Freeman PE20V2118G User Manual

MODEL: PE20V2118G

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIME GLOBAL PRODUCTS, INC.

WARNING:

Failure to follow warnings could result in DEATH OR SERIOUS INJURY.

PE2118G-V2 08/18

MODEL: PE20V2118G

MODEL: PE20V2118G

SYMBOLS

GENERAL SAFETY INSTRUCTIONS

UNPACKING

SPECIFICATIONS

FEATURES

OPERATION

USING BELT HOOK

LOADING FASTENERS

UNLOADING FASTENERS

DEPTH OF DRIVE

SETTING TOOL FIRING SETTINGS

WORK CONTACT ELEMENT

NO-MAR PAD

REMOVING BATTERY

CLEARING JAMS

CHARGING BATTERY

CHARGING A HOT BATTERY PACK

BATTERIES

BATTERY PACK REMOVAL AND RECYCLING

MAINTENANCE

TROUBLESHOOTING

WEARABLE PARTS

WARRANTIES

3

3 - 5

6

6

6

6 - 11

6

7

8

8

8 - 9

9

9

9

10

10

11

11

11

11

12 - 13

13

14

WARNING

The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. Please be aware of the potential hazards, and take all necessary precautions to avoid risk of injuries.

SAVE THIS MANUAL

To avoid serious personal injury, do not attempt to use this product until you read the manual

thoroughly and understand it completely. Save this manual and review frequently for safe operation

and instructing others who may use this tool. Keep this manual for the safety warnings, precautions,

operations, inspections and maintenance information. Store this manual and the receipt in a safe and

dry place for future reference.

SYMBOLS

In this manual, on the labels, packages and all other information provided with this tool, the following signal

words and meanings are intended to explain the levels of risk associated with this tool.

SYMBOLS

GENERAL SAFETY

INSTRUCTIONS

CALIFORNIA PROPOSITION 65

WARNING:

This product can expose you to chemicals including lead, which is known to

the State of California to cause cancer

and birth defects or other reproductive

harm. For more information go to

www.P65Warnings.ca.gov.

WORK AREA

Keep the work area clean and well lit. Cluttered

benches and dark areas increase the risk of

accidents.

Do not operate the tool in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. The tool could

create a spark which may ignite flammable liquids,

gases or dust.

Keep bystanders, children, and others away

while operating the tool. Distractions could result

in improper use and cause injury.

Keep proper footing and balance at all times.

Proper footing and balance enables better control

of the tool in unexpected situations.

Do not use on a ladder or unstable supports.

Stable footing on a solid surface enables better

control of the tool in unexpected situations.

PERSONAL SAFETY

Always wear eye protection. Operator and others

in the work area should always wear ANSI-Z87.1

approved safety goggles with side shields. Eye

protection is used to guard against flying debris,

which may cause severe eye injury.

SIGNAL MEANING

WARNING:

CAUTION:

CAUTION:

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

(Without symbol) Indicates a situation that may result in

property damage.

Always wear ANSI S3.19 approved hearing

protection when using the tool. Prolonged

exposure to high intensity noise may cause hearing

loss.

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

Stay alert. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating the tool may

cause serious injury.

Avoid prolonged use. The tool’s repetitive motion

and vibration can cause harm to your hands or

arms. The user can use gloves for extra cushion,

take frequent breaks and limit daily use to prevent

this issue.

This tool vibrates with use. Continuous

operation can be harmful to your hands and

arms. Stop using the tool if you feel tingling or pain.

Resume work after recovery. Seek medical advice

if serious symptoms occur.

Make sure there are no hidden electrical cables,

gas pipes, etc. while working on the work piece.

These hazards could harm the user if damaged

while using this tool.

Never place hands or any other body parts in

the fastener discharge area of the tool. The tool

might eject a fastener and could result in death

or serious personal injury.

For overhead work, wear a safety helmet.

Wash hands after handling this product or its

power cord. They may contain chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

ELECTRICAL SAFETY

The chargers power plug must match the

outlet. Never modify the plug or plug the tool into

outlets that do not match the plug.

Avoid contact with grounded elements such as

metal tables, pipes, ranges or refrigerators.

Contact with these elements can put you at risk of

electrical shock.

02

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

03

MODEL: PE20V2118G MODEL: PE20V2118G

When operating the tool keep tool away from

wet conditions. Wet tools can cause electrical

shock.

Always inspect electrical cord for damage

before and after use. A damaged cord can cause

electrical shock.

If you are operating the tool outside use a

extension cord that is rated for outdoor use.

If the user must use the tool in damp

conditions, use a ground fault circuit interrupter (GFCI).

TOOL USE AND CARE

Know this tool. Read this manual carefully, learn

its applications and limitations, as well as the

specific potential hazards related to this tool.

Only use fasteners that are recommended for

your tool model by the manufacturer. Do not use

the wrong fasteners or load them incorrectly, as this

can cause jams or damage to the tool.

When you are able to, secure work pieces to a

stable platform using clamps or other tools.

Always have a firm footing and grip on the tool

to counteract any force that may be enacted

during the operation of the tool.

Practice safe working practices and ensure all

relevant legal requirements are being followed

when using this tool.

Never point the tool at the user or others in the

work area. This could cause serious injury.

The tool should not be forced, use the correct

tool for your application. The correct tool will do

the job better and safer at the rate for which the tool

is being used.

Before making adjustments, changing

accessories, or storing the tool disconnect the

tool from the battery. This

injury from the power tool.

Remove any adjustment wrenches or keys

before activating the tool. Leaving adjustment

accessories on the moving parts on the tool will

increase the risk of injury.

Check for misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the tool’s operation. If

damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained

tools.

Maintain tool with care. A properly maintained

tool will function more smoothly and prevent

binding, making it easier to use.

Check operation of the tool before use. Do not

use the tool if the workpiece contact mechanism is

not working correctly as accidental driving of a

fastener may occur.

Never use this tool in a manner that could

cause a fastener to be directed toward anything

other than the workpiece.

will reduce the risk of

Do not remove,tamper with, or otherwise cause

the trigger to lock or trigger to become inoperable. Do not operate any tool which has been

modified in a like fashion. Death or serious personal injury could result.

Always assume the tool contains fasteners.

Respect the tool; no horseplay.

Avoid using the tool when the magazine is

empty. Accelerated wear on the tool may occur.

Store the tool away from children or untrained

persons when not in use. The tool can be

dangerous when used by untrained persons.

Do not use the tool for anything other than its

intended use.

Do not use the tool if

actuate properly. Any tool that cannot be

controlled with the trigger is dangerous and must

be repaired.

Keep the tool and its handle dry, clean and free

of oil and grease. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any strong solvents

to clean your tool.

Never use gasoline or other flammable liquids

to clean the tool. Never use the tool in the

presence of flammable liquids or gases. Vapors

could ignite by a spark and cause an explosion

which will result in death or serious injury.

Do not use the tool as a hammer.

Never press the trigger of the tool when it is not

intended to be used.

Do not drop or throw the tool. Dropping or

throwing the tool can result in damage that will

make the tool unusable or unsafe. If the tool has

been dropped or thrown, examine the tool closely

for bent, cracked or broken parts. STOP and repair

before using or serious injury could occur.

Do not operate the tool if it does not contain a

legible warning label.

the trigger does not

BATTERY AND CHARGER USE AND

CARE

Only use batteries that are recommended for

this tool by the manufacturer. Use of any other

battery may cause risk of injury or fire.

When the battery is not in use, keep it away

from metal objects that could connect one

terminal to another. If the terminals are connect-

ed the battery could cause fire or burns.

Keep the battery free of abusive situations, if a

battery is damaged it can eject battery liquid. If

you come in contact with the battery liquid flush the

contact area with water. If your eye comes in

contact with the battery liquid flush with water and

seek medical help. Battery liquid can cause

irritation or burns.

Do not store batteries in areas that can reach or

exceed 105°F (such as outside sheds or metal

buildings in the summer).

Only charge the battery with a charger recommended by the manufacturer. Use of any other

charger may cause risk of injury or fire.

Do not use chargers for anything other than

charging manufacturer recommended

batteries, otherwise electric shock could occur.

Do not expose the charger to rain or snow.

Make sure the charger’s cord is located in an

area where it will not be damaged.

Extension cords should not be used unless

absolutely necessary. Improper use of an

extension cord can result in electric shock.

Do not place an object on top of the charger.

This could block ventilation slots and cause

excessive internal heat.

Do not use the charger if it has been subjected

to a hard blow, has been dropped, or damaged

otherwise. Take the charger to an authorized

repair center.

Do not disassemble the charger. If the charger

needs to be repaired take it to an authorized repair

center.

Before cleaning the charger make sure to

unplug it from any power source. This will

reduce the risk of an electrical shock.

Never connect two chargers together.

WARNING:

Do not open the battery for any reason. If

the battery is damaged or cracked do not

insert it into the charger. Electric shock

can be caused by a damaged battery. Be

sure to dispose of all batteries at a

service center for recycling.

WARNING:

Do not burn batteries or expose them to

extreme heat. This could cause the

battery to explode.

WARNING:

Do not allow liquid to get into the

charger, electric shock could result.

WARNING:

Electrocution hazard. Do not touch or

allow conductive objects to touch the

charging terminals. Electric shock or

electrocution could occur.

TOOL SERVICE

Only use accessories that are identified by the

manufacturer for the specific tool model.

Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of

injury.

Tool service must only be performed by a

qualified repair personnel.

OPERATION

Do not drive fasteners near the edge of the

material. The workpiece may split causing the

fastener to

work area.

Do not carry the tool from place to place while

holding the trigger. Accidental discharge could

result.

During normal use the tool will recoil immediately

after driving a fastener. This is a normal function of

the tool. Do not attempt to prevent the recoil by

holding the tool against the work. Restriction to the

recoil can result in a second fastener being driven

from the tool. Grip the handle firmly and let the tool

do the work. Failure to heed this warning can result

in serious personal injury.

Do not drive fasteners on top of other fasteners or

with the tool at an overly steep angle as this may

cause deflection of fasteners which could cause

injury.

Do not actuate the tool unless you intend to drive

a fastener into the workpiece.

Always handle the tool with care:

Respect the tool as a working implement.

Never engage in horseplay.

Never pull the trigger unless nose is directed

toward the workpiece.

Keep others at a safe distance from the tool

while tool is in operation as accidental

actuation may occur, possibly causing injury.

ricochet, injuring you or people in the

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 05HTTP://WWW.FREEMANTOOLS.COM 1-888-669-567204

UNPACKING

This tool has been shipped completely assembled.

Carefully remove the tool and any accessories from

the box.

Inspect the tool carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

tool.

If any parts are damaged or missing, please call

1-888-669-5672.

WARNING:

If any parts are missing do not operate

this tool until the missing parts are

replaced. Failure to do so could result in

serious personal injury.

WARNING:

Do not attempt to modify this tool or

create accessories not recommended

for use with this tool. Any such alteration

or modification is misuse and could

result in hazardous conditions leading to

possible serious personal injury.

SPECIFICATIONS

MODEL: PE20V2118G MODEL: PE20V2118G

LED LIGHT INDICATOR

To warn user of nail jams, low battery, and empty

magazine

LED WORKING LIGHT

Helps to illuminate the working surface

EASY ACCESS NOSE

For clearing jams

DEPTH ADJUSTMENT WHEEL

To control driving depth of fastener

SELECT FIRE SWITCH

For quick selection of bump/single firing mode

BELT HOOK

LITHIUM ION BATTERY

OPERATION

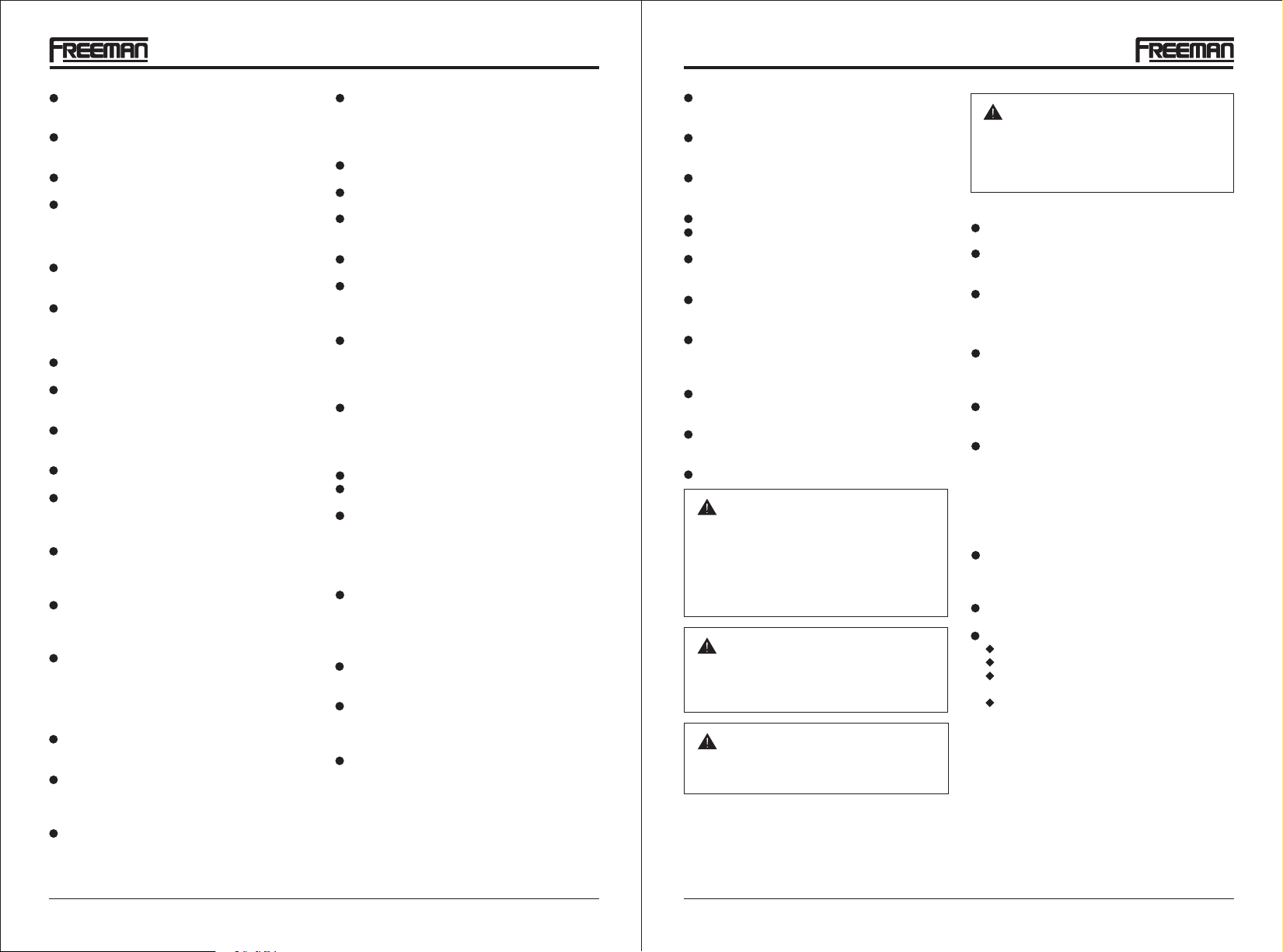

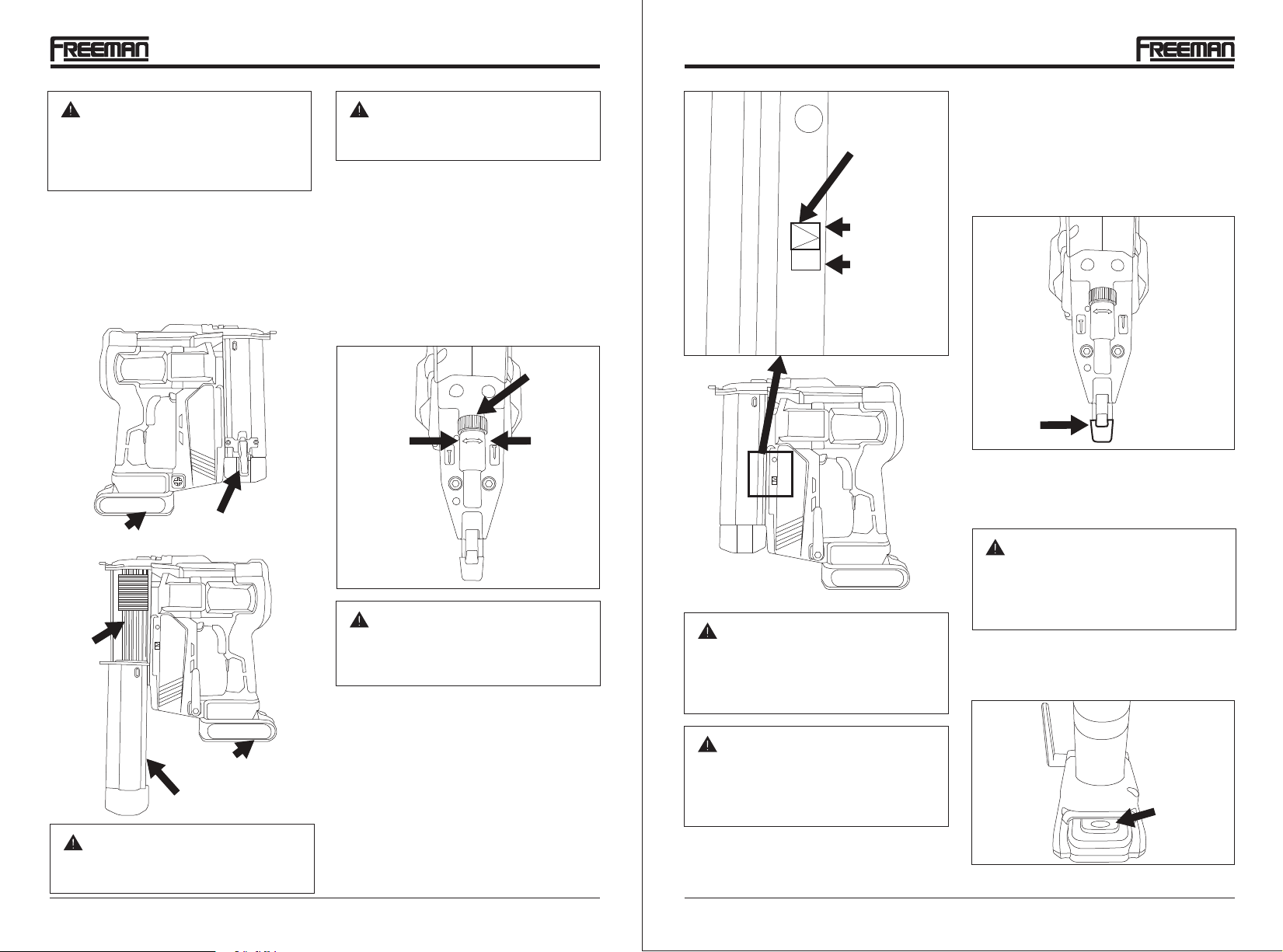

USING BELT HOOK

1.

Use a screw driver to loosen the belt hook bolt by

rotating the bolt in a counter clockwise direction.

2.

Rotate the belt hook to the desired position.

3.

Use the screw driver to tighten the belt hook bolt

and lock the belt hook into position.

LOADING FASTENERS

1.

Push down on the latch button(A). Pull back on the

magazine cover(B).

2.

Insert a stick of fasteners into the magazine rail(C).

For brad nails, the pointed ends of the fasteners

are resting on the bottom edge of the magazine

when loading.

For staples, the head of the staples are resting

on the top of the magazine.

3.

Push the magazine cover(B) forward until the latch

button pops up.

Latch Button(A)

Narrow Crown

Staples(C)

Magazine Rail(C)

Magazine Cover(B)

WARNING:

The tool may fire when it is first connected to the power source. Always disconnect the tool to the power source before

loading fasteners to prevent injury from

unintended cycling. Always make sure

the tool’s magazine is empty at the

beginning of each work session, before

connecting to the power source.

BATTERY CHARGE

INPUT VOLTAGE

FIRING SPEED

MAGAZINE CAPACITY

SHOTS PER CHARGE

CHARGE TIME

WEIGHT

FASTENER TYPE

FASTENER LENGTH

120V, 60Hz

20V Max DC, 36Wh

30 nails/staples per minute

100 nails/staples

400

30 min

6.17 lbs

18 GA Brad Nails & 18 GA

1/4” Narrow Crown Staples

Nails: 3/4” - 2”

Staples: 3/4” - 1 5/8”

FEATURES

HIGH POWER TECHNOLOGY

Provides fast firing speeds

ERGONOMIC HANDLE

For comfortable use and decreased slipping

06

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

Belt Hook

Belt Hook Bolt

Brad Nails(C)

Magazine Rail(C)

WARNING:

Only use fasteners that are recommended for use with this tool by the manufacturer. Fasteners not identified for use

with this tool by the tool’s manufacturer

could result in a risk to persons or tool

damage when used in this tool.

WARNING:

Keep the tool pointed away from

yourself and others when loading fasteners. Failure to do so could result in

serious personal injury.

Magazine Cover(B)

WARNING:

Never load fasteners with the workpiece

contact or trigger activated. Doing so

could result in possible serious personal

injury.

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672

07

WARNING:

Never load fasteners with the workpiece

contact or trigger activated. Doing so

could result in possible serious personal

injury.

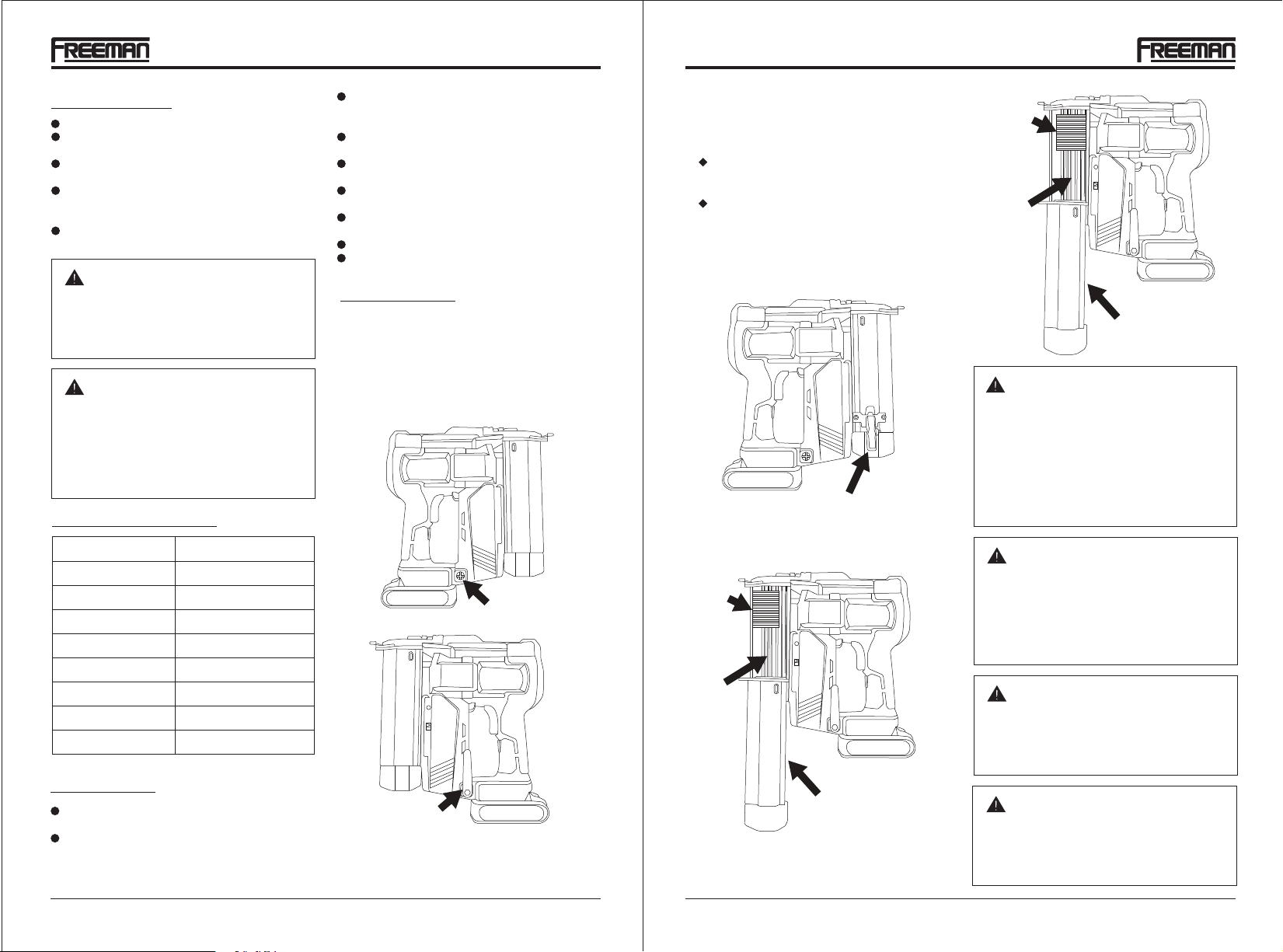

UNLOADING FASTENERS

1.

Remove Battery.

2.

Push down on the latch button(A). Pull back on the

magazine cover(B).

3.

Remove all fasteners from the magazine rail(C).

4.

Push the magazine cover(B) forward until the latch

button pops up.

Battery

Magazine Rail(C)

Latch Button(A)

Battery

Magazine Cover(B)

WARNING:

Always unload all fasteners before

removing the tool from service.

MODEL: PE20V2118G MODEL: PE20V2118G

WARNING:

Always disconnect the power source

before unloading.

DEPTH OF DRIVE

The driving depth of the fasteners is adjustable. To

adjust the depth, use the drive depth adjustment

wheel(G) on the top of the tools nose.

1.

Rotate the depth adjustment wheel in a clockwise

direction when the nose of the tool is pointed away

from you to increase the fastener depth of drive.

2.

Rotate the depth adjustment wheel in a counterclockwise direction when the nose of the tool is

pointed away from you to decrease the depth of

drive.

Depth

Adjustment

Wheel (G)

Increase

Depth of

Drive

Decrease

Depth of

Drive

CAUTION:

It is advisable to test the depth of drive

on a scrap workpiece to determine the

required depth for the application.

SETTING TOOL FIRING SETTINGS

Push the fire selection switch up to select single

1.

sequential fire. This mode requires the trigger to

be pulled each time a fastener is driven. The tool

can be actuated by depressing the work contact

element against the work surface after pulling the

trigger.

Push the fire selection switch down to select bump

2.

fire. This will enable you to fire a shot by holding

down the trigger and pressing the nose of the gun

down on the work piece as many times as is

necessary.

Fire Selection

Switch

Single Sequential

Firing Position

Bump Fire

Position

WARNING:

Always know the operational mode of

the tool before use. Failure to know the

operational mode could result in death

or serious personal injury.

WARNING:

An improperly functioning tool must not

be used. Do not actuate the tool unless

the tool is placed firmly against the work

place.

WORK CONTACT ELEMENT

Check the operation of the work contact element trip

mechanism before each use. The WCE must move

freely without binding through its entire travel

distance. The WCE spring must return the WCE to its

fully extended position after being depressed. Do not

operate the tool if the WCE trip mechanism is not

operating properly. Personal injury may occur.

Work

Contact

Element

NO-MAR PAD

The no-mar pad attached to the nose of the tool helps

to prevent marring and denting when working with

softer woods.

WARNING:

Disconnect the tool from the battery

before removing or replacing the no-mar

pad. Failure to do so could result in

serious personal injury.

REMOVING BATTERY

1.

Press battery release button.

2.

Pull battery free of the nailer/stapler body.

Battery

Release

Button

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 09HTTP://WWW.FREEMANTOOLS.COM 1-888-669-567208

MODEL: PE20V2118G MODEL: PE20V2118G

CLEARING JAMS

Occasionally, a fastener may become jammed in the

firing mechanism of the tool, making the tool inoperable. To remove a jammed fastener, follow the steps

below:

Disconnect the battery from the tool.

1.

Push down on the latch button(A). Pull back on the

2.

magazine cover(B).

Remove fasteners from the magazine.

3.

Latch

Button(A)

Use wrench to loose four bolts and remove the

4.

nose cover.

Bolt x 4

Magazine

Cover(B)

5.

Use a flat screw driver to remove the jammed

fastener and push the drive blade back into place.

CHARGING BATTERY

To charge the battery line up the slot of the battery

1.

with the slot of the charger and slide into place.

The battery indication light should turn from green

2.

to red when the battery is charging.

When the indication light has turned green the

3.

battery should be fully charged.

CHARGING A HOT BATTERY PACK

After a tool has been used for a prolong amount of

time the batteries in the battery pack will become hot.

This only occurs when the tool has been used

continuously for a extended period of time. When the

battery becomes hot let it cool for 30 minutes before

recharging. Refer to the CHARGING BATTERY

section for normal charging of batteries. If the

charger does not charge your battery under normal

circumstances, contact the authorized dealer.

BATTERIES

These batteries will wear out over time, like all

batteries. If this happens do not disassemble the

battery and attempt to fix it. This could cause serious

burns especially when wearing rings and jewelry. To

have the longest possible battery life, we suggest the

following.

Once a battery pack has been fully charged

remove it from the charger

The battery should be stored in a temperature

that is below 80°F and away from moisture

Batteries should be stored with a 30%-50%

charge

If a battery has been stored for six months or

more charge the battery as normal

BATTERY PACK REMOVAL AND

RECYCLING

Please recycle all worn batteries.

This battery contains lithium-ion

batteries. Local and state

regulations may prohibit disposal

of lithium-ion batteries in

ordinary trash. Consult your local

waste authority for information

regarding available recycling

and/or options.

Remove the tool battery.

Slide magazine cover down to remove nails and

expose the nail channel.

Use a small amount of air tool oil on a clean cloth to

swab and wipe down the nail channel, untill all

traces of glue are removed.

Reinstall nails in the magazine and close the

magazine cover.

COLD WEATHER OPERATION

When you are operating the tool in below freezing

environments:

1.

Before using the tool be sure to keep it as warm as

possible

2.

Fire the tool into a scrap piece of material 5 to 6

times.

CLEANING

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and maybe damaged

by their use. Use clean cloths to remove dirt, dust , oil,

grease, etc.

MAINTENANCE

WARNING:

Any time inspection, maintenance, and

cleaning are done be sure to remove the

battery from the tool and empty all

fasteners from the magazine.

CLEANING THE NAIL CHANNEL

Problems with driving nails or cycling of nails while

firing may be due to glue residue from the nail strips.

If this is the case clean the area around the driving

mechanism.

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 11HTTP://WWW.FREEMANTOOLS.COM 1-888-669-567210

MODEL: PE20V2118G MODEL: PE20V2118G

TROUBLESHOOTING

WARNING:

Stop using tool immediately if any of the following problems occur. Serious personal

injury could result. Any repairs or replacements must be done by a qualified service

person or an authorized service center.

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTIONS

Tool doesn’t turn on

(LED lights do not

turn on).

Tool doesn’t actuate

(LED lights do turn

on).

Tool does not

actuate (LED light

is red).

Tool operates, but

no fastener is

driven.

Tool operates, but

does not drive the

fastener fully.

The internal electronics of the tool

have not reset.

The battery is low or not charged.

The battery is damaged.

The work contact element is locked

into position.

The battery terminals are dirty.

Damaged internal electronics.

Work contact element is not

depressed.

Work contact element is jammed.

Damaged electronics.

The battery charge is low.

The battery is to hot.

A fastener is jammed in the tool.

No nails in the magazine.

Incorrect fastener has been loaded.

Debris in nose piece.

Debris in magazine.

Worn magazine or drive blade.

The battery has a low charge or is

damaged.

The depth adjust is set too shallow.

Tool is not press firmly against the

workpiece.

Material and fastener length is too

rigorous on the tool.

Remove the battery from the tool, wait 3

seconds and reinsert.

Charge the battery.

Replace the battery.

Unlock the work contact element.

Clean the battery terminals.

See authorized service center.

If the tool is set in the single fire setting,

release the trigger or work contact element

Then try refiring the tool.

Unlock the work contact element.

See authorized service center.

Charge or replace battery.

Let the tool cool down.

Remove the battery from the tool and clear

the jam from the gun. Then push the drive

blade back and reinsert the battery.

Load more fasteners in the magazine.

Insert the fasteners recommended by the

manufacturer.

Clean the nose piece with pneumatic air

tool oil and a clean cloth.

Clean the magazine with pneumatic air tool

oil and a clean cloth.

See authorized service center.

Charge or replace the battery.

Rotate the depth adjust towards the deeper

setting.

Press down more firmly on the workpiece.

Choose a more appropriate material and

fastener for your application.

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTIONS

Load fasteners recommended by the

manufacturer

Charge or replace battery

Clean the nose piece with pneumatic air

tool oil and a clean cloth

Clean the magazine with pneumatic air tool

oil and a clean cloth

See authorized service center

See authorized service center

Jammed fastener

The incorrect fastener is loaded in

the tool

Low battery charge or damaged

battery

Debris is in nose piece

Debris is in magazine

Worn magazine

Worn or damaged pusher spring

WARNING:

Only use Freeman Authorized Repair Parts. For questions please call 1-888-669-5672 or

visit our website at http://www.freemantools.com

WEARABLE PARTS

Repair parts can be ordered from our website: http://www.freemantools.com

HTTP://WWW.FREEMANTOOLS.COM 1-888-669-5672 13HTTP://WWW.FREEMANTOOLS.COM 1-888-669-567212

Loading...

Loading...