Page 1

Automatic Ice Makers

Máquinas automáticas para hacer hielo

Machines automatiques pour

la fabrication des glaçons

User’s Manual (pages 1 - 28)

Manual del usuario (páginas 29 a 58)

Manuel de l’utilisateur (pages 59 à 87)

Be sure ice maker is standing upright 24 hours prior to plug-in

Esté seguro que la máquina esté parada en posición vertical

24 horas antes que sea conectada.

Soyez sûrs que la machine se tient debout 24 heures

avant qu’elle se branche

Models/Modelos/Modèles : FIM70, FIM90, FIM120

.

.

Page 2

TABLE OF CONTENTS

Page

ICE MAKER SAFETY ······························ 2

IMPORTANT SAFEGUARDS ·························· 3 - 5

TECHNICAL INFORMATION ·························· 5

INTRODUCTION ································· 6

COMPONENT LOCATIONS ··························· 7

ICE MAKER INSTALLATION ·························· 8 - 14

Unpacking ································· 8

Location Requirements··························· 8 - 10

Electrical Requirements ·························· 10

Leveling the Ice Maker··························· 11

Water Supply and Drain Connections ··················· 11 - 12

Installation Types······························ 13 - 14

OPERATION···································· 14 - 17

Final Checklist before Operation······················ 14

Operating Method ····························· 15

How the Machine Makes Ice························ 15 - 16

Normal Sounds ······························· 16 - 17

Preparing the Ice Maker for Long Storage ················· 17

CLEANING AND MAINTENANCE ······················· 18 - 25

Exterior Cleaning······························ 18 - 19

Condenser Cleaning ···························· 19

Interior Cleaning ······························ 20 - 22

Ice Making System Cleaning························ 22 - 23

Control Box ································ 24 - 25

MAJOR FUNCTIONS ······························· 25

TROUBLESHOOTING ······························ 26 - 27

LIMITED WARRANTY ······························ 28

SPANISH VERSION OF THIS MANUAL ···················· 29 - 58

FRENCH VERSION OF THIS MANUAL ···················· 59 - 87

We reserve the right to make changes in specifications and design without prior

notice.

1

Page 3

ICE MAKER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the Safety Alert Symbol. This symbol alerts you to

potential hazards that can injure or kill you and others. All safety

messages will follow the Safety Alert Symbol and either the words

“DANGER”, “WARNING” OR “CAUTION”.

DANGER means that failure to heed this

safety statement may result in severe

personal injury or death.

WARNING means that failure to heed

this safety statement may result in

extensive product damage, serious

personal injury, or death.

CAUTION means that failure to heed

this safety statement may result in minor

or moderate personal injury, or property

or equipment damage.

All safety messages will alert you to what the potential hazard is, tell you how to reduce the

chance of injury, and let you know what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock or injury

when using your ice maker, follow these basic precautions:

• Plug into grounded 3-prong outlet • Disconnect power before cleaning

• Do not remove grounding prong • Disconnect power before servicing

• Do not use an adapter • Replace all panels before operating

• Do not use an extension cord • Use 2 or more people to move &

install ice maker

SAVE THESE INSTRUCTIONS

Page 4

IMPORTANT SAFEGUARDS

Before the ice maker is used, it must be properly positioned and installed

as described in this manual, so read the manual carefully. Franklin

Industries strongly recommends that you have a professional install your

new machine. The warranty may be affected or voided by an incorrect

installation. To reduce the risk of fire, electrical shock or injury when

using the ice maker, follow basic precautions, including the following:

Plug into a grounded 3-prong outlet; do not remove grounding prong, do not use an

•

adapter, and do not use an extension cord.

It is recommended that a separate circuit, serving only your ice maker, be provided.

•

Use receptacles that cannot be turned off by a switch or pull chain.

Do not connect or disconnect the electric plug when your hands are wet.

•

Never clean ice maker parts with flammable fluids. These fumes can create a fire

•

hazard or explosion. Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. The fumes can create a fire

hazard or explosion.

Before proceeding with cleaning and maintenance operations, make sure the power

•

line of the unit is disconnected and the water line is shut off (EXCEPTION: when

cleaning the machine’s ice making and water systems – see pages 22-24).

Before operating, put all panels back into place.

•

Unplug the ice maker or disconnect power before cleaning or servicing. Failure to do

•

so can result in electrical shock or death.

Do not attempt to repair or replace any part of your ice maker unless it is specifically

•

recommended in this manual. All other servicing should be referred to a qualified

technician.

When you disassemble the front cover, do not use too much force, as the wire leads

•

connected to the power switch can be inadvertently disconnected.

Use two or more people to move and install ice maker. Failure to do so can result in

•

back or other injury.

To ensure proper ventilation for your ice maker, the front of the unit must be

•

completely unobstructed. Choose a well-ventilated area with temperatures above

55ºF (13ºC) and below 90ºF (32ºC). This unit MUST be installed in an area protected

from the elements, such as wind, rain, water spray or drips.

3

Page 5

The ice maker should not be located next to ovens, grills or other sources of high heat.

•

The ice maker must be installed with all electrical, water and drain connections in

•

accordance with state and local codes. A standard electrical supply (115 VAC only,

60 Hz, 15 A), properly grounded in accordance with the National Electrical Code and

local codes and ordinances is required.

Do not kink or pinch the power supply cord or drain lines between the ice maker and

•

the cabinet.

The fuse (or circuit breaker) size should be 15 amperes.

•

It is important for the ice maker to be leveled in order to work properly. You may

•

need to make several adjustments to level it.

All installations must be in accordance with local plumbing code requirements.

•

Make certain that the hoses are not pinched or kinked or damaged during installation.

•

Check for leaks after connection.

•

Never allow children to operate, play with or crawl inside the ice maker.

•

Although the unit has been tested at the factory, due to long-term transit and storage,

•

the first batch of cubes must be discarded.

Never turn the water supply tap off when the ice maker is working.

•

If the ice maker will not be used for a long time, before the next use it must be

•

thoroughly cleaned. Follow carefully any instructions provided for cleaning or use of

sanitizing solution. Do not leave any solution inside the ice maker after cleaning.

DO NOT touch the condenser fins. The condenser fins are sharp and can be easily

•

damaged.

DO NOT use solvent-based cleaning agents or abrasives on the interior. These

•

cleaners may transmit taste to the ice cubes, or damage or discolor the interior.

The ice machine cleaner contains acids. DO NOT use or mix with any other

•

solvent-based cleaner products. Use rubber gloves to protect hands. Carefully read the

material safety instructions on the container of the ice machine cleaner.

Do not use this apparatus for other than its intended purpose.

•

SAVE THESE INSTRUCTIONS

Electrical Connection

Do not, under any circumstances, cut or remove the third (ground) prong from the power

cord. For personal safety, this appliance must be properly grounded. The power cord of

this appliance is equipped with a 3-prong grounding plug that mates with a standard

3-prong grounding wall outlet to minimize the possibility of electric shock hazard from

the appliance. Have the wall outlet and circuit checked by a qualified electrician to make

sure the outlet is properly grounded. When a standard 2-prong wall outlet is encountered,

4

Page 6

it is your responsibility and obligation to have it replaced with a properly grounded

3-prong wall outlet. The ice maker should always be plugged into its own individual

electrical outlet which has a voltage rating that matches the rating label on the appliance.

This provides the best performance and also prevents overloading house wiring circuits

which could cause a fire hazard from overheated wires. Never unplug your ice maker by

pulling on the power cord. Always grip the plug firmly and pull straight out from the

outlet. Repair or replace immediately all power cords that have become frayed or

otherwise damaged. Do not use a cord that shows cracks or abrasion damage along its

length or at either end. When moving the ice maker, be careful not to damage the power

cord.

Extension Cord

Because of potential safety hazards under certain conditions, it is strongly recommended

that you do not use an extension cord with this ice maker.

Technical Information

Model FIM70 FIM90 FIM120

Rated power

Ice-making rated current 6.7A 7.3A 7.5A

Ice-harvest rated current 11.2A 11.7A 11.8A

Refrigerant R134a, 6.88 oz. R134a, 8.96 oz. R134a, 9.92 oz.

High side pressure 320 psi 320 psi 320 psi

Low side pressure 120 psi 120 psi 120 psi

Width x depth x height 16.5”x21.3”x32.5” 22.1”x21.3”x32.5” 22.1”x21.3”x32.5”

Unit weight 91 lbs 106 lbs 102 lbs

Ice-making capacity Up to 65 lbs/day* Up to 83 lbs/day* Up to 110 lbs/day*

The technical data and performance index listed above should be used for reference only.

They are subject to change.

115VAC ~ 60Hz ~

470W

115VAC ~ 60Hz ~

520W

115VAC ~ 60Hz ~

580W

* The actual quantity of ice produced per day can vary with room and water conditions.

5

Page 7

INTRODUCTION

The Franklin Chef® FIM Series of Ice Makers finds wide application in households,

bars, restaurants, hotels, supermarkets, etc. These units produce crystal-clear, gourmet

cube ice, and offer convenience for homeowners and hotel guests. An insulated ice

storage bin is built into each ice maker.

This user’s manual is intended as a resource for persons installing, using and servicing

models FIM70, FIM90 and FIM120. It contains valuable information on safety and

maintenance. Franklin Industries strongly recommends that this manual be kept in a place

where it can be accessed when needed.

Every Franklin Chef® Ice Maker is designed and manufactured according to the highest

standards of safety and performance. It meets or exceeds the safety standard of UL563

and sanitation standard NSF12.

Franklin Industries L.L.C. assumes no liability or responsibility of any kind for products

manufactured by Franklin that have been altered in any way, including the use of any

parts and/or other components not specifically approved by Franklin Industries L.L.C.

Franklin Industries reserves the right to make design changes and/or improvements at any

time. Specifications and designs are subject to change without notice.

6

Page 8

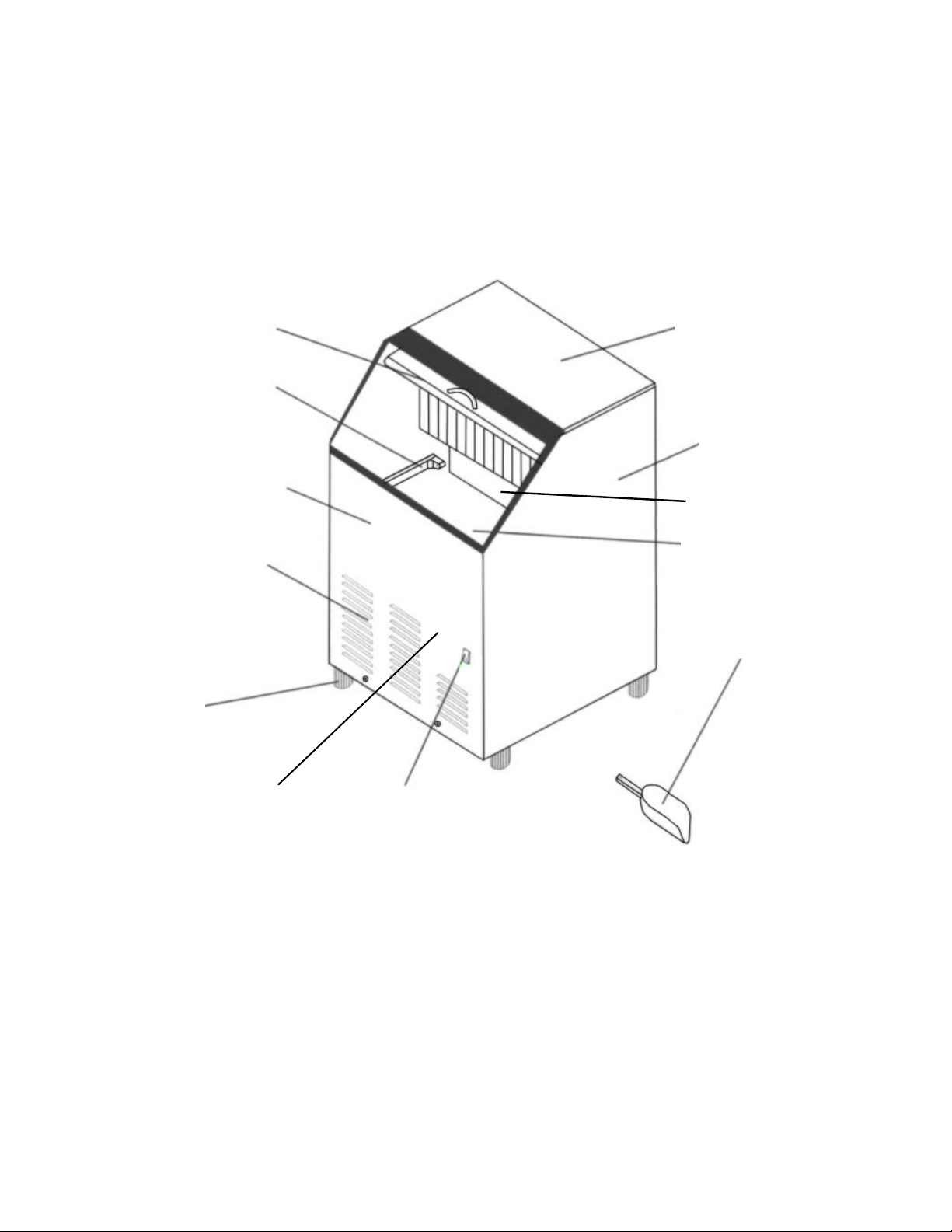

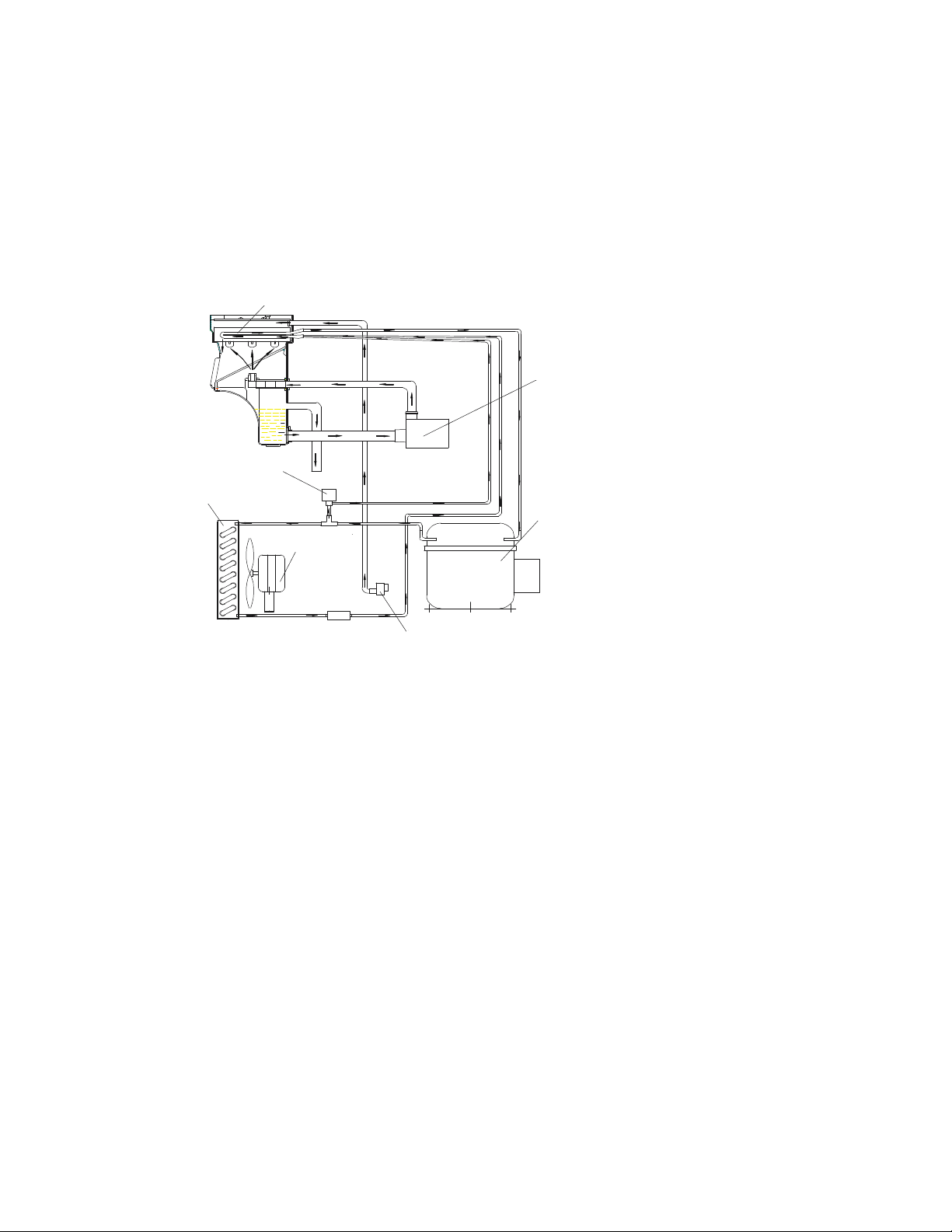

COMPONENT LOCATIONS

Ice cube full

sensor

Ventilation

louvers

Leveling

caster

Door

Front cover

Top cover

Right side

Water sump

Ice storage bin

Ice scoop

Control box

(behind front cover)

Power switch

7

Page 9

ICE MAKER INSTALLATION

Unpacking

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

Remove packaging materials

IMPORTANT: Do not remove any permanent instruction labels or the data label on your

ice maker.

Remove tape and glue from your ice maker before using.

To remove any remaining tape or glue, rub the area briskly with your thumb. Tape or

•

glue residue can also be easily removed by rubbing a small amount of liquid dish soap

over the adhesive with your fingers. Wipe with warm water and dry.

Do not use sharp instruments, rubbing alcohol, flammable fluids, or abrasive cleaners

•

to remove tape or glue. These products can damage the surface of your ice maker.

Cleaning before use

After you remove all of the packaging materials, clean the inside of your ice maker before

using it. See “Interior Cleaning” in the Cleaning and Maintenance section.

Location Requirements

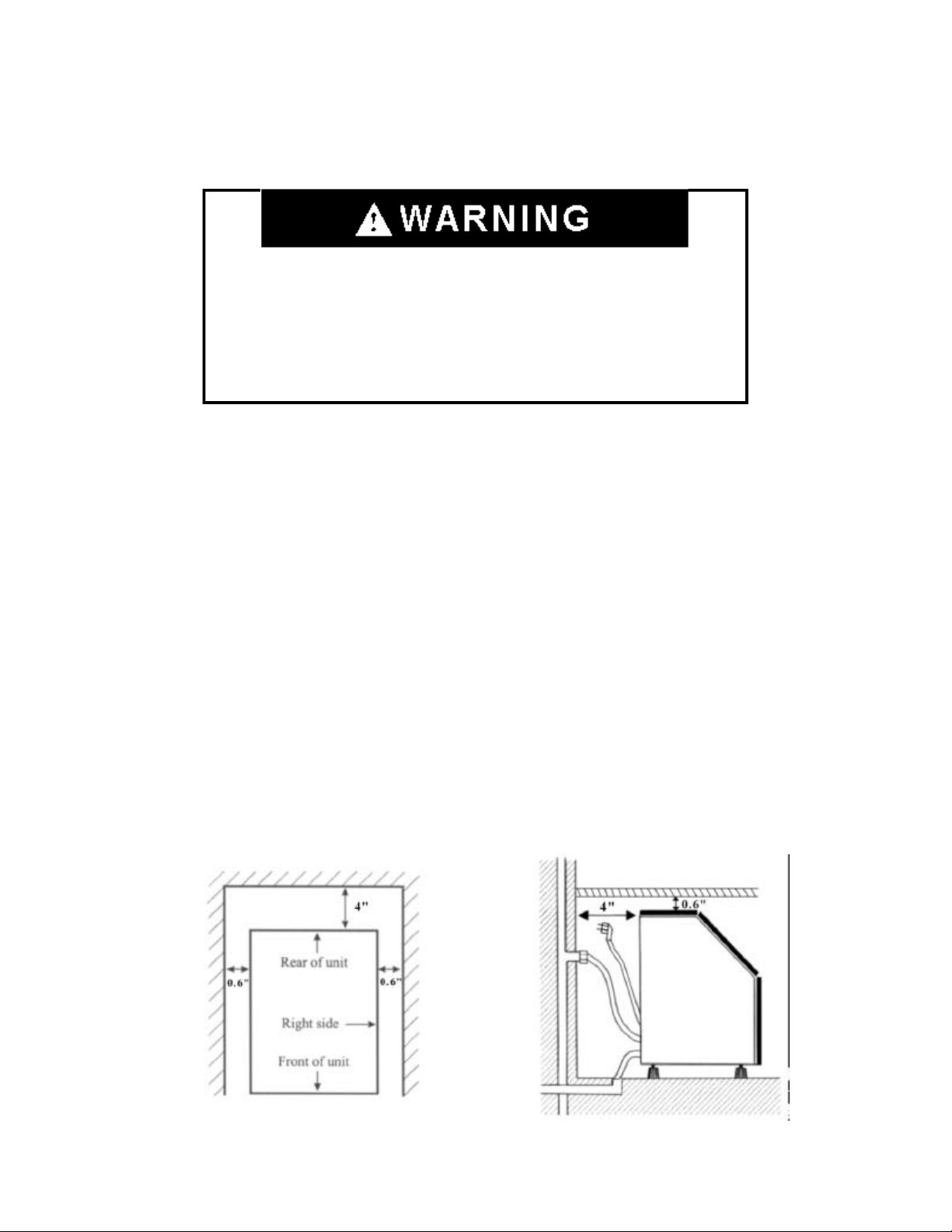

INSTALLATION CLEARANCES:

TOP VIEW

SIDE VIEW

8

Page 10

To ensure proper ventilation for your ice maker, the front of the unit must be

•

completely unobstructed. Allow at least 101 mm (4”) clearance at rear, and 15 mm

(0.6”) at top and sides for proper air circulation. The installation should allow the ice

maker to be pulled forward for servicing if necessary.

When installing the ice maker under a counter, follow the recommended spacing

•

dimensions shown. Place electrical and water supplies and drain fixtures in the

recommended locations as shown.

Choose a well-ventilated area with temperatures above 55ºF (13ºC) and below 90ºF

•

(32ºC). This unit MUST be installed in an area protected from the elements, such as

wind, rain, water spray or drips.

The unit should not be located next to ovens, grills or other sources of high heat.

•

Installation of the ice maker requires a cold water supply inlet of 6.35 mm (1/4 in.)

•

soft copper tubing with a shut-off valve and a gravity-drain system.

(NOTE: Runoff water can also be drained into a sink via a pump – not included –

when a gravity drain is not available.)

The ice maker requires a continuous water supply with a minimum pressure of 20

•

psig and a static pressure not to exceed 80 psig. The temperature of the water feeding

into the ice maker should be between 41ºF (5ºC) and 77ºF (25ºC) for proper

operation.

Normal operating ambient temperature should be between 55ºF

(13ºC) to 90ºF (32ºC). Normal operating water temperature

should be between 41ºF (5ºC) and 77ºF (25ºC). Operation of

the ice maker for extended periods outside of these normal

temperature ranges may affect production capacity.

In general, it is always a good idea to filter the water. A water filter, if it is of the

•

proper type, can remove taste and odors as well as particles. Where water is very

hard, softened water may result in white, mushy cubes that stick together. Deionized

water is not recommended.

The ice maker must be installed with all electrical, water and drain connections in

•

accordance with state and local codes.

The unit should be located on a firm and level surface. It is important for the ice

•

maker to be leveled in order to work properly. If needed, you can adjust the height of

the ice maker by revolving the feet. See the “Leveling the Ice Maker” section.

9

Page 11

A standard electrical supply (115 VAC only, 60 Hz, 15 A), properly grounded in

•

accordance with the National Electrical Code and local codes and ordinances is

required.

IMPORTANT: Do not kink or pinch the power supply cord between the ice maker

•

and wall or cabinet.

Electrical Requirements

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Never remove the grounding prong from the plug.

Never use an adapter.

Never use an extension cord.

Failure to follow these instructions can result in fire,

electrical shock or death.

Before you move your ice maker into its final location, it is important to make sure you

have the proper electrical connection.

A standard electrical supply (115 VAC only, 60 Hz, 15 A), properly grounded in

accordance with the National Electrical Code and local codes and ordinances, is required.

It is recommended that a separate circuit, serving only your ice maker, be provided. Use

receptacles that cannot be turned off by a switch or pull chain.

The fuse (or circuit breaker) size should be 15 amperes.

Recommended grounding method

For your personal safety, this appliance must be grounded. This appliance is equipped

with a power supply cord having a 3-prong grounding plug. To minimize possible shock

hazard, the cord must be plugged into a mating 3-pronged and grounding-type wall

receptacle, grounded in accordance with the National Electrical Code and local codes and

ordinances. If a mating wall receptacle is not available, it is the personal responsibility of the

customer to have a properly grounded, 3-prong wall receptacle installed by a qualified electrician.

10

Page 12

Leveling the Ice Maker

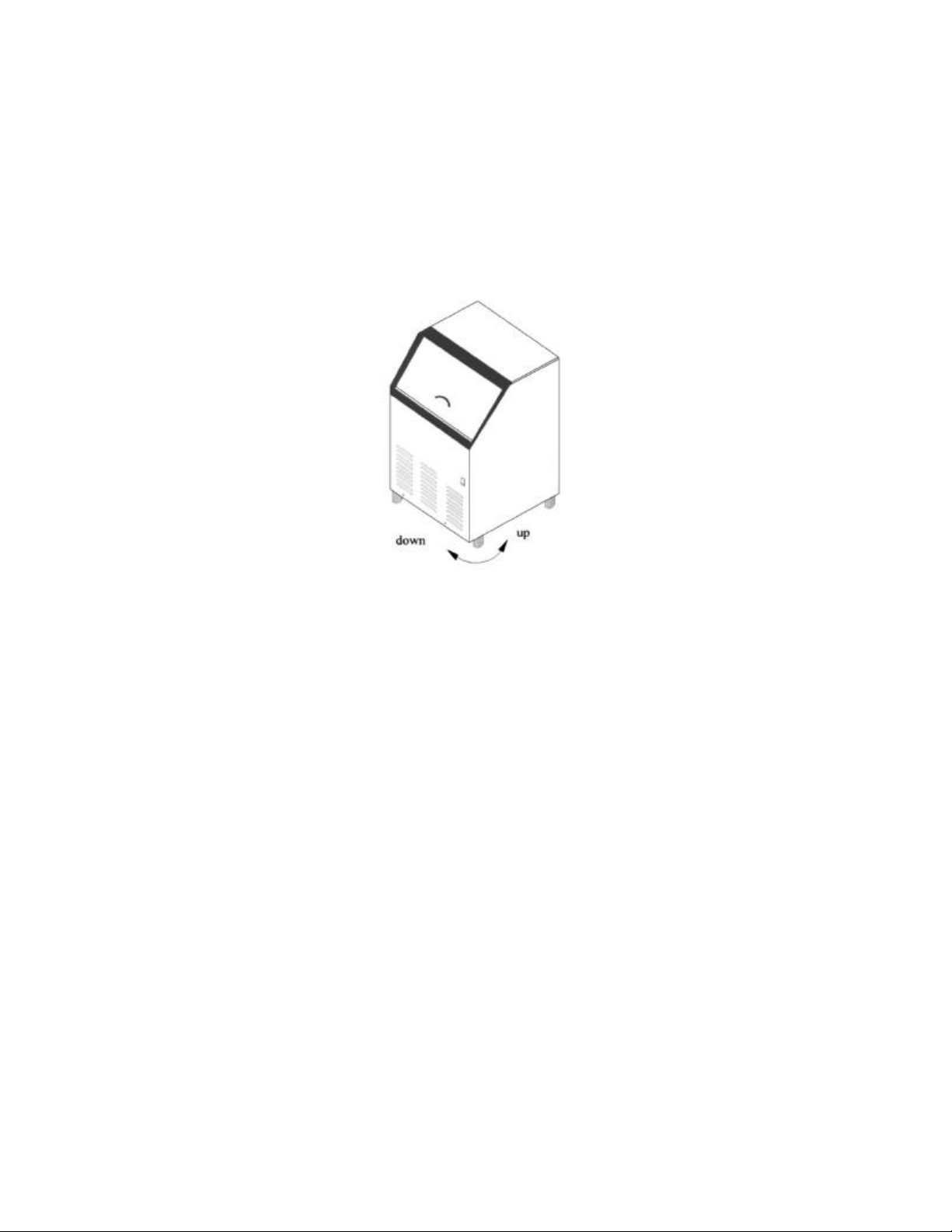

It is important for the ice maker to be leveled in order to work properly. It can be raised

or lowered by rotating the plastic sheaths around each of the four rolling casters on the

bottom of the machine. If you find that the surface is not level, rotate the casters until the

ice maker becomes level. You may need to make several adjustments to level it. We

recommend using a carpenter’s level to check the machine.

You will find that the casters make it easy for one person to move the machine. This is

useful for cleaning and sanitizing the surface on which the ice maker is installed because

it allows you to move the unit and have easy access to the surface to be cleaned.

IMPORTANT: Once you are ready to install the ice maker in a cabinet or directly on the

floor, you must adjust the feet to level the ice maker and lock the rollers. If the floor is

level, just revolve the two front feet to touch the floor. (See illustration.)

Water Supply and Drain Connections

The water supply and drain should be ready at the point of installation. A wall outlet

directly behind the ice maker will make installation easier.

IMPORTANT:

1. All installations must be in accordance with local plumbing code requirements.

Professional installation is recommended.

2. Make certain that the hoses are not pinched or kinked or damaged during installation.

3. Check for leaks after connection.

Tools required:

1/2 in. open-end wrench

•

Phillips screwdriver

•

11

Page 13

Connecting the water line:

1. Turn off main water supply. Turn on nearest faucet long enough to clear line of water.

2. Find a 1/2 in. to 3/4 in. vertical cold water pipe near the installation location. The

distance should be less than 10 feet. The water supply hose provided with the ice

maker is about 10 feet.

3. A shut-off valve must be installed to the main water supply. If the water pipe has a

plain piece of copper tubing, attach a ¼” O.D. compression union to the tubing and

remove the nut.

4. Connect nuts of water supply hose to tap and water inlet valve. Tighten firmly by

hand, then one-half turn with wrench.

5. Turn on main water supply and tap. Check for water supply connection leaks. Tighten

any connections (including connections at the valve) or nuts that leak.

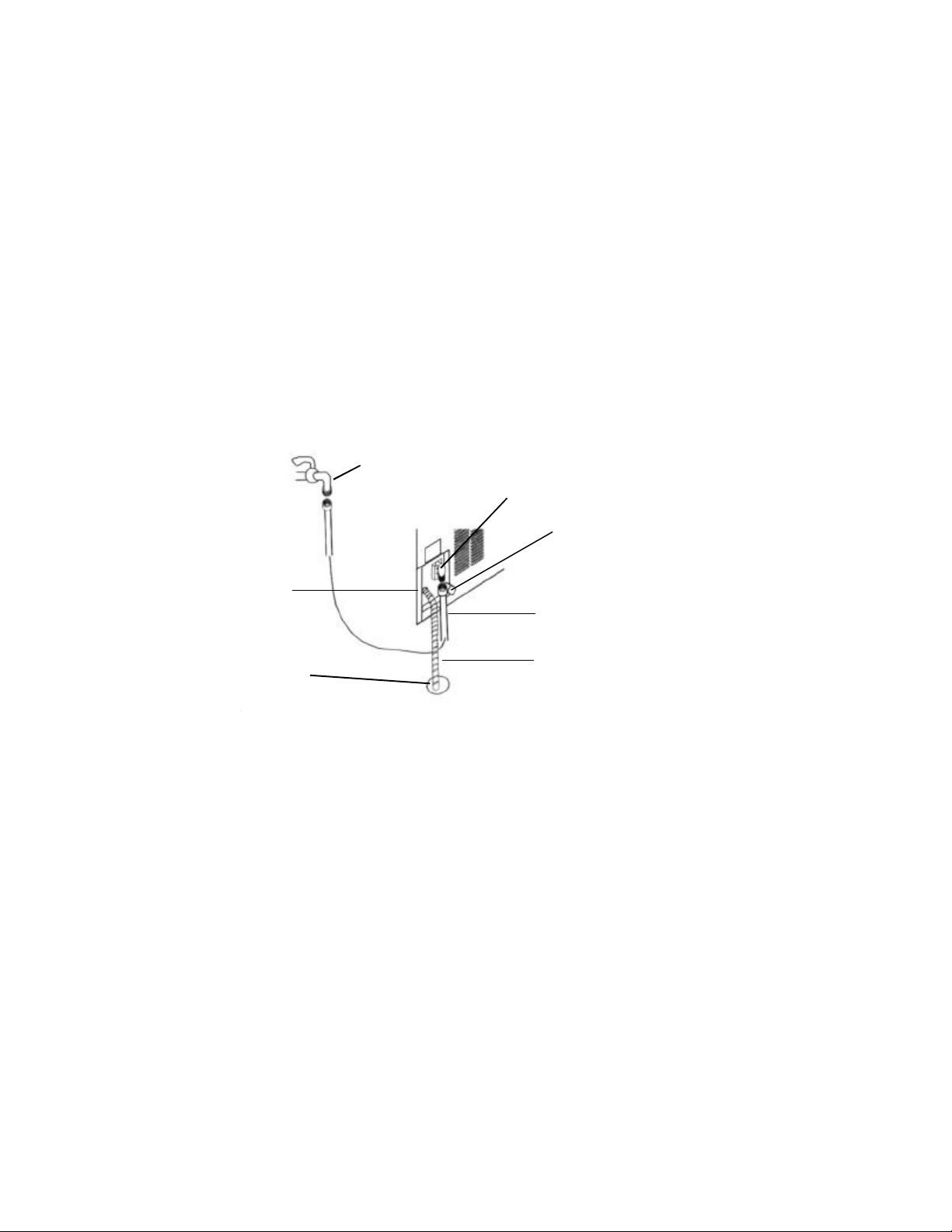

Water tap (1/4” o.d.)

Water inlet valve

Nut of water

draining hole

Drain outlet

Water supply line

Floor drain

NOTE: Connection to the water line may vary according to installation requirements.

Connecting the drain line:

A gravity drain system is used in this type ice maker. Excess water flows to the drain

through the drain line provided with the ice maker.

1. Find the floor drain near the ice maker. The distance should be less than 10 feet as the

length of the long drain line provided with the ice maker is about 10 feet.

2. Find the drain outlet on the back of ice maker. Connect one end of the long drain line

to the drain outlet of the machine, the other end to the floor drain.

3. All horizontal runs of drain lines must have a fall of ¼” per foot. An air gap will

likely be required between the ice maker drain tube and the drain/waste receptacle. A

standpipe with a trap below it would be acceptable for the drain/waste receptacle.

NOTE: If you cannot locate a floor or wall drain that allows the drain line to descend

¼” per foot, you may wish to purchase a drain pump from your local Franklin supplier.

Drain line

4. Pour 1 gallon of water into the ice storage bin to check for leaks at all drain connections

and at the nut of the drain water hole. Tighten any connections or nuts that leak.

IMPORTANT: Poor drainage will cause a high rate of ice melting in the ice storage bin.

12

Page 14

Installation Types

This ice maker has been designed for Mobile (free-standing) installation. It can also be

Enclosed (as under a cabinet) or Built-in (sealed to the floor), although this last option is

not the preferred method of installation. In every case, there must be adequate air space

around the unit for ventilation purposes (see diagrams on page 8).

Mobile Installation:

A mobile installation will allow you to install the icemaker free-standing in any place you

desire provided you have access to a water supply and drainage facilities. You must

follow the stated instructions for

a. Electrical requirements

b. Water supply and drain connections

c. Leveling the icemaker.

Enclosed Installation:

An enclosed installation will allow you to install the ice maker under a cabinet, or in a

kitchen cabinet provided the required clearance space around the ice maker is respected.

This installation has the same requirements as a mobile installation.

The unit should be placed in the cabinet by sliding it into the cabinet’s opening and then

leveling it properly.

IMPORTANT: For Mobile and Enclosed installations you must use flexible water and

drain connections to the water supply and drain. This will allow the moving of the ice

maker for cleaning. Use the water and drain hoses supplied with the unit for these

connections.

Built-in Installation:

If this method of installation is chosen, it will still be necessary to allow adequate

ventilation space around the unit. The following additional items must be observed.

1. Place the ice maker in front of the installation location. Remove the feet and place

the unit flat on the floor or on a platform depending on your installation requirements.

2. The water supply line and drain line must be plumbed before connecting to the ice

maker.

3. Turn on the main water supply and tap. Check for water supply connection leaks.

Tighten any connections (including connections at the valve) or nuts that leak.

4. Pour 1 gallon of water into the ice storage bin to check for leaks at all drain connec-

tions and the nut of the drain water hole. Tighten any connections or nuts that leak.

(This procedure will also indicate if the drainpipe is kinked or pinched.)

13

Page 15

5. If the electrical outlet for the ice maker is behind the cabinet, plug in the ice maker.

6. Push the ice maker into position.

7. Seal all around the cabinet to the floor with an approved caulking compound.

OPERATION

Final Check List before Operation

1. Have all packing materials and tape been removed from the interior and exterior of

the ice maker?

2. Did you clean the ice storage bin?

3. Have the installation instructions been followed, including connecting the machine to

water, drain and electricity?

4. Has the machine been leveled?

5. Is the ice maker in a site where the ambient temperature is between 13º C (55º F) and

32ºC (90ºF) and the water temperature within 5º C (41º F) and 25º C (77º F) all year

round?

6. Has the water supply pressure been checked to ensure a minimum of 20 psig with a

static pressure not to exceed 80 psig?

7. Is there a clearance of at least 4 in. (101 mm) at the rear, and 0.6 in. (15 mm) at the

sides and top for proper air circulation?

8. Has the power supply voltage been checked or tested against the nameplate rating?

And has proper grounding been installed in the ice maker?

9. Is the ice maker plugged in?

10. Did you turn on the main water supply and the tap?

11. Did you check for leaks at all water supply and drainpipe connections?

14

Page 16

Operating Method

1. Switch on the Power switch on the right

side panel. The light will be on. The ice

maker will start working automatically

and feeding water.

2. After the first feeding of the water, the

machine will automatically go to the ice

making stage, and the sound of water

spraying will be heard.

3.

Ice will be harvested to the ice storage

bin. When the storage bin is filled to the

point that the ice-full sensor is covered,

the ice maker will automatically stop

working. The machine will restart

making ice once the storage bin is less

than full.

4. Excess water will flow through the drain

outlet at the back of the machine and empty into the floor drain.

IMPORTANT:

Although the unit has been tested at the factory, due to long-term transit and storage,

•

the first batch of cubes must be discarded.

Never turn the water supply tap off when the icemaker is working.

•

How the Machine Makes Ice

There are two distinct cycles: freeze and harvest.

During the freeze cycle, water is sprayed against the evaporator surface.

In the harvest cycle, the ice is released and water enters the machine. A complete cycle

takes about 20 minutes, but is dependent on temperature and operating conditions.

Freeze: During the freeze cycle the compressor is pumping refrigerant, the fan motor is

blowing air, and the water pump is circulating water. When the batch of ice has been

fully formed, the ice maker stops the freeze cycle and begins to harvest the ice.

15

Page 17

Harvest: During the harvest cycle the compressor is still operating, but the water pump

has stopped. Two other components have been energized: the hot gas valve and the water

inlet valve. These two valves open and warm up the freezing surface, allowing the cubes to

fall into the bin. The freeze cycle will restart when all the cubes have been harvested.

How the machine uses water:

Evaporator

Water pump

Hot gas valve

Condenser

Compressor

Fan motor

Water inlet valve

freezing portion of the ice-making cycle, the water in the sump will become highly

concentrated with mineral impurities.

The ice maker

begins with a fixed

charge of water that

is contained in the

water sump. As the

water is sprayed

against the freezing

evaporator surface,

the portion of water

that does not contain

mineral impurities

will freeze and stick

to the ice cube molds.

The water containing

impurities falls back

into the water sump.

Gradually, during the

During the harvest cycle, fresh water flows into the machine to dilute the bin water and

rinse the concentrated minerals down the drain.

Normal Sounds

Your new ice maker may make sounds that are not familiar to you. Most of the new

sounds are normal. Hard surfaces like the floor and walls can make the sounds seem

louder than they actually are. The following describes the kinds of sounds that might be

new to you and what may be making them.

You will hear a swooshing sound when the water valve opens to fill the water sump

•

for each cycle.

Rattling noises may come from the flow of the refrigerant or the water line. Items

•

stored on top of the ice maker can also make noises.

The high-efficiency compressor may make a pulsating or high-pitched sound.

•

16

Page 18

Water running from the water sump to the evaporator plate may make a splashing

•

sound.

Water running from the evaporator to the water sump may make a splashing sound.

•

As each cycle ends, you may hear a gurgling sound due to the refrigerant flowing in

•

your ice maker.

You may hear air being forced over the condenser by the condenser fan.

•

During the harvest cycle, you may hear the sound of ice cubes falling into the ice

•

storage bin.

When you first start the ice maker, you may hear water running continuously. The ice

•

maker is programmed to run a rinse cycle before it begins to make ice.

Preparing the Ice Maker for Long Storage

If the ice maker will not be used for a long time, or is to be moved to another place, it

will be necessary to drain the system of water.

1. Shut off the water supply at the main water source.

2. Disconnect the water supply line from the water inlet valve.

3. Disconnect the drain pipe to the drain line or floor drain.

4. Allow the ice maker to run for an hour or more until all remaining ice cubes have

been ejected from the ice maker assembly.

5. Shut off the electric supply at main electrical power source.

6. Screw off the nut of the water drain hole at the back of the machine, drain out water

residue completely (do not loosen or screw off the nut at other times), then tighten the

nut after finishing.

7. Drop the door open to allow for circulation and prevent mold and mildew.

8. Leave water supply line and power cord disconnected until ready to reuse.

17

Page 19

CLEANING AND MAINTENANCE

If the ice maker is left unused for a long time, before the next

use it must be thoroughly cleaned. Follow carefully any

instructions provided for cleaning or use of sanitizing solution.

Do not leave any solution inside the ice maker after cleaning.

Periodic cleaning and proper maintenance will ensure efficiency, top performance, and

long life. The maintenance intervals listed are based on normal conditions. You may want

to shorten the intervals if you have pets, or the unit is used outdoors, or there are other

special considerations.

What shouldn’t be done

Never keep anything in the ice storage bin that is not ice: objects like wine and beer

bottles are not only unsanitary, but the labels may slip off and plug up the drain.

What should be kept clean

There are 4 things to keep clean:

1. The exterior

2. The condenser

3. The interior

4. The ice making system

Before proceeding with cleaning and maintenance operations,

make sure the power line of the unit is disconnected and the water

line is shut off (EXCEPTION: Ice maker system cleaning).

Exterior Cleaning

The door and cabinet may be cleaned with a mild detergent and warm water solution such

as 1 oz of dishwashing liquid mixed with 2 gallons of warm water. Do not use solventbased or abrasive cleaners. Use a soft sponge and rinse with clean water. Wipe with a soft

clean towel to prevent water spotting.

18

Page 20

Stainless steel can discolor when exposed to chlorine gas and should be cleaned. Clean

stainless steel with a mild detergent and warm water solution and a damp cloth. Never

use abrasive cleaning agents.

NOTICE: Stainless steel exposed to chlorine gas and moisture, such as in areas with

spas or swimming pools, may show some discoloration. Discoloration from chlorine gas

is normal.

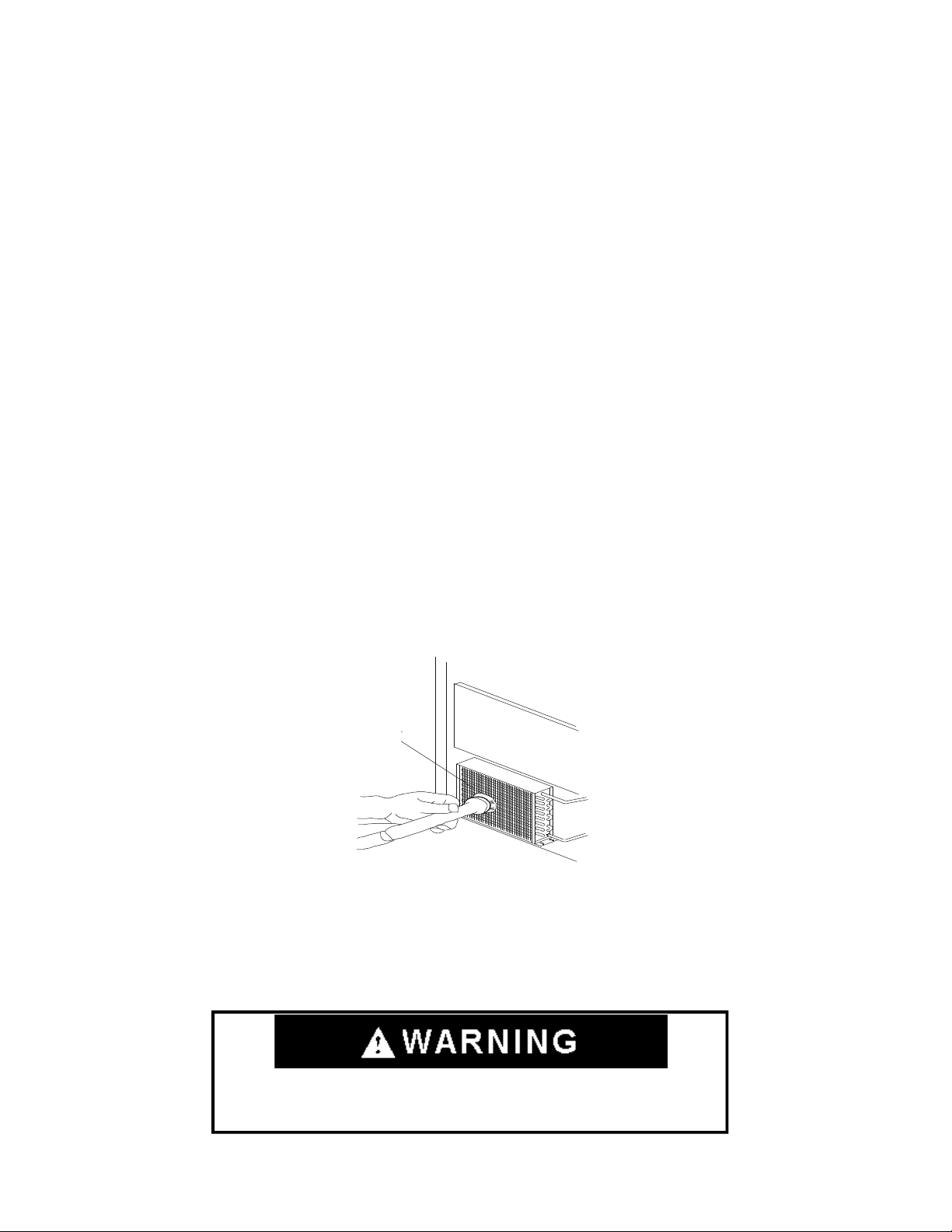

Condenser Cleaning

A dirty or clogged condenser prevents proper airflow, reduces ice making capacity, and

causes higher than recommended operating temperatures that may lead to component

failure. Have the condenser cleaned at least once every six months.

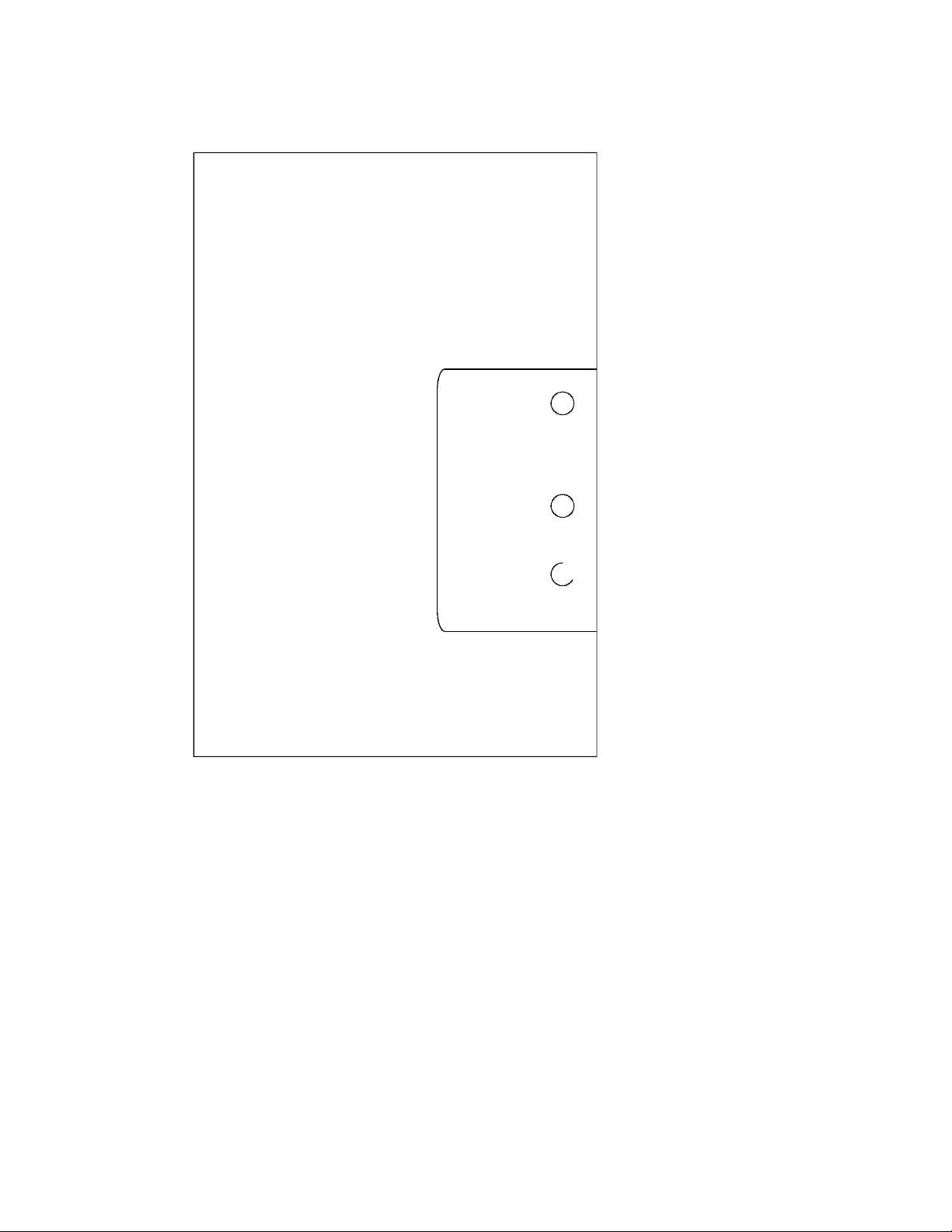

1. Unplug the ice maker or disconnect power.

2. Remove the 2 screws at the bottom of the front cover.

3. Grasp the lower edge of the front cover at the right and left sides, raise it a little and

then pull down.

NOTE: Do not use too much force, as the wire leads connected to the power switch

can be inadvertently disconnected.

4. Locate the condenser surface.

Condenser

surface

5. Remove dirt and lint from the condenser fins and the unit compartment with a brush

attachment on a vacuum cleaner.

6. Reassemble the front cover.

7. Plug in the ice maker or reconnect power.

DO NOT touch condenser fins. They are sharp and

can be damaged easily.

19

Page 21

Interior Cleaning

The ice storage bin should be sanitized occasionally. Clean the bin before the ice maker is

used for the first time and reused after stopping for an extended period of time. It is

usually convenient to sanitize the bin after the ice making system has been cleaned and

the storage bin is empty.

1. Disconnect power to the unit.

2. Open the door and with a clean cloth, wipe down the interior with a sanitizing

solution made of 1 ounce of household bleach or chlorine and 2 gallons of hot water

(95º to 115ºF).

3. Rinse thoroughly with clear water. The waste water will be drained off through the

drainpipe.

4. Reconnect power to the unit.

The ice scoop should be washed regularly. Wash it just like any other food container.

DO NOT use solvent-based cleaning agents or abrasives on

the interior. These cleaners may transmit taste to the ice

cubes, or damage or discolor the interior.

IMPORTANT NOTE: The sprinkler should only be cleaned when you find that some of

the ice cubes are improperly shaped during ice making. Cleaning the ice making system

should follow cleaning of the sprinkler.

1. Disconnect power to the unit and open the door.

20

Page 22

2. Take out the row of flake covers by snapping one end up and pulling forward.

3. Remove the slideway from the water sump.

4. Find the sprinkler arm and raise it. Disconnect it from the water tube which is

connected at the back of the sprinkler arm.

5. A de-scaling solution can be prepared in a plastic basin with Nu-Calgon Nickel-Safe

Ice Machine Cleaner. Mix 4 ounces of the ice machine cleaner per gallon of warm

water.

Page 23

6. Wipe down the interior of the water sump with the de-scaling solution and warm

water. Rinse thoroughly with clear water.

7. Reassemble the sprinkler arm, slideway and row of flake covers.

8. Perform steps 1, 3, 6, 7 and 8 of the Ice Making System Cleaning procedure below.

Ice Making System Cleaning

Minerals that are removed from water

during the freezing cycle will eventually

form a hard scaly deposit in the water

system. Cleaning the system regularly helps

remove the mineral scale buildup. How

often you need to clean the system depends

upon how hard your water is or how

effective your filtration may be. With hard

water of 15 to 20 grains/gal. (4 to 5

grains/liter), you may need to clean the

system as often as every 6 months.

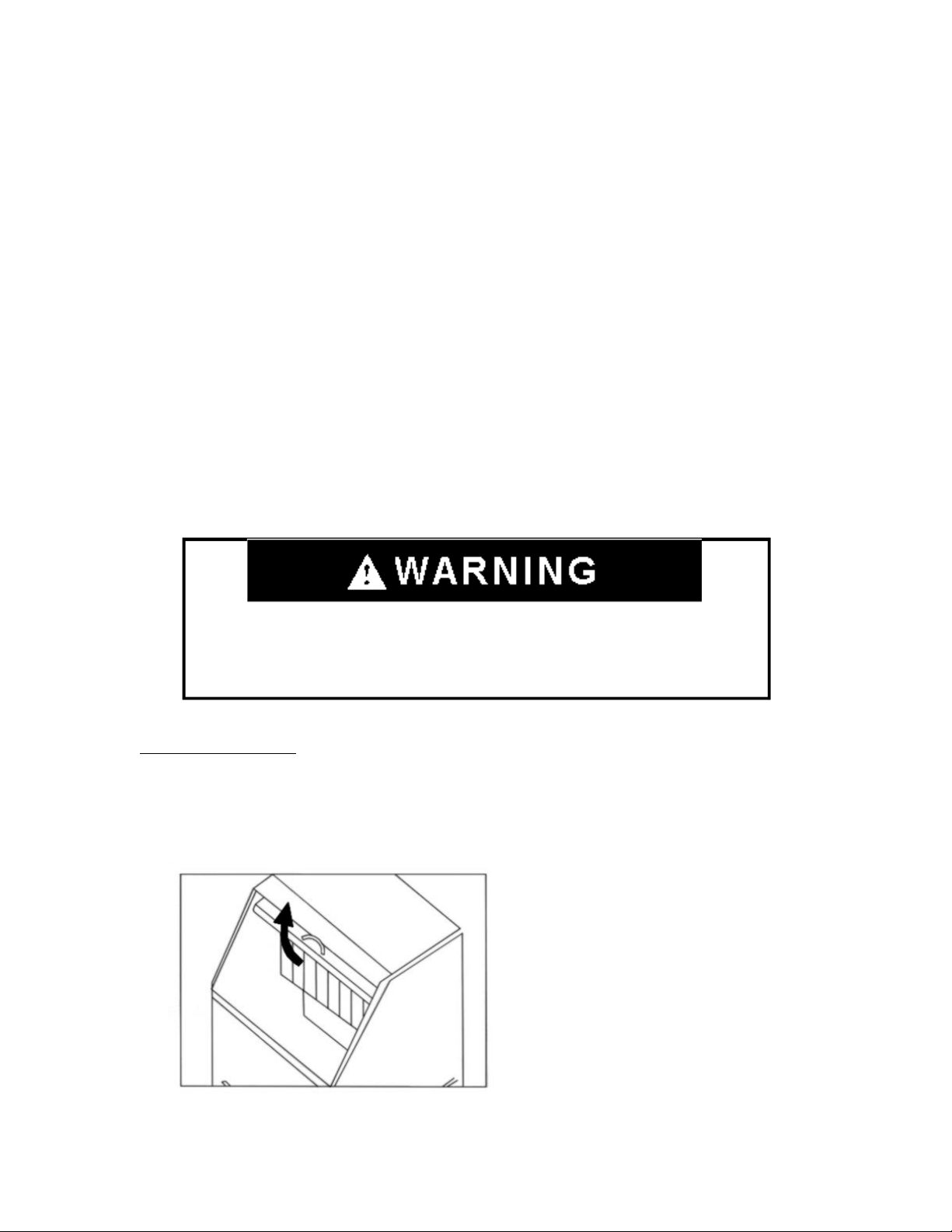

1. Turn off power to the ice maker. Keep the ice maker connected to the water supply

and drainpipe.

2. Open the door and scoop out all of the ice cubes. Either discard them or save them in

an ice chest or cooler.

3. Remove the 2 screws in the front cover and push for-

ward to remove the front cover. Locate the control box.

NOTES: Do not use too much force, as the wire leads

connected to the power switch can be inadvertently

disconnected.

Use care in the area of the control box. Do not expose

it to moisture.

4. Turn on the power to the ice maker. Pour 8 oz. of

Nickel-Safe Ice Machine Cleaner solution into the

water sump. Add 8 oz. of tap water. After

about 5 minutes, press down the “Clean”

button on the Control Box. (See figures

here and on page 24.) The machine will

run the Automatic Clean Mode.

Control Box

22

Page 24

5. Allow 30 minutes for proper cleaning. After cleaning, shut off the power switch, and

unscrew the nut of the water-draining hole on the rear of the unit. Drain off the waste

water to some container, and then screw the nut on tightly when the waste water is

fully drained off.

The ice machine cleaner contains acids.

DO NOT use or mix with any other solvent-based cleaner

products.

Use rubber gloves to protect hands. Carefully read the material

safety instructions on the container of the ice machine cleaner.

DISCARD the first batch of ice produced after cleaning.

6. Repeat steps 4 and 5 (without Ice Maker Cleaning Solution) to rinse the ice making

system 3 times.

NOTE: The use of the Ice Maker Cleaner Solution in the water sump during the rinse

is not needed.

7. Prepare a sanitizing solution made of 1 ounce of household bleach and 2 gallons of

hot water (95º to 115º F). Remove the flake covers and slideway from the water sump

and wipe the entire bin inside and out, covering the entire surface of the walls.

8. Fill a spray bottle with the sanitizing solution and spray all corners and edges, making

sure to cover all surfaces with the solution. Soak the flake covers and slideway in the

solution and put back in place after drying.

9. Allow the solution to be in contact for at least 3 minutes, then dry.

10. Repeat step 6 to rinse the ice making system one more time.

11. Reassemble the front cover.

12. Turn on the power again. The machine will return to the regular ice making mode.

Discard the first batch of ice.

23

Page 25

Control Box (behind front cover)

Descriptions of LEDs and buttons:

1. Red LED: Ice Full indicator light.

When this LED is lit, the ice storage bin is full of ice or there is something between

the two arms of the ice-full sensor in the ice storage bin. The unit will stop working.

When ice cubes are taken out o f the ice storage bin, clearing the sensor, the red LED

will keep flashing for 3 minutes. Then the unit will restart and return to the ice

making mode.

2. Green LED: Ice Making indicator light.

When this LED is lit, the unit is working in the Ice Making mode controlled by a

temperature probe on the evaporator. When the green LED is flashing, the unit is

working in the Ice Making mode controlled by a fixed timer.

24

Page 26

3. Yellow LED: Ice Harvest indicator light.

When this LED is lit, the unit is working in the Ice Harvest mode controlled by a

temperature probe on the evaporator. When the yellow LED is flashing, the unit is

working in the Ice Harvest mode controlled by a fixed timer.

4. Clean button: When this button is pressed, the unit enters the Cleaning mode. The

green and yellow LEDs flash together. To stop the Cleaning mode, just press the

button again.

5. Mode button: Mainly for service. When this button is pressed, unit can change from

Ice Making mode to Ice Harvest mode, or from Ice Harvest mode to Ice Making

mode. You can judge the mode from the status of the green and yellow LEDs.

6. Ice size adjust: Turn the screw clockwise, and the size of individual ice cubes will

be larger in the next cycle; the cycle time will be longer. Turn the knob counterclockwise, and the ice size will be smaller in the next cycle. It is not recommended

that the ice size be adjusted after installation.

7. If the red, green and yellow LEDs are flashing together, the machine is not working.

The major fuse of the control box has failed. Call for service.

NOTE: Avoid letting water contact the control box.

MAJOR FUNCTIONS

1. Completely automatic operating procedure.

2. When the ice storage bin is full of ice cubes, the machine stops working automatically

and starts again after the cubes are removed.

3. The different colors of the LED display indicate various work modes.

4. Indication of failure of major control box fuse.

5. The fan motor responds to the ambient temperature. If it is cold, the motor will stop

working to keep the cooling system in good working condition.

6. Ice cube size is adjustable.

7. A sensitive probe and accurate timer enhance the performance of the ice maker.

8. Manual Clean mode to start or stop the ice making system cleaning.

9. Built-in compressor protection system.

25

Page 27

TROUBLESHOOTING

Before Calling for Service

If the unit appears to be malfunctioning, read through the OPERATION section of this

manual first. If the problem persists, check the TROUBLESHOOTING GUIDE below

and on the following page. The problem could be something very simple which can be

solved without a service call.

Troubleshooting Guide

Problem Possible Cause Probable Correction

The ice maker is unplugged. Plug the ice maker in.

Replace fuse. If it happens again, call

The machine

doesn’t operate.

The fuse is blown.

The ice maker power

switch is OFF.

for service to check for a short circuit

in the ice maker.

Turn the ice maker power switch ON.

The water doesn’t

feed in after the ice

maker starts.

Machine makes

ice, but ice storage

bin does not fill up

with ice.

The ice storage bin is full of

ice.

The water supply tap is

turned off.

The water supply line is not

connected properly.

The bin should fill up and

the machine shut off in

9-14 hours. If not, the

condenser may be dirty.

The bin drain may be

partially restricted.

The airflow to the ice

maker may be obstructed.

The ambient temperature

and water temperature are

high, or machine is near

some heat source.

Remove some ice; make sure the

ice-full sensor is free of ice.

Turn on the water supply tap.

Reconnect the water supply line.

Clean the condenser.

Clean out the drain; check the

installation.

Check the installation.

Check the installation.

26

Page 28

Problem Possible Cause Probable Correction

Water is leaking

from the unit.

Cubes are partially

formed or are

white at the

bottom.

The ice cubes are

incomplete when

being dumped.

A few water drops fall to

the floor when you open the

door to take out ice from

ice storage bin.

Water supply connection

leaking.

Nut of water drain hole

leaking.

Drain hose connection

leaking.

Not enough water in the

water sump.

The sprinkler is blocked. Clean it; see “Interior Cleaning”.

Normal condensation on the door or

some water together with ice. Take

care when you take out ice.

Tighten fitting. See “Connecting the

Water Line”.

Tighten the nut.

Tighten fitting. See “Connecting the

Drain”.

Check if the water supply pressure is

below 20 psig.

Check water supply; filter may be

restricted.

Check for a water leak at the water sump.

Check if water inlet valve is restricted.

Noise during

operation

The ice maker

stops suddenly

while making ice.

The body of the

ice maker is

electrified.

Scale occurs

frequently inside

the machine.

The feet are not leveled and

locked.

Certain sounds are normal. See “Normal Sounds”.

The electricity is off. Reconnect the power supply line.

The room temperature is

out of the stated range.

The ventilation louvers are

covered.

The grounding line isn’t in

the socket.

The hardness of the water is

too high.

Level and lock the feet. See “Leveling

the Ice Maker”.

Cut off the electricity; let the ice maker

stop working till the temperature

returns within the stated range.

Remove the obstruction.

Use a socket meeting the required

electrical standard.

Use a water-softening device installed

in front of the water inlet valve.

27

Page 29

Limited Warranty

Franklin Industries, L.L.C., warrants this product to be free from defects in materials and

workmanship for a period of one year from the date of the original purchase or delivery.

Any parts that are determined to be defective will be replaced or repaired, at its sole

discretion, by Franklin at no charge as long as it has been determined that the unit was

operated in accordance with the instructions attached or furnished with the product. If

the unit proves to be defective, your first course of action should be to follow the

retailer’s return policy.

This warranty covers units only in the continental United States and does not cover the

following:

• Damage from improper voltage or installation

Damage in shipping

•

•

Defects other than manufacturing defects

• Any installation expenses that may be incurred

• Labor or repairs after the initial 12-month period

• Damage from abuse, misuse, accident, alteration or lack of

proper care or maintenance

•

Improper or incorrectly performed maintenance or repairs

• Use of parts not recommended by Franklin Industries

• Damage due to acts of God.

This limited warranty is given in lieu of all other warranties expressed or implied. This

warranty does not cover incidental or consequential damages. Some States do not allow

the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty provides you with specific legal rights and you may have other rights

which vary from State to State. Consult the written materials accompanying your product

for the safe and proper operation.

This warranty may not be assigned.

For warranty service, contact:

Franklin Industries, L.L.C.

4100 First Avenue

Brooklyn, NY 11232-3321

Tel. : 1-888-424-8278

Website: www.franklinchef.com

When service is required, have on hand the Model and Serial numbers found on the rating

label on the back of the unit, as well as proof of purchase such as a sales or gift receipt.

28

Page 30

Page 31

ÍNDICE

Página

SÍMBOLOS Y ADVERTENCIAS DE SEGURIDAD ·············· 30

ADVERTENCIAS DE SEGURIDAD······················· 31 - 33

INFORMACIÓN TÉCNICA···························· 34

INTRODUCCIÓN ································· 35

UBICACIÓN DE COMPONENTES DE LA MÁQUINA ············ 36

INSTALACIÓN DE LA MÁQUINA ······················· 37 - 43

Desembalaje ································ 37

Requisitos del lugar de instalación ····················· 37 - 39

Requisitos de alimentación eléctrica ···················· 39 - 40

Nivelación de la máquina ························· 40

Conexiones de entrada de agua y drenaje ················· 40 - 42

Tipos de instalación ···························· 42 - 43

USO DE LA MÁQUINA ····························· 44 - 47

Lista de control final antes de la puesta en servicio ············ 44

Método de uso ······························· 45

Ciclos de funcionamiento de la máquina·················· 45 - 46

Sonidos normales ······························ 46 - 47

Preparación de la máquina para almacenamiento prolongado ······· 47

LIMPIEZA Y MANTENIMIENTO ························ 48 - 55

Limpieza externa ······························ 48 - 49

Limpieza del condensador ························· 49

Limpieza interna ······························ 50 - 52

Limpieza del sistema para hacer hielo ··················· 52 - 53

Tablero de control ····························· 54 - 55

FUNCIONES PRINCIPALES ··························· 55

DIAGNÓSTICO DE FALLAS··························· 56 - 57

GARANTÍA LIMITADA ····························· 58

Nos reservamos el derecho de efectuar modificaciones de diseño y de

especificaciones técnicas, sin obligación de aviso previo.

29

Page 32

SÍMBOLOS Y ADVERTENCIAS DE SEGURIDAD

Su seguridad y la seguridad de los demás es de suma importancia.

Tanto en este manual como en la máquina, encontrará varios mensajes de importantes de

seguridad. Lea y observe siempre los mensajes de seguridad.

Este es el símbolo de Alerta de Seguridad. Advierte sobre posibles

riesgos que pueden causar accidentes lesivos e incluso fatales, tanto

para usted como para los demás. Los mensajes se verán a

continuación del símbolo de Alerta de Seguridad, junto con una de

las siguientes palabras: "PELIGRO", "ADVERTENCIA" o

“PRECAUCIÓN”.

PELIGRO indica que el incumplimiento de la medida de seguridad podría

causar lesiones personales graves e

incluso la muerte.

ADVERTENCIA indica que el

incumplimiento de la medida de

seguridad podría causar daños al

producto, lesiones personales graves e

incluso la muerte.

PRECAUCIÓN indica que el

incumplimiento de la medida de

seguridad podría causar lesiones

personales menores o moderadas, o

daños materiales o al equipo.

Los mensajes de seguridad especificarán cuál es el peligro potencial, cómo reducir las

Page 33

ADVERTENCIAS DE SEGURIDAD

Leer atentamente este manual, ya que antes de poner en servicio la

máquina para hacer hielo, es necesario ubicarla e instalarla tal como

aquí se explica. Franklin Industries recomiendan fuertemente que un

mecánico profesional instala su máquina nueva. La garantía se puede

afectar o anular por una instalación inexacta. Para disminuir el riesgo

de incendio, electrocución o lesiones personales accidentales durante

el uso de la máquina, es importante tomar ciertas precauciones

elementales, tal como las siguientes:

Enchufar la máquina a un tomacorriente para enchufe de tres patas, con descarga a

•

tierra. No eliminar la pata de descarga a tierra, no usar un adaptador de 3 a 2 patas, ni

usar un cordón prolongador.

Es recomendable alimentar eléctricamente la máquina con un circuito exclusivamente

•

dedicado a la misma. No usar un tomacorriente al que se pueda cortar la alimentación

desde una llave de luz u otro interruptor común.

No conectar ni desconectar el enchufe con las manos mojadas.

•

No limpiar ninguna de las partes de la máquina con líquidos inflamables. Los vapores

•

de estos líquidos podrían representar un riesgo de incendio o explosión. No guardar ni

usar gasolina ni otros líquidos o vapores inflamables cerca de esta máquina (ni de

otros artefactos eléctricos). Los vapores de estos líquidos podrían representar un

riesgo de incendio o explosión.

Antes de iniciar tareas de limpieza y/o mantenimiento, se debe cortar la alimentación

•

eléctrica y cerrar el paso de suministro de agua (EXCEPCIÓN: limpieza del sistema

para hacer hielo – vea las páginas 52 y 53 ).

Volver a colocar todos los paneles y tapas antes de poner la máquina en servicio.

•

Desenchufar la máquina o cortar la alimentación eléctrica del circuito antes de

•

efectuar tareas de limpieza o mantenimiento. Si no lo hace, puede dar por resultado la

electrocución o la muerta.

No efectuar reparaciones por cuenta propia ni cambio de partes de la máquina para

•

hacer hielo, a menos que así sea recomendado en este manual. Para los demás trabajos

de reparación y mantenimiento, solicitar los servicios de un técnico especializado.

Cuando desmonta la tapa frontal, no tirar demasiado desde que los alambres

•

conectados al botón de encendido se pueden desconectar por inadvertencia.

31

Page 34

Mover e instalar la máquina entre dos personas como mínimo. Si lo hace una sola

•

persona, hay riesgo de que se lesione por el esfuerzo excesivo.

Para que la máquina tenga ventilación adecuada, no debe haber ninguna obstrucción

•

en el frente de la misma. Elegir un lugar bien ventilado para instalarla, con

temperaturas superiores a 55º F (13º C) e inferiores a 90º F (32º C). Esta máquina

DEBE instalarse en un lugar protegido contra el viento, la lluvia y el goteo de agua.

No instalar la máquina para hacer hielo cerca de hornos, parrillas ni otros elementos

•

que generen calor excesivo.

Las conexiones eléctricas, de agua y de drenaje de la máquina para hacer hielo, deben

•

cumplir con todas las reglamentaciones vigentes que correspondan a nivel municipal

y estatal. La máquina se debe conectar a un tomacorriente de 115 Voltios de corriente

alterna, 60 Hz, 15 Amperes de capacidad, con descarga a tierra, instalado de acuerdo con

el Código Eléctrico Nacional (National Electrical Code) y los reglamentos municipales.

Asegurarse de que el cordón eléctrico no quede atrapado, torsionado ni presionado

•

entre la máquina y otro objeto.

El fusible o interruptor termomagnético de alimentación del circuito debe ser de 15

•

amperes de capacidad.

Para que la máquina funcione correctamente, es importante que esté bien nivelada.

•

Podría ser necesario hacer varios ajustes de la posición hasta que quede correctamente

nivelada.

La instalación de plomería debe cumplir con los reglamentos municipales vigentes

•

que correspondan.

Tomar precauciones para no aplastar ni dañar las tuberías durante la instalación.

•

Al terminar las conexiones, verificar que no hayan pérdidas en las tuberías.

•

No permitir que los niños usen, jueguen ni entren a la máquina para hacer hielo.

•

Si bien la máquina ha sido probada en fábrica, puede pasar mucho tiempo almacenada

•

y en tránsito. Por ello, se debe desechar la primera partida de cubos de hielo.

No cortar nunca el suministro de la línea de agua cuando la máquina está en

•

funcionamiento.

Cuando la máquina permanece sin usar durante un período prolongado, es necesario

•

limpiarla bien antes ponerla nuevamente en servicio. Siga atentamente las

instrucciones suministradas para la limpieza y/o el uso de soluciones desinfectantes.

Después de limpiar la máquina, no debe quedar absolutamente ningún residuo de

solución de limpieza en su interior.

NO tocar las aletas del condensador. Las aletas del condensador son filosas y además

•

se pueden dañar con facilidad.

NO usar productos de limpieza abrasivos ni con solventes en el interior de la

•

máquina. Estos productos de limpieza pueden impregnar de olor los cubos de hielo y

descolorar o dañar el interior de la unidad.

El producto de limpieza para la máquina contiene ácidos. NO usarlo ni mezclarlo con

•

ningún otro producto de limpieza que contenga solvente. Usar guantes de goma para

32

Page 35

protegerse las manos. Leer atentamente las instrucciones de seguridad para el manejo

del material, que se encuentran en el envase del producto de limpieza de la máquina.

No usar este artefacto para propósitos ajenos a su función original.

•

CONSERVAR ESTAS INSTRUCCIONES

Conexión eléctrica

No cortar ni quitar por ningún motivo la pata de descarga a tierra del enchufe del cordón.

Por razones de seguridad personal, esta máquina debe tener circuito de descarga a tierra.

El cordón eléctrico de esta máquina tiene 3 patas, una de las cuales es la descarga a tierra,

y debe enchufarse a un tomacorriente de 3 patas con circuito de tierra, a fin de reducir al

mínimo las posibilidades de electrocución accidental. Es conveniente hacer revisar por un

electricista profesional el tomacorriente y el circuito del mismo para verificar que tengan

descarga a tierra. Si el tomacorriente disponible para enchufar la máquina fuera uno de

dos patas solamente, es responsabilidad del usuario cambiarlo por uno de tres patas con

circuito de descarga a tierra. La máquina debe tener su tomacorriente individual, cuyo

voltaje coincida con el especificado en la etiqueta o placa de datos de la misma. Esto no

sólo es mejor para máquina, sino también para evitar sobrecargar los otros circuitos de la

instalación, con el consiguiente riesgo de incendio por sobrecalentamiento de los cables.

No desenchufar la máquina tirando del cordón. Tomar directamente el enchufe y tirar

firmemente hacia afuera. Reparar o cambiar inmediatamente los cordones eléctricos

quemados o dañados. No continuar usando un cordón eléctrico que esté agrietado o

dañado en cualquier lugar. Tomar precauciones para no dañar el cordón eléctrico cuando

se mueve la máquina para hacer hielo.

Cordón prolongador

Por razones de seguridad, se recomienda enfáticamente no usar un cordón prolongador

para enchufar esta máquina.

33

Page 36

Información técnica

Modelo FIM70 FIM90 FIM120

Alimentación eléctrica

Corriente nominal

haciendo hielo

Corriente nominal en

recolección de hielo

115VCA ~ 60Hz ~

470W

6,7A 7,3A 7,5A

11,2A 11,7A 11,8A

115VCA ~ 60Hz ~

520W

115VCA ~ 60Hz ~

580W

Refrigerante R134a; 0,195 Kg R134a; 0,255 Kg R134a; 0,282 Kg

Presión del circuito

de alta

Presión del circuito

de baja

Ancho x profundidad x

altura

320 lib./pulg

120 lib./pulg

420 mm x 540 mm

x 840 mm

2

2

320 lib./pulg

120 lib./pulg

560 mm x 540 mm

x 840 mm

2

2

320 lib./pulg

120 lib./pulg

560 mm x 540 mm

x 840 mm

2

2

Pesa 41,4 Kg 48,2 Kg 46,4 Kg

Capacidad

Hasta 29,5 Kg de

hielo por día*

Hasta 37,7 Kg de

hielo por día*

Hasta 50 Kg de

hielo por día*

Los datos técnicos y los parámetros funcionales mencionados anteriormente se deben

usar como valores de referencia únicamente. Estos datos están sujetos a cambio.

* La cantidad de hielo producida por día podría variar de acuerdo con la temperatura ambiente y la

temperatura del agua.

34

Page 37

INTRODUCCIÓN

Las máquinas para hacer hielo Franklin Chef serie FIM son aptas para uso doméstico, en

bares, restaurantes, hoteles, supermercados, etc. Producen cubos de hielo de impecable

transparencia, y son cómodas y prácticas para uso en el hogar como para huéspedes de

hoteles. Cada máquina tiene integrado un recipiente de hielo con aislación térmica.

Este manual tiene información destinada a las personas que instalan, usan y reparan los

modelos FIM70, FIM90 y FIM120. Tiene datos e información importantes sobre

seguridad y mantenimiento. Franklin Industries recomienda guardar este manual a mano

para consultarlo en caso de que sea necesario.

Cada máquina para hacer hielo Franklin Chef fue diseñada y fabricada bajo las normas

más exigentes de seguridad y tecnología. Cumple y supera las normas de seguridad

UL563 y la norma de saneamiento NSF12.

Franklin Industries L.L.C. no asume ninguna responsabilidad por los productos que

hayan sido modificados de cualquier manera, incluyendo el cambio de partes y/o

componentes por otras/otros que no sean específicamente aprobadas por Franklin

Industries L.L.C. Franklin Industries se reserva el derecho de implementar en cualquier

momento cambios de diseño y/o mejoras del producto. Las especificaciones técnicas y el

diseño están sujetos a cambio sin obligación de aviso previo.

35

Page 38

UBICACIÓN DE COMPONENTES

DE LA MÁQUINA

Sensor de lleno

de hielo

Tapa frontal

Tablillas de

ventilación

Rodillos

para nivelar

Puerta

Tapa superior

Lado derecho

Recipiente

de agua

Recipiente

de hielo

Cuchara

para hielo

Tablero de control

(detrás de la tapa

frontal)

Botón de encendido

36

Page 39

INSTALACIÓN de la MÁQUINA

Desembalaje

Peligro de peso excesivo

Mover e instalar la máquina entre dos personas como mínimo.

Si lo hace una sola persona, hay riesgo de que se lesione por el

esfuerzo excesivo.

Quitar los materiales de embalaje

IMPORTANTE: No quitar las etiquetas fijas de instrucciones ni la etiqueta de datos de la

máquina para hacer hielo.

Quitar las cintas adhesivas y residuos de adhesivo antes de poner en servicio la máquina.

Para ello, frotar enérgicamente con los dedos, en seco o con una solución de agua y

•

detergente. Después limpiar con agua tibia y secar la superficie.

No usar instrumentos filosos, alcohol, fluidos inflamables ni productos abrasivos de

•

limpieza para quitar cinta adhesiva o residuos de adhesivo. Estos productos pueden

dañar la superficie de la máquina.

Limpieza antes de poner en servicio la máquina

Después de quitar todos los materiales de embalaje, limpiar el interior de la máquina. Ver

las instrucciones de “Limpieza interior” en la sección de “Limpieza y mantenimiento”.

Requisitos del lugar de instalación

Distancias de Instalación:

Vista superior (pulg.)

Parte trasera

Lado derecho

Frente del unidad

Vista lateral (pulg.)

37

Page 40

Para que la máquina tenga ventilación adecuada, no debe haber ninguna obstrucción

•

en el frente de la misma. Para que haya suficiente circulación de aire, dejar una

distancia mínima de separación de 101 mm (4”) en la parte de atrás, y de 15 mm

(0,6”) en la parte superior y de ambos lados. Debe quedar suficiente espacio para

poder desplazar la máquina hacia adelante cuando fuera necesario hacer tareas de

mantenimiento.

Si se instala la máquina bajo una mesada o un mostrador, dejar las distancias de

•

separación indicadas en el diagrama anterior. Hacer las acometidas y conexiones

eléctricas, de agua y de drenaje en los lugares indicados en la ilustración.

Elegir un lugar bien ventilado para instalarla, con temperaturas superiores a 55º F

•

(13º C) e inferiores a 90º F (32º C). Esta máquina DEBE instalarse en un lugar

protegido contra el viento, la lluvia y el goteo de agua.

No instalar la máquina para hacer hielo cerca de hornos, parrillas ni otros elementos

•

que generen calor excesivo.

El suministro de agua fría debe llegar por medio de un tubo de cobre de 6,35 mm

•

(¼"), con válvula de paso. Para la evacuación del drenaje use una línea por gravedad.

(NOTA: También existe la opción de evacuar el agua residual a un fregadero por

medio de una bomba - no incluida - cuando una línea por gravedad no está disponible.)

La máquina debe recibir suministro continuo de agua, a una presión minima de 20

•

psig y una presión estática nada menos que 80 psig. La temperatura del agua que

entra a la máquina debe ser entre 41º F (5º C) y 77º F (25º C) para que la máquina

funcione en condiciones óptimas.

La temperatura ambiente normal de servicio debe ser entre

55° F (13° C) y 90° F (32° C). La temperatura normal del

agua debe ser entre 41° F (5° C) y 77°F (25° C). Si la

máquina funciona por períodos prolongados fuera de estos

valores de temperatura, se verá afectado su rendimiento.

Normalmente es conveniente filtrar el agua que se suministra a la máquina. Un filtro

•

adecuado para este tipo de servicio puede eliminar del agua olores, gusto y partículas

suspendidas. El agua tratada por su dureza puede producir cubos de hielo blancos y

porosos, que se pegan entre sí. No se recomienda el uso de agua desionizada.

Las conexiones eléctricas, de agua y de drenaje de la máquina para hacer hielo, deben

•

cumplir con todas las reglamentaciones vigentes que correspondan a nivel municipal

y estatal.

Instalar la unidad sobre una superficie firme y bien nivelada. Para que la máquina

•

funcione correctamente, es importante que esté bien nivelada. Haciendo girar las

38

Page 41

patas, se puede regular la altura de la máquina. En la sección “Nivelación de la

máquina” se pueden ver más detalles de este procedimiento.

La máquina se debe conectar a un tomacorriente de 115 Voltios de corriente alterna,

•

60 Hz, 15 Amperes de capacidad, con descarga a tierra, instalado de acuerdo con el

Código Eléctrico Nacional (National Electrical Code) y los reglamentos municipales..

IMPORTANTE: Asegurarse de que el cordón eléctrico no quede atrapado, torsionado

•

ni presionado entre la máquina y otro objeto.

Requisitos de alimentación eléctrica

Peligro de electrocución

Enchufar la máquina a un tomacorriente de 3 patas con descarga a tierra.

No eliminar la pata de conexión a tierra del enchufe.

No usar un adaptador de 3 a 2 patas.

No usar un cordón prolongador para enchufar la máquina.

El incumplimiento de estas instrucciones podría causar incendio,

electrocución o un accidente fatal.

Antes de trasladar la máquina a su lugar definitivo de instalación, verificar que la

alimentación eléctrica sea la que corresponda.

La máquina se debe conectar a un tomacorriente de 115 Voltios de corriente alterna, 60

Hz, 15 Amperes de capacidad, con descarga a tierra, instalado de acuerdo con el Código

Eléctrico Nacional (National Electrical Code) y los reglamentos municipales.

Es recomendable alimentar eléctricamente la máquina con un circuito exclusivamente

dedicado a la misma. No usar un tomacorriente al que se pueda cortar la alimentación

desde una llave de luz u otro interruptor común.

El fusible o interruptor termomagnético de alimentación del circuito debe ser de 15

amperes de capacidad.

39

Page 42

Circuito de descarga a tierra

Por razones de seguridad personal, esta máquina debe tener circuito de descarga a tierra.

La máquina viene equipada con un cordón eléctrico con un enchufe de 3 patas, una de la

cuales es la conexión al circuito de tierra. Para reducir al mínimo las posibilidades de

electrocución, el enchufe se debe conectar a un tomacorriente de 3 patas con circuito de

descarga a tierra instalado de acuerdo con el Código Eléctrico Nacional (National

Electrical Code) y los reglamentos municipales que correspondan. Si el tomacorriente

disponible no tuviera tercera pata de descarga a tierra, es responsabilidad del usuario

cambiarlo y hacer instalar un circuito de descarga a tierra con un electricista profesional.

Nivelación de la máquina

Para que la máquina funcione correctamente, es importante que esté bien nivelada. Se

puede levantar o puede ser bajada girando las vainas plásticas alrededor de cada una de

las cuatro patas/rodillos rodantes en el fondo de la máquina. Si usted encuentra que la

superficie no es a nivel, gira las patas/rodillos hasta que la máquina llegue a ser a nivel.

Podría ser necesario hacer varios ajustes de la posición hasta que quede correctamente

nivelada. Recomendamos usar un nivel del carpintero para verificar la máquina.

La combinación de cuatro patas/rodillos

permite que una sola persona pueda mover la

máquina con facilidad. Es una práctica

solución para mover la máquina sin mayor

esfuerzo hacia adelante para limpiar y

desinfectar la superficie inferior.

IMPORTANTE: Una vez que la máquina está

instalada, ya sea en un gabinete o

directamente sobre el piso, regular la altura

de las patas para nivelarla y trabar los

rodillos. Si el piso estuviera nivelado,

simplemente girar las dos patas frontales

hasta que toquen el piso (véase la

ilustración).

abajo

arriba

Conexiones de entrada de agua y drenaje

Las conexiones de suministro de agua y de salida de drenaje deben estar preparadas en el

lugar de instalación. Cuando se instala la máquina bajo una mesada o mostrador, la

instalación se simplificará considerablemente si hubiera un tomacorriente directamente

detrás de la máquina.

40

Page 43

IMPORTANTE:

1. La instalación de plomería debe cumplir con los reglamentos municipales vigentes

que correspondan. La instalación profesional se recomienda.

2. Tomar precauciones para no aplastar ni dañar las tuberías durante la instalación.

3. Al terminar las conexiones, verificar que no hayan pérdidas en las tuberías.

Herramientas necesarias:

Llave de boca abierta de ½"

•

Destornillador Phillips

•

Conexión de la línea de agua:

1. Cortar el paso de agua en la línea principal. Abrir la canilla más cercana para dejar

salir toda el agua que haya quedado en la línea.

2. Buscar un tramo vertical de tubería de agua fría de ½" a ¾", que se encuentre a menos

de 10 pies de distancia (unos 3 metros) del lugar de instalación, ya que el tubo de

entrada de agua suministrado con la máquina tiene una longitud aproximada de 10 pies.

3. Instalar una válvula de paso en la línea de suministro de agua. Si la línea de agua

tiene un tubo de cobre, conectar un acople a compresión de ¼” de diámetro externo y

Page 44

Conexión del drenaje:

Con este tipo de máquina para hacer hielo, se utiliza un drenaje por gravedad. El agua

excesiva fluye al drenaje por la línea de drenaje suministrada con la máquina para hacer

hielo.

1. Ubique el drenaje en piso cerca de la máquina para hacer hielo. La línea de drenaje

debería estar a menos de 10 pies (unos 3 metros) de distancia de la máquina, ya que

esa es la longitud aproximada del tubo largo de drenaje suministrado con la máquina.

2. Ubique la salida de drenaje en el trasero de la máquina. Conectar un extremo del

tubo largo de drenaje a la salida de drenaje de la máquina, y el otro extremo al drenaje

en piso.

3. Todos los tramos horizontales de líneas de drenaje deben tener una pendiente mínima

de ¼" por pie (21 mm por metro). Probablemente sea necesario que quede un espacio

de aire entre el tubo de drenaje de la máquina y el recipiente de drenaje. Para el

receptáculo de drenaje, es aceptable un tubo vertical con un sifón detrás. Un drenaje

de piso también es aceptable. NOTA: Si no puede encontrar un drenaje de piso ni de

pared que permite que la línea de drenaje descienda ¼" por pie, puede comprar una

bomba para drenar de su suministrador Franklin local.

4. Cargar un galón (3,8 litros) de agua en el recipiente de hielo y comprobar que no

hayan pérdidas en todas las conexiones de drenaje, incluyendo la tuerca del orificio

de salida de drenaje de la máquina. Si se detectaran pérdidas, ajustar las conexiones y

tuercas que correspondan.

IMPORTANTE: Si el drenaje es insuficiente, el hielo contenido en el recipiente se

derretirá rápidamente.

Tipos de instalación

Esta máquina para hacer hielo es apta para ser instalada de tres maneras: Libre (sola, no

empotrada), en cerramiento (insertada, pero no empotrada) y empotrada, aunque esta

última opción no sea el método preferido de la instalación. En cada caso, debe tener el

espacio aéreo adecuado alrededor de la unidad para ventilación (vea las esquemas en la

página 37).

Instalación libre:

La máquina se puede instalar independientemente en cualquier lugar adonde se tenga

acceso a una línea de agua y una línea de drenaje. Para la instalación, se deben seguir

todas las instrucciones mencionadas anteriormente, en lo referido a:

a. Requisitos de la instalación eléctrica

b. Conexiones a líneas de suministro de agua y salida de drenaje

c. Nivelación de la máquina.

42

Page 45

Instalación en cerramiento:

En este caso, la máquina se puede instalar bajo un gabinete o bajo un mueble de cocina,

manteniendo las distancias de separación que corresponden. El resto de la instalación

debe cumplir los mismos requisitos mencionados para la instalación libre.

Así se instale en un mueble de cocina o bajo un gabinete, la máquina se debe quedar bien

nivelada.

IMPORTANTE: Tanto para la instalación libre como encerrada, se deben usar tuberías

flexibles para suministro de agua y para salida de drenaje. Esto permitirá mover la

máquina para efectuar limpieza, sin tener que desconectar las tuberías. Estas conexiones

se pueden hacer con las mangueras de agua y de drenaje que se suministran con la

unidad.

Instalación empotrada:

Si este método de instalación se escoge, será todavía necesario tener el espacio aéreo

adecuado alrededor de la unidad para ventilación (vea las esquemas en la página 37).

Cuando la máquina se instale empotrada, observar las siguientes instrucciones

adicionales:

1. Colocar la máquina frente al lugar de instalación. Desmontar las patas y colocar la

máquina sobre el piso o sobre una plataforma (depende de las características de

instalación).

2. Dejar preparadas las conexiones de suministro de agua y de drenaje antes de instalar

la máquina.

3. Abrir el paso en la línea de agua y abrir la válvula de suministro de agua a la

máquina. Verificar que las conexiones no tengan pérdidas. Si hubieran pérdidas,

ajustar bien todas las conexiones (incluyendo las de la válvula) y tuercas.

4. Cargar un galón (3,8 litros) de agua en el recipiente de hielo y comprobar que no

hayan pérdidas en todas las conexiones de drenaje, incluyendo la tuerca del orificio

de salida de drenaje de la máquina. Si se detectaran pérdidas, ajustar las conexiones y

tuercas que correspondan. Este procedimiento indicará también si el tubo de salida de

drenaje esté estrangulado o presionado.

5. Si el tomacorriente estuviera detrás del empotramiento, enchufar la máquina en este

momento.

6. Mover la máquina a la posición definitiva.

7. Aplicar un sellante compatible con esta aplicación para cerrar el espacio entre el

gabinete y la unidad.

43

Page 46

USO DE LA MÁQUINA

Lista de control final antes de la puesta en servicio

1. ¿Se han quitado todos los materiales de embalaje y cintas adhesivas del interior y

exterior de la máquina?

2. ¿Se ha limpiado el recipiente de hielo?

3. ¿Se han seguido todos los pasos de instalación, incluyendo los concernientes a las

conexiones de agua, drenaje y electricidad?

4. ¿Se ha nivelado la máquina? ¿Se han trabado las patas?

5. ¿La temperatura ambiente en el sitio de instalación de la máquina se mantiene entre

13º C (55º F) y 32º C (90º F) durante todo el año? Igualmente, ¿ se mantiene la

temperatura del agua corriente entre 5º C (41º F) y 25º C (77º F)?

6. ¿Se ha verificado que la presión del agua sea como mínimo 20psig y con una presión

estática nada menos que 80 psig?

7. ¿Se ha dejado una separación mínima de 101 mm (4 pulgadas) en la parte de atrás y

de 15 mm (0,6 pulgadas) a los costados y arriba, para que haya suficiente circulación

de aire?

8. ¿Se ha medido el voltaje de alimentación para verificar que cumpla con las

especificaciones de la máquina? ¿Se ha verificado que la máquina esté conectada a un

circuito de descarga a tierra?

9. ¿Está enchufada la máquina?

10. ¿Se encuentra abierta la válvula de paso de suministro de agua?

11. ¿Se ha comprobado que no hayan pérdidas en las conexiones de las tuberías de

entrada de agua y salida de drenaje?

44

Page 47