Page 1

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 1 -

Preface

FR200H series is a enhanced type during all FRECON inverters group, special design for

HVAC, air conditioner and water-supply industry, use for fan, pumps and other loads, support 2

modes water supply of fixed variable-frequency pump and cycle variable-frequency pumps, flexible

control logic of add/reduce pumps, dormancy/awaken based on pressure, timing rotate control and

other special functions.

When debugging the product, please refer to debugging guide in the user manual. Product

maintenance please refers to FR200 user manual.

IMPORTANT NOTES

◆To illustrate the details of the products,pictures in this manual based on products with outer

casing or safety cover being removed.When using this product, please be sure to well install

outer casing or covering by the rules, and operating in accordance with the manual contents.

◆The illustrations this manual for illustration only and may vary with different products you have

ordered.

◆The company is committed to continuous improvement of products, product features will

continue to upgrade, and the information provided is subject to change without notice.

◆If you are using have questions; please contact our regional agents or our customer service

center. Customer Service Tel 0755 -33067999.

◆The company's other products please visit our website: http://www.frecon.com.cn

Page 2

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 2 -

Contents

Preface ........................................................................................................................................ - 1 -

Contents ...................................................................................................................................... - 2 -

Chapter 1 Product Information ................................................................................................... - 3 -

1.1 Nameplate information ....................................................................................................... - 3 -

1.2 Information of FR200H Product Model ................................................................................ - 4 -

1.3 Terminal Configuration ........................................................................................................ - 4 -

1.4 Configuration, Mounting Dimensions and Weight ................................................................ - 8 -

Chapter 2 Debugging Guide ..................................................................................................... - 10 -

Chapter 3 List of Parameters .................................................................................................... - 11 -

3.1 Standard Function Parameters ......................................................................................... - 11 -

Chapter 4 Maintenance and troubleshooting .......................................................................... - 27 -

Page 3

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 3 -

Chapter 1 Product Information

1.1 Nameplate information

Fig.1-1 Nameplate information

Model Explanation

Model show on product nameplate contains information below

FR200 H-4T-7.5G/011P B

Product series code:

FR200H

Input voltage:

2: 220V(-15%~+30%)

4: 380V(-15%~+30%)

Input voltage phases:

S:Single-phase

T:Three-phase

Industry-specific series

code H: special use for

multi-pumps constant

pressure water supply

Brake unit:

None: No Braking Unit

B: Built-in brake unit(30kW

following built,37 ~ 75kW optional

built,No built above 90kW)

Adaptable Motor (kW)And Type of

Motor:7.5G:7.5kW(General type)

011P:11kW(Fan pump type)

Figure 1-2 Product Model Number Naming Rule

Page 4

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 4 -

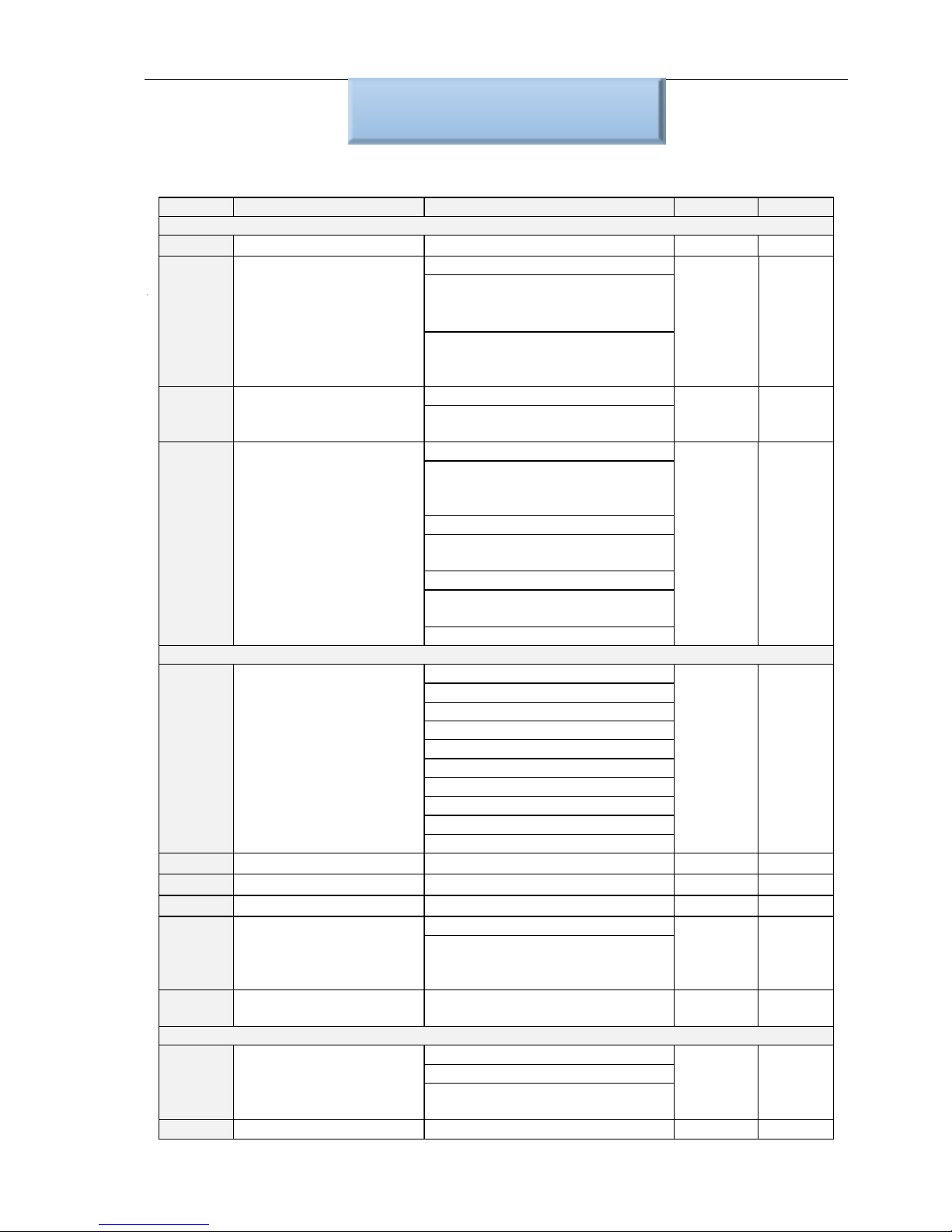

1.2 Information of FR200H Product Model

Table 1-1FR200HProduct model and technical data

Model No.

Power

capacity

KVA

Rated

Input current

A

Rated output

current

A

Applicable motor

kW HP

3-Phase: 380V,50/60Hz Range: -15%~+30%

FR200H-4T-0.7G/1.5PB

1.5

3.4

2.5

0.75

1

FR200H-4T-1.5G/2.2PB

3

5.0

4.2

1.5

2

FR200H-4T-2.2GB

4

5.8

5.5

2.2

3

FR200H-4T-4.0G/5.5PB

6

11

9.5

3.7、4

5

FR200H-4T-5.5G/7.5PB

8.9

14.6

13

5.5

7.5

FR200H-4T-7.5G/011PB

11

20.5

17

7.5

10

FR200H-4T-011G/015PB

17

26

25

11

15

FR200H-4T-015G/018PB

21

35

32

15

20

FR200H-4T-018G/022PB

24

38.5

37

18.5

25

FR200H-4T-022G/030PB

30

46.5

45

22

30

FR200H-4T-030G/037PB

40

62

60

30

40

FR200H-4T-037G/045P

57

76

75

37

50

FR200H-4T-037G/045PB

FR200H-4T-045G/055P

69

92

91

45

60

FR200H-4T-045G/055PB

FR200H-4T-055G/075P

85

113

112

55

70

FR200H-4T-055G/075PB

FR200H-4T-075G/090P

114

157

150

75

100

FR200H-4T-075G/090PB

FR200H-4T-090G/110P

134

160*

176

90

125

FR200H-4T-110G/132P

160

190*

210

110

150

FR200H-4T-132G/160P

192

232*

253

132

175

FR200H-4T-160G/185P

231

282*

304

160

210

FR200H-4T-185G/200P

240

326*

350

185

250

FR200H-4T-200G/220P

250

352*

377

200

260

FR200H-4T-220G/250P

280

385*

426

220

300

FR200H-4T-250G/280P

355

437*

470

250

330

FR200H-4T-280G/315P

396

491*

520

280

370

FR200H-4T-315G/355P

445

580*

600

315

420

FR200H-4T-355G/400P

500

624*

650

355

470

FR200H-4T-400G/450P

565

690*

725

400

530

FR200H-4T-450G/500P

623

765*

800

450

600

1.3 Terminal Configuration

1.3.1 Main Circuit Terminals

a: 1.5~2.2kWMain Circuit Terminals

(+)

(-)

R

S

T

U

V

POWER

Control circuit

terminals

Main circuit

terminals

Upload and

download interfaces

Fig.1-3 1.5~2.2kW Schematic of main circuit terminals

Page 5

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 5 -

b:4~18.5kW Main Circuit Terminals

Control circuit

terminals

Main circuit

terminals

Upload and

download interfaces

PB

(+)

(-)

RFI

Fig.1-4 4.0~18.5kW Schematic of main circuit terminals

c: 22~30kW Main Circuit Terminals

Solution 1:

Fig.1-5 22~37kW Main Circuit Terminals(Solution 1)Schematic

Solution 2:

Fig.1-6 22~37kW Main Circuit Terminals(Solution 2)Schematic

d: 45~90kW Main Circuit Terminals

Fig.1-7 45~90kW Main Circuit TerminalsSchematic

Page 6

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 6 -

e: 110~315kW Main Circuit TerminalsSchematic

Fig.1-8 110~315kW Main Circuit TerminalsSchematic

f:355-400kW Main Circuit Terminals

Fig.1-9 355~400kW Main Circuit TerminalsSchematic

Table 1-2 main circuit terminal functions

Terminal marks

Functions

R/L1、S/L2、T/L3

AC power input terminals for connecting to 3-phase AC380V

power supply.

U/T1、V/T2、W/T3

AC output terminals of inverter for connecting to 3-phase

induction motor.

(+)、(-)

Positive and negative terminals of internal DC bus.

B

Connecting terminals of braking resistor. One end connected

to + and the other to B.

Grounding terminal

2.3.2 Control circuit terminals

Fig. 1-10 control circuit terminalsschematic

DI1

+24V

DI2

PLC

DI3

COM

DI4

DI5

COM

DI6

Y1

Y2

+10V

R1A R1B

R1C

R2A R2B

R2C

AO1

AI1

GND

AI2

485+

AI3

485-

PE

DI7/HI

AO2

GND

Page 7

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 7 -

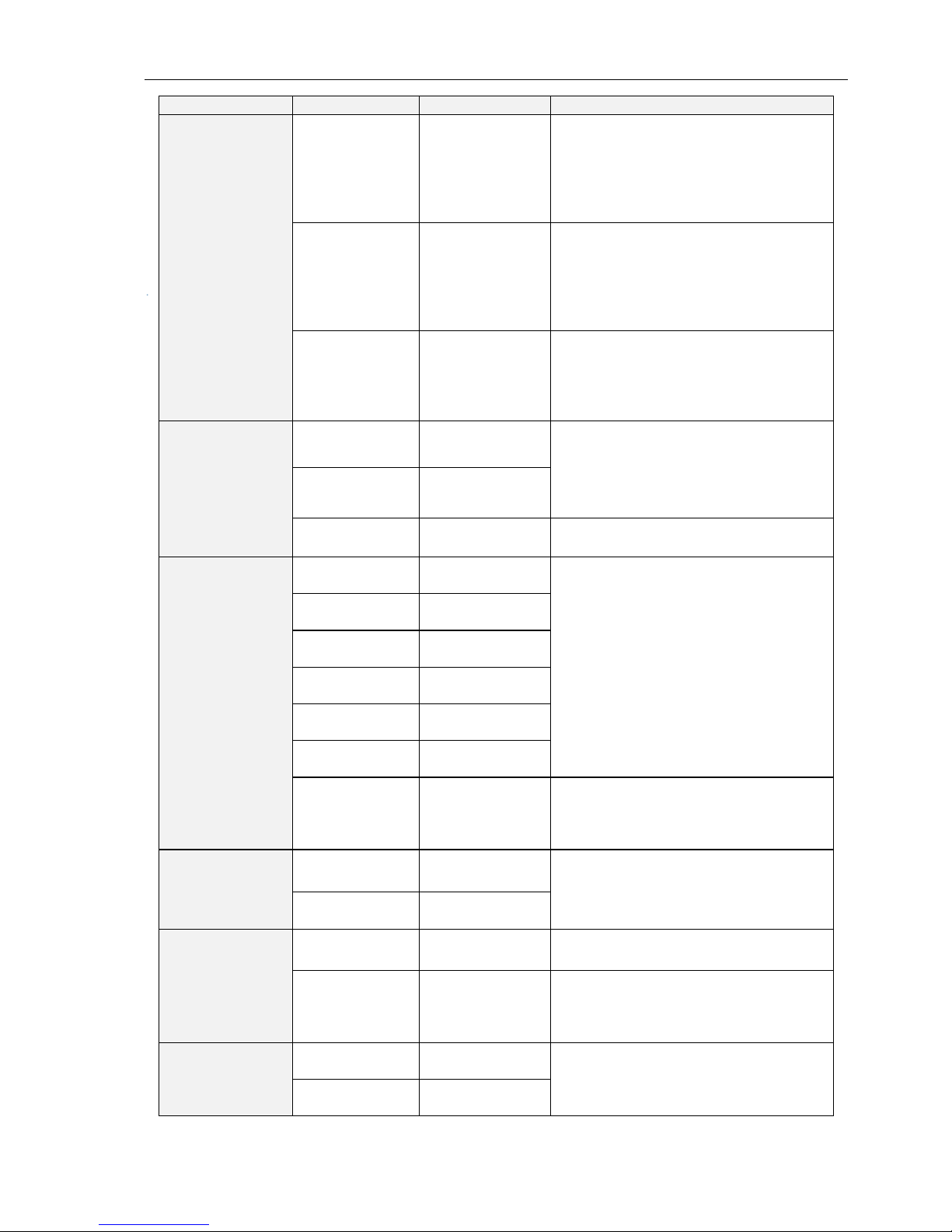

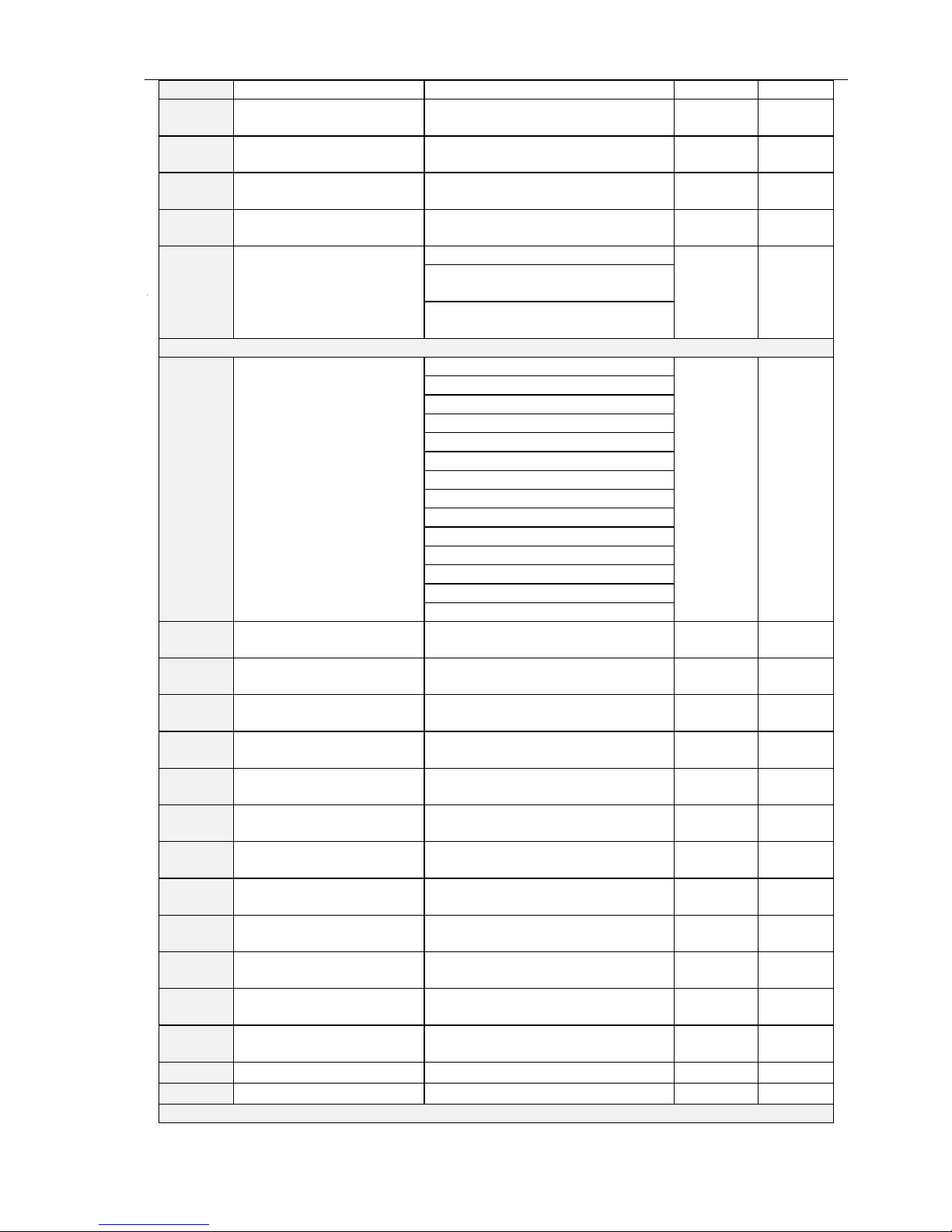

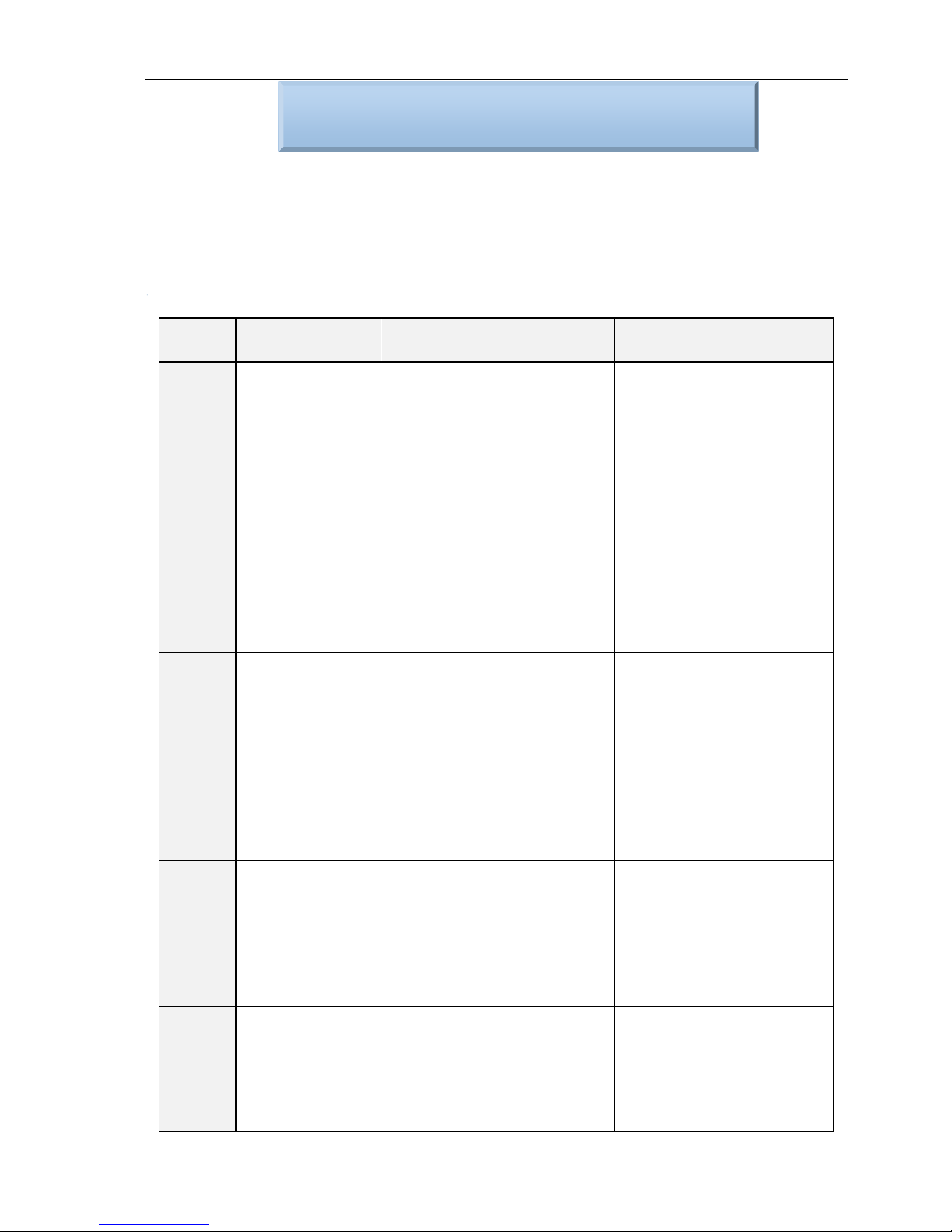

Table 1-3 FR200H Description of control circuit terminals

Type

Terminal

Name

Function Description

Power supply

+10V-GND

External +10 V

power supply

Provide +10 V power supply to

external unit.

Generally, it provides power supply to

externalpotentiometer with resistance

range of 1–5 kΩ.

Maximum output current: 10 mA

+24V-COM

External +24V

power

supply Applying

to Overvoltage

Category II

circuit

Provide +24 V power supply to

external unit.

Generally, it provides power supply to

DI/Do terminals and external sensors.

Maximum output current: 200 mA

PLC

Input terminal

of

external power

supply

Connect to +24 V by default.

When DI1-DI7 need to be driven by

externalsignal, PLC needs to be

connected to externalpower supply

and be disconnected from +24 V.

Analog input

AI1-GND

Analog input 1

Input voltage range: DC 0~10V/0~

20mA,decided by toggle switches

AI1、AI2 on the control board

Impedance: 250 kΩ (voltage input),

250 Ω (current input)

AI2-GND

Analog input 2

AI3-GND

Analog input 3

Input Voltage Range: DC -10~+10V

Input impedance: 250kΩ

Switch input

DI1- COM

Switch input

terminals 1

Maximum input frequency: 200Hz

Impedance: 2.4kΩ

Voltage range for level input: 9V~

30V

DI2- COM

Switch input

terminals 2

DI3- COM

Switch input

terminals 3

DI4- COM

Switch input

terminals 4

DI5- COM

Switch input

terminals 5

DI6- COM

Switch input

terminals 6

DI7/HI-COM

Switch input

terminals 7 OR

High-speed

pulse input

Besides features of DI1–DI6, it can be

used for high-speed pulse input.

Maximum input frequency: 100 kHz

Analog

output

AO1-GND

Analog output

terminal 1

Output voltage range: DC 0~10V/0~

20mA,decided by toggle switches

AO1、AO2 on the control board

Impedance requirements≥10kΩ

AO2-GND

Analog output

terminal 2

Switch output

Y1-COM

Open collector

output 1

Voltage range: 0~24V

Current range: 0~50mA

Y2/HO-COM

Open collector

output 2 OR

High-speed

pulse output

Besides features of Y1, it can be used

forHigh-speed pulse output channels.

The maximum output frequency:

100kHz

Relay output

R1A-R1C

Normally open

terminal

Contact driving capacity:

AC250V,3A,COSØ=0.4.

DC 30V,1A

R1B-R1C

Normally

closedterminal

Page 8

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 8 -

R2A-R2C

Normally open

terminal

R2B-R2C

Normally

closedterminal

485

Communication

485+-485-

485

Communication

Terminals

Rate:

4800/9600/19200/38400/57600/

115200bps

Termination resistor is set by the

toggle switch on the control panel

RS485

GND

485

Communication

shielded

ground

Shield

PE

Shield Ground

Ground terminal for shield

Auxiliary

Interface

External

operation

panel interface

Use standard network cable

Maximum cable distance: 50m

UP/DOWNLOAD

Parameter

copy interface

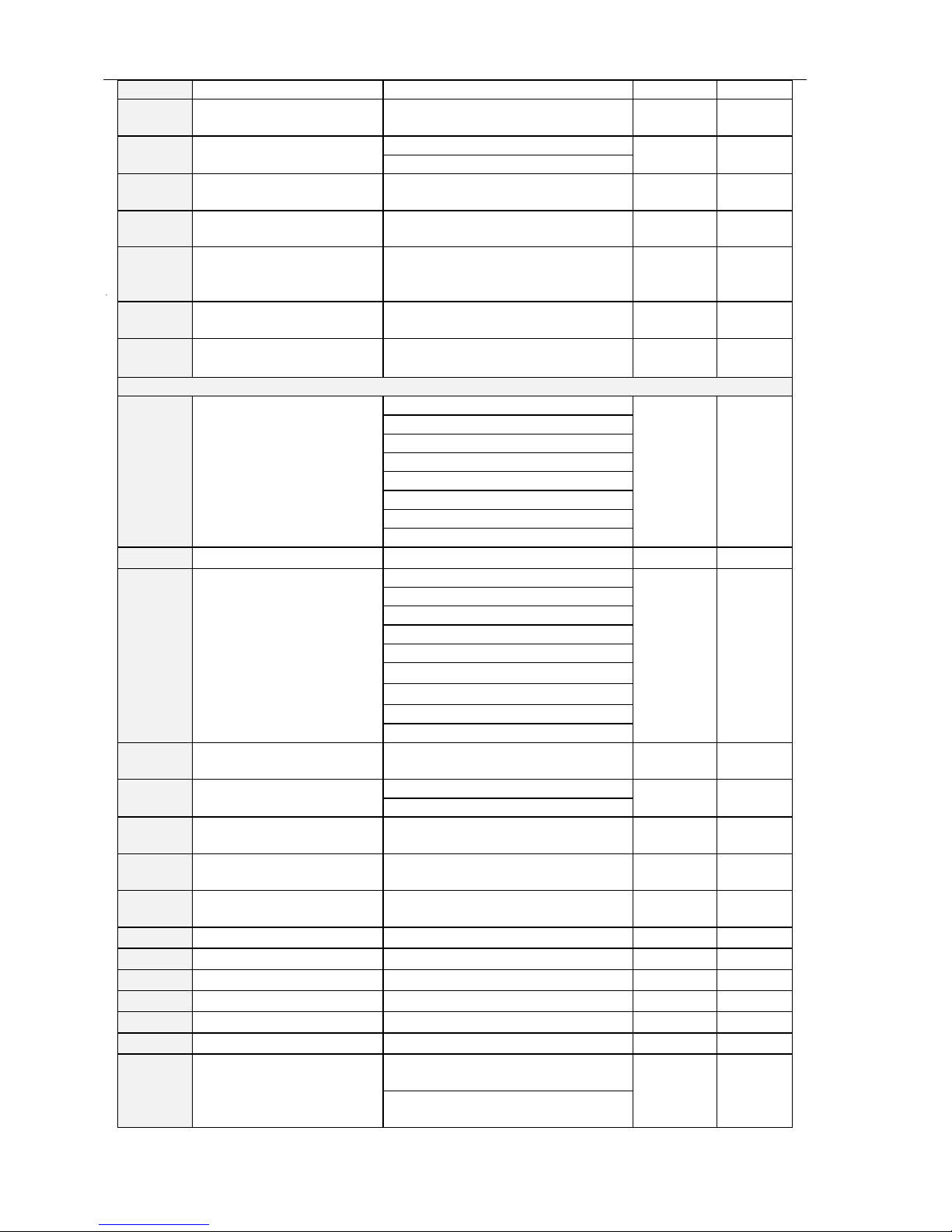

1.4 Configuration, Mounting Dimensions and Weight

a:1.5~18.5kW Dimensions and wall mounting dimensions

Fig. 1-11 1.5~18.5kW Wall installation diagram

b: 22~400kW Dimensions and wall mounting dimensions

Fig.1-12 22~160kW Wall installation diagram (1) Fig. 1-13185~400kW Wall installation diagram (2)

W1

H1

H

W

D

4Xd

W1

W

H1

H

D

4xd

H

W

D

H1

d W1 W1

Page 9

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 9 -

Table 1-4 Configuration, mounting dimensions and weight

Model NO.

External and installation dimensions(mm)

Weight

(Kg)

W

W1 H H1

D

Mounting

Hole

Diameter

3-Phase: 380V,50/60Hz Range: -15%~+30%

FR200H-4T-0.7G/1.5PB

117

107

187

177

160

4.5

1.9

FR200H-4T-1.5G/2.2PB

FR200H-4T-2.2GB

FR200H-4T-4.0G/5.5PB

146

131

249

236

177

5.5

3.2

FR200H-4T-5.5G/7.5PB

FR200H-4T-7.5G/011PB

FR200H-4T-011G/015PB

198

183

300

287

185

5.5

5.4

FR200H-4T-015G/018PB

FR200H-4T-018G/022PB

255

176

459

443

220 7 15.5

FR200H-4T-022G/030PB

FR200H-4T-030G/037PB

FR200H-4T-037G/045P

270

130

590

572

260 7 27.5

FR200H-4T-045G/055P

FR200H-4T-055G/075P

357

230

590

572

260 7 37

FR200H-4T-075G/090P

FR200H-4T-090G/110P

430

320

830

802

293

12

77.7

FR200H-4T-110G/132P

FR200H-4T-132G/160P

FR200H-4T-160G/185P

500

180

1107

1078

328

14

138.5

FR200H-4T-185G/200P

FR200H-4T-200G/220P

FR200H-4T-220G/250P

660

230

1160

1130

340

14

190

FR200H-4T-250G/280P

FR200H-4T-280G/315P

FR200H-4T-315G/355P

810

300

1140*

1110

400

14

196

FR200H-4T-355G/400P

FR200H-4T-400G/450P

* Note: 1. 110~315kw optional base height is 263mm.

2. 355~400kw dc reactor can be installed in a trench or cabinet independently, if the vertical installation,

need to purchase base (dc reactor can be installed in the base), base height is 400 mm.

Page 10

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 10 -

Chapter 2 Debugging Guide

FR200H series special purpose inverter for multi-pumps constant pressure water supply specially

developed for constant pressure water supply industry, featured with 2 modes below:

Mode 1: fixed variable frequency control mode wirings:

DI1

DI2

DI3

DI4

DI6

COM

FR200H

DI5

Q3

Q4

Default Signal

Q2

10V

AI1

AI2

GND

Given

Feedback

FWD

REV

Q5

DI7

R1A

R1C

R2A

R2C

KA1

KA2

Y1

Y2

24V

M1

M2

M3

M4

M5

L1

L2

L3

220V

KM2

KM3

KM4

KM5

R1A

R1C

R2A

R2C

KA1

KA2

R

S

T

U

V

W

Inside the dotted line is powerfrequency pumps, can be added on

customers’ requirements up to 4 pcs

Fig. 2-1 Fixed Pumps Mode Wirings

Mode 2: two variable frequency pumps cycle control mode wirings:

DI1

DI2

DI3

DI4

DI6

COM

FR200H

DI5

Q3

Q4

Default Value

Q2

10V

AI1

AI2

GND

Given

Feedback

FWD

REV

Q5

DI7

R1A

R1C

R2A

R2C

KA1

KA2

Y1

Y2

24V

M1

L1

L2

L3

M2

KM1

KM2

KM3

KM4

U

V

W

R

S

T

220V

KM1

KM2

KM3

KM4

R1A

R1C

R2A

R2C

KA1

KA2

Fig. 2-2 two variable frequency cycle mode wirings

Page 11

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 11 -

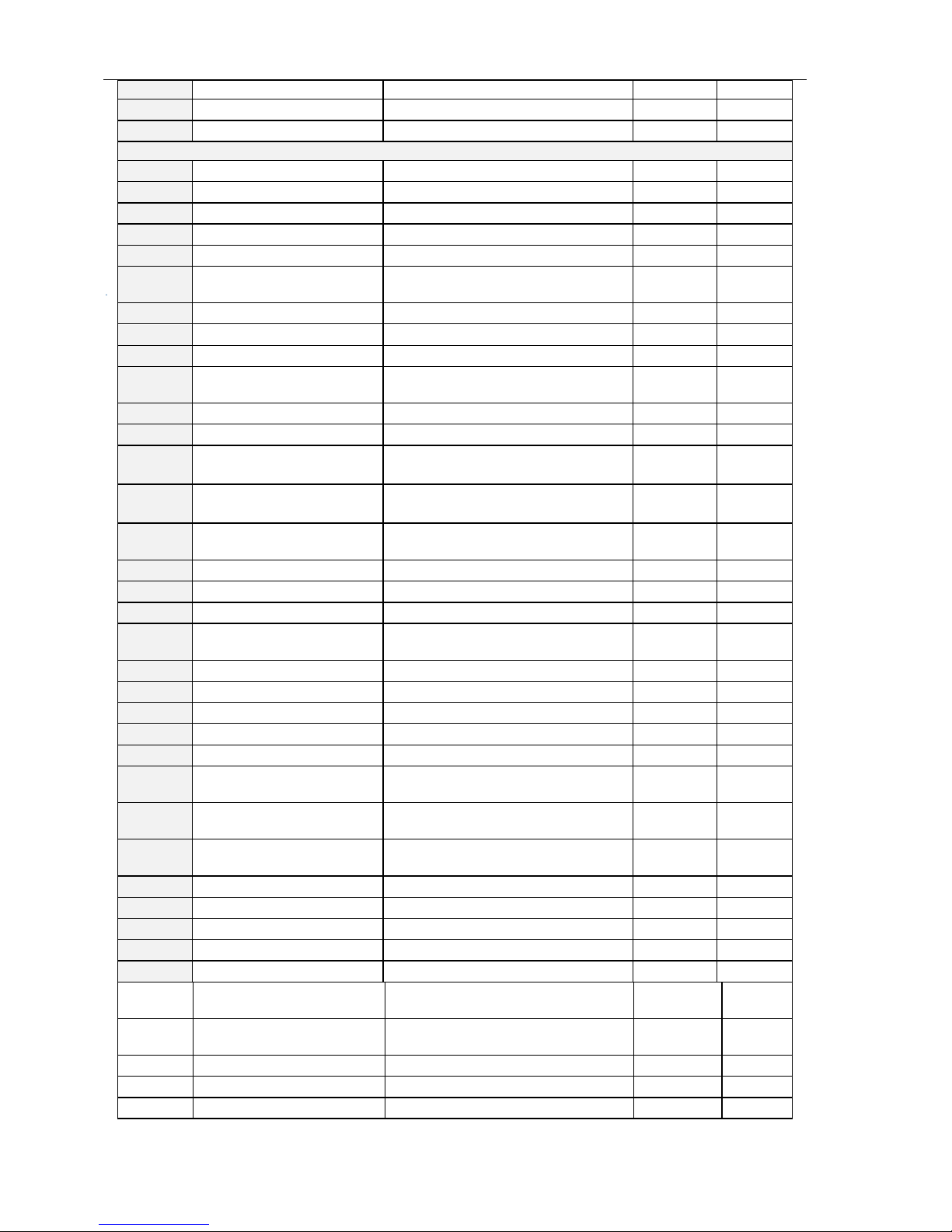

Chapter 3 List of Parameters

3.1 Standard Function Parameters

Table 3-1 Standard Function Parameters

Param.

Parameter Name

Instructions

Default

Attr

Group F00: System Parameters

F00.00

User Password

0~65535

0

×

F00.01

Display of Parameters

0: Display all parameters

0

×

1: Only display F00.00, F00.01

and user-defined parameters

F17.00~F17.29

2: Only display F00.00, F00.01,

and the parameters different with

factory default

F00.03

G/P type display

0: G type (constant torque load)

1

×

1: P type (variable torque load

e.g. fan and pump)

F00.04

Parameter Initialization

0: Invalid

0

×

1: Restore all parameters to

factory default (excluding motor

parameters)

2: Clear fault record

3: Restore user backup

parameters

4: Back up user parameters

5: Restore factory default(include

motor parameters)

6: Clear power dissipation

Group F01: Frequency Command

F01.01

Master Frequency

Command Source

0: Master digital setting (F01.02)

6

×

1: keypad potentiometer

2: Analog input AI1

3: Communication

4: Multi-reference

5: PLC

6: Process PID output

7: DI7/HI pulse input

8: Analog input AI2

9: Analog input AI3

F01.08

Maximum frequency

20.00~600.00Hz

50.00Hz

×

F01.09

Upper limit frequency

Fdown~Fmax

50.00Hz

×

F01.10

Lower limit frequency

0.00~Fu

0.00Hz

×

F01.11

Operation when

command frequency

lower than lower limit

frequency

0: Run at lower limit frequency

0

×

1: Run at 0 Hz would be

activated after the time delay set

by F01.12

F01.12

Lower limit frequency

running time

0.0~6000.0s

60.0s

×

Group F02: Start/Stop Control

F02.00

Run command

0: Keypad control (LED off)

1

×

1: Terminal control (LED on)

2: Communication control (LED

blinking)

F02.12

Stop mode

0: Ramp to stop

0

Page 12

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 12 -

1: Coast to stop

F02.20

0Hz output selection

0:No-voltage output

0

×

1:Voltage output

Group F03: Accel/Decel Parameters

F03.00

Accel time 1

0.0~6000.0s

15s

△

F03.01

Decel time 1

0.0~6000.0s

15s

△

Group F04 Digital Input

F04.00

Function of terminal DI1

00: No function

01: Running forward (FWD)

02: Running reverse (REV)

03: Three-wire running control

04: JOG forward (FJOG)

05: JOG reverse (RJOG)

06: Coast to stop

07: Fault reset (RESET)

08: Running pause

09: External fault input

10: Terminal Up

11: Terminal DOWN

12: UP/DOWN (including ∧/∨

key) adjustment clear

13: Multi-step frequency terminal

1

14: Multi-step frequency terminal

2

15: Multi-step frequency terminal

3

16: Multi-step frequency terminal

4

17: Accel/Decel time determinant

1

18: Accel/Decel time determinant

2

19: Accel/Decel disabled(ramp

stop not inclusive)

20: Given frequency switching as

the auxiliary frequency source

21: PLC status reset

22: Simple PLC paused

23: ID paused

24: PID adjustment direction

25: PID integration paused

26: PID parameter switch

27: Swing frequency

pause(output the

currentfrequency)

28: Swing frequency reset(output

the central frequency)

29: Run command switched to

keypad control

30: Run command switched to

terminal control

31: Run command switched to

communication control

32: Count input

33: Count clear

34: Length pulse input

35: Length clear

1

×

F04.01

Function of terminal DI2

2

×

F04.02

Function of terminal DI3

7

×

F04.03

Function of terminal DI4

13

×

F04.04

Function of terminal DI5

0

×

F04.05

Function of terminal DI6

0

×

F04.06

Function of terminal DI7

0

×

Page 13

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 13 -

36: DC brake input command at

stop

37:Speed/Torque control switch

38: Disable reverse

39: Disable forward

50: Special purpose inverter

enable

51: No.1 pump status

52: No.2 pump status

53: No.3 pump status

54: No.4 pump status

55: No.5 pump status

F04.13

Terminal DI1~DI5

positive/negative logic

DI5、DI4、DI3、DI2、DI1

00000

0: Positive logic(Terminals are on

at 0V/off at 24V)

1: Negative Logic (Terminals are

off at 0V/on at 24V)

F04.14

Terminal DI6~AI3

positive/negative logic

AI3、AI2、AI1、DI7、DI6

00000

0: Positive logic

1: Negative Logic

Group F05 Digital Output

F05.00

Y1 output function

00: No output

01: Drive is running

02: Fault output

03: Frequency-level detection

(FDT1)

04: Frequency-level detection

(FDT2)

05: Drive in 0Hz running 1 (no

output at stop)

06: Drive in 0Hz running 2(output

at stop)

07: Upper limit frequency

attained

08: Lower limit frequency

attained

09: Frequency attained

10: Inverter is ready to work

11: Drive (motor) overloaded

alarm

12: Inverter overheat warning

13: Current running time attained

14: Accumulative power-on time

attained

15: Consecutive running time

attained

16: PLC cycle completed

17: Set count value attained

18: Designated count value

attained

19: Length attained

20: Under-load warning

21: Brake output

22: DI1

23: DI2

30: No.1 pump power-frequency

control terminal

31: No.2 pump power-frequency

1

×

F05.01

Y2 output function

3

×

F05.02

Relay 1 output function

2

×

F05.03

Relay 2 output function

11

×

Page 14

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 14 -

control terminal

32: No.3 pump power-frequency

control terminal

33: No.4 pump power-frequency

control terminal

34: No.5 pump power-frequency

control terminal

35: No.1 pump

variable-frequency control

terminal

36: No.2 pump

variable-frequency control

terminal

F05.08

Enabled state of digital

output

Unit: Y1

0000

0: Positive Logic

1: Negative Logic

Decade: Y2 (same as unit)

Hundreds place: Relay 1 output

(same asunit)

Thousands place: Relay 2 output

(same as unit)

Group F07 Analog and Pulse Output

F07.00

AO1 output function

00: No output

1

×

F07.01

AO2 output function

01: Output frequency

2

×

F07.02

Y2/HO output function

(when used as HO)

02: Command frequency

1

×

03: Output current (rated current)

04: Output voltage(rated voltage)

05: Output power

06: Bus voltage

07: +10V

08: keypad potentiometer

09: AI1

10: AI2

11: AI3

12: HI (100% to 10.00kHz)

13: Output torque (torque

absolute value)

Group F08 Parameters of Motor 1

F08.01

Rated power of motor 1

0.10~600.00kW

Model

defined

×

F08.02

Rated voltage of motor 1

60~660V

Model

defined

×

F08.03

Rated current of motor 1

0.1~1500.0A

Model

defined

×

F08.04

Rated frequency of

motor 1

20.00~Fmax

Model

defined

×

F08.05

Rated speed of motor 1

1~30000

Model

defined

×

F08.07

The rated power factor

of async motor 1

0.50~0.99

Model

defined

×

F08.08

Stator resistance R1 of

async motor 1

0.001~65.535Ω

Model

defined

×

F08.09

Rotor resistance R2 of

async motor 1

0.001~65.535Ω

Model

defined

×

F08.10

Leakage inductance L1

of async motor 1

0.001~65.535mH

Model

defined

×

F08.11

Mutual inductance L2 of

0.1~6553.5mH

Model

×

Page 15

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 15 -

asynchronous motor 1

defined

F08.12

No-load current of

async motor 1

0.1~1500.0A

Model

defined

×

F08.13

Field weakening coeff 1

of async motor 1

0.0~100.0

87%

×

F08.14

Field weakening coeff 2

of async motor 1

0.0~100.0

75%

×

F08.15

Field weakening coeff 3

of async motor 1

0.0~100.0

70%

×

F08.30

Autotuning of motor 1

0: No autotuning

0

×

1: Static autotuning of async

motor

2: Rotary autotuning of async

motor

Group F09 V/f Control Parameters of Motor 1

F09.00

V/f curve setting

00: LinearV/F

3

×

01: Multi-stage V/F

02: 1.2nd power V/F

03: 1.4th power V/F

04: 1.6th power V/F

05: 1.8th power V/F

06: 2.0nd power V/F

07: V/F complete separation

08: V/F half separation

09: 1.2 power inverse curve V/F

10: 1.4 power inverse curve V/F

11: 1.6 power inverse curve V/F

12: 1.8 power inverse curve V/F

13: 2.0 power inverse curve V/F

F09.01

Torque boost

0.0%–30.0% 0.0% (fixed

torque boost)

0.0%

△

F09.02

Cut-off frequency of

torque boost

0.00~Fmax

50.00Hz

△

F09.03

Multi-point V/F

frequency 1(F1)

0.00~F09.05

0.00Hz

△

F09.04

Multi-point V/F voltage 1

(V1)

0.0~100.0

0.0%

△

F09.05

Multi-point V/F

frequency 2(F2)

F09.03~F09.05

5.00Hz

△

F09.06

Multi-point V/F voltage 2

(V2)

0.0~100.0

14.0%

△

F09.07

Multi-point V/F

frequency 3(F3)

F09.05~F09.09

25.00Hz

△

F09.08

Multi-point V/F voltage 3

(V3)

0.0~100.0

50.0%

△

F09.09

Multi-point V/F

frequency 4(F4)

F09.07~rated motor frequency

50.00Hz

△

F09.10

Multi-point V/F voltage 4

(V4)

0.0~100.0 Ue=100.0%

100.0%

△

F09.11

V/F slip compensation

gain

0.0~300.0%

80.0%

△

F09.12

Stator voltagedrop

compensation gain

0.0~200.0%

100.0%

△

F09.13

Excitation boost gain

0.0~200.0%

100.0%

△

F09.14

Oscillation Suppression

0.0~300.0%

100.0%

△

Group F11 Protection Parameters

Page 16

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 16 -

F11.00

Current limit control

0: Current limit disabled

2

×

1: Current limit mode 1

2: Current limit mode 2

F11.01

Current limit

100.0~200.0%

150.0%

×

F11.02

Frequency decreasing

time(limit current in

constant speed

operation)

0.0~6000.0s

5.0s

△

F11.03

Current limit mode 2

proportion gain

0.1~100.0%

3.0%

△

F11.04

Current limit mode 2

integral time

0.00~10.00 s (0.00: integral

is invalid)

10.00s

△

F11.05

Overvoltage Stall

Control

0: Overvoltage stall disabled

1

×

1: Overvoltage stall mode 1

2: Overvoltage stall mode 2

F11.06

Overvoltage Stall

Voltage

600~800V(380V inverter)

320~400V(220V inverter)

730V

370V

×

F11.07

Overvoltage Stall

Mode 2 Proportion Gain

0.1~100.0%

50.0%

△

F11.08

Overvoltage Stall

Mode 2 frequency

limited

0.00~50.00Hz

5.00Hz

△

F11.10

Protection action 1

Unit's place: Bus undervoltage

03330

×

0: Fault reported and coast to

stop

1: Stop according to the stop

mode

2: Fault reported but continue

torun

3: Fault protection disabled

Ten's digit :Power input phase

Loss (Err09)(Same as unit's

place )

Hundred's digit :Power output

phase loss(Err10)(Same as unit's

place )

Thousand's digit:Motor

overload(Err11)(Same as unit's

place )

Ten thousand's digit:Inverter

overload(Err12)(Same as unit's

place )

F11.11

Protection action 2

External equipment fault(Err13)

00000

×

0: Fault reported and coast to

stop

1: Stop according to the stop

mode

2: Fault reported but continue

torun

Ten's digit: EEPROM read/write

fault (Err15) (Same as unit's

place)

Hundred's digit: Communication

overtime error (Err18) (Same as

unit's place)

Thousand's digit: PID feedback

Page 17

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 17 -

loss (Err19) (Same as unit's

place)

Ten thousand's digit: Continuous

running time reached (Err20)

(Same as unit's place)

F11.12

Protection action 3

Unit's place: Module temperature

detection disconnection(Err24)

00030

×

0: Fault reported and coast to

stop

1: Stop according to the stop

mode

2: Fault reported but continue to

run

Ten's digit: Load becoming 0

(Err25) (Same as unit's place)

Hundred's digit:reserved

thousand's digit:reserved

Ten thousand's digit:reserved

F11.14

Frequency selection for

continuing to run upon

fault

0: Current running frequency

1

×

1: Set frequency

2: Frequency upper limit

3: Frequency lower limit

4: Backup frequency upon

abnormality

F11.15

Backup frequency upon

abnormality

0.00~Fmax

0.00Hz

×

F11.17

Motor overload

protection time

30.0~300.0s

60.0s

×

F11.18

Overload alarm

Unit's place: detection option:

000

×

0: Always detect

1: Detect at constant speed only

Ten's digit :compared object

0: Rated current of motor

1: Rated current of drive

Hundred’s digit:report error or not

0:Do not report

1:Report

F11.19

Overload alarm

threshold

20.0~200.0%

130.0%

×

F11.20

Overload alarm

activated time that

exceeding threshold

0.1~60.0s

5.0s

×

F11.21

Inverter overheat

warning threshold

50~overheatTemperature

Model

defined

×

F11.22

Detection level of power

loss

5.0~100.0%

20.0%

×

F11.23

Detection time of power

loss

0.1~60.0s

5.0s

×

F11.24

Action selection at

instantaneous power

failure

0: Disabled

0

×

1: Enabled

F11.25

Decel time at

instantaneous power

failure

0.0~6000.0s

5.0s

△

F11.26

Rapid current limit

0: Disabled

0

×

1: Enabled

F11.27

Times of automatic

0~20

0

×

Page 18

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 18 -

reset

F11.28

Interval of automatic

reset

0.1~100.0s

1.0s

×

F11.29

DO action during fault

auto reset

0: Not act

0

×

1: Act

F11.30

Instant Power-failure

Bus Voltage

60.0%~Recovery Voltage

80%

F11.31

Instant Power-failure

Recovery Voltage

Power Failure Voltage~100.0%

85%

F11.32

Instant Power-failure

Voltage Adjustment

Time

0.01~10.00s

0.1

F11.33

Instant Power-failure

Gain K

0.1~100.0%

40.0%

F11.34

Instant Power-failure

Integral Time Ti

0.00~10.00s (0.00: Integral

Invalid)

0.1

Group F13 Process PID

F13.00

PID setting

0: F13.01 digital setting

2

×

1: keypad potentiometer

2: AI1

3: Communication

4: Multi-Reference

5: DI7/HI pulse input

6: AI2

7: AI3

F13.01

PID digital setting

0.0~100.0%

50.0%

△

F13.02

PID feedback

0: AI1

1

×

1: AI2

2: Communication

3: AI1+AI2

4: AI1-AI2

5: Max{AI1,AI2}

6: Min{AI1,AI2}

7: DI7/HI pulse input

8: AI3

F13.03

PID setting

feedbackrange

0~6000.0

100.0

△

F13.04

PID action direction

0: Forward action

0

×

1: Reverse action

F13.05

Filtering time of PID

setting

0.000~10.000s

0.000s

△

F13.06

Filtering time of PID

feedback

0.000~10.000s

0.000s

△

F13.07

Filtering time of PID

output

0.000~10.000s

0.000s

△

F13.08

Proportional gain Kp1

0.0~100.0

1.0

△

F13.09

Integration time Ti1

0.01~10.00s

0.10s

△

F13.10

Differential time Td1

0.000~10.000s

0.000s

△

F13.11

Proportional gain Kp2

0.0~100.0

1.0

△

F13.12

Integration time Ti2

0.01~10.00s

0.10s

△

F13.13

Differential time Td2

0.000~10.000s

0.000s

△

F13.14

PID setting

feedbackrange

0: No switch, determined by

parameters Kp1, Ti1 and Td1

0

×

1: Auto switch on the basis of

input offset

Page 19

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 19 -

2: Switched by terminal

F13.15

PID parameter

switchover

deviation 1

0.0~100.0%

20.0%

×

F13.16

PID parameter

switchover

deviation 2

0.0~100.0%

80.0%

×

F13.17

PID offset limit

0.0~100.0%

0.0%

×

F13.18

PID integral property

Unit's digit (Whether to stop

integral operation when the

output reaches the limit)

00

×

0: Continue integral operation

1: Stop integral operation

Ten's digit (Integral separated)

0: Invalid

1: Valid

F13.19

PID differential limit

0.0~100.0%

0.5%

×

F13.20

PID initial value

0.0~100.0%

0.0%

×

F13.21

Holding time of PID

initial value

0.0~6000.0s

0.0s

×

F13.22

PID output frequency

upper limit

PID output frequency lower

limit~100.0%(100.0%

corresponds to maximum

frequency )

100.0%

×

F13.23

PID output frequency

lower limit

–100.0%~PID output frequency

upper limit

0.0%

×

F13.24

Detection value of

PID feedback loss

0.0~100.0%

0.0%: Not judging feedback loss

0.0%

×

F13.25

Detection time of

PID feedback loss

0.0~30.0s

1.0s

×

F13.26

PID operation at stop

Uinit’s digit:PID operation

0: No PID operation at stop

1: PID operation at stop

000

×

Ten’s digit:Output limit

0: Do not limit

1: limit

Hundred’s digit:PID digital given

by UP/DOWN

0: Clear to zero when power off

1: Preserve whenpower off

F13.27

UP/DOWN speed of PID

digital given

0.0~100% (0.0% valid)

0.0%

△

Group F14: Swing Frequency, Fixed Length ,Wakeup and Count

F14.10

Wakeup frequency

Dormant frequency (F14.12)~

Fmax

0.00Hz

△

F14.11

Wakeup delay time

0.0~6000.0s

0.0s

△

F14.12

Dormant frequency

0.00~Wakeup frequency

0.00Hz

△

F14.13

Dormant delay time

0.0~6000.0s

0.0s

△

F14.14

Wakeup Mode Selection

0: frequency wakeup

0

×

1: pressure wakeup

F14.15

Dormant Mode

Selection

0: frequency dormant

0

×

1: pressure dormant

F14.16

Pressure Feedback

Source

0: AI1

0

×

1: AI2

2: DI7/HI Pulse Input

Page 20

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 20 -

3: AI3

F14.17

Wakeup Pressure

0.0%~Dormant Pressure

10.0%

△

F14.18

Dormant Pressure

Wakeup Pressure~100.0%

50.0%

△

Group U00 Status Monitoring

U00.00

Running frequency

0.00~Fu

0.00Hz

⊙

U00.01

Set frequency

0.00~Fmax

0.00Hz

⊙

U00.02

Output voltage

0~660V

0.0V

⊙

U00.03

Output current

0.0~3000.0A

0.0A

⊙

U00.04

Output power

-3000.0~3000.0kW

0.0kW

⊙

U00.05

Estimated Motor

Speed

0~60000rm

0rm

⊙

U00.06

Bus voltage

0~1200V

0V

⊙

U00.07

Synchronous Frequency

0.00~Fu

0.00Hz

⊙

U00.08

PLC step

1~15

1

⊙

U00.09

Program Operation

Time

0.0~6000.0s(h)

0.0s(h)

⊙

U00.10

PID set

0~60000

0

⊙

U00.11

PID feedback

0~60000

0

⊙

U00.12

Status of DI1~DI5

digital input terminal

DI5 DI4 DI3 DI2 DI1

00000

⊙

U00.13

Status of DI6~DI7

digital input terminal

DI7 DI6

00

⊙

U00.14

Status of digital output

terminal

R2 R1 Y2 Y1

0000

⊙

U00.15

AI1 input

0.0~100.0%

0.0%

⊙

U00.16

AI2 input

0.0~100.0%

0.0%

⊙

U00.17

AI3 input

-100.0~100.0%

0.0%

⊙

U00.18

Keypad potentiometer

input

0.0~100.0%

0.0%

⊙

U00.19

HI input

0.00~100.00kHz

0.00kHz

⊙

U00.20

AO1 output

0.0~100.0%

0.0%

⊙

U00.21

AO2 output

0.0~100.0%

0.0%

⊙

U00.22

HO output

0.00~100.00kHz

0.00kHz

⊙

U00.23

Temperature of inverter

-40.0℃~120.0℃

0.0℃

⊙

U00.24

Accumulative power-on

time

0~65535min

0min

⊙

U00.25

Accumulative running

time

0~6553.5min

0.0min

⊙

U00.26

Cumulative power-on

time

0~65535h

0h

⊙

U00.27

Cumulative running time

0~65535h

0h

⊙

U00.28

Count value

0~65535

0

⊙

U00.29

Length value

0~65535m

0m

⊙

U00.30

Linear speed

0~65535m/min

0m/Min

U00.31

Output torque

0.0~300.0%

0.0%

⊙

U00.32

Motor temperature by

PTC

-40℃~200℃

0℃

⊙

U00.33

Speed detected by

encoder

0~60000rpm

0rpm

⊙

U00.34

Encoder lines

0~65535

0

⊙

U00.35

Power dissipation

0~65535kWh

0kWh

⊙

U00.36

VDI1~VDI5 input state

VDI5 VDI4 VDI3 VDI2 VDI1

00000

⊙

Page 21

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 21 -

U00.37

VDO1~VDO5 output

state

VDO5 VDO4 VDO3 VDO2 VDO1

00000

⊙

Group U01 Fault Record

U01.00

Current Fault Type

Err00: No fault

0

⊙

Err01: Accel overcurrent

Err02: Decel overcurrent

Err03: Constant-speed

overcurrent

Err04: Accel overvoltage

Err05: Decel overvoltage

Err06: Constant-speed

overvoltage

Err07: Bus undervoltage

Err08: Short circuit

Err09: Power input phase loss

Err10: Power output phase loss

Err11: Motor overload

Err12: Inverter overload

Err13: External equipment fault

Err14: Module overheat

Err15: EEPROM read/write fault

Err16: Motor auto-tuning

cancelled

Err17: Motor auto-tuning fault

Err18: Communication overtime

error

Err19: PID feedback loss

Err20: Continuous running time

reached

Err21: Parameter upload fault

Err22: Parameter download

fault

Err23: Braking unit fault

Err24: Module temperature

detection disconnection

Err25: Load becoming 0

Err26: With-wave current limit

fault

Err27: Inverter soft-start relay is

off

Err28: Software

versioncompatibility fault

Err29: Instantaneous

overcurrent

Err30: Instantaneous

overvoltage

U01.01

Running frequency

when the latest fault

occurred

0.00~Fu

0.00Hz

⊙

U01.02

Output current when the

latest fault occurred

0.0~3000.0A

0.0A

⊙

U01.03

Bus voltage when the

latest fault occurred

0~1200V

0V

⊙

U01.04

Cumulative running time

when the latest fault

occurred

0~65535h

0h

⊙

Page 22

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 22 -

U01.05

Code of previous fault

Same as U01.00

0

⊙

U01.06

Running frequency

when previous fault

occurred

0.00~Fu

0.00Hz

⊙

U01.07

Output current when

previous fault occurred

0.0~3000.0A

0.0A

⊙

U01.08

Bus voltage when

previous fault occurred

0~1200V

0V

⊙

U01.09

Cumulative running time

when previous fault

occurred

0~65535h

0h

⊙

U01.10

Before-previous fault

code

Same as U01.00

0

⊙

U01.11

Running frequency

when before-previous

fault occurred

0.00~Fu

0.00Hz

⊙

U01.12

Output current when

before-previous fault

occurred

0.0~3000.0A

0.0A

⊙

U01.13

Bus voltage when

before-previous fault

occurred

0~1200V

0V

⊙

U01.14

Cumulative running time

when before-previous

fault occurred

0~65535h

0h

⊙

H00 group: multi-pumps constant pressure water supply

H00.00

Special purpose

inverter function enable

0: Invalid

0

×

1: Valid

H00.01

Work modes selection

0: fixed variable-frequency

pumps mode

1: 2 variable-frequency pumps

cycle mode

0

×

H00.02

Frequency for add

pumps

Frequency for reduce

pumps~max frequency

50.00Hz

△

H00.03

Frequency for reduce

pumps

0.00Hz~frequency for add

pumps

5.00Hz

△

H00.04

Pressure tolerance for

add pumps

0.0~100.0%

0.0%

△

H00.05

Pressure tolerance for

reduce pumps

0.0~100.0%

0.0%

△

H00.06

Added pumps delay

0.0~300.0s

20.0s

△

H00.07

Reduced pumps delay

0.0~300.0s

15.0s

△

H00.08

Time for added pumps

speed arrival max

0.0~300.0s

1.0s

△

H00.09

Time for reduced

pumps zero-flow

0.0~300.0s

1.0s

△

H00.10

Switching time

0.1~10.0s

1.0s

×

H00.11

Pumps Status

Unit: No.1 pump status

0:Spare

1:Enable

Decade: No.2 pump status(same

with unit)

Hundreds: No.3 pump

status(same with unit)

Kilobit: No.4 pump status(same

with unit)

00011

△

Page 23

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 23 -

Myriabit: No.5 pump status(same

with unit)

H00.12

Timing rotate or not

0:fixed order

1:start first stop first

2:timing rotate

0

×

H00.13

Gap of timing rotate

1~60000Min

240Min

×

H00.14

Inverter action selection

when adding or

reducing pump in

single-variable pump

mode

0:Inverter stop

0

×

1:Inverter not stop

3.2 H00 group function code detailed explanation

H00.00

Special purpose

inverters function enable

0: Invalid

0

×

1: Valid

0: Invalid

Standard type

1: Valid

Special purpose type for multi-pumps constant water supply, H00 group parameters valid

H00.01

Work mode selection

0: Fixed variable-frequency

pump mode

0

×

1: 2 variable-frequency pumps

cycle mode

0: Fixed variable-frequency pump mode

Inverter 3-phase output control a certain pump as fixed variable-frequency pump, other pumps

power-frequency run/stop controlled by programmable D0 output. (max control 1*fixed

variable-frequency pump+4*power-frequency pumps), power-frequency pump conform to “start first

stop first”. Under this mode, 4*power-frequency pumps corresponding to No.2~5 pumps, according to

the specific site situation requirements for the numbers of power-frequency pumps, which can be

achieved by set multi-functions input (51~54) and H00.11, for more details please refer to H00.11

instructions. Wirings refer to Figure 3-1.

DI1

DI2

DI3

DI4

DI6

COM

FR200H

DI5

Q3

Q4

Default Value

Q2

RST

M4

M3

M2

M1

10V

AI1

AI2

GND

Given

Feedback

U

V

W

KM1

KM2

KM3

FWD

REV

Q5

DI7

R1A

R1C

R2A

R2C

220V

KM1

KM2

KM3

KM4

R1A

R1C

R2A

R2C

KA1

KA2

3-phase power supply

24V

PLC

KA1

KA2

Y1

Y2

24V

M5

KM4

Figure 3-1 Fixed Variable-frequency Pumps Mode Wirings

Page 24

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 24 -

Fixed variable-frequency pumps mode parameters setting instructions

F01.01=6 (PID preset)

F02.00=1 (external terminals)

F04.02=9(external default

input)

F05.00=31(No.2

power-frequency pump)

F05.01=32 (No.3

power-frequency pump)

F05.02=33(No.4

power-frequency pump)

F05.03=34(No.5

power-frequency pump)

F13.00=2 (AI1 Pressure

Preset)

F13.02=1AI2(Pressure

Feedback)

H00.01=0(single-variable

pump, multi-power

frequency pump)

H00.11=1111(all pumps start)

Note: in case of using 2 pumps or 3 pumps, set parameter (H00.11 pump status) corresponding to set

the un-usage pump to be 0, the pump stops.

1: 2 variable-frequency pumps cycle mode

Water supply system doesn’t fix a certain pump as variable-frequency pump, when system pressure is

insufficient, the running variable-frequency pump firstly switch to grid-power frequency running, and

then variable-frequency enable the next new pump, the pump is the new variable-frequency pump.

When the system has too much pressure, power-frequency pump stops. The same moment at most

only one pump work as variable-frequency pump, another one work on power-frequency, (can control

2*variable-frequency pumps work in cycle). Wirings refer to Figure 3-2.

DI1

DI2

DI3

DI4

COM

DI5

Q2

Default Value

Q1

R

S

T

M1

10V

AI1

AI2

GND

Given

Feedbac

k

U

V

W

KM1

FWD

REV

R1A

R1C

R2A

R2C

220V

KM1

KM2

KM3

KM4

R1A

R1C

R2A

R2C

KA1

KA2

3-phase power supply

24V

PLC

M2

KM2

KM3

KM4

KA1

KA2

Y1

Y2

24V

FR200H

Figure 3-2 2 variable-frequency pumps cycle mode

2 variable-frequency pumps cycle modeparameters setting instructions:

F01.01=6(ID preset)

F02.00=1(External terminals)

F04.02=9(External default

input)

F05.00=36(No.2

variable-frequency pump)

F05.01=31(No.2

power-frequency pump)

F05.02=35(No.1

variable-frequency pump)

F05.03=30(No.1

power-frequency pump)

F13.00=2(AI1 pressure

preset)

F13.02=1 (AI2 pressure

feedback)

H00.01=1(multi-variable

pumps)

H00.11=0011(all pumps start)

Note: when set parameter (H00.11 pump status) of corresponding unused pump to be zero (spare),

the pump stops.

H00.02

Frequency for add

pumps

Frequency for reduce

pumps~max frequency

50.00Hz

△

H00.03

Frequency for reduce

0.00Hz~frequency for add

5.00Hz

△

Page 25

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 25 -

pumps

pumps

H00.04

Pressure tolerance for

add pumps

0.0~100.0%

0.0%

△

H00.05

Pressure tolerance for

reduce pumps

0.0~100.0%

0.0%

△

H00.06

Added pumps delay

0.0~300.0s

20.0s

△

H00.07

Reduced pumps delay

0.0~300.0s

15.0s

△

Add pumps: running frequency≥H00.02 set value, feedback pressure<set pressure-pressure

tolerance, and last the delay time set by H00.06, meet the terms of add pumps, add pump.

Reduce pumps: running frequency≤H00.03 set value, feedback pressure>set pressure+pressure

tolerance, and last the delay time set by H00.07, meet the terms of reduce pumps, reduce pump.

H00.08

Time for added pumps

speed arrival max

0.0~300.0s

1.0s

△

H00.09

Time for reduced pumps

zero-flow

0.0~300.0s

1.0s

△

Time for added pumps speed arrival max: when command for adding pumps being sent, a

delay(H00.08 parameters) been start, which makes the pump arrive at its rated speedbefore start

another pump(avoid shaking).

Time for reduced pumps zero-flow: when command for adding pumps being sent, a delay(H00.09

parameters) been start, which makes the pump can stop effectively before stop another pump(avoid

shaking).

H00.10

Switching time

0.1~10.0s

1.0s

×

This function mainly use for protection inverter and AC power supply from short-circuited, which

caused by contactor action delay when a motor switched from variable frequency to power frequency.

Set the shortest time larger than the total of relay action time and contactor action time, generally

the contactor action from connect to disconnect takes longer time than switch from disconnect to

connect, please operate on longer time.

H00.11

Pump status

Unit: No.1 pump status

0:spare

1:start

Decades: No.2 pump status

(same with unit)

Hundreds: No.3 pump status

(same with unit)

Thousands: No.4 pump

status(same with unit)

Myriabit: No.5 pump

status(same with unit)

00011

△

Spare: Control terminals DI1~DI7 are multi-functional terminals, which define their functions by

setting the value of F04.00~F04.03. Repeat definition is allowed, one of the re-defined

terminals valid, the function valid. 51~54 is special functions for constant pressure water

supply, instructions as below: 51~54:No.1~No.4 pumps status.

Start: When function of DI1~DI7 terminal defined as 51~54, terminals valid, then the corresponding

pumps allowed to run, if terminals invalid, and F04.00~F04.03 corresponding pumps status

selected to be 1: start, then the pumps allowed to run, if selected to be 0: spare, then the

pumps not allowed to run.

H00.12

Timing rotate or not

0:fixed order

1:start first stop first

2:timing rotate

0

×

0: fixed order: start the pumps from small to large.

1: start first stop first: firstly start the running time shortest one when add pumps, firstly stop the

running time longest one when reduce pumps.

2: timing rotate:(1)Single variable pump, with assisted pump switched, timing rotate. When 2 pcs or

more than 2 pcs assisted pumps running at the same time, if system meets the term of reduce

pumps, the firstly started pump will stop first; if the one of them keep running more than H00.13

(timing rotate gap), the assisted pump stops, and start the pump with longest stop time. (2) Multi

Page 26

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 26 -

variable pump, with assisted pump, with timing rotate. Start current variable pump, when the

running frequency higher than frequency for add pumps, start H00.06 delay, if the frequency

still higher than frequency for add pumps after the delay, then start the other assisted pump.

When variable pump keep running within a certain time, no need to start assisted pumps, if the

time ,more than timing rotate time set by H00.12, then stop the current variable pump, switch

the assisted pump to variable pump.

H00.13

Gap of timing rotate

1~60000Min

240Min

×

Single variable mode: when parts of power-frequency motor running, water supply system under

stable, to avoid parts of motor keep running in a long time, timing rotate time set for limit the longest

running time.

Multi variable mode: when only variable pumps running, and keep running time more than set timing

rotate time, then stop the current running pump and switch to another variable pump.

H00.14

Inverter action selection

when adding or reducing

pump in single-variable

pump mode

0: Inverter stop

0

×

1: Inverter not stop

0:Inverter stop

In single-varialble pump mode, when adding or reducing pump , inverter will stop.

1: inverter not stop

In single-varialble pump mode, when adding or reducing pump , inverter will not stop.

Page 27

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 27 -

Chapter 4 Maintenance and troubleshooting

FR200H inverter provides a number of warning information and protection, when a fault occurs,

the protective function is activated, the inverter will stop output, inverter fault relay contact, and in the

inverter displays the fault code on the display panel. Before seeking service user can press the

self-examination tips in this section, analyze problems, and identify solutions. If the problem still

cannot be excluded, seek services, or contact the dealer you purchase the driver with my company.

Display

Fault Name

Possible Causes

Solutions

Err01

Accel overcurrent

1: The output circuit is

grounded or short circuited.

2: The acceleration time is too

short.

3: Manual torque boost or V/F

curve is not appropriate.

4: The voltage is too low.

5: The startup operation is

performed on the rotating

motor.

6: A sudden load is added

during acceleration.

7: The AC drive model is of too

small power class.

1: Eliminate external faults.

2: Increase the acceleration

time.

3: Adjust the manual torque

boost or V/F curve.

4: Adjust the voltage to

normal range.

5: Select rotational speed

tracking restart or start the

motor after it stops.

6: Remove the added load.

7: Select an AC drive of

higher power class

Err02

Decel overcurrent

1: The output circuit is

grounded or short circuited.

2: The deceleration time is too

short.

3: The voltage is too low.

4: A sudden load is added

during deceleration.

5: The braking unit and

braking resistor are not

installed.

1: Eliminate external faults.

2: Increase the deceleration

time.

3: Adjust the voltage to

normal range.

4: Remove the added load.

5: Install the braking unit and

braking resistor.

Err03

Constant-speed

overcurrent

1: The output circuit is

grounded or short circuited.

2: The voltage is too low.

3: A sudden load is added

during operation.

4: The AC drive model is of too

small power class.

1: Eliminate external faults

2: Adjust the voltage to

normal range.

3: Remove the added load

4: Select an AC drive of

higher power class.

Err04

Accel overvoltage

1: The input voltage is too

high.

2: An external force drives the

motor during acceleration.

3: The acceleration time is too

short.

1: Adjust the voltage to

normal range.

2: Cancel the external force

or install a braking resistor.

3: Increase the acceleration

time.

Page 28

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 28 -

4: The braking unit and

braking resistor are not

installed.

4: Install the braking unit and

braking resistor.

Err05

Decel

overvoltage

1: The input voltage is too

high.

2: An external force drives the

motor during deceleration.

3: The deceleration time is too

short.

4: The braking unit and

braking resistor are not

installed.

1: Adjust the voltage to

normal range.

2: Cancel the external force

or install the braking resistor.

3: Increase the deceleration

time.

4: Install the braking unit and

braking resistor.

Err06

Constant-speed

overvoltage

1: The input voltage is too high

2: An external force drives the

motor during deceleration.

1: Adjust the voltage to

normal range.

2: Cancel the external force

or install the braking resistor.

Err07

Bus undervoltage

1: Instantaneous power failure

occurs on the input power

supply.

2: The AC drive's input voltage

is not within the allowable

range.

3: The bus voltage is

abnormal.

4: The rectifier bridge and

buffer resistor are faulty.

5: The drive board is faulty.

6: The main control board is

faulty.

1: Reset the fault.

2: Adjust the voltage to

normal range.

3: Contact the agent or

Frecon.

Err08

Short circuit

1: The output circuit is

grounded or short circuited.

2: The connecting cable of the

motor is too long.

3: The module overheats.

4: The internal connections

become loose.

5:The main control board is

faulty

6: The drive board is faulty.

7: The inverter module is

faulty.

1: Eliminate external faults.

2: Install a reactor or an

output filter.

3: Check the air filter and the

cooling fan.

4: Connect all cables

properly.

5: Contact the agent or

Frecon.

Err09

Power input

phase loss

1: The three-phase power

input is abnormal.

2: The drive board is faulty.

3: The lightening board is

faulty.

4: The main control board is

faulty.

1: Eliminate external faults.

2: Contact the agent or

FRECON.

Page 29

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 29 -

Err10

Power output

phase loss

1: The cable connecting the

AC drive and the motor is

faulty.

2: The AC drive's three-phase

outputs are unbalanced when

the motor is running.

3: The drive board is faulty.

4: The module is faulty.

1: Eliminate external faults.

2: Check whether the motor

Three-phase winding is

normal.

3: Contact the agent or

Frecon.

Err11

Motor overload

1: F11-17 is set improperly.

2: The load is too heavy or

locked-rotor occurs on the

motor.

3: The AC drive model is of too

small power class.

1: Set F11-17 correctly.

2: Reduce the load and

check the motor and the

mechanical condition.

3: Select an AC drive of

higher power class.

Err12

Inverter overload

1: The load is too heavy or

locked-rotor occurs on the

motor.

2: The AC drive model is of too

small power class.

1: Reduce the load and

check the motor and

mechanical condition.

2: Select an AC drive of

higher power class.

Err13

External

equipment fault

1: External fault signal is input

via DI.

Reset the operation.

Err14

Module overheat

1: The ambient temperature is

too high.

2: The air filter is blocked.

3: The fan is damaged.

4: The thermally sensitive

resistor of the module is

damaged.

5: The inverter module is

damaged.

1: Lower the ambient

temperature.

2: Clean the air filter.

3: Replace the damaged

fan.

4: Replace the damaged

thermally sensitive resistor.

5: Replace the inverter

module.

Err15

EEPROM

read/write fault

The EEPROM chip is

damaged.

Replace the main control

board.

Err16

Motor auto-tuning

cancelled

Since the identification

process, press STOP / RST

key

Press STOP / RST key to

reset

Err17

Motor auto-tuning

fault

1: the motor and the inverter

output terminals are not

connected

2: The motor does not

disengage the load

3: The electrical fault

1: check the connection

between the inverter and

motor

2: The motor is disengaged

load

3: Check the motor

Err18

Communication

overtime

error

1: The PC is not working

properly

2: The communication line is

not normal

3: F15 set communication

parameters set incorrectly

1: Check the PC Connection

2: Check the communication

cable

3: The communication

parameters are set correctly

Err19

PID feedback

loss

PID feedback set value is less

than F13.24

Check the PID feedback

signal or set to an

appropriate value F13.24

Page 30

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 30 -

Err20

Continuous

running time

reached

Set the running time to reach

this function

reference F05.14

Description

Err21

Parameter upload

fault

1: Is not installed or is not

plugged parameter copy card

2: Parameter copy card

anomalies

3: The control board

abnormalities

1: a copy of the card is

properly installed

parameters

2: for technical support

3: for technical support

Err22

Parameter

download fault

1: Is not installed or is not

plugged parameter copy card

2: Parameter copy card

anomalies

3: The control board

abnormalities

1: A copy of the card is

properly installed

parameters

2: For technical support

3: For technical support

Err23

Braking unit fault

1: The brake line failure or

damage the brake pipe

2: An external braking resistor

is too small

1: Check the brake unit,

replace the brake pipe

2: Increasing the braking

resistor

Err24

Module

temperature

detection

disconnection

The temperature sensor

failure or cable break

For technical support

Err25

Load becoming0

The AC drive running current

is lower than F11.22

Check that the load is

disconnected or the setting

F11-22 and F11-23 is

correct.

Err26

With-wave

current limit fault

1: The load is too heavy or

locked rotor occurs on the

motor.

2: The AC drive model is of too

small power class.

1: Reduce the load and

check the motor and

mechanical condition.

2: Select an AC drive of

higher power class.

Err27

Inverter soft-start

relay is off

1: The grid voltage is too low

2: Rectifier module failure

1: Check the grid voltage

2: Demand for technical

support

Err28

Software version

compatibility fault

1: The upper and lower

transmission module

parameters in the parameter

version of the control panel

version mismatch.

re-upload module

parameters to pass down

Err29

Instantaneous

overcurrent

1. Inverter output circuit being

grounded or short-circuit;

2. The acceleration and

deceleration time is too short;

3. Manually torque boost or

V/F curve not appropriate;

4. Voltage too low;

5. Start the running motor;

6. Sudden-load in the acce

process;

1. Troubleshooting

peripheral problems;

2. To increase the

acceleration time;

3. Adjust the manually

torque boost or V/F curve;

4. Adjust the voltage to

normal range;

5. Select RPM track start or

start after motor stopped;

Page 31

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 31 -

7. Model selection of inverter

power is too small.

6. Cancel sudden-load;

7. Select the inverter with

larger power.

Err30

Instantaneous

overvoltage

1: Input voltage is too high;

2. There is external force drag

the motor to run in dece

process;

3. The deceleration time is too

short;

4.No installation of braking

resistor.

1: Adjust the voltage to

normal range;

2. Cancel external force or

install brake resistor;

3. To increase the

deceleration time;

4.Install braking resistor

Err40

Set running time

finished

1. Cumulative running time

(U00.27) no less than using

time (F00.25)

1. Contact distributors

Page 32

FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 32 -

Loading...

Loading...