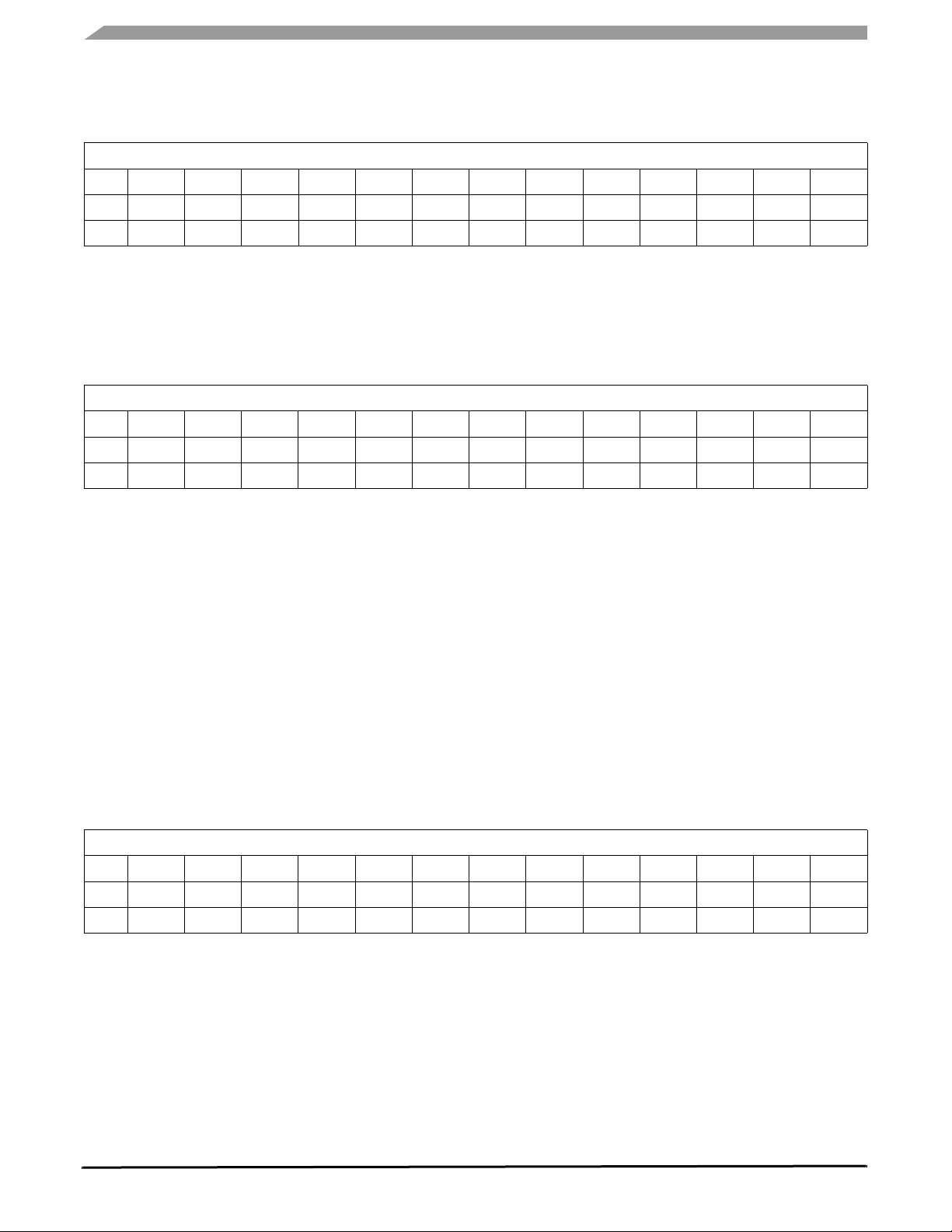

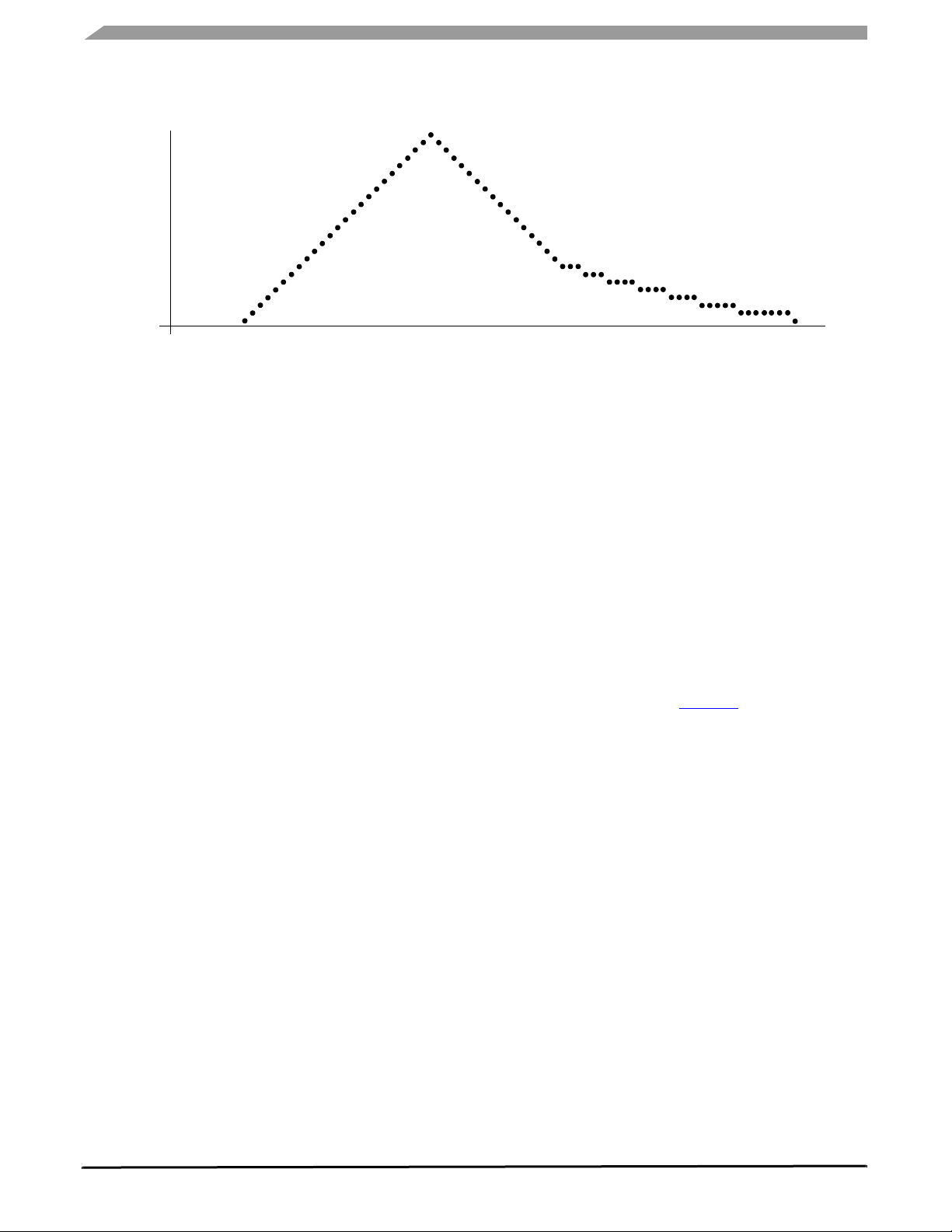

During normal operation, both step motor rotors are

STATE MACHINE OPERATION

The two-phase step motor has maximum allowable

velocities and acceleration and deceleration.The purpose of

the step motor state machine is to drive the motor with

maximum performance while remaining within the motor’s

voltage, velocity, and acceleration constraints.

microstepped with 24

Figure 9). A complete electrical revolution results in two

degrees of pointer movement. There is a second (smaller)

state machine in the IC controlling these microsteps. This

state machine receives clockwise or counter-clockwise index

commands at intervals, stepping the motor in the appropriate

direction by adjusting the current in each coil. Normalized

values are provided in

steps per electrical revolution (see

Table 20, page 23.

33970

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

Page 23

I

MAX

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

+

I

MAX

I

MAX

0

812345670 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

I

COIL

+

I

COIL

I

MAX

0

812345670 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Figure 9. Clockwise Microsteps

Table 20. Coil Step Value

Step Angle SINE Angle*

SINE Current

Flow

0 0 0 + 0 0 1 + 255 FF

1 15 0.259 + 66 42 0.965 + 247 F7

2 30 0.5 + 128 80 0.866 + 222 DE

3 45 0.707 + 181 B5 0.707 + 181 B5

4 60 0.866 + 222 DE 0.5 + 128 80

5 75 0.966 + 247 F7 0.259 + 66 42

6 90 1 + 255 FF 0 + 0 0

7 105 0.966 + 247 F7 -0.259 - 66 42

8 120 0.866 + 222 DE -0.5 - 128 80

9 135 0.707 + 181 B5 -0.707 - 181 B5

10 150 0.5 + 128 80 -0.866 - 222 DE

11 165 0.259 + 66 42 -0.966 - 247 F7

12 180 0 + 0 0 -1 - 255 FF

13 195 -0.259 - 66 42 -0.966 - 247 F7

14 210 -0.5 - 128 80 -0.867 - 222 DE

15 225 -0.707 - 181 B5 -0.707 - 181 B5

16 240 -0.866 - 222 DE -0.5 - 128 80

17 255 -0.966 - 247 F7 -0.259 - 66 42

18 270 -1 - 255 FF 0 + 0 0

19 285 -0.966 - 247 F7 0.259 + 66 42

20 300 -0.866 - 222 DE 0.5 + 128 80

21 315 -0.707 - 181 B5 0.707 + 181 B5

22 330 -0.5 - 128 80 0.866 + 222 DE

23 345 -0.259 - 66 42 0.966 + 247 F7

8-Bit Value

(DEC)

8-Bit Value

(HEX)

COS Angle*

COS Current

Flow

8-Bit Value

(DEC)

8-Bit Value

(HEX)

33970

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

Page 24

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

Table 20. Coil Step Value

* Denotes normalized values.

The motor is stepped by providing index commands at

intervals. The time between steps defines the motor velocity,

and the changing time defines the motor acceleration.

The state machine uses a table to define the allowed time

and also the maximum velocity. A useful side effect of the

table is that it also allows the direct determination of the

position at which the velocity should reduce to allow the

motor to stop at the desired position.

The motor equations of motion are generated as follows.

(The units of position are steps, and velocity and acceleration

are in steps/second and steps/second².)

From an initial position of 0 with an initial velocity (u), the

motor position (s) at a time (t) is:

2

1

atuts +=

2

For unit steps, the time between steps is:

2

++−

auu

=⇒

t

2

a

This defines the time increment between steps when the

motor is initially travelling at a velocity u. In the ROM, this time

is quantized to multiples of the system clock by rounding

upwards, ensuring acceleration never exceeds the allowed

value. The actual velocity and acceleration is calculated from

the time step actually used.

Using

v2 = u2 + 2as

and

v = u + at

and solving for v in terms of u, s, and t gives:

/

2

v =

- u

t

The correct value of t to use in this equation is the

quantized value obtained above.

From these equations a set of recursive equations can be

generated to give the allowed time step between motor

indexes when the motor is accelerating from a stop to its

maximum velocity.

Starting from a position p of 0 and a velocity v of 0, these

equations define the time interval between steps at each

position. To drive the motor at maximum performance, index

commands are given to the motor at these intervals. A table

is generated giving the time step

⎡

⎢

t

=∆

n

⎢

⎢

⎡⎤

where indicates rounding up.

=

v

n

∆

t at an index position n.

0

=

p

0

0

=

v

0

2

−−

nn

a

−

v

n

∆

t

n

⎤

avv

2

++−

11

⎥

⎥

⎥

12−

Pn = n

Note Pn = n. This means on the n th step the motor has

indexed by n positions and has been accelerating steadily at

the maximum allowed rate. This is critical because it also

indicates the minimum distance the motor must travel while

decelerating to a stop. For example, the stopping distance is