Page 1

Model No. F624.3

Serial No.

Write the serial number in the

space above for reference.

Serial Number Decal

(inside tower)

QUESTIONS?

If you have questions, or if parts

are damaged or missing, please

see HOW TO CONTACT

CUSTOMER CARE on the back

cover of this manual.

OWNERʼS MANUAL

CAUTION

Read all precautions and instructions in this manual before using

this equipment. Keep this manual

for future reference.

www.freemotionfitness.com

Page 2

TABLE OF CONTENTS

IMPORTANT PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ARNING DECAL PLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

W

BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MAINTENANCE AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CABLE DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

PART LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

EXPLODED DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

HOW TO CONTACT CUSTOMER CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

FREEMOTION is a registered trademark of ICON IP, Inc.

2

Page 3

IMPORTANT PRECAUTIONS

WARNING: To reduce the risk of serious injury, read all important precautions and

nstructions in this manual and all warnings on your strength equipment before using your strength

i

equipment. FreeMotion Fitness assumes no responsibility for personal injury or property damage

sustained by or through the use of this product.

1. Before beginning any exercise program,

consult your physician. This is especially

important for persons over age 35 or persons with pre-existing health problems.

2. Use the strength equipment only as

described in this manual.

3. It is the purchaserʼs responsibility to ensure

that there is enough space around the

strength equipment for the intended exercise. Do not crowd the strength equipment.

4. Using the two 9/16" anchor holes in the

base of the tower to provide maximum stability, the strength equipment must be

anchored to the floor where required or

whenever possible.

5. Use the strength equipment only on a level

surface. Cover the floor beneath the

strength equipment to protect the floor.

6. It is the responsibility of the owner to

ensure that all users of the strength equipment are adequately informed of all

precautions, have read and understood all

warning and caution labels, and are

informed of how to use the strength equipment properly.

7. Keep children under age 12 and pets away

from the strength equipment at all times.

8. Keep hands and feet away from moving

parts. Do not lean on or rest your hands on

the strength equipment when it is in use.

9. Always wear athletic shoes for foot protection while exercising.

10. All users of the strength equipment should

be instructed to report any injury or

strength equipment irregularity to facility

staff immediately.

11. Make sure the weight pin is completely

inserted into one of the weight plates.

12. Make sure the handles are attached securely

before each use of the strength equipment.

13. Check all cables, cable connections, and

pulleys before each use of the strength

equipment. Make sure all parts are properly

tightened. Replace any worn parts

immediately.

14. Make sure the cables remain on the pulleys

at all times. If the cable binds while you are

exercising, stop immediately and make sure

the cable is on the pulleys and nothing is

interfering with the cable or pulleys.

15. The strength equipment is designed to support a maximum user weight of 350 lbs.

(159 kg).

16. Over exercising may result in serious injury

or death. If you feel faint or if you experience pain while exercising, stop

immediately and cool down.

3

Page 4

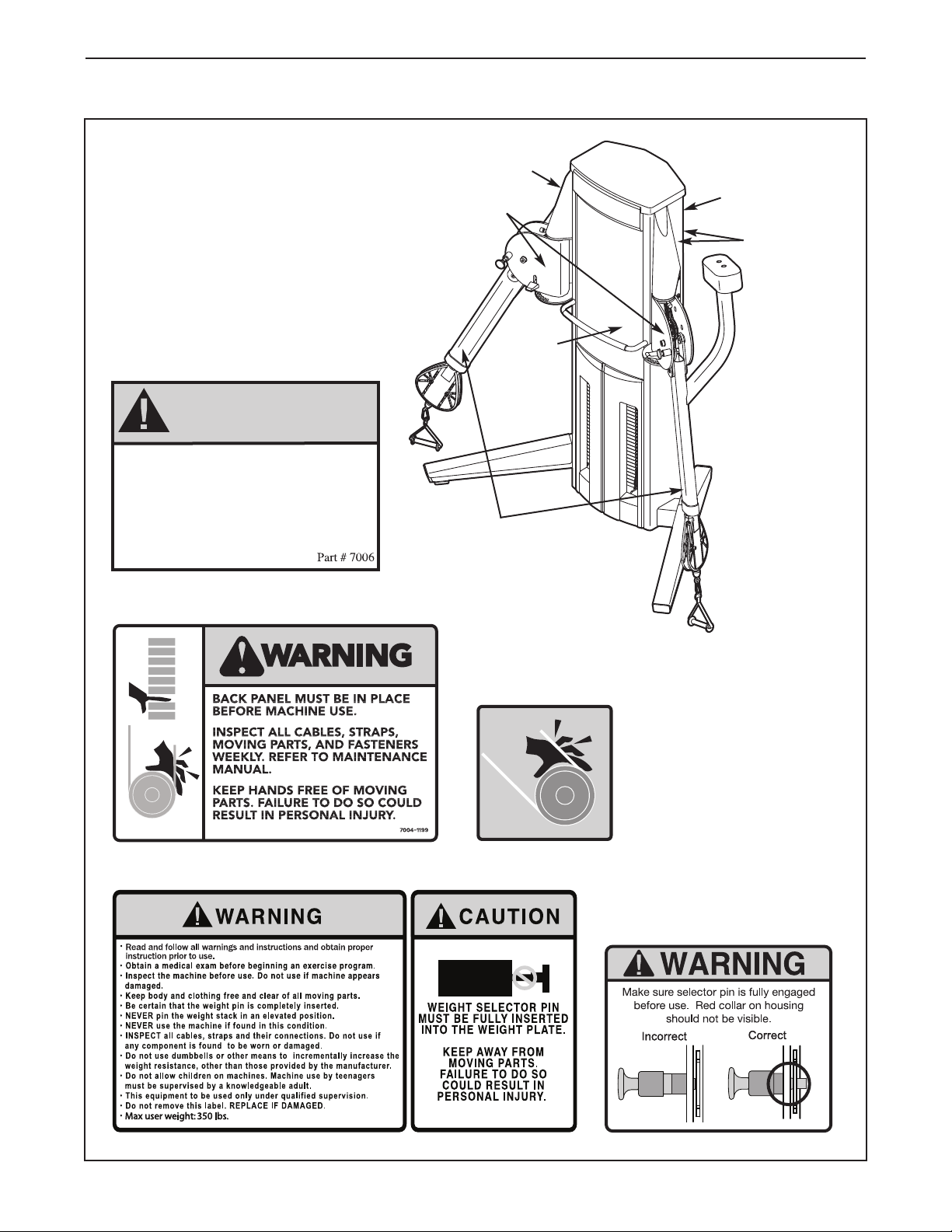

WARNING DECAL PLACEMENT

DO NOT USE

MACHINE FROM

THIS SIDE

WARNING

This drawing shows the location(s)

of the warning decal(s). If a decal

is missing or illegible, see the

back cover of this manual and

request a free replacement

decal. Apply the decal in the

location shown. Note: The

decal(s) may not be shown at

actual size.

Decal 1

Decal 1

Decal 5

Decal 3

Decal 4

ecal 2 (inside

D

access cover)

Decal 1

Decal 2

Decal 3

Decal 4 (This decal is part of the instruction placard)

Decal 5

4

Page 5

BEFORE YOU BEGIN

Thank you for selecting the FREEMOTION®DUAL

CABLE CROSS strength equipment. With unrestricted

motion, you can work your bodyʼs muscle groups

ogether—the same way you do naturally—and train

t

more specifically and efficiently.

For your benefit, read this manual carefully before

using the strength equipment. If you have questions

after reading this manual, please see the back cover

Arm Bracket

Adjustment Knob

Lever Handle

Handlebar

of this manual. To help us assist you, note the product

model number and serial number before contacting

us. The model number and the location of the serial

umber decal are shown on the front cover of this

n

manual.

Before reading further, please review the drawing

below and familiarize yourself with the parts that are

labeled.

Length: 5 ft. 2 in. (157 cm)

Width: 10 ft. 3 in. (312 cm)

Weight: 1246 lbs. (565 kg)

Tower

Counterweight

Swivel

Arm

Handle

Weights

Weight Pin

5

Page 6

ADJUSTMENTS

This section explains how to adjust the strength equipment. Make sure all parts are properly tightened each time

he strength equipment is used. Replace any worn parts immediately.

t

ADJUSTING THE RESISTANCE

To change the amount of resistance for your workout, insert a weight pin into the desired weight.

Make sure that the weight pin is fully inserted

into the weight stack.

Weight

Stack

Weight

Pin

ADJUSTING THE ARMS

To change the position of an arm, pull the adjustment knob outward and move the arm to the

desired position. Engage the knob into the arm

bracket. Make sure that the collar on the adjust-

ment knob is not visible.

ADJUSTING THE ARM BRACKETS

To change the position of an arm bracket, press the

lever handle to disengage the selector pin (not

shown) and move the arm bracket to the desired

position. Release the lever handle and engage the

selector pin into the arm bracket.

Arm

Bracket

Adjustment

Knob

Arm

Lever

Handle

6

Page 7

MAINTENANCE AND TROUBLESHOOTING

For optimal performance of the strength equipment and to reduce the chances of injury to users, you must perform preventive maintenance on a regular basis. Instruct all personnel to perform the procedures described in

his section. Personnel must also record and report any accident. To maintain the strength equipmentʼs warranty,

t

use only FREEMOTION parts for repair or replacement. If there are any questions or concerns, see HOW TO

CONTACT CUSTOMER CARE on the back cover of this manual.

DAILY MAINTENANCE

Upholstery and Frame—General Cleaning

1. Clean the strength equipment using a soft cloth

dampened with a light solution of mild soap and

warm water. If necessary, use a soft bristle brush

with the cleaning solution.

2. Rinse the area thoroughly using a soft cloth dampened with clean water. Dry thoroughly.

Upholstery—Difficult Stains

1. Spray the stain with a non-abrasive household

cleaner such as FORMULA 409

GREEN®, or a similar product. Rub the stained

area gently and let the cleaning solution sit for a

few minutes.

2. Rinse the area thoroughly using a soft cloth dampened with clean water. Dry thoroughly.

3. Repeat these steps if necessary using a soft bristle brush.

Optional Method for Difficult Stains

1. Rub the stained area gently using a soft cloth

dampened with rubbing alcohol.

2. Rinse the area thoroughly using a soft cloth dampened with clean water. Dry thoroughly.

CAUTION: When using any cleaning product, try it

first in an unnoticeable place to ensure that there is no

damage to the material. Follow the directions and the

safety precautions of the manufacturer of each cleaning product used. FreeMotion Fitness and its vendors

cannot be held liable for damage or injuries resulting

from the use or misuse of cleaning products. IMPOR-

TANT: Do not use abrasive cleaners, which may

scratch the strength equipment. Strong cleaners and

abrasives will damage decals; use caution around

decals. Do not use solvents such as lacquer thinner,

kerosene, gasoline, or similar liquids.

®

cleaner, SIMPLE

WEEKLY MAINTENANCE

Hardware

Check all nuts and bolts and tighten them as required.

IMPORTANT: All FREEMOTION cushions have dense

plywood supports with tee-nuts that are used to bolt

the cushions to the strength equipment. Because the

tee-nuts are held by the plywood, they will not withstand the torque that standard nuts and bolts will.

When tightening the bolts securing a cushion, turn

them only until they are snug and the cushion does

not move or feel loose. Overtightening may strip the

tee-nuts from the plywood and make it impossible to

remove the cushion in the future.

Cables

1. Check each cable for proper tension (see CABLE

ADJUSTMENT on page 8).

2. Check the entire length of each cable by slowly

performing one repetition on the strength equipment; inspect the cable that is exposed on the

exterior of the strength equipment and the cable

inside the tower. Run your fingers along the cable,

paying close attention at the bends and attachment points. Watch for the following conditions,

which may indicate a worn cable in need of

replacement:

A. a torn or split cable sheath that exposes the

cable

B. a kinked or severely bent cable

C. a curled or twisted sheath

D. a stretched cable sheath, showing a thinning

cross-section

A

B

C

D

7

Page 8

able Traps

C

Check the cable traps to ensure that they are not rub-

ing against the cables and that they are holding the

b

cables in the grooves of the pulleys. If a cable trap is

not correctly aligned, loosen the bolt slightly, readjust

the cable trap as necessary, and retighten the bolt.

orrect Alignment

C

Cable

Cable

Traps

Pulley

Traps

f there is too much tension on the cables, the weight

I

carriage will not rest on the next weight, and it may be

ifficult to insert the weight pin into the weights.

d

If there is not enough tension on the cables, the

weight carriage will not be lifted immediately when the

epetition is begun. Ideally, the cables should not

r

move more than 1/2 in. (1.3 cm) from the resting position before the weight carriage is lifted.

If there is too much tension or not enough tension on

a cable, adjust the cable as described in the following

steps.

Weight Carriage Pulley Adjustment

Tools required: 5/16" hex key, 9/16" open-end wrench

Rubbing

Incorrect Alignment

Rubbing

Out of

Alignment

WEIGHT GUIDE LUBRICATION

Clean and lubricate the full length of each weight

guide by wiping it with a soft cloth containing a lightweight motor oil, 10W-40 or 10W-30 weight. Apply

only a light coating over the entire length of the weight

®

guide. Do not use TEFLON

-based lubricants.

CABLE ADJUSTMENT

For the strength equipment to function correctly, the

cables must be tensioned correctly. To check the tension of the cables, insert the weight pin into the weight

carriage. Next, slowly raise and lower the weight carriage by performing one repetition. The weight

carriage should come to rest just on top of the next

weight when the repetition is completed.

1. Remove the access cover by pulling it free at the

bottom and then sliding it upward until the two sets

of tabs release.

2. Loosen the locknut attaching the pulley in the

bracket on the weight carriage.

Pulley

Slot

Weight

Carriage

3. Move the pulley to the appropriate location in the

bracket. If more slack is needed in the cable,

move the pulley upward. If less slack is needed in

the cable, move the pulley downward.

4. Make sure that the cable trap is properly oriented

(see CABLE TRAPS at the left) and retighten the

locknut attaching the pulley to the bracket.

5. Check the tension of the cables as described

above. Readjust as necessary.

6. Slowly perform a repetition using a light load and

have someone make sure that the cable is not

derailed from a pulley or rubbing on a cable trap.

7. Replace the access cover.

8

Page 9

ADDITIONAL ADJUSTMENTS

andle End Adjustment

H

Tools required: 1/8" hex key, cable cutters, torque

wrench, utility knife

4. Cut off one inch of the cable end using cable cutters. Note: Using any other tool may flatten or

isrupt the end strands so that it may be diffi-

d

cult to reinsert the cable into the hole of the

cable lock.

Note: Make this adjustment only if the pulley in the

weight carriage has been fully adjusted to the bottom

of the slot in the bracket and the cable requires more

tension.

Note: This adjustment is only for increasing the cable

tension, because it requires shortening the cable. Only

one end of the cable should be shortened.

1. Create slack in the cable by removing the weight

pin and pulling the handle out six to eight inches.

Insert the weight pin into the third weight plate and

the tube on the bottom of the weight carriage.

2. Push the black rubber cable stop off the aluminum

cable lock and slide the cable stop upward a few

inches.

5. Cut off one inch of the black cable sheath from the

end of the cable.

6. Reinsert the cable and the sheath into the cable

lock so that all of the bare cable is in the hole.

7. Retighten the four set screws into the threaded

holes. Tighten the set screws equally until they

contact the cable. Then, tighten each screw alternately 1/4 turn, until all are set to 85 inch/pounds

(9.6 Newton-meters).

8. Slide the rubber cable stop over the cable lock,

remove the weight pin, and lower the handle.

9. Check for proper tension on the cable as

described in CABLE ADJUSTMENT, on page 8.

ADJUSTMENT KNOB

If an adjustment knob sticks, it will need to be relubricated. Disassemble the knob and apply a light coating

of lithium grease. Reassemble the knob as shown in

the diagram.

Cable Stop

Cable

Set Screws

3. Loosen the four set screws in the cable lock and

pull the cable free.

Set Screws

Cable Lock

Adjustment Knob Diagram

Adjustment

Pin

If the adjustment knob still does not function properly,

the spring may need to be replaced. To order a new

spring, see the back cover of this manual.

Spring

Housing

Knob

9

Page 10

EIGHT STACK SERVICING

W

ervicing the weight stack involves replacing the

S

bushings in the weight carriage. To order these parts,

see HOW TO CONTACT CUSTOMER CARE on the

back cover of this manual.

1. Remove the access cover by pulling it free at the

bottom and then sliding it upward until the two sets

of tabs release.

. Clean and lubricate the weight guides by wiping

7

them using a soft cloth containing a lightweight

otor oil, 10W-40 or 10W-30 weight. Apply only a

m

light coating over the entire length. See WEIGHT

GUIDE LUBRICATION on page 8.

. Replace the weight carriage on the weight guides.

8

Reattach the pulley, cable, and cable traps.

9. Reattach the weight guides to the top of the tower.

2. Loosen the top bolt or nuts on each weight guide.

Remove the bolts or nuts and let the weight

guides slide down to the floor.

3. To remove the weight carriage, first unbolt the pulley(s) to release the cable using a 5/16" hex key

and a 9/16" open-end wrench.

4. Slide the weight carriage upward off the top of the

weight guides. Note: Pull the weight guides toward

the back of the equipment for increased clearance.

5. Unscrew and remove the two existing weight

guide bushings from the weight carriage. Discard

the weight guide bushings you just removed.

Weight Guide

Bushings

Weight

Carriage

10. Insert the weight pin into the weight carriage. Pull

the handle, lifting the weight carriage all the way to

the top. Slowly return the handle to the resting

position.

If the weight carriage sticks, loosen one of the

weight guide bolts or nuts. Lift the weight carriage

to the top again. Retighten the weight guide bolt or

nuts. Check the full travel again and readjust the

weight guides if necessary.

11. Slowly perform a repetition and have someone

make sure that the cable is not derailed from a

pulley or rubbing on a cable trap.

12. Replace the access cover.

6. Tighten two new weight guide bushings into the

weight carriage.

10

Page 11

CABLE DIAGRAM

The cable diagram shows the proper route of the cables. Use the diagram to make sure that the cables and the

cable traps have been assembled correctly. If the cables have not been correctly routed, the strength equipment

will not function properly and damage may occur. The numbers show the correct route of the cables. Make sure

hat the cable traps do not touch or bind the cables.

t

7

6

5

4

3

9

9

7

6

5

10

4

3

10

8

2

1

2

8

2

2

1

11

Page 12

PART LIST Model No. F624.3 R0413A

ey No. Qty. Description Key No. Qty. Description

K

1

2

31Right Stabilizer

41Left Stabilizer

5

6

72Counterweight

82Pulley Paddle A

91Right Arm Bracket

10 1 Left Arm Bracket

11 4 #10 x 1/2" Flat Head Screw

12 1 Left Cable Cover

13 46 Weight

14 1 Left Weight Carriage

15 2 Arm Cover

16 2 Stabilizer Cover

17 1 Right Weight Carriage

18 1 Lower Cover

19 4 Foot

20 1 Handlebar

21 4 Weight Guide

22 4 Weight Cushion

23 8 Bumper

24 2 Lever Handle

25 2 Lever

26 2 Trunnion

27 18 Pulley

28 2 Retainer Ring

29 2 Selector Pin

30 4 Spring

31 8 Pivot Pulley Bearing

32 2 3/8" x 2 1/4" Bolt

33 4 Serrated Washer

34 2 Weight Pin

35 8 3/8" x 1/2" Button Screw

36 4 3/8" x 4 1/2" Socket Head Screw

37 4 3/8" x 1 3/4" Bolt

38 6 3/8" x 2" Bolt

39 2 Pulley Bracket

40 4 3/4" Bushing

41 8 1/2" x 1" Socket Head Screw

42 4 3/4" x 1/2" Shoulder Bolt

43 2 Cable

44 2 Cable Stop

45 8 1/4" x 3/8" Set Screw

46 2 Cable Lock

47 2 Indicator

48 1 Upper Left Pivot Plate

49 1 Lower Left Pivot Plate

50 1 Upper Right Pivot Plate

1 Tower

1 Rear Cover

1 Right Arm

1 Left Arm

5

1 1 Lower Right Pivot Plate

5

2 4 Stabilizer Cap

53 2 1" Steel Washer

54 2 Locator

5

5 1 Tower Cover

5

6 9 1/4" x 3/8" Button Head Screw

57 2 3/8" x 1/2" Shoulder Screw

58 1 Handlebar Cover

59 4 5/16" x 5/8" Socket Head Screw

60 4 1/4" x 3/4" Socket Head Screw

61 2 Horizontal Adjustment Bracket

62 2 1" Wave Washer

63 8 Stabilizer Cap Screw

64 1 Right Cable Cover

65 2 Roller Pin

66 2 Long Magnetic Tape

67 2 Short Magnetic Tape

68 4 Weight Guide Bushing

69 2 #10 x 1/2" Screw

70 4 3/8" Jam Nut

71 2 Pop Pin Cover

72 12 Cable Trap

73 16 3/8" Locknut

74 8 1/4" x 1/2" Button Screw

75 2 Handle

76 2 Cable Clip

77 1 Ankle Strap

78 4 #8 x 1" Flat Head Screw

79 8 3/8" x 3/4" Socket Screw

80 2 Pop Pin

81 2 5/16" Washer

82 8 5/8" Lock Washer

83 2 Cover Spacer

84 8 5/8" Jam Nut

85 4 5/16" x 5/8" Set Screw

86 16 1/2" Locknut

87 2 Knob

88 4 3/8" x 1" Bolt

89 4 #8 x 1" Pan Head Screw

90 16 1/2" x 1 1/2" Socket Flat Head Bolt

91 6 3/8" x 1 1/2" Button Head Bolt

92 6 3/8" Pinch Nut

93 4 1" Nylon Washer

94 2 Double Cable Trap

95 8 1/4" Clip Nut

96 1 Hook Fastener

97 1 Loop Fastener

98 2 Pulley Paddle B

*–Ownerʼs Manual

Note: Specifications are subject to change without notice. For information about ordering replacement parts, see

the back cover of this manual. *These parts are not illustrated.

12

Page 13

4

16

26

28

31

27

11

73

8

19

35

35

41

43

44

46

45

45

75

19

76

7

36

6

80

30

87

27

92

91

27

42

40

40

85

23

23

85

42

12

74

74

10

20

58

79

81

79

81

86

90

61

93

31

31

93

79

86

90

49

52

63

63

52

29

30

24

65

60

25

47

54

57

48

69

15

53

62

37

78

89

27

11

98

95

95

95

71

EXPLODED DRAWING A Model No. F624.3 R0413A

13

Page 14

56

55

1

33

13

23

2

70

43

18

84

84

82

84

82

84

21

21

68

68

34

34

39

73

27

72

38

88

73

73

88

73

32

88

39

27

72

27

27

73

73

32

56

56

56

22

22

13

17

14

94

94

72

72

72

38

73

7

3

38

73

38

73

2

7

2

7

27

27

38

73

33

33

33

70

70

43

70

59

23

67

66

96

97

72

72

72

72

83

EXPLODED DRAWING B Model No. F624.3 R0413A

14

Page 15

27

41

16

35

61

42

26

27

27

93

79

86

74

64

37

91

31

51

5

80

87

30

7

36

3

6

31

8

73

28

3

23

23

85

85

40

92

90

74

19

19

35

90

86

31

93

9

43

44

46

45

45

27

91

40

42

76

75

77

52

63

63

63

52

15

69

60

30

29

25

65

24

50

57

54

47

62

53

78

89

11

11

98

71

95

95

95

EXPLODED DRAWING C Model No. F624.3 R0413A

15

Page 16

HOW TO CONTACT CUSTOMER CARE

If you have questions after reading this manual, or if parts are damaged or missing, please contact Customer

Care at one of the phone numbers or addresses listed below. Please note the model number, serial number,

nd name of the product (see the front cover of this manual) before contacting Customer Care. If you

a

are ordering replacement parts, please also note the key number and description of each part (see the

PART LIST and the EXPLODED DRAWING near the end of this manual).

In the United States and Canada

Call: 1-800-201-2109, Mon.–Fri. 8 a.m.–5 p.m. MT

Write:

FreeMotion Fitness

1500 South 1000 West

Logan, UT 84321-9813

United States

Outside the United States and Canada

Call: 001-435-786-3521

Email: intlcustomercare@freemotionfitness.com

Part No. 318474 R0413A Printed in USA © 2011 ICON IP, Inc.

Loading...

Loading...