Franke Foodservice FF 1900 Installation Manual

FF 1900 SERIES

Swivelling spout faucet

Installation guide

1/7

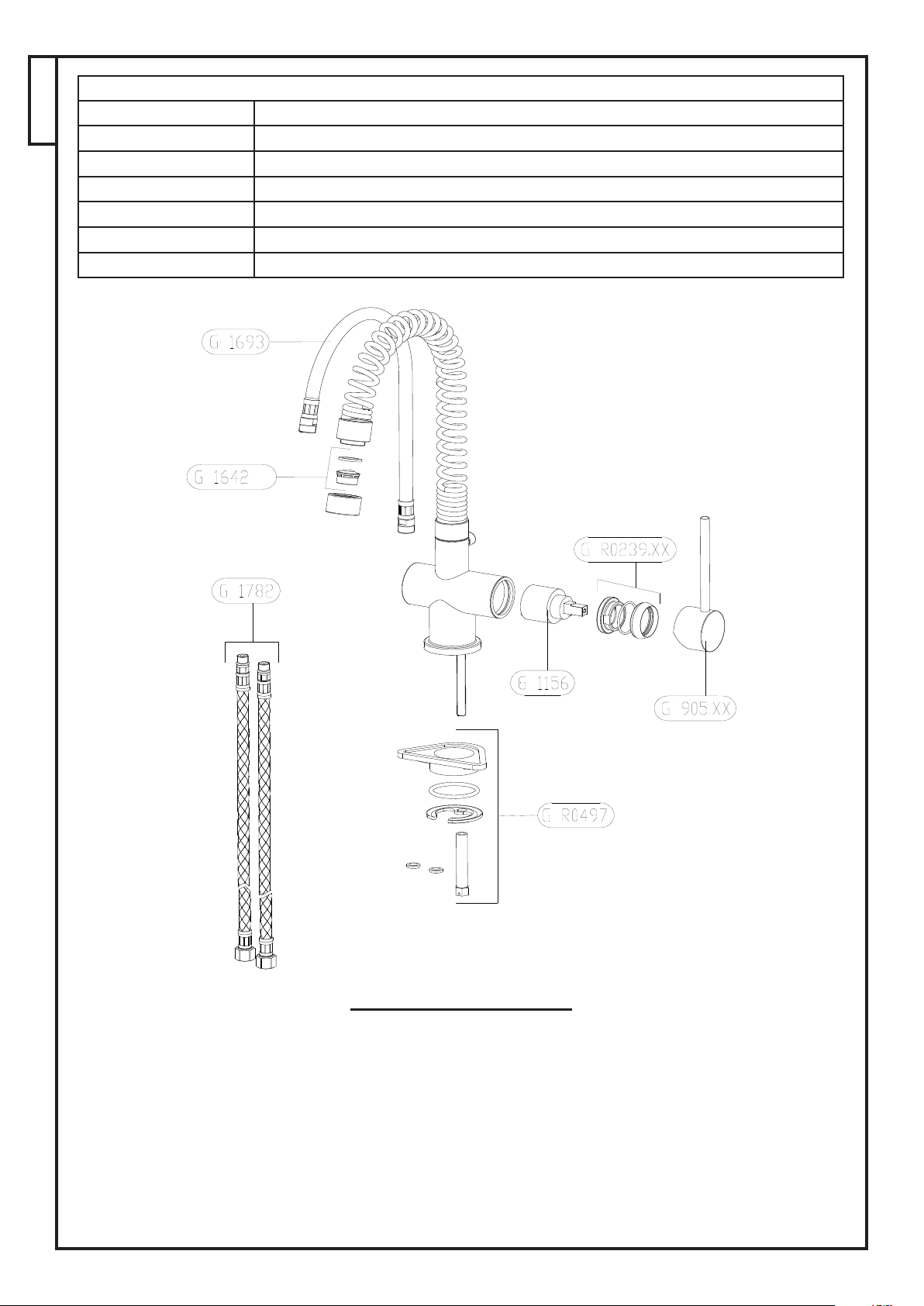

PARTS LIST

G 905.XX Handle

G R0239.XX Ring cap kit

G 1156 Cartridge

G R0497 Fastening set (rubber washer, triangular flange, metal washer, threaded nut)

G 1693 Flexible hose

G 1782 Supply flexible hoses

G 1642 Aerator

TECHNICAL DATA

Maximum water flow 2.2 gpm - 60 PSI

Recommended presure range 25-100 PSI - Over 100 PSI PRV required

Complies with Proposition 65, NSF 61, UPC and C-UPC requirements.

ENGLISH

Faucet installation

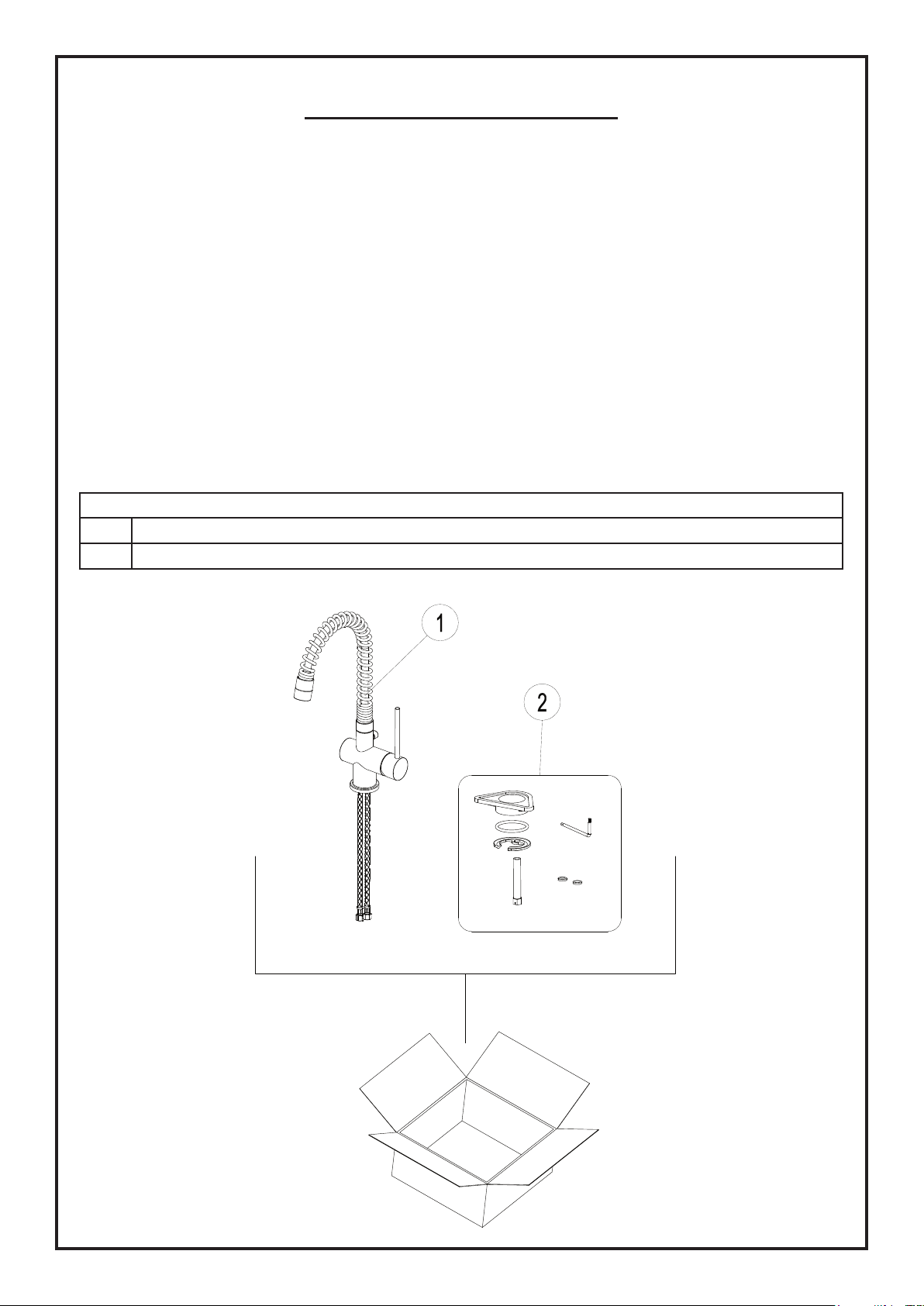

1. Remove all contents from the package and check for completeness (see itemized

table and picture).

NOTE:

Call us immediately if you see inconsistencies. (1-800-626-5771)

or visit

www.frankeksd.com

info.fks@franke.com

TABLE OF CONTENT

1 Faucet

2 Fastening set (rubber washer, triangular flange, metal washer, threaded nut)

2/7

3/7

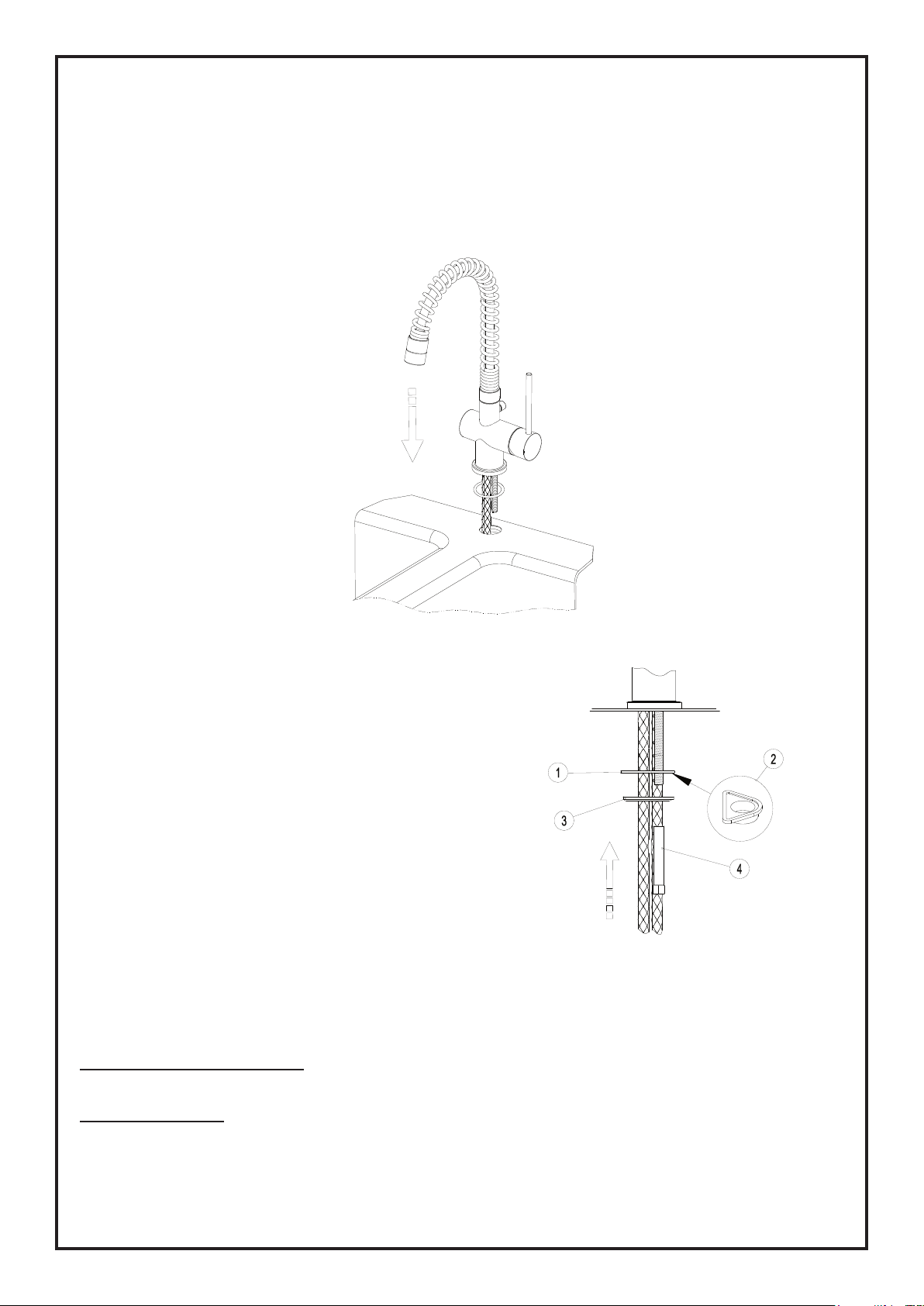

4. Install the mounting hardware (GR0497) to the threaded shank in the following

sequence:

1 - round flat fiber washer

2 - triangular shaped plastic support

3 - flat metal washer

4 - thread brass nut

5. Assure that the handle and spout are properly aligned in forward position

6. Tighten the brass nut (4) with the provided wrench or use other professional

tools.

NOTE:

solid surface installation: The sub-countertop mounting surface needs to be flat and

free of debris; otherwise the faucet will not sit properly.

Tile installation: Avoid installations near or on top of grout lines. The faucet will not

sit secure when sitting on such.

2. Remove all mounting hardware from protecting plastic bag.

3. Place the large O-ring over the faucet shank and place the faucet into the desired

location

NOTE:

the rubber O-ring should be sitting on top of the countertop and between the faucet

body. DO NOT use putty or other sealant at this location

4/7

7. Flush out debris from water lines and faucet.

1. Point the open end of the spout toward the sink drain.

2. Open faucet handle - cold side first - by turning handle to the right and mov-

ing it upward

3. Let the faucet run on cold for 15 to 30 seconds.

4. Open faucet handle - hot side second - by turning handle to the left and mov-

ing it upward.

5. Let the faucet run on cold for 15 to 30 seconds.

6. Turn faucet off.

7. Test for leaks under the cabinet.

5/7

Standard maintenance and trouble shooting

General maintenance

Clean aerator periodically.

Do not use harsh detergents, solvents, chemical agents, metallic sponges, etc. that could

harm the surface.

Clean only with a soft sponge and soapy water,

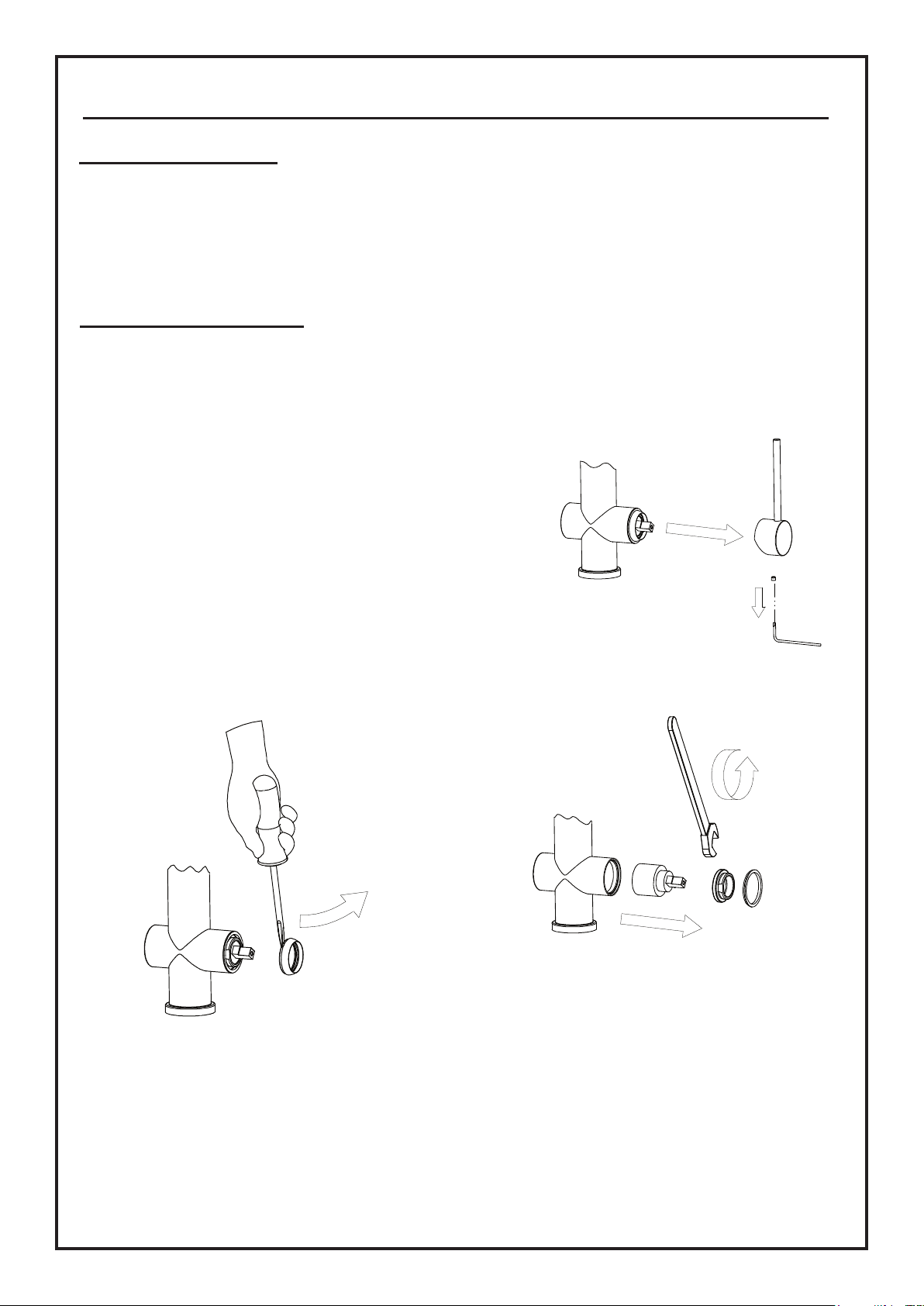

Replacing the Cartridge

1. Shut off the water supply to the faucet.

2. Open the faucet briefly to relief any pressure inside the faucet.

3. Move the faucet handle to the “OFF” position.

4. Use a the provided allen key to loosen the set screw which is accessible

from the back of the handle.

5. Lift the handle from the cartridge.

6. Find the small notch at the base of the chrome ring cap and carefully pry

up against this to remove the cap.

7. Remove the brass retaining ring.

8. Lift out the cartridge.

9. Ensure that the seats and O-rings are in good condition

10. Remove potential mineral deposits from inside the faucet body.

11. Install the new cartridge so that the central pivots fit into the corresponding

seats.

13. Re-assemble faucet in reverse order.

14. Test for leakage.

Key 2.5 mm

Key 28 mm

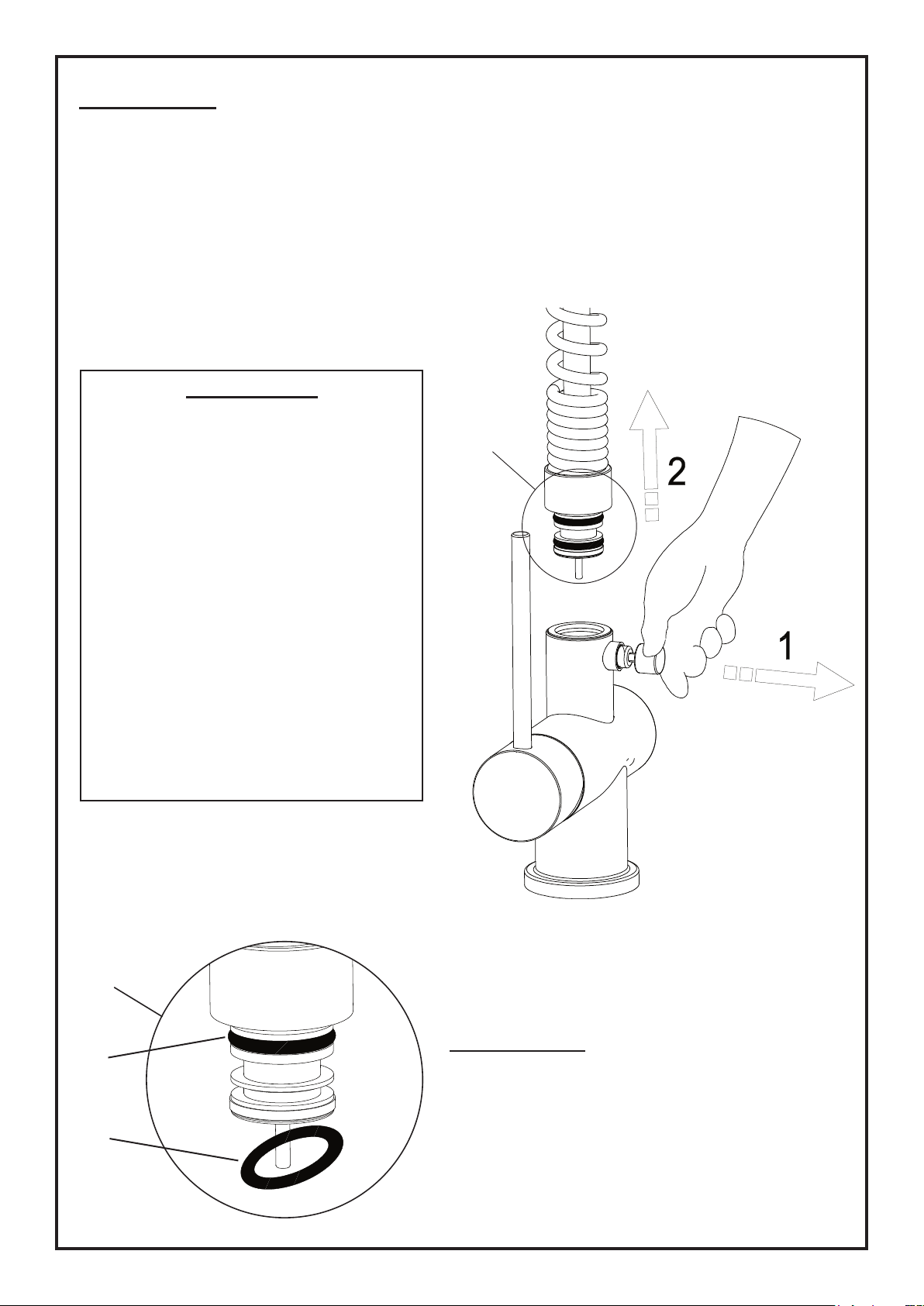

Spout cleaning

This phase is very delicate. Please carry it out only if necessary and only after having

closed water flow. This is primarily for cleaning of the exterior flex hose and spring.

To carry out the cleaning it is possible to detach the spout from the body in the following

way:

1 - pull out the knob as indicated in the picture

2 - take out the spout keeping the knob pulled out

X

OK

To install the spout again pull out the knob,

push softly the spout in and release the knob

ATTENTION:

During the spout installation, be careful not

to damage or move the gaskets positioned at

the base of the same. These gaskets guarantee

watertight. If gaskets leaves their seat proceed

to right placing that before spout installation.

IMPORTANT

- Some spout components not in

contact with water can be damaged if

exposed to high temperatures. Rinse

only with cold water and soap and dry

with a soft cloth. Do not use either the

dish-washer or hot / warm water.

- The gaskets lubricating grease must

not be taken off during the cleaning

phase since it guarantees softness in

the spout rotation.

Lubricated components can undergo

gradual drying caused by usage. This

could be the reason of a progressive

stiffening of spout rotation.

NO

X

6/7

Loading...

Loading...