FRC InControl TGA300, InControl TGA400 User Manual

Document Number:

XE-TGA3PM-R0A

MASTER PRESSURE DISPLAY

TGA300

TGA300 Rev180405

PRESSURE GOVERNOR,

ENGINE MONITORING, AND

MODELS: TGA300, TGA400

TGA400

TEL 631.724.8888 FAX 631.360.9727 TOLL FREE 1.800.645.0074

FIRE RESEARCH CORPORATION

www.reresearch.com

26 Southern Blvd., Nesconset, NY 11767

1

TGA300 Rev180405

CONTENTS

CONTENTS ................................................................................................................ 2

INTRODUCTION ...................................................................................................... 4

Overview ................................................................................................................ 4

Features .................................................................................................................. 4

Specications ......................................................................................................... 5

GENERAL DESCRIPTION ....................................................................................... 6

Components ........................................................................................................... 6

Controls and Indicators .......................................................................................... 8

INSTALLATION ...................................................................................................... 10

Install Control Module ......................................................................................... 10

Install Pressure Sensors ....................................................................................... 11

Install Sensors ...................................................................................................... 12

Install Buzzer ....................................................................................................... 12

Install High-Idle Kit ............................................................................................. 12

Install Remote Governor Option.......................................................................... 12

OPERATION ............................................................................................................ 13

Controls ................................................................................................................ 13

Error Codes and Fault Warnings .......................................................................... 14

Pressure Mode Operation..................................................................................... 15

RPM Mode Operation .......................................................................................... 17

Switching Between Operating Modes ................................................................. 18

Pump Discharge Pressure is High at Engine Idle ................................................ 18

RPM Limit with Discharge Pressure Less than 100 PSI ..................................... 18

Remote Governor Option..................................................................................... 18

Detailed Information ............................................................................................ 19

High-Idle .............................................................................................................. 19

Preset Settings (Pressure or RPM) ....................................................................... 20

PROGRAMMING .................................................................................................... 21

Access Password Protected Programs ................................................................. 23

CALIBRATION ........................................................................................................ 25

Pump Pressure Sensor (Code C1 and C2) ........................................................... 26

Engine RPM (Code C3) ....................................................................................... 26

WIRING .................................................................................................................... 27

Connectors and Cables......................................................................................... 27

Secondary Controller, Cables and Connections ................................................... 28

Pressure Sensor .................................................................................................... 29

Common OEM Diagnostic Connector ................................................................. 30

Cummins Harness Connections ........................................................................... 31

Detroit Diesel Harness Connections .................................................................... 32

Navistar Harness Connections ............................................................................. 33

Navistar / International Chassis Harness Connections ........................................ 34

Table of Contents

2

TGA300 Rev180405

Caterpillar Harness Connections ......................................................................... 35

Ford Harness Connections ................................................................................... 36

Mack Harness Connections ................................................................................. 39

Scania Harness Connections—Type A ................................................................ 40

Scania BCI Harness Connections—Type D ........................................................ 41

Mercedes Harness Connections ........................................................................... 42

ACTROS Wiring.................................................................................................. 43

John Deere Harness Connections ........................................................................ 44

MAN Harness Connections ................................................................................. 45

IVECO Harness Connections .............................................................................. 46

High-Idle Wiring .................................................................................................. 47

FLYBACK DIODE INFORMATION ...................................................................... 48

List of Tables

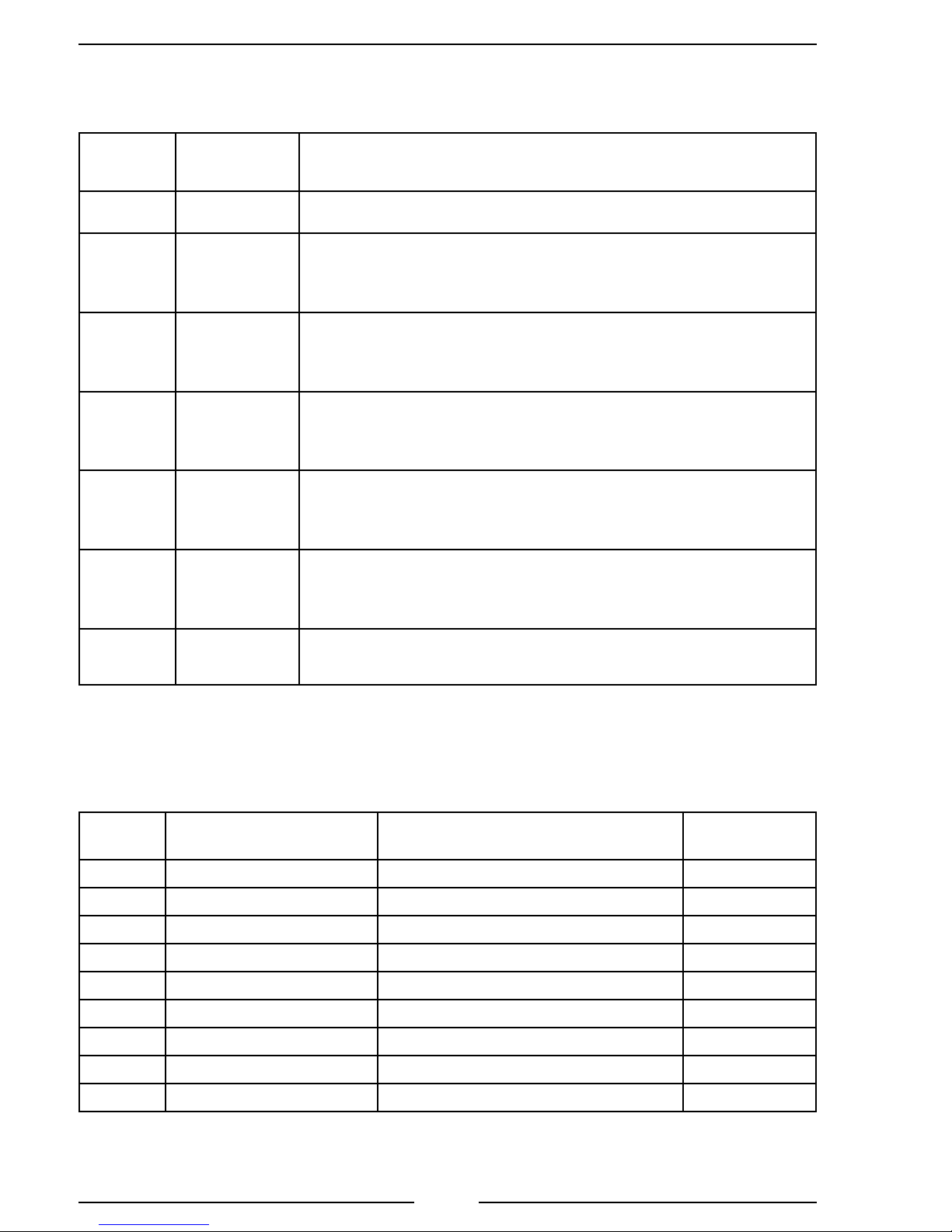

Table 1. Pressure Sensor Output Voltage ........................................................................ 5

Table 2. Error Codes ..................................................................................................... 14

Table 3. Fault Warning Codes ....................................................................................... 14

Table 4. Operator Password Protected Program Functions .......................................... 24

Table 5. Calibration Codes Quick Reference Chart ...................................................... 25

List of Figures

Figure 1. Controls and Indicators .................................................................................... 9

Figure 2. Control Module Mounting Dimensions......................................................... 10

Figure 3. Pressure Sensor Dimensions .......................................................................... 11

Figure 4. TGA 12-Pin Connector Wiring ...................................................................... 27

Figure 5. TGA 8-Pin Connector Wiring ........................................................................ 28

Figure 6. Pressure Sensor Wiring .................................................................................. 29

Figure 7. Common OEM 9-Pin Diagnostic Connector ................................................. 30

Figure 8. Cummins TGA301/401 Wiring ..................................................................... 31

Figure 9. Detroit Diesel TGA302/402 Wiring .............................................................. 32

Figure 10. Navistar TGA304/404 Wiring ..................................................................... 33

Figure 11. Navistar/International Chassis TGA304/404 Wiring .................................... 34

Figure 12. Caterpillar TGA305/405 Wiring .................................................................. 35

Figure 13. Ford TGA306/406 J1939 Translator Module Wiring ................................... 37

Figure 14. Ford TGA306/406 PCM Wiring ................................................................... 38

Figure 15. Mack TGA307/407 Wiring ........................................................................... 39

Figure 16. Scania TGA308/408 Wiring—Type A .......................................................... 40

Figure 17. Scania TGA308/408 Wiring—Type D ......................................................... 41

Figure 18. Mercedes TGA310/410 Wiring ................................................................... 43

Figure 19. John Deere TGA316/416 Wiring .................................................................. 44

Figure 20. MAN TGA324/424 Wiring .......................................................................... 45

Figure 21. IVECO TGA326/426 Wiring........................................................................ 46

Figure 22. High Idle Wiring .......................................................................................... 47

Figure 23. Flyback Diode ............................................................................................. 48

3

TGA300 Rev180405

INTRODUCTION

Overview

The Fire Research all-in-one pressure governor and instrument panel uses state-ofthe-art programmable, microprocessor technology. It maintains a steady pump discharge

pressure by controlling engine speed or holds a selected engine RPM. It offers complete

engine control and remote display in a single compact unit.

The governor operates in one of two modes, pressure or RPM. In pressure mode

it maintains a constant pump discharge pressure. The discharge pressure is monitored,

compared to the selected pressure setting, and the engine RPM is varied to keep the

discharge pressure at the selected setting. In RPM mode it maintains a constant engine

RPM. The pump discharge pressure is monitored and can vary, but, as a safety feature,

it will be limited to an increase of 30 PSI. If the discharge pressure increases 30 PSI

the governor automatically lowers the engine RPM to prevent a high pressure surge.

All controls and indicators are located on the front of the control module.

Features

J1939 CAN Bus for Engine Information and Control

Power Up in Pressure Mode

Automatic Regulation of Pump Discharge Pressure

Manual Control of Pressure or Engine RPM Settings

Programmable Presets

Diagnostic Capabilities

No Pressure or RPM Variation When Changing Modes

Limits Increase of Pressure When in RPM Mode

Recognition of No Water Condition with Automatic Response

Interlock Signal Recognition with Throttle Ready LED

Return to Engine Idle with the Push of a Button

Display Brightness Automatically Adjusts for Day or Night Operation

kPa, Bar, °C Options

Remote Governor Option

4

TGA300 Rev180405

Specications

The governor is available in various models. Each model is programmed to interface

with specic engines. All models provide the same functions, controls, and digital

readouts for the management of pump discharge pressure.

Control Module

Supply Power: 12/24 VDC

Supply Current: 1.8 Amp

Dimensions: 10 1/2" Wide by 5 1/2" High

Unit of Measure: PSI °F (Program Option for kPa, Bar, °C)

LED Bar Graphs

Engine Oil Pressure: 10 - 100 PSI

Engine Coolant Temperature: 150 - 240 °F

Transmission Temperature: 140 - 300 °F

Battery Voltage: 11.5 to 15.5 VDC (12 V)

23.0 - 30 VDC (24 V)

Pressure Sensor

Discharge Intake

Model Number: XE-FP4000PT3 XE-IO3100PT3

Pressure Range: 0 - 600 PSI -30 in/Hg - 600 PSI

Proof Pressure: 1200 PSI 1200 PSI

Excitation Voltage: 5 VDC 5 VDC

Output Voltage: 0.5 - 4.75 VDC (See Table 1)

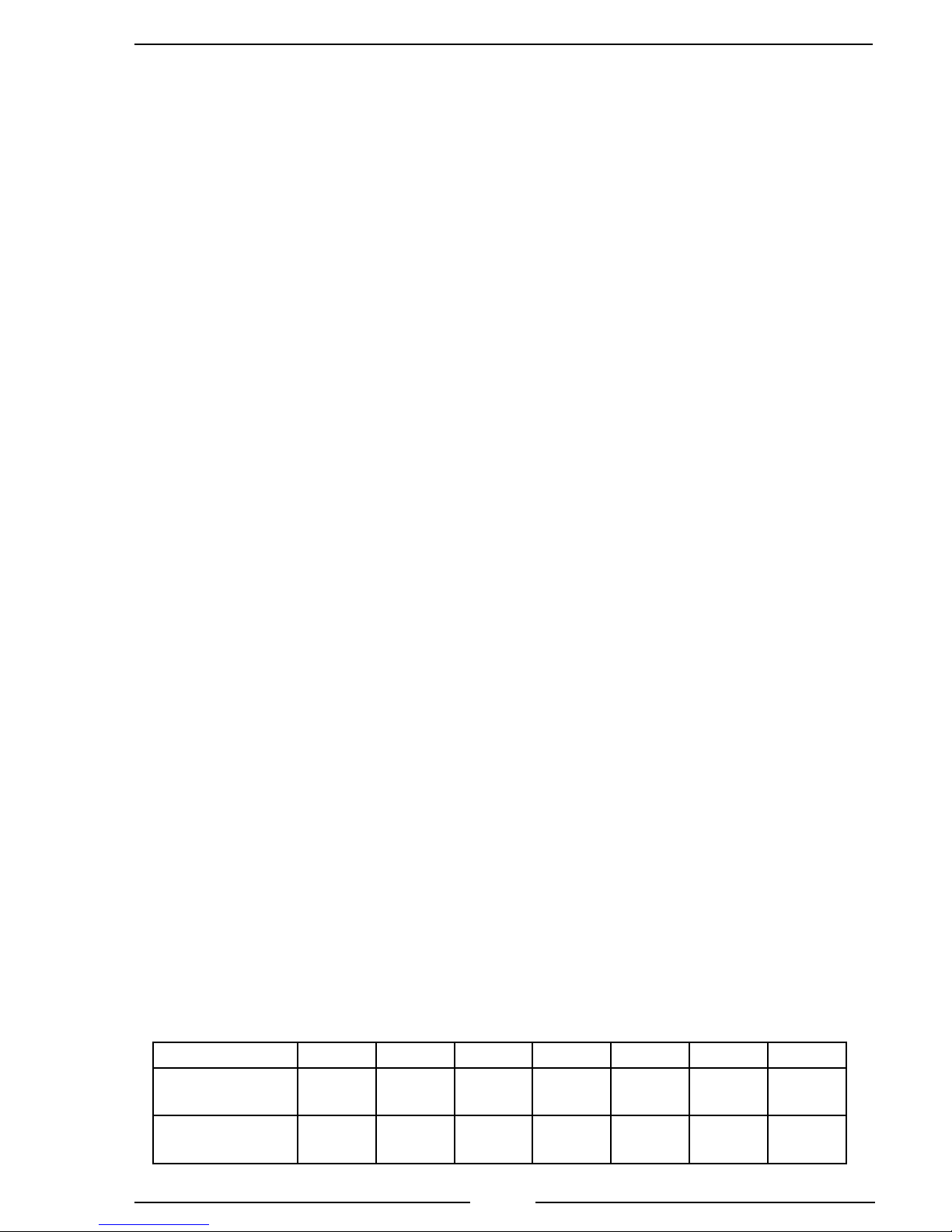

Table 1. Pressure Sensor Output Voltage

0psi 100psi 150psi 200psi 250psi 300psi 600psi

Discharge Sensor

XE-FP4000PT3

Intake Sensor

XE-IO3100PT3

0.5vdc 1.21vdc 1.56vdc 1.92vdc 2.27vdc 2.625vdc 4.75vdc

0.604vdc 1.295vdc 1.640vdc 1.985vd 2.331vdc 2.667vdc 4.75vdc

5

TGA300 Rev180405

GENERAL DESCRIPTION

The all-in-one pressure governor and instrument panel is programmed from the

factory or during installation. It is compatible with the following engines types:

TGA301/401 Cummins IS Series

TGA302/402 Detroit Diesel

TGA304/404 Navistar

TGA305/405 Caterpillar

TGA306/406 Ford

TGA307/406 Mack

TGA308/408 Scania

TGA310/410 Mercedes

TGA316/416 John Deere

TGA324/424 MAN

TGA326/426 IVECO

All controls and indicators are located on the front of the control module.

Components

The information available on the J1939 databus varies depending on the particular

engine type. The sensors (if any) that need to be installed will also vary depending on

the engine.

The INControl pressure governor and instrument panel consist of the following

components:

Control Module

Intake Pressure Sensor

Discharge Pressure Sensor

Audible Alarm Buzzer

Engine Oil Pressure Sensor (As Necessary)

Engine Coolant Temperature Sensor (As Necessary)

Transmission Temperature Sensor (As Necessary)

Cables

6

TGA300 Rev180405

Control Module

The control module is waterproof and uses 10 1/2 by 5 1/2 inches of panel space.

All controls, indicators, and displays are located on the front of the control module.

The TGA300 Series uses push buttons to adjust pressure and RPM settings. The

TGA400 Series uses the FRC hand throttle style control knob to adjust pressure and

RPM settings. (Refer to Controls and Indicators.)

Intake Pressure Sensor

The pressure sensor is mounted on the pump intake manifold. It provides an input

signal to the control module that is proportional to the intake pressure.

Discharge Pressure Sensor

The pressure sensor is mounted on the pump discharge manifold. It provides an

input signal to the control module that is proportional to the discharge pressure.

Audible Alarm Buzzer

A ground is provided at the 8-pin connector pin 7 to activate the buzzer (max

current: 300mA). The buzzer will sound when a fault code becomes activated.

(See Table 3 for the Fault Warning Codes list/descriptions on page 15.)

Cables

There are two standard cables and one optional cable that connect to the control

module. One 8-pin connector and one 12-pin connector. (Refer to Wiring Section.)

High-Idle (Optional)

The governor programming includes a high-idle function. To activate the high-idle

provide a +12 VDC to High-Idle Active Input. (Refer to High-Idle Wiring.).

The high idle is set to 1000 RPM at the factory. (This value will vary depending on

the specic engine.) To adjust this setting refer to High Idle in the Operation Section.

7

TGA300 Rev180405

Controls and Indicators

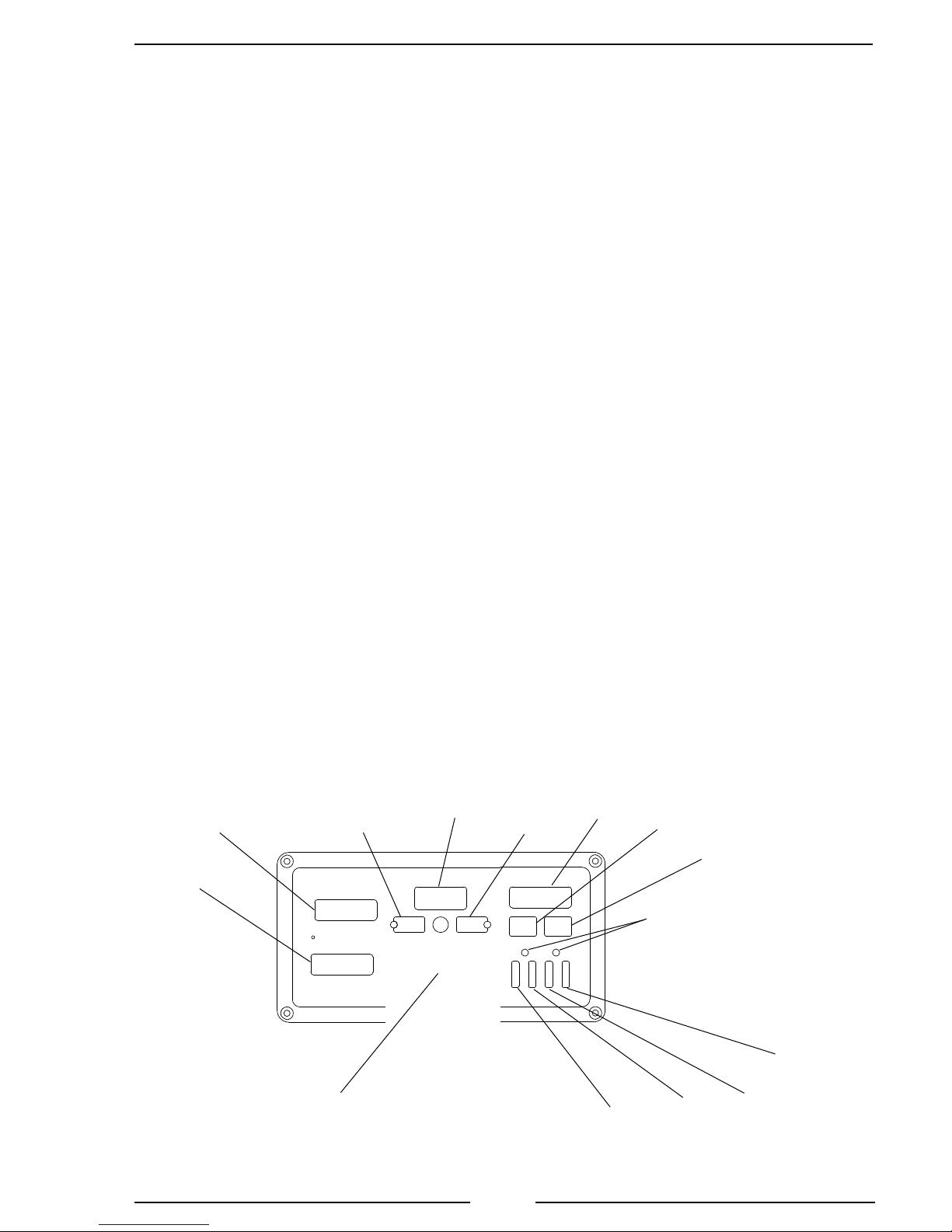

All controls and indicators are located on the front of the control module. (Refer to

Figure 1.) Displays and LED brightness automatically adjusts for day or night operation.

PUMP DISCHARGE and PUMP INTAKE Displays

Shows the pump discharge and intake pressures during normal operations.

Message Display

The message display shows the pressure or RPM setting during normal operations

and warning alarms as they occur. It shows the time and date when the throttle ready

LED is off. It also shows stored data and program features.

PRESSURE Button and LED

Selects the pressure mode of operation, the LED is on to indicate operation in the

pressure mode.

RPM Button and LED

Selects the RPM mode of operation, the LED is on to indicate operation in the

RPM mode.

THROTTLE READY LED

This LED is on when the required interlock conditions are met and the governor

is ready to begin pump operations.

IDLE Button

When pressed immediately sets the engine RPM to idle. This button can be used

in an emergency or for normal shutdown after operations.

PRESET Button

Press to change/select a pre-programmed value for pressure or RPM setting.

DEC / INC Buttons (TGA300 Only)

During operations the buttons increase and decrease pressure or RPM setting.

Control Knob (TGA400 Only)

When rotated changes the pressure or RPM setting. The setting will increase or

decrease proportionally to the speed and direction the control knob is rotated.

RPM Display

Shows the engine RPM during normal operations.

8

TGA300 Rev180405

SILENCE Button

Suppresses audio alarms. Used when accessing program features.

MENU Button

Used to access detailed information and program features. The detailed information

includes the exact measure and units for monitored functions. Each time the MENU

button is pressed the display scrolls to show the next value

CHECK ENGINE / STOP ENGINE LEDs

Repeats the engine warnings from the cab.

Engine Oil Pressure LED Display

Shows pressure in safe range with green LEDs. The LEDs ash red when the

pressure is low.

Engine Coolant Temperature LED Display

Shows temperature in safe range with green LEDs. The LEDs ash red when the

temperature is high.

Pump Transmission Temperature LED Display

Shows temperature in safe range with green LEDs. The LEDs ash red when the

temperature is high.

Battery Voltage LED Display

Shows voltage in safe range with green LEDs. The LEDs ash red when the voltage

is outside normal limits.

PUMP

DISCHARGE

Display

PUMP

INTAKE

Display

PRESSURE

Button and

LED

Message

Display

RPM

Button and

LED

RPM

Display

SILENCE

Button

MENU

Button

CHECK ENGINE/

STOP ENGINE

LEDs

TGA300: IDLE, PRESET, INC, and DEC buttons

Governor Controls

TGA400: Control Knob, IDLE and PRESET buttons.

Engine Oil

Pressure

Display

Temperature

Figure 1. Controls and Indicators

9

Engine

Display

Battery

Voltage

Display

Transmission

Temperature

Display

TGA300 Rev180405

INSTALLATION

When the governor is programmed at the factory there is a label on the governor

that species the engine type. If there is no label the engine type must be veried and/

or programmed.

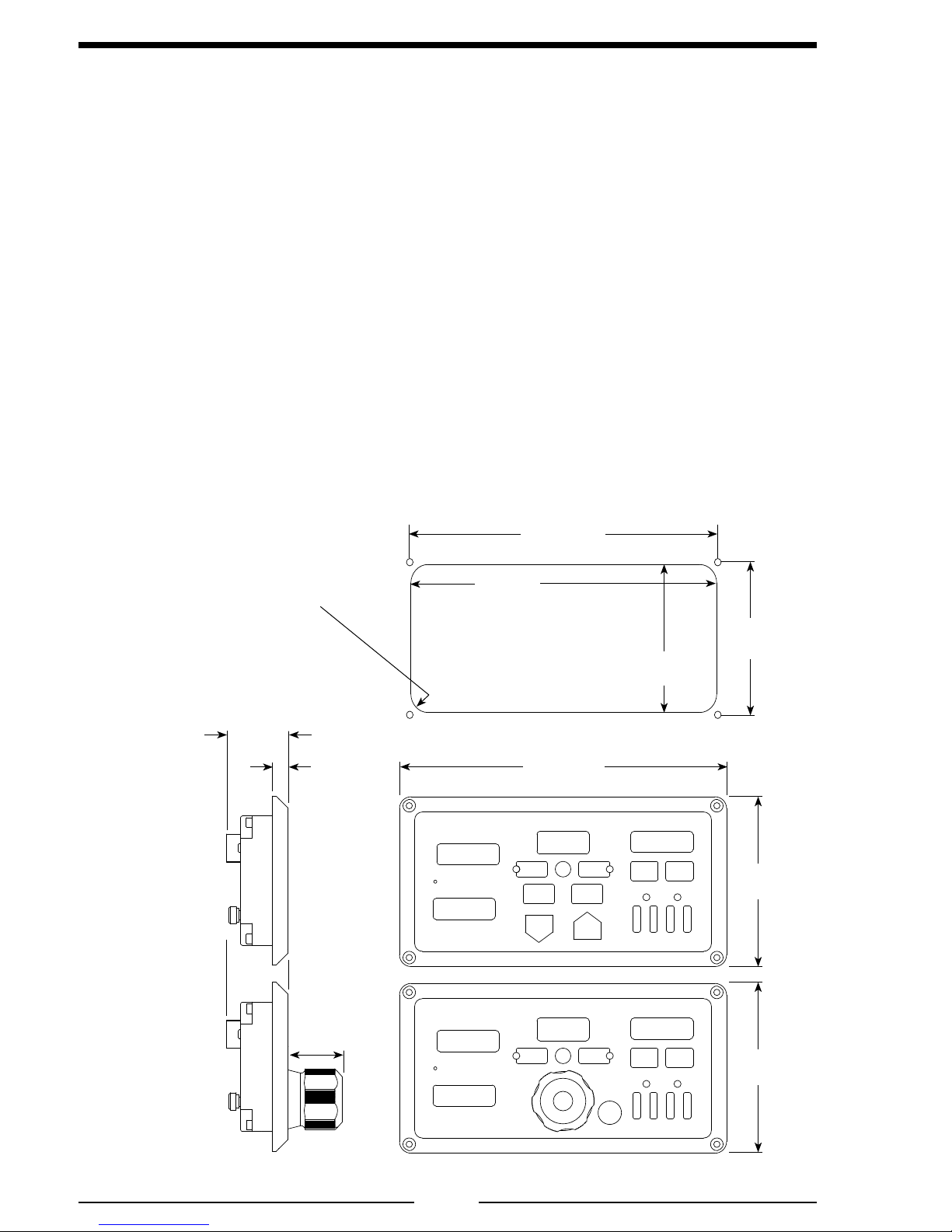

Install Control Module

1. Measure and mark mounting location for control module panel cutout and

mounting screw holes. Make sure there is clearance behind the panel for

the module and cables before cutting holes. Refer to Figure 2 for layout and

dimensions.

2. Cut out a 9 3/4 by 4 1/4 inch hole and drill four holes for mounting screws.

3. Place control module in position and secure with four screws (10-32 mounting

hardware is recommended).

4. Connect cables at rear of the control module. (Refer to Wiring Section.)

Mounting holes are

clearance or tapped

for 10-32 screws.

TGA300

Maximum

Radius

1/4"

2"

1/2"

9 3/4"

9 7/8"

Panel

Cutout

10 1/2"

4 7/8"

4 1/4"

5 1/2"

1 3/4"

TGA400

Figure 2. Control Module Mounting Dimensions

5 1/2"

10

TGA300 Rev180405

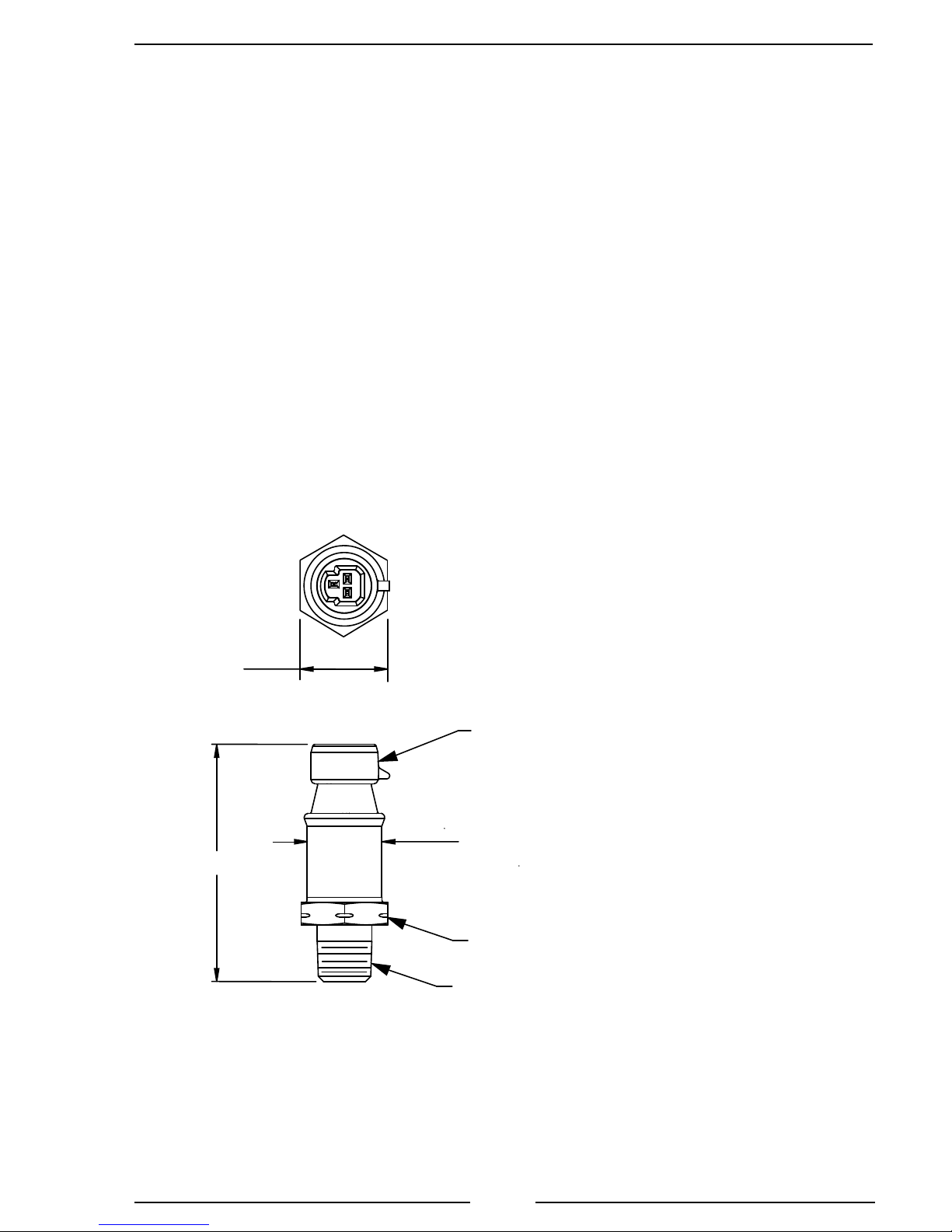

Install Pressure Sensors

Two pressure sensors are mounted on the pump manifolds, one on the discharge

and one on the intake. If there is a check valve in the discharge side of the pump,

mount the discharge sensor before the check valve. T-ttings can be used to mount

the pressure sensors.

Note: Install the pressure sensor upright so that water in the end of the pressure

sensor is able to drain back into the pipe.

1. Screw the sensor into a 1/4-18 NPT hole.

Caution: Do not use the main body that houses the electronics to tighten the

pressure sensor. Damage to the sensor may occur.

2. Tighten the sensor with a 7/8 inch wrench on the lower hex tting.

3. Connect the pressure sensor cable from the control module to the pressure

sensor. (Refer to Wiring Section.)

0.87 [22.05]

Across Flats

2.37 [60.30]

Caution: Do not use the main

body that houses the electronics

to tighten the sensor. Damage to

the sensor may occur.

Packard

Metri Pack

Connector

0.75 [18.95]

7/8" Hex

1/4-18 NPT

Inch [mm]

Figure 3. Pressure Sensor Dimensions

Caution: The discharge and intake

pressure sensors are the same size.

Ensure the correct sensor is installed on

the correct manifold. Refer to Table 1.

11

TGA300 Rev180405

Install Sensors

The information available on the J1939 databus varies depending on the particular

engine type. The sensors (if any) that need to be installed will also vary depending on

the engine.

The sensors are wired to the optional 6-pin connector at the rear of the control

module. Refer to the Wiring Section for connector pinout and wiring information.

Install Buzzer

Install the buzzer close to the control module so the audible warning is easily

associated with the visual warning on the display.

The optional buzzer provided by FRC requires a cutout hole of 1-1/8" (1.125").

Pin 7 on the 8-pin connector at the rear of the control module is used to connect

the buzzer. Connect the ground side of the buzzer to pin 7. (Maximum current through

pin 7 is 300 mA.) Refer to the Wiring section (Figure 5).

Install High-Idle Kit

The high-idle is activated when +12 VDC is provided to pin 4 (High-Idle Active

Input) of the 8-pin connector and to pin 3 (Interlock Input) of the 12-pin connector.

Refer to High-Idle Wiring.

Note: It is important that the connection to the Interlock Input from the

High-Idle circuit be isolated from the apparatus interlock wiring with the

two diodes. The pump must NOT be engaged when using the high-idle

function and the THROTTLE READY LED will be off.

Install Remote Governor Option

Refer to Install Control Module for dimensions. The remote governor is connected

to power, the J1939 CAN Bus, and the FRC datalink. Refer to Wiring Section.

Note: Program code P303 SYS TYPE must be set to REMOTE in the

remote governor program.

12

TGA300 Rev180405

OPERATION

Note: When power is applied to the governor the message display shows the

Software Program Revision Number for ve (5) seconds. It can also be viewed

with P101 code, refer to Programming Section.

On power up the governor is in the pressure mode of operation. The RPM display shows

engine RPM, the four LED bar graphs are green indicating readings within normal ranges,

and the message display will alternate between showing the date and time.

If a monitored function is not within normal parameters the display ashes, the RPM

display shows an error or fault warning code and a description shows in the message display.

(Refer to Table 2. Error Codes or Table 3. Fault Warning Codes.)

If one of the inputs displayed by the LED bar graphs is not within normal range the

LEDs will be red and ashing.

When all necessary throttle enables are active and the interlock circuit is complete, the

THROTTLE READY LED lights and the governor is ready to control the engine RPM.

Controls

INC/DEC Buttons (TGA300 Only)

The INC and DEC buttons are used to change pressure and RPM settings or program

preset values. The rate and amount the numbers change when a button is pressed depends

on the mode and how long the button is held.

Pressure Mode. Press either button momentarily to change the pressure setting by

1 PSI. Press and hold the button for more than 2 seconds and the pressure setting

changes by 5 PSI twice, then by 10 PSI until the button is released.

RPM Mode. Press either button momentarily to change the RPM setting by 10 RPM.

Press and hold the button for more than 2 seconds and the RPM setting changes by

50 RPM twice, then by 100 RPM until the button is released.

Control Knob (TGA400 Only)

The control knob is used to adjust pressure and RPM settings. The governor senses

how fast and in what direction the control knob is rotated and send a signal to the ECM to

increase or decrease the engine RPM proportionally.

If the control knob is rotated quickly; the engine RPM changes quickly.

If the control knob is rotated slowly; the engine RPM changes slowly.

• Rotate the control knob clockwise* to increase engine RPM.

• Rotate the control knob counterclockwise* to decrease engine RPM.

• Press the red IDLE button to immediately return the engine to idle.

*NOTE: Opposite knob rotation option is available to increase/decrease the

engine RPM.

13

TGA300 Rev180405

Error Codes and Fault Warnings

Table 2. Error Codes

RPM

Display

Message

Display

E01 NO DATA

E02 NO RPM

E04 NO OIL

SENSOR

E05 NO D. PSR

SENSOR

E06 NO I. PSR

SENSOR

E07 NO ENG T

SENSOR

E16 NO FRC

DATALINK

Probable Cause

Note: Not all inputs are used for all engines.

>J1939 CAN bus cable not connected / connected to wrong port

>Broken wire / bad connector contact on cable

Engine RPM not detected

>Data cable not connected / connected to wrong port

>Engine not running / ignition key on

>Broken wire / bad connector contact on alternator cable

No Engine Oil Pressure Data Detected (w/separate sensor input)

>Sensor cable not connected

>Broken wire / bad connector contact on sensor cable

>Defective pressure sensor

No Discharge Pressure Sensor Detected

>Sensor cable not connected

>Broken wire / bad connector contact on sensor cable

>Defective pressure sensor

No Intake Pressure Sensor Detected

>Sensor cable not connected

>Broken wire / bad connector contact on sensor cable

>Defective pressure sensor

No Coolant Temperature Data Detected (w/separate sensor input)

>Sensor cable not connected

>Broken wire / bad connector contact on sensor cable

>Defective temperature sensor

>FRC datalink cable not connected / connected to wrong port

>Broken wire / bad connector contact on cable

Note: E5 and E6 show on a remote governor not programmed correctly (code P303).

Table 3. Fault Warning Codes

RPM

Display

F01 HI BATT VOLTAGE

F02 LOW BATT VOLTAGE

F03 HI TRANS TEMP

F04 LOW OIL PRESSURE

F05 DPFR

F06 IPFR

F07 HI ENG TEMP

F08 NO WATER

F09 ENG NOT RESPOND

Message Display Description Factory

Default Setting

High Battery Voltage 15.5 V

Low Battery Voltage 11.8 V*

High Transmission Temperature 300 °F

Low Engine Oil Pressure 8 PSI**

Discharge Sensor High Voltage

Intake Sensor High Voltage

High Engine Coolant Temperature 220 °F**

Out of Water Mode

Engine Does Not Respond

* 11.8 engine running, 11.7 engine off.

** J1939 compliant—engine ECM will issue this warning.

14

TGA300 Rev180405

Pressure Mode Operation

In the pressure mode of operation the PRESSURE LED is on. The governor

maintains a constant discharge pressure within system capabilities. It adjusts the engine

RPM automatically to compensate for variations in pressure.

There is a maximum engine RPM programmed in the governor for pressure mode.

If the engine reaches the programmed maximum RPM the message display ashes MAX

RPM / OPERATOR and the engine RPM is not allowed to go higher. (The maximum

engine RPM is normally set at 2100 and is programmable.)

If the discharge pressure is below 15 PSI when the operator increases the pressure

setting, the display shows PRESS LOW.

Note: When changing from RPM to pressure mode during operations, hold

the PRESSURE button for 3 seconds. The pressure setting is the pressure

that the pump was operating at in RPM mode.

1. Press PRESSURE button to select the pressure mode.

Result: PRESSURE LED goes on.

2. Press PRESET and/or INC/DEC or rotate the control knob to select pressure

setting.

Result: Message display shows pressure setting, engine RPM changes.

3. Press IDLE button after operations to bring engine to idle RPM.

Result: Message display shows IDLE ENGINE, engine at idle RPM.

Opening/Closing Discharge Valves

In pressure mode the governor maintains the pressure setting regardless of the

number of discharge lines that are opened or closed providing there is sufcient water

supplied. As lines are opened the discharge pressure starts to drop, and the governor

raises the engine RPM to maintain the required pressure. As lines are closed and the

discharge pressure starts to rise, the governor lowers the engine RPM to maintain the

required pressure.

Operating From a Pressurized Supply

When operating from a pressurized water source (hydrant, in-relay, etc.), the intake

supply should be routed through a valve. If the pressurized source fails, the pump

operator can close the valve. This eliminates the chance of sharp pressure spikes at

the pump intake if the supply is resumed suddenly. The operator must open this valve

slowly when the supply is resumed to help prevent pressure spikes.

Note: The following description Running Away From Water, Low Water,

or No Supply Water is for software with a revision number V500.03 and

newer. Prior revisions should be updated. (Refer to Programming Section

to view the software revision number.)

15

TGA300 Rev180405

Running Away From Water, Low Water, or No Supply Water

There are situations during pump operations when there may be low or no supply

water. This can be due to an empty water tank, a problem on the intake line, air in the

pump, changing the water source, or an insufcient water supply.

The governor constantly monitors discharge pressure and compares it to engine

RPM. It is programmed to limit RPM increases when conditions arise that fall outside

of normal operating parameters.

Running Away From Water: If the discharge pressure starts dropping while

operating in pressure mode, the governor increases the engine RPM and attempts to

maintain the selected pressure setting. If pressure drops and an increase in RPM does

not bring the pressure back up, the governor recognizes this as a running away from

water condition. When this condition occurs the governor switches to the RPM limit

mode and controls the engine RPM accordingly.

RPM Limit Mode: When the RPM limit mode is in effect the PRESSURE

LED stays on. To alert the operator the RPM LED and the RPM display ash, and the

message display ashes OPERATOR / RPM LIMIT. In this mode the pressure setting

does not change and the PRESET button is disabled. When the pressure comes back

up to the selected pressure setting, the RPM limit mode is canceled and the governor

switches to normal operation in pressure mode at the selected pressure.

In some cases the pressure may not come back up but remains at a level above 45

PSI. In the RPM limit mode, the governor behaves like a manual throttle and the operator

can raise or lower the engine RPM by pressing INC/DEC or rotating the control knob.

If the RPM is manually lowered to a point where the pump is not running away from

water and pressure is stable, the RPM limit mode is canceled. The governor switches

to normal operation in pressure mode with the current discharge pressure as the new

pressure setting.

If the engine is set to idle using the IDLE button, the governor comes out of RPM

Limit Mode and cancels the pressure setting.

Low Water Cycle: If the discharge pressure is below 45 PSI, but stays above 15

PSI, the governor enters a low water cycle and the message display ashes LO WATER.

It sets the engine at 1100 RPM. If the pressure does not rise above 45 PSI in 7 seconds,

the governor sets the engine RPM at idle. The governor repeats the low water cycle as

long as the discharge pressure is between 15 and 45 PSI. When the pressure rises above

45 PSI the governor resumes normal operation. (The values for RPM and PSI in the

low water cycle are programmable and may vary for some engine/pump combinations.)

No Supply Water: If the discharge pressure is below 15 PSI, the engine RPM

is set at idle and the message display ashes NO WATER. If, within 3 minutes, the

discharge pressure rises above 15 PSI the governor enters the low water cycle. If the

discharge pressure does not rise above 15 PSI within 3 minutes, the governor switches

to idle mode and cancels the pressure setting. To restart pump operations, the operator

must take action (press PRESET and/or INC/DEC or rotate control knob to select

pressure setting).

16

Loading...

Loading...