Freescale Semiconductor

Technical Data

5.0 A H-Bridge

The 33886 is a monolithic H-Bridge ideal for fractional horsepower

DC-motor and bi-directional thrust solenoid control. The IC

incorporates internal control logic, charge pump, gate drive, and low

R

continuous inductive DC load currents up to 5.0 A. Output loads can

be pulse width modulated (PWM-ed) at frequencies up to 10 kHz.

overtemperature conditions. Two independent inputs control the two

half-bridge totem-pole outputs. Two disable inputs force the H-Bridge

outputs to tri-state (exhibit high impedance).

-40°C

up to 40 V with derating of the specifications. The IC is available in a

surface mount power package with exposed pad for heatsinking.

Features

• Similar to the MC33186DH1 with Enhanced Features

• 5.0 V to 40 V Continuous Operation

•120 mΩ R

• TTL / CMOS Compatible Inputs

• PWM Frequencies up to 10 kHz

• Active Current Limiting via Internal Constant OFF-Time PWM (with

• Output Short Circuit Protection

• Undervoltage Shutdown

• Fault Status Reporting

• Pb-Free Packaging Designated by Suffix Code VW

MOSFET output circuitry. The 33886 is able to control

DS(ON)

A Fault Status output reports undervoltage, short circuit, and

The 33886 is parametrically specified over a temperature range of

≤ T

≤ 125°C, 5.0 V ≤ V+ ≤ 28 V. The IC can also be operated

A

H-Bridge MOSFETs

DS(ON)

Temperature-Dependent Threshold Reduction)

Document order number: MC33886

ORDERING INFORMATION

Device

MC33886DH/R2

MC33886VW/R2

Rev 7.0, 07/2005

33886

H-BRIDGE

VW SUFFIX (Pb-free)

DH SUFFIX

98ASH70702A

20-TERMINAL HSOP

Temperature

Range (T

- 40°C to 125°C 20 HSOP

)

A

Package

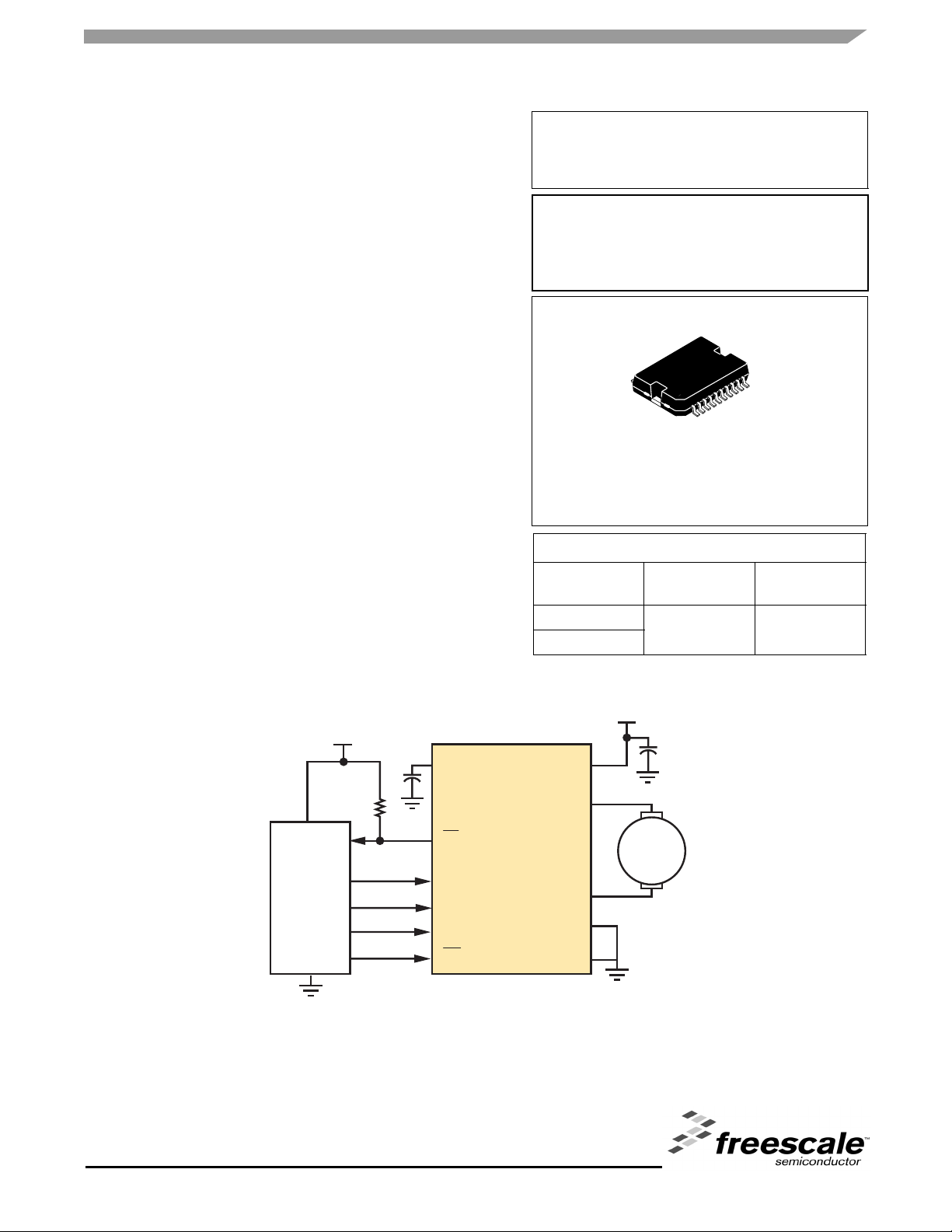

5.0 V

IN

OUT

MCU

OUT

OUT

OUT

Figure 1. 33886 Simplified Application Diagram

© Freescale Semiconductor, Inc., 2005. All rights reserved.

C

FS

IN1

IN2

D1

D2

CP

V+

33886

V+

OUT1

MOTOR

OUT2

PGND

AGND

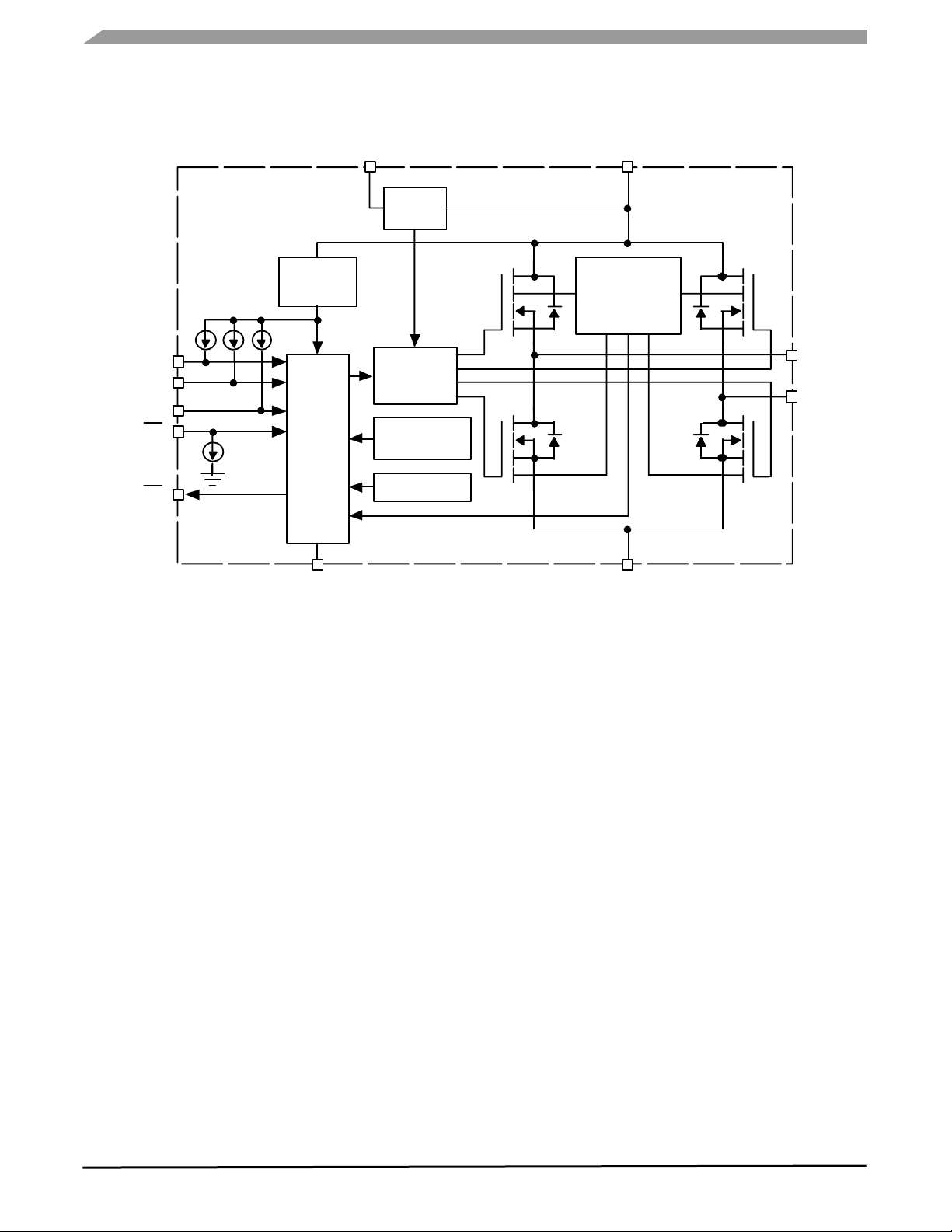

INTERNAL BLOCK DIAGRAM

INTERNAL BLOCK DIAGRAM

C

C

CP

CP

Charge

Charge

Pump

Pump

V

V+

PWR

IN1

IN2

D1

D2

FS

80 µA

80 uA

(each)

25 uA

25 µA

5.0 V

5.0 V

Regulator

Regulator

Gate Drive

Gate Drive

Over-

Control

Over-

temperature

temperature

Logic

Undervoltage

Undervoltage

Figure 2. 33886 Simplified Internal Block Diagram

Curre n t Li m it,

Current Limit,

Overcurrent

Short Circuit

Sense

Sense Circuit

Ci rcuit

PGNDAGND

OUT 1

OUT 2

33886

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

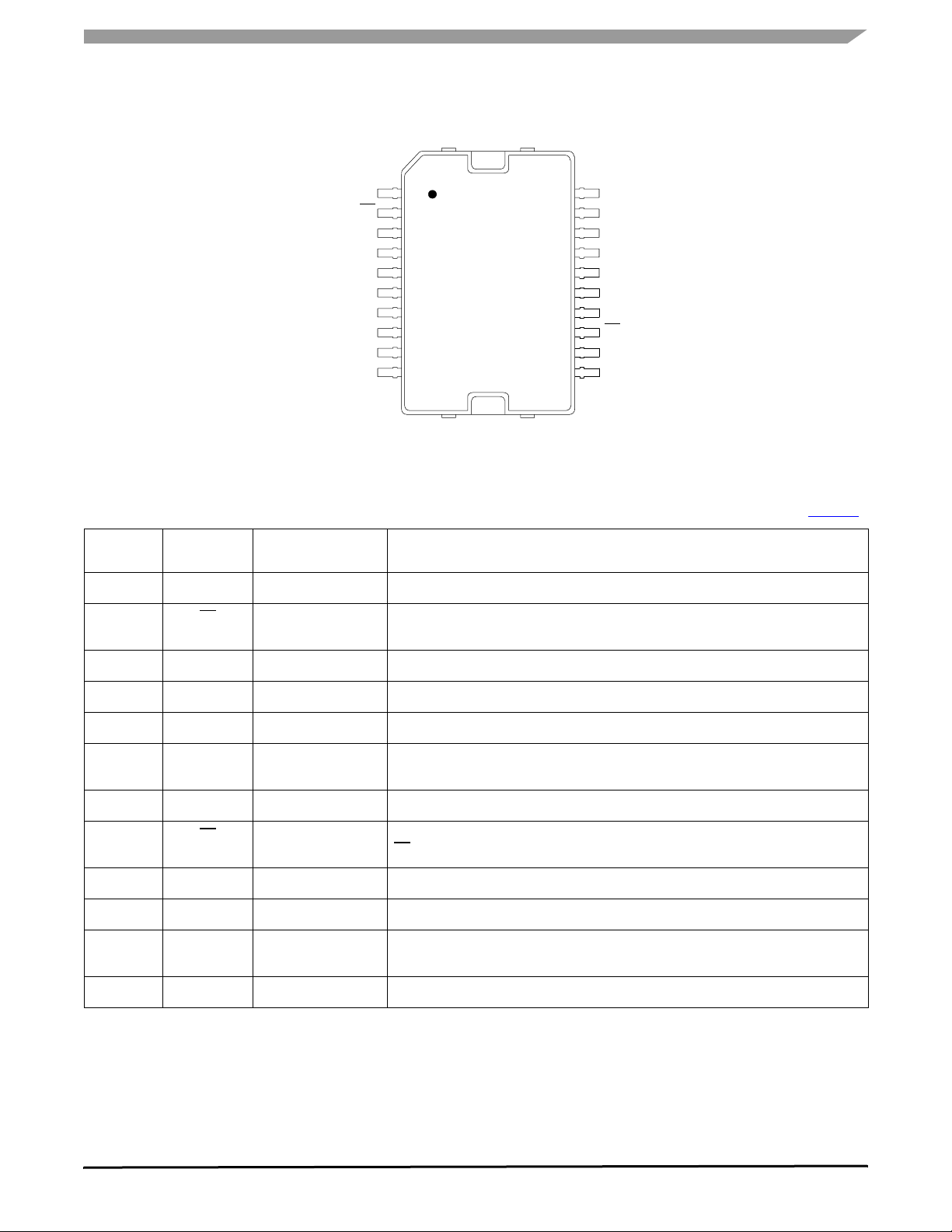

TERMINAL CONNECTIONS

TERMINAL CONNECTIONS

DNCAGND

IN2

D1

CCP

V+

OUT2

OUT2

D2

PGND

PGND

FS

IN1

V+

V+

OUT1

OUT1

DNC

PGND

PGND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

Figure 3. 33886 Terminal Connections

Table 1. 33886 Terminal Definitions

A functional description of each terminal can be found in the Functional Terminal Description section beginning on page

Terminal

Number

1 AGND Analog Ground

2 FS Fault Status for H-

Terminal

Name

Formal Name Definition

Low-current analog signal ground.

Open drain active Low Fault Status output requiring a pull-up resistor to 5.0 V.

Bridge

15.

3 IN1 Logic Input Control 1

4, 5, 16 V+ Positive Power Supply

6, 7 OUT1 H-Bridge Output 1

8, 20 DNC Do Not Connect

9 –12 PGND Power Ground

13 D2 Disable 2

14, 15 OUT2 H-Bridge Output 2

17 CCP Charge Pump Capacitor

18 D1 Disable 1

19 IN2 Logic Input Control 2

True logic input control of OUT1 (i.e., IN1 logic High = OUT1 logic High).

Positive supply connections.

Output 1 of H-Bridge.

Either do not connect (leave floating) or connect these terminals to ground in the

application. They are test mode terminals used in manufacturing only.

Device high-current power ground.

Active Low input used to simultaneously tri-state disable both H-Bridge outputs. When

D2

is logic Low, both outputs are tri-stated.

Output 2 of H-Bridge.

External reservoir capacitor connection for internal charge pump capacitor.

Active High input used to simultaneously tri-state disable both H-Bridge outputs. When

D1 is logic High, both outputs are tri-stated.

True logic input control of OUT2 (i.e., IN2 logic High = OUT2 logic High).

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

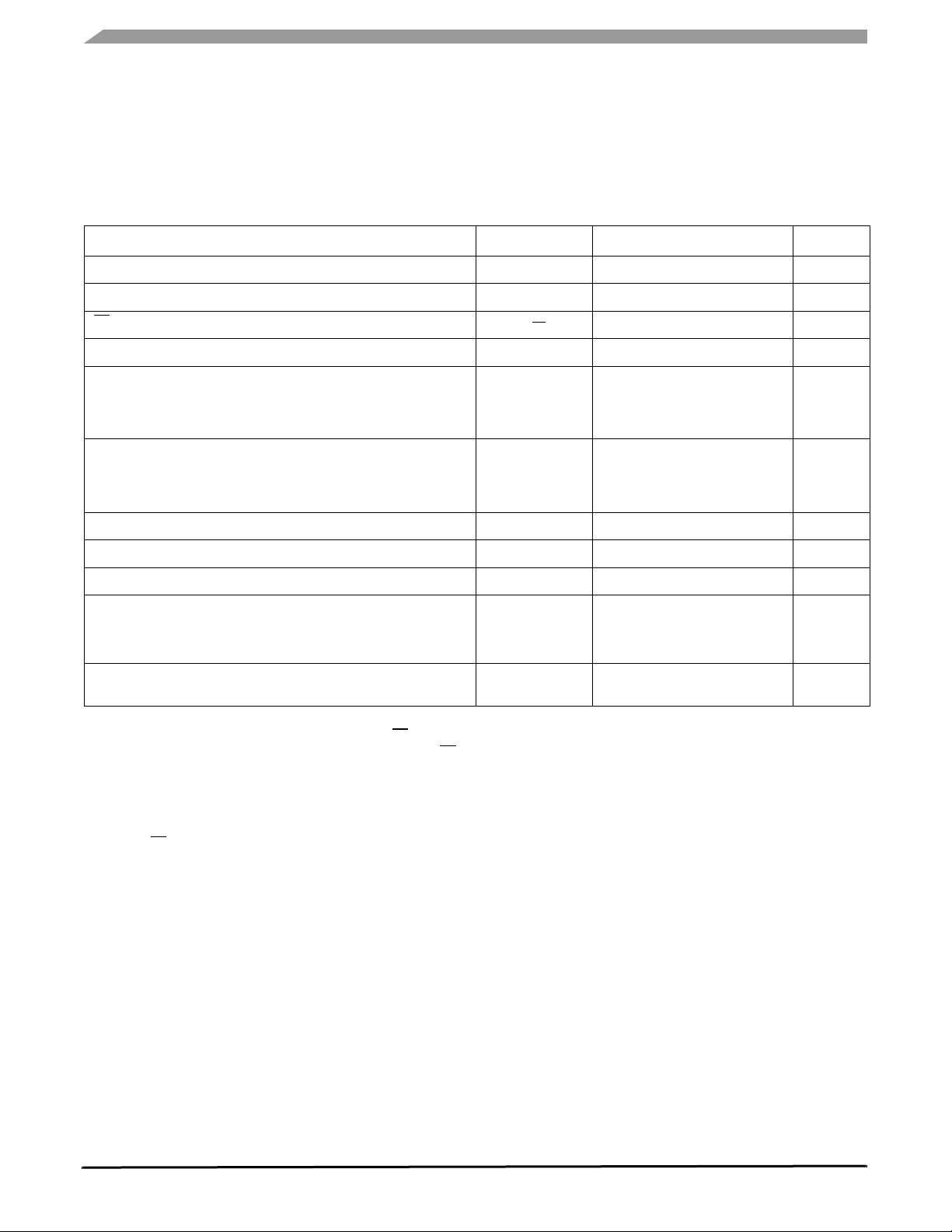

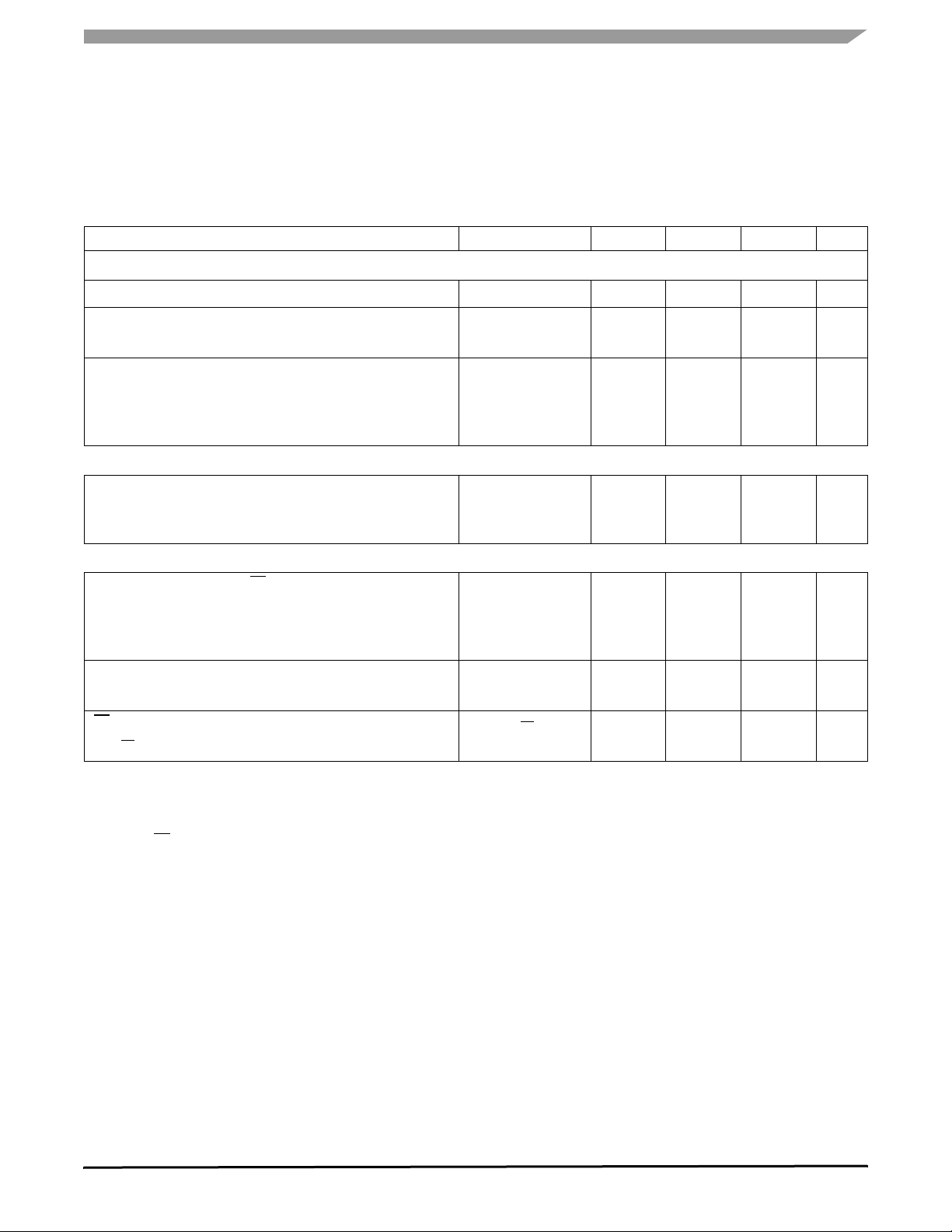

MAXIMUM RATINGS

MAXIMUM RATINGS

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Rating Symbol Value Unit

Supply Voltage

Input Voltage

Status Output

FS

Continuous Current

(1)

(2)

(3)

ESD Voltage for DH Package

Human Body Model

Machine Model

(4)

(5)

ESD Voltage for VW Package

Human Body Model

Machine Model

(4)

(5)

Storage Temperature

Ambient Operating Temperature

(7)

Operating Junction Temperature

Terminal Soldering Temperature

(8)

DH Suffix

VW (Pb-Free Suffix)

Approximate Junction-to-Board Thermal Resistance (and Package

Dissipation = 6.0 W)

(9)

V+ 40 V

V

V

I

OUT

V

ESD1

V

ESD2

V

ESD1

V

ESD2

T

STG

T

T

T

SOLDER

IN

FS

A

J

-0.1 to 7.0 V

7.0 V

5.0 A

(6)

±2000

±200

±2000

±200

-65 to 150 °C

-40 to 125 °C

-40 to 150 °C

220

260

R

JB

θ

~5.0

V

V

°C

°C/W

Notes

1. Exceeding the input voltage on IN1, IN2, D1, or D2

2. Exceeding the pull-up resistor voltage on the open drain FS

3. Continuous current capability so long as junction temperature is ≤ 150

4. ESD1 testing is performed in accordance with the Human Body Model (C

5. ESD2 testing is performed in accordance with the Machine Model (C

may cause a malfunction or permanent damage to the device.

terminal may cause permanent damage to the device.

°C.

ZAP

= 200 pF, R

ZAP

= 100 pF, R

ZAP

= 1500 Ω).

ZAP

= 0 Ω).

6. All terminals are capable of Human Body Model ESD voltages of ±2000 V with two exceptions pertaining only to the DH suffix package:

to PGND is capable of ±1500 V and (2) OUT1 to AGND is capable of ±1000 V.

(1) D2

7. The limiting factor is junction temperature, taking into account the power dissipation, thermal resistance, and heatsinking.

8. Terminal soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits

may cause malfunction or permanent damage to the device.

9. Exposed heatsink pad plus the power and ground terminals comprise the main heat conduction paths. The actual R

(junction-to-PC

θ

JB

board) values will vary depending on solder thickness and composition and copper trace.

33886

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

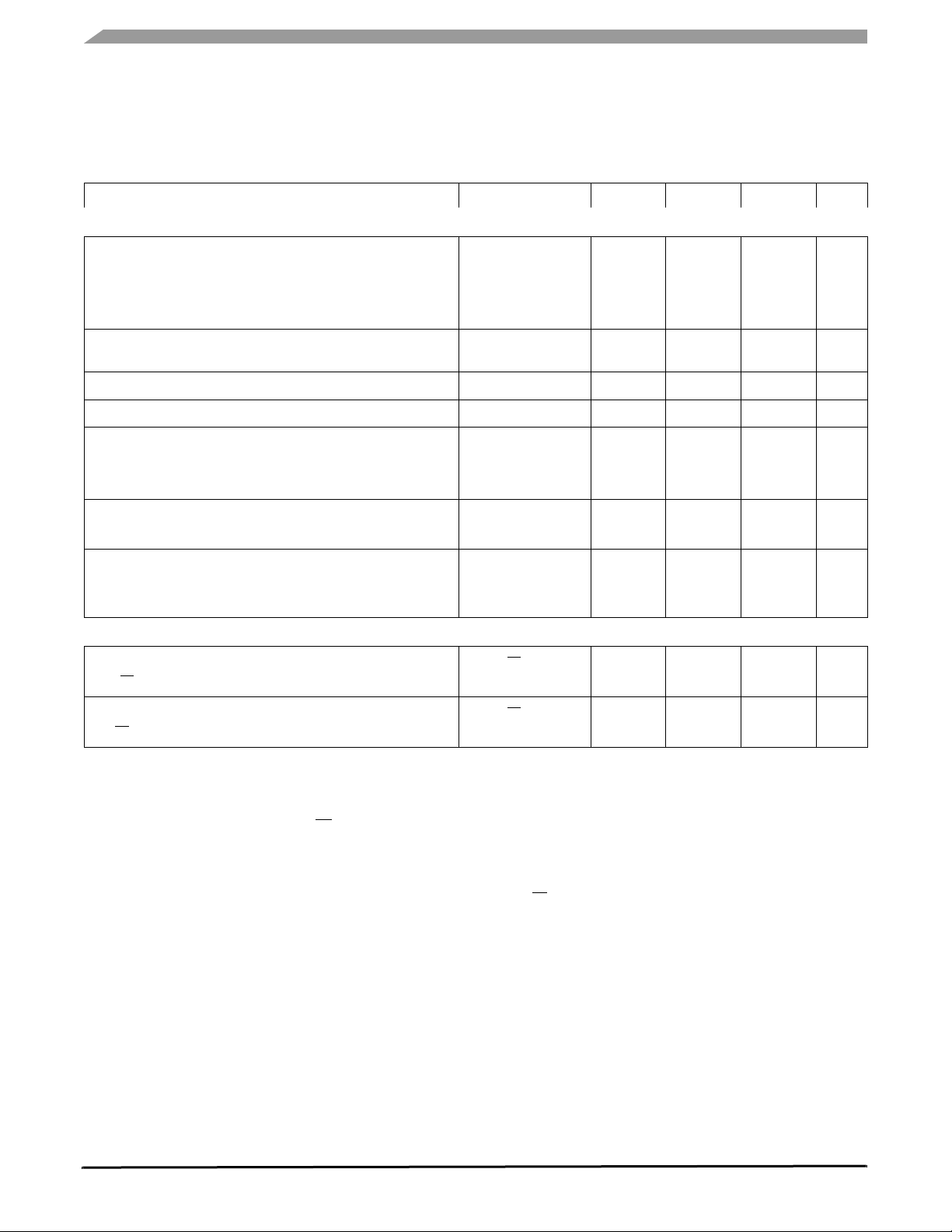

STATIC ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 5.0 V ≤ V+ ≤ 28 V and -40°C ≤ TA ≤ 125°C unless otherwise noted. Typical values noted

reflect the approximate parameter mean at T

Characteristic Symbol Min Typ Max Unit

Power Supply

Operating Voltage Range

Standby Supply Current

V

= 5.0 V, I

EN

OUT

Threshold Supply Voltage

Switch-OFF

Switch-ON

Hysteresis

CHARGE PUMP

(10)

= 0 A

= 25°C under nominal conditions unless otherwise noted.

A

V+ 5.0 – 40 V

I

Q (standby)

––20

V+

(thres-OFF)

V+

(thres-ON)

V+

(hys)

4.15

4.5

150

4.4

4.75

–

4.65

5.0

–

mA

V

V

mV

Charge Pump Voltage

V+ = 5.0 V

8.0 V ≤ V+ ≤ 40 V

V

- V +

CP

3.35

–

–

–

–

20

CONTROL INPUTS

Input Voltage (IN1, IN2, D1, D2)

Threshold High

Threshold Low

Hysteresis

Input Current (IN1, IN2, D1)

VIN = 0 V

D2

Input Current

(12)

V D2 = 5.0 V

(11)

V

V

V

HYS

I

IN

I

D2

IH

IL

3.5

–

0.7

1.0

–

–

–

1.4

–

-200 -80 –

–25100

Notes

10. Specifications are characterized over the range of 5.0 V ≤ V+ ≤ 28 V. Operation > 28 V will cause some parameters to exceed listed

min/max values. Refer to typical operating curves to extrapolate values for operation > 28 V but ≤ 40 V.

11. Inputs IN1, IN2, and D1 have independent internal pull-up current sources.

12. The D2

input incorporates an active internal pull-down current sink.

V

V

µA

µA

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

STATIC ELECTRICAL CHARACTERISTICS

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 5.0 V

reflect the approximate parameter mean at T

Characteristic Symbol Min Typ Max Unit

POWER OUTPUTS (OUT1, OUT2)

Output-ON Resistance

5.0 V ≤ V+ ≤ 28 V, TJ = 25°C

8.0 V ≤ V+

5.0 V ≤ V+

≤ 28 V, TJ = 150°C

≤ 8.0 V, TJ = 150°C

(13)

≤ V+ ≤ 28 V and -40°C ≤ T

= 25°C under nominal conditions unless otherwise noted.

A

≤ 125°C unless otherwise noted. Typical values noted

A

R

DS(ON)

–

–

–

120

–

–

mΩ

–

225

300

Active Current Limiting Threshold (via Internal Constant OFF-Time

(14)

PWM)

High-Side Short Circuit Detection Threshold

Low-Side Short Circuit Detection Threshold

Leakage Current

V

= V+

OUT

= GND

V

OUT

Output FET Body Diode Forward Voltage Drop

I

= 3.0 A

OUT

(15)

(16)

Switch-OFF

Thermal Shutdown

Hysteresis

FAULT STATUS

Fault Status Leakage Current

(17)

(18)

V FS = 5.0 V

Fault Status Set Voltage

(19)

I FS = 300 µA

I

LIM

I

SCH

I

SCL

I

OUT(leak)

V

F

T

LIM

T

HYS

I

FS(leak)

V

FS(LOW)

5.2 6.5 7.8

11 – –

8.0 – –

–

–

100

30

200

60

––2.0

175

–

15

–

–

–

––10

––1.0

µA

°C

µA

Notes

13. Output-ON resistance as measured from output to V+ and ground.

14. Product with date codes of December 2002, week 51, will exhibit the values indicated in this table. Product with earlier date codes may

exhibit a minimum of 6.0 A and a maximum of 8.5 A.

15. Outputs switched OFF with D1 or D2

.

16. Parameter is guaranteed by design but not production tested.

17. Fault Status output is an open drain output requiring a pull-up resistor to 5.0 V.

18. Fault Status Leakage Current is measured with Fault Status High and not set.

19. Fault Status Set Voltage is measured with Fault Status Low and set with I

= 300 µA.

FS

A

A

A

V

V

33886

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

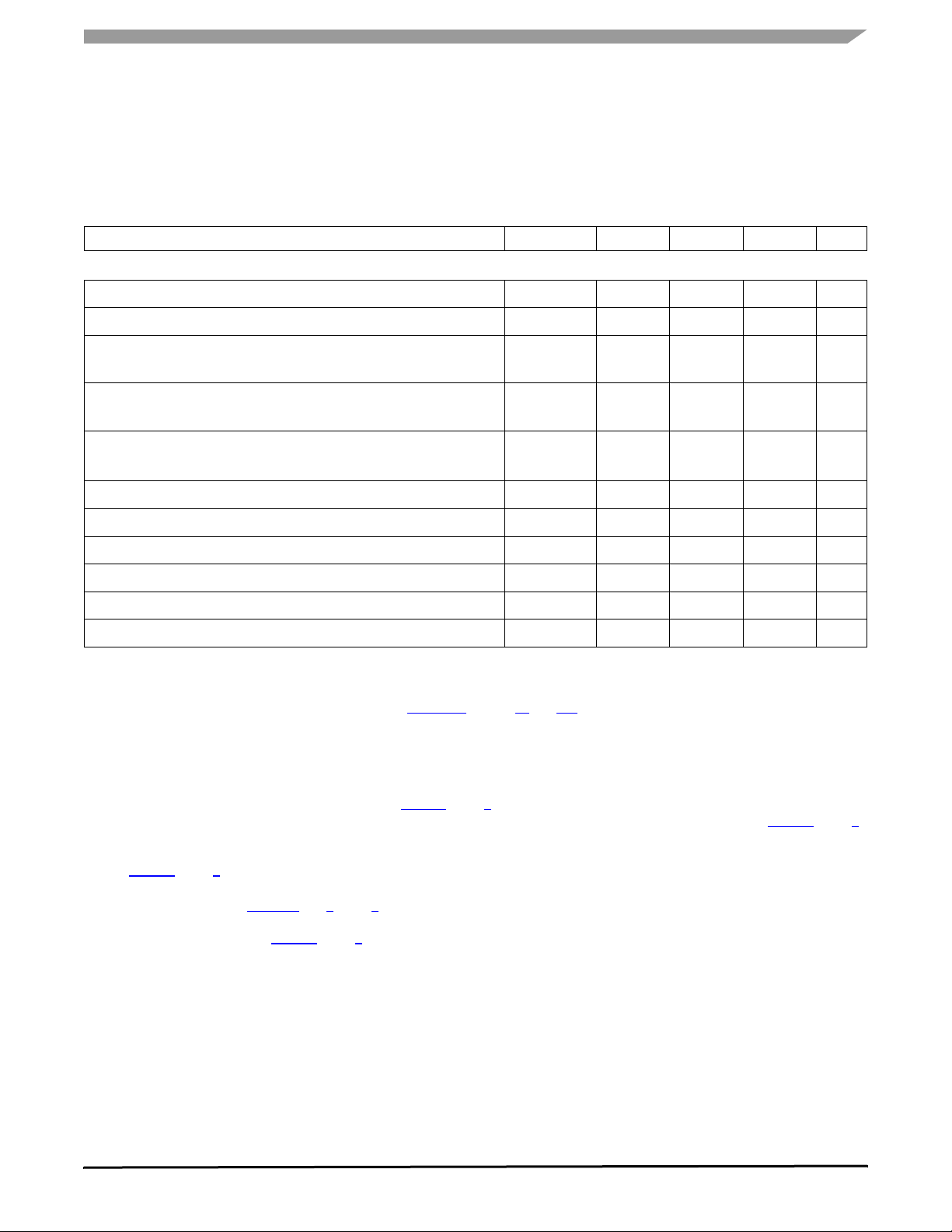

DYNAMIC ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 5.0 V ≤ V+ ≤ 28 V and -40°C ≤ TA ≤ 125°C unless otherwise noted. Typical values noted

reflect the approximate parameter mean at T

Characteristic Symbol Min Typ Max Unit

TIMING CHARACTERISTICS

OUT

(20)

(22)

(22)

= 3.0 A

(23)

PWM Frequency

Maximum Switching Frequency During Active Current Limiting

Output ON Delay

V+ = 14 V

Output OFF Delay

V+ = 14 V

Output Rise and Fall Time

V+ = 14 V, I

= 25°C under nominal conditions unless otherwise noted.

A

(21)

f

f

t

d

PWM

MAX

(ON)

––10kHz

––20kHz

––18

t

d (OFF)

––18

, t

t

f

r

2.0 5.0 8.0

µs

µs

µs

Output Latch-OFF Time

Output Blanking Time

Output FET Body Diode Reverse Recovery Time

Disable Delay Time

Short Circuit / Overtemperature Turn-

(25)

OFF Time

(26)

Power-OFF Delay Time

(24)

t

a

t

b

t

r r

t

d (disable)

t

FAULT

t

pod

15 20.5 26

12 16.5 21

100 – –

––8.0µs

–4.0–µs

–1.05.0ms

Notes

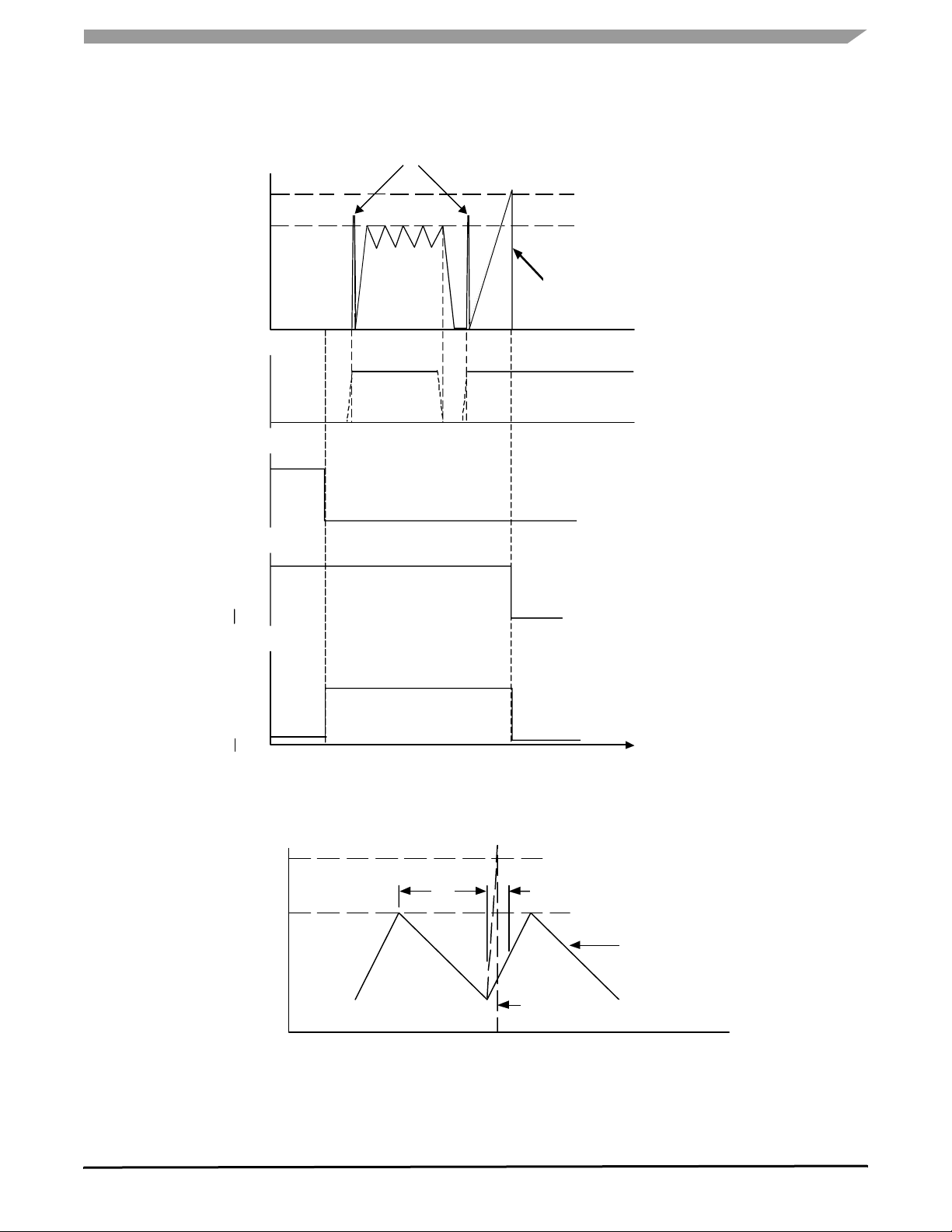

20. The outputs can be PWM controlled from an external source. This is typically done by holding one input high while applying a PWM

pulse train to the other input. The maximum PWM frequency obtainable is a compromise between switching losses and switching

frequency. Refer to Typical Switching Waveforms, Figures 10

through 17, pp. 10–11.

21. The Maximum Switching Frequency during active current limiting is internally implemented. The internal control produces a constant

OFF-time PWM of the output. The output load current effects the Maximum Switching Frequency.

22. Output Delay is the time duration from the midpoint of the IN1 or IN2 input signal to the 10% or 90% point (dependent on the transition

direction) of the OUT1 or OUT2 signal. If the output is transitioning High-to-Low, the delay is from the midpoint of the input signal to the

90% point of the output response signal. If the output is transitioning Low-to-High, the delay is from the midpoint of the input signal to

the 10% point of the output response signal. See Figure 4

23. Rise Time is from the 10% to the 90% level and Fall Time is from the 90% to the 10% level of the output signal. See Figure 6

, page 8.

, page 8.

24. Parameter is guaranteed by design but not production tested.

25. Disable Delay Time is the time duration from the midpoint of the D (disable) input signal to 10% of the output tri-state response. See

Figure 5

, page 8.

26. Increasing currents will become limited at I

state latch-OFF. See Figures 8

above 160

°C will cause the active current limiting to progressively “fold-back” (or decrease) to 2.5 A typical at 175°C where thermal

latch-OFF will occur. See Figure 7

and 9, page 9. Active current limiting will cause junction temperatures to rise. A junction temperature

, page 8.

. Hard shorts will breach the I

LIM

SCH

or I

limit, forcing the output into an immediate tri-

SCL

µs

µs

ns

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

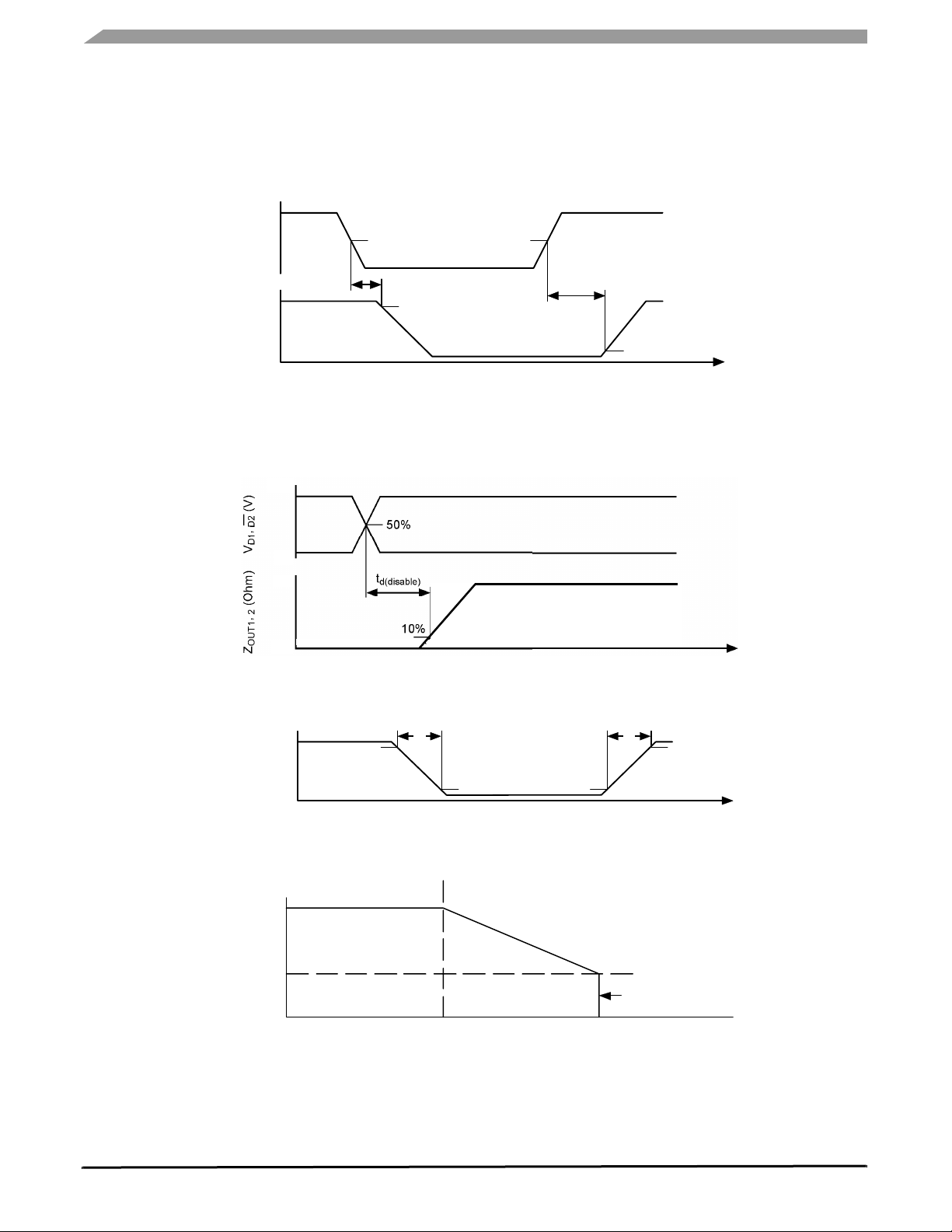

TIMING DIAGRAMS

TIMING DIAGRAMS

5.0

)

V

(

2

N

I

,

1

N

I

V

0

V

)

PWR

V

(

2

,

1

T

U

O

V

0

5.0 V

50%

t

d(ON)

50%

90%

TIME

Figure 4. Output Delay Time

t

d(OFF)

10%

0 V

∞Ω

0 Ω

Figure 5. Disable Delay Time

V

)

PWR

V

(

2

,

1

T

U

O

V

0

90%

t

f

10%

10%

t

r

90%

Figure 6. Output Switching Time

)

A

(

T

6.5

6.6

N

E

R

R

U

C

T

2.5

U

CURRENT (A)

P

,

T

U

O

I

,

,

X

A

M

I

I

LIM

LIM

160 175

TJ, JUNCTION TEMPERATURE (oC)

Thermal Shutdown

Figure 7. Active Current Limiting Versus Temperature (Typical)

33886

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

)

TIM

E

A

(

T

N

E

R

R

U

C

T

U

P

T

, CURRENT (A)

U

O

,

,

OUT

D

I

A

O

OUT

L

I

8.0

6.5

Diode Reverse

Re c o ve r y Sp i ke s

Load Capacitance and/or

Diode Reverse Recovery Spikes

I

Short Circuit Detect Threshold

SCL

Typ. Short Ckt. Detect Threshold

for Low-Side FETs

Typical Current Limiting Threshold

Typ. Curr ent Limit Threshold

PWM

Active

Current

Current

Limiting

Limiting

(See Figure 7)

(See Figure 6)

(See Figure 7)

Hard Short Detect an d Lat ch-OFF

Hard Short Detect and Latch-Off

0

N

I

C

I

G

O

L

,

n

N

I

N

I

C

I

G

O

L

,

1

D

N

I

C

I

G

O

L

,

2

D

T

U

O

C

I

G

O

L

,

S

SF I

F

[1]

[0]

[1]

[0]

[1]

[0]

[1]

[0]

IN2 or IN1

IN1 OR IN 2

IN1 or IN2

IN2

Ou tp u ts

Outputs

Tristated

Tri-stated

IN1 IN2

IN1

IN2

Outputs

Outputs

Tristated

Tri-stated

IN1 or IN2

IN2IN1

OR

IN2 or IN1

IN2 IN1OR

Outputs Operat ional

Outputs Operational

(per Input Contr ol Condition)

(per Input Control Condition)

Figure 8. Active Current Limiting Versus Time

OR IN1

)

A

(

T

N

E

R

R

U

C

T

U

P

T

, CURRENT (A)

U

O

,

OUT

D

I

A

O

L

I

8.0

6.5

t

a

I

Short Circuit Detect Threshold

Short Circuit Detect Threshold

Overcurrent Minimum Threshold

SCL

ta = Output Latch-OFF Time

ta= Tristate Output OFF Time

t

b

= Output Blanking Time

t

t

= Current Limit Blank Time

b

b

Typical Current

Typical PWM Load

Limiting Waveform

Current Limiting

Waveform

Hard Output

Hard Short Detect

Short Latch-OFF

Latch-Off Prevented During t

b

TIME

Figure 9. Active Current Limiting Detail

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

TYPICAL SWITCHING WAVEFORMS

TYPICAL SWITCHING WAVEFORMS

Important For all plots, the following applies:

• Ch2 = 2.0 A per division

•L

•L

•R

= 533 µH @ 1.0 kHz

LOAD

= 530 µH @ 10.0 kHz

LOAD

= 4.0 Ω

LOAD

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+= 24 V f

=1.0 kHz Duty Cycle= 10%

PWM

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+= 34 V f

=1.0 kHz Duty Cycle=90%

PWM

Figure 12. Output Voltage and Current vs. Input Voltage

at V+ = 34 V, PMW Frequency of 1.0 kHz,

and Duty Cycle of 90%, Showing Device in

Current Limiting Mode

Figure 10. Output Voltage and Current vs. Input Voltage

at V+ = 24 V, PMW Frequency of 1.0 kHz,

and Duty Cycle of 10%

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+=24 V f

=1.0 kHz Duty Cycle= 50%

PWM

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+=22 V f

=1.0 kHz Duty Cycle= 90%

PWM

Figure 13. Output Voltage and Current vs. Input Voltage

at V+

= 22 V, PMW Frequency of 1.0 kHz,

and Duty Cycle of 90%

Figure 11. Output Voltage and Current vs. Input Voltage

at V+

= 24 V, PMW Frequency of 1.0 kHz,

and Duty Cycle of 50%

33886

Analog Integrated Circuit Device Data

10 Freescale Semiconductor

TYPICAL SWITCHING WAVEFORMS

%

%

%

%

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+=24 V f

=10 kHz Duty Cycle=50

PWM

Figure 14. Output Voltage and Current vs. Input Voltage

at V+

= 24 V, PMW Frequency of 10 kHz,

and Duty Cycle of 50%

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+=12 V f

=20 kHz Duty Cycle= 50

PWM

Figure 16. Output Voltage and Current vs. Input Voltage

at V+

= 12 V, PMW Frequency of 20 kHz,

and Duty Cycle of 50% for a Purely Resistive Load

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+=24 V f

=10 kHz Duty Cycle= 90

PWM

Figure 15. Output Voltage and Current vs. Input Voltage

at V+

= 24 V, PMW Frequency of 10 kHz,

and Duty Cycle of 90%

Output Voltage

(OUT1)

I

OUT

Input Voltage

(IN1)

V+= 12 V f

=20 kHz Duty Cycle=90

PWM

Figure 17. Output Voltage and Current vs. Input Voltage

at V+

= 12 V, PMW Frequency of 20 kHz,

and Duty Cycle of 90% for a Purely Resistive Load

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

TYPICAL SWITCHING WAVEFORMS

Table 5. Truth Table

The tri-state conditions and the fault status are reset using D1 or

D2. The truth table uses the following notations: L = Low,

H = High, X = High or Low, and Z = High impedance (all output power transistors are switched off).

Device State

D1 D2 IN1 IN2 FS OUT1 OUT2

Forward

Reverse

Freewheeling Low

Freewheeling High

Disable 1 (D1)

Disable 2 (D2

IN1 Disconnected

IN2 Disconnected

D1 Disconnected

D2 Disconnected

Undervoltage

Overtemperature

Short Circuit

Notes

27. In the case of an undervoltage condition, the outputs tri-state and the fault status is set logic Low. Upon undervoltage recovery, fault

28. When a short circuit or overtemperature condition is detected, the power outputs are tri-state latched-OFF independent of the input

)

(27)

(28)

(28)

status is reset automatically or automatically cleared and the outputs are restored to their original operating condition.

signals and the fault status flag is set logic Low.

LHHL H H L

LHLH H L H

LHLL H L L

LHHH H H H

HXXX L Z Z

XLXX L Z Z

LHZX H H X

LHXZ H X H

ZXXX L Z Z

XZXX L Z Z

XXXX L Z Z

XXXX L Z Z

XXXX L Z Z

Input Conditions

Fault Status

Flag

Output States

33886

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

0.40

0.35

0.30

0.25

0.20

Ohms

0.15

0.10

ELECTRICAL PERFORMANCE CURVES

ELECTRICAL PERFORMANCE CURVES

0.05

0.0

59117131519 3733 35 3927 412917 21 23 25 31

Volts

Figure 18. Typical High-Side R

DS(ON)

Versus V+

0.13

0.128

0.126

Ohms

0.124

OHMS

0.122

0.12

59117131519 3733 35 3927 412917 21 23 25 31

Volts

V

PWR

Figure 19. Typical Low-Side R

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

DS(ON)

Versus V+

33886

ELECTRICAL PERFORMANCE CURVES

9.0

8.0

7.0

6.0

5.0

OHMS

4.0

milli amperes

3.0

2.0

1.0

0.0

59117131519 3733 35 3927 412917 21 23 25 31

Volts

V

PWR

Figure 20. Typical Quiescent Supply Current Versus V+

33886

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

FUNCTIONAL DESCRIPTION

INTRODUCTION

FUNCTIONAL DESCRIPTION

INTRODUCTION

Numerous protection and operational features (speed,

torque, direction, dynamic braking, and PWM control), in

addition to the 5.0 A current capability, make the 33886 a

very attractive, cost-effective solution for controlling a broad

range of fractional horsepower DC motors. A pair of 33886

devices can be used to control bipolar stepper motors in both

directions. In addition, the 33886 can be used to control

permanent magnet solenoids in a push-pull variable force

fashion using PWM control. The 33886 can also be used to

excite transformer primary windings with a switched square

wave to produce secondary winding AC currents.

As shown in Figure 2

, the 33886 is a fully protected monolithic H-Bridge

page 2

with Fault Status reporting. For a DC motor to run the input

conditions need be as follows: D1 input logic Low, D2 input

logic High, FS

and the other IN logic High to define output polarity. The

33886 can execute dynamic braking by simultaneously

turning on either both high-side

MOSFETs in the output H-Bridge; e.g., IN1 and IN2 logic

High or IN1 and IN2 logic Low.

The 33886 outputs are capable of providing a continuous

DC load current of 5.0 A from a 40 V V+ source. An internal

charge pump supports PWM frequencies up to 10 kHz. An

flag cleared (logic High), with one IN logic Low

, Simplified Internal Block Diagram,

MOSFETs or both low-side

external pull-up resistor is required for the open drain FS

terminal for fault status reporting.

Two independent inputs (IN1 and IN2) provide control of

the two totem-pole half-bridge outputs. Two disable inputs

(D1 and D2

impedance state (all H-Bridge switches OFF).

The 33886 has undervoltage shutdown with automatic

recovery, active current limiting, output short-circuit latchOFF, and overtemperature latch-OFF. An undervoltage

shutdown, output short circuit latch-OFF, or overtemperature

latch-OFF fault condition will cause the outputs to turn OFF

(i.e., become high impedance or tri-stated) and the fault

output flag to be set Low. Either of the Disable inputs or V+

must be “toggled” to clear the fault flag.

The short circuit / overtemperature shutdown scheme is

unique and best described as using a junction temperaturedependent active current “fold back” protection scheme.

When a short circuit condition is experienced, the current

limited output is “ramped down” as the junction temperature

increases above 160°C, until at 175°C the current has

decreased to about 2.5 A. Above 175°C, overtemperature

shutdown (latch-OFF) occurs. This feature allows the device

to remain in operation for a longer time with unexpected

loads, while still retaining adequate protection for both the

device and the load.

) are for forcing the H-Bridge outputs to a high

FUNCTIONAL TERMINAL DESCRIPTION

POWER/ANALOG GROUNDS (PGND AND AGND)

Power and analog ground terminals. The power and

analog ground terminals should be connected together with a

very low impedance connection.

POSITIVE POWER SUPPLY (V+)

V+ terminals are the power supply inputs to the device. All

V+ terminals must be connected together on the printed

circuit board with as short as possible traces offering as low

impedance as possible between terminals.

V+ terminals have an undervoltage threshold. If the supply

voltage drops below a V+ undervoltage threshold, the output

power stage switches to a tri-state condition and the fault

status flag is set and the Fault Status terminal voltage

switched to a logic Low. When the supply voltage returns to a

level that is above the threshold, the power stage

automatically resumes normal operation according to the

established condition of the input terminals and the fault

status flag is automatically reset logic High.

FAULT STATUS (FS)

This terminal is the device fault status output. This output

is an active Low open drain structure requiring a pull-up

resistor to 5.0 V. Refer to Table 5,

Truth Table, page 12.

LOGIC INPUT 1, 2 AND DISABLE1, 2 (IN1, IN2, D1,

AND

D2)

These terminals are input control terminals used to control

the outputs. These terminals are 5.0 V CMOS-compatible

inputs with hysteresis. The IN1 and IN2 independently control

OUT1 and OUT2, respectively. D1 and D2

inputs used to tri-state disable the H-Bridge outputs.

When either D1 or D2

Low) in the disable state, outputs OUT1 and OUT2 are both

tri-state disabled; however, the rest of the device circuitry is

fully operational and the supply I

to a few milliamperes. Refer to Table 5,

Static Electrical Characteristics

is set (D1 = logic High or D2 = logic

Q (standby)

table, page 5.

are complimentary

current is reduced

Truth Table, and

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

FUNCTIONAL DESCRIPTION

FUNCTIONAL TERMINAL DESCRIPTION

H-BRIDGE OUTPUT 1, 2 (OUT1 AND OUT2)

These terminals are the outputs of the H-Bridge with

integrated output FET body diodes. The bridge output is

controlled using the IN1, IN2, D1, and D2

have active current limiting above 6.5 A. The outputs also

have thermal shutdown (tri-state latch-OFF) with hysteresis

as well as short circuit latch-OFF protection.

A disable timer (time t

) incorporated to detect currents

b

that are higher than active current limit is activated at each

inputs. The outputs

output activation to facilitate detecting hard output short

conditions (see Figure 9, page 9).

CHARGE PUMP CAPACITOR (CCP)

Charge pump output terminal. A filter capacitor (up to

33 nF) can be connected from the CCP terminal and PGND.

The device can operate without the external capacitor,

C

although the

the device to perform at maximum speed, timing, and PWM

frequency.

capacitor helps to reduce noise and allows

CP

33886

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

FUNCTIONAL DEVICE OPERATION

FUNCTIONAL DEVICE OPERATION

FUNCTIONAL TERMINAL DESCRIPTION

SHORT CIRCUIT PROTECTION

If an output short circuit condition is detected, the power

outputs tri-state (latch-OFF) independent of the input (IN1

and IN2) states, and the fault status output flag is set logic

Low. If the D1 input changes from logic High to logic Low, or

D2 input changes from logic Low to logic High, the

if the

output bridge will become operational again and the fault

status flag will be reset (cleared) to a logic High state.

The output stage will always switch into the mode defined

by the input terminals (IN1, IN2, D1, and D2

), provided the

device junction temperature is within the specified operating

temperature.

ACTIVE CURRENT LIMITING

The maximum current flow under normal operating

conditions is internally limited to I

the maximum current value is reached, the output stages are

tri-stated for a fixed time (t

) of 20 µs typical. Depending on

a

the time constant associated with the load characteristics, the

current decreases during the tri-state duration until the next

output ON cycle occurs (see Figures 9

page 10, respectively).

The current limiting threshold value is dependent upon the

device junction temperature. When -40°C < TJ < 160°C, I

is between 5.2 A and 7.8 A. When T

current decreases linearly down to 2.5 A typical at 175°C.

Above 175°C the device overtemperature circuit detects T

and overtemperature shutdown occurs (see Figure 7

page 8). This feature allows the device to remain operational

for a longer time but at a regressing output performance level

at junction temperatures above 160°C.

(5.2 A to 7.8 A). When

LIM

and 12, page 9 and

exceeds 160°C, the I

J

LIM

LIM

LIM

,

OVERTEMPERATURE SHUTDOWN AND

HYSTERESIS

If an overtemperature condition occurs, the power outputs

are tri-state (latched-OFF) independent of the input signals

and the fault status flag is set logic Low.

To reset from this condition, D1 must change from logic

High to logic Low, or D2

must change from logic Low to logic

High. When reset, the output stage switches ON again,

provided that the junction temperature is now below the

overtemperature threshold limit minus the hysteresis.

Note Resetting from the fault condition will clear the fault

status flag.

MAIN DIFFERENCES COMPARED TO

MC33186DH1

• COD terminal has been removed. Terminal 8 is now a Do

Not Connect (DNC) terminal.

• Terminal 20 is no longer connected in the 20 HSOP

package. It is now a DNC terminal.

•R

transistor.

• Maximum temperature operation is now 160°C, as

minimum thermal shutdown temperature has increased.

• Current regulation limiting foldback is implemented above

160°C T

• Thermal resistance junction to case has been increased

from ~2.0°C/W to ~5.0°C/W.

max at TJ = 150°C is now 225 mΩ per each output

DS(ON)

.

J

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

FUNCTIONAL DEVICE OPERATION

PERFORMANCE

PERFORMANCE

The 33886 is designed for enhanced thermal

performance. The significant feature of this device is the

exposed copper pad on which the power die is soldered. This

pad is soldered on a PCB to provide heat flow to ambient and

also to provide thermal capacitance. The more copper area

on the PCB, the better the power dissipation and transient

behavior will be.

Example Characterization on a double-sided PCB:

bottom side area of copper is 7.8 cm

(see Figure 21

); grid array of 24 vias 0.3 mm in diameter.

Top Side

2

; top surface is 2.7 cm2

Bottom Side

Figure 21. PCB Test Layout

Figure 22 shows the thermal response with the device

soldered on to the test PCB described in Figure 21.

100

10

Rth (°C/W)

1

0,1

0,001 0,01 0,1 1 10 100 1000 10000

t, Time (s)

Figure 22. 33886 Thermal Response

33886

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

TYPICAL APPLICATIONS

TYPICAL APPLICATIONS

A typical application schematic is shown in Figure 23. For

precision high-current applications in harsh, noisy

AGND

OUT1

PGND

environments, the V+ by-pass capacitor may need to be

substantially larger.

DC

MOTOR

V+

33886

V+

C

CP

33 nF

+

47 µF

OUT2

D2

D1

FS

IN1

IN2

IN2

IN1

FS

D1

D2

Figure 23. 33886 Typical Application Schematic

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

PACKAGING

PACKAGE DIMENSIONS

PACKAGING

PACKAGE DIMENSIONS

Important For the most current revision of the package, visit www.freescale.com and perform a keyword search on 98ASH70702A listed

below.

DH SUFFIX

VW (Pb-FREE) SUFFIX

20-TERMINAL HSOP

PLASTIC PACKAGE

98ASH70702A

ISSUE A

PIN ONE ID

GAUGE

PLANE

D2

A

bbb C

B

A2

18X

X 45

h

_

E2

1

e

20

D

e/2

10

11

EXPOSED

HEATSINK AREA

E1

Y

10X

E

M

bbb C

A

B

DATUM

H

PLANE

E3

D1

E4

BOTTOM VIEW

b1

c1

b

M

A

C

SEATING

PLANE

c

aaa C

SECTION W–W

L1

q

W

W

L

A1

A3

NOTES:

1. CONTROLLING DIMENSION: MILLIMETER.

2. DIMENSIONS AND TOLERANCES PER ASME

Y14.5M, 1994.

3. DATUM PLANE –H– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DIMENSIONS D AND E1 DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.150 PER SIDE. DIMENSIONS D AND E1 DO

INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –H–.

5. DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE b DIMENSION AT MAXIMUM MATERIAL

CONDITION.

6. DATUMS –A– AND –B– TO BE DETERMINED AT

DATUM PLANE –H–.

7. DIMENSION D DOES NOT INCLUDE TIEBAR

PROTRUSIONS. ALLOWABLE TIEBAR

PROTRUSIONS ARE 0.150 PER SIDE.

MILLIMETERS

DIM MIN MAX

A 3.000 3.400

A1 0.100 0.300

A2 2.900 3.100

A3 0.00 0.100

D 15.800 16.000

D1 11.700 12.600

D2 0.900 1.100

E 13.950 14.450

E1 10.900 11.100

E2 2.500 2.700

E3 6.400 7.200

E4 2.700 2.900

L 0.840 1.100

L1 0.350 BSC

b 0.400 0.520

b1 0.400 0.482

c 0.230 0.320

c1 0.230 0.280

e 1.270 BSC

h ––– 1.100

q

0 8

__

aaa 0.200

bbb 0.100

(1.600)

DETAIL Y

33886

Analog Integrated Circuit Device Data

20 Freescale Semiconductor

ADDITIONAL DOCUMENTATION

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM - REVISION 2.0

THERMAL ADDENDUM - REVISION 2.0

5.0 A H-Bridge

Introduction

This thermal addendum is provided as a supplement to the MC33186

technical data sheet. The addendum provides thermal performance

information that may be critical in the design and development of system

applications. All electrical, application, and packaging information is provided

in the data sheet.

Packaging and Thermal Considerations

The MC33186 is offered in a 20 terminal HSOP exposed pad, single die

package. There is a single heat source (P), a single junction temperature

(T

), and thermal resistance (R

J

T

J

The stated values are solely for a thermal performance comparison of one

package to another in a standardized environment. This methodology is not

meant to and will not predict the performance of a package in an applicationspecific environment. Stated values were obtained by measurement and

simulation according to the standards listed below.

).

θJA

θJA

.

P

=

R

33886

20-TERMINAL

HSOP-EP

VW SUFFIX (Pb-free)

DH SUFFIX

98ASH70702A

20-TERMINAL HSOP

Note For package dimensions, refer to

the 33886 device data sheet.

Standards

Table 6. Thermal Performance Comparison

Thermal Resistance [°C/W]

(1)(2)

R

θJA

(2)(3)

R

θJB

(1)(4)

R

θJA

(5)

R

θJC

NOTES:

1.Per JEDEC JESD51-2 at natural convection, still air condition.

2.2s2p thermal test board per JEDEC JESD51-5 and JESD51-7.

3.Per JEDEC JESD51-8, with the board temperature on the center

trace near the center lead.

4.Single layer thermal test board per JEDEC JESD51-3 and

JESD51-5.

5.Thermal resistance between the die junction and the exposed

pad surface; cold plate attached to the package bottom side,

remaining surfaces insulated.

20

6.0

52

1.0

1.0

1.0

0.2

0.2

* All measurements

are in millimeters

Soldermast

openings

20 Terminal HSOP-EP

1.27 mm Pitch

16.0 mm x 11.0 mm Body

12.2 mm x 6.9 mm Exposed Pad

Thermal vias

connected to top

buried plane

Figure 24. Thermal Land Pattern for Direct Thermal

Attachment According to JESD51-5

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM - REVISION 2.0

A

DNCAGND

IN2

D1

C

CP

V+

OUT2

OUT2

D2

PGND

11

PGND

FS

IN1

V+

V+

OUT1

OUT1

DNC

PGND

PGND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

33886 Terminal Connections

20-Terminal HSOP

1.27 mm Pitch

16.0 mm x 11.0 mm Body

12.2 mm x 6.9 mm Exposed Pad

Figure 25. Thermal Test Board

Device on Thermal Test Board

Material: Single layer printed circuit board

FR4, 1.6 mm thickness

Cu traces, 0.07 mm thickness

Outline: 80 mm x 100 mm board area,

including edge connector for thermal

testing

Area A: Cu heat-spreading areas on board

surface

Ambient Conditions: Natural convection, still air

Table 7. Thermal Resistance Performance

Thermal

Resistance

R

JA

θ

R

JS

θ

Area A (mm

2

) °C/W

0.0 52

300 36

600 32

0.0 10

300 7.0

600 6.0

R

is the thermal resistance between die junction and

JA

θ

ambient air.

R

is the thermal resistance between die junction and the

JS

θ

reference location on the board surface near a center lead of the

package (see

33886

Figure 25).

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

60

]

50

40

ADDITIONAL DOCUMENTATION

THERMAL ADDENDUM - REVISION 2.0

100

10

1

Thermal Resistance [ºC/W

30

R

x

θ

JA

20

10

0

0 300 600

Heat spreading area A [mm²]

Figure 26. Device on Thermal Test Board R

R

x

θ

JA

θJA

Thermal Resistance [ºC/W]

0.1

1.00E-03 1.00E-02 1.00E-01 1.00E+00 1.00E+01 1.00E+02 1.00E+03 1.00E+04

Time(s)

Figure 27. Transient Thermal Resistance R

JA

θ

time[s]

Device on Thermal Test Board Area A = 600 (mm2)

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

REVISION HISTORY

REVISION HISTORY

Revision Date Description of Changes

7.0

7/2005

• Implemented Revision History page

• Added Thermal Addendum

• Converted to Freescale format

33886

Analog Integrated Circuit Device Data

24 Freescale Semiconductor

NOTES

NOTES

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 25

NOTES

NOTES

33886

Analog Integrated Circuit Device Data

26 Freescale Semiconductor

NOTES

NOTES

33886

Analog Integrated Circuit Device Data

Freescale Semiconductor 27

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc., 2005. All rights reserved.

MC33886

Rev 7.0

07/2005

Loading...

Loading...