1:8 Scale 4WD Electric Belt Driving

Buggy Manual

福瑞达模型有限公司

DONGGUAN FREERCHOBBY CO.,LTD

TEL/FAX :+86-769-82927540

www.freerchobby.com

Contents

Preface……………………………………………………….....3

Safety Guidelines……………………………………………...3

Li-Po Battery Charging………………………………………..4

Operation Steps………………………………………………..5

Recommended Maintenance Tools……………………….....7

F8E-BX Exploded View…………………………………….....31

Spare Parts List……………………………………………......32

F8E-BX Installing view……………………………………….7-30

Receiver Connection……………………………………….....4

3

Thanks for purchasing F8E-BX (1:8 scale 4WD Belt Driving

Buggy) from FREE RC HOBBY . This model was designed

by experienced design team from FRC hobby, and we tested

repeatedly and improved. Believe that FRC products will

bring more fun for you. Enjoy it!

Attention:

● Please read CD before operating to avoid any injuries for person or

property.

Preface

● Please pay more attention to the warnings and cautions in the manual.

Improper operation may cause personal and /or property damage. FRC

hobby has no control over damage resulting from shipping, improper

construction or improper usage.

● To prevent any serious injury and / or damage to property, please be

responsible when operating all remote controlled models.

Safety Guidelines

● This product is not suitable for children under 14 years of age

without the direct supervision of a responsible and knowledgeable

adult。

● Carefully read all of the warnings and cautions for any parts

used in the construction and use of your model.

● Keep small parts out of reach of small children. Children must

not be allowed to put any parts in their mouth.

● After using your model, please do NOT touch the equipment on

the model such as motor and ESC, because they generate high

temperatures. You may seriously burn yourself.

● This model car is not intended for use on public places and can

conflict with or disrupt pedestrian or vehicular traffic.

4

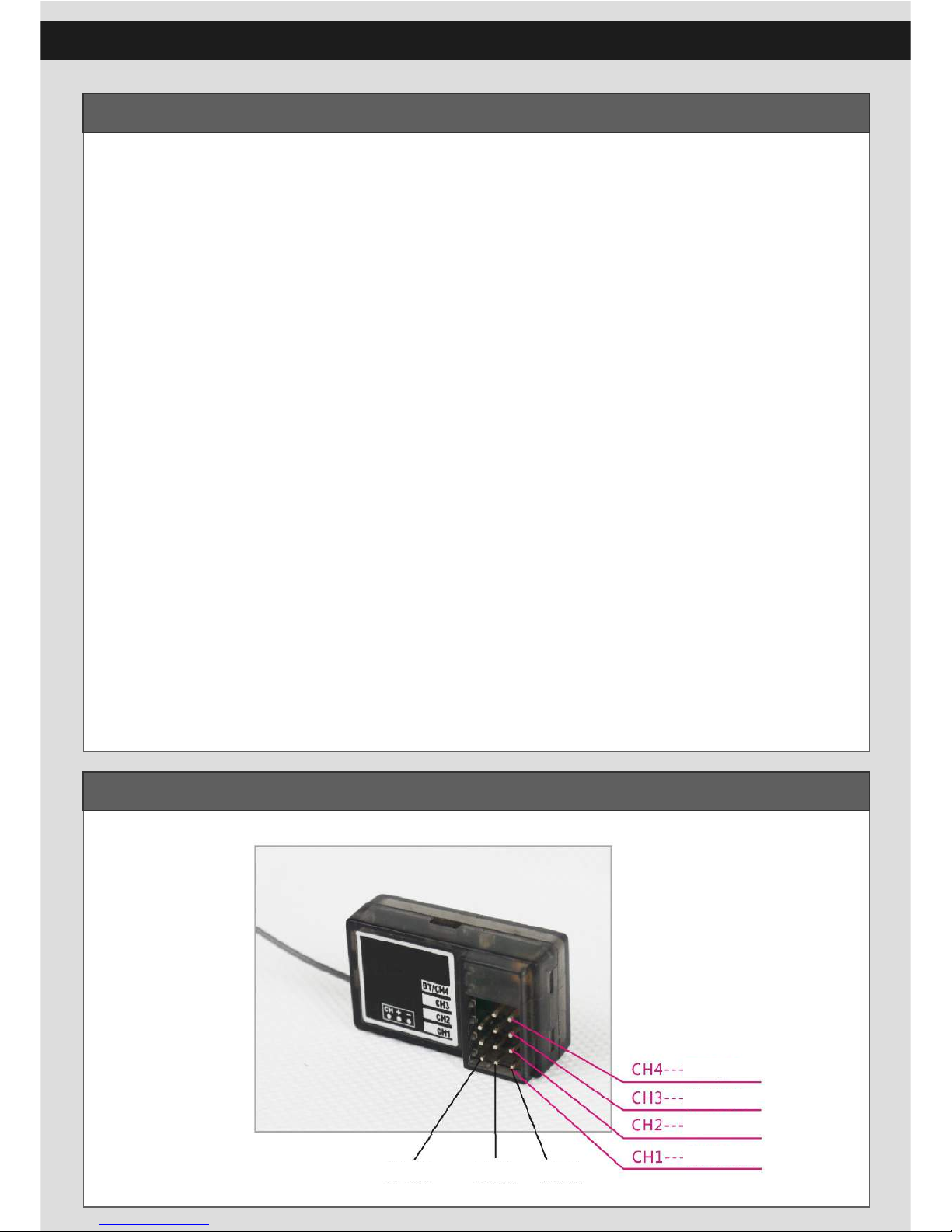

Re-Linking the Transmitter and Receiver

Power Input

Channel 3

ESC

Steering Servo

Signal Wire

Power +

Power -

Li-Po Battery Charging

Charging Procedure

● Connecting the power supply, the light of the charger will indicate

red and green alternately.

● Connecting battery and charger,the light of the charger will indicate red.

● When the three lights indicate green,charging finished.

● Take off all of the connector.

Caution

● Please take out the battery from the car and take off the T-plugs before

charging.

● Please put the battery and charger at cooling place and far away from

the heat source and tinder when charging.

● Please use balance charger for charging.

● Please take care and not take the charger and battery out of your reach ,

please take off the power and move to the safe place if you find

something anomalous when they are charging.

5

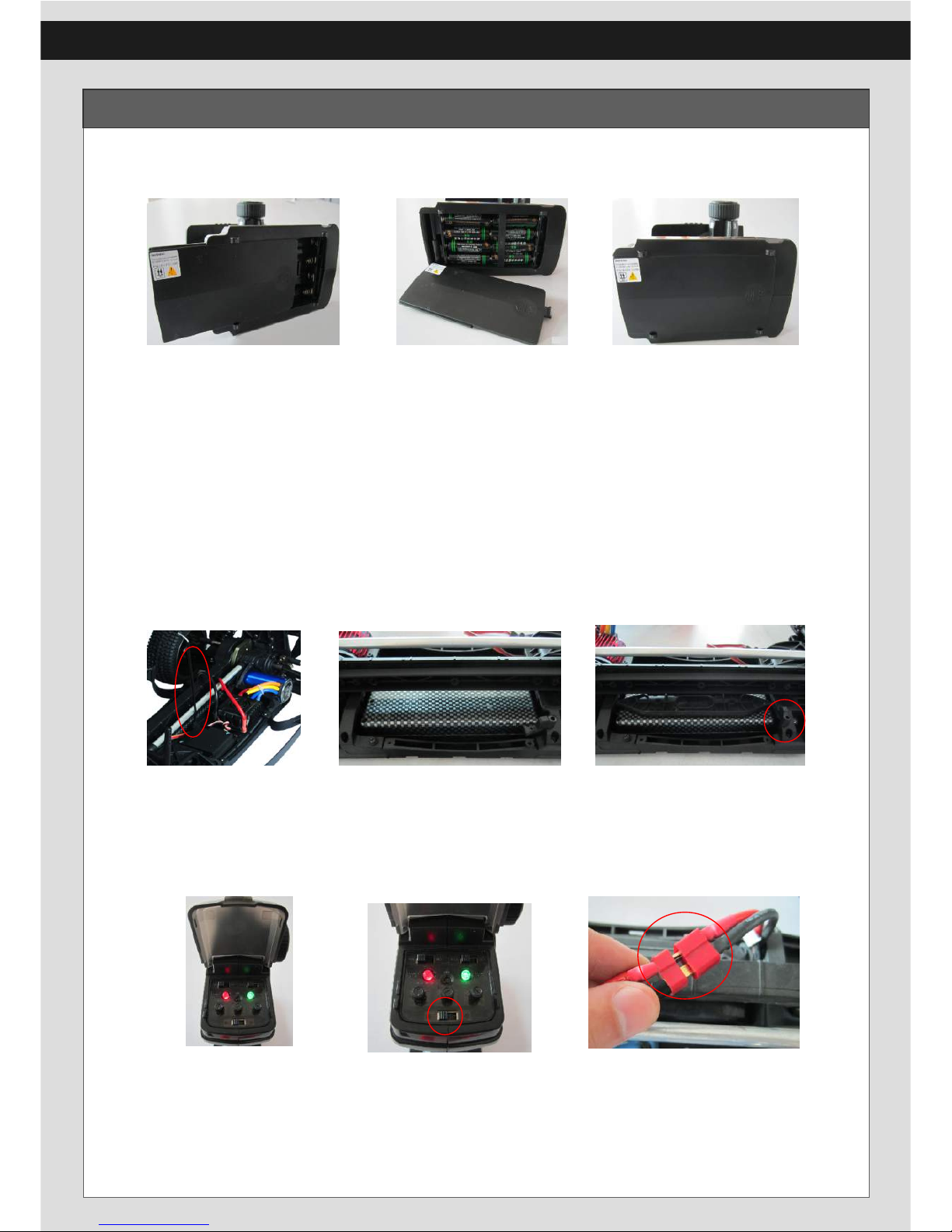

Driving Procedure

I、Driving Procedure

1. Open the cover of transmitter.

2. Insert the battery (pay attention to negative and positive).

3. Close the cover of transmitter.

Attention: It is suggested to use AA1.5V Alkaline battery in order

to achieve a better performance for transmitter. Please

don’t mix the new and old battery. Please take off the

battery from the transmitter if not to use.

4. Install antenna tube correctly.

5. Put the battery into the slot.

6. Close the battery tray.

7. Turn the throttle button and steering trim button to the middle position, and then

±120°.

8. Please turn on the transmitter first and then turn on switch of ESC. After

connecting, there is sound from motor, it means motor is standby.

6

II、Finishing Driving

1. Turn off the ESC switch, and then disconnect the power.

2. Turn off the transmitter.

3. Take off the battery.

Driving Procedure

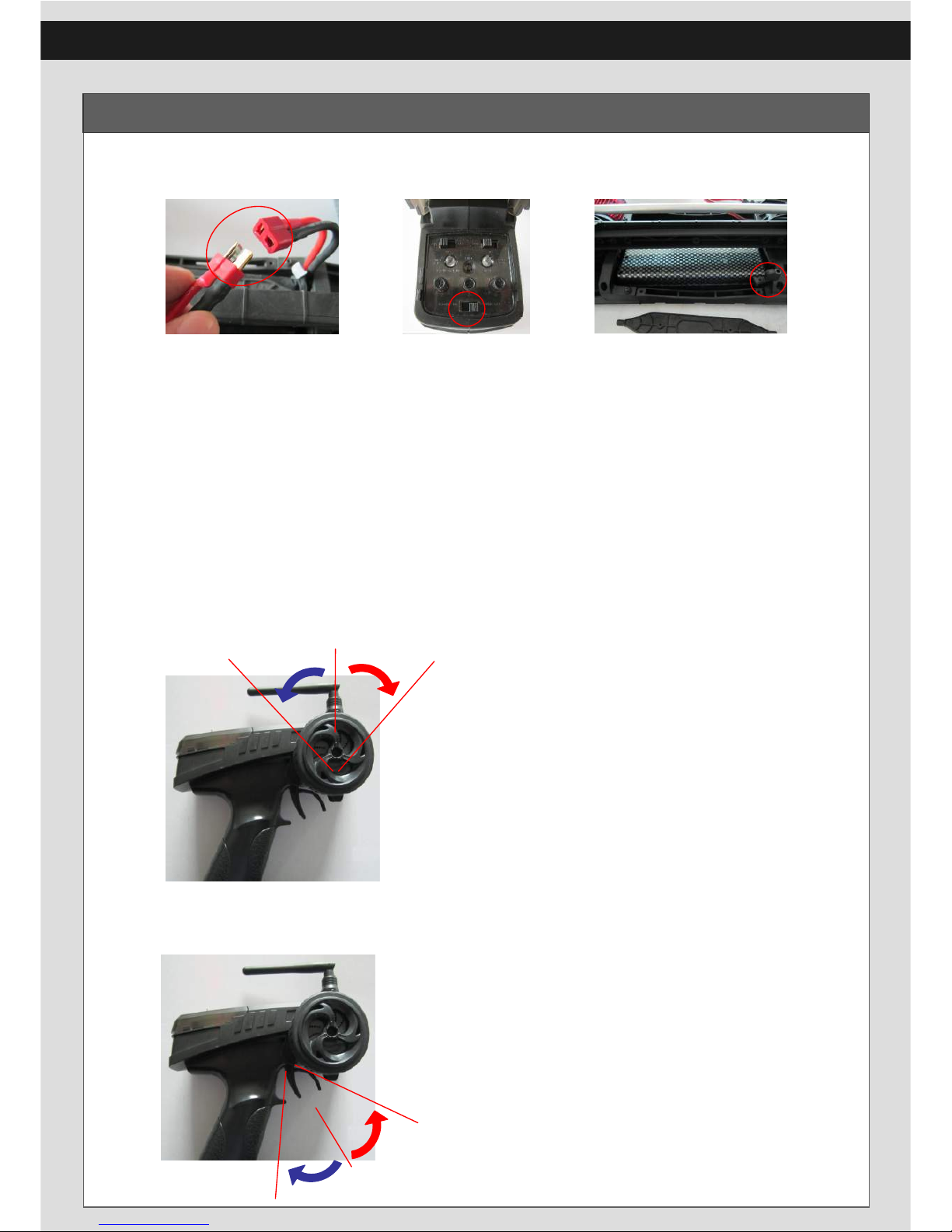

III、Transmitter adjustment

Turn on the transmitter first, connect the output plug of

battery and input plug of ESC, then turn on the ESC switch

(please pay more attention to positive and negative). You

will hear tone or the light will flash.

IV、Steering Control Method

V、Throttle Control Method

1. Rotate the steering wheel to the

left and right, the vehicle will also

have the corresponding steering.

The direction for the steering

wheel and car is the same.

2. Please adjust the neutral button

when the vehicle is not driven straightly.

1. Push down the throttle, the vehicle will

move forward.

2. When push up the throttle, the vehicle will

brake. The vehicle will move backward

when doing action of brake-neutral-brake.

3. When pushing the throttle, the vehicle has

no action (with Di-Di-Di sound), but the

steering function is normal, you should

adjust the throttle neutral button.

Brake

Backward

Forward

7

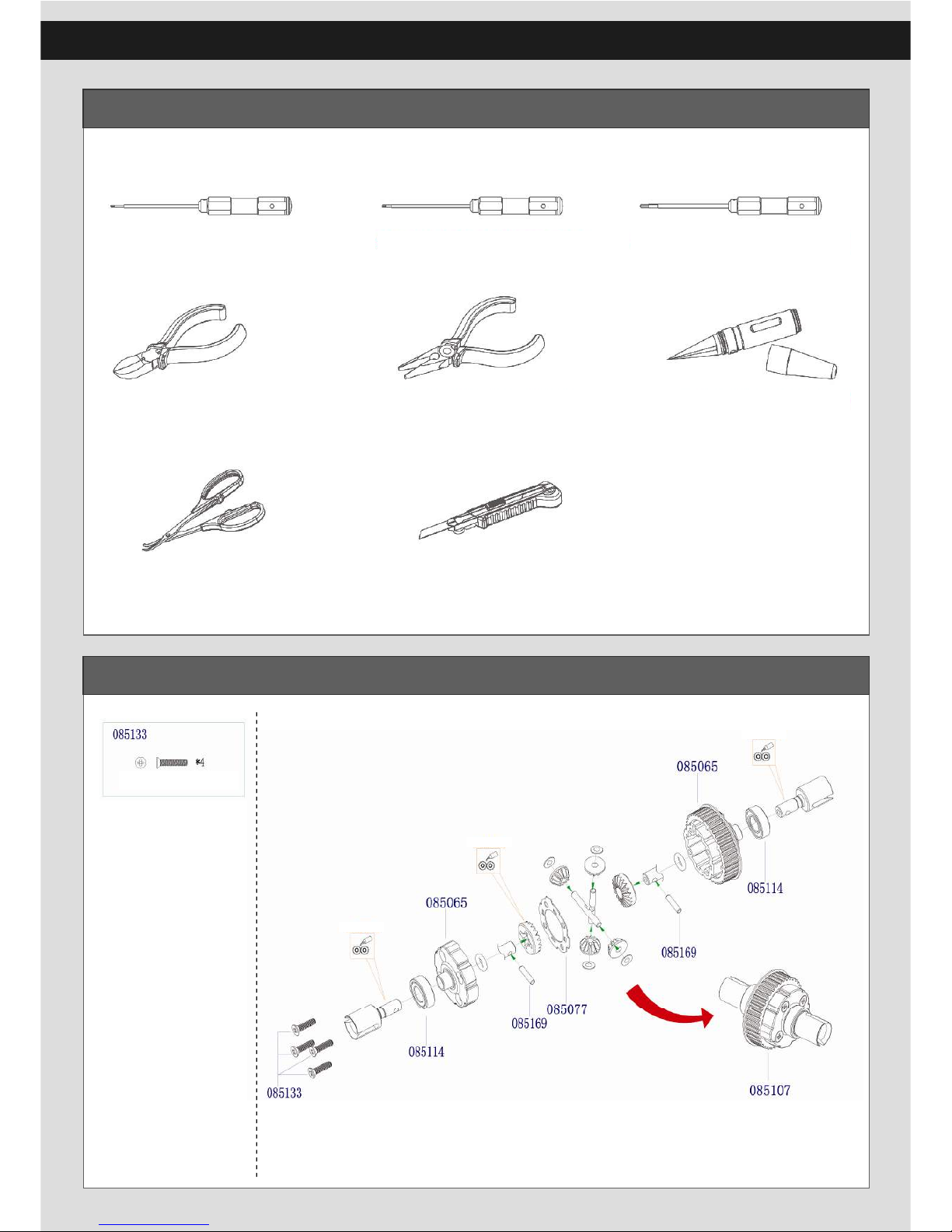

Recommended Maintenance Tools

Differential Build X 2

M3 X 16 Countersunk Phillips

Self-tapping Screws

Add grease

Add grease

Add grease

1.5mm Hex Screwdriver 2.0mm Hex Screwdriver 2.5mm Hex Screwdriver

Diagonal Cutting Plier Needle-nose Plier Reamer

Bend Scissors Knife

8

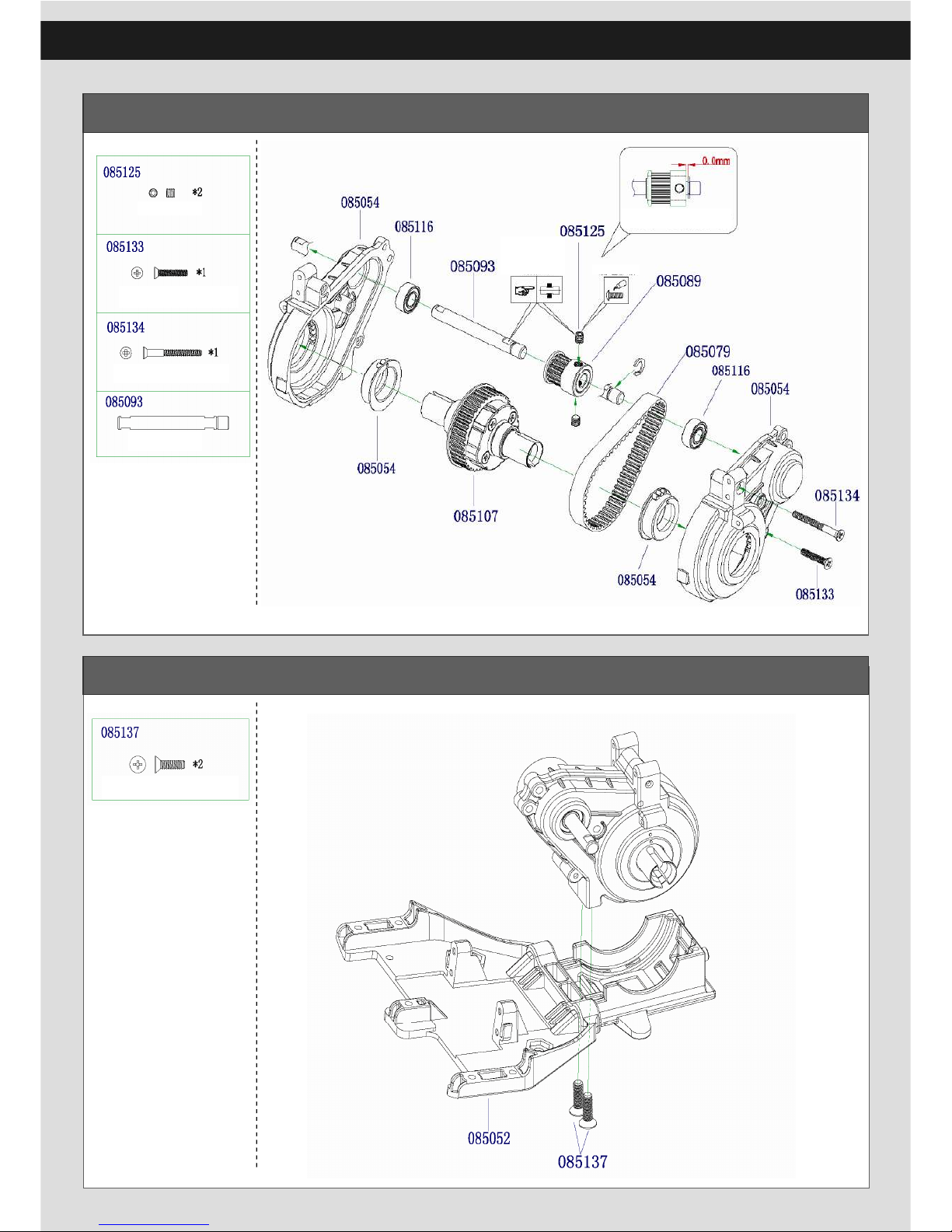

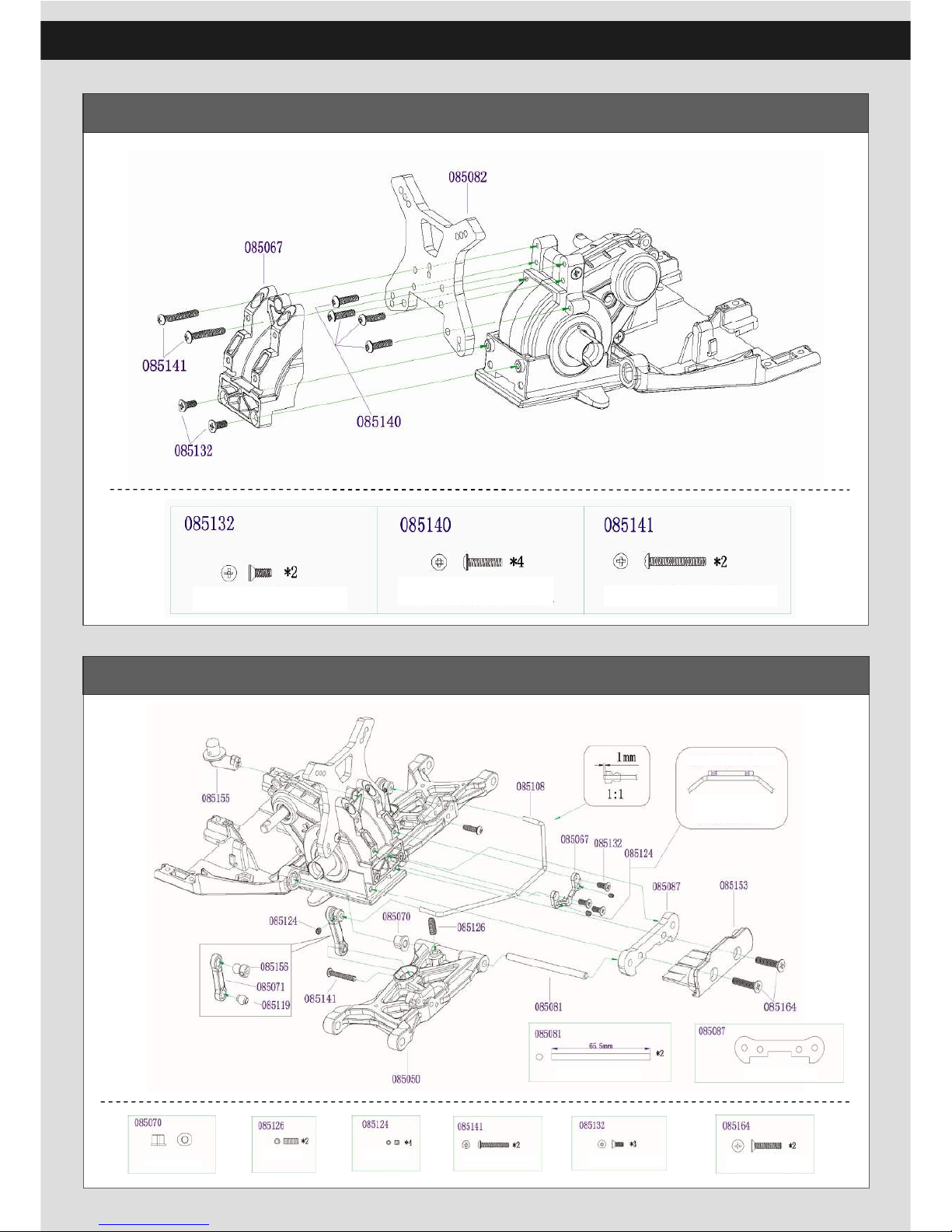

Front Gear Box Build

Front Gear Box Assembly

M3 X 16 Countersunk Phillips

Self-tapping Screws

M3 X 28 Countersunk Phillips

Self-tapping Screws

Front Shaft

Set Screw Should

be tighten on the flat

place

Add thread lock

15T Belt gear installing

M4 X 14 Countersunk Phillips

Self-tapping Screws

M4 X 4 Set Screw

Front Shock Tower Assembly

Front lower Arm/Front Sway Bar Assembly

9

M3 X 8 Countersunk Phillips

Self-tapping Screws

M3 X 12 Button Phillips Selftapping Screws

M3 X 20 Button Phillips Selftapping Screws

Set screw and

Sway-bar installing

The set screw is only

used for sway-bar

adjustment, not againest

to sway-bar movement.

Fronr lower arm plate

Arm pin bushing

M3 X 8 Countersunk Phillips

Self-tapping Screws

M3 X 20 Button Phillips

Self-tapping Screws

Lower Arm Pin A

M4 X 20 Countersunk Phillips

Self-tapping Screws

M3 X 3 Set screw

M4 X 10 Set screw

10

Steering Knuckle Assembly

Front Upper Link Assembly

Front lower arm

bushing

C-Mounting

Bushing

M4 X 18 Button Phillips

Machine Screws

CVD Drive shaft

Out Drive

M3 X 16 Button Phillips

Machine Screws

11

Servo Assembly

Steering Set Assembly

M3 X 10 Button Phillips

Machine Screws

M3 X 3 Set Screws

M3 X 12 Button Phillips

Machine Screws

M3 X 16 Button Phillips

Machine Screws

M4 X 10 Countersunk Phillips

Machine Screws

Add grease

Add grease

The Servo Installing:

1.linking the servo and tansmi tter,find the neutral.

2.put the servo arm into the servo gear,the servo arm

should be vertical to the ser vo.

3.tighten the screws

M3 X 6 Button Phillips

Machine Screws

Add grease

Add grease

Add grease

Add grease

Add grease

Add thread lock

Add grease

Add grease

12

Front Upper Plate Assembly

Front Belt Gear Assembly

M3 X 28 Button Phillips

Machine Screws

M4 X 10 Button Phillips

Machine Screws

Servo Wires

Add thread lock

Add thread lock

M4 X 4 Set Screw

M3 X 20 Button Phillips

Self-tapping Screw

Servo Wires

Set screw should be

tighten on the flat place.

Add grease

13

Front Shock Build

Front Shock Assembly

Front Shock Spring

Front Shock Shaft

No Bubble

more than

M3 Step Lock Nut

M3 X 20 Button Phillips Selftapping Screws

M3 X 26 Button Phillips

Machine Screws

14

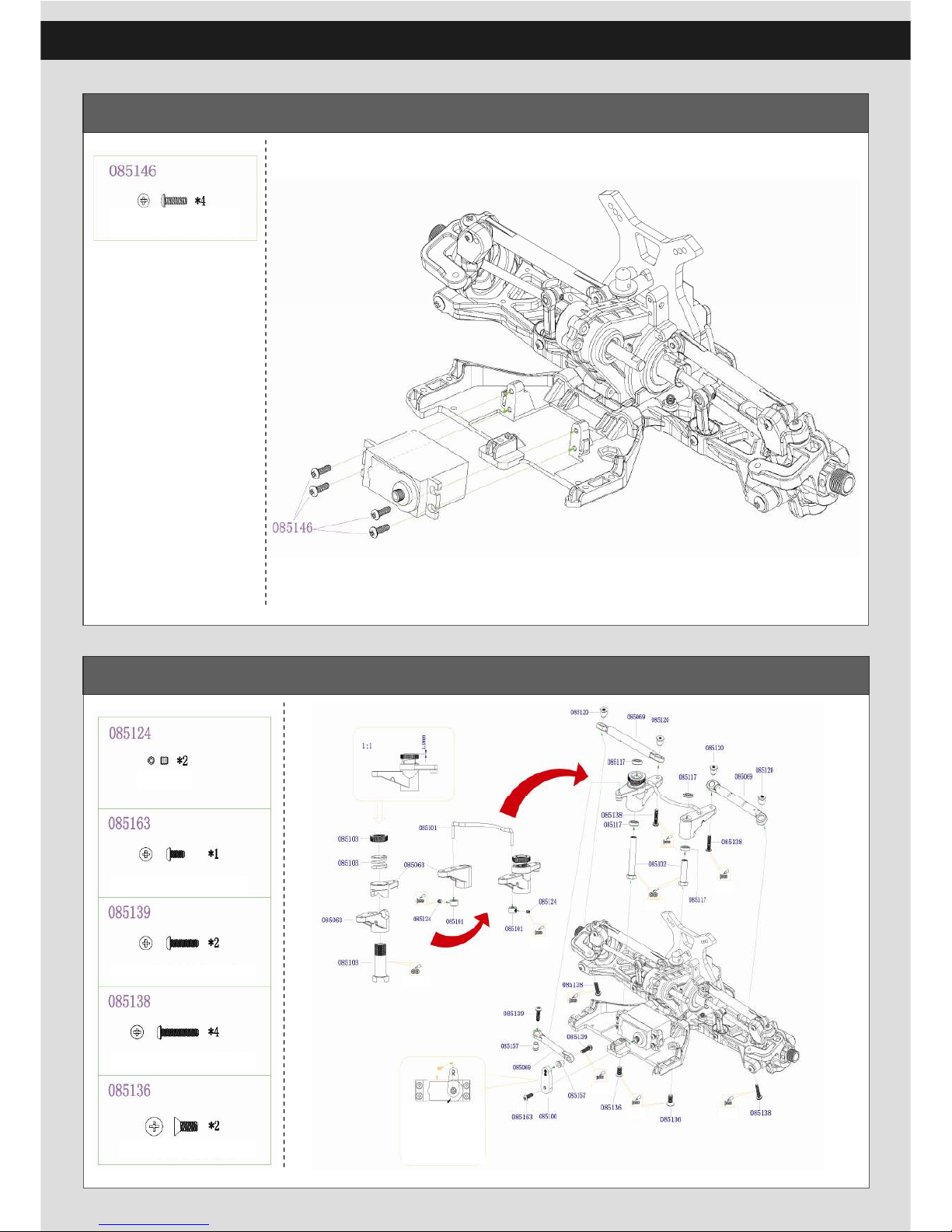

Rear Gear Box Build

Rear Gear Box Assembly

M4 X 4 Set Screw

M3 X 16 Countersunk

Phillips Self-tapping Screws

M3 X 28 Countersunk Phillips

Self-tapping Screws

Front Shaft

15T Gear Installing

Add thread lock

Set screw should be tighten

on the flat place

M4 X 14 Countersunk Phillips

Self-tapping Screws

15

Rear Shock Tower Aseembly

Rear Lower Arm /Rear Sway Bar Assembly

M3 X 12 Countersunk Phillips

Self-tapping Screws

M3 X 20 Countersunk Phillips

Self-tapping Screws

Add grease

M3 X 3 Set Screw

M4 X 10 Set Screw

Sway Bar Upper Ball

Suspension Arm

Pin Bushing

Rear Suspension Arm

Pin Bushing(Rear)

M3 X 20 Button Phillips

Machine Screws

M4 X 20 Countersunk

Phillips Machine Screws

Sway Bar Mounting

16

Rear Hub Carrier Build

Rear Upper Turnbuckle Assembly

Rear lower Suspension Arm Pin B

Rear Driver Shaft

Rear Axle

Add grease

Rear Upper Turnbuckle

M3 X 16 Button Phillips

Machine Screws

M3 X 22 Button Phillips

Machine Screws

M3 Lock Nut

17

Rear Shock Build

Rear Shock Assembly

Rear Shock Spring

Rear Shock Shaft

More than

No Bubbles

M3 X 20 Button Phillips

Self-tapping Screws

M3 Step Lock Nut

M3 X 26 Button Phillips

Machine Screws

18

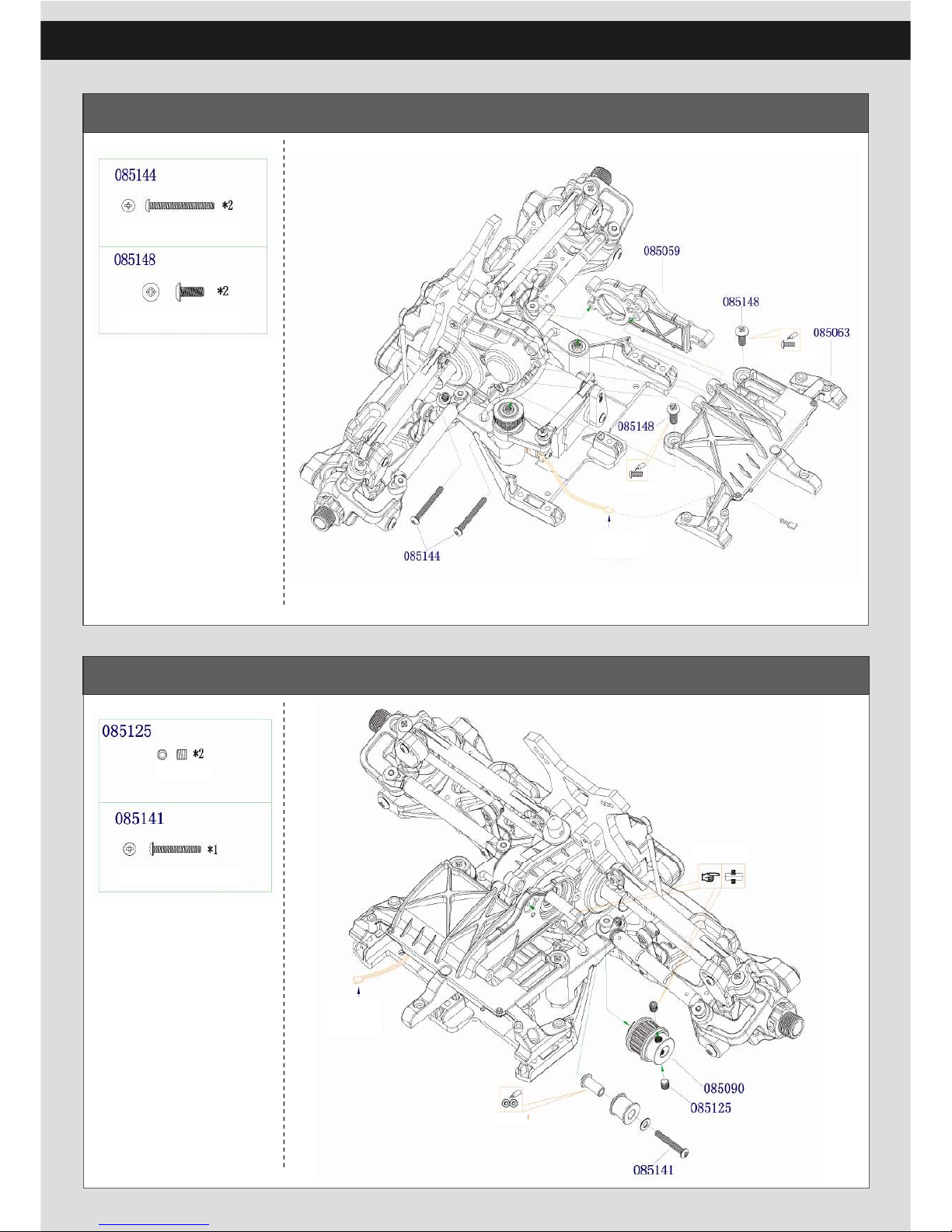

Motor Mount Assembly

Front Suspension Assembly

M3 X 26 Button

Phillips Machine Screws

M3 X 16 Button Phillips

Machine Screws

M3 X 8 Countersunk Phillips

Self-tapping Screws

This part is

upgrade part

Add thread lock

Add thread lock

Add thread

lock

Add thread lock

M3 Lock Nut

M3 X 22 Button Phillips

Machine Screws

M3 X 20 Button Phillips

Machine Screws

M3 X 28 Countersunk

Phillips Machine Screws

19

Rear Suspension Assembly

Rear Belt Box Assembly

M3 Lock Nut

M3 X 22 Button Phillips

Machine Screws

M3 X 20 Button Phillips

Machine Screws

M3 X 12 Countersunk

Phillips Machine Screws

Add thread lock

Add thread lock

20

Middle Belt Assembly

Can Adjust

the belt

M3 Lock Nut M3 X 22 Button

Phillips Machine

Screws

Can Adjust

the belt

21

65T Main Gear Assembly

Front Belt Box Assembly

M4 Lock nut

M3 X 8 Countersunk Phillips

Self-tapping Screws

Main Gear

Spring

22

Middle Belt Box Assembly

Motor Assembly

M3 X 8 Countersunk

Phillips Self-tapping Screws

Set Screw should be

tighten on the falt place

M3 X 12 Button Phillips

Machine Screws

Motor Mounting:

1.it can install 15T or 17

T pinion gear,but please

use the appropriate

mounting hole for the

different pinion gear.

2.it can install different

diameter motor,

36mm(standard),40mm

(option),42(option).

Add thread lock

23

Rear Belt Box Assembly

Receiver Box Assembly

M3 X 8 Countersunk

Phillips Self-tapping Screws

M3 X 20 Button Phillips

Self-tapping Screws

M3 X 8 Countersunk

Phillips Self-tapping Screws

24

ESC Assembly

Middle Brace Assembly

AB Glue

Please use AB glue

Add thread lock

M3 X 28 Button Phillips

Self-tapping Screws

M3 X 26 Button Phillips

Self-tapping Screws

Please use AB glue

AB Glue

Double side tape

Double side tape

25

Battery Assembly

Battery Tray Assembly

26

Battery Tray Button Assembly

M3 X 12 Button Phillips

Self-tapping Screws

27

Fan Brace Assembly

T parts are

option parts

M3 X 10 Button Phillips

Self-tapping Screws

M3 X 16 Button

Phillips Machine Screws

28

Tail Wing Build

Tail Wing Assembly

M3 X 16 Button Phillips

Self-tapping Screws

M3 X 12 Button Phillips

Self-tapping Screws

M3 X 3 Set screw

M3 X 22 Button Phillips

Machine Screws

M3 lock nut

M3 X 16 Button Phillips

Self-tapping Screws

29

Tire Build

Put the insert into the tire

Put the tire on the rim .

Drop the CA glue into the

gap between the tire and rim .

CA Glue

30

Tire Assembly

Bodyshell Assembly

31

Spare Part List

32

Spare Part List

33

Spare Part List

34

Spare Part List

Ball Head of Shock Ends

35

Spare Part List

Glass Fiber

36

Spare Part List

Small Belt

Ball Head of Shock Ends

37

F8E-BX Exploded View

福瑞达模型有限公司

DONGGUAN FREERCHOBBY CO.,LTD

TEL/FAX :+86-769-82927540

www.freerchobby.com

Thank you

Loading...

Loading...