Franke Foodservice FGC 906 XS Installation Manual

EN

1

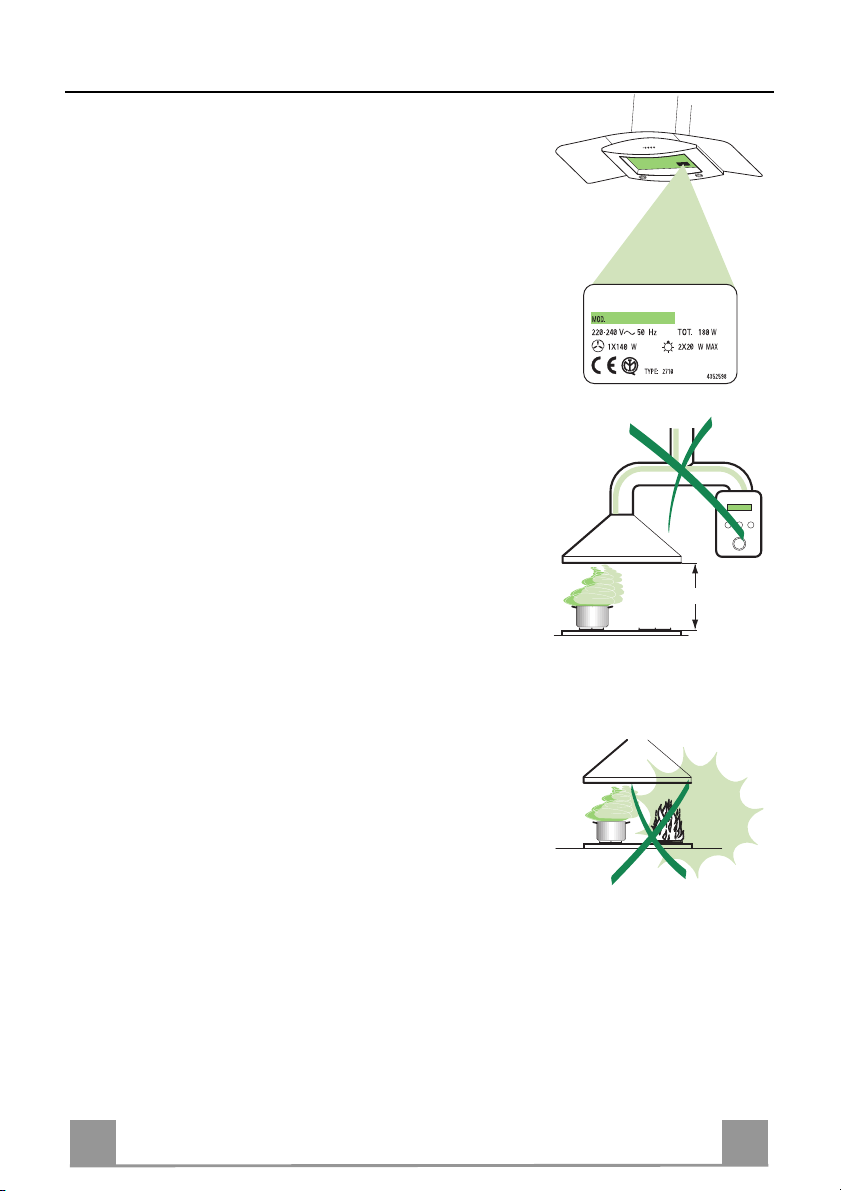

RECOMMENDATIONS AND SUGGESTIONS

650 mm min.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances

(e.g. gas burning appliances), a sufficient degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directly with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designed exclusively for domestic use to

eliminate kitchen smells.

• Never use the hood for purposes other than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• The hood should not be used by children or persons not instructed in

its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

14

EN

1

300

490

265

254

107.5

150

545

80

598 / 898

ø150

ø120

51

70

572

min. 730

max. 1000

650 min.

253

63

4181

126

2.1

2.2

2

12c

12a

7.2.1 11

11

12a

9

7.3

14.1

15

1

1

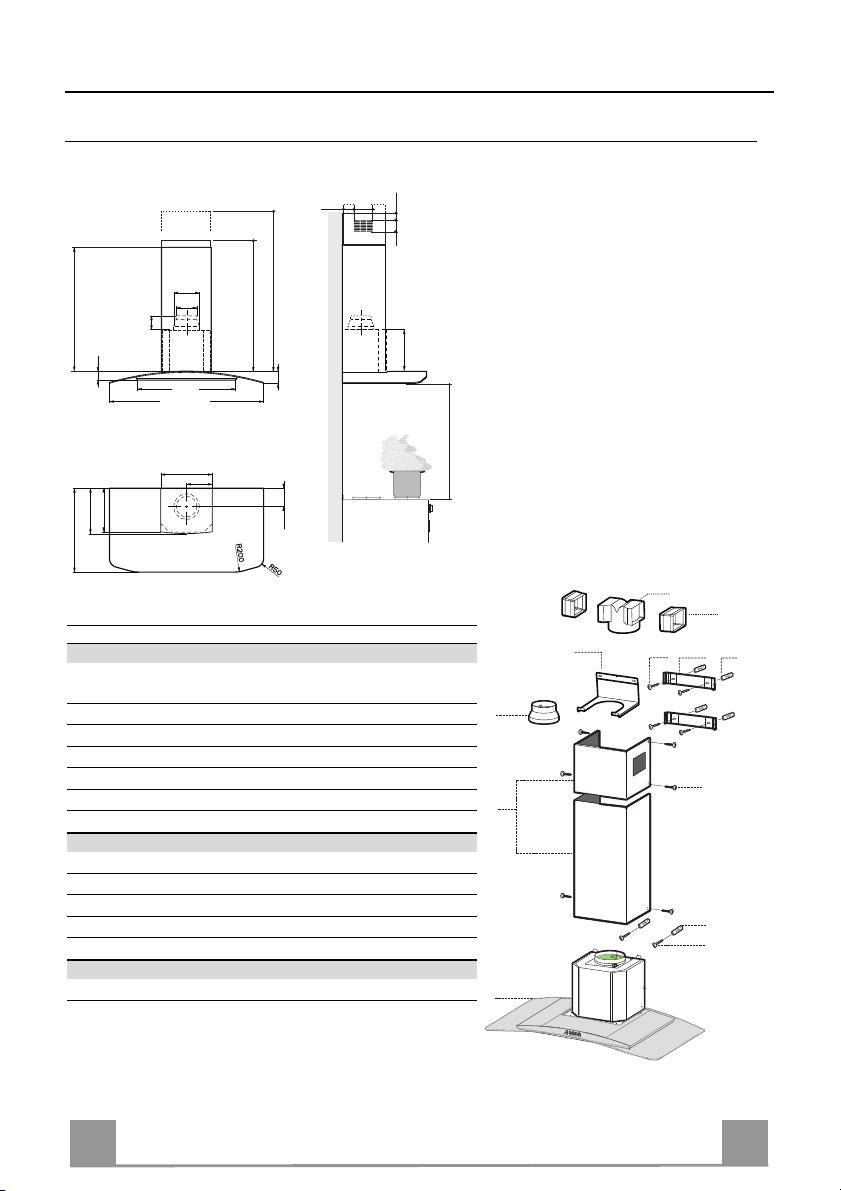

CHARACTERISTICS

Dimensions

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

9 1 Reducer Flange ø 150-120 mm

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

Ref. Q.ty Installation Components

7.2.1 2 Upper Chimney Section Fixing Brackets

7.3 1 Air Outlet Connection Support

11 6 Wall Plugs

12a 6 Screws 4,2 x 44,4

12c 6 Screws 2,9 x 9,5

Q.ty Documentation

1 Instruction Manual

Filters

15

EN

1

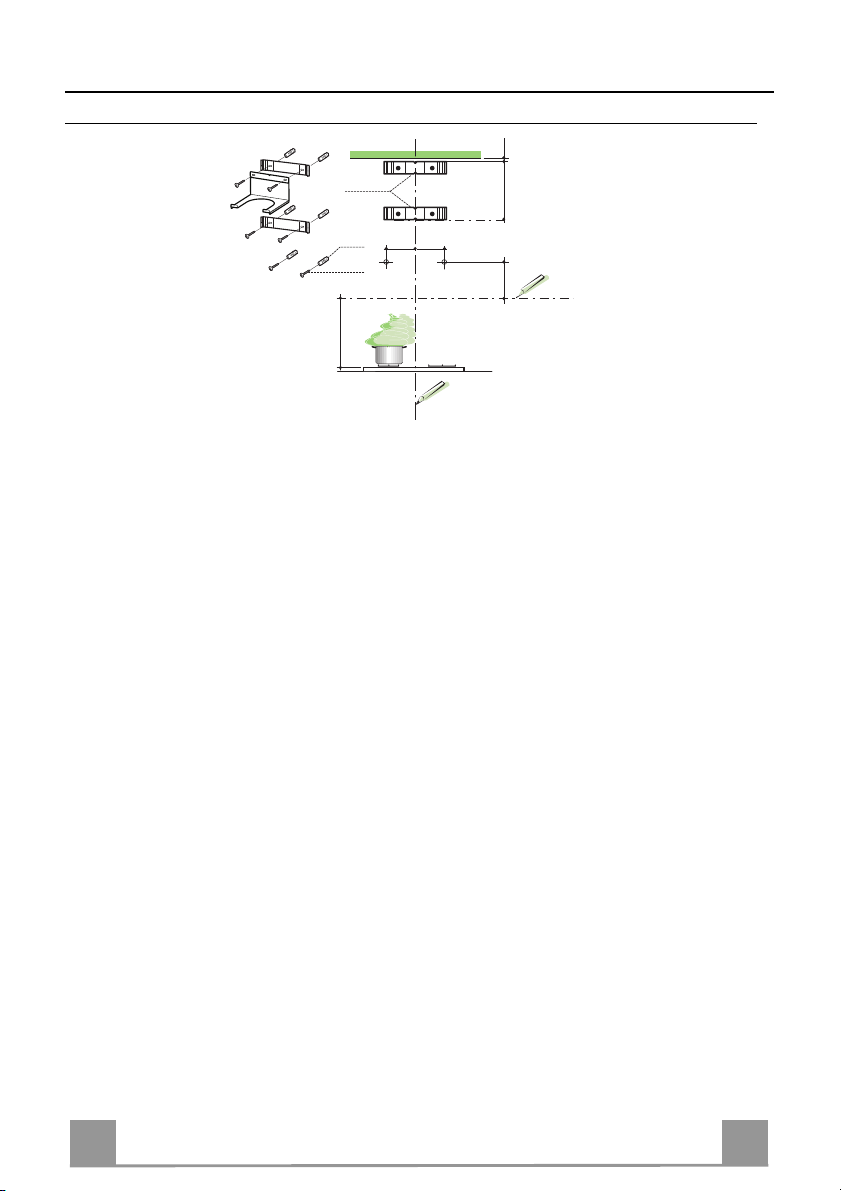

INSTALLATION

11

12a

310

X

116

1÷2

116

650 min.

7.2.1

Wall drilling and bracket fixing

Wall marking:

• Draw a vertical line on the supporting wall up to the ceiling, or as high as practical, at the

centre of the area in which the hood will be installed.

• Draw a horizontal line at 650 mm above the hob.

• Place bracket 7.2.1 on the wall as shown about 1-2 mm from the ceiling or upper limit aligning the centre (notch) with the vertical reference line.

• Mark the wall at the centres of the holes in the bracket.

• Place bracket 7.2.1 on the wall as shown at X mm below the first bracket (X = height of the

upper chimney section supplied), aligning the centre (notch) with the vertical line.

• Mark the wall at the centres of the holes in the bracket.

• Mark a reference point as indicated at 116 mm from the vertical reference line and 310 mm

above the horizontal reference line.

• Repeat this operation on the other side.

• Drill ø 8 mm holes at all the centre points marked.

• Insert the wall plugs 11 in the holes.

• Fix the lower bracket 7.2.1 using the 12a screws (4,2 x 44,4) supplied.

• Fix the upper bracket 7.2.1 and the air outlet connection support 7.3 together using the 2

screws 12a (4,2 x 44,4) supplied.

• Insert the two screws 12a (4,2 x 44,4) supplied in the hood body fixing holes, leaving a gap

of 5-6 mm between the wall and the head of the screw.

16

Loading...

Loading...