Franke Foodservice OV1317U-5 Installation Manual

Installation of Franke

Undermount Sinks

METHOD ONE

NOTE: These instructions apply only to:

SURELL BY FORMICA AVONITE (CLASS 1)

CORIAN BY DUPONT FOUNTAINHEAD BY NEVAMAR

For all other polymer based materials, or natural stone countertops,

refer to Installation Method Two following.

• Franke undermount sinks have a highly polished sink rim. To highlight this unique design feature,

our installation system reveals up to 3/8” of the sink rim.

• Franke Kindred Canada accepts no liability for damage to the solid surface countertop, or sink

fixture, during installation.

• Inspect the sink fixture for any shipping damage, prior to installation. Do not install a damaged unit.

• Aesthetics are essential to presentation of the installed sink unit. Take the necessary care to

ensure that the exposed silicone joint is kept to a minimum, the sink is properly aligned to the

cut-out, and excess silicone is cleaned from the sink.

HARDWARE SUPPLIED BY FRANKE KINDRED CANADA

Franke Kindred Canada has supplied within the sink carton: 3 1/2" strainers (waste assembly), a die-cut

corrugated template, homeowner's manual, and a hardware kit. The intention of the hardware kit is to clamp

the sink rim to the underside of the countertop, and backup the silicone seal.

This kit includes the following: Use for Method One Use for Method Two

Machine screws ✔✔

Brackets ✔✔

Thumbscrews ✔✔

Tee nuts ✔

1" diameter PVC discs ✔

Loctite Prism 401 ✔

THE FABRICATOR WILL REQUIRE:

• An assortment of clamps

• A solvent such as methyl hydrate or denatured alcohol

• Silicone sealant

• 1/2" plywood buildup

• 180 grit sandpaper

• Jig saw

• 1 1/2” router guide bushing

• 1/2" straight cutter bit

Franke Kindred Canada Customer Service: 1-866-687-7465 http://ca.franke-ws.com

080831237

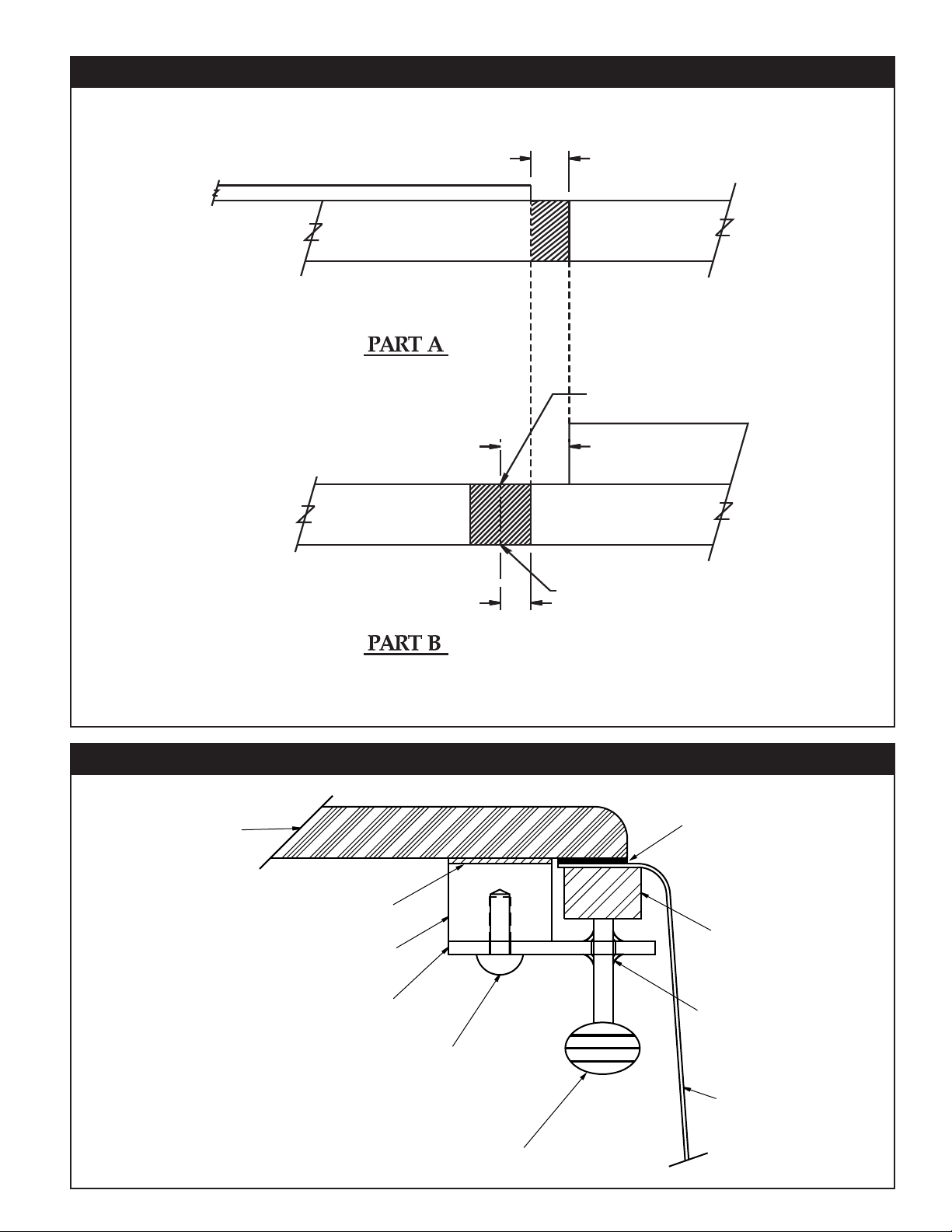

FABRICATOR TEMPLATE PREPARATION

• The die-cut corrugated template supplied by Franke Kindred Canada follows the exact size and shape of the

finished countertop cut-out.

• The cut-out will reveal approximately 3/8" of the mirror finished sink rim.

• We recommend that the corrugated plug template be used to create a female template from 1/2" plywood.

• Scribe a line that is 1/2" offset from the corrugated template onto 1/2" plywood. Cut on this line with a

jig saw. Sand cut-out edge clean and smooth (Figure 1 - Part A).

SINK INSTALLATION PROCEDURE (METHOD ONE)

1. Clamp 1/2" plywood female template on

top surface of countertop, in desired

position. This position will be determined

by relationship of sink rim to cabinet

gables, cabinet supporting members, and

deck mounted fittings.

2. Trace edge of template with router guide

bushing and straight cutter bit

(Figure 1

- Part B).

3. Finish cut-out edge with desired router bit

(ie. chamfer, Roman Ogee etc.).

4. Align sink to cut-out so that a uniform

reveal of approximately 3/8" shows around

the periphery of the cut-out.

Clamp the sink in place.

5. Flip the countertop and sink unit so that the

sink is upside down. Outline the edge of the

sink rim with a pencil line.

6. Remove clamps and sink from countertop.

7. Select position of 1" diameter discs around

rim of sink so that they don't interfere with

cabinet obstructions, or deck mounted

fittings. Discs should be spaced

approximately 12" apart. (Figures 2& 3).

8. Lightly sand bottom of disc and countertop

(beyond pencil line) with 180 grit

sandpaper to prepare for bonding.

9. Remove any sanding residue, and clean

with solvent. Adhesive bond will only be

effective with a clean, oil-free surface.

10.Use Loctite Prism 401 to bond disc to

countertop in desired position. Offset disc

by 1/16" from pencil outline to allow for

any re-alignment of sink.

11.Clean sink rim and countertop mating

surface with solvent.

12.Assemble sink strainers to sink.

13.Apply a continuous (translucent colour)

silicone bead around the sink rim.

(We recommend Dow Corning 786, or

General Electric SCS1700).

14.Position sink within outline of discs.

15.Cut 1/2" thick plywood buildup into 3/4"

strips (length is dictated by the sink rim

dimensions).

16.Lay up plywood strips around the sink rim.

17.Assemble balance of Franke hardware to

discs (Figure 2), and lightly hand tighten

thumbscrews.

18.Flip countertop and sink unit rightside up.

19.Re-align sink to cut-out, if required.

20.Hand tighten all thumbscrews. Take care

not to overtighten and stress countertop.

21.Use additional temporary clamps, if

necessary, to pull sink rim up to countertop

until silicone seal has cured.

22.Use a non-abrasive cloth and solvent to

remove excess silicone that has been

squeezed out beyond the cut-out edge.

Do not use any metal implements that

will scratch the sink.

Residual silicone that has cured on the

sink rim may be removed with Silicone be

Gone®, followed by cleaning with Peek®

to remove any tarnish.

23.Apply silicone to the thumbscrew thread

and bracket joint so that the assembly will

not loosen with vibration.

24.Leave Homeowner's manual at job site for

plumber.

080831237

1 1/2" O.D. COLLAR

(ROUTER GUIDE BUSHING)

COUNTERTOP

CUT-OUT SCRAP

FRANKE CORRUGATED PLUG

3/4"

CUT-OUT SCRAP

1/4"

1/2" STRAIGHT CUTTER BIT

1/2" PLYWOOD

TEMPLATE

1/2" PLYWOOD

T

EMPLATE

1

/2"

1/2" X 3/4" PLYWOOD STRIP

STAINLESS STEEL SINK

THUMBSCREW

PVC DISC

SOLID SURFACE COUNTERTOP

• SURELL

• CORIAN

• AVONITE (CLASS 1)

• FOUNTAINHEAD

BOND DISC TO COUNTERTOP WITH

CYANOACRYLATE ADHESIVE (LOCTITE PRISM 401)

BRACKET

MACHINE SCREW

SILICONE

SEAL SINK FLANGE WITH

SILICONE SEALANT

TEMPLATE PREPARATION (FIGURE 1)

HARDWARE KIT SCHEMATIC (FIGURE 2)

92004

080831237

Installation of Franke

Undermount Sinks

METHOD TWO

NOTE: These instructions apply to installation of

Franke Undermount Sinks with

GRANITE COUNTERTOPS

and any

POLYMER BASED MATERIALS

that are not compatible with the adhesive that has been supplied.

• Franke Undermount sinks have a highly polished sink rim. To highlight this unique design feature,

our installation system reveals up to 3/8” of the sink rim.

• Franke Kindred Canada accepts no liability for damage to the natural stone or solid surface

countertop, or sink fixture, during installation.

• Inspect the sink fixture for any shipping damage, prior to installation. Do not install a damaged unit.

• Aesthetics are essential to presentation of the installed sink unit. Take the necessary care to

ensure that the exposed silicone joint is kept to a minimum, the sink is properly aligned to the

cut-out, and excess silicone is cleaned from the sink.

HARDWARE SUPPLIED BY FRANKE KINDRED CANADA

Franke Kindred Canada has supplied within the sink carton a die-cut corrugated template, 3 1/2" sink

strainers (waste assembly), Homeowner's manual, and hardware kit. The kit is intended to clamp the sink rim

to the underside of the countertop, and backup the silicone seal.

This kit includes the following: Use for Method One Use for Method Two

Machine screws ✔✔

Brackets ✔✔

Thumbscrews ✔✔

Tee nuts ✔

1" diameter PVC discs ✔

Loctite Prism 401 ✔

THE FABRICATOR WILL REQUIRE:

• An assortment of clamps

• A solvent such as methyl hydrate or denatured alcohol

• Silicone sealant

• 1/2" plywood buildup

• 180 grit sandpaper

Franke Kindred Canada Customer Service: 1-866-687-7465 http://ca.franke-ws.com

• Jig saw

• 1 1/2” router guide bushing

• 1/2" straight cutter bit

080831237

Loading...

Loading...