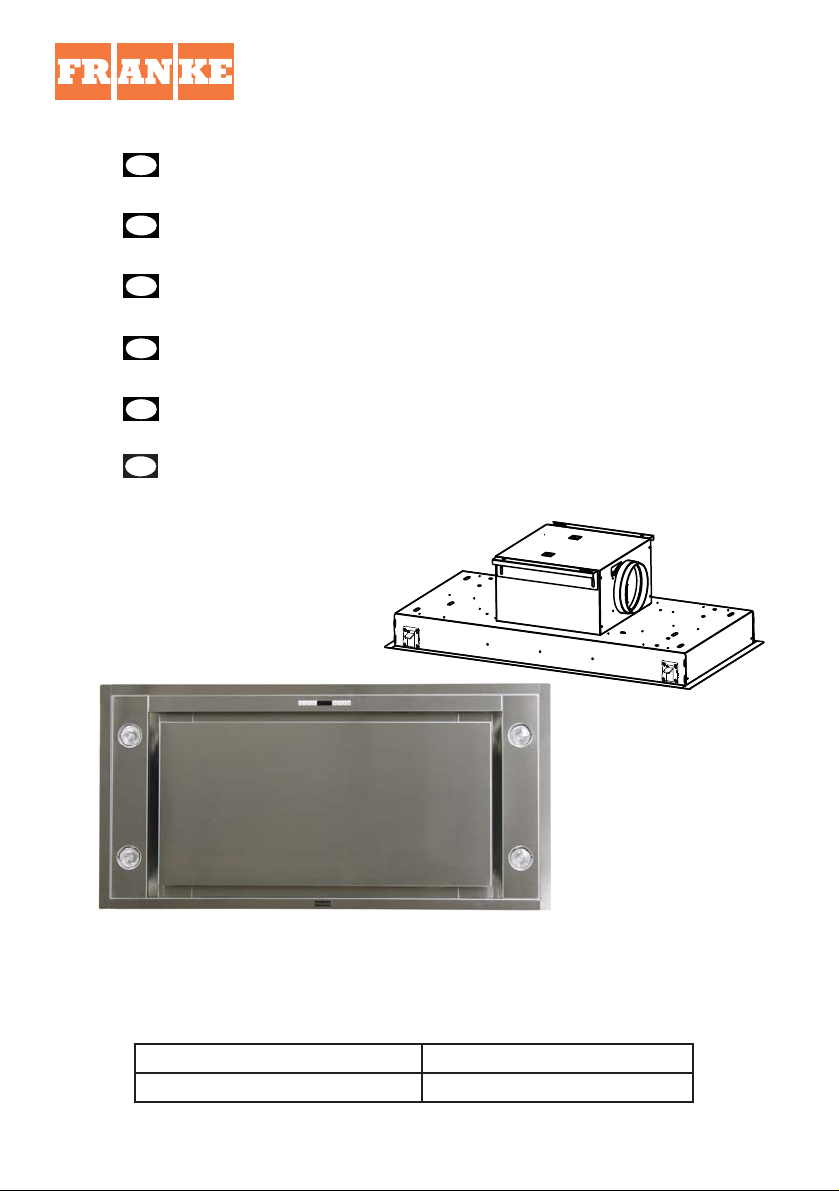

Franke Foodservice FGAS E FX 1400 CE XS WM Installation Manual

Mode d’emploi et installation

FR

Hotte de Cuisine

Instructions for use and installation

GB

Cooker Hood

Bedienungsanleitung und Einrichtung

DE

Dunstabzugshaube

Istruzioni per l’uso e l’installazione

IT

Cappa

Instrucciones de instalacion e utilizacion

E

Campana

Instructies voor het gebruik en installeren

NL

Dampkap

Galaxy Slim Energy FX

110.0180.538 FGAS E FX 1000 CE XS

110.0180.561 FGAS E FX 1400 CE XS WM

F SOMMAIRE

GB CONTENTS

RACCORDEMENT ÉLECTRIQUE

CONSEILS D’INSTALLATIONS

POSE DE L’APPAREIL

FONCTIONNEMENT

CONSEILS D’UTILISATIONS

ENTRETIEN

GARANTIE ET SERVICE APRÈS-VENTE

REMARQUES

D INHALT

NETZANSCHLUSS

MONTAGEHILFEN

MONTAGE DES GERÄTES

BETRIEB DES GERÄTES

NUTZUNG

WARTUNG UND REINIGUNG

GARANTIE UND KUNDENDIENST

WICHTIGE HINVEISE

ELECTRICAL WIRING

INSTALLATION ADVICE

FITTING THE APPLIANCE

OPERATION

USEFUL HINTS

MAINTENANCE

GUARANTEE AND AFTER-SALES-SERVICES

REMARKS

I CONTENUTI

COLLEGAMENTO ELETTRICO

CONSIGLI DI INSTALLAZIONE

POSA DELL’ APPARECCHIO

FUNZIONAMENTO

CONSIGLI DI UTILIZZO

MANUTENZIONE

GARANZIA ED ASSISTENZA TECNICA

NOTE

E SUMARIO

CONEXION ELECTRICA

CONSEJOS DE INSTALACION

INSTALACION DEL APARATO

FUNCIONAMIENTO

CONSEJOS DE UTILIZACION

MANTENIMIENTO

GARANTIA Y ASSISTENCIA TECNICA

NOTA

NL INHOUD

ELECTRISCHE BEDRADING

MONTAGE AANWIJZING

AANSLUITEN VAN HET APPARAAT

FUNKTIONEREN

GEBRUIKSADVIES

ONDERHOUD

AFTER SALES SERVICE

OPMERKINGEN

GB

Thank you for buying a FRANKE product which has been manufactured to the highest quality standards

to meet your requirements.

We recommend you carefully read this booklet in which you will nd instructions for installation, hints for

use and maintenance.

The Instructions for Use apply to several versions of this appliance. Accordingly, you may nd descriptions of individual features that do not apply to your specic appliance.

With this kit it is possible to place the blower of the kitchen hood to a remote position inside the house.

Installation of the kit must be carried out by qualied staff, following all the rules given by the relevant

authorities concerning the exhaust air ducting. The manufacturer will not be liable for any damages

resulting from incorrect or from improper installation.

1 ELECTRICAL

• This cooker hood is tted with a 3-core mains cable with a standard 10/16A earthed plug.

• Alternatively the hood can be connected to the mains supply via a double-pole switch having 3mm

minimum contact gap on each pole.

• Before connecting to the mains supply ensure that the mains voltage corresponds to the voltage on

the rating plate inside the cooker hood.

• Technical Specication: Voltage 220-240 V, single phase ~ 50 Hz / 220 V - 60Hz.

2 INSTALLATION ADVICE

• Ensure the cooker hood is tted in compliance with the recommended xing heights: 150cm maximum.

• To ensure the safe operation of this cooker hood, we recommend that the hood should not be tted

below 65cm (for electric) or (70cm for gas) the measurements taken from the surface of the cooking

appliance to the underside of the cooker hood.

• It is a possible re risk if the hood is not sited as recommended.

• To ensure the best results, the cooking fumes should be able to rise naturally towards the inlet grilles

on the underside of the cooker hood and the cooker hood should be positioned away from doors and

windows, which will create turbulence.

• Ducting

• If the room where the hood is to be used contains a fuel-burning appliance such as a central heating

boiler then its ue must be of the room sealed or balanced ue type.

• If other types of ue or appliances are tted ensure that there is an adequate supply of fresh air to

the room. Ensure the kitchen is tted with an airbrick, which should have a cross-sectional measurement

equivalent to the diameter of the ducting being tted, if not larger.

• The ducting system for this cooker hood must not be connected to any existing ventilation system,

which is being used for any other purposes or to a mechanically controlled ventilation ducting.

• The ducting used must be made from re retardant materials and the correct diameter must be used,

as incorrect sized ducting will affect the performance of this cooker hood.

• When the cooker hood is used in conjunction with other appliances supplied with energy other than

electricity, the negative pressure in the room must not exceed 0.04 mbar to prevent the fumes from

combustion being drawn back into the room.

• The appliance is for domestic use only and should not be operated by children or people who are

inrm without supervision.

• This appliance must be positioned so that the wall socket is accessible.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

3 FITTING

Any permanent electrical installation must comply with the latest regulations concerning this type of installation and a qualied electrician must carry out the work. Non-compliance could cause serious accidents

7

GB

or injury and would deem the manufacturers guarantee null and void.

IMPORTANT - The wires in this mains lead are coloured in accordance with the following code :

green / yellow : earth blue : neutral brown : live

As the colours of the wires in the mains lead of this appliance may not correspond with the coloured

markings identifying the terminals in your plug, proceed as follows.

- The wire which is coloured green and yellow must be connected to the terminal in the plug which is

marked with the letter E or by the earth symbol

- The wire which is coloured blue must be connected to the terminal which is marked with the letter N

or coloured black.

- The wire which is coloured brown must be connected to the terminal which is marked with the letter

L or coloured red.

ATTENTION: Do not forget to use adequate plugs to the support brackets. Enquire after the manufacturers. Do an embedding if necessary. The manufacturer accepts no responsibility in case of a

faulty hanging due to the drilling and the setting up of plugs in the ceiling.

1) Unpack the hood parcel.

• FIXING BY THE STRUCTURE : LAYING OUT BEFORE FITTING THE HOOD

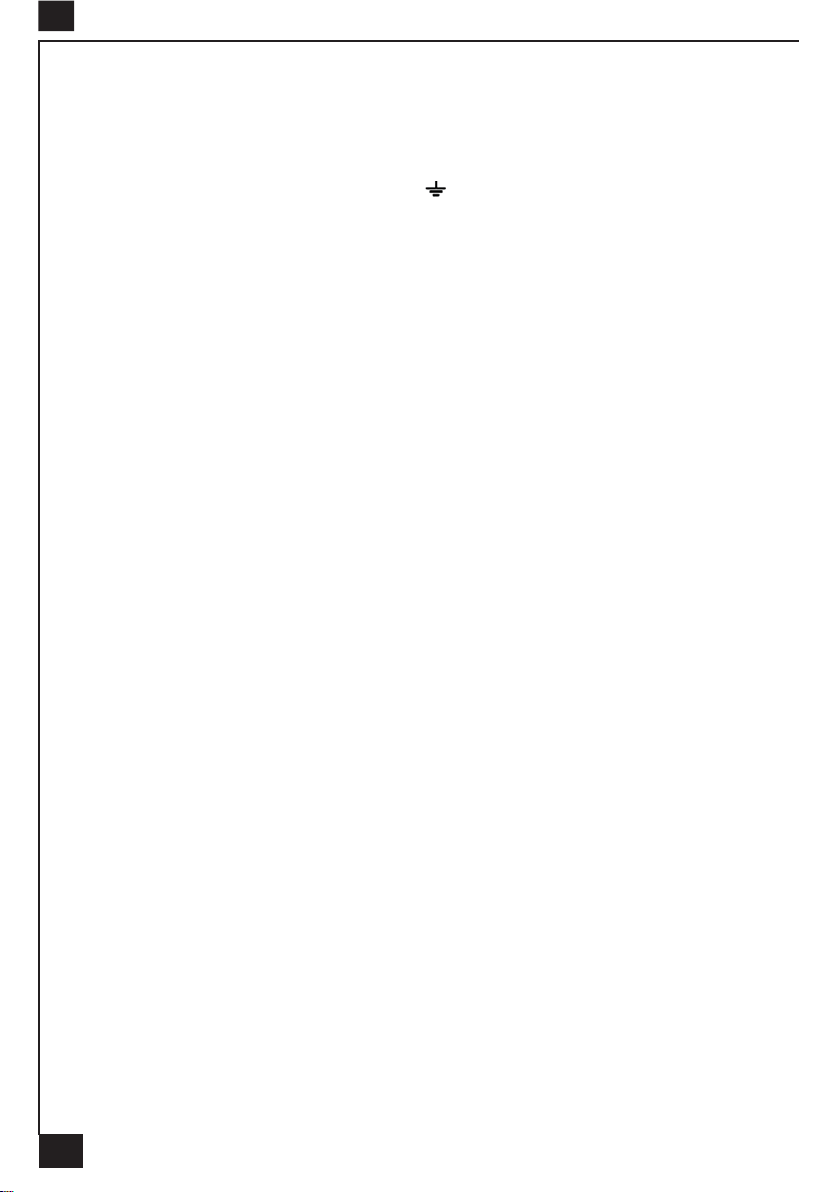

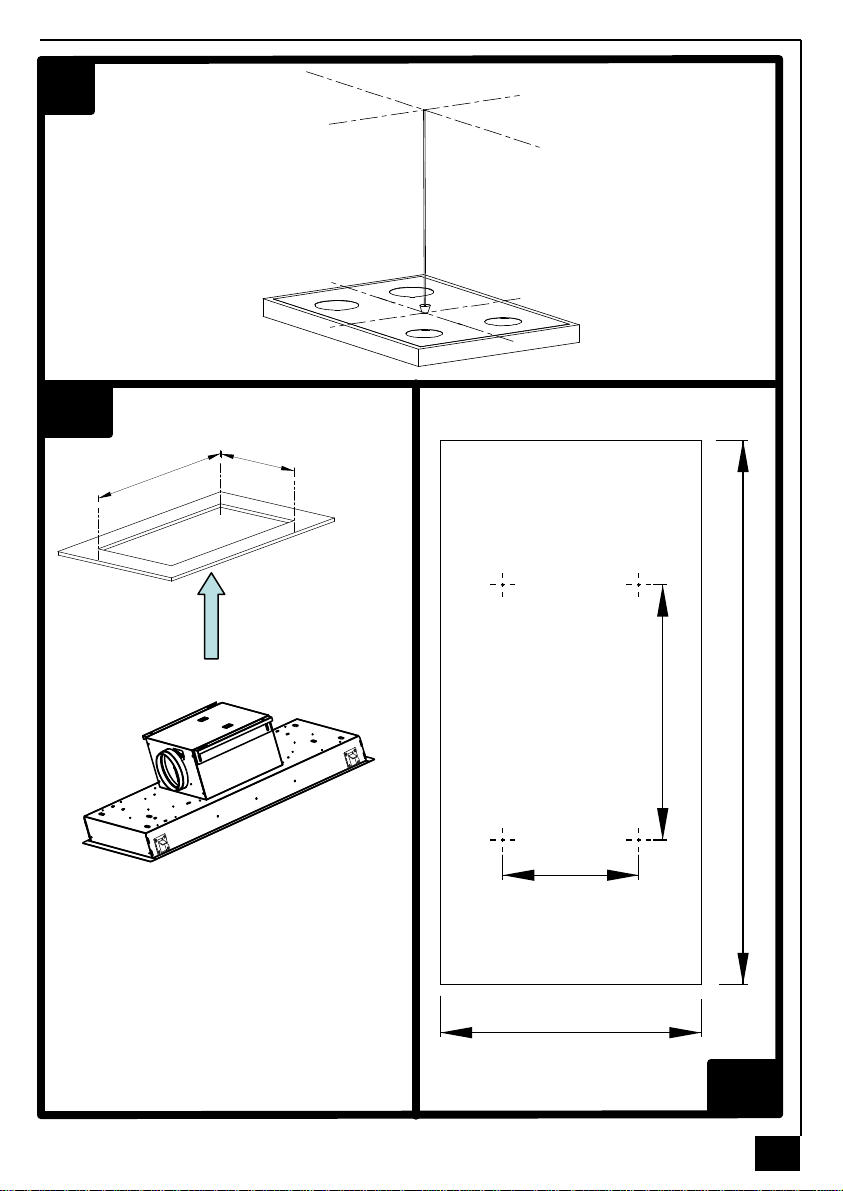

2) Mark the centre of the cooking appliance onto the ceiling with a plumb line. Draw the horizontal axes

running parallel to the stove top onto the ceiling as illustrated Fig. 1.

3) To carry out the cutting of embedding in the suspended ceiling (Fig 2a).

4) To mark the centers of different drillings to be carried out on the ceiling. (Fig 2b)

5) Drill the different holes with the appropriate masonry bit :

- The cut-out for the ducting Ø 150 mm in the extraction

mode when ducting runs through the ceiling.

- The mains supply cords.

- The 4 xing holes for Ø 10 mm nuts and bolts.

When xing the cooker hood to a plasterboard ceiling ensure it is reinforced as illustrated in Fig. 3 and

attach using four Ø10mm nuts and bolts; ensuring the bolts as sleeved between the plasterboard and the

joist supports to prevent the ceiling being damaged when the bolts are tightened up.

If the ceiling is concrete, use eight Ø 10 mm steel rawl bolts. Plastic rawl plugs must not be used. Fit the

motor housing (Fig. 4): 4 positions with 90°.

6) To adjust the height of the motor housing: 20 mm of adjustment (Fig. 5).

7) Open the deector ( Fig. 6 Rep. 12) by pushing / unlocking (Fig. 14).

8) To remove the metal lters.

• DUCTING

The hood is more effective when used in the extraction mode (ducted to the outside). When the cooker

hood is ducted to the outside, charcoal lters are not required.

The ducting used must be 150 mm (6 INS), rigid circular pipe and must be manufactured from re retardant material, produced to BS.476 or DIN 4102-B1. Wherever possible utilise rigid circular pipe which has

a smooth interior, rather than the expanding concertina type ducting.

Maximum length of ducting run:

- 4 metres with 1 x 90° bend.

- 3 metres with 2 x 90° bends.

- 2 metres with 3 x 90° bends.

The above assumes our 150 mm (6 INS) ducting is being installed. Please note ducting components and

ducting kits are optional accessories and have to be ordered, they are not automatically supplied with the

chimney hood.

IN THE EXTRACTION MODE:

a- Fit the non-return backow aps C over the round outlet item 6 on top of the canopy while pressing

down until they snap into position, and then connect the ducting 150mm (6 INS) and secure the connections with appropriate clamping rings or adhesive tape (Fig. 8).

b- Make the electrical connection of the motor as described in the section titled ELECTRICAL.

c- Place the canopy under the motor housing and x it with the screws provided as illustrated in Fig. 10.

Attention: 2 persons are necessary to secure this operation..

d- Connect the electrical plug of the motor cord on the body hood (Fig.7).

or coloured green or green and yellow.

8

GB

e- Check the connectors of the motor (Fig 9).

f- Test the lights and the fan motor.

g- Fit the metal grease lters and close the deector.

IN THE RECIRCULATION MODE:

a- To carry out an inlet for recycling air in the kitchen (Fig.11).

b- Connect the ducting 150mm (6 INS) not provided between motors item 6 and the recirculation spigot

and secure the connections with appropriate clamping rings or adhesive tape (Fig. 12).

c- Make the electrical connection of the motor as described in the section titled ELECTRICAL.

d- Place the canopy under the motor housing and x it with the crews provided as illustrated in Fig. 10.

Attention: 2 persons are necessary to secure this operation.

e- Connect the electrical plug of the motor cord on the body hood (Fig.7).

f- Check the connectors of the motor (Fig 9).

g- Test the lights and the fan motor.

h- Fit the charcoal lter onto the inlets of the motor (Fig. 13).

i- Fit the metal grease lters and close the deector.

• CLIPPAGE ON THE FALSE CEILING

2) Mark the centre of the cooking appliance onto the ceiling with a plumb line. Draw the horizontal axes

running parallel to the stove top onto the ceiling as illustrated Fig. 1.

3) To carry out the cutting of embedding in the suspended ceiling (Fig 2a).

4) To remove the lighting front panel (Fig. 15).

5) To unscrew the screws of the clips according to the thickness of the false ceiling (Fig. 16). When xing

the cooker hood to a plasterboard ceiling ensure it is reinforced as illustrated in Fig. 17. For the false

ceiling in MDF of 18 mm, 4 holds of compensation (2 mm thickness) are provided with the hood.

6) Open the deector ( Fig. 6 Rep. 12) by pushing / unlocking (Fig. 14).

7) To remove the metal lters.

IN THE EXTRACTION MODE:

a- Fit the non-return backow aps C over the round outlet item 6 on top of the canopy while pressing

down until they snap into position, and then connect the ducting 150mm (6 INS) and secure the connections with appropriate clamping rings or adhesive tape (Fig. 8).

b- Make the electrical connection of the motor as described in the section titled ELECTRICAL.

c- Place the canopy under the motor housing and x it with the screws provided as illustrated in Fig. 10

or clip the hood on the false ceiling (Fig. 15), to tighten the screws (Fig. 16) and to t back the lighing

front panel.

Attention: 2 persons are necessary to secure this operation..

d- Connect the electrical plug of the motor cord on the body hood (Fig.7).

e- Check the connectors of the motor (Fig 9).

f- Test the lights and the fan motor.

g- Fit the metal grease lters and close the deector.

IN THE RECIRCULATION MODE:

a- To carry out an inlet for recycling air in the kitchen (Fig.11).

b- Connect the ducting 150mm (6 INS) not provided between motors item 6 and the recirculation spigot

and secure the connections with appropriate clamping rings or adhesive tape (Fig. 12).

c- Make the electrical connection of the motor as described in the section titled ELECTRICAL.

d- Place the canopy under the motor housing and x it with the screws provided as illustrated in Fig. 10

or clip the hood on the false ceiling (Fig. 15), to tighten the screws (Fig. 16) and to t back the lighing

front panel.

Attention: 2 persons are necessary to secure this operation.

e- Connect the electrical plug of the motor cord on the body hood (Fig.7).

f- Check the connectors of the motor (Fig 9).

g- Test the lights and the fan motor.

h- Fit the charcoal lter onto the inlets of the motor (Fig. 13).

i- Fit the metal grease lters and close the deector.

9

GB

4 OPERATION

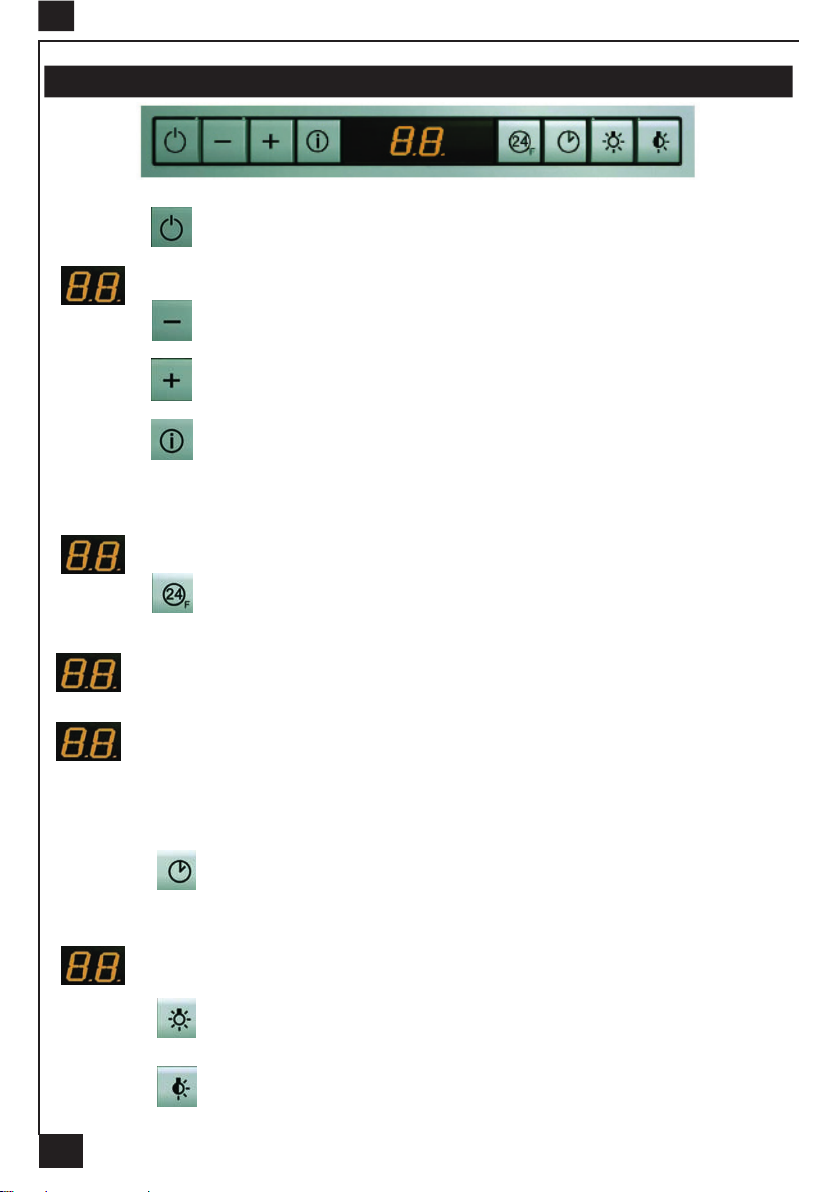

Control board

Key : On / Off

Switches the extractor motor on and off at the latest selected speed.

Key

Decreases the suction speed.

Key

Increases the suction speed.

Key : Intensive speed

By pressing this key it is possible to activate the intensive speed from any previously se-lected speed.

The intensive speed can be acti-vated even when the motor is OFF. This speed has been timed at 10

minutes. After that time the system activates automatically the latest selected speed. This function is

suitable for cooking conditions when vapours and smells are of the utmost emission.

Indicates the selected speed.

: Speed control

: Speed control

HI appears. The spot down on the right side ashes once a second.

Key

By pressing this key it is possible to set up the motor to a suction speed at 100 m3/h lasting 10 minutes every hour. After this the motor switches off automatically.

When the lter saturation is going on it is pos-sible to reset the alarm by pressing this key

for about 3 seconds. The indication is visible only when the motor is off.

FF Indicates that the metal grease lters saturation alarm has been triggered, and the lters

need to be washed. The alarm is triggered after 100 working hours.

EF Indicates that the charcoal lter satura-tion alarm has been triggered, and the l-ter has

to be replaced; the metal grease lters must also be washed. The charcoal lter is triggered after 200

working hours.

Key : Stop delay 30 minutes

By pressing this key it is possible to set the delayed shutdown of the appliance to 30 min-utes. This

function is suitable for a complete elimination of the residual smells. It can be activated at any position,

and it is deactivated by pressing the key again or by switching off the motor.

down. The spot down on the right side ashes.

Key

Turns light on and off .

Key

Turns the second light unit on and off (ambient lighting).

Indicates the 24-function. The spot down on the right side ashes and the motor is on.

Once the process is nished the previous indi-cation disappears:

Indicates alternately the selected speed of the hood and the time left before the hood shut-

: Air Renewing

: Lighting

: Lighting

10

5 USEFUL HINTS

• To obtain the best performance we recommend you to switch ‘ON’ the cooker hood a few minutes (in

the boost setting) before you start cooking and you should leave it running for approximately 15 minutes

after nishing.

• IMPORTANT: NEVER DO FLAMBÉ COOKING UNDER THIS COOKER HOOD

• Do not leave frying pans unattended during use as over-heated fat and oil might catch re.

• Do not leave naked ames under this cooker hood.

• Switch ‘OFF’ the electric and gas before removing pots and pans.

• Ensure heating areas on your hotplate are covered with pots and pans when using the hotplate

and cooker hood simultaneously.

6 MAINTENANCE

Before carrying out any maintenance or cleaning isolate the cooker hood from the mains supply.

The cooker hood must be kept clean; a build up of fat or grease may cause a re hazard.

Casing

• Wipe the cooker hood frequently with a clean cloth, which has been immersed in warm water containing a mild detergent and wrung out.

• Never use excessive amounts of water when cleaning particularly around the control panel.

• Never use scouring pads or abrasive cleaners.

• Always wear protective gloves when cleaning the cooker hood.

Metal Grease Filters : The metal grease lters absorb grease and dust during cooking in order to keep

clean the cooker hood inside. The grease lters should be cleaned once a month or more frequently if

the hood is used for more than 3 hours per day.

To remove and replace the metal grease lters

• Remove the metal grease lters one at a time by releasing the catches on the lters; the lters can

now be removed.

• The metal grease lters should be washed, by hand, in mild soapy water or in a dishwasher.

• Allow to dry before replacing.

Active Charcoal Filter : The charcoal lter cannot be cleaned. The lter should be replaced at least

every three months or more frequently if the hood is used for more than three hours per day.

To remove and replace the lter

• Remove the metal grease lters.

• Press against the two retaining clips, which hold the charcoal lter in place and this will allow the lter

to drop down and be removed.

• Clean the surrounding area and metal grease lters as directed above.

• Insert the replacement lter and ensure the two retaining clips are correctly located.

• Replace the metal grease lters.

Extraction tube : Check every 6 months that the dirty air is being extracted correctly. Comply with local

rules and regulations with regard to the extraction of ventilated air.

Lighting : If the lamp fails to function check to ensure it is tted correctly into the holder. If lamp failure

has occurred then it should be replaced with identical replacement.

Do not replace with any other type of lamp and do not t a lamp with a higher rating.

Remote control handset : Caution, the remote control handset must be tted with standard LR03-AAA

size 1.5V zinc-carbon alkaline batteries. These batteries should give a long life and constant discharge

throughout their life. These batteries must be disposed of properly and could explode if damaged or

exposed to heat. Do not dispose of on re. Dispose of batteries in the appropriate sort

GB

11

GB

7 GUARANTEE AND AFTER SALES SERVICE

• In the event of any malfunction or anomaly, notify your tter who will have to check the appliance and its connection.

• In the event of damage to the mains supply cable, this can only be replaced by at approved repair

centre appointed by the manufacturer who will have the required tools and equipment to carry out any

repairs properly. Repairs carried out by other persons will invalidate the guarantee.

• Use only genuine spare parts. Should these warnings fail to be observed it could affect the safety of

your cooker hood.

• When ordering spare parts quote the model number and serial number written on the rating plate,

which is found on the casing behind the grease lters inside the hood.

• Proof of purchase will be required when requesting service. Therefore, please have your receipt

available when requesting service as this constitutes the date from which your guarantee commenced.

This Guarantee does not cover :

- Damage or calls resulting from transportation, improper use or neglect, the replacement of any light

bulbs or lters or removable parts of glass or plastic.

These items are considered to be consumable under the terms of this guarantee.

8 REMARKS

This appliance complies with European regulations on low voltages Directive 2006/95/CE on electrical

safety, and with the following European regulations: Directive 2004/108/CE on electromagnetic compatibility and Directive 93/68 on EC marking.

When this crossed-out wheeled bin symbol

ered by the European directive 2002/96/EC.Your product is designed and manufactured with high quality

materials and components, which can be recycled and reused.Please inform yourself about the local

separate collection system for electrical and electronic product. Please act according to your local rules

and do not dispose of your old products with your normal household waste. The correct disposal of your

old product will help prevent potential negative consequences for the environment and human health.

is attached to a product it means the product is cov-

12

1

2a

960 - 1360 mm

460 - 560 mm

069 0631 /

450

240

064 065 /

2b

37

Loading...

Loading...