MODEL: PFS16

16 GA FENCING

16 GA FENCING

16 GA FENCING

STAPLER

STAPLER

STAPLER

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIME GLOBAL PRODUCTS, INC.

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIME GLOBAL PRODUCTS, INC.

WARNING:

Failure to follow warnings could result in DEATH OR SERIOUS INJURY.

SAVE THIS MANUAL FOR FUTURE REFERENCE

IMFPFS16-V1 04/18

MODEL: PFS16

MODEL: PFS16

GENERALSAFETYRULES

UNPACKING

FEATURES

P3

P6

P6

OPERATION

ADJUSTING THE EXHAUST

LOADING FASTENERS

UNLOADING FASTENERS

CLEARING JAMS

SETTING THE AIR PRESSURE

DEPTH ADJUSTMENT

FIRING THE TOOL

MAINTENANCE

RECOMMENDED HOOKUP

TROUBLESHOOTING

WEARABLE PARTS

WARRANTIES

P7

P7

P7

P8

P8

P8

P9

P9

P10

P11

P11

P12

WARNING:

The warnings and precautions discussed in this manual cannot cover all possible conditions

and situations that may occur. Please be aware of the potential hazards, and take all

necessary precautions to avoid risk of injuries.

SAVE THIS MANUAL

●

Keep this manual for the safety

war n i n g, p recaut i ons, o perati o ns,

i ns pe c t i o n s a n d m a i n t e na nc e

in formation. Ke ep this ma nua l an d

the receipt in a safe and dry place for

future reference.

!

WARNING:

To avoid serious personal injury,

do n ot atte mpt to use this product

u n t il y o u r e a d t h e m a n u a l

thorou g h l y and u n d e rsta n d i t

completely. Save this manual and

review frequently for continuing

saf e opera tion a nd inst ructi ng

others who may use this tool.

SYMBOLS

●

The following signal words and meanings are intended to explain the levels of risk

associated with this tool, and can be found in the manual, packaging, labeling, and

all other information provided with this tool:

SYMBOLS SIGNAL MEANING

!

!

WARNING:

CAUTION:

CAUTION:

GENERAL SAFETY RULES

SIN S T RUCTIO N S P ERTAIN I N G T O A

RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS.

!

WARNING:

When using tools, basic precautions

s h o u l d a l w a y s b e f o l l o w e d ,

including the following:

CALIFORNIA PROPOSITION 65

!

WARNING:

This product can expose you to

chemicals including lead, which is

known to the State of California to

cause cancer and birth defects or

other reproductive harm. For more

information, go to

www.P65Warnings.ca.gov.

WORK AREA

Keep the work area clean and wel l

●

lit. Cluttered benches and dark areas

increase the risks of accidents.

Do not operate the tool in explo sive

●

a t m o s ph e r e s , s uc h a s i n t h e

presence of flammable l i q u i d s ,

gases, or dust. The tool creates a

spark which m ay ignit e f lammable

liquids, gases or dust.

Keep byst a n d e rs, childre n , a n d

●

others away while operati ng t he

tool . Distr a ction s could resu l t in

improper use and cause injury.

A v o i d u n in t e n ti o n a l m i sf i r e s .

●

A l w a y s u s e c a u t i o n t o a v o i d

accidentally firing. Do not point at

yourself or anyone else regardless if

it contains fasteners or not.

Indicates a potentially hazardous situation,which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation, which, if

not avoided, may result in minor or moderate injury.

(Without symbol) Indicates a situation that may result

in property damage.

PERSONAL SAFETY

Do not nail on top of another nail. This nail

can cause the nail to be deflected and hit

someone, or cause the tool to react and

result in a risk of injury to persons.

Remove finger from the trigger when not

driving fasteners. Never carry the tool with

finger on trigger, the tool is able to fire a

fastener.

Always wear eye protection. Operator and

others in the work area should always wear

ANSI-approved safety goggles with side

shields. Eye protection is used to guard

against flying fasteners and debris, which

may cause severe eye injury.

Always wear hearing protection when

using the tool. Prolonged exposure to high

intensity noise may cause hearing loss.

Use safety equipment. A dust mask, nonskid safety shoes and a hard hat must be

used for the applicable conditions. Wear a

full face shield if you are producing metal

filings or wood chips.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your long

hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating the tool may cause serious injury.

Avoid unintentional firing. Keep fingers

away from trigger when not driving

fasteners, especially when connecting the

tool to the air supply.

Keep proper footing and balance at all

times. Proper footing and balance enables

better control of the tool in unexpected

situations.

02

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

03

MODEL: PFS16 MODEL: PFS16

Do not use on a ladder or unstable

supports. Stable footing on a solid surface

enables better control of the tool in

unexpected situations.

Make sure the hose is f ree o f

obstructions or snags. Entangled or

snarled hoses can cause loss of balance or

footing and may become damaged,

resulting in possible injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Do not attach the hose or tool to your

body.

Attach the hose to the structure to

reduce the risk of loss of balance if the

hose shifts.

Always assume that the tool contains

fasteners. Do not point the tool toward

yourself or anyone whether it contains

fasteners or not.

Wash hands after handling. This product

or its power cord may contain chemicals

known to the State of California to cause

ca nce r and birt h d efects or oth er

reproductive harm.

TOOL USE AND CARE

Know this tool. Read manual carefully,

●

learn its applications and limitations, as

well as the specific potential hazards

related to this tool.

O n l y u s e f a s t e n er s t h a t a r e

●

recommended for your models. Do not

use the wrong fasteners or load the

fasteners incorrectly.

Check for misalignment or binding of

●

moving parts, breakage of parts, and any

other condition that may affect the tool’s

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools.

Maintain tools with care. Keep tool clean.

●

A properly maintained tool reduces the risk

of binding and is easier to control.

Store tools out of the reach of children

●

and other untrained people. Tools are

dangerous in the hands of untrained users.

●

Check operation of the tool before use.

Do not use the tool if the workpiece contact

mechanism is not working correctly as

accidental driving of a fastener may occur.

Do not use tool if trigger does not actuate

●

properly. Any tool that cannot be controlled

with the trigger is dangerous and must be

repaired.

Do not force tool. Use the correct tool for

●

your application. The correct tool will do the

job better and safer at the rate for which it

is designed.

Use clamps or another practical way to

●

secure and support the workpiece to a

stable platform. Holding a tool by hand or

against the body is unstable and may lead

to loss of control.

Keep the tool and its handle dry, clean

●

and free from oil and grease. Always use a

clean cloth when cleaning. Never use brake

fluids, gasoline, petroleum-based products,

or any strong solvents to clean your tool.

Do not use the tool as a hammer.

●

●

Never use this tool in a manner that could

cause a fastener to be directed toward

anything other than the workpiece.

●

Never use gasoline or other flammable

liquids to clean the tool. Never use the

tool in the presence of flammable liquids or

gases. Vapors could ignite by a spark and

cause an explosion which will result in

death or serious personal injury.

Do not remove, tamper with, or otherwise

●

cause the trigger lock or trigger to

become inoperable. Do not operate any

tool which has been modified in a like

fashion. Death or serious personal injury

could result.

Do not touch the trigger unless driving

●

fasteners. Never attach air line to tool or

carry tool while touching the trigger. The

tool could eject a fastener which will result

in death or serious personal injury. Also

actuate the trigger lock to the safe position

when not in use.

Always fit tool with a fitting or hose the

●

coupling on or near the tool that in a way

all compressed air in the the remaining

tool is discharged at the time the fitting

or hose coupling is disconnected. Do not

use a check valve or any other fitting which

allows air to remain in the tool. Death or

serious personal injury could occur.

Never place hands or any other body

●

parts in the fastener discharge area of

the tool. The tool might eject a fastener

and could result in death or serious

personal injury.

Never carry the tool by the air hose or

●

pull the hose to move the tool or a

compressor. Keep hoses away from heat,

oil and sharp edges. Replace any hose that

is weak, worn, or otherwise damaged.

Personal injury or tool damage could occur.

Always assume the tool contains

●

fasteners. Respect the tool as a working

implement; no horseplay.

Always keep others at a safe distance

●

from the work area in case of accidental

discharge of fasteners. Do not point the

tool toward yourself or anyone whether it

contains fasteners or not. Accidental

triggering of the tool could result in death or

serious personal injury.

Do not drop or throw the tool. Dropping or

●

throwing the tool can result in damage that

will make the tool unusable or unsafe. If the

tool has been dropped or thrown, examine

the tool closely for an air leak or bent,

cracked or broken parts. STOP and repair

before using, or serious injury could occur.

Avoid using the tool when the magazine

●

is empty. Accelerated wear on the tool may

occur.

Clean and check all air supply hoses and

●

fittings before connecting the tool to an

air supply. Replace any damaged or worn

hoses or fittings. Tool performance or

durability may be reduced.

Do not use the tool if it leaks air or does

●

not function properly.

Do not operate the tool if it does not

●

contain a legible warning label.

Always carry the tool by the handle. Never

●

carry the tool by the air hose.

TOOL SERVICE

Only use accessories that are identified

●

by the manufacturer for the specific tool

model.

Use of unauthorized parts or failure to

●

follow maintenance instructions may

create a risk of injury.

Only use the lubricants supplied with the

●

tool or specified by the manufacturer.

Tool service must be performed only by

●

qualified repair personnel.

OPERATION

Do not drive fasteners near edge of the

●

workpiece. The workpiece may split

causing the fastener or ricochet, potentially

injuring you or people around.

Do not carry the tool from place to place

●

holding the trigger. Accidental discharge

could result. Choice of triggering method is

important. Check manual for triggering

options.

During normal use the tool will recoil

●

immediately after driving a fastener. This

is a

normal function of the tool. Do not attempt

to prevent the recoil by holding the tool

against the workpiece. Restriction to the

recoil can result in a second fastener being

driven from the tool. Grip the handle firmly

and let the tool do the work. Failure to heed

this warning can result in serious personal

injury.

Do not drive fasteners on top of other

●

fasteners or with the tool at an overly

steep angl may cause deflection of e. This

fasteners which could cause injury.

Do not actuate the tool unless you intend

●

to drive a fastener into the workpiece.

Always handle the tool with care:

●

Respect the tool as a working implement.

◆

Never engage in horseplay.

◆

Never pull the trigger unless nose

◆

isdirected toward the workpiece.

Keep others a safe distance from the tool

◆

while tool is in operation as accidental

actuation may occur,possibly causing

injury.

AIR SUPPLY AND CONNECTIONS

The connector on the tool must not hold

●

p r es s u r e w he n a i r s u p p l y i s

disconnected. If an incorrect fitting is used,

the tool can remain charged with air after

disconnecting and thus will be able to drive

a fastener even after the air line is

disconnected, possibly causing injury.

Do not use any type of reactive gases,

●

including, but not limited to, oxygen and

combustible gases, as a power source.

Use filtered, lubricated, and regulated

compressed air only. Use of a reactive gas

instead of compressed air may cause the

tool to explode which will cause death or

serious personal injury.

On l y us e a pres s u r e - r e g u l a t e d

●

compressed air source to limit the air

pressure supplied to the tool. The

regulated pressure must not exceed 100

psi. If the regulator fails, the pressure

delivered to the tool must not exceed 200

psi. The tool could explode which will cause

death or serious personal injury.

Always disconnect the air source:

●

Before unloading or making adjustments.

When maintaining the tool.

When clearing a jam.

When touching the safety yoke.

When tool is not in use.

When moving to a different work area.

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

0504

MODEL: PFS16 MODEL: PFS16

Such precautionary measures reduce the risk

of injury to persons.

LOADINGTOOL

Do not load the tool with fasteners when

●

any one of the operating controls is

activated.

Never place a hand or any part of body in

●

fastener discharge area of tool.

Never point the tool at anyone.

●

Do not pull the trigger or depress the

●

wo rkp iece contac t as accidental

actuation may occur, possibly causing

injury.

!

WARNING:

Th e warnin gs and pre cautions

discussed above cannot cover all

possible conditions and situations that

may occur. It must be understood by

the user that common sense and

caution are factors which cannot be

built into this product, but must be

supplied by the user.

UNPACKING

This tool has been shipped completely

●

assembled.

Carefully remove the tool and any

●

accessories from the box.

Inspect the tool carefully to make sure no

●

breakage or damage occurred during

shipping.

Do not discard the packing material until

●

you have carefully inspected and

satisfactorily operated the tool.

If any parts are damaged or missing,

●

please call 1-888-669-5672.

!

WARNING:

If any parts are missing do not operate

this tool until the missing parts are

replaced. Failure to do so could result

in possible serious personal injury.

!

WARNING:

Do not attempt to modify this tool or

create accessories not recommended

for use with this tool. Any such

alteration or modification is misuse

an d cou ld resu lt i n haz ard ous

condition leading to possible serious

personal injury.

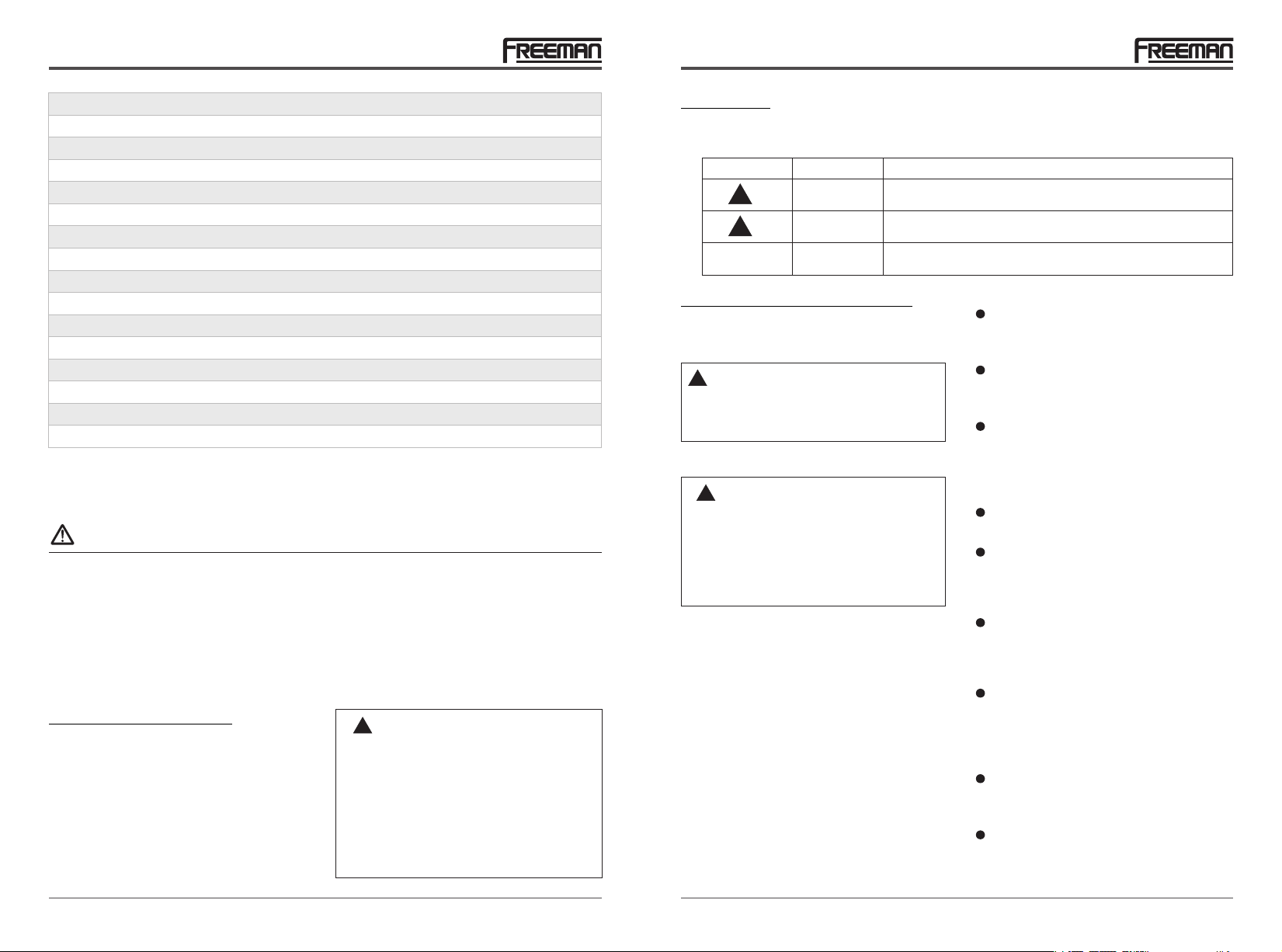

FEATURES

SPECIFICATIONS

AIR CONSUMPTION: 6.35 SCFM with 100

fasteners per minute @ 90 psi

AIR INLET: 1/4 inch NPT

MAGAZINE CAPACITY:

100 fasteners, 16 gauge

WEIGHT: 4.34 lbs

MAXIMUM PRESSURE: 100 psi

PRESSURE RANGE: 60 psi – 100 psi

FASTENER LENGTH RANGE:

3/4 inch to 1 inch

3/4”

7/8”

1”

(16 G a.)

Compatible with generic brands of 16 gauge

fencing staples.

FEATURES

360°ADJUSTABLE EXHAUST

Allows user to direct air away from face.

ONE PIECE DRIVER BLADE

For increased durability.

ANODIZED ALUMINUM CYLINDER AND

MAGAZINE

For long lasting durability.

COMFORT-GRIP HANDLE

For increased comfort and control.

ERGONOMICALLY ENGINEERED BODY

Rugged and Comfortable resulting in a

light-weight tool great for extended use.

ADJUSTABLE DEPTH

Depth is easily adjustable for various

applications.

QUICK-JAM RELEASE

Allows for easy access clearing in the

event of a jam.

18mm

22mm

25mm

OPERATION

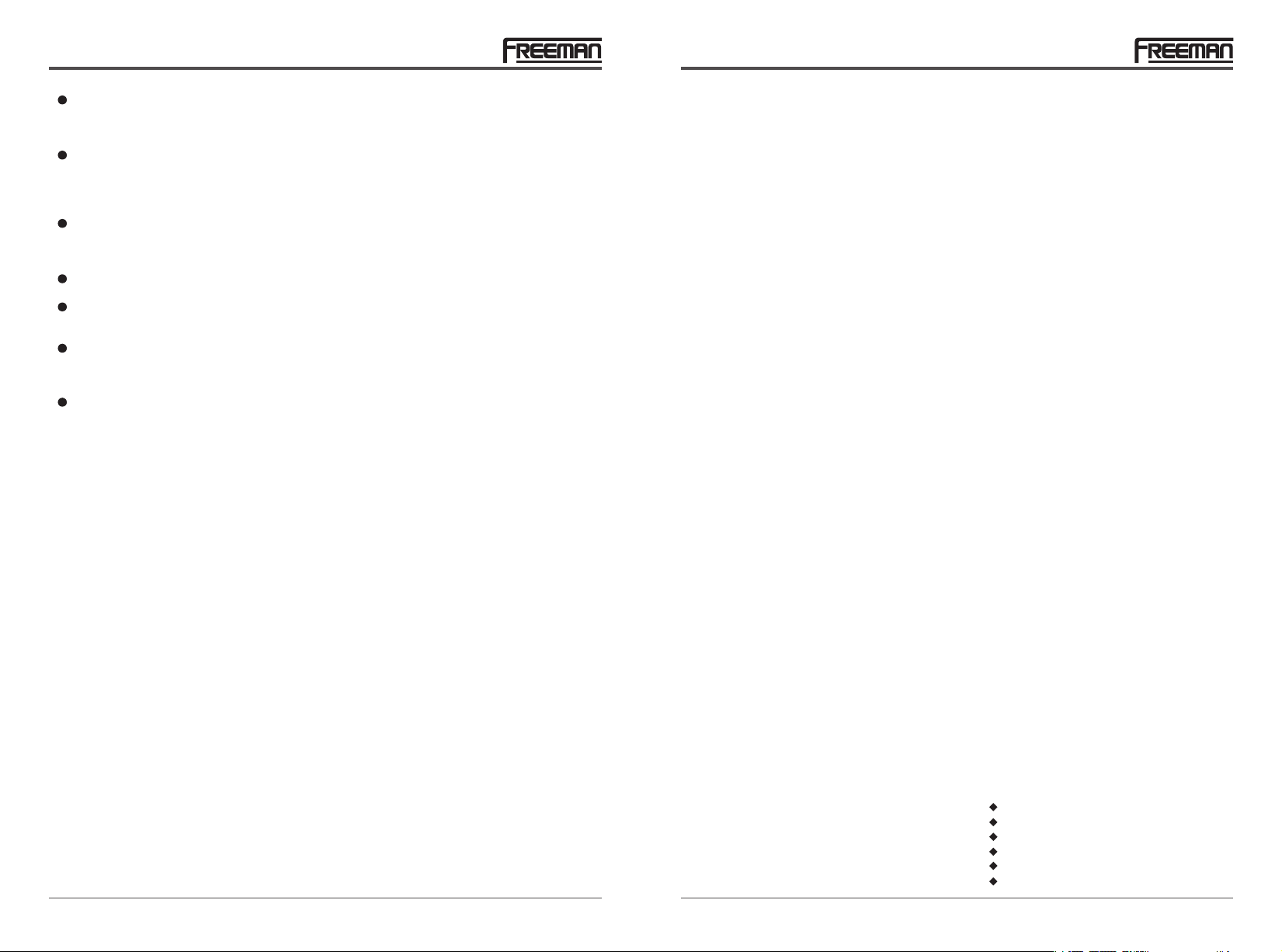

ADJUSTING THE EXHAUST

The adjustable exhaust on the cap of the tool

allows users to direct the exhaust according

to operator preference. To adjust the direction,

turn the exhaust cap in the desired direction.

LOADING FASTENERS

Connect the tool to the air supply.

1.

Pull the Pusher backward until the Pusher

2.

Pin set into the Stop Hole.

Insert appropriate nail strips from the top

3.

of magazine.

Pull the Pusher Handle to get the Pusher

4.

Pin released from the Stop Hole to let the

Pusher go back to move fasteners up to

the driving mechanism. The Pusher will

stop when it rests against the end of the

fastener.

Stop Hole

Pusher handle

Pull backwards

Pusher

Pusher Pin

PULL

Pusher

Handle

us

P

Staples

(16Ga.)

rwar

o

h f

d

Stop Hole

!

WARNING:

The tool may fire when it is first

connected to the air source. Always

connect the tool to the air source

before loading fasteners to prevent

injury from unintended cycling. Always

make sure the tool’s magazine is empty

at the beginning of each work session,

before connecting to an air source.

!

WARNING:

Only use those fasteners recommended

for use with this tool. Fasteners not

identified for use with this tool by the

tool manufacturer can result in a risk of

injury to persons or tool damage when

used in this tool.

!

WARNING:

Keep the tool pointed away from

yourself and others when loading

fasteners. Failure to do so could result

in possible serious personal injury.

!

WARNING:

Neve r l o a d f asteners with t h e

workpiece contact or trigger activated.

Doing so could result in possible

serious personal injury.

UNLOADING FASTENERS

Unloading is the reverse of loading, except

always disconnect the air source before

unloading.

!

WARNING:

Always unload all fasteners before

removing tool from service.

!

!

WARNING:

Always disconnect the air source before

unloading.

06

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

07

MODEL: PFS16 MODEL: PFS16

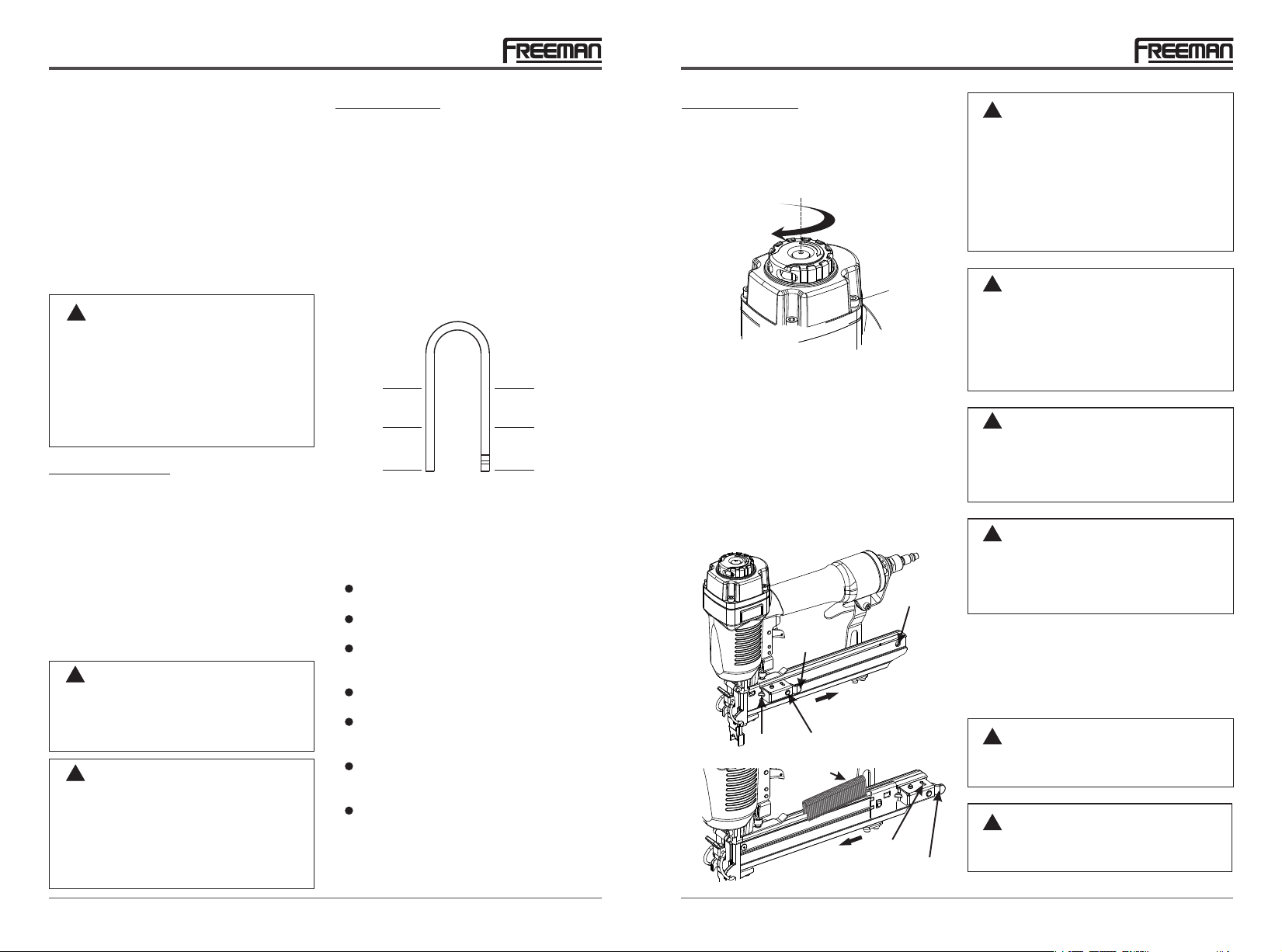

CLEARING JAMS

Occasionally, a fastener may become

jammed in the firing mechanism of the

tool, making the tool inoperable. To

remove a jammed fastener, follow these

steps below:

Disconnect the tool from air source.

1.

2.

Remove fasteners from the tool. Failure to

do so will cause the fasteners to eject

from the front of the tool.

3.

Pull up on the Latch and open the Nose

Cover.

4.

Using caution not to bend or damage the

driver blade, using pliers or a screwdriver

if required to clear the jammed fastener.

5.

Close the jam release and latch.

6.

Reconnect the tool to the air source.

7.

Reload the tool with fasteners.

Latch

Nose Cover

!

WARNING:

Make sure there is no fastener in the

magazine before clearing a jam.

!

WARNING:

Disconnect the tool from the air source

whenever clearing a jam. After

disconnecting the tool from the air

compressor, there should still be

enough air pressure to fire the tool.

After the air hose is disconnected,

always fire the tool into scrap wood

repeatedly to make sure all of the

compressed air is expended.

SETTING THE AIR PRESSURE

The amount of air pressure required depends

on the size of the fasteners and the workpiece

material.

Begin testing the depth of drive by driving a

test nail into the same type of workpiece

material used for the actual job.

Drive a test fastener with the air pressure set

at 90-95 psi. Raise or lower the air pressure to

find the lowest setting that will perform the job

with consistent results.

It may be possible to achieve the desired

depth with air pressure adjustments alone.

DEPTH ADJUSTMENT

The driving depth of the fasteners is

adjustable. To adjust the depth, use the drive

depth adjustment wheel (H) on the tool.

1.

Disconnect the tool from air source.

2.

Turn the depth wheel left or right to

change the driving depth.

3.

Reconnect the tool to the air source.

4.

Drive a test nail after each adjustment until

the desired depth is set.

Adjustment

wheel (H)

Too Deep

Turn the adjustment knob count clockwise

Too Shallow

Turn the adjustment knobclockwise

Flush

Adjustment

wheel (H)

Flush

CAUTION:

It is advisable to test the depth on a

scrap workpiece to determine the

required depth for the application.

To determine depth of drive, first adjust

the air pressure and drive a test

fastener. Never exceed 100 psi.

FIRING THE TOOL

(SINGLE SEQUENTIAL MODE)

The tool is specially designed for single

sequential mode. This mode requires the

trigger to be pulled each time a fastener is

driven. The too l can be actuated by

depressing the work contact element against

the work surface followed by pulling the

trigger. The trigger must be released to reset

the tool before another fastener can be driven.

!

WARNING:

During normal use the tool will recoil

immediately after driving a fastener.

This is a normal function of the tool.

Do not attempt to prevent the recoil

by holding the tool against the work.

Restriction to the recoil can result in

a second fastener being driven from

the tool. Grip the handle firmly and

let the tool do the work. Failure to

heed this warning can result in

serious personal injury.

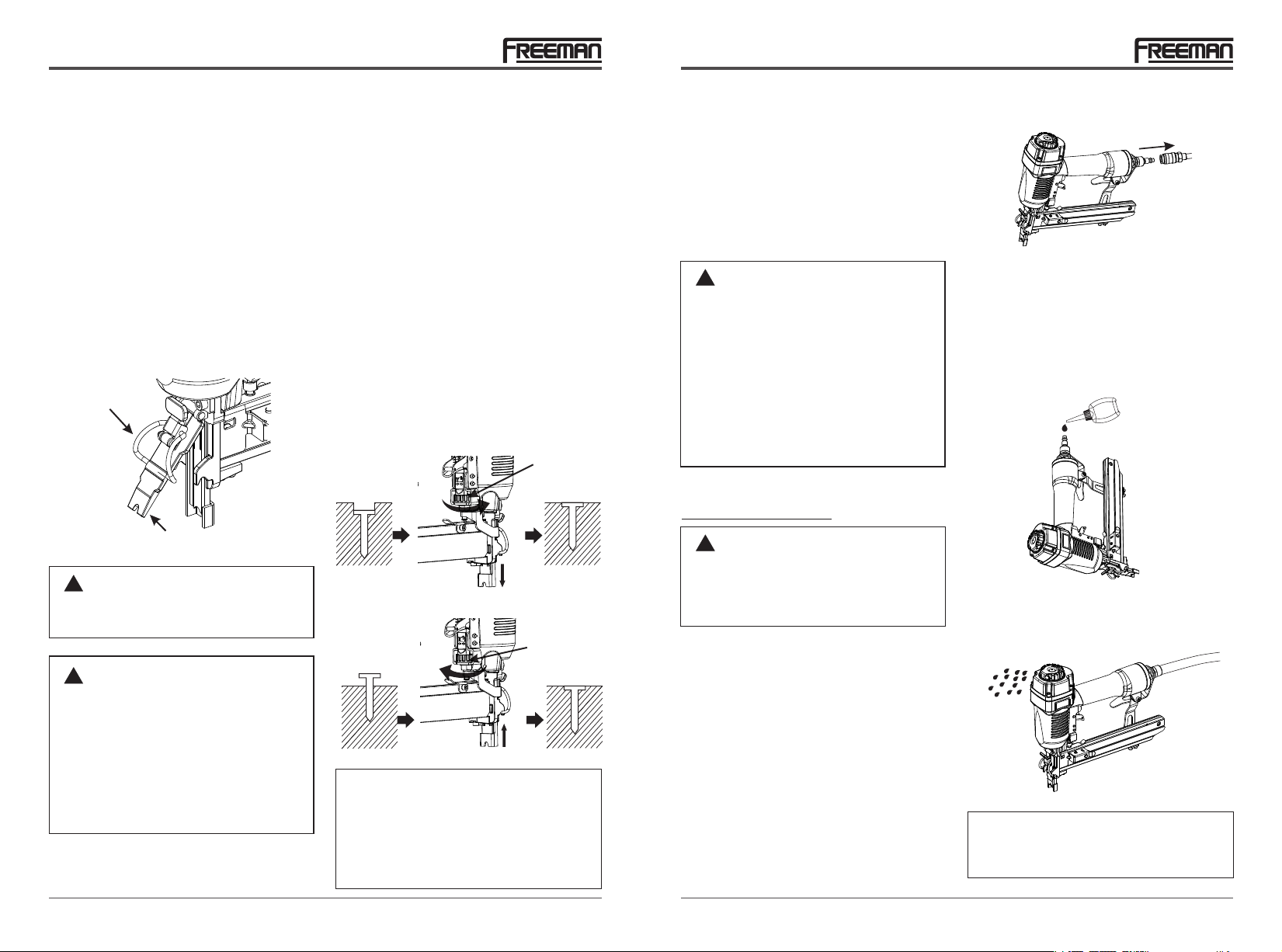

MAINTENANCE

!

WARNING:

Any time inspection, maintenance, and

cleaning are done:

◆Disconnectthetoolfromtheairsource.

◆Empty the magazine completely.

ANTI-DUST

Each tool is packed with an anti-dustcap on

the air connector.

Keep the anti-dust cap cover the air

connector when the tool is not in use.

LUBRICATION

Frequent, but not excessive, lubrication is

required for best performance. Oil for the tool

is added through the air line connection and

will lubricate the internal parts.

1.

Disconnect the tool from the air source to

add the lubricant.

2.

Turn the tool so the air inlet is facing up.

Place 2 - 3 drops of pneumatic fastening

tool oil into air inlet. Do not use detergent

oils, oil additives, or other air-tool oils as

theselubricantswillcauseaccelerated

weartothesealsandbumpersinthetool,

resultinginpoortoolperformance and

frequenttoolmaintenance.

3.

After adding oil, connect the tool to the

air source, run tool briefly. Wipe off any

excess oil from the cap exhaust.

CAUTION:

Lubricate tool only with specified

lubricants.

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

0908

MODEL: PFS16 MODEL: PFS16

CLEANING

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to

damage from various types of commercial

solvents and maybe damaged by their use.

Use clean cloths to remove dirt, dust, oil,

grease, etc.

!

WARNING:

Do not at any time let brake fluids,

gasoline, petroleum-based products,

penetration oils, ect., come in contact

with plastic parts. Chemicals can

damage, weaken or destroy plastic

which may result in serious personal

injury.

COLD WEATHER OPERATION

For cold weather operation, near and below

freezing, the moisture in the air line may

freeze and prevent tool operation. We

recommend the use of air tool lubricant or

permanent antifreeze (ethylene glycol) as a

cold weather lubricant.

CAUTION:

Do not store tools in a cold weather

environment to prevent frost or ice

formation on the tool's operating valves

and mechanisms that could cause tool

failure.

Quick

coupler

Air hose

Quick

connector

RECOMMENDED HOOKUP

1.

The air compressor must be able to

maintain a minimum of 60 psi when the

tool is being used. An inadequate air

supply can cause a loss of power and

inconsistent driving.

2.

An oiler can be used to provide oil

circulation through the tool. A filter can be

used to remove liquid and solid impurities

which can rust or gum up internal parts of

the tool.

3.

Always use air supply hoses with a

minimum working pressure rating equal to

or greater than the pressure from the

power source if a regulator fails, or 150

psi, whichever is greater. Use 3/8" air hose

for runs up to 50' and use a 3/8" quick

coupler on the air hose.

4.

Use a pre ssure re g ulato r on the

compressor, with an operating pressure of

0-125 psi. A pressure regulator is required

to control the operating pressure of the

tool between 60 and 100 psi.

CAUTION:

The air compressor must be able to

maintain a minimum of 60 psi when the

tool is being used. An inadequate air

supply can cause a loss of power and

inconsistent driving.

!

WARNING:

Do not connect with an air compressor

which can potentially exceed 200 psi. As

tool may burst, possibly causing injury.

Filter

Oiler

TROUBLESHOOTING

!

WARNING:

Stop using tool immediately if any of the following problems occur. Serious personal

injury could result. Any repairs or replacements must be done by a qualified service

person or an authorized service center.

PROBLEMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

Air leaking at the

trigger valve area.

Air leaking between

the housing and nose.

Air leaking between

the housing and cap.

Tool cannot work.

The tool has a loss

of power or can not

drive the nail enough.

Fasteners are jammed

in the tool.

!

WARNING:

Only use Freeman authorized repair parts. For questions please call 1-888-669-5672 or

visit our website at http://www.freemantools.com

O-rings in trigger valve housing are

damaged.

1.Loose screws in housing.

2.Damaged O-rings.

3.Damaged to bumper.

1.Loose screws.

2.Damaged gasket.

1.Nail jammed in the nose.

2.Low nails triggering anti-dry-fire

mechanism.

3.Dirt in nose piece.

4.Damaged or jammed magazine

prevents feeding nails.

5.Inadequate air flow.

6.Worn O-ring on piston or lack

of lubrication.

7.Damaged O-ring on trigger valve.

1.Inadequate lubrication.

2.Insufficient air supply.

3.Tool is not set up correctly.

1.Incorrect fasteners.

2.Damaged fasteners.

3.Magazine or nose screws are loose.

4.Driver is damaged.

Replace o-rings on trigger valve.

Check operation of Work Contact

Element (WCE).

1.Tighten screws.

2.Replace O-rings.

3.Replace bumper.

1.Tighten screws.

2.Replace gasket.

1.Clear the jammed nail.

2.Load more nails.

3.Clear drive channel.

4.Replace or clean magazine.

5.Verify adequate air supply.

6.Replace and lubricate o-rings.

7.Replace trigger valve kit.

1.Lubricate the tool.

2.Verify adequate air supply.

3.Adjust the DEPTH ADJUSTMENT

wheel, or remove NON-MARRING

pad.

1.Verify that fasteners are the correct

size.

2.Clean and replace fasteners.

3.Tighten screws.

4.Replace driver.

10

Quick

connector

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

Quick

coupler

Regulator

Compressor

WEARABLE PARTS

Repair parts can be ordered from our website: http://www.freemantools.com

11

MODEL: PFS16

PGP INC. PRODUCT WARRANTIES

FREEMAN Pneumatic Nail Guns Warranties

7 Year Professional Tool Warranty

The Freeman Tool limited warranty extends exclusively to the original purchaser of the Freeman

Product, begins on the date of purchase and excludes wearable parts. During the warranty period

Prime Global Products, Inc. (PGP) expressly warrants that the Freeman Product is free from defect

in materials and workmanship subject to the exceptions and limitations contained herein. PGP shall

at its option, repair, replace, or offer a full refund for a Freeman Product that has a defect in

materials or workmanship.

90 Day Wearable Parts Warranty

The Freeman wearable parts limited warranty extends exclusively to the original purchaser of the

Freeman Product and begins on the date of purchase, and includes driver blades, bumpers, O-rings,

pistons, piston rings, and gaskets. During the warranty period PGP expressly warrants that the

Freeman Product is free from defect in materials and workmanship subject to the exceptions and

limitations contained herein. PGP shall at its option, repair, replace, or offer a full refund for a

Freeman Product that has a defect in materials or workmanship.

MODELO: PFS16

A DATED SALES RECEIPT OR PROOF OF PURCHASE FROM THE ORIGINAL RETAIL PURCHASER

IS REQUIRED TO MAKE A WARRANTY CLAIM. Warranty registration is also required and can be

accomplished through On-Line Product Registration at www freemantools com, select SUPPORT, . .

select PRODUCT REGISTRATION. To make a warranty claim, the original purchaser must return the

Freeman Nail Gun, postage prepaid and insured, with proof of purchase to PGP or any of its

authorized service centers. For questions please call 1-888-669-5672. Other than the postage and

insurance requirement, no charge will be made for repairs covered by this warranty.

Warranty Exclusions

These Warranties do not apply where:

Repairs or alterations have been made, or attempted, by others, and/or the unauthorized use of

non-conforming parts or accessories.

Repairs are required due to normal wear and tear.

The Nail Gun has been abused, misused, improperly maintained or operated, including: the

failure to use clean, dry, regulated compressed air at the recommended pressure; accidents

caused by use of the Product after partial failure.Freeman

The Product is used commercially in assembly lines or production lines. The Freeman Freeman

Product is intended for use by individuals and these warranties do not extend to such

commercial uses.

NO WARRANTY, ORAL OR WRITTEN, EXPRESSED OR IMPLIED, OTHER THAN THE ABOVE

WARRANTIES IS MADE WITH REGARD TO THIS FREEMAN PRODUCT. ANY IMPLIED

WARRANTIES WILL BE LIMITED IN DURATION TO THE APPLICABLE WARRANTY PERIOD

SPECIFIED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THE ABOVE MAY NOT APPLY TO YOU. YOUR REMEDIES ARE SOLELY

AND EXCLUSIVELY AS STATED ABOVE. PGP SHALL IN NO EVENT BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR SPECIAL DAMAGES. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. IN NO EVENT, WHETHER

AS A RESULT OF A BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE) OR

OTHERWISE, SHALL PGP’S LIABILITY EXCEED THE PRICE OF THE PRODUCT WHICH HAS

GIVEN RISE TO THE CLAIM OR LIABILITY. ANY LIABILITY CONNECTED WITH THE USE OF

THIS PRODUCT SHALL TERMINATE UPON THE EXIRATION OF THE WARRANTY PERIOD

SPECIFIED ABOVE. NO EMPLOYEE OR REPRESENTATION OF PGP, OR ANY DISTRIBUTOR OR

DEALER IS AUTHORIZED TO MAKE ANY CHANGE OR MODIFICATION OF THIS WARRANTY.

These warranties give you specific legal rights. you may also have other rights which vary from state

to state.

THESE WARRANTIES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

ENGRAPADORA DE CERCADO

ENGRAPADORA DE CERCADO

ENGRAPADORA DE CERCADO

DE CALIBRE 16

DE CALIBRE 16

DE CALIBRE 16

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIME GLOBAL PRODUCTS, INC.

ADVERTENCIA:

No seguir las advertencias correctamente puede causar

LA MUERTE O LESIONES GRAVES.

GUARDA ESTE MANUAL PARA CONSULTARLO EN EL FUTURO.

12 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

NORMAS GENERALES DE SEGURIDAD

DESEMPACAR

CARACTERÍSTICAS

P15

P19

P19

OPERACIÓN

CÓMO AJUSTAR EL ESCAPE

CÓMO CARGAR LOS SUJETADORES

CÓMO DESCARGAR LOS SUJETADORES

CÓMO RETIRAR SUJETADORES ATASCADOS

CÓMO CONFIGURAR LA PRESIÓN DE AIRE

AJUSTE DE PROFUNDIDAD

CÓMO ACTIVAR LA HERRAMIENTA

MANTENIMIENTO

CONEXIÓN RECOMENDADA

SOLUCIÓN DE PROBLEMAS

PIEZAS DESGASTADAS

GARANTIAS

P20

P20

P20

P21

P21

P21

P22

P22

P24

P25

P26

P26

ADVERTENCIA:

Las advertencias y precauciones mencionadas en este manual no abarcan todas las

condiciones y situaciones posibles. Es perfectamente comprensible que no podemos fabricar

el sentido común y la precaución como partes de ningún producto, el usuario es el

responsable de obrar en consecuencia.

GUARDAR ESTE MANUAL

!

●

Guarda este manual para tener a mano las

advertencias de seguridad,precauciones,

o p e r a c i o n e s , i n s p e c c i o n e s y

mantenimiento. Guarda este manual y

elrecibo en un lugar seguro y seco para

consultarlo en el futuro.

ADVERTENCIA:

Para evitar lesiones personales graves,

no intentes usar este producto hasta

haber leído y comprendido el manual

por completo. Guarda este manual y

consúltalo con frecuencia para un

funcionamiento seguro y para instruir

a otros usuarios de esta herramienta.

SÍMBOLOS

●

Símbolos en este manual, las etiquetas, envases y en toda la información provista con esta

herramienta. Las siguientes palabras de aviso y significados tienen el objetivo de explicar los

niveles de riesgo asociados con esta herramienta.

SÍMBOLOS AVISO SIGNIFICADO

!

!

ADVERTENCIA:

PRECAUCIÓN:

PRECAUCIÓN:

NORMAS GENERALES DE

SEGURIDAD

INSTRUCCIONES EN REFERENCIA AL PELIGRO

DE INCENDIOS, CHOQUE ELECTRICO O

LESIONES PERSONALES.

!

ADVERTENCIA:

Cuando se usen herramientas, siempre

se deberán seguir precauciones

básicas, incluyendo las siguientes:

PROPOSICIÓN 65 DE CALIFORNIA

!

ADVERTENCIA:

Este producto puede exponerlos a

productos químicos incluyendo

plomo, que es conocido por el

Estado de California para causar

cáncer y defectos de nacimiento u

otros daños reproductiveos. Para

obtener más información, visite

www.P65Warnings.ca.gov.

ÁREA DE TRABAJO

Mantenga el área de trabajo limpia y bien

●

iluminada. Los ban cos de trab ajo

desordenados y las áreas oscuras aumentan

el riesgo de accidentes.

No utilice la herramienta en atmósferas en

●

las que exista riesgo de explosión, como

por ejemplo en presencia de líquidos

inflamables, gases o polvo. La herramienta

produce una chispa que podría encender

líquidos inflamables, gases o polvo.

Mantenga a los transeúntes, niños y a otras

●

personas alejadas cuando esté utilizando la

herramienta. Las distracciones podrían

resultar en el uso inapropiado y causar

lesiones.

Evite los disparos accidentales. Siempre

●

tenga precaución para evitar disparos

Indica una situación potencialmente peligrosa que, de no evitarse,

podría causar la muerte o lesiones graves.

Indica una situación potencialmente peligrosa que, de no evitarse,

podría causar la muerte o lesiones graves.

(Sin símbolo) Indica una situación que puede resultar en daños a

la propiedad.

accidentales. No a punte la herramienta hacia

usted u otra persona, aun cuando no

contenga sujetadores.

SEGURIDAD PERSONAL

No clave sobre otro clavo. Esto puede

●

causar que el clavo se desvíe y alcance a

alguien, o que la herramienta reaccione de

alguna manera y lesione a alguien.

Retire el dedo del gatillo cuando no

●

coloca sujetadores. Nunca transporte la

herramienta con el dedo en el gatillo, ya

que la herramienta puede disparar un

sujetador.

Usa siempre protección para los ojos. El

●

operador y las otras personas en el área de

trabajo deben usar siempre gafas de

seguridad con protectores laterales,

aprobadas por ANSI. La protección de los

ojos se utiliza para resguardarlos de los

fijadores y residuos que puedan saltar, los

cuales pueden causar lesiones graves en

los ojos.

Usa siempre protección auditiva cuando

●

utilices la herramienta. La exposición

prolongada a ruidos de alta intensidad

puede causar la pérdida de la audición.

Usa un equipo de seguridad. Se deben

●

usar una máscara antipolvo, calzado de

seguridad antideslizante y un casco rígido

en condiciones donde sean necesarios.

Usa una máscara protectora completa si

estás trabajando con virutas de madera o

limaduras de metales

Usa la vestimenta adecuada. No utilices

●

ropa o joyas sueltas. Recoge el cabello

largo. Mantén el cabello, la ropa y los

guantes alejados de las partes móviles. La

ropa y las joyas sueltas o el cabello largo

pueden quedar atrapados en las partes

móviles.

14-Sp 15-Sp

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

Cuando utilices una herramienta de

motor mantente alerta, observa lo que

estás haciendo y utiliza el sentido común.

No utilices la herramienta si estás cansado

o bajo el efecto de drogas, alcohol o

medicamentos.Un momento de distracción

durante la operación de la herramienta

puede causar lesiones graves.

Para evitar disparos accidentales

mantenga los dedos alejados del gatillo

cuando no accione los sujetadores,

especialmente cuando conecte la

herramienta al suministro de aire.

Mantén siempre una posición firme y el

equilibrio adecuado. Una posición firme y

el l equilibrio adecuado permiten controlar

mejor la herramienta en situaciones

inesperadas.

No la utilices sobre una escalera de tijera

o soportes inestables. Una posición

estable sobre una superficie sólida permite

un mejor control de la herramienta en

situaciones imprevistas.

Asegúrate de que la manguera esté libre

de o b s truccio n e s o trabas. L a s

mangueras atascadas o enredadas pueden

causar la pérdida del equilibrio o la

estabilidad y pueden dañarse y causar

lesiones.

No se extienda demasiado. Mantenga un

apoyo de pies y un equilibrio adecuados en

todo momento. Un apoyo de pies y

equilibrio adecuados permiten un mejor

control de la herramienta en situaciones

inesperadas.

No fije la manguera o herramienta a su

cuerpo.

Fije la manguera a la estructura para

reducir el riesgo de pérdida de equilibrio

en caso que la manguera se mueva.

Sie m pre d é por s entado q ue la

herramienta contiene sujetadores. No

apunte la herramienta hacia usted u otra

pe rsona, aun cuando no contenga

sujetadores.

Lá v e s e l as m a n o s des p u és d e

manipularlo. Este producto o su cable

eléctrico pueden contener sustancias

químicas reconocidas por el estado de

California como causantes de cáncer,

defectos congénitos y otros daños en el

aparato reproductivo.

USO Y CUIDADO DE LA HERRAMIENTA

Infórmate sobre la herramienta. Lee el

manual con cuidado, aprende sobre sus

aplicaciones y limitaciones, como también

sobre los riesgos específicos y potenciales

relacionados con la herramienta.

U s a ú n i c a m e n te l o s f i j a d o r e s

recomendados para el modelo. No uses

los fijadores incorrectos ni los cargues de

forma inadecuada.

Comprueba que las piezas móviles no

estén desalineadas ni bloqueadas, que

no haya piezas dañadas o cualquier otra

cond i ción q u e pueda a f ectar e l

funcionamiento de la herramienta. Si está

dañada, repara la herramienta antes de

utilizarla. Muchos accidentes se deben al

ma n te ni mi en to i nco r r e ct o d e la

herramienta.

Cuida la herramienta para mantenerla en

buenas condiciones. Mantén limpia la

herramienta. Una herramienta con el

mantenimiento adecuado corre menos

riesgo de bloquearse y es más fácil de

controlar.

Guarda las herramientas fuera del

alcance de los niños y otras personas que

no sepan co m o u t i l i z a r las. L a s

herramientas son peligrosas en manos de

usuarios que no saben como utilizarlas.

Comprueba el funcionamiento de la

herramienta antes de usarla. No uses la

herramienta si el mecanismo de contacto

de la pieza de trabajo no funciona

correctamente para evitar disparar los

fijadores accidentalmente.

No utilice la herramienta si el gatillo no se

acciona correctamente. Toda herramienta

que no pueda controlarse con el gatillo es

peligrosa y debe repararse.

No fuerces la herramienta. Utiliza la

herramienta correcta según la aplicación.

La herramienta correcta realizará el trabajo

mejor y con más seguridad a la velocidad

para la cual está diseñada.

Usa abrazaderas u otra forma práctica

para asegurar y sujetar la pieza de

trabajo a una plataforma estable.

Sostener la herramienta con la mano o

apoyarla contra el cuerpo no ofrece la

estabilidad adecuada y puede causar

pérdida de control.

Mantén la herramienta y el mango secos,

limpios y libres de aceite o grasa. Usa

siempre un paño limpio para la limpieza.

Nunca uses líquido de freno, gasolina,

productos a base de petróleo ni solventes

para limpiar la herramienta.

No utilices la herramienta como martillo.

No utilices esta herramienta de tal

manera que los fijadores se dirijan hacia

cualquier otra cosa que no sea la pieza

de trabajo.

Nunca utilice gasolina ni ningún otro

líquido inflamable para limpiar la

herramienta. Nunca utilice la herramienta

en pre senc ia d e lí quid os o gas es

infl a mables. Lo s vapo res p o d rían

encenderse por una chispa y causar una

explosión que podría provocar lesiones

personales graves o la muerte.

No retire, fuerce ni haga que el gatillo o el

seguro del mismo queden inutilizables.

No haga funcionar ninguna herramienta

que se haya modificado de dicha manera,

en caso contrario podrían ocurrir lesiones

personales graves o la muerte.

No apriete el gatillo a menos que coloque

sujetadores. Nunca fije el conducto de aire

comprimido ni cargue la herramienta

mientras aprieta el gatillo. La herramienta

podría lanzar un sujetador y provocar

lesiones personales graves o la muerte.

Siempre coloque el seguro del gatillo en la

posición de seguridad cuando no use la

herramienta.

Siempre fije la manguera con un

conector o acoplador de manguera sobre

o cerca de la herramienta, de forma tal

que todo el aire comprimido en la

herramienta se descargue al momento

en que el conector o el acoplador de la

manguera estén desconectados. No

utilice una válvula de control ni ningún otro

con ector que per mita que el a i re

permanezca en la herramienta, en caso

contrar io p odrí an o curr ir l esio nes

personales graves o la muerte.

Nunca coloque las manos ni otra parte

del cuerpo en el área de descarga de

sujetadores de la herramienta. La

herramienta podría lanzar un sujetador y

provocar lesiones personales graves o la

muerte.

Nunca transporte la herramienta de la

manguera de aire comprimido ni jale la

manguera para mover la herramienta o

un compresor. Mantenga las mangueras

alejadas del calor, el aceite y los bordes

filosos. Reemplace las mangueras dañadas

o desgastadas, en caso contrario podrían

ocurrir lesiones personales o daños en la

herramienta.

Sie m pre d é por s entado q ue la

herramienta contiene sujetadores.

Considere la herrami enta como un

implemento de trabajo y no juegue con ella.

Siempre mantenga a las demás personas

a una distancia segura del lugar de

trabajo, en caso se produzcan descargas

accidentales de sujetadores. No Apunte la

herramienta hacia usted u otra persona,

aun cuando no contenga sujetadores. La

activación accidental de la herramienta

podría provocar lesiones personales graves

o la muerte.

No deje caer ni lance la herramienta.Ya

que esto podría ocasionar daños en la

herramienta y causar que la misma ya no

sea utilizable o segura. Si la herramienta ha

sufrido caídas o ha sido lanzada, examínela

atentamente y revise si hay piezas

dobladas, rajadas o rotas y si hay fuga de

aire comprimido. NO PROSIGA y repárela

antes de usarla, en caso contrario podrían

ocurrir lesiones graves.

Evite usar la herramienta cuando el

cargador está vacío. Ya que esto puede

prod ucir des gaste acelera do en la

herramienta.

Limpie y revise todas las mangueras y

conectores de suministro de aire

comprimido antes de conectar la

herramienta a un suministro de aire

comprimido. Reemplace las mangueras y

conectores dañados o desgastados, de lo

contrario el rendimiento o la durabilidad de

la herramienta podrían verse reducidos.

No utilices la herramienta si pierde aire o

no funciona correctamente.

No utilices la herramienta si no tiene una

etiqueta de advertencia legible.

Siempre sujeta la herramienta por el

mango. Nunca la sujetes por la manguera

de aire.

REPARACIÓN DE LA HERRAMIENTA

Usa únicamente accesorios identificados

●

por el fabricante para ese modelo

específico de herramienta.

La utilización de piezas no autorizadas o

●

el incumplimiento de las instrucciones de

mantenimiento pueden aumentar el

riesgo de lesiones.

Usa únicamente los lubricantes provistos

●

con la herramienta o especificados por el

fabricante.

La reparación de la herramienta debe ser

●

realizada únicamente por personal

calificado.

16-Sp 17-Sp

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

FUNCIONAMIENTO

No coloques fijadores cerca del borde del

●

material. La pieza de trabajo puede

partirse y hacer que el fijador rebote y te

dañe a ti o a las personas alrededor.

No traslade la herramienta de un lugar a

otro presionando el gatillo. Esto podría

provocar una descarga accidental. La

opción del método de disparos es

importante. Verifique el manual para las

opciones de disparo.

Durante el uso normal la herramienta se

rebobinará de inmediato luego de

accionar un sujetador. Esta es una función

normal de la herramienta. No intente evitar

la rebobinación sosteniendo la herramienta

en contr a de l fun c ionam iento . La

restricción para rebobinar puede provocar

que se accione un segundo sujetador

desde la herramienta. Sujete la manija

firmemente y permita que la herramienta

re alic e el tra bajo . No se guir est a

advertencia puede provocar graves

lesiones personales.

No coloques fijadores sobre otros

fijadores o con la herramienta a un

ángulo demasiado inclinado ya que esto

puede causar el desvío de los fijadores y

provocar lesiones.

No uses la herramienta a menos que

pretendas colocar un fijador en la pieza

de trabajo.

Opera siempre la herramienta con

cuidado:

Re s pe ta l a he r r ami e n ta c o m o

implemento de trabajo.

Nunca la uses en bromas y juegos.

Nunca jale el gatillo a menos que la

punta esté orientada directamente hacia

el trabajo.

Mantén a los demás a una distancia

segura de la herramienta ya que puede

acc i onarse acc i dental m ente, y

posiblemente causar lesiones.

ENTRADA DE AIRE Y CONEXIONES

El conector de la herramienta no debe

●

estar bajo presión al desconectar la

entrada de aire. Si se utiliza un acoplador

incorrecto, la herramienta puede quedar

cargada de aire luego de la desconexión y

podría disparar fijadores incluso con la

línea de aire desconectada y ello puede

causar lesiones.

No utilice ningún tipo de gases reactivos,

●

lo que incluye pero no se limita al oxígeno

o agases combustibles, como fuente de

alimentación. Use únicamente aire

comprimido filtrado, lubricado y regulado.

El uso de gas reactivo en lugar de aire

co m p r im i do pued e hace r que la

herramienta explote, lo cual produciría

lesiones personales Graves o la muerte.

Use únicamente una fuente de aire

comprimido de presión regulada para

limitar la presión de aire suministrada a la

herramienta. La presión regulada no debe

superar los 6,89 bar. Si el regulador falla, la

presión enviada a la herramienta no debe

superar los 13,79 bar, de lo contrario la

herramienta podría explotar y causar

lesiones personales graves o la muerte.

Desconecta siempre la fuente de aire:

Antes de descargar o realizar ajustes.

Al realizar el mantenimiento de la

herramienta.

Al desatascarla.

Al tocar la horquilla de seguridad.

Cuando la herramienta no está en uso.

Al desplazarse a otra área de trabajo.

Dichas medidas de precaución reducirán el

riesgo de lesiones a personas.

CARGAR LA HERRAMIENTA

No cargues la herramienta con fijadores

●

si alguno de los controles operativos está

activado.

Nunca coloques la mano ni ninguna otra

●

parte del cuerpo en el área de descarga

de los fijadores.

Nunca apuntes la herramienta hacia las

●

personas.

No jale el gatillo ni presione la pieza de

●

trabajo en contacto ya que se podría

a c c i o na r a c c i d en ta lm en te y

posiblemente causar lesiones.

!

ADVERTENCIA:

Las advertencias y precauciones

mencionadas anteriormente no abarcan

todas las condiciones y situaciones

p o s i bl e s . E s p e rf e ct a m en t e

comprensible que no podemos fabricar

el sentido común y la precaución como

partes de ningún producto, el usuario

es e l res pons able d e obra r en

consecuencia.

DESEMPACAR

Es ta h erra mien ta s e ha envi ado

●

completamente ensamblada.

Retira cuidadosamente la herramienta y

●

los accesorios de la caja.

I n s p e c c i o n a l a h e r r a m i e n t a

●

cuidadosamente para asegurarte de que

no haya ocurrido ninguna rotura ni daño

durante el envío.

No deseches el material de empaque

●

hasta qu e h a y as inspeccio n a d o

c u i d a d o s a m e n t e y u t i l i z a d o

satisfactoriamente la herramienta.

●

Si alguna pieza está dañada o falta, llama

al 1-888-669-5672.

!

ADVERTENCIA:

Si falta alguna pieza, no utilices esta

herramienta hasta reemplazarla. De no

seguir esta advertencia, pueden

producirse lesiones graves.

!

ADVERTENCIA:

No intentes modificar esta herramienta

o c o n s t r u i r a c c e s o r i o s n o

recomendados para la misma. Tales

mod ific acio nes o camb ios s on

considerados un mal uso y pueden

resultar en condiciones peligrosas que

a su vez pueden posiblemente causar

lesiones.

CARACTERÍSTICAS

ESPECIFICACIONES

CONSUMO DE AIRE: 6,35 SCFM con 100

sujetadores por minuto a 6,20 bar

ENTRADA DE AIRE: NPT DE 1/4’’

CAPACIDAD DEL CARGADOR:

100 sujetadores de calibre 16

PESO DE LA HERRAMIENTA: 1,97 kgs

PRESIÓN MÁXIMA: 6,89 bar

RANGO DE PRESIÓN: 4,14-6,89 bar

RANGO EN LARGO DE SUJETADORES::

18mm (3/4”) a 25mm (1”)

3/4”

6/7”

1”

(Ca libre 1 6)

Compatible con genérico marca de grapas de

cercado calibre 16 .

CARACTERÍSTICAS

ESCAPE AJUSTABLE EN 360 GRADOS

Permite al usuario controlar el aire lejos de

los cara.

HOJA DE UNA PIEZA

Para mayor durabilidad.

CARGADOR Y CILINDRO DE ALUMINIO

ANODIZADO

Para una mayor durabilidad.

CÓMODA MANIJA DE AGARRE

Para mayor comodidad y control.

ESTRUCTURA DE DISEÑO ERGONÓMICO

Resistente y cómoda, que resulta en una

herramienta liviana ideal para un uso

prolongado.

PROFUNDIDAD AJUSTABLE

La profundidad se ajusta fácilmente para

varias aplicaciones.

LIBERACIÓN RÁPIDA DE ATASCOS

Permite un fácil acceso a la eliminación en

el caso de un atasco.

18mm

22mm

25mm

18-Sp 19-Sp

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

OPERACIÓN

CÓMO AJUSTAR EL ESCAPE

El escape ajustable en la cubierta de la

herramienta permite a los usuarios controlar

los escapes de acuerdo a las preferencias del

operador. Para ajustar la dirección, gire la

cubierta del tubo de escape a la dirección

deseada.

CÓMO CARGAR LOS SUJETADORES

Conecte la herramienta a la fuente de aire.

1.

Tire del Empujador hacia atrás hasta que el

Clavija de Empujador puesto en la Dejar de

Agujero.

2.

Insertar tiras de clavos adecuados desde la

cima de la revista.

3.

Tire de la Manija de Empujador para

conseguir el Clavija de Empujador liberado

de la parada del agujero para que el

4.

Empujador volver a mover los sujetadores

hasta el mecanismo de accionamiento. El

empujador se detendrá cuando se apoya

contra el extremo del elemento de fijación.

Dejar de

Agujero

Manija de

Empujador

Tire hacia atrás

Clavija de Empujador

Empujador

e

HALAR

Dejar de

Agujero

Manija de

Empujador

E

mpu

Grapas

c

r ha

a

j

lant

ade

a

i

!

ADVERTENCIA:

La herramienta puede dispararse al ser

conectada por primera vez a la fuente de

aire. Conecta siempre la herramienta a

la fuente de aire antes de cargar los

fijadores para evitar lesiones causadas

por ciclos accidentales. Asegúrate

siempre de que el cargador de la

herramienta esté vacío al comienzo de

cada sesión de trabajo, antes de

conectarla a una fuente de aire.

!

ADVERTENCIA:

Use s olame nte l os suje tador es

recomendados para esta herramienta.

Los sujetadores no identificados por el

fabricante de la herramienta para usarse

con la misma pueden causar lesiones a

las personas o daños en la herramienta

cuando se usan con ella.

!

ADVERTENCIA:

Mantenga la herramienta en dirección

opuesta a usted y otras personas al

cargar los sujetadores. No hacerlo

podría provocar lesiones personales

graves.

!

ADVERTENCIA:

Nunca cargue el sujetador con la pieza

de trabajo en contacto o el gatillo

activado. Esto podría provocar lesiones

personales graves.

CÓMO DESCARGAR LOS SUJETADORES

La descarga es lo opuesto a la carga,

(Excepción) siempre desconecte la fuente de

aire antes de realizar la descarga.

!

ADVERTENCIA:

Si e m p r e d e s c a rg u e tod o s lo s

su jeta dores a nte s de retirar la

herramienta del servicio.

!

ADVERTENCIA:

Conecta siempre la herramienta a la

fuente de aire antes de cargar los

fijadores para evitar lesiones causadas

por ciclos accidentales.

CÓMO RETIRAR SUJETADORES

ATASCADOS

En ocasiones, un sujetador puede atascarse

en el mecanismo de disparo, dejando la

herramienta inoperante. Para retirar el

sujetador atascado, siga los siguientes pasos:

Desconecta la herramienta de la fuente de

1.

aire.

Retire los sujetadores de la herramienta. No

2.

hacerlo podría p r o v o c a r que l os

sujetadores se expulsen desde la parte

frontal de la herramienta.

Jale el Pestillo hacia arriba y abra la

3.

Cubierta de la nariz.

Tenga cuidado de no doblar o dañar la hoja,

4.

si e s nec e s a r i o us e pinz a s o u n

destornillador para limpiar el sujetador

atascado.

Cierre la liberación de atascos y el pestillo.

5.

Después reconecta la fuente de aire a la

6.

herramienta.

Vuelve a cargar la herramienta con

7.

fijadores.

Pestillo

Cubierta de la nariz

!

ADVERTENCIA:

Asegúrese de que no haya sujetadores

en el cargador antes de retirar un

sujetador atascado.

!

ADVERTENCIA:

Desconecte la herramienta de la fuente

de aire cada vez que retire un sujetador

atascado. Luego de desconectar la

herramienta del compresor de aire,

debería haber suficiente presión de aire

para disparar. Luego de desconectar la

manguera de aire, siempre dispare la

herramienta varias veces sobre un trozo

de made ra q ue no u tili ce para

asegurarse de que se expenda todo el

aire comprimido.

CÓMO CONFIGURAR LA

PRESIÓN DE AIRE

La cantidad de presión de aire requerida

depende del tamaño de los fijadores y del

material de la pieza de trabajo.

Comienza por comprobar la profundidad de

clavado disparando un clavo de prueba hacia

una pieza de trabajo del mismo material

utilizado para el trabajo real.

Dispara un fijador de prueba con la presión de

aire configurada a 6,20-6,55 bar. Aumenta o

reduce la presión de aire para hallar la

configuración más baja posible para realizar el

trabajo con resultados uniformes.

Es posible que se pueda lograr la profundidad

deseada ajustando únicamente la presión de

aire.

AJUSTE DE PROFUNDIDAD

La profundidad de disparo de los sujetadores

es ajustable. Para ajustar la profundidad, utilice

la rueda de ajuste de profundidad de disparo (F)

en la herramienta.

1.

Desconecta la herramienta de la fuente de

aire.

Gire la rueda de profundidad hacia la

2.

izquierda o hacia la derecha para cambiar

la profundidad de disparo.

3.

Después reconecta la fuente de aire a la

herramienta.

Dispare un clavo de prueba luego de

4.

realizar cada ajuste hasta establecer la

profundidad deseada.

20-Sp 21-Sp

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

Desconecta la herramienta de la fuente de

Rueda de

Demasiado

profundo

Gire el pomo de ajuste en contrario al de las agujas del

reloj

Demasiado

poco profundo

Gire el pomo de ajuste en el sentido de las agujas del reloj

ajuste (H)

Al ras

Rueda de

ajuste (H)

Al ras

PRECAUCIÓN:

Se recomienda probar la profundidad en

una pieza de trabajo de desecho para

determinar la profundidad requerida

para la aplicación. Para determinar la

profundidad de disparo, primero ajuste

la presión de aire y dispare un sujetador

de prueba. Nunca supere los 6,89 bar.

CÓMO ACTIVAR LA HERRAMIENTA

( MODO DE ACCIÓN SECUENCIAL SIMPLE)

La herramienta está diseñada especialmente

para el modo secuencial simple. Este modo

requiere que se jale el gatillo cada vez que se

dispara un sujetador. Se puede accionar la

herramienta presionando el elemento de

contacto de trabajo contra la superficie de

trabajo seguido de la presión del gatillo.

Se debe liberar el gatillo para reiniciar la

herramienta antes de que se dispare otro

sujetador.

!

ADVERTENCIA:

Durante el uso normal la herramienta se

rebobinará de inmediato luego de

accionar un sujetador. Esta es una

función normal de la herramienta. No

i n t en te ev i ta r l a r e bob i n ac ión

sosteniendo la herramienta en contra del

funcionamiento. La restricción para

rebobinar puede provocar que se

accione un segundo sujetador desde la

herramienta. Sujete la manija firmemente

y permita que la herramienta realice el

trabajo. No seguir esta advertencia

pue de p rovo c ar grave s le s iones

personales.

MANTENIMIENTO

!

ADVERTENCIA:

A n t e s d e i n s p e c c i o n a r, d a r

mantenimiento y limpiar:

◆Desconecta la herramienta de la fuente

de aire.

◆Vacía el cargador por completo.

FUNCIÓN ANTIPOLVO

Todas las herramientas vienen con un tapón

antipolvo en el conector de aire; verifícalo si lo

tienes después de desempacar la herramienta.

Mantén el tapón antipolvo para cubrir el

conector de aire.

LUBRICACIÓN

Frecuente, pero la lubricación es necesaria

para un mejor rendimiento luego de periodos

de uso prolongados. Si se agrega aceite a la

herramienta a través de la conexión de la línea

de aire se lubricarán las piezas internas.

1.

aire, a agre g u e lubricantes para

herramientas.

2. Gire la herramienta de forma tal que la

entrada de aire dé hacia arriba. Coloque 2 a

3 gotas d eac eite neumá tico de la

herramienta de la cerradura en la entrada

de aire. No utilices aceite detergente ni

aditivos puesto que estos Lubricantes

causarán el desgaste acelerado de los

sellos y amortiguadores de la herramienta,

lo que resultará en el mal funcionamiento

de la misma y elevará la frecuencia del

mantenimiento.

3.

Después de agregar el aceite, haga

funcionar la herramienta por un breve

periodo. Limpie el exceso de aceite de la

salida de la cubierta.

PRECAUCIÓN:

Lubrica la herramienta únicamente con

los lubricantes especificados.

LIMPIEZA

Evita el uso de solventes para limpiar las piezas

plásticas.

La mayoría de los plásticos pueden dañarse

con facilidad al usar varios tipos de solventes

comerciales. Usa paños limpios para limpiar la

suciedad, polvo, grasa, etc.

!

ADVERTENCIA:

En ningún momento dejes que líquidos

para freno, gasolina, productos a base de

petróleo, aceites penetrantes, etc. entren

en contacto con las piezas plásticas.

Estos químicos pueden dañar, debilitar o

destruir el plástico, lo que puede provocar

lesiones graves.

OPERACIÓN EN CLIMAS FRÍOS

En caso de operación en climas fríos, cerca o

debajo del punto de congelamiento, la

humedad en la línea de aire puede congelarse

evitando el funcionamiento de la herramienta.

Recomendamos usar lubricantes para

herramientas neumáticas o un anticongelante

permanente (glicol de etileno) como lubricante

para climas fríos.

PRECAUCIÓN:

No almacenes la herramienta en un

ambiente de clima frío para evitar la

formación de escarcha o hielo sobre las

válvulas y mecanismos operativos de la

herramienta, pues la misma podría

dejar de funcionar.

22-Sp 23-Sp

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

CONEXIÓN RECOMENDADA

El compresor de aire debe ser capaz de

1.

mantener un mínimo de 4,14 bar mientras

la herramienta está en uso. Un suministro

inadecuado de aire puede causar una

pérdida de potencia y un clavado desigual.

.2

Se puede usar un lubricador para

proporcionar circulación de aceite en toda

la herramienta. Se puede usar un filtro

para retirar las impurezas líquidas y

sólidas, las que pueden oxidar piezas

internas de la herramienta o hacer que

éstas se apelmacen.

3.

Siempre u s e mangueras d e a i re

comprimido con una clasificación de

presión de trabajo igual o superior a la

presión de la fuente de alimentación en

caso que el regulador falle, o de bar, 10,34

el que sea mayor. Use mangueras de aire

co mprimido de 3/8” para (9 ,5mm)

distancias de hasta 15,24 m y use un

acoplador de conexión rápida de 3/8”

(9,5 m m ) e n l a man g u era d e a i re

comprimido.

4.

Use un regulador de presión en el

compresor con una presión de trabajo de

0 a 8,62 bar. Se necesita un regulador de

presión que controle la presión de trabajo

de la herramienta entre 4,14 bar y 6,89

bar.

PRECAUCIÓN:

El compresor de aire debe ser capaz de

mantener un mínimo de bar 4,14

mientras la herramienta está en uso. Un

suministro inadecuado de aire puede

causar una pérdida de potencia y un

clavado desigual.

!

ADVERTENCIA:

No conectes la herramienta a un

compresor de aire que pueda exceder

las 13,79 bar, La herramienta podría

explotar y posiblemente provocar

lesiones.

SOLUCIÓN DE PROBLEMAS

!

ADVERTENCIA:

Deje de utilizar inmediatamente la herramienta si se presenta alguno de los problemas

descritos a continuación, de lo contrario podrían ocurrir lesiones personales graves.

Cualquier reparación o reemplazo debe llevarse a cabo por un técnico calificado o un

centro de servicio autorizado.

PROBLEMA CAUSA POSIBLE ACCIONES CORRECTIVAS

Fuga de aire en el

de la válvula del gatillo.

Fuga de aire entre

el armazón y el borde.

Fuga de aire entre el

armazón y la cubierta.

La herramienta no

puede funcionar.

Las juntas tóricas en el armazón de la

válvula del gatillo están dañadas.

1. Hay tornillos flojos en el armazón.

2. Juntas tóricas dañadas.

3. Protector dañado.

1. Tornillos sueltos.

2. Empaquetadura dañada.

1. Nail atascado en la nariz.

2. Bajo las uñas desencadenando

anti-fuego seco mecanismo.

3. La suciedad en la pieza de la nariz.

4. Revista dañada o atascada evita

alimentar las uñas.

5. Flujo de aire inadecuado.

6. Desgaste de la junta tórica en el

pistón o falta de lubricación.

7. Junta tórica dañada en la válvula

de gatillo.

Cambie las juntas tóricas.

1. Apriete los tornillos.

2. Cambie las juntas tóricas.

3. Cambie el protector.

1.Apriete los tornillos.

2. Cambie la empaquetadura.

1. Borrar el clavo atascado.

2. Cargue más clavos.

3. Canal de accionamiento claro.

4. Reemplace o limpie la revista.

5. Verifique el suministro de aire

adecuado.

6. Cambie y lubrique las juntas

tóricas.

7. Reemplace el kit de la válvula

de gatillo.

Acople

rápido

Conector rápido

Manguera

de aire

Conector

rápido

Acople

rápido

Lubricador

Regulador

Filtro

Compresor

La herramienta pierde

velocidad o potencia.

Los sujetadores se

atascan en la

herramienta.

!

ADVERTENCIA:

Use sólo piezas de repuesto autorizadas por Freeman. Si tiene preguntas llame al 1-888-669-

1. lubricación inadecuada.

2. Suministro de aire insuficiente.

3. La herramienta no está configurada

correctamente.

1. sujetadores incorrectos.

2. sujetadores dañados.

3. Los tornillos de la revista o nariz

están sueltos.

4. El conductor está dañado.

5672 o visite nuestro sitio Web en http://www.freemantools.com

1. Lubricar la herramienta.

2. Verificar el suministro de aire

adecuado.

3. Ajuste el AJUSTE DE

PROFUNDIDAD rueda, o quita

NON-MARRING almohadilla.

1. Verifique que los sujetadores

tengan el tamaño correcto.

2. Limpie y reemplace los sujetadores.

3. Apretar los tornillos.

4. Reemplace el controlador.

24-Sp 25-SpHTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODEL: PFS16 MODEL: PFS16

PIEZAS DESGASTADAS

Puede pedir piezas de repuesto en nuestro sitio Web: http://www.freemantools.com

GARANTÍAS DE LOS PRODUCTOS PGP INC.

Garantía de pistola neumática para clavos Freeman

Garantía de 7 años para herramientas profesionales

la garantía limitada para herramientas Freeman se extiende en forma exclusiva al comprador

original del producto Freeman, comienza en la fecha de compra y excluye todas las piezas de

desgaste. Durante el período de garantía Prima Global Products, Inc. (PGP) garantiza expresamente

que el producto Freeman está libre de defectos de material y mano de obra con sujeción a las

excepciones y limitaciones contenidas en el presente. A su elección, PGP reparará, remplazará u

ofrecerá un reembolso completo por un producto Freeman que tenga un defecto de material o

mano de obra.

Garantía de 90 días para piezas de desgaste

la garantía limitada para piezas de desgaste se extiende en forma exclusiva al comprador original

del producto Freeman, comienza en la fecha de compra e incluye las hojas guías, los protectores,

juntas tóricas, pistones, aros de pistón y empaquetaduras. Durante el período de garantía PGP

expresamente garantiza que el producto Freeman está libre de defectos de material y mano de

obra con sujeción a las excepciones y limitaciones contenidas en el presente. A su elección, PGP

reparará, remplazará u ofrecerá una reembolso completo por un producto Freeman que tenga un

defecto de material o mano de obra.

PARA HACER UN RECLAMO DE GARANTÍA SE REQUIERE EL ORIGINAL DEL RECIBO O PRUEBA

DE COMPRA QUE EMITIÓ EL VENDEDOR DONDE SE INDIQUE LA FECHA DE COMPRA. También

se necesita registrar la garantía lo que se podrá hacer a través del proceso de registro de producto

en línea en www freemantools com, seleccione SOPORTE, luego REGISTRO DE PRODUCTO. . .

Para hacer un reclamo de garantía, el comprador original deberá enviar a PGP o a uno de sus

centros de servicios autorizados la Pistola para Clavos Freeman, franqueo postal prepagado y

garantizado, incluyendo la prueba de compra. Para cualquier consulta llame al 1-888-669-5672. No

se hará cobro alguno por las reparaciones que estén cubiertas por la presente garantía, con

excepción del costo del franqueo postal y los requisitos de seguro.

EN LA PRESENTE GARANTÍA NO SE DA NINGUNA OTRA GARANTÍA, ORAL O ESCRITA,

EXPRESA O IMPLÍCITA, QUE NO SEA LA QUE SE INDICA LÍNEAS ARRIBA EN RELACIÓN A

ESTE PRODUCTO FREEMAN. TODA GARANTÍA IMPLÍCITA TENDRÁ UNA DURACIÓN

LIMITADA AL PERÍODO DE GARANTÍA APLICABLE QUE SE MENCIONA AQUÍ. ALGUNOS

ESTADOS NO PERMITEN LIMITACIONES SOBRE CUÁNTO TIEMPO DURA UNA GARANTÍA

IMPLÍCITA, POR LO QUE LO AQUÍ CONSIGNADO PODRÍA NO APLICARSE A SU CASO. SUS

RECURSOS LEGALES SE LIMITAN ÚNICA Y EXCLUSIVAMENTE A LO AQUÍ CONSIGNADO.

EN NINGÚN CASO PGP SERÁ RESPONSABLE POR DAÑOS INDIRECTOS, FORTUITOS O

CUANTIFICABLES, POR LO QUE LA LIMITACIÓN O EXCLUSIÓN AQUÍ CONTENIDA PUEDE

NO APLICARSE A SU CASO. EN NINGÚN CASO, SEA COMO RESULTADO DE UN

INCUMPLIMIENTO DE CONTRATO, DE GARANTÍA, AGRAVIO (INCLUYENDO NEGLIGENCIA) U

OTRO, LA RESPONSABILIDAD DE PGP EXCEDERÁ EL PRECIO DEL PRODUCTO QUE DIO

ORIGEN AL RECLAMO DE GARANTÍA O A LA RESPONSABILIDAD. TODA OBLIGACIÓN

RELACIONADA CON EL USO DE ESTE PRODUCTO TERMINARÁ AL VENCIMIENTO DEL

PERÍODO DE GARANTÍA AQUÍ ESPECIFICADO. NINGÚN EMPLEADO O REPRESENTANTE DE

PGP, O CUALQUIER OTRO AGENTE O DISTRIBUIDOR, ESTÁ AUTORIZADO A REALIZAR

CAMBIOS O MODIFICACIONES A ESTA GARANTÍA.

La presente garantía le da al comprador derechos legales específicos. El comprador podría tener

otros derechos que varían de un estado a otro.

ESTAS GARANTíAS ESTÁN SUJETAS A CAMBIO SIN PREVIO AVISO.

Exclusiones de la garantía

Esta garantía no se aplicará en ninguno de los siguientes casos:

Cuando se hayan hecho, o intentado hacer, reparaciones o modificaciones por otros o cuando

se haya usado sin autorización piezas o accesorios no conformes.

Cuando se requiera hacer reparaciones debido al desgaste lógico y normal.

Cuando se haya usado inadecuadamente la pistola para clavos o no se haya operado en forma

apropiada o no se le haya dado el mantenimiento que correspondía, incluyendo: no usar aire

comprimido regulado, seco y limpio a la presión recomendada; accidentes provocados por uso

del producto después de una falla parcial.Freeman

El producto se usa comercialmente en líneas de ensamblaje o de producción. El Freeman

producto está diseñado para ser usado por personas particulares y es por eso que Freeman

esta garantía no se extiende a usos comerciales.

26-Sp 27-SpHTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

MODÈLE: PFS16

MODÈLE: PFS16

CL TURE AGRAFEUSE

Ô

CL TURE AGRAFEUSE

Ô

CL TURE AGRAFEUSE Ô