Page 1

X

With transport option

Supplier: This manual must be given

to the user/care giver of this

wheelchair.

Rider: Before using this wheelchair,

read this entire manual and

save for future reference.

Centre of Gravity

Tilt in Space Wheelchair

Standard, Extra Wide

& Paediatric

User Guide

Part No. 1536525 Issue 05

11-5-2010

Page 2

Page 3

Table of Contents

Useful Symbols In This Guide 2

Introduction 3

Warranty Terms & Conditions 4

Limitation of Liability 5

Intended Use 6

Safety & Operating Limits 7-16

Weight Limit 7

Reaching For An Object From

A Wheelchair 7-8

Transferring To Another Seat 9-10

Tilting The Chair 11

Kerbs, Or Obstacles 30mm

To 50mm High 12

Steps, Stairs Or Obstacles Over

50mm High 13

Upward & Downward Slopes

(Operating Limits) 14

Summary Of Safety Instructions 15

General Descriptions 16

CGX™ Features 17

Use 18-24

Unfolding the CGX™ 18

Folding the CGX™ 19

Main Frame 20

Angle Adjustable Footplates 21-22

Individual Flip Up Footplates 22

Quick Release Axle 22

Flip Back Arm 23

Locking Flip Back Arm 23

Castors 23

Wheel Locks 23-24

Tilting The CGX™ 26

Changing Frame And Seat

Widths 27

Cleaning And Maintenance 27

Storage 27

Troubleshooting - Mechanical 28-29

Transportation 30-31

Product End Of Life 31

Contacting INVACARE 32-33

Adjustments 24-26

Folding Back 24

Backpost Angle And Depth

Adjustment 24

Flip Arm/Locking Arm 25

Castor Fork Adjustment 25

Wheel Lock Adjustment 25

Anti Tip Lever Adjustment 26

1

Page 4

Useful Symbols

Useful Symbols In This Manual

WARNING!

This symbol warns you of danger! Always follow the instructions to

avoid injury to the user or damage to the product!

EXPLOSION HAZARD!

This symbol warns you of an explosion hazard, an example of

which can be caused by excessive tyre pressure in a pneumatic

tyre!

• Always follow the instructionsto avoid injury tothe user or

damagetotheproduct.

NOTE:

This symbol identies general information which is intended to

simplify working with your product and which refers to special

functions.

REQUIREMENTS:

This symbol identies a list of various tools, components and

items which you will need in order to carry out certain work.

TRANSPORTATION:

This symbol identies important information relevant to

transporting your wheelchair in a motor vehicle.

2

Page 5

Introduction

Introduction

Thank you for purchasing your Freedom Designs, Inc. CGX™

wheelchair. The CGX™ combines state-of-the-art technology with

durablility and function to meet all of your changing needs. This

operating manual will provide you with a detailed guide for proper use as

well as instructions on the care of your new CGX™ wheelchair. Please

follow the instructions carefully, paying special attention to the ‘Safety

Precaution’ section.

It is important that you read the entire operating manual before operating

the CGX™. After consulting your operating manual, if you have further

questions, please contact one of our authorised dealers.

Note for Customers

INVACARE provides a wide range of wheelchairs to meet the

requirements of customers. However, the decision on the type of model

to be prescribed rests exlusively with experienced advisors.

INVACARE or its appointed representative shall not be held responsible

if a wheelchair is used that is unsuitable for the user’s level of disability,

if the wheelchair itself is incorrectly used or if a problem arises due to

poor maintenance.

The information set out in this manual may be modied without prior

notice. This manual contains copyright information. All rights are

reserved. No part of this document may be photocopied or reproduced

without prior written agreement from INVACARE or its appointed

representative.

This manual gives details of all the options of the CGX™

wheelchair. It describes the options, operation and adjustments

that mey be required. However, your INVACARE retailer will be

able to give you further information and demonstration.

3

Page 6

Warranty Terms &

Conditions

Warranty Terms & Conditions

Standard INVACARE Terms

This is to certify that your wheelchair is warranted by INVACARE Ltd. for a

period of 1 year for parts, 2 years for hardware and frames.

1. Only INVACARE chairs purchased at full price are warranted against

defective workmanship and materials.

2. If a defect or fault is discovered the INVACARE dealer from whom the

wheelchair was obtained should be notied immediately.

3. The manufacturer will not accept responsibility for damage caused by misuse or

non-observance of the instructions set out in the user manual.

4. During the period of the warranty any parts that have become

defective, due to faulty workmanship or materials, will be renewed or

repaired without charge by the INVACARE dealer.

5. The warranty will be invalid should any unauthorised alteration be made

to the equipment.

6. The purchaser’s statutory rights under the Consumer Protection Act are

not affected.

4

Page 7

Limitation of Liability

Limitation of Liability

This warranty does not extend to the consequential costs from fault

clearance, in particular freight and travel costs, loss of earnings,

expenses, etc.

• Natural wear and tear.

• Inappropriate or incorrect use.

• Defective assembly or setting-up by the purchaser or third parties.

• Defective or neglectful treatment.

• Use of unsuitable spares.

5

Page 8

Intended Use

Intended Use

The CGX™ manual wheelchair has been designed to provide mobility and

comfort for persons with impaired mobility.

The wheelchair has been designed to be used by a seated user with a carer/

attendant in both indoor and outdoor environments.

The wheelchair has, in its standard format, been designed to accomodate

users who weigh up to a maximum weight of 90kg on a chair width from 10” to

18”, and 136kg on a chair width from 18” to 22”, have all limbs intact and have

sufcent upper body strength to maintain a safe position within the wheelchair

without the addition of supporting aids.

Adaptations from the standard wheelchair format are available to

accommodate users who do not meet the above criteria but these will only be

considered after a suitable risk assessment has been carried out by the product

prescriber. For example, a user with either a full or partial amputation or other

condition, which affects the natural centre of gravity will need to have a stability

evaluation to minimize the risk of inadvertent tipping.

The wheelchair should only be used in accordance with the safety advice given

within this user guide. Failure to follow the recommended advice within this user

guide could lead to personal injury.

No claims are made that the product will medically improve the circumstances

or condition of the user.

6

Page 9

Safety & Operating

Limits

Safety & Operating Limits

Stability and Equilibrium

To ensure that the wheelchair remains stable and is manipulated correctly,

you must always maintain good equilibrium. Many actions cause the user

of a wheelchair to reach out, lean over or move about within the wheelchair

and outside it. These actions will change your centre of gravity and weight

distribution of the wheelchair. Your wheelchair has been designed to remain

stable for normal everyday use if it is used correctly taking the precautions

recommended in this manual.

Weight Limit

The maximum user weight limit is 90 kg on a chair width from 10” to 18”, and

163kg on a chair width from 18” to 22”.

However, the wheelchair user’s level of activity is important. For example, an

active user weighing 75kg may subject the wheelchair to more stress than

a less active user weighing 114kg. We recommend very active wheelchair

users to choose an appropriate design of wheelchair. Your INVACARE approved

distributor will advise you on the best model.

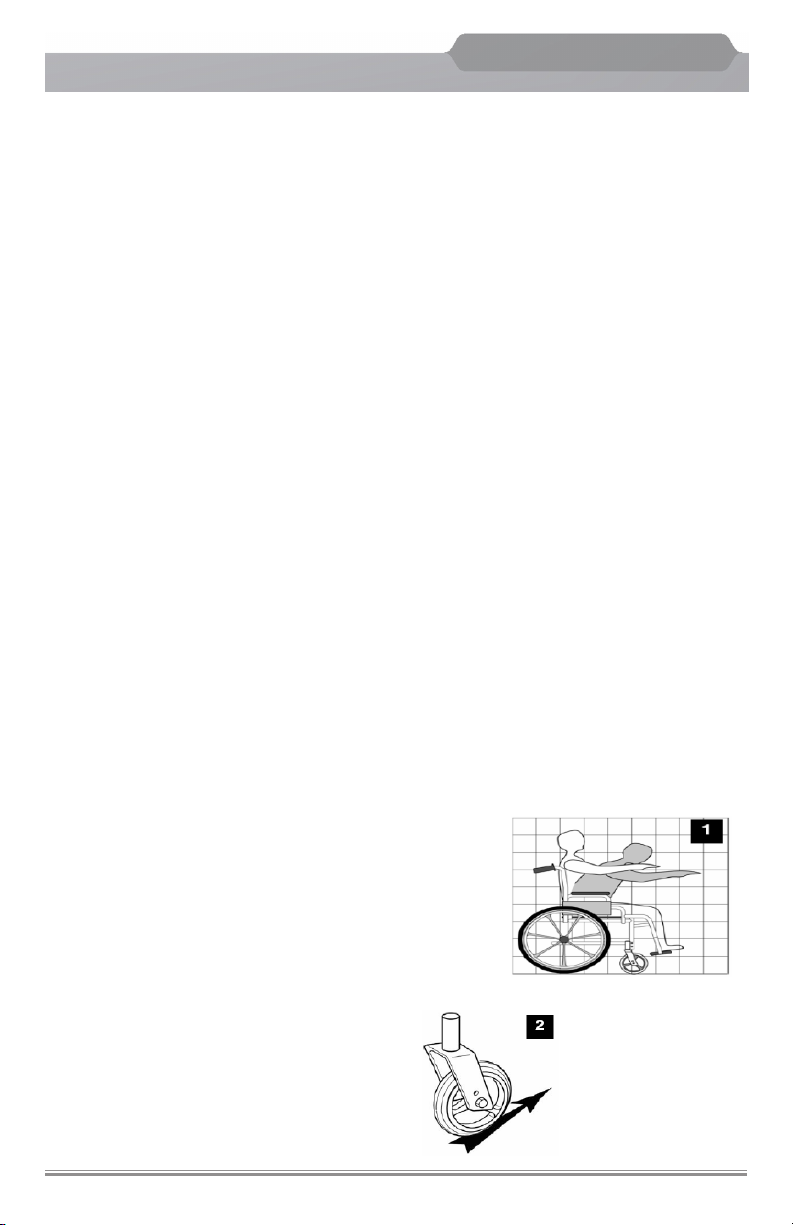

Reaching For An Object From A Wheelchair

The limitations on reaching out from a wheelchair shown in Figure 1 have been

produced using a representative sample of wheelchair users. Only the arms

should extend beyond the seat of the wheelchair. For safety reasons, the body

and head should remain within the wheelbase.

Position the castors to give the longest possible wheelbase (Figure 2). Lock the

manual brakes on the rear wheels.

7

Page 10

Safety & Operating

Limits

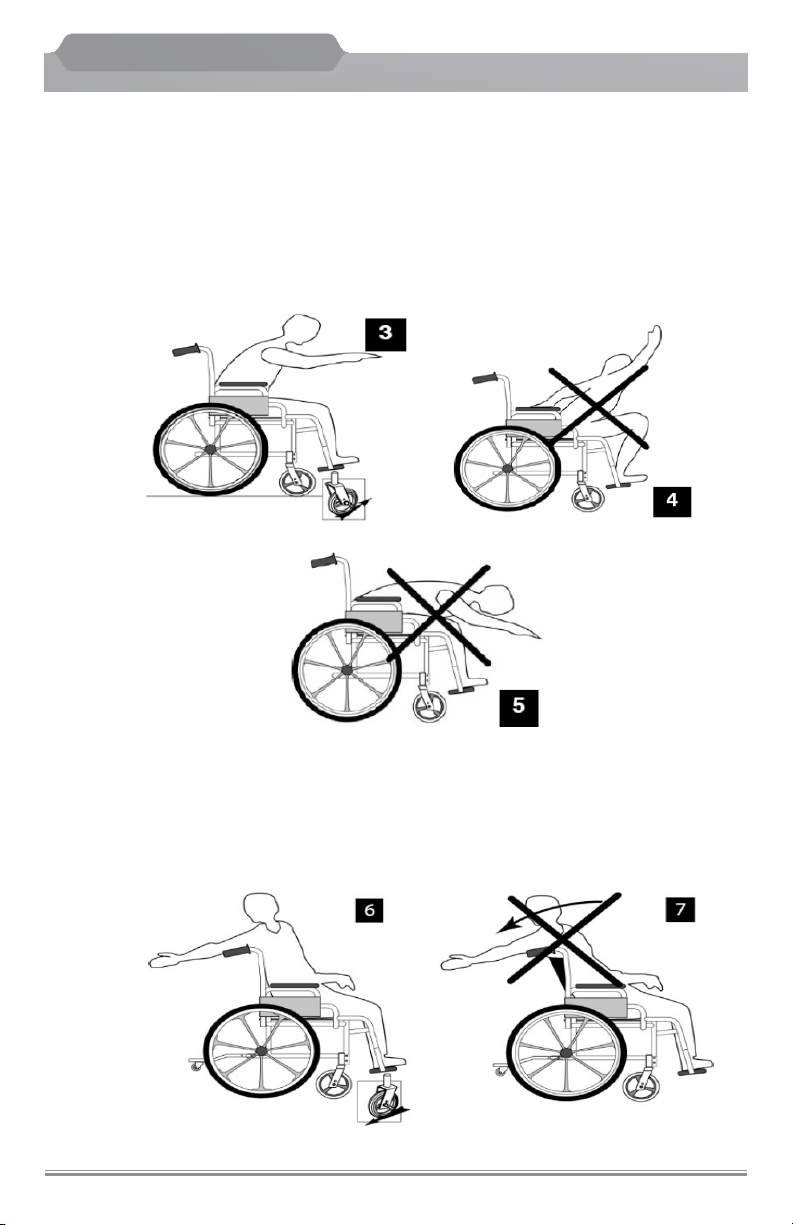

Leaning Forwards

(Figures 3, 4, 5)

Move the wheelchair as close as possible to the object you wish to reach. Only

reach out for objects that are within arm’s length in a normal sitting position.

Leaning Backwards

(Figures 6, 7)

Move the wheelchair as close as possible to the object you wish to reach. Only

lean back for objects that are within arm’s length in a normal sitting position.

8

Page 11

Safety & Operating

!

Limits

!

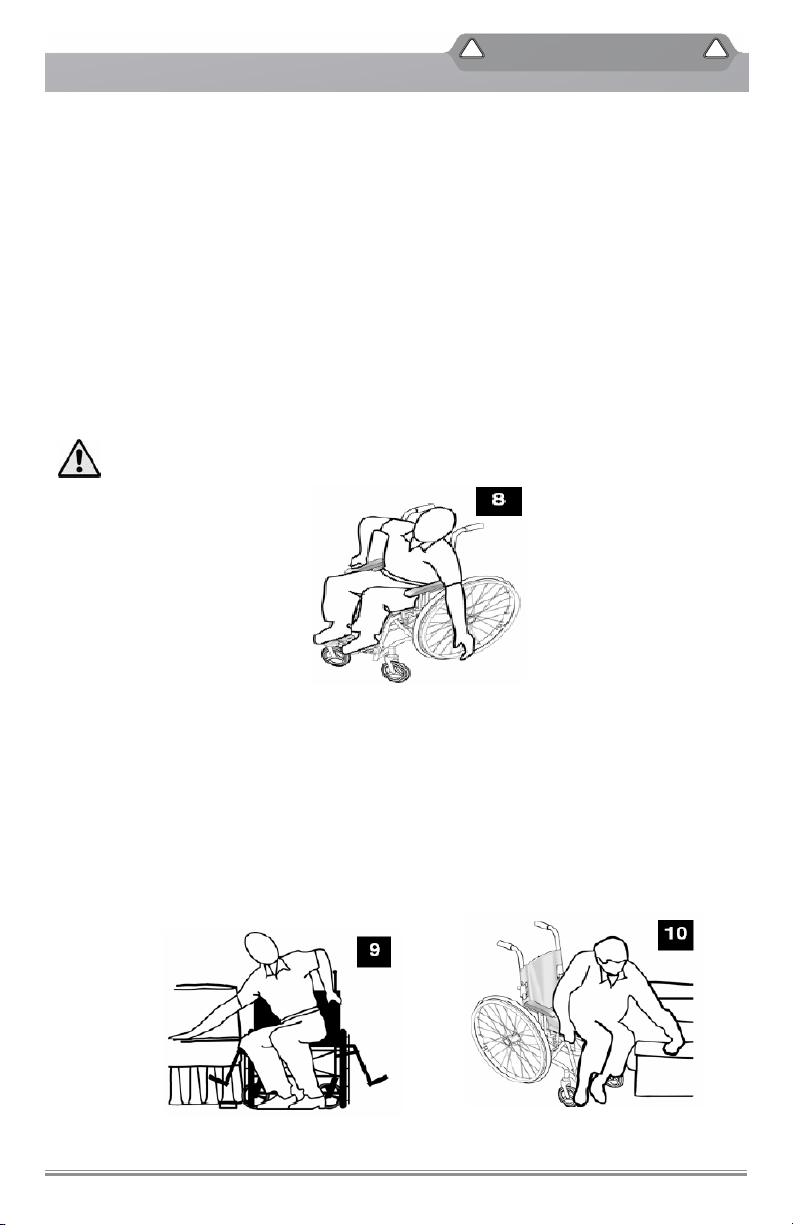

Transferring To Other Seats

Leaning To One Side

(Figure 8)

This is a dangerous manoeuvre as it is easy to tip sideways.

To move up to an object and lean over, you must use the castors as a means of

keeping the wheelchair stable and balanced.

For your safety, it is essential to be in the correct position.

Do not try to pick something up from the oor if this would upset your balance.

It is possible to move from and to a manually propelled chair if the

following guidelines are followed. INVACARE does not reccomend any particular

method for transferring: This is the responsibility of a medical advisor who should

consider your level of disablity and type of wheelchair. When transferring, either

to get out of or return to your wheelchair, make sure that the gap between the

two seats is as small as possible.

(Figures 9, 10)

9

Page 12

Safety & Operating

!

Limits

!

When transferring, either to get out of or return to your wheelchair, make sure

that the manual brakes on the rear wheels are on to prevent the wheels moving

(Figure 11).

Turn both castors towards the seat to which you wish to move. Lift up the

footplates (Figure 12).

Do not stand on the footplates.

If possible, swing the legrest hangers out to the side to clear the passage

(Figure 13).

If possible, ip up the armrests on the side between the wheelchair and the

other seat (Figure 14).

Note: Never stand on the footplates (Figure 15).

10

Page 13

Safety & Operating

!

Limits

!

Tilting The Wheelchair

To tilt the wheelchair (Figure 16), a second person should grip the handle

rmly. Warn the user of the wheelchair before tilting it and remind him/her

to lean backwards. Check that the user’s feet and hands are clear of all the

wheels. Push smoothly until the wheelchair is at the point of equilibrium. At this

stage, the helper will feel a difference in weight distribution. Turn the wheelchair

in the direction required and negotiate the obstacle.

Lower the front of the wheelchair smoothly, holding the handles rmly. Do not

lower the wheelchair suddenly for the last few centimeters before returning to

the normal position, this may cause discomfort.

11

Page 14

Safety & Operating

!

Limits

!

Kerbs, Or Obstacles 30mm To 50mm High

Method 1 - Negotiating the obstacle forwards

(Figure 17)

The helper should tilt the wheelchair until the castors have passed over the

kerb. Move the wheelchair forwards and lower the castors gently onto the

pavement. Push the wheelchair until the rear wheels touch the kerb. Lift and

push until the rear wheels have mounted the kerb. Do not just lift by the handles

on the backrest.

Method 2 - Negotiating the obstacle backwards

(Figure 18)

The helper should stand on the pavement and turn the wheelchair until the

rear wheels are against the kerb. Tilt the wheelchair backwards to the point of

equilibrium and, in a continuous movement, pull the wheelchair until the rear

wheels mount the kerb and pass onto the pavement. Do not lower the castors

to the ground until you have pulled the rest of the wheelchair sufciently far to

clear the kerb.

Note: Folding backs should always be checked to ensure they are engaged.

12

Page 15

Safety & Operating

!

Limits

!

Steps, Stairs Or Obstacles Over 50mm High

We recommend that you take very great care when taking a wheelchair up or

down stairs. Two people are required for this.

ADVICE TO SECOND OR THIRD PERSONS:

Make sure that you get hold of xed, non-removable parts only!

Using the following procedure for going upstairs (Figure 19): Tilt the

wheelchair to its point of equilibrium. One helper (at the back) holds the

wheelchair up against the rst step, gripping the handles rmly to lift. The

second helper, holding a rmly xed part of the front frame, lifts the wheelchair

above the stairs and holds it while the rst helper places one foot on the

following step and repeats the operation. The wheelchair must not be lowered

until the last step has been negotiated and until the chair is clear of the stairs.

Escalators

Do not use an escalator when moving a wheelchair from one oor to another.

This might cause serious injury.

13

Page 16

Safety & Operating

!

Limits

!

Upward & Downward Slopes (Operating Limits)

Do not attempt to go up or down slopes greater than 10% without assistance

(Figure 20).

Always go straight up and down slopes otherwise the wheelchair might overturn

(Figure 21).

14

Page 17

Safety & Operating

Limits

Summary Of Safety Instructions

Summary of instructions for use for improved safety:

• User weight limit (including accessories): 90kg on a chair width from 10”

to 18”, and 136kg on a chair width from 18” to 22”.

• Do not try to reach objects if you have to move forward on the seat.

• Do not try to reach objects on the ground if you have to lean down beyond

the safety limits.

• Do not lean too far back to reach objects behind you: you may tip over.

• Do not move your weight, or your sitting position in the direction in which

you wish to go: you may tip over.

• Always apply both manual brakes before trying to get out of or back into

the wheelchair.

• The manual brakes are not designed for slowing you down.

• Do not try to stop a moving wheelchair using the manual brakes.

• Do not use an escalator for moving a wheelchair from one oor to another.

(This may cause serious injury).

• Do not use your wheelchair if the tyres are not inated to the correct

pressure shown on the side.

• Do not over-inate the tyres. Failure to comply with these instructions

may cause the tyre to burst and cause bodily injury.

• Carry out the regular checks recommended in this guide and by your

INVACARE approved retailer.

• Use your wheelchair with respect for other people.

• Do not use your wheelchair as a transport seat in a vehicle. unless it is

not practical for the user to be transferred (Refer to page 31 - Transport).

15

Page 18

General Descriptions

General Descriptions

Each wheelchair is specially designed to meet the requirements of its user. This

manual describes how to adjust the chairs in this range, enabling you to nd out

how to adjust the wheelchair to suit your needs.

General Descriptions

Your wheelchair has a number of main parts which will be mentioned

throughout this manual. These parts are described below.

Support is provided by the backrest, seat and armrests.

The chassis comprises of the side frames and cross brace. This is the

essential supporting framework of the wheelchair on which all the other parts

are mounted.

The front castors comprise of the fork and wheels. The front wheels provide

contact with the ground and the rotating forks steer the chair.

Manual brake - The manual brake is used to park the wheelchair.

Swing away footrest support and leg rest - These are connected to the

chassis and can be swung away to make transfer easier to and from the

wheelchair.

The footplate assembly comprises of the adjustable tube and foot plate.

These support your feet.

The heel support strap or calf support strap. These two straps support your

feet or legs in the best position.

These parts are illustrated on the following page.

16

Page 19

Features

Freedom CGX

TM

9

2

6

2

8

3

5

4

12

14

1

10 11

13

1. Base Frame

2. Seat Frame

3. Backpost

4. Backpost Pivot Plate

5. Backpost Trigger Mechanism

6 Castor Wheel

7. Castor Fork

8. Seating

9. Footrest Assembly

10. Tilt Mechanism

11. Anti Tip Lever

12. Rear Wheel

13. Quick Release Axle

14. Wheel lock

17

Page 20

Unfolding the Freedom CGX

TM

For ease of transporting and lifting, the

chair back can easily be unfolded and

folded.

Always engage the wheel locks by pushing

forward or pulling back on the levers before

unfolding the chair.

1. Place wheels on quick release axles

and push into axle receiver on frame

until quick release push button “pops

out” and wheels are secure.

2. Set the wheel lock on each side.

3. Unfolding the back assembly is

accomplished by grasping the push

handles or straight back posts and

pulling them to an upright position

where they will lock into place.

4. Push the ip back armrests down to

the at position

18

Page 21

Folding the Freedom CGX

TM

1. Set wheel locks.

2. Flip back the armrests to the upright

position.

3. Pull up on the trigger mechanism for

the backposts and push the backposts

to the at position over the seat rails.

19

Page 22

Main Frame

Anti-Tip Device

Flip-up, removable anti-tip levers come

standard on the CGX™.

The anti-tip levers are preset at the factory.

The anti-tips may be adjusted vertically

(see “Anti-Tip Adjustment”, Page 26).

They can also be ipped up out of the way

or removed.

Toiptheanti-tipleversup, push in on

the button shown at left. Rotate the lever

inward and upward. The lever will snap

into place in the upward position.

Reverse procedure to place the anti-tips in

the lowered position for use.

To remove the anti-tip levers, push in on

the button at the top of the bend and pull

backward. The anti-tip will slide free of the

frame.

Warning:

Under normal use, anti-tip devices will

prevent the wheelchair from tipping

over backward. Anti-tip devices are to

stay on the chair, in the lower position

shown, when in use and should not be

altered or disabled.

Wheels and Tyres

The CGX™ wheelchair offers the

following tyre options:

12”, 16” and 18” (check prescription form

for options).

Wheels may be removed from the chair

by releasing the quick release axles. (See

quick release axles—Page 22)

Check pneumatic tyres weekly for proper

ination level listed on the tyre sidewall.

For wheel lock effectiveness, proper tyre

ination must be maintained.

No-at inserts are available for the pneumatic

mag wheels.

20

Page 23

Main Frame

Angle Adjustable Footboard

1. To attach the footboard to the frame, place

the footboard clamps on the frame. Set the

clamps at the desired height. Insert the

receiver into the clamps and tighten the two

(2) hex head screws on each side.

2. To remove the footboard for transfer, unscrew

the knob assemblies underneath the receivers.

Lift the footboard upward, out of the receivers.

3. To attach the footboard after transfer, align

the footboard ttings into the receivers.

Turn the knobs on each side to tighten.

4. To change the angle of the footboard, use an

allen key and loosen the flat head

screws on the top of the footboard. When

the desired an gle or depth is reached,

tighten bot h screws.

21

Page 24

Main Frame

Angle Adjustable Footboard…….

5. To change the height of the footboard on the

frame, loosen the two (2) hex head screws

on footboard frame clamps. Set the desired

height and tighten.

Steps 1 & 2

Step 3

!

Warning:

In all footplate and hanger adjustments, be

sure that all screws are tightened securely

for your safety.

Individual Flip Up Footplates

Adjustment of the individual ip-up footplates

are as follows:

1. The individual footplates easily ip by lifting

from underneath the footplate to ip up or

push down on the footplate to ip down.

To adjust the height of the footplate :

2. Remove the hex head screws on the side

of the hanger. Seat the footplate at the

desired height. Insert the screws through

the corresponding holes in the hanger tube

and tighten.

3. To adjust the angle of the ip-up footplate,

loosen the lock nuts under the footplate.

Set the foot plate at the desired angle and

re-tighten nuts.

Quick Release Axle

The CGX™ is equipped with double lock

quick release axles that release with the push

of a button. This double lock quick release

mechanism allows the large drive wheels to be

easily removed for transportation or storage.

!

To remove the rear wheel:

1. Unlock the wheel lock.

2. Grasp the frame with one hand.

3. With the other hand, squeeze the quick

release button.

4. The wheel will then pull off easily.

22

Page 25

Main Frame

!

Warning:

The axle is not properly locked until the

outside quick release button pops out to its

fully extended position.

Flip Back Arm

The CGX™ is shipped with ip back armrest

as standard equipment. The ip back armrests

are non removable and are available in either

locking or non-locking.

Locking Flip Back Arm

To ip the arm back, push the trigger mechanism

forward as shown and lift arm upward.

Castors

The CGX™ is shipped with 76mm (3”), 102mm

(5”), 152mm (6”), or 178mm (7”) polyurethane

castors with castor forks or a variety of 127mm

(5”) or 152mm (6”) wheels.

!

Wheel Locks

The CGX™ comes standard with push or pull to

lock wheel locks or hub locks.

Push or Pull to Lock Wheel Locks

To lock wheels in place:

1. Grasp the lever of the wheel lock with your

hand.

2. Push lever forward (push to lock) or pull

lever back (pull to lock) to engage the wheel

lock. Reverse procedure to release the lock.

23

Page 26

Adjustments

Caution:

Always set the wheel locks when entering

or leaving the wheelchair. Wheel locks are

not designed to slow the wheelchair down

when it is moving. Wheel locks hold the

wheelchair in place when it is at a complete

stop.

Wheel Lock Options

The CGX™ also offers the option of wheel lock

extensions.

Adjustments

Folding Back

Pull Up

A

The CGX™ comes standard with a folding

back.

1. To fold the back down, pull upward on the

trigger while pushing backposts forward

toward seat.

2. To place the backpost to the upright position,

pull backposts up until trigger snaps into

place.

Note: The backposts fold down completely

whenusingasolidseatandback.Whenusing

a sling seat and back the backposts will only

foldpartially.

Backpost Angle Adjustment

The angle and depth of the backposts may

be adjusted independently. To adjust the back

angle, remove the top screw (A). Tilt the back

to the desired angle, aligning holes in the back

hinge with threaded holes in back mount bracket.

Re-install screw and tighten securely.

Backpost Depth Adjustment

Remove (2) screws, washers and nuts (B).

B

Slide back hinge assembly to the new position,

aligning holes in mount bracket with holes in

frame tube. Re-install hardware and tighten

securely.

24

Page 27

Adjustments

Flip Arm / Locking Arm

To adjust height of armrests, loosen and

remove the bolts and nuts holding the arm

to the backpost tube. Align holes in arm with

holes in backpost tube at desired height.

Re-assemble with bolts and nuts.

Castor Fork Adjustment

Interchanging castors can easily be done with

dual hole castor forks. Currently, 3”, 4” 5”,

6” & 7” castors are available for use (check

prescription form for options). To adjust, loosen

the bolt and remove the castor. Change the

castor and/or position the castor upward or

downward in pre-drilled holes on the castor

fork. Replace the bolt and tighten securely.

Note: When changing the size of the

castorwheel,itwillalsobenecessarytochange

thesize oftherear wheelinorder tokeepthe

wheelchairframeparallelwiththeoor.

Wheel Lock Adjustment

When the rear wheel is repositioned, it is important

that the wheel lock is readjusted also.

1. Adjustment can be made by loosening the

1/4-20 x 1” (25.4mm) button head screws

and sliding the wheel lock assembly along the

frame tubing so that the wheel lock contacts

the tyre in the locked position. Continue to

adjust until the knurl ed grip handle

embeds in to the tyre approximately

6.35mm (1/4”) when in the locked position.

Tighten the screw until wheel lock is snug

to frame tube.

Warning:

Wheel locks are not designed to slow the

chair down when it is moving. When the

chair is stopped, engaging properly adjusted

wheel locks will prevent the Drive wheels

from turning.

25

Page 28

Adjustments

Anti-tip Lever Adjustment

1. Remove the screw, nut and washers that

attach the roller assembly to the lever.

2. Align holes in roller assembly with holes in

lever at desired height (recommended at

38.1mm (1-1/2”) to 50.8mm (2”) off of the

ground).

3. Re-install screw, washers and nut—tighten

securely.

Warning:

!

Under normal use, anti-tip devices will

prevent the wheelchair from tipping over

backward. Anti-tip devices are to stay on

the chair in the lowered position, at all times

when in use and should not be altered or

disabled.

Tilting the Freedom CGX™

With the chair on a level surface:

1. Set the wheel locks.

2. Hold the handgrips with both hands.

3. Press down and hold the foot tilt lever with

your right foot.

4. Push the back handles forward for less tilt

or pull rearward for greater posterior tilt.

5. When the desired tilt is achieved, lift up on

your foot to engage the tilt lock mechanism.

6. Set the lockout for the foot tilt lever after the

desired tilt angle has been achieved.

!

!

Warning:

The locking pin must be installed whenever

the chair is in motion.

!

26

Page 29

Cleaning

Adjustments

Changing Frame and Seat Width

The seat and fr ame can be widened in

25.4mm (1”) increments. The frame can be

widened independently to allow for additional

lateral stability.

To widen the frame:

Remove the screws (x 6) located at the lower

arrows (shown at left) under the frame cross

members on each side. Slide the frame out to

desired width. Align holes in cross members

with holes in telescoping frame tubes. Re-install

the screws and tighten securely.

To widen the seat and back:

Remove the (x 4) screws at the two (2) center

arrows on underside of each side of the seat

and the one (1) screw on the back spreader

bar at the top arrow (shown at right). Slide the

frames out to desired width, align holes and

re-install screws. Tighten securely.

It is important for optimum performance to clean and maintain your CGX™. We

recommend that the frame nish be cleaned with mild soap and water.

In order to operate the CGX™ properly and safely, routine maintenance will extend the

life and efciency of your wheelchair.

Safety Inspection Checklist

Follow these maintenance procedures for optimum performance of your CGX™

wheelchair:

1. Check to see that the wheelchair rolls straight.

2. Tyres: Check for at spots, wear and proper ination.

3. Wheel lock:

a. Check to see that the locks engage easily.

b. Check that the locks are free of wear

c. Check to see that the locks do not interfere with the tyres when rolling.

4. Ensure that all fasteners are secure.

5. Castors: Inspect axle for proper tension. Spin the castor. The castor should spin

freely and come to a gradual stop.

Storage

The CGX™ folds down to a small unit and the rear wheels may be removed. We

suggest when storing the wheelchair, that it be stored in an indoor, cool and dry area.

27

Page 30

Trouble Shooting

A list of authorised repair facilities may be obtained from:

Invacare UK Ltd.

Pencoed Technology Park

Pencoed

Bridgend

CF35 5HZ

Tel: 01656 776222

Fax: 01656 776220

E Mail: ordersuk@invacare.com

Invacare Ireland

Unit 5, Seatown Business Campus

Seatown Road

Swords

County Dublin

Ireland

Tel: + 353 1 8107084

Fax: + 353 1 8107085

E Mail: ireland@invacare.com

Web: www.invacare.ie

Trouble Shooting - Mechanical

Initial a djustments should be mad e to suit p ersonal body structure/u ser

capabilit y and preference. Th ereafter, follow these maintenance procedures:

Chair Veers

Left/ Right

X X X

X X X X

Slugg ish Tu rn/

Perfo rmanc e

X X

Casto rs

“flut ter”

Squea ks &

Rattl es

Solut ions

If pneumati c, check tyres fo r

correct and eq ual pressur e

Check for l oos e stem nuts /bo lts

Check that bot h castors c ont act

ground at t he same time

Looseness in Chair C hair “3 Wheels” Solutions

X

X

28

If pneumati c, check tyres fo r c orrect a nd

equal press ure

Check for l oos e stem nuts /bo lts

Page 31

Trouble Shooting

Checking The General Condition

For maint enance operations, consu lt your dis tributor who has all the necessary

informati on.

Ask your distributor to annually inspect you r wheelchair thoroughly and carry

out in de pth maintenance. Regular maintenanc e allows defective or wo rn parts

to be ide ntified and improves the normal ope ration of your wheelchai r.

The follo wing table shows what to check when the wheelchair is deliv ered,

each week , each month and at 6 mo nthly inter vals.

Checks to be Made:

1. General:

The wheelch air moves in a st rai ght line (n o

resistance or drag)

2. Manual brak es:

The manual bra kes do not tou ch the tyre s w hen

moving

The manual bra kes are eas y t o o perate

The articul ati ons are not wo rn and do n ot sho w signs

of play

3. Frame work

Examine the m t o check tha t t hey are not wo rn or bent

4. Clothing pr otectors/armrest upholstery

Check that all fixings ar e i n p osition and ti ghtened

5. Armrests

Firmly atta che d but easy to rem ove

6. Arm Pads/ Foam

Check that the padding is in go od condi tio n

7. Seat and ba ckrest upholstery

Check that it is in good con dit ion

8. Castors

Check the a xle to ensure tha t i t is cor rec tly tighten ed,

by turning the castor. T he casto r s hou ld stop

gradually

9. Fork / Fork tube

Check that all the fittin gs are in plac e

10. Pneumatic and solid tyres

If the whee lch air has pne uma tic tyres, che ck that

they are co rre ctly inflat ed (th e pressu re is shown on

sidewall)

If the whee lch air has sol id tyr es, chec k t he running

surface

Freedom D es igns, Inc.

29

On

deliv ery

Wee kly Mo nthly

X X

X X

X X

X X

X X

X

X X

X X

X X

X X

X X

X X

X X

Freedom C GX

6

Month ly

TM

Page 32

Transport

Transport

INVACARE always advises that a wheelchair secured in a vehicle

will not provide the equivalent level of vehicle seating systems and

recommends transfer to the vehicle seating, but also recognises that it is

not always practical for the user to be transferred. In those cases where it is

considered that the user must be transported whilst within the wheelchair,

then the following advice should be followed.

Note: The wheelchair user safety during transportation largely depends

upon the diligence of the person securing the tie downs and passenger

restraints.

1. Seek conrmation from the transporter that the vehicle is suitable

designed and equipped to transport a passenger seated in a

wheelchair.

2. Any part of the wheelchair (accessories, etc.) that can be easily

detached should be removed and stored in the vehicle luggage hold

during transportation.

3. The wheelchair should always be transported in a forward facing

direction. Rearward facing is only acceptable if the occupant’s head

and back can be supported by a suitable bulkhead.

4. INVACARE recommends that the wheelchair be secured by 4-Point

webbing tie down systems as manufactured by Unwin Safety Systems

or Koller Safety Resraint Engineers.

5. When attaching tie down systems to the wheelchair it is imperative

these are xed onto the main frame of the wheelchair and not onto

any attachments or accessories (not wheels, handrims, castors,

footrests, anti tipping levers etc.). Tie down points are indicated by the

tie down stickers in the correct areas.

6. The tie downs should be secured, as close as possible, at an angle

of 45 degrees to ensure maximum effectiveness of the restraint in all

directions.

7. The occupant should be restrained independently of the wheelchair by

a suitable approved passenger safety belt or harness. Pelvic restraint

or lap belts supplied with the wheelchair may be used in addition to but

never as a substitute for approved passenger restraints.

30

Page 33

Transport

Product End Of Life

Even though your wheelchair has been designed to provide a long and trouble free life

it is inevitable that wear, tear and usage will eventually render the product unusable.

• INVACARE recommends that the average usable life of this product is ve

years, providing the product has been correctly maintained according to the

manufacturer’s recommendations.

When the time comes to replace your wheelchair please remember to dispose of the

product responsibly and recycle any recyclable parts as mentioned in this user guide.

This product may contain substances that could be harmful to the environment if

disposed of in areas (landlls) that are not appropriate according to legislation. The

“crossed out wheelie bin” symbol (as shown) is placed on this product to encourage you

to recycle wherever possible.

Please be environmentally responsible and recycle this

product through your recycling facility at its end of life.

Disposal

• The equipment packaging is potentially recyclable.

• The metal parts are used for scrap metal recycling.

• The plastic parts are used for plastic recycling.

• Disposal must be carried out in accordance with respective national legal

provisions.

• If in doubt ask your local government authority for details of local waste

management companies and recycling facilities.

31

Page 34

Contact Invacare

Contacting Invacare

For quest ions or support, please contact you r authorised INVACA RE dealer.

They have the necessary experienc e, equipmen t, and knowledge

concernin g your wheelchair which enables the m to offer you an al l round

satisfact ory service.

Should yo u wish to contact us dir ectly, we are at yo ur service under the

following telephone numbers:

European Headquarter:

Invacare International

Sàrl, Rou te de Cité-Ouest 2, CH-1196

Gland

Tel: (41 ) (0)22 354 60 10

Fax: (41) (0)22 354 60 11

hqeurope@ invacare.com

www.invacare.co.uk

Sales Units:

Belgium & Luxemburg:

Aquatec G mbH

Alemannen strasse 10, D-88316 Isny

Tel: (49 ) (0)7562 7 00 0

Fax: (49) (0)7562 7 00 66

infor@aqu atec.de

Ulrich Alber GmbH

Vor dem Weissen S tein 21, D-72461

Albstadt- Tailfingen

Tel: (49 ) (0)7432 2 006 0

Fax: (49) (0)7432 2006 299

info@ulri ch-alber.de

Invacare nv

Autobaan 22, B-8210 Loppem

Tel: (32 ) (0)50 83 10 10

Fax: (32) (0)50 83 10 11

belgium@i nvacare.com

Denmark:

Invacare AIS

Sdr. Ringvej 39, DK-2 605 Brøndby

Tel: (45 ) (0)36 90 00 00

Fax: (45) (0)36 90 00 01

denmark@i nvacare.com

Deutschland & Eastern Europe

Invacare Deutschland GmbH

Kleistraβ e 49, D-32457 Porta

Wesfa lica

Tel: (49 ) (0)5761 7 5 40

Fax: (49) (0)5731 754 191

info@inva care.de

España:

Invacare SA

c/Areny s /n, Poligon Industrial d e

Celrà, E- 17460 Clerà (Gironà)

Tel: (34 ) (0)972 49 32 00

Fax: (34) (0)972 49 32 20

contactsp @invacare.com

France:

Invacare Poirier SAS

Route de St Roch, F-37230 Fondett s

Tel: (34 ) (0)2 47 6 2 64 66

Fax: (34) (0)2 47 42 12 24

contactfr @invacare.com

Italia:

Invacare Mecc San s.r.l.

Via d ei Pini 62, I-36016 Thiene (VI)

Tel: (39 ) 0445 38 0 0 59

Fax: (39) 0445 38 00 34

italia@in vacare.com

32

Page 35

Contact Invacare

Nederland:

Invacare BV

Celsiusst raat 46, NL-6716 BZ Ede

Tel: (31 ) (0)318 69 5 757

Fax: (31) (0)318 695 758

mobility@ invacare.com

care@inva care.com

Norge:

Invacare AS

Grensesvi ngen 9, Postboks 6230,

Etterstad , N-0603 Oslo

Tel: (47 ) (0)22 57 95 00

Fax: (47) (0)22 57 95 01

norway@in vacare.com

island@in vacare.com

Österreich:

Mobitec M obilitatshilfen GmbH

Herzog Od ilostrasse 101, A-5310

Mondsee

Tel: (43 ) (0)6232 5 535 0

Fax: (43) (0)6232 5535 4

offic e@mobitec-austria.com

austria@i nvacare.com

Switzerland

Dolomite AB

Box 55, V. Gö tgatan 5, S -33421

Anderstor p

Tel: (46 ) (0)371 58 84 00

Fax: (46) (0)371 170 90

info@dolo mite.se

Ireland:

Unit 5, S eatown Business Campus

Seatown R oad

Swords

County Du blin

Ireland

Tel: + 3 53 1 810708 4

Fax: + 35 3 1 8107085

E Mail: i reland@invacare.com

Web: www.invacare .ie

United Kingdom:

Invacare UK Ltd.

Pencoed Technology Park

Pencoed

Bridgend

CF35 5HZ

Tel: 016 56 776222

Fax: 0165 6 776220

Email: uk @invacare.com

Web: www.invacare .com

Mobitec R ehab AG

Benkenstr asse 260, CH-4108

Witterswi l

Tel: (41 ) (0)61 487 70 80

Fax: (41) (0)61 487 70 81

offic e@mobitec-rehab.ch

switserla nd@invacare.com

Sverige &Suomi:

Invacare AB

Fagerstag atan 9, S-163 91 Spånga

Tel: (46 ) (0)8 761 70 90

Fax: (46) (0)8 761 81 08

sweden@in vacare.com

finland@i nvacare.com

33

Page 36

User Guide

Part No. 1536525 Issue 05

11-5-2010

Loading...

Loading...