REMOTE THROTTLE

FOR CUMMINS CELECT and CELECT+

ENGINES SERIES M11, N14, L10

MODEL : RTU 1

OPERATING INSTRUCTIONS

IDLE

REV1297NB RTU1.P65

PRESETPRESET

PRESET

PRESETPRESET

INCREASE

FRC

s

12001200

1200

12001200

s

SETTING

DECREASE

RTU

FIRE RESEARCH CORP. 26 Southern Blvd., Nesconset, NY11767

TEL ( 516 ) 724-8888 FAX ( 516 ) 360-9727

TOLL FREE 1-800-645-0074

Page 1

RTU

Remote Throttle

Introduction:

The R TU is a state of the art electronic remote throttle designed for fire apparatus

equipped with the Cummins CELECT and CELECT+ electronic engine control

system. This includes the M11, N14 and L10 series engines. The RTU is connected

to the CELECT or CELECT+ through the J1922 data link via a twisted pair cable.

This arrangement allowes the MP ( master processor ) of the R TU to communicate

with the ECM (electronic control module) of the engine constantly . The RTU can be

used to vary the engine speed through use of the "INCREASE" and "DECREASE"

pushbuttons. A "PRESET" switch allows an operator to quicly bring the engine RPM

to a predetermined value with one press of a button.

An optional high idle kit (PRO-38H) may be purchased that plugs directly into the

R TU that allows engine RPM to be brought to a preselected RPM value through a

toggle switch. Wiring for this option can be found in Fig 7 of this manual.

REV1297NB RTU1.P65

Page 2

MECHANICAL INSTALLATION

Before proceeding with any installation, please check to make sure you have the following components. STOP and call the factory if any components are missing. Components supplied are as follows :

1) Throttle controller

2) Extension cable for power

3) Extension cable for J1922 data link

MECHANICAL - installing the display module

The control module can be mounted anywhere on the pump panel. The display module

has a square flange with overall dimensions of 4.25"X4.25". A cutout hole of 3.75" in

diameter is required to fit the cylindrical can of the module into the panel. Insert the

Throttle controller into the cutout hole and locate the four bolt holes. The holes are for

10-32 screws and are set up on a 3.5" bolt square at the four corners of the flange.

REV1297NB RTU1.P65

(Some units are longer)

Page 3

ELECTRICAL INSTALLATION

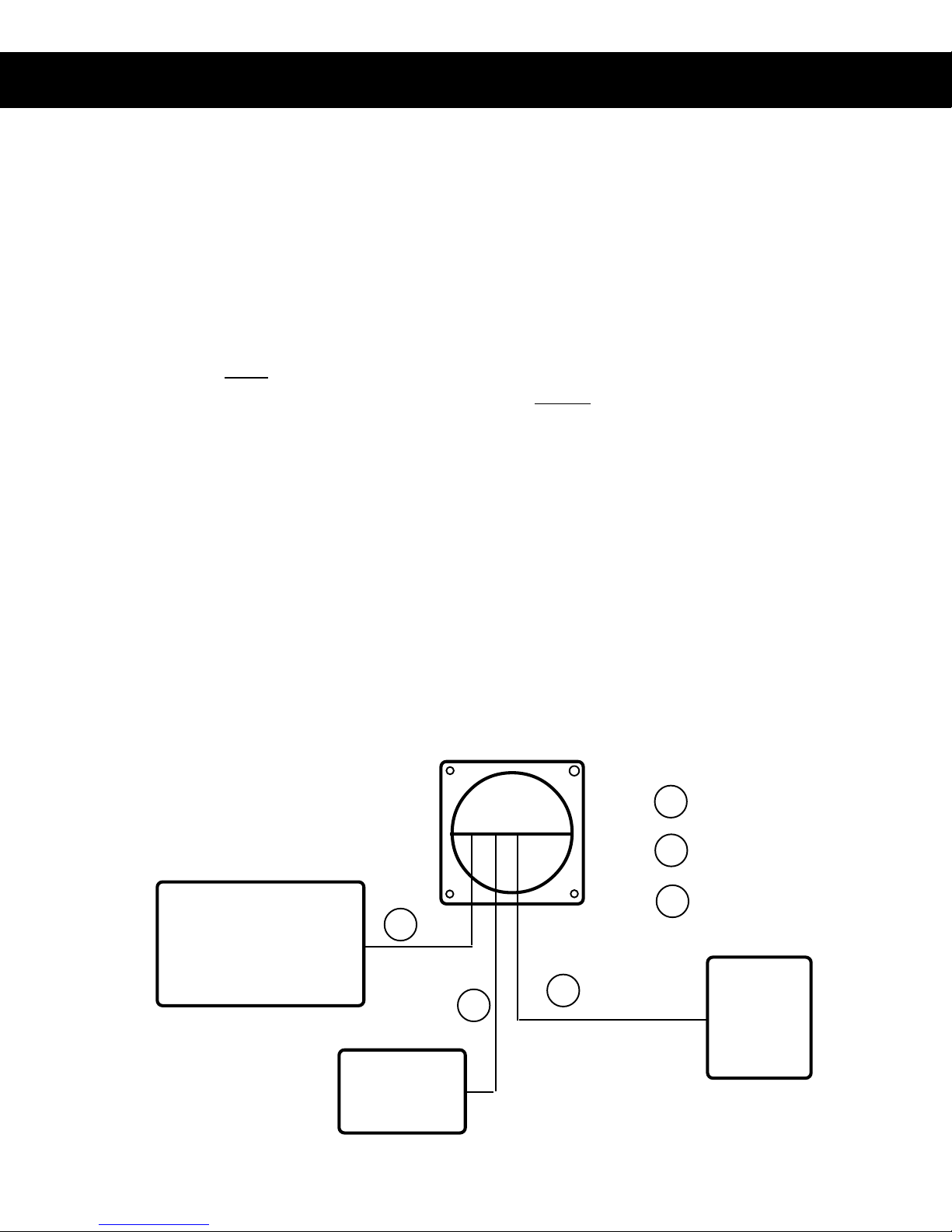

Wiring for the RTU 1 system is very simple. Refer to fig 1 below. All extension cables are

supplied with unique connectors that simplify the interconnections. See fig 2 for cables.

1) Use the extension cable supplied, provide 12VDC and ground to the electronic

module on the wire labeled POWER on the back of the module. Leave the white wire

disconnected until step 3.

2) Connect the cable for the J1922 data link. The J1922 datalink is a data wire consisting

of two wires leading from connector A of the ECM. On more recent Cummins ECMs

(CELECT+),

pin 5 on connector A of the ECM is the positive (+) (wire #020) and should

be connected to the R TU's red DATA J1922 wire. Pin 23 is the negative (-) (wire #021)

and should be connected to the R TU's black DATA J1922 wire. The cable used is a

shielded twisted pair cable.

NOTE:

If you have an older Cummins CELECT engine, there may be a 2 pin Packard connector

for the J1922 data link located near the CELECT ECM by the bulkhead. Check that the

positive (+) wire comes from pin 10 on the A connector. The negative (-) comes from pin

20 on the A connector.)

3) The R TU will not be active until you provide 12V to the white wire. This connection

should be wired through the pump engaged interlock and the parking brake for safety . In

this manner, the RTU will not receive an "active" signal until these conditions are met.

4) If HIGH IDLE option was

CONTROL MODULE

ordered, refer to Figure 7 for

wiring instructions.

REV1297NB RTU1.P65

RED = 12 VDC

BLACK = GND

WHITE = Interlock.

12VDC signal required

FIG 1.

1

CELECT

ECM

RTU 1

2

Page 4

Power cable

1

J1922 data link cable

2

High Idle cable

3

3

HIGH

IDLE

Refer to Figure 7

EXTENSION CABLES

POWER

RED = 12VDC

Figure 2

THROTTLE

RTU 1

BLACK = GND

DA TA LINK

J1922

REV1297NB RTU1.P65

HIGH IDLE

Red = 12VDC

Black = GND

White = From INT-110

3 pins plug

Deutsch DT series

3 pins receptacle

Deutsch DT series

T o High Idle inside cab

(see Fig 7)

To J1922 data link

at CELECT ECM

5'

Power

12'

High Idle

12'

2 pins Packard plug 2 pins Packard receptacle

J1922 data link

Page 5

OPERATING THE RTU

Simple to use !

The R TU is engineered with ease of operations in mind. All functions on the control

module are self explanatory . The LED display which shows the desired RPM setting is

easily visible both day and night.

How to operate :

When the R TU is on, the display will show 'IDLE' to indicate that the engine is at idle.

There are 4 pushbuttons on the control module :

1) The "Increase" and "Decrease" switches allow easy selection of desired RPM from

IDLE to maximum governed speed. Depress "Increase" to ramp the engine RPM up,

and depress "Decrease" to ramp the engine RPM down. The RPM will ramp up or

down at 50 RPM increment when pressed momentarily . When the pushbutton is held

down for more than 2 seconds, the R TU will ramp up or down in 100 RPM increments.

Release the pushbutton when desired RPM is reached.

REV1297NB RTU1.P65

2) The "IDLE" switch will bring engine to idle immediately after operations.

3) The "PRESET" switch ramps engine to the preset RPM quickly and conveniently

with the momentary touch of a single button.

(After the "PRESET" switch is used, the "Increase" and "Decrease" switches can still

be used to change the selected RPM easily.)

How do I change the preset RPM ?

a) Make sure the engine is at idle before proceeding. If the R TU does not display IDLE

in the display window , press the "IDLE" switch.

b) Press the "PRESET" switch with your left thumb and hold it in until the display

begins to flash. With your right hand press the "Increase" or "Decrease" switch to

change the flashing display until it reads the desired RPM.

c) When the desired RPM is obtained, release the "PRESET" switch and the RPM

shown in the window has become the new preset RPM and will be stored in the R TU's

memory .

Page 6

FUNCTIONS FOR SWITCHES ...

Figure 3

4

PRESETPRESET

PRESET

PRESETPRESET

FRC

1

IDLE

12001200

1200

12001200

SETTING

RTU

INCREASE

s

2

s

3

DECREASE

REV1297NB RTU1.P65

1) The " IDLE " switch brings engine to idle immediately after operations

2) The " INCREASE " switch ramps engine RPM up

3) The " DECREASE " switch ramps engine RPM down

4) The " PRESET " switch ramps engine to the preset RPM quickly and conveniently .

Page 7

Specifications :

Control Module :

Dimensions :

Response : Idle to full governed speed

Pressure Recovery : On open/close valve

Max. RPM :

Operational :

RPM mode :

Electrical :

Power :

Current :

Microprocessor :

4.25"W X 4.25"H X 3.75"D

3 seconds maximum

1 1/2 seconds

2000 RPM

REV1297NB RTU1.P65

Idle to 2000 RPM

12 VDC

1/2 A continuous

8 Bit single chip MicroComputer

Page 8

X-Hi-Idle.p65 rev11Sep97nb

OPTIONAL

HIGH IDLE

OPERA TION

Part # PRO-38H

If you did not order the optional remote high idle, ensure that the

dummy plug (supplied) is installed on the end of the high idle cable! If

you did not receive a dummy plug, or have lost it, you NEED one!

For wiring instructions, refer to the next page.

All Fire Research PRO and RTU series governors have an additional cable port

labeled “high idle” which can be used to provide a high idle switch at a remote location

on the vehicle. The PRO-38H High Idle Kit provides all the necessary components

needed to hook up this optional switch, including locking potentiometer, dpdt switch,

12V lamp indicator and 12 foot cable.

How do I activate the high idle ?

T o activate the high idle, simply toggle the high idle switch to “ON”. The high idle

activated indicator light will go on and the engine will rise to the preset speed (set by

the locking potentiometer).

How do I change the high idle speed ?

Loosen the lock nut on the potentiometer . Use a small screw driver to rotate the potentiometer to raise the RPM. Using the tachometer in the cab as a reference, monitor the

speed of the engine until you reach the desired speed. Once the desired RPM is

reached, tighten the lock nut to lock in the new high idle speed.

WARNING : Turn off high idle before shutting the engine off !

Page 9

X-Hi-Idle.p65 rev11Sep97nb

OPTIONAL

HIGH IDLE

From Control Module

Red

Black

WIRING

Supply 12 VDC when the parking

brake is on and the transmission is in

White

neutral.

Part # PRO-38H

GND

2500 ohm potentiometer

High idle indicator light

High idle ON/OFF switch

Diode

Figure 7

O.K. to pump

Interlock

white wire on the

power cable

Diode

Note: Some FRC governors require an RPM sensor to be mounted on the drive shaft.

If you have one of these units, be sure that the sensor is mounted on a section of shaft

that spins even when the pump is not engaged or the high idle may not be able to function

except when the pump is in gear. If there is no room to mount the sensor in such a

location, a special “Alternator connection” for RPM signal may be required. This option

may not be available for all devices, so be sure to call FRC for details.

Page 10

Field Service and Warranty

Our aim is to minimize or eliminate field service, so be sure to call technical support (800) 645 0074 as soon as you think there may be a problem in operation or

installation of the R TU governor . A simple call will go a long way toward quickly

diagnosing a problem and determining what parts, if any , may need to be replaced

under this warranty .

Fire Research Corp. (FRC) warrants to replace the RTU unit for any defect in materials or workmanship. This warranty shall apply for a period of one

year after the unit goes in service. This period will begin upon official delivery

date of the vehicle by a truck body manufacturer or upon installation by the

enduser in cases where the unit is retro-fit to an existing unit.

During the warranty period, FRC will replace any of the component parts of a

defective unit by next day air freight by UPS or comparable courier, as our

stock permits, free of charge.

REV081597NB

After the warranty period, FRC warrants to ship to the customer by quickest way , a

temporary unit (as stock permits) for the customer to use while the defective unit is

being repaired in order to minimize down time.

As the PRO was designed to be extremely reliable and has passed stringent third

party testing, FRC expects minimal field defects.

Page 11

Loading...

Loading...