Frauscher Sensortechnik GmbH WSC001 Technical Documentation Manual

D4586-1

Technical documentation

Wheel sensor Signal Converter

WSC001

Frauscher Sensortechnik GmbH

Gewerbestraße 1 | 4774 St. Marienkirchen | Austria

Tel. +43 (0) 7711 2920-0 | Fax +43 (0) 7711 2920-25

office@frauscher.com | www.frauscher.com

Name

Signature

Date

Technical documentation

Wheel sensor Signal Converter

WSC001

Classified

Prepared:

Manuela Kothbauer

sign. Kothbauer

2017-03-31

Checked:

David Schön

sign. Schön

2017-03-31

D4586-1

Released:

Martin Rosenberger

sign. Rosenberger

2017-03-31

EN

1 / 58

© Frauscher Sensortechnik GmbH – All rights reserved. The reprinting, reproduction, storage on or in any data media or in any retrieval system, even if only in the form of extracts,

or the transfer to third parties, is only permitted with the express written consent of Frauscher Sensortechnik GmbH.

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 2 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Masthead

Copyright 2017 by Frauscher Sensortechnik GmbH – Austria

The content of this documentation may not be reproduced in any form, either partially or as a

whole, nor disclosed to third parties without prior written consent of Frauscher.

All trademarks or registered trademarks mentioned herein are property of their respective owners.

All rights reserved.

Your opinion matters

With your comments and suggestions you assist us in our intention to continuously improve the

quality and practical relevance of the documentation.

Please send your suggestions for improvement to: documentation@frauscher.com

Thank you for your feedback.

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 3 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Table of contents

Review list....................................................................................................................................... 6

Bibliography .................................................................................................................................... 6

List of standards ............................................................................................................................. 7

1 About this documentation ............................................................... 8

1.1 Typographical conventions.............................................................................................. 8

1.1.1 Pictograms ...................................................................................................................... 8

1.1.2 Styles of writing and other formal principles .................................................................... 8

1.2 Units of measurement ..................................................................................................... 9

1.3 Abbreviations ................................................................................................................ 10

1.4 Terms and definitions .................................................................................................... 12

1.5 Target group ................................................................................................................. 14

2 Safety .............................................................................................. 15

2.1 General protective provisions ........................................................................................ 15

2.2 Qualified personnel ....................................................................................................... 15

2.3 Safety-conscious working.............................................................................................. 15

2.4 Intended use ................................................................................................................. 16

3 Structure and function ................................................................... 17

3.1 Front panel elements and function ................................................................................ 17

3.2 Interfaces ...................................................................................................................... 20

3.2.1 Diagnostic interface “Serial Interface” ........................................................................... 22

3.2.2 Interface “wheel sensor” ................................................................................................ 22

3.2.3 Interface “power supply” ................................................................................................ 23

3.2.4 Interfaces “optocoupler outputs” .................................................................................... 25

4 Basic conditions for the installation ............................................. 26

4.1 Environmental conditions .............................................................................................. 26

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 4 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

4.2 Electromagnetic compatibility ........................................................................................ 26

5 Configuration.................................................................................. 27

5.1 General setting of the DIP-switches .............................................................................. 27

5.2 DIP-switches of the WSC .............................................................................................. 28

5.2.1 Configuration of system outputs and/or direction outputs .............................................. 29

5.2.1.1 Configuration with 1 wheel sensor RSR110-001 ........................................................... 30

5.2.1.2 Configuration with 1 wheel sensor RSR110-001 or 2 wheel sensors RSR110-002 ....... 30

5.2.1.3 Configuration with 1 wheel sensor RSR110-001 or 1 wheel sensor RSR110-002 ......... 31

5.2.2 Configuration of the normal status of all optocoupler outputs ........................................ 31

5.2.3 Configuration of the system output extension time ........................................................ 33

5.2.4 Configuration of the direction pulse duration ................................................................. 34

6 Signal diagrams ............................................................................. 35

6.1 Switching times and switching levels ............................................................................. 35

6.2 Traversings ................................................................................................................... 36

6.2.1 Correct traversing of one wheel .................................................................................... 36

6.2.2 Traversing of one wheel without overlap ....................................................................... 38

6.3 Behaviour in case of wire break .................................................................................... 39

6.4 Behaviour in case of overcurrent ................................................................................... 40

7 Installation ...................................................................................... 41

7.1 Wiring of the Wheel sensor Signal Converter WSC ....................................................... 41

7.2 Mounting and dismounting of the WSC ......................................................................... 44

8 Commissioning .............................................................................. 45

8.1 Adjustment .................................................................................................................... 45

8.1.1 Adjustment by using the AMB ....................................................................................... 45

8.1.2 Adjustment by means of the DIP-switch with DIP-no. 8 ................................................. 46

8.2 Data request with Advanced Service Display ASD ........................................................ 47

8.2.1 “INFO” tab ..................................................................................................................... 48

8.2.2 “STATUS” tab ............................................................................................................... 49

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 5 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

8.2.3 “STATISTICS” tab ......................................................................................................... 50

9 Maintenance ................................................................................... 51

9.1 Required measuring equipment and tools ..................................................................... 51

9.2 Visual inspection and mechanical check of the wheel sensor ................................ ........ 51

9.3 Check of the sensor currents of the wheel sensor ......................................................... 52

9.4 Check of the occupancy detection capability ................................................................. 52

10 Repair .............................................................................................. 54

10.1 Troubleshooting of the WSC ......................................................................................... 54

10.1.1 LED indications on the WSC ......................................................................................... 54

10.1.2 Measurements on the WSC with connected wheel sensor RSR110 .............................. 57

11 Removal from service .................................................................... 58

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 6 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Version

Date

Prepared by

Sections modified

Modifications

1

2017-03-31

Manuela Kothbauer

all

initial version

D-Number

Title

Version1

D2860

Brief instruction testing plate PB200 GS03

4

D4231

Mounting, commissioning and maintenance manual wheel sensor

RSR110

1

D4232

Application guide wheel sensor RSR110

1

D21004

Brief description Advanced Service Display ASD101

2

1

Review list

Bibliography

The stated or a higher version is valid.

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 7 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Number

Title

Issue/

version

DIN EN 60715

Dimensions of low-voltage switchgear and controlgear

Standardized mounting on rails for mechanical support

of electrical devices in switchgear and controlgear

installations

2001

EN 50121-4

Railway applications – Electromagnetic compatibility –

Part 4: Emission and immunity of the signalling and

telecommunications apparatus

2015

EN 50124-1

Railway applications – Insulation coordination – Part 1:

Basic requirements – Clearances and creepage distances for all electrical and electronic equipment

2006

EN 50125-3

Railway applications – Environmental conditions for

equipment – Part 3: Equipment for signalling and telecommunications

2003

EN 50128

Railway applications – Communication, signalling and

processing systems – Software for railway control and

protection systems

2011

EN 60529

Degrees of protection provided by enclosures (IP Code)

2014

EN 60721-3-1

Classification of environmental conditions – Part 3:

Classification of groups of environmental parameters

and their severities – Section 1: Storage

1997

EN 60721-3-2

Classification of environmental conditions – Part 3:

Classification of groups of environmental parameters

and their severities – Section 2: Transportation

1997

EN 60721-3-3

Classification of environmental conditions – Part 3:

Classification of groups of environmental parameters

and their severities – Section 3: Stationary use at

weatherprotected locations

1995

List of standards

-1

125-3

60721-3-2

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 8 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Description

1 About this documentation

This documentation provides information about the product features and the required information

for the configuration and installation of the Wheel sensor Signal Converter WSC001.

1.1 Typographical conventions

The following typographical conventions are applied in this documentation:

1.1.1 Pictograms

Important notes

Important notes contain information and instructions regarding the availability and the safe operation of the system.

Important information and notes are shown as follows:

1.1.2 Styles of writing and other formal principles

Orders

• Contents (descriptions, figures, tables etc.) are generally described in this documentation “from

left to right” and “from top to bottom”.

Numbers

• Decimal places of decimal numbers are separated by a comma (,) (e.g.: 123,45).

• For reasons of better readability, digits of four- or multi-figure decimal numbers are arranged

from right to left with thousands separators in groups of three digits (e.g. 1 234).

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 9 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

1.2 Units of measurement

In this documentation the following units of measurement are used:

bit bit

°C degree in Celsius (degree in Fahrenheit °F = °C * 1,8 + 32)

m metre (yard = m * 1,09361)

mA milliampere

mm millimetre (inch = mm * 0,0393701)

ms millisecond

Ω ohm

s second

V volt

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 10 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

1.3 Abbreviations

In this documentation the following abbreviations are used:

0b prefix of a binary number

0x prefix of a hexadecimal number

A measurement A, vertical mounting position of the wheel sensor

AEI Automatic Equipment Identification

AMB Adjustment and Maintenance Box

ASD Advanced Service Display

B measurement B, horizontal mounting position of the wheel sensor

DC direct current

DIN German Institute for Standardization

DIP Dual In-line Package (DIP-switch)

EMC electromagnetic compatibility

EN European standard

GAK trackside connection box

GND ground

GS equipment version

IEC International Electrotechnical Commission

IPxx International Protection (protection type, e.g. IP65)

LED light-emitting diode

PB testing plate

PWR Power supply

Ri direction pulse of a traversing

Ri1 direction pulse, direction 1

Ri2 direction pulse, direction 2

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 11 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

RJ45 Registered Jack (standardised connectors/sockets for data transmission in

networks)

RSR wheel sensor

RSR110 wheel sensor, type RSR110

SIL Safety Integrity Level

SPS Programmable Logic Controller (PLC)

Sys system pulse

Sys1 system pulse of sensor system 1

Sys2 system pulse of sensor system 2

SYS1 sensor system 1

SYS2 sensor system 2

USB Universal Serial Bus

WSC Wheel sensor Signal Converter

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 12 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

1.4 Terms and definitions

commissioning Test on an item carried out on site, to prove that it is

correctly installed and can operate correctly

(IEC 60050-151-16-24).

damped One or two sensor systems of a wheel sensor indi-

cate an occupancy (generally in the case of traversing by a train wheel and/or when damped by a testing

plate).

digital filtering time The digital filtering time is the time for which the

sensor current must fall below the trigger level or exceed the tripping level, before the sensor system is

considered to be “damped” or “not damped”.

direction pulse duration The direction pulse duration is the time for which the

direction pulse applies at the output. The direction

pulse duration is retriggerable.

interference voltage Voltage that may occur at the ends of outdoor

equipment cables as a result of inductive or capacitive influences to earth.

maintenance, corrective The maintenance carried out after fault recognition

and intended to put an item into a state in which it

can perform a required function

(IEC 60050-191-07-08).

Synonym: repair

maintenance, preventive The maintenance carried out at predetermined inter-

vals or according to prescribed criteria and intended

to reduce the probability of failure or the degradation

of the functioning of an item (IEC 60050-191-07-07).

Synonym: servicing

maintenance, servicing The maintenance carried out at predetermined inter-

vals or according to prescribed criteria and intended

to reduce the probability of failure or the degradation

of the functioning of an item (IEC 60050-191-07-07).

Synonym: preventive maintenance

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 13 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

normal operating sensor current level The normal operating sensor current level corre-

sponds to the sensor current at the time of a successfully carried out adjustment and is to be equated

with 100 % (adjustment value).

normal operating sensor current (RSR110) The sensor current is referred to as “normal operat-

ing sensor current” if the wheel sensor is correctly

mounted on the rail, successfully adjusted and not

damped.

overcurrent level If the sensor current exceeds the overcurrent level for

the time > overcurrent suppression time, then the

evaluation board identifies the behaviour as “overcur-

rent”.

overcurrent suppression time The overcurrent suppression time is the minimum

time for which the sensor current must exceed the

overcurrent level, so that the evaluation board identifies the behaviour as “overcurrent”. The sensor sys-

tem is then considered to be “faulty”.

overlap “Overlap” means that both sensor systems are

damped.

repair The maintenance carried out after fault recognition

and intended to put an item into a state in which it

can perform a required function

(IEC 60050-191-07-08).

Synonym: corrective maintenance

system output delay time The system output delay time is the time, which

passes after the digital filtering time until the switching operation at the system output, when the sensor

current falls below the trigger level.

system output extension time The system output extension time is the time, which

passes after the digital filtering time until the switching operation at the system output, when the sensor

current exceeds the tripping level. The system output

extension time is retriggerable.

top-hat rail rail with hat-shaped cross-section according to

DIN EN 60715, type TH 35-7.5, perforated

1 About this documentation

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 14 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

trigger level If the sensor current falls below the trigger level for

the time > digital filtering time, then the sensor system is considered to be “damped”.

tripping level If the sensor current exceeds the tripping level for the

time > digital filtering time, then the sensor system is

considered to be “not damped”.

wire break level If the sensor current falls below the wire break level

for the time > wire break suppression time, then the

evaluation board identifies the behaviour as “wire

break”.

wire break suppression time The wire break suppression time is the minimum time

for which the sensor current must fall below the wire

break level, so that the evaluation board identifies the

behaviour as “wire break”. The sensor system is then

considered to be “faulty”.

wire short-circuit level If the sensor current exceeds the wire short-circuit

level for the time > overcurrent suppression time,

then the evaluation board identifies the behaviour as

“wire short-circuit”.

1.5 Target group

This documentation is intended for project engineers and technicians with subject-specific

knowledge who are responsible for configuration, installation, commissioning, operation and

maintenance of Frauscher components.

2 Safety

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 15 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

The component described in this documentation must only be used for non-safetyrelevant applications.

All operational protective provisions of the rail operator must be observed.

The railway operator must ensure that only authorised personnel or people in the company of authorised personnel have access to Frauscher components.

Prior to and during works on the track, safety measures must be carried out according

to the applicable railway regulations.

Working on Frauscher components (configuration, installation, commissioning and

maintenance) must only be carried out by trained and skilled personnel.

2 Safety

This documentation contains important warning and safety information, which must be observed by

the user. Only by compliance with these prerequisites and safety measures, a correct operation

can be ensured.

2.1 General protective provisions

Frauscher components must be used in the original condition (= characteristics and functions as

described in the respective documentation).

Only the settings described in the respective documentation may be carried out. Apart from that,

arbitrary changes of the components are not permitted.

However, if changes of a component should be required, then Frauscher must be consulted in any

case and in advance.

2.2 Qualified personnel

2.3 Safety-conscious working

• The railway operator is responsible for occupational safety.

• Frauscher components may only be operated in proper condition.

• All actions carried out on Frauscher components must not impair the safety of people or the

function of the system.

• Unauthorized alterations and modifications must not be carried out on Frauscher components.

2 Safety

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 16 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

2.4 Intended use

The product is intended for a specific operation purpose described in the documentation. If applied

outside the intended use described, in the case of non-compliance with the documentation or in the

case of non-compliance with required prerequisites and safety measures, no warranty and/or

liability shall apply.

3 Structure and function

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 17 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

Element

Description

PWR (LED)

status indicator of the power supply

Sys1 (LED)

status indicator of sensor system 1

Sys2 (LED)

status indicator of sensor system 2

DIP-switches

configuration of the outputs and

adjustment of the wheel sensor via WSC

Serial Interface

(RJ45-socket)

connection socket for diagnostic interface

(Advanced Service Display ASD)

Type key:

WSC001

board identification

10…36 V DC

permissible supply voltage

GSxx

equipment version (starting at 01)

3 Structure and function

The WSC in combination with the wheel sensor RSR110 provides outputs that are triggered by a

passing wheel of a rail vehicle.

Examples of possible applications:

• trigger for AEI card reader

• trigger for lubrication system

• trigger for hot box detection system

• trigger for vision monitoring system

• trigger for warning system

• trigger for flat wheel detection system

3.1 Front panel elements and function

The front panel of the WSC is designed as follows:

Figure 3.1: Front panel of the WSC

3 Structure and function

Classified

Technical documentation Wheel sensor Signal Converter WSC001

D4586-1

EN

- 18 -

© 2017 by Frauscher Sensortechnik GmbH – Austria

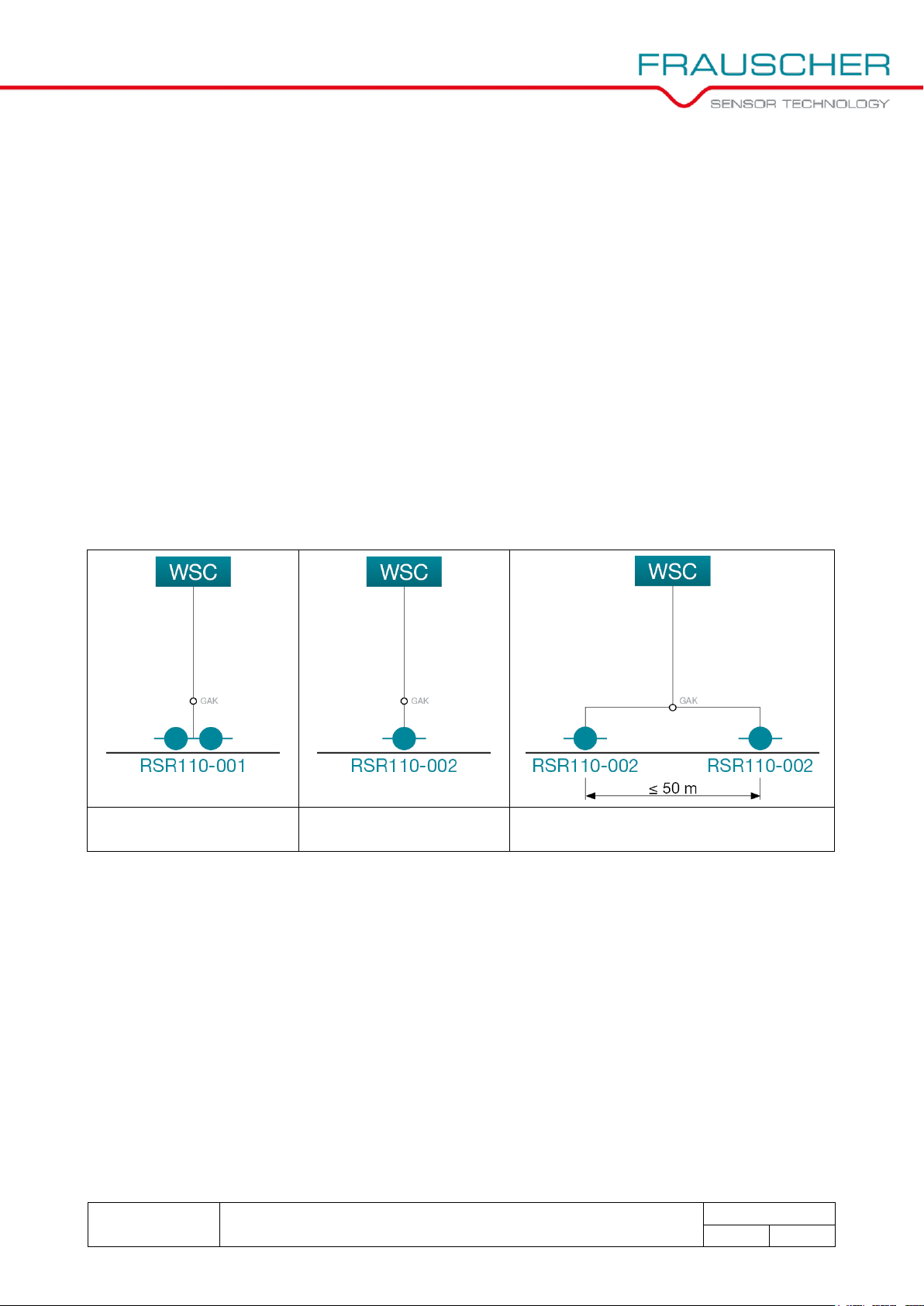

WSC combined with

1 RSR110-001

WSC combined with

1 RSR110-002

WSC combined with

2 RSR110-002

The WSC complies with the requirements of SIL 0 according to EN 50128.

The WSC processes the wheel sensor information of the wheel sensors RSR110-001 and

RSR110-002.

The wheel sensor RSR110-001 is equipped with 2 sensor systems and can output the status of

the sensor systems (damped, not damped or faulty) and the travel direction.

The wheel sensor RSR110-002 is equipped with 1 sensor system and can output the status of the

sensor system (damped, not damped or faulty).

The WSC can be combined with:

• 1 wheel sensor RSR110-001

• 1 wheel sensor RSR110-002

• 2 wheel sensors RSR110-002

Figure 3.2: Block diagrams with possible combinations of the WSC with RSR110-001 or RSR110-002

In order to limit the interference voltage, the distance between 2 wheel sensors RSR110-002 that

are connected to the same WSC must not exceed 50 m and the distance between the WSC and

the higher-ranking system must not exceed 30 m.

The WSC supplies the wheel sensors with voltage and converts the analogue signals of the wheel

sensors into digital signals. The digital signals are transmitted as digital switching signals to a

higher-ranking system via optocoupler outputs.

Loading...

Loading...