Page 1

EF1-230V Hand-Held Welder

Operating Manual

For use Only with UPP™ Electrofusion Components

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433

• www.franklinfueling.com

Page 2

2

Warning

UPP™ welding units must never be operated in Zone1

or Zone 0 areas!

Hazardous area denitions are from European Directive 1999/92/EC (further

guidelines can be found in the APEA Blue Book 2nd Edition).Further guidelines

are found in IEC 60079-10-1, “Explosive atmospheres - Part 10-1: Classication

of areas - Explosive gas atmospheres”

Safety

• The EF1 is designed for usage on construction sites and meets applicable

European and International safety standards. The machine should be

handled with the care usually given to electrical equipment, especially during

transport.

•

The machine must only be used outside of hazardous areas (zones 0, 1 and 2).

• Each time it is used, check the condition of the machine, particularly the

mains power cable. If any damage is discovered, contact the supplier

immediately and do not use the machine.

• Check the state of the welding cables before use and replace them if there is

any doubt about their condition.

• Protect the welder from getting wet.

• Always check that the power source is within the parameters shown below

before using the EF1.

• Never lift or pull the machine by its power cable or the welding cables.

Never

disconnect welding cables by pulling the cable; always pull off the connectors.

• Never re-weld a tting that is still warm. Serious re or burn damage

can occur and hot material may be ejected from the weld zone. Power

conducting elements may become exposed creating an electrical shock

hazard.

Liability Restrictions

All liabilities of the supplier are invalidated in the following cases:

• The EF1 is used outside the indicated application area.

• Non-UPP™ ttings or pipe are used.

• The operator has not been trained to use the EF1 or the UPP™ system.

• Operating instructions have not been observed.

• Unauthorised repairs, maintenance or modications have been carried out.

• The EF1 has been used outside of its technical specication.

• Safety instructions have not been observed.

• Improper or inadequate maintenance.

• Misuse, physical abuse or any use not in accordance with the operating

manual or good industry practice.

• Improper site preparation or site maintenance.

Page 3

3

Technical Specications

Stock code _________________ EF1-230V

Supply voltage ______________ 230 V +/- 15% (194 V to 264 V)

Supply frequency ____________ 50/60 Hz (40 Hz to 70 Hz)

Supply power _______________ 2.8 kW / 3.5 kVA

Supply protection ____________ Class 1 earthed (grounded)

Environmental protection ______ IP65

Operating temperature ________ -15 ºC (5 ºF) to +45 ºC (113 ºF)

Shipping dimensions 460 mm (18") wide x 210 mm (8.3") deep

x 210 mm (8.3”) high

Shipping weight _____________ 3.6 kg (8 lb)

Power Supply

Welder must be powered with:

• A quality 230 VAC, 50 Hz power supply with maximum tolerance of ± 15%.

• A quality generator capable of supplying a minimum of 2.8 kW (3.5 kVA).

Note that an earth-spike (grounding rod) must be used with generators.

If used with a 110v to 230v step-up transformer follow these specications:

• Safety Isolating transformer: 3.3 kVA minimum.

• Auto transformer: 3.3 kVa minimum.

Extension Cords / Cables

Extension cables must comply with or be equivalent to H07RN-F

specications. Cable use must comply with the following table.

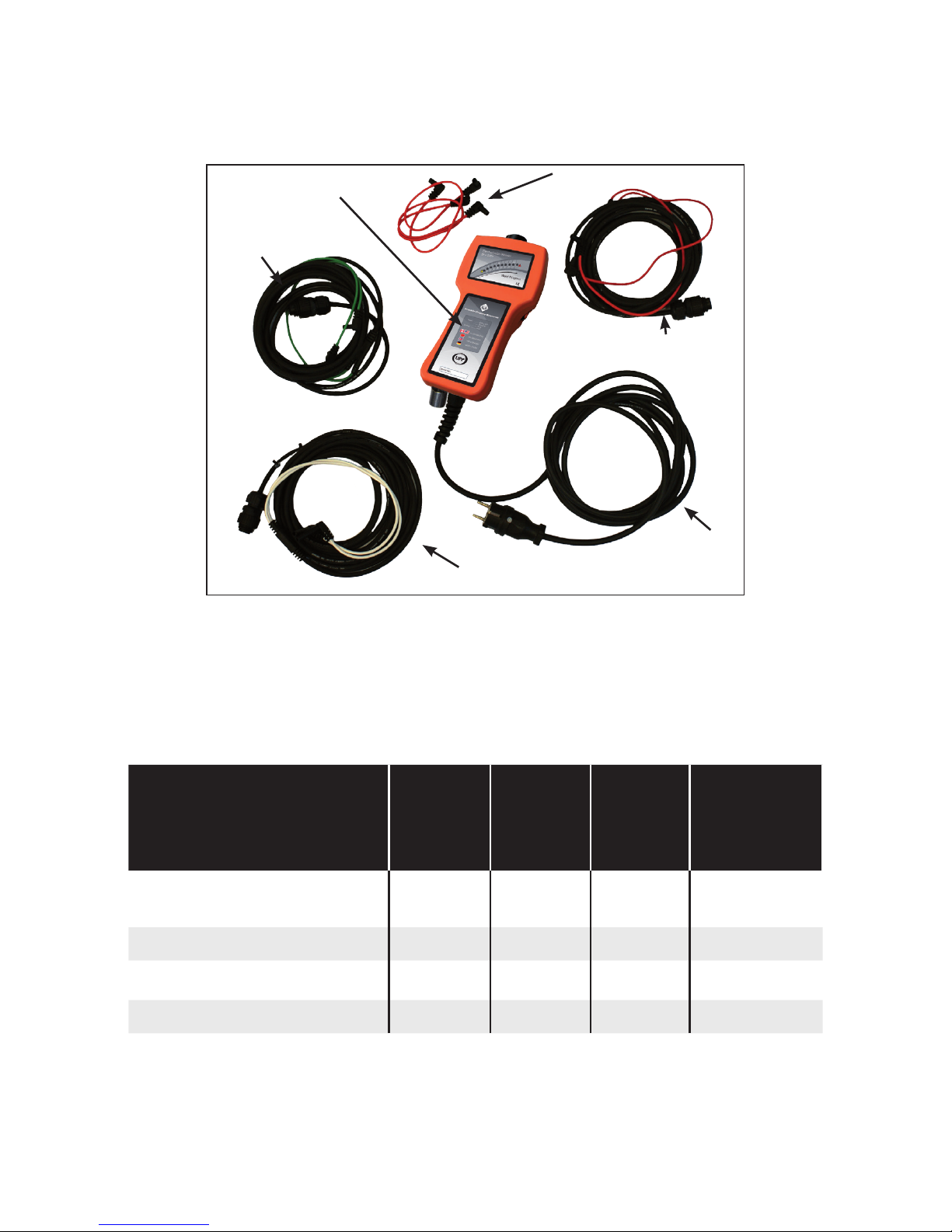

Wire Size

Metric

AWG Wire

Size

Maximum

Length,

meters

Maximum

Length, feet

1.5 mm 15 25 82

2.5 mm 13 50 164

4.0 mm 11 75 246

Note: All cable must be unwound from reel to prevent inductive heating

effects.

Page 4

4

Note: EF1 welding cables use special 7 pin connectors.

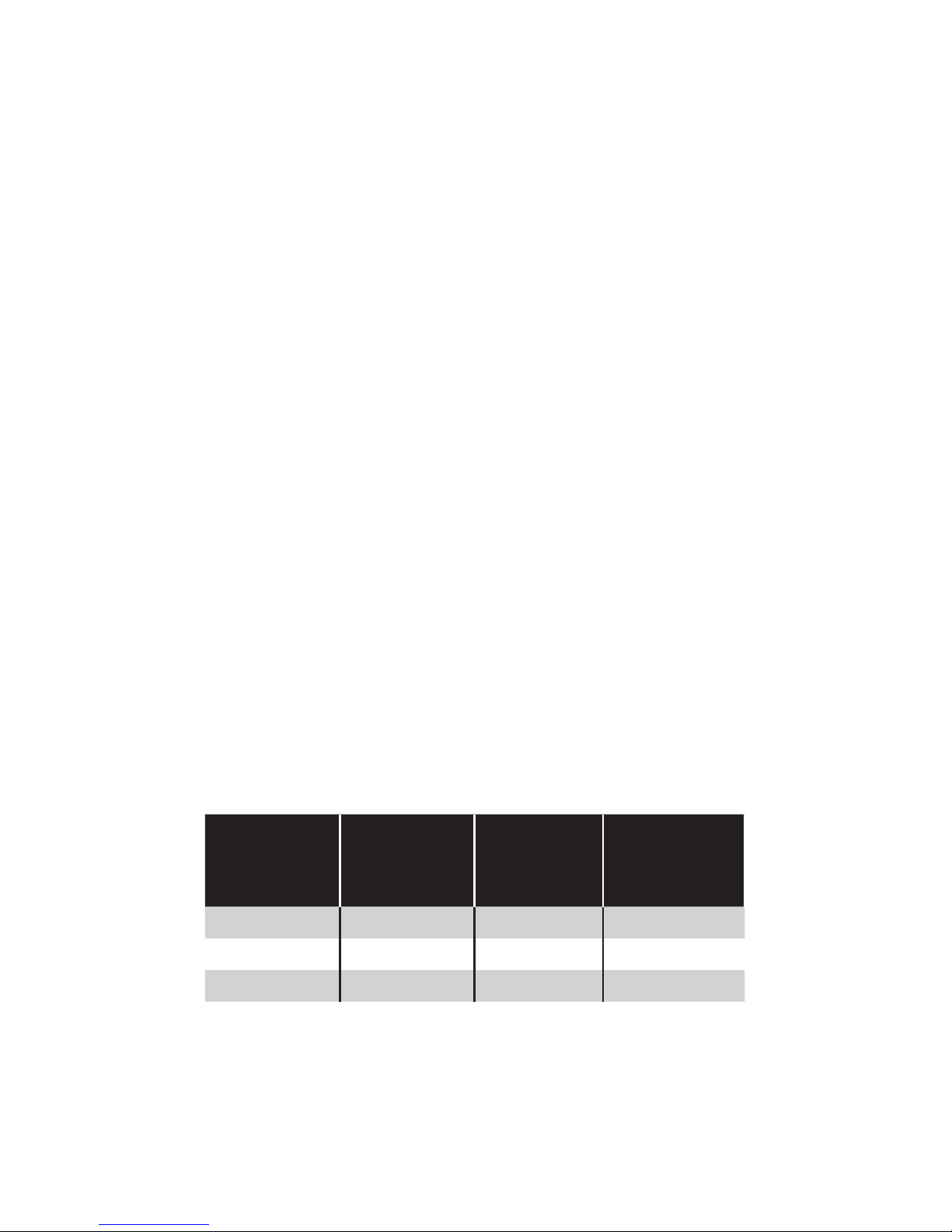

Parts

Bridging cables (x2)

EF

1 Electrofusion Welder

7pin Secondary

welding cable

Power cable

7 Pin Fusion chamber welding cable

Application

The EF1 is designed to automatically weld UPP™ Primary and Secondary

Containment electrofusion ttings, Electrofusion Chambers and Large

diameter 10 amp ttings. This is done by using color-coded welding leads as

shown below.

Type

of

Fitting

Welding

Cable

Colour

Size of

Welding

Pin

(mm)

Current

(amps)

Weld Time

@ 20C

(Seconds)

Primary and Gemini

Secondary ttings

Red 4 4 184

Secondary Green 2 5 80

Fusion Chamber White 2.3 7 360

Large Diameter (10amp) Black 2 10 365

The EF1 can be used in ambient temperatures between -15 °C (5 ºF) and

+45 °C (113 ºF). Only personnel fully trained and certied in the use and

installation of the UPP™ system should use this equipment.

7 pin Primary and Gemini

Secondary welding cable

Page 5

5

Main Features

UPP™ electrofusion ttings are welded using a constant current. The EF1

automatically recognizes the tting when connected and applies the correct

amount of energy for a successful weld.

7 pin Weld cable

connector

Fault

indicator

Weld progress

LED’s

Temperature sensor

Power on Indicator

ON / OFF Switch (on

side of unit)

START / STOP button

The EF1 takes the ambient temperature into account when calculating the

energy required to weld correctly. It must therefore be allowed to reach

ambient temperature before use and must be at the same temperature as the

tting to be welded. The temperature sensor is located adjacent to the power

cable entry gland.

The EF1 works on standard alternating current and either a mains connection

or a generator can be used. Generators must have a rated output of at least

3.5 kVA and power input must be between 194 and 264 volts at 40 to 70 Hz.

The EF1 has an on / off button, a weld start button and an LED display

showing the weld progress. The LEDs can also show any fault conditions that

may affect the weld.

Page 6

6

Using the EF1

• Ensure that the machine is positioned outside hazardous zones

ATEX 0, 1 and 2.

• Allow the machine and ttings to reach the ambient temperature of the site.

• Keep the machine out of direct sunlight and free of any obstruction.

• Make sure ttings and pipe have been prepared in accordance with UPP™

Installation instructions.

Follow the steps below to weld Electrofusion ttings.

1. Connect the required welding lead to the EF1 Welder:

PRIMARY and GEMINI SECONDARY ttings = RED (ORANGE) cable

SECONDARY ttings = GREEN cable

FUSION CHAMBER = WHITE cable

10 AMP ttings = BLACK cable

2. Connect the welding lead to the UPP™ fusion tting(s), making sure

connectors are rmly pushed onto the pins.

3. Connect the EF1 Welder to suitable 230V power supply.

4. Turn the unit ON. All LEDs light in sequence, then green Power LED

remains on.

5. Momentarily depress the orange START button until rst weld light

illuminates. The rst weld light comes on, then successive LEDs light

up until green 100% LED is lit, showing weld is complete.

6. Disconnect welding lead from tting. The 100% LED and Power LED

remains on.

7. ALWAYS Reset for next weld by holding START button for 3 seconds.

All LEDs will light in sequence, then the green power LED remains on.

Other Important Tips

• Switch off the machine during breaks and at the end of the job.

• The weld cycle can be stopped at any time by pressing the START/STOP

button. This will generate an error code and you must wait for the tting to

cool before attempting to continue.

• If you have any doubt about a welded joint, UPP™ ttings can be welded

again provided they are left to cool at ambient temperature for a minimum of

one hour.

Never re-weld a tting that is still warm. Serious re

damage can occur and hot material may be ejected from

the weld zone creating a burning hazard.

Power conducting elements may become exposed

creating an electrical shock hazard.

Warning

Warning

Page 7

7

A

B

Multiple Welds

In Primary mode the EF1 can

simultaneously weld up to three

UPP™ ttings, provided that:

• The sum of the resistance values

(circled number on UPP™

ttings) does not exceed 10.

• The UPP™ ttings are

connected to the EF1 in series

using the bridging leads provided

(see photos A & B).

You can ensure that you have

connected the ttings correctly and

that the welds are successful by

checking that all of the connected

ttings get warm and that all of the

indicator pins are exposed at the

end of the welding time. Fusion

ttings with X or no marking may

NOT be welded in series.

Maintenance

• There are no user serviceable parts inside the EF1 welding unit.

• Damaged or defective products should be returned to an approved service agent for

repair or calibration.

• Welding unit and cables should be checked for damage or defects and parts repaired

or replaced prior to each use.

• The welding unit can be cleaned using a soft brush or cloth.

• After use, carefully coil cables and store in the compartments provided in the carry

case.

• Electrical Safety Testing “Portable Appliance Test” (PAT) should be carried out in

accordance with local legislation.

• It is recommended that the welder is returned to Franklin Fueling Systems on a

regular basis, at around 3 year intervals, for checking and recalibrating.

Page 8

8

Fault Indicators

When an error has occurred during the weld cycle that will have an effect on

the success of the joint, the red warning LED on the right side of the display

will light up. Also one of the “weld progress” lights will light up at the same time

to show what type of fault has occurred.

Error

LED

Fault

Indicated

Meaning Solution

1

Power supply

failure during

weld

The power supply was

off at sometime during

the weld

• Check and repair power supply

• Check plug connection

• Check cables are not damaged or

broken

• Re-weld tting only after it is allowed

to cool to ambient temperature

2

Stop button

pressed

during weld

Stop button was

pressed

• Re-weld tting only after it is allowed

to cool to ambient temperature

3

Power supply

out of limits

Supply frequency not

between 40 and 70

Hz, or Voltage not

between 194 & 264V

• Check and rectify generator output

• Check mains supply

• Make sure supply is to required

specication

4

Ambient

temperature

out of range

Temperature of the

EF1 is not between

-15° C (5º F) and

+45° C (113º F)

• Allow EF1 and tting to cool in the

shade

• Wait for ambient temperature to return

to range

5

No output

current

(open circuit)

Loose connection to

terminal pin

Loose contact in the

welding circuit

Faulty tting

Start button not

depressed for long

enough

• Make sure connectors are pushed

rmly on to terminal pins

• Check welding cable connection and

continuity

• Move generator closer and use shorter

extension cord

• Replace tting

• See operating sequence, step 5

6

Low output

current

Resistance value of

tting is too high

Too many ttings

connected in series

(Primary mode only)

Input voltage too low

• Use only UPP™ electrofusion ttings

and correct welding cable

• Check resistance codes on ttings - do

not exceed a sum total of 10

• Check supply voltage

• Check extension leads being used are

to specication

7

High output

current

Regulation error in

electronics

• Switch off machine and switch on

again after 10 seconds.

• Ensure welder is within temperature

range

• If problem persists, return EF1 to

supplier

The EF1 can be reset after a fault has been remedied by pressing and holding

the START / STOP button for 3 seconds.

Page 9

9

According to the European Directive 2008/34/EC

Waste Electrical and Electronic Equipment (WEEE),

when no longer suitable for use, this equipment must

be separately collected and sent for recycling.

According to the European Directive 2008/35/EC

Restriction of Hazardous Substances (RoHS), this

equipment does not contain more than the agreed levels

of Lead, Cadmium, Mercury, Hexavalent Chromium,

Polybrominated Biphenyl (PBB) and Polybrominated

Diphenyl Ether (PBDE) ame retardants.

Declaration of Conformity

This welding unit has been designed to comply with the harmonised standards

under “New Approach” directives and has been CE Marked accordingly.

The applicable standards are:

• 2004/108/EC Electromagnetic compatibility.

• 2006/95/EC Low voltage equipment.

• 98/37/EC Machinery safety.

• 94/62/EC Packaging and packaging waste.

• 2008/34/EC Waste electrical and electronic equipment.

• 2008/35/EC Restriction of hazardous substances.

Disposal

The equipment and packaging should be sorted for

environmentally friendly recycling.

IMPORTANT!

Do not dispose of this equipment into

household waste.

Andrea Ticci Signed on behalf of Franklin Fueling Systems

RoHS Compliant

Directive 2008/

35/ EC

Page 10

10

Page intentionally blank

Page 11

11

Page intentionally blank

Page 12

©FFS 2014 408001010 Rev4

Loading...

Loading...