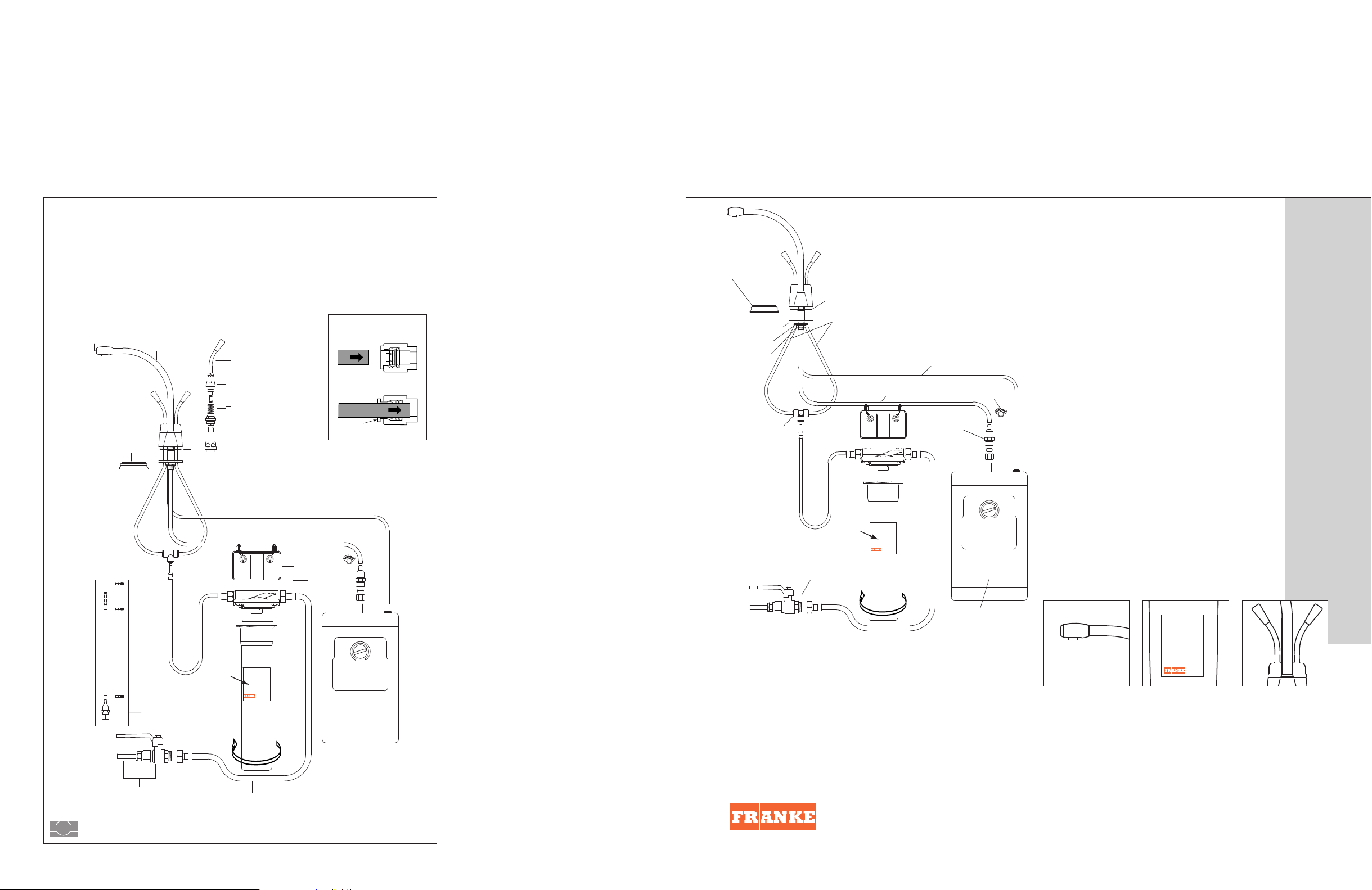

Franke Foodservice LB2000 Installation Manual

Franke Little Butler

Cold Lever Kit - FR 9205*

Hot Lever Kit - FR 9105*

Cold Valve & Seat Set - Fr 9203

Hot Valve & Seat Set - FR 9103

Cover - FR 9101*

Fixing Kit - FR 9107

Optional Base Ring

FRTR 00 - Chrome

FRTR 10 - White

FRTR 90 - Nu Brass

End Cap FR 9108*

Flow Straightener

FR9180

Spout & Shank

FR 9220*

FR 9204

Norprene Tube

Repair Kit - FR 9211

*Where Indicated Specify Color

Bracket

S

ERIAL NUMBER

FR

000000

Franke Triflow

FR9629

FR9623

FR 9628

FR9622

FR9136

FR9627

Serial

Number

Location

O Ring Seal

Inlet Tubes

12" Long

On LB2000 Series,

Base Ring only

supplied on the

following models:-

LB2009

LB2019

LB2089

Clamp Plate

L

ock Washer

Backnut

Tube To Heater

1

8" Long

Norprene Tube From

Heater 18" Long

Bracket

Hose Clip

Hose

Connector

1/4" T Connector

Push Fit

3/8" Supply Tube

Shut Off Valve

Heating Tank

Serial

Number

Location

SERIAL NUMBER

FR

0

00000

Franke Triflow

Bracket

Flow

Plastic 3/8" to Hose

connector PCAID

Hose Clip

Metal Tube To Heater

18" Long

Clear Rubber Tube

18" Long

SERIAL NUMBER

FR

000000

Franke Triflow

Gray Collar

US

Katadyn

Katadyn

Franke Little Butler

Spare Parts & Warranty

Spare Parts

For out-of-warranty maintenance and repairs, other than routine cartridge

changes, we recommend you employ a Registered Plumber.

Before ordering spare parts, determine the correct reference number from the

exploded diagram. Quote this number, and where appropriate, the color of your

faucet

Diagram B

ush Fit Connections

P

Katadyn of Switzerland

Exclusive suppliers of Filter Cartridgesfor Franke Triflow

Limited Warranty

ongratulations on the purchase of a Franke product.

C

anke is one of the world’s largest manufacturers of

Fr

itchen systems. Our products are manufactured using

k

st degree of technology quality and design. As

the highe

esult we are proud to offer the following warranty.

a r

Franke inc. Kitchen Systems Division, warrants the

quality of its water dispensing systems to be free from

manufacturing defects for a period of

date of purchase.

This warranty applies only to the original owner,

g the product has been installed in accordance

providin

ith our installation instructions, used as recommended

w

and in a norm

a warranty claim, the owner will be required to provide

proof of purchase. This warranty covers all components

necessary to restore the product to good working

condition. Franke reserves the right to inspect the

installation prior to the replacement of the product or

component part.

This warranty does not cover misuse or abuse,

accidental damage, scuffs or scratches, abnormal

usage, negligence or damage caused by improper

maintenance or cleaning. Normal wear of parts is

excluded from warranty. Damage caused by impurities

or acts beyond our control are not covered. Any product

or part which has been repaired or altered in any

manner outside of Franke’s factory, unless previously

authorized in writing by Franke, willvoid warranty.

l

ep

r

installation costs. This warranty does not allow

recovery of incidental or consequential damages such

as loss of use, delay, property damage or other

consequential damage, and Franke accepts no liability

for such damages.

The Franke warranty is limited to the above condition

and to the warranty period specified herein and is

clusive. Franke

x

e

expressed or implied, including the IMPLIED

WARRANTIES OF MERCHANTABILITY AND/OR FITNESS

FOR

specific legal rights which may vary from state to state.

at

Wh

complete the product registration card and mail directly

within two weeks of the installation date. Failure to do

so m

Cartridge life will depend upon input water quality,

s

e

pr

warranty. All projections are estimates and are not

guarantees of any particular level or range of

f

per

al residential application. In the event of

acement excludes transportation and anylabor re-

DISCLAIMSal

PARTICULAR PURPOSE.

A

ou must do:

y

void this warranty.

y

a

ure and usage rates and is not covered by this

s

e or product life.

anc

orm

The p

c

ur

five years from the

other warranties,

l

warranty gives you

s

Thi

haser should promptly

Any

904003

Franke Consumer Products Inc

chen Systems Division

Kit

3050 Campus Drive, Suite 500

A19440

d, P

Hatfiel

A

US

Phone +1 215 822 6590

Fax +1 215 822 5873

fks.filter@franke.com

www.frankeksd.com

Installation and User Guide

Hot and Cold Water Dispensing System

Model Series LB2000

Please register this product

You can register your Franke Little Butler in the following

ays:

w

omplete the registration card enclosed or

l C

s.filter@franke.com

l: fk

ai

l Em

eksd.com

ank

line: www

l On

l Phone: +1 215 822 6590

ax: +1 215 822 5873

l F

.fr

Franke Little Butler

Franke Little Butler

Installation, Care and Maintenance

Overview of the System Concept

For safety reasons, this hot water dispensing system features a

“non pressurized” heating tank. This means that the incoming

water is first routed through the valve in the dispensing head,

where line pressure feeding the system terminates. When the

valve is activated, water is directed down to feed the inlet at the

top of the heater tank, displacing heated water up through the

spout. When the valve is off, the tank is open to atmosphere

(via the spout), making it impossible for the tank to be

subjected to stress from an overheating condition.

Overview of Installation

There are three main components to the system, the dispensing

head, the filter and the heating tank. The Dispensing head

comes with three 1/4” copper tubes and one “Norprene” tube.

The two shorter (12”) copper tubes are connected to the

incoming water supply via the filter. The supply to the cold side

may be diverted through a chiller before the dispensing head if

required. The longer (18”) copper tube is connected to the inlet

of the tank. The “Norprene” tube is connected to the outlet of

the tank using the hose connector.

Preparing for the Installation

As with any sink related device, it is much easier to mount the

dispensing head of this system onto the sink before the sink is

mounted into the countertop. A mounting hole of 1

diameter (standard sink ledge drilling) is required.

It is always recommended to take the components and locate

their optimum positions before starting the installation. This

particularly applies to the heating tank as it must be positioned

for the connections to the dispensing head, while at the same

g other mec

oidin

time av

oducts, a hot water dispenser includes an electrical

g pr

in

lumb

p

system. The heating tank is furnished with a grounded power

d and plug. A grounded non-switchable outlet for this

or

c

connection must be provided beneath the sink.

IMPORTANT: Do not plug in the unit until all water connections

have been made and the tank is filled completely.

Making the Supply Provision

Provide a branch compression connection for a

tube. This should be done with a conventional tee and the

shut-off valve provided. Flush the pipework before installing.

nting the Dispensing Head

Mou

s

ube

per t

op

The c

straightened before installation. Position the base ring (if

lied) and O ring and feed the tubes and shank through the

p

up

s

hole in the sink ledge or counter. Assemble the clamp plate

locking washer and backnut (hexagon to the top for thin sinks)

fingertight. Turn the dispensing head and the spout until the

handles and spout are in the required position for use and fully

tighten the backnut, thi

Mounting the Heating Tank

The heating tank must be located on a back or side wall below

the sink, space will be needed underneath the tank for access

hanics under the sink. Unlike most

are coiled for packing and must be carefully

s will lock the spout in position.

3

/

” supply

8

3

/

”

8

to the drain plug. Determine the best position to enable the

tubing connections to be made and mark the position for the

mounting bracket (approximately 2” below the top of the tank).

Attach the mounting bracket to the wall and hang the tank in

position.

IMPORTANT: During installation the tank should remain

unplugged with the thermostatic control in the “off” position.

The tank must be filled with water before power is connected.

A “dry start” will void the warranty (see “Fill the System”). DO

NOT connect this product to the mains water supply, where the

supply pressure exceeds 100psi (7 bar). If in any doubt, please

ask your registered plumber to check the water pressures.

Failure to comply will invalidate the product warranty.

Filter System Installation

1 Make sure to remove any protective packing from

around the cartridge and remove the plastic plugs from

the inlet and outlet of the filter cap.

Please note: The cartridge is fragile and may break if

mishandled or dropped.

2 Undo the two halves of the filter housing. Hold Cap

whilst pressing down on the safety clip and unscrew

Housing a quarter turn in the direction of the arrow

shown. Place housing to one side.

3 Wet the two ‘O’ seals on the threaded end of the new

cartridge, then screw it firmly into the female thread in

the Cap.

4 Fit Cap and Housing back together and turn a quarter

turn in the opposite direction of the arrow shown to

lock.

ition the s

s

o

5 P

water supply.

6 Position the filter to allow easy access for future

cartridge changes.

7 P

o

sition the tubes neatly to avoid side strain and the

sibility of accidental damage.

s

po

8 Water must flow through the filter in the direction of the

arrow on the top of cap.

or optimum filter performance use the stop valve to set

9 F

ed w

er

lt

the fi

liters/min).

10 Check system carefully for leaks.

se

a

e

11 Pl

local plumbing codes.

you need to remove the hose from the push fit

12 If

connector, (see diagram B) use your thumb and

forefinger to hold in the collar while gently pulling the

tube out.

Fill the System - DO NOT PLUG IN YET

urn on the shut off valve. Operate the hot lever on the

T

dispensing head and hold down until water flows from the end

en

ur

s

op valve to allow easy access to turn off

t

3

w to

er flo

at

e

at

th

the in

2

/4 - 3 1/2 pint

allation complies with the

t

s

s/min (1

1

/2 - 2

Installation, Care and Maintenance

of the spout. This will take a little while as the tank (capacity

two quarts) and the filter housing has to be filled. Operate the

cold lever on the dispensing head and hold down until water

flows from the end of the spout. Check all connections. Check

for leaks.

Plug in and Turn On

Plug in to electrical supply and turn control to ‘ON’. Depending

on the temperature of the incoming water it will take from 10 to

15 minutes for the water to reach it’s optimum, near boiling,

temperature. A ‘perking’ sound from the tank and water

dripping from the spout near the end of each heating cycle is

normal.

IMPORTANT ELECTRICAL REQUIREMENTS: Do not under any

circumstances, remove the power supply grounding prong. For

your personal safety, this appliance must be grounded. This

appliance is equipped with a power supply cord having a three

prong grounding plug. To avoid possible shock hazard, the cord

must be plugged into a mating three prong grounding type wall

receptacle. A 15 or 20 Amp circuit is acceptable. If a mating

wall receptacle is not available, it is the personal responsibility

and obligation of the customer to have a properly grounded

three prong wall receptacle installed by a qualified electrician.

An extension cord should not be used with this appliance, such

use may result in a fire, electrical shock or other personal

injury.

Seasonal Shutdown

If you plan to be away from home for extended periods, or

the filter housing may be subject to the risk of freezing, the

following procedure must be carried out:

Turn the heating tank thermostat control to "off" and

1

lug the el

np

u

2 Operate the hot lever until the water runs cold.

3 Shut-off the mains water supply. A stop valve was

lied w

p

up

s

found located on the adjacent pipe work.

4 Operate both levers to confirm that the water supply is

turned off, and to release the pressure in the system.

ition a s

s

o

P

5

from the housing. Lift the filter unit from its retaining

bracket. Holding Cap, press down on the safety clip and

unscrew Housing a quarter turn in the direction of the

arrow shown. Lower housing from filter cartridge.

Position cap back onto its retaining bracket and allow

water to drain from filter, as it remains saturated.

our w

P

6

water and then rinse well. Place to one side.

7 Disconnect the supply tube from the shut off valve and

place end into receptacle.

8 Disconnect filtered water tube from outlet of filter cap

lace end into receptacle.

and p

9 Position a suitable receptacle underneath the heating

ectrical supply.

ith the system for this purpose, and will be

able receptacle to catch residual water

uit

ater away from Housing, wash in warm soapy

tank. Remove the drain plug from the underside and

allow the heating tank to drain.

10 Operate both levers to drain water from the faucet.

11 Replace drain plug into bottom of heating tank,

reconnect the supply tube to the shut off valve and

reconnect the filtered water tube to the filter cap.

12 Fit Cap and Housing back together and turn a quarter

turn in the opposite direction of the arrow shown to

k.

loc

13 When the risk of freezing subsides and you wish to use

the system again, open the mains supply to the filter.

Run the filtered water for 2 minutes to flush the system

and check carefully for leaks. The system should now be

ready for use.

the product warranty.

DO NOT PLUG IN ELECTRICAL SUPPLY WHILE THE TANK IS EMPTY

Troubleshooting

Should your dispenser not work correctly, check the list below

before calling for service. The following things are not covered

by the warranty.

[WARNING! Do not operate both levers at the same time as this

can build up pressure in the heating tank causing the bladder

to expand and eventually burst. Such damage is not covered

by the warranty]

Water is not hot:

Check if electrical supply to heating tank is plugged in.

Turn temperature control knob clockwise as far as possible.

t the temperature again after 15 minutes.

s

e

T

if fuse is blown or circuit breaker is open.

k

Chec

ater continuously drips or sputters from spout:

w

Hot

For safety reasons this Faucet may drip or splutter after use.

This venting prevents a build-up of pressure in the heating tank.

If this becomes excessive;

T

urn the c

Chec

not kinked.

Chec

necessary.

Water does not flow:

Chec

Chec

Check the condition of the filter and clean or replace if

nec

at

W

Lower temperature setting.

lowering of the thermostat setting does not stop the boiling,

If

unplug the power supply cord and contact an authorized

service office.

lt

Fi

i

It

monthly intervals.

ontrol knob counter-clockwise to lower temperature.

the tubes connecting the faucet to the storage tank are

k

k the condition of the filter and clean or replace if

k the shut off valve is open.

ly tube is kinked.

p

up

s

if

k

ssary.

e

or vapor appears:

s

l

er boi

er renewal

ommended th

ec

r

s

Allowing the unit to freeze will invalidate

at the filter cartridge is changed at six-

Loading...

Loading...