MODEL:PBR50Q

SAVETHISMANUALFORFUTUREREFERENCE

WARNING:

FailuretofollowwarningscouldresultinDEATHORSERIOUSINJURY.

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIMEGLOBALPRODUCTS,INC.

IMF300502AV10/10

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

PRIMEGLOBALPRODUCTS,INC.

ROPEMILLPARKWAYWOODSTOCK,GA.30188201

03

Thewarningsandprecautionsdiscussedinthemanualcannotcoverallpossibleconditionsand

situationsthatmayoccur.Itmustbeunderstoodbytheuserthatcommonsenseandcautionare

factorswhichcannotbebuiltintothisproduct,butmustbesuppliedbytheuser.

WARNING:

GENERALSAFETYRULES

UNPACKING

FEATURES

OPERATION

MAINTENANCE

RECOMMENDEDHOOKUP

TROUBLESHOOTING

WEARINGPARTS

WARRANTIES

USINGBELTHOOK

ADJUSTINGTHEEXHAUST

LOADINGFASTENERS

UNLOADINGFASTENERS

CLEARINGJAMS

NON-MARRINGPAD

SETTINGTHEAIRPRESSURE

DEPTHADJUSTMENT

FIRINGTHETOOL

WORKCONTACTELEMENT(WCE)

P3

P6

P7

P7

P7

P7

P8

P8

P8

P8

P9

P9

P9

P9

P10

P11

P11

P11

SAVETHISMANUAL

Keepthismanualforthesafetywarnings,

precautions,operations,inspectionsand

maintenance.Keepthismanualandthe

receiptinasafeanddryplaceforfuture

reference.

SYMBOLS

Inthismanual,onthelabels,packagesandallotherinformationprovidedwiththistool.Thefollowing

signalwordsandmeaningsareintendedtoexplainthelevelsofriskassociatedwiththistool.

Toavoidseriouspersonalinjury,donot

attempttousethisproductuntilyouread

thoroughlyandunderstandit

completely.Savethismanualandreview

frequentlyforcontinuingsafeoperation

andinstructingotherswhomayusethis

tool.

themanual

WARNING:

!

SYMBOLS SIGNAL MEANING

!

!

WARNING:

CAUTION:

CAUTION:

Indicatesapotentiallyhazardoussituation,which,ifnotavoided,

couldresultindeathorseriousinjury.

Indicatesapotentiallyhazardoussituation,which,ifnotavoided,

mayresultinminorormoderateinjury.

(Withoutsymbol)Indicatesasituationthatmayresultin

propertydamage.

●

●

GENERALSAFETYRULES

WORKAREA

Keeptheworkareacleanandwelllighted.

Keepbystanders,children,andothersaway

whileoperatingthetool.

Clutteredbenchesanddarkareasincreasethe

risksofaccidents.

Distractionscould

resultinimproperuseandcauseinjury.

Donotoperatethetoolinexplosive

atmospheres,suchasinthepresenceof

flammableliquids,gases,ordust.

Avoidunintentionalmisfires.

Thetool

createsasparkwhichmayigniteflammable

liquids,gasesordust.

Alwaysuse

cautiontoavoidaccidentallyfiring.Donotpoint

towardsyourselforanyonewhetheritcontains

fastenersornot.

●

●

●

●

●

●

●

●

●

●

INSTRUCTIONSPERTAININGTOARISKOF

FIRE,ELECTRICSHOCK,ORINJURYTO

PERSONS

CALIFORNIAPROPOSITION65

WARNING:

!

Whenusingtools,basicprecautions

shouldalwaysbefollowed,includingthe

following:

WARNING:

!

Thisproductoritspowercordmay

containchemicalsknowntotheState

ofCaliforniatocausecancerandbirth

defectsorotherreproductiveharm.

Washhandsafterhandling.

PERSONALSAFETY

someone,orcausethetooltoreactandresult

inariskofinjurytopersons.

Adustmask,nonskidsafetyshoesandahardhatmustbeused

fortheapplicableconditions.Wearafullface

shieldifyouareproducingmetalfilingsorwood

chips.

Containlonghair.Keepyourhair,

clothing,andglovesawayfrommovingparts.

Looseclothes,jewelry,orlonghaircanbe

caughtinmovingparts.

Donotusetoolwhiletiredorunder

theinfluenceofdrugs,alcohol,ormedication.A

momentofinattentionwhileoperatingthetool

maycauseseriousinjury.

Properfootingandbalanceenablesbetter

controlofthetoolinunexpectedsituations.

Stablefootingonasolidsurfaceenablesbetter

controlofthetoolinunexpectedsituations.

Removefingerfromthetriggerwhennot

drivingfasteners.

Alwaysweareyeprotection.

Alwayswearhearingprotectionwhen

usingthetool.

Nevercarrythetoolwith

fingerontrigger,thetoolisabletofirea

fastener.

Operatorand

othersintheworkareashouldalwayswear

ANSI-approvedsafetygoggleswithside

shields.Eyeprotectionisusedtoguardagainst

flyingfastenersanddebris,whichmaycause

severeeyeinjury.Youcanusethegoggles

packedwiththetool.

Prolongedexposuretohigh

intensitynoisemaycausehearingloss.

Usesafetyequipment.

Dressproperly.Donotwearlooseclothing

orjewelry.

Stayalert,watchwhatyouaredoingand

usecommonsensewhenoperatinga

powertool.

Avoidunintentionalfiring.Keepfingers

awayfromtriggerwhennotdriving

fasteners,especiallywhenconnectingthe

tooltotheairsupply.

Keepproperfootingandbalanceatalltimes.

Donotuseonaladderorunstablesupports.

●

●

02

MODEL:PBR50Q MODEL:PBR50Q

HTTP://WWWFREEMANTOOLSCOM1-888-669-5672.. HTTP://WWWFREEMANTOOLSCOM1-888-669-5672..

Donotnailontopofanothernail. Thisis

abletocausethenailtobedeflectedandhit

●

●

0504

TOOLUSEANDCARE

●

●

●

●

●

●

●

●

●

Knowthistool. Readmanualcarefully,learn

itsapplicationsandlimitations,aswellasthe

specificpotentialhazardsrelatedtothistool.

Useonlyfastenersthatarerecommended

foryourmodels.

Checkformisalignmentorbindingof

movingparts,breakageofparts,andany

otherconditionthatmayaffectthetool's

operation.

Maintaintoolswithcare.

Storetoolsoutofthereachofchildrenand

otheruntrainedpeople.

Checkoperationofthetoolbeforeuse.

Donotusetooliftriggerdoesnotactuate

properly.

Donotforcetool.

Useclampsoranotherpracticalwayto

secureandsupporttheworkpiecetoa

stableplatform.

Donotusethewrong

fastenersorloadthefastenersincorrectly.

Ifdamaged,havethetoolserviced

beforeusing.Manyaccidentsarecausedby

poorlymaintainedtools.

Keeptoolclean.A

properlymaintainedtool,reducestheriskof

bindingandiseasiertocontrol.

Toolsaredangerous

inthehandsofuntrainedusers.

Do

notusethetooliftheworkpiececontact

mechanismisnotworkingcorrectlyas

accidentaldrivingofafastenermayoccur.

Anytoolthatcannotbecontrolled

withthetriggerisdangerousandmustbe

repaired.

Usethecorrecttoolforyour

application.Thecorrecttoolwilldothejobbetter

andsaferattherateforwhichitisdesigned.

Holdingatoolbyhandor

againstthebodyisunstableandmayleadto

lossofcontrol.

TOOLSERVICE

Useonlyaccessoriesthatareidentifiedby

themanufacturerforthespecifictoolmodel.

Useofunauthorizedpartsorfailureto

followmaintenanceinstructionsmaycreate

ariskofinjury.

Useonlythelubricantssuppliedwiththe

toolorspecifiedbythemanufacturer.

Toolservicemustbeperformedonlyby

qualifiedrepairpersonnel.

OPERATION

Donotdrivefastenersnearedgeofmaterial.

Theworkpiecemaysplitcausingthefasteneror

ricochet,injuringyouorpeoplearound.

Donotcarrythetoolfromplacetoplace

holdingthetrigger.Accidentaldischarge

couldresult.

Duringnormalusethetoolwillrecoil

immediatelyafterdrivingafastener.

Donotdrivefastenersontopofother

fastenersorwiththetoolatanoverlysteep

angleasthismaycausedeflectionof

fastenerswhichcouldcauseinjury.

Choiceoftriggeringmethodis

important.Checkmanualfortriggeringoptions.

Thisis

anormalfunctionofthetool.Donotattemptto

preventtherecoilbyholdingthetoolagainstthe

work.Restrictiontotherecoilcanresultina

secondfastenerbeingdrivenfromthetool.Grip

thehandlefirmlyandletthetooldothework.

Failuretoheedthiswarningcanresultinserious

personalinjury.

●

●

●

●

●

●

●

●

Makesurethehoseisfreeofobstructions

orsnags. Entangledorsnarledhosescan

causelossofbalanceorfootingandmay

becomedamaged,resultinginpossibleinjury.

Donotoverreach.Keepproperfootingand

balanceatalltimes.

Donotattachthehoseortooltoyourbody.

Alwaysassumethatthetoolcontains

fasteners.Donotpointthetooltoward

yourselforanyonewhetheritcontains

fastenersornot.

Washhandsafterhandling.

Properfootingand

balanceenablesbettercontrolofthetoolin

unexpectedsituations.

Attachthehosetothestructuretoreducethe

riskoflossofbalanceifthehoseshifts.

Thisproductor

itspowercordmaycontainchemicalsknownto

theStateofCaliforniatocausecancerandbirth

defectsorotherreproductiveharm.

●

●

●

●

●

●

●

●

●

●

●

●

Keepthetoolanditshandledry,cleanand

freefromoilandgrease.

Donotusethetoolasahammer.

Neverusethistoolinamannerthatcould

causeafastenertobedirectedtoward

anythingotherthantheworkpiece.

Neverusegasolineorotherflammable

liquidstocleanthetool.

Donotremove,tamperwith,orotherwise

causethetriggerlockortriggertobecome

inoperable.

Donottouchthetriggerunlessdriving

fasteners.

Alwaysfittoolwithafittingorhose

couplingonornearthetoolinsucha

mannerthatallcompressedairinthetoolis

dischargedatthetimethefittingorhose

couplingisdisconnected.

Neverplacehandsoranyotherbodyparts

inthefastenerdischargeareaofthetool.

Nevercarrythetoolbytheairhoseorpull

thehosetomovethetooloracompressor.

Alwaysassumethetoolcontainsfasteners.

Alwayskeepothersatasafedistancefrom

theworkareaincaseofaccidental

dischargeoffasteners.

Alwaysuseaclean

clothwhencleaning.Neverusebrakefluids,

gasoline,petroleum-basedproducts,orany

strongsolventstocleanyourtool.

Neverusethetoolin

thepresenceofflammableliquidsorgases.

Vaporscouldignitebyasparkandcausean

explosionwhichwillresultindeathorserious

personalinjury.

Donotoperateanytoolwhichhas

beenmodifiedinalikefashion.Deathor

seriouspersonalinjurycouldresult.

Neverattachairlinetotoolorcarry

toolwhiletouchingthetrigger.Thetoolcould

ejectafastenerwhichwillresultindeathor

seriouspersonalinjury.Alsoactuatethetrigger

locktothesafepositionwhennotinuse.

Donotuseacheck

valveoranyotherfittingwhichallowsairto

remaininthetool.Deathorseriouspersonal

injurycouldoccur.

Thetoolmightejectafastenerandcouldresult

indeathorseriouspersonalinjury.

Keephosesawayfromheat,oilandsharp

edges.Replaceanyhosethatisdamaged,

weakorworn.Personalinjuryortooldamage

couldoccur.

Respectthetoolasaworkingimplement;no

horseplay.

Donotpointthetool

towardyourselforanyonewhetheritcontains

fastenersornot.Accidentaltriggeringofthetool

couldresultindeathorseriouspersonalinjury.

●

●

●

●

●

Donotdroporthrowthetool.

Avoidusingthetoolwhenthemagazineis

empty.

Cleanandcheckallairsupplyhosesand

fittingsbeforeconnectingthetooltoanair

supply.

Donotuseth

Droppingor

throwingthetoolcanresultindamagethatwill

makethetoolunusableorunsafe.Ifthetoolhas

beendroppedorthrown,examinethetool

closelyforbent,crackedorbrokenpartsandair

leaks.STOPandrepairbeforeusing,orserious

injurycouldoccur.

Acceleratedwearonthetoolmay

occur.

Replaceanydamagedorwornhoses

orfittings.Toolperformanceordurabilitymay

bereduced.

etoolifitleaksairordoesnot

functionproperly.

Donotoperatethetoolifitdoesnotcontain

alegiblewarninglabel.

Alwayscarrythetoolbythehandle.Never

carrythetoolbytheairhose.

●

●

Donotactuatethetoolunlessyouintendto

driveafastenerintotheworkpiece.

Alwayshandlethetoolwithcare:

◆Respectthetoolasaworkingimplement.

◆ Neverpullthetriggerunlessnoseisdirected

towardthework.

◆Neverengageinhorseplay.

◆ Keepothersasafedistancefromthetool

whiletoolisinoperationasaccidental

actuationmayoccur,possiblycausinginjury.

●

●

AIRSUPPLYANDCONNECTIONS

Theconnectoronthetoolmustnothold

pressurewhenairsupplyisdisconnected.

Donotuseanytypeofreactivegases,

including,butnotlimitedto,oxygenand

combustiblegases,asapowersource.

Useonlyapressure-regulatedcompressed

airsourcetolimittheairpressuresupplied

tothetool.

If

anincorrectfittingisused,thetoolcanremain

chargedwithairafterdisconnectingandthus

willbeabletodriveafastenerevenaftertheair

lineisdisconnected,possiblycausinginjury.

Use

filtered,lubricated,regulatedcompressedair

only.Useofareactivegasinsteadof

compressedairmaycausethetooltoexplode

whichwillcausedeathorseriouspersonal

injury.

Theregulatedpressuremustnot

exceed100psi.Iftheregulatorfails,the

pressuredeliveredtothetoolmustnotexceed

200psi.Thetoolcouldexplodewhichwillcause

deathorseriouspersonalinjury.

Alwaysdisconnectairresource:

◆Beforeunloadingormakingadjustments.

◆Whenmaintainingthetool.

◆Whenclearingajam.

◆Whentouchingthesafetyyoke.

◆Whentoolisnotinuse.

◆Whenmovingtoadifferentworkarea.

Suchprecautionarymeasuresreducetheriskof

injurytopersons.

●

●

●

●

LOADINGTOOL

Donotloadthetoolwithfastenerswhen

anyoneoftheoperatingcontrolsis

activated.

Neverplaceahandoranypartofbodyin

fastenerdischargeareaoftool.

Neverpointtoolatanyone.

Donotpullthetriggerordepressthe

workpiececontactasaccidentalactuation

mayoccur,possiblycausinginjury.

●

●

●

●

HTTP://WWWFREEMANTOOLSCOM1-888-669-5672.. HTTP://WWWFREEMANTOOLSCOM1-888-669-5672..

MODEL:PBR50Q MODEL:PBR50Q

●

●

●

0706

●

FEATURES

360ADJUSTABLEEXHAUST

OIL-FREEDESIGN

COMFORT-GRIPHANDLE

ERGONOMICALLYENGINEEREDBODY

°

Allowsusertodirectairawayfromdebris.

Forlessmaintenance.

Forlonglastingdurability.

Forincreasedcomfortandcontrol.

ANODIZEDALUMINUMCYLINDERAND

MAGAZINE

AIRFILTER

ADJUSTABLEDEPTH

QUICK-JAMRELEASE

NON-MARRINGSAFETYCONTACT

RuggedandComfortableresultinginalightweighttoolgreatforextendeduse.

Keepsinteriorcomponentsdebrisfree,

extendingtoollife.

Depthiseasilyadjustableforvarious

applications.

Allowsforeasyaccessclearingintheeventofa

jam.

Eliminatesdamagetoworkingsurface.

●

●

ADJUSTINGTHEEXHAUST

Theadjustableexhaustonthecapofthetoolallows

userstodirecttheexhaustaccordingtooperator

preference.Toadjustthedirection,turntheexhaust

capinthedesireddirection.

Thetoolmayfirewhenitisfirst

connectedtotheairresource.Always

connectthetooltotheairresource

beforeloadingfastenerstopreventinjury

fromunintendedcycling.Alwaysmake

surethetool'smagazineisemptyatthe

beginningofeachworksession,before

connectingtoanairresource.

WARNING:

!

Useonlythosefastenersrecommended

forusewiththistool.Fastenersnot

identifiedforusewiththistoolbythetool

manufacturerareabletoresultinariskof

injurytopersonsortooldamagewhen

usedinthistool.

WARNING:

!

Connectthetooltotheairresource.

Pushdownonthelatchbutton(B).Pullbackon

themagazinecover(C).

Insertastickoffastenersintothemagazine

rail(D).Makesurethepointedendsofthe

fastenersarerestingonthebottomledgeofthe

magazinewhenloading.Makesurethe

fastenersarenotdirtyordamaged.

Pushthemagazinecover(C)forwarduntillatch

buttonpopsup.

●

●

●

OPERATION

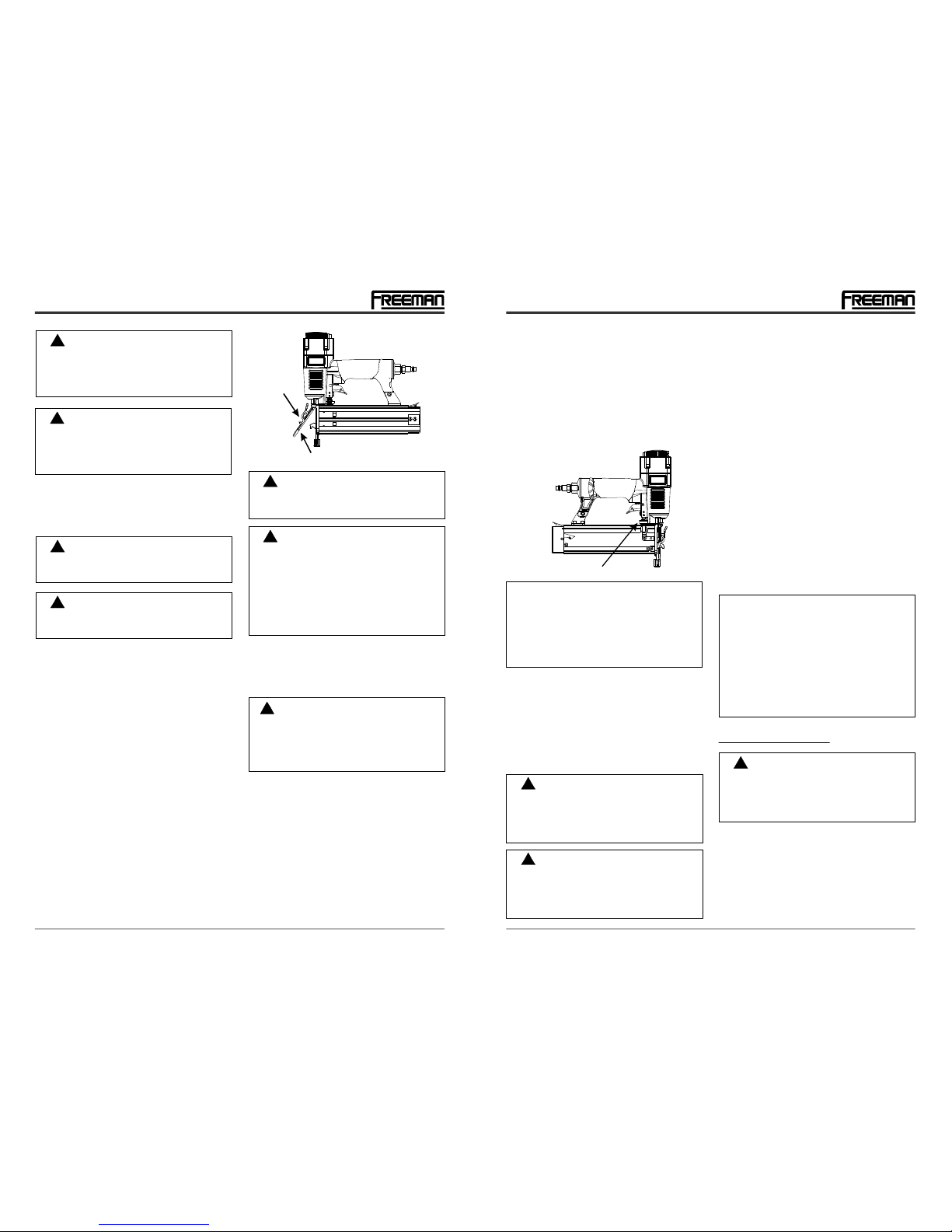

USINGBELTHOOK

⒈

⒉

⒊

⒋

LOADINGFASTENERS

Loosenandremovethehookscrewandnut(A).

Savethescrewandnutforfutureuse.

Positionthehookinyourpreferredposition.

Usingthelongerscrewpackedwithhook,

fastenhooktotool.

Thetoolispackedwithaseparatehooksystem.

Assemblethehookonthetoolbeforeusingthe

hook.Thehookcanbepositionedonbothleftand

rightsides.

●

●

●

⒈

⒉

Hooknut(A)

Hook

Latchbutton(B)

Magazinecover(C)

Magazinerail(D)

Thewarningsandprecautionsdiscussed

abovecannotcoverallpossible

conditionsandsituationsthatmayoccur.

Itmustbeunderstoodbytheuserthat

commonsenseandcautionarefactors

whichcannotbebuiltintothisproduct,

butmustbesuppliedbytheuser.

WARNING:

!

UNPACKING

Thistoolhasbeenshippedcompletely

assembled.

Makesurethatallitemslistedinthepacking

listareincluded.

Carefullyremovethetoolandany

accessoriesfromthebox.

Inspectthetoolcarefullytomakesureno

breakageordamageoccurredduring

shipping.

Donotdiscardthepackingmaterialuntilyou

havecarefullyinspectedandsatisfactorily

operatedthetool.

Ifanypartsaredamagedormissing,please

call1-888-669-5672.

●

●

●

●

●

●

FEATURES

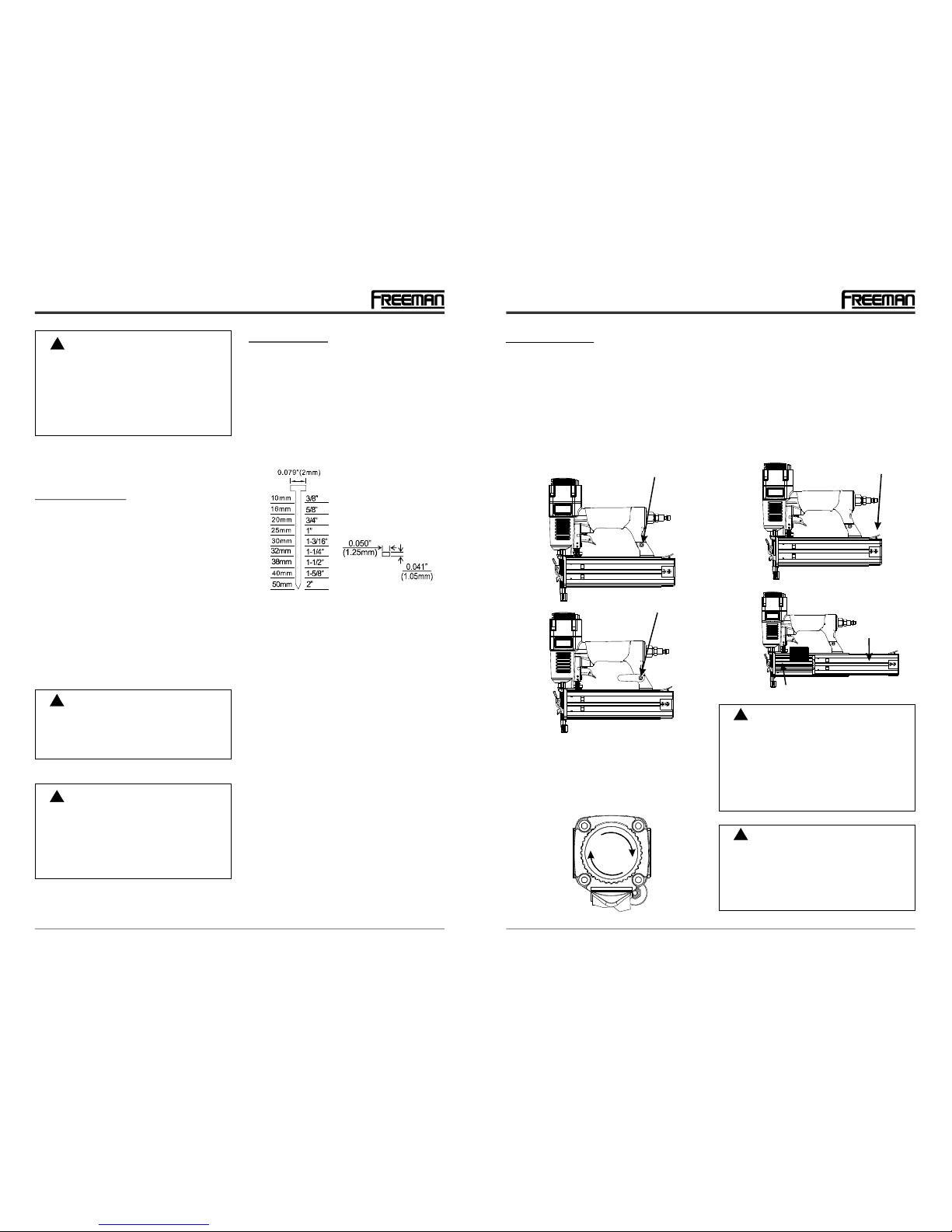

SPECIFICATIONS

REQUIRES:

AIRINLET:

MAGAZINECAPACITY:

WEIGHT:

MAXIMUMPRESSURE:

PRESSURERANGE:

5.87SCFMwith100

fastenersperminute@90psi

1/4inchNPT

100fasteners,18gauge

2.91lbs

100psi

60psi100psi–

PINSIZERANGE:3/8inchto2inch

Ifanypartsaremissingdonotoperate

thistooluntilthemissingpartsare

replaced.Failuretodosocouldresultin

possibleseriouspersonalinjury.

WARNING:

!

Donotattempttomodifythistoolor

createaccessoriesnotrecommendedfor

usewiththistool.Anysuchalterationor

modificationismisuseandcouldresult

inhazardousconditionleadingto

possibleseriouspersonalinjury.

WARNING:

!

Compatiblewithall18GaugeBradNails.

HTTP://WWWFREEMANTOOLSCOM1-888-669-5672.. HTTP://WWWFREEMANTOOLSCOM1-888-669-5672..

MODEL:PBR50Q MODEL:PBR50Q

0908

MAINTENANCE

Anytimeinspection,maintenance,and

cleaningaredone:

◆Disconnectthetoolfromtheairresource.

Emptythemagazinecompletely.◆

WARNING:

!

Makesurethereisnofastenerin

magazinebeforeclearingajam.

WARNING:

!

Disconnectthetoolfromtheairsource

wheneverclearingajam.After

disconnectingthetoolfromtheair

compressor,thereshouldstillbeenough

airpressuretofirethetool.Aftertheair

hoseisdisconnected,alwaysfirethetool

intoscrapwoodrepeatedlytomakesure

allofthecompressedairisexpended.

WARNING:

!

SETTINGTHEAIRPRESSURE

Theamountofairpressurerequireddependson

thesizeofthefastenersandtheworkpiecematerial.

Begintestingthedepthofdrivebydrivingatestnail

intothesametypeofworkpiecematerialusedfor

theactualjob.Driveatestfastenerwiththeair

pressuresetat90-95psi.Raiseorlowertheair

pressuretofindthelowestsettingthatwillperform

thejobwithconsistentresults.Itmaybepossibleto

achievethedesireddepthwithairpressure

adjustmentsalone.

NON-MARRINGPAD

Theno-marringpadattachedthenoseofthetool

helpspreventmarringanddentingwhenworking

withsofterwoods.

Disconnectthetoolfromtheairsource

beforeremovingorreplacingthenomarringpad.Failuretodosocouldresult

inseriouspersonalinjury.

WARNING:

!

DEPTHADJUSTMENT

Thedrivingdepthofthefastenersareadjustable.

Toadjustthedepth,usethedrivedepthadjustment

wheel(G)ontherightsideofthetool.

Disconnectthetoolfromairresource.

Turnthedepthwheelleftorrighttochangethe

drivingdepth.

Reconnectthetooltotheairresource.

Driveatestnailaftereachadjustmentuntilthe

desireddepthisset.

Itisadvisabletotestthedepthonascrap

workpiecetodeterminetherequired

depthfortheapplication.

Todeterminedepthofdrive,firstadjust

theairpressureanddriveatestfastener.

Neverexceed120psi.

CAUTION:

Eachtoolispackedwithananti-dustcapontheair

connector,

Keeptheanti-dustcapcovertheairconnector

whenthetoolisnotinuse.

checkitafterunpacking.

Adjustmentwheel(G)

1.

2.

3.

4.

ANTIDUST-

Alwaysknowtheoperationalmodeofthe

toolbeforeusing.Failuretoknowthe

operationalmodecouldresultindeathor

seriouspersonalinjury.

WARNING:

!

FIRINGTHETOOL

Thetoolisspeciallydesignedforsinglesequential

mode.Thismoderequiresthetriggertobepulled

eachtimeafastenerisdriven.Thetoolcanbe

actuatedbydepressingtheWCEagainstthework

surfacefollowedpullingthetrigger.

Thetriggermustbereleasedtoresetthetoolbefore

Animproperlyfunctioningtoolmustnot

beused.Donotactuatethetoolunlessthe

toolisplacedfirmlyagainstthework

place.

WARNING:

!

WORKCONTACTELEMENT(WCE)

Disconnecttheairsupplyfromthetool.

Removeallfastenersfromthemagazine.

Makesurethetriggerandworkcontactelement

movefreelyupanddownwithoutstickingor

binding.

Reconnectairsupplytothetool.

Depresstheworkcontactelementagainstthe

worksurfacewithoutpullingthetrigger.Thetool

mustnotoperate.Donotusethetoolifit

operateswithoutpullingthetrigger.Personal

injurymayresult.

Removethetoolfromtheworksurface.The

workcontactelement(WCE)mustreturntoits

originaldownposition.Thetoolmustnot

operate.Donotusethetoolifitoperateswhile

liftedfromtheworksurface.Personalinjurymay

result.

Pullthetriggeranddepresstheworkcontact

element(WCE)againsttheworksurface.The

toolmustnotoperate.

Depresstheworkcontactelement(WCE)

againstthesurface.Pullthetrigger.Thetool

mustoperate.

⒈

⒉

⒊

⒋

⒌

⒍

⒎

⒏

Checktheoperationoftheworkcontact

elementtripmechanismbeforeeachuse.

TheWCEmustmovefreelywithout

bindingthroughitsentiretraveldistance.

TheWCEspringmustreturntheWCEto

itsfullyextendedpositionafterbeing

depressed.Donotoperatethetoolifthe

WCEtripmechanismisnotoperating

properly.Personalinjurymayoccur.

CAUTION:

Keepthetoolpointedawayfromyourself

andotherswhenloadingfasteners.

Failuretodosocouldresultinpossible

seriouspersonalinjury.

WARNING:

!

Neverloadfastenerswiththeworkpiece

contactortriggeractivated.Doingso

couldresultinpossibleseriouspersonal

injury.

WARNING:

!

UNLOADINGFASTENERS

Unloadingisthereverseofloading.Always

disconnecttheairresourcebeforeunloading.

Alwaysunloadallfastenersbeforeremoving

toolfromservice.

WARNING:

!

Alwaysdisconnecttheairresourcebefore

unloading.

WARNING:

!

CLEARINGJAMS

Disconnectthetoolfromairresource.

Removefastenersfromthetool.Failuretodo

sowillcausethefastenerstoejectfromthefront

ofthetool.

Pulluponthelatch(E)andopenthejam

release(F).

Usingcautionnottobendordamagethedriver

blade,usingpliersorascrewdriverifrequiredto

clearthejammedfastener.

Closethejamreleaseandlatch.

Reconnectthetooltotheairresource.

Reloadthetoolwithfasteners.

Occasionally,afastenermaybecomejammedin

thefiringmechanismofthetool,makingthetool

inoperable.Toremoveajammedfastener,follow

thestepsbelow:

⒈

⒉

⒊

⒋

⒌

⒍

⒎

Latch(E)

Jamrelease(F)

HTTP://WWWFREEMANTOOLSCOM1-888-669-5672.. HTTP://WWWFREEMANTOOLSCOM1-888-669-5672..

MODEL:PBR50Q MODEL:PBR50Q

11

10

Thetoolisuniquelydesignednottoneeddaily

lubrication.Butlubricationisrequiredforbest

performanceafterlongperiodsofuse.Oilfor

pneumaticfasteningtoolsisaddedthroughtheair

lineconnectionandwilllubricateinternalparts.Do

notusedetergentoiloradditives.Theselubricants

willcauseacceleratedweartothesealsand

bumpersinthetool,resultinginpoortool

performanceandfrequenttoolmaintenance.

LUBRICATION

Donotatanytimeletbrakefluids,

gasoline,petroleum-basedproducts,

penetrationoils,ect.,comeincontact

withplasticparts.Chemicalscandamage,

weakenordestroyplasticwhichmay

resultinseriouspersonalinjury.

WARNING:

!

Donotstoretoolsinacoldweather

environmenttopreventfrostorice

formationonthetool'soperatingvalves

andmechanismsthatcouldcausetool

failure.

CAUTION:

COLDWEATHEROPERATION

Forcoldweatheroperation,nearandbelow

freezing,themoistureintheairlinemayfreezeand

preventtooloperation.Werecommendtheuseof

airtoollubricantorpermanentantifreeze(ethylene

glycol)asacoldweatherlubricant.

Lubricatetoolonlywithspecified

lubricants.

CAUTION:

Avoidusingsolventswhencleaningplasticparts.

Mostplasticsaresusceptibletodamagefrom

varioustypesofcommercialsolventsandmaybe

damagedbytheiruse.Usecleanclothstoremove

dirt,dust,oil,grease,etc.

CLEARING

RECOMMENDEDHOOKUP

Theaircompressormustbeableto

maintainaminimumof60psiwhenthe

toolisbeingused.Aninadequateair

supplycancausealossofpowerand

inconsistentdriving.

CAUTION:

Donotconnectwithanaircompressor

whichcanpotentiallyexceed200psi.As

toolmayburst,possiblycausinginjury.

WARNING:

!

Theaircompressormustbeabletomaintaina

minimumof60psiwhenthetoolisbeingused.

Aninadequateairsupplycancausealossof

powerandinconsistentdriving.

Anoilercanbeusedtoprovideoilcirculation

throughthetool.Afiltercanbeusedtoremove

liquidandsolidimpuritieswhichcanrustorgum

upinternalpartsofthetool.

Alwaysuseairsupplyhoseswithaminimum

workingpressureratingequaltoorgreaterthan

thepressurefromthepowersourceifa

regulatorfails,or150psi,whicheverisgreater.

Use3/8airhoseforrunsupto50.Use1/2air

hosesfor50runorlonger.Forbetter

performance,installa3/8quickplug(1/4NPT

thread)withaninsidediameterof.315(8mm)

onthetooland3/8quickcouplerontheair

hose.

Useapressureregulatoronthecompressor,

withanoperatingpressureof0-125psi.A

pressureregulatorisrequiredtocontrolthe

operatingpressureofthetoolbetween60and

”’”

’

””

”

”

⒈

⒉

⒊

⒋

TROUBLESHOOTING

Stopusingtoolimmediatelyifanyofthefollowingproblemsoccur.Seriouspersonalinjury

couldresult.Anyrepairsorreplacementsmustbedonebyaqualifiedservicepersonoran

authorizedservicecenter.

WARNING:

!

Airleakingattrigger

valvearea.

O-ringsintriggervalvehousingare

damaged

Replaceo-rings.Checkoperation

ofWorkContactElement(WCE)

Airleakingbetween

housingAndnose.

Loosescrewsinhousing

1.DamagedO-rings

2.Damagedtobumper

Tightenscrews

1.Replaceo-rings

2.Replacebumper

Airleakingbetween

housingandCap.

1.Loosescrews

2.Damagedgasket

1.Tightenscrews

2.Replacegasket

1.Replacebumper

2.Cleandrivechannel

3.Cleanmagazine

4.Replacespring

5.Checkfitting,hose,orcompressor

6.Replaceandlubricateo-rings

7.Replaceo-rings

8.Tightenscrewsandfittings

9.Replacegasket

1.Wornbumper

2.Dirtinnosepiece

3.Dirtordamagepreventfastenersor

pusherfrommovingfreelyinmagazine

4.Damagedpusherspring

5.Inadequateairflowtotool

6.WornO-ringonpistonorlack

oflubrication

7.DamagedO-ringontriggervalve

8.Airleaks

9.Capsealleaking

Toolskipsdriving

fastener

PROBLEMS POSSIBLECAUSE(S) CORRECTIVEACTION

1.Lubricatenailer

2.Replacespring

3.Replacedamagedinternalparts

1.Toolnotlubricatedsufficiently

2.Brokenspringincylindercap

3.Exhaustportincapisblocked

Toolrunssloworhas

lossofpower

1.Replaceguide

2.Useonlyrecommendedfasteners

3.Replacewithundamagedfasteners

4.Tightenscrews

5.Replacedriver

1.Guideondriverisworn

2.Fastenersarenotcorrectsize

3.Fastenersarebent

4.Magazineornosescrewsareloose

5.Driverisdamaged

Fastenersarejammed

intool

HTTP://WWWFREEMANTOOLSCOM1-888-669-5672.. HTTP://WWWFREEMANTOOLSCOM1-888-669-5672..

MODEL:PBR50Q MODEL:PBR50Q

UseonlyFreemanAuthorizedRepairParts.Forquestionspleasecall1-888-669-5672orvisit

ourwebsiteat http://www.freemantools.com

WARNING:

!

WEARINGPARTS

Repairpartscanbeorderedfromourwebsite:http://www.freemantools.com

Loading...

Loading...