Free Hot Water Freedom 5003, Freedom 5002 Installation, Operation And Maintenance Manual

_______________________________________________________________________________

SRCC OG-300 Certified Solar Water Heating System

Free Hot Water Collector 5000 Series – Freedom 5002, 5003

2011044A - Liberty - 4002 XG

2011044B - Liberty - 4003 XG

2011047A - Liberty - 4002 XE

2011047B - Liberty - 4003 XE

Type: AC Circulating Pump and Differential Control

Installation, Operation and Maintenance Manual

The solar energy system described by this manual, when properly installed and maintained, meets the minimum

standards established by the SRCC. This certification does not imply endorsement or warranty of this product by

SRCC.

Version 2011.02

_______________________________________________________________________________

Free Hot Water 2146 Bering Dr. San Jose, CA 95131 Tel: 408 218 3660 Fax 408 872 4142 www.FreeHotWater.com

Table of Contents

Safety Information ................................................................................................................................................... 3

Transport Note .................................................................................................................................................. 4

Installation, Operation And Maintenance Manual .................................................................................................. 5

Introduction ....................................................................................................................................................... 5

System Description ........................................................................................................................................... 6

Specifications .................................................................................................................................................... 6

Freeze Protection .............................................................................................................................................. 7

Tools Needed .................................................................................................................................................... 8

Collector Specifications ........................................................................................................................................... 9

Collector Certification OG100 ......................................................................................................................... 10

Pressure drop and flow rates .......................................................................................................................... 11

General Closed Loop System Schematics ....................................................................................................... 12

Precautions ..................................................................................................................................................... 14

Collector Orientation ...................................................................................................................................... 16

Installation Steps for Roof Mounting .................................................................................................................... 17

Pitched Roof Mounting ................................................................................................................................... 17

Recommend Anchor Points ............................................................................................................................ 20

Flat Roof Installation Instructions ................................................................................................................... 22

Installing the Solar Tank ........................................................................................................................................ 24

Basic plumbing connection diagram ............................................................................................................... 26

Commissioning ................................................................................................................................................ 27

Regular Care .................................................................................................................................................... 28

Anode Replacement ........................................................................................................................................ 29

Pump Station and Controller ................................................................................................................................. 34

Mounting ........................................................................................................................................................ 35

Options ............................................................................................................................................................ 36

Installing the Expansion Tank ................................................................................................................................ 38

Solar Thermal Controller ........................................................................................................................................ 39

System Pressure Guide ......................................................................................................................................... 45

Charging the System ....................................................................................................................................... 46

Propylene Glycol Material Safety Data Sheet .................................................................................................. 48

Labels .................................................................................................................................................................... 50

Systems Parts List ................................................................................................................................................. 52

Trouble Shooting .................................................................................................................................................. 53

Vacation Planning ........................................................................................................................................... 56

Maintenance Notes ........................................................................................................................................ 57

Installer Information ............................................................................................................................................. 58

Warranty & Guaranty ............................................................................................................................................ 58

Collector Warranty Certificate ............................................................................................................... 59

Page 2

Page 3

Attention: Do not lift the collectors by the connections and or the screw threads

Page 4

DOMESTIC SOLAR WATER HEATER SYSTEM

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The Free Hot Water domestic solar water heating system has gone through an extensive design, technical and

performance review by the Solar Rating & Certification Corporation (SRCC). The installation of your Free Hot Water

system is intended to be executed by properly licensed and experienced professional contractors in accordance with

SRCC Standard OG-300, "Operating Guidelines and Minimum Standards For Certifying", and must conform to

applicable federal, state and local regulations, codes, ordinances and standards governing the installation of solar

water heating systems.

The solar energy system described by this manual, when properly installed and maintained, meets the minimum

standards established by the SRCC. This certification does not imply endorsement or warranty of this product by the

SRCC. OG-300 system certification is granted to Free Hot Water by the SRCC. It may not be used for any commercial

purpose without the prior written consent of Free Hot Water. Free Hot Water must approve any deviation from the

materials and methods described in this manual in writing.

CONGRATULATIONS!

Congratulations on investing in one of the most advanced solar water heating systems available. Utilizing the free,

environmentally friendly energy from the sun to heat water for your home makes so much sense. Solar energy is

efficient, safe and reliable and your decision to use solar energy is helping to preserve our environment and to

reduce our rapid depletion of non renewable, fossil fuels.

The FREE HOT WATER solar water heating system uses the sun’s energy as a source of heat to produce hot water for

domestic household use. Designed to meet the certification requirements of SRCC 0G-300, FREE HOT WATER solar

water heating systems are reliable, and can typically generate from 50% to 80% of your annual household water

heating needs from the sun. Your remaining hot water needs can be supplied by your existing electric or gas water

heater or boiler. Results will vary based upon on your specific region in the country. Your new Free Hot Water

System uses state-of-the-art technology and will provide you with many years of maintenance free and dependable

service. If you have any questions, please feel free to contact your local dealer or our home office.

Introduction

The system performance varies as a function of the household hot water load. The ambient air temperature, the

roof pitch and orientation along with seasonal solar intensity will determine the amount of hot water generated by

your FREE HOT WATER solar water heating system.

Your FREE HOT WATER solar water heating system uses a circulation pump that circulates a propylene glycol heat

transfer fluid throughout the system. This fluid protects the collector piping from freezing, prevents corrosion of

system components, and keeps scale deposits from forming that could reduce the performance of the system.

Proper maintenance of the propylene glycol in the system can protect the solar water heating system to minus 40°

Fahrenheit. This manual is intended to familiarize you with the proper installation and maintenance of your FREE

HOT WATER solar water heating system. This system must be installed by a licensed solar or plumbing contractor in

accordance with SRCC Standard OG-300 and all applicable national, state and local codes. Failure to follow the

procedures described in this manual can void the manufacturers’ warranty.

Page 5

System Description

The FREE HOT WATER solar water heating system is a closed-loop active solar system which, when installed with a

suitable auxiliary heat source, can act as the primary source of domestic hot water for residential use. The system

components provided with the FREE HOT WATER solar water heating system include the solar collectors, collector

flashings, solar loop pipe and fittings, solar storage tank, solar pump station and controller, temperature sensors,

expansion tank, air separator, mixing valve, and non-toxic propylene glycol heat transfer fluid. The solar collector is

the engine of the FREE HOT WATER solar water heating system.

When the sun is shining, the heat energy is absorbed by the solar collector and transferred to the heat transfer fluid

circulating through the solar collectors. The system pump efficiently circulates this heated fluid through the

collector’s piping and the heat exchanger located in the solar storage tank. As the heat transfer fluid passes through

the heat exchanger, the heat in the fluid is transferred by conduction to the potable water in your solar storage tank

causing the temperature in the tank to rise. This process continues as long as the sun is shining or until the

temperature in the solar storage tanks reaches its maximum temperature set point.

General Instructions

Installation must only be carried out by qualified personnel. The entire information in these instructions is intended

exclusively for such qualified personnel. Only the supplied material should be used for the installation. Prior to starting

installation and operation of the solar collector system, please inform yourself about the applicable local standards and

regulations. The use of a carrying strap is recommended for transporting the collector. The collector must not be lifted

at the connections or on the threading. Avoid impacts and mechanical influences on the collector, in particular on the

solar glass, the rear panel and pipe connections.

The collectors may only be mounted on sufficiently load-bearing roof surfaces and substructures. It is imperative that

the static load bearing capacity of the roof or substructure is checked in terms of local and regional conditions prior to

installation of the collectors by the customer, if necessary through the involvement of a structural engineer.

Particular attention should be paid to the quality of the (timber) substructure in terms of the stability of the screw

connections necessary for fastening the collectors.

Specifications

The FREE HOT WATER solar water heating system is designed to produce domestic hot water from either solar

collector, an electrical or gas backup, or a boiler back up (provided by others). The FREE HOT WATER systems can

also be used as a solar preheat system to conventional electric or gas water heaters (provided by others).

Collectors and flashings

FREE HOT WATER solar collectors and flashings allow for a low profile, roof integrated, solar panel installation. The

FREE HOT WATER collector is made up of copper tubes and a plate that is covered with a highly selective absorber

coating; this assembly is enclosed in a well insulated aluminum frame or “box” and covered with low-iron tempered

glass glazing. FREE HOT WATER solar water heating systems are available for integration onto either shingle or tile

roofs. The collector is suitable for angles between 15° (minimum) and 75° (maximum). The collector connections

and the ventilation openings must be protected against the penetration of water as well as against contamination

through dust etc.

Page 6

Solar Storage Tank

All FREE HOT WATER solar water heating systems will include a solar storage tank with the solar heat exchanger

located in the bottom section of the tank to heat the entire water volume of the tank. The tank contains a

thermometer located on the outside of the tank so you will know the temperature in the tank.

Collector Loop Piping

FREE HOT WATER solar water heating systems are designed for use with copper pipe or pre-insulated corrugated

stainless steel flexible piping. No other piping may be substituted for use in the solar loop. Collector piping

installation requires the use of copper and brass fittings in the collector loop. Piping in new solar installations may

have dirt, grease, or other impurities that over time affect the quality of the propylene glycol heat transfer fluid. A

thorough cleaning is required before charging the system with glycol. All vertical piping between the storage tank

and the collector shall be supported at each story or at maximum intervals of ten feet (10’) using pipe hangers. If

additional supports are needed, copper plumbers tape or tube strap may be used. The pipe insulation may not be

compressed or crimped by the strapping material.

The installation of all horizontal and vertical piping may not reduce the performance or rating of any structural

member or fire rated assembly. Adhere to all applicable local codes and ordinances.

The collector loop cold supply and hot return lines must be well insulated with the high quality flexible closed cell

insulation to minimize heat loss. There shall be no exposed piping or fittings. The wall thickness of the pipe

insulation should not be less than ¾”. Any above ground exterior pipe insulation that may be subject to UV

degradation must be wrapped with foil tape or painted with two coats of high quality water-based acrylic resin

coating.

Pump Station Controller

All FREE HOT WATER solar water heating systems include a pump station controller that include the temperature

and pressure gauges, pressure relief valve, check valves, ball valves, fill and drain valves, and differential controller

required to properly operate the FREE HOT WATER solar water heating system. The system temperatures for the

collector and storage tank can be read from the differential controller. Typical tank operating temperatures can

range from the cold supply of 40°-80° F up to 180° F which represents the high limit of the tank. This will vary

depending on the climate where the system is installed. The collector temperature sensor should be 5°-20° F above

the tank sensor during normal operation. During idle periods, when there is no sun, the collector will read the

ambient temperature and when there is full sun upward to 250° F.

Balance of Systems

The balance of components in all FREE HOT WATER solar water heating systems: solar loop pipe and fittings,

temperature sensors, expansion tank, air separator, mixing valve, and non-toxic propylene glycol heat transfer fluid

components carry temperature and pressure ratings required of the FREE HOT WATER solar water heating system

design.

Freeze Protection

The FREE HOT WATER solar water heating system can be operated down to ambient temperatures of –40°F using

proper concentrations of propylene glycol. Freeze tolerance limits are based upon an assumed set of environmental

conditions. Refer to the propylene glycol specification sheet under the “Flushing and filling” section of this manual

for recommended concentration of propylene glycol and distilled water to provide adequate freeze protection in

your specific climate. The differential controller uses temperature sensors to monitor the temperature difference

between the collector and the solar storage tank. The controller turns on when the collector is 20° F above tank

Page 7

temperature and turns off when the differential drops below 10° F. HOUGHTON CHEMICAL CORPORATION “ECONOTHERM” ” and “Safe-T-Therm” propylene glycol heat transfer fluid shall be used in this system as the primary freeze

protection agent. Unauthorized fluid substitutions can result in a threat to health, welfare and safety and may cause

the system piping to freeze.

All component warranties express or implied, are voided if uninhibited glycol, potable or distilled water are

substituted for the specified heat transfer fluid described in this manual, or if the heat transfer fluid is not

maintained in accordance with the manufacturer’s instructions.

Freeze tolerance limits are based upon an assumed set of environmental conditions. Extended periods of cold

weather, including ambient air temperatures above the specified limit may cause freezing in exposed parts of the

system. It is the owner’s responsibility to protect the system in accordance with Free Hot Water’s instructions if the

ambient air temperature approaches the specified freeze tolerance limit.

Legal Guarantee

Legal guarantee claims can only be made if the supplier's own antifreeze has been used and maintenance has been

carried out correctly. Installation by qualified personnel with absolute adherence to the instructions is a prerequisite

for the justification of claims.

Tools Needed

Page 8

Collector Specifications

High Performance Thermal Collector

Intelligent Design Deep Drawn Aluminum Tray

Selective Absorbent Coating

Thermal Insulation Rockwool

Tempered Low Iron Glass

Suitable for Closed & Open Loop Systems

Pitched and Flat Roof Installation Systems

Dimensions - 79.5 X 40 X 3

Thermal Output –1.35 Kw per hour

Max Stagnation (f) 410 Max PSI-116

Absorber Capacity 1.1 gal.

Manifold 3/4 - Risers 3/8

Free Hot Water item #: FHWC-FC-50221

Gross Area: 2.070 m2, 22.28 sf

Net Aperture: 1.85 m2, 19.91 sf

Recommended Tilt Angle 5-60 degrees

Weight - 84 Lbs

10 Year Limited Warranty

Approvals - SRCC OG 100

SRCC Daily BTU's - 23,100

Page 9

Page 10

Collectors

Up to 6

Up to 13

Up to 22

Up to 45

Pipe Diameter (inch)

½”

¾”

1”

1-¼”

Flow Rate (kg/h)

50

100

150

200

250

300

350

400

450

Pressure Loss (mbar)

1.7

4.1

7.3

11.2

15.8

21.1

27.1

33.9

41.4

Pressure drop and flow rates

Mass flow rate

To ensure the performance of the collector, a specific flow rate of .5 gallons per minute is to be selected

up to a collector panel size of approximately 27 sq. ft.

Pipe diameters

Dimensions table with a specific flow rate of .5 gallons per minute

Pressure loss collector for anti-freeze / water mixture (40% / 60%) at a thermal conducting temperature

of 122° F.

Pressure loss curve: �p = 0,0001443x² + 0,0270143x

Pressure loss collector for anti-freeze / water mixture (40% / 60%), Temperature of 122° F

Page 11

Page 12

Page 13

Precautions

For safety reasons you should only fill the collectors when there is no direct irradiation from the sun (covering the

collectors can be an option). Especially in regions exposed to frost, for flat plate collectors you should use a mixture

of anti freeze with water (40% anti freeze). The solar thermal system should be filled and commissioned within one

week of installation, because heat build-up in the collector array can damage the flat gaskets in empty systems. If

this is not possible, the flat gaskets should be replaced before commissioning to prevent leakage.

Attention : Anti freeze that is not premixed must be mixed with water prior to charging the system

Recommended antifreeze for flat plate collectors – FHWM-GY-50005

25% antifreeze / 75% water mix - freeze point 14°F

40% antifreeze / 60% water mix - freeze point -5°F

50% antifreeze / 50% water mix - freeze point -25°F

It may not be possible to completely empty collectors one they have been filled. For this reason collectors exposed

to frost should only be filled with a distilled water/antifreeze mixture, also for pressure and function tests.

Alternatively, the pressure test can also be carried out using compressed air and leak detection spray.

Installing the temperature sensor

The temperature sensor should be installed in the sensor sleeve nearest to the collector array flow. To ensure

optimal contact between the sensor and the surrounding environment, the gap between the sensor sleeve and the

sensor element should be filled with a suitable conducting compound. All materials used for installing temperature

sensors (sensor element, conducting compound, cables, sealing and insulating materials) must be suitably

temperature resistant (up to 482° F).

Operating pressure: The maximum operating pressure is 145 psi.

Bleeding

The system must be bled:

- When commissioning the system (after filling the collectors)

- 4 weeks after commissioning

- When necessary, e.g. if there are malfunctions

Warning: Risk of scalding due to steam and hot heat transfer fluid!

Page 14

Only operate the bleeding valve if the temperature of the heat transfer fluid is < 140° F.

When bleeding the system, the collectors must not be hot! Cover the collectors and, if possible, bleed the system in

the morning.

See Material Safety Data Sheet on page 45 for safety information.

Check heat transfer fluid

The heat transfer fluid must be checked every two years with regard to its antifreeze and pH value.

- Check antifreeze using antifreeze tester and replace or refill if necessary!

Target value is ca. - 77° F and - 22° F depending on climatic conditions.

- Check pH value with a pH indicator rod (target value approx. pH 7.5):

If the limit pH value is less than ≤ pH 7, replace the heat transfer fluid.

Maintenance of the collector

The collector or the collector array must be inspected visually, once a year, for any damage, leaks and

contamination. Additional recommendations on operation and maintenance can be found in the supplier's general

documentation and instructions on commissioning and maintenance.

Connecting the collectors to one another

The collectors must be connected to one another and/or to the connection pipes using the supplied connectors.

When tightening the union nuts and/or compression fittings, always balance (counter) the torque* with a pipe wrench

or another spanner to prevent damage to the absorber.

Do not run the solar collector(s) without a Pressure Relief Valve, safety valve in the system to avoid over pressure in

the solar circuit.

Warning: Freeze tolerance limits are based upon an assumed set of environmental conditions.

Warning: If the freezing point of the fluid in an exposed part of the system is above the freeze tolerance

limit specified for the system: Extended period of cold weather, including ambient air temperatures

above the specified limit, may cause freezing in exposed parts of the system. It is the owner’s

responsibility to protect the system in accordance with the Supplier’s instructions if the air temperature is

anticipated to approach the specified freeze tolerance limit.

Page 15

Solar Collector Orientation

Operating your Free Hot Water solar water heater for optimal efficiency is based on the correct orientation, pitch,

and location of the solar collectors. In North America, collectors should be oriented due south, however may be

oriented up to 45 degrees east or west of due south with minimal losses in solar gain. Optimal pitch is +/– 10° from

the latitude of the installation site.

Free Hot Water solar collectors must be installed at a minimum pitch of 15 degrees from horizontal, and for optimal

performance, the recommended pitch is between 15–60 degrees. The collector should be mounted as close to the

storage tank as possible to minimize heat loss in the piping runs. The solar collector must be located in an area of

the roof that will be un-shaded for the majority of the day (from 9:00–3:00) all year round. Adjacent buildings and

trees should be checked for possible winter shading.

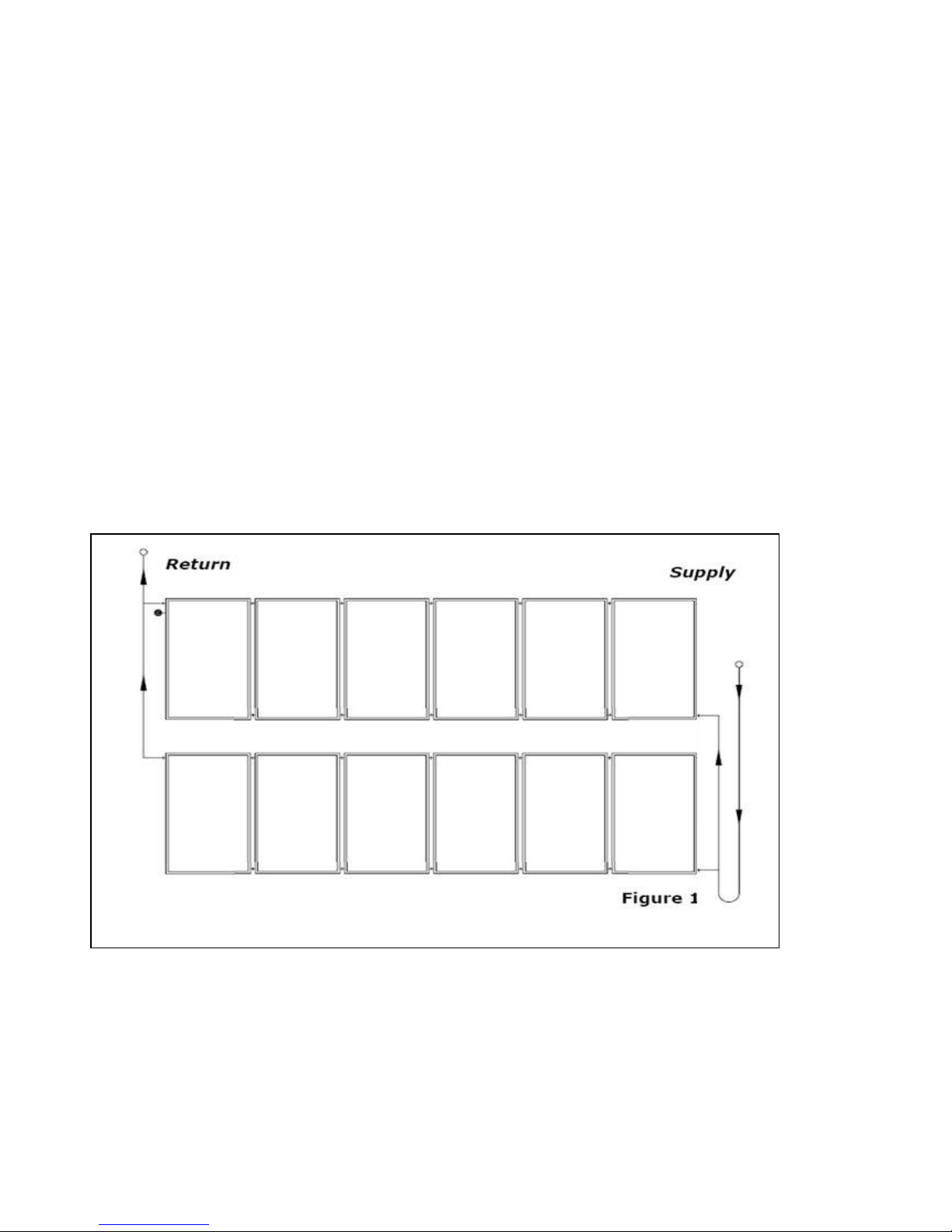

The following diagram below is an example of how the collectors can be connected to one another. However, the

actual connection may be different depending on structural conditions. A maximum of 6 collectors may be

connected in a series! If a collector panel is made up of more than 6 collectors, the panel must be connected several

times in parallel

Page 16

Installation Steps for Pitched Roof Mounting

1. Locate and mark the roof rafters into which the solar collector mounting brackets will be mounted

(one way to find rafters is to see the “tails” at the edge of the roof).

2. To create a set point for plumbing and level installation, measure the distance from the edge of the

roof to the desired mounting points and mark the points where the collector mounting brackets will be

installed (fig 1.2).

*Note: you need to install a screw into one of the holes in the mounting bracket, not both holes (fig

1.1).

* Note: for collector model 7000 upper and lower mounting bracket should be 78” apart measured

from top of top bracket to bottom of bottom bracket.

* Note: both the bottom and the top mounting brackets should be placed as per figure 2.0 from each

other as possible in the width dimension.

Fig 1.1 Fig 1.2

3. Determine where penetration will be to connect the solar hot water collector with the storage tank

and/or the water supply (use 2 pre-insulated ¾” steel flex hoses or 2 insulated ¾” copper pipes for

that connection).

Note: *For a two-collector system that will be elevated above the roof surface, a good location for this

penetration is directly between the two collectors.

4. Holes should be slightly overlapping to form a sideways “8” shape (see illustration 1.3). Mark the

penetration before making holes. If you are installing on a composition shingle roof make holes 5”

below the bottom of the shingle above the penetration.

Page 17

Fig 1.3

5. Using a hole saw, cut the hole (penetration) for the 2 hoses or pipes from step 3.

6. If using flex hose: before connecting the hose, measure, cut, and lay out the hose, including enough

length for 8’ of hose above the roof. Pull the hose through the hole.

7. Begin mounting bracket installation with bottom bracket. Mark a straight chalk line between the 2

bottom bracket mounting points.

8. For composition shingle roof, DO NOT PENETRATE THE COMPOSITION SHINGLE. Before installing

9. Next, using a cutting tool, cut out a piece of the roof material beneath the top layer of the composition

Page 18

Fig 1.4

screws, lift the composition shingle at the install point and slide the mounting bracket in, beneath the

top composition shingle. Place the bracket so that the top surface composition shingle clears the

bracket when folded (lifted) up or down and mark an outline of the mounting bracket where the

mounting bracket will be fastened to the roof rafter or other appropriate mounting substrate. The

marked area should be 1.5” wide and 2.5” high.

shingle (the top layer will NOT be penetrated for the mounting brackets) as marked 1.5” X 2.5” in the

shape of the mounting bracket.

Cutting out a piece of roofing material will provide for a flush-mounted roofing bracket.

Loading...

Loading...