Page 1

Freescale Semiconductor

Advance Information

Dual DBUS Master with

Document Number: MC33780

Rev 4.0, 11/2006

Differential Drive and

Frequency Spreading

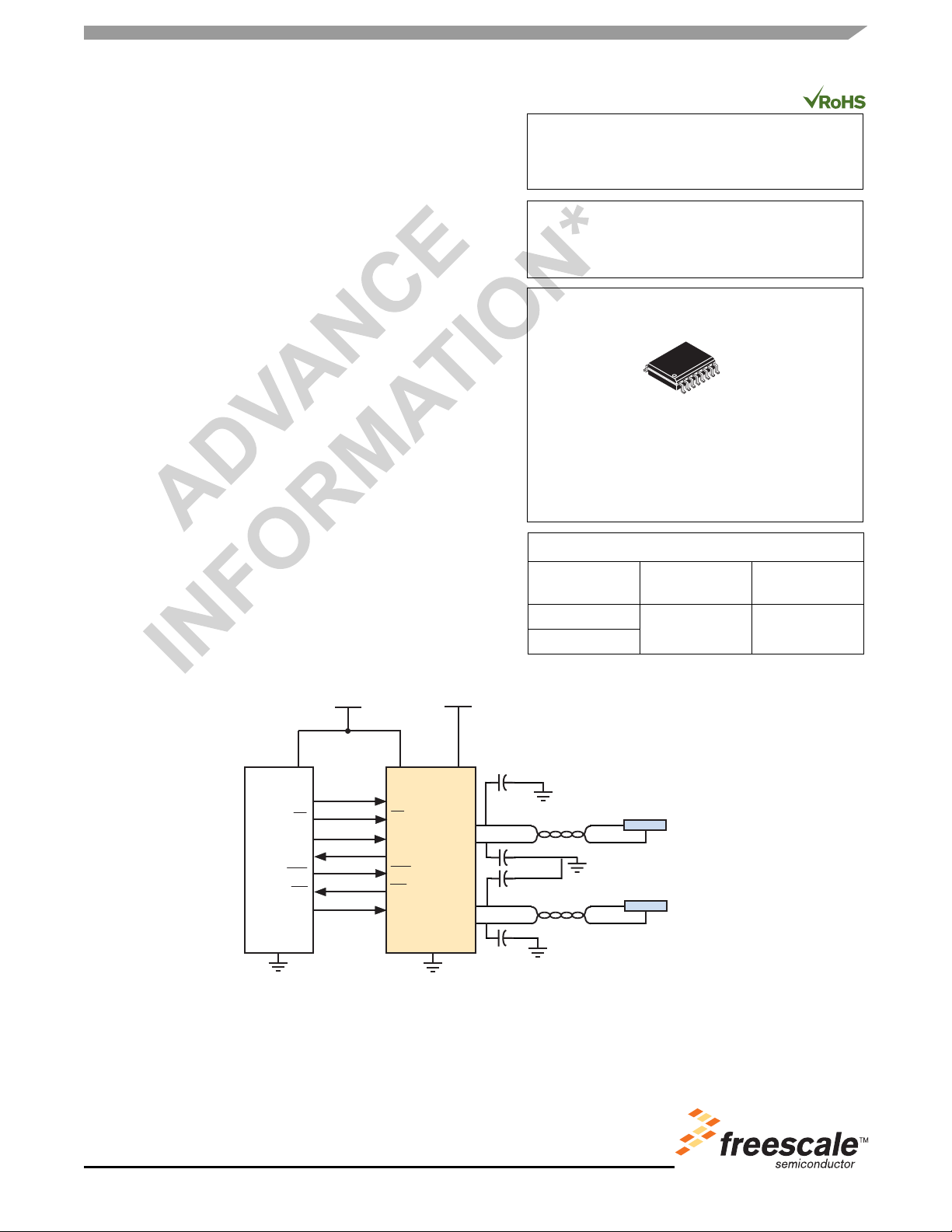

The 33780 is a master device for two differential DBUS buses. It

contains the logic to interface the buses to a standard serial

peripheral interface (SPI) port and the analog circuitry to drive data

and power over the bus as well as receive data from the remote slave

devices.

The differential mode of the 33780 generates lower electromagnetic interference (EMI) in situations where data rates and wiring

make this a problem. Frequency spreading further reduces interference by spreading the energy across many channels, reducing

the energy in any single channel.

Features

• Two Independent DBUS I /Os

• Common SPI Interface for All Operations

• Open-Drain Interrupt Output with Pull-up

• Maskable Interrupts for Send and Receive Data Status

• Automatic Message Cyclical Redundancy Checking (CRC)

Generation and Checking

• Four-Stage Transmit and Receive Buffers

• 8- to 16-Bit Messages with 0- to 8-Bit CRC

• Independent Frequency Spreading for Each Channel

• Pb-Free Packaging Designated by Suffix Code EG

DIFFERENTIAL DBUS MASTER

ORDERING INFORMATION

Device

MC33780EG/R2

MCZ33780EG/R2

33780

EG (PB-FREE SUFFIX)

98ASB42567B

16-PIN SOICW

Temperature

Range (T

-40°C to 85°C 16 SOICW

)

A

Package

+5.0 V +25 V

MCU

VCC

SCLK

CS

MOSI

MISO

RST

INT

CLK

GND

VCC

SCLK

CS

MOSI

MISO

RST

INT

CLK

33780

VSUP

D0H

D0L

D1H

D1L

GND

Figure 1. 33780 Simplified Application Diagram

* This document contains certain information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2006. All rights reserved.

DSI/DBUS SLAVE

Twisted Pair

4.7 nF capacitors from D0H, D0L, D1H

and D1L to circuit ground are required

for proper operation.

33793

DSI/DBUS SLAVE

33793

Page 2

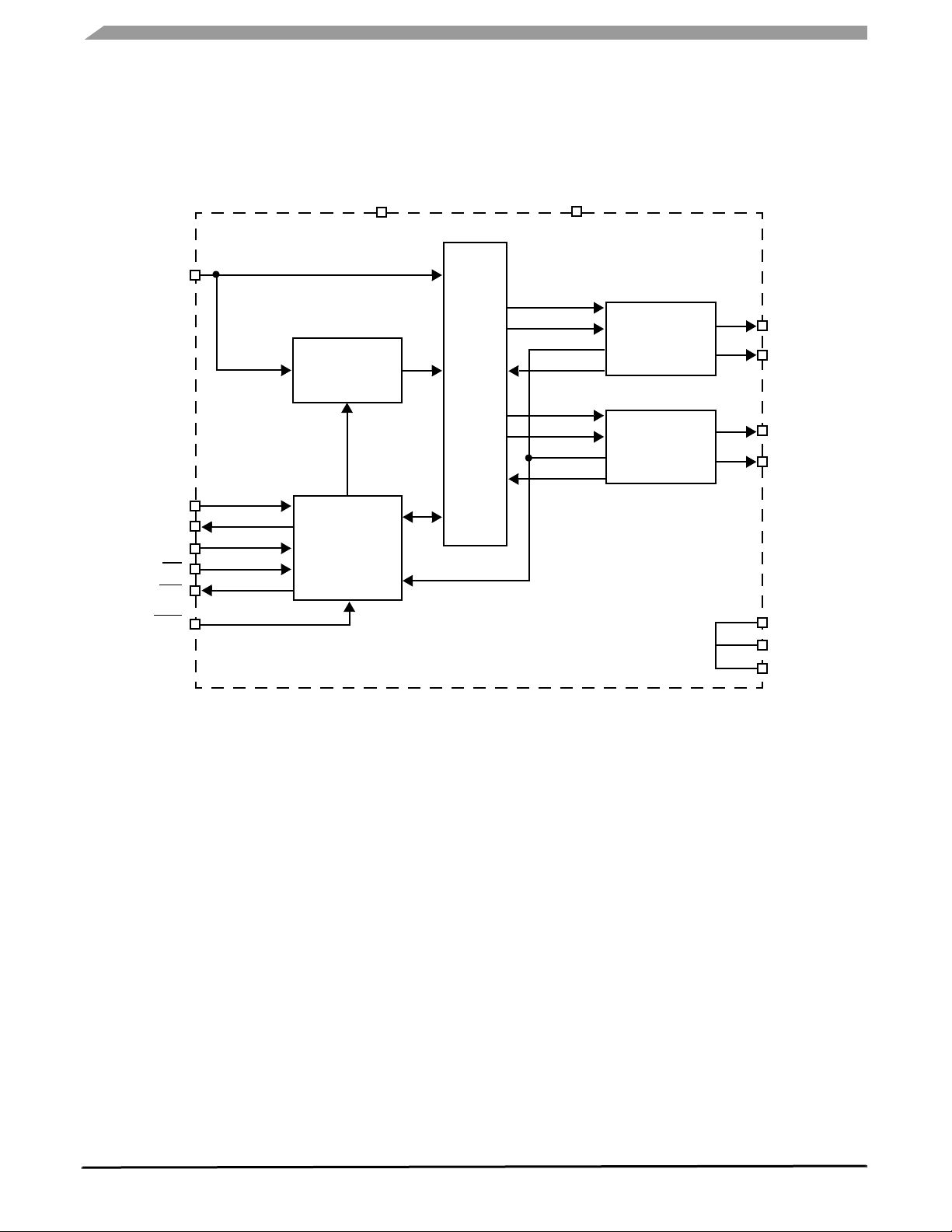

INTERNAL BLOCK DIAGRAM

CLK

INTERNAL BLOCK DIAGRAM

VCC VSUP

Spreader

Protocol Engine

DSIF

DSIS

DSIR

DSIF

DSIS

DSIR

DBUS

Driver/Receiver

DBUS

Driver/Receiver

D0H

D0L

D1H

D1L

SCLK

MISO

MOSI

CS

INT

RST

SPI,

Registers and

Interrupt

Generator

Figure 2. 33780 Internal Block Diagram

T

LIM

GND

GND

GND

33780

Analog Integrated Circuit Device Data

2 Freescale Semiconductor

Page 3

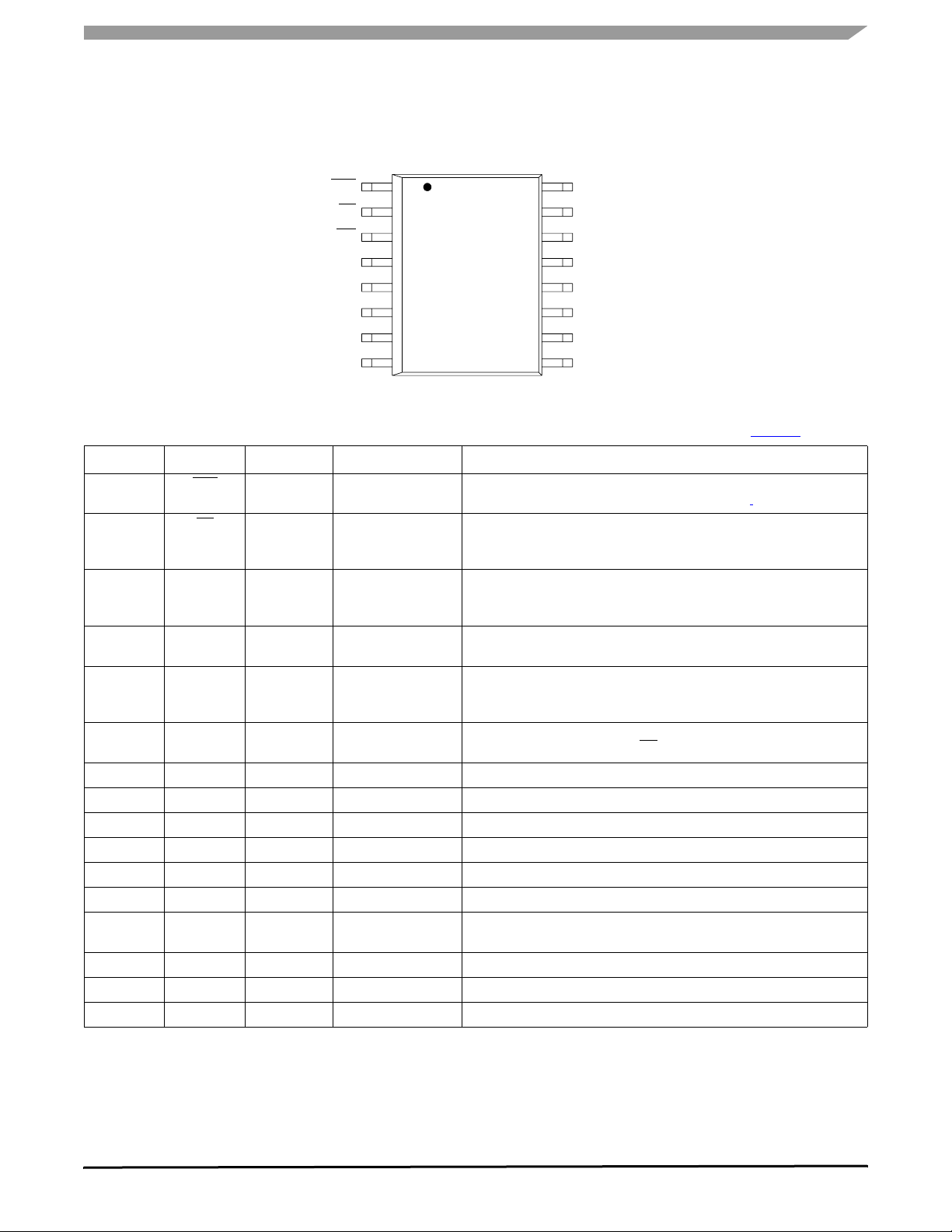

PIN CONNECTIONS

PIN CONNECTIONS

RST

CS

INT

MOSI

SCLK

MISO

CLK

GND

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND

D0L

D0H

VSUP

D1H

D1L

GND

VCC

Figure 3. 33780 Pin Connections

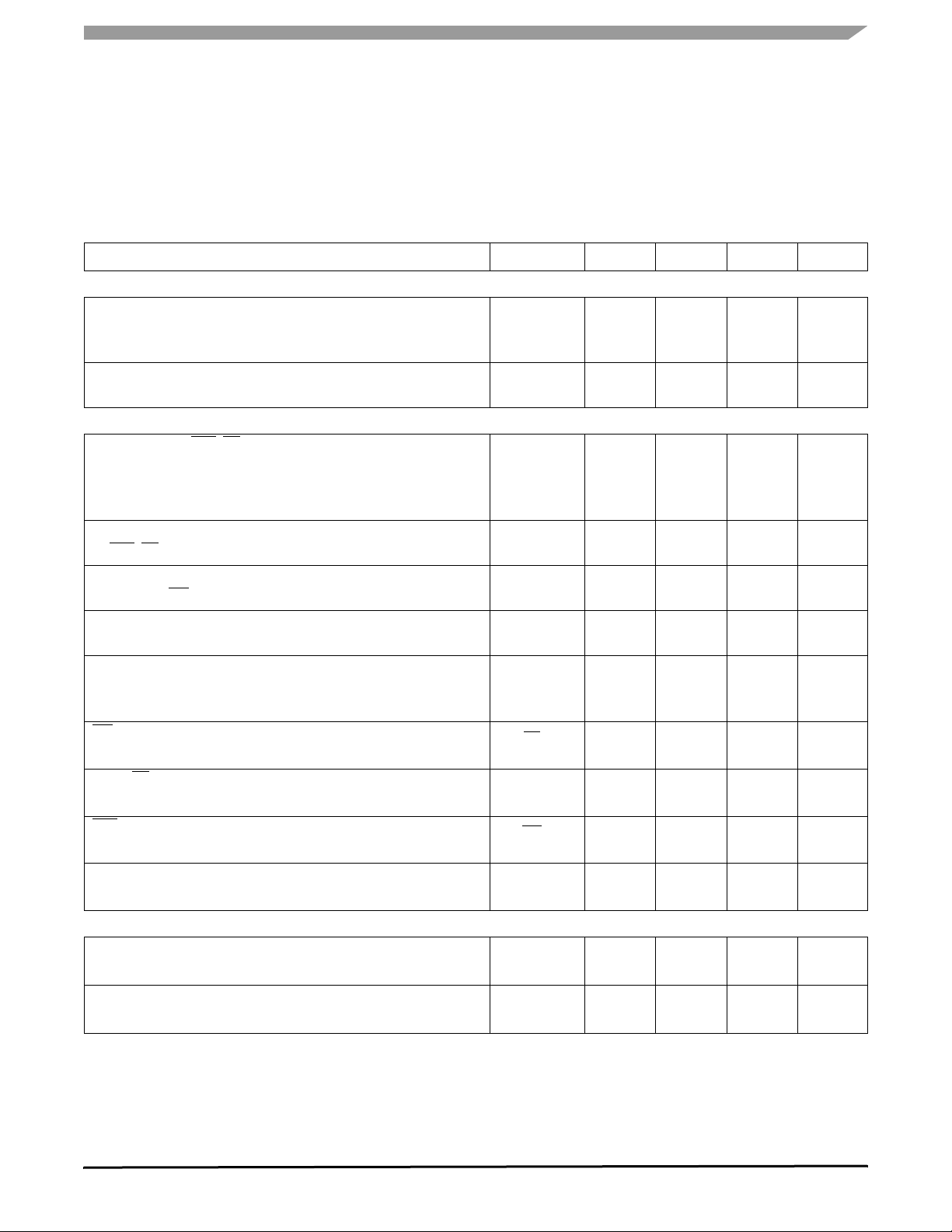

Table 1. 33780 Pin Definitions

A functional description of each pin can be found in the Functional Pin Descriptions section beginning on page 13.

Pin Pin Name Pin Function Formal Name Definition

1 RST Reset IC Reset

2 CS Input SPI Chip Select Input

3 INT Output Interrupt Output

4 MOSI Input Master Out Slave In

5 SCLK Input Serial Data Clock

6 MISO Output Master In Slave Out

7 CLK Input Clock Input

8 GND Ground Ground

9 VCC Input Logic Supply

10 GND Ground Power Ground

11 D1L Output Driver Low-Side Bus 1

12 D1H Output Driver High-Side Bus 1

13 VSUP Output Positive Supply for

Bus Output

14 D0H Output Driver High-Side Bus 0

15 D0L Output Driver Low-Side Bus 0

16 GND Ground Power Ground

A low level on this pin returns all registers to a known state as indicated

in the section entitled

Register and Bit Descriptions.

When this signal is high, SPI signals are ignored. Asserting this pin low

starts an SPI transaction. The SPI transaction is signaled as completed

when this signal returns high.

This output will be asserted low when an enabled interrupt condition

occurs. It contains a pullup current source that will perform a pullup when

unasserted.

SPI data into this IC. This data input is sampled on the positive edge of

SCLK.

Clocks in /out the data to/from the SPI. MISO data changes on the

negative transition of the SCLK. MOSI is sampled on the positive edge of

the SCLK.

SPI data sent to the MCU by this device. This data output changes on the

negative edge of SCLK. When

CS is high, this pin is high impedance.

4.0 MHz clock input.

Ground reference for analog and digital circuits.

Logic power source input.

Bus 1 power return.

Bus 1 low side.

Bus 1 high side.

This supply input is used to provide the positive level output of the bus.

Bus 0 high side.

Bus 0 low side.

Bus 0 power return.

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 3

Page 4

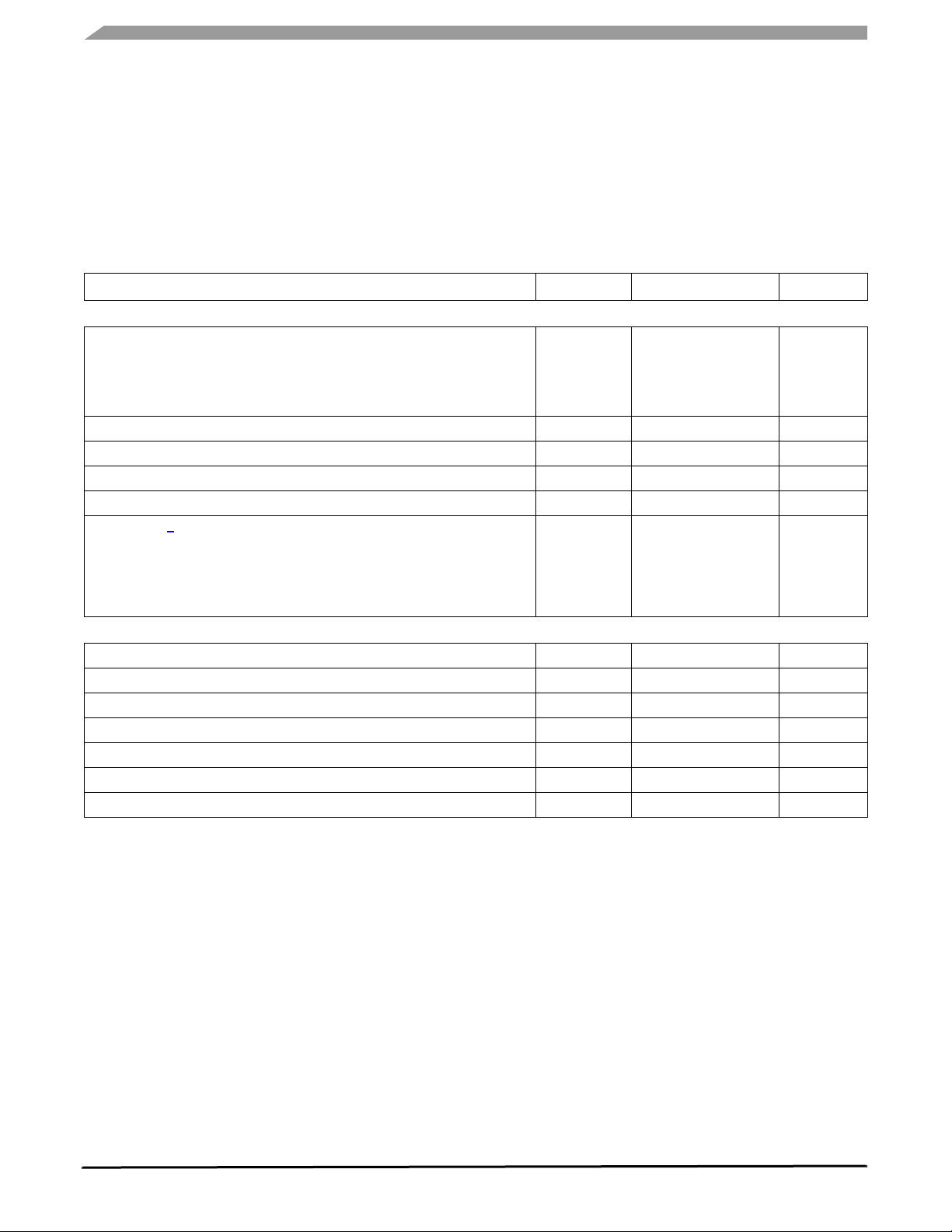

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

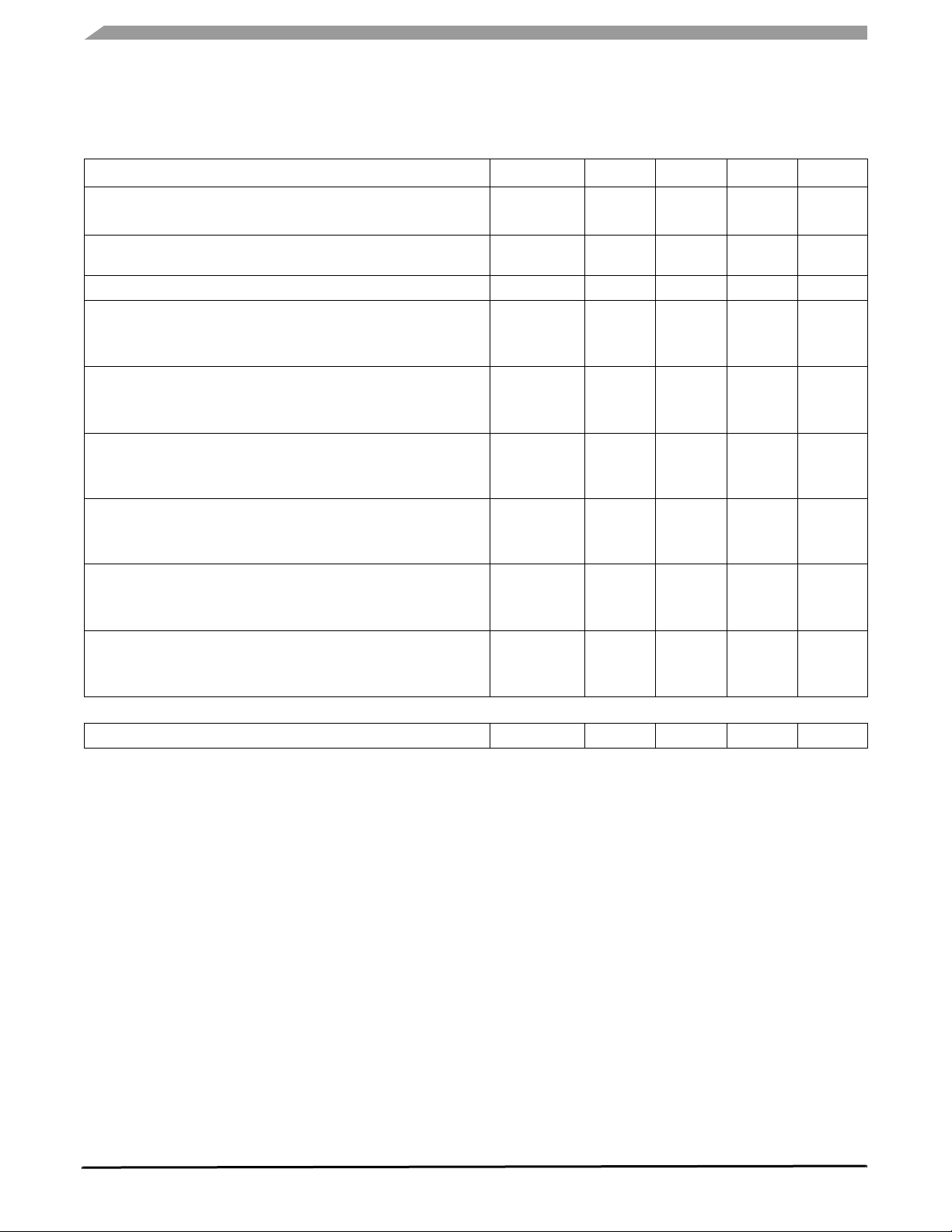

Table 2. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or

permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

Supply Voltages

V

SUP

Load Dump V

V

CC

(300 ms maximum)

SUP

Maximum Voltage on Logic Input /Output Pins

Maximum Voltage on DBUS Pins

Maximum DBUS Pin Current

Maximum Logic Pin Current

ESD Voltage 1

Human Body Model (HBM)

Machine Model (MM)

Charge Device Model (CDM)

THERMAL RATINGS

Storage Temperature

Operating Ambient Temperature

Operating Junction Temperature

Thermal Shutdown

Resistance, Junction-to-Ambient

Resistance, Junction-to-Board

Peak Package Reflow Temperature During Reflow

(2), (3)

Notes

1. ESD1 testing is performed in accordance with the Human Body Model (HBM) (C

performed in accordance with the Machine Model (MM) (C

= 200 pF, R

ZAP

2. Pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may

cause malfunction or permanent damage to the device.

3. Freescale’s Package Reflow capability meets Pb-free requirements for JEDEC standard J-STD-020C. For Peak Package Reflow

Temperature and Moisture Sensitivity Levels (MSL),

Go to www.freescale.com, search by part number [e.g. remove prefixes/suffixes and enter the core ID to view all orderable parts. (i.e.

MC33xxxD enter 33xxx), and review parametrics.

V

SUP

V

SUPLD

V

CC

– -0.3 to V

V

DBUS

I

DBUS

I

LOGIC

V

ESD

-0.3 to 26.5

40

-0.3 to 7.0

+ 0.3 V

CC

-0.3 to V

+ 0.3 V

SUP

400 mA

20 mA

±2000

±200

±750 for corner pins

±500 for others

T

STG

T

A

T

J

T

SD

R

JA

Θ

R

JB

Θ

T

PPRT

= 100 pF, R

ZAP

= 0 Ω); and Charge Body Model (CBM).

ZAP

-55 to 150 °C

-40 to 85 °C

-40 to 150 °C

155 to 190 °C

109 °C/W

50 °C/W

Note 3 °C

= 1500 Ω); ESD2 testing is

ZAP

V

V

33780

Analog Integrated Circuit Device Data

4 Freescale Semiconductor

Page 5

STATIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

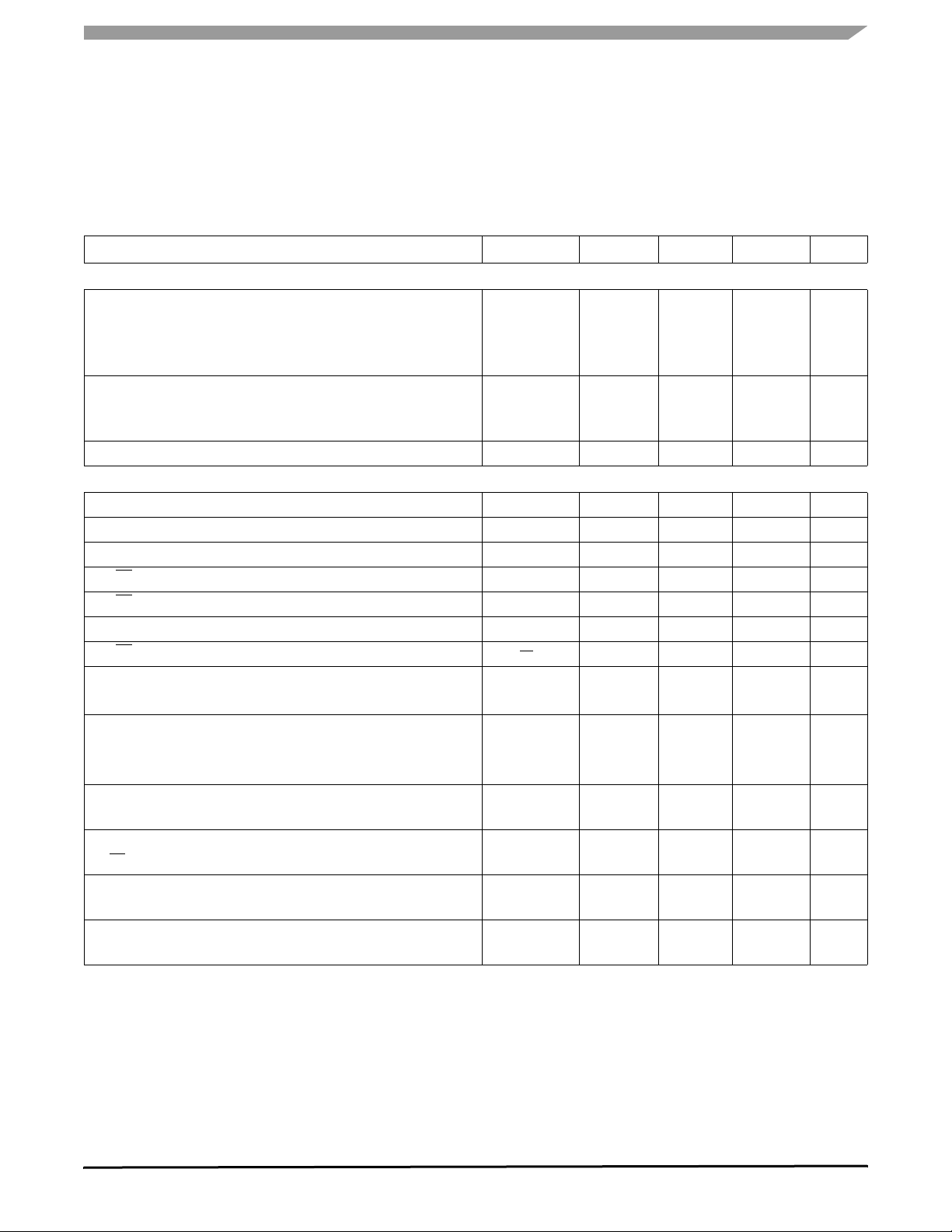

Table 3. Static Electrical Characteristics

Characteristics noted under conditions 4.75 V ≤ VCC ≤ 5.25 V, 9.0 V ≤ V

noted. Voltages relative to GND unless otherwise noted. Typical values noted reflect the approximate parameter means at

TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

≤ 25 V,- 40°C ≤ T

SUP

≤ 85°C unless otherwise

A

POWER INPUT REQUIREMENTS (V

I

Supply Current (| I

VSUP

| ≤ 10 µA) (Test Mode, CLK = 4.0 MHz)

BUS

SUP

, VCC)

Idle, HiZ

Signal High, Signal Low

I

Supply Current (Test Mode, CLK = 4.0 MHz)

VCC

Signal High, Signal Low

MICROCONTROLLER INTERFACE (RST, CS, MOSI, SCLK, AND CLK)

I / O Logic Levels (RST, CS, MOSI, SCLK, and CLK)

Input High

Input Low

Input Hysteresis

Input Capacitance

(4)

(4)

RST, CS, MOSI, SCLK, and CLK

Output Low Voltage

MISO and INT Pins = 0.3 mA

Output High Voltage

MISO Pin = - 0.3 mA

Output Leakage Current

MISO Pin = 0 V

MISO Pin = V

CC

INT Pullup Current

V

= V

CC

- 1.0 V

OUT

SCLK, CS Pullup Current

V

= V

CC

- 1.0 V

OUT

RST Pulldown Current

V

= 1.0 V

OUT

CLK, MOSI Pulldown Current

V

= 1.0 V

OUT

BUS TRANSMITTER (D0H, D0L, D1H, D1L)

Output Bus Idle Voltage (Differential)

InH = -200 mA, InL = 200 mA

(5)

Output Signal High Voltage (Differential)

-12.5 mA ≤ InH ≤ 1.0 mA, -1.0 mA ≤ InL ≤ 12.5 mA

(5)

Notes

4 Not measured in production.

5 InH = bus current at DnH, InL = bus current at DnL.

6V

DnD

= V

DnH

- V

DnL

.

I

VSUP

I

VCC

V

V

V

HYST

C

V

OL

V

OH

I

MISO

I

INTPU

I

PU

I

RSTPD

I

PD

V

DnD(

IDLE)

V

DnD (HIGH)

mA

–

–

6.5

15

10

23

mA

– 4.5 6.0

IH

IL

I

0.7

–

–

–

–

500

0.3

–

–

V

V

mV

CC

CC

pF

– 10 20

V

0 – 0.8

V

V

- 0.8 – V

CC

CC

µA

-10

-10

–

–

10

10

µA

-100 -75 -50

µA

-20 -10 -5.0

µA

4.0 7.0 10

µA

5.0 10 20

(6)

V

- 2.5 – –

SUP

(6)

V

V

4.175 4.5 4.825

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 5

Page 6

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

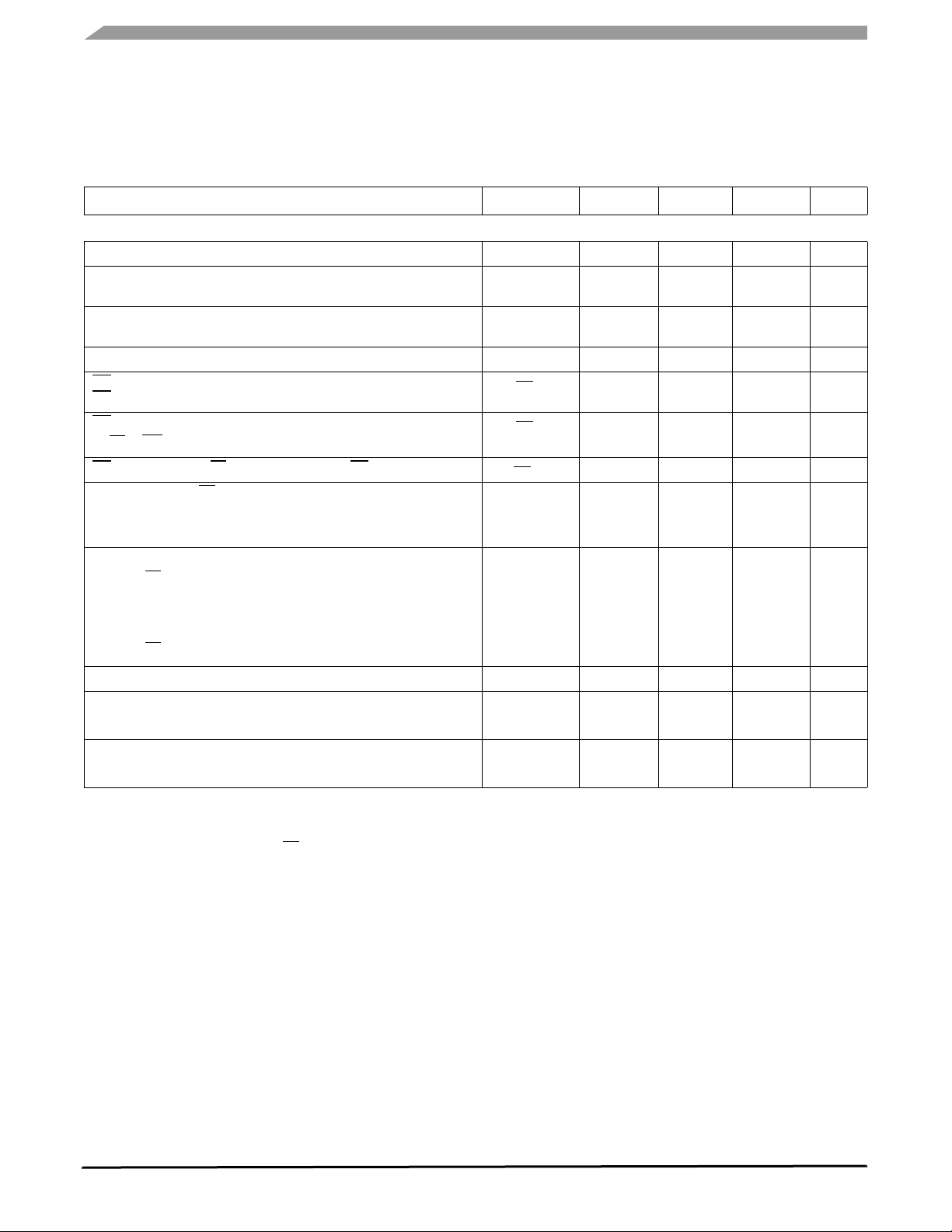

Table 3. Static Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V ≤ VCC ≤ 5.25 V, 9.0 V ≤ V

≤ 25 V,- 40°C ≤ T

SUP

≤ 85°C unless otherwise

A

noted. Voltages relative to GND unless otherwise noted. Typical values noted reflect the approximate parameter means at

TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

Output Signal Low Voltage (Differential)

-12.5 mA ≤ InH ≤ 1.0 mA, -1.0 mA ≤ InL ≤ 12.5 mA

(5)

Vmid, (DnH + DnL) / 2 (Voltage Halfway Between Bus High Side and

Bus Low Side)

VCM Peak-to-Peak, Vmid (Signal High) - Vmid (Signal Low)

(7)

Output High-Side (DnH) Idle Driver Current Limit (DnL open)

Source: DnH = 0 V

Sink: DnH = V

SUP

Output Low-Side (DnL) Idle Driver Current Limit (DnH open)

Source: DnL = 0 V

Sink: DnL = V

SUP

Output High-Side (DnH) Signal Driver Overcurrent Shutdown

Source: Signal High, Signal Low

Sink: Signal High, Signal Low

Output Low-Side (DnL) Signal Driver Overcurrent Shutdown

Source: Signal High, Signal Low

Sink: Signal High, Signal Low

Disabled High-Side (DnH) Bus Leakage (DnL open)

DnH = 0 V

DnH = V

SUP

Disabled Low-Side (DnL) Bus Leakage (DnH open)

DnL = 0 V

DnL = V

SUP

BUS RECEIVER (D0H, D0L, D1H, D1L)

Comparator Trip Point

Notes

7 Not measured in production.

V

DnD (LOW)

I

ICL (HIGH)

I

ICL (LOW)

I

SCL (HIGH)

I

SCL (LOW)

I

LK(HIGH)

I

LK(LOW)

COMP(TRIP) 5.0 6.0 7.0 mA

(6)

V

1.175 1.5 1.825

V

mid

V

CM

pp

V

/ 2 -

V

SUP

1.0

/ 2 V

SUP

SUP

2 + 1.0

/

– 0.3 – V

V

mA

-400

100

–

–

-200

–

mA

–

200

–

–

-100

400

mA

-100

30

–

–

-30

100

mA

-100

30

–

–

-30

100

mA

-1.0

-1.0

-0.18

0.25

1.0

1.0

mA

-1.0

-1.0

-0.4

0.08

1.0

1.0

33780

Analog Integrated Circuit Device Data

6 Freescale Semiconductor

Page 7

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics

Characteristics noted under conditions 4.75 V ≤ VCC ≤ 5.25 V, 9.0 V ≤ V

noted. Voltages relative to GND unless otherwise noted. Typical values noted reflect the approximate parameter means at

TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

CLOCK

CLK Periods

Time High

Time Low

Period (System requirement)

CLK Transition (System requirement)

(8)

(8)

Time for Low-to-High Transition of the CLK Input Signal

Time for High-to-Low Transition of the CLK Input Signal

Reset Low Time

SPI INTERFACE TIMING

SPI Clock Cycle Time

SPI Clock High Time

SPI Clock Low Time

SPI CS Lead Time

SPI CS Lag Time

SPI SCLK Time Between Bytes

SPI CS Time Between Bursts

(9)

(9)

(8)

(8)

Data Setup Time

MOSI Valid Before SCLK Rising Edge

(9)

Data Hold Time

MOSI Valid After SCLK Rising Edge

MISO Valid After SCLK Falling Edge

(9)

(8)

Data Valid Time

SCLK Falling Edge to MISO Valid, C = 100 pF

Output Disable Time

CS Rise to MISO Hi-Z

Rise Time (30% VCC to 70% VCC)

(8)

SCLK, MISO

Fall Time (70% VCC to 30% VCC)

(8)

SCLK, MISO

Notes

8 Not measured in production.

9 SPI signal timing from the production test equipment is programmed to ensure compliance.

tCLKHI

tCLKLO

tCLKPER

tCLKLH

tCLKHL

tRSTLO 100 – – ns

tCYC 200 – – ns

tLEAD 100 – – ns

tLAG 100 – – ns

tCSHI 80 – – ns

≤ 25 V, - 40°C ≤ TA ≤ 85°C unless otherwise

SUP

75

75

245

–

–

–

–

250

–

–

–

–

255

50

50

tHI 80 – – ns

tLO 80 – – ns

tHI 80 – – ns

tSU

25 – –

tH

tHO

t

V

25

–

0

–

–

–

– – 50

t

DIS

– – 100

t

R

– – 25

t

F

– – 25

ns

ns

ns

ns

ns

ns

ns

ns

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 7

Page 8

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V ≤ VCC ≤ 5.25 V, 9.0 V ≤ V

≤ 25 V, - 40°C ≤ TA ≤ 85°C unless otherwise

SUP

noted. Voltages relative to GND unless otherwise noted. Typical values noted reflect the approximate parameter means at

TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

BUS TRANSMITTER

(10), (13)

(14)

(14)

(10)

t

SLEW (IDLE)

t

SLEW (SIGNAL)

D

RATE

t

BIT

t

INTON

t

INTON

t

INTOFF

t

DBUSSTART1

t

DBUSSTART2

t

DVLD1

t

DVLD2

t

DVLD3

t

DVLD4

2.0 4.5 8.0 V/µs

3.0 4.5 8.0 V/µs

– – 150 kbps

6.67 – – µs

– – 1/3 * tBIT

+0.2

– – 0.2

– – 0.2 µs

1/3 * t

1/3 * t

0.25

0.25

BIT

BIT

–

–

–

–

6.0

0.8

0.8

0.8

2/3 * t

4/3 * t

6.56

1.3

1.3

1.3

BIT

BIT

Idle-to-Signal and Signal-to-Idle Slew Rate (12 ≤ V

SUP

≤ 25 V)

Signal High-to-Low and Signal Low-to-High Slew Rate

(See Data Valid DSIS to DnD Timing)

Communication Data Rate Capability

(13)

(Ensured by Transmitter Data

Valid and Receiver Delay Measurements)

Signal Bit Time (1 / D

INT Turn ON Delay, DBUS Transaction End to Receive FIFO

INT Low

INT Turn ON Delay (C = 100 pF)

INT Turn OFF Delay, CS/SCLK Rising Edge to INT High

(11), (15)

CS to INT Low

DBUS Start Delay, CS/SCLK Rising Edge to DBUS

RATE

(13)

)

(12)

(11), (13), (15)

Spread Spectrum Mode Disabled

Spread Spectrum Mode Enabled

Data Valid

(10), (12)

DSIF (CS) = 0.5 * VCC to DnD Fall = 5.5 V

DSIS (MOSI) = 0.5 * VCC to DnD Fall = 0.2 * ∆V

DSIS (MOSI) = 0.5 * VCC to DnD Rise = 0.8 * ∆V

DnD

DnD

DSIF (CS) = 0.5 * VCC to DnD Rise = 6.5 V

µs

µs

µs

µs

Signal Driver Overcurrent Shutdown Delay

Signal Low Time for Logic Zero

33.3% Duty Cycle

(16)

Signal Low Time for Logic One

66.7% Duty Cycle

(16)

t

OC

t0

L

O

t1

L

O

2.0 – 20 µs

2/3 * t

1/3 * t

-0.8 2/3 * t

BIT

-0.8 1/3 * t

BIT

-0.6 2/3 * t

BIT

-0.6 1/3 * t

BIT

BIT

BIT

µs

-0.4

µs

-0.4

Notes

10 C = 7.5 nF from DnH to DnL and 4.7 nF from DnH and DnL to GND, capacitor tolerance = ±10%.

11 In the case where the SPI write to DnL (initiating a DBUS transaction start or causing an interrupt) is the last byte in the burst sequence,

timing is from rising edge of

CS. Otherwise, timing is from the first SCLK rising edge of the next SPI burst byte.

12 Delays are measured in test mode to determine the delay for analog signal paths.

13 Not measured in production.

14 ∆V

DnD

= V

DnD(HIGH)

- V

DnD(LOW).

15 Internal digital delay only.

16 Guaranteed by design.

33780

Analog Integrated Circuit Device Data

8 Freescale Semiconductor

Page 9

DYNAMIC ELECTRICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Table 4. Dynamic Electrical Characteristics (continued)

Characteristics noted under conditions 4.75 V ≤ VCC ≤ 5.25 V, 9.0 V ≤ V

≤ 25 V, - 40°C ≤ TA ≤ 85°C unless otherwise

SUP

noted. Voltages relative to GND unless otherwise noted. Typical values noted reflect the approximate parameter means at

TA = 25°C under nominal conditions unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

BUS RECEIVER

Receiver Delay Time (I

I

= -6.0 mA to DSIR (INT) = 0.5 * V

RSP

I

= -6.0 mA to DSIR (INT) = 0.5 * V

RSP

Receiver Delay Time (I

2.0

mA step)

I

RSP

I

RSP

(17)

= COMP(TRIP) to DSIR (INT) = 0.5 * V

= COMP(TRIP) to DSIR (INT) = 0.5 * V

= 0 mA / 11 mA step)

RSP

= COMP(TRIP) - 2.0 mA/COMP(TRIP) +

RSP

SPREAD SPECTRUM

Central Frequency Range

Bit Period Deviation (+/-) (f

CEN

Min ≤ f

CEN

DEV[1:0] = 10

DEV[1:0] = 01 @ f

Frame Jitter (Max) (f

=138.5KHz (Typ)

CEN

Min ≤ f

CEN

CEN

≤ f

CEN

DEV On

DEV Off

Notes

17 Delays are measured in test mode to determine the delay for analog signal path.

(17)

CC

CC

CC

CC

≤ f

Max)

CEN

Max) (PLL On)

t

DRH

t

DRL

t

DRH

t

DRL

f

CEN

t

DEV10

t

DEV01

J

FRDEVON

J

FRDEVOFF

250

250

500

500

–

–

–

–

750

750

1500

1500

132 – 148 kHz

400

800

–

–

–

–

–

–

600

1100

±1.0

±1.0

ns

ns

ns

µs

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 9

Page 10

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

TIMING DIAGRAMS

DSIS

DSIF

DnD

DSIR

5.0 V

0 V

5.0 V

0 V

V

SUP

6.5 V

5.5 V

4.5 V

3.9 V

2.1 V

1.5 V

I

OUT

6.0 mA

0 mA

5.0 V

0 V

t

CYC

t

DVLD1

t

CYC

t

CYC

t

CYC

Logic 1 Logic 0

t

t

SLEW(FRAME)

t

DVLD3

t

DVLD2

t1

LO

t

DRH

t

DRL

t

SLEW(SIGNAL)

t0

LO

DVLD4

Figure 4. DBUS Timing Characteristics

33780

Analog Integrated Circuit Device Data

10 Freescale Semiconductor

Page 11

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

DnH

V

V

V

V

DnL

DnH

+ 2.25 V

mid

+ 0.75 V

mid

- 0.75 V

mid

- 2.25 V

mid

V

V

SUP

V

SUP

mid

0 V

Figure 5. DBUS Normal Bus Waveforms

Overvoltage

Threshold

V

mid

V

mid

V

(Clamped)

mid

V

mid

V

mid

DnL

+ 2.25 V

+ 0.75 V

- 0.75 V

- 2.25 V

0 V

Figure 6. DBUS Overvoltage Bus Waveforms

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 11

Page 12

ELECTRICAL CHARACTERISTICS

TIMING DIAGRAMS

CS

SCLK

MOSI

MISO

X = Don’t care

V

V

V

IL

t

LEAD

V

IH

V

IL

t

V

IH

V

IL

t

OH

OL

A

X

V

V

= 70% VCC, VOH = 70% V

IH

= 30% VCC, VOL = 30% V

IL

SU

MSB

t

H

MSB

CC

CC

V

IH

V

t

CYC

t

HI

t

LO

t

V

t

F

V

IH

t

HO

t

R

V

IH

LSB

V

IL

LSB

LSB

t

LAG

t

DIS

IL

V

IH

V

OH

V

OL

Figure 7. SPI Interface Timing

DBUS

(DnH-DnL)

INT

CS

SCLK

MOSI

t

INTON

Figure 8. INT and Bus Start Timing

t

DBUSSTART

t

INTOFF

33780

Analog Integrated Circuit Device Data

12 Freescale Semiconductor

Page 13

FUNCTIONAL DESCRIPTIONS

INTRODUCTION

FUNCTIONAL DESCRIPTIONS

INTRODUCTION

The 33780 is intended to be used as a master device in a

distributed system. It contains both protocol generators and

physical interfaces to allow an MCU to communicate with

devices on the bus using only a simple SPI in te rfa c e . Tw o

differential busses are provided.

Using a loop-back wire allows operation of the bus in the

presence of an open circuit. This is immediate and no

interruption is caused by the open circuit. The differential

outputs have reduced electromagnetic radiation and

susceptibility.

The equivalent bus capacitance consists of capacitors

connected between the two bus wires and capacitors

between the bus wires and ground. Because the voltage

change on either of the bus wires to ground is only 1/2 the

amount of change between the two bus wires, the

capacitance to ground only conducts half as much current as

it would if connected directly across the bus. The equivalent

bus capacitance of a capacitor to ground from the bus wires

is one half of the actual amount of the capacitor. The amount

of capacitance from either bus wire to ground should be kept

the same in order to achieve the lowest radiated EMI energy.

The 4.7

nF capacitors required between the bus wires and

ground result in an equivalent of 2.35

across the bus as seen by either bus wire.

Table 5 shows the voltages used for operation. Low side

(LS) is the bus wire that is the most negative and high side

(HS) is the bus wire that is the most positive.

the bus waveforms in normal operation.

Table 5. High-Side and Low-Side Typical Voltages (Voltage Relative to Ground)

Low Side High Side

IDLE HIGH LOW IDLE HIGH LOW

0 Vmid - 2.25

Notes

18 Vmid = V

SUP

/ 2.

(18)

Vmid - 0.75

(18)

V

SUP

Vmid + 2.25

(18)

FUNCTIONAL PIN DESCRIPTIONS

nF of capacitance

Figure 5 shows

Vmid + 0.75

(18)

RESET (RST)

When pulled low, this will reset all internal registers to a

known state as indicated in the section entitled

Descriptions.

Register and Bit

CHIP SELECT (CS)

This input is used to select the SPI port when pulled to

ground. When high, the SPI signals are ignored. The SPI

transaction is signaled as completed when this signal returns

high.

INTERRUPT (INT)

This output will be asserted ow when an enabled interrupt

condition occurs. It contains an internal current pull-up

source so that it will remain high when not active. The output

is open-drain so that it can be ORed together with other opendrain outputs so that this IC or any of the others can assert an

interrupt.

MASTER OUT/SLAVE IN (MOSI)

This is the SPI data input to the device. This data is

sampled on the positive (rising) edge of SCLK.

SERIAL CLOCK (SCLK)

This is the clock signal from the SPI master device. It

controls the clocking of data to the device and data read from

the device.

MASTER IN/SLAVE OUT (MISO)

This is the SPI data from the device to the SPI master (the

MCU). Data changes on the negative (falling) transition of the

SCLK.

CLOCK (CLK)

This is the main clock source for the internal logic. It must

be 4.0 MHz.

GROUND (GND)

Ground source for both logic and DBUS return.

POWER SOURCE (VCC)

Logic power source. Nominal value is +5.0 V. This should

be bypassed with a small capacitor to ground (0.01-0.1

µF)

LOW-SIDE BUS (DnL)

There are two independent LOW-SIDE outputs, D0L and

D1L They comprise the low-side differential output signal of

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 13

Page 14

FUNCTIONAL DESCRIPTIONS

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

the DBUS physical layer as shown in Figure 5. They also

provide power to the slave modules during the DBUS idle

time. The output of DnL should have a bypass capacitor of

4.7 nF to ground.

HIGH-SIDE BUS (DnH)

There are two independent HIGH-SIDE outputs, D0H and

D1H They comprise the high-side differential output signal of

the DBUS physical layer. They also provide power to the

slave modules during the DBUS idle time. See

Figure 5. The

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

SPI and

Registers

Interrupt

Generator

output of DnL should have a bypass capacitor of 4.7 nF to

ground.

POSITIVE SUPPLY FOR BUS OUTPUT (VSUP)

This 9.0 V to 25 V power supply is used to provide power

to the slave devices attached to the DBUS. During the bus

idle time, the storage capacitors in the slave modules are

charged up to maintain a regulated supply to the slave

device.

DBUS

Driver/Receiver

Protocol

Engine

Figure 9. Block Illustration

The 33780 is controlled by an MCU through an SPI

interface. It handles the digital and physical layer portions of

a DBUS master node. Two separate DBUS channels are

included, each capable of interfacing to up to 15 DBUS slave

devices (nodes). The physical layer uses a two-wire bus with

analog wave-shaped voltage and current signals. Refer to

Figure 1.

Major subsystems include the following:

•SPI interface to an MCU

•A register pointer block

•Two channels of DBUS protocol state logic

•CRC block for each channel

•Control and status registers

•4-level FIFOs on each transmit and receive buffer

SPI AND REGISTERS

This block contains the SPI interface logic and the control

and response registers that are written to and read from the

SPI interface.

The IC is an SPI slave-type device, so MOSI (Master-OutSlave-In) is an input and MISO (Master-In-Slave-Out) is an

output.

CS and SCLK are also inputs.

The SPI port will handle byte and multi-byte transfers. It

addresses 22 registers. The 33780 combines the functions of

both the 68HC55 (DSID) and the 33790 (DSIP). The 33780

uses the eight control registers defined in the DSID, and the

remaining registers are needed for the additional modes of

operation in the 33780. The organization of the registers is

described in the section entitled

Descriptions.

Register and Bit

INTERRUPT GENERATOR

This circuit accepts unmasked interrupt inputs for data

flow. It drives an open-drain output that allows the output to

be OR connected with other open-drain outputs so that this

IC or any of the others can assert an interrupt. An unmasked

interrupt will cause the

can be generated by two circumstances: (1)

register becoming empty, or (2)

not empty. Both of these events occur at the end of a DBUS

transaction. Either of these two events will generate an

interrupt when enabled by setting bits in the DnCTRL

registers.

Similarly, the interrupt signal can be cleared in two ways:

the Transmit FIFO becomes not empty, or (2) the Receive

(1)

FIFO becomes empty. Both of these events are checked at

the end of an SPI word (either with CS rising or with the rising

edge of SCLK of a new data byte in an SPI burst).

INT to pull down the output. Interrupts

a Transmit FIFO

the Receive FIFO becoming

33780

Analog Integrated Circuit Device Data

14 Freescale Semiconductor

Page 15

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

FUNCTIONAL DESCRIPTIONS

PROTOCOL ENGINE

This block converts the data to be transmitted from the

registers into the DBUS sequences, and converts DBUS

response sequences to data in the registers. It generates the

proper DBUS timing.

DSIR

DSIS

DSIF

Differential

Signal

Generation

Control

Comp.

Signal

Signal

The DBUS transmit protocol uses a return to 1 type data

with a duty cycle determined by the logic state. The protocol

requires Cyclical Redundancy Check (CRC) generation and

validation.

Idle

DnH

Common

Mode

Correction

DnL

Idle

Overvoltage

T

LIM

Figure 10. Driver/Receiver Block Diagram

DBUS DRIVER / RECEIVER (PHYSICAL LAYER)

This block translates the transmit data to the voltage and

current needed to drive the DBUS. It also detects the

response current from the slave devices and translates that

current into digital levels. These circuits can drive their

T

LIM

Table 5.

Table 6.

DSIR DnD

outputs to the levels listed in

The internal signal DSIF controls the Idle to Signalling

state change, and internal signal DSIS controls the signal

level, high or low. DSIR is the slave device response signal to

the logic. This is shown in

Table 6. Internal Signal Truth Table

DSIF DSIS

0 0 0 Return Data Signal Low

0 1 0 Return Data Signal High

1 0 0 0 High Impedance

1 1 0 0 Idle

X X 1 0 High Impedance

The DBUS driver block diagram is shown in Figure 10. The

circuit uses independent drivers for the Idle and Signal states.

This allows each driver to be optimized for its function. The

Idle driver is active in Idle and during the transitions from Idle

to Signal high and Signal high to Idle. The Signal driver is only

active during actual signaling. Both drivers are disabled in

HiZ.

The Idle driver is required to supply a high current to

recharge the Slave device storage capacitors. It is also

required to drive the DBUS load capacitances and control the

slew rate over a wide supply voltage range. The DnH and

DnL Idle drivers are each optimized for their specific drive

requirements.

The Signal driver is optimized for driving the DBUS load,

and has the requirement of good slew rate control and

stability over a wide range of load conditions. The DnH and

DnL outputs use identical Signal driver circuits.

To ensure stability of the Signal driver, capacitors must be

connected between each output and ground. These are the

DBUS common mode capacitors. In addition, a bypass

capacitor is required at V

. These capacitors must be

SUP

located close to the IC pins and provide a low impedance

path to ground.

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 15

Page 16

FUNCTIONAL DESCRIPTIONS

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

The DSIF signal controls the state of the drivers, enabling

the Idle drivers or Signal drivers as is appropriate. A

comparator in the Control block compares the DnL output

voltage with the internal Signal high voltage to determine the

transition from Idle driver to Signal driver. The overvoltage

signal modifies the driver characteristics. This is described in

more detail in the

Load Dump Operation section.

The overtemperature signal is also applied to this block.

The Differential Signal Generation block converts the

DSIS signal to the DBUS differential signal voltage levels.

This differential signal is buffered and slew rate controlled by

the Signal drivers. This block is active in all driver modes.

A special requirement of the differential bus is to maintain

a low common mode voltage. This is especially important

during the Idle to Signal transition in order to produce a

smooth changeover to the Signal driver. This is accomplished

by monitoring the common mode voltage and modifying the

Idle driver slew rates. This is the function of the Common

Mode Correction block. An additional feature to make a

smooth changeover and minimize undershoot is to reduce

the slew rate as the changeover point is approached. This

block is not illustrated in

Figure 10.

A sense resistor between the Signal driver and the DnH

output detects the Slave device response current. A

comparator (Comp.) generates the signal DSIR that is

supplied to the logic.

The comparator consists of a sense amplifier with offset

(VOS), a filter capacitor and logic gate with buffers to produce

the logic signal (DSIR). The sense amplifier is a ‘gm’ stage

that amplifies the voltage across the sense resistor (R

S

) to

produce an output current that charges and discharges a filter

capacitor. The voltage across the filter capacitor is compared

with the threshold voltage of the logic gate to produce the

output signal. The voltage across the filter capacitor is

I

BUS

Figure 11.

clamped between VCC and ground. See

R

S

DnH

V

OS

gm

I

O

V

TH

C

DSIR

Figure 11. Receive Filter

Definitions

•C = value of filter capacitor = 2.0 pF

•VTH = threshold of logic gate = VCC/2 = 2.5 V

•A = current gain from sense resistor to filter capacitor =

IO / I

= 3.0 µA/mA (the amplifier saturates with an

BUS

output current of ± 40 µA)

•I

[mA] = bus response current.

BUS

•ITH[mA] = response current threshold = VOS/RS = 6

The filter delay time is given by:

t [µs] = (C * VTH) / A (I

- ITH) = 1.7 / (I

BUS

BUS

- ITH)

The filter characteristic can also be expressed as the

product of the overdrive current (I

- ITH) and the duration of

BUS

the interference pulse, which must be less than 1.7 µs * mA

for the interference to be filtered.

33780

Analog Integrated Circuit Device Data

16 Freescale Semiconductor

Page 17

SPREAD SPECTRUM

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

FUNCTIONAL DESCRIPTIONS

OFFSET[8:0]

PLLOFF

PLL Logic

SSUD

Center

Frequency

DAC

SSEN

DEV[1:0]

Modulation

DAC

Spreader Logic

PRBS[1:0]

Figure 12. Spread Spectrum Block Diagram

The dominant source of radiated electromagnetic

interference (EMI) from the DBUS bus is due to the regular

periodic frequency of the data bits. At a steady bit rate, the

time period for each bit is the same, which results in a steady

fundamental frequency plus harmonics. This results in

undesired signals appearing at multiples of the frequency

that can be strong enough to interfere with a desired signal.

A significant decrease of radiated EMI can be achieved by

randomly changing the duration of each bit. This can

significantly reduce the amplitude by having the signal spend

a much smaller percentage of time at any specific frequency.

The signal strength of the fundamental and harmonics are

reduced directly by the percentage of time it spends on a

specific frequency. For instance, if the bit rate is 136

there will be a harmonic at 680

kHz. If it is changed in

frequency so that only 1/10 of the bits are at the 136

rate, the signal energy at 680

kHz will be reduced by 90%.

kbps,

kbps

A circuit to do this is included in this IC and can perform the

spreading of the signal independently for each channel. This

is done in the Spread Spectrum (SS) Block Diagram shown

Figure 12.

in

Spreading can be enabled by setting the SSENn bits in the

DnSSCTRL registers. There are 64 possible bit durations that

are equally spaced between the shortest and longest bit

times. Because they are evenly spaced by a time difference

and not by a frequency difference (the reciprocal of time), all

frequency domain parameters of the SS block are expressed

in units of time.

CLK (4.0 MHz typ)

VCO

CLK_VCOn (408 kHz typ)

VCO

The output of the voltage-controlled oscillator (VCO) is

used as the bit rate clock. Three cycles of this clock are used

to create each bit of data on the DBUS.

There are two voltages that control the period (1/

frequency) of the signal coming from the VCO. The voltage

coming from the Center Frequency DAC (Digital-to-Analog

Converter) in

Figure 12 is used to keep the average period

constant. The voltage coming from the Spreader DAC

changes the period in random steps to spread the signal. The

Phase Locked Loop (PLL)-derived changes are much slower

to update the period than the ones derived from the Spreader

Logic. This prevents the two “loops” from interacting with

each other.

PLL

The PLL loop compensates for temperature drift and the

variations in processing of the IC that would otherwise

change the average data rate (center frequency). It does this

by comparing a time reference derived from the clock signal

MHz) to the period of the VCO output. If the ratio is not

(4.0

correct, it will change the frequency of the VCO by changing

the digital value it sends to the Center Frequency DAC.

The PLL has fast and slow update rates for making these

changes. It enters a fast update mode automatically anytime

the OFFSET register is written to using the SPI, or following

a reset. This fast acquisition mode consists of 64 VCO update

cycles (1.4

is done to quickly adjust the center frequency after changes

have been made. After the fast acquisition, the PLL switches

ms per update cycle) that last about 90 ms. This

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 17

Page 18

FUNCTIONAL DESCRIPTIONS

FUNCTIONAL INTERNAL BLOCK DESCRIPTION

automatically to a slow acquisition mode (180.224 ms per

update cycle, based on 4.0 MHz clock).

SPREADER LOGIC

The Spreader Logic contains a pseudo-random binary

sequence (PRBS) generator and time compensation

circuitry. The PRBS can generate maximal length sequences

of 6, 7, 11, and 15 bits. Maximal length means there is no

repeat of the sequence until 2

where n is the selected length.

n

counts have been reached,

A special feature of the Spreader Logic is that the bit

periods are chosen in a way to keep the length of the frame

constant, provided that the total number of bits is even. This

is useful if the time between samples made by the slaves

must be kept relatively constant. Without this feature, the time

from sample-to-sample would vary randomly.

The DEV1 and DEV0 bits in the DnSSCTRL register

control whether the deviation is enabled or disabled.

The Spreader Logic is synchronized to only change the

value of the digital word to the Spreader DAC at the

beginning of a DBUS bit. When spreading is enabled, these

changes will occur once per DBUS bit-time.

33780

Analog Integrated Circuit Device Data

18 Freescale Semiconductor

Page 19

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

SPI COMMUNICATIONS

All SPI transactions start with a command byte and can be

followed by 1 or more bytes of data. The start of an SPI

transaction is signaled by

sent (bit 7) of the first byte signals a read or write (write = 1)

of data. The last five bits (bits 4

CS being asserted low. The first bit

– 0) of the comman d set a

pointer to the desired register. Bits 5 and 6 are unused. See

Figure 13. As long as CS is asserted low, each additional byte

sent over the SPI will be a read / write of data to the sequential

next register. After address 10101 is written to, the next write

will wrap around to address 00000.

Bit 7 6 5 4 3 2 1 0

R/W X X ADDR4 ADDR3 ADDR2 ADDR1 ADDR0

Figure 13. SPI Communications, First Byte of Burst Transfer

The receive FIFO is popped only when the SPI reads or

writes the low data register (DnL). The Control and Status

registers can be read without affecting the receive FIFO. The

transmit FIFO is popped at the end of the DBUS transaction.

Figure 14 shows an example of a write operation. This

example assumes the last SPI transaction read or wrote the

data from register 00011 and is now pointing at 00100

(D01STAT). During the first byte of the SPI transaction, the

first MOSI bit is 1 (write) and the last five are 00000. During

this command byte, MISO returns the data from register

updates the data in register 00000 with new data while

reading back the old data via MISO.

Although it looks like the read and write for an address are

occurring at the same time, the changes caused earlier

during the same burst would not be reflected by the data

returned, because the D01STAT is latched at

When a short word is selected for Bus 0 (MS0 in D0CTRL

is set), the D0H register is skipped in the sequence. The

same is true for the D1H register when MS1 is set and

SWLEN1 = 1000.

00100 (D01STAT). During the next SPI transactions, MOSI

CLK

SCLK

MOS I

MI SO

CSB

CS

WRITE COMMAND

WRITE COMMAND

POINT TO 00000

POINT TO 00000

DATA FROM

DATA FROM

D01STAT (00100)

DSI01 STAT( 00 100)

DATA TO DS I0 H

DATA TO D0H

(00000)

(00000)

DATA FROM

DATA FROM D0H

(00000)

DSI0H ( 00 000)

DATA TO DSI0L

DATA TO D0L

(00001)

(00001)

DATA FROM D0L

DATA FROM

(00001)

DSI0L (00001)

DATA TO DSI1H

DATA TO D1H

DATA FROM

DATA FROM D1H

DS I1 H (0 0010 )

(00010)

(0 00 10 )

(00010)

DATA TO DSI1 L

DATA TO D1L

(00011)

(000 11)

DATA FROM

DATA FROM D1L

(00011)

D S I 1L (0001 1)

CS going low.

Figure 14. SPI Burst Transfer Example

DBUS COMMUNICATIONS

The DBUS messages contain data from the DnH and DnL

registers. A CRC pattern is automatically appended to each

Bit n . . . . . . . . . . . . . . . . Bit 0 CRC n . . . . . CRC 0

message. The data and CRC lengths are programmed by the

DnLENGTH register.

Figure 15 shows the structure of the

DBUS message.

Figure 15. DBUS Communications Message

DBUS Driver/Receiver communications involve a frame

(DSIF), a data signal (DSIS), and a data return (DSIR) signal.

These are signals internal to the IC associated with the

protocol engine.

A message starts with a falling edge on the DSIF signal,

which marks the start of a frame. There is a one bit-time delay

before the MSB of data appears on the DSIS pin. Data bits

start with a falling edge on DSIS. The low time is 1/3 of the bit

time for a 1, and 2/3 of a bit time for a 0. Data is transmitted

on DSIS and received on DSIR pins simultaneously. Receive

data is the captured level on the DSIR pin at the end of each

bit time. At the end of the bit time for the last CRC bit, the

DSIF pin returns to a logic high (Idle level). A minimum delay

is imposed between successive frames as determined by the

DnCTRL register.

Users initiate a message by writing (via the SPI interface

from the MCU) to the low byte of the data register (DnL).

When 9- to 16-bit messages are to be sent, the user writes to

the DnH register first and then the DnL register before the

combined 9 to 16-bit data value DnH:DnL is sent on the

DBUS. The user should first check the TFNFn status flag to

be sure the transmit FIFO is not full before writing a new data

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 19

Page 20

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

value to DnH and/or DnL. When the minimum inter-frame

delay has been satisfied, the DSIF pin will go low, indicating

the start of a new transfer frame.

DBUS Driver/Receiver communications involve a frame

(DSIF), a data signal (DSIS), and a data return (DSIR) signal.

These are signals internal to the IC asso ci at ed with the

prData is shifted out of DSIS (MSB first) and shifted into DSIR

at the same time. As a message is received, it is stored bitby-bit into the next available recei ve FIFO location . For each

data value in the receive FIFO, there is a one-bit status flag

to indicate whether or not there was a CRC error while

receiving the data. At the end of a DBUS transfer (and after

the CRC error status is stable), the RFNEn flag is set (if it was

not already) to indicate there is data in the receive FIFO to be

read.

DATA RATE

In non-spread spectrum mode, the data rate is determined

by the system clock (CLK) and the programmable clock

divider. (The Clock Divider ratio n is defined in

Data Rate = f

/ (27 * n)

CLK

In spread spectrum mode, the data rate is determined by

the system clock (CLK) and the DnOFFSETL/H register

programming. Note the programmable clock divider does not

control the data rate in Spread Spectrum mode. Refer to

Register and Bit Descriptions section for details.

The following table gives the correspondence between the

offset and the data rate for f

= 4.0 MHz.

CLK

Table 7. Data Rate versus OFFSET (Spread Spectrum)

OFFSET Data Rate

HEX DEC kHz

00 0 121.2

3F 63 136.1

7A 122 150.1

9F 159 158.9

For other clock frequencies, the data rate can be

computed using the following formula:

Data Rate = (f

/ 33) * (1 + OFFSET / 512)

CLK

Table 10.)

CRC GENERATION / CHECKING

Whenever a message is sent on the DBUS, a 0- to 8-bit

CRC value is computed and serially sent as the next n bits

after the LSB of the data. The CRC length, polynomial, and

initial seed are determined by the CRCLEN[3:0],

CRCPOLY[7:0], and CRCSEED[7:0] control register fields.

The message, including the CRC bits, is passed along to a

remote peripheral, which computes a separate CRC value as

the message data is received. If this computed CRC does not

agree with the CRC value received in the message, the

peripheral device considers the message invalid.

Messages received include a 0- to 8-bit CRC value, which

was computed in the peripheral device that is responding. As

the message is received, a separate 0- to 8-bit CRC value is

computed and is compared with the CRC value in the

received message. If these values do not agree, the message

is considered invalid and the ERn status bits in the D01STAT

register are set as the receive data is transferred into the

receive data buffer.

When no remote peripheral responds to a message, the

data pattern received will be all zeros with a CRC value of 0,

which may be detected as a CRC error depending on the

values of CRCLEN[3:0], CRCPOLY[7:0], and

CRCSEED[7:0]. On the other hand, if a remote peripheral is

attached and responds with all zeros with a CRC value of

1010, this may be detected as a non-error condition.

CRC COMPUTATION

The CRC algorithm uses a programmable initialization

value, or seed, of CRCSEED[7:0] and a programmable

polynomial of CRCPOLY[7:0].

description of the CRC algorithm for the DBUS standard 4-bit

CRC with its initial value of 1010. A seed value is chosen so

that a zero data value will generate a CRC value of 1010. A

block diagram of the default CRC calculation is shown in

Figure 17.

Figure 16 is a VHDL

--------------------------------------------------------------------------

-- Calculates the 4-bit CRC (x^4 + 1) serially for 8 to 16 bits of data.

33780

Analog Integrated Circuit Device Data

20 Freescale Semiconductor

Page 21

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

-------------------------------------------------------------------------constant CRCPoly: std_logic_vector: = “0001”; -- x^4 +1

constant InitCrc: std_logic_vector: = “1010”;

procedure SerialCalculateCRC4(CRC: input std_logic_vector;Data: in std_logic) is variable

Xor1: std_logic;

begin

Xor1: = CRC(3) xor Data;

CRC: = CRC(2 downto 0) & ‘0’; -- Shift left 1 bit

if Xor1 = ‘1’ then

CRC: = CRC xor CRCPoly

end if;

end SerialCalculateCRC4;

Figure 16. CRC Algorithm

C3

T

1X4 0X3 0X2 0X1 +X0 = X4+1++ ++

C2

C1

T

T

Figure 17. Default CRC Block Diagram

MESSAGE SIZE SPECIAL CASES

The response to any 8- to 15-bit message is expected to

be another 8- to 15-bit message and the response to any

16-bit message is expected to be another 16-bit message.

This gives rise to some special cases when there is a

transition from one message size to a different message size.

Some messages must be long words (16 bits of data), others

can be short words (8 to 15 bits of data).

The following are examples where the word is a standard

DSI formatted short word (8 bits of data and 4 bits of CRC).

Example 1: If the previous message was a short word and

the current message is a long word, the response message

(which is also a short word) finishes before the current

message frame and the CRC bits look like data bits in the

long word format. Since the CRC validation of this short word

message response is not reliable, this short word response

should not be used.

Example 2: If the previous message was a long word and

the current message is a short word, the response message

(which is also a long word) cannot finish before the current

message frame. Bits three to zero of the data and the CRC

bits are lost. Data bits seven to four of the 16-bit response

message look like the CRC bits of an 8-bit response and

almost certainly would not be correct. Because the response

C0

T

Input Data

is incomplete and the CRC check is probably not valid, this

response is not useful.

The long word to short word message size transition

normally only occurs after setting up the DBUS peripherals.

During address setup, a message with address 0000 is sent

to attempt to set the address of the next peripheral on the

daisy-chained bus. Before any peripherals have been

assigned an address, their bus switches are opened so the

addressing message only goes to the first peripheral in line.

As each peripheral gets an address, it closes its bus switch

so the next address assignment command can reach the next

peripheral in line on the bus. Each peripheral responds to an

address assignment only once (during the next message

after the command that set its address). After the last

peripheral has been assigned an address, any subsequent

address assignments will receive no response. When the

master MCU fails to receive a response, it knows it has

passed the last peripheral. At this point, short word messages

may be sent. The first such message will have no meaningful

response associated with it.

The first message after reset is also a special case

because there was no previous message, therefore there will

be no meaningful response during the first message transfer.

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 21

Page 22

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

CLK_VCO0

MISO

SCLK

CS

MOSI

CLK

INT

RST

Channel 0

Clock Select and Divider

SPI & Registers

Interrupt

status regs

control regs

enable regs

poly regs

seed regs

length regs

SS ct rl regs

SS o ffsetregs

SS Up/Dwn regs

register pointer

bit pointer

SPI XFER

BitClock 0

RX0 Data

RX0 Status

TX0 Data

TX0 Status

RX1 Data

RX1 Status

TX1Data

TX1 Status

RX FIFO

RX Buffer

RX Buffer

RX Buffer

RX Buffer

TX FIFO

TX Buffer

TX Buffer

TX Buffer

TX Buffer

RX FIFO

RX Buffer

RX Buffer

RX Buffer

RX Buffer

TX FIFO

TX Buffer

TX Buffer

TX Buffer

TX Buffer

k

c

e

h

C

C

R

C

CH0

e

t

a

r

e

n

e

G

C

R

C

CH0Enable

CH1Enable

k

c

e

h

C

C

R

C

CH1

e

t

a

r

e

n

e

G

C

R

C

r

e

y

a

L

l

a

c

i

s

y

h

P

0

H

C

S

U

B

D

o

T

r

e

y

a

L

l

a

c

i

s

y

h

P

1

H

C

S

U

B

D

o

T

CLK_VCO1

CLK

Channel 1

Clock Select and Divider

Bit Clock 1

Figure 18. Logic Block Diagram

LOGIC BLOCK DIAGRAM DESCRIPTION

Figure 18, Logic Block Diagram, shows a block diagram of

the major logic blocks in the IC.

REGISTERS

The register set consists of control, status, transmit, and

receive types. They are written and read using the SPI

interface and are affected by events in the IC. Detailed

SPI

The SPI is a standard serial peripheral interface. This

descriptions of their operation and use can be found

throughout later sections of this data sheet.

interface provides two-way communications between the IC

and an MCU. The MCU can write to registers that control the

operation of the IC and read back the conditions in the IC

using the SPI. It can also write data to be sent out on the

DBUS and read data that was returned on the DBUS. The

register pointer and bit pointer are used to control which

registers and bits are being written to and read from using the

SPI. Its operation is described in detail in the section entitled

SPI Communications on page 19.

33780

INTERRUPT

The Interrupt block controls the INT output pin. The main

purpose of the Interrupt is to quickly inform the MCU when

data has been received via the DBUS or when the DBUS

transmit buffer is empty. The

level on the pin low. The internal pull-up current or an external

resistor to V

is used to pull this pin high. This is done so

CC

that other ICs can be connected to the interrupt pin on the

INT output can only drive the

Analog Integrated Circuit Device Data

22 Freescale Semiconductor

Page 23

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

MCU. If the DBUS IC or any of the other ICs want to assert

an interrupt to the MCU, they can do so by pulling the pin low.

This is similar to a logical OR of the outputs because this IC

or any of the others can assert the interrupt to the MCU. The

operation of the Interrupt is described in detail in the section

Interrupt Generator on page 14.

titled

RST

Asserting this pin low will cause the part to reset, forcing

registers to a known state. The description for these registers

shows the bit values that will occur due to a reset. All bus

activity will be halted and not allowed to restart, and no SPI

activity will be recognized until the

level.

RST goes to a logic high

CLOCK SELECT AND DIVIDER

There is an independent Clock Select and Divider for each

channel. These circuits are controlled by register writes to the

SPI and can select whether the Spread Spectrum Clock

(CLK_VCOn) is used for the bit clock or the unspread clock is

used. They also contain dividers that can be selected to

reduce the bit rate by integer ratios in the unspread mode

only.

RXFIFO

The RXFIFO is an automatic register set that allows up to

responses to be stored without being transferred to the

four

MCU via the SPI. This is done so that data will not be lost

even if the MCU takes time to read the response data. When

the MCU reads a response from one of the DBUS registers,

the earliest response to be received is the one read. In other

words, the first in response will be the first out (FIFO). When

the RXFIFO becomes not empty and interrupts are enabled,

the MCU receives an interrupt via

INT.

TXFIFO

The TXFIFO is an automatic register set that allows up to

four transmit data packets to be stored for future

transmission on the DBUS. This is done to prevent the

overwrite of transmit data if the transmission of the previous

data has not been completed. The oldest data in the registers

is the first to be sent when the DBUS is ready to send. In other

words, the first data put into the regist ers to be sent will be the

first out when the DBUS is available (FIFO). When the

TXFIFO becomes empty and interrupts are enabled, the

MCU receives an interrupt via

INT.

CH0/CH1 ENABLE

The output of these signals control whether the DBUS can

drive power and signalling onto the bus. These are directly

controlled by bits written to the control registers.

CH0/CH1 OUTPUTS

These signals control the physical layer drivers and

receive data from the physical layer receivers. The physical

layer will convert the 0 V to 5.0 V low power logic signals to

the higher voltage (up to 26.5 V) and drive (150 mA nominal)

levels necessary for the DBUS to be used. It also converts

the low current (0

response signal from the slave to logic voltage levels to allow

the response from the slaves to be received. These internal

signals are named DSIF, DSIS, and DSIR.

mA to 11 mA typical) loading of the

CRC GENERATORS

Each channel contains a CRC generator that adds a series

of bits to each of the transmitted data words sent out on the

DBUS. The CRC bits are created from the data pattern and

are used by the slave devices to determine if one or more of

the data bits sent was in error. The detailed operation and

control of this function is covered in the section entitled

Generation / Checking on page 20.

CRC

CRC CHECK

This circuit checks the CRC bits that have been added to

the end of the response by the slave device. For a given

pattern of received data a new CRC is generated and

compared to the CRC bits received. If they do not match, a

bit is set in the status register indicating a CRC error for the

response. This bit is read back using the SPI during the same

SPI transaction that reads the response in order to keep them

associated with each other. The CRC bits are removed by the

IC and not seen by the MCU when reading the data registers.

Operation of the CRC Check is covered in the section entitled

CRC Generation / Checking on page 20.

SPI AND PROTOCOL ENGINE STATE MACHINES

Although the SPI clock and the DBUS input clock both

typically come from the same MCU system clock in an MCU

plus 33780 system, there is no guaranteed relationship

between these clocks, so the system was designed as if

these clocks were asynchronous. The FIFO architecture

eliminated most of the cases where these clocks need to

interact, and the remaining cases were designed with extra

care to prevent asynchronous problems.

Figure 19 explains the notation used in the subsequent

state diagrams. Entry to the IDLE state is asynchronous and

all other state transitions are synchronous. The note in the

upper right corner of the figure identifies which edge of which

clock or signal is used to synchronize state transitions. Each

arrow or arc has a condition that must be true before the

transition can take place. This condition can be the value of a

single signal or a more complex logic function. A slash (/)

indicates the end of the condition or equation, which must be

true for a transition to occur. The statement or statements

after the slash are executed during the transition to the next

state. These state diagrams are not a complete description of

the entire MC33780, they are intended to include just enough

relevant data to understand the operation of the state

machines and basic functions.

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 23

Page 24

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

ASYNCHRONOUS RESET/

ACTION(S);

IDLE

STATE_1

Figure 19. State Diagram Notation

Figure 20, describes how SPI transfers lead to transmit

FIFO push operations or transfer abort actions. State

transitions in this state machine are synchronous with rising

edges of the SPI clock (SCLK). The initial state, SPI_IDLE, is

entered asynchronously whenever internal reset becomes

active or the SPI chip select (

entry to the idle state, the SPI_WRITE signal is deactivated

and the SPI bit counter is set to 7 (it will count down as bits

are received).

When the CS goes low (active), the first SPI transfer will be

a command byte and the first bit indicates a write or read

command. The SPI_WRITE signal takes on the value of this

first bit, and the state machine enters the SPI_CMD_XFER

state, where the remaining bits of the command byte are

received. The last five bits of the command set the initial

value of the register pointer. After the command byte is

complete, the state machine advances to the SPI_BURST

CS) input is de-asserted. Upon

STATE TRANSITIONS OCCUR

ON POS EDGE OF XXX CLK

SYNCHRONOUS CONDITIONS/

ACTION(S);

state, which remains active until

CS goes high (or the

MC33780 is reset).

In the SPI_BURST state, new SPI characters are readfrom, or written-to-and-read-from, MC33780 registers. If the

control register (or CRC polynomial, CRC seed, CRC length,

or spread spectrum control) is written, an ABORT request is

generated that will immediately stop any DBUS transfer that

was in progress (refer to the DBUS transfer state diagram). If

the DATA register low byte is written, a transmit FIFO push

operation is generated (see transmit FIFO state diagram). If

the DATA register low byte is accessed (read or written) and

there is at least one entry in the receive FIFO, a receive FIFO

pop operation is generated.

When a DBUS transfer results in both an R_FIFO_PUSH

and an X_FIFO_POP, the R_FIFO_PUSH is performed first

to avoid the possibility of the transmit FIFO from getting

ahead of the receive FIFO.

RSTB ACTIVE or CSB INACTIVE/

SPI_WRITE = 0;

SPI_BIT_PTR = 7;

SPI_IDLE

SPI_CMD_XFER

LAST_SPI_BIT/

SPI_BIT_PTR = 7;

REG_PTR = REG_PTR +1 (rolls over to 0 after 21);

if SPI_WRITE & REG_PTR = CTRL or POLY or SEED or LENGTH or SSCTRL then ABORT;

if SPI_WRITE & REG_PTR = DATA_L then X_FIFO_PUSH;

if R_FIFO_NOT_EMPTY & REG_PTR = DATA_L then R_FIFO_POP;

SPI_BURST

Figure 20. State Diagram of SPI Transfer

Figure 21 describes what happens during DBUS serial

transfers. State transfers in this state machine are

synchronous with positive edges on the scaled DBUS 1/3rd

bit clock and the initial state is WAIT_FRAME_DLY. Initial

STATE TRANSITIONS OCCUR

ON POS EDGE OF SCLK

CSB ACTIVE/

SPI_WRITE= MOSI;

~LAST_SPI_BIT/

SPI_BIT_PTR = SPI_BIT_PTR-1;

LAST_SPI_BIT/

SPI_BIT_PTR = 7;

INIT_REG_PTR FROM CMD BITS[4:0]

~LAST_SPI_BIT/

SPI_BIT_PTR = SPI_BIT_PTR-1;

entry into this state is caused by a reset, abort, or by enable

becoming inactive. These conditions cause an asynchronous

entry into this state. The exit to the next state,

WAIT_SIG_DLY_0, needs to be synchronous.

33780

Analog Integrated Circuit Device Data

24 Freescale Semiconductor

Page 25

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

When enable is true and there is at least one valid entry in

the transmit FIFO, the DBUS frame signal is driven low to

start a frame. States WAIT_SIG_DLY_0 through

WAIT_SIG_DLY_2 create a one DBUS bit-time delay before

the start of the first data bit. After WAIT_SIG_DLY_2, the

DBUS_BIT_PTR gets initialized to the total word length, as

determined by the MSx, SWLENx, and CRCLENx bits. The

XFER_DBUS_BIT_0 state is then entered.

XFER_DBUS_BIT_0 through XFER_DBUS_BIT_2 form a

loop where each pass corresponds to one DBUS bit time.

During the first third of the bit the DSIxS signal is low, during

the second third DSIxS is low for a zero or high for a one,

during the last third of the bit time DSIxS is high. Provided this

is not the end of the last CRC bit, the bit pointer is

decremented and the loop is repeated.

After the last CRC bit, the DBUS_R_PUSH state is

entered. This state ensures that the CRC flag is stable prior

to adjusting the receive (and transmit) FIFO pointers. The

DBUS_X_POP state prevents an X_FIFO_POP from

occurring at the same time as an R_FIFO_PUSH.

After DBUS_X_POP, the state transitions back to the

WAIT_FRAME_DLY state. This state ensures proper frame

spacing is allowed to charge up the storage capacitors in

remote nodes. Notice that the delay counter was reset at the

end of the last CRC bit so the delay period can start to time

out even while the DBUS_R_PUSH and DBUS_X_POP

states are being processed.

Figure 22 describes the operation of the transmit FIFO.

This FIFO is four levels deep, including the stage which is

written into by the SPI and the stage which provides the data

for the current DBUS serial transfer. State transitions in this

state machine occur at the trailing edges of X_FIFO_PUSH

and X_FIFO_POP.

When this FIFO is completely empty, the SPI can write

four new values to fill the FIFO without waiting for any action

on the DBUS side of the FIFO. Values are pushed into the

FIFO from the SPI interface and values are popped after they

have been serially sent out of the DBUS interface. When the

FIFO is full, additional attempts to write new data from the

SPI side are ignored (the host MCU should be sure the

TFNFx status bit is set before writing more data to the FIFO).

Reset, abort, or enable going to zero causes

asynchronous entry to the TX_IDLE state, which

corresponds to the FIFO empty condition. The push and pop

pointers are cleared and X_FIFO_EMPTY is set to true.

X_FIFO_PUSH causes the push pointer to be incremental,

X_FIFO_EMPTY to be set to false, and the state to transition

to TX_NOT_EMPTY. The push request comes from the SPI

transfer state machine after a new value has been written into

the FIFO.

RSTB ACTIVE or ABORT or ~EN/

RESET_DELAY_CNTR;

DSIF = 1, DSIS = 1;

WAIT_FRAME_DLY

DELAY_OVER &

X_FIFO_NOT_EMPTY/

DSIF = 0;

WAIT_SIG_DLY_0

DBUS_BIT_PTR = 8 to 15, OR 23;

DSIS = 0;

XFER_DBUS_BIT_0 XFER_DBUS_BIT_1 XFER_DEBUS_BIT_2

X_FIFO_POP = 0;

DBUS_X_POP

STATE TRANSISITONS OCCUR

ON POS EDGE OF SCALED

DBUS 1/3

WAIT_SIG_DLY[0..2] CAUSES 1 BIT-TIME DLY TO 1

WAIT_SIG_DLY_1 WAIT_SIG_DLY_2

DSIS = DATA; DSIS = 1;

R_FIFO_PUSH = 0;

DBUS_R_PUSH

Figure 21. State Diagram of DBUS Transfer

RD

BIT CLOCK

ST

~LAST_CRC_BIT/

LAST_CRC-BIT/

BIT FALLING EDGE

DBUS_BIT_PTR = DBUS_BIT_PTR-1;

DSIS = 0;

DSIF = 1, DSIS = 1;

RESET DELAY_CNR;

R_FIFO_PUSH = 1

X_FIFO_POP = 1;

33780

Analog Integrated Circuit Device Data

Freescale Semiconductor 25

Page 26

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

~EN or ABORT or RSTB ACTIVE/

X_PUSH_PTR = 0;

X_POP_PTR = 0;

X_FIFO_EMPTY = TRUE;

X_FIFO_POP & X_POP_PTR = X_PUSH_PTR-1/

X_POP_PTR = X_POP_PTR+1;

X_FIFO_EMPTY = TRUE;

STATE TRANSISTIONS OCCUR

ON NEG EDGES OF X_FIFO_PUSH

AND X_FIFO_POP

TX_IDLE

X_FIFO_PUSH/

X_PUSH_PTR = X_PUSH_PTR+1;

X_FIFO_EMPTY = FALSE;

X_FIFO_POP & X_POP_PTR != X_PUSH_PTR-1/

X_POP_PTR = X_POP_PTR+1;

X_FIFO_POP/

X_FIFO_POP = X_FIFO_POP+1;

TX_NOT_EMPTY

Figure 22. State Diagram of Transmit FIFO

From TX_NOT_EMPTY, several things can happen.

Additional values can be pushed into the FIFO if the push

pointer is the same as the pop pointer minus one. This push

fills the FIFO so the state advances to TX_FULL. Each time

a new data value is pushed into the FIFO, the push pointer is

incriminated. From TX_NOT_EMPTY, values may also be

popped from the FIFO, freeing a stage for additional data. If

the pop pointer is the same as the push pointer minus one,

the pop removes the last value in the FIFO, so

X_FIFO_EMPTY is set to true and the state changes back to

TX_IDLE. Each time a value is popped, the pop pointer is

incremental.

When the transmit FIFO is full, no additional data can be

written into the FIFO, so no new push requests will be

generated. From TX_FULL, the only valid change is caused

by a pop, which causes the pop pointer to increment and the

state goes back to TX_NOT_EMPTY. (Of course reset, abort,

or disable could cause the state to asynchronously change to

the TX_IDLE state.)

Figure 23 describes the operation of the receive FIFO.

State transitions in this state machine occur at the trailing

edges of R_FIFO_PUSH and R_FIFO_POP. The receive

FIFO is four levels deep, including the stage which receives

X_FIFO_PUSH & X_PUSHPTR != X_POP_PTR-1

X_PUSH_PTR = X_PUSH_PTR+1;

X_FIFO_PUSH & X_PUSH_PTR = X_POP_PTR-1/

X_PUSH_PTR = X_PUSH_PTR+1;

TX_FULL

serial data from the current DBUS transfer and the stage

that is accessible for SPI reads. In order to assure coherence

of data and status, each FIFO stage includes an extra bit for

the CRC error status for each received data word. Also for

coherency, the DBUS transfer state machine imposes a

delay at the end of a DBUS transfer to assure that the CRC

status is stable before issuing the R_FIFO_PUSH request.

The RX_IDLE state is asynchronously entered at system

reset, when the enable bit goes low, or when there is an

abort.

During normal operation of the receive FIFO, values are

pushed into the FIFO from the DBUS serial interface, causing

the push pointer to increment. After the SPI has read a data

word, the receive FIFO is popped, which makes the location

available for additional data from the DBUS interface (it is the

user's responsibility to read status and data within the same

burst to assure coherence). The RX_NOT_EMPTY state is

active as long as there is some data in the FIFO.

The RX_FULL state is entered when enough data has

been pushed into the FIFO from the DBUS interface to cause

the push pointer to catch up to the pop pointer. Since it is not

possible to introduce another DBUS serial character without

reading (pop) the receive FIFO, it is not possible to overflow

the receive FIFO.

33780

Analog Integrated Circuit Device Data

26 Freescale Semiconductor

Page 27

FUNCTIONAL DEVICE OPERATION

LOGIC COMMANDS AND REGISTERS

~EN or ABORT or RSTB ACTIVE/

R_PUSH_PTR = 0;

R_POP_PTR = 0;

R_FIFO_EMPTY = TRUE;

R_FIFO_POP & R_POP_PTR = R_PUSH_PTR-1/

R_POP_PTR = R_POP_PTR+1;

R_FIFO_EMPTY = TRUE;

R_FIFO_POP & R_POP_PTR != R_PUSH_PTR-1/

R_POP_PTR = R_POP_PTR+1;

R_FIFO_POP/

R_FIFO_POP = R_FIFO_POP+1;

OVERFLOW = FALSE;

RX_IDLE

RX_NOT_EMPTY

RX_FULL

Figure 23. State Diagram of Receive FIFO

REGISTER AND BIT DESCRIPTIONS

The 33780 has 22 registers, shown in Table 8. The lower

8 (00000 through 00111) are compatible with the 8 registers

STATE TRANSISTIONS OCCUR

ON NEGATIVE EDGES OF R_FIFO_PUSH

AND R_FIFO_POP